in Bearbeitung

Camille Bauer Metrawatt AG

http://www.camillebauer.com

Device handbook

CENTRAX CU3000 / CU5000

Operating Instructions CENTRAX CU3000 / CU5000 (2018-11)

Aargauerstrasse 7

CH-5610 Wohlen / Switzerland

Phone: +41 56 6 18 21 11

Telefax: +4 1 56 618 35 35

E-Mail: info@cbmag.com

Legal information

Warning notices

In this document warning notices are used, which you have to observe to ensure personal safety and to prevent

damage to property. Depending on the degree of danger the following symbols are used:

If the warning notice is not followed death or severe personal injury

will result.

If the warning notice is not followed damage to property or severe

personal injury may result.

If the warning notice is not followed the device may be damaged or

may not fulfill the expected functionality.

Qualified personnel

The product described in this document may be handled by personnel only, which is qualified for the respective

task. Qualified personnel have the training and experience to identify risks and potential hazards when working

with the product. Qualified pers onn el are als o able to understand and follow the given safety and warning

notices.

Intended use

The product described in this document may be used only for the application specified. The maximum electrical

supply data and ambient conditions specified in the technical data section must be adhered. For the perfect and

safe operation of the device proper transport and storage as well as professional assembly, installation,

handling and maintenance are required.

Disclaimer of liability

The content of this document has been reviewed to ensure correctness. Nevertheless it may contain errors or

inconsistencies and we cannot guarantee completeness and correctness. This is especially true for different

language versions of this document. This document is regularly reviewed and updated. Necessary corrections

will be included in subsequent version and are available via our webpa ge http://www.camillebauer.com

Feedback

If you detect errors in this document or if there is necessary information missing, please inform us via e-mail to:

customer-support@camillebauer.com

.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 2/106

Contents

1. Introduction .................................................................................................................................................... 5

1.1 Purpose of this document .......................................................................................................................... 5

1.2 Scope of supply ......................................................................................................................................... 5

1.3 Further documents ..................................................................................................................................... 5

2. Safety notes .................................................................................................................................................... 6

3. Device overview ............................................................................................................................................. 6

3.1 Brief description ......................................................................................................................................... 6

3.2 Available measurement data ..................................................................................................................... 6

4. Mechanical mounting .................................................................................................................................... 7

4.1 CENTRAX CU3000 ................................................................................................................................... 7

4.2 CENTRAX CU5000 ................................................................................................................................... 8

5. Electrical connections ................................................................................................................................... 9

5.1 General safety notes.................................................................................................................................. 9

5.2 Terminal assignments of the I/O extensions ...........................................................................................10

5.2.1 CENTRAX CU3000 .........................................................................................................................10

5.2.2 CENTRAX CU5000 .........................................................................................................................11

5.3 Possible cross sections and tightening torques ......................................................................................11

5.4 Inputs .......................................................................................................................................................12

5.5 Power supply ...........................................................................................................................................24

5.6 Relays ......................................................................................................................................................24

5.7 Digital inputs ............................................................................................................................................24

5.8 Digital outputs ..........................................................................................................................................25

5.9 Analog outputs .........................................................................................................................................26

5.10 Fault current detection .............................................................................................................................27

5.11 Modbus interface RS485 ..........................................................................................................................29

5.12 Uninterruptible power supply (UPS) ........................................................................................................29

5.13 GPS time synchronization ........................................................................................................................30

6. Commissioning ............................................................................................................................................32

6.1 Parametrization of the device functionality ..............................................................................................33

6.2 Operating LED (CU5000 only) .................................................................................................................33

6.3 Installation check .....................................................................................................................................33

6.4 Ethernet installation .................................................................................................................................35

6.4.1 Settings ...........................................................................................................................................35

6.4.2 Connection of the standard interface ..............................................................................................37

6.4.3 Connection of the IEC61850 interface ............................................................................................38

6.4.4 MAC addresses ..............................................................................................................................38

6.4.5 Communication tests ......................................................................................................................38

6.4.6 Resetting the communication settings of the CU5000 ....................................................................39

6.5 Protection against device dat a chang ing .................................................................................................39

7. Operating the device ....................................................................................................................................40

7.1 Operating elements .................................................................................................................................40

7.2 Selecting the information to display .........................................................................................................40

7.3 Measurement displays and used symbols ..............................................................................................41

7.4 Resetting measurement data ..................................................................................................................43

7.5 Configuration ...........................................................................................................................................43

7.5.1 Configuration at the device ................................................................................................................43

7.5.2 Configuration via web browser ..........................................................................................................44

7.6 Monitoring fault-currents ..........................................................................................................................46

7.7 Data recording .........................................................................................................................................48

7.7.1 Periodical data ................................................................................................................................48

7.7.2 Events .............................................................................................................................................51

7.7.3 Disturbance recorder ......................................................................................................................52

7.7.4 Micro SD card (CU3000 only) .........................................................................................................54

7.8 Timeouts ..................................................................................................................................................55

8. CODESYS Quick Start .................................................................................................................................56

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 3/106

8.1 CODESYS development environment .................................................................................................... 56

8.2 CENTRAX device description ................................................................................................................. 56

8.3 Create a project ...................................................................................................................................... 57

8.4 CU3000/CU5000 Device tree ................................................................................................................. 58

8.5 Selection of the I/O extension modules .................................................................................................. 58

8.6 Using the Modbus master functionality ................................................................................................... 59

8.7 Creating the CODESYS application ....................................................................................................... 63

8.7.1 Using remanent variables .................................................................................................................. 63

8.7.2 Using the data logger ......................................................................................................................... 63

8.8 Creating own visualizations .................................................................................................................... 65

8.8.1 Adding a visualization to the project ................................................................................................ 65

8.8.2 Target visualization (TargetVisu) .................................................................................................... 65

8.8.3 WEB visualizations (WebVisu) ........................................................................................................ 66

8.9 Establishing a connection to the device ................................................................................................. 67

8.10 Loading the application to the device ...................................................................................................... 68

8.11 Loading the application on-site................................................................................................................ 71

8.11.1 Creating a boot application ............................................................................................................. 71

8.11.2 Deleting the active application ........................................................................................................ 71

8.11.3 Loading the application ................................................................................................................... 71

8.11.4 Starting the app lic a tio n .................................................................................................................... 72

8.11.5 Resetting the active application ...................................................................................................... 72

8.12 Reset ...................................................................................................................................................... 73

8.13 Project management ............................................................................................................................... 74

8.14 Services .................................................................................................................................................. 74

8.13 Example projects .................................................................................................................................... 74

9. Service, maintenance and disposal .......................................................................................................... 75

9.1 Calibration and new adjustment ............................................................................................................. 75

9.2 Cleaning .................................................................................................................................................. 75

9.3 Battery ..................................................................................................................................................... 75

9.4 Disposal .................................................................................................................................................. 75

10. Technical data ............................................................................................................................................. 76

11. Dimensional drawings ................................................................................................................................ 82

Annex .................................................................................................................................................................. 83

A Description of measured quantities .......................................................................................................... 83

A1 Basic measurements .............................................................................................................................. 83

A2 Harmonic analysis .................................................................................................................................. 87

A3 System imbalance .................................................................................................................................. 88

A4 Mean values and trend ........................................................................................................................... 89

A5 Meters ..................................................................................................................................................... 90

B Display matrices .......................................................................................................................................... 91

B0 Used abbreviations for the measurements ............................................................................................. 91

B1 Display matrices for single phase system .............................................................................................. 95

B2 Display matrices for split-phase (two-phase) systems ........................................................................... 96

B3 Display matrices for 3-wire system, balanced load ................................................................................ 97

B4 Display matrices for 3-wire system, balanced load, phase shift ............................................................. 98

B5 Display matrices for 3-wire systems, unbalanced loa d .......................................................................... 99

B6 Display matrices for 3-wire systems, unbalanced load, Aron ............................................................... 100

B7 Display matrices for 4-wire system, balanced load .............................................................................. 101

B8 Display matrices for 4-wire systems, unbalanced loa d ........................................................................ 102

B8 Display matrices for 4-wire system, unbalanced lo ad, O pen-Y ............................................................ 103

C Logic functions .......................................................................................................................................... 104

D FCC statement ........................................................................................................................................... 105

INDEX ................................................................................................................................................................ 106

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 4/106

1. Introduction

1.1 Purpose of this document

This document describes the universal measurement device for heavy-current quantities CENTRAX

CU3000 / CU5000. It is intended to be used by:

• Installation personnel and commissioning engineers

• Service and maintenance personnel

• Planners

Scope

This handbook is valid for all hardware versions of the CU3000 / CU5000. Some of the functions

described in this document are available only, if the necessary optional components are included in the

device.

Required knowledge

A general knowledge in the field of electrical engineering is required. For assembly and installation of the

device knowledge of applicable national safety regulations and installation standard is required.

1.2 Scope of supply

• Measurement device

• Safety instructions (multiple languages)

• Mounting set: 2 mounting clamps (CU3000 only)

• Battery pack (optional, for devices with UPS only)

1.3 Further documents

The following documents are provided el ec tronic a lly via http://www.camillebauer.com/cu3000-en or

http://www.camillebauer.com/cu5000-en :

• Safety instructions

• Data sheet

• Modbus basics: General description of the communication protocol

• Modbus interface CENTRAX CUx000: Register description of Modbus RTU/TCP communication

• IEC61850 interface SINEAX AMx000/DM5000, LINAX PQx000, CENTRAX CUx000

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 5/106

2. Safety notes

Device may only be disposed in a professiona l manner!

The installation and commissioning should only be carried out by trained personnel.

Check the following points before commissioning:

– that the maximum values for all the connections are not exceeded, see "Technical data"

section,

– that the connection wires are not damaged, and that they are not live during wiring,

– that the power flow direction and the phase rotation are correct.

The instrument must be taken out of service if safe operation is no longer possible (e.g. visible

damage). In this case, all the connections must be switched off. The instrument must be

returned to the factory or to an authorized service dealer.

It is forbidden to open the housing and to make modifications to the instrument. The instrument

is not equipped with an integrated circuit breaker. During installation check that a labeled switch

is installed and that it can easily be reached by the operators.

Unauthorized repair or alteration of the unit invalidates the warranty.

3. Device overview

3.1 Brief description

The CENTRAX CU3000/CU5000 is a com pr ehens ive ins trument for the universal measurement and

monitoring in power systems , supplemented by a freely programmable control application based on

CODESYS. A full parameterization of all functions of the device is possible directly at the device (for

versions with display) or via web browser. The control application is created using the CODESYS

development environment, can access all measurement data of the device, process these values logically

and mathematically and pass the results via bus or analog or digital outputs.

Using additional, optional components the opportunities of the device may be extended. You may choose

from I/O extensions, communication interfaces and data logging. The PLC functionality is available in

three performance classes. The nameplates on the device give further details about the present version.

3.2 Available measurement data

The device provides measurements in the following subcategories:

a) Instantaneous values: Present TRMS values and associated min/max values

b) Energy: Power mean-values with trend and history as well as energy meters. With the data logger

option “periodical data” mean-value progressions (load profiles) and periodical meter readings are

available as well.

c) Harmonics: Total harmonic distortion THD/TDD, individual harmonics and their maximum values

d) Phasor diagram: Overview of all current and voltage phasors and phase sequence check

e) Waveform of current and voltage inputs

f) Events: Disturbance recordings if the corresponding option is implemented.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 6/106

4. Mechanical mounti ng

Please ensure that the operating temperature limits are not exceeded when

determining the place of mounting (place of measurement).

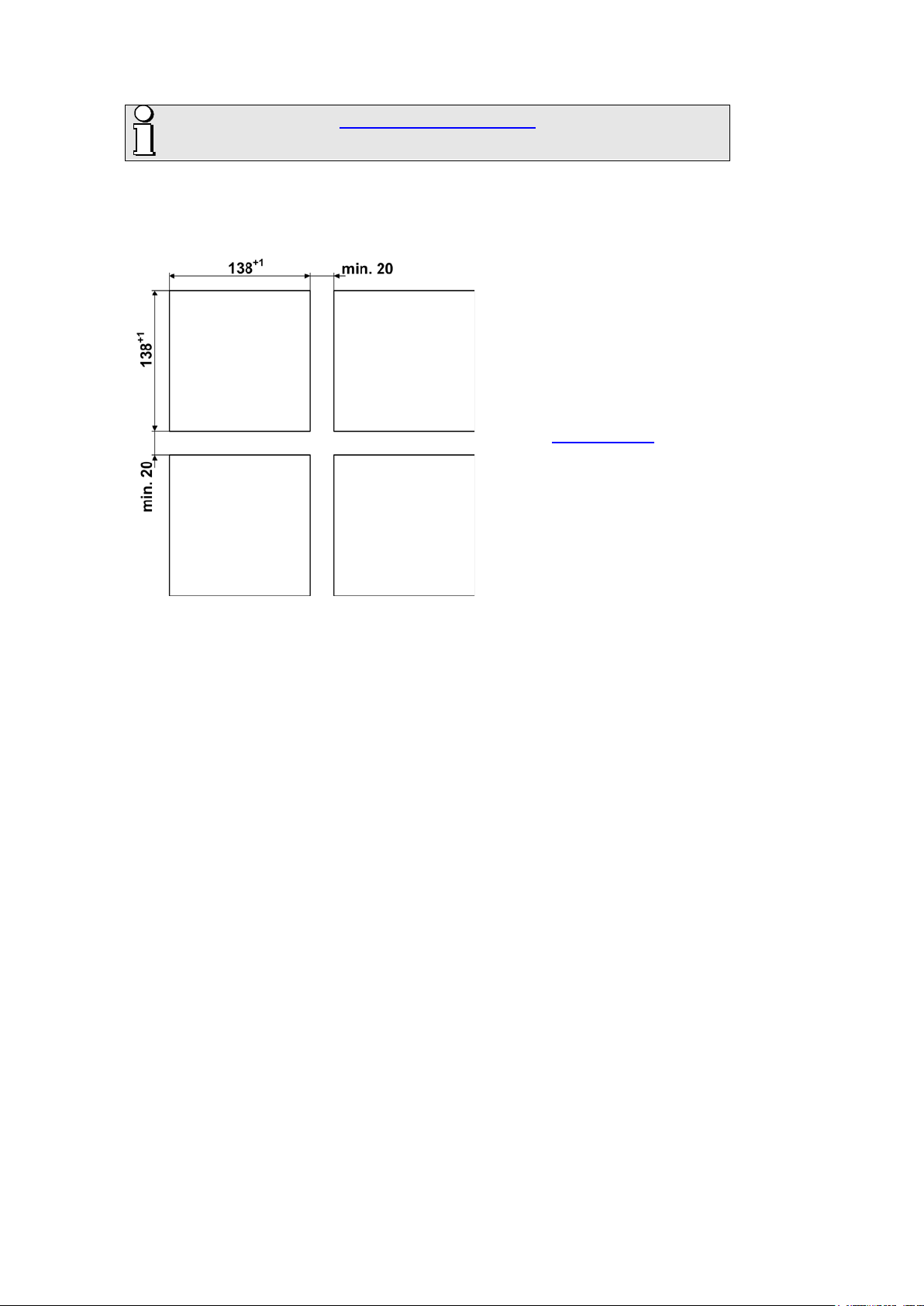

4.1 CENTRAX CU3000

► The CU3000 is designed for panel mounting

Dimensional drawing CU3000:

See section 11

Panel cutout CU3000

Mounting of the device

The device is suitable for panel widths up to 8mm.

a) Slide the device into the cutout from

the outside

b) From the side slide in the mounting

clamps into the intended openings and

pull them back about 2 mm

c) Tighten the fixation screws until the

device is tightly fixed with the panel

Demounting of the device

The demounting of the device may be performed only if all connected wires are out of service. Remove all

plug-in terminals and all connections of the current and voltage inputs. Pay attention to the fact, that

current transformers must be shortened before removing the current connections to the device. Then

demount the device in the opposite order of mounting.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 7/106

4.2 CE NT RAX CU5000

The device can be clipped onto a top-hat rail according to EN 60715.

Dimensional drawing CU5000: See section 11

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 8/106

5. Electrical connections

Ensure under all circumstances that the leads are free of potential

when connecting them!

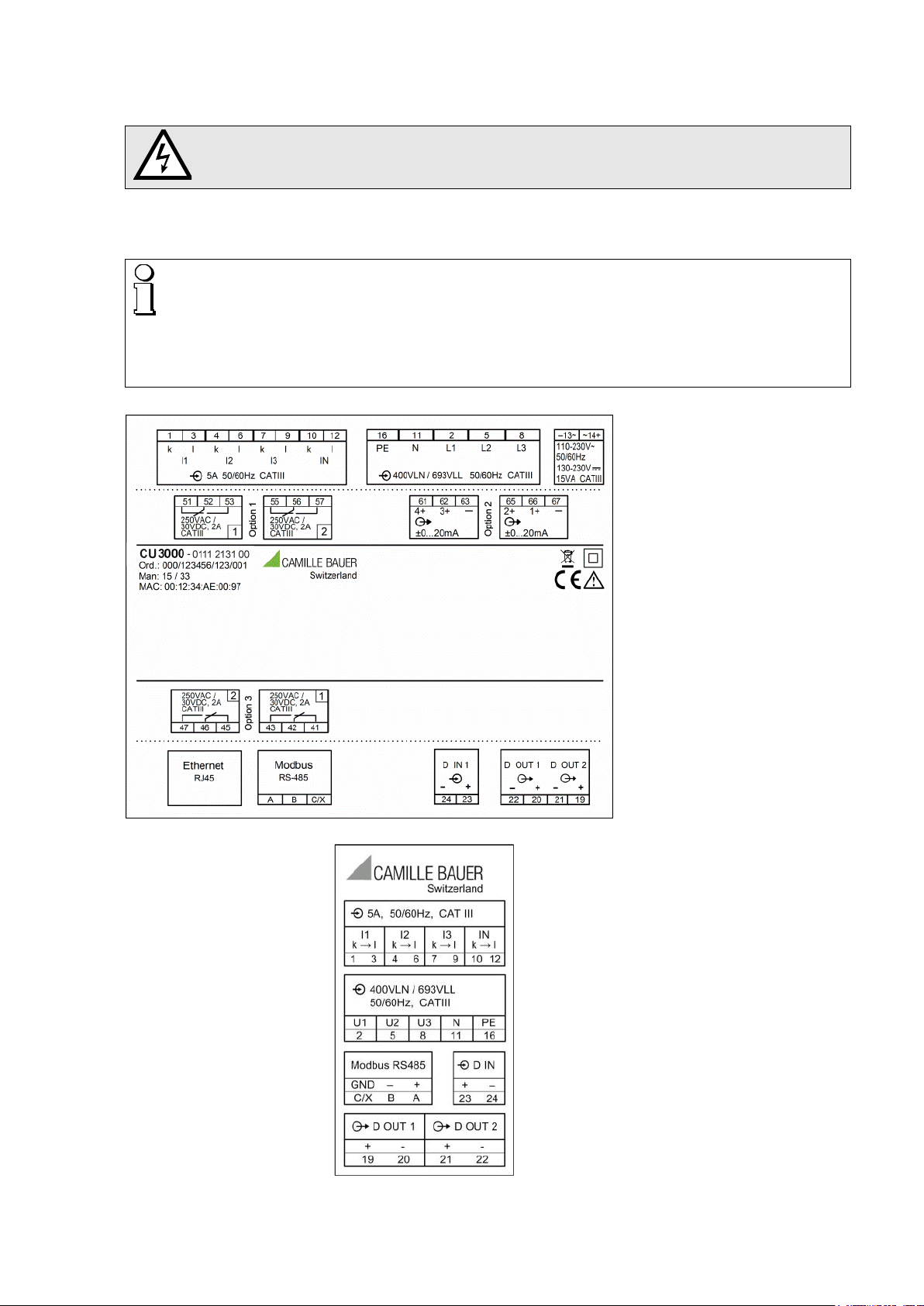

5.1 General safety notes

Please observe that the data on the type plate must be adhered to!

The national provisions have to be observed in the installation and material selection of electric lines,

e.g. in Germany VDE 0100 “Conditions concerning the erection of heavy current facilities with rated

voltages below 1000 V”!

Nameplate of a CU3000 with

• Ethernet interface

• Modbus/RTU interface

• 4 relay outputs

• 4 analog outputs

Nameplate of a CU5000 with

• TFT display

• Ethernet interface

• Modbus/RTU interface

• 2 relay outputs

• 4 analog outputs

• UPS

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 9/106

Symbol Meaning

CE conformity mark. The device fulfills the requirements of the applicable EU

Measurement category CAT III for current / voltage inputs, power supply and relay

Device may only be disposed of in a professional manner!

Double insulation, device of protection class 2

directives.

Caution! General hazard point. Read the operating instructions.

General symbol: Power supply

General symbol: Input

General symbol: Output

CAT III

outputs

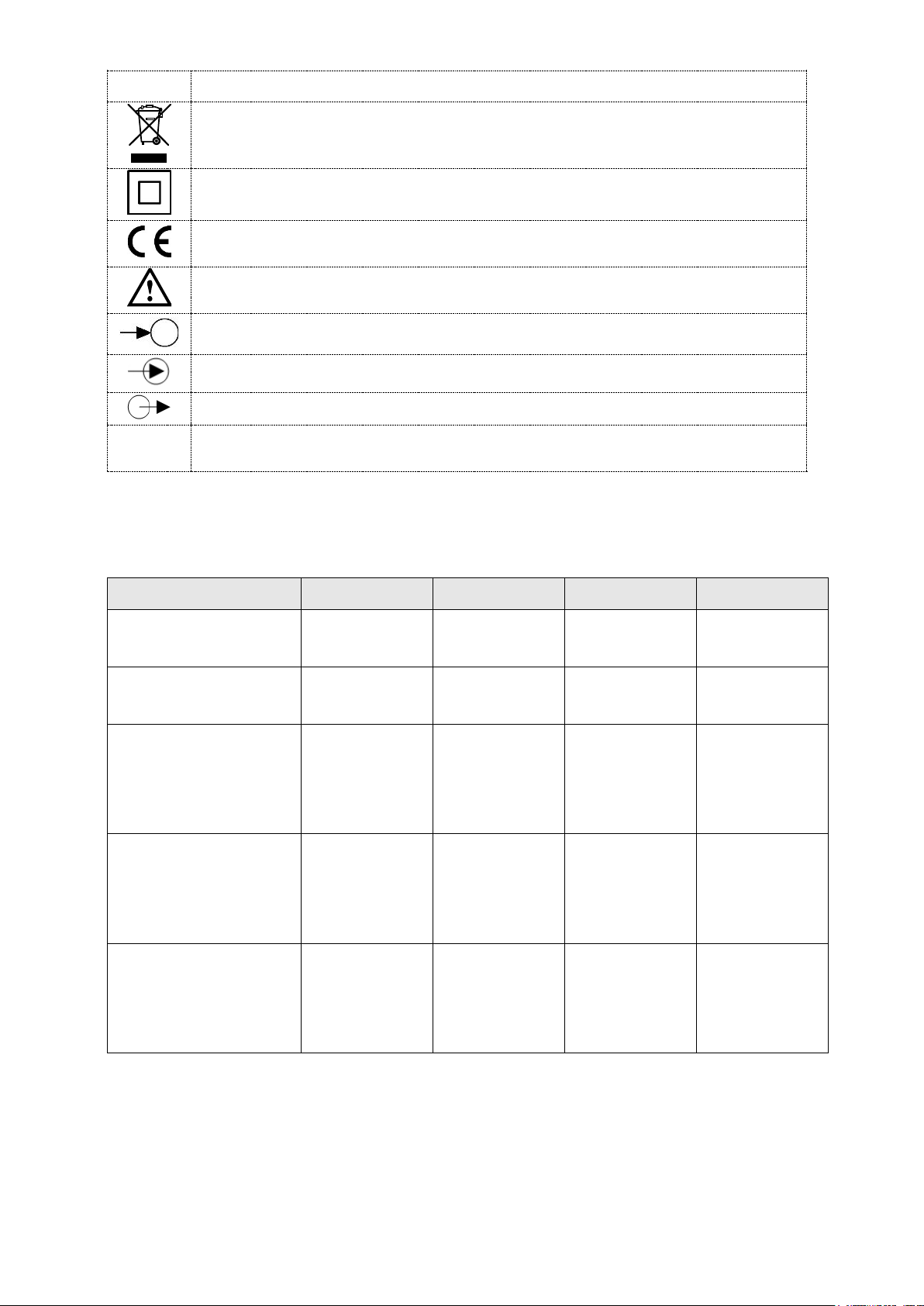

5.2 Terminal assignments of the I/O extensions

5.2.1 CENTRAX CU3000 Function Option 1 Option 2 Option 3 Option 4

2 relay outputs

1.1: 51,52,53

1.2: 55,56,57

1.1: 56(+), 57(-)

2 analog outputs

1.2: 55(+), 57(-)

1.1: 56(+), 57(-)

1.2: 55(+), 57(-)

4 analog outputs

1.3: 52(+), 53(-)

1.4: 51(+), 53(-)

1.1: 51(-), 53(+)

1.2: 52(-), 53(+)

4 digital inputs (active)

1.3: 55(-), 57(+)

1.4: 56(-), 57(+)

2.1: 61,62,63

2.2: 65,66,67

2.1: 66(+), 67(-)

2.2: 65(+), 67(-)

2.1: 66(+), 67(-)

2.2: 65(+), 67(-)

2.3: 62(+), 63(-)

2.4: 61(+), 63(-)

2.1: 61(-), 63(+)

2.2: 62(-), 63(+)

2.3: 65(-), 67(+)

2.4: 66(-), 67(+)

3.1: 41,42,43

3.2: 45,46,47

3.1: 46(+), 47(-)

3.2: 45(+), 47(-)

3.1: 46(+), 47(-)

3.2: 45(+), 47(-)

3.3: 42(+), 43(-)

3.4: 41(+), 43(-)

3.1: 41(-), 43(+)

3.2: 42(-), 43(+)

3.3: 45(-), 47(+)

3.4: 46(-), 47(+)

4.1: 31,32,33

4.2: 35,36,37

4.1: 36(+), 37(-)

4.2: 35(+), 37(-)

4.1: 36(+), 37(-)

4.2: 35(+), 37(-)

4.3: 32(+), 33(-)

4.4: 31(+), 33(-)

4.1: 31(-), 33(+)

4.2: 32(-), 33(+)

4.3: 35(-), 37(+)

4.4: 36(-), 37(+)

1.1: 51(+), 53(-)

1.2: 52(+), 53(-)

4 digital inputs (passive)

1.3: 55(+), 57(-)

1.4: 56(+), 57(-)

2.1: 61(+), 63(-)

2.2: 62(+), 63(-)

2.3: 65(+), 67(-)

2.4: 66(+), 67(-)

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 10/106

3.1: 41(+), 43(-)

3.2: 42(+), 43(-)

3.3: 45(+), 47(-)

3.4: 46(+), 47(-)

4.1: 31(+), 33(-)

4.2: 32(+), 33(-)

4.3: 35(+), 37(-)

4.4: 36(+), 37(-)

5.2.2 CENTRAX CU5000

Inputs L1(2), L2(5), L3(8), N(11), PE(16), I1(1-3), I2(4-6), I3(7-9) , IN(10-12), power supply (13-14)

I/O's, relays, RS485 connector (A, B, C/X)

Function Option 1 Option 2

2 relay outputs

2 analog outputs

4 analog outputs

4 digital inputs (active)

4 digital inputs (passive)

1.1: X1.1 / X1.2 / X1.3

1.2: X2.1 / X2.2 / X2.3

1.1: X2.2(+) / X2. 3(-)

1.2: X2.1(+) / X2. 3(-)

1.1: X2.2(+) / X2.3(-)

1.2: X2.1(+) / X2.3(-)

1.3: X1.2(+) / X1.3(-)

1.4: X1.1(+) / X1.3(-)

1.1: X1.1(-) / X1.3(+)

1.2: X1.2(-) / X1.3(+)

1.3: X2.1(-) / X2.3(+)

1.4: X2.2(-) / X2.3(+)

1.1: X1.1(+) / X1.3(-)

1.2: X1.2(+) / X1.3(-)

1.3: X2.1(+) / X2.3(-)

1.4: X2.2(+) / X2.3(-)

2.1: X3.1 / X3.2 / X3.3

2.2: X4.1 / X4.2 / X4.3

2.1: X4.2(+) / X4.3 (-)

2.2: X4.1(+) / X4.3 (-)

2.1: X4.2(+) / X4.3(-)

2.2: X4.1(+) / X4.3(-)

2.3: X3.2(+) / X3.3(-)

2.4: X3.1(+) / X3.3(-)

2.1: X3.1(-) / X3.3(+)

2.2: X3.2(-) / X3.3(+)

2.3: X4.1(-) / X4.3(+)

2.4: X4.2(-) / X4.3(+)

2.1: X3.1(+) / X3.3(-)

2.2: X3.2(+) / X3.3(-)

2.3: X4.1(+) / X4.3(-)

2.4: X4.2(+) / X4.3(-)

5.3 Possible cro ss secti ons and tightening torques

Single wire

1 x 0,5 ... 6.0mm2 or 2 x 0,5 ... 2.5mm

2

Multiwire with end splices

1 x 0,5 ... 4.0mm2 or 2 x 0,5 ... 2.5mm

2

Tightening torque

0.5…0.6Nm resp. 4.42…5.31 lbf in

Single wire

1 x 0.5 ... 2.5mm2 or 2 x 0.5 ... 1.0mm

2

Multiwire with end splices

1 x 0.5 ... 2.5mm2 or 2 x 0.5 ... 1.5mm

2

Tightening torque

0.5…0.6Nm resp. 4.42…5.31 lbf in

You may have to remove first the plug-in terminals to get access to the screw terminals of the current

inputs.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 11/106

5.4 Inputs

All voltage measurement inputs must originate at circuit breakers or fuses rated 5 Amps or

The connection of the inputs depends on the configured system (connection type).

less. This does not apply to the neutral connector. You have to provide a method for

manually removing power from the device, such as a clearly labeled circuit breaker or a

fused disconnect switch.

When using voltage transformers you have to ensure that their secondary connections

never will be short-circuited.

No fuse may be connected upstream of the current measurement inputs!

When using current transformers their secondary connectors must be short-circuited

during installation and before removing the device. Never open the secondary circuit under

load.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 12/106

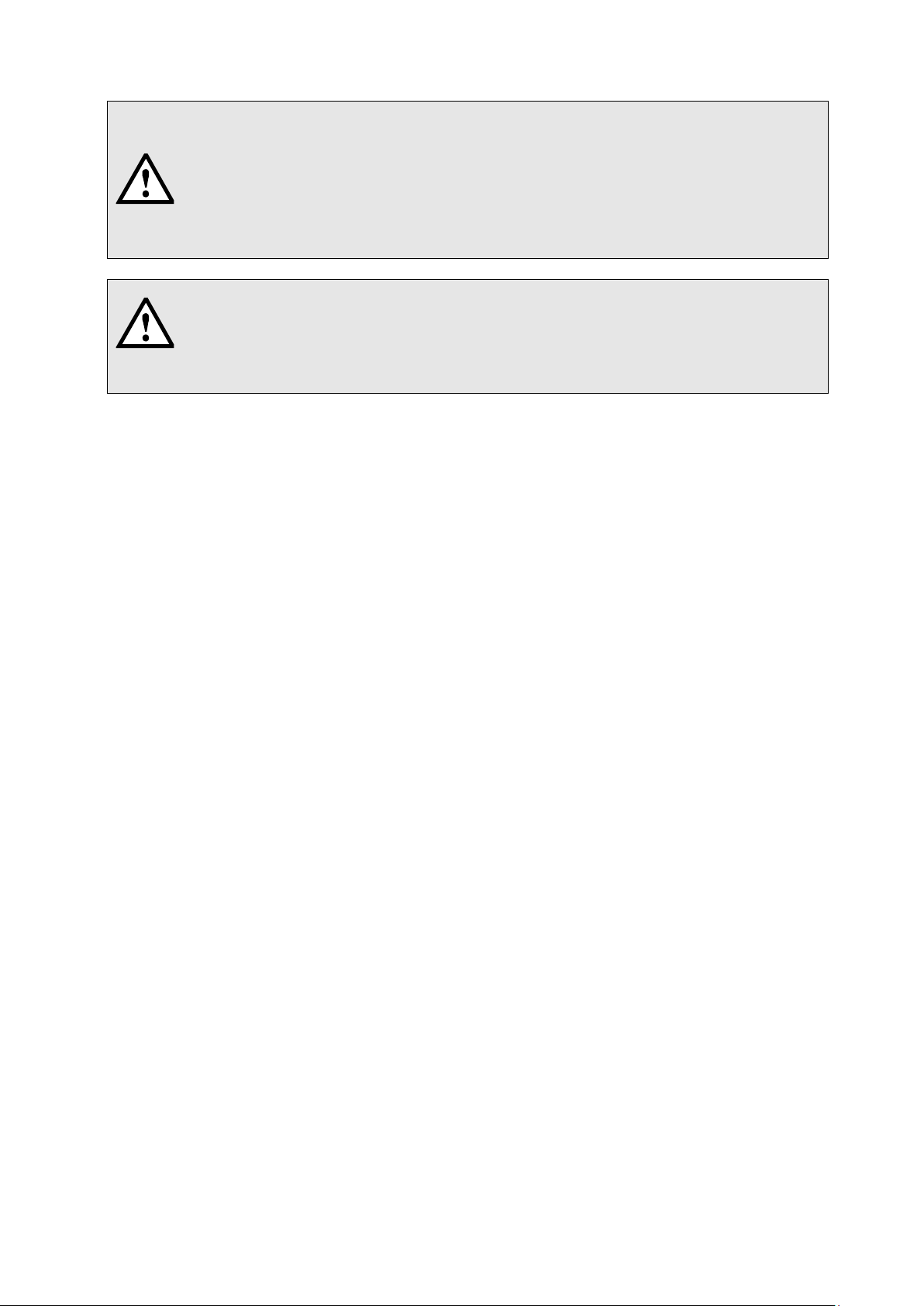

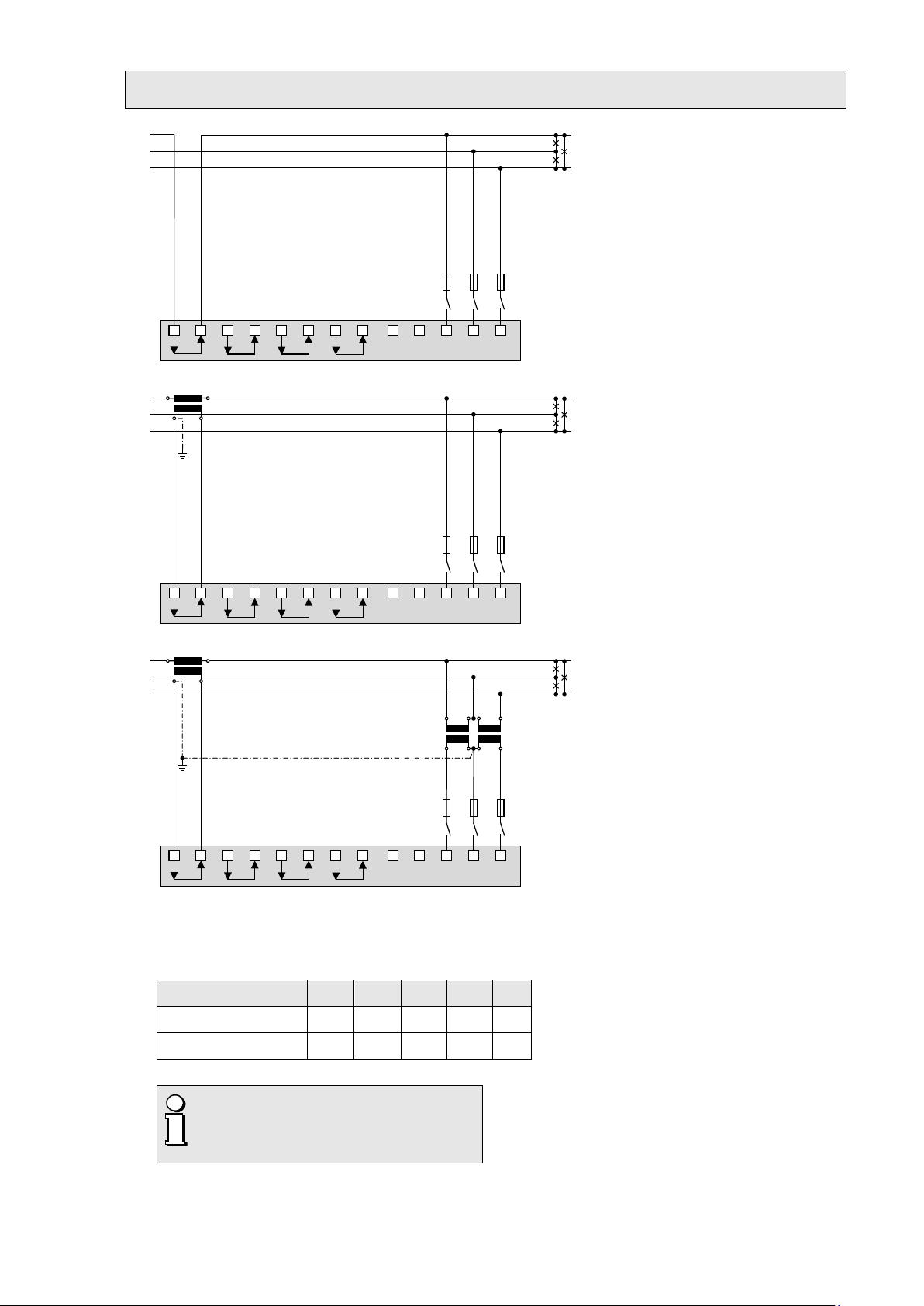

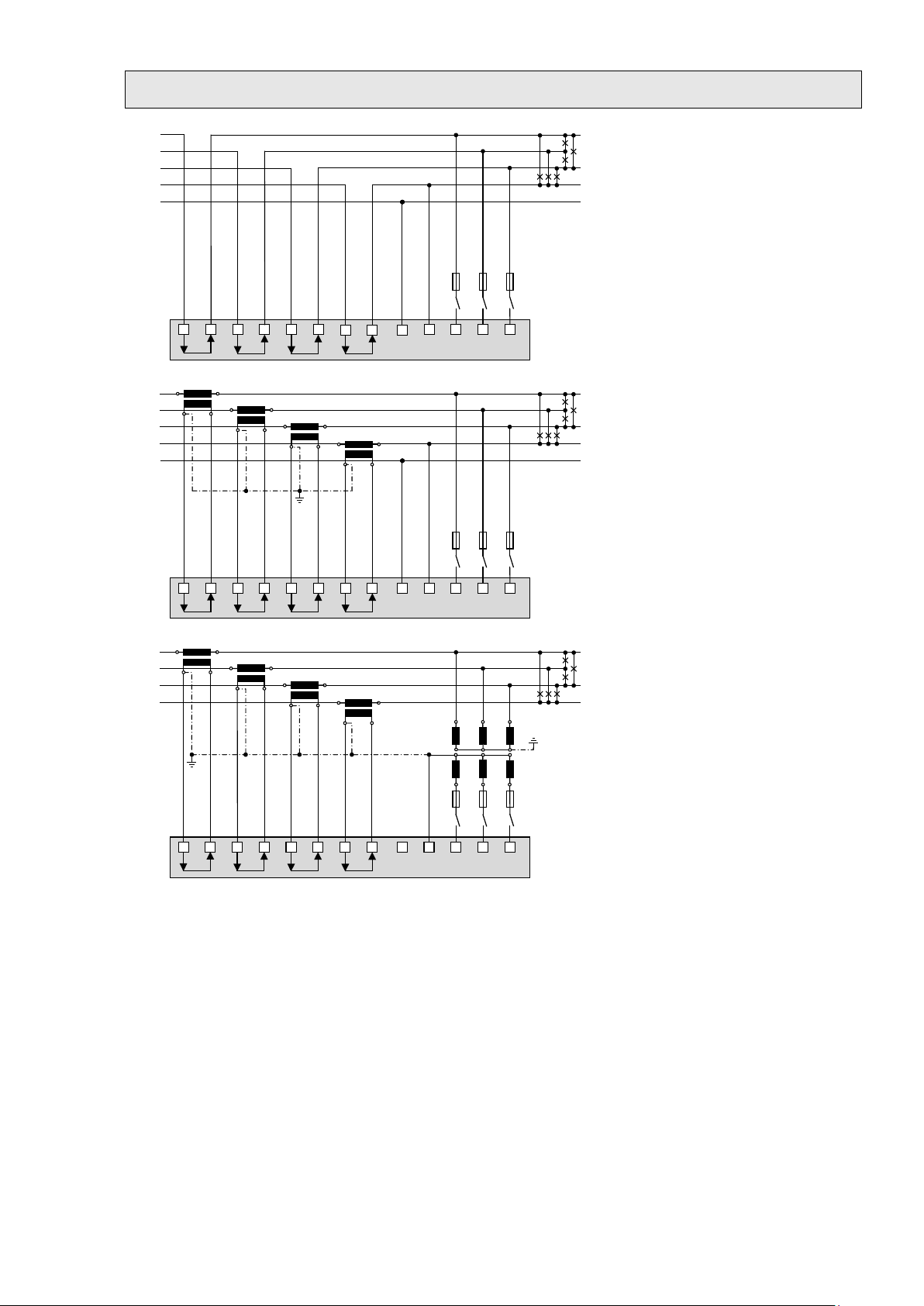

Single-phase AC mains

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

N

5 A

(UL listed)

PE

L1 L2

L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

N

5 A

(

UL listed)

K

k

L

l

K

k

L

l

PE

L1

N

K

k

L

l

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

5 A

(UL listed)

PE

K

k

L

l

u

U

v

V

u

U

v

V

Direct connection

If current I

or voltage UNE does not need to be

N

measured, connection of IN resp. PE can be

omitted.

With current transformer

If current IN does not need to be measured, the

corresponding transformer can be omitted.

If voltage U

connection of PE can be omitted.

does not need to be measured,

NE

With current and voltage transformer

If current IN or voltage UNE does not need to be

measured, the corresponding transformers can be

omitted.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 13/106

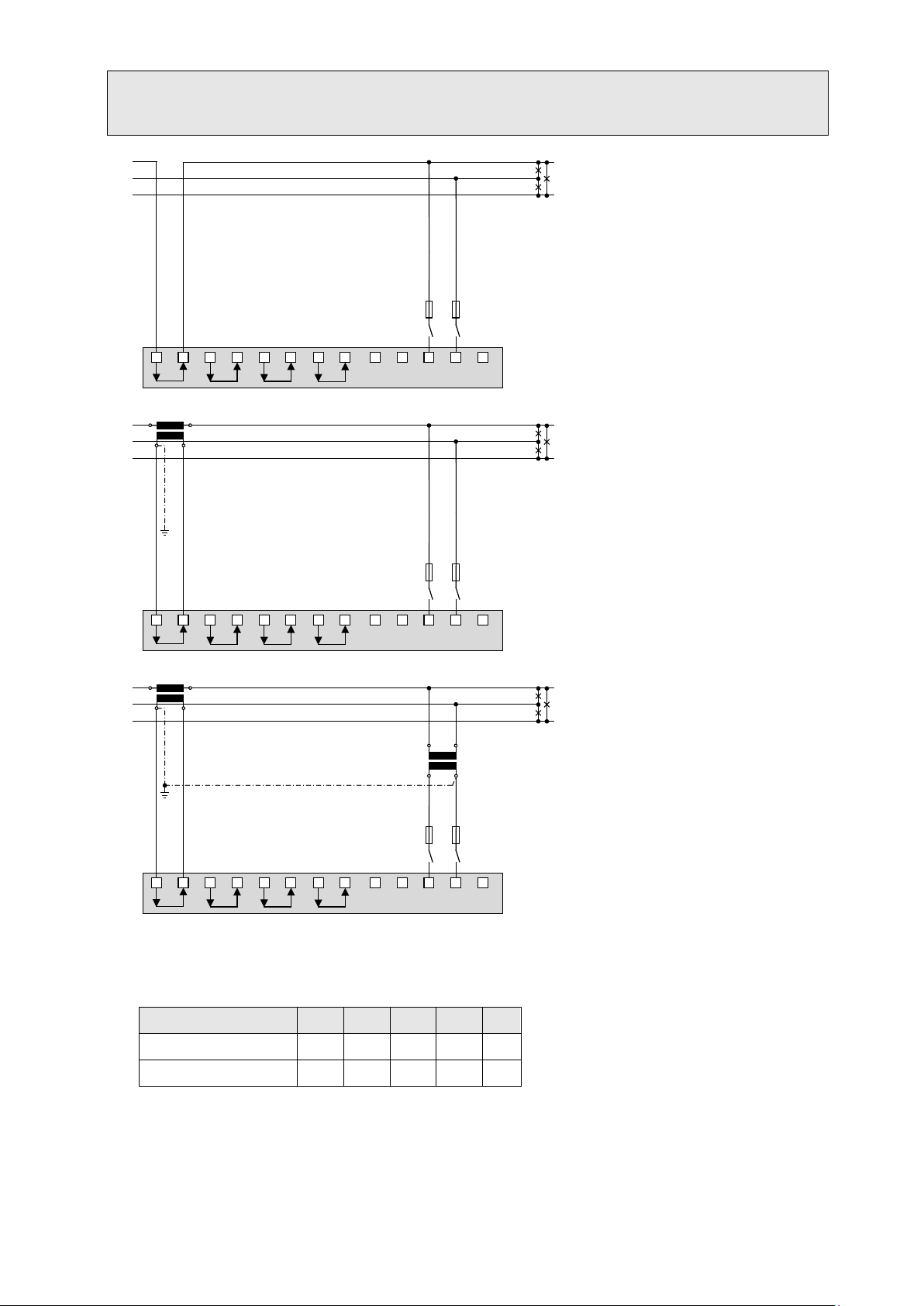

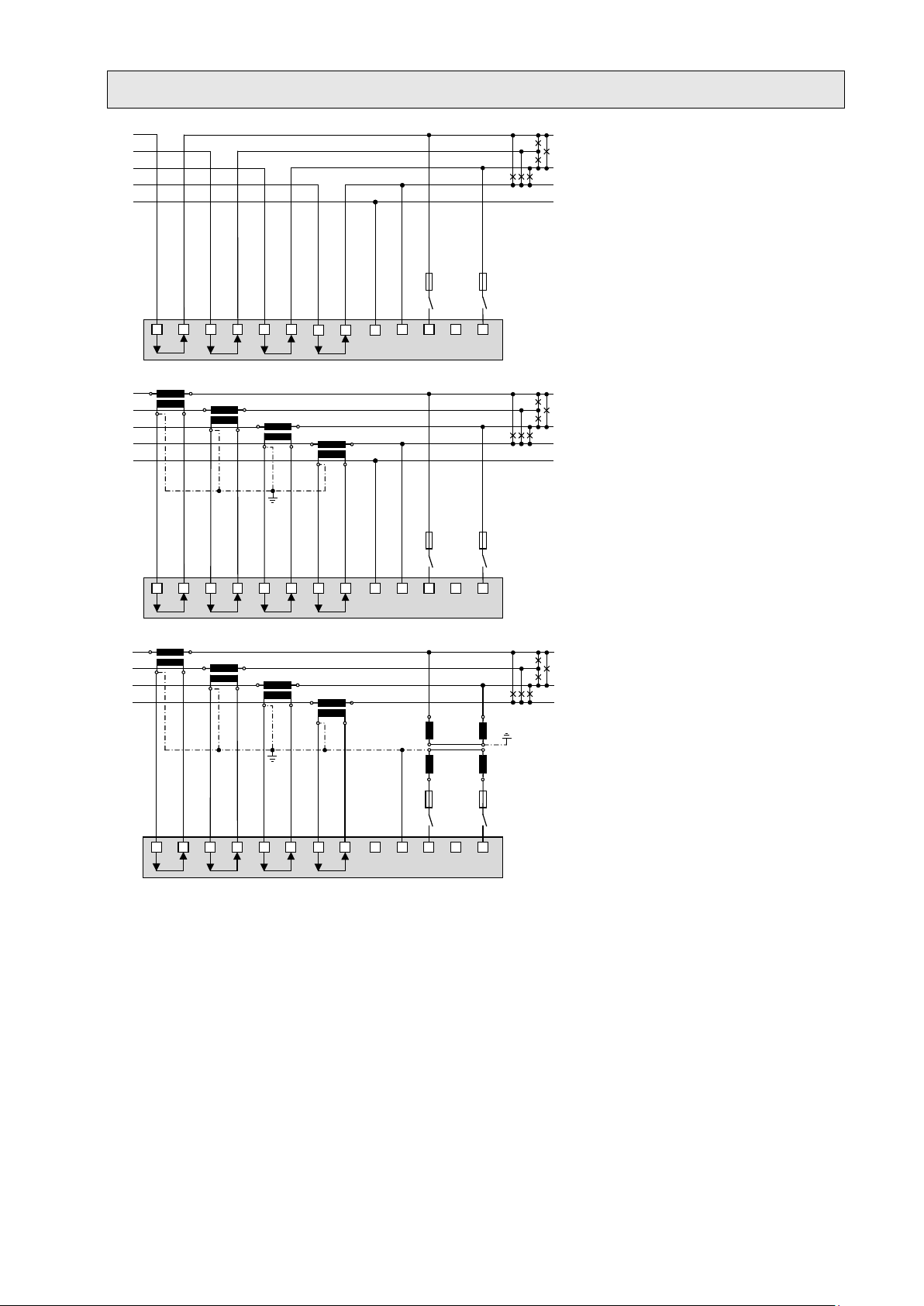

Three wire system, balanced load, phase shift

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

5 A

(

UL listed)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

5 A

(UL listed)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

5 A

(UL listed)

u

U

v

V

current measurement: L1, voltage measurement: L1-L2

Direct connection

With current transformer

With current and voltage transformers

In case of current measurement via L2 or L3 connect the device

according to the following table:

Terminals 1 3 2 5 8

Current meas. via L2 I2(k) I2(l) L2 L3 Current meas. via L3 I3(k) I3(l) L3 L1 -

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 14/106

Three wire system, balanced load, phase shift

L1 L2 L3

N

I1

31

I2

4

I3

9

7

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

5 A

(UL listed)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

5 A

(UL listed)

L

1 L2 L

3

N

I1

31

I2

4

I3

9

7

IN

PE

6

10

12 16

11 2

5 8

K

k

L

l

5 A

(

UL listed)

u

U

v

V

current measurement: L1, voltage measurement: L2-L3

Direct connection

With current transformer

With current and voltage transformers

In case of current measurement via L2 or L3 connect the device

according to the following table:

Terminals 1 3 2 5 8

Current meas. via L2 I2(k) I2(l) - L3 L1

Current meas. via L3 I3(k) I3(l) - L1 L2

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 15/106

Three wire system, balanced load, phase shift

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

5 A

(UL listed

)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

5 A

(UL listed)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

5 A

(UL listed)

v

V

u

U

current measurement: L1, voltage measurement: L3-L1

Direct connection

With current transformer

With current and voltage transformers

In case of current measurement via L2 or L3 connect the device

according to the following table:

Terminals 1 3 2 5 8

Current meas. via L2

Current meas. via L3

I2(k)

I2(l)

I3(k) I3(l) L3 - L2

L2 - L1

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 16/106

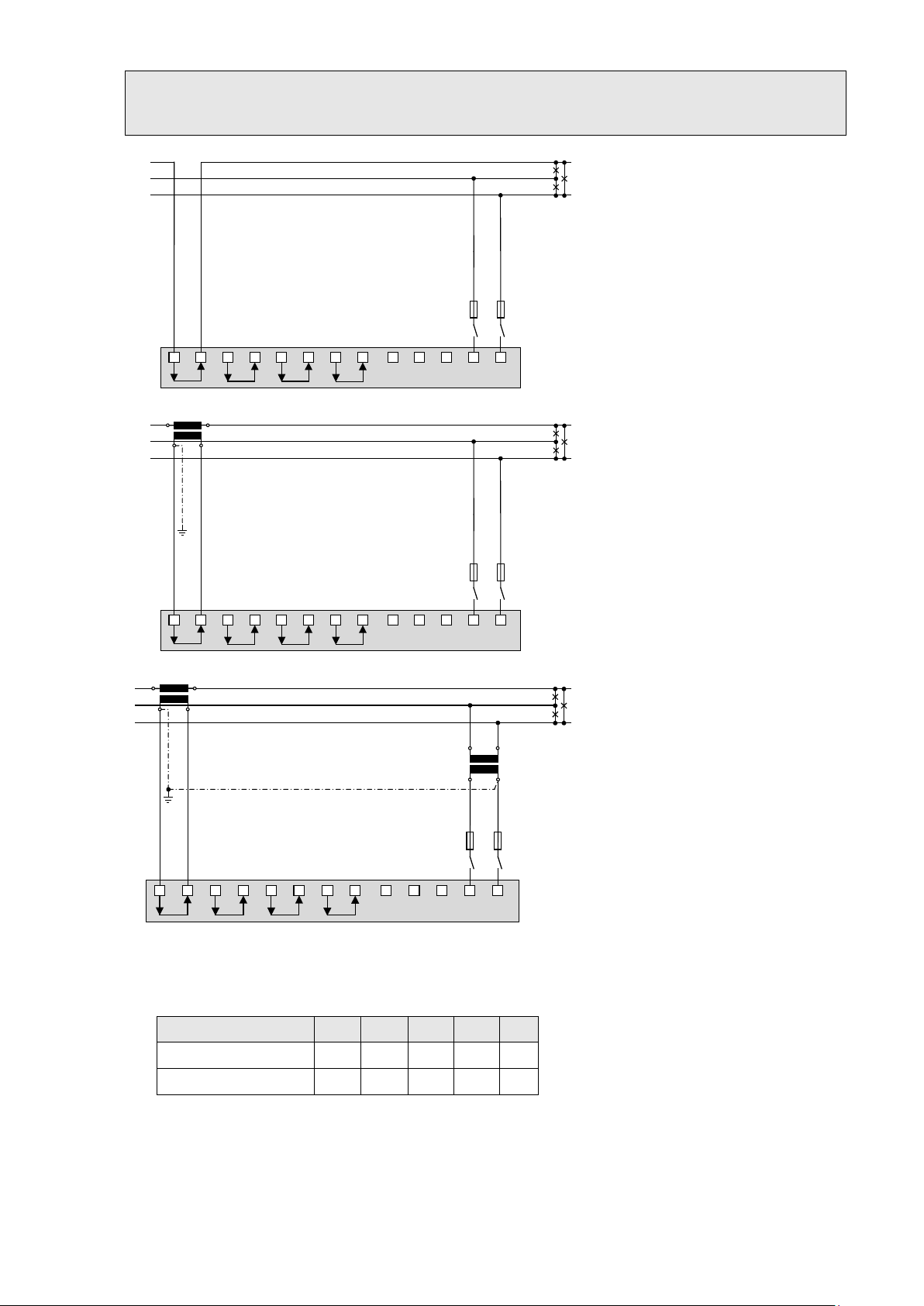

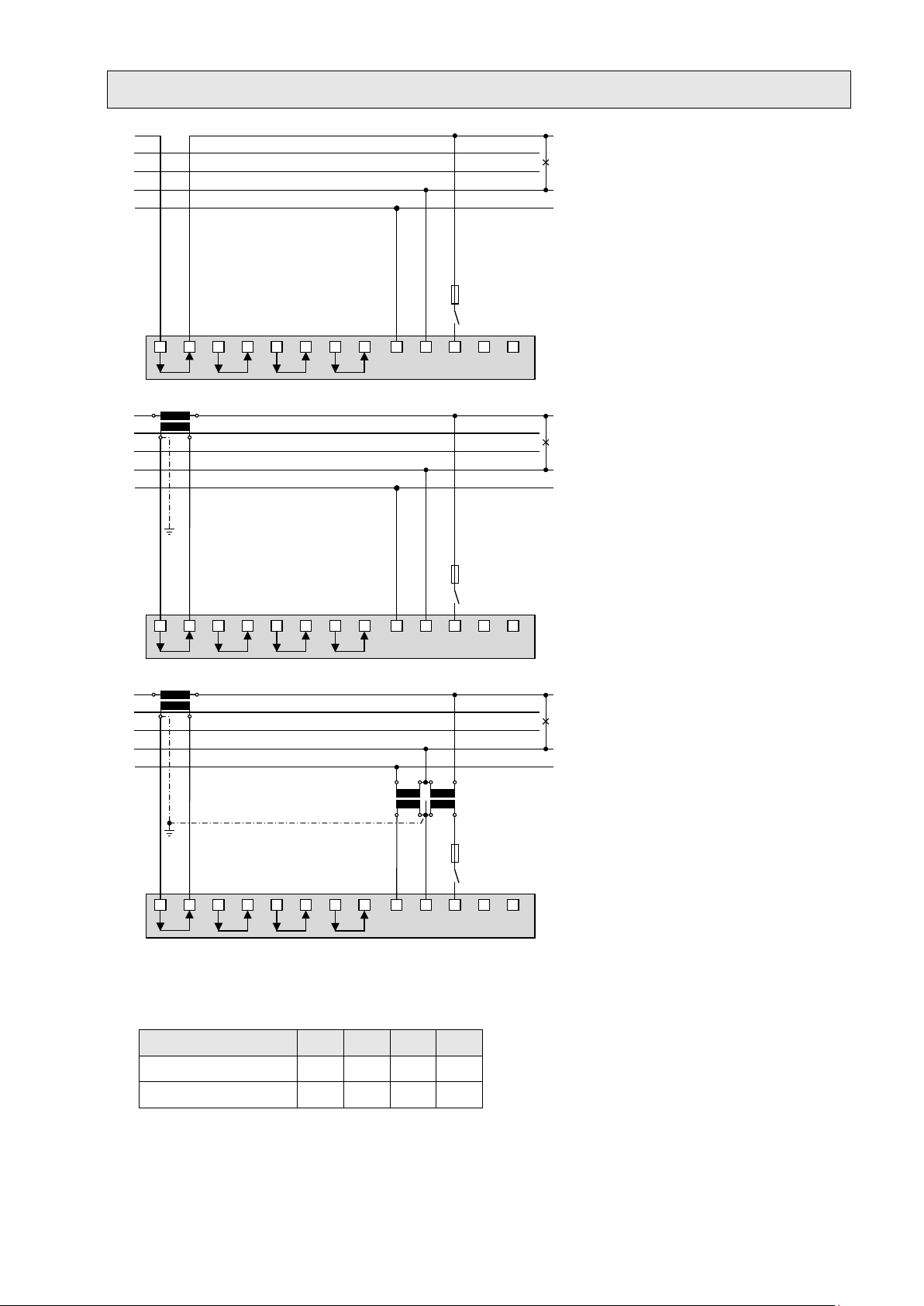

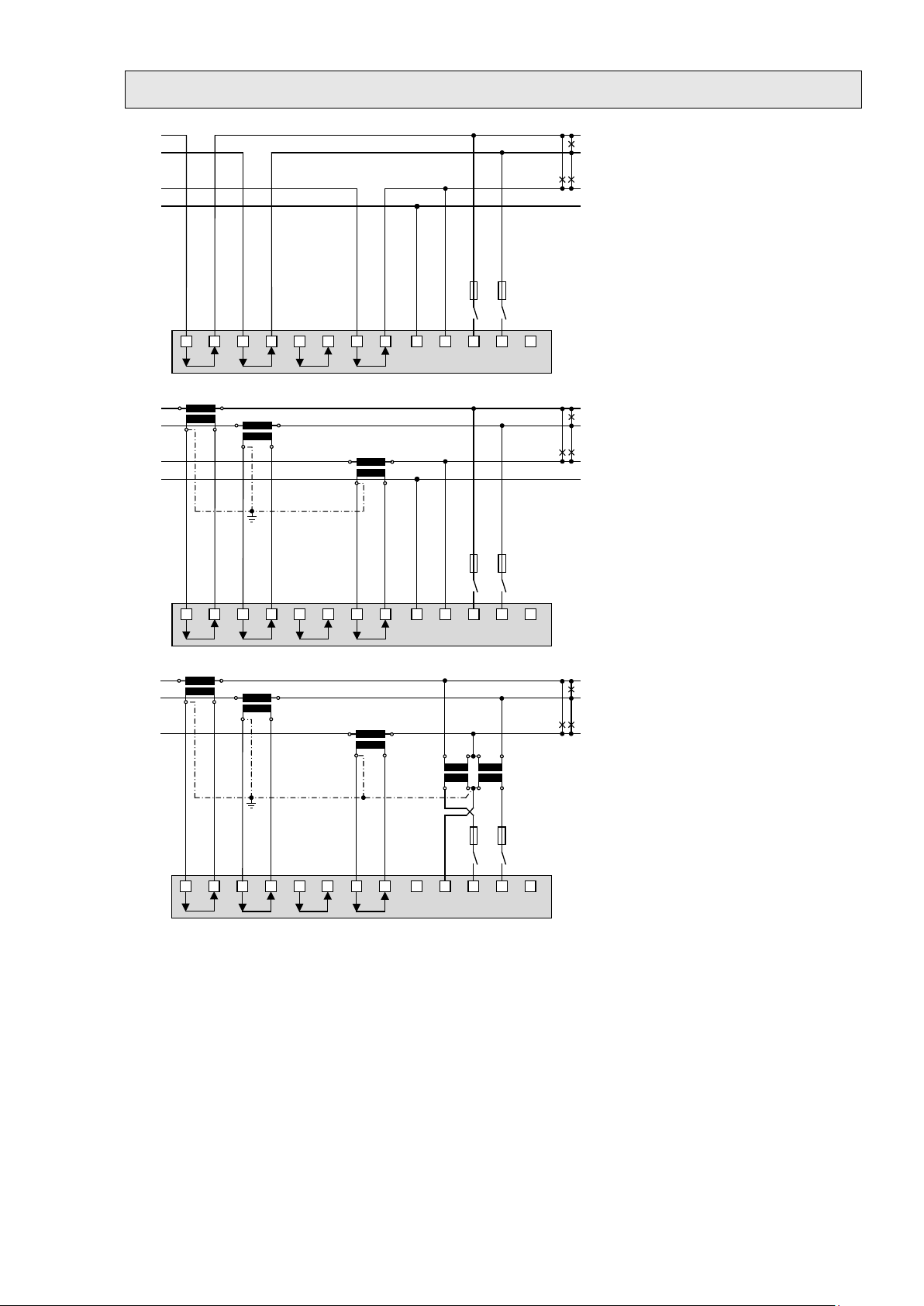

Three wire system, balanced load, current measurement via L1

L1 L

2

L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

5 A

(

UL listed)

L1

L2

L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2

5 8

L1

L2

L3

K

k

L

l

5 A

(UL listed

)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

5 A

(UL listed)

uUvVu

U

v

V

Direct connection

With current transformer

With current and voltage transformers

In case of current measurement via L2 or L3 connect the device

according to the following table:

Terminals 1 3 2 5 8

Current meas. via L2

Current meas. via L3

By rotating the voltage connections the

measurements U12, U23 and U31 will be

assigned interchanged!

I2(k)

I2(l)

I3(k) I3(l) L3 L1 L2

L2 L3 L1

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 17/106

Four wire system, balanced load, current measurement via L1

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L

3

N

5 A

(UL listed)

PE

L

1

L2

L3

N

I1

31

I

2

4

I

3

9

7

IN

PE

6

10

12

16

11

2

5

8

L

1

L

2

L

3

N

K

k

L

l

5 A

(

UL listed

)

PE

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

N

K

k

L

l

5 A

(UL listed)

uUv

V

uUv

V

PE

Direct connection

If voltage U

connection of PE can be omitted.

does not need to be measured,

NE

With current transformer

If voltage UNE does not need to be measured,

connection of PE can be omitted.

With current and voltage transformer

If voltage UNE does not need to be measured, the

corresponding transformer can be omitted.

In case of current measurement via L2 or L3 connect the device

according to the following table:

Terminals 1 3 2 11

Current meas. via L2

Current meas. via L3

I2(k)

I2(l)

I3(k) I3(l) L3 N

L2 N

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 18/106

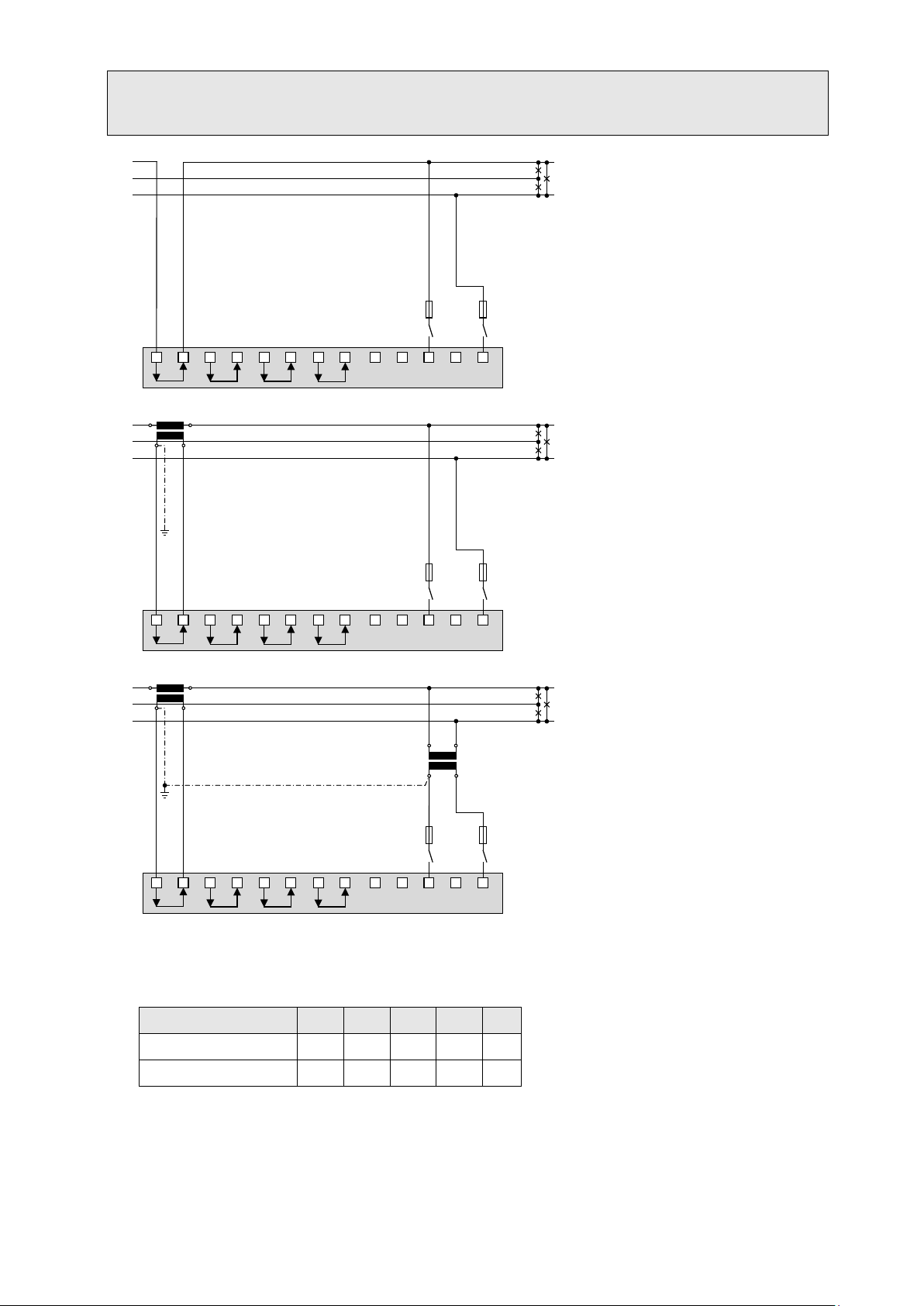

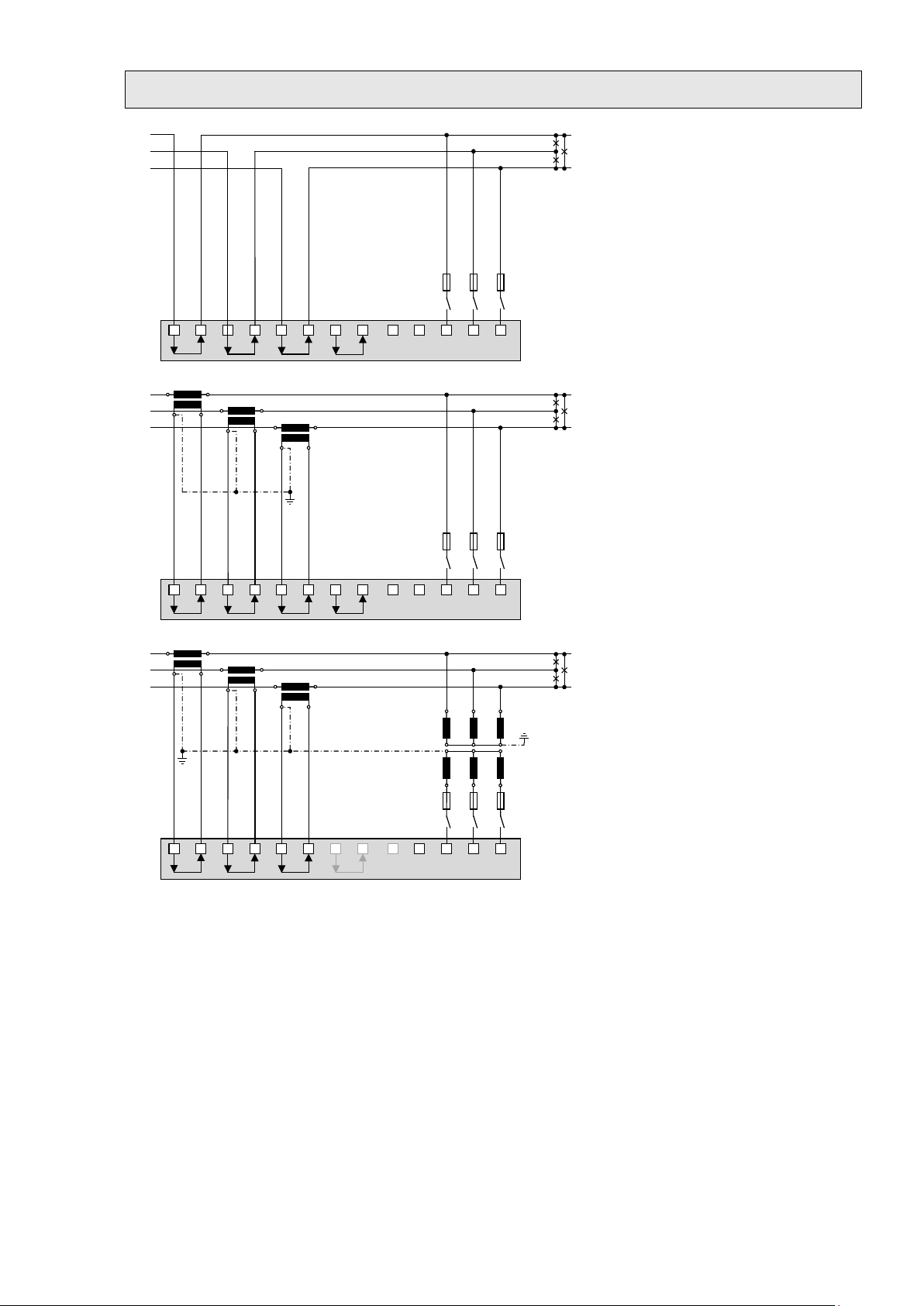

Three wire system, unbalanced load

L1 L

2

L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

5 A

(UL listed

)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

K

k

L

l

K

k

L

l

5 A

(UL listed)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

K

k

L

l

K

k

L

l

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

6

10 12 16

11 2 5 8

x

u

X

U

X

U

X

U

x

u

x

u

5 A

(UL listed)

Direct connection

With current transformers

With current and 3 single-pole isolated

voltage transformers

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 19/106

Three wire system, unbalanced load, Aron connection

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10

12 16

11 2 5 8

L1

L2

L3

5 A

(

UL listed

)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

K

k

L

l

5 A

(UL listed)

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

K

k

L

l

K

k

L

l

x

u

X

U

X

U

X

U

x

u

x

u

5 A

(UL listed)

Direct connection

With current transformers

With current and 3 single-pole isolated

voltage transformers

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 20/106

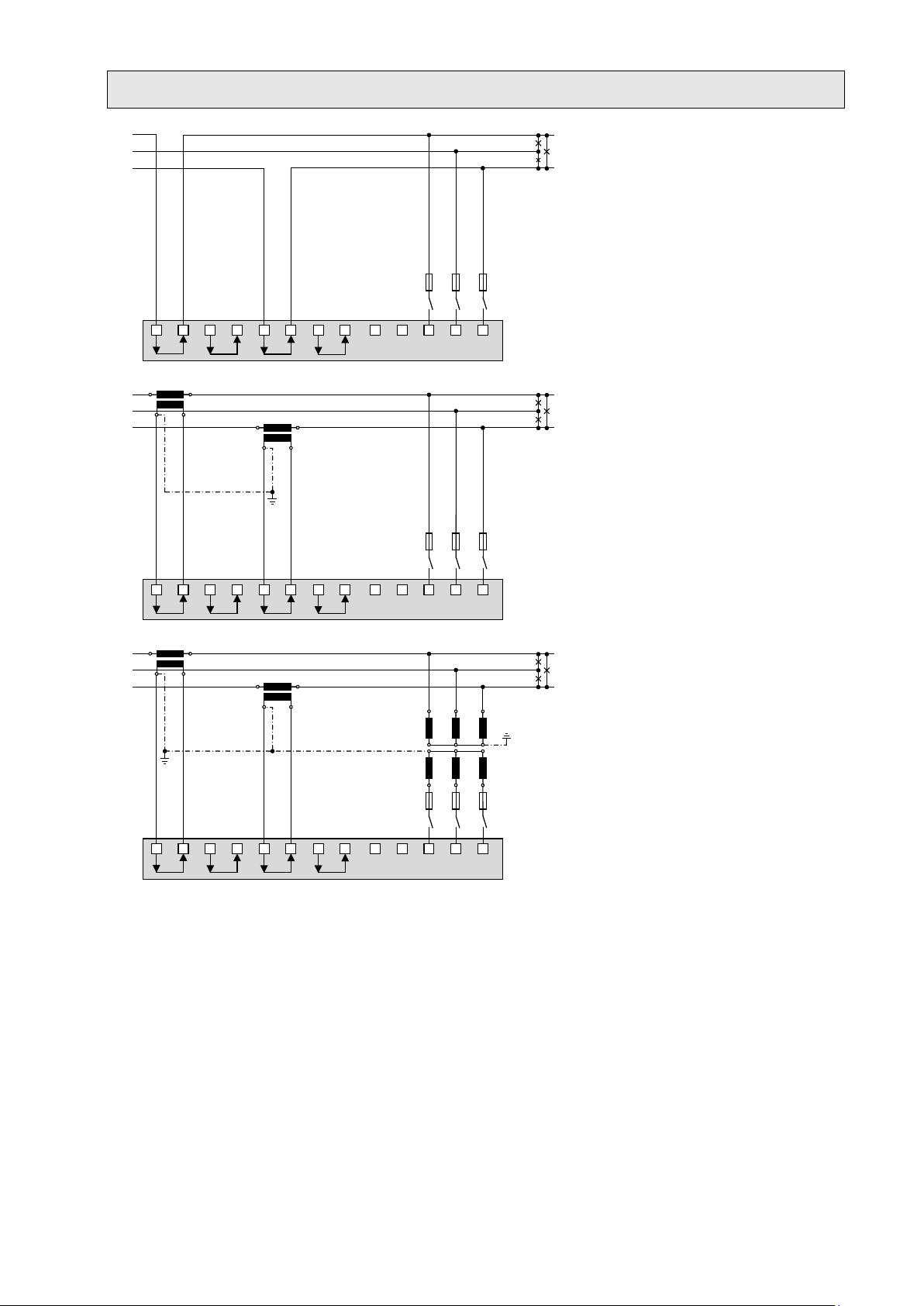

Four wire system, unbalanced load

L1 L2 L3

N

I

1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

N

5 A

(UL listed)

PE

L

1

L2 L3

N

I1

31

I

2

4

I

3

97

IN

PE

6

10

12 16

11

2 5 8

L

1

L2

L3

N

K

k

L

l

K

k

L

l

K

k

L

l

5 A

(

UL listed)

PE

K

k

L

l

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

L3

N

K

k

L

l

K

k

L

l

K

k

L

l

x

u

X

U

X

U

X

U

x

u

x

u

5 A

(UL listed)

K

k

L

l

Direct connection

If current I

or voltage UNE does not need to be

N

measured, connection of IN resp. PE can be

omitted.

With current transformer

If voltage UNE does not need to be measured,

connection of PE can be omitted.

If current I

corresponding transformer can be omitted.

does not need to be measured, the

N

With current and voltage transformer

If current IN does not need to be measured, the

corresponding transformer can be omitted.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 21/106

Four wire system, unbalanced load, Open-Y

L

1 L2 L3

N

I

1

3

1

I2

4

I3

97

IN

PE

6

10

12 16

11 2 5 8

L1

L

2

L3

N

5 A

(UL listed)

PE

N

L

1

L2

L3

N

I1

31

I

2

4

I

3

97

IN

PE

6

10

12 16

11 2

5 8

L1

L

2

L

3

N

5 A

(UL listed

)

PE

N

K

k

L

l

K

k

L

l

K

k

L

l

K

k

L

l

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L

2

L3

N

5 A

(UL listed)

N

K

k

L

l

K

k

L

l

K

k

L

l

K

k

L

l

x

u

X

U

X

U

x

u

Direct connection

If current I

or voltage UNE does not need to be

N

measured, connection of IN resp. PE can be

omitted.

With current transformer

If voltage UNE does not need to be measured,

connection of PE can be omitted.

If current I

corresponding transformer can be omitted.

does not need to be measured, the

N

With current and voltage transformer

If current IN does not need to be measured, the

corresponding transformer can be omitted.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 22/106

Split-phase ("two phase system"), unbalanced load

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

N

5 A

(UL listed)

PE

L1 L2 L3

N

I1

31

I2

4

I3

97

IN

PE

6

10 12 16

11 2 5 8

L1

L2

N

K

k

L

l

K

k

L

l

5 A

(UL listed)

K

k

L

l

PE

L1 L2

L3

N

I1

31

I2

4

I3

97

IN

PE

6

10

12 16

11 2 5

8

L1

L2

N

K

k

L

l

K

k

L

l

5 A

(UL listed)

K

k

L

l

u

U

v

V

u

U

v

V

Direct connection

With current transformers

With current and voltage transformer

In systems without a primary neutral conductor a

voltage transformer with a secondary center tap

can also be used.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 23/106

5.5 Power supply

A marked and easily accessible curr en t limiting switch has to be arranged in the vicinity of

the device for turning off the power supply. Fusing should be 10 Amps or less and must be

rated for the available voltage and fault current.

5.6 Relays

When the device is switched off the relay contacts are de-energized, but dangerous

voltages may be present.

Relays are available for device versions with corresponding I/O extensions only.

CU3000 CU5000

I/O extension y x

1 5

2 6

3 4

4 3

5.7 Digital inputs

The device provides a standard passive digital input. In addition, depending on the device version, there

may be 4-channel passive or active digital input modules available.

Usage of the standard digital input

► Status input

► Meter tariff switching

Usage of the inputs of the optional input modules

► Counting input for pulses of meters for any kind of energy (pulse width 70…250ms)

► Operating feedback of loads for operating time counters

► Trigger and release signal for monitoring functions

Passive inputs (external power sup ply with 12 / 24 VDC required)

The power supply shall not exceed 30V DC!

CU3000 CU5000

Technical data

Input current < 7,0 mA

Logical ZERO - 3 up to + 5 V

Logical ONE 8 up to 30 V

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 24/106

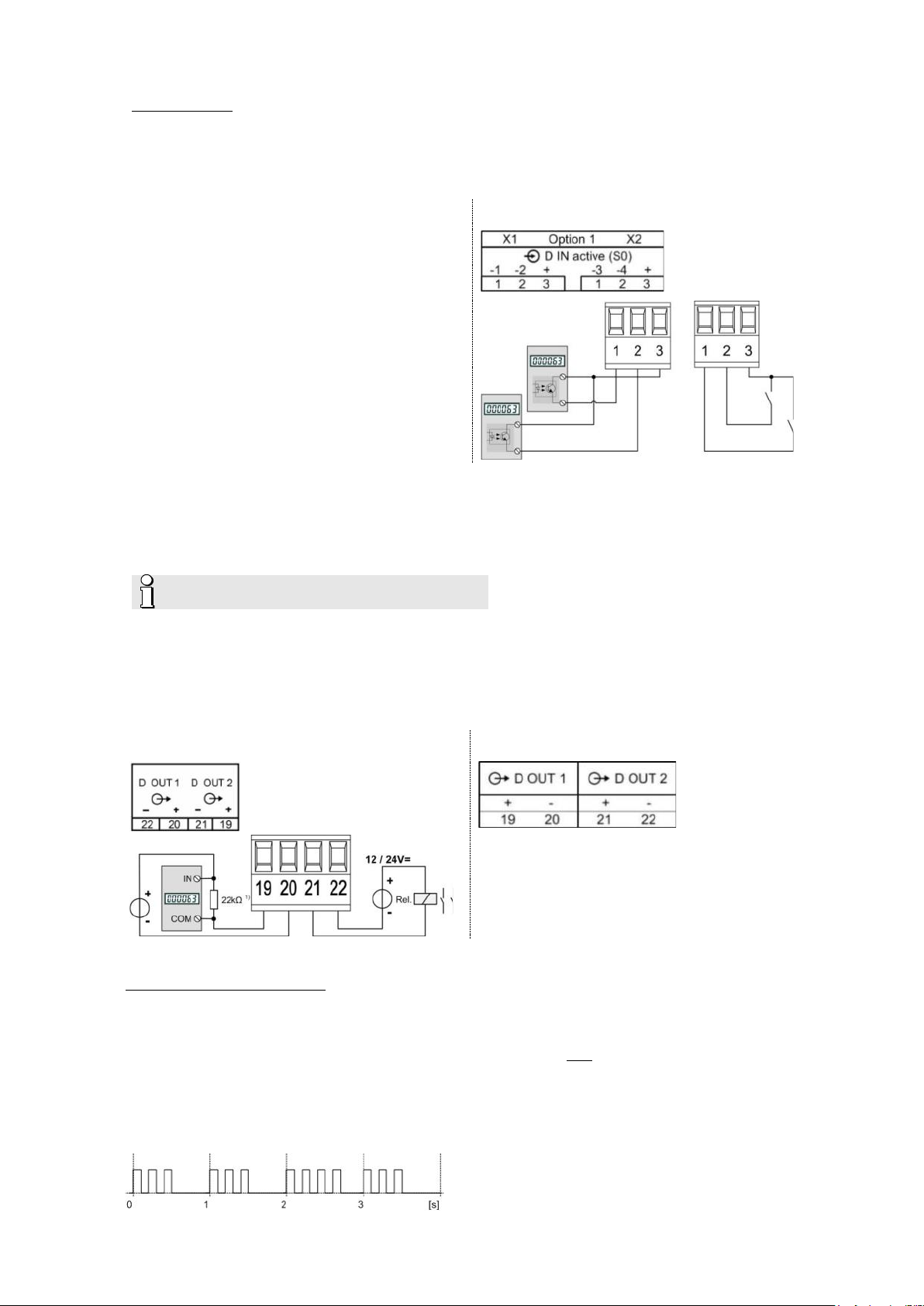

Active inputs (no external power supply required)

Technical data (acc. EN62053-31, class B)

Open circuit voltage ≤ 15 V

Short circuit current < 15 mA

Current at R

=800Ω ≥ 2 mA

ON

CU3000 CU5000

Example with meter pulse and status inputs

5.8 Digital outputs

The device has two standard digital outputs for which an external 12 / 24 VDC power supply is required.

The power supply shall not exceed 30V DC!

Usage as digital output

► Alarm output

► State reporting

► Pulse output to an external counter (acc. EN62053-31)

► Remote controlled output

CU3000 CU5000

1)

Recommended if input impedance of counter > 100 kΩ

Driving a counter mechanism

The width of the energy pulses can be selected within a range of 30 up to 250ms, but have to be adapted

to the external counter mechanism.

Electro mechanical meters typically need a pulse width of 50...100ms.

Electronic meters are partly capable to detect pulses in the kHz range. There are two types: NPN (active

negative edge) and PNP (active positive edge). For this device a PNP is required. The pulse width has to

be ≥ 30ms (acc. EN62053-31). The delay between two pulses has to be at least the puls e widt h. T he

smaller the pulse width, the higher the sensitivity to disturbances.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 25/106

Driving a relay

Rated current 50 mA (60 mA max.)

Switching frequency (S0) ≤ 20 Hz

Leakage current 0,01 mA

Voltage drop < 3 V

Load capacity 400 Ω … 1 MΩ

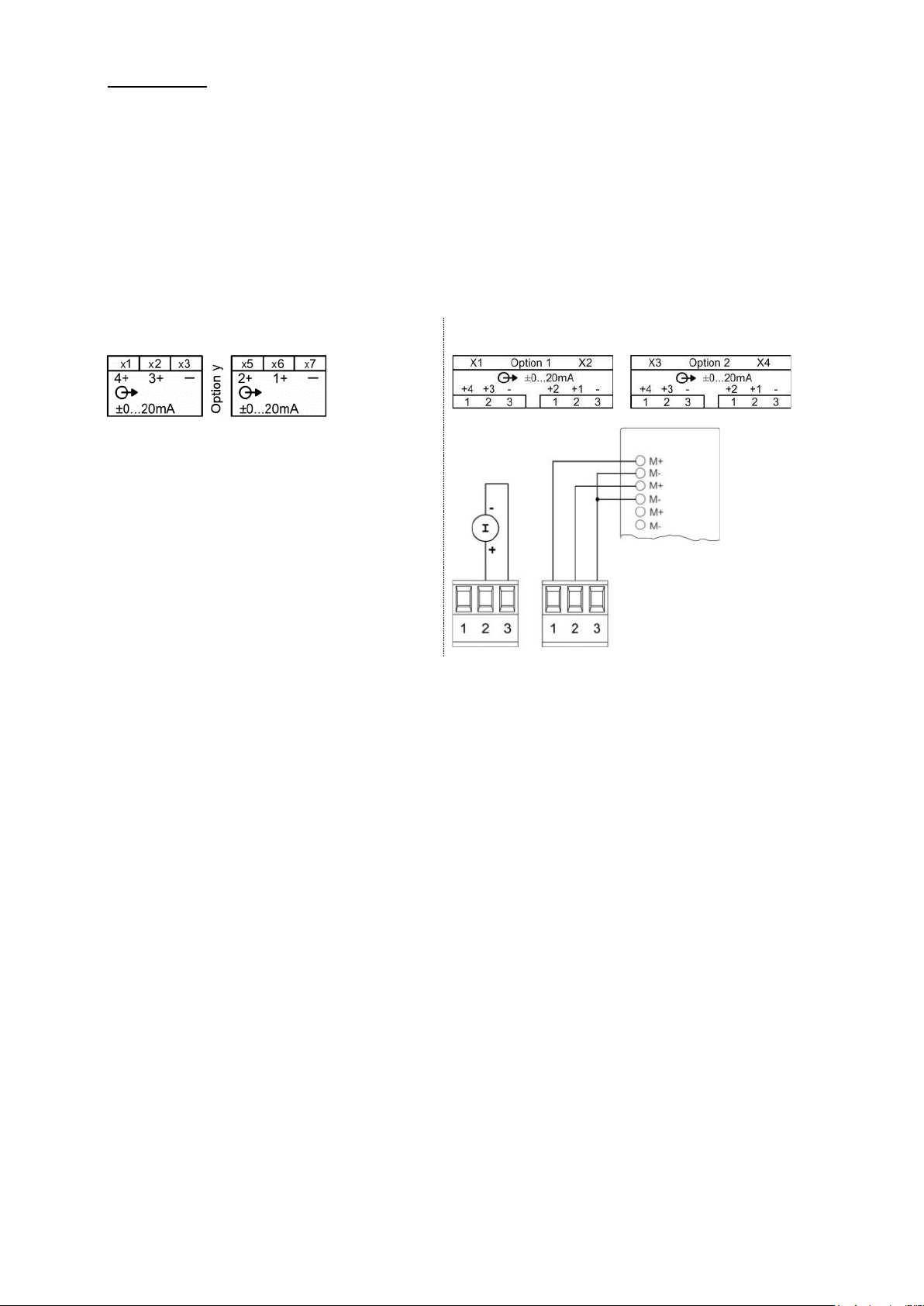

5.9 Analog outputs

Analog outputs are available for devices with corresponding I/O extensions only. See nameplate. Analog

outputs may be remote controlled.

CU3000 CU5000

Connection to an analog input card of a PLC or a control system

The device is an isolated measurement device. The individual outputs are galvanically connected, but the

modules are isolated from each other. To reduce the influence of disturbances shielded a twisted-pair

cables should be used. The shield should be connected to earth on both opposite ends. If there are

potential differences between the ends of the cable the shield should be earthed on one side only to

prevent from equalizing currents.

Under all circumstances consider as well appropriate remarks in the instruction manual of the system to

connect.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 26/106

5.10 Fault current detection

Use only transformers intended for this application

catalog

divergent specifications may damage the measurement in

CU3000

CU5000

The current transformers including the conductor isolation must guarantee in total a

reinforced or double insulation between the mains circuit connected on the primary

and the measuring inputs of the device

Only one measurement range may be connected per measuring channel!

The COM connectors of both measurement channels are internally connected.

For 2mA inputs a connection monitoring (breakage) is

signaled for the respective measurement channels if either the current transfomer is

disconnected or the connection to the transformer is interrupted.

Each fault current module provides two channels for monitoring differential or fault currents in earthed

AC current systems. In any case measurement has to be performed via suitable current transformers, a

direct measurement is not possible. The module is not suited for monitoring operating currents of normally

live conductors (L1, L2, L3, N).

Measurement ranges

Each channel provides two measurement ranges:

a) Measurement range 1A

• Application: Direct measurement of a fault or earth wire current

• Meas. transformer: Current transformer 1/1 bis 1000/1A; 0.2 up to 1.5VA;

Instrument security factor FS5

b) Measurement range 2mA

• Application: Residual current monitoring (RCM)

• Meas. transformer: Residual current transformer 500/1 up to 1000/1A

Rated burden 100 Ω / 0.025 VA up to 200 Ω / 0.06 VA

, according to our current transformer

, or transformers that fulfill the above specification. Using transformers with

puts.

Connection

Erweiterung y x

1 5

2 6

3 4

4 3

side

.

implemented. An alarm state is

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 27/106

Example: Fault current monitoring in a TNS system

Hints

(1) If the current transfomers for the fault current detection needs to be grounded on the secondary side

this has to be done via the COM connector.

(2) Note that all conductors have to cross the residual current transformer

in the same direction.

(3) A possible fault current flows through the protective

earth conductor (PE). It can only be detected if the PE

conductor is not routed through the residual current

transformer. If this cannot be avoided, e.g. due to using

a multi-wire cable with all conductors, the PE conductor

must be returned through the transformer.

(4) The cable or individual conductors should be routed through the

transformer as centered as possible in order to minimize

measurement errors.

(5) Neither the current transformers nor the measurement leads should be mounted or installed close to

strong magnetic fields. Measurement lines should also not be laid in parallel to power lines.

(6) For measurement range 1A only: The rated output of the transformer must be chosen that it is

reached when the rated secondary current (1A) flows. Consider that the burden of the transformer is

not only made up by the burden of the measurement input, but also by the resistance of the

measurement lines and the self-consumption of the transformer (copper losses).

A rated output selected too low leads to saturation losses in the transformer. The secondary

rated current can no longer be reached as the transformer reaches its limits before.

A rated output selected too high or an exceeding instrument security factor (>FS5) may cause

damage to the measuring inputs in case of overload.

(7) For the connection of the transformer to the fault detection module use …

2

Conductor cross sections of 1.0 up to 2.5mm

Pairwise twisted connections in case of short cable lengths

Shielded cables (shield grounded on one side only) in disturbed environment or in case of long

cable lengths

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 28/106

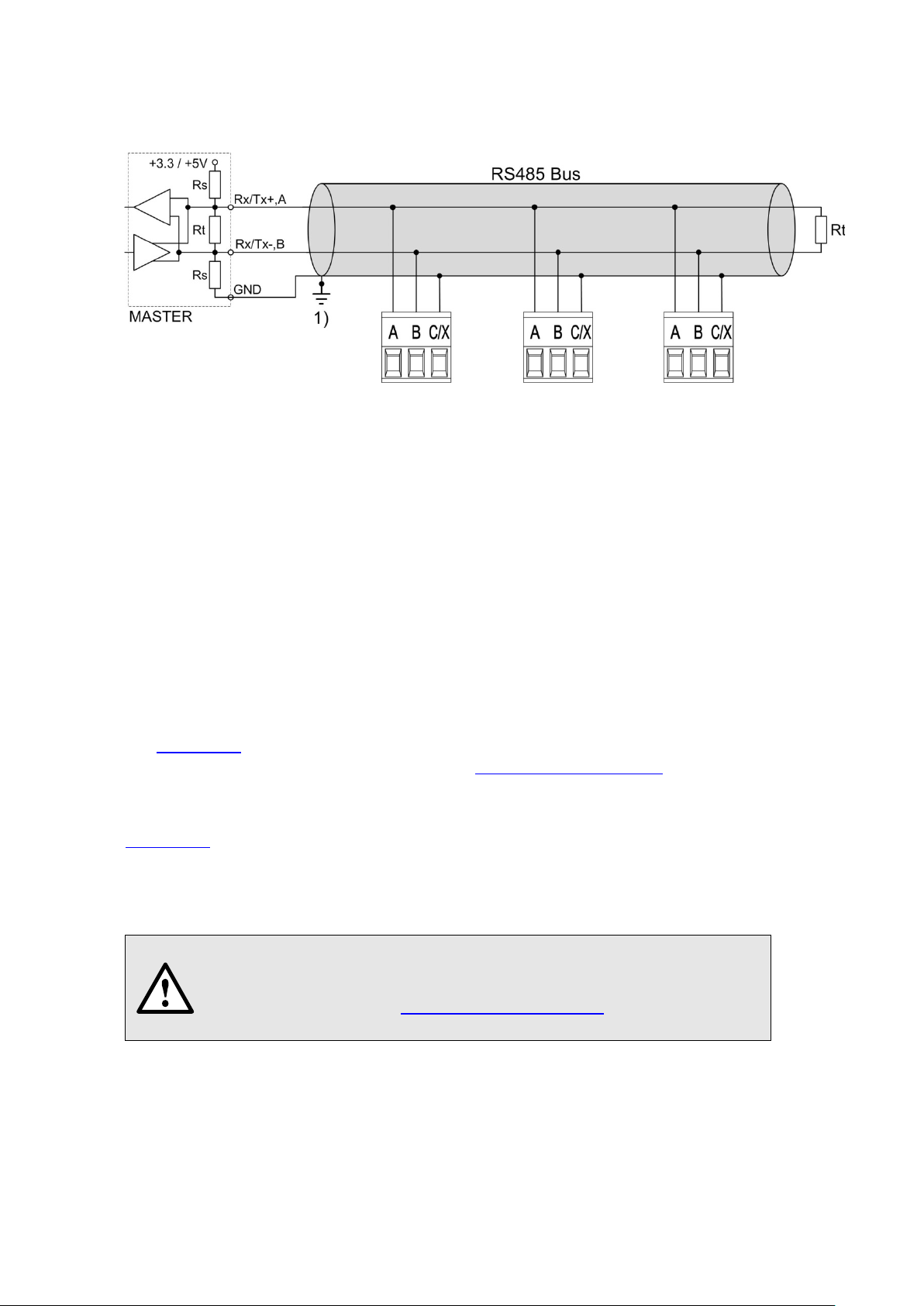

5.11 Modbus interface RS485

Via the optional Modbus interface measurement data may be provided for a superior system. However,

the Modbus interface cannot be used for device parameterization.

1) One ground connection only.

This is possibly made within the

master (PC).

Rt: Termination resistors: 120 Ω each

for long cables (> approx. 10 m)

Rs: Bus supply resistors,

390 Ω each

The signal wires (A, B) have to be t wist ed. G ND ( C/X) can be connected via a wire or via th e c abl e sc r een.

In disturbed environments shielded cables must be used. Supply resistors (Rs) have to be present in bus

master (PC) interface. Stubs should be avoided when connecting the devices. A pure line network is ideal.

You may connect up to 32 Modbus devices to the bus. A proper operation requires that all devices

connected to the bus have equal communication settings (baud rate, transmission format) and unique

Modbus addresses.

The bus system is operated half duplex and may be extended to a maximum length of 1200 m without

repeater.

5.12 Uninterruptible power supply (UPS)

The battery pack for the uninterruptible power supply is supplied separately. Please note that compared to

the storage temperature range of the base unit the storage temperature range of the battery pack is

restricted.

Ensure that devices with uninterruptible power supply are used in an environment in accordance with the

specification

recharged.

. Outside this operating temperature range, it is not ensured that the battery pack is

Due to aging the capacity of the battery decreases. To ensure a successful operation of the device during

power interuptions the batt ery needs to be replaced every 3 up to 5 years.

Potential for Fire or Burning. Do do not disassemble, crush, heat or burn the

removed battery pack.

Replace battery pack with a battery pack of the same type only. Use of another

battery may present a risk of fire or explosion.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 29/106

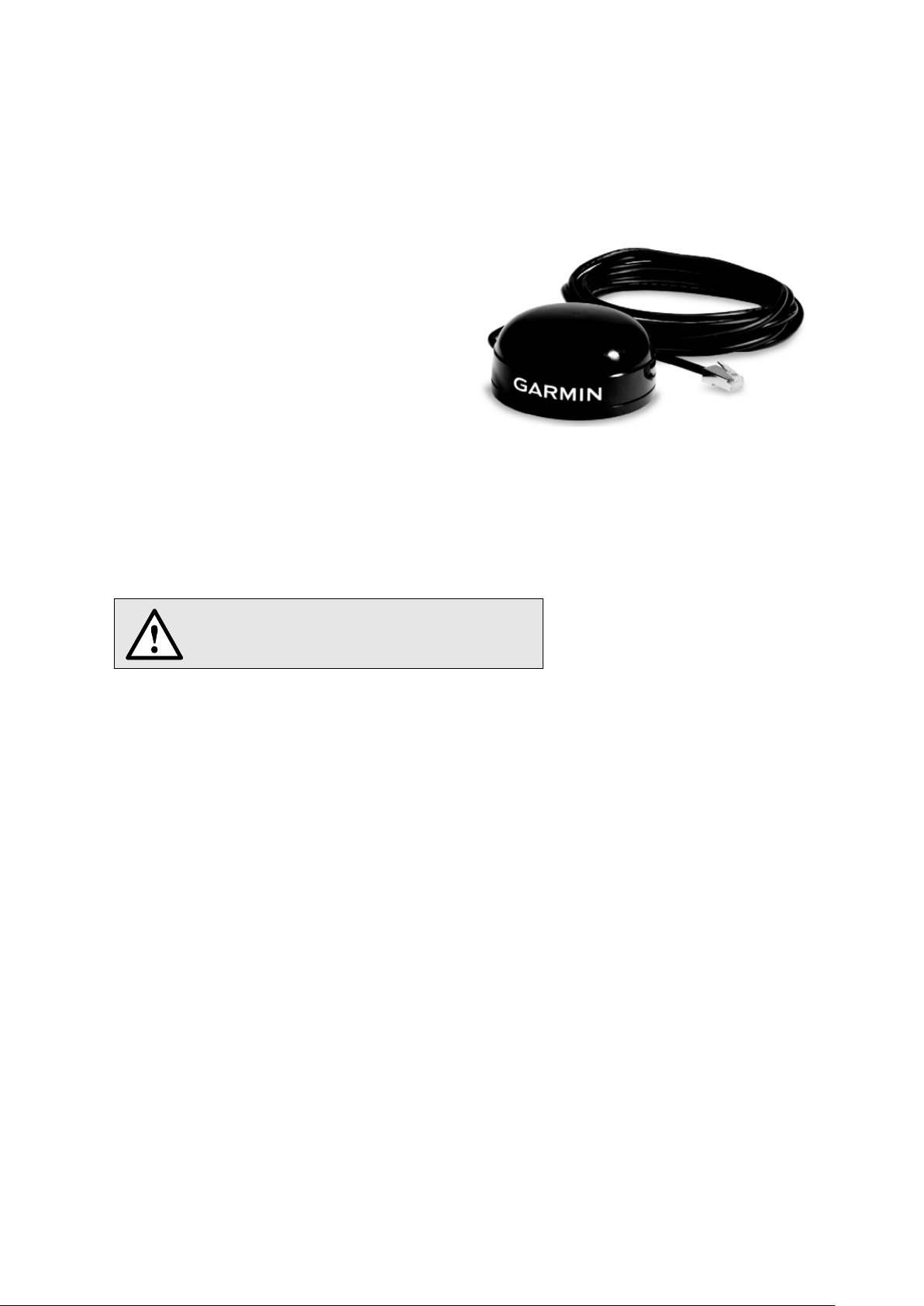

5.13 GPS time synchronization

Only use the receiver Garmin GPS 16x-LVS (article

The optional GPS connection module serves for connecting a GPS receiver as a very accurate time

synchronization source for the measurement device. The GPS receiver, available as an accessory, is

used as outdoor antenna to process data from multiple GPS satellites simultaneously.

GPS receiver

no. 181‘131), offered as an accessory. This device

is preconfigured by us and provides the required

time information (sentences) without further

configuration effort .

• Protection: IPx7 (waterproof)

• Operating temperature: -30…80°C

• Storage temperature: -40…80°C

• 1Hz pulse accuracy: 1μs

• Connector: RJ45

Choosing a mounting location

For a correct operation the GPS receiver requires data from at least 3 satellites at the same time.

Therefore position the receiver so that the clearest possible view of the sky and horizon in all direction is

obtained. This can be on the roof of a building, at best without reception being restricted by other

buildings or obstacles. Avoid mounting the receiver next to large areas of conductible material, as this

may cause poor signal reception. It should be also not closer than 1 meter away from any other antenna.

If lightning protection is required, this must be

provided by the user himself.

Mounting the GPS receiver

• The GPS receiver Garmi n G PS 16x -LVS

can be flush mounted by means of 3 M4

screws.

• 120° distribution over a circle of ø71.6mm

• Thread length max. 8mm. Using longer

screws may damage the GPS receiver.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 30/106

Connecting the GPS receiver

When connecting a GPS receiver for the first time or when it has been out of

operation for a long time, it may take up to 1 hour for finding enough satellites f

GPS receiver operation and thus for a reliable time synchronization.

Never connect the RJ45 connector of the connecting cable

directly to a network device such as a router or switch. These

devices could be damaged.

The GPS receiver is plugged directly into the GPS connection module. The connection cable has a length

of 5 m. It may be extended using an RJ45 coupling and an Ethernet cable. The connection cable should

not be laid in parallel to live conductors. Twisting or sharp kinking of the cable should be avoided.

Commissioning

• In the settings menu change time synchronization to „NTP server / GPS“

• Check the time synchronization status

• The time synchronization can be restarted by switching the time synchronization off and on again.

• Time synchronization via GPS and NTP server may work in parallel. If both synchronization sources

are available, the system uses the more accurate time source, which is normally GPS.

or

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 31/106

6. Commissioning

Measurement input

Before commissioning you have to check if the connection data of the device match the data

of the plant (see nameplates).

If so, you can start to put the device into operation by switching on the power supply and the

measurement inputs.

Measurement input

Input voltage

Input current

System frequency

1 Works no.

2 Test and conformity marks

3 Assignment voltage inputs

4 Assignment current inputs

5 Assignment power supply

6 Load capacity relay

outputs

…………………………………………………………………………………………………………………………

Input voltage

Input current

System frequency

1 Works no.

2 Test and conformity marks

3 Assignment voltage inputs

4 Assignment current inputs

5 Assignment power supply

6 Load capacity relay

outputs

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 32/106

6.1 Parametrization of the device functionality

Missing phase or magnitude too

A full parameterization of all functions of the device is possible directly at the device (for devices with

display only) or via web browser.

See: Configuration (7.5)

6.2 Operating LED (CU5000 only)

The operating LED shows the present device state.

Procedure LED display

Booting of device

Firmware update

Factory reset or reset of communication

settings

• Flashes green (1 Hz)

• If successful: Change to static green display

• Change to update mode: Static red

• During update: Flashes red (1 Hz)

• If successful or cancelled: Booting of device

• During reset: Flashes red (1 Hz)

• Then: Booting of device

6.3 Installation ch ec k

The correct connection of the current and voltage inputs can be checked in two ways.

a) Sense of rotation check: Using the sequence of the current and voltage phasors the sense of

rotation is determined and compared to the configured one. The phase rotation indicator is arranged

in the menu “Phasor diagram”.

Test requirement: Magnitude of all connected voltages at least 5% of nominal, magnitude of all

connected currents at least 0.2% of nominal.

Possible results

Correct sense of rotation

Wrong sense of rotation

small

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 33/106

b) Phasor verification: The phasor diagram shows a technical visualization of the current and voltage

The diagram is always built basing on the voltage of

the reference channel (direction 3 o’clock)

phasors, using a counter-clockwise rotation, independent of the real sense of rotation.

Correct installation (expectation)

• Voltage sequence in clock-wise order

L1 L2 L3 (0° -120° 120°)

• Current sequence in clock-wise order

L1 L2 L3

• Similar angle between voltage and current phasors in

all phases (approx. -20°)

What’s wrong?

• Voltage sequence: L1 L2 L3

• Current sequence: L1 L3 L2; Current L2 is out of

the expected sequence

• Angle U-I: Angle between UL2 and IL2 is approx. 180°

wrong

Required correction

Exchanging the connections of current I2

What’s wrong?

• Voltage sequence: L1 L3 L2; L3 and L2 seem to

be interchanged

• Current sequence: L1 L2 L3

• Angle U-I: Angle between U

wrong

Required correction

Exchanging the connections of the voltages L2 and L3

and IL2 is approx. 180°

L2

What’s wrong?

• Voltage sequence: L1 L3 L2; L3 and L2 seems to

be exchanged

• Current sequence: L1 L3 L2; Current L2 is out of

the expected sequence

• Angle U-I: Angles between UL2 / IL2 and UL3 / IL3 do not

correspond to the expectations

Required correction

Exchanging the connections of the voltages L2 and L3

and reversing the polarity of the current input I

What’s wrong?

• Voltage sequence: L1 L2 L3

• Current sequence: L2 L3 L1

• Angle U-I: The U-I angles do not correspond to the

expectation, but are similar

Required correction

Cyclical exchange of the voltage connections: L1L3,

L2L1, L3L2. As an alternative the sequence of all

current may be changed as well (more effort required).

2

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 34/106

6.4 Ethernet installation

6.4.1 Settings

Before devices can be connected to an existing Ethernet network, you have to ensure that they

will not disturb the normal network service. The rule is:

The device can be equipped with multiple Ethernet interfaces whose network settings can be configured

independently.

Interface Application Default IP Settings via menu

Standard Configuration / Modbus TCP 192.168.1.101 Settings | Communication | Ethernet

IEC 61850 IEC61850 communication 192.168.1.102 Settings | IEC61850 | Ethernet

The following settings have to be arranged with the network administrator:

- IP address: This one must be unique, i.e. may be assigned in the network only once.

- Subnet mask: Defines how many devices are directly addressable in the network. This setting is equal

for all the devices. Examples

None of the devices to connect is allowed to have the same IP address

than another device already installed

.

- Gateway address: Is used to resolve addresses during communication between different networks. It

should contain a valid address within the directly addressable network.

- DNS-S erv e r x: Is used to resolve a domain name into an address, if e.g. a name (pool.ntp.org) is used

for the NTP server. Further informations

.

- Hostname: Individual designation for each device. Via the hostname the device can be uniquely

identified in the network. Therefore for each device a unique name should be assigned.

- NTP-Server x: NTP servers are used as base for time synchronization

- Modbus/TCP Port: Selection of the TCP port to be used for Modbus/TCP communication. Standard

setting is 502. See also TCP ports

.

Network settings of Standard interface

Network settings of IEC61850 interface

For a direct communication between device and PC both devices need to be in the same network when

the subnet mask is applied:

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 35/106

Example 1

11000000 10101000 00000001 01100101

255.255.255.224

11111111 11111111 11111111 11100000

xxxxx

192.168. 1. 96

11000000 10101000 00000001 01100000

11000000 10101000 00000001 01111111

Example 2

192.168. 57. 64

11000000 10101000 00111001 01000000

255.255.252. 0

11111111 11111111 11111100 00000000

xx xxxxxxxx

192.168. 56. 0

11000000 10101000 00111000 00000000

192.168. 59.255

11000000 10101000 00111011 11111111

decimal binary

IP address

Subnet mask

variable range

First address

Last address

► The device 192.168.1.101 can access directly the devices 192.168.1.96 … 192.168.1.127

IP address

Subnet mask

variable range

First address

Last address

► The device 192.168.57.64 can access directly the devices 192.168.56.0 ... 192.168.59.255

DHCP

If a DHCP server is available, alternatively the mode „DHCP“ or „DHCP, addresses only“ can be

selected for the Standard inter f ace. The device then gets all necessary information from the DHCP server.

The difference between the two modes is that for “DHCP” also the DNS server address is obtained.

192.168. 1.101

192.168. 1.127

decimal binary

The settings obtained from the DHCP server can be retrieved locally via the service menu.

Depending on the settings of the DHCP server the provided IP address can change on each

reboot of the device. Thus it’s recommended to use the DHCP mode during commissioning

only.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 36/106

Time synchronization via NTP protocol

CU3000

CU5000

For the time synchronization of devices via Ethernet NTP (Network Time Protocol) is the standard.

Corresponding time servers are used in computer networks, but are also available for free via Internet.

Using NTP it's possible to hold all devices on a common time base.

Two different NTP servers may be defined. If the first server is not available the second server is used for

trying to synchronize the time.

If a public NTP server is used, e.g. “pool.ntp.org”, a name resolution is required. This normally happens

via a DNS server. So, the IP address of the DNS server must be set in the communication settings of the

Ethernet interface to make a communication with the NTP server, and thus time synchronization, possible.

Your network administrator can provide you the necessary information.

The time synchronization of the Standard interface can be performed via a GPS receiver

as well.

TCP ports

The TCP communication is done via so-called ports. The number of the used port allows determining the

type of communication. As a standard Modbus/TCP communication is performed via TCP port 502, NTP

uses port 123. However, the port for the Modbus/TCP telegrams may be modified. You may provide a

unique port to each of the devices, e.g. 503, 504, 505 etc., for an easier analysis of the telegram traffic.

Independent of these setting a communication via port 502 is always supported. The device allows at

least 5 connections to different clients at the same time.

Firewall

Due to security reasons nowadays each network is protected by means of a firewall. When configuring the

firewall you have to decide which communication is desired and which have to be blocked. The TCP port

502 for the Modbus/TCP communication normally is considered to be unsafe and is often disabled. This

may lead to a situation where no communication between networks (e.g. via Internet) is possible.

6.4.2 Connection of the standard interface

The RJ45 connector serves for direct connecting an Ethernet cable.

Interface: RJ45 socket, Ethernet 100BaseTX

Mode: 10/100 MBit/s, full / half duplex, Auto-negotiation

Protocols: http, Modbus/TCP, NTP

Functionality of the LED's

• LED left: Switched on as soon as a network connection exists (link)

• LED right: Switched-on during communication with the device (activity)

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 37/106

6.4.3 Connection of the IEC61850 interface

CU3000

CU5000

• LED green: On if a network connection (link) exists, flashes during communication

CU3000

CU5000

The RJ45 sockets X1 and X2 serve for direct connecting Ethernet cables. Both ports are equivalent and

internally connected via a switch.

Interface: RJ45 sockets, Ethernet 100BaseTX

Mode: 10/100 MBit/s, full / half duplex, Auto-negotiation

Protocols: IEC61850, NTP

Functionality of the LED's

6.4.4 MAC addresses

For uniquely identifying Ethernet connections in a network, to each connection a unique MAC address is

assigned. Compared to the IP address, which may be modified by the user at any time, the MAC address

is statically.

Standard Ethernet interface

IEC61850 Ethernet-Schnittstelle

6.4.5 Communication tes ts

Via the service menu on the device website you may check if the selected network structure is valid. The

device must be able to reach the DNS server via gateway. The DNS server then allows resolving the URL

of the NTP server to an IP address. The Standard Ethernet interface serves as interface for the

communication tests.

• Ping: Connection test to any network device, (initial: g at e wa y address )

• DNS: Test, if the name resolution via DNS works (initial: URL of NTP server)

• NTP: Test, if the selected NTP-Server is in fact a time server (stratum x)

NTP server test

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 38/106

6.4.6 Resetting the communication settings of the CU5000

If the communication settings of the Standard

interface are no longer known, they can be

reset to the default settings by pressing the

sunk-in reset button (located below the

operating LED) for at least 3s. During the reset

the operating LED flashes red. After the reset

the device is rebooted.

6.5 Protection against device data changing

Configuration or measurement data stored in the device may be modified via either service or settings

menu. To protect these data a security system may be activated (default: not activated). If the security

system is active the user hat to enter a password before executing protected functions. Subsequent to a

successful password input the access remains open until the user leaves the settings / service menu or

an input timeout occurs.

For activating the security system a password input is required. The factory default is: “1234”.

The password can be modified by the user. Permitted characters are ‘a‘…‘z‘,

‘A‘…‘Z‘ and ‘0‘…‘9‘, length 4…12 characters.

ATTENTION: A reset to factory default will reset also the password. But for a factory

reset the present password needs to be entered. If this password is no longer known

the device must be sent back to the factory!

Representation

Security system

active

Security system

deactivated / inactive

Device display

Webpage

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 39/106

7. Operating the devic e

7.1 Operating elements

CU3000 CU5000

The operation of devices with display is performed by means of 6 keys:

4 keys for navigation ( , , , ) and for the selection of values

OK for selection or confirmation

ESC for menu display, terminate or cancel

The function of the operating keys changes in some measurement displays, during parameterization and

in service functions. For the CU3000 the valid functionality of the keys is then shown in a help bar.

7.2 Selecting the information to display

CU3000 CU5000

For devices with display, information selection is performed via menu. Menu items may contain further

sub-menus.

Displaying the menu

Press ESC. Each time the key is pressed a change to a higher menu level is performed, if present.

Displaying information

The menu item chosen using , can be selected using OK. Repeat the procedure in possible submenus

until the required information is displayed.

Return to measurement display

After 2 min. without interaction the menu is automatically closed and the last active measurement display

is shown.

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 40/106

7.3 Measurement displays and used symbols

For displaying measurement information the device uses both numerical and numerical-graphical

measurement displays.

Examples Measurement information

2 measured quantities

4 measured quantities

2x4 measured quantities

2x4 measured quantities with Min/Max

Graphical measurement display

Further examples

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 41/106

Incoming / outgoing / inductive / capacitive

The device provides information for all four quadrants.

Σ HT

Σ LT

ø

Examples

Quadrants are normally identified using the roman numbers

I, II, III and IV, as shown in the adjacent graphic. Depending

on whether the system is viewed from the producer or

consumer side, the interpretation of the quadrants is

changing: The energy built from the active power in the

quadrants I+IV can either been seen as delivered or

consumed active energy.

By avoiding terms like incoming / outgoing energy and

inductive or capacitive load when displaying data, an

independent interpretation of the 4-quadrant information

becomes possible. Instead the quadrant numbers I, II, III or

IV, a combination of them or an appropriate graphical

representation is used. You can select your own point of

view by selecting the reference arrow system (load or

generator) in the settings of the measurement.

Used symbols

For defining a measurement uniquely, a short description (e.g. U

sufficient. Some measurements need further information, which is given by one of the following symbols

or a combination of these symbols:

I,II,III,IV

Mean-value

Mean-value trend

Bimetal function (current)

Energy quadrants I+IV

Energy quadrants II+III

Energy quadrants I+II

Energy quadrants III+IV

Quadrants

) and a unit (e.g. V) are often not

1N

TRMS True root-mean-square val ue

RMS

(H1) Fundamental component only

Meter (high tariff)

Meter (low tariff)

Maximum value

Minimum value

Root-mean square value (e.g.

fundamental or harmonic content only)

Average (of RMS values)

CU3000: Meters with tariff and

quadrant information

PM 1001606 000 07 Device handbook CENTRAX CU3000-CU5000 42/106

CU5000: User mean values, last

value

CU5000: User mean values, trend

7.4 Resetting measurement data

• Minimum and maximum values may be reset during operation. The reset may be performed in

groups using the service menu.

Group Values to be reset

1 Min/max values of voltages, currents and frequency

2 Min/max values of Power quantities (P,Q,Q(H1),D,S); min. load factors

3 Min/max values of power mean-values, bimetal slave pointers and free selectable mean-values

4 Maximum values of harmonic analysis: THD U/I, TDD I, individual harmonics U/I

5 All imbalance maximum values of voltage and current

• Meter contents may be individually set or reset during operation using the service menu

• Recorded logger data can be individually reset via the service menu. This makes sense whenever the

configuration of the quantities to record has been changed.

7.5 Configuration

7.5.1 Configuration at the device

A full parameterization of the device can be performed via the menu “Settings”. With the exception of the

“Country and clock” menu, all modifications will not take effect before the user accepts the query “Store