Page 1

LTR20121002, Rev. A

12/30/11

Page 2

Preparing for Your New Inground Spa

Diverter Knobs.......................29

Inground Spa Installation Checklist.......4

Planning the Best Location For Your Spa...4

Planning the Best Place for the Outdoor

Equipment Pack.......................5

Inground Spa Site Preparation...........5

Spa Shell Dimensions and Side Views .....6

Electrical Requirements – US and Canada 13

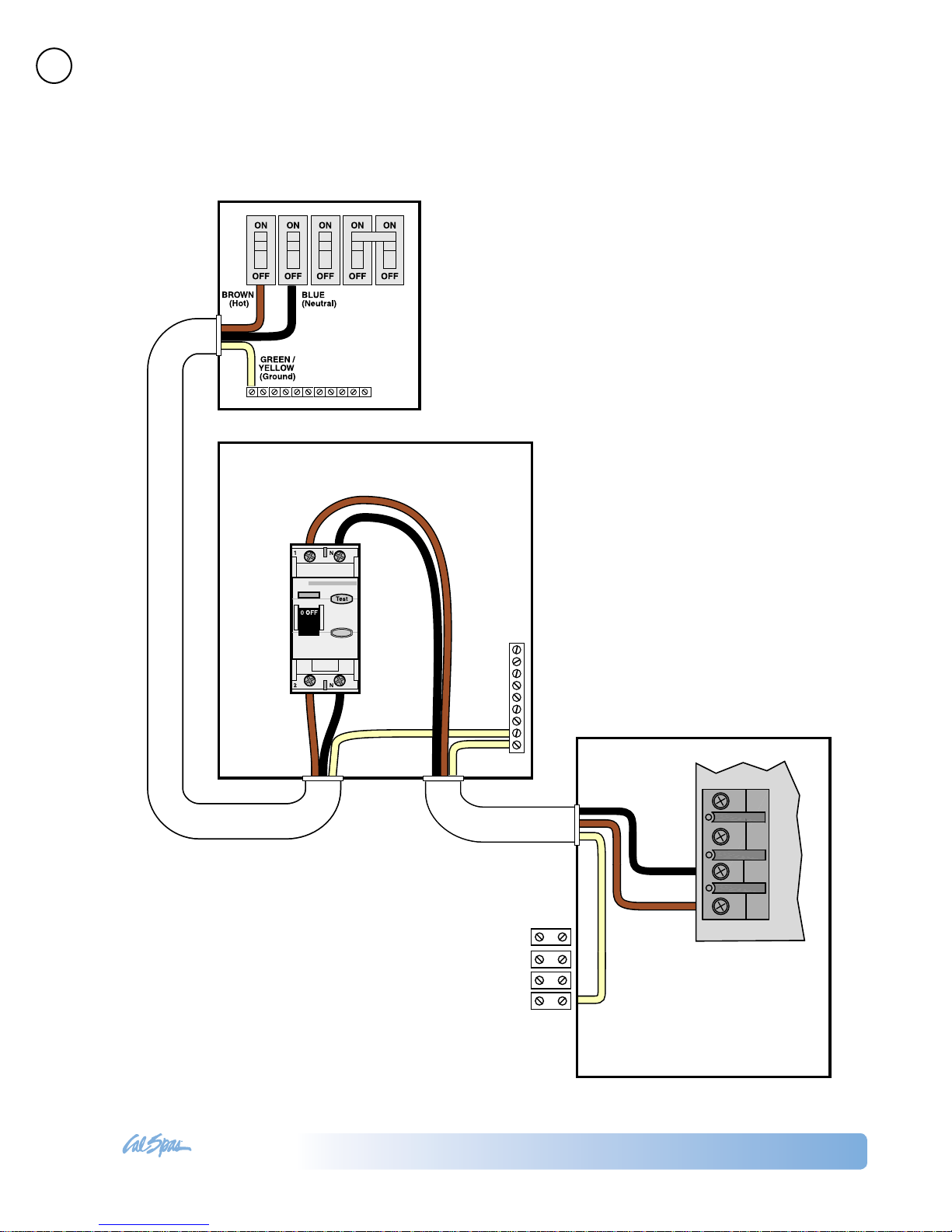

GFCI Wiring Diagram .................14

Electrical Installation -- Europe.........15

RCD Wiring Diagram ..................16

Installing the Inground Shell ...........17

Equipment Pack Plumbing Connections...18

Plumbing Connections ................18

Electrical and Electronic Connection .....20

Pouring the Deck.....................23

9800 Electronic Control Operation

Clear Water Plan

The Key to Clear Water ................30

Testing and Adjusting Spa Water........31

Sanitation...........................32

Filter Cleaning .......................33

Bather Load . . . . . . . . . . . . . . . . . . . . . . . . .34

Starting the Spa with Fresh Water.......34

Maintenance Schedule ................35

Cleaning and Maintenance

Removing and Reseating the Pillows.....36

Spa Cover...........................36

Draining Your Spa ....................37

Cleaning and Replacing the Filter........37

Winterizing (Cold Climate Draining) .....37

Cleaning Your Spa ....................38

Appendix

Diagnostic Messages..................27

Adjustable Jets ......................29

Copyright 2011 LMS, Inc. All rights reserved. Duplication without written consent is strictly

prohibited.

Cal Spas® is a registered trademark.

Due to continuous improvement programs, all models, operation, and/or specications are

subject to change without prior notice.

Replacement Parts ...................39

Warranty ...........................39

LTR20121002, Rev. A

12/30/11

100-1074

CONTACT INFORMATION

For customer service, please contact

your authorized dealer immediately. If

you need additional information and/

or assistance, please contact:

LMS Customer Service Department

1462 East Ninth Street

Pomona, CA 91766.

Toll Free: 1-800-CAL-SPAS

Fax: 1-909-629-3890

www.calspas.com

Page 3

www. c al sp a s. co m

Important Safety Instructions

When installing and using this electrical equipment,

always follow basic safety precautions. Following

these instructions will help make your rst spa session a pleasurable one.

104˚F (40˚C) are considered safe for a healthy

adult. Lower water temperatures are recommended

for young children and when spa use exceeds 10

minutes.

3

Read This First!

READ AND FOLLOW ALL INSTRUCTIONS

NOTE: A licensed electrician may be required to upgrade your standard receptacle and/or circuit breaker.

DANGER -- RISK OF ACCIDENTAL DROWNING: Do not allow children to be in or around a spa

unless a responsible adult supervises them. Keep

the spa cover on and locked when not in use. See

instructions enclosed with your cover for locking procedures.

DANGER -- RISK OF INJURY: The suction ttings

in this spa are sized to match the specic water ow

created by the pump. Should the need arise to re-

place the suction ttings, or the pump, be sure the

ow rates are compatible.

DANGER -- RISK OF INJURY: Never operate the

spa if the suction tting or lter baskets are broken

or missing.

DANGER -- RISK OF INJURY: Never replace a

suction tting with one that is rated less than the

ow rate marked on the original suction tting.

DANGER -- RISK OF ELECTRIC SHOCK: Install

the spa at least ve feet (1.5 meters) from all metal

surfaces. As an alternative, a spa may be installed

within 5 feet of metal surfaces if each metal surface

is permanently bonded by a minimum #8 AWG solid

copper conductor to the outside of the spa’s control

box.

DANGER -- RISK OF ELECTRIC SHOCK: Do

not permit any external electrical appliances, such

as lights, telephones, radios, televisions, and etc.,

within ve feet (1.5 meters) of the spa. Never attempt to operate any electrical device from inside

the spa. This does not apply to lights built in to the

spa as factory options from Cal Spas™.

WARNING -- RISK OF INJURY

The spa water should never exceed 104˚F (40˚C).

Water temperatures between 100˚F (38˚C) and

High water temperatures have a high potential for

causing fetal damage during pregnancy. Women

who are pregnant, or who think they are pregnant,

should always check with their physician prior to spa

usage.

The use of alcohol, drugs or medication before or

during spa use may lead to unconsciousness, with

the possibility of drowning.

Persons suffering from obesity, a medical history of

heart disease, low or high blood pressure, circulatory system problems or diabetes should consult a

physician before using the spa.

Persons using medications should consult a physician before using the spa since some medications

may induce drowsiness while others may affect

heart rate, blood pressure and circulation.

Hyperthermia Danger

Prolonged exposure to hot air or water can induce

hyperthermia. Hyperthermia occurs when the inter-

nal temperature of the body reaches a level 3˚F to

6˚F above the normal body temperature of 98.6˚F

(or 2˚C to 4˚C above 37˚C). While hyperthermia

has many health benets, it is important not to allow

your body’s core temperature to rise above 103˚F

(39.5˚C). Symptoms of excessive hyperthermia in-

clude dizziness, lethargy, drowsiness and fainting.

The effects of excessive hyperthermia may include:

Failure to perceive heat•

Failure to recognize the need to exit spa or hot •

tub

Unawareness of impending hazard•

Fetal damage in pregnant women•

Physical inability to exit the spa•

Unconsciousness•

WARNING: The use of alcohol, drugs, or medication can greatly increase the risk of fatal hyperthermia.

Inground Spas

LTR20121002, Rev. A

Page 4

www. c al sp a s. co m

4

Preparing for Your New Inground Spa

Most cities and counties require permits for exterior construction and electrical circuits. In addition, some

communities have codes requiring residential barriers such as fencing and/or self-closing gates on property to

prevent unsupervised access to the property by children. Your dealer can provide information on which permits

may be required and how to obtain them prior to the delivery of your Cal Spa.

Inground Spa Installation Checklist

Before Delivery

Planning the Best Location For Your Spa

Preparing for Your New Inground Spa

Safety First

Do not place your spa within 10 feet (3 m) of overhead power lines.

Make sure the spa is positioned so that access to the

equipment compartment and all side panels will not

be blocked. Be certain that your installation will meet

all city and local safety codes and requirements.

Consider How You Will Use Your Spa

How you intend to use your spa will help you determine where you should position it. For example,

will you use your spa for recreational or therapeutic

purposes? If your spa is mainly used for family recreation, be sure to leave plenty of room around it for

activity. If you will use it for relaxation and therapy,

you’ll probably want to create a specic mood around

it.

Plan for Your Environment

If you live in a region where it snows in the winter

or rains frequently, place the spa near a house entry.

By doing this, you will have a place to change clothes

and not be uncomfortable.

Consider Your Privacy

In a cold-weather climate, bare trees won’t provide

much privacy. Think of your spa’s surroundings during all seasons to determine your best privacy op-

Plan your delivery route

Choose a suitable location for the shell and

equipment pack

Excavate the hole

Install dedicated electrical supply

Install dedicated NG line for gas heater

After Delivery

Remove spa from shipping platform

Install shell in ground

Install equipment pack

Connect plumbing

Connect electrical components

Pour the deck

tions. Consider the view of your neighbors as well

when you plan the location of your spa.

Provide A View With Your Spa

Think about the direction you will be facing when

sitting in your spa. Do you have a special landscaped

area in your yard that you nd enjoyable? Perhaps

there is an area that catches a soothing breeze during the day or a lovely sunset in the evening.

Keep Your Spa Clean

Prevent dirt and contaminants from being tracked

into your spa by placing a foot mat at the spa’s entrance where the bather’s can clean their feet before

entering your spa. You may also consider keeping a

small water-lled basin nearby for bathers to rinse

their feet before entering your spa.

In planning your spa’s location, consider a location

where the path to and from the house can be kept

clean and free of debris.

Allow For Service Access

Many people choose to install a decorative structure

around their spa. If you are installing your spa with

any type of structure on the outside, such as a gazebo, remember to allow access for service. It is always

best to design special installations so that the spa can

still be accessed.

Inground Spas

LTR20121002, Rev. A

Page 5

www. c al sp a s. co m

Planning the Best Place for the Outdoor Equipment Pack

The Designer Spa series requires an external equipment pack. When locating the outdoor equipment

pack, you will want to consider the following:

The equipment pack must be located within a •

maximum of 15 feet from the spa.

owner’s manual for important location and safety

information.)

The equipment base and heater must be placed •

on either a 3 1/2” cement slab or 3” paving

stones.

5

Preparing for Your New Inground Spa

Ensure the equipment running its normal ltra-•

tion cycles does not make too much noise for spa

owners and/or neighbors.

Ensure the equipment can be easily serviced for •

lter cleaning and periodic inspections in the location chosen.

If you are using a gas heater, you will need to •

consider wind and drafts as well as heater ex-

haust for proper heater placement. (See heater

Inground Spa Site Preparation

Ensure there is enough room for the spa and •

equipment.

Plan for proper electrical and gas service to both •

the equipment area and spa side.

Ensure the required at, level foundation can be •

constructed in the area chosen.

The spa must be properly back-lled with wet •

sand, underneath and on all four sides.

Never place any spa in a sealed area. Water must •

be able either to be absorbed into the surrounding area or channeled away. Water build-up under and/or around the spa, will cause the spa to

oat out of the ground.

Grading Prior to Excavation

Selection of the Designer Spas site will determine

how much grading will have to be accomplished prior

to the actual dig for the spa. Naturally, a level area is

best because it will require the least amount of preparation for the dig, but in many cases there is no level

area, therefore, the site must be prepared to accept

the spa prior to dig. The spa site should be elevated

slightly higher than the surrounding area.

When dealing with slopes, the severity of the slope

will determine if retaining walls must be built in order

to have a level area for the spa. If the slope is relatively minor, contact your local building safety.

Site Excavation – Hard Bottom

For hard bottom placement for inground spas, you

will need a smooth and at concrete surface at least

Make sure the equipment area selected will not •

be in an area where water could run or stand.

If the area receives direct sunlight, you will want •

to provide some protection for the equipment

portion of the equipment pack.

The equipment pack and heater are delivered separately. Do not cover gas heaters unless properly vent-

ed. (See heater owner’s manual for important safety

information.)

4” thick as large as the bottom contact points. Be

sure not to seal the bottom off and making a sealed

box. You will need adequate water drainage for escape under the spa. A gravel beds around the concrete base will help with this.

Site Excavation – Sand Bottom

With the spa area and all elevations planned including your decided type of decking, you are now ready

to proceed with the dig. An ideal excavation is one

that is as close as possible to the dimensions of the

spa shell, but with the following rules in mind. The

excavation should be 2” to 4” deeper than the actual

spa for your sand bed. The sand bed is to level the

spa shell and provide a perfect support base with no

voids when the spa is lowered into the hole. Your

excavation should be approximately one foot longer

and one foot wider than the spa shell. This will allow

for a six inch over dig all the way around the spa once

it is in place. Additional hand excavation will be re-

quired to insure the skimmer will t in the excavation

when attached to the spa.

Sand or rock dust must be used to bed the shell into

the excavation and for backll. In no event is dirt to

be used. One of the easiest ways to know how much

sand is needed to be placed on the bottom of the

excavation is to set a grade stake at all four corners,

and one on each side of the center line in the bottom

of the hole. If there are areas that are deeper than

2” to 4”, these can be lled with sand and are of no

consequence.

Inground Spas

LTR20121002, Rev. A

Page 6

www. c al sp a s. co m

6

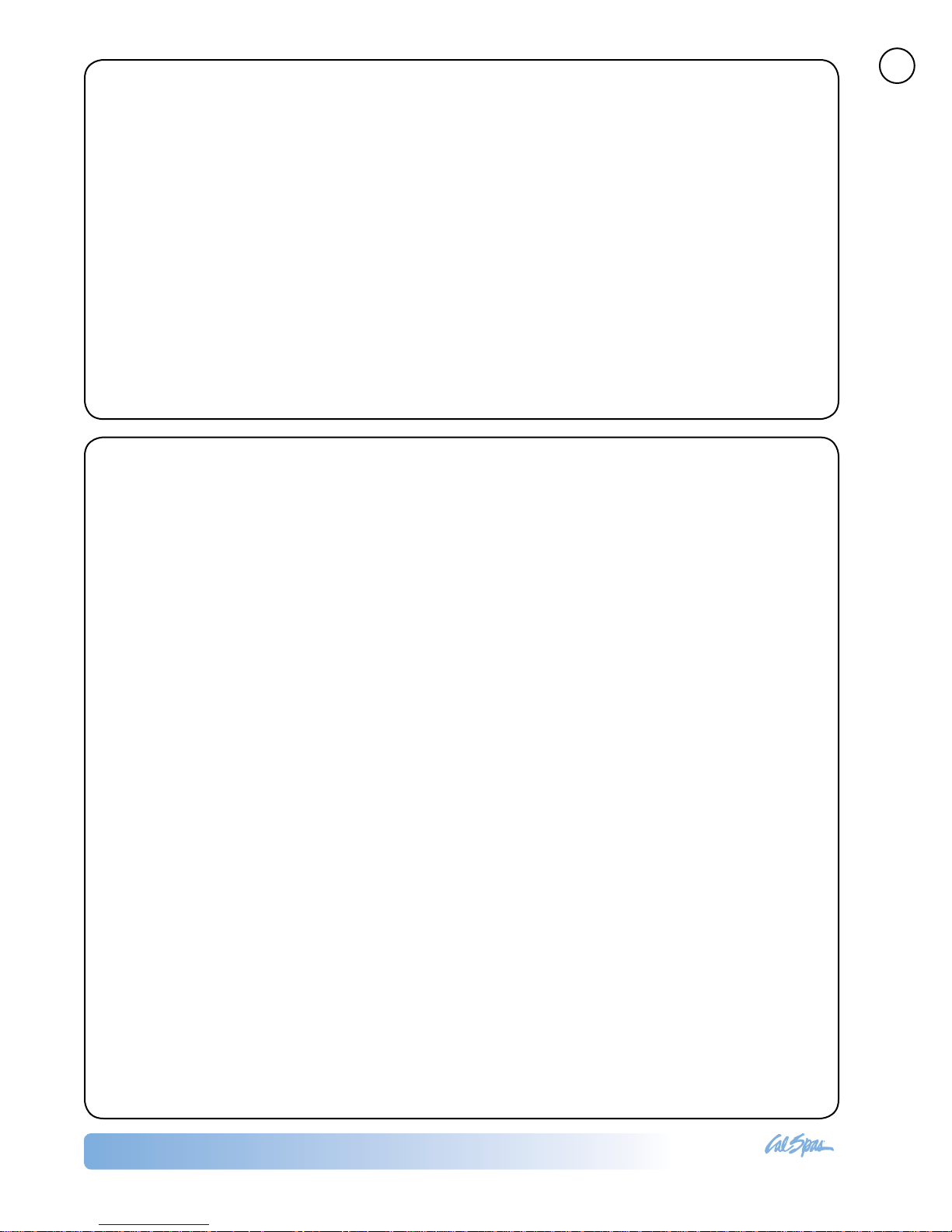

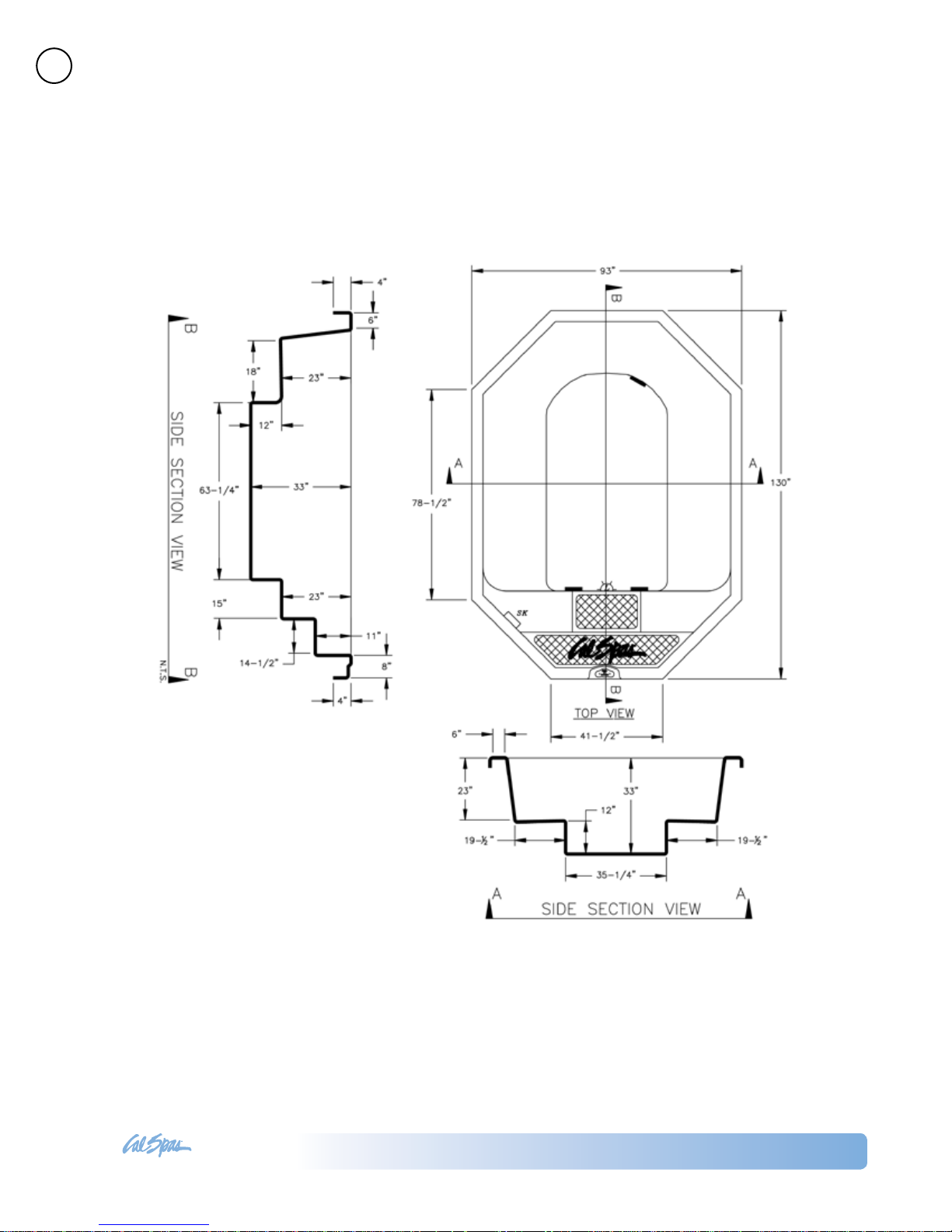

Spa Shell Dimensions and Side Views

IG-401

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 7

www. c al sp a s. co m

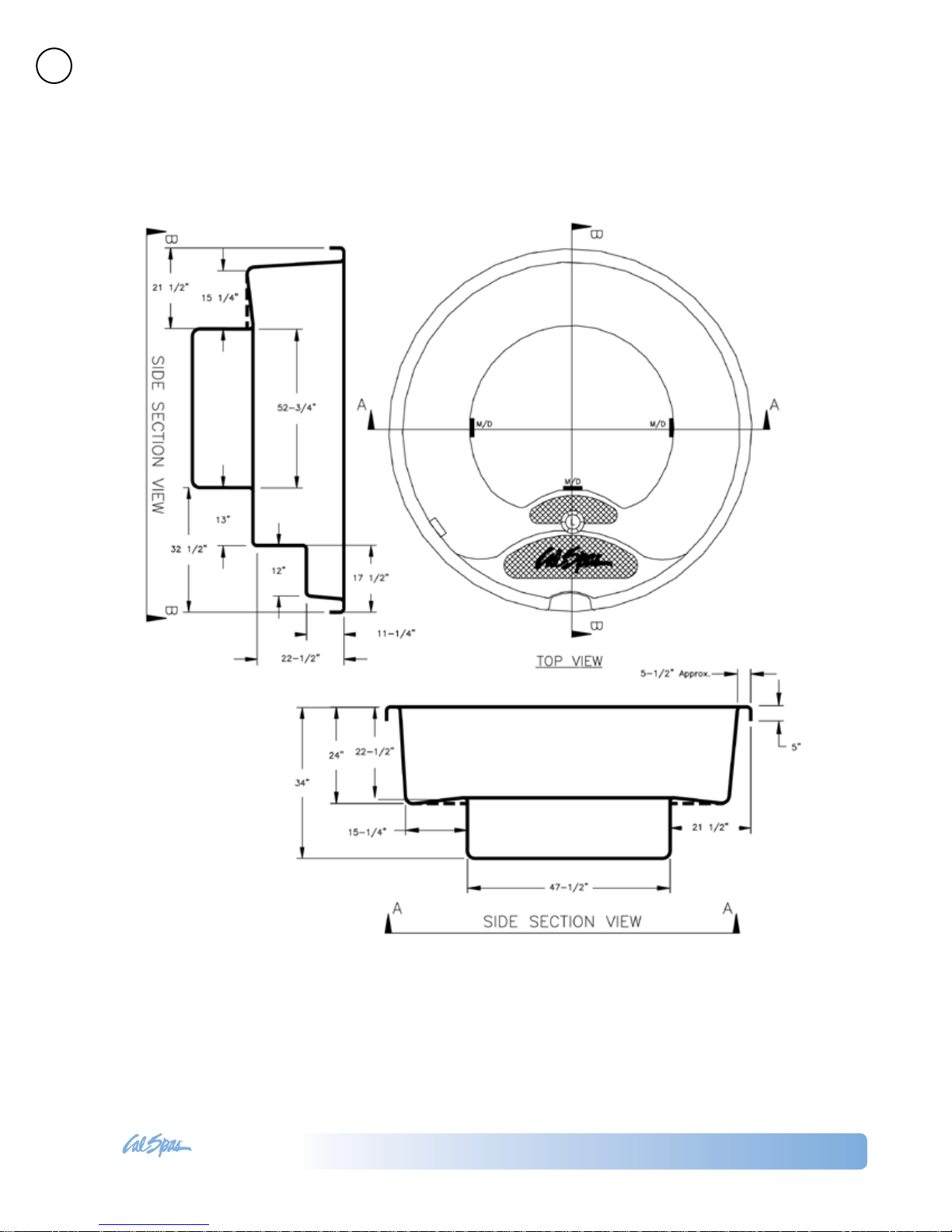

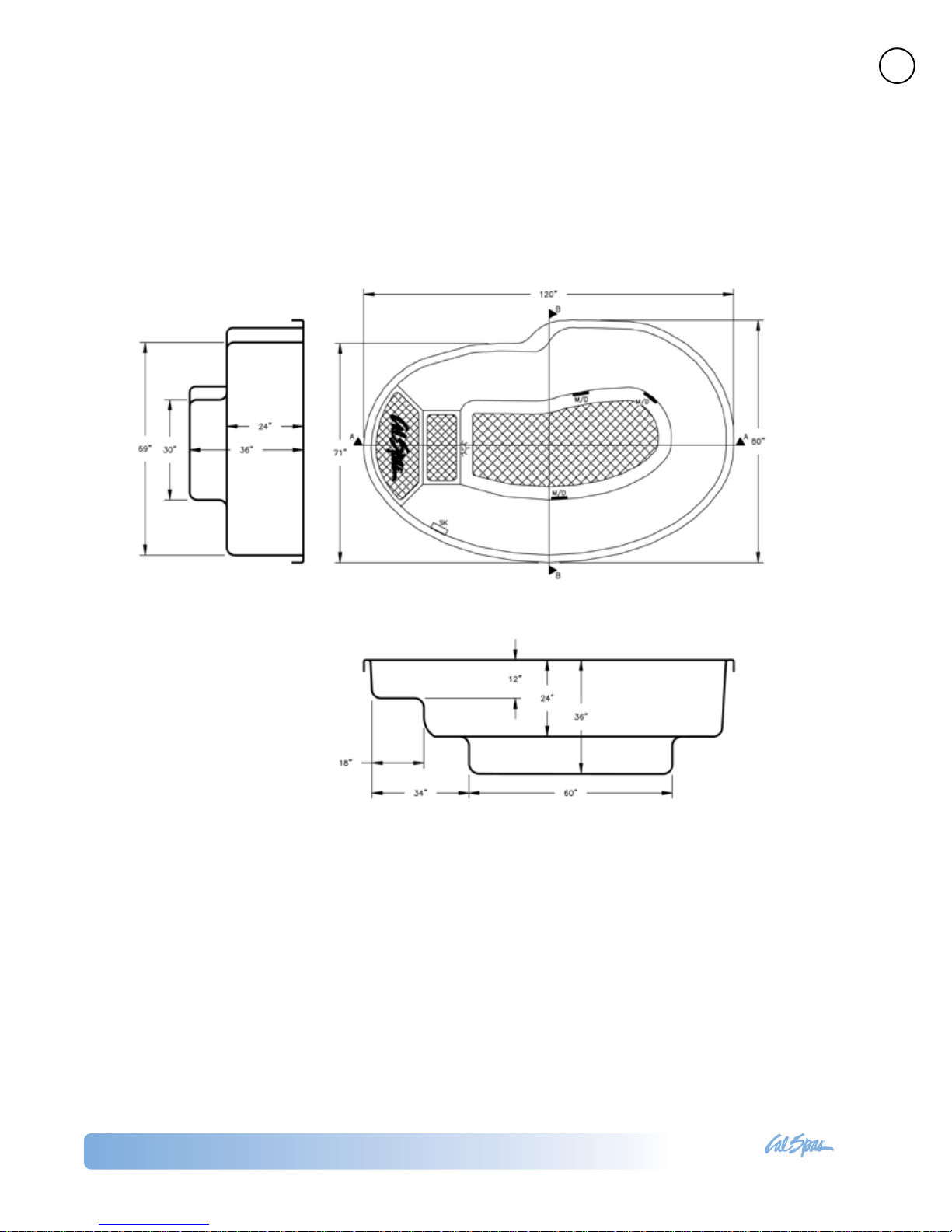

IG-402

7

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 8

www. c al sp a s. co m

8

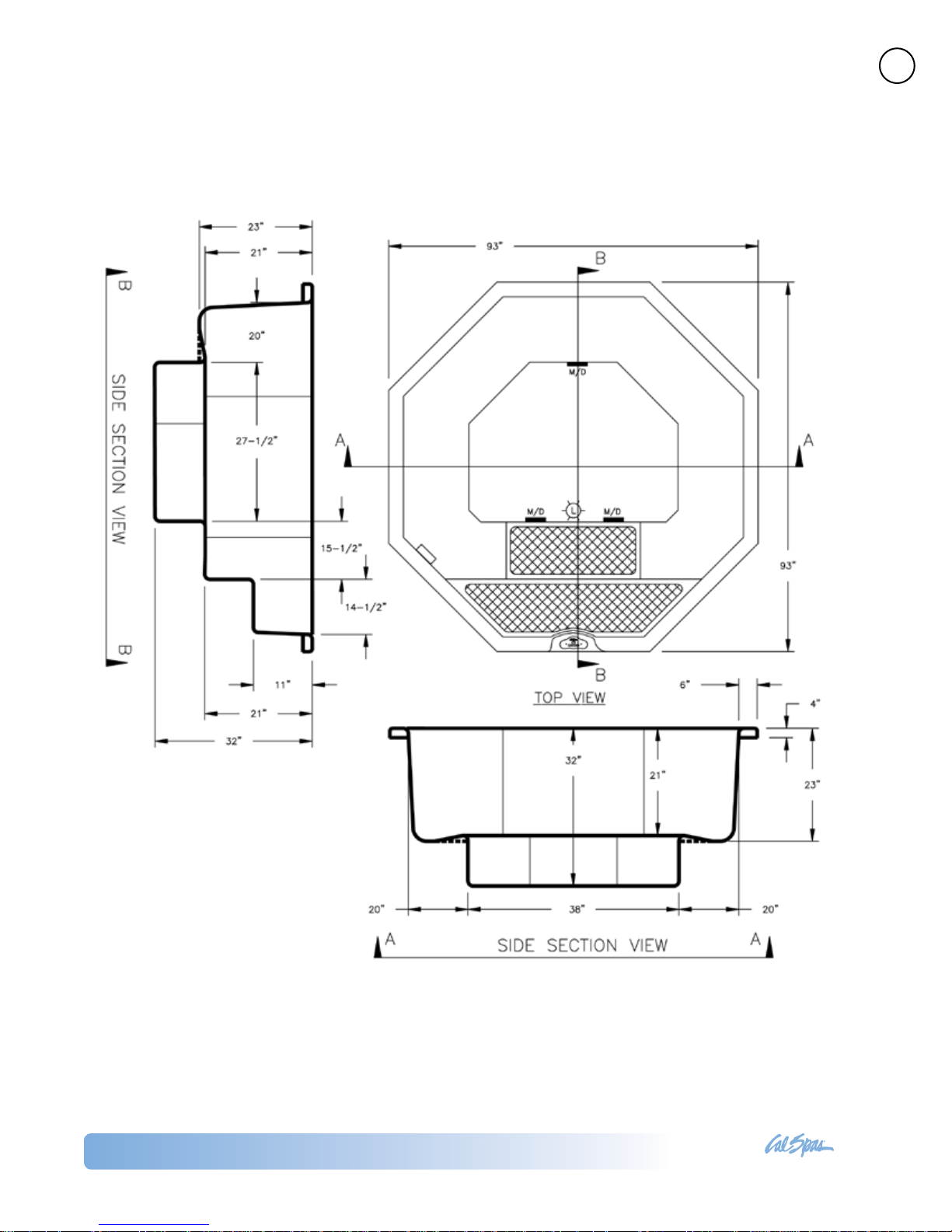

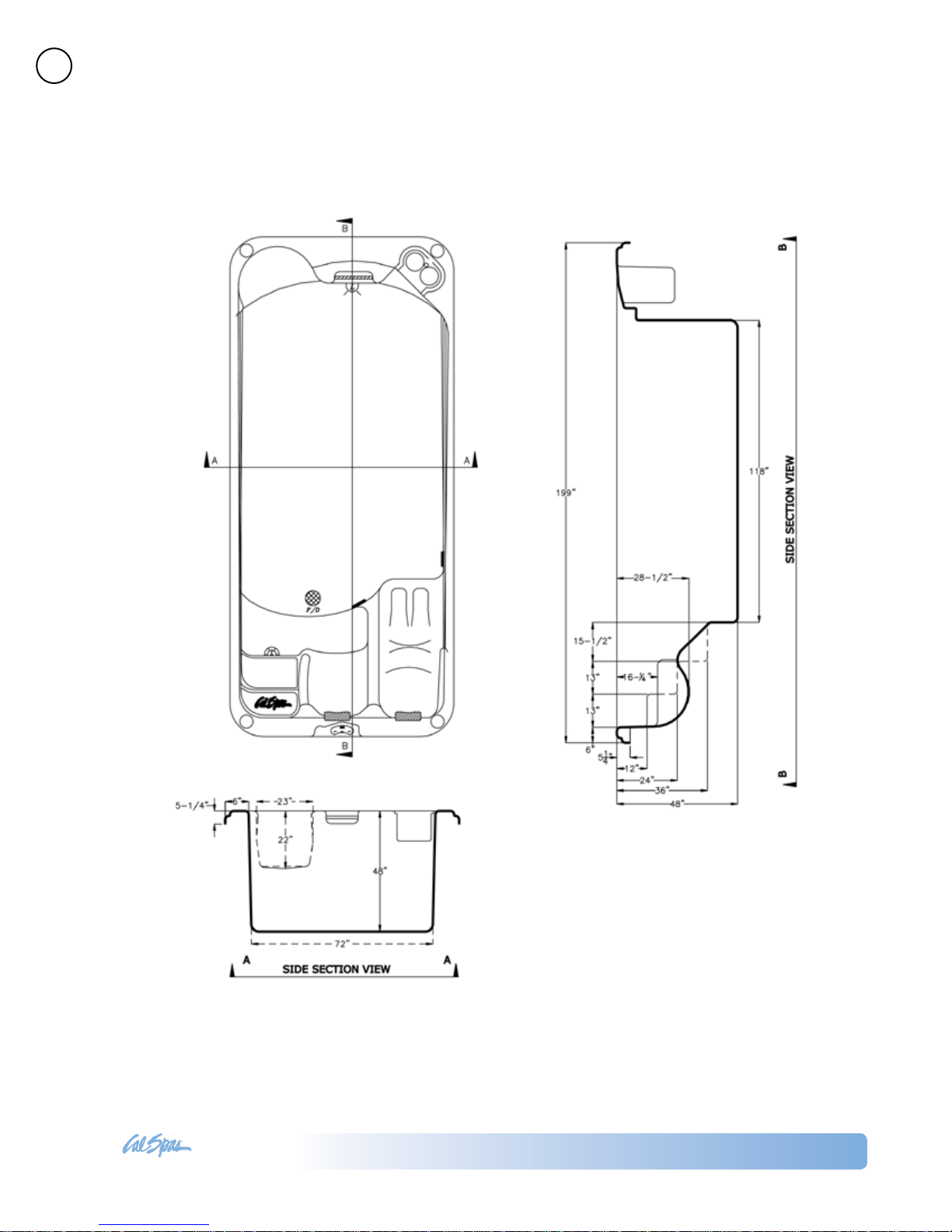

IG-403

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 9

www. c al sp a s. co m

IG-404

9

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 10

www. c al sp a s. co m

10

IG-405

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 11

www. c al sp a s. co m

IG-406

11

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 12

www. c al sp a s. co m

12

IG-407

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 13

www. c al sp a s. co m

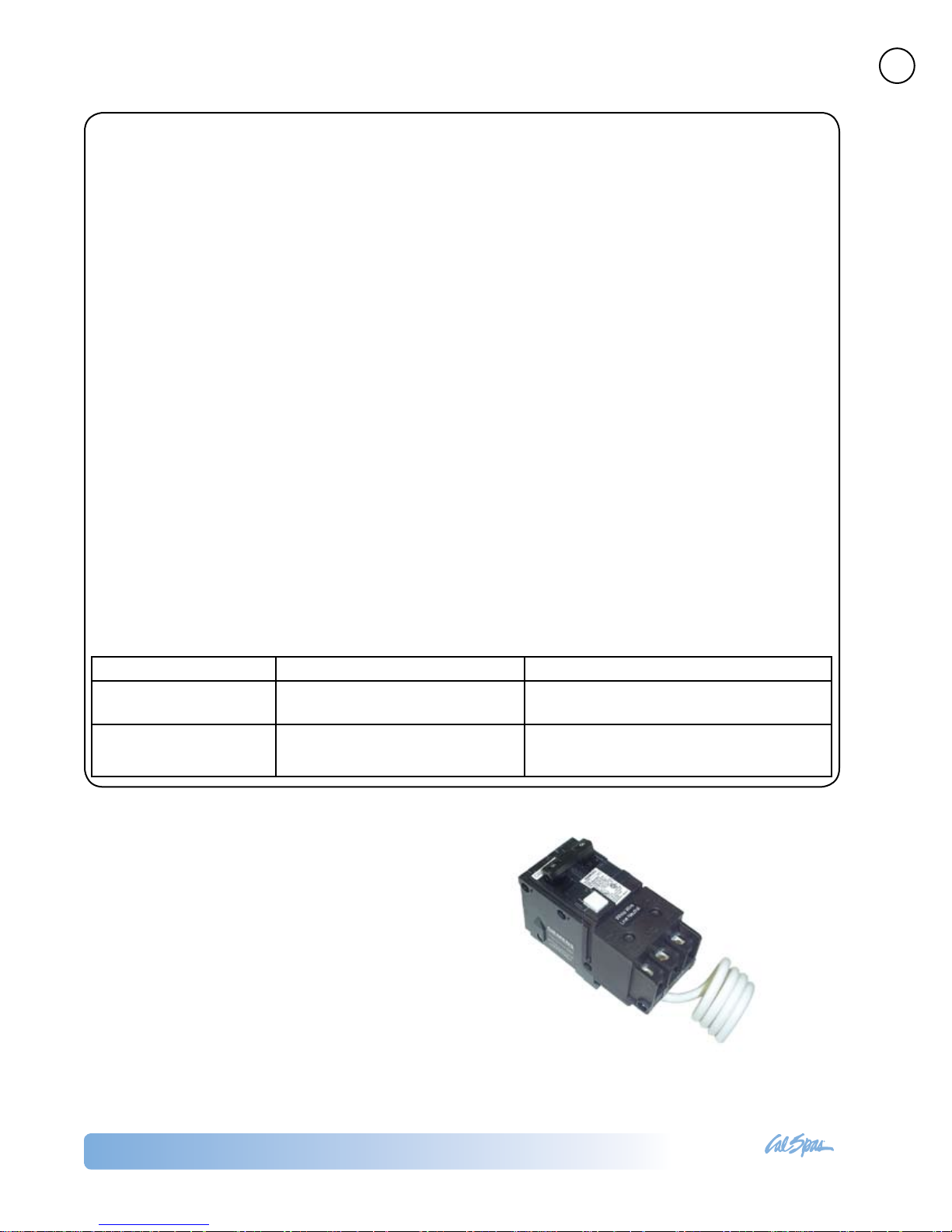

Electrical Requirements – US and Canada

13

Preparing for Your New Inground Spa

All 240V spas must be permanently connected (hard

wired) to the power supply. These instructions de-

scribe the only acceptable electrical wiring procedure.

Spas wired in any other way will void your warranty

and may result in serious injury. See the wiring diagram on page 14.

When installed in the United States, the electrical

wiring of this spa must meet the requirements of National Electric Code, ANSI/NFPA 70-2008 and any applicable local, state, and federal codes. The electrical

circuit must be installed by an electrical contractor

and approved by a local building / electrical inspector.

GFCI and Wiring Requirements

The power supplied to the spa must be on a dedicated GFCI protected circuit as required by ANSI/

NFPA 70 with no other appliances or lights sharing

the power.

Use copper wire with THHN insulation. Do not use

aluminum wire.

Use the table below to determine your GFCI and wiring requirements.

Wire runs over 85 feet must increase wire gauge to

the next lower number. For example: A normal 50

amp GFCI with four #8 AWG Copper wires run over

85 feet would require you to go to four #6 AWG copper wires.

Read and follow the heater manufacturer’s safety and

installation instructions prior to installation and operation. Incorrect installation may damage the heater

and void its warranty.

Testing the GFCI Breaker

Test the GFCI breaker prior to rst use and periodically when the spa is powered. To test the GFCI breaker

follow these instructions (spa should be operating):

Press the TEST button on the GFCI. The GFCI will 1.

trip and the spa will shut off.

Reset the GFCI breaker by switching the breaker 2.

to the full OFF position, wait a moment, then turn

the breaker back on. The spa should have power

again.

Spa Model GFCI Required Wires Required

Designer inground spas

with one 5.5 kW heater

Designer inground spa

with two 5.5 kW heaters

One 50 amp GFCI Four #6 AWG copper wires

Service 1: One 50 amp GFCI

Service 2: One 30 amp GFCI

Service 1: Four #6 AWG copper wires

Service 2: Three #8 AWG copper wires

Inground Spas

LTR20121002, Rev. A

Page 14

www. c al sp a s. co m

14

GFCI Wiring Diagram

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 15

www. c al sp a s. co m

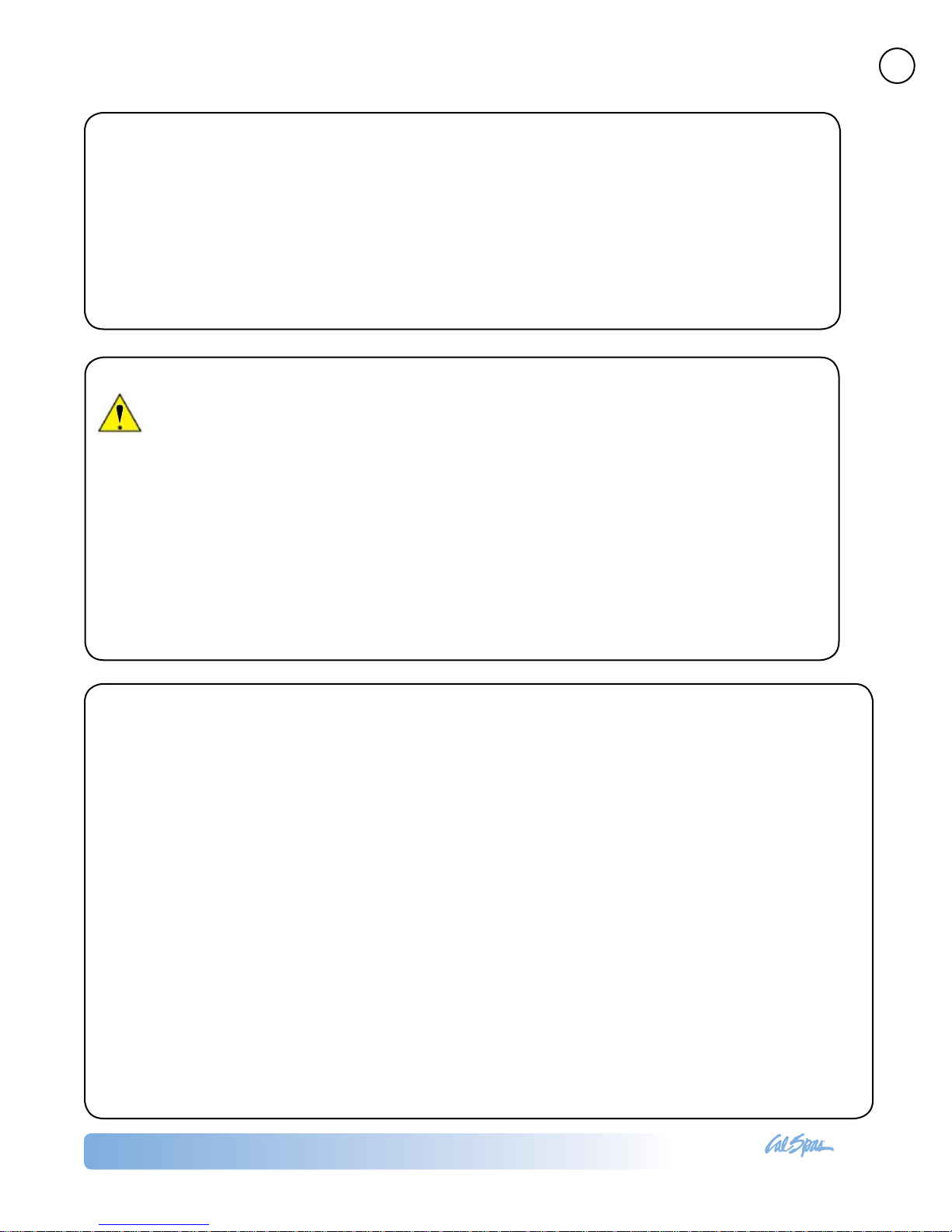

Electrical Installation -- Europe

15

Preparing for Your New Inground Spa

All 230V spas must be permanently connected (hard

wired) to the power supply. These instructions de-

scribe the only acceptable electrical wiring procedure.

Spas wired in any other way will void your warranty

and may result in serious injury.

This the only acceptable electrical wiring procedure.

Spas wired in any other way will void your warranty.

See the wiring diagram on page 16.

The electrical wiring of this spa must meet the requirements of any applicable local, state, and federal

codes. The electrical circuit must be installed by an

electrical contractor and approved by a local building

/ electrical inspector.

RCD and Wiring Requirements

The power supplied to the spa must be on a dedicated RCD protected circuit with no other appliances

or lights sharing the power.

Use copper wire with THHN insulation. Do not use

aluminum wire.

Use the table below to determine your GFCI and wiring requirements.

Wire runs over 85 feet must increase wire gauge to

the next lower number. For example: A normal 50

amp RCD with four #8 AWG copper wires run over

85 feet would require you to go to four #6 AWG copper wires.

Testing the RCD Breaker

Test the RCD breaker prior to rst use and periodically when the spa is powered. To test the RCD breaker

follow these instructions (spa should be operating):

Press the TEST button on the RCD. The RCD will 1.

trip and the spa will shut off.

Reset the RCD breaker by switching the breaker 2.

to the full OFF position, wait a moment, then turn

the breaker back on. The spa should have power

again.

Spa Model GFCI Required Wires Required

Designer inground spas with one 3

kW heater

Designer inground spa with one 3

kW heater and one 5.5 kW heater

One 32 amp RCD or two 16 amp

RCDs

Service 1: One 32 amp RCD or

two 16 amp RCDs

Service 2: One 32 amp RCD or

two 16 amp RCDs

Four #10 AWG copper wires

Service 1: Four #10 AWG copper

wires

Service 2: Three #10 AWG copper

wires

Inground Spas

LTR20121002, Rev. A

Page 16

www. c al sp a s. co m

16

GREEN/

YELLOW

(Ground)

GREEN/

YELLOW

(Ground)

GREEN/

YELLOW

(Ground)

CIRCUIT BOARD

RCD Wiring Diagram

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 17

www. c al sp a s. co m

Installing the Inground Shell

17

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 18

www. c al sp a s. co m

18

Equipment Pack Plumbing Connections

Equipment Pack Specications

All Inground spas except IGJ-407:

Equipment pack weight = 250 lbs.

IGJ-407:

Equipment pack weight = 300 lbs.

One 2.5 HP heat pump

One 4 HP swim pump

Note: Equipment pack cannot exceed 15 feet from

spa.

Plumbing Connections

Preparing for Your New Inground Spa

IMPORTANT! Always check local codes prior to any

inground spa installation.

Once the spa and equipment are properly located, you

will want to lay out the plumbing run.

Trenches should be deep and wide enough to allow

all pipes to be buried below the frost line and should

be in as straight a line from the spa to the equipment

as possible. Check local code requirements for underground pipes. Always know what is under the ground

before you dig anywhere.

You will need 2” ex or PVC lines for your suction, intake, and air line. In ground spas have marked intake

and suction lines, making it easy nd and connect to

and from the spa and equipment pack.

The plumbing run should not be any longer than 15

feet to maximize water pressure. Another way to max-

imize water pressure is to limit (or even eliminate) the

use of 90˚ elbows in your plumbing run. A more direct

plumbing run using 45˚ elbows is more efcient, and

promotes increased water pressure.

Identifying Plumbing Lines

The spa’s plumbing lines are clearly marked during

water testing at the factory. This is done to assist installers in properly identifying the installation. We still

recommend that the installers verify plumbing lines

prior to gluing. This can be done by using one of the

following techniques.

Air Test

The air test requires a wet/dry vacuum. Locate the

plumbing line you wish to identify and secure the vacuum hose to cut open end. Turn on the vacuum, enter

the spa and listen for vacuum suction sound from in-

side the spa side lter canister. If you hear the suction

sound in the canister, the line is properly marked and

can be connected to the suction side of the pump on

the equipment pack.

Water Test

The water test requires a garden hose and water

source. Locate the plumbing line you wish to identify

and secure the outlet side of the garden hose to cut

open end. Turn on the water supply to the garden

hose, enter the spa and look for water inside the spa

side lter canister. If you see water in the canister the

line is properly marked and can be connected to the

suction side of the pump on the equipment pack.

If any plumbing line is not properly marked or not

marked at all, follow either the air or water test proce-

dure until all lines are identied prior to gluing.

NOTE: Once complete, water test the plumbing run

for at least three days prior to covering any plumbing

trenches and back-lling spa cavity completely.

NOTE: Some local inspectors require pressure testing the plumbing lines. Although the spa is pressure

tested at the factory, local inspectors may insist on

pressure testing the plumbing run between the spa

and equipment pack.

Inground Spas

LTR20121002, Rev. A

Page 19

www. c al sp a s. co m

19

Gate/Slice Valves

The use of gate valves is recommended on all plumb-

ing lines (both suction and return lines). These valves

are used to contain the spa’s water in either the equipment or the spa. This will assist in the pump priming

process and future servicing without needing to drain

the spa.

NOTE: When draining the spa to perform maintenance, always close the gate valves prior to draining.

This will maintain the pumps prime.

Connecting Plumbing to Remote

Equipment

Connecting the plumbing from the spa to the equipment pack must be performed in accordance to local

and city codes.

NOTE: Most codes require plumbing to be rigid PVC

schedule 40 or heavier in both above and below

ground installations. In most cases, the use of exible

PVC plumbing is acceptable when properly buried in

trenches.

Most water plumbing lines are 2” or larger and must

be schedule 40 or heavier PVC. When plumbing, mini-

mize the use of 90˚ elbows as much as possible. The

use of 45˚ elbows will increase the amount of jet pressure you will have over the use of 90˚ elbows.

The plumbing on the spa shell is labeled by the factory

in the following manner:

Pump 1 Suction: 2” line that connects the spa lter

and bottom drain assembly to the front of pump 1.

Pump 1 Return: 2” line that connects the top of pump

1, through the equipment lter and heater back to

selected jets in the spa.

Pump 2 Suction: 2” line that connects the spa lter

and bottom drain assembly to the front of pump 2.

Pump 2 Return: 2” line that connects the top of pump

2 back to selected jets in the spa.

Ozone Line: 1” line that connects to a 1” exible line

extending off the bottom of the equipment pack lter

canister through an ozone injector (If ozone equipped)

and connected to ozone port on the spa.

Air Blower: 1 1/2” line that is plumbed out of the air

blower (located on the equipment pack) and extended

up 18” above the spas water level to prevent water

ooding the air blower.

Air Venturi: 1/2” line that is plumbed 18” above the

spa’s water level.

Topside Control Panel and Temp Sensor: 1” line that

connects to the bottom of the control box located on

the equipment pack.

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 20

www. c al sp a s. co m

20

Electrical and Electronic Connection

Remote Equipment Topside Control

Panel

The next few steps to complete the installation should

be performed along with installation of the tempera-

ture sensor and 12V spa light wiring (if applicable). All

of these components are generally installed using the

same conduit.

Locate the topside control panel extension loom 1.

in the control box mounted with the equipment

pack. This extension loom and attached black ter-

minal connector (see gure at right) will be used

to connect the topside control panel to the control

box.

Connect one end of the black terminal connector 2.

to the topside control panel cable.

Connect the other end of the terminal connector 3.

to the extension loom.

Preparing for Your New Inground Spa

NOTE: This connection must be kept dry. We recommend that a waterproof junction box be used in installations where moisture could penetrate this terminal

connector.

Lay out the extension loom to verify that you have 4.

enough length to reach the control box. Remember that conduit runs are not generally run in a

straight line. Every bend, and up and down run

consumes line length. Take this into consideration

when verifying electrical and plumbing runs.

Connect the extension loom to the control panel 5.

location on the circuit board located inside the

control box. You will also need to connect both

the temperature and high limit sensors to the cir-

cuit board prior to testing. (See the temperature

and high limit installation instruction on the next

page for proper identication and see the wiring

diagram on the inside cover of the control box for

proper placement.)

Turn on the power supply to the spa equipment 6.

and briey test all functions on the topside control

panel to verify that both connections and extension loom are in working order before proceeding

with the installation.

NOTE: Circuit board programming will not allow spa

operation without both the temperature and high

limit sensors being properly connected to the circuit

board.

Once topside panel operation is veried. Turn off 7.

power, disconnect the extension loom from the

circuit board and GENTLY route through conduit

to complete installation.

NOTE: This loom and its connector are not meant to

withstand heavy pulling. Make sure, when routing the

extension loom and temperature sensor lines through

conduit, you exercise extreme caution.

Once properly run through the conduit, repeat steps

5 and 6 above.

Inground Spas

LTR20121002, Rev. A

Page 21

www. c al sp a s. co m

21

Inground Spa Light Installation Instructions

On spas ordered with inground lights, the factory

installs the light niche for you. The next steps of

installation should be performed by a qualied licensed

electrician.

Always read and follow light manufacturer’s safety

and installation instructions prior to installation and

operation. Incorrect installation may damage the light

and void its warranty.

The light circuit must be on a GFCI protected service

(alone or with a switch).

The water resistant junction box (or for 12 volt models,

the low voltage transformer) must be located:

at least 8” (20 cm) above water level•

at least 4” (10 cm) above ground level, and•

at least 48” (121 cm) away from the spa.•

See gure below.

Light niche and any metallic items in a 5’ (152 cm)

radius must be properly bonded with #8 AWG

grounding wire.

Connect rigid conduit to the 3/4” hub located at 1.

the back of the light niche and run to a water re-

sistant junction box (or for 12 volt models to a low

voltage transformer) no further than 25’ (7.6m).

Remember this is a water cooled light, so the conduit and all connections must be leakproof.

Feed the light cord through the rigid conduit to 2.

the junction box, leaving at least 4 feet of cord at

the end of the light xture. This slack in the light

cord will allow servicing without draining the spa

in the future.

Wrap light cord slack around back of light housing 3.

and attach light to niche with mounting screw.

Cut the cord at the junction box, leaving at least 4.

6” (15 cm) of cord to make connections.

Strip 6” (15 cm) of the out cord jacket to expose 5.

the three insulated wires. Be careful not to damage the insulation on the three inner wires.

Connect the three wires to the corresponding cir-6.

cuit wires in the junction box and secure the junction box cover in place.

Replace the light assembly in the niche and tight-7.

en the special pilot screw.

Fill the spa until the underwater light is completely 8.

submerged in water before operating the light for

more than 10 seconds. Turn on the main switch or

circuit breaker, as well as the spa light control, to

check for proper operation

Important: Make sure spa light is submerged in

at least 18” of water prior to testing.

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 22

www. c al sp a s. co m

22

Preparing for Your New Inground Spa

Inground Spas

LTR20121002, Rev. A

Page 23

www. c al sp a s. co m

Pouring the Deck

23

Preparing for Your New Inground Spa

It is recommended that all electrical hook ups and all

plumbing be completed before pouring the concrete.

Make certain all electrical inspections on lights, bonding and all other electrical work have been completed

and checked off by the local inspectors prior to pro-

ceeding with your concrete or nish work. It is a good

idea to run the spa for at least 24 hours before pouring

the concrete to insure there are no leaks. We understand you want to enjoy your spa now, but a 24 hour

period with your spa running will let you know of any

problems before they will be extremely hard to x.

The type of decking you have selected will have determined the grade of the spa. If you are pouring a

regular deck up to the spas coping, then the top of

the coping should be 4” above the surrounding area.

In either event, it is recommended to dig out an area

around the spa exposing the ange of the coping and

just under it. This is important, as concrete should be

packed under and over the ange of the spa, as the

deck is poured. This will lock the spa into the concrete

and provide for a much stronger bond of the spa to

the deck. It will also eliminate cracking of the deck

where it meets the spa.

When setting your outside forms, remember you want

any water from rain or splash out to run off the deck,

not into the spa. If your deck is going to tie into an existing deck, then some type of drain system should be

planned to handle the run off. Proper drainage planning is very important.

An experienced concrete nisher should always be

used when pouring spa decks, especially when you

are doing a cantilevered deck, as the forms must be

taken off at the proper time to allow nishing of the

inside of the form.

Inground Spas

LTR20121002, Rev. A

Page 24

www. c al sp a s. co m

24

9800 Electronic Control Operation

Initial Start-up

When rst powered up, your spa will perform a self-diagnostic check and then automatically go into priming

mode. The topside will display PR to indicate this. Priming mode will be active for less than ve minutes. When

the spa has nished priming, the heater will be activated and the water temperature will be maintained in standard mode. The spa will automatically heat to 100°F (37.5°C) at start-up until you change the set temperature

as listed in the “Temperature Adjustment” section below.

These instructions will describe features and options

that your particular spa may not be equipped with.

Temperature Adjustment

Operating Your Spa

80°F - 104°F (26.0°C - 40.0°C)

The start-up temperature is set at

100°F (37.5°C). The last measured

temperature is constantly displayed

on the control panel. Note that the last

measured spa temperature is displayed.

The displayed temperature will be updated

when the pump has been running for at least two

minutes.

Press the “UP” or “DOWN” buttons once to display the

set temperature. Each time either button is pressed

again, the set temperature will increase or decrease

depending on which button is pressed. After three

seconds, the control panel will automatically display

the last measured spa temperature.

Time

When time hasn’t been programmed, the “TIME” icon

ashes. To set the time, press the “TIME” button and

then the “MODE/PROG” button. Use the “UP” and

“DOWN” buttons to adjust time. See the next page

for more detailed instructions.

Standard, Economy, Sleep, and Standby

Modes

Mode/Prog: This button is used to switch between

standard, economy, and sleep modes.

Press “MODE/PROG” to enter mode program-1.

ming.

Press the “DOWN” button to cycle through to the 2.

desired mode.

Press “MODE/PROG” to conrm selection.3.

Standard Mode: This is programmed to maintain

the desired temperature. Note that the last measured

spa temperature displayed is current only when the

pump has been running for at least two minutes. The

“STAND” icon will display until the mode is changed.

Economy Mode: Economy mode heats the spa to the

set temperature only during lter cycles. The “ECON”

icon will display until the mode is changed. Pressing

the “JETS 1” button while in economy mode puts the

spa in standard-in-economy mode, which operates the

same as standard mode but reverts back to economy

mode automatically after one hour. During this time,

pressing the “MODE/PROG” button will revert to economy mode immediately.

Sleep Mode: Sleep mode heats the spa to within

20°F (6.7°C) of the set temperature only during lter

cycles. The “SLEEP” icon will display until the mode is

changed.

Standby Mode: Pressing “Warm” or “Cool” then

“JETS 2” will turn off all spa functions temporarily. This

is helpful when changing a lter. Pressing any button

resets the spa.

Jets 1 and Jets 2

Press the “JETS 1” button once to turn pump 1 on

or off and to shift between low and high speeds if

equipped. If left running, the low speed turns off af-

ter two hours and the high speed turns off after 15

minutes. On non-circulation systems, the low speed of

pump 1 runs when the blower or any other pump is

on. It may also activate for at least two minutes every

30 minutes to detect the spa temperature and then

to heat to the set temperature if needed, depending

upon the mode. When the low speed turns on automatically, it cannot be deactivated from the panel;

however, the high speed may be started.

Option

This is an optional feature. Press the “OPTION” button to turn the optional equipment on and off. If left

Inground Spas

LTR20121002, Rev. A

Page 25

www. c al sp a s. co m

25

on, the equipment will automatically turn off after 15

minutes.

Light

Press the “LIGHT” button to turn the spa light on and

off and to shift between dim and bright settings if your

light is dimmable. On dim, the control panel will show

the center circle plus one quarter of the light beams.

Half of the light beams will show on medium brightness, and all of the light beams will show on bright.

Invert

Press the “INVERT” button to change the numbers

in the display to read upside down. Another press

returns the display to the right-side-up position. This

enables you to read the display while you are in the

spa.

Locking the Panel

To lock the panel:

Press “TIME”, “JETS 1”, and the “UP” button within •

three seconds. When locked, the panel will display

“LOCK”. All buttons are frozen except the “TIME”

button.

To unlock the panel:

Press “TIME”, “JETS 1” then the “DOWN” button •

within three seconds.

Setting the Temperature Lock

To activate the temperature lock:

Press the “UP” or “DOWN” button, “TIME”, “JETS •

1”, then the “UP” button within three seconds. The

panel will display “TEMP LOCK” when the set temperature is locked.

To unlock the set temperature:

Press the “UP” or “DOWN” button, “TIME”, “JETS •

1”, and then the “DOWN” button.

Circulation Pump

This is an optional feature. The circulation pump will

come on when the system is checking temperature,

during lter cycles, during freeze conditions, or when

another pump is on.

Preset Filter Cycles

There are two lter cycles per day. The start and end

times of each cycle are programmable. To program,

set the time as instructed above, then press “MODE/

PROG” to advance to the next setting (or to exit after

the last setting). The default lter cycles are as fol-

lows:

The rst lter cycle is automatically activated at •

8:00 AM and operates the pump until 10:00 AM.

The “FILTER 1” indicator icon will light when lter

1 is running.

The second lter cycle is automatically activated •

at 8:00 PM and operates the pump until 10:00 PM.

The “FILTER 2” indicator icon will light when lter

2 is running.

The pump and the ozone generator will run during ltration. At the start of each lter cycle, the blower will

run on highest speed for 30 seconds to clean out the

air channels. The lowest speed of pump 2 and pump

3 will run for ve minutes. In the event of power loss

or shut down, the time of day will need to be reset for

lter cycles to run according to your desired programming.

Clean-up Cycle

When the pump or blower is turned on by a button

press, a clean-up cycle begins 30 minutes after the

pump or blower is turned off or times out. The pump

and the ozone generator will run for one hour.

Ozone

This is an optional feature. On most systems, the

ozone generator (if installed) runs during lter cycles

(except when pump 1 is operating at high speed on a

non-circ system) and during clean-up cycles. On some

systems, the ozone generator operates whenever the

pump runs. If your system is congured with the optional ozone disable feature, the ozone generator will

turn off for one hour any time a function button (“JETS

1”, “JETS 2”, “OPTION” etc.) is pressed.

Freeze Protection

If the temperature sensors detect a drop to 44°F

within the heater, the pump automatically activates

to provide freeze protection. The equipment stays

on until four minutes after the sensors detect that

the spa temperature has risen to 45°F or higher. In

colder climates, an optional additional freeze sensor

may be added to protect against freeze conditions that

may not be sensed by the standard sensors. Auxiliary

freeze sensor protection acts similarly except with the

temperature thresholds determined by the switch and

without a four-minute delay in turnoff.

Operating Your Spa

Inground Spas

LTR20121002, Rev. A

Page 26

www. c al sp a s. co m

26

Operating Your Spa

Periodic Reminder Messages

Press the “Mode” button to reset a displayed reminder.

Message Frequency Action Required

rPH

rSA

rCL

rtg

rdr

rCO

rCH

Your new Cal Spa comes equipped with an electric heater. Following the directions listed below will ensure

the most efcient operation:

Every 7 days Test and adjust chemical levels per manufacturer’s instructions.

Every 7 days Test and adjust chemical levels per manufacturer’s instructions.

Every 30 days Remove, clean, and reinstall lter per manufacturer’s instructions.

Every 30 days Test and reset GFCI per manufacturer’s instructions. Drain and rell

spa per manufacturer’s instructions.

Every 90 days Drain and rell spa per manufacturer’s instructions.

Every 180 days Clean and condition spa cover

Every 365 days Install New Bio-Clean™ Filter

NOTE: This method is only for spa usage under two hours a week.

Keep the spa’s operating temperature 5˚ F below the desired usage temperature when not in use. One •

or two hours before use, set the temperature to the desired temperature.

If the spa usage exceeds two hours a week, the set temperature should remain at the desired usage •

temperature.

The air venturis should be used sparingly. When open, water temperature drops quite rapidly and can •

also dissipate chemicals.

Allowing the water temperature to lower more than 10˚F below the desired usage temperature and reheating

it prior to usage will cause the heater to operate longer than it normally would maintaining the desired temperature. Doing this will increase your operating cost and makes your heater work more than necessary.

Inground Spas

LTR20121002, Rev. A

Page 27

www. c al sp a s. co m

Diagnostic Messages

Message Meaning Action Required

No message

on display

BUF Internal problem detected. Repair required. Contact your dealer or service organi-

dr Insufcient water detected in

dry

dY

Ec Indicates heater is in Economy

--F or --C Temperature unknown After the pump has been running for two minutes, the

HL

HFL

IC

ICE

LF Persistent low ow problems.

OH

OHS

1) Spa temperature is unknown. 1) After pump has been running for 2 minutes temperature will be displayed.

2) Spa is in Economy or Sleep

mode.

3) Power has been cut off to the

spa.

heater. Spa will be shut down for

15 minutes.

Insufcient water detected in

heater. Spa is shut down.

(Displays on third occurrence of

dr message.)

Mode.

A difference in readings between

temperature sensors has been

detected indicating a possible

water ow problem.

Potential freeze condition detected.

Heater is shut down, but other

spa functions continue to run

normally. Displays on the fth

occurrence of the HL or HFL message within 24 hours.

Overheat protection. The spa has

shut down. One of the sensors

has detected that the spa water

is 110°F.

2) In Economy or Sleep mode, the pump may be off for

hours outside a lter cycle. If you wish to see the cur-

rent spa temperature, either switch to Standard mode

or turn Jets1 on for at least two minutes.

3) The control panel will be disabled until power returns. Spa settings and time of day will be preserved for

30 days with a battery back-up.

zation.

Check water level in spa. Rell if necessary. Make sure

pumps are been primed and lter cartridges are clean.

Press any button to reset or wait 15 minutes and spa

will automatically reset. If message spa does not reset,

call your dealer or service organization.

Follow directions for dr message and press any button

to reset spa. Spa will not automatically reset when dry

or dY is displayed.

None.

temperature will be displayed.

Make sure spa is lled to proper level and that pumps

are primed and lter cartridges are clean. If message

does not reset, call your dealer or service organization.

No action required. The pumps and the blower will automatically activate regardless of spa status.

Follow action required for HL or HFL message. Heating

capacity of the spa will not reset automatically. Press

any button to reset.

DO NOT ENTER THE WATER. Remove the spa cover and

allow water to cool. At 107°F, the spa should automatically reset. If spa does not reset, shut off the power to

the spa and call your dealer or service organization.

27

Operating Your Spa

Inground Spas

LTR20121002, Rev. A

Page 28

www. c al sp a s. co m

28

Operating Your Spa

Message Meaning Action Required

HH

OHH

Overheat protection (spa is shutdown). One sensor has detected

118˚F (48˚C) at the heater.

DO NOT ENTER THE WATER!

Remove the spa cover and allow spa to cool below

107˚F (42˚C). Press any button on the topside display

to reset spa. If spa will not reset after spa has cooled,

turn off power for approximately 30 seconds and then

turn power back on. If display message is repeated then

shut the power off to the spa and call your dealer or

service organization.

Pr When your spa is rst actuated, it

will go into priming mode.

The priming mode will last for up to four minutes and

then the spa will begin to heat and maintain the water

temperature in the Standard mode.

SF Safety Suction. Spa is shut down. The display will show SF when a vacuum switch closes.

All functions will turn off and the system will be disabled

until a panel button is pressed.

SL Indicates heater is in Sleep Mode. None.

SA

Sb

SNA

Spa is shut down. The sensor

that is plugged into the sensor

“A” or “B” jack is not working.

If the problem persists, contact your dealer or service

organization. (May appear temporarily in an overheat

situation and disappear when the heater cools.)

Snb

Sns

Sn

Sensors are out of balance.

If this is alternating with the •

Contact your dealer or service organization.

temperature, it may just be a

temporary condition.

If the display shows only this •

message (periodically blinking), the spa is shut down.

ST Indicates heater is in Standard

Mode.

Stby Pressing a button combination

on the user panel has activated

Standby Mode.

None.

Press any button to leave Standby Mode and return to

normal operation.

Inground Spas

LTR20121002, Rev. A

Page 29

www. c al sp a s. co m

Adjustable Jets

29

Operating Your Spa

Diverter Knobs

Almost all of the jets in your spa are adjustable.

Rotating the face of an adjustable jet to the left

(counter-clockwise) will decrease the amount of

water ow through the jet. Rotating the face of an

adjustable jet to the right (clockwise) will increase

the amount of water ow through the jet.

Neck jets adjust in the opposite directions (counterclockwise to increase, clockwise to decrease).

Diverter knobs are 1” and 2” knobs located around

the top of your spa. They allow you to divert water

through jets from one side of the spa to the other, or

in most cases from oor jets to wall jets. This is accomplished by rotating the diverter knob to the left

(counterclockwise), decreas-

ing the amount

of water ow

through a section of jets. To

increase the

amount of water

ow through the

other section

of jets, rotate

the handle to

the right (clockwise).

Inground Spas

LTR20121002, Rev. A

Page 30

www. c al sp a s. co m

30

Filtration

Ing et augait alit esto dolut dio doleniam quat am vel etue

vendiam quis duip ea ating et utem quam, sendit, velesequisit am dunt niscil ilit alit nonumsan utatin utat num voloreril

in ut pratie dionull umsandio consed dolumsandit at. Rat,

consequi tinim ilisi bla feuis euguerc ilisi.

Em verit iliqui endiam nulluptat lamcore minibh elestio numsandip eraesectem diatio ercing ea cortis delissed dunt

utpatisi.

Ut vel ut wis atis nonullut augiam augait lore dolore erci te ea

consequat.

Met prate er sit dolor iriureetuer si.

Feummy nullamcore magna ad dio er

sequamconum nis eu feugiamet, vent

et wisis ero dolore dip exeraestie estie

vel inisci elisl ut diat, cons aut alit lut

lore tin hent adiam iustrud molor

sustis essit wiscilit wisi.

Regularity

Ing et augait alit esto dolut dio doleniam quat am vel etue

vendiam quis duip ea ating et utem quam, sendit, velesequisit am dunt niscil ilit alit nonumsan utatin utat num voloreril

in ut pratie dionull umsandio consed dolumsandit at. Rat,

consequi tinim ilisi bla feuis euguerc ilisi.

Em verit iliqui endiam nulluptat lamcore minibh elestio numsandip eraesectem diatio ercing ea cortis delissed dunt

utpatisi.

Ut vel ut wis atis nonullut augiam augait lore dolore erci te ea

consequat.

Met prate er sit dolor iriureetuer si.

Feummy nullamcore magna ad dio er

sequamconum nis eu feugiamet, vent

et wisis ero dolore dip exeraestie estie

vel inisci elisl ut diat, cons aut alit lut

lore tin hent adiam iustrud molor

sustis essit wiscilit wisi.

Sanitation

Ing et augait alit esto dolut dio doleniam quat am vel etue vendiam quis

duip ea ating et utem quam, sendit,

velesequisit am dunt niscil ilit alit nonumsan utatin utat num voloreril in ut

pratie dionull umsandio consed

dolumsandit at. Rat, consequi tinim ilisi bla feuis euguerc ilisi.

Em verit iliqui endiam nulluptat lamcore minibh elestio numsandip eraesectem diatio ercing ea cortis delissed dunt

utpatisi.

Ut vel ut wis atis nonullut augiam augait lore dolore erci te ea

consequat.

Met prate er sit dolor iriureetuer si. Feummy nullamcore

magna ad dio er sequamconum nis eu feugiamet, vent et

wisis ero dolore dip exeraestie estie vel inisci elisl ut diat, cons

aut alit lut lore tin hent adiam iustrud molor sustis essit wiscilit wisi.

Chemical Balance

Ing et augait alit esto dolut dio doleniam quat am vel etue vendiam quis

duip ea ating et utem quam, sendit,

velesequisit am dunt niscil ilit alit nonumsan utatin utat num voloreril in ut

pratie dionull umsandio consed

dolumsandit at. Rat, consequi tinim

ilisi bla feuis euguerc ilisi.

Em verit iliqui endiam nulluptat lamcore minibh elestio numsandip eraesectem diatio ercing ea cortis delissed dunt

utpatisi.

Ut vel ut wis atis nonullut augiam augait lore dolore erci te ea

consequat.

Met prate er sit dolor iriureetuer si. Feummy nullamcore

magna ad dio er sequamconum nis eu feugiamet, vent et

wisis ero dolore dip exeraestie estie vel inisci elisl ut diat, cons

aut alit lut lore tin hent adiam iustrud molor sustis essit wiscilit wisi.

F

i

l

t

r

a

t

i

o

n

R

e

g

u

l

a

r

i

t

y

C

h

e

m

i

c

a

l

B

a

l

a

n

c

e

S

a

n

i

t

a

t

i

o

n

Your Key

To Clear

Water

Clear Water Plan

This section is intended for new spa owners with

no experience with water chemistry. Everyone’s experience with maintaining water quality is different,

but there are some general concepts you need to

know.

Water maintenance is not difcult, although it requires regular attention. The most important thing

to understand about taking care of your spa water is

that preventive action is much easier than correcting

Clear Water Plan

water quality issues.

The Key to Clear Water

Excellent water quality is a simple matter of four things:

Regularity

Clear water requires regular maintenance.

Establish a routine based on a regular

schedule for your spa water maintenance.

Maintaining your water quality helps the en-

joyment of your spa and extends your spa’s

life by preventing damage from neglect and

chemical abuse.

See page 35 for the schedule of recommended maintenance.

Sanitation

Sanitizers kill bacteria and

viruses and keep the water

clean. A low sanitizer level

will allow microbes to grow

quickly in the spa water.

We recommend using either chlorine or bromine as your sanitizer.

See page 32 for learn how to use sanitizer.

Contents of this section:

Testing and Adjusting Spa Water

Sanitation

Filtration

Bather Load

Starting the Spa with Fresh Water

Maintenance Schedule

Troubleshooting Water Clarity Problems

Cleaning your lter regularly is the easiest

and most effective single thing you can do

to keep your water clear.

A clogged or dirty lter will cause the heater

and pump to work harder than they need

to, possibly causing them to fail.

The spa’s heating system will only function

with the proper amount

of water ow through the

system.

See page 33 for lter clean-

ing instructions.

You will need to test and

adjust the chemical balance of your spa water. Al-

though this is not difcult,

it needs to be done regularly.

Depending on your choice of sanitizer, you

need to test the level of calcium hardness,

total alkalinity, and pH.

See page 32 for learn how to balance your

spa water.

Filtration

Chemical Balance

Inground Spas

LTR20121002, Rev. A

Page 31

www. c al sp a s. co m

Testing and Adjusting Spa Water

8.2

8.0

7.8

7.6

7.4

7.2

7.0

6.8

6.6

Too alkaline,

causes scaling

Ideal balance

Too acidic,

causes corrosion

Need to lower the pH level

Need to raise the pH level

You have two types of testing methods to choose from:

The • reagent test kit is a method which provides a high level of accuracy. It is available in either liquid

or tablet form.

Test strips • are a convenient testing method commonly used by spa owners.

31

Clear Water Plan

Balancing the Total Alkalinity

Total alkalinity (TA) is the measure of the total levels of carbonates, bicarbonates, hydroxides, and

other alkaline substances in the water. TA can be

considered a “pH buffer”. It is the measure of the

ability of the water to resist changes in pH level.

The recommended total alkalinity is 80 - 120

ppm.

If the TA is too low, the pH level will uctuate wide-

ly from high to low. Low TA can be corrected by

adding a pH-alkalinity increaser.

If the TA is too high, the pH level will tend to be

too high and may be difcult to bring down. High

TA can be corrected by adding a pH-alkalinity decreaser.

When the TA is balanced, it normally remains stable, although adding water with high or low alkalinity will raise or lower the TA level.

Balancing the pH

The pH level is the measure of the balance between

acidity and alkalinity.

Balancing the Calcium Hardness

Calcium hardness (CH) is a measure of the total

amount of dissolved calcium in the water. Calcium

helps control the corrosive nature of the spa’s water and is why soft water is not recommended. The

low calcium content of soft water is very corrosive

to the equipment and can cause staining of the spa

shell.

The recommended calcium hardness is 150

- 200 ppm.

If the CH is too low, add a calcium hardness increaser.

If the CH is too high, dilute the spa water with soft

water.

When the CH is balanced, it normally remains stable, although adding soft water or very hard water

will raise or lower the CH level.

If the pH is too low, it can cause corrosion of metal xtures and the heating element. Low pH can be corrected

by adding a pH-alkalinity increaser.

If the pH is too high, it can cause scaling by allowing

metals or minerals to form deposits and stain spa surfaces. High pH can be corrected by adding a pH-alkalinity decreaser.

Testing For: Ideal Range (ppm)

Total Alkalinity 80 120

Calcium Hardness 150 200

pH 7.4 7.6

Inground Spas

LTR20121002, Rev. A

Minimum Maximum

Page 32

www. c al sp a s. co m

32

Sanitation

After you ll your spa, you need to decide which chemical sanitizer you wish to use. Consult your Cal Spas

dealer for the right decision with regards to your lifestyle and spa usage.

We recommend either bromine or chlorine as your sanitizer. Both work well when maintained regularly.

Sanitizers kill bacteria and other organic waste by breaking them down to non-harmful levels and are ltered

Clear Water Plan

out.

Make sure you follow all instructions.

Whichever plan you decide on, follow it completely and don’t take shortcuts. It will provide you with clean,

safe, clear spa water with a minimum of effort.

DO NOT use trichlor. Trichlor is very acidic and the hot temperature of the spa causes it to

dissolve too quickly. It will cause damage to your spa and will void your warranty.

Using Chlorine as a Sanitizer

If you choose to use chlorine as a sanitizer, only

use granulated chlorine, not liquid chlorine.

Once a week, check the chlorine level using either

a test strip or a reagent kit. See the table on the

following page for the ideal range.

Add one or two tablespoons of granulated chlorine

to the spa water weekly. Note that chlorine dissipation rate will be faster at higher water temperatures and slower at lower temperatures.

When you add chlorine, open all of the jets and run

the spa at high speed with the cover open for at

least 30 minutes.

Follow the maintenance schedule on page 35.

Testing For: Ideal Range

Chlorine level

Without ozonator

Using Bromine as a Sanitizer

Bromine is a very effective sanitizer that produces

low chemical odors. Unlike chlorine, it can break

down bacteria and other impurities to a safe level

with a low burn-out rate.

Bromine is available in both granulated and tablet form. Use granulated bromine to establish your

bromine base. Use tablets to maintain it.

When you begin with fresh water, add 2 ounces of

granulated bromide. Open all of the jets and run

the spa at high speed. This is your base bromine

level as the tablets will take a while to dissolve.

Place three or four bromine tablets in the chamber

inside the oater.

Follow the maintenance schedule on page 35.

(ppm)

Minimum Maximum

3.0 5.0

With ozonator

Bromine level

Without ozonator

With ozonator

2.0 4.0

6.7 11.0

5.7 10.0

Inground Spas

LTR20121002, Rev. A

Page 33

www. c al sp a s. co m

Shocking the Water

In addition to using a chemical sanitizer, you will periodically need to shock the water. Shocking the water

helps remove burned-out chemicals, bacteria, and other organic material from your spa’s water and improves your sanitizer’s effectiveness.

Do not use chlorinating shock, which will damage your spa’s jets and pump seals. Only use an oxidizer shock.

It can be used with either chlorine or bromine sanitizers.

Add one ounce of oxidizer shock once a week, after heavy bather loads, or if the water has a strong odor.

Spa must be running with all of the jets on high for 30 minutes with the cover open. If necessary, repeat

oxidizer shock in 30 minute intervals.

Chemical Safety

Read and follow all printed instructions listed on bottles, packages. Failure to follow

chemical directions may result in serious injury, sickness, or even death.

33

Clear Water Plan

Do not exceed chemical dosages as recommended

in the Clear Water Plan or on chemical bottles and

packages.

Never change chemical brands or types without com-

pletely draining, ushing and thoroughly cleaning the

spa and cover rst.

Never mix chemicals together.

Do not allow chemicals to come in contact with skin,

eyes or clothing. Remove and wash clothing that

Filter Cleaning

The lter is the part of your spa that removes the

debris from the water and needs to be cleaned on a

regular basis to maximize your spa’s ltering performance and heating efciency.

In addition to spraying off the lter weekly to remove

surface debris, your lter should be deep cleaned

periodically to dissolve scale and particles that get

lodged deep within the lter bers and impede the

ltration process. Even if the lter looks clean, scale

and particles can clog the bers and prevent water

from owing through the lter resulting in the most

common spa problem—no heat, caused by a dirty

lter.

We recommend you clean your lter once a month

and replace it once a year or as necessary.

Remove the lter by turning it counterclockwise, 1.

unscrewing the bottom threads, then pulling it

up and out.

may have been exposed to chemical contact prior to

wearing them again.

Inhaling or ingesting chemicals will cause serious injury, sickness, or even death.

Chemicals must be stored completely out of the

reach of children in an area that is well vented, cool,

and dry. Failure to provide a proper area for chemical

storage may result in serious injury, sickness, re explosion and even death. Do not store your chemicals

inside the equipment area of your spa.

Place the dirty lter into a bucket of water deep 2.

enough to cover the lter. Add 8 oz of liquid lter

cleaner to the bucket of water.

Note: It is a good idea to keep a spare lter to

use in the spa while the dirty lter is being deep

cleaned. This way, you can rotate the lters and

both will last longer.

Twist off the tablet tube and set it aside3.

Soak the lter for a minimum of 24 hours.4.

Spray the lter with a water hose. Spray each 5.

pleat carefully.

Put fresh bromine in the tablet tube (if you use 6.

it as a sanitizer) and twist it back on top of the

lter.

Reinstall the lter. Do not overtighten.7.

Inground Spas

LTR20121002, Rev. A

Page 34

www. c al sp a s. co m

34

Bather Load

“Bather Load” is the term used to describe the number of people using a spa, combined with the length

of usage, and the frequency of usage. All these factors have a great effect on the spa water. The higher

the bather load, the more chemicals need to be add-

ed and a longer ltration time will be needed.

Clear Water Plan

All versions of the Cal Spas Clear Water Plan are

designed for spas with average bather load (3 to

Starting the Spa with Fresh Water

Prior to lling a spa for the rst time, or after a routine draining, you will want to follow this start-up

plan to extend water life and performance.

As with all chemical dosages listed in these Clear

Water Plans, start-up dosages are intended for 500-

gallon spas. Please adjust the chemical dosages to

the capacity of your particular spa.

Clean the surface of the spa with a multi-purpose 1.

cleaner.

4 people, 15 minutes of usage, three times a week

at 100 degrees) If your bather load exceeds these

guidelines, and you experience water quality prob-

lems, increase the amount of ltration rst, (go to the

next higher ltration number) then if water quality

is still not adequate, consult the advice of your Cal

Spas dealer for additional chemical or system recommendations. Be sure to give them your bather load

information.

Adjust total alkalinity (acceptable range is •

80-120ppm).

Adjust pH if necessary (between 7.2 to 7.8).•

Add either chlorine or bromine (but not both).5.

Chlorine: Add two tablespoons of granulated chlo-

rine to the spa water.

Bromine: Add 2 oz of granulated bromine to estab-

lish a bromine base.

Apply a protective coat of surface protectant to 2.

the acrylic surface.

Fill the spa to the proper water level with normal 3.

tap water. (Do not use soft water.)

Use test strip and balance the spa water.4.

Water level is very important to the operation of your spa. If the water level is too low or too high, your spa will not operate properly. The water level

should be about six inches from the top when the spa is not being used.

Add 2 bromine tablets to bromine oat-

er.

Turn on jets for 15 minutes. Leave spa uncov-6.

ered during this time.

Put cover on spa and allow to heat up to desired 7.

temperature.

Inground Spas

LTR20121002, Rev. A

Page 35

www. c al sp a s. co m

Maintenance Schedule

35

Clear Water Plan

Each time you rell the spa

Prior to each use Test the spa water using either test strips a reagent test kit. Adjust

Once a week Test the spa water using either test strips a reagent test kit. Adjust

Once a month Deep clean your spa’s lter. (Follow lter cleaning instruction at

Every two to four months Drain and clean your spa with multi-purpose cleaner.

Once a year

Follow the section “Starting the Spa with Fresh Water”.

chemical levels as necessary.

chemical levels as necessary.

beginning of Clear Water Plan)

Polish the acrylic surface with a surface protectant.

Clean and treat spa cover, pillows, and Cal Select cabinet (if

equipped).

Rell your spa, following the section “Starting the Spa with Fresh

Water”.

Replace lter cartridges if the pleats appear frayed.

We recommend that your spa water be changed every 4 to 6 months. You may nd the need to change your

spa water more frequently with heavy use. When empty, your spa should be cleaned with a non-abrasive allsurface cleaner, and then rinsed thoroughly.

Inground Spas

LTR20121002, Rev. A

Page 36

www. c al sp a s. co m

36

Cleaning and Maintenance

Removing and Reseating the Pillows

You can remove the pillows for cleaning and maintenance quickly and easily. This method works for all types

of pillows.

Grab the lower edge of the pillow with both hands rmly and pull up. As you do this, the pillow inserts will

pop out of the holes.

Cleaning and Maintenance

Reseat the pillows by aligning the pillow inserts with the holes and striking the pillow hard enough to insert

the pegs back into the holes.

Spa Cover

Important! Keep the spa covered when not in use!

Covered spas will use less electricity in maintain-•

ing your set temperature.

Covering your spa will protect your spa’s nish •

from the sun’s ultraviolet rays.

You are required to keep the spa covered to •

maintain warranty coverage.

Covering your spa helps prevent children from •

drowning in the spa.

See the manual enclosed with your cover for instructions on mounting the locks and how to lock and unlock the cover.

In addition, while the spa cover is rigid, it is not designed to support any weight. Therefore, as a safety

precaution and to preserve the life of your cover, you

must not sit, stand, or lie on it; nor should you place

objects of any kind on top of it.

Inground Spas

LTR20121002, Rev. A

Page 37

www. c al sp a s. co m

Draining Your Spa

Your spa should be drained every four to six months, and relled with fresh tap water. The following is the

recommended method for draining your spa.

Turn off the power at the breaker.1.

Remove all lters.2.

Hook up the female end of a garden hose to the drain tting (if equipped).3.

Place the other end of the garden hose where you would like the water to drain to.4.

Let spa drain completely, then remove garden hose and rell.5.

Cleaning and Replacing the Filter

Filtration is one of the most important steps you can take to ensure clean, clear water. It is far less expensive

to x water clarity problems by ltering your spa than by using excessive amounts of chemicals, excessive

ltration times, or by water replacement.

See the section “Clear Water Plan” for more information on cleaning your lter.

37

Cleaning and Maintenance

Winterizing (Cold Climate Draining)

In many areas of the country, the temperature drops below 32˚F (0°C). We recommend that you always

have your spa full of water and running at normal spa temperatures (80˚F to 100˚F, 26.7°C to 37.8°C). This

will help reduce the risk of freezing in your spa and your spa’s equipment.

WARNING: If you nd the need to drain your spa, please be aware of the potential of freezing in your spas

equipment and plumbing. Even if the directions below are followed perfectly, there is no guarantee that your

spa will not suffer freeze damage and thereby void the warranty coverage.

Open all lter covers.1.

Remove the lter baskets and lters.2.

Drain your spa completely as described in the instructions above.3.

Remove drain plugs from the front of the pumps.4.

Disconnect the unions from both sides of the pump.5.

Use a wet/dry vacuum to blow any remaining water out of the jets and equipment area.6.

Cover your spa with a good spa cover and an all-weather tarp to ensure that neither rain nor snow enters

the spa.

Inground Spas

LTR20121002, Rev. A

Page 38

www. c al sp a s. co m

38

Cleaning Your Spa

Spa Cover and Pillows

Due to the constant punishment your spa cover and pillows receive, you should protect them by applying

a vinyl and leather cleaner as part of your monthly maintenance plan. Use a product that is specically

designed to protect spa covers and pillows from chemical and ultraviolet light damage without leaving an

oily residue behind that is normally associated with common automotive vinyl protectants.

Warning: Do not use automotive vinyl protectants on spa covers or pillows. These products are gener-

ally oil-based and will cause severe water clarity issues that are difcult to correct.

Spa Shell

Each time you drain your spa, before you rell it you should clean your spa shell with an all-purpose

Cleaning and Maintenance

cleaner and apply a coat of surface protectant.

Use a low detergent, non-abrasive cleaner specically formulated to clean the spa without damaging its

acrylic nish.

Use a non-oil based surface protectant that is specically formulated to protect the spa’s nish from the

chemicals and minerals associated with normal spa use.

Inground Spas

LTR20121002, Rev. A

Page 39

www. c al sp a s. co m

39

Appendix

Replacement Parts

Jets

ELE 2” Euro No Eyeball

PLU282050W

mfc 3” Directional

PLU283050W

PSR 5” Rim

PLU285052W

Appendix

Lights

Light Inground 100W 120V

30’

LIT16000100

Waltting, Clear Lens Cap,

Jumbo Spa Light, 5”

LIT16100153

Red Lens Insert, Jumbo Spa

Light

LIT16100155

Blue Lens Insert, Jumbo Spa

Light

SW Swim

Standard face PLU21700565

LIT16100156

Covers

DIJ-401

93” Round

DIJ-405

93 x 130

DIJ-407

93 x 200

Deluxe

Rust

ACU02200310 ACU02200311 ACU02200315 ACU02200316 ACU02200312 ACU02200313 ACU02200314

ACU02200540 ACU02200541 ACU02200542 ACU02200543 ACU02200544 ACU02200545 ACU02200546

ACU02200300 ACU02200301 ACU02200305 ACU02200306 ACU02200302 ACU02200303 ACU02200304

Deluxe

Gray

Deluxe

Slate

Deluxe

Palomino

Deluxe

Teal

Deluxe

Navy

Deluxe

Hunter

Warranty

Cal Spas Designer Inground Spas do not come with a warranty. If you have any questions, contact Cal Spas

customer service at 1-800-CAL-SPAS.

Inground Spas

LTR20121002, Rev. A

Page 40

LMS Customer Service Department

1462 East Ninth Street

Pomona, CA 91766

Toll Free: 1-800-CAL-SPAS

Fax: 1-909-629-3890

www.calspas.com

LTR20121002, Rev. A

12/30/11

Loading...

Loading...