Page 1

FROG-A 24U

VEHICULAR SWING GATE OPERATOR

INSTALLATION MANUAL

Your model may look different than the model illustrated in this manual.

THIS PRODUCT IS TO BE INSTALLED AND

SERVICED BY A TRAINED GATE SYSTEMS

TECHNICIAN ONLY.

Visit www.liftmaster.com to locate a

professional installing dealer in your

area.

This model is for use on vehicular passage gates

ONLY and not intended for use on pedestrian

passage gates.

This model is intended for use in Class I

vehicular swing gate applications.

Page 2

TABLE OF CONTENTS

SAFETY 1

SAFETY SYMBOL AND SIGNAL WORD REVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

UL325 MODEL CLASSIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY INSTALLATION INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GATE CONSTRUCTION INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REQUIRED ENTRAPMENT PROTECTION DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IMPORTANT SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INTRODUCTION 7

OPERATOR SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CARTON INVENTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

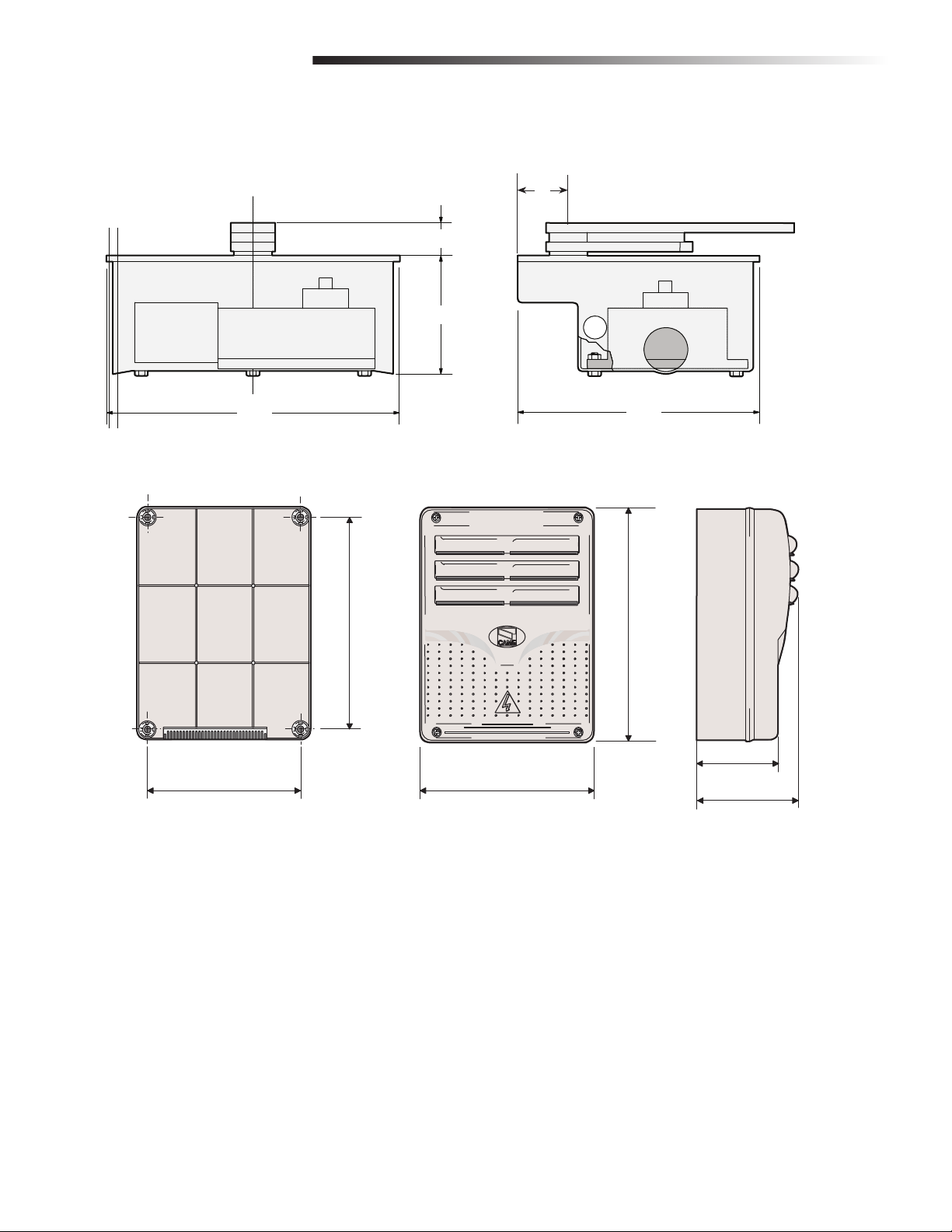

OPERATOR AND CONTROL PANEL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PREPARATION 9

TOOLS AND MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

WIRING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SITE PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INSTALL THE IN-GROUND CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FASTEN THE GEARMOTOR AND ASSEMBLE THE OPERATOR . . . . . . . . . . . . . . . . . . 11

MOUNT THE CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WIRING 13

OVERVIEW OF CONTROL PANEL AND ELECTRONIC CARD . . . . . . . . . . . . . . . . . . . . 13

WIRE THE OPERATOR(S) TO THE CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . 14

WIRE THE ENTRAPMENT PROTECTION DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WIRE THE ENTRAPMENT PROTECTION DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PROGRAMMING 18

USING THE MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

FACTORY SETTINGS (DEFAULTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

BASIC SETUP FOR TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

INSTALL AND PROGRAM THE

SECURITY+ 2.0™ RADIO CARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MENU DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ADJUSTMENTS 24

ADJUST THE BOLT IN THE MOTOR ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ADJUST THE LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MANUAL RELEASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TEST PHOTOELECTRIC SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MAINTENANCE 26

MAINTENANCE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ADDITIONAL SERVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

TROUBLESHOOTING 28

DISPOSAL 28

DISPOSAL OF PACKING MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DISPOSAL OF PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

REPAIR PARTS 29

WARRANTY 30

OPTIONAL WIRING 17

ACCESSORY POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

COMMAND AND CONTROL DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

WARNING DEVICES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SAFETY

SAFETY SYMBOL AND SIGNAL WORD

REVIEW

When you see these Safety Symbols and Signal Words on the following pages, they

will alert you to the possibility of serious injury or death if you do not comply with

the warnings that accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will alert you to the

possibility of damage to your gate and/or the gate operator if you do not comply

with the cautionary statements that accompany it. Read them carefully.

IMPORTANT NOTE

• BEFORE attempting to install, operate or maintain the operator, you must read

and fully understand this manual and follow all safety instructions.

• DO NOT attempt repair or service of your gate operator unless you are an

Authorized Service Technician.

SAFETY SYMBOL AND SIGNAL WORD REVIEW

MECHANICAL

ELECTRICAL

1

Page 3

SAFETY

UL325 MODEL CLASSIFICATIONS

CLASS I – RESIDENTIAL VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a home of one-to four

single family dwellings, or a garage or parking area associated therewith.

UL325 ENTRAPMENT PROTECTION REQUIREMENTS

This chart illustrates the entrapment protection requirements for the UL325 classes.

GATE OPERATOR ENTRAPMENT PROTECTION

UL325 Classification Swing Gate Operator

Primary Type Secondary Type

CLASS I-CLASS IV A B1 or B2

In order to complete a proper installation you must satisfy the entrapment

protection chart shown. That means that the installation must have one primary

means of entrapment protection and one independent secondary means of

entrapment protection. Both primary and secondary entrapment protection

methods must be designed, arranged or configured to protect against entrapments

in both the open and close directions of gate travel.

For Example: For a gate system that is installed on a single-family residence

(UL325 Class I) you must provide the following: As your primary type of

entrapment protection you must provide

• Type A - Inherent (built into the operator) entrapment sensing and at least

one of the following as your secondary entrapment protection:

• Type B1 - Non-contact sensors such as photoelectric sensors,

• Type B2 - Contact sensors such as gate edges

UL325 MODEL CLASSIFICATIONS

NOTE: UL requires that all installations must have warning signs placed in plain view

on both sides of the gate to warn pedestrians of the dangers of motorized gate

systems.

2

Page 4

SAFETY

SAFETY INSTALLATION INFORMATION

SAFETY INSTALLATION INFORMATION

1. Vehicular gate systems provide convenience and security. Gate systems are comprised of many component parts. The gate operator is only one component. Each gate

system is specifically designed for an individual application.

2. Gate operating system designers, installers and users must take into account the possible hazards associated with each individual application. Improperly designed, installed

or maintained systems can create risks for the user as well as the bystander. Gate systems design and installation must reduce public exposure to potential hazards.

3. A gate operator can create high levels of force in its function as a component part of a gate system. Therefore, safety features must be incorporated into every design.

Specific safety features include:

• Gate Edges • Guards for Exposed Rollers

• Photoelectric Sensors • Screen Mesh

• Vertical Posts • Instructional and Precautionary Signage

4. Install the gate operator only when:

a. The operator is appropriate for the construction and the usage class of the gate.

b. All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4 feet (1.2 m) above the ground to prevent a 2-1/4

inches (6 cm) diameter sphere from passing through the openings anywhere in the gate, and in that portion of the adjacent fence that the gate covers in the open

position.

c. All exposed pinch points are eliminated or guarded, and guarding is supplied for exposed rollers.

5. The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access opening. The pedestrian access opening shall

be designed to promote pedestrian usage. Locate the gate such that persons will not come in contact with the vehicular gate during the entire path of travel of the vehicular

gate.

6. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when opening and closing to reduce the risk of

entrapment. Swinging gates shall not open into public access areas.

7. The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

8. Controls intended for user activation must be located at least 6 feet (1.8 m) away from any moving part of the gate and where the user is prevented from reaching over,

under, around or through the gate to operate the controls. Outdoor or easily accessible controls shall have a security feature to prevent unauthorized use.

9. The Stop and/or Reset (if provided separately) must be located in the line-of-sight of the gate. Activation of the reset control shall not cause the operator to start.

10. A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

11. For a gate operator utilizing a non-contact sensor:

a. Reference owner’s manual regarding placement of non-contact sensor for each type of application.

b. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the gate is still moving.

c. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter reachable by a moving gate or barrier.

12. For a gate operator utilizing a contact sensor such as an edge sensor:

a. One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading edge, trailing edge and post mounted both inside

and outside of a vehicular horizontal slide gate.

b. One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

c. A hard wired contact sensor shall be located and its wiring arranged so the communication between the sensor and the gate operator is not subject to mechanical

damage.

d. A wireless contact sensor such as the one that transmits radio frequency (RF) signals to the gate operator for entrapment protection functions shall be located where the

transmission of the signals are not obstructed or impeded by building structures, natural landscaping or similar obstruction. A wireless contact sensor shall function

under the intended end-use conditions.

e. One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the bottom edge of a swing gate is greater than 6

inches (152 mm) above the ground at any point in its arc of travel, one or more contact sensors shall be located on the bottom edge.

f. One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

3

Page 5

SAFETY

GATE CONSTRUCTION INFORMATION

GATE CONSTRUCTION INFORMATION

Vehicular gates should be installed in accordance with ASTM F2200: Standard Specification for Automated Vehicular Gate Construction. For a copy, contact ASTM directly at

610-832-9585 or www.astm.org.

1. GENERAL REQUIREMENTS

1.1 Gates shall be constructed in accordance with the provisions given for the

appropriate gate type listed, refer to ASTM F2200 for additional gate types.

1.2 Gates shall be designed, constructed and installed to not fall over more than

45 degrees from the vertical plane, when a gate is detached from the

supporting hardware.

1.3 Gates shall have smooth bottom edges, with vertical bottom edged

protrusions not exceeding 0.50 inches (12.7 mm) when other than the

exceptions listed in ASTM F2200.

1.4 The minimum height for barbed tape shall not be less than 8 feet (2.44 m)

above grade and for barbed wire shall not be less than 6 feet (1.83 m)

above grade.

1.5 An existing gate latch shall be disabled when a manually operated gate is

retrofitted with a powered gate operator.

1.6 A gate latch shall not be installed on an automatically operated gate.

1.7 Protrusions shall not be permitted on any gate, refer to ASTM F2200 for

Exceptions.

1.8 Gates shall be designed, constructed and installed such that their movement

shall not be initiated by gravity when an automatic operator is disconnected.

1.9 A pedestrian gate shall not be incorporated into a vehicular gate panel or

that portion of the adjacent fence that the gate covers in the open position.

2. SPECIFIC APPLICATIONS

2.1 Any non-automated gate that is to be automated shall be upgraded to

conform to the provisions of this specification.

2.2 This specification shall not apply to gates generally used for pedestrian

access and to vehicular gates not to be automated.

2.3 Any existing automated gate, when the operator requires replacement, shall

be upgraded to conform to the provisions of this specification in effect at

that time.

3. VEHICULAR HORIZONTAL SLIDE GATES

3.1 The following provisions shall apply to Class I, Class II and Class III vehicular

horizontal slide gates:

3.1.1 All weight bearing exposed rollers 8 feet (2.44 m), or less, above grade

shall be guarded or covered.

3.1.2 All openings located between 48 inches (1.22 m) and 72 inches (1.83 m)

above grade shall be designed, guarded or screened to prevent a 4 inch

(102 mm) diameter sphere from passing through the openings anywhere in

the gate, and in that portion of the adjacent fence that covers in the open

position.

3.1.3 A gap, measured in the horizontal plane parallel to the roadway, between a

fixed stationary object nearest the roadway, (such as a gate support post)

and the gate frame when the gate is in either the fully open position or the

fully closed position, shall not exceed 2 1/4 inches (57 mm), refer to ASTM

F2200 for Exception.

3.1.4 Positive stops shall be required to limit travel to the designed fully open and

fully closed positions. These stops shall be installed at either the top of the

gate, or at the bottom of the gate where such stops shall horizontally or

vertically project no more than is required to perform their intended

function.

3.1.5 All gates shall be designed with sufficient lateral stability to assure that the

gate will enter a receiver guide, refer to ASTM F2200 for panel types.

3.2 The following provisions shall apply to Class IV vehicular horizontal slide

gates:

3.2.1 All weight bearing exposed rollers 8 feet (2.44 m), or less, above grade

shall be guarded or covered.

3.2.2 Positive stops shall be required to limit travel to the designed fully open and

fully closed positions. These stops shall be installed at either the top of the

gate, or at the bottom of the gate where such stops shall horizontally or

vertically project no more than is required to perform their intended

function.

4. VEHICULAR HORIZONTAL SWING GATES

4.1 The following provisions shall apply to Class 1, Class II and Class III vehicular

horizontal swing gates:

4.1.1 Gates shall be designed, constructed and installed so as not to create an

entrapment area between the gate and the supporting structure or other

fixed object when the gate moves toward the fully open position, subject to

the provisions in the 4.1.1.1 and 4.1.1.2.

4.1.1.1 The width of an object (such as a wall, pillar or column) covered by a swing

gate when in the open position shall not exceed 4 inches (102 mm),

measured from the centerline of the pivot point of the gate, refer to ASTM

F2200 for exception.

4.1.1.2 Except for the zone specified in Section 4.1.1.1, the distance between a

fixed object such as a wall, pillar or column, and a swing gate when in the

open position shall not be less than 16 inches (406 mm), refer to ASTM

F2200 for exception.

4.2 Class IV vehicular horizontal swing gates shall be designed, constructed and

installed in accordance with security related parameters specific to the

application in question.

4

Page 6

SAFETY

REQUIRED ENTRAPMENT PROTECTION DEVICES

REQUIRED ENTRAPMENT PROTECTION DEVICES

To prevent SERIOUS INJURY or DEATH from a moving gate:

• Entrapment protection devices MUST be installed to protect anyone who may

come near a moving gate.

• Locate entrapment protection devices to protect in BOTH the open and close

gate cycles.

An entrapment zone is every location or point of contact where a person can become entrapped between a moving gate and a stationary object. All gate operator systems

REQUIRE two independent entrapment protection systems for each entrapment zone. This operator contains an inherent (internal) entrapment protection system (the primary

entrapment protection system) and REQUIRES the addition of an external entrapment protection system (non-contact photoelectric sensor or contact safety edge sensor) for

EACH entrapment zone.

Your application may contain one or many entrapment zones. Property owners are obligated to test entrapment protection devices monthly.

CONTACT SENSORS (EDGE SENSORS)

If the electrically activated edge sensor comes in contact with an obstruction while the gate is moving, the gate will stop and reverse. The gate will not be able to travel in that

direction until the obstruction is cleared. Use model G65MGO20, G65MGR20 or G65MGS20.

3 Edge Contact Sensor

• Locate entrapment protection devices to protect between moving gate and

RIGID objects, such as posts or walls.

Edge Sensor for Open Cycle Edge Sensor for Close Cycle

!

NON-CONTACT SENSORS

If the photoelectric sensor beam gets blocked while the gate is moving, the gate will stop and reverse. The gate will not be able to travel in that direction until the obstruction

is cleared. Use DIR10 photoelectric sensors.

Sensor for Close Cycle

Sensor for Open Cycle

!

!

5

Page 7

SAFETY

IMPORTANT SAFETY INFORMATION

IMPORTANT SAFETY INFORMATION

To prevent SERIOUS INJURY or DEATH:

• READ AND FOLLOW ALL INSTRUCTIONS.

• Pinch points must be guarded at all times. Install enclosed-style gate tracks and

roller guards.

• Place screen mesh 4 feet (1.2 m) high on the gate to prevent access through

openings anywhere the gate may travel.

• Mount controls at least 6 feet (1.8 m) from the gate or ANY moving part of the

gate.

• Install Warning signs on EACH side of gate in PLAIN VIEW. Permanently secure

each Warning sign in a suitable manner using fastening holes.

• This operator is intended for vehicular use only. To prevent INJURY to

pedestrians, a separate pedestrian access should be supplied, visible from the

gate. Locate the pedestrian access where there is not a chance of INJURY at any

point during full movement of the gate.

• Contact sensors MUST be located at the leading and trailing edges, and post

mounted both inside and outside a horizontal slide gate. Non-contact sensors

such as photo eyes MUST be mounted across the gate opening and operate

during BOTH the open and close cycles.

• Entrapment protection devices MUST be installed to protect anyone who may

come near a moving gate.

• Locate entrapment protection devices to protect in BOTH the open and close

gate cycles.

• Locate entrapment protection devices to protect between moving gate and RIGID

objects, such as posts or walls.

• Too much force on gate will interfere with proper operation of safety reversal

system.

• NEVER increase force beyond minimum amount required to move gate.

• NEVER use force adjustments to compensate for a binding or sticking gate.

• If one control (force or travel limits) is adjusted, the other control may also

need adjustment.

• ANY maintenance to the operator or in the area near the operator MUST NOT

be performed until disconnecting the electrical power. Upon completion of

maintenance the area MUST be cleared and secured, at that time the unit may

be returned to service.

• Disconnect power at the fuse box BEFORE proceeding. Operator MUST be

properly grounded and connected in accordance with national and local

electrical codes.

• ALL electrical connections MUST be made by a qualified individual.

• DO NOT install ANY wiring or attempt to run the operator without consulting the

wiring diagram. We recommend that you install an edge sensor BEFORE

proceeding with the control station installation.

• ALL power wiring should be on a dedicated circuit and well protected. The

location of the power disconnect should be visible and clearly labeled.

• ALL power and control wiring MUST be run in separate conduit.

• NEVER let children operate or play with gate controls. Keep the remote control

away from children.

• Without a properly installed safety reversal system, persons (particularly small

children) could be SERIOUSLY INJURED or KILLED by a moving gate.

• ALWAYS keep people and objects away from the gate. NO ONE SHOULD CROSS

THE PATH OF THE MOVING GATE.

• The entrance is for vehicles ONLY. Pedestrians MUST use separate entrance.

• Test the gate operator monthly. The gate MUST reverse on contact with a rigid

object or reverse when an object activates the non-contact sensors. After

adjusting the force or the limit of travel, retest the gate operator. Failure to

adjust and retest the gate operator properly can increase the risk of INJURY or

DEATH.

• Use the manual disconnect release ONLY when the gate is not moving.

• KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a

qualified service person make repairs to gate hardware.

• ALL maintenance MUST be performed by a trained professional.

• Activate gate ONLY when it can be seen clearly, is properly adjusted and there

are no obstructions to gate travel.

• SAVE THESE INSTRUCTIONS.

To protect against fire and electrocution:

• DISCONNECT power BEFORE installing or servicing operator.

• To AVOID damaging gas, power or other underground utility lines, contact

underground utility locating companies BEFORE digging more than 18 inches

(46 cm) deep.

For continued protection against fire:

• Replace ONLY with fuse of same type and rating.

6

Page 8

INTRODUCTION

OPERATOR SPECIFICATIONS

This model is intended for use in vehicular swing gate applications:

OPERATOR SPECIFICATIONS + CARTON INVENTORY

Gate Classifications: CLASS I

Main AC Supply: 120 Vac, 50/60Hz

Input Rating: 500 Watts at 120Vac

Main Supply (Motor): 7.5 Amps at 24Vdc

Maximum Torque: 320N

Cycle Time: 12 seconds 90 degree open @ 100% speed

15 seconds 90 degree close @ 100% speed

Gear ratio: 1/1152

Accessory Power: 24 Vac nominal Class II limited to 37W

Maximum Gate Weight/Length: 850 lbs. at 12ft.

Maximum Opening: 110 degrees

CARTON INVENTORY

Daily Cycle Rate AC power: Continuous duty

Ambient Temperature: -20°C to 55°C (-4°F to 131°F)

Fuse Protection Motor: 10 Amp

Fuse Protection Accessories: 2 A

Fuse Protection Control Board: 630 mA-F

Fuse Protection Electrolock: 3.15 A

Fuse Protection Line: 5 A

* The company CAME Cancelli Automatici is ISO 9001:2000 quality certified; it has

also obtained the ISO 14001 environmental safeguarding certification. CAME

engineers and manufactures all of its products in Italy.

This product complies with the following standards: UL-325 and CSA C22.2 NO.247-

92.

NOT SHOWN: Hardware for control panel and manual

Gate Bracket

Gate Arm

Cover

Curved Arm

Control Panel

In-Ground Case

Gearmotor

Hardware

Manual Release

Warning Signs (2)

7

Page 9

INTRODUCTION

OPERATOR AND CONTROL PANEL DIMENSIONS

OPERATOR AND CONTROL PANEL DIMENSIONS

OPERATOR

CONTROL PANEL

16"

(40.63 cm)

2.6"

(6.60 cm)

2.3" (5.84 cm)

6.2" (15.74 cm)

13"

(33 cm)

11.61" (29.48 cm)

8.46" (21.48 cm) 9.45" (24 cm)

12.60" (32 cm)

4.72"

(11.98 cm)

5.71"

(14.50 cm)

8

Page 10

PREPARATION

TOOLS AND MATERIALS

Make sure you have all the tools and materials required for the installation. The

installation should be completed in accordance with all national and local standards

and regulations.

The following tools may be needed for your installation:

TOOLS AND MATERIALS + WIRING CHART + SITE PREPARATION

• Drill and Drill Bits

• Hack Saw

• Welder

• Tape Measure

• Pliers

• Screwdrivers

• Shears

• Plumb Bob

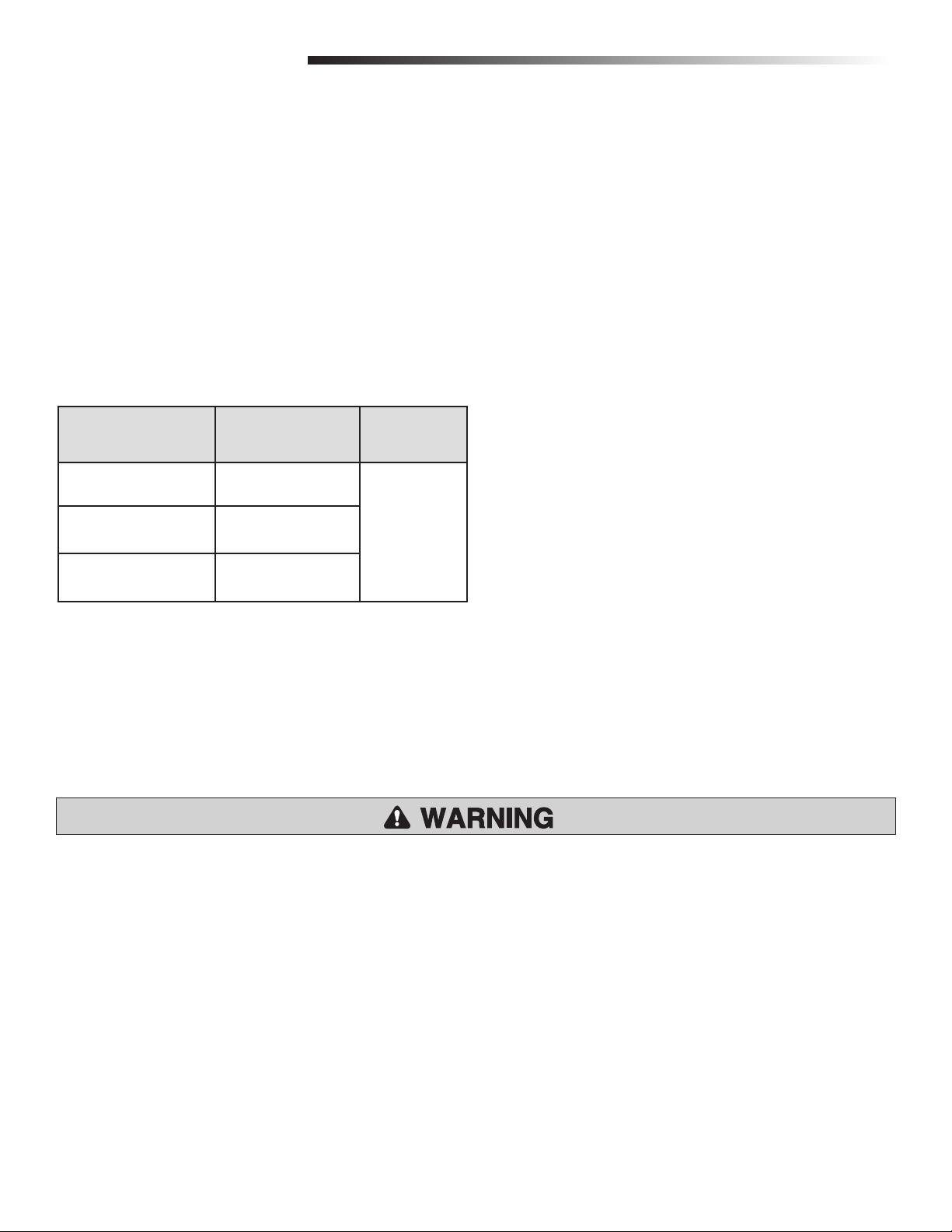

WIRING CHART

Always check first for local and national electrical codes.

CONNECTION/DEVICE AMERICAN WIRE GAUGE

(AWG)

Control panel power supply

120V

Motor power supply 24V 20AWG

Safety and control

NOTE: If the length of the wire differs from that specified in the table, then you

must determine the proper wire gauge based on the actual power draw of the

devices connected and the local electrical codes. For connections that require several,

sequential loads, the sizes provided in the table must be re-evaluated based on

actual power draw and distances. When connecting products that are not specified in

this manual, refer to the instructions provided with said products.

NOTE: Use copper conductors only.

devices

14AWG

20AWG

WIRE LENGTH

3 ft. up to 100 ft.

SITE PREPARATION

INSTALLATION MUST BE PERFORMED BY AN EXPERT QUALIFIED PERSONNEL AND IN FULL COMPLIANCE WITH

CURRENT REGULATIONS. Gate must be constructed and installed according to ASTM F2200 standards.

Before installation, perform the following:

Make sure you have a suitable omnipolar cut-off device with contacts more than 1/32” in (3 mm) apart, and independent (sectioned off) power supply.

1

Fix tubing to drain away any water leaks which may cause oxidation.

2

Make sure the structure of the gate is sturdy, the hinges work and that there is no friction between moving and non-moving parts.

3

Make sure that there is a mechanical stop for closing.

4

Check that any connections inside the container (that provide continuity to the safety circuit) are fitted with additional insulation compared to other internal live parts.

5

Make sure you have suitable tubing and conduits for the electrical cables to pass through and be protected against mechanical damage.

6

9

Page 11

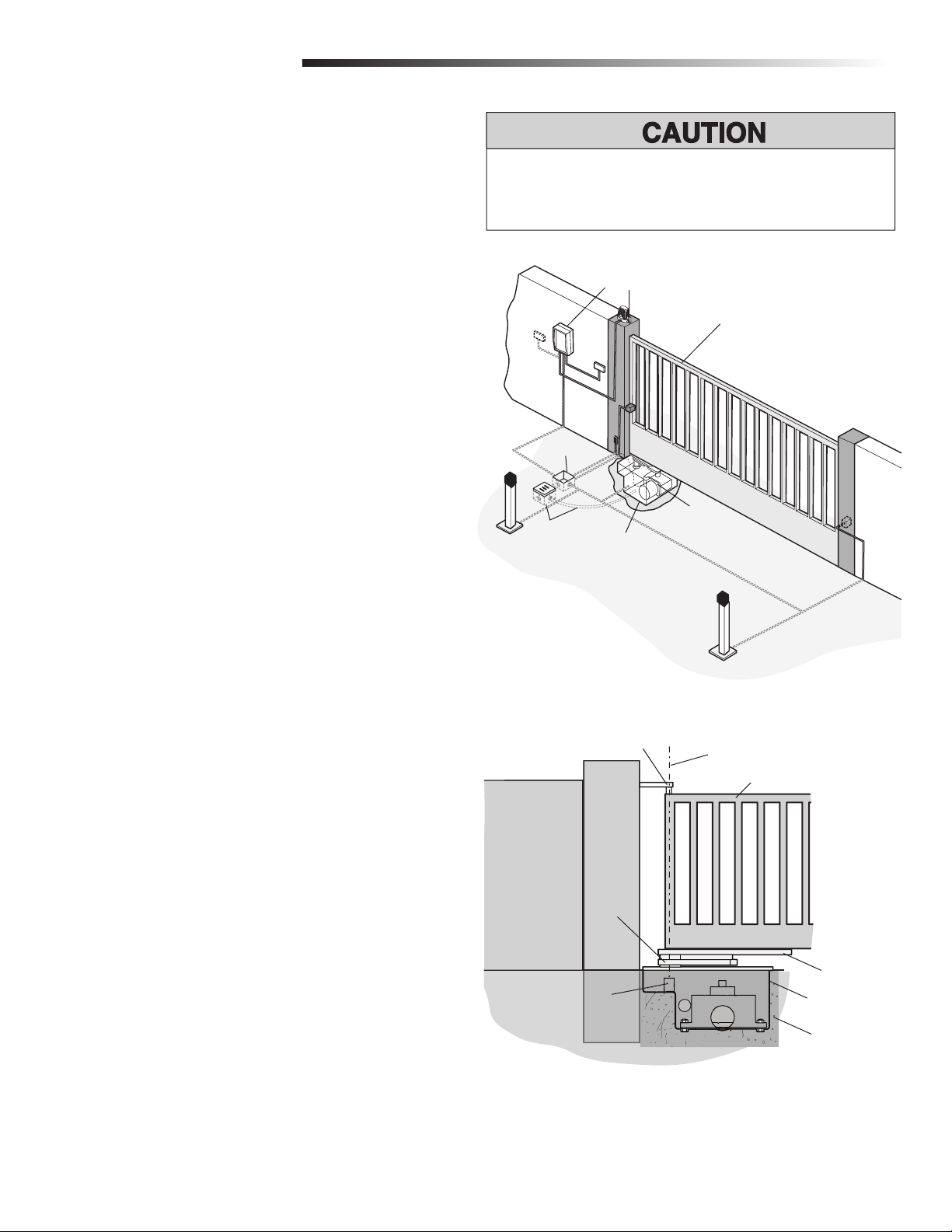

INSTALLATION

INSTALL THE IN-GROUND CASE

Check the national and local building codes before installation. The instructions and

illustrations in this manual are examples ONLY. Your installation may vary depending

on space, obstructions, and accessories. It is up to the installer to select the most

suitable solution. Installation and assembly is quick and easy with the in-ground case.

Determine the location for the in-ground case (Figure 1). The location will

1

depend on the supporting structure and desired opening. When the operator is

installed the rotation pin should be centered with the hinge of gate (Figure 2).

INSTALL THE IN-GROUND CASE

• To AVOID damaging gas, power or other underground utility lines, contact

underground utility locating companies BEFORE digging more than 18 inches

(46 cm) deep.

Figure 1

Control Box

Hang a Plumb Bob from the hinge to help locate the center point of the

2

rotation pin to determine the size and location of the hole for the in-ground

case. Dig the hole for the in-ground case.

Prepare a trench and install the the junction boxes, electrical conduits, and

3

drainage tube (Figure 1).

NOTE: ALL power and control wiring MUST be run in separate conduit. The

number of conduits will depend on your site and the accessories to be

installed.

Prepare a drainage system to drain away any water. The drainage system will

4

prevent water leaks which may cause oxidation (Figure 1).

Set the in-ground case in the hole and make sure the conduit and drainage

5

pipes are inserted into separate knockout holes.

Level the in-ground case. The upper edge of the case should be 1 inch (25

6

mm) above the ground. IMPORTANT: Hang a Plumb Bob from the hinge to

make sure the rotation pin in the in-ground case is aligned with the upper

hinge on the gate (Figure 2).

Backfill the hole with concrete. Allow the concrete to cure for at least 24

7

hours.

Drainage System

Figure 2

Gate

Junction Box

Operator

In-Ground Case

Gate Hinge

MUST be aligned

Gate

10

Gate

Arm

Rotation

Pin

Gate Bracket

In-Ground Case

Concrete

Page 12

INSTALLATION

FASTEN THE GEARMOTOR AND ASSEMBLE

THE OPERATOR

Determine whether your installation is right or left-hand and follow the instructions

accordingly.

FASTEN THE GEARMOTOR AND ASSEMBLE THE OPERATOR

Figure 1: Left Hand Installation

Gate Bracket

(Gate in OPEN position)

Remove the white plastic film on the bottom of the in-ground case.

1

Fasten the gearmotor to the bolts on the bottom of the in-ground case using

2

the nuts and washers provided.

Insert the bolt into the motor arm and secure with the nut. This bolt will be

3

adjusted in a later step when power is applied to the operator (Adjustments

section, page 24).

Ensure the rotation pin is greased and insert the gate arm over the rotation

4

pin.

Insert the curved arm between the motor arm and the gate arm.

5

Attach the manual release to the gate bracket. NOTE: Your manual release

6

may be different. Ensure the manual release is released.

Insert the gate bracket into the gate arm.

7

Position the gate between the upper gate hinge and the rotation pin on the

8

operator.

Secure the gate bracket to the gate by tack welding the gate bracket every 1

9

inch (25 mm) to 1-1/2 inches (38 mm) along the contact surface. Avoid any

welding near the threaded screws.

Manual Release

Curved Arm

Gearmotor

Figure 1: Right Hand Installation

(Gate in OPEN position)

Gate Arm

Bolt

Motor Arm

Nut

Gate Arm

Bolt

Motor Arm

Nut

Gate Bracket

Manual Release

Gearmotor

Curved Arm

Determine the close position of the gate and install a close end stop

10

(Figure 2).

Figure 2

90°

Close End Stop(s)

90°

11

Page 13

INSTALLATION

MOUNT THE CONTROL PANEL

MOUNT THE CONTROL PANEL

The control panel MUST be mounted within 5 feet (1.52 m) of the gate operator.

Attach the control panel to the mounting surface with cross slot Phillips head

1

bolts in a protected area (Figure 1).

Assemble the plastic hinges (Figure 2A).

2

Insert the hinge with the tabs into the slot along the side of the control panel

3

(on the left or right as you wish).

Secure the hinges with the washers and screws (Figure 2B). There should be

4

two hinges on each side.

Insert the other half of the hinge into the slots on the cover.

5

After the adjustments and programming are complete, attach the cover using

6

the provided screws (Figure 3).

Figure 1

8.4”

11.6

Figure 2A

Figure 2B

tabs

12

Figure 3

Page 14

WIRING

OVERVIEW OF CONTROL PANEL AND

ELECTRONIC CARD

1 Transformer

2 Card fuse (630mA-F 250VAC 5X20mm)

3 Accessories fuse (2A-F 250VAC 5X20mm)

4 Electrolock fuse (3.15A-F 250VAC 5X20mm)

5 Display

6 Display -contrast adjustment

7 Security+ 2.0™ radio card connector

8 Warning LED-Open contact error

9 Programming buttons

10 Accessory and Command Device Terminals

11 Power Supply Terminals-120 VAC

12 Line fuse (5A-F 250VAC 5X20mm)

13 120V-Power LED

14 Motor 1 fuse 1 (10A-F 250VAC 6X32mm)

15 Motor 1 fuse 2 (10A-F 250VAC 6x32mm)

OVERVIEW OF CONTROL PANEL AND ELECTRONIC CARD

To protect against fire and electrocution:

• DISCONNECT power BEFORE installing or servicing operator.

1

26V

17V

0V

120V

0

1

26V

17V

0V

120V

0

4

3

2

5

9

14

6

15

7

12

11

8

10

13

13

Page 15

WIRING

WIRE THE OPERATOR(S) TO THE CONTROL PANEL

WIRE THE OPERATOR(S) TO THE CONTROL

PANEL

Turn off the AC power from the main power source circuit breaker.

1

Insert the cables through a watertight connector mounted in the back of the

2

control panel.

Determine the open and close limit microswitch wires (Figure 1). Wire the

3

motor and microswitch wires as shown according to your application

(Figure 2).

Connect 120 Vac power to the power supply terminals on the electronic card,

4

50/60Hz frequency maximum.

Tighten watertight connector nut.

5

Do not apply AC power until instructed.

NOTE: The electronic card is equipped with an amperometric sensor which

constantly monitors the motor’s drive. If the gate encounters an obstacle, the sensor

immediately detects the overload on the operator and the gate reverses.

Figure 1

Microswitch (Open Limit)

Motor Wires

Microswitch (Close Limit)

Microswitch (Close Limit)

Figure 2: Single Gate Operator (Right-Hand)

N2 (Black Motor Wire)

120 Vac Power

M2 (White Motor Wire)

Right-HandLeft-Hand

Microswitch (Open Limit)

Motor Wires

2 (Brown Wires)

FC2 (Blue Close Limit Microswitch Wire)

FA2 (Blue Open Limit Microswitch Wire)

Figure 2: Single Gate Operator (Left-Hand)

N2 (White Motor Wire)

120 Vac Power

M2 (Black Motor Wire)

Figure 2: Dual Gate Operators

N2 (Black Motor Wires)

M2 (White Motor Wires)

N1 (White Motor Wires)

M1 (Black Motor Wires)

120 Vac Power

2 (Brown Microswitch Wires)

FA1 Left Hand Operator

(Blue Microswitch Open

Limit Wire)

FC1 Left Hand Operator

(Blue Microswitch Close

Limit Wire)

2 (Brown Microswitch Wires)

FC2 (Blue Close Limit Microswitch Wire)

FA2 (Blue Open Limit Microswitch Wire)

FC2 Right Hand Operator

(Blue Microswitch Close

Limit Wire)

FA2 Right Hand Operator

(Blue Microswitch Open

Limit Wire)

14

Page 16

WIRING

WIRE THE ENTRAPMENT PROTECTION

DEVICES

WIRE THE ENTRAPMENT PROTECTION DEVICES

An entrapment protection device such as photoelectric sensors or an edge MUST be

wired to the operator and then configured for your application. Refer to page 18 page 21 for programming information.

PHOTOELECTRIC SENSORS

Entrapment protection devices are required.

Input for UL325 compliant entrapment protection devices such as photoelectric

sensors. Configure either CX, CY, or CZ (N.C.) contacts.

NOTE: If not used deactivate the contacts using the programming menu.

C1 “OPEN WHILE CLOSING” (N.C.) Contact

If the photoelectric sensor beam is blocked while the gate is closing, the gate will stop

and reverse to the fully open position.

C2 “CLOSE WHILE OPENING” (N.C.) Contact

If the photoelectric sensor beam is blocked while the gate is opening, the gate will

stop and reverse to the fully closed position.

C3 “PARTIAL STOP”(N.C.) Contact

If the photoelectric sensor beam is blocked while the gate is moving, the gate will

stop and automatically shuts (if this function has been selected).

RX

DIR10 Photoelectric Sensors:

TX

C4 “STANDBY OBSTACLE” (N.C.) Contact

If the photoelectric sensor beam is blocked while the gate is moving, the gate will

stop and once the obstruction is removed the gate will resume moving in the same

direction.

15

Page 17

WIRING

WIRE THE ENTRAPMENT PROTECTION

DEVICES

WIRE THE ENTRAPMENT PROTECTION DEVICES

Two-wire normally open edge

EDGE SENSORS (CONTACT)

An entrapment protection devices such as photoelectric sensors or an edge MUST be

wired to the operator and then configured for your application using the

programming menu. Refer to page 18 - page 21 for programming information.

Configure either CX, CY, or CZ (N.C.) contacts.

C7 “OPEN WHILE CLOSING” (N.C.) Contact

This input functions to reverse the gate to the open limit when activated during the

close cycle.

NOTE: If not used, deactivate.

C8 “CLOSE WHILE OPENING” (N.C.) Contact

This input functions to reverse the gate to the close limit when the edge is activated

during the opening cycle.

NOTE: If not used, deactivate.

Transmitter

Wireless Communicator

PWR Relay

24V C

CNONC

Receiver

16

Page 18

OPTIONAL WIRING

ACCESSORY POWER

ACCESSORY POWER + COMMAND AND CONTROL DEVICES

Command devices and accessories are 24V power. The overall power for accessories

CANNOT exceed 37W.

Terminals 10 and 11 provide power for the following accessories:

• 24 Vac normally

• 24 Vdc when the emergency batteries are working

COMMAND AND CONTROL DEVICES

Stop button (N.C. contact)

• Cancels automatic closing (A.C.T.). To resume normal operation, press the

command button or the remote control button.

NOTE: If not used, select "Disabled" in the "Functions" menu.

To protect against fire and electrocution:

• DISCONNECT power BEFORE installing or servicing operator.

+

-

Key selector and/or open button (N.O. contact)

• Gate opening command.

Key selector and/or partial opening button (N.O. contact)

• Partial gate opening

Key selector and/or closing button (N.O. contact)

• Gate closing command.

Key selector and/or command button (N.O. contact)

• Gate opening and closing command.

• By pressing the button or turning the key, the gate reverses direction or stops

depending on the 2-7 settings in the "Functions" menu.

17

Page 19

OPTIONAL WIRING

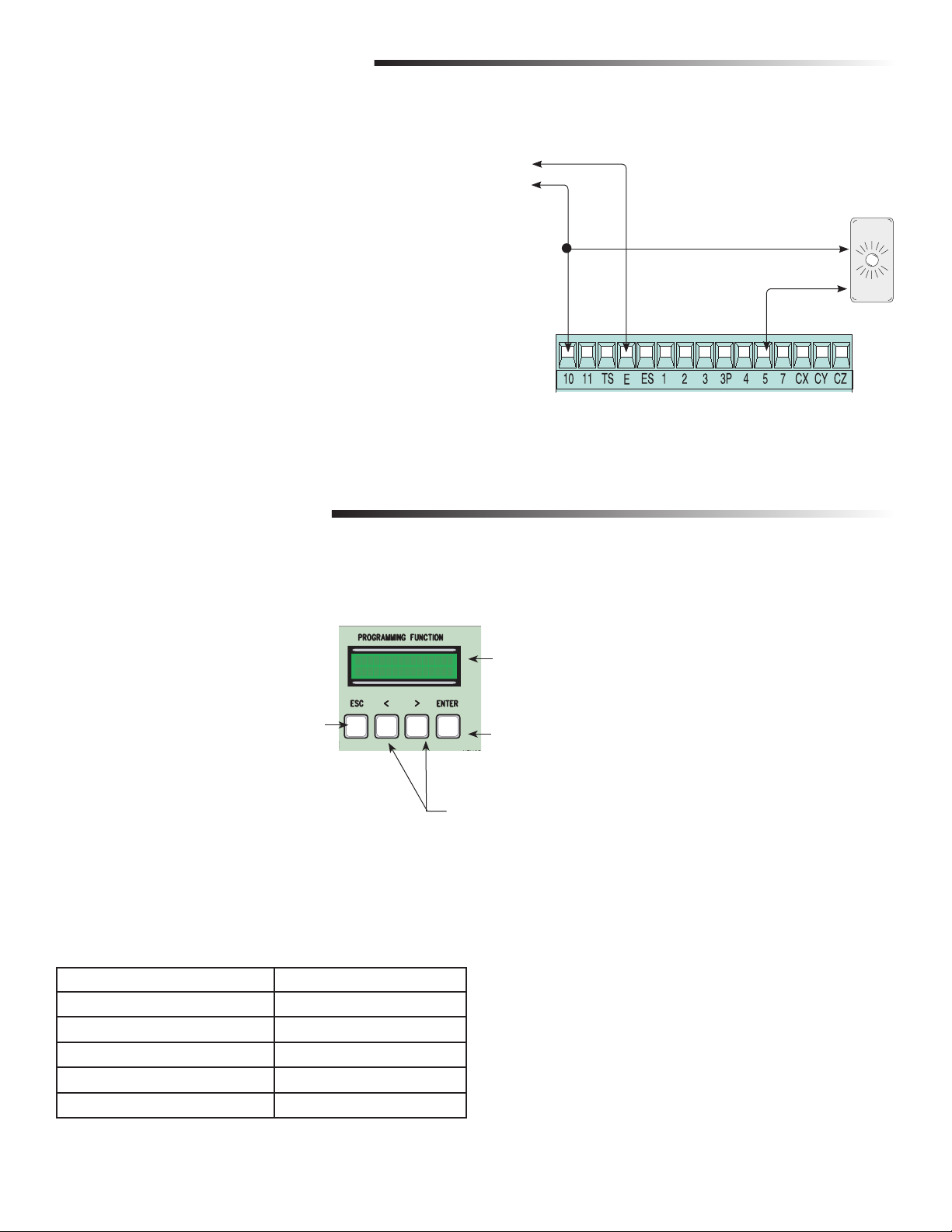

WARNING DEVICES

Open-gate indicator light

• Signals that gate is open; turns off when the gate is closed.

• Contact power: 24V A.C. - 25W maximum

• Socket rating 24V-3W maximum

NOTE: If the operator detects two sequential obstructions while running, the

electronic card activates the warning device and blocks the signal from the remote

control for 5 minutes. After 5 minutes, the alarm is deactivated and the signal for the

remote controls are restored and the PROG LED goes off. To restore normal operation

prior to the 5 minutes, press the total stop key and the PROG LED goes off.

APPLY AC POWER TO THE OPERATOR AND PROCEED TO

THE PROGRAMMING SECTION TO COMPLETE THE

OPERATOR CONFIGURATION.

Warning

Device

WARNING DEVICES

Flashing Light

PROGRAMMING

USING THE MENU

Lingua

Italiano

Þß

{

The ESC button is used to:

• exit the menu

• cancel changes

FACTORY SETTINGS (DEFAULTS)

PROGRAMMED FUNCTIONS FACTORY DEFAULTS

Total stop Enabled (NC stop)

CX, CY, and CZ Contacts Enabled

Speed 100%

Automatic Close Timer (ACT) 10 seconds

Motor Frog

USING THE MENU + FACTORY SETTINGS (DEFAULTS)

The <...> symbols on the display

indicate the current selection.

{

The ENTER button is to:

{

• press and hold for 1 second to enter the menu

• confirm and set values

The < > buttons are used to:

{

• move from one menu to another

• increase or decrease values

18

Page 20

PROGRAMMING

BASIC SETUP FOR TYPICAL APPLICATIONS

Set the LANGUAGE: Press and hold the ENTER button for 1 second to

1

see the menu on the display. Select LANGUAGE > (Choose the desired

language).

Set the basic function for the entrapment protection devices: Select

2

FUNCTIONS then select the following menus to either determine the

functionality or disable the entrapment protection devices:

• Total Stop > Disabled

• CX Input > (Choose either C1, C2, C3, C4, C7, C8, or

Deactivated)

• CY Input > (Choose either C1, C2, C3, C4, C7, C8, or

Deactivated)

• CZ Input > (Choose either C1, C2, C3, C4, C7, C8, or

Deactivated)

Select number of motors: Select IMP. RUN > No. Motors (Choose

3

either M1 & M2 for dual gates or M2 for a single gate).

Select motor type: Select IMP. RUN > Motor type > FROG

4

BASIC SETUP FOR TYPICAL APPLICATIONS

Set the Configuration: Select FUNCTIONS > Config. > FCAP

5

RALLCH.

Set the End Stop: Select FUNCTIONS > endstop > N.O.

6

Basic setup of your operator is now complete. For additional programming and

settings refer to the "Menu Descriptions" pages.

19

Page 21

PROGRAMMING

INSTALL AND PROGRAM THE SECURITY+ 2.0™ RADIO CARD

INSTALL AND PROGRAM THE

SECURITY+ 2.0™ RADIO CARD

Disconnect all power to the operator.

1

Insert the Security+ 2.0™ radio card into the slot on the electronic card.

2

Connect power.

3

NOTE: The electronic card picks up the Security+ 2.0™ radio card when the

operator is powered up.

Press the button on the Security+ 2.0™ radio card (the LED will light).

4

Press the button on the remote control (the LED on the radio card will go out

5

if programming is successful).

Activate the display menu by holding the ENTER button for one second.

6

Navigate to USERS > Add User > Choose Confirm? (yes).

7

From the Related Func. menu choose the desired function (2-7, Open,

8

B1-B2, 2-3P, or Disabled) and then press the ENTER button to make the

selection. The menu will display "Waiting Code".

NOTICE: This device complies with Part 15 of the FCC rules and Industry Canada (IC) licence-exempt RSS-210. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the

equipment.

This Class B digital apparatus complies with Canadian ICES-003.

While the "Waiting Code" is displayed, press and hold the remote control

9

button. The display will flash the code and then exit to the Add User menu

indicating programming is complete.

To program additional remote controls follow steps 5 and 6 above only.

Electronic Card

Display

ENTER Button

Radio Card Slot

ERASE THE SECURITY+ 2.0™ RADIO CARD MEMORY

Press and hold the button on the Security+ 2.0™ radio card until the LED

1

goes out (approximately 6 seconds). The memory is now erased.

20

Page 22

PROGRAMMING

MENU DESCRIPTIONS

The menu is used to configure the operator based on your application and the devices that are connected to the operator.

NOTE: The encoder menu only appears if "Config." is selected from the "Functions" menu.

MAIN MENU SUB MENU DESCRIPTION

LANGUAGE The language menu determines the language for the menu. Factory default is Italian.

English Select for English

Francais Select for French

Deutsch Select for German

Espanol Select for Spanish

Italiano Select for Italian

FUNCTIONS The functions menu determines how your operator will function.

AutoClose Automatic Close: Activates or deactivates the automatic close timer (ACT). The automatic close timer (ACT) activates at each opening

Maintained Act Maintained Action: The gate works by constant pressure to open (button 2-3) and constant pressure to close (button 2-4) or if set to the

Obstacle Det. Obstacle Detected: When motor is stopped (gate closed or after a total stop command) it prevents any movement if an entrapment

Safety Test Safety Test: Allows the electronic card to check the efficiency of any entrapment protection devices (i.e. photoelectric sensors) after every

Preflashing

Ram hit funct.

Total Stop

CX Input

CY Input

CZ Input

CI. Thrust

Lock

Config. Configuration:

endstop

cmd 2-7

cmd 2-3P

endpoint. The time may be adjusted, and is dependent on any entrapment protection devices that may activate; and it does not activate after

a total safety “stop” or during a power outage.

“On Closing” function, only button 2-4. (Remote Control functionality is disabled).

protection devices, such as the photoelectric sensors, detect an obstacle.

open or close command.

Pre-Flashing: After an opening or closing command, the flashing light, connected to 10-5, starts flashing before the gate begins to

un. Pre-flashing can be enabled using the FUNCTIONS menu and the timing period can be set using the TIMING ADJ menu, however,

r

when the gate is closed and pre-flashing is enabled the opening will be delayed for the duration of the pre-flashing period but the

light will not start flashing until the gate starts moving.

Ram Blow: Before opening the gate(s) will press onto the mechanical endstop for a few seconds, to help release the electrolock (to set the

time, see “Ram timing” in the Adjust Timings menu).

Total Stop: This function stops the gate and consequently excludes any automatic closing cycle; for movement to Resume, you need

o use the keypad or remote control. Insert entrapment protection device on [1-2] if used, select “Deactivated” if unused.

t

CX Input: The N.C. safety contact input can take on the following functions: C1 (re-opening when closing), C2 (re-closing when

pening), C3 (partial stop), C4 (obstacle stall), C7 (re-opening when closing, for sensitive edges), C8 (re-closing when opening, for

o

sensitive edges) or, be deactivated. Refer to entrapment protection devices.

CY Input: Safety contact input can take on the following functions: C1 (re-opening when closing), C2 (re-closing when opening), C3

artial stop), C4 (obstacle stall), C7 (re-opening when closing, for sensitive edges), C8 (re-closing when opening, for sensitive edges)

(p

or, be deactivated. Refer to entrapment protection devices.

CZ Input: Safety contact input can take on the following functions: C1 (re-opening when closing), C2 (re-closing when opening), C3

artial stop), C4 (obstacle stall), C7 (re-opening when closing, for sensitive edges), C8 (re-closing when opening, for sensitive edges)

(p

or, be deactivated. Refer to entrapment protection devices.

Closing thrust: At the endpoint stage during closing, the gearmotors perform a final closing-thrust of the doors for a few seconds.

Lock: To lock the gate(s).

- Encoder: Managing decelerations, obstacle detection and sensitivity (default function): (AX3024U, AX5024U, FROG-A24E, A1824U, FROGJU, F7024E)

- Slow run: Decelerations when opening and closing.

cap-RallCh.: End stop when opening and deceleration when closing.

- F

- Time of Run: Timed end stop.

- Limit switch (endstop): Opening and closing endstop.

Endstop: C

function in the FUNCTIONS menu.

Command 2-7: Setting the 2-7 contact to step-by- step mode (open-close) or sequential (open-stop-close-stop).

Co

the time set on “Partial opening” from the Adjust Times menu).

onfigure the endpoints are normally closed or open contacts. NOTE: This function appears only if selected from the “Config.”

mmand 2-3P: Setting the 2-3P contact to opening (second gate opens fully) or partial (second gate opens partially depending on

MENU DESCRIPTIONS

21

Page 23

PROGRAMMING

MAIN MENU SUB MENU DESCRIPTION

FUNCTIONS (continued...) The functions menu determines how your operator will function.

Lamp E E Lamp: Setting up the flashing light or cycle lamp or courtesy lamp connected on 10-E:

- Courtesy Light: Outdoor lamp that can be freely positioned, for additional lighting of the driveway - stays on for 5 minutes.

- Cycle: Outdoor lamp, which can be positioned at leisure, for better illumination in the parking/driveway area. The light stay

the moment the gate begins to open, until it is fully closed (including automatic closing time).

If the automatic closing function is not enabled, the light stays on only during gate movement.

- Flashing Light: Signals the gate opening or closing movement.

Output B1-B2

Imp. Run Gate-Run Setting Menu

No. Motors

Motor type

B1-B2 Output: S

Number of Motors: Set the number of motors, either one or two, depending on the number of gate(s) installed on the system (M1 &

M2 setting is for dual gates, M2 is for single gate).

Motor Type: Select FROG for the motor type.

etting contact B1-B2 to MONO-STABLE or BI-STABLE (switch) mode.

MENU DESCRIPTIONS

s on from

High Speed %

Low Down Spd

Soft Start

Sens. Amperom

Run Amperom

Slow down time Deceleration Time: Gate leaf deceleration time before each endpoint. The time can be set anywhere between 0” to 30”.

% Speed of Action: Setting up the speed during gate operation, expressed as a percentage between 20% and 100%.

% Speed of Deceleration: Setting up the deceleration speed, expressed as a percentage between 5% and 50%.

Delayed Start: A

Amperometric Sensitivity: T

When the amperometric sensitivity is on, and an obstacle is detected, depending on the configuration, the gearmotor works in the f

ways:

- timed endpoint: it stops while performing a gate run;

- end point: it inverts direction of travel during operation;

- decelerations: it inverts direction of travel during operation, while during the deceleration phase it stops;

- Fcap-RallCh.: it inverts direction of travel during operation, while during the deceleration phase it only stops when on a closing run.

When the amperometric sensitivity is off, and an obstacle is detected, the gearmotor stops when the maximum current threshold is

exceeded (i.e. overload).

NOTE: T

his function appears only if the “encoder” function is not selected in the FUNCTIONS menu.

Gate Run Amperometrics: Setting the gearmotor sensitivity in the presence of obstacles.

NOTE: This function only appears if the amperometric sensitivity is selected (not with encoder configuration).

his function only appears if the decelerations and Fcap-RallCh. are selected.

NOTE: T

TIMING ADJ. Time setting menu

ACT

Partial ACT

Cycle Time

Op. Delay M1

CI. Delay M2

Lock Time

Ram hit time

Slow down time Partial Opening: Opening time of the second (M2) gate leaf. The time can set between 5 and 60 seconds.

Automatic closing: To set the waiting time when gate is in the open position. Once this time is elapsed, the gate closes automatically.

The waiting time can be set to between 0” and 300”.

Automatic Partial Closing: Waiting time of the (M2) second gate when in the open position. Once this time interval has elapsed, the

gate automatically closes. The waiting time interval can go anywhere from 0” to 300”.

Cycle Time: The working time of the motor during opening or closing phases is anywhere from 10” to 150”.

M1 Delayed Opening: The waiting time of the (M1) first gate lead, unlike the (M2) second one, after each opening command. The

waiting time can be set to between 0” and 10”.

M2 Delayed Closing: The waiting time of the (M2) second gate leaf, unlike the (M1) first one, after each closing command.

The waiting time can be set to between 0” and 60”.

Lock Time: The time required for releasing the electro-lock after each opening command. The time of operation can be set to between 1”

and 5”.

Ram blow time: The gearmotorʼs thrust time when fully closing and opening after each command .The thrust time can be set to between

1” and 3”.

fter an open or close command, the gate(s) start at a slow speed for a few seconds.

he level of gearmotor sensitivity in the face of obstacles during operation.

ollowing

22

Page 24

PROGRAMMING

MAIN MENU SUB MENU DESCRIPTION

USERS The USERS menu is used to program remote controls.

Add User

Add User: To create a new user and assigned function (max. 250 users).

MENU DESCRIPTIONS

Mod. name

Mod. code

Related Func

Remove Usr.

Delete all Usr

Backup data

Restore backup

Mod. Name: To change a user number or existing name to another name.

Mod Code: To change a userʼs current code.

Related Function: To change the function assigned to the user.

Remove User: To remove an existing user. Confirm the use you wish to remove with the ENTER button.

Delete all users: To cancel all registered users. Confi rm cancellation of all users with ENTER button.

Backup data: To save the users in the memory roll. Confi rm saving of users on the memory roll with ENTER button.

Restore backup: To load the data saved on the memory roll onto card (if the card is of the same version it loads both users and

settings, otherwise it only loads the users).

INFO Info Menu

Version

Version: To view software version.

Number of gate runs: To view the number of runs performed by the operator.

Standby Mssg: To view the starting message, confirm with ENTER to change text. Use the ENTER button to move the cursor forward,

SC to move it backwards and <> to select the letter of number. Confirm the text by pressing the ENTER key for a few seconds.

E

System reset: Resets the system to the original factory settings. Press ENTER key to confirm.

TEST MOT. Motor Test Menu

TEST MOT.

MOT TEST.: The MOT test checks that gearmotors are rotating in the proper direction.

: Gate leaf opening run of the first (M1) gearmotor. If the direction is wrong, invert the motorʼs p

M1

M2: Gate leaf opening run of the second (M2) gearmotor. If the direction is wrong, invert the motorʼs p

hases.

hases.

23

Page 25

ADJUSTMENTS

Curved Arm

Motor Arm

Bolt

Nut

Curved Arm

Motor Arm

Bolt

Nut

ADJUST THE BOLT IN THE MOTOR ARM + ADJUST THE LIMITS

ADJUST THE BOLT IN THE MOTOR ARM

Electronically shut the gate against the closing end stop. Adjust the bolt until it

1

touches the curved arm.

When testing, adjust the screw to allow proper closing pressure of the gate

2

and allow the gate to reconnect when manually released.

Once the adjustment is complete, secure the nut.

3

Left-Hand Installation

Right-Hand Installation

ADJUST THE LIMITS

BRAKE MICROSWITCHES

Run the operator so the gate is a maximum of 20 inches from being fully

1

opened.

Position the microswitches close to the magnet. Ensure the close limit

2

microswitch is positioned so the operator starts to slow down within the last six

inches of gate travel. This type of end stop reads the magnetic field. You may

have to repeat the procedure to increase the precision of the adjustment.

20”

Endstop

holding plate

(Right-Hand Installation)

Microswitch (Open Limit)

Magnet

Microswitch (Close Limit)

24

Page 26

ADJUSTMENTS

MANUAL RELEASE

The manual release allows you to manually open or close the gate. The manual

release allows the gate to hook back up when closing. Manual release operations

need to be carried out during emergency procedures and with the power

disconnected.

Refer to the individual manual release instruction for more information.

MANUAL RELEASE + TEST PHOTOELECTRIC SENSORS

Manual Release

TEST PHOTOELECTRIC SENSORS

Each open/close command, the electronic card verifies the photoelectric

sensors are connected and working. Any problems with the photoelectric

sensors will cause the (PROG) LED to flash on the electronic card, which

cancels any commands from the remote control or push-button.

Electrical connection to operate the photoelectric sensors safety test:

1

• Connect the transmitter and receiver as shown in the diagram.

From the functions menu, select “Safety Tests” and select either CX - CY - CZ

2

inputs to activate the test.

After all adjustments have been completed, attach the cover to the

operator with the provided screws.

DIR10 Photoelectric Sensors:

#

48

.#

48

25

Page 27

MAINTENANCE

MAINTENANCE CHART

MAINTENANCE CHART

Disconnect all power to the operator before servicing.

DESCRIPTION TASK CHECK AT LEAST ONCE EVERY

MONTH 6 MONTHS 3 YEARS

Entrapment Protection Devices Check and test for proper operation X

Warning Signs Make sure they are present X

Manual Disconnect Check and test for proper operation X

Gate Inspect for wear or damage and lubricate as needed X

Accessories Check all for proper operation X

Electrical Inspect all wire connections X

Chassis Mounting Bolts Check for tightness X

Operator Inspect for wear or damage X

NOTES:

• Severe or high cycle usage will require more frequent maintenance checks.

• Limits may have to be reset after any major gate adjustments.

• It is suggested that while at the site voltage readings be taken at the operator.

Using a digital voltmeter, verify that the incoming voltage to the operator it is

within ten percent of the operator’s rating.

26

Page 28

MAINTENANCE

MAINTENANCE LOG + ADDITIONAL SERVICES

ADDITIONAL SERVICES

Use the table below to log any additional services, repairs or modifications performed by a PROFESSIONAL TECHNICIAN:

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed:

____________________________________________________________________________________________

___________________________________________________________________________________________

___________________

Installer’s stamp Operator name

Job performed: ____________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________

_________________________________________________________________________________

Date of job

Technician’s signature

Requester’s signature

27

Page 29

TROUBLESHOOTING

MALFUNCTION POTENTIAL CAUSE CHECK AND REMEDIES

The gate will not open or close • There is no power

• The operator is in manual release mode.

• The remote control batteries are run down

• The remote control is broken

• The stop button is either stuck or broken

• The opening/closing button or the key selector are stuck

• Photoelectric sensors in partial stop mode

The gate opens but will not close • The photoelectric sensors are engaged

• Edge sensor triggered

The gate closes but will not open • Edge sensor triggered • Call assistance

The flasher does not work • The bulb is burnt • Call assistance

• Check that the power is on

• Reconnect operator

• Replace batteries

• Call assistance

• Call assistance

• Call assistance

• Call assistance

• Check that photoelectric sensors are clean and in

good working order

• Call assistance

TROUBLESHOOTING

DISPOSAL

DISPOSAL OF PACKING MATERIALS

The packing components (cardboard, plastic, etc.) are solid urban waste and may be

disposed of without any particular difficulty, by simply separating them so that they

can be recycled.

Before acting always check the local laws on the matter.

DO NOT DISPOSE OF IN NATURE!

DISPOSAL OF PRODUCT

Our products are made using different types of materials. The majority of them

(aluminium, plastic, iron, electric cables) can be considered to be solid urban waste.

They may be recycled at authorised firms. Other components (electrical circuit board,

remote control batteries etc.) may contain hazardous waste. They must, thus, be

removed and turned in to licensed firms for their disposal.

Before acting always check the local laws on the matter.

DISPOSAL

DO NOT DISPOSE OF IN NATURE!

28

Page 30

REPAIR PARTS

Item Description Part Number

1 Curved Lever 119RIA046

2 Motor Arm 119RIA045

3 Endstop Assembly Support 119RIA058

Endstop Assembly 119RIA057

4 Gear Motor Box 119RIA013

5 Motor 119RIA088

6 Slow Shaft 119RIA015

7 Worm Gear 119RIA016

8 Lower Flange 119RIA014

9 Limit Switch Assembly with Switch 119RIA059

NOT SHOWN-

Control Panel- case only 119RTR375

Transformer 119RIR374

Electronic card (ZLJ24U) 3199ZLJ24U

Security+ 2.0™ Radio Card AF43CH

1

5

2

3

9

4

6

7

29

8

Page 31

WARRANTY

MANUFACTURER’S 3-YEAR LIMITED WARRANTY

VERIFICATION OF THE WARRANTY PERIOD REQUIRES COPIES OF RECEIPTS OR OTHER PROOF OF PURCHASE.

WARRANTY CANNOT BE HONORED WITHOUT PROOF OF PURCHASE. PLEASE RETAIN THOSE RECORDS.

Came Americas Automation, LLC (“CAME®”) products are warranted by CAME® against defects in materials and manufacturer workmanship for a period of thirty-six (36)

months from the date of purchase, provided the recommended installation manual and procedure have been followed. CAME®’s sole obligation under this warranty is limited

to repairing or replacing, at our option, any parts which shall be determined by CAME® to be defective, and is conditioned upon CAME® receiving notice of any such defect

within the warranty period. Claims under this warranty may only be made by a purchaser of CAME® products (the “Customer”).

®

CAME

reserves the right to make the final determination as to whether there is a defect in the materials and/or workmanship, and whether or not a product is within the

warranty period. CAME

abuse, or modifications not authorized by CAME® or for any damages which may arise out of the use of CAME® products.

CAME® sells its products through authorized distributors. This warranty on CAME® products is NOT VALID if the products have been purchased from an unauthorized

distributor, reseller, online E-tailer ( e.g., E-bay®), or if a product serial number has been altered, removed, or replaced in any way. To verify that you are buying from an

authorized CAME distributor or reseller please call 1-800-528-2806.

In the case of product failure due to defective material or manufacturer workmanship within the thirty-six (36) months warranty period, the product will be repaired or

replaced (at the manufacturer’s option) at no charge to the Customer, if returned, freight prepaid, to CAME AMERICAS AUTOMATION, LLC, 11345 NW 122nd Street Medley,

Florida 33178.

IMPORTANT: Obtain a Return Goods Authorization (RGA) number before returning item(s) to our facilities by submitting a warranty claim and request for RGA with our

customer service department. Products shipped without an RGA number will not be accepted. Replacements or repaired parts are covered by this warranty for the remainder

of the thirty-six (36) month warranty for the original product or six (6) months from the date of repair or replacement, whichever is greater. CAME® will pay shipping costs

at the ground transport rate for the return to owner of item(s) repaired under warranty.

®

is not responsible for any damages or other costs caused by, or which may result from installation, handling, non-recommended operation, product

The manufacturer will not be responsible for any charges or damages incurred in the removal of the defective parts for repair, or the reinstallation of these parts after repair.

Use of any (00021996.doc V.2) components that are not CAME® specified (e.g. batteries, light bulbs, drive belts, chains or transformers) will void the warranty. This warranty

shall be void if damage to the product(s) was due to improper installation or use, neglect, accident, use of non-CAME® specified or approved components or replacement

parts, connection to an improper power source, tampering, or if damage was caused by lightning strikes, power surges, wind, fire, flood, insects, or other natural agents or

disasters.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state (or jurisdiction to jurisdiction.) CAME’s responsibility for

malfunctions and defects in equipment is limited to repair and replacement as set forth in this warranty statement.

THE CUSTOMER ACKNOWLEDGES AND AGREES THAT THIS WARRANTY IS MADE EXPRESSLY IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES FOR THE PRODUCT(S),

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES AND CONDITIONS OF MERCHANTABLE QUALITY, MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR

ANY OTHER EXPRESS OR IMPLIED WARRANTY ARISING OUT OF LAW, STATUTE, USAGE OF TRADE OR COURSE OF DEALINGS.

The warranty hereunder is limited in time to the term of the limited warranty period reflected in this limited warranty. No warranties, whether express or implied, will apply

after the limited warranty period has expired. Some states do not allow limitations on the term of an implied warranty, so this limitation may not apply to you.

For installation and service information call:

1-800-528-2806

Or visit us online at:

www.liftmaster.com

30

Page 32

845 Larch Avenue

Elmhurst, Illinois 60126-1196

01-36710C © 2012, The Chamberlain Group, Inc. – All Rights Reserved

Page 33

FROG-A 24U

ACTIONNEUR DE BARRIÈRE VÉHICULAIRE À PIVOTEMENT

MANUEL D'INSTALLATION

Votre modèle peut sembler différent de celui illustré dans ce manuel.

CE PRODUIT DOIT ÊTRE EXCLUSIVEMENT

INSTALLÉ ET ENTRETENU PAR UN

PERSONNEL DÛMENT FORMÉ SUR LES

SYSTÈMES DE BARRIÈRE.

Rendez visite à www.liftmaster.com pour

localiser le revendeur-installateur le plus

proche de chez vous.

Ce modèle est pour utilisation sur les barrières

de passage véhiculaire UNIQUEMENT et n'est

pas conçu pour utilisation sur les barrières de

passage piétonnier.

Ce modèle est conçu pour utilisation dans les

applications de barrière véhiculaire à

pivotement de Classe 1.

Page 34

TABLE DES MATIÈRES

SÉCURITÉ 1

REVUE DES SYMBOLES DE SÉCURITÉ ET DES MOTS DE SIGNALEMENT . . . . . . . . . . 1

CLASSIFICATIONS DU MODÈLE UL325 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INFORMATIONS SUR L'INSTALLATION SÉCURITAIRE . . . . . . . . . . . . . . . . . . . . . . . 3

RENSEIGNEMENT SUR LA CONSTRUCTION DE LA BARRIÈRE . . . . . . . . . . . . . . . . . 4

DISPOSITIFS DE PROTECTION CONTRE LE PIÉGEAGE EXIGÉS . . . . . . . . . . . . . . . . . 5

RENSEIGNEMENTS DE SÉCURITÉ IMPORTANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INTRODUCTION 7

SPÉCIFICATIONS DE L'ACTIONNEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INVENTAIRE DE L'EMBALLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DIMENSIONS DE L'ACTIONNEUR ET DU PANNEAU DE COMMANDE . . . . . . . . . . . . 8

PRÉPARATION 9

OUTILS ET MATÉRIAUX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TABLEAU DE CÂBLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PRÉPARATION DU SITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INSTALLATION DU BOÎTIER ENTERRÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FIXATION DU MOTEUR À ENGRENAGE ET ASSEMBLAGE DE L'ACTIONNEUR . . . . . 11

MONTAGE DU PANNEAU DE COMMANDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CÂBLAGE 13

VUE D'ENSEMBLE DU PANNEAU DE COMMANDE ET DE LA CARTE ÉLECTRONIQUE 13

CÂBLAGE DE OU DES ACTIONNEURS AU PANNEAU DE COMMANDE . . . . . . . . . . 14

CÂBLAGE DES DISPOSITIFS DE PROTECTION CONTRE LE PIÉGEAGE . . . . . . . . . . . 15

CÂBLAGE DES DISPOSITIFS DE PROTECTION CONTRE LE PIÉGEAGE . . . . . . . . . . . 16

PROGRAMMATION 18

UTILISATION DU MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

RÉGLAGES D'USINE (DÉFAUTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CONFIGURATION DE BASE POUR APPLICATIONS TYPIQUES . . . . . . . . . . . . . . . . 19

INSTALLER ET PROGRAMMER LA CARTE RADIO SECURITY+ 2.0™. . . . . . . . . . . . 20

DESCRIPTIONS DE MENUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

RÉGLAGES 24

RÉGLAGE DU BOULON DANS LE BRAS DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . 24

RÉGLAGE DES LIMITES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DÉGAGEMENT MANUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TEST DES CAPTEURS PHOTOÉLECTRIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ENTRETIEN 26

TABLEAU D'ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SERVICES SUPPLÉMENTAIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DÉPANNAGE 28

DISPOSITION 28

DISPOSITION DES MATÉRIAUX D'EMBALLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DISPOSITION DU PRODUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

PIÈCES DE RECHANGE 29

GARANTIE 30

CÂBLAGE OPTIONNEL 17

ALIMENTATION ACCESSOIRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DISPOSITIFS DE COMMANDE ET DE CONTRÔLE . . . . . . . . . . . . . . . . . . . . . . . . . 17

DISPOSITIFS D'AVERTISSEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SÉCURITÉ

REVUE DES SYMBOLES DE SÉCURITÉ ET DES

MOTS DE SIGNALEMENT

Lorsque vous verrez ces symboles de sécurité et ces mots de signalement sur les

pages suivantes, ils vous aviseront de la possibilité de blessures graves ou de mort si

vous ne vous conformez pas aux avertissements qui les accompagnent. Le danger

peut être de source mécanique ou provenir d'un choc électrique. Lisez attentivement

les avertissements.

Lorsque vous verrez ce mot-indicateur sur les pages suivantes, il vous alertera de la

possibilité de détériorations de la barrière et/ou de l'actionneur de barrière si vous

ne vous conformez pas aux avertissements l'accompagnant. Lisez-les attentivement.

REMARQUE IMPORTANTE

• AVANT d'essayer d'installer, de faire fonctionner ou d'assurer l'entretien du

dispositif de fermeture, vous devez lire et comprendre intégralement ce manuel et

appliquer toutes les instructions de sécurité.

• N'ESSAYEZ PAS de réparer ou d'entretenir votre actionneur de barrière à moins

d'être un technicien d'entretien agréé.

REVUE DES SYMBOLES DE SÉCURITÉ ET DES MOTS DE

SIGNALEMENT

AVERTISSEMENT

MÉCANIQUE

AVERTISSEMENT

ÉLECTRIQUE

ATTENTION

1

Page 35

SÉCURITÉ

CLASSIFICATIONS DU MODÈLE UL325

CLASSE 1 – ACTIONNEUR DE BARRIÈRE VÉHICULAIRE

RÉSIDENTIEL

Un actionneur (ou système) de barrière véhiculaire conçu pour utilisation dans une

habitation de un à quatre logements individuels ou un garage ou une zone de

stationnement associé à celle-ci.

EXIGENCES DE PROTECTION CONTRE LE PIÉGEAGE

UL325

Ce tableau illustre les exigences de protection contre le piégeage pour les classes

UL325.

PROTECTION CONTRE LE PIÉGEAGE DE L'ACTIONNEUR DE BARRIÈRE

Classification UL325 Actionneur de barrière à pivotement

Type primaire Type secondaire

CLASSE I-CLASSE IV A B1 ou B2

Pour compléter une installation correcte, vous devez vous conformer au tableau

de protection contre le piégeage montré. Ceci signifie que l'installation doit avoir

un moyen primaire de protection contre le piégeage et un moyen secondaire

indépendant de protection contre le piégeage. Les deux méthodes de protection

contre le piégeage primaire et secondaire doivent être conçues, arrangées et

configurées pour protéger contre le piégeage tant dans la direction ouverture que

dans la direction fermeture du déplacement de la barrière.

Par exemple: Pour un système de barrière qui est installé sur une résidence

unifamiliale (Classe I UL325) vous devez fournir les éléments suivants: Comme

principal type de protection contre le piégeage, vous devez fournir

• Type A - Détection de piégeage inhérente (intégrée à l'actionneur) et au

moins un des éléments suivants comme protection secondaire

contre le piégeage :

• Type B1 - Capteurs sans contact comme des capteurs photoélectriques,

• Type B2 - Capteur à contact comme des arêtes de barrière

CLASSIFICATIONS DU MODÈLE UL325

REMARQUE : UL exige que toutes les installations aient des panneaux

d'avertissements placés bien en vue des deux côtés de la barrière pour avertir les

piétons des dangers des systèmes de barrière motorisée.

2

Page 36

SÉCURITÉ

INFORMATIONS SUR L'INSTALLATION SÉCURITAIRE

INFORMATIONS SUR L'INSTALLATION SÉCURITAIRE

1. Les systèmes de barrières véhiculaires fournissent commodité et sécurité. Les systèmes de barrières se composent de plusieurs pièces. L'actionneur de barrières n'est

qu'une des composantes. Chaque système de barrière est conçu spécifiquement pour des applications individuelles.

2. Les concepteurs, installateurs et utilisateurs des systèmes de barrières doivent tenir compte des dangers possibles associés à chaque installation individuelle. Une

conception, installation ou entretien inapproprié peuvent engendrer des risques pour les utilisateurs ainsi que les passants. La conception ainsi que l'installation doivent

réduire l'exposition du public à des risques de danger potentiels.

3. Un actionneur de barrière peut générer de hauts niveaux de force lors de son fonctionnement en tant que composante d'une partie du système de barrière. Des

caractéristiques de sécurité doivent donc être incorporées lors de chaque conception. Les caractéristiques en sécurité comportent :

• Arêtes de barrière • Gardes pour rouleaux exposés

• Capteurs photoélectriques • Mailles d'écrans

• Poteaux verticaux • Panneaux indicateurs pour instructions et avertissements