Page 1

Device handbook

APLUS-LED

Operating Instructions APLUS with LED display or without display

157 679-19 (PM 1000357 000 01) 04/2016

Camille Bauer Metrawatt AG

Aargauerstr asse 7

CH-5610 Wohlen / Switzerland

Phone: +41 56 618 21 11

Telefax: +41 56 618 35 35

e-Mail: info@cbmag.com

http://www.camillebauer.com

Page 2

2/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Legal information

Warning notices

In this document warning notices are used, which you have to observe to ensure personal safety and to prevent

damage to property. Depending on the degree of danger the following symbols are used:

If the warning notice is not followed death or severe personal injury

will result.

If the warning notice is not followed damage to property or severe

personal injury may result.

If the warning notice is not followed the device may be damaged or

may not fulfill the expected functionality.

Qualified personnel

The product described in this document may be handled by personnel only, which is qualified for the respective

task. Qualified personnel have the training and experience to identify risks and potential hazards when working

with the product. Qualified personn el are als o able to understa nd and follow the given safety and warning

notices.

Intended use

The product described in this document may be used only for the application specified. The maximum electrical

supply data and ambient conditions specified in the technical data section must be adhered. For the perfect and

safe operation of the device proper transport and storage as well as professional assembly, installation,

handling and maintenance are required.

Disclaimer of liability

The content of this document has been reviewed to ensure correctness. Nevertheless it may contain errors or

inconsistencies and we cannot guarantee completeness and correctness. This is especially true for different

language versions of this document. This document is regularly reviewed and updated. Necessary corrections

will be included in subsequent version and are available via our webpage http://www.camillebauer.com

.

Feedback

If you detect errors in this document or if there is necessary information missing, please inform us via e-mail to:

customer-support@camillebauer.com

Page 3

3/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Contents

1. Introduction ..................................................................................................................... 5

1.1 Purpose of this document ........................................................................................................ 5

1.2 Scope of supply ....................................................................................................................... 5

1.3 Further documents .................................................................................................................. 5

2. Security notes .................................................................................................................. 6

3. Device overview............................................................................................................... 6

3.1 Brief description ....................................................................................................................... 6

3.2 Possible modes of operation ................................................................................................... 7

3.3 Monitoring and alarming .......................................................................................................... 8

3.3.1 Alarming concept ................................................................................................................................. 8

3.3.2 Logic components ..............................................................................................................................10

3.3.3 Limit values ........................................................................................................................................11

3.3.4 Sequence of evaluation .....................................................................................................................12

3.4 Free Modbus image .............................................................................................................. 13

4. Mechanical mounting .................................................................................................... 14

4.1 Panel cutout .......................................................................................................................... 14

4.2 Mounting of the device .......................................................................................................... 14

4.3 Demounting of the device ...................................................................................................... 14

5. Electrical connections .................................................................................................. 15

5.1 General safety notes ............................................................................................................. 15

5.2 Electrical connections of the I/Os .......................................................................................... 16

5.3 Possible cross sections and tightening torques ..................................................................... 16

5.4 Inputs .................................................................................................................................... 17

5.5 Rogowski current inputs ........................................................................................................ 21

5.6 Power supply ......................................................................................................................... 22

5.7 Relays ................................................................................................................................... 22

5.8 Digital inputs and outputs ...................................................................................................... 23

5.9 Analog outputs ...................................................................................................................... 25

5.10 Modbus interface RS485 X4 and / or X8 ............................................................................... 25

5.11 Profibus DP interface............................................................................................................ 26

6. Commissioning.............................................................................................................. 27

6.1 Software installation CB-Manager ......................................................................................... 27

6.2 Parametrization of the device functionality ............................................................................. 28

6.3 Installation check ................................................................................................................... 29

6.4 Installation of Ethernet devices .............................................................................................. 30

6.4.1 Connection ......................................................................................................................................30

6.4.2 Network installation using the CB-Manager software .....................................................................31

6.4.3 Network installation by means of local programming .....................................................................32

6.4.4 Time synchronization via NTP-protocol ..........................................................................................33

6.4.5 TCP ports for data transmission .....................................................................................................33

6.5 Installation of Profibus DP devices ........................................................................................ 34

6.6 Protection against device data changing ............................................................................... 35

7. Operating the device ..................................................................................................... 36

7.1 Display and operating elements ............................................................................................ 36

7.2 Operating modes ................................................................................................................... 37

7.3 Setting the display brightness ................................................................................................ 38

7.4 Display modes ....................................................................................................................... 39

7.5 Meter reading ........................................................................................................................ 42

Page 4

4/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

7.6 Alarm handling ...................................................................................................................... 43

7.6.1 Alarm state display on the device ..................................................................................................... 43

7.6.2 Display of alarm texts ........................................................................................................................ 43

7.6.3 Acknowledgment of alarms via display ............................................................................................. 44

7.7 Resetting of measurements .................................................................................................. 45

7.8 Configuration ........................................................................................................................ 46

7.8.1 Selection of the parameter to edit ..................................................................................................... 50

7.8.2 Discrete selection .............................................................................................................................. 51

7.8.3 Setting value ..................................................................................................................................... 51

7.9 Data logger ........................................................................................................................... 52

7.9.1 Activation of data logger recording ................................................................................................... 52

7.9.2 SD card ............................................................................................................................................. 52

7.9.3 Access to logger data ....................................................................................................................... 53

7.9.4 Logger data analysis ......................................................................................................................... 53

8. Service, maintenance and disposal ............................................................................. 54

8.1 Protection of data integrity .................................................................................................... 54

8.2 Calibration and new adjustment ............................................................................................ 54

8.3 Cleaning................................................................................................................................ 54

8.4 Battery .................................................................................................................................. 54

8.5 Disposal ................................................................................................................................ 54

9. Technical data ................................................................................................................ 55

10. Dimensional drawings ................................................................................................... 60

Annex ................................................................................................................................... 62

A Description of measured quantities ............................................................................. 62

A1 Basic measurements............................................................................................................. 62

A2 Harmonic analysis ................................................................................................................. 65

A3 System imbalance ................................................................................................................. 66

A4 Reactive power ..................................................................................................................... 67

A5 Mean values and trend .......................................................................................................... 69

A6 Meters ................................................................................................................................... 70

B Dis pl ay matrices in FULL mode ................................................................................... 71

B0 Used abbreviations for the measurements ............................................................................ 71

B1 Display matrix single phase system ...................................................................................... 78

B2 Display matrix Split-phase (two-phase) systems ................................................................... 79

B3 Display matrix 3-wire system, balanced load ......................................................................... 80

B4 Display matrix 3-wire systems, unbalanced load ................................................................... 81

B5 Display matrix 3-wire systems, unbalanced load, Aron .......................................................... 82

B6 Display matrix 4-wire system, balanced load ......................................................................... 83

B7 Display matrix 4-wire systems, unbalanced load ................................................................... 84

B8 Display matrix 4-wire system, unbalanced load, Open-Y ....................................................... 85

B9 Display matrix of mean-values of power quantities ................................................................ 86

C FCC statement ............................................................................................................... 87

INDEX ................................................................................................................................... 88

Page 5

5/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

1. Introduction

1.1 Purpose of this document

This document describes the universal measurement device for heavy-current quantities APLUS. It is

intended to be used by:

• Installation personnel and commissioning engineers

• Service and maintenance personnel

• Planners

Scope

This handbook is valid for all hardware versions of the A

PLUS with LED display or without display. Some of

the functions described in this document are available only, if the necessary optional components are

included in the device.

Required knowledge

A general knowledge in the field of electrical engineering is required. For assembly and installation of the

device knowledge of applicable national safety regulations and installation standard is required.

1.2 Scope of supply

• Measurement device APLUS

• Safety instruct ions (multiple languages)

• Connection set basic unit: Plug-in terminals and mounting clamps

• Optional: Connection set I/O extension: Plug-in terminals

1.3 Further documents

Via our homepage http://www.camillebauer.com further documents about the APLUS can be downloaded:

• Safety instructions APLUS

• Data sheet A

PLUS

• Modbus basics: General description of the communication protocol

• Modbus interface A

PLUS: Register descript ion of Modbus/RTU communication via RS-485

• Modbus/TCP interface A

PLUS: Register description of Modbus/TCP communication via Ethernet

Page 6

6/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

2. Security notes

Device may only be disposed in a professional manner !

The installation and commissioning should only be carried out by trained personnel.

Check the following points before commissioning:

– that the maximum values for all the connections are not exceeded, see "Technical data"

section,

– that the connection wires are not damaged, and that they are not live during wiring,

– that the power flow direction and the phase rotation are correct.

The instrument must be taken out of service if safe operation is no longer possible (e.g. visible

damage). In this case, all the connections must be switched off. The instrument must be

returned to the factory or to an authorized service dealer.

It is forbidden to open the housing and to make modifications to the instrument. The instrument

is not equipped with an integrated circuit breaker. During installation check that a labeled switch

is installed and that it can easily be reached by the operators.

Unauthorized repair or alteration of the unit invalidates the warranty.

3. Device overview

3.1 Brief description

The APLUS is a comprehens ive instrument for the u niversal measurem ent, monitoring and power quality

analysis in power systems. The device can be adapted fast and easily to the meas urement task by means

of the CB-Manager software. T he universal measurement s ystem of the device may be used directl y for

any power system , from single ph ase up to 4-wire unbalanced netw orks, without hardware m odifications.

Independent of measurement task and outer influences always the same high performance is achieved.

Using additional, opt ional com ponents the opportunities of the A

PLUS m ay be extended . You may choose

from I/O extens ions, communic ation interf aces or data log ger. The nam eplate on the d evice gives f urther

details about the present version.

The version with top-ha t rail adapter instead of the display has th e same dimens ions and connec tions as

the version with display and supports the same options.

Page 7

7/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

3.2 Possible modes of operation

The APLUS can cover a wide range of possible input ranges without any hardware variance. The adaption

to the input signal is performed by means of variable amplifying levels for current and voltage inputs.

Depending on the application it makes sense to fix these levels by means of the configuration or to let

them stay variable to achieve a maximum accuracy during measurement. The differentiation, if the

amplifying remains constant or is adapted to the present value, is done during the definition of the input

configuration by means of the parameter "auto-scaling".

The disadvantage of auto-scaling is t hat whe n an amplifying level needs to be changed, a settling time of

at least one cycle of the power frequency must be allowed until the signals have stabilized again. During

this short time the measurement results remain frozen.

Continuous measurement

An absolute uninterrupted measurement of all quantities assumes that auto-scaling is deactivated for both

voltage and current inputs.

Metering

The uncertainty of the active energy meters of the A

PLUS is given with class 0.5S. To fulfill the high

requirements of the underlying meter standard EN 62053-22 also small currents have to be measured

very accurate. To do so, auto-scaling must be activated for current inputs. For metering applications the

system voltage is assumed to be quite constant, nominal value acc. standard, wherefore auto-scaling for

voltages is not required. The subsequent example shows an appropriate configuration, which also

conforms to the factory setting of the device.

Dynamic monitoring of limit values

An important criterion when monitoring the quality of the supply voltage is the possibility to detect short

sags of the system voltage. To be able to follow the progress of the voltage auto-scaling of the voltage

inputs should be deactivated. Thereby you have to consider that a possible swell of the voltage may be

detected only up to the configured overriding (20% of rated voltage in the above example), because the

switching of the measurement range is locked in both directions.

This applies analogously to all quantities of the system, whose progress should be monitored. For power

quantities the voltage amplification as well as the current amplification is influenced. However, which basic

quantities may vary how much can differ from application to application.

Page 8

8/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

3.3 Monitoring and alarming

The logic module integrated in the APLUS is a powerful feature to monitor critical situations without delay

on device side. By implementing this local intelligence a safe monitoring can be realized which is

independent of the readiness of the control system.

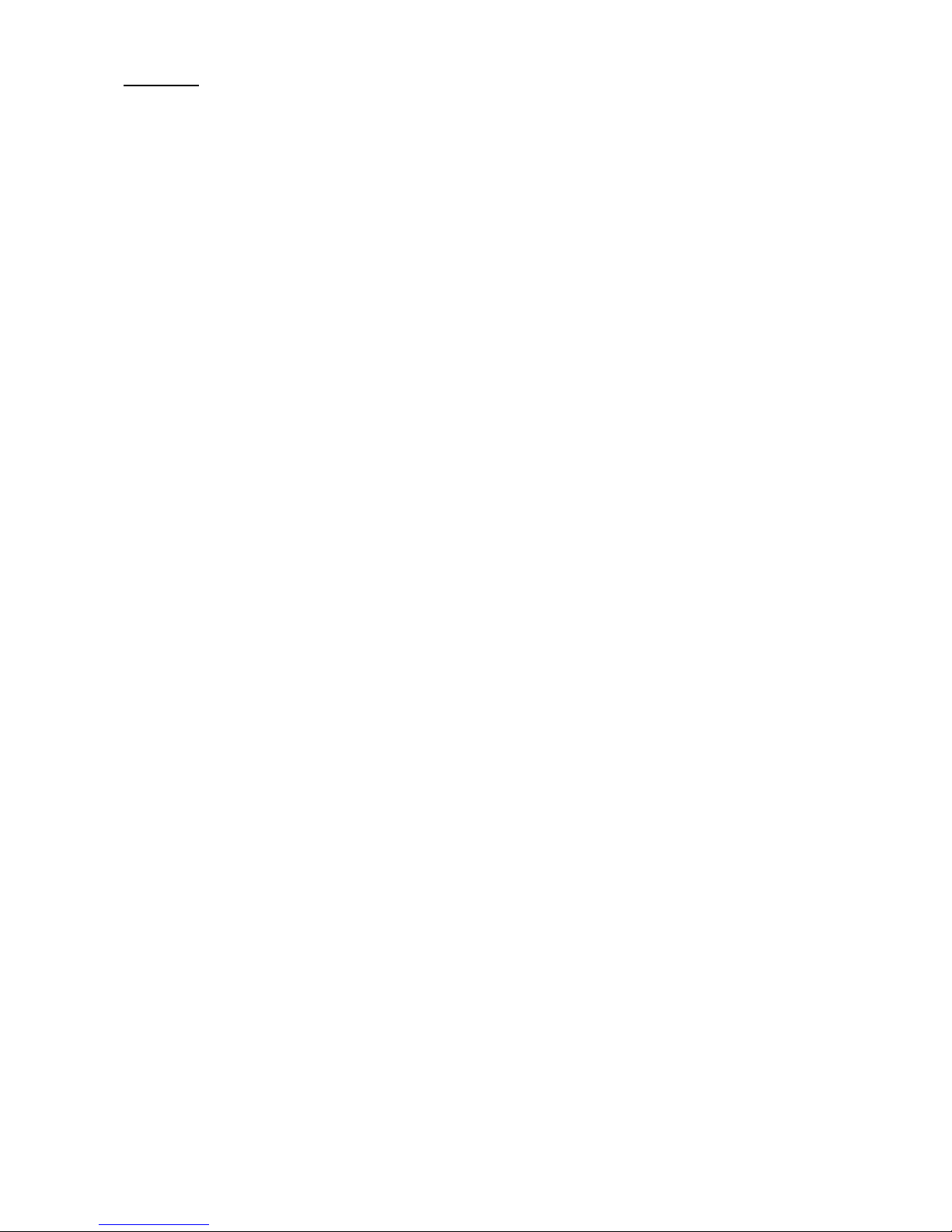

3.3.1 Alarming concept

How alarms are handled is decided during the configuration of the device. For that in the logic module you

can define if LED's are used for alarm state display and how resp. when a possibly activated action, such

as the switching of a relay, will be reset. These configuration parameters are highlighted in yellow in the

following chart.

LED ON

Alarm

acknowledged

?

Alarm state

still persists ?

slow flashing

Y

Y

Y

N

N

Acknowledg.

of LEDS

required ?

Stop

flashing

LED OFF

Alarm state

still persists ?

N

Y

N

Fast

flashing

ALARM

LED used

for alarm

display ?

No action

N

Action

configurated

?

Perform action

Alarm state

still persists ?

Y

N

Action

resettable

?

Reset

?

Action reset

Y

N

N

Y

N

Y

Y

► Acknowledgment: This procedure affects the state of the LED only

If an alarm state is visualized via LED, its occurence must be acknowledged v ia displ a y (see:

Acknowledgment of alarms via display), no matter if it is still active (fast flashing) or has dropped-out

already (slow flashing). By acknowledging an alarm, only the flashing of the LED stops, but a reset of the

alarm action is performed only if the display is configured as a possible source for alarm reset.

Acknowledgment is not required if "acknowledgement of alarm LEDs required" in the

logic module configuration is not selected.

► Alarm reset : This procedure affects the states of the follow-up action and the LEDs

If an alarm state occurs a follow-up action (e.g. the switching of a relay) can be triggered. This follow-up

action is normally reset as soon as the alarm condition no longer exists. But the alarm handling may be

configured as well in a way that only by means of an alarm reset the subsequ ent o perati on is withdra w n.

This way an alarm remains stored until a reset is performed, even if the alarm situation no longer exists.

Possible sources for an alarm reset are the display, a digital input, another logical state of the logic

module or a command via the bus interface.

Hint: If an alarm is reset, the alarm state visualized via LED is acknowledged at the same time.

On the next page some signal flow examples are shown.

Page 9

9/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Z: Logic output determined from all involved logic

inputs

D: Corresponds to signal Z, delayed by the switch-in

resp. dropout delay

A: Output signal of the logic function

S: State of the subsequent operation (e.g. of a relay),

corresponds normally to A, but may be inverted

(subsequent operation: relay OFF)

1) Alarm reset inactive, switch-in and dropout delay 3s, follow-up action not inverted

Acknowledgment of

LED, inactive alarm

Acknowledgment of

LED, active alarm

2) Alarm reset active, switch-in and dropout delay 0s, follow-up action inverted

Reset when alarm is

inactive

Reset when alarm is

still active

Page 10

10/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

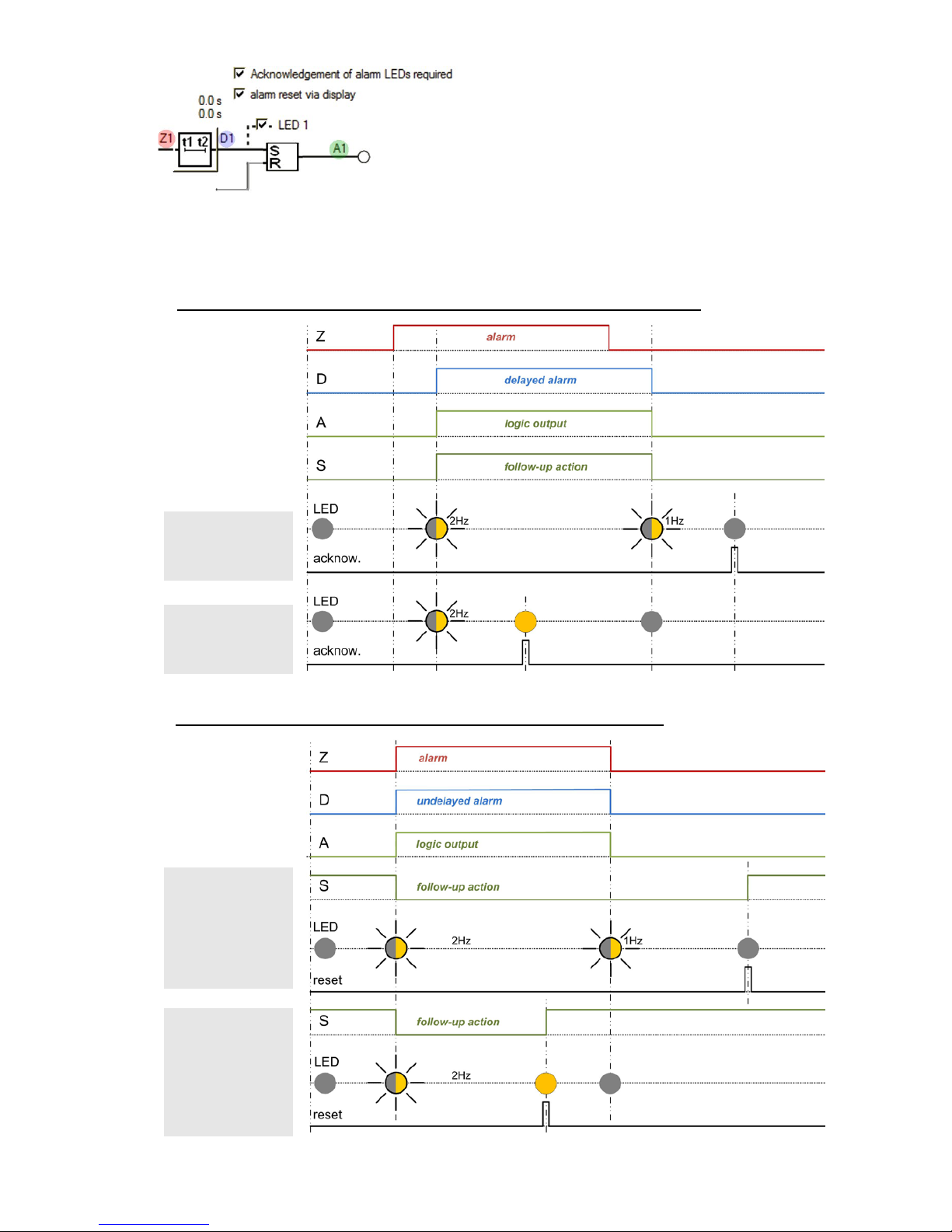

3.3.2 Logic components

The logic outputs are calculated via a two level logical combination of states, which are present at the

inputs. Usable components are AND, OR and XOR gates as well as their inversions NAND, NOR and

XNOR.

The principal function of the logical gates is given in the following table, for simplicity shown for gates with

two inputs only.

function symbol

older symbols

truth table plain text

ANSI 91-1984

DIN 40700 (alt)

AND

A B Y 0 0

0

0 1 0

1 0 0 1 1

1

Function is true if all input

conditions are fulfilled

NAND

A B Y

0 0 1

0 1 1 1 0 1 1 1 0

Function is true if at least

one of the input

conditions is not fulfilled

OR

A B Y

0 0 0 0 1 1 1 0 1 1 1

1

Function is true if at least

one of the input

conditions is fulfilled

NOR

A B Y 0 0 1 0 1 0 1 0

0

1 1 0

Function is true if none of

the input conditions is

fulfilled

XOR

A B Y

0 0 0

0 1 1

1 0 1

1 1 0

Function is true if exactly

one of the input

conditions is fulfilled

XNOR

A B Y

0 0 1

0 1 0

1 0 0 1 1

1

Function is true if all of

the input conditions are

fulfilled or all conditions

are not fulfilled

The logic components of the first level may combine up to three, the components of the second level up to

four input conditions. If individual inputs are not used, their state is automatically set to a condition which

has no influence on the logic result.

Page 11

11/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

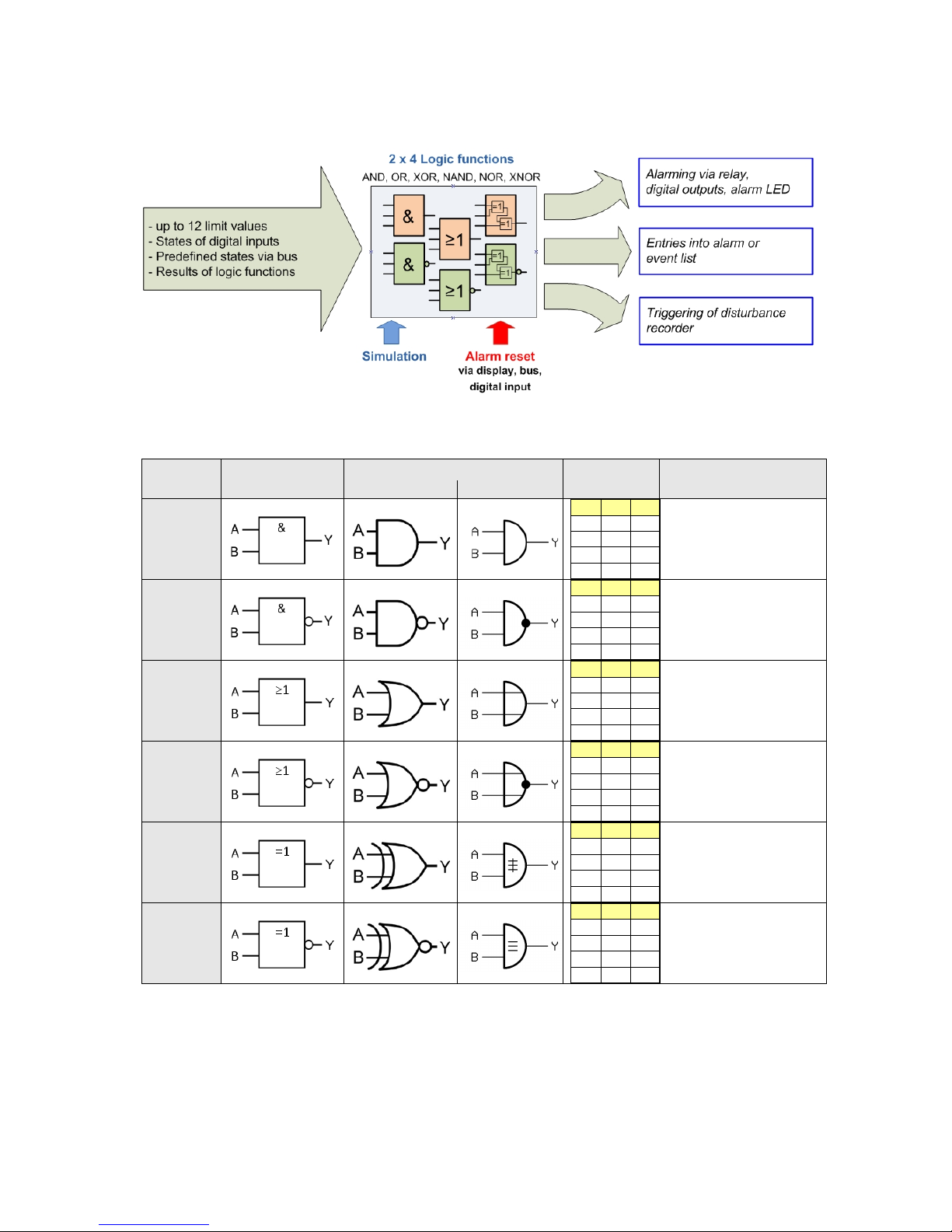

3.3.3 Limit values

States of limit values are the most important input quantities of the logic module. Depending on the

application, limits either monitor the exceeding of a given value (upper limit) or the fall below a given value

(lower limit). Limits are defined by means of two parameters, the limit for the ON and the limit for the OFF

state. The hysteresis is the difference between these two values.

Upper limit: The limit for ON state (

L.On

) is higher than the limit for the OFF state (

L.OFF

)

Limit for OFF state

Limit state

0

1

Limit for ON state

► The state 1 (true) results if the limit for ON state is exceeded. It remains until the value falls below the

limit for OFF state again.

► The state 0 (false) results if the limit for ON state is not yet reached or if, following the activation of the

limit value, the value falls below the limit for OFF state again.

Lower limit: The limit for ON state (

L.On

) is smaller than the limit for OFF state (

L.OFF

)

Limit for ON state

Limit state

0

1

Limit for OFF state

► The state 1 (true) results if the value falls below the limit for ON state. It remains until the value

exceeds the limit for OFF state again.

► The state 0 (false) results if the value is higher than the limit for ON state or if, following the activation

of the limit value, the value exceeds the limit for OFF state again.

If for a limit value the limit for ON state and the limit for OFF state are configured to

the same value, it will be treated as an upper limit value with a hysteresis of 0%.

Limit values may be used to control the running of operating hour counters. As long as the limit values

are fulfilled (logical 1) the operating hour counters keep on running. Not only operating times may be

measured, but e.g. time under overload condition (additional stress) as well.

Page 12

12/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

3.3.4 Sequence of evaluation

The evaluation of the logic module is performed from top to bottom and from left to right:

1. Y1, Y2, Y3, Y4

2. Z1, Z2, Z3, Z4

3. D1, D2, D3, D4

4. A1, A2, A3, A4

► The evaluation is performed once each cycle of the power frequency, e.g. every 20ms at 50Hz. But the

time between two evaluations will never be longer than 25ms.

► If the logical states Y1...Y4, Z1...Z4, D1...D4 and A 1...A 4 are used as inputs, their changed states will

be included in the evaluation of the next interval

► Exception: In the first evaluation level the state of previous logical functions may be used as input

without delay, e.g. the state Y1 for the logical functions with output Y2, Y3 or Y4.

Page 13

13/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

3.4 Free Modbus image

Accessing measured data of a Modbus device often needs some special effort, if the interesting

measurements are stored in different, non continuous register areas. This way multiple telegrams must be

sent to the device to read all data. This needs time and it's very likely, that the measurements don't

originate from the same measurement cycle.

A free assembly of the data to read helps a lot. The A

PLUS supports, along with the still available classical

Modbus image with thousands of registers, the facility to assemble two different images, which may be

read with one telegram only. These freely assembled images are refreshed after each measurement cycle

and therefore always provide the most present values.

The free float image

Up to 60 instantaneous, mean, unbalance or THD/TDD values may be arranged in any sequence on the

register addresses 41840-41958. All of these values are floating point numbers, which allocate 2 registers

per value. Meter values are not possible because they have another format.

The free integer image

Some older control systems are not able to handle float values. To make it possible to work with the data

of the device up to 20 16-Bit integer values can be derived from the existing measurement values. These

values will then be stored in the free Modbus image (register 41800 up to 41819) as integer values with

selectable range of values.

Example: Current transformer 100/5A, measurement current phase 1, over range 20%

► The reference value is 120A (maximum measurable current)

► The integer value shall be 12'000 if the measurement is 120A

After selecting the measured quantity and entering the register va lue of 12'000 automatically a scaling

factor of 100.0 is calculated. The measurement I1 therefore will be multiplied by 100.0 before it is

converted into an integer value and stored in the Modbus image.

Also in the integer image instantaneous, mean, unbalance or THD/TDD values may be arranged.

For devices with Profibus interface the Modbus image is used for the assembly of the

cyclical telegram. Via Modbus the same image can be used, but it’s not possible to use it

independently.

The Modbus communication of the A

PLUS is described in a separate document. Depending on the

communication hardware selected, either the manual for Modbus/RTU or Modbus/TCP protocol should be

used. These documents can be downloaded via our homepage http://www.camillebauer.com

.

► W157 695: Modbus/RTU interface APLUS (communication interface RS485)

► W162 636: Modbus/TCP interface A

PLUS (communication interface Ethernet)

Page 14

14/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

4. Mechanic al mounting

► The standard version of the APLUS is designed for panel mounting as shown below

► The version without display with top-hat rail adapter may be clipped onto a top-hat rail according to

EN50022

Please ensure that the operating temperature limits are not exceeded when

determining the place of mounting (place of measurement):

-10 ... 55°C

4.1 Panel cutout

Dimensional drawing A

PLUS:

See section 10

4.2 Mounting of the device

The APLUS is suitable for panel widths up to 10mm.

a) Slide the device into the cutout from

the outside

b) From the side slide in th e m ounting

clamps into the intended openings and

pull them back about 2 mm

c) Tighten the fixation screws until the

device is tightly fixed with the panel

4.3 Demounting of the device

The demounting of the device may be performed only if all connected wires are out of service. Remove

all plug-in terminals and all connections of the current and voltage inputs . Pay attention to the fact, that

current transformers must be shortened before removing the current connections to the device. Then

demount the device in the opposite order of mounting (4.2).

Page 15

15/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

5. Electrical connections

Ensure under all circumstances that the leads are free of potential

when connecting them !

5.1 General safety notes

Please observe that the data on the type plate must be adhered to !

The national provisions (e.g. in Germany VDE 0100 “Conditions concerning the erection of heavy

current facilities with rated voltages below 1000 V”) have to be observed in the installation and material

selection of electric lines!

Nameplate of a

device equipped

with RS485

interface and I/O

extension 1

Symbol Meaning

Device may only be disposed of in a professional manner!

Double insulation, device of protection class 2

CE conformity mark. The device fulfills the requirements of the applicable EU

directives.

Products with this mark comply with both the Canadian (CSA) and the American (UL)

requirements.

Caution! General hazard point. Read the operating instructions.

General symbol: Input

General symbol: Output

CAT III Measurement category CAT III for current / voltage inputs and power supply

CAT II

Measurement category CAT II for relay outputs

Page 16

16/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

5.2 Electrical connections of the I/Os

I/O no. Terminal No. APLUS I/O extension 1 I/O extension 2

1 X2 1, 2, 3 Relay

2 X3 1, 2 Digital input

3 X3 3, 4 Digital output

4 X5 1, 2, 3 Relay Relay

5 X6 1, 2, 3 Relay

Relay

6 X7 1, 2 Digital I/O Digital I/O

7 X7 3, 4 Digital I/O Digital I/O

8 X7 5, 6 Analog output ±20mA Digital I/O

9 X7 7, 8 Analog output ±20mA Digital I/O

10 X7 9, 10 Analog output ±20mA Digital I/O

11 X7 11, 12 Analog output ±20mA Digital I/O

I/O no. -

as used in the CB-Manager software

5.3 Possible cross sectio n s and tightening torques

Inputs L1, L2, L3, N, I1 k-l, I2 k-l, I3 k-l

Single wire

1 x 0,5 ... 4,0mm2 or 2 x 0,5 ... 2,5mm

2

Multiwire with end splices

1 x 0,5 ... 2,5mm2 or 2 x 0,5 ... 1,5mm

2

Tightening torque

0,5…0,6Nm resp. 4,42…5,31 lbf in

Power suppl y X1, Relays X2, X5, X6

Single wire

1 x 0,5 ... 2,5mm2 or 2 x 0,5 ... 1,0mm

2

Multiwire with end splices

1 x 0,5 ... 2,5mm2 or 2 x 0,5 ... 1,5mm

2

Tightening torque

0,5…0,6Nm resp. 4,42…5,31 lbf in

I/O's X3, X7 and RS485 connector X4

Single wire

1 x 0,5 ... 1,5mm2 or 2 x 0,25 ... 0,75mm

2

Multiwire with end splices

1 x 0,5 ... 1,0mm2 or 2 x 0,25 ... 0,5mm

2

Tightening torque

0,2…0,25Nm resp. 1,77…2,21 lbf in

Page 17

17/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

5.4 Inputs

All voltage measurement inputs must originate at circuit breakers or fuses rated 10 Amps or

less. This does not apply to the neutral connector. You have to provide a method for

manually removing power from the device, such as a clearly labeled circuit breaker or a

fused disconnect switch.

When using voltage transformers you have to ensure that their secondary connections

never will be short-circuited.

No fuse may be connected upstream of the current measurement inputs !

When using current transformers their secondary connectors must be short-circuited

during installation and before removing the device. Never open the secondary circuit under

load.

The connection of the inputs depends on the configured system (connection type). The required device

external fusing of the voltage inputs is not shown in the following connection diagrams.

Single-phase AC mains

1L

Direct connection

L1 L2 L3 N I1 I

2 I3

l ll l k

k

k

A

PLUS

L1

N

With current and voltage transformer

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

L1

N

K

k

L

l

U

u

V

v

With current transformer

L1 L2 L3 N I

1 I2 I3

l ll l kk

k

A

PLUS

L1

N

K

k

L

l

Page 18

18/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Three wire system, balanced load, current measurement via L1

3L.b

Direct connection

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

L1

L2

L3

With current and voltage transformer

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

L1

K

k

L

l

L2

L3

UuVvUuV

v

With current transformer

L1 L2 L3 N I1 I2 I3

l ll l kkk

APLUS

L1

K

k

L

l

L2

L3

In case of current measurement via L2 or L3 connect

voltages according to the following table:

Current Terminals L1 L2 L3

L2 I1-k I1-l L2 L3 L1

L3 I1-k I1-l L3 L1 L2

By rotating the voltage connections the

measurements U12, U23 and U31 will be

assigned interchanged !

Four wire system, balanced load, current measurement via L1

4L.b

Direct connection

L1 L2 L3 N I1 I2

I

3

l ll

l kk

k

A

PLUS

L1

N

L2

L3

With current and voltage transformer

L1 L2 L

3 N I1 I2 I3

l ll l

kkk

A

PLUS

L1

N

K

k

L

l

U

u

V

v

L2

L3

With current transformer

L1 L2 L3 N I

1 I2 I3

l ll l kk

k

A

PLUS

L1

N

K

k

L

l

L2

L3

In case of current measurement via L2 or L3 connect

voltages according to the following table:

Current Terminals L1 N

L2 I1-k I1-l L2 N

L3 I1-k I1-l L3 N

Page 19

19/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Three wire system, unbalanced load

3L.Ub

Direct connection

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

L1

L2

L3

With current and 3 single-pole isolated voltage

transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

K

k

L

l

L1

L2

L3

XUXUX

U

x x x

u uu

With current transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

APLUS

K

k

L

l

K

k

L

l

K

k

L

l

L1

L2

L3

Three wire system, unbalanced load, Aron connection

3L.UA

Direct connection

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

L1

L2

L3

With current and 3 single-pole isolated voltage

transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

L1

L2

L3

XUXUX

U

x x x

u uu

With current transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

L1

L2

L3

Page 20

20/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Four wire system, unbalanced load

4L.Ub

Direct connection

L

1

L

2

L

3

N

I

1

I

2

I

3

l

l

l

l

k

k

k

A

PLUS

L

1

L

2

L

3

N

With current and 3 single-pole isolated voltage

transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

K

k

L

l

L1

L2

L3

N

XUX

U

X

U

x x x

u uu

With current transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

K

k

L

l

L1

L2

L3

N

Four wire system, unbalanced load, Open-Y

4L.UY

Direct connection

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

L1

L2

L3

N

With current and 2 single-pole isolated voltage

transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

K

k

L

l

L1

L2

L3

N

XUX

U

x x

u u

With current transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

K

k

L

l

L1

L2

L3

N

Page 21

21/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Split-phase ("two phase system"), unbalanced load

SP.PH

Direct connection

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

L1

L2

N

With current transformers

L1 L2 L3 N I1 I2 I3

l ll l kkk

A

PLUS

K

k

L

l

K

k

L

l

L1

L2

N

5.5 Rogowski current inputs

The connection of the Rogowski coils is performed depending on the selected system type, as shown in

chapter 5.4 above. However, instead of current transformers a Rogowski coils is placed around each

current-carrying conductor. This is subsequently shown for the measurement in a 4-wire low-voltage

system.

When connecting the coils you must follow the safety notices given in the operating

instructions of the Rogowski coil. The current direction shown on the coils must match the

real current direction and has to be the same for all phases.

In order to suppress injected interferences

the shielding (green) is connected always to

the l terminal of the current inputs (I1-l, I2-l

resp. I3-l).

Page 22

22/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

5.6 Power supply

A marked and easily accessible curren t limiting switch has to be arranged in the vicinity of

the device for turning off the power supply. Fusing should be 10 Amps or less and must be

rated for the available voltage and fault current.

5.7 Relays

When the device is switched off the relay contacts are de-energized, but dangerous

voltages may be present.

The relay X2 is part of the basic unit and therefore always available.

The relays X5 and X6 are provided for device versions with I/O

extension PCB only.

The plug-in terminals have different colours to prevent mixing up the

connections. The pin assignment is the same for all relays:

Page 23

23/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

5.8 Digital inputs and outputs

For the digital inputs / outputs an external power supply of 12 / 24V DC is required.

The power supply shall not exceed 30V DC !

The plug-in terminal X7 is available for device versions with I/O

extension PCB only.

The number of digital inputs / outputs varies depending on the

optional built-in PCB, see nameplate. The operating direction of

the digital I/Os on X7 may be individually selected by means of

the PC software.

The assignment of the connections depends on

whether an I/O is configured to be a digital input or a

digital output.

Example

Device with I/O extension 2 (2 relays + 6 digital I/Os)

The digital I/Os on plug-in terminal X7 are individ ually

programmable as input or output .

On plug-in terminal X3 a digital input and a digital output are

provided statically. Their operating direction may not be

modified.

Usage as digital input

► Meter tariff switching

► Operating feedback of loads for operating time counters

► Trigger and release signal for logic module

► Pulse input for meters of any kind of energy

► Clock synchronization

► Synchronization of billing intervals in accordance with energy provider

Technical data

Input current < 7,0 mA

Counting frequency (S0) ≤ 16 Hz

Logical ZERO - 3 up to + 5 V

Logical ONE 8 up to 30 V

Page 24

24/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Usage as digital output

► Alarm output for logic module

► State reporting

► Pulse output to an external counter (acc. EN62053-31)

► Remote controllable state output via bus interface

Driving a relay

Technical data

Rated current 50 mA (60 mA max.)

Switching frequency (S0) ≤ 20 Hz

Leakage current 0,01 mA

Voltage drop < 3 V

Load capacity 400 Ω … 1 MΩ

Driving a counter mechanism

1) Recommended if input

impedance

of counter > 100 kΩ

The width of the energy pulses can be selected by means of the PC

software but have to be adapted to the counter mechanism. Once a

second there is a decision how many pulses have to be output.

Therefore the delay between two pulses may not be used to

determine the present power demand.

Electro mechanical meters typically need a pulse width of

50...100ms.

Electronic meters are partly capable to detect pulses in the kHz

range. There are the types NPN (active negative edge) and PNP

(active positive edge). For the APLUS a PNP type is required. The

pulse width has to be at least 30ms (acc. EN62053-31). The delay

between to pulses corresponds at least to the pulse width. The

smaller the pulse width, the higher the sensitivity to disturbances.

Page 25

25/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

5.9 Analog outputs

Analog outputs are available for devices with I/O extension 1 only. See nameplate.

Connection to an analog input card of a PLC or a

control system

The A

PLUS is an isolated measurement device. In

addition the particular outputs are galvanically

isolated. To reduce the influence of disturbances

shielded a twisted-pair cables should be used. The

shield should be connected to earth on both opposite

ends. If there a potential differences between the ends

of the cable the shield should be earthed on one side

only to prevent from equalizing currents.

Under all circumstances consider as well appropriate

remarks in the instruction manual of the system to

connect.

5.10 Modbus interface RS485 X4 and / or X8

Depending on the device version up to two Modbus interfaces are available on the plug-in positions X4

and / or X8. These are galvanically isolated. The connection terminals are distinguished by color: X4

(gray), X8 (black).

1) One ground connect ion only . T his

is possibly made within the

master (PC).

Rt: Termination resistors: 120 Ω each

for long cables (> approx. 10 m)

Rs: Bus supply resistors,

390 Ω each

The signal wires (X4-1, X4-2 resp. X8-1, X8-2) have to be twisted. GND (X4-3 resp. X8-3) can be

connected via a wire or via the cable screen. In disturbed environments shielded cables must be used.

Supply resistors (Rs) have to be present in bus master (PC) interface. Stubs should be avoided when

connecting the devices. A pure daisy chain network is ideal.

You may connect up to 32 Modbus devices to each bus. A proper operation requires that all devices

connected to the respective bus have equal communication settings (baud rate, transmission format) and

unique Modbus addresses. If there are two Modbus interfaces, their settings may be different.

The bus system is operated half duplex and may be extended to a maximum length of 1200 m without

repeater.

Page 26

26/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

5.11 Profibus DP interface

The 9-pin DSUB socket serves the connection of a standard Profibus plug. In a bus terminal device, the

bus line must be terminated with resistors in the bus plug. Then standard pin assignment is as follows:

Pin Name Description

3 B RxD/TxD-P

4 RTS Request to send: CNTR-P (TTL)

5 GND Data groun d

6 +5V VP

8 A RxD/TxD-N

LED BF (Bus failure, yellow)

Status Description

ON Startup state or internal communication error

Flashing (2Hz) Parameterization check failed

OFF Cyclical operation; no error

LED BA (Bus alive, green)

Status Description

OFF Startup state; no Profibus communication

Flashing (2Hz) Profibus detected; waiting for parameterization from master

ON Parameterization ok; Profibus communication active

Page 27

27/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

6. Commissioning

Before commissioning you have to check if the connection data of the transducer match the

data of the plant (see nameplate).

If so, you can start to put the device into operation by switching on the power supply and the

measurement inputs.

Measurement input

Input voltage

Input current

System frequency

1 Works no.

2 Test and conformity marks

3 Assignment voltage inputs

4 Assignment current inputs

5 Assignment power supply

6 Load capacity relay outputs

6.1 Software installation CB-Manager

A complete parametrization of the device is possible via configuration interface only, using the PC

software CB-Manager. The software may be downloaded free of charge from our homepage

http://www.camillebauer.com

.

The file "Read-me-first" provides all necessary information for the installation of the

CB-Manager software and assistance for possible problems.

Functionality of the CB-Manager software

The software is primary a tool for the configuration of different devices (A

PLUS, CAM, VR660, A200R,

V604s) and supports the user during commissioning and service. It allows as well the reading and

visualization of measured data.

►Acquisition and modification of all device features

►Setting of real-time clock and time zone, selection of time synchronization method

►Archiving of configuration and measurement files

►Visualization of present measurements

►Reading, setting and resetting of meters

►Reading and resetting of minimum/maximum values

►Starting, stopping and resetting of the optional data logger

►Recording of measurement progressions during commissioning

►Check for correct device connection

►Simulation of states or outputs to test subsequent circuits

►Adjust the security system as protection against unauthorized access or manipulations

The CB-Manager software provides a comprehensive help facility, which describes in detail the operation

of the software as well as all possible parameter settings.

Page 28

28/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

6.2 Parametrization of the device functionality

Operating the software

The device configuration is divided into registers, which contain thematically the different function blocks

of the device, e.g. "input", "limit values", "display". Thereby of course there are interdependencies, which

have to be considered. If e.g. a current limit value is defined and subsequently the ratio of the current

transformer is changed, there is a high probability that the limit value is changed as well. Therefore a

meaningful sequence must be kept during setting the parameters. The easiest way is to handle register

by register and line by line:

► Device (set the device version, if not read directly from the device)

If an I/O extension unit is used: Fix the data direction of the digital I/O's. Do to so just click on the

appropriate entry and change the data direction in the I/O register. So it's assured that these I/O's

can be used in the intended way. If e.g. you miss to change de basic setting "digital input" the

appropriate channel can't be used as output in the logic module.

► Input, especially system and transformer ratios

► Mean values >> Limit values >> Logic module >> I/O 1-3

► if present: I/O 4,5 >> I/O 6,7 >> I/O 8,9 >> I/O 10,11

► Operating hours

► if present: Logger >> Interface (Ethernet, Profibus DP) >> Display

► Modbus-Image (if you want to define your own Modbus image)

► Time zone (for automatical handling of daylight saving time)

Page 29

29/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

ONLINE / OFFLINE

The parametrization may be performed ONLINE (with existing connection to the device) or OFFLINE

(without connection to the device). To perform an ONLINE configuration first the configuration of the

connected device, and therewith its hardware version, is read. A modified configuration can then be

downloaded to the device and stored on the hard disk of the computer for archiving.

An OFFLINE parametrization can be used to prepare device configurations, to store them on disk and to

download it to the devices, once you are in the field where the devices are installed. To make this work,

the device versions selected during parametrization must agree with the versions on site.

6.3 Installation check

Check if inputs are connected correctly

► Voltage (at least 20% U

rated

) and current (at least 2% I

rated

) must be present

Using the connection check, which is integrated in the visualization of the instantaneous values, the

correct connection of the current and voltage inputs may be checked. The phase sequence will be

checked, as well as if there are open connections or reversed current connections (which change the

direction of the current).

The image below shows open current connections (red description I1, I2, I3). This arises because the

individual currents are below 2% of the rated value.

Simulation of I/O's

To check if subsequent circuits will work properly with the measurement data provided by the A

PLUS all

analog, digital and relay outputs may be simulated, by predefining any output value resp. discrete state by

means of the CB-Manager software.

Also all functions of the logic module, which allows performing any combination of logical states, may be

predefined. This way e.g. an alarming due to a violation of a limit value can be simulated.

Page 30

30/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

6.4 Installation of Ethernet devices

6.4.1 Connection

Before devices can be connected to an existing Ethernet network, you have to ensure that they

will not disturb the normal network service. The rule is:

None of the devices to connect is allowed to have the same IP address

than another device already installed

The factory setting of the IP address of APLUS is: 192.168.1.101

The standard RJ45 connector serves for direct connecting an Ethernet cable. If the PC is directly

connected to the device a cross-wired cable must be used.

The network installation of the devices is done by means of the CB-Manager software (see 6.4.2

) or

directly via the local programming on the display. As soon as all devices have a unique network address

they may be accessed by means of a suitable Modbus master client.

Interface: RJ45 connector, Ethernet 100BaseTX

Mode: 10/100 MBit/s, full / half duplex, Auto-negotiation

Protocols: Modbus/TCP, NTP

Function of the LED's

LED 1 (Green)

ON as soon as a network connection exists

Flashing when data is transmitted via Ethernet connection

LED 2 (Orange)

Flashing with 4 Hz during start-up

ON during Modbus/TCP communication with the device

To have a unique identification of Ethernet

devices in a network, to each connection a

unique MAC address is assigned. This

address is given on the nameplate, in the

example 00-12-34-AE-00-01.

Compared to the IP address, which may be

modified by the user any time, the MAC

address is statically.

Page 31

31/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

6.4.2 Network installation using the CB-Manager software

For the subsequent Modbus/TCP communication a unique network address must be assigned to each of

the devices. This can be done very easily, using the CB-Manager software to search for devices which

have a MAC address 00-12-34-AE-xx-xx, which identifies the device as A

PLUS of Camille Bauer. Because

this is performed by means of a UDP broadcast telegram, the devices are allowed to have the same

network address at the beginning, e.g. "192.168.1.101" as factory default.

As soon as to all the devices network settings with unique IP address have been assigned, they may be

accessed and read using the Modbus/TCP protocol.

Select "settings" under options

| interface. The interface type

has to be set to "TCP-IP".

Devices in the local network

Set settings to "CAM, APLUS".

Along with all A

PLUS also

SINEAX CAM devices installed

in the same network will be

shown. The identification of the

devices is possible by means

of their MAC address, which is

given on the nameplate (see

chapter 6.4.1

).

To assign a unique network

address to a device, select it in

the list and the click on

"change".

The following settings have to be arranged with the

network administrator:

- IP address: This one must be unique, i.e. ma y be

assigned in the network only once.

- Subnet mask: Defines how many devices are

directly addressable in the network . This setting is

equal for all the devices.

- Default gateway: Is used to resolve addresses

during communication between different networks.

Should contain a valid address within the own

network.

- Hostname: Individual designation for each device.

Helps to identify the device in the device list.

Page 32

32/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

Example

Initial situation Installed system

192.168.1.101 192.168.1.101 192.168.1.101

IP

192.168.57.230 192.168.57.231 192.168.57.232

00-12-34-AE-00-01 00-12-34-AE-00-04 00-12-34-AE-00-07

MAC

00-12-34-AE-00-01 00-12-34-AE-00-04 00-12-34-AE-00-07

Devices outside the local network

Devices which are not in the same network as the PC (e.g. in the Internet) can not be found and have to

be added manually to the device list by means of

. The type of the device must be selected previously.

To each entry you have to assign a unique IP and MAC address, which are different from the initial value.

Otherwise it's not possible to add further entries.

The setting of the network parameters must be performed before mounting the device. As an alternative

this may be done in the destination network via Ethernet interface.

6.4.3 Network installation by means of local programming

The network settings IP address, subnet mask and gateway can also be configured directly via the local

programming of the A

PLUS on site.

This facility is shown in chapter 7.8

Page 33

33/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

6.4.4 Time synchronization via NTP-protocol

For the time synchronization via Ethernet NTP (Network Time Protocol) is the standard. Corresponding

time servers are used in computer networks, but are also available for free via Internet. Using NTP it's

possible to hold all devices on a common time base.

Two different NTP servers may be defined. If the first server is not available the second server is used for

trying to synchronize the time. Adjusting of the clock is performed in the interval selected (15min. up to

24h). If no time synchronization is desired, to both NTP servers the address 0.0.0.0 have to be assigned.

The setting of the addresses is done by means of the CB-Manager software. The NTP data is arranged in

the register "Ethernet" of the device configuration.

Activation

To activate the time synchronization via NTP, the "Synchronisation RTC" must be checked by means of

the checkbox.

6.4.5 TCP ports for data transmission

TCP ports

The TCP communication is done via so-called ports. The number of the used port allows determining the

type of communication. As a standard Modbus/TCP communication is performed via TCP port 502, NTP

uses port 123. However, the port for the Modbus/TCP telegrams may be modified. You may provide a

unique port to each of the devices, e.g. 503, 504, 505 etc., for an easier analysis of the telegram traffic.

The setting of the Modbus TCP port is done as shown above. Independent of these setting a

communication via port 502 is always supported. The device allows at least 5 connections to different

clients at the same time.

Firewall

Due to security reasons nowadays each network is protected by means of a firewall. When configuring the

firewall you have to decide which communication is desired and which have to be blocked. The TCP port

502 for the Modbus/TCP communication normally is considered to be unsafe and is very often disabled.

This may lead to a situation where no communication between networks (e.g. via Internet) is possible.

Page 34

34/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

6.5 Installation of Profibus DP devices

The Profibus DP interface allows data exchange with a control system via Profibus-DP V0. The modular

device model provides maximum protocol efficiency.

Required measured variables are determined during engineering and arranged as a fixed process image.

The control system does not require any intelligence for the evaluation of the data (no tunneling protocol).

Bus parameterising facilitates simple and fast commissioning. On-site the parameters in accordance wit h

the configuration menu

can be set, especially:

- Device address

- Accepting master parameterization (Check_User_Prm)

- Establishing communication to the master (Go_Online)

- Setting device address via master (Set_Slave_Addr_Supp)

For the assembly of the cyclical Profibus telegram the Modbus image is used. Via Modbus

the same image can be used, but it’s no longer possible to use it independently.

GSD parameterization

Typically the parameterization of the Profibus slave is done on the control system. During startup the

A

PLUS adopts these settings. Doing so the parameterization of the input parameters (input system,

transformer ratios etc.) as well as the assembly of the Modbus image will be overwritten. Other parts of

the configuration, such as parameterization of I/O’s or settings of limit values, remain unchanged.

All necessary informations for the parameterization are part of the DMF (GSD) file. This one can be

downloaded from our homepage http://www.camillebauer.com

.

The assumption of the engineered parameters can be prevented by deactivating the Check_User_Prm

flag. The parameterization locally set will not be changed this way.

Cyclical data exchange

The user can compose its own „station“ with all required quantities. Up to 60 measured quantities can be

modularly concatenated. You may choose from instantaneous values of the system and imbalance

analysis, mean-values of power quantities and freely selectable quantities as well as meter values.

Subsequent to the adoption of the parameterization, the A

PLUS is ready for the cyclical data exchange with

the control system.

Page 35

35/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

6.6 Protection against device data changing

Data stored in the device may be modified or reset via communication interface or via the keys on the

device itself. To restrict these possibilities on-s it e , via CB-Manager the security system in the device can

be activated (factory default: not activated). For the definition of these user rights in the software the input

of an administrator login is required. The factory default is:

user: admin

password: admin

The administrator password may be modified, but a

reset can be performed in our factory only !

For one user via device and one user via interface (special login) the access to the following functions can

individually be granted: Configuration of the device, modification of RTC parameters, modification of limit

values, reset of min/max or meter values, alarm acknowledgment, display mode changing.

Page 36

36/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

7. Operating the device

7.1 Display and operating elements

12ud3nU-

Phase reference of measurement, sign of measurement,

minimum or maximum value, e.g. U

1N

(maximum value)

230.4

oL

4-digit display of measurements. On each change of the measurement

display the short form of the quantities to display is shown first.

If a measurement is out of the measurable range the string "oL" is shown

instead of a measured value.

kVAWMGSPMDrHzccelkvar

Unit, measuring procedure, measurement type

e.g. kVAr (reactive power)

POWER FA

8-digit meter display, 4-digit measurement display (P,Q,S,U,I) or 20-digit

Alarm text display (e.g. "

POWER FAILURE L1")

kMGWArhdumWUh

Unit for meter quantities, high or low tariff, e.g. MWh high tariff

Unit for the quantities Px, Qx, Sx, Ux, Ix

State display of alarms, e.g. Alarm 1 active

short Display of alarm state texts

>2s

Reading of meter contents

Functionality depends on operating time, either 'short' or > 2s. To be

used for measurement selection, brightness adjustment, navigation in

menus, reset operations.

Page 37

37/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

7.2 Operating modes

The device supports, along with the configuration mode, three different operating modes. Normally the

device is in the measurement display mode, but may be temporarily switched for the reading of the meters

or for the display of alarm texts.

Measurement display

: Is the normal operating mode of the

device. By means of the navigation keys different measurement

display can be selected. Depending on the selected display mode

and the system monitored different measurement displays are

available.

► Available display modes

Meter reading

: By pressing the key for a longer time an

operating mode is started, which allows to read all the meter

contents via line 4. This mode is automatically stopped after 30s

without any key pressed or via the key . If this mode is active

no measurement info is displayed on line 1 to 3.

► Meter reading

Alarm display

: By shortly pressing the key an operating

mode is started, which allows to display alarm state texts and to

acknowledge alarms via line 4. If there are no configured alarms

the message "No LED used" is displayed and then the mode is

stopped. Otherwise the mode is automatically stopped after 30s

without any key pressed or via the key . If this mode is active

no measurement info is displayed on line 1 to.

► Monitoring and alarming

► Alarm handling

Page 38

38/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

7.3 Setting the display brightness

The brightness of the display can be set to one of thirteen levels.

Brighter: Press key longer than 2s; brightness will increase in steps

Darker: Press key longer than 2s; brightnes s w ill dec reas e in ste ps

Page 39

39/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

7.4 Display modes

The device supports four different display modes. They differ in the way measurement data is presented

and which measurement data is provided.

► The selection of the display mode is described under Configuration

FULL mode

The measurement images of all displayable data are arranged in a matrix form. The selection is

performed by means of the arrow keys:

One image to the left. If first: most right image is displayed

Most left image of the next line is displayed. If last: First line.

Most left image of the previous line is displayed. If first: Last line.

One image to the right. If last: most left image is displayed

The fourth line of each image is allocated to a programmable meter value (METER), which does not

change even if another measurement image is selected.

► The complete display matrices are shown in Annex B

U12

U12_MAX

U12_MIN

DEV_UMAX

U23

U23_MAX

U23_MIUN

DEV_UMAX_MAX

U31

U31_MAX

U31_MIN

METER

METER

METER

METER

UR1

UNB_UR2_UR1

UR2

UNB_UR2_UR1_MAX

U0

METER

METER I1

I1_MAX

IB1

IB1_MAX

DEV_IMAX

I2

I2_MAX

IB2

IB2_MAX

DEV_IMAX_MAX

I3

I3_MAX

IB3

IB3_MAX

METER

METER

METER

METER

METER

IR1

UNB_IR2_IR1

IR2

UNB_IR2_IR1_MAX

I0

METER

METER

P

P_MAX

METER

Q

Q_MAX

METER

S

S_MAX

METER

PF

PF

PFG

PFG

PF_MIN_IN_L

PF_MIN_OUT_L

PFG_MIN_IN_L

PFG_MIN_OUT_L

PF_MIN_IN_C

PF_MIN_OUT_C

PFG_MIN_IN_C

PFG_MIN_OUT_C

METER

METER

METER

METER F_MAX

F

F_MIN

METER

P

U_MEAN

PF P

Q

I_MEAN P S

S P Q F

METER

METER

METER

METER

D

QG

D_MAX

QG_MAX

METER

METER dd.mm

OPR_CNTR1

OPR_CNTR

hh.mm

OPR_CNTR2

ss

OPR_CNTR3

METER

METER

METER

THD_U12

THD_U23

THD_U31

THD_U12_MAX

THD_U23_MAX

THD_U31_MAX

METER

METER

METER

TDD_I1

TDD_I2

TDD_I3

TDD_I1_MAX

TDD_I2_MAX

TDD_I3_MAX

METER

METER

METER

Example for 3-wire system, unbalanced load (harmonics and power mean-values not shown )

Page 40

40/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

REDUCED mode

This display mode is a reduced version of the FULL mode. Some of the images or complete lines, e.g. the

grayed data in the below example, can be hidden. So the display may be adapted easily to the

information requirements on-site.

The selection of the measurement images is done via the arrow keys:

One image to the left. If first: most right image is displayed

Most left image of the next line is displayed. If last: First line.

Most left image of the previous line is displayed. If first: Last line.

One image to the right. If last: most left image is displayed

The fourth line of each image is allocated to a programmable meter value (METER), which does not

change even if another measurement image is selected.

U12

U12_MAX

U12_MIN

DEV_UMAX

U23

U23_MAX

U23_MIUN

DEV_UMAX_MAX

U31

U31_MAX

U31_MIN

METER

METER

METER

METER

UR1

UNB_UR2_UR1

UR2

UNB_UR2_UR1_MAX

U0

METER

METER

I1

I1_MAX

IB1

IB1_MAX

DEV_IMAX

I2

I2_MAX

IB2

IB2_MAX

DEV_IMAX_MAX

I3

I3_MAX

IB3

IB3_MAX

METER

METER

METER

METER

METER

IR1

UNB_IR2_IR1

IR2

UNB_IR2_IR1_MAX

I0

METER

METER

P

P_MAX

METER

Q

Q_MAX

METER

S

S_MAX

METER PF

PF

PFG

PFG

PF_MIN_IN_L

PF_MIN_OUT_L

PFG_MIN_IN_L

PFG_MIN_OUT_L

PF_MIN_IN_C

PF_MIN_OUT_C

PFG_MIN_IN_C

PFG_MIN_OUT_C

METER

METER

METER

METER

F_MAX

F

F_MIN

METER

P

U_MEAN

PF

P

Q

I_MEAN P S

S P Q

F

METER

METER

METER

METER D QG

D_MAX

QG_MAX

METER

METER

dd.mm

OPR_CNTR1

OPR_CNTR

hh.mm

OPR_CNTR2

ss

OPR_CNTR3

METER

METER

METER

THD_U12

THD_U23

THD_U31

THD_U12_MAX

THD_U23_MAX

THD_U31_MAX

METER

METER

METER TDD_I1

TDD_I2

TDD_I3

TDD_I1_MAX

TDD_I2_MAX

TDD_I3_MAX

METER

METER

METER

Example for 3-wire system, unbalanced load (harmonics and power mean-values not shown)

Page 41

41/89 Device handbook APLUS with / without LED display, 157 679-19, 04/2016

USER mode

This display mode allows a free assembly of up to 20 measurement images. Also the fourth line may be

different for each image. Any meter value or another quantity (Ux, Ix, Px, Qx, Sx) may be assigned. The

images are arranged among each other and selectable via the keys and :

Image of the next line is displayed. If last: First line.

Image of the previous line is displayed. If first: Last line.

The USER mode also allows defining one of the 20 measurement images to be a predefined image,

which is displayed always after a programmable time without user action. This switch back is performed

even if in the meantime a change to the FULL or REDUCED mode was performed. This way an always

equal appearance of the device can be defined in advance.

U1N I1 PF1 ΣP1incoming

U2N I2 PF2 ΣP2incoming

U3N I3 PF3

ΣP3incoming

P1

P2 P3

P Q1

Q2 Q3 Q THD_U1

THD_U2

THD_U3

ΣQincoming

dd.mm

hh.mm ss ΣPincoming

Example with 8 free assembled measurement images

LOOP mode

In the LOOP mode all of the measurement images of the USER mode are displayed one after the other

with a programmable time delay. When a change to the LOOP mode is performed a possibly active