By California Instruments.

Model 251TL / 351TL

AC Power Source

User and Programming Manual

Revision C

November 2001

Copyright 2001

All rights reserved.

P/N 7351-960

TEL: +1 (858) 677-9040

FAX: +1 (858) 677-0940

Email: sales@calinst.com

Web Site: http://www.calinst.com

User and Programming Manual - Rev C

User and Programming Manual

AC Power Source

California Instruments

Models:

• 251TL, 351TL

• Options: -L22, -OP1, -SKT, -RMS, -EXT

Copyright 2001 California Instruments, Rev C, November 2001

TL Series November 2001 i

User and Programming Manual - Rev C

SAFETY SUMMARY

This power source contains high voltage and current circuits that are potentially lethal.

Because of its size and weight, electrical and mechanical stability must be ensured. The

following safety guidelines must be followed when operating or servicing this equipment.

These guidelines are not a substitute for vigilance and common sense. If this power

source is not used as specified in this manual, the protection provided by this equipment

may be impaired. California Instruments assumes no liability for the customer's failure to

comply with these requirements.

APPLYING POWER AND GROUNDING

Verify the correct voltage is applied to the unit (100 / 115 / 200 or 230 VAC Nominal). Verify that the

input power wiring is connected to a properly grounded utility outlet.

FUSES

Use only fuses of the specified current, voltage, and protection speed.

Do not short out the fuse holder or use a repaired fuse.

The main supplies in the 351TL use a North American ferrule fuse rated at

30A. (Fast Acting)

DO NOT OPERATE IN A VOLATILE ATMOSPHERE

Do not operate the power source in the presence of flammable gases or fumes. This product is

designed to operate in a controlled environment. Do not expose to rain or snow.

DO NOT TOUCH ENERGIZED CIRCUITS

Disconnect the power cable before servicing this equipment. Only qualified service personnel

may remove covers, replace components or make adjustments.

DO NOT SERVICE ALONE

Do not remove covers, replace components, or make adjustments unless another person, who

can administer first aid, is present.

DO NOT EXCEED INPUT RATINGS

Do not exceed the rated input voltage or frequency. Additional hazards may be introduced

because of component failure or improper operation.

DO NOT MODIFY INSTRUMENT OR SUBSTITUTE PARTS

Do not modify this instrument or substitute parts. Additional hazards may be introduced because

of component failure or improper operation.

MOVING THE POWER SOURCE

When moving the power source, observe the following:

1. Remove all AC power to unit.

2. Use two people to prevent injury.

SURFACE STABILITY

Operate the power source only on a level surface.

ii November 2001 TL Series

User and Programming Manual - Rev C

Electrical Safety Symbols Used in This Manual

TL Series November 2001 iii

User and Programming Manual - Rev C

WARRANTY INFORMATION

CALIFORNIA INSTRUMENTS CORPORATION warrants each instrument manufactured by

them to be free from defects in material and workmanship for a period of one year from the

date of shipment to the original purchaser. Excepted from this warranty are fuses and

batteries that carry the warranty of their original manufacturer where applicable.

CALIFORNIA INSTRUMENTS will service, replace, or adjust any defective part or parts, free

of charge, when the instrument is returned freight prepaid, and when examination reveals

that the fault has not occurred because of misuse, abnormal conditions of operation, user

modification, or attempted user repair. Equipment repaired beyond the effective date of

warranty or when abnormal usage has occurred will be charged at applicable rates.

CALIFORNIA INSTRUMENTS will submit an estimate for such charges before commencing

repair, if so requested.

If a fault develops, notify CALIFORNIA INSTRUMENTS at support@calinst.com or its local

representative, giving full details of the difficulty, including the model number and serial

number. On receipt of this information, service information or a Return Material Authorization

(RMA) number will be given. Add the RMA number furnished to the shipping label. Pack the

instrument carefully to prevent transportation damage, affix label to shipping container, and

ship freight prepaid to the factory. CALIFORNIA INSTRUMENTS shall not be responsible for

repair of damage due to improper handling or packing. Instruments returned without RMA

No. or freight collect may be refused at California Instruments discretion. Instruments

repaired under Warranty will be returned either via prepaid surface freight or low cost

airfreight at California Instruments discretion. Instruments repaired outside the Warranty

period will be returned freight collect, Ex Works CALIFORNIA INSTRUMENTS 9689 Towne

Centre Drive, San Diego, CA 92121-1964. If requested, an estimate of repair charges will

be made before work begins on repairs not covered by the Warranty.

SERVICE PROCEDURE

DAMAGE IN TRANSIT

The instrument should be tested when it is received. If it fails to operate properly, or is

damaged in any way, a claim should be filed immediately with the carrier. The claim agent

should obtain a full report of the damage, and a copy of this report should be forwarded to us

by fax or email (Fax: 858 677 0940, Email: support@calinst.com). CALIFORNIA

INSTRUMENTS will prepare an estimate of repair cost and repair the instrument when

authorized by the claim agent. Please include model number and serial number when

referring to the instrument.

SPARE PARTS

To order spare parts, user manuals, or determine the correct replacement part for your

California Instruments products, please contact the Customer Service department by phone

at + 1 858 677 9040, press 2 or by email support@calinst.com.

iv November 2001 TL Series

User and Programming Manual - Rev C

Table of Contents

1 Introduction.....................................................................................................................................1

1.1 General Description...............................................................................................................................1

1.2 Accessory Equipment/Rack Slides........................................................................................................1

2 Specifications..................................................................................................................................3

2.1 Electrical................................................................................................................................................3

2.2 Measurements [Option].........................................................................................................................6

2.3 System Specification.............................................................................................................................7

2.4 Unit Protection.......................................................................................................................................8

2.5 Mechanical.............................................................................................................................................8

2.6 Environmental........................................................................................................................................9

2.7 Regulatory.............................................................................................................................................9

2.8 Front Panel Controls............................................................................................................................10

2.9 Available Options.................................................................................................................................10

3 Installation and Functional Test....................................................................................................11

3.1 Unpacking............................................................................................................................................11

3.2 Power Requirements...........................................................................................................................11

3.3 Input Voltage Range Selection............................................................................................................13

3.4 Mechanical Installation........................................................................................................................17

3.5 Input Wiring.........................................................................................................................................17

3.6 Output Connections.............................................................................................................................17

3.7 Output Voltage Ranges.......................................................................................................................18

3.8 Functional Test....................................................................................................................................19

3.9 Current Limit - Modes of Operation.....................................................................................................21

4 Front Panel Operation ..................................................................................................................23

4.1 Functional Controls..............................................................................................................................23

4.2 How to Examples.................................................................................................................................28

4.3 Setting the Power on Initialization Values............................................................................................31

4.4 Current Limit Modes............................................................................................................................32

4.5 Function Strobe [Option]......................................................................................................................33

4.6 Remote Inhibit [Option]........................................................................................................................33

5 Principle of Operation ...................................................................................................................35

5.1 General................................................................................................................................................35

5.2 Overall Description..............................................................................................................................35

5.3 Input Power Supply..............................................................................................................................35

5.4 Range Relay Board.............................................................................................................................39

5.5 Amplifier...............................................................................................................................................39

5.6 Controller Module................................................................................................................................39

5.7 IEEE 488/ RS232 Interface [Option]....................................................................................................40

6 Calibration.....................................................................................................................................43

6.1 Calibration Equipment.........................................................................................................................43

6.2 Selecting Calibration Mode..................................................................................................................44

6.3 Routine Calibration..............................................................................................................................45

6.4 Non-Routine Calibration......................................................................................................................49

7 Service..........................................................................................................................................53

7.1 General................................................................................................................................................53

7.2 Basic Operation...................................................................................................................................53

7.3 Module Removal..................................................................................................................................55

7.4 Replaceable Parts...............................................................................................................................58

TL Series November 2001 v

User and Programming Manual - Rev C

8 Remote Control ............................................................................................................................59

8.1 Introduction.........................................................................................................................................59

8.2 PGUI32 Program Requirements.........................................................................................................59

8.3 IEEE Interface.....................................................................................................................................61

8.4 RS232C Interface................................................................................................................................62

8.5 PGUI32 Setup and Installation............................................................................................................ 64

8.6 Trouble Shooting - RS232C................................................................................................................66

8.7 Trouble Shooting - IEEE-488 / GPIB...................................................................................................69

8.8 PGUI32 Distribution Files.................................................................................................................... 70

8.9 Software Registration.......................................................................................................................... 71

9 Introduction to SCPI .....................................................................................................................73

9.1 Conventions Used in This Manual.......................................................................................................73

9.2 The SCPI Commands and Messages.................................................................................................73

9.3 Using Queries .....................................................................................................................................76

9.4 Structure of a SCPI Message..............................................................................................................76

9.5 SCPI Data Formats.............................................................................................................................79

10 SCPI Command Reference......................................................................................................81

10.1 Subsystem Commands....................................................................................................................... 81

10.2 Calibration Subsystem ........................................................................................................................82

10.3 Measurement Subsystem....................................................................................................................87

10.4 Source Subsystem.............................................................................................................................. 90

10.5 Output Subsystem............................................................................................................................... 94

10.6 Limit Subsystem..................................................................................................................................97

10.7 Display Subsystem.............................................................................................................................. 99

10.8 System Commands...........................................................................................................................100

10.9 Common Commands ........................................................................................................................102

11 Programming Examples .........................................................................................................110

11.1 Introduction ....................................................................................................................................... 110

11.2 Programming the Output...................................................................................................................110

11.3 Making Measurements......................................................................................................................112

12 Status Registers......................................................................................................................114

12.1 Power-On Conditions........................................................................................................................114

12.2 Standard Event Status Group ........................................................................................................... 115

12.3 Status Byte Register..........................................................................................................................115

12.4 Examples...........................................................................................................................................116

Appendix A : SCPI Command tree....................................................................................................117

Appendix B : SCPI Conformance Information...................................................................................118

Appendix C : Error Messages............................................................................................................119

Index..................................................................................................................................................120

vi November 2001 TL Series

User and Programming Manual - Rev C

List of Figures

Figure 2-1: Output Power Rating as a Function of Voltage and Load PF.............................................5

Figure 3-1: Model 251TL / 351TL AC Power Source..........................................................................11

Figure 3-2: Rear Panel View...............................................................................................................12

Figure 3-3: Connections to T1 for 105 - 125V Line Input....................................................................14

Figure 3-4: Connections to T1 for 210 - 250V Line Input....................................................................16

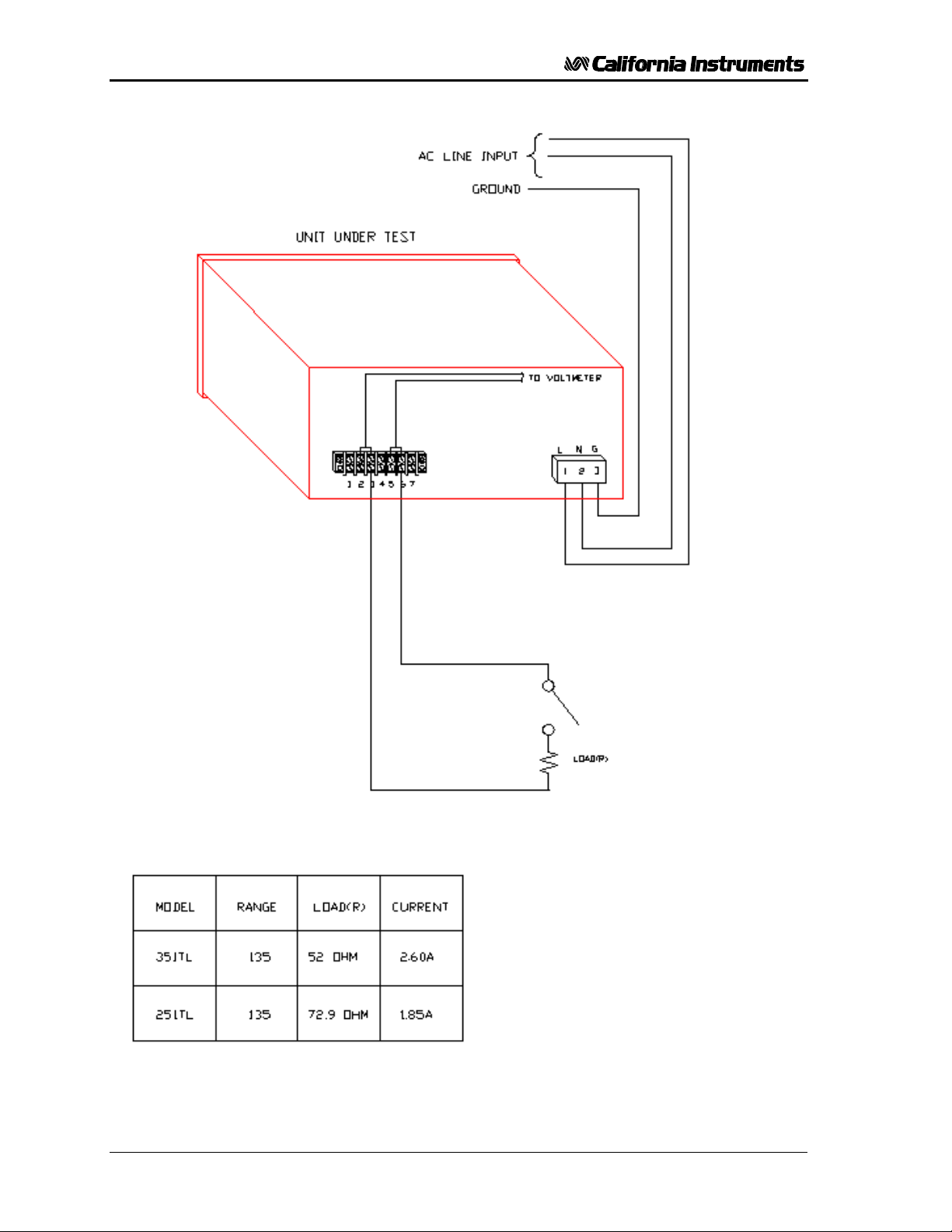

Figure 3-5: Test Setup 351TL.............................................................................................................20

Figure 4-1: Front Panel View ..............................................................................................................23

Figure 4-2: Voltage Auto Range Switch Over Points..........................................................................25

Figure 4-3: Shuttle Knob.....................................................................................................................26

Figure 5-1: AC Power System Block Diagram....................................................................................37

Figure 6-1: Test Equipment Hookup for Routine Output and Voltage Measurement Calibration.......45

Figure 6-2: Test Equipment Hook-up for Current and Power Measurement Calibration....................46

Figure 6-3: Internal Adjustments.........................................................................................................51

Figure 7-1: Assembly Location ...........................................................................................................56

Figure 8-1: Rear Panel View...............................................................................................................60

Figure 8-2: GPIB Address Selection Switch .......................................................................................61

Figure 8-3: RS232C Interface Cable Wiring Diagram.........................................................................64

Figure 8-4: System Properties Dialog Box..........................................................................................67

Figure 8-5: Advanced Port Settings Dialog Box..................................................................................67

Figure 8-6: COM Port Properties Dialog Box......................................................................................67

Figure 8-7: NI AT-GPIB/TNT Settings ................................................................................................69

Figure 8-8: NI AT-GPIB/TNT Advanced Settings Dialog ....................................................................69

Figure 9-1: Partial Command Tree.....................................................................................................74

Figure 9-2: Command Message Structure..........................................................................................76

Figure 12-1: AC Source Status System Model.................................................................................114

TL Series November 2001 vii

User and Programming Manual - Rev C

List of Tables

Table 4-1: Factory Default Power on Settings....................................................................................31

Table 6-1: Load Resistors and Current...............................................................................................43

Table 6-2: CAL Mode Status LED Indicators......................................................................................44

Table 7-1: Basic Symptoms................................................................................................................53

Table 7-2: Poor Output Voltage Accuracy..........................................................................................53

Table 7-3: Poor Output Voltage Regulation........................................................................................53

Table 7-4: Distorted Output ................................................................................................................54

Table 7-5: Unit Shuts Down After 3-5 Seconds..................................................................................54

Table 7-6: No Output and No Lights on Front Panel ..........................................................................54

Table 7-7: No Output But "Display" Is On..........................................................................................54

Table 7-8: Replaceable Parts .............................................................................................................58

Table 10-1: Mode Command Encoding..............................................................................................99

Table 10-2: Bit Configuration of Standard Event Status Enable Register ........................................103

Table 10-3: Bit Configuration of Standard Event Status Register.....................................................104

Table 10-4: *RST Default Parameter Values....................................................................................106

Table 10-5: Status Registers - Power on Conditions........................................................................106

Table 10-6: Bit Configuration of Status Byte Register ......................................................................108

Table 12-1: Bus Error Messages......................................................................................................119

viii November 2001 TL Series

User and Programming Manual - Rev C

RMS

RMS

1 Introduction

This instruction manual contains information on the installation, operation, calibration and

maintenance of the 351TL and 251TL AC power source.

1.1 General Description

The 351TL AC source is a 350 VA programmable AC power source. The 251TL is a 250 VA

version of the power source. In addition to the standard models, several options are

available that may change the voltage and frequency ranges of the power source. This user

manual covers the following models:

Model Voltage ranges Max. Current

351TL 135 V

270 V

251TL 135 V

270 V

The output voltage High and Low terminals are isolated from the chassis, and earth ground.

The AC input can be either 105 V

91 V

RMS

to 109 V

RMS

or 182 V

RMS

to 125 V

RMS

to 217 V

RMS

Simple front panel controls enable the voltage, current limit and frequency to be changed.

An optional RS232C and IEEE 488 interface is available for applications that require remote

control and measurements.

1.2 Accessory Equipment/Rack Slides

General Devices Company Model C300-120-B308 rack slides (option -RMS) may be

attached to the sides of the power source using 10-32 X 3/8 flat head screws.

2.8 A

RMS

RMS

RMS

AC, 210 V

RMS

1.4 A

2.4 A

1.2 A

RMS

RMS

RMS

RMS

to 250 V

at 47 to 67 Hz line frequency.

RMS

AC,

TL Series November 2001 1

User and Programming Manual - Rev C

This page intentionally left blank

2 November 2001 TL Series

User and Programming Manual - Rev C

2 Specifications

All specifications at 23 ±5°C unless noted otherwise.

2.1 Electrical

Input

Line Voltage:

115 V

230 V

100 V

200 V

nominal, 105 V

RMS

nominal, 210 V

RMS

nominal, 91 V

RMS

nominal, 182 V

RMS

RMS

RMS

RMS

RMS

to 125 V

to 250 V

to 109 V

to 217 V

RMS

RMS

RMS

RMS

AC

AC

Unit must be configured for correct Line input voltage.

Line Current: 9 A

maximum, line voltage = 115 VAC, full-load

RMS

PF = 0.7

Inrush Current:

150 A

75 A

for 115V line

pk

for 230V line

pk

Input power factor: 0.7 at full-load and 115 VAC input

Line Frequency: 47 Hz - 67 Hz

Isolation Voltage: Input to output = 2300 VAC, input to chassis = 1350 VAC

Output

Parameter Specification

Voltage

Range 0 to 135 V

or 270 V

RMS

(standard ranges)

RMS

Resolution 0.1 volt

Accuracy

± 0.1 % of calibrated range, 45 Hz - 100 Hz

± 0.2 % of calibrated range, 100 Hz - 5000 Hz

± 0.3 % of calibrated range, 5000 Hz - 8000 Hz

Load Regulation 0.1 % of FS. Add 0.05% above 2000 Hz

TL Series November 2001 3

User and Programming Manual - Rev C

Parameter Specification

External Sense Will compensate for up to 5% of voltage drop up to 2kHz

Line Regulation 0.02 % of FS

Settling time From start of voltage change from 5.0 V

voltage to within 2% of final value:

Distortion (THD

into linear load)

<0.5 % maximum 45 to 499 Hz

<1.0 % above 500 Hz

<2.0% 1000 to 8000Hz

DC Offset voltage AC Coupled transformer output

Output noise -73 db typical

( 20 kHz to 1 MHz at full load )

Temperature

± 0.02 % of full scale per degree C

coefficient:

Stability (24 hours) ± 0.015 % of full scale under constant load, line and

temperature

Total Power

PT = 0.7

351TL: 350 VA from 90 to 100% of V range

251TL: 250 VA from 78 to 100% of V range

Current (Refer to Figure 2-1 for derating)

Output

V Range

351TL

251TL

RMS

No load: 16 msec

Full load: 300 msec

(16 msec to within 15 % of final value)

Amps rms Amps peak

135

270

135

270

2.8

1.4

2.4

1.2

or higher

6

3

6

3

Adjustable Limit 0.0 to Maximum available RMS current for selected

voltage range.

Accuracy Programmed value + 5, -0 % of maximum RMS current

4 November 2001 TL Series

User and Programming Manual - Rev C

Parameter Specification

Frequency

Range 351TL 16.0 - 8000 Hz

Resolution 0.01 Hz from 16.00 to 80.00 Hz

Accuracy

Maximum output voltage available from 45 Hz.

0.1 Hz from 80.1 Hz to 800.0 Hz

1 Hz from 801 Hz to 8000 Hz

± 0.02% of programmed value

Temperature

± 5 ppm per degree Celsius

coefficient

Stability ± 15 ppm per year

Figure 2-1: Output Power Rating as a Function of Voltage and Load PF

TL Series November 2001 5

User and Programming Manual - Rev C

2.2 Measurements [Option]

Parameter Specification Unit

True RMS Current

Available on standard unit.

Range 0.000 - 4.000 A

Accuracy 0.2 % FS + 0.3 % reading

Resolution 0.001 A

Temp

Coefficients

Peak Current Requires Option -OP1

Range 0.00 – 12.00 A

Accuracy 0.5 % FS + 0.5 % reading

Resolution 0.01 A

Crest Factor

Available over bus only. Requires interface Option -OP1

Range 0.00 - 4.00

Accuracy 0.05

Resolution 0.01

True RMS Voltage Standard Unit: Available over bus only.

-OP1 option: Front Panel and bus.

Range 0.0 - 300.0 V

Accuracy 0.1 % FS + 0.05 % reading

Resolution 0.1 V

Temp

Coefficients

Real Power Requires Option -OP1

Range 0 - 400.0 W

Accuracy 0.2 % FS + 0.5 % reading

Resolution 0.2 W

Temp

Coefficients

Apparent Power

Available over bus only. Requires -OP1 option

Range (Remote only) 0 - 400.0 VA

Accuracy 0.3 % FS + 0.8 % reading

Resolution 2 VA

Power Factor

Requires -OP1 option

Range 0.00 - 1.00

Resolution 0..01

0.016

0.05

0.06

RMS

RMS

% FS / °C

PEAK

PEAK

RMS

RMS

V / °C

% FS /°C

6 November 2001 TL Series

User and Programming Manual - Rev C

2.3 System Specification

Parameter Specification

Setup storage Eight non volatile front panel setup registers available through

interface. Power on setting register available from front panel.

Interface (Option package -OP1 required)

RS-232C Bi-directional serial interface

Rear panel connector: 9 pin D shell

Handshake: CTS, RTS

Data bits: 8

Stop bits: 1

Parity: None

Baud rate: 19200

Command syntax: IEEE 488.2 commands and SCPI

IEEE-488 GPIB Interface

Rear panel connector: 24 pin D-shell

IEEE address: set using dip switch on rear panel from

0 to 31

IEEE functions: SH1, AH1, T8, L4, RL2, SRQ 0, PP 0,

DC 0, DT 0, C0

Terminators: LF, CRLF, EOI

Command syntax: IEEE 488.2 commands and SCPI

Remote Inhibit (Option package -OP1 required)

Rear panel connector: BNC

Input Contact closure to ground or logic low TTL

signal required to turn off output.

Automatic recovery when RI signal is

removed.

Function Strobe (Option package -OP1 required)

Rear panel connector: BNC

Output Active low TTL signal. Signal driven low for

approximately 400 µsec any time output

voltage or frequency programmed value

changes. Signal level may be changed by

removing jumpers to open collector.

TL Series November 2001 7

User and Programming Manual - Rev C

2.4 Unit Protection

Parameter Specification

Input Overcurrent: Electronic current limit with circuit breaker.

Transients: Surge protection to withstand EN50082-1 (IEC 801-4, 5) levels.

Output Overcurrent: Constant current operation. (Standard)

0.1 Second shutdown (constant voltage mode Option)

Output Short Circuit: Peak current limit.

Shutdown (constant voltage mode Option).

Overtemperature: Automatic shutdown.

2.5 Mechanical

Parameter Specification

Dimensions: Height Width Depth Unit

13.26 48.26 56.62 cm

5.22 19 22.29 inches

Unit Weight: 34 Kg / 75 lbs

Material: Steel chassis and panels.

Aluminum cover.

Finish: Yellow iridite, painted semi-gloss polyurethane

Cooling: Fan cooled with air intake on the sides and exhaust to the rear.

Internal Construction: Modular sub assemblies.

Chassis Slides: P/N 210960 / Option -RMS

General Devices Model CTS-1-20-B307-2

Front Panel Mounted Output Connection:

Wonpro Universal outlet socket (option -SKT)

Rear Panel Mounted Connectors:

RS232C I/F DB 9

IEEE-488 I/F D-shell 24 pin

Remote Inhibit BNC (requires -OP1 option package)

Function Strobe BNC (requires -OP1 option package)

AC Output Amp 1-480705-1

External Sense Amp 1-480705-1

Line Input Kulka 9-85-3 Terminal block

8 November 2001 TL Series

User and Programming Manual - Rev C

2.6 Environmental

Parameter Specification

Operating Temp: 0 degrees to + 40 degrees Celsius.

Storage Temp: - 40 degrees to + 85 degrees Celsius.

Humidity:

Altitude Operating: 15000 feet / 6000 meters maximum.

Creepage and

Clearance:

Insulation: Rated to Installation Category (Overvoltage Category) II

Vibration: Designed to meet NSTA 1A transportation levels.

Shock: Designed to meet NSTA 1A transportation levels.

2.7 Regulatory

Parameter Specification

Electromagnetic

Emissions and

Immunity:

Acoustic Noise: 65 dBA maximum at 0% to 50% load, 75 dBA maximum greater

Operating: ≤ 90% RH up to 40° C., non condensing

Storage: ≤ 90% RH up to 40° C, ≤75% RH up to 70° C.

VA Power: Full VA power output :0 - 6000 feet / 0 - 2000

meters.

Derate VA power 5 % per 1000 feet from 6000 to

15000 feet / 2000 to 6000 meters.

Rated for Pollution Degree 2.

Designed to EN50081-1 and EN50082-1 European Emissions

and Immunity standards as required for the “CE” marking.

than 50% load to 100% load. Measured at one meter.

Safety: Designed to EN61010-1 European safety standards as required

for the “CE” marking.

Remote Control

TL Series November 2001 9

User and Programming Manual - Rev C

2.8 Front Panel Controls

Parameter Specification

Controls: Shuttle knobs:

Allows continuous change of Voltage, Frequency and Current

limit. Voltage change is inactive on single voltage range

configuration units.

Function keys:

Controls Output state, Voltage range and Display mode.

Displays: Two, 4 digits, 0.5” LCD display. For viewing programmed voltage,

frequency, current limit and for displaying measured current.

Status Indicators: 10 LEDs to indicate:

REMOTE, FAULT, OUTPUT (ON/OFF), VOLTAGE RANGE

HIGH, VOLTAGE RANGE AUTO

FREQUENCY, CURRENT, PEAK CURRENT, POWER, POWER

FACTOR DISPLAY MODES (Refer to paragraph 4.1.2).

2.9 Available Options

Option Description

-OP1 Option package 1 includes:

-RMS Rack mount slides

-SKT Universal front panel dual outlet socket.

-EXT Removes controller and allows external oscillator input.

1

• Measurement Functions

• Combined IEEE-488 / RS232C interface.

• Remote Inhibit Input

• Function Strobe Output

P/N 211045 / Option -RMS

General Devices Model C300S-120-B308

1

Additional options may have been made available since this manual revision. Installed options are listed on

the power source’s type sticker. A manual addendum may be issued for new options not covered by this

manual.

10 November 2001 TL Series

User and Programming Manual - Rev C

3 Installation and Functional Test

3.1 Unpacking

Inspect the unit for any possible shipping damage immediately upon receipt. If damage is

evident, notify the carrier. DO NOT return an instrument to the factory without prior

approval. Do not destroy the packing container until the unit has been inspected for damage

in shipment.

3.2 Power Requirements

The AC Power System has been designed to operate from a single phase AC line voltage.

The nominal operating voltage is 100V, 115V, 200V or 230V line input. The Power Source

line input setting is shown on the type sticker located on the rear panel.

Figure 3-1: Model 251TL / 351TL AC Power Source

WARNING: Do not connect the unit to a 400-480 service, as the result will be a severely

damaged unit.

Do not connect the unit to AC line input unless the nominal line input settings

match those of the available AC line voltage.

TL Series November 2001 11

User and Programming Manual - Rev C

3.2.1 AC Line Voltage

The AC Power Source has been designed to operate from either of the following AC line

voltage ranges:

1) 91 to 109 V

2) 82 to 217 V

3) 105 to 125 V

4) 210 to 250 V

RMS

RMS

RMS

RMS

CAUTION: The AC Power Source will be damaged if it is operated at an input voltage

that is outside its configured input range.

The input voltage range is set at the factory. Section 3.3 gives the procedure to change the

input voltage range. The location for connection of the INPUT line is shown in Figure 3-2.

3.2.2 Line Frequency Operating Range

The AC Power Source has been designed to operate with a line frequency from 47Hz to

67 Hz.

3.2.3 Input Power

The input power to the AC Power Source depends upon line and load conditions and may be

as high as 1000 watts.

Figure 3-2: Rear Panel View

12 November 2001 TL Series

User and Programming Manual - Rev C

4

5

3.3 Input Voltage Range Selection

WARNING: The line voltage is present in certain sections of this Power Source.

DEATH: On contact may result if personnel fail to observe safety precautions.

Do not touch electric circuits when power is applied. Servicing should

only be performed by trained personnel.

The input voltage range is configured by changing the taps on the input transformer. See

Figure 3-3 or Figure 3-4 for the location of the jumpers and input wires.

3.3.1 Voltage Range Configuration (105 – 125 V)

In order to change the voltage range configuration:

1. Turn off the input circuit breaker.

2. Disconnect AC input power to the source by unplugging the power cord.

3. Remove the AC Power Source top cover by removing (14) #6-32 x 5/16” FLH

screws. There are 7 screws on the sides and 7 screws on the top that hold the

cover.

Remove the (2) #6-32 x 1” PHN screws and lock washers that hold the amplifier near

the outside panel.

Remove the (2) #6-32 x 3/8” PHN screws and lock washers located near the

connector, attaching the red insulator to the center bracket.

The line input voltage range is set by the configuration of the Input Transformer, T1. To

configure T1 for the 105-125 volt range, make the following connections to T1 (refer to

Figure 3-3) :

Jumper terminals 1 and 4.

Jumper terminals 3 and 6.

Connect the input line from the Circuit Breaker to Terminals 1 and 6.

TL Series November 2001 13

User and Programming Manual - Rev C

Figure 3-3: Connections to T1 for 105 - 125V Line Input

14 November 2001 TL Series

User and Programming Manual - Rev C

3.3.2 High Input Voltage Range Configuration (210 – 250 V)

In order to change the voltage range configuration:

1. Turn off the input circuit breaker.

2. Disconnect AC input power at TB1.

3. Remove the AC Power Source top cover by removing (14) #6-32 x 5/16” FLH

screws. There are a total of 7 screws on the sides and another 7 screws on the top

that secure the top cover.

The line input voltage range is set by the configuration of the Input Transformer, T1. To

configure T1 for the 210-250 volt range, make the following connections to T1 (refer to

Figure 3-4) :

Jumper terminals 3 and 4.

Connect the input line from the Circuit Breaker to Terminals 1 and 6.

Remove all other connections to Terminals 1 through 6.

TL Series November 2001 15

User and Programming Manual - Rev C

Figure 3-4: Connections to T1 for 210 - 250V Line Input

16 November 2001 TL Series

User and Programming Manual - Rev C

3.4 Mechanical Installation

The power source has been designed for rack mounting in a standard 19 inch rack. The unit

must be supported from the sides with optional rack slides. See Accessory Equipment/Rack

Slides in Section 1.2. The cooling fan at the rear of the unit must be free of any obstructions

which would interfere with the flow of air. A 2.5 inch (6.35cm) clearance should be

maintained between the rear of the unit and the rear panel of the mounting cabinet. Keep in

mind that adequate ventilation of the mounting cabinet must be maintained for sufficient

cooling of the power source. Use louvered side panels, and/or perforated rear panels to

assure adequate airflow. Also, the air intake holes on the sides of the power source must not

be obstructed when mounted inside cabinet. See Figure 3-1.

3.5 Input Wiring

The AC Power Source must be operated from a three-wire single-phase service. The mains

source must have a current rating greater than or equal to 10 A for the low input range. Use

the supplied safety cover/strain relief when connecting the input wires to the power source.

Refer to Figure 3-2 for the input power connections. When connecting the input wires to

input terminal block, make sure the safety grounding wire from the strain relief grommet is

longer than the Line and Neutral wire so that the ground wire will be the last one to take any

strain. For low-range input operation (115V) we recommend #12 AWG input wires as a

minimum. For high-range input operation (230V) #14AWG is recommended. For European

applications (230V), the following input cordset may also be used:

Panel Components # 86518030 Rated 16A, 250V, 70° C, 3x 1.5mm² conductor size. VDE

approved. Install as described above for discreet wiring.

3.6 Output Connections

The output terminal block is located at the rear of the power source or on the front panel with

Option -SKT. All load connections must be made on the rear panel terminal block or from

the front panel socket if the -SKT Option is installed. The remote sense inputs are normally

jumpered directly to the adjacent power output pins on the output connector. If the sense

terminals are not connected to the power output pins, the output voltage may rise significantly

above the programmed value. When connecting the output wires, use the supplied safety

cover/strain relief and mount over the output connector. Also mount the supplied snap-on

ferrite filter around the output wiring between the output terminals and the strain relief

grommet. Enclose ferrite filter with the safety cover.

If the load is a significant distance from the output terminal strip it may be desirable to sense

the output voltage directly at the load. If remote sensing is to be used, then the size of the

output power wiring must be heavy enough to prevent a voltage difference greater than 7% of

the programmed value from the power output pins to the sense input pins.

The Remote Sense inputs must be connected or an output voltage 7% higher than the

programmed output will be generated. If the Power Source is configured for constant

voltage, a fault will be generated.

TL Series November 2001 17

User and Programming Manual - Rev C

3.7 Output Voltage Ranges

The standard 351TL AC power source has two output voltage ranges 0-135 VAC and

0-270 VAC. The operator may switch from one range to the other at will with no special

precautions except to remember that the output voltage will go to zero voltage whenever a

range change takes place.

Certain options available on the 351TL series may result in different voltage range values or

a single voltage range only. Certain models may be ordered with a single voltage range only.

On single voltage range units, the Range change button has no function and the LED

indicator is not used.

351TL AC power source models with dual voltage ranges offer an auto voltage range change

mode. In this mode, the voltage range is automatically changed when the user sets a

voltage above 135 or below 131 V

The AUTO mode can be selected by pressing the range change button until the AUTO mode

LED illuminates. To take the AC power source out of the AUTO voltage range mode, press

the Voltage range button briefly. This will put the unit in the present range but takes it out of

auto mode.

RMS

.

Note: Even in AUTO mode, the output temporarily goes to zero volts when a

voltage range change occurs. If this is not acceptable, the AC source

should be operated in the high voltage range only and not in AUTO

mode.

18 November 2001 TL Series

User and Programming Manual - Rev C

3.8 Functional Test

CAUTION: Work carefully when performing these tests - hazardous voltages are

present on the input and output during this test.

Refer to Figure 3-5 for the test set up. Use the following load resistor values:

Model Voltage Range Resistor Current (A

351TL 135

270

251TL 135

270

52 Ω

208 Ω

72.9 Ω

292 Ω

2.60

1.30

1.85

.92

RMS

)

1. Connect an oscilloscope, voltmeter and/or distortion analyzer to the AC source output at

the rear panel output terminal.

2. Connect the AC power input voltage connections to the AC source input terminals.

Connect the sense input to the adjacent power pin on the rear panel connector. Turn on

the power switch located at the rear panel.

3. Verify that the front panel LCD display reads out the initial start up voltage and frequency.

4. Select the low voltage range. Set the frequency to 60 Hz with the right shuttle. Select the

current function with the Frequency/Current selector. Set the current limit to the

maximum value using the right shuttle. Set the output voltage to 135V with the left

shuttle.

5. Enable the output by pressing the output “on/off” button in the top right of the front panel.

The green LED above the button will illuminate when the output is on. The output should

be a clean 135V AC sinewave having less than 0.5 % distortion.

6. Apply full load (refer to table on Figure 3-5) to the output of the source and verify the

output remains within 0.05 % of the initial 135V . The output should still be clean and the

distortion should still be less than 0.5 % at 60 Hz.

7. Using the right shuttle set the output current limit value to 2 amps (1 amp for the 251TL).

If the unit is configured for Constant Current mode, the system should go into current

limit and reduce the output voltage. This may create additional distortion on the output

voltage. If the unit is configured for Constant Voltage mode (factory default), an error

message will appear on the display (err. -300) that indicates an output fault condition and

the output will go off. Return the current value to the maximum current and disconnect

the load.

8. Repeat steps 4 through 7 but set the output for the following: Hi voltage range and the

current limit to maximum value. Refer to the table above for the relevant resistor values.

For units that are factory configured with a single voltage range, these steps do not have

to be repeated.

In the event the power source does not pass the functional test, refer to the calibration

procedure in Section 6 or call California Instrument’s customer satisfaction department for

further assistance.

TL Series November 2001 19

User and Programming Manual - Rev C

Figure 3-5: Test Setup 351TL

20 November 2001 TL Series

User and Programming Manual - Rev C

3.9 Current Limit - Modes of Operation

When the Power Source is shipped from the factory, it is configured for the Constant Current

Mode of operation. This mode means if the load current exceeds the programmed Current

Limit value, the output current will continue at the programmed value.

The Power Source can be configured to operate in the Constant Voltage mode. In this mode

of operation, if the load current exceeds the Current Limit value, the output voltage will

default with the output relay open. The Constant Voltage mode is only usable if the default

voltage is set for 5.0 volts. If the default is any other voltage, the power source may display a

fault at power up.

To configure the Power Source, remove the input line voltage connection from the rear

panel. Remove the top cover. Install jumpers W1 and W2 on the front panel controller.

Reinstall the top cover.

TL Series November 2001 21

Loading...

Loading...