Camco Residential Electric water heater Troubleshooting Manual

2 3

90˚F

150˚F

125˚F

90˚F

150˚F

125˚F

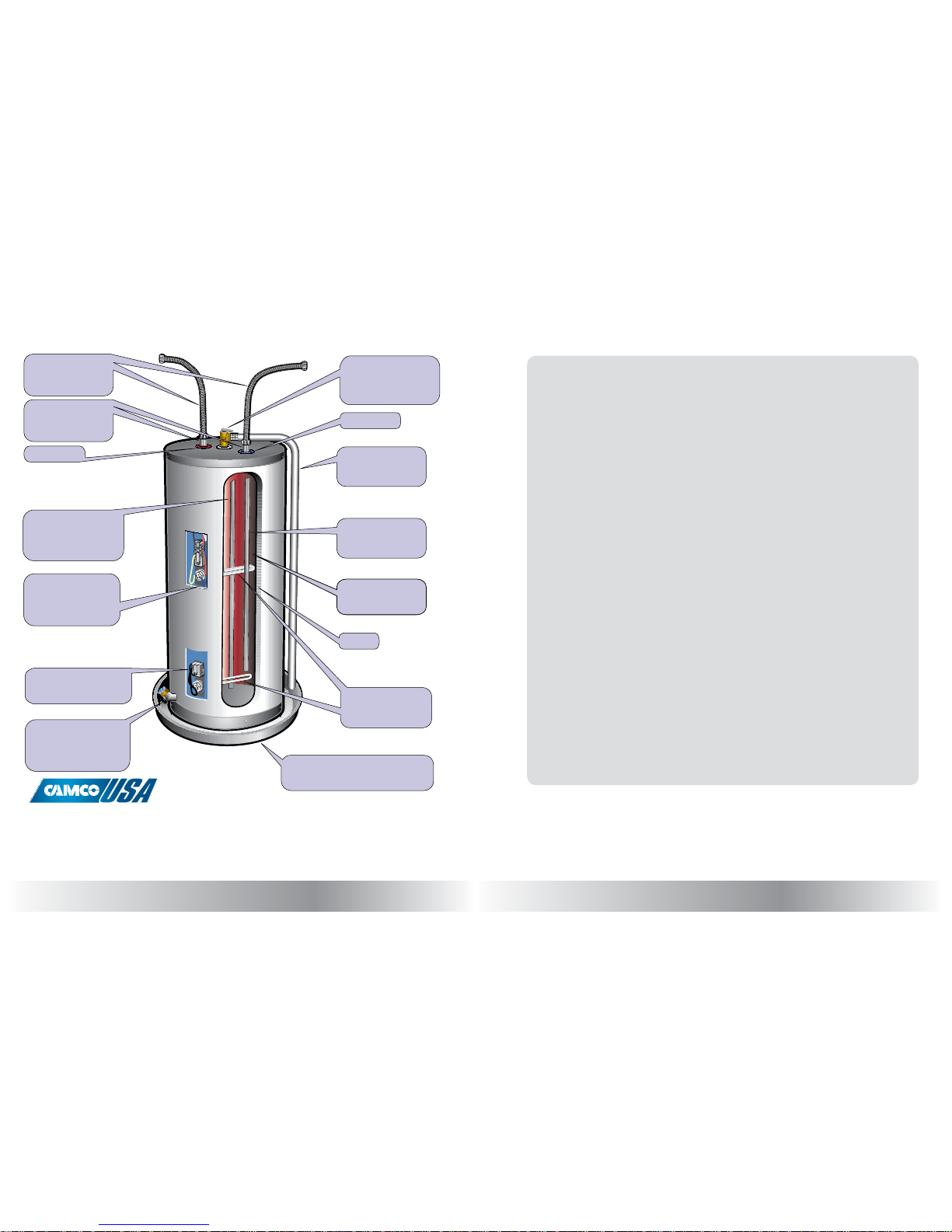

Residential Water Heater Construction

Table of Contents

Drain valve— a metal or plastic

valve used when draining

heater for periodic cleaning or

replacement of a defective water

heater element

Lower thermostat— controls

lower heating element to

maintain desired temperature

Upper thermostat— turns

heating elements on or off

to maintain preset or desired

temperature; regulates power

to the lower thermostat

Anode rod— a rod

composed of sacrificial metal

that prevents deterioration of

the steel tank and elements

by controlling electrolysis

Hot water outlet

Dielectric nipples or

Heat Traps with

thermoplastic lining—

prevents thread corrosion

Flexible stainless steel

or copper connectors—

connects to hot and cold

water pipe system

Drain pan— plastic or metal pan to collect and

drain off leaking water or water from activated

T & P valve; must be plumbed to drain

Heating element—

a resistant type electrical

component to generate heat

Insulation

Steel tank with glass

lining—

to prevent corrosion

Cold water dip tube—

a non-metallic tube that

directs incoming cold water

to the bottom of the tank

Run-off tube— carries

water or steam safely to

drain or drain pan if T & P

valve activates

Cold water inlet

Temperature and pressure

(T & P) valve— safety device

to relieve excessive pressure

and/or temperature buildup

in tank

Limited Warranty: Elements will be replaced to the original purchaser if proven defective in materials or workmanship. No labor

costs are included in this warranty. Complete warranty information available upon request. Warranty is void if element is installed in

anything other than a residential hot water heater.

Standard and Better Elements – 1 year from purchase date.

Premium Elements – 5 years from purchase date.

Our return policy is limited to the replacement of original purchase. No other liability, responsibility or warranty is expressed or implied, including any regarding merchantability or suitability for a particular purpose.

Residential Water Heater Construction .............................................................2

Choosing the Correct Heating Element .............................................................4

Element Flange Styles .......................................................................................... 5

Thermostats ............................................................................................................7

Double Element Thermostats ..............................................................................8

Double Element Thermostat Wiring ...................................................................9

Single Element Thermostat Wiring ...................................................................10

Testing Elements and Thermostats for Failure ..............................................11

Dip Tubes, Run-off Tubes and Anode Rods ....................................................12

Drain Pans, Dielectric Nipples & Heat Traps, T & P Valves ........................13

Frequently Asked Questions about Water Heater Parts ...............................14

Troubleshooting Guide ........................................................................................16

Speciality Items ....................................................................................................18

4 5

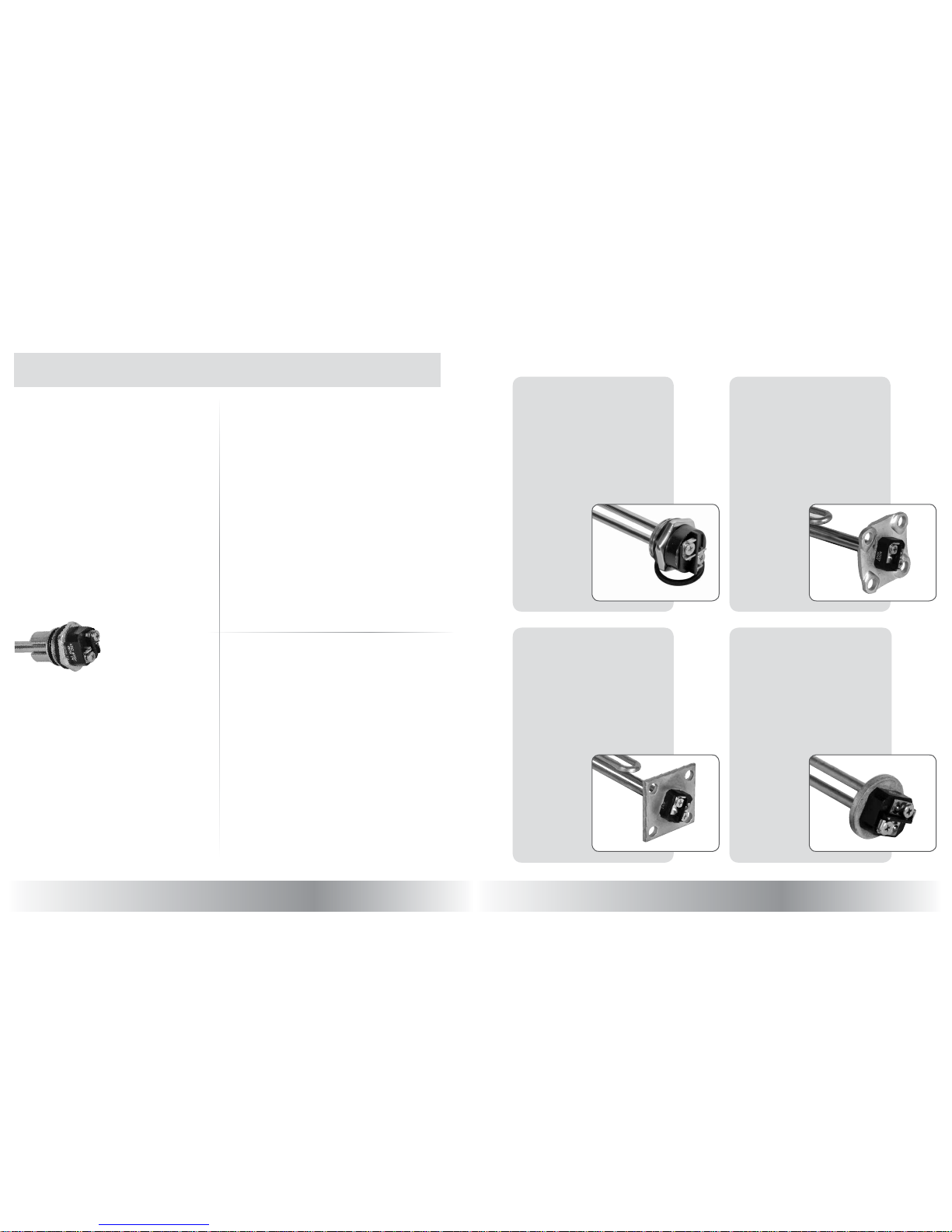

1. Element Flange Style

Water heater elements are offered in several styles.

Since the development of the modern water heater,

manufacturers have used various methods of installing

elements in their water heaters. There are still many of

these older units in operation today that have the older

style elements. The most common are the Universal

Flange, Flat Flange and the Round Head style. The

Universal and the Flat Flange elements are bolted to

the tank with four 3/8" bolts. The Round Head element

is secured to the tank with a separate 4-bolt flange.

Note: The Universal Adapter Kit (Camco #07223) will adapt

a screw-in style element to a bolt-in style element that can

replace the above elements.

Today, all manufacturers of residential water heaters use

only Screw-in style elements. This style provides for easy

installation and serviceability because it screws into a spud

welded directly on the tank of the water heater. The thread

is a 1" (diameter) x 11-1/2 NPSM thread and is standard for

all residential water heaters that use screw-in elements.

EXCEPTION: For a period

of time, State Industries

manufactured a Duron brand

heater that used a 1-3/8"

thread. These elements are

not interchangeable with the

standard 1" threaded element.

2. Voltages and Wattages

The majority of residential style water heaters use

240v power. The 120v elements are primarily used

for smaller water heaters, point-of-use heaters and

in locations where a 240v circuit is not available.

The wattage rating, which determines the heat

output, of the 240v elements can be anywhere

from 1000 watts to 6000 watts. The wattage rating

of 120v elements is 1000 watts to 2500 watts.

Each model water heater is designed for a specific

voltage/wattage rated element. The replacement

element must be the same voltage and wattage

as the element being replaced. Never exceed the

nameplate rating on the water heater.

Choosing the Correct Heating Element Element Flange Styles

When choosing the correct replacement element, three factors must be considered:

1. Element Flange Style (Screw-In, Flat, etc...) 2. Voltage/wattage 3. Watt-density

3. Watt-Density

Another significant difference that should be noted

when choosing a replacement element is the

watt-density construction. Whether the element is

120v or 240v, screw-in or bolt-in, there are three

watt-density ratings available. The watt-density

of an element is basically the amount of heat

concentrated on any point on the surface of

the element.

The lower the watt-density, the greater the amount

of element surface. The heat per square inch of the

surface is reduced, but the total surface is increased

so that the total heat of the element is the same for a

particular wattage. Generally, a lower watt-density in

an element would mean a longer expected life. The

lower watt-density elements normally last longer in

water with high lime content. It helps lower lime

deposit build-up. The fold-back feature of most low

watt-density and Lime Life elements is to keep the

length short enough to fit all tanks.

STANDARD:

Regular High Watt-Density Element

Most common; same as original equipment provided with

most water heaters. It is the least expensive. Can be used in

all replacement situations if the same wattage and voltage

are used.

BETTER: Low Watt Density Element

Most are fold-back elements. Better suited for areas with

problem water (hard water, lime, etc). The lower wattdensity provides no loss of efficiency, yet reduces lime

deposit build-up. Can be used to replace any high wattdensity element if same wattage and voltage are used.

Normally it is more expensive than high watt-density.

PREMIUM: Lime Life Element

Carries a limited 5 year warranty. Ultra low watt-density and

special metal surface (premium grade nickel and stainless

steel) reduce chances of lime build-up. Also resists dryfiring. Ideal for problem water areas and locations with

intermittent water supply. Higher initial cost, but may last

the life of the water heater.

Screw-In Flange

Fits most GE, Rheem, Rudd, Richmond,

Montgomery Ward, Sears/ Kenmore,

State, Norge, Westinghouse, Reliance,

Noland, A.O. Smith, Bradford White,

GS Wood, Maytag, Whirlpool and

Duro-Matic water heaters, some

Mor-Flo, American and Craftmaster

prior to 1991 and all water heaters

manufactured after 1994.

Universal Flange

Fits older Bradford-White, U.S. Water

Heater, most D&R, Day and Night,

Briggs, Jackson, Tennessee Tank and

early models of State and A.O. Smith.

Round Head Style

Fits July 1975 or older models of State,

Reliance, Sears, J.C. Penney, Crane and

some A.O. Smith. Camco no longer

stocks this style. To replace this style,

use a Screw-In Flange element with a

Universal Adapter Kit (#07223).

Flat Flange

Fits most older Mor-Flo, American,

Craftmaster, some older State, Reliance,

Rheem, Rudd, Richmond, Montgomery

Ward, Norge, Intertherm and

Westinghouse models. Fits some Briggs,

Bradford-White, U.S. Water Heater,

Republic, Day and Night, Jackson,

Tennessee Tank and Duro-Matic.

6 7

Thermostat Settings

All residential thermostats are factory

preset at 120°. This is a safe, energyefficient setting. If a higher or lower

setting is desired or required, the

thermostat dial may be turned to the

new setting. A flat head screwdriver

may be needed to turn the dial.

Use caution when setting to higher

setting. Scalding can occur.

Therm-O-Disc thermostats have the

temperature settings marked on the

dial. Apcom thermostats do not have

the temperatures on the dial.

Apcom settings:

White Dot = 110° F

Hot = 120° F

A = 130° F

B = 140° F

C = 150° F

Very Hot = 160° F

The settings on both the Apcom and

the Therm-O-Disc thermostats are

accurate to +/- 5° F.

Thermostats

Double Element Water Heaters

The majority of residential water

heaters are designed with two elements

controlled by two different thermostats.

(See drawings on pages 8–9.) The upper

thermostat is the “brain” of the water

heater. It controls the heat generated

by the upper and lower element. Most,

if not all, residential water heaters are

designed to have the upper and lower

thermostats work separately. The lower

element provides the main heat supply.

The upper and the lower thermostats

never operate simultaneously.

The upper thermostat has a safety

device attached to it called a High Limit

Control (HLC). It has a heat sensor that

will shut down the power to the heater

if the temperature of the tank exceeds

safety limits. The button may be reset to

restore power to the heater.

Do not reset the HLC until the problem

causing the unit to trip is corrected.

Operation Cycle of Double Element Water Heaters

1. The upper thermostat senses cold

water and has energized the upper

element. Although contacts on both

thermostats are normally closed

in response to the cold water, the

double throw upper thermostat

completes the circuit only to the

upper heating element. Because of

the double throw action, power to

the lower thermostat is cut off.

2. As the upper element operates,

it heats the water above it

(approximately one quarter of the

tank’s capacity).

3. The water in the upper quarter of

the tank is heated until it reaches

the temperature set on the upper

thermostat. The upper thermostat

then breaks the circuit to the upper

heating element and completes the

circuit to the lower thermostat.

4. The lower element then operates and

heats the remainder of the water in

the tank.

5.

The lower thermostat breaks the

circuit to the lower element when

the water in the lower portion of

the tank has been heated to its set

temperature. The entire tank is now

filled with hot water.

6. As hot water is drawn from the top

of the tank, cool water comes in at

the bottom through the dip tube.

The lower thermostat reacts to the

entering cold water by closing its

contacts, energizing the lower heating

element and heating the water as it

enters the tank.

7. Thermostats are factory preset

at 120°F.

High watt-density and low watt-density elements are

manufactured with a resistance coil wire imbedded in

a magnesium oxide material covered by copper tubing.

Water heater elements are designed to operate only in

water. Dry-firing (applying power to an element with

inadequate or no water in the tank) raises the internal

and tubing temperatures on the copper element to cause

melt-down of the sheath and failure of the internal heating

resistance wire. The expected life of a dry-fired copper

element is 30-45 seconds. In a dry tank the element

temperature may reach 1900 to 2000° F.

Lime Life elements are manufactured of

premium grade nickel and stainless steel

and will resist dry-firing.

Evidence of Dry-Firing

1. The element shaft is annealed so soft you can bend it

with your fingers.

2. Shows evidence of melting.

3. Plastic terminal block melted, even slightly, indicates

that you have positive proof that element was dry-fired.

An immersion element that has been dry-fired has

been misused and therefore is not covered by any

manufacturer’s warranty.

NOTE: A melted sheath can also be caused by

an electrical storm, which is obviously not a

defect in material or workmanship and is therefore

not covered by warranty.

Dry-Fired Elements

Dry-fired means the element operated without being

immersed in water.

We bring this to your attention with the hope that

it will be of some value to you, as it might avoid the

cost and effort of returning the elements.

1

2

4

3

Exhibit A

Element Conversion Kit

Use a standard screw-in element to replace a flat,

universal or round flange element using the Element

Conversion Kit.

This adapter kit is intended for use with a screw-in type

element to replace water heater elements that look like

figures 1, 2 or 3.

Directions:

1. Remove screws and discard old element

and thermostat bracket.

2. Install screw-in element and gasket supplied with element

into square adapter flange. Tighten firmly.

3. Install gasket (supplied with this kit) in element seat, being

careful to ensure a good seat. See diagrams above to

determine which gasket to use.

4. Install element with new thermostat bracket using old

screws or new ones provided. Be careful that screws

are not too long and bottom out against the tank.

Fig. 1: Universal Fig 2: Flat

Fig 3: Round

Element Removal

A long socket wrench is needed to remove and install the

Screw-in style elements. The Camco element wrench

(#09943, 09951, 09883) is designed specifically for the

standard and the Duron screw-in elements.

Replacement gasket goes here.

Apcom Style

Therm-O-Disc Style

Loading...

Loading...