Page 1

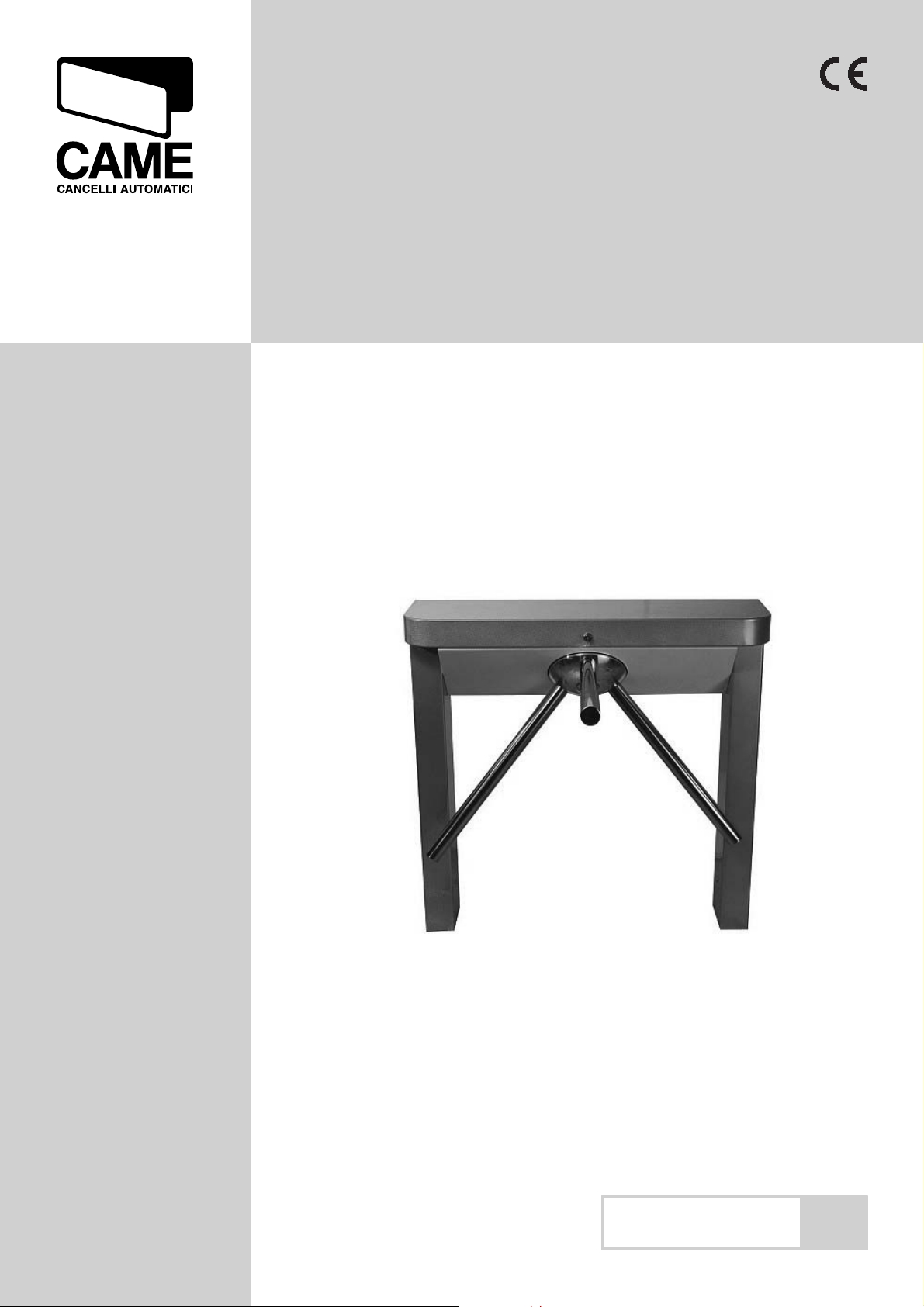

TRIPOD

BRIDGE SERIES

TURNSTILE

INSTALLATION MANUAL

PSAP01A - PSAP01O - PSAP07

English

EN

Page 2

EN

ENGLISH

WARNING!

Important instructions for the safety of people:

READ CAREFULLY!

Foreword

• Use of the products must be restricted to its intended use

(i.e. that for which it was expressly built for). Any other use is

to be considered dangerous. Came Cancelli Automatici S.p.A.

is not liable for any damage resulting from improper, wrongful

ENGLISH

or unreasonable use • Keep these warnings with the installation and use manuals issued with the automated system.

Before installing

(preliminary check: in case of a negative

outcome, do not proceed before having

complied with the safety obligations)

• Make sure that the parts you intend to automate are in

good working order, and that they are properly balanced

and aligned. Also, make sure that proper mechanical stops

are already in place • If the operator will be installed at a

height of less than 2.5 m from the ground or other access

level, check whether you will need any protections and/or

warnings • Any gate leaves, fi tted with pedestrian entrances,

onto which you will install an operator, must have a blocking

mechanism when the gate is in motion • Make sure that the

opening of the automated gate is not an entrapment hazard

as regards any surrounding fi xed parts • Do not mount the

operator upside down or onto any elements that may fold

under its weight. If needed, add suitable reinforcements at

the points where it is secured • Do not install onto gates on

either an upward or downward slope (i.e. that are not on fl at,

level ground) • Check that any lawn watering devices will not

wet the gearmotor from the bottom up.

are working properly • Where necessary and in plain sight,

apply the Warning Sings (e.g. gate plate).

Special instructions and

advice for users

• Keep the gate’s area of operation clean and clear of any

obstacles. Trim any vegetation that may interfere with the

photocells • Do not allow children to play with the fi xed command devices, or in the gate’s area of operation. Keep any

remote control devices (i.e. transmitters) away from the children as well • Frequently check the system, to see whether

any anomalies or signs of wear and tear appear on the moving

parts, on the component parts, on the securing points, on the

cables and any accessible connections. Keep any joints (i.e.

hinges) lubricated and clean, and do the same where friction may occur (i.e. slide rails) • Perform functional tests on

photocells and sensitive edges, every six months. Keep glass

panels constantly clean (use a slightly water-moistened cloth;

do not use solvents or any other chemical products) • If the

system requires repairs or modifi cations, release the operator

and do not use it until safety conditions have been restored

• Cut off the power supply before releasing the operator for

manual openings. See instructions • Users are FORBIDDEN

to carry out ANY ACTIONS THAT THEY HAVE NOT BEEN

EXPRESSLY ASKED TO DO OR SO INDICATED in the manuals. Any repairs, modifi cations to the settings and extraordinary maintenance MUST BE DONE BY THE TECHNICAL

ASSISTANCE STAFF • On the periodic maintenance log, note

down the checks you have done.

Installation

• Carefully section off the entire site to prevent unauthorised

access, especially by minors and children • Be careful when

handling operators that weigh more than 20 Kg (see installation manual). In such cases, employ proper weight handling

safety equipment • All opening commands (e.g. buttons, key

selectors, magnetic detectors, etc.) must be installed at least

1.85 m from the gate’s area of operation perimeter - or where

they cannot be reached from the outside of the gate. Also,

the direct commands (e.g. push button, or proximity devices,

etc.) must be installed at a height of at least 1.5 m and must

not be accessible to the public • All ‘maintained action’ commands, must be placed where the moving gate leaves, transit

areas and driveways are completely visible • If missing, apply a permanent label that shows the position of the release

mechanism • Before delivering to the client, verify that the

system is EN 12453 (impact test) standard compliant. Make

sure that the operator has been properly adjusted and that the

safety and protection devices, as well as the manual release

Special instructions and

advice for all

• Avoid working near the hinges or moving mechanical parts

• Stay clear of the gate’s area of operation when in motion •

Do not resist the direction of movement of the gate; this may

present a safety hazard • At all times be extremely careful

about dangerous points that must be indicated by proper

pictograms and/or black and yellow stripes • When using

a selector or command in ‘maintained action’ mode, keep

checking that there are no people in the area of operation of

the moving parts. Do this until you release the command •

The gate may move at any time without warning • Always cut

the power when cleaning performing maintenance.

CAME cancelli automatici s.p.a.

Via Martiri della Libertà, 15

31030 Dosson di Casier

TREVISO - ITALY

www.came.it - info@came.it

Page 3

General conditions of sale

1. GENERAL POINTS

These general conditions shall apply to all purchase agreements for Came Cancelli Automatici SpA materials, hereinafter called “the

company”.

2. OFFERS AND QUOTATIONS

The company’s quotations are valid for a 30-day period at the most starting from the date they are sent.

3. ORDERS

The sale agreement is executed once the written order is confirmed by Came Cancelli Automatici Spa or when the order is fulfilled by

the company. Orders that are addressed, and signed by clients, to Came Cancelli Automatici SpA are deemed to be firm and irrevocable

for 30 days starting from the date they are received by the company. Any change or addition to the single provisions of these general

conditions or single provisions of the order which was originally addressed by the client, shall have no validity unless otherwise approved

in writing by the company. For any changes to the order, the company reserves the right to cancel both the changes an the original order.

The delivery date for the goods appearing on the orders is always and in any case exclusively indicative, and any delays of such term may

never justify claims for compensation or cancellation of contract.

Particularly, the company reserves the right to extend the delivery terms or cancellation of order in the event of: force majeure or events

that are beyond the control of the company; change of the Client’s legal status; difficulty in sourcing raw materials and component parts.

4. DELI VERY AN D FORWARDING

The place of production or registered office of the company shall be the place of fulfilment for delivery. The cost and risk of the travelling

goods is borne by the buyer ex works, pursuant to the 2000 incoterms. Unless otherwise agreed, the company establishes, for and on

behalf of the client, the type of shipping, the travel route and type of carrier. The company reserves the right to carry out partial deliveries

and fulfilment of orders, thereby issuing a separate invoice each time: in this case all partial deliveries shall be autonomously invoiced and

the terms of payment shall begin as of the date on each invoice; the client may not, therefore, defer payment of partial orders, until the last

deliver y is made as concerns the original order.

5. PRICES AND PRICE LISTS

The prices are intended for goods delivered free to the company’s registered office, not including VAT, with normal packaging, and not

including forwarding expenses. Any reference to list prices shall refer to the latest price list published by the company, which theretofore

cancels any previous price lists.

6. PAYMENTS

Non-payment within the established terms, shall result in the application of interest pursuant to Lgs. Decr. 09/10/2002 n. 231 and

subsequent amendments and upgrades, with any possible greater damage unprejudiced. Any delay in payment, shall mean that the client

shall owe the company, any losses due to exchange rates. The client may not advance any demands nor raise any exceptions as concerns

the company, unless after having paid the goods it purchased. The company reserves the right to block all shipping and supply orders

underway in the face of any irregularities in the payments, without need of prior notice nor compensatory damages of any kind.

7. RETURNS AND CLAIMS

All claims must be filed in writing within 8 days of receiving the goods, whether such claims refer to the quantity or quality of the delivered

goods. Returned goods shall be accepted by company only following a written agreement, and only for new and packaged goods. Any

returned goods must be complete of their relative transport documents, showing the company’s written authorisation to accept the

returned goods including the quality and quantity of the returned goods.

The returned goods shall not be accepted by the company unless carried out in the above mentioned manner and, especially, returned

goods shall not be accepted if received at any of the company’s premises.

8. GUARANTEE

The company guarantees the proper functioning of the products that it provides, as per the technical characteristics that are expressly

shown on its products’ technical sheets. The guarantee shall not apply in the case of any environmental interferences of any nature, which

could cause disturbances in the functioning of any existing or future installations (radio frequencies – proximity of electric power lines…).

The guarantee does not cover the normal wear and tear of the equipment, or mistakes made during the mounting phase or due to

maintenance flaws, and in any case it does not cover any cases in which flaws in the functioning can be traced back to factors stemming

from anything other than manufacturing.

The deadlines for filing a claim for any flaws or for the statute of limitations for actions to which the buyer is entitled are those foreseen by

Italian law. The company at its own leisure, may decide to withdraw any goods supplied which it has ascertained as faulty, or decide to

repair said ascertained flaws. The client may not request to be compensated for any indirect damages, missed gains, production losses,

and in any case may not expect as compensation any sums greater than the value of the supplied components or products.

9. REPAIRS

Repairs to purchased items request by the client shall be carried out by the company following an agreement on the price of said repairs.

In any case the expenses for labour and shipping (roundtrip) shall be borne by the client.

10. RESE RVATION OF TITLE

It is expressly agreed that, any delivered goods remain owned by the company until the client pays the entire balance, regardless of who

is in possession of said goods. Transport expenses and any other expenses needed to retrieve the equipment, therein including any

extraordinar y expenses as well as any repeatable ones, shall be borne by the client.

11. APPLICCABLE L AW – SET TLEMENT OF ANY DIS PUTES Any arising dispute resulting from the sale agreement, shall be settled

according to the Italian law, thereby excluding any other law and in supplement to the Vienna Convention on the international sale of

goods. All disputes shall be subject to Italian jurisdiction and come under the exclusive competence of the Tribunal of Treviso, Italy.

12. PROVISION S ON THE SAFEGUARDING OF PERSONAL DATA .

Pursuant to current legislation for the safeguarding of personal data, clients are aware that their personal data is inputted into the

company’s databank, which is necessary for the proper carrying out of the contractual relationship and for compliance with certain

provisions of law, as well as for purposes of statistics, promotion, marketing, commercial, credit protection, management and transfer of

the same .

The personal data of the buying party are processed through automated and paper-based tools by authorised persons, by using safety

procedures designed to guarantee confidentiality. The personal data of the client may by shared with Public Bodies, companies of the

group, credit recovery firms, or consortiums or associations with business scopes, market research scopes, or marketing scopes. The

data processor shall be the company, and the client may address said company to uphold their own rights as per law. To this end the

buying party is aware that at any time it may access its personal data, ask that it be updated, corrected and /or prohibit it from being used.

ENGLISH

Page 4

#

2

119G3074

0.1

“IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLATION”

“WARNING: WRONG INSTALLATION MAY CAUSE SERIOUS INJURY, FOLLOW ALL INSTALLATION INSTRUCTIONS”

“THIS MANUAL IS EXCLUSIVELY MEANT FOR PROFESSIONAL INSTALLERS OR OTHER COMPETENT PERSONS”

1 Legend of symbols

This symbol shows parts to be read carefully.

This symbol shows parts related to safety.

This symbol shows what to tell users.

ENGLISH

This symbol shows parts that exclusively concern electromechanical models.

2 Conditions of use

2.1 Intended use

The BRIDGE electromechanical turnstile is designed to select transit flows in high-volume passage areas, and in highly frequented contexts like stadiums, airports, stations, public buildings and in any other places where high-volume flows need to be

regulated and/or selected.

Any installation or use other than that shown in this manual is prohibited.

3 Reference Legislation

The product being described herein complies with the following legislation: see compliance statement.

4 Description

4.1 Turnstile

This product is designed and built by CAME Cancelli Automatici S.p.A. in compliance with the current safety legislation. Guaranteed

24 months unless tampered with.

Selective, bidirectional, electromechanical turnstile, entirely made of AISI 304 stainless steel with “scotch-brite” fi nish, fi tted with

a removable top cover with key lock, and removable side legs. The aluminium tripod head bears a shiny fi nish and stainless steel,

shiny-polished arms.

It works by allowing only one person to transit through in the desired direction. A command on the device releases the mechanism

to manually push the tripod arm until the mechanical brake slows the tripod down to its resting position, until a new command is

given.

The complete range:

BPAP01A – Counter-clockwise monodirectional, mechanical trnstile complete with hydraulic brake. Body made of varnished steel.

BPAP01O – Clockwise monodirectional, mechanical turnstile complete with hydraulic brake. Body made of varnished steel.

BPAP07 - Bidirectional, electromechanical turnstile, body in galvanised, varnished steel with hydraulic brake, electronic board, and

LED stop/go directional lights.

4.2 Technical Data and dimensions

PSAP01A - PSAP01O

Protection rating: IP44

Weight: 60 Kg

Suggested distance between one

turnstile and another in case of

multiple installation.

900

800

770

250

PSAP07

Power: 230V A.C. 50/60 Hz

Power Draw: 233 mA max

Insulation class: II

Protection rating: IP44

Weight: 50 Kg

#

Ø 40

900

80

Ø25

150

820

160

800

0.1 02/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAM E cancelli automatici s.p.a. to notify users.

119 G3 074 ver.

- Manual code:

Pag.

Page 5

3

119G3074

0.1

5 Application examples

Warning: an exit fitted with a turnstile cannot be an emergency exit. There must always also be an emergency exit

for physically impaired persons.

Standard installation

EXIT

Multiple installation

SWIMMING POOL

Against the wall installation

ENGLISH

Platform installation

6 Installation

Only skilled, qualified staff must perform the installation, in full compliance of the current legislation.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Before installing the automated device, please:

• Set up a proper omnipolar cut-off device, with contacts more than 3 mm apart, and power source isolation;

• Set up proper tubing and conduits for the electrical cables to go through with enough protection from any mechanical damage;

•

Check that any connections within the container (made to give continuity to the protection circuit) have additional isolation

compared to the other internal power conductors.

© CAME cancelli automatici s.p.a. -

6.1 Tools and equipment

Make sure you have all the tools and materials needed to carry out the installation in total safety and in compliance with current

0.1 02/2009

legislation. The figures shows examples of installers’ tools.

119 G3 074 ver.

:

Manual code

-

Pag.

Page 6

4

119G3074

0.1

6.2 Positioning the turnstile

Depending on the measurements of the Depending on the measurements of the transit opening, choose where to position the

turnstile and any accessories.

Set up electrical cable conduits next to the turnstile.

If the floor cannot be dug, then use the (TRPE) platform to secure the turnstile and any accessories.

6.3 Disassembling and securing the turnstile to the ground

Warning: installation required two people. Use hoisting equipment to move and position the turnstile.

ENGLISH

When securing, the turnstile may be unstable and could tip over, so be careful not to lean onto it until securing in

complete.

Use the issued key to release the lock on the front of the turnstile

and remove the upper cover.

Warning: when opening the cover be careful not to rip

the display cables. You may have to disconnect them .

Check that the floor where the turnstile is anchored is level

and without warping.

Slide the lateral door upwards.

0.1 02/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAM E cancelli automatici s.p.a. to notify users.

119 G3 074 ver.

- Manual code:

Pag.

Page 7

5

119G3074

0.1

Position the turnstile in the exact point where it will be

anchored and mark the holes with a pencil.

MM

ENGLISH

Ø20 mm

Ø40 mm

Remove the turnstile and apply (Ø 12mm) holes where you have

marked them.

Insert the Ø 12mm, minimum length 50 mm gussets into the

holes you have made.

Position the turnstile along the gussets and run any cable

conduits through the central hole.

Using a ratching driver, secure the turnstile to the ground.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

© CAME cancelli automatici s.p.a. -

0.1 02/2009

119 G3 074 ver.

:

Manual code

-

Pag.

Page 8

6

119G3074

0.1

7 Electric cabling

Once the turnstile is secured to the ground, carry out the following cable connections.

Run through the conduits as shown in the figure

and carry out the shown connections.

The cables inserted into the electrical panel

box must be secured using the apposite

cable gland.

ENGLISH

L

N

+ E

10

-

EbA EbA EbI EbI

S12EM432111

S2

7.1 Cable types and sections

Connections Cable types Cable length 1 < 10 m

Power to electrical panel 230V

Power to accessories 2 x 0,5 mm

FROR CEI

20-22

3G x 1,5 mm

CEI EN

Command and safety devices 2 x 0,5 mm

50267-2-1

2

2

2

Cable length

10 < 20 m

3G x 2,5 mm

2 x 0,5 mm

2 x 0,5 mm

2

2

2

N.B. If the cable length differs to that shown in the table, determine cable section based on the actual power draw by the connected

devices and according to what is prescribed by law CEI EN 60304-1.

For sequential connections on the same line, length-measurements by the table must be converted on the basis of draw and actual

distances.

To connect any products not mentioned in this manual, see documentation provided with said products.

Cable length

20 < 30 m

3G x 4 mm

2 x 1 mm

2

2

2 x 0,5 mm

2

8 Control panel

8.1 General description

The control panel is powered by 230V A.C. on terminals L-N, with

max frequency of 50/60Hz.

The 24V current emitted by the board is of the SELV type.

The command and control devices and accessories are 24V D.C..

Warning! The accessories must not comprehensively exceed

35W.

All connections are quick-fuse protected, see table.

The functions and user interface are set and displayed on the

software-managed display.

The defi nable command and control functionalities are:

- clock-wise activation;

- counter clock-wise activation;

- override release command;

- emergency command.

FUSE TABLE

To protect: Fuse rating:

Control board (line) 1,6A-F

Accessories 1,6A-F

0.1 02/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAM E cancelli automatici s.p.a. to notify users.

119 G3 074 ver.

WARNING: before doing any work inside the equipment, cut the

power mains.

- Manual code:

Pag.

Page 9

7

119G3074

0.1

8.2 Main Components

Transformer1.

Transformer connection terminals2.

1.6A accessories Fuse3.

1

Endpoint connection terminal4.

1.6A line fuse 5.

230V A.C. control board power terminals6.

Terminals for connecting accessories and command 7.

ENGLISH

and control systems.

Electro-block connection terminal board8.

Stop/Go lights connection terminal board (optional)9.

2

3

9

2

4

+ E

EbA EbA EbI EbI

-

5

L

10

N

S2

S1 2 EM 4 3 2 1 11

6

7

9 Electrical connections

9.1 Power

N

L

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

9.2 Connecting devices to the control panel

© CAME cancelli automatici s.p.a. -

E

-

+

0.1 02/2009

Connect the earth to the terminal fi tted on the turnstile.

White

Brown

Green

8

230V A.C. power, 50/60Hz

frequency

Endpoint

Blu

White

119 G3 074 ver.

:

Manual code

-

Pag.

L1T

L2T

24V

0V

Pink

Red

Transformer

Page 10

EbI EbI

8

119G3074

0.1

EbA EbA

ENGLISH

9.3 Connecting optional devices to the control panel

Electroblocks

Terminals to power accessories:

24V A.C. / 500 mA

Stop Button / (N.C. Contact)

Activating the contact causes the turnstile to completely

block.

Clockwise activating button / (N.O. contact)

If after 10” no other command is given, the turnstile

automatically reblocks.

Counter-clockwise activating button / (N.O. Contact)

If after 10” no other command is given, the turnstile

automatically reblocks.

Emergency button / (N.C. contact)

Activating the contact frees the turnstile to turn in any direction and if maintained inhibits all other commands.

0.1 02/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAM E cancelli automatici s.p.a. to notify users.

119 G3 074 ver.

10 11 1 2 3 4 EM 2 S1 S2

- Manual code:

Pag.

Page 11

9

119G3074

0.1

9.4 Connecting optional anti-intrusion devices to the control panel

10 11 1 2 3 4 EM 2 S1 S2

10 11 1 2 3 4 EM 2 S1 S2

-

+

Photocell

Photocell

Anti-intrusion

sensor.

Anti-intrusion

sensor.

Anti-intrusion photocell (N.C. contact)

Anti-intrusion sensors placed in line with the

passage way, activate a Buzzer, in case of any

climb-over attempts.

ENGLISH

Pressure sensor / (N.C. contact)

Anti-intrusion sensors placed under the turnstile’s top cover, which activate the Buzzer, in case

of any climb-over attempts.

Buzzer

Alarm buzzer activated by anti-intrusion devices

in case of any climb-over attempts.

Contact output: 12V D.C. – 100mA

Once the power is connected, wait 10 seconds before proceeding with any operations.

10 Safety instruction

Warning: opening the turnstile only 60° will cause the tripod to automatically return.

Warning: by leaning on the tripod arm before it is released, the release will not take place and the turnstile will stay

closed.

Important general safety instructions

This product must be only used for its specific intended purpose. Any other use is wrongful and therefore dangerous. The manufacturer is not liable for any harm or damage caused by improper, wrongful or unreasonable use.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Danger voltage running through

parts

Impact danger

© CAME cancelli automatici s.p.a. -

0.1 02/2009

119 G3 074 ver.

:

Do not allow children to play or loiter in the operating range of the turnstile.

Manual code

Keep command and control devices out of reach of children, to prevent the turnstile from being accidentally activated.

-

Immediately suspend use of the turnstile if any anomalies are manifested.

Pag.

Transit prohibited during operation.

Page 12

10

119G3074

0.1

11 Maintenance

11.1 Periodic maintenance

Carry out the following periodic maintenance:

Check turnstile’s internal cabling, check that cables are not disconnected or damaged.

By turning the tripod, check for any faulty movements and that the rotation is homogenous. A sudden blocking may indicate a

malfunction.

By trying to move it, try to properly secure the turnstile to the ground, because unstable securing can result in danger.

Do not clean the turnstile with chemical products that may damage the stainless steel, do not use abrasive substances

ENGLISH

or rags that may scratch the surface.

11.2 Trouble shooting

DISFUNCTIONS POSSIBLE CAUSES CHECKS AND REMEDIES

The turnstile

stays released in

both directions of

travel

• No power

• Stop button is stuck or broken

• Emergency button is pressed

• Electroblocks are not working.

• Check power source

• Call assistance

• Reload the emergency button

• Call assistance

The turnstile only

releases in one

direction

The turnstile stays

blocked

The turnstile

• One of the electroblock is broken down

• The spring of one of the electroblocks has become disconnec

• Call assistance

• Call assistance

ted

• The person passing through leaned on the arm before the

release took place.

• Both electroblocks stay wound up

• Tell the person not to lean on the arm

and try to release

• Call assistance

• The hydraulic brake is not working properly • Call assistance

blocks suddenly

12 De-commissioning and disposal

Came Cancelli Automatici company is ISO 9001:2000 certified for its in-house quality system and ISO 14001 certified in terms of its

environmental practices.We kindly ask you to keep on respecting the environment – CAME considers this one of the fundamentals

of its own development and market operation strategies, by simply following these brief disposal instructions:

DISPOSING OF THE PACK AGING

The packaging components (cardboard, plastic, etc.) are considered solid urban waste and may disposed without any trouble in the

proper cycling bins supplied by your municipality.

DO NOT DISPOSE OF IN THE ENVIRONMENT

DISPOSING OF THE PRODUCT

Our products are made with different materials. The majority of these (i.e. aluminium, plastic, iron, electrical cables) consist of solid

urban waste. They can be recycled at authorised recycling centres. Other components (electronic boards, remote control batteries,

etc.) may contain toxic substances.

They must therefore be removed and turned into authorised firms that will dispose of them properly. Before proceeding it is always

best to check the specific legislation in your municipality.

DO NOT DISPOSE OF IN THE ENVIRONMENT

0.1 02/2009 © CAME cancelli automatici s.p.a. - The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAM E cancelli automatici s.p.a. to notify users.

119 G3 074 ver.

10 - Manual code:

Pag.

Page 13

11

119G3074

0.1

13 Declaration

MANUFACTURER’S STATEMENT

Pursuant to Low Voltage Directive 2006/95/CE

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

31030 Dosson di Casier - Treviso - ITALY

tel (+39) 0422 4940 - fax (+39) 0422 4941

internet: www.came.it - e-mail: info@came.it

Hereby states under its own liability, that these products to automate gates, and garage

doors, called:

BRIDGE

comply with the essential requirements and pertinent directives and the applicable parts of

the reference legislation listed below.

2006/95/CE LOW VOLTAGE DIRECTIVE

2004/108/CE ELECTROMAGNETIC COMPATABILITY DIRECTIVE

EN 13241-1 EN 61000-6-2

EN 60335-1 EN 61000-6-3

Reference code to request a facsimile: DDF L EN O001A

It is prohibited to operate the product/s described in this declaration, before

it is entirely complete and/or incorporated in compliance with what is set

IMPORTANT WARNING!

forth by Machine Directive 98/37/CE

MANAGING DIRECTOR

Mr Gianni Michielan

ENGLISH

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

© CAME cancelli automatici s.p.a. -

0.1 02/2009

119 G3 074 ver.

:

Manual code

11 -

Pag.

Page 14

CAME F rance S.a .

CAME France S.a.

Nanter re Ce dex -

CAME G mbh S eefel d

Seefel d

CAME Autom atism es S.a.

Marsei lle -

CAME G mbh

Korntal

CAME Autom atism os S.a.

Madri d -

CAME Ameri cas Autom ation Llc

Sunris e

CAME Autom atism os Ca talun ya S.a.

Sant Vice nc De l Hor ts -

CAME M iddle East Fzco

Dubai -

Paf - CAME

Rio D e Mou ro -

CAME P olska Sp.Zo.o

War szawa -

CAME U nited King dom L td.

Nottin gham

S.c. CAME Roma nia S.r.l .

Bucare st -

CAME B elgiu m Spr l

Lessi nes -

CAME R ussia

Moskva

CAME

Cancel li A utoma tici S.p.a.

Dosso n Di Casie r

CAME N ord s .r.l.

Colog no Mo nzese

CAME S ervice I talia S.r.l.

Dosso n Di Casie r

Assist enza Tecnica 800 295830

CAME S ud s. r.l.

Napol i

Engl ish

119G3074

0.1

7, Rue Des Haras

Z.i. Des Hautes Patures

Nanterre Cedex - FRANCE

92737

(+33) 1 46 13 05 05

(+33) 1 46 13 05 00

CAME Gmbh Seefeld

Akazienstrasse, 9

16356

Seefeld

Bei Berlin - DEUTSCHLAND

(+49) 33 3988390

(+49) 33 39883985

0.1 02/2009 © CAME cancelli automatici s.p.a.

CAME Automatismes S.a.

3, Rue Odette Jasse

13015

Marseille - FRANCE

(+33) 4 95 06 33 70

(+33) 4 91 60 69 05

CAME Automatismos S.a.

C/juan De Mariana, N. 17-local

Madrid - SPAIN

28045

(+34) 91 52 85 009

(+34) 91 46 85 442

CAME Automatismos Catalunya S.a.

P.i. Moli Dels Frares N. 23 C/a

08620

Sant Vicenc Del Horts - SPAIN

(+34) 93 65 67 694

(+34) 93 67 24 505

Paf - CAME

Estrada Nacional 249-4 Ao Km 4,35

Cabra Figa - Trajouce

2635-047

Rio De Mouro - PORTUGAL

(+351) 219 257 471

(+35) 219 257 485

CAME United Kingdom Ltd.

Unit 3 Orchard Business Park

Town Street, Sandiacre

Nottingham - Ng10 5du - UNITED KINGDOM

(+44) 115 9210430

(+44) 115 9210431

Kornwestheimer Str. 37

Munchingen Bei Stuttgart - DEUTSCHLAND

(+49) 71 5037830

(+49) 71 50378383

CAME Americas Automation Llc

1560 Sawgrass Corporate Pkwy, 4th Floor

Sunrise, FL 33323 - U.S.A

(+1) 305 433 3307

(+1) 305 396 3331

CAME Middle East Fzco

Po Box 17131 Warehouse N. Be02

South Zone - Jebel Ali Free Zone -

(+971) 4 8860046

(+971) 4 8860048

CAME Polska Sp.Zo.o

01-237

Warszawa - POLAND

(+48) 22 8365076

(+48) 22 8363296

S.c. CAME Romania S.r.l.

B-dul Mihai Eminescu, Nr. 2, Bloc R2

Scara A, Parter, Ap. 3

Buftea, Judet Ilfov

Bucarest - ROMANIA

(+40) 21 3007344

(+40) 21 3007344

CAME Gmbh

70825

Korntal

Dubai - U.A.E.

Ul. Ordona 1

CAME Belgium Sprl

119 G3 074 ver.

Zoning Ouest 7

7860

Lessines - BELGIUM

(+32) 68 333014

Leningradskij Prospekt, Dom 80

125190,

(+32) 68 338019

CAME Russia

Pod’ezd 3, offi ce 608

Moskva - RUSSIA

(+7) 495 937 33 07

(+7) 495 937 33 08

English - Manual code:

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

CAME

Cancelli Automatici S.p.a.

Via Martiri Della Libertà, 15

31030

Dosson Di Casier (Tv)

(+39) 0422 4940

(+39) 0422 4941

20093

CAME Nord s.r.l.

Piazza Castello, 16

Cologno Monzese (MI)

(+39) 02 26708293

(+39) 02 25490288

Informazioni Commerciali 800 848095

www.came.it

CAME Service Italia S.r.l.

Via Della Pace, 28

31030

Dosson Di Casier (Tv)

(+39) 0422 383532

(+39) 0422 490044

Assistenza Tecnica 800 295830

CAME Sud s.r.l.

Via F. Imparato, 198

Cm2 Lotto A/7

80146

Napoli

(+39) 081 7524455

(+39) 081 7529109

Loading...

Loading...