CAME FROG J User Manual

IN-GROUND OPERATOR FOR SWING GATES

FROG SERIES

INSTALLATION MANUAL

FROG J

“IMPORTANT INSTALLATION, SAFETY INSTRUCTIONS”

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL OR QUALIFIED INSTALLERS”

ENGLISH

1 Legend of symbols

This symbol tells you to read the section with particular care.

This symbol tells you that the sections concern safety issues.

This symbol tells you what to say to the end-users.

2 Intended use and application

2.1 Intended use

The FROG-J operator is designed to automate swing gates used in residential or condominium settings.

The use of this product for purposes other than those described above and installation executed in a manner other than

as instructed in this technical manual are prohibited.

2.2 Application

For intensive use and condominiums: max weight of the gate 200kg, and max length 1.8m.

3 Reference Standards

The company: CAME Cancelli Automatici s.p.a. is ISO 9001:2000 quality certified; is has also obtained the ISO 14001 environmental safeguarding certification. Came engineers and manufactures all of its products in Italy.

This product complies with the following standards: EN 12978, UNI EN 954-1, CEI EN 60335-1, UNI EN 12453.

4 Description

4.1 Gate Operator

This product is engineered and manufactured by CAME cancelli automatici s.p.a. and complies with current safety regulations.

Guaranteed 24 months if not tampered with.

The main component parts of the operator are a foundation casing, a release group, a gearmotor and a transmission arm.

The foundation casing is made of 1.5 mm thick ABS plastic on the sides and of 4mm galvanised steel on the bottom plate. Inside

is housed the release group with custom key for manually releasing the operator. The gearmotor, is made of cast aluminium in

which works an irreversible, gear-ratio and, endless screw and helical crown system.

4.2 Technical features

FROG J

Control board power supply: 230 A.C. 50/60Hz

Motor power supply: 24V D.C. 50/60Hz

Max draw: 10 A

Nominal voltage: 240W

Max Torque.: 260N

Opening time (90°): 15 s

Gear ratio: 1/1396,5

Duty cycle: Intensive use

Protection Rating: IP67

Weight: .. kg

Insulation rating:

#

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

2

#

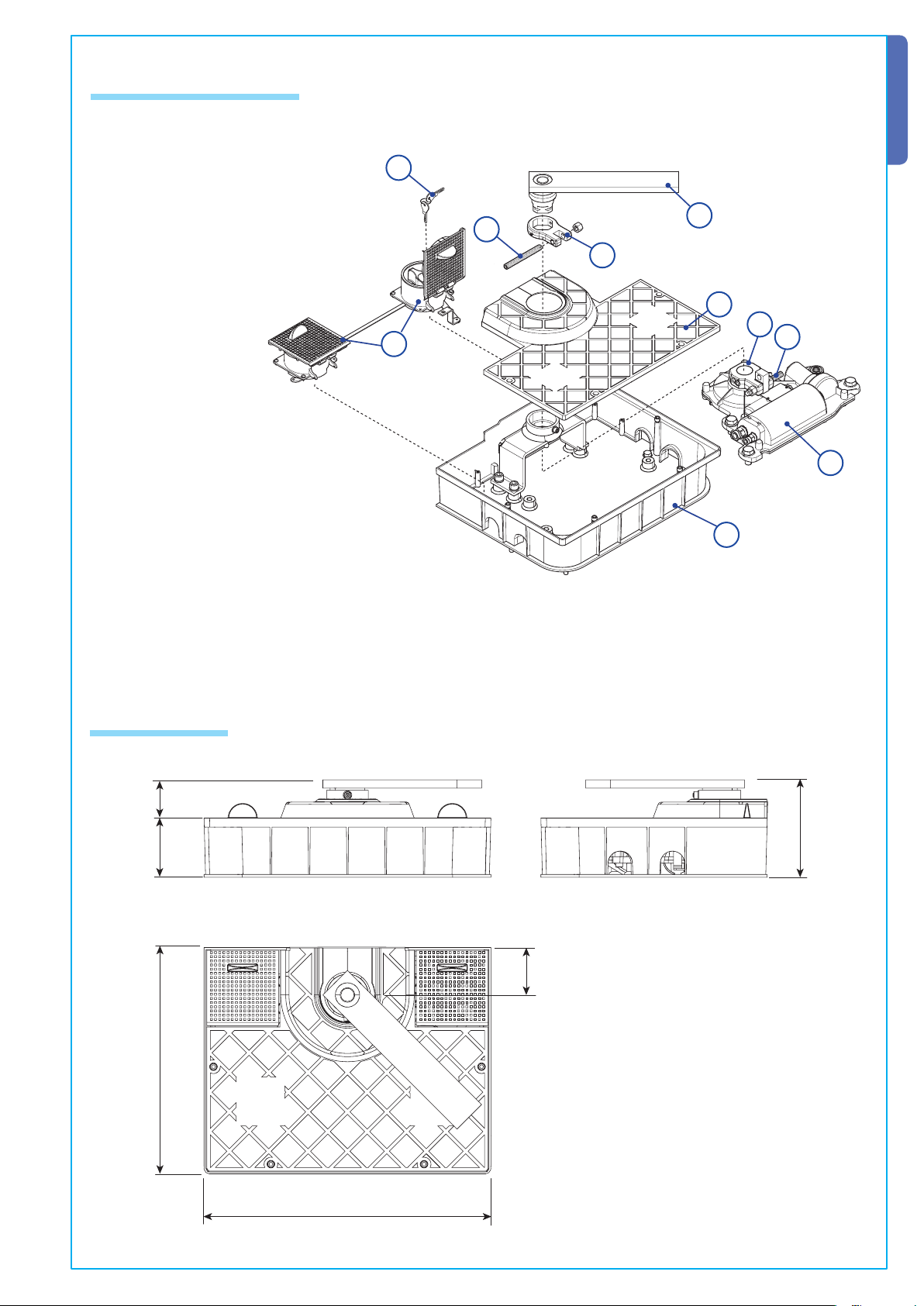

4.3 Description of parts

FROG J OPERATO

1) Gate pin-housing ring

2) Gearmotor pin-housing ring

3) Gearmotor mobile ring

4) Endstop adjustment set screw

5) Release group

6) Cover

7) Operator

8) In-ground case

9) Custom key for release

group

ENGLISH

9

4

2

5

1

6

3

4

7

4.4 Dimensions

8

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

(mm)

3

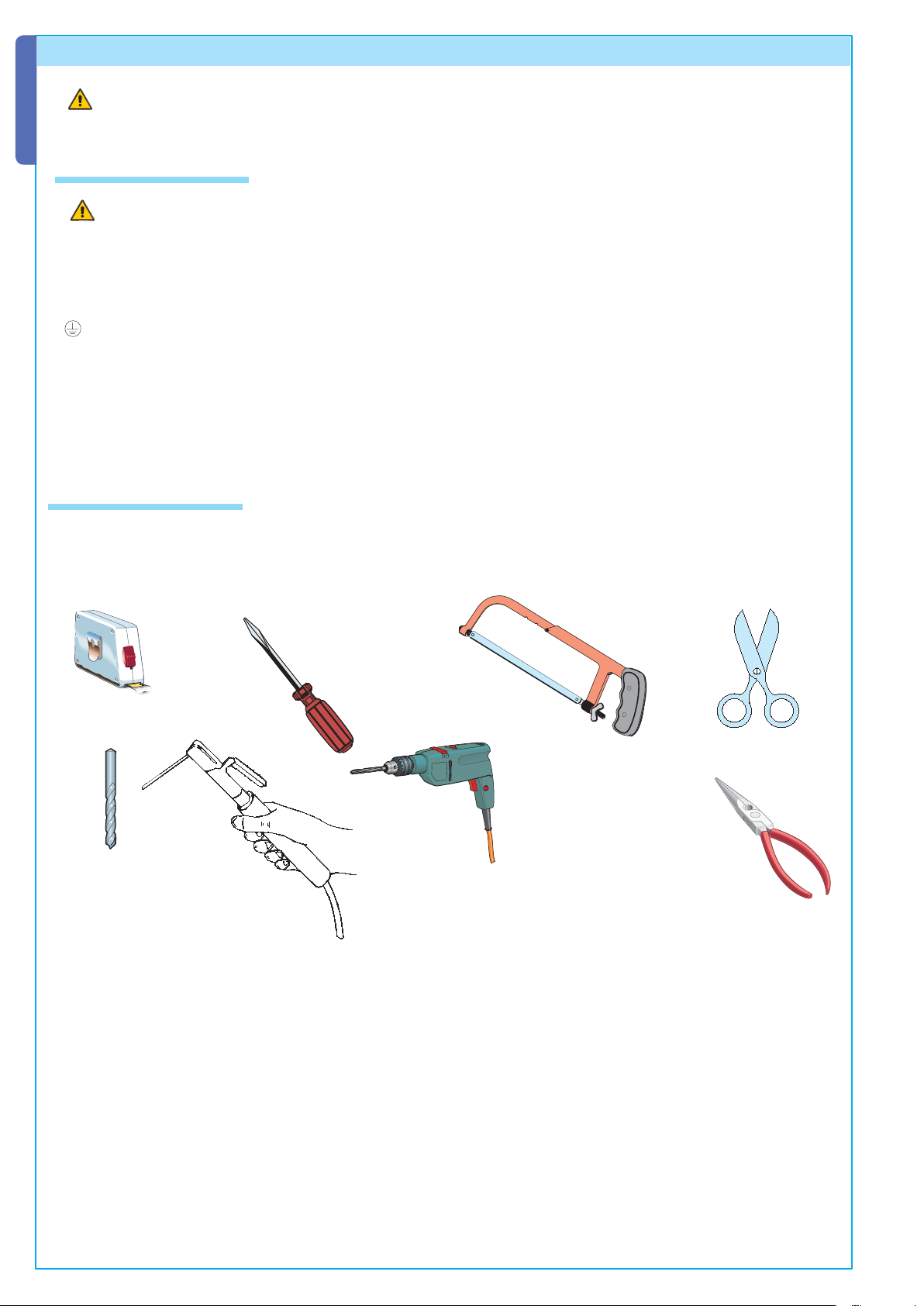

5 Installation

Installation must be carried out by expert qualified personnel and in full compliance with current regulations.

ENGLISH

5.1 Preliminary checks

Before installing, do the following:

• Make sure you have a suitable omnipolar cut-of f device with contacts more than 3 mm apart, and independent (sectioned off)

power supply.

• Make sure you have suitable tubing and conduits for the electrical cables to pass through and be protected against mechanical

damage.

• Fit tubing to drain away any water leaks which may cause oxidation.

• Make sure that any connections inside the case (that provide continuance to the protective circuit) be fitted with extra

insulation as compared to the other conductive parts inside;

• Make sure the structure of the gate is sturdy, the hinges work and that the is no friction between moving and non-moving

parts.

• Make sure there is a mechanical stop for opening and closing.

5.2 Tools and materials

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance with the current standards and regulations. The following figure illustrates the minimum equipment needed by the

installer.

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

4

5.3 Cable list and minimum thickness

Connections Type of cable Length of cable 1 < 10 m L. of cable 10 < 20 m L. of cable 20 < 30 m

Control panel power supply 230 3F

3G x 1,5 mm

Motor power supply 24V 3 x 1 mm

flashing lamp 2 x 0,5 mm

Photocell transmitters 2 x 0,5 mm

Photocell receivers 4 x 0,5 mm

Accessories power supply 2 x 0,5 mm

FROR CEI

20-22

CEI EN

50267-2-1

2

2

2

2

2

2

3G x 2,5 mm

3 x 1,5 mm

2 x 1 mm

2 x 0.5 mm

4 x 0,5 mm

2 x 0,5 mm

2

2

2

2

2

2

3G x 4 mm

3 x 2,5 mm

2 x 1,5 mm

2 x 0,5 mm

4 x 0,5 mm

2 x 1 mm

2

2

2

2

2

2

ENGLISH

Control and safety devices 2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 0,5 mm

2

Antenna connection RG58 max. 10 m

N.B.: If the cable length differs from that specified in the table, then you must determine the proper cable diameter in the basis

of the actual power draw by the connected devices and depending on the standards specified in CEI EN 60204-1.

For connections that require several, sequential loads, the sizes given on the table must be re-evaluated based on actual power

draw and distances.When connecting products that are not specified in this manual, please follow the documentation provided

with said products.

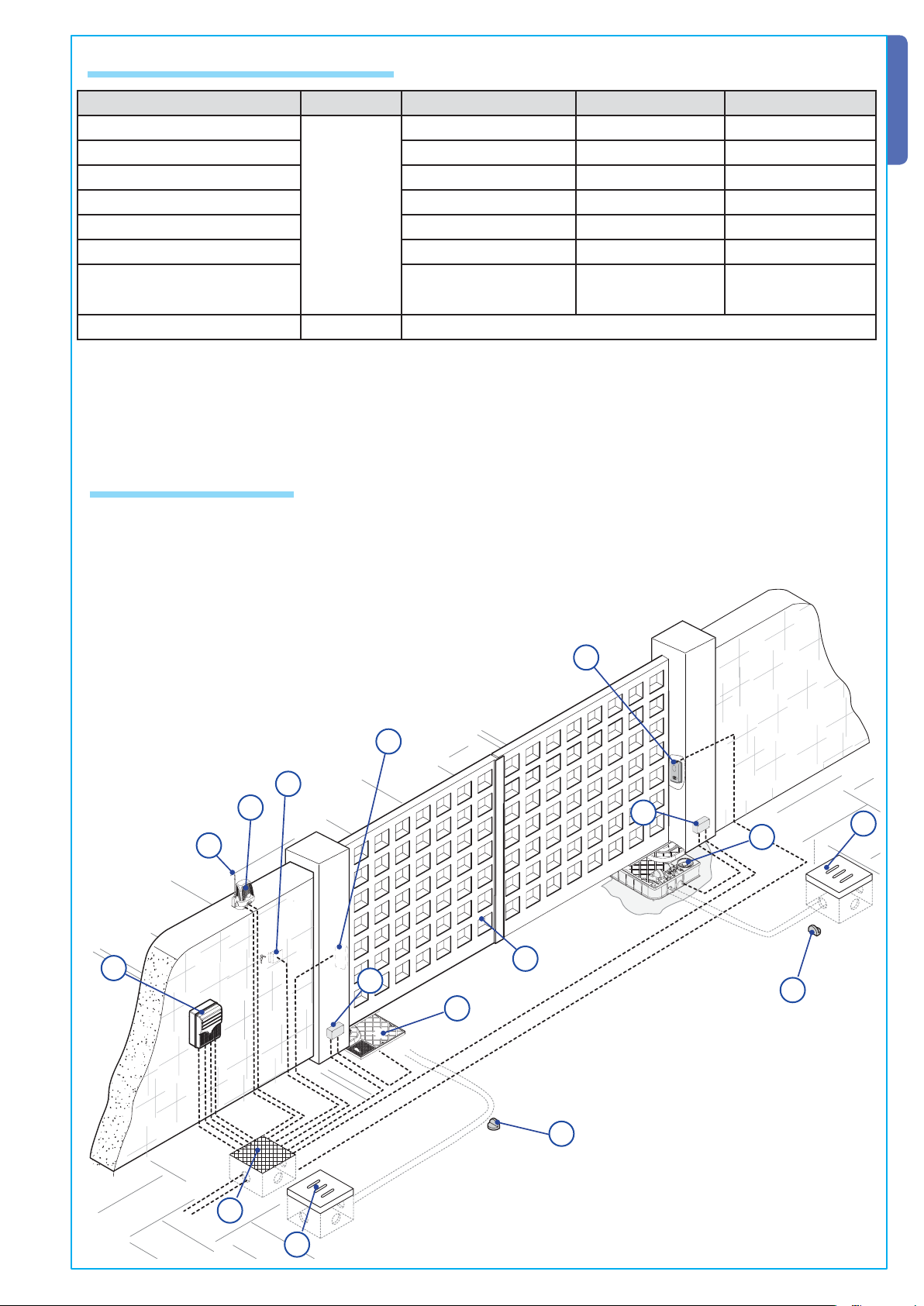

5.4 Standard installation

1) FROG-J unit

2) Control panel

3) Custom key release

4) Shunt box for connecting the gearmotor

5) Reception antenna

6) Flashing light

7) Selector switch

8) Photocells

9) Electric cable junction box

10) Drainage pit

11) Mechanical gate stops

8

8

7

6

5

2

11

4

4

10

3

11

1

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

11

9

10

5

Loading...

Loading...