Page 1

SERIE GARD

Documentazione

Tecnica

CANCELLI AUTOMATICI

ROAD BARRIER

G12000

56

rev. 2.0

03/2001

©

CAME

CANCELLI

AUTOMATICI

119G56-GB

Page 2

Description:

GENERAL CHARACTERISTICS

Models:

Optional accessories:

- Motorised barrier for control of

passages with width of up to 12 m.

- Designed and built entirely by

CAME S.p.A., meets UNI 8612 safety

standards, with IP54 degree of

protection.

- Guaranteed 12 months, unless

tampered with.

G12000

Barrier with double, non-reversible 24

V DC gear motor. Galvanised steel

housing with painted finish.

Accessories supplied:

G0121

LB35

Circuit card for installation of an

emergency battery.

G0461

Package of red phosphorescent

strips for the barrier bar.

- Aluminium barrier bar composed of:

Ø120 mm tube with L=6200 mm

Ø100 mm tube with L=6000 mm.

- Hardware and accessories for

mounting the barrier bar.

- Fixed support for the barrier.

II

Important: For easy installation and maintenance, be sure to use CAME original control equipment, safety systems and

II

accessories.

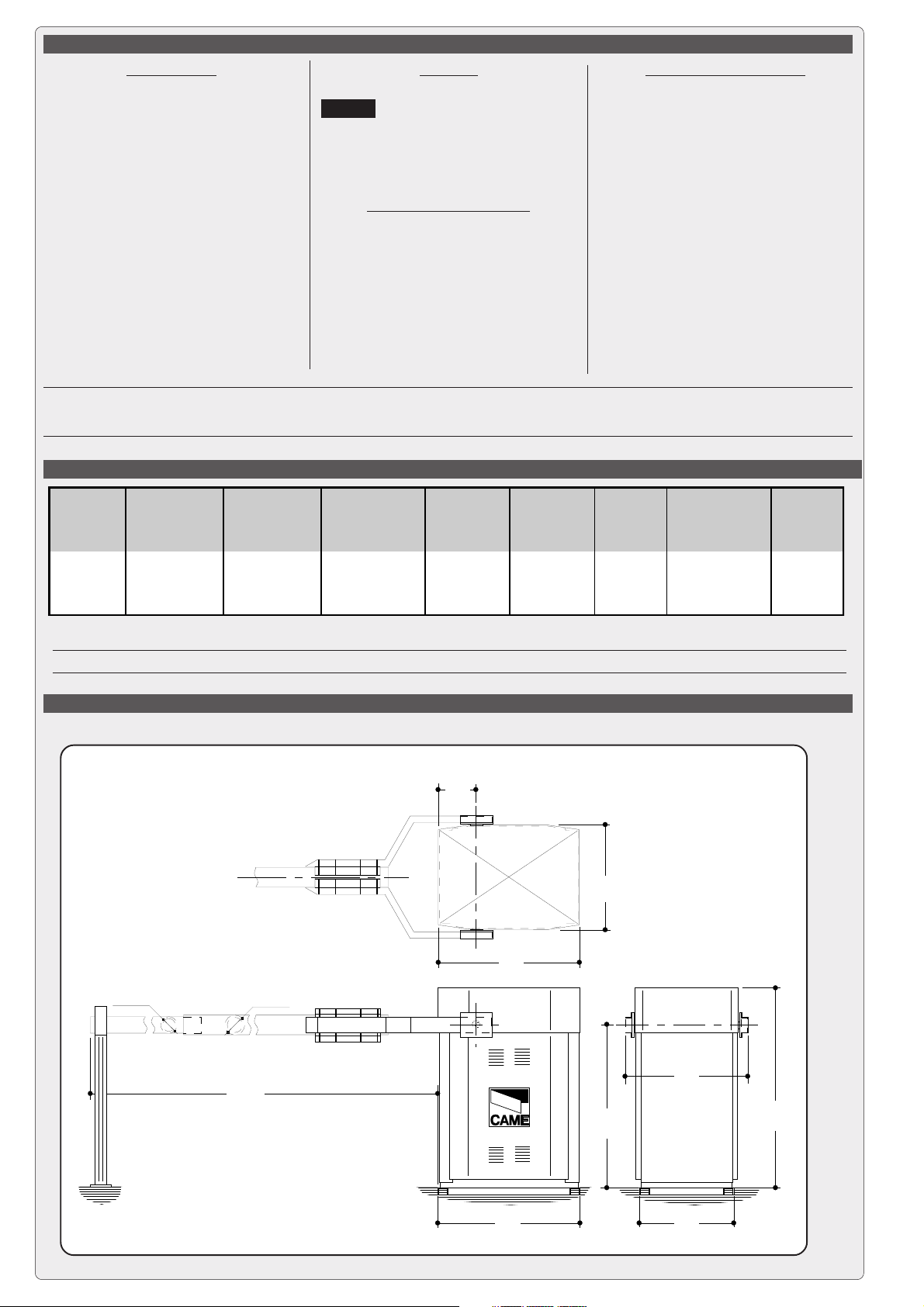

TECHNICAL CHARACTERISTIC

PRODUCT

VERSION

VOLTAGE

REQUIREMENT

CURRENT DRAW

TOTAL MOTOR

POWER RATING

DUTY CYCLE

REDUCTION

RATIO

TORQUE

DURATION OF

OPENING CYCLE

WEIGHT

1.0

230 V A.C.

24 V D.C.

15 A max 300 W 50 % 1/202 600 Nm 10 s 783 kg *

(* Weight of G12000 barrier structure = 250 Kg / Weight of counterweight plates = 500 Kg / Weight of G0121 bar = 33 Kg)

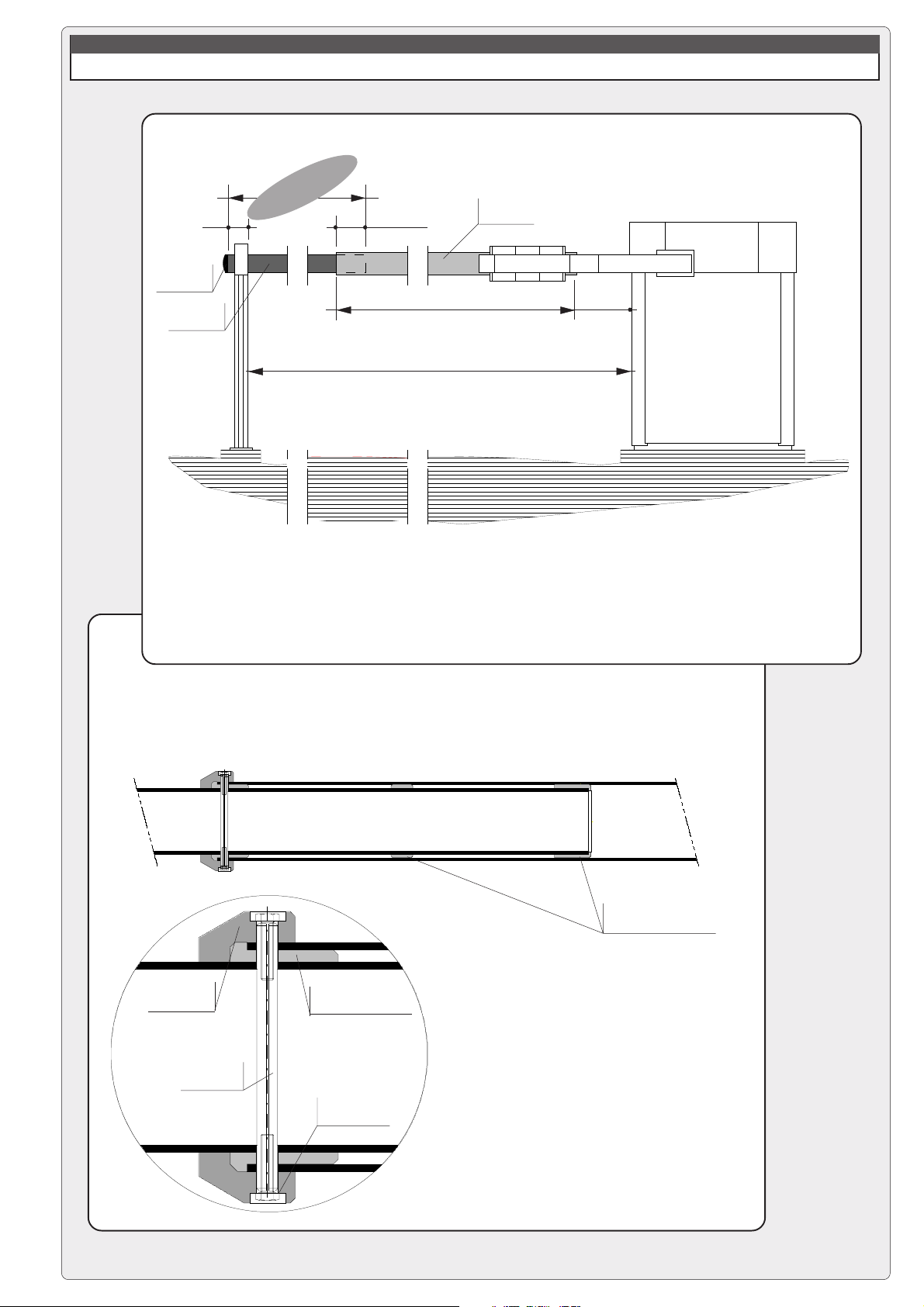

CENTRE LINES AND EXTERNAL DIMENSIONS

235

645

865

ø100

ø120

- pag. - pag.

- pag.

- pag. - pag.

22

- english - - english -

2

- english -

- english - - english -

22

12000

1000

760

1230

580865

Page 3

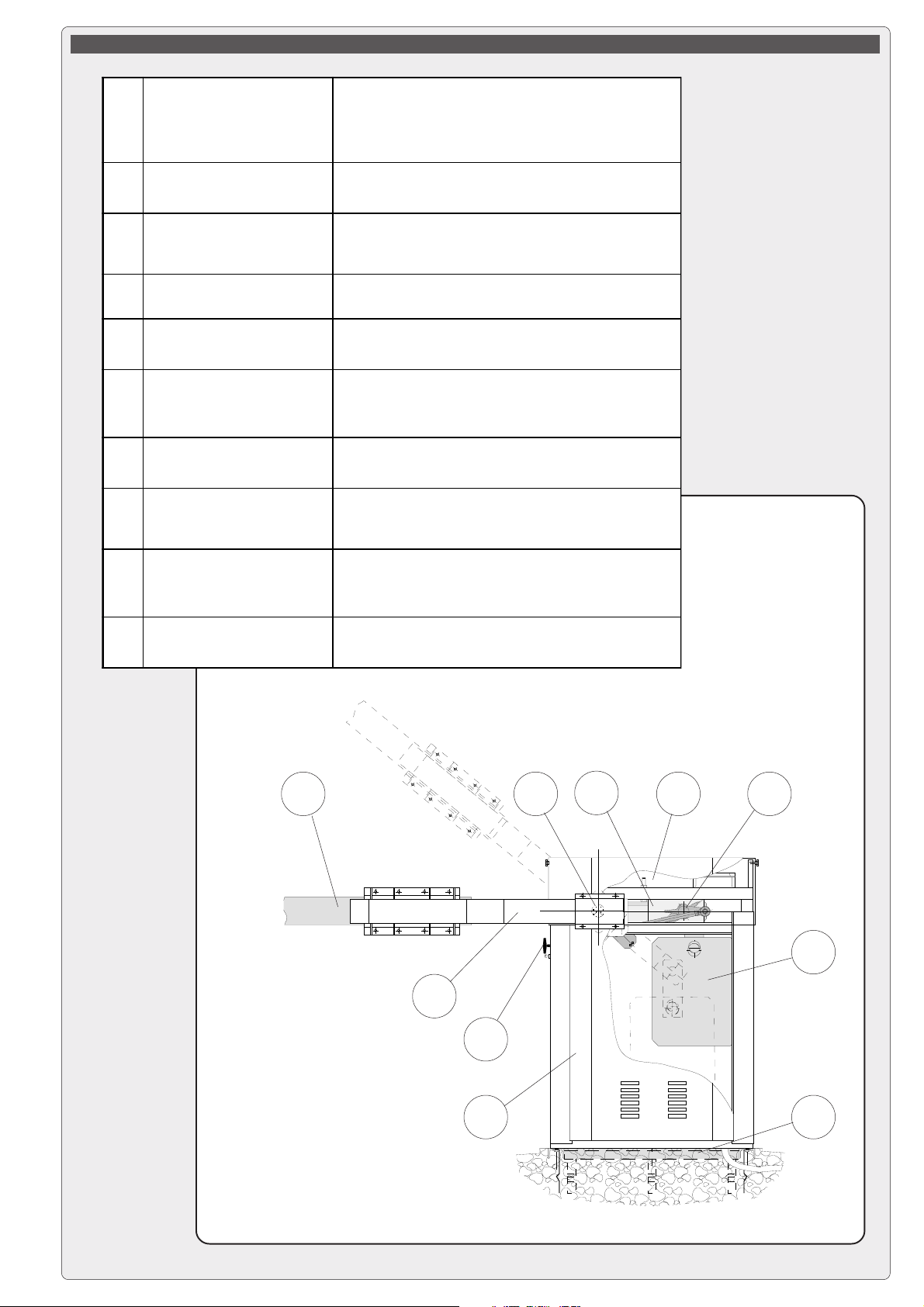

1

REDUCTION GEAR UNIT

DESCRIPTION OF MAIN COMPONENTES

24 VDC motors;

non-reversible reduction gear with die-cast aluminium

housing; uses worm gear reduction system which is

permanently lubricated with liquid grease.

2

TRANSMISSION LEVERS

3

ROTATION SHAFT

COUNTERWEIGHT

4

SYSTEM

5

RELEASE SYSTEM

6

HOUSING

7

MOUNTING BASE

8

BARRIER BAR FORK

9

BARRIER BAR

In forged, galvanised steel; adjustment rods in drawn

hexagonal metal; self-lubricating joints.

In C40 recycled steel, mounted on single-unit

supports with terminal flanges for installation of

barrier bar fork.

Uses 25 Kg rectangular plates which are assembled

as needed.

Manual, with PVC handle and cord in self-lubricating

sheath; safety lock.

Load-bearing structure in steel profiles, and external

cover in press-bent 25/10 sheet steel. Both are

galvanised and painted RAL 2004 orange.

U-profile in galvanised steel, complete with anchor

stays and bolts for attachment of housing structure.

In galvanised steel painted RAL 9005 black; supplied

in two symmetrical parts which are ready for

assembly.

In 6060 TA16 aluminium alloy painted RAL 9010

white; supplied in two circular sections (Ø120 and

Ø100 mm) which are assembled to the desired size.

10

CONTROL PANEL

Housing in ABS with IP54 level of protection,

installed in horizontal position.

123109

4

8

5

6

7

33

- pag. - pag.

- english - - english -

- pag.

3

- english -

- pag. - pag.

- english - - english -

33

Page 4

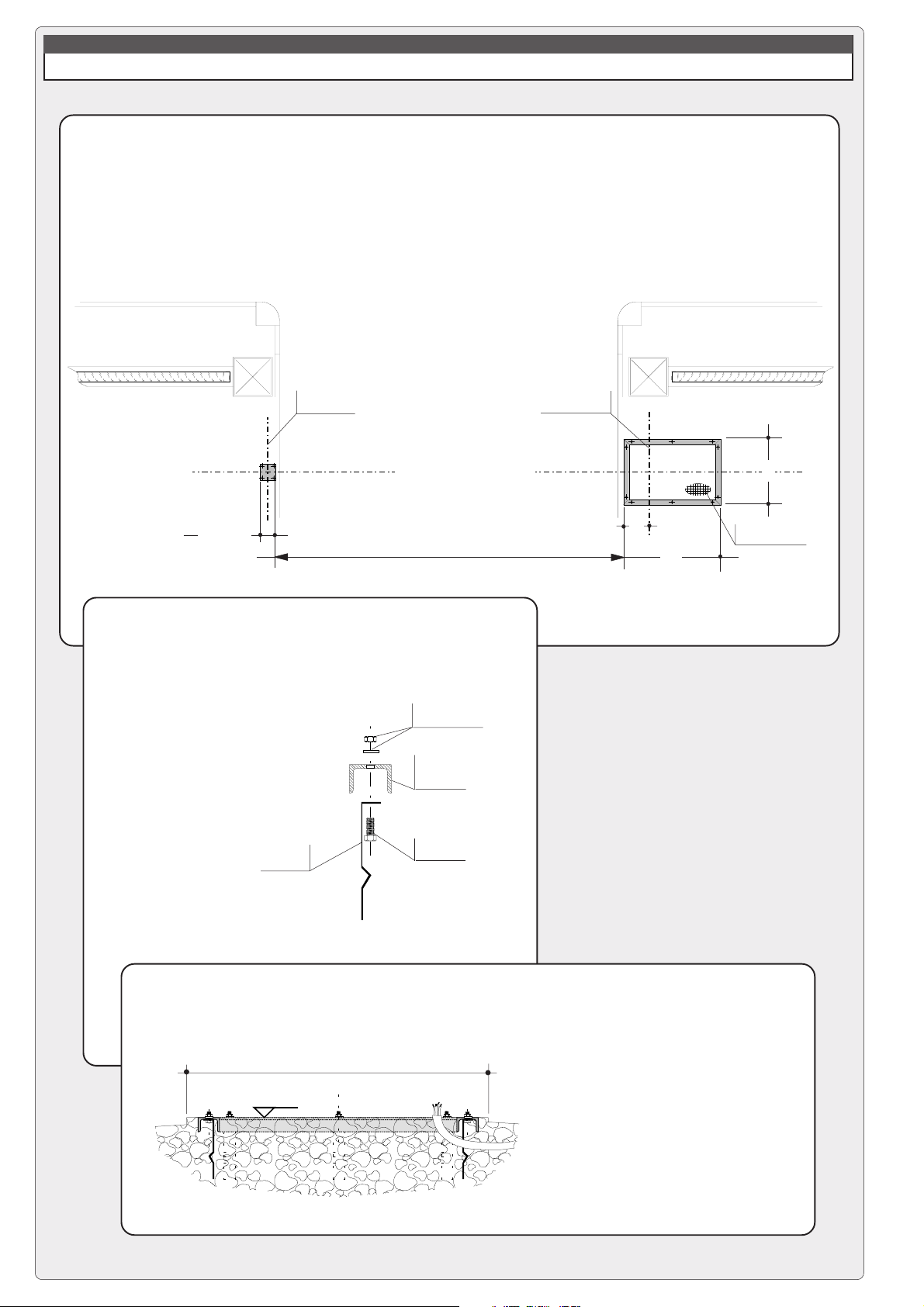

DESCRIPTION OF ASSEMBLY PROCEDURE

1 - ASSEMBLY OF FIXED STRUCTURES, MARKING

a) determine the desired positions

for the housing as well as for the

fixed support for the barrier bar;

mark the longitudinal and

transverse axes of the barrier.

axis of support

for barrier bar

120 x 120

b) detach the mounting base

from the housing and mount

the anchor stays on the base;

apply grease and/or removable

tape to protect the threaded

bolts protruding from the top.

anchor stay

barrier bar rotation

longitudinal axis of barrier

LN = USEFUL NET WIDTH OF PASSAGE = 11850 mm MAX

mounting nut

and washer

UNP 65x42

profile of

mounting base

anchor

screw

6500 mm MIN

axis of

235

865

580

recommended

area for cable exit

- pag. - pag.

- pag.

- pag. - pag.

44

- english - - english -

4

- english -

- english - - english -

44

profile of cement base

c) Sink everything into the

relative cement bases. Be

sure that the mounting base is

perfectly level, and that the

electrical cables for the unit

protrude in the area indicated.

Page 5

END CAP

REAR TUBE

150

DESCRIPTION OF ASSEMBLY PROCEDUREDESCRIPTION OF ASSEMBLY PROCEDURE

DESCRIPTION OF ASSEMBLY PROCEDURE

DESCRIPTION OF ASSEMBLY PROCEDUREDESCRIPTION OF ASSEMBLY PROCEDURE

2 - PRELIMINARY ASSEMBLY OF THE BARRIER BAR

- 5850

N

= L

TP

L

500

depth of

insertion

fixed length 6200 mm

LN

FRONT TUBE

300

REAR TUBE

mounting jaw

a) use the indicated formula to determine length LTP of the rear tube

(Ø100 mm), cut the tube to the correct length and install the end cap.

FRONT TUBE

thrust rings already installed on

Ø100 mm rear tube

thrust ring to be latched

onto the centring pin

centring pin

mounting screw

on mounting jaw

b) assemble the barrier bar by

sliding the rear tube into the front

tube (Ø120 mm, fixed length of 6200

mm) and inserting the centring pin;

next, install and tighten the two

mounting jaws;

- pag. - pag.

- pag.

- pag. - pag.

55

- english - - english -

5

- english -

- english - - english -

55

Page 6

DESCRIPTION OF ASSEMBLY PROCEDURE

3 - INSTALLING THE BARRIER

a) remove the cover of the housing (by lifting) and remove the sides

of the housing (by raising and withdrawing them from below); clean

the cement bases and free the bolts on the anchor stays by

removing the protection tape and nuts;

b) position and mount the

housing on the mounting

base;

c) position and mount the

fixed support for the barrier

bar, and make sure it is in

perfect longitudinal alignment

with the housing;

d) with the aid of a stand and the fixed

support, place the barrier bar at the

approximate height and axis of

operation;

f

e) install the fork and unite the two

e

mounting jaws on the barrier bar, but

do not tighten the bolts;

f) next, mount the barrier bar on the

e

terminal plates of the rotation shaft,

but do not tighten the bolts;

f

- pag. - pag.

- pag.

- pag. - pag.

66

- english - - english -

6

- english -

- english - - english -

66

g) check for misalignment and adjust if necessary; then, firmly tighten

the bar onto the fork and firmly tighten the fork onto the housing.

Page 7

DESCRIPTION OF ASSEMBLY PROCEDURE

4- ASSEMBLING THE COUNTERWEIGHTS; ADJUSTING AND BALANCING THE BARRIER BAR

a) install the release handle,

turn the safety key and rotate

the handle to

release the

gear

motors;

c) balance the bar so

that it stays in position

when it is manually

placed at a 45° angle;

b) insert the counterweight

plates on the support,

alternatively on the

left and right, until

the bar shows

signs of raising.

N.B.: if not all the

counterweight

plates are used,

they must be

fixed with a hose

clamp, to avoid

possible release

during movement.

Hose clamp

d) adjust the vertical

mechanical stop by fixing the

angle of the open barrier bar

so that it does not exceed 90°;

e) adjust the horizontal

mechanical stop when

the barrier bar is in the

lowered position;

- pag. - pag.

- pag.

- pag. - pag.

77

- english - - english -

7

- english -

- english - - english -

77

Page 8

ZL37B CONTROL PANEL

DESCRIPTION & CONTROL LOGIC

MAIN COMPONENTS

1) Transformer

Rallentamento

Velocità

C

O

M

Decele ration

Ralentissement

Geschw.

Abnahme

Deceleración

Speed

Vitesse

Geschw.

Velocidad

1

2) Connectors for power

supply motor

3) Terminal block for motor

connections

4) 2A accessories fuse

5) Amperometric sensitivity

2

"B" "A"

9

adjustment (trimmer

SENS)

6) 3,15A line fuse

10

0

Rall.

Vel.

11

3

4

7) Terminal block for external

connections

8) Jumper for selection of

type of control for button

in 2-7

9) Connectors for connection

to battery charger LB35

12

10) Button for memorizing

code numebers

11) Automatic closing time

5

21 345678910

13

6

74

14

7

adjustment (trimmer TCA)

12) Radio code / automatic

closing signal LED

13) Radiofrequency board

socket (see table pag. 11)

14) "Funcion selection" dipswitch

15) Terminal block for antenna

15

connections

8

This control board is powered by

230V a.c. across terminals L1 and

L2, and is protected by a 3.15A fuse

on the main power line.

Control systems are (24) powered by

low voltage and protected with by a

2A fuse.

The total power consumption of 24V

accessories must not exceed 40 W.

Safety

Photocells can be connected to

obtain:

a)Re-opening during the closing

cycle;

b)Total stop: the movement of the bar

is interrupted, and the automatic

closure cycle is disactivated. Use the

keyboard or the radio transmitter to

resume movement of the bar;

c)Immediate closure (the bar is

lowered automatically after the

vehicle has passed the safety

devices, on the terminals 2-C5 of the

control panel;

- Amperometric safety device: see

NOTE;

Accessories which can be

connected to this unit

- LB35 board, used to power the

automation system using battery

power in case of a power failure. When

the power supply is restored, the

batteries are recharged automatically

(refer to instruction sheet);

- Flashing signal light when bar is in

motion;

- Plug-in radio receiver.

Other functions available

- Automatic closing: The automatic

closing timer is automatically activated

at the end of the opening cycle. The

preset, adjustable automatic closing

time is automatically interrupted by the

activation of any safety system, and

is deactivated after a total stop

command or in case of power failure;

- Obstacle detection: When the motor

is stopped (bar is closed, open or halfopen after an emergency stop

command), the transmitter and the

control pushbutton will be deactivated

if an obstacle is detected by one of the

safety devices (for example, the

photocells);

- “Human presence” operation;

- Flashing light activated before

opening and closing cycle begins;

- Activation of a 24V output signal

during the movement phases and in

the closed position;

- "Slave" operation when two motors

are used in combination (see page

15);

- Function that increases the braking

action on the barrier;

- Selection of command sequence:

-open-close-reverse;

-open only.

Adjustments

- Trimmer TCA = Automatic closing

time: 0" to 120";

- Trimmer SENS = Sensitivity of

amperometric safety system: min/

max.

Important: Shut off the mains power

and disconnect the batteries before

servicing the inside of the unit.

- Fixed operating time of 20 sec.

NOTA

When an obstacle is encountered, the amperometric locking device intervenes as follows:

a) if in the aperture phase, the bar stops;

b) if in the closure phase, the movement of the bar is reversed.

N.B.: In situation (b), if an obstacle is detected three times, the bar stops during aperture, and automatic closure is

disactivated.

Use the keyboard or the radio transmitter to resume movement of the bar.

- pag. - pag.

- pag.

- pag. - pag.

88

- english - - english -

8

- english -

- english - - english -

88

Page 9

QUADRO ELETTRICO ZL37B

M

N

ALLACCIAMENTI & REGOLAZIONI ELETTRONICHE

M

N

F

FA

F

FC

L1

L2

10

11

10

E

FA FC F PT

L1 L2

E+10 - 1 1 1 2 C 1 C 5735

24V A.C. motor

Connection limit switch deceleration opens

Connection limit switch deceleration closes

230V A.C. power

Accessory power: 24V A.C. max. 40W

during movement (e.g. flashing light)

24V output

during movement and in the closed position

DIP 3 OFF

DIP 3 ON

10

5

1

2

2

3

2

7

2

C1

2

C5

24V - 3W max. "barrier open" warning light

STOP button (N.C.)

(see selection functions)

OPEN button (N.O.)

Connector (N.O.) radio and/or pushbutton.

See DIP 2 for command type

Button operation: closure only

Contact (N.C.) for re-opening during closure, if not

used ....

Contact (N.C.) of immediate closure, if not used ....

To install additional pushbutton arrays,

connect:

- the stop buttons in

- the open and warning light in parallel

74

serie

jumper n°8

74

2-C1

E 10 111 2 3 5 7C1 C

dip 8 ON

!"#$%

&'

5

ON

Antenna connection

- pag. - pag.

- pag.

- pag. - pag.

99

- english - - english -

9

- english -

- english - - english -

99

Page 10

ZL37B CONTROL PANEL

SELECTION FUNCTION

0

Vel.

Rall.

1 345678910

2

74

ON OFF

activated deactivated

1

1 = function

automatic closure

1

- deactivated immediate closure (8 ON)

ON OFF

activated deactivated

2

2 = function

"open only"

by radio remote control

2

(when receiver is installed)

ON OFF

deactivated activated

2

2 = funcion

"open-close-inversion"

by radio remote control

2

(when receiver is installed)

1 2 3 4 5 6 7 8 9 10

ON OFF

activated deactivated

5

5 = funcion

flashing light en opening

and closing

ON OFF

activated deactivated

6

6 = function

obstacle detection

(with motor at end of

travel)

ON OFF

activated deactivated

7

7 = function

slave

ON

OFF

5

6

7

ON OFF

activated deactivated

3

movement and in the closed

3 = funcion

24V output during

3

position

ON OFF

deactivated activated

3

3 = function

24V output during

movement

3

ON OFF

activated deactivated

4

4 = funcion

"human presence"

4

ON OFF

deactivated activated

8

8 = function

immediate closure

- connect safety device

across 2-C5;

- deactivate automatic

closure (1 OFF)

8

ON OFF

deactivated activated

9

9 = function

total stop

- connect safety device

across 1-2

ON OFF

activated deactivated

10

10 = function

increase braking action on

barrier bar

10

9

- pag. - pag.

- pag.

- pag. - pag.

1010

10

1010

- english - - english -

- english -

- english - - english -

Page 11

É

0

Vel.

Rall.

74

1 345678910

2

ZL37B CONTROL PANEL

ADJUSTMENTS

SENS.

T.C.A.

REGOLAZION E TRIMMERS

TRIMMERS A DJUSTMENT

R

GLAGE TRIMMERS

EINT ELLU NG TRIM MERS

REGULACIÓN TRIMMERS

Trimmer SENS.

Trimmer T.C.A.

= Adjustment of amperometric sensitivity min./max.

= Adjustment automatic closing time from a minimun of 0 seconds to a maximum of 120

seconds.

A. insertan AF card **.

B. encode transmitter/s.

C. store code in the motherboard.

A

PROGRAMMING THE REMOTE CONTROL

PROCEDURE

AF BOARD INSERTION

Frequency / MHz Radiofrequency board Tra ns m it te r

FM 26.995 AF130

TFM

FM 30.900 AF150

AM 26.995 AF26

TOP

AM 30.900 AF30

AF43S / AF43SM TAM / TOP

AM 433.92

AF43SR ATOM O

The AF board should ALWAYS be inserted when the

power is off because the motherboard only recognises it

when it is powered.

TOP TAM

(**) On AM transmitters operating at 433.92 MHz (TOP and

TAM series), position the jumper connection on circuit card

AF43S as shown on the sheet.

AF

MOTHERBOARD

"AF" BOARD

1111

- pag. - pag.

- english - - english -

- pag.

11

- english -

- pag. - pag.

- english - - english -

1111

Page 12

B

TRANSMITTER ENCODING

TOP

QUARTZ

STANDARD ENCODING PROCEDURE

T262L/M-T264L/M-T2622M

T302L/M-T304L/M-T3022M

1.assign a code (also on file)

2.connect encoding jumper J

3.register code

4.disconnect jumper J

T2622M - T3022M

1° code

P1 P2

P1=CH1

P2=CH2

P1

P2

code

2.

OFF

ON

1.

J

3.

Press P1 or P2 in sequence in order to register

the code; at the tenth pulse, a double beep will

confirm that registration has occurred

4.

J

P1=OFF

J

P2=ON

2° code

P1

P2

J

T264L/M - T304L/M

P1=CH1 - P2=CH2

P3=CH3 - P4=CH4

P1 P2

P3 P4

OFF

ON

P3=CH1

P4=CH2

J

P1 P2

fig. A

J

P1=CH1

P2=CH2

T262L/M - T302L/M

The first encoding operation must be carried out

whilst keeping the jumpers positioned for

channels 1 and 2 as per fig. A; see fig. B for any

subsequent settings on different channels.

fig. B

P1=CH1 - P2=CH3

P1=CH1 - P2=CH4

P1=CH3 - P2=CH2

P1=CH3 - P2=CH4

- pag. - pag.

- pag.

- pag. - pag.

1212

12

1212

- english - - english -

- english -

- english - - english -

Page 13

ATOMO

AT01 - AT02

see instruction sheet inside the pack of AF43SR circuit card

T432M - T312M

P1 P2

P3 P4

P1 P2

1 2 3 4 5 6 7 8 9 10

P1=CH1

P2=CH2

P3=CH3

P4=CH4

1 2 3 4 5 6 7 8 9 10

D

1 2 3 4

C

T434M - T314M

set code only

set the code to dip-switch C and channel to D (P1=CH1

and P2=CH2, default setting)

P1

1 2 3 4 1 2 3 4 1 2 3 41 2 3 4

CH1 CH2 CH3

CH4

P2

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

CH1 CH2 CH3

CH4

T432S

see instructions on pack

TAM

T432

T434

T438

C

TFM

T132

T134

T138

see instruction sheet inside the parck

T152

T154

T158

- pag. - pag.

- pag.

- pag. - pag.

1313

13

1313

- english - - english -

- english -

- english - - english -

Page 14

C

-

While holding down key "CH" signal LED flashing (Fig.1), press the control key on the transmitter: the lights up of

CODE STORAGE

LED sign the code stored (Fig.2).

IMPORTANT: Do not store the code on the circuit card unless the barrier is closed.

N.B.: If you wish to change the code on your transmitters in the future, simply repeat the procedure described

above.

Fig. 1

CH

Flashing LED

Fig. 2

1 345678910

2

4

CH

Lit LED

1 345678910

2

AF radiofrequency board

- pag. - pag.

- pag.

- pag. - pag.

1414

14

1414

- english - - english -

- english -

- english - - english -

4

Page 15

ZL37B CONTROL PANEL

CONNECTIONS FOR 2 COMBINED MOTORS CONTROLLED TOGETHER

1) On one of the two control panels, set

Dip 7 to ON in order to select the motor

controlled externally (slave).

2) Wire the electrical connections only on the terminal board

for the pilot motor in the normal.

C

O

M

0

Rall.

Rallentamento

Deceleration

Ralentissement

Geschw.

Abnahme

Deceleración

"B" "A"

Vel.

74

Velocità

Speed

Vitesse

Geschw.

Velocidad

21 345678910

L1 L2

FA FC F PT

E+10 - 11 1 2 C 1 C 5735

MN

3) Connect the two control panels using the interlock terminals as shown in

the figure.

Pilot motor 1° terminal block

E

+10 - 1 1 1 2 C 1 C 5

7

5

3

INTERBLOCCO

Slave motor 2° terminal block

E

+10 - 1 1 1 2 C 1 C 5

7

5

3

INTERBLOCCO

- pag. - pag.

- pag.

- pag. - pag.

1515

15

1515

- english - - english -

- english -

- english - - english -

Page 16

NOTE

All data checked with the maximum care. However, no liability is accepted for any error or omission.

ASSISTENZA TECNICA

NUMERO VERDE

800 295830

EB

W

www.came.it

E-MAIL

CANCELLI AUTOMATICI

info@came.it

CAME CANCELLI AUTOMATICI S.P.A.

DOSSON DI CASIER (TREVISO)

(+39) 0422 490960 (+39) 0422 490944

SISTEMA QUALITÀ

CERTIFICATO

CAME LOMBARDIA S.R.L.______COLOGNO M. (MI)

(+39) 02 26708293 (+39) 02 25490288

CAME SUD S.R.L. ___________________NAPOLI

(+39) 081 7524455 (+39) 081 7529109

CAME (AMERICA) L.L.C.____________MIAMI ( FL)

(+1) 305 5930227 (+1) 305 5939823

CAME AUTOMATISMOS S.A__________MADRID

(+34) 091 5285009 (+34) 091 4685442

CAME BELGIUM__________________LESSINES

(+32) 068 333014 (+32) 068 338019

CAME FRANCE S.A.____NANTERRE CEDEX (PARIS)

(+33) 01 46130505 (+33) 01 46130500

CAME GMBH________KORNTAL BEI (STUTTGART)

(+49) 07 11839590 (+49) 07 118395925

CAME GMBH____________SEEFELD BEI (BERLIN)

(+49) 03 33988390 (+49) 03 339885508

CAME PL SP.ZO.O______________WARSZAWA

(+48) 022 8699933 (+48) 022 6399933

CAME UNITED KINGDOM LTD___NOTTINGHAM

(+44) 01159 387200 (+44) 01159 382694

Loading...

Loading...