Cameron Nuflo Mc-iii EXP User Manual

NUFLOTM

MC-III™ EXP

Flow Analyzer

User Manual

Manual No. 9A-50165003, Rev. 02

NuFlo and MC-III are trademarks of Cameron.

Modbus is a registered trademark of the Modbus Organization, Inc.

Windows is a registered trademark of Microsoft Corporation.

Acrobat Reader is a registered trademark of Adobe Systems Incorporated.

© 2008 Cameron International Corporation (“Cameron”). All information contained in this publication is confidential and proprietary property of Cameron. Any reproduction or use of these instructions, drawings, or photographs without the express written permission of an officer of Cameron is forbidden.

All Rights Reserved.

Printed in the United States of America.

Manual No. 9A-50165003, Rev. 02

September 2008

MC-III™ EXP Flow Analyzer |

Table of Contents |

Contents |

|

Section 1—Introduction.................................................................................................................................... |

1 |

Operation............................................................................................................................................................ |

1 |

Key Product Features ........................................................................................................................................ |

3 |

LCD Display.................................................................................................................................................. |

4 |

Keypad......................................................................................................................................................... |

4 |

Interface Software........................................................................................................................................ |

6 |

Power Supply............................................................................................................................................... |

6 |

Multipoint Linearization................................................................................................................................. |

6 |

Gas Volume Correction................................................................................................................................ |

6 |

Input Options................................................................................................................................................ |

6 |

Output Options............................................................................................................................................. |

6 |

Flow Log Archival ........................................................................................................................................ |

7 |

Event Log Archival ....................................................................................................................................... |

7 |

Password-Protected Security....................................................................................................................... |

7 |

Optional Features................................................................................................................................................ |

7 |

Explosion-Proof Reset/Control Switch.......................................................................................................... |

7 |

Explosion-Proof Communications Adapter................................................................................................... |

7 |

RS-485 IS Barrier......................................................................................................................................... |

8 |

Commonly Used Functions................................................................................................................................. |

8 |

Reading Totals.............................................................................................................................................. |

8 |

Saving Totals to Memory.............................................................................................................................. |

8 |

Resetting the Total........................................................................................................................................ |

8 |

Viewing Daily and Hourly Logs..................................................................................................................... |

9 |

Saving and Uploading Configuration Files................................................................................................... |

9 |

Exporting Log Data....................................................................................................................................... |

9 |

Saving Log Data in a Report........................................................................................................................ |

9 |

Section 2—Installation..................................................................................................................................... |

11 |

Preparation......................................................................................................................................................... |

11 |

Connection to the Flowmeter............................................................................................................................. |

11 |

Instrument Dimensions..................................................................................................................................... |

12 |

Field Wiring Connections.................................................................................................................................. |

13 |

Power Supply Wiring......................................................................................................................................... |

14 |

Internal Power Supply................................................................................................................................ |

14 |

External Power Supply .............................................................................................................................. |

14 |

Input Wiring....................................................................................................................................................... |

15 |

Turbine Flowmeter (TFM) Input.................................................................................................................. |

15 |

Pulse Input.................................................................................................................................................. |

15 |

Remote Reset Input.................................................................................................................................... |

16 |

Output Wiring.................................................................................................................................................... |

17 |

Pulse Output .............................................................................................................................................. |

17 |

Analog (4-20 mA) Rate Output .................................................................................................................. |

17 |

Flowmeter Frequency Output..................................................................................................................... |

18 |

RS-485 Output............................................................................................................................................ |

19 |

Section 3—Configuration and Operation via Keypad.................................................................................. |

23 |

Entering a Calibration Factor ........................................................................................................................... |

24 |

Entering a Calculated Divisor............................................................................................................................ |

25 |

Setting Input Type and Sensitivity..................................................................................................................... |

26 |

Configuring the Total Display............................................................................................................................ |

27 |

Table of Contents |

MC-III™ EXP Flow Analyzer |

Configuring the Rate Display............................................................................................................................ |

28 |

Configuring the 4-20 mA Rate Output............................................................................................................... |

29 |

Configuring the Pulse Output............................................................................................................................ |

32 |

Entering the Slave Address............................................................................................................................... |

33 |

Entering the Baud Rate..................................................................................................................................... |

33 |

Section 4—Configuration and Operation via Software............................................................................... |

35 |

Installing the Software....................................................................................................................................... |

35 |

Accessing Help................................................................................................................................................. |

35 |

Connecting to the Software............................................................................................................................... |

36 |

Automating Functions on Software Startup................................................................................................ |

37 |

Changing Autorun Settings......................................................................................................................... |

38 |

Express Connect Option............................................................................................................................. |

38 |

Changing the Communications Port........................................................................................................... |

39 |

Software Connection in Multi-Device Network........................................................................................... |

39 |

Setting Log Download Preferences................................................................................................................... |

41 |

Configuring the MC-III EXP............................................................................................................................... |

42 |

Configuration Wizard.................................................................................................................................. |

44 |

MC-III Main Screen..................................................................................................................................... |

46 |

Buttons and Tools....................................................................................................................................... |

47 |

Configuration Submenus (See Scroll Bar on MC-III Main Screen) ............................................................ |

48 |

Configuration Submenus (cont’d)............................................................................................................... |

49 |

System Setup.................................................................................................................................................... |

50 |

Time/Date Synchronization ........................................................................................................................ |

50 |

Contract Hour............................................................................................................................................. |

50 |

LCD Contrast Adjustment........................................................................................................................... |

50 |

Security Setup............................................................................................................................................ |

51 |

Firmware Version Number.......................................................................................................................... |

51 |

Serial Number............................................................................................................................................. |

51 |

Communications Port........................................................................................................................................ |

51 |

Slave Address............................................................................................................................................. |

51 |

Baud Rate .................................................................................................................................................. |

52 |

Bus Delay................................................................................................................................................... |

53 |

Bus Timeout................................................................................................................................................ |

53 |

Software Communication Options.............................................................................................................. |

53 |

Wellsite Information........................................................................................................................................... |

53 |

Turbine Input..................................................................................................................................................... |

54 |

Volume Display........................................................................................................................................... |

54 |

Rate Display............................................................................................................................................... |

54 |

Input Type and Sensitivity Configuration.................................................................................................... |

55 |

Cut-Off Thresholds..................................................................................................................................... |

55 |

Calculation Period...................................................................................................................................... |

55 |

K-Factor Entry................................................................................................................................................... |

56 |

K-Factor Units............................................................................................................................................. |

56 |

K-Factor Type............................................................................................................................................. |

56 |

K-Factor Backup......................................................................................................................................... |

57 |

Gas Volume Correction (Supercompressibility Calculation)....................................................................... |

58 |

4-20 mA Output................................................................................................................................................. |

60 |

Enabling 4-20 mA Output .......................................................................................................................... |

62 |

4-20 mA Output Testing.............................................................................................................................. |

62 |

Pulse Output..................................................................................................................................................... |

63 |

Configuring Pulse Output........................................................................................................................... |

64 |

Pulse Output Testing................................................................................................................................... |

65 |

ii

MC-III™ EXP Flow Analyzer |

Table of Contents |

Saving and Uploading Configuration Files........................................................................................................ |

66 |

Saving a Configuration File........................................................................................................................ |

66 |

Uploading a Configuration File................................................................................................................... |

67 |

Advanced Access ............................................................................................................................................. |

69 |

Section 5—Flow Logs and Event Logs......................................................................................................... |

71 |

Auto-Save Log Formats.................................................................................................................................... |

71 |

Log Directory and Filenames............................................................................................................................ |

72 |

Flow Archive...................................................................................................................................................... |

72 |

Downloading Flow Logs............................................................................................................................. |

73 |

Viewing Trend Charts................................................................................................................................. |

75 |

Printing/Saving a Report............................................................................................................................. |

75 |

Viewing a Saved Report............................................................................................................................. |

77 |

Exporting Flow Logs .................................................................................................................................. |

79 |

Event Archive.................................................................................................................................................... |

80 |

Downloading Event Logs............................................................................................................................ |

81 |

Printing/Saving a Report............................................................................................................................. |

82 |

Exporting Event Logs ................................................................................................................................ |

82 |

Section 6 - MC-III EXP Maintenance.............................................................................................................. |

85 |

Lithium Battery Replacement............................................................................................................................ |

85 |

Alkaline Battery Replacement........................................................................................................................... |

87 |

Circuit Assembly Replacement......................................................................................................................... |

89 |

Keypad Replacement........................................................................................................................................ |

91 |

Firmware Update............................................................................................................................................... |

92 |

Spare Parts List................................................................................................................................................. |

93 |

Optional Parts List............................................................................................................................................. |

93 |

Appendix A—MC-III EXP Hardware Options................................................................................................ |

A-1 |

Explosion-Proof Reset/Control Switch............................................................................................................. |

A-1 |

Explosion-Proof Communications Adapter....................................................................................................... |

A-3 |

Appendix B—Software Program Options.................................................................................................... |

B-1 |

General Options............................................................................................................................................... |

B-1 |

Autorun Options............................................................................................................................................... |

B-2 |

Communications Options................................................................................................................................. |

B-3 |

Express Connect Option............................................................................................................................ |

B-4 |

Auto-Negotiate Option............................................................................................................................... |

B-4 |

Enable Auto-Negotiated Baud Rate Option............................................................................................... |

B-4 |

Request-to-Send (RTS) Line Option.......................................................................................................... |

B-4 |

Enable Modbus Address Support for Firmware Versions 1.06 through 1.08............................................. |

B-4 |

Timing Parameters.................................................................................................................................... |

B-4 |

Downloading Options....................................................................................................................................... |

B-5 |

Advanced Options............................................................................................................................................ |

B-6 |

Clear EEPROM......................................................................................................................................... |

B-6 |

Automatic Data Logging............................................................................................................................ |

B-6 |

Appendix C—Lithium Battery Information.................................................................................................. |

C-1 |

Lithium Battery Disposal ................................................................................................................................. |

C-1 |

Transportation Information............................................................................................................................... |

C-1 |

Material Safety Data Sheet.............................................................................................................................. |

C-1 |

iii

Table of Contents |

MC-III™ EXP Flow Analyzer |

Appendix D—Communications Protocol..................................................................................................... |

D-1 |

Introduction...................................................................................................................................................... |

D-1 |

Supported Commands..................................................................................................................................... |

D-1 |

Data Types....................................................................................................................................................... |

D-1 |

Registers ......................................................................................................................................................... |

D-2 |

System Configuration................................................................................................................................ |

D-3 |

Product Code (register 1000).................................................................................................................... |

D-4 |

Firmware/Register Table Version Numbers (registers 1001, 1002)........................................................... |

D-4 |

Manufacture Date/Sales Date (registers 1003, 1004)............................................................................... |

D-4 |

Slave Address (register 1009)................................................................................................................... |

D-4 |

Baud Rate (register 1010)......................................................................................................................... |

D-4 |

Real Time.................................................................................................................................................. |

D-5 |

Input Configuration.................................................................................................................................... |

D-5 |

Output Configuration................................................................................................................................. |

D-8 |

Holding Registers (16-bit Mode)................................................................................................................ |

D-9 |

Base Units/Configured Units................................................................................................................... |

D-11 |

Conversion Factors................................................................................................................................. |

D-11 |

Polling Registers...................................................................................................................................... |

D-11 |

Pointer/Daily/Event Pointer (registers 17001 through 17006)................................................................. |

D-11 |

Real Date (registers 17007, 17008)........................................................................................................ |

D-11 |

Real Time (registers 17009, 17010)........................................................................................................ |

D-12 |

Totals ...................................................................................................................................................... |

D-12 |

Pulse Output Pulses (register 17077)...................................................................................................... |

D-12 |

Analog Output Current (register 17079).................................................................................................. |

D-12 |

Calculated K-Factor (register 17081)...................................................................................................... |

D-12 |

Holding Registers (32-bit Mode).............................................................................................................. |

D-12 |

Control Register....................................................................................................................................... |

D-14 |

Wellsite Parameters................................................................................................................................. |

D-15 |

Log Data.................................................................................................................................................. |

D-15 |

Enron Registers....................................................................................................................................... |

D-16 |

Enron Hourly/Daily Record Format.......................................................................................................... |

D-16 |

Enron Event Record Format.................................................................................................................... |

D-16 |

Reset Status............................................................................................................................................ |

D-17 |

Log Capacity............................................................................................................................................ |

D-17 |

iv

MC-III™ EXP Flow Analyzer |

Section 1 |

Section 1—Introduction

The NuFlo™ MC-III™ EXP Flow Analyzer (Figure 1.1) packs a full spectrum of gas and liquid measurement functionality, high-speed performance, and log archive and retrieval capabilities in an easy-to-use, explosionproof totalizer. Commonly used operations can be accessed from the six-button keypad on the front of the instrument or from the dynamic interface software, allowing you to calibrate and configure the unit quickly and easily.

Operation

The MC-III EXP calculates and displays instantaneous flow rates and accumulated totals based on a turbine flowmeter input signal. The

MC-III’s microprocessor circuitry counts the pulses generated by a companion flowmeter, converts that data into volume and rate values in accordance with calibration settings, and displays the totalized data on a two-line liquid

crystal display (LCD). The eight-digit top readout indicates total flow volume; the six-digit bottom readout indicates flow rate.

With the press of a single key, totals are saved to nonvolatile memory, minimizing the risk of data loss even if a power outage occurs.

Up to 384 daily logs, 768 hourly logs, and 345 event logs can be archived and accessed quickly on demand.

Offering a variety of user-configurable display options, input and output options, RS-485 Modbus® compatibility, flow logging, and turbine flowmeter linearization, the MC-III EXP is one of the most versatile totalizers on the market. For

specifications, see Table 1.1, page 2. Figure 1.1—MC-III EXP flow analyzer

An optional explosion-proof reset switch further expands the unit’s versatility, making it possible to reset the total and view daily flow logs without opening the enclosure.

Section 1 MC-III™ EXP Flow Analyzer

|

Table 1.1—MC-III EXP Specifications |

||

Enclosure |

CSA-approved for US and Canada |

|

|

|

Class I, Div. 1, Groups B, C, D (explosion-proof) |

|

|

|

Type 4 enclosure |

|

|

|

T6 temperature class |

|

|

System Power |

Internal power supply |

|

|

|

• 3.6 VDC, D-size lithium battery (2-year typical life) |

|

|

|

• alkaline battery pack containing 3 C-size industrial-grade batteries |

|

|

|

External power supply (6 to 30 VDC) with internal battery backup (reverse |

|

|

|

polarity protected) |

|

|

|

Loop-powered (4-20 mA) with internal battery backup |

|

|

|

(reverse polarity protected) |

|

|

|

Loop power: 8 to 30 VDC |

|

|

|

Load resistance: 1100 ohms @ 30 VDC; 200 ohms @ 12 VDC |

|

|

Operating Temperature |

Lithium-Powered: -40°C |

to 70°C (-40°F to 158°F) |

|

|

Alkaline-Powered: -18°C |

to 55°C (0°F to 130°F) |

|

|

LCD contrast is reduced below -20°C (-4°F) |

|

|

LCD Display |

8-digit Total (volume) display (7-segment characters) |

|

|

|

6-digit Rate display (11-segment characters for easy-to-read prompts) |

|

|

|

0.3” character height |

|

|

|

Adjustable contrast and update period |

|

|

|

User-selectable units of measurement (Total): |

|

|

|

• Preprogrammed units: BBL, GAL, LIT, M3, CF, SCF, any unit x 1000 |

|

|

|

• User-defined units |

|

|

|

User-selectable units of measurement (Rate): |

|

|

|

• Preprogrammed units: BBL, GAL, LIT, M3, CF, SCF (per DAY, HR, |

|

|

|

MIN, SEC), any unit x 1000 (per DAY, HR, MIN, SEC) |

|

|

|

• User-defined units |

|

|

Keypad |

6-key membrane switch |

|

|

Communications/ |

RS-485 Modbus® communications with transfer speeds up to 115.2K (allows |

|

|

Archive Retrieval |

full download in less than 1 minute) |

|

|

Logging |

384 daily logs |

|

|

|

768 hourly logs |

|

|

|

345 event logs |

|

|

Inputs |

Turbine Meter Input |

|

|

|

Configurable sensitivity adjustment via front panel |

|

|

|

Sensitivity adjustment range: 20 mV P-P to 40 mV P-P |

|

|

|

Frequency range: 0 to 3500 Hz |

|

|

|

Remote Reset Input |

|

|

|

Optically-isolated input |

|

|

|

3.0 to 30 VDC |

|

|

|

Pulse duration > 3 seconds to reset |

|

|

|

Explosion-Proof Reset Switch (option) |

|

|

|

Press and hold > 3 seconds, then release to reset total |

|

|

|

Press and hold < 1 second, then release to view daily log data |

|

|

|

|

|

|

MC-III™ EXP Flow Analyzer Section 1

|

Table 1.1—MC-III EXP Specifications |

Inputs (cont’d) |

Pulse Input |

|

Optically-isolated input |

|

3.0 to 30 VDC |

Outputs |

Analog Output |

|

4-20 mA, loop-powered (two-wire) |

|

16-bit resolution |

|

Accuracy: 0.1% of full scale @ 25°C, 50 PPM/°C temperature drift |

|

Loop power: 8.0 to 30 VDC |

|

Zero and full-scale engineering values configurable from front panel |

|

RS-485 Communications |

|

Baud rates: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600 and up |

|

to 115.2K |

|

Volumetric Pulse Output |

|

Solid-state relay |

|

Output rating: 60 mA max. @ 50 VDC, on-state drop = 1.4 VDC @ 50 mA, |

|

0.25 VDC @ 10 mA |

|

Configurable pulse width (duration): 10 to 60,000 ms |

|

Amp & Square (Flowmeter Frequency) Output |

|

Open-drain transistor output of turbine meter input signal |

|

Output rating: 50 mA @ 30 VDC, on-state drop = 0.3 VDC @ 50 mA, |

|

0.1 VDC @ 10 mA |

|

(Analog output and amp & square outputs cannot be used simultaneously.) |

Modbus® |

RTU mode Modbus® supports 16-bit and 32-bit holding registers. For more |

|

information, see Appendix D. |

Enron Modbus® |

Flow log parameters (time stamp, period total, period run time, and supply |

|

voltage) and download method are Enron-compatible. |

System Requirements |

Operating System - Windows 2000 or later (Windows XP recommended) |

|

Computer/Processor - 1 GHz or faster Pentium-compatible CPU |

|

Memory - 128 MB of RAM |

|

Hard Disk Space - 21 MB for program files, 30 MB for Adobe Reader, |

|

adequate space for data files |

|

Drive - CD-ROM for install |

|

Display - 800 x 600 (SVGA), 16-bit (thousands of colors) color display or |

|

greater |

|

Browser - Internet Explorer 4 or later |

|

Internet Connection - for web links, tech support |

|

Communications Port - physical or virtual RS-232 compatible serial port |

Key Product Features

This section presents an overview of key features of the MC-III EXP. Many of these features are discussed in more detail in Sections 3 and 4 (configuration procedures) and Section 5 (flow log archival).

Key features discussed here include:

•LCD display

•keypad

•interface software

Section 1 |

MC-III™ EXP Flow Analyzer |

•power supply

•calibration options

•input options

•output options

•flow log archival

•password-protected security

•explosion-proof reset switch (option)

•RS-485 IS barrier (option)

LCD Display

The liquid crystal display (Figure 1.2, page 5) provides a simultaneous indication of accumulated total (top readout) and flow rate (bottom readout). The eight-digit total display uses 7-segment characters to form numbers and letters, which results in a combination of uppercase and lowercase letters. The six-digit flow rate display uses 11-segment characters to form numbers and letters for improved readability. When the keypad is used to calibrate the MC-III EXP, the name of the menu option selected appears in the lower (rate) display, and settings are entered in the top (total) display.

Flow volume can be measured in barrels, gallons, liters, cubic meters, cubic feet, standard cubic feet or other user-defined units. A multiplication factor is also available for indicating flow volume in terms of 1,000 units.

The unit of measure for the Total readout and the decimal point position are selected by the operator during calibration. If a user-defined unit is used, none of the preprogrammed volume units will be visible on the display during operation.

Flow rate can be measured in a wide variety of preprogrammed units, or other user-defined units. The flow rate unit of measure is selected in two steps: (1) a volume unit is chosen and (2) a time-base unit (per day, per hour, per minute, or per second) is chosen. Users can choose any combination of preprogrammed volume and time units in establishing the flow rate engineering unit (for example, gallons per hour, gallons per day, or gallons per minute). Also, the volume unit used for the flow rate can be different from the volume unit used to read Total volume. The unit of measure for the Rate readout and the decimal point position are selected by the operator during calibration.

The daily index (Day) display is a two-digit number for selecting a daily archive log for viewing. The number shown here represents the number of days that have passed since the log was saved. For example, an entry of

01 would yield yesterday’s log. An entry of 05 would yield the log generated 5 days ago. Up to 99 consecutive daily logs can be viewed using the keypad. In addition, up to 384 daily logs, 768 hourly logs, and 345 event logs can be viewed through the interface software.

The LCD contrast can be adjusted with the interface software (see Section 4).

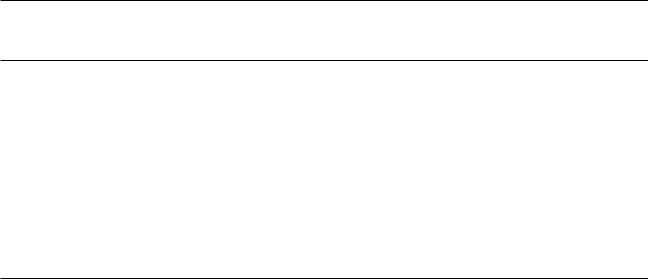

Keypad

The six-button keypad allows users to perform a basic configuration of the instrument. Figure 1.3, page 5, summarizes the functions that can be accessed with each button. Most parameters can be configured in

seconds by selecting one of the three menu keys (K-Factor, Output, or Display), navigating settings with the arrow buttons, and saving the selections with the Enter key.

Section 3 contains procedures for configuring the MC-III EXP using the keypad. Icons of the six buttons provide a pictorial reference to help guide users through each step of configuration.

|

MC-III™ EXP Flow Analyzer |

Section 1 |

|

|

|

Important: Some configuration parameters are accessible only through the interface software. See Section 4 for instructions on configuring the instrument using the software.

|

00000000CF |

|

|||||

|

|

|

|

|

|

M3 |

|

|

|

|

|

|

|

BBL |

Total |

|

|

|

|

|

|

GAL |

|

|

|

|

|

00 STANDARD CF |

|

LIT |

|

Day |

|

|

|

X1000 |

|

||

|

3 |

|

X1000 |

Rate |

|||

|

GALLIT |

000000 |

/DAY/HR |

||||

|

M |

|

|

|

|

/SEC |

|

|

BBL |

|

|

/MIN |

|

||

Figure 1.2—LCD display showing location of the Total, Rate, and daily index (Day) displays. Only the units of measurement selected for displaying total and rate will be visible during normal operation.

Calibrate instrument

Set flowmeter input sensitivity Select pulse input

Enable/disable/set up 4-20 mA output

Enable/disable/set up pulse output

Enter slave address

Enter baud rate

Set engineering units for Total readout

Set engineering units for Rate readout

Set decimal placement for both readouts

+ &!#4/2 /54054 $)30,!9 -%.5 -%.5 -%.5

4OTAL

$AY

$AY

2ATE

During calibration, navigates between submenus and scrolls through menu selections

During operation, accesses daily volume archive

%.4%2

,/' 4%34 3!6%

2%3%434/4!,

2%3%434/4!,

During calibration, incrementally changes digits and decimal point position, on/off settings

During operation, tests temperature and system voltage

During calibration, saves calibration settings

During operation, saves Total to nonvolatile memory

Note: To zero the Total readout, press the LOG (left arrow) and SAVE (ENTER) keys simultaneously.

Figure 1.3—MC-III EXP keypad functions

Section 1 |

MC-III™ EXP Flow Analyzer |

Interface Software

Developed within the familiar Windows environment, the MC-III interface software is an intuitive and easy-to-use application that provides access to all controls for setting up and operating the instrument. The interface tailors the controls to the user’s needs, providing three options for configuring the instrument:

•a “Configuration Wizard,” which steps through the most common configuration tasks

•individual configuration menus for accessing specific settings

•an advanced menu that gives host programmers access to Modbus® registers

For instructions on installing the interface software and entering configuration parameters via the interface software, see Section 4.

Power Supply

The MC-III EXP is shipped with either a lithium battery or an alkaline battery pack. Alternately, the MC-III

EXP may be powered by an external power source; in this case, the lithium battery or alkaline battery pack provides a backup power supply, significantly extending battery service life. Low-power microprocessor technology enables the MC-III EXP to operate approximately 2 years on a single lithium battery.

Wiring diagrams for connecting an external power supply are provided in Section 2.

Multipoint Linearization

The MC-III interface software supports up to 12 calibration points in addition to single-point calibration based on the K-factor provided with the turbine flowmeter. See K-Factor Type, page 56, for more information.

Gas Volume Correction

Gas turbine meters are calibrated in actual cubic feet (ACF), and measure gas in actual cubic feet. In some applications, a user may benefit from referencing gas measurements back to standard conditions by measuring in terms of standard cubic feet (SCF). The MC-III EXP makes this process quick and easy, by using fixed average values for the flowing gas temperature and flowing gas pressure. See Gas Volume Correction, page 58, for more information.

Input Options

The flowmeter signal can be obtained from a magnetic pickup or a pre-amplifier device. The sensitivity of the flowmeter input may be adjusted with the instrument keypad or the interface software. See Section 2 for wiring diagrams. See Sections 3 and 4 for configuration procedures.

Output Options

The MC-III EXP standard circuitry provides:

•a scaled pulse output representing an increment in volume for each pulse

•a loop-powered 4-20 mA output representing the flow rate

•a flowmeter frequency output for use with remote equipment to derive flow rate and volume

•an RS-485 output for communication with interface software or other telemetry equipment

When the 4-20 mA rate output feature is used, the MC-III EXP is powered by the current loop, and the lithium battery or alkaline battery pack is used as a backup supply.

The pulse output and 4-20 mA output features should be turned off when not required for reduced current consumption. See Section 2 for wiring diagrams. See Sections 3 and 4 for configuration procedures.

MC-III™ EXP Flow Analyzer |

Section 1 |

Flow Log Archival

The MC-III EXP saves up to 384 daily logs and 768 hourly logs in nonvolatile memory. By connecting with the interface software, users can download the logs for viewing and/or printing in tabular format or in a trend chart.

Users can also export daily and hourly logs to a spreadsheet. For more information, see Section 5.

Event Log Archival

The MC-III EXP saves up to 345 user event logs. Event logs are generated to track user changes such as K-

Factor changes, input setting changes, power-on reset and “watch-dog” reset, flow cut-off and frequency cutoff.

By connecting with the interface software, users can download the logs for viewing and/or printing in tabular format. In addition to showing old and new values, each event log is time-stamped, and includes the register associated with the change. For more information, see Section 5.

Password-Protected Security

A keypad security access code prevents unauthorized personnel from altering the calibration or accumulated volume data in the instrument. The security feature may be disabled if this protection is not required.

Password-protected security access is enabled using the interface software. When this feature is enabled, the user will be prompted for a password when attempting to enter any menu from the keypad. For more information, see Security Setup, page 51.

Optional Features

Explosion-Proof Reset/Control Switch

An optional external reset/control switch can be mounted in either of the conduit openings near the top of the MC-III EXP enclosure, allowing the user to zero the total and view daily logs instantaneously without opening the enclosure or accessing the interface software. When the switch assembly is ordered with an MCIII EXP, it is factory installed. When ordered separately, the switch assembly is easily installed using the instructions provided in this manual. For installation and wiring instructions, see Appendix A.

Zeroing the Total. To reset the total with an explosion-proof switch, press and hold the switch for 3 seconds, then release it.

Important: When resetting the total with the explosion-proof reset switch, do not release the switch prematurely. Releasing the switch too quickly (before 3 seconds have passed) will activate the daily log view function and WILL NOT reset the volume to zero.

Viewing Daily Logs. To view daily logs with the explosion-proof switch, press the switch for 1 second and release it. Subsequent press-and-release actions increment the daily index, allowing the user to select a specific daily total. Additionally, when the log viewing function times out, the accumulated total is automatically saved to memory.

Saving the Total. When the daily log display times out, the MC-III EXP will automatically save the accumulated total.

Explosion-Proof Communications Adapter

An explosion-proof communications adapter provides an RS-485 connection for connecting a laptop or PC to the instrument without removing the instrument cover. When the adapter is ordered with an MC-III EXP,

Section 1 |

MC-III™ EXP Flow Analyzer |

it is factory installed. It may be relocated to either conduit opening in the instrument housing. When ordered separately, the adapter is easily installed using the instructions provided in this manual. For installation and wiring instructions, see Appendix A.

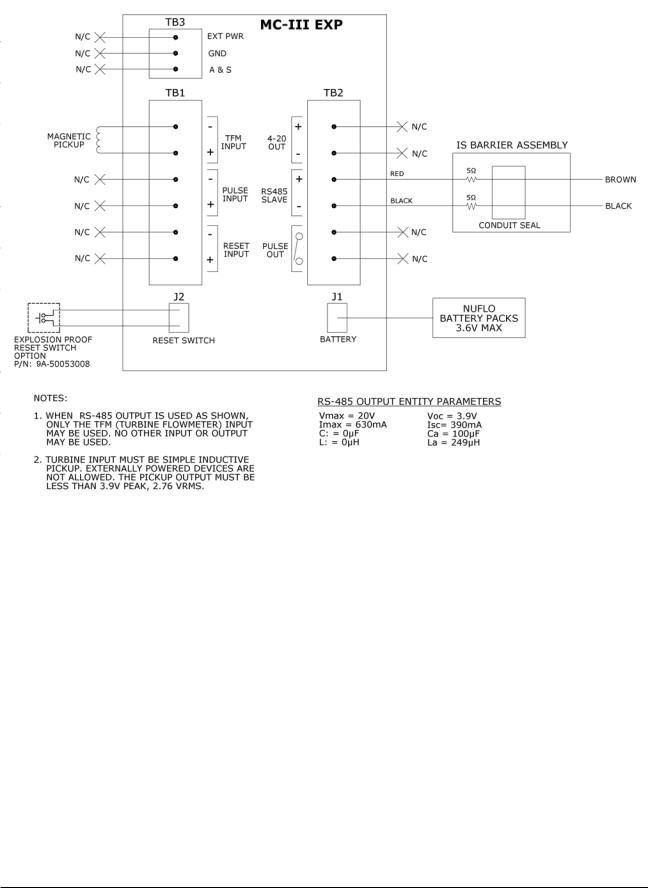

RS-485 IS Barrier

The MC-III EXP’s RS-485 output is approved for intrinsically safe installations. An intrinsically safe barrier assembly with a conduit seal enables the RS-485 output to be used as an intrinsically safe output. In such installations, only the turbine flowmeter input may be used. See Figure 2.15 (page 21) for an IS barrier assembly wiring diagram.

Commonly Used Functions

While the functions of the MC-III EXP are too numerous to mention, some of the most commonly used functions are detailed in this section. They include:

•reading the rate and accumulated total

•saving totals to memory

•resetting the total

•viewing daily and hourly logs

•saving and uploading configuration files

•exporting log data to spreadsheet

•saving log data in a report

Reading Totals

Current totals can be viewed from the LCD on the front of the MC-III EXP or from the interface software

(MC-III Main screen). The software calculates the flow total and updates the LCD display every 4 seconds, by default. The user can adjust the calculation period with the interface software. See Calculation Period, page 55, for more information.

Saving Totals to Memory

Hourly and daily totals are automatically saved to nonvolatile memory. A user may also save an accumulated total at any time by opening the enclosure and pressing ENTER (SAVE) on the keypad. In the event of a power failure, the last saved total will be displayed on the LCD when power is restored. See also ExplosionProof Reset/Control Switch, page 7.

Note: |

Always save the accumulated total before replacing batteries. |

|

|

Resetting the Total

Totals can be reset to zero using the keypad, the interface software, an explosion-proof switch mounted in the top of the enclosure (if equipped), or a pulse from an external device.

•To reset the total with the keypad, press LEFT ARROW (LOG) and ENTER (SAVE) keys simultaneously.

•To reset the total with the interface software, double-click the NuFlo MC-III icon on the computer desktop and wait for the software to connect to the instrument; then select MC-III Main from the Device Autorun Options screen, and click on the “Reset Flow Total” button in the lower right corner of the Main screen.

MC-III™ EXP Flow Analyzer |

Section 1 |

•To reset the total with an explosion-proof switch, press and hold the switch for 3 seconds, then release it. See also Explosion-Proof Reset/Control Switch, page 7.

•To reset the total with an external pulse generator located in safe area, configure the pulse to be active for

3 seconds. See also Remote Reset Input, page 16.

Viewing Daily and Hourly Logs

Each day, as the user-defined contract hour passes, a daily flow total is saved to nonvolatile memory. Hourly logs are also automatically saved. A total of 384 daily logs and 768 hourly logs are accessible for viewing and exporting using the interface software. See Section 5 for details.

Up to 99 daily flow log totals can be viewed from the LCD. Hourly flow log totals are accessible only through the interface software.

To view daily flow totals from the LCD, perform the following steps:

1.Press the LEFTARROW (LOG) key on the keypad. The words “Daily Volume Archive” will scroll across the bottom of the LCD and the day index will display “01.” The daily flow total recorded at the last contract hour will appear at the top of the LCD.

The index number represents the number of days previous to the current date. For example, yesterday’s totals are read by entering an index of “01”; totals from two days previous are read by entering “02.”

2.Press UPARROW (TEST) to increment the index (01, 02, 03...); press LEFTARROW (LOG) to decrement the index (01, 99, 98...).

3.Press Enter (Save) to exit the Daily Volume Archive menu. (After 2 minutes of inactivity, the Daily Volume Archive menu will timeout and the total readout will be restored automatically.)

The optional explosion-proof reset switch also allows users to view daily log totals. For more information, see

Explosion-Proof Reset/Control Switch, page 7.

Saving and Uploading Configuration Files

The MC-III interface software allows users to save an unlimited number of configuration files to their computer. In the event that a configuration setting gets changed unintentionally or a user simply wants to restore the settings he used previously, the user can upload the configuration file and resume operation within minutes. The upload function also allows a configuration file to be loaded quickly into multiple devices. The default directory for saving configuration files is C:\NuFlo log data\MC-III. However, the user can specify a different location, if desired.

For complete information, see Saving and Uploading Configuration Files, page 66.

Exporting Log Data

Flow logs and event logs can be directly exported to an .xls or .csv file. For complete information, see

Exporting Flow Logs, page 79, and Exporting Event Logs, page 82. The default directory for exported logs is

C:\NuFlo log data\MC-III. However, the user can specify a different location, if desired.

Saving Log Data in a Report

Flow logs can be saved in a report format that can be loaded back into the software for viewing or printing at a later time. For complete information, see Printing/Saving a Report, page 75. The default directory for log reports is C:\NuFlo log data\MC-III\<WELL NAME>. However, the user can specify a different location.

Section 1 |

MC-III™ EXP Flow Analyzer |

10

MC-III™ EXP Flow Analyzer |

Section 2 |

Section 2—Installation

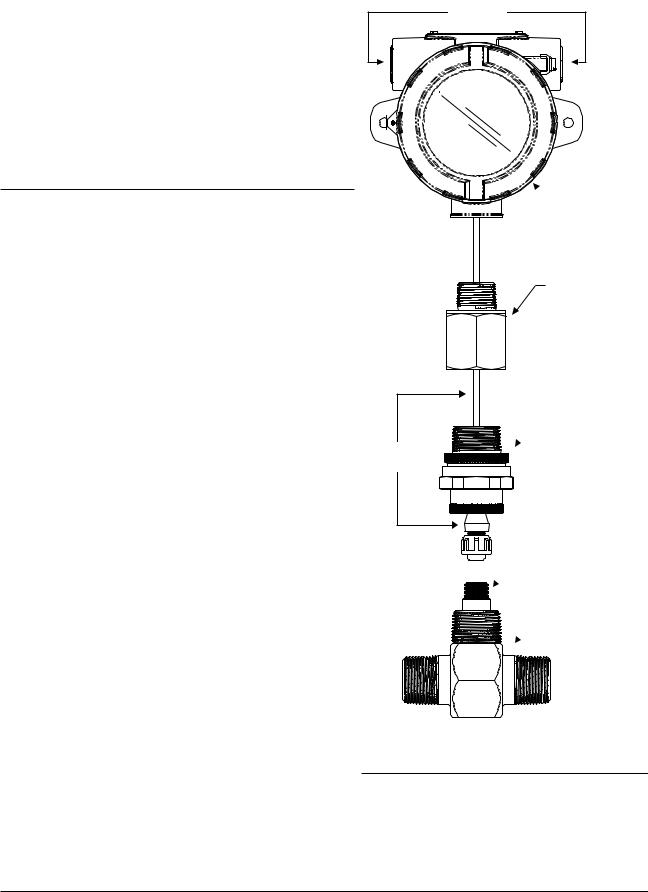

The MC-III™ EXP is fully assembled at the time of shipment and ready for mounting to a flowmeter. The MC-III EXP is shipped with ¾” recessed pipe plugs installed facing right and left, and the pipe union facing downward (Figure 2.1). If the device is equipped with an explosion-proof reset switch, only one plug is required. The switch may be installed in the right or left conduit opening.

Warning: |

To prevent ignition of hazardous |

|

atmospheres, do not remove the cover |

|

while circuits are alive. Under normal |

|

conditions, the MC-III EXP poses no |

|

hazard when opened in a safe area. |

|

|

Preparation

Before attempting to install the MC-III EXP, make sure the flowmeter and magnetic pickup are installed as follows:

1.Install the turbine flowmeter in the flow line.

2.Lightly grease the threads on both ends of the magnetic pickup, taking care to keep grease off of the connector contacts. If the connector is plastic, apply grease only to the end that threads into the meter.

3.Install the magnetic pickup in the flowmeter.

4.After the flowmeter and magnetic pickup are installed in the flow line, mount the MC-III EXP flow analyzer as described below.

Connection to the Flowmeter

To install the MC-III EXP on a turbine flowmeter, perform the following steps:

1.Position the MC-III EXP above the flowmeter.

2.Plug the MC-III EXP cable connector into the magnetic pickup and hand-tighten the knurled nut on the connector.

3.Screw the MC-III EXP onto the flowmeter threads surrounding the magnetic pickup with the display facing the desired direction.

4.Tighten all sections of the pipe union.

Pipe plugs |

Explosion-proof

Explosion-proof

enclosure

3/4-in. to 1-in. pipe adapter

1-in. pipe union

1-in. pipe union

Cable assembly

Magnetic pickup

Magnetic pickup

Turbine flowmeter

Turbine flowmeter

Figure 2.1—Connection of MC-III EXP to a flowmeter

Caution: |

Do not use Teflon® tape on |

|

threads of the union, adapter, or |

|

pipe plugs. Use of Teflon® tape |

|

will void the explosion-proof |

|

rating of the instrument. |

|

|

11

Section 2 |

MC-III™ EXP Flow Analyzer |

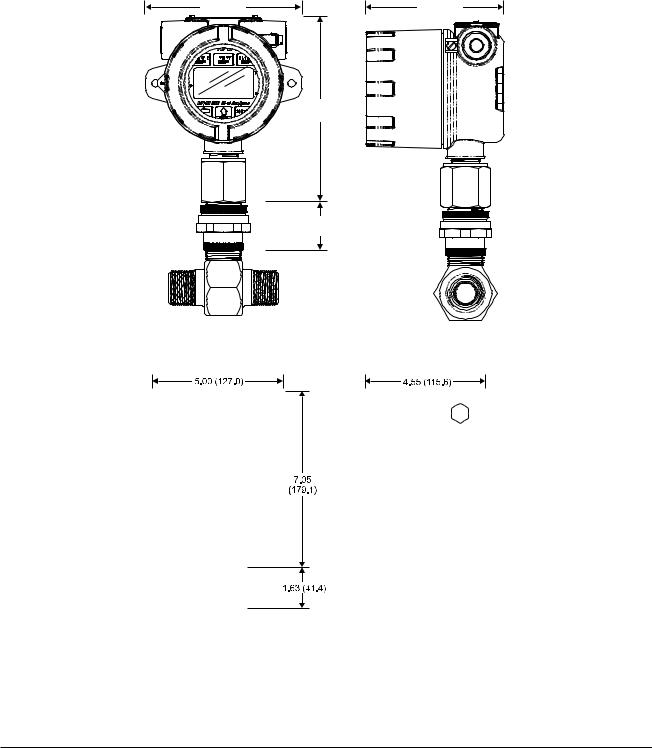

Instrument Dimensions

The MC-III EXP may include either of two enclosure styles. The standard enclosure shown on the cover of this manual and in Figure 2.2 features mounting holes on either side of the display window, allowing it to be mounted to a flat bulkhead.

The alternate enclosure (Figure 2.3) does not have the bulkhead mounting holes on the sides, and a bright red ring frames the display window. The alternate enclosure is slightly taller than the standard enclosure.

5.71 (145) |

5.00 (127) |

6.73

(171.1)

1.75

(44.5)

Figure 2.2—Mount dimensions in inches (millimeters) with standard enclosure

Figure 2.3—Mount dimensions in inches (millimeters) with alternate enclosure

12

MC-III™ EXP Flow Analyzer |

Section 2 |

Field Wiring Connections |

|

Warning: |

To prevent ignition of hazardous atmospheres, do not remove the cover while circuits are |

|

alive. Under normal conditions, the MC-III EXP poses no hazard when opened in a safe |

|

area. |

To wire the MC-III EXP for operation, complete the following field connections:

1.Unscrew the cover of the enclosure counter-clockwise until it separates from the main body of the enclosure.

2.Using a small standard blade screwdriver, remove the two #4-40 × 7/8” screws located to the right and left side of the display.

3.Lift the display/keypad assembly from the enclosure, making sure the circuit assembly does not contact the enclosure.

4.Connect the lithium battery or alkaline battery pack to the J1 connector on the circuit assembly.

5.Connect wiring for external power, if appropriate. See Figure 2.4, page 14.

6.Connect the flowmeter or pulse input wiring to terminal block TB1. See Figures 2.5 and 2.6, page 15.

7.Connect wiring for the remote reset input to terminal block TB1, if appropriate. See Figures 2.7 and 2.8, page 16.

8.Connect wiring for output signals, if appropriate. See Figures 2.9 through 2.14, pages 17 through 20.

9.Place the circuit assembly over the standoffs and fasten with the two #4-40 × 7/8” screws, ensuring that all connector wiring is inside the enclosure and in no position where it may be damaged when the enclosure cover is replaced.

10. Recalibrate the MC-III EXP (if necessary).

11. If external and internal power supplies were removed, reset the clock to ensure that the time stamps in the log data are accurate. The clock is reset using the MC-III interface software. See Time/Date Synchronization, page 50.

12. Replace the enclosure cover by threading it onto the enclosure in a clockwise direction.

13

Section 2 |

MC-III™ EXP Flow Analyzer |

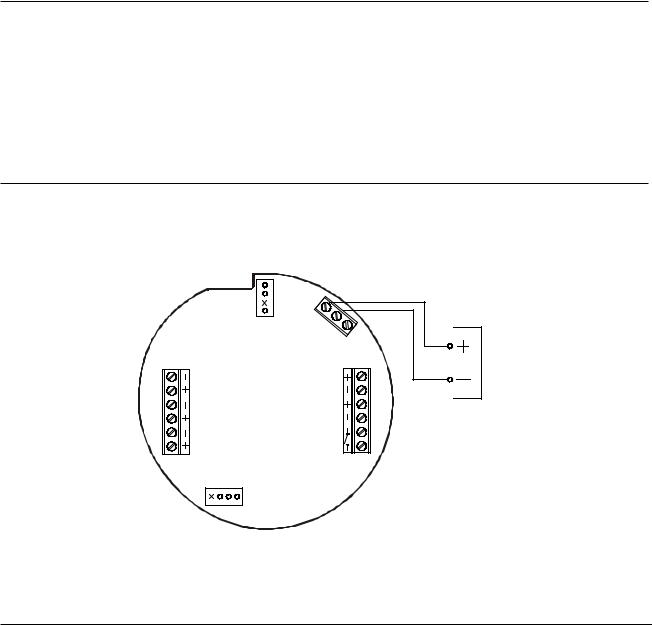

Power Supply Wiring

Internal Power Supply

The MC-III EXP is shipped with either of two internal power supplies:

•a 3.6-V lithium battery or

•a shrink-wrapped alkaline battery pack containing three C-size industrial-grade batteries

Low-power microprocessor technology enables the MC-III EXP analyzer to operate approximately 2 years on a single lithium battery. The lithium battery is strongly recommended for use in extreme temperatures (below

-20°C).

Users can power the instrument from an external power supply or a 4-20 mA current loop, and use the lithium or alkaline battery as a backup power supply. The use of an alternate power source extends battery life and helps ensure that timekeeping and volume accumulation will not be interrupted during a power failure.

Caution: |

If the MC-III EXP is installed in a hazardous location, all field wiring must conform to wir- |

|

ing methods for explosion-proof installations as defined in the National Electric Code for |

|

installations within the United States or as specified in the Canadian Electric Code for |

|

installations within Canada. State and local wiring ordinances may also apply. |

|

|

External Power Supply

The MC-III EXP can be connected to a remote power supply by a two-conductor cable (Figure 2.4). The power supply and cable must be capable of supplying 6 to 30 VDC @ 10 mA. This capability is available only if the 4-20 mA rate output is not used.

Caution: |

When using the amp & square output with the external power supply, make sure the |

|

power supplies for both features share a common negative (-) terminal or that they are |

|

totally isolated from each other, since both share a common negative (-) connection. |

|

|

TB1

INPUT INPUT

RESET PULSE TFM

RESET

SWITCH

J2

BATTERY

J1

|

|

|

|

C |

|

|

|

|

|

D |

|

|

|

|

|

V |

|

|

|

|

|

0 |

|

|

|

|

|

-3 |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

EXT POWER |

|

|

|

|||

|

|

|

GND |

|

3 |

|

|

|

|

|

A&S |

|

|

|

|

|

|

B |

||

|

|

|

|

|

T |

|

TB2

PULSE RS485 20-4 OUT SLAVE OUT

P O W E R S U P P LY 6 to 30 V D C

Figure 2.4—External power supply wiring

14

MC-III™ EXP Flow Analyzer |

Section 2 |

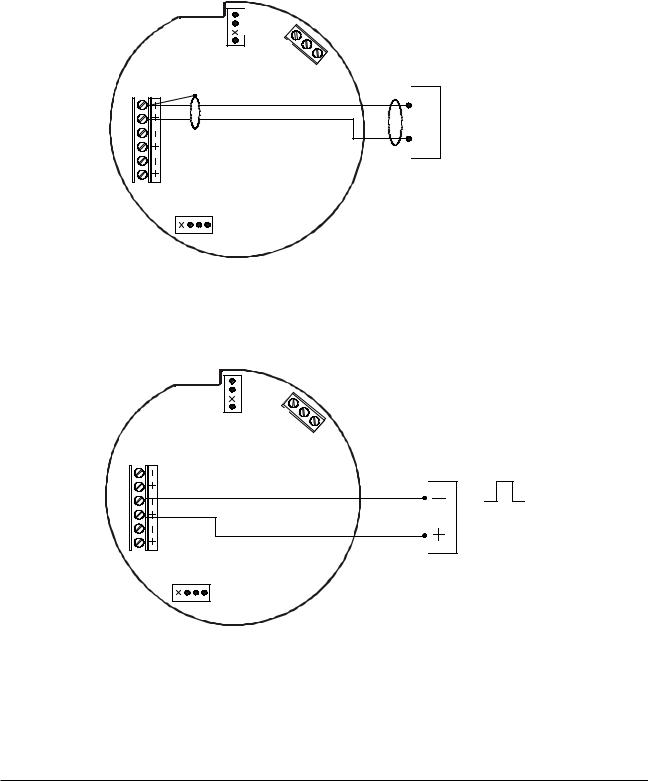

Input Wiring

Turbine Flowmeter (TFM) Input

The TFM input provides the turbine flowmeter input signal generated by a magnetic pickup, enabling the MCIII to calculate and display instantaneous flow rates and accumulated totals.

BATTERY |

|

C |

|

|

0 |

|

-3 |

|

|

6 |

|

J1 |

EXT POWER |

|

|

|

|

T |

3 |

|

TB1

TFM |

PULSE INPUT |

RESET INPUT |

RESET

SWITCH

J2

A

B

TU R B IN E

M A G N E TIC P IC K U P V M A X = 3.9 V

Figure 2.5—Flowmeter input wiring

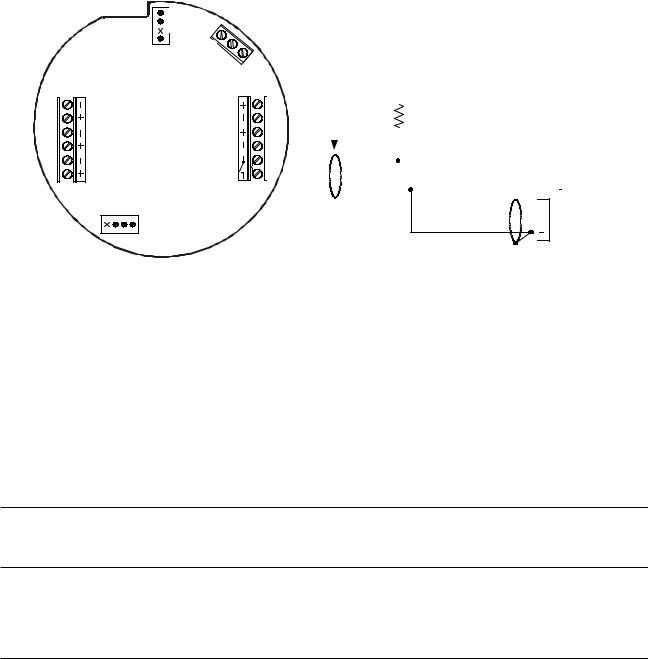

Pulse Input

The pulse input provides an optically isolated input in systems where a preamplifier is inserted between the sensor and the MC-III EXP.

BATTERY

J1

|

|

|

|

C |

|

|

|

D |

|

|

|

V |

|

|

|

0 |

|

|

|

-3 |

|

|

|

|

6 |

|

|

|

|

EXT POWER |

|

|||

TB1

TFM |

PULSE INPUT |

RESET INPUT |

RESET

SWITCH

J2

Figure 2.6—Pulse input wiring

P U LS E IN P U T 3 TO 30 V D C

15

Section 2 |

MC-III™ EXP Flow Analyzer |

Remote Reset Input

The remote reset input allows the operator to reset the accumulated volume on the MC-III EXP to zero without opening the enclosure. This input is optically isolated. The input is shown connected in two ways, with a power supply and switch in a remote location (Figure 2.7), and with a pulse generator in a remote location (Figure 2.8). The remote reset input can also be controlled with an optional explosion-proof switch mounted in the top of the enclosure. See Appendix A for installation and wiring instructions.

The reset input, reset pulse, or local reset switch must be active for 3 seconds to clear the total. (The explosion-proof switch can also be used to view daily logs and to save the accumulated volume to memory without opening the enclosure. See Explosion-Proof Reset/Control Switch, page 7, for more information.)

BATTERY |

|

|

V |

C |

|

|

0 |

D |

|

|

-3 |

|

|

|

|

6 |

|

|

|

J1 |

EXT POWER |

|

||

|

|

|

|

|

T |

3 |

|

TB1

TFM |

PULSE INPUT |

RESET INPUT |

RESET

SWITCH

J2

P O W E R S U P P LY 3 to 30 V D C

Figure 2.7—Reset input wiring (when power supply and reset switch are in a safe area)

BATTERY |

|

|

V |

C |

|

|

|

0 |

D |

||

|

-3 |

|

|

|

|

|

6 |

|

|

|

|

J1 |

EXT POWER |

|

|||

|

|

|

|

|

|

T |

3 |

|

TB1

TFM |

PULSE INPUT |

RESET INPUT |

RESET

SWITCH

J2

R E S E T P U LS E 3 TO 30 V D C

Figure 2.8—Reset pulse input wiring (when pulse generator is in a safe area)

16

MC-III™ EXP Flow Analyzer |

Section 2 |

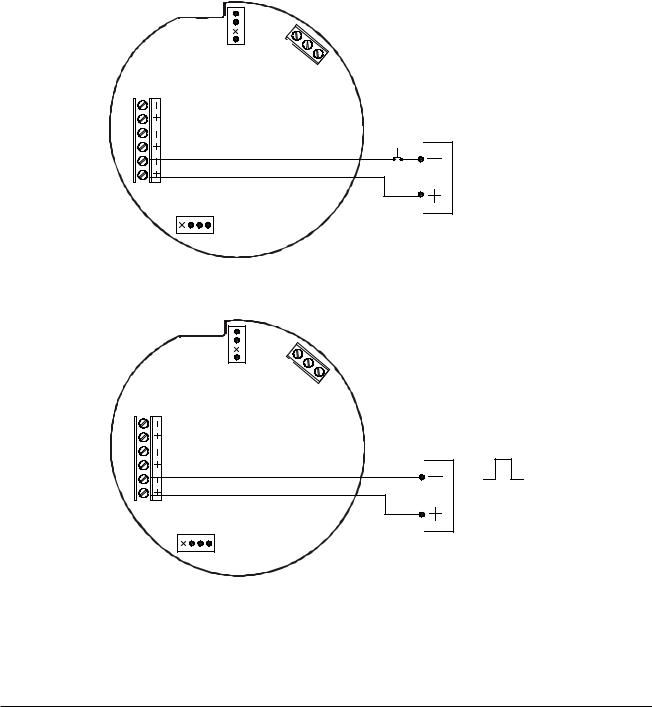

Output Wiring

The MC-III EXP supports four outputs: pulse output, 4 to 20 mA output, flowmeter frequency (amp & square) output, and RS-485 output. Wiring diagrams for each feature are provided below.

Pulse Output

The pulse output is a solid-state relay. Each pulse represents a user-defined volume. Because the circuit is isolated, it can be used in conjunction with any other feature on the MC-III EXP. A two-conductor cable from the MC-III EXP to the remote location is required (Figure 2.9). The maximum current rating of the pulse output circuit is 60 mA at 50 VDC.

For information on configuring the pulse output with the keypad, see page 32. For information on configuring the pulse output with the interface software, see page 64.

TB1

TFM |

PULSE INPUT |

RESET INPUT |

RESET

SWITCH

J2

BATTERY |

|

|

V |

C |

|

|

|

0 |

D |

||

|

-3 |

|

|

|

|

|

6 |

|

|

|

|

J1 |

EXT POWER |

|

|||

|

|

|

|

|

|

|

3 |

B |

|

T |

|

TB2

20-4 OUT |

RS485 SLAVE |

PULSE OUT |

* R esistor m ay be included in pulse readout device . S ize the resistor to lim it the current to 60 m A .

|

|

|

Leave this |

* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

PO W ER SU PPLY |

|

||||||||||||

|

|

|

end of shield |

|

|

|

|

|

5 to 50 VD C |

|

|||||||||

|

|

|

disconnected . |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PU LSE R EAD O U T

D EVIC E

Figure 2.9—Pulse output wiring

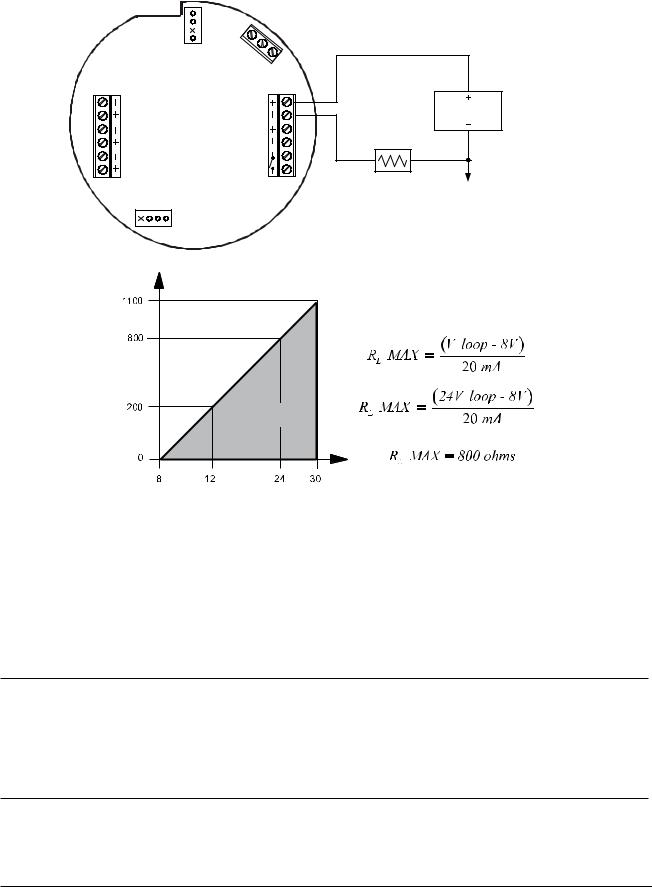

Analog (4-20 mA) Rate Output

The 4-20 mA rate output provides a linear current output that represents flow rate. This output requires a twoconductor cable connected to an 8 to 30 VDC power supply (voltage required is dependent on loop resistance) and a current readout device located in the remote location. The 4-20 mA rate output current loop also powers the MC-III EXP. The internal battery (lithium or alkaline) provides a power supply backup to maintain timekeeping accuracy and to continue accumulating volume in the event that the 4-20 mA current loop fails.

Figure 2.10, page 18, shows the minimum required voltage to power the instrument for a given loop resistance. In addition, the mathematical relationship between loop voltage and load resistance is given. For example, if a power supply voltage of 24 volts is available to power the current loop, the maximum load resistance would be 800 ohms.

Caution: |

The 4-20 mA rate output and the flowmeter frequency output circuits are not isolated |

|

from each other and cannot be used simultaneously. When the 4-20 mA output option is |

|

used, do not connect external power to TB3. |

For information on configuring the 4-20 mA rate output with the keypad, see page 29. For information on configuring the 4-20 mA rate output with the interface software, see page 60.

17

Section 2 |

MC-III™ EXP Flow Analyzer |

TB1

INPUT INPUT

RESET PULSE TFM

RESET

SWITCH

J2

BATTERY

J1

|

|

|

|

C |

|

|

|

D |

|

|

|

V |

|

|

|

0 |

|

|

|

-3 |

|

|

|

|

6 |

|

|

|

|

EXT POWER |

|

|||

GND

A&S

PULSE RS485 20-4 OUT SLAVE OUT

|

3 |

B |

|

T |

|

TB2

RESISTANCE (OHMS) |

OPERATING |

LOAD |

REGION |

|

PO W ER SU PPLY 8 to 30 VD C

* LO AD |

*R esistor m ay be included in readout device .

4-20 m A and

flow m eter frequency (am p & square) cannot be used

sim ultaneously.

LOOP SUPPLY VOLTAGE (VDC)

Figure 2.10—4-20 mA rate output wiring

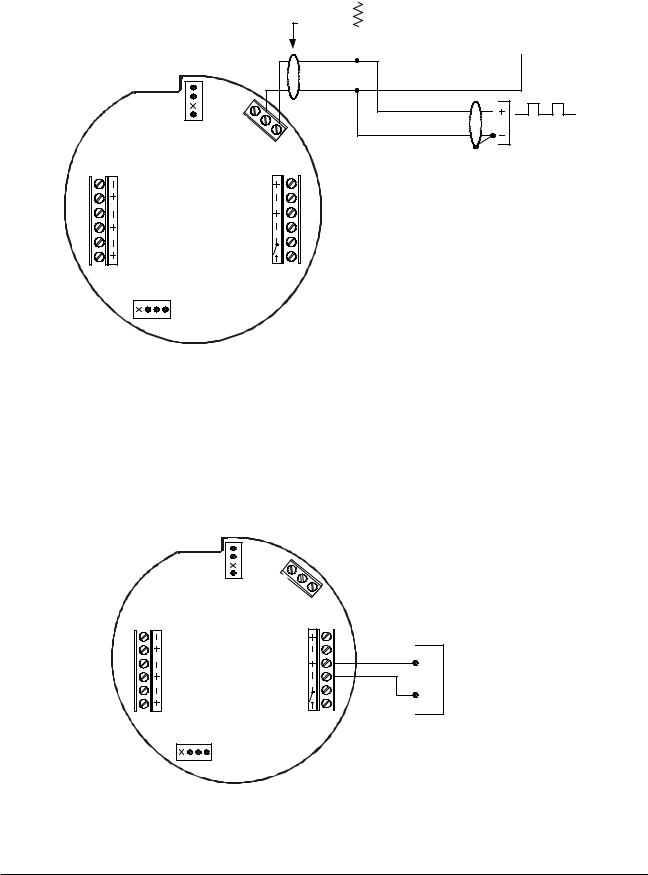

Flowmeter Frequency Output

The flowmeter frequency (amp & square) output provides an open drain transistor output at the turbine meter frequency, which may be used to provide flow rate and/or total information to peripheral equipment. The output requires a two-conductor cable from the MC-III EXP to the remote frequency readout device requiring

50 mA or less and a 5 to 30 VDC power supply (Figure 2.11, page 19).

Caution: |

The flowmeter frequency output and 4-20 mA rate output are not isolated from each other |

|

and cannot be used simultaneously. |

|

|

|

|

Caution: |

When using the flowmeter frequency output and powering the device from an |

|

external power supply, make sure both power supplies share a common negative (-) |

|

terminal or are totally isolated from each other. |

The flowmeter frequency output terminals on the MC-III EXP circuit assembly are labeled A & S to represent “amp & square” output.

18

MC-III™ EXP Flow Analyzer |

Section 2 |

TB1

TFM |

PULSE INPUT |

RESET INPUT |

RESET

SWITCH

J2

Leave this |

* |

|

|

|

|

|

|

|

|

||

|

|

|

|

||

|

|

PO W ER SU PPLY |

|||

end of shield |

|

|

5 to 30 VD C |

||

disconnected . |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BATTERY |

|

|

V |

C |

|

|

|

|

|

0 |

D |

|

|

|

|

|

-3 |

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

J1 |

EXT POWER |

|

|

|

FR EQ U EN C Y |

||

|

|

|

|

|

|

||

|

|

|

|

|

T |

|

R EAD O U T D EVIC E |

|

|

|

|

|

|

|

|

|

|

|

|

|

TB2 |

* |

R esistor m ay be included in frequency |

|

|

|

|

20-4 OUT |

|

||

|

|

|

|

|

readout device . Size the resistor to lim it |

||

|

|

|

|

RS485 SLAVE |

|

|

the current to 50 m A . |

|

|

|

|

|

|

4-20 m A and flow m eter frequency |

|

|

|

|

|

|

|

|

|

|

|

|

|

PULSE OUT |

|

|

(am p & square) cannot be used |

|

|

|

|

|

|

sim ultaneously . |

|

Figure 2.11—Flowmeter frequency (amp & square) output wiring

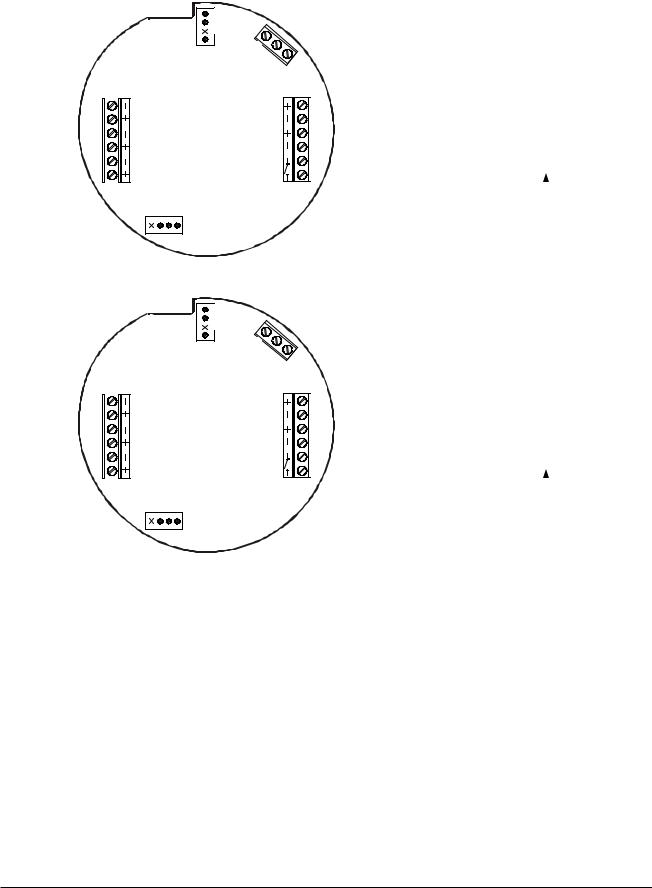

RS-485 Output

The RS-485 output is required for communication with the interface software. Wiring diagrams are provided for a permanent connection (Figure 2.12), as well as for temporary laptop connections using an RS-485 to RS232 converter (Figures 2.13 and 2.14, page 20).

Additionally, the RS-485 output is approved for intrinsically safe installations. An intrinsically safe installation requires an intrinsically safe barrier assembly with a conduit seal (Figure 2.15, page 21). In such installations, only the turbine flowmeter input may be used.

TB1

TFM |

PULSE INPUT |

RESET INPUT |

RESET

SWITCH

J2

BATTERY |

|

|

V |

C |

|

|

|

0 |

D |

||

|

-3 |

|

|

|

|

|

6 |

|

|

|

|

J1 |

EXT POWER |

|

|||

|

|

|

|

|

|

T |

3 |

|

TB2

20-4 OUT |

|

RS485 SLAVE |

B |

|

|

PULSE OUT |

A |

|

R S -485

C om m unications

Figure 2.12—RS-485 output (permanent connection)

19

Section 2 |

MC-III™ EXP Flow Analyzer |

BATTERY |

|

|

V |

C |

|

|

|

|

0 |

D |

|

||

|