Page 1

PyroMini Series

Operator’s Guide

Page 2

2

INTERNATIONAL OPERATOR’S GUIDE

DE: Laden Sie die Bedienungsanleitung unter:

EN: Download the operator’s guide at:

ES: Descargue el manual de instrucciones en:

FR: Téléchargez le manuel d’instructions sur:

IT: Scarica il manuale di istruzioni su:

www.calex.co.uk/pyromini

Page 3

3

The PyroMini Series is a range of miniature non-contact infrared temperature sensors with

separate electronics modules.

All models have an adjustable emissivity setting and are capable of measuring a wide variety

of target materials, including food, paper, textiles, plastics, leather, tobacco, pharmaceuticals,

chemicals, rubber, coal and asphalt.

General-purpose PyroMini models measure non-reflective non-metals, or painted or coated

metals, at temperatures from -20°C to 1000°C.

PyroMini 2.2 models have a shor t measurement wavelength. They are ideal for measuring

reflective surfaces such as uncoated iron and steel, as well as many other high-temperature

applications. They are capable of measuring temperatures from 100°C to 2000°C.

The optional touch screen interface provides temperature indication, alarms, sensor

configuration and data logging to MicroSD Card. The optional high-temperature sensing head

on general-purpose models may be used in ambient temperatures of up to 180°C without

cooling. The low-noise cable on high ambient temperature models is resistant to interference

from movement, so it is ideal for mounting on moving objects such as robot arms.

A choice of optics is available to measure small or large targets at short or long distances, and

there is a choice of 4-20 mA, RS485 Modbus and alarm relay outputs.

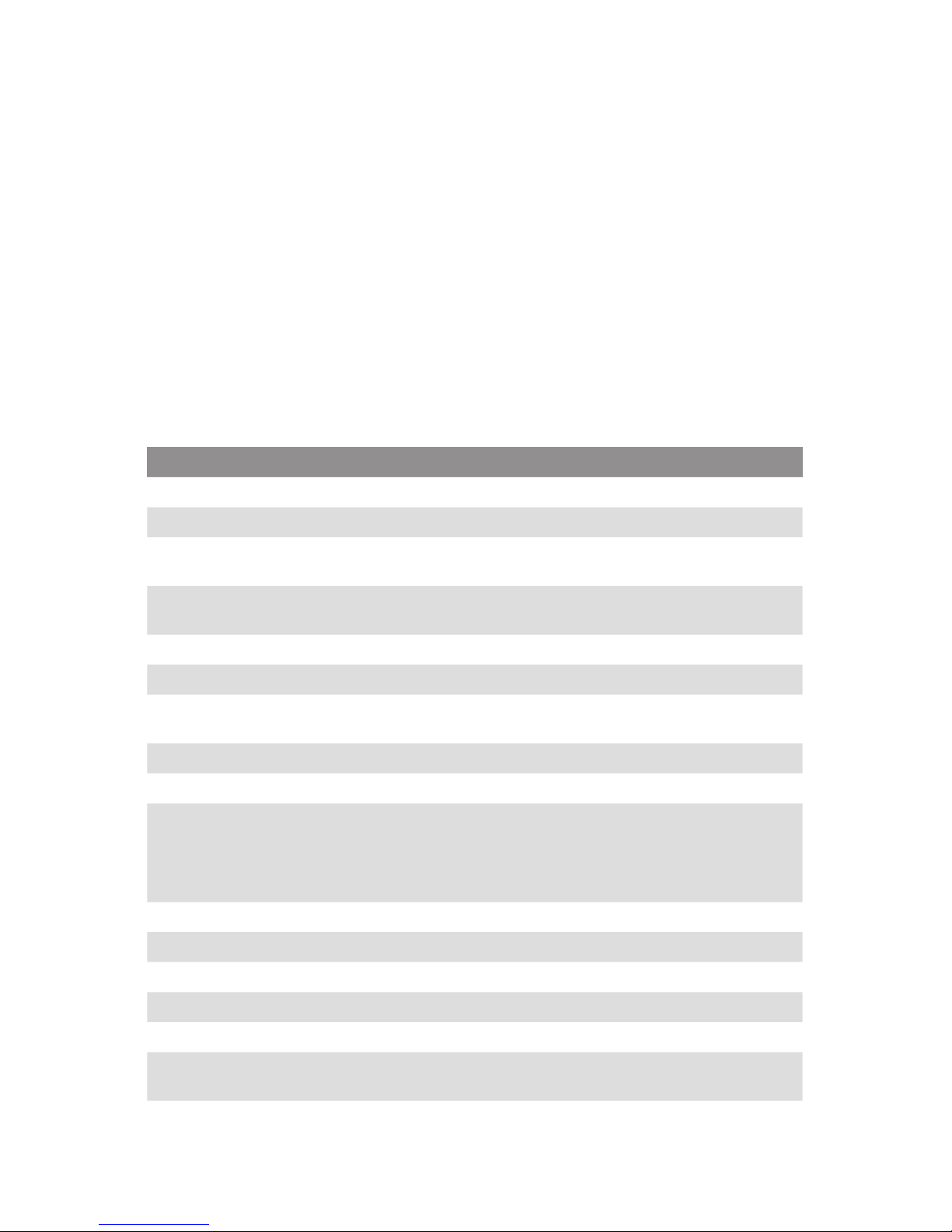

SPECIFICATION

PyroMini PyroMini 2.2

Temperature Range See table of Model Numbers

Maximum Temperature

Span (-CRT models)

Full temperature range (up to 1550°C)

Minimum Temperature

Span (-CRT models)

100°C

Output 4 to 20 mA or RS485 Modbus

Field of View See table of Model Numbers

Accuracy ± 1°C or 1%,

whichever is greater

± 2°C or 1%,

whichever is greater

Repeatability ± 0.5°C or 0.5%, whichever is greater

Emissivity Setting Range 0.20 to 1.00 0.10 to 1.00

Emissivity Setting Method • -CB models: via two rotary switches

in electronics module

• -BB and -BT models: via RS485

• -CRT and -BT models: via touch screen

Response Time, t

90

240 ms (90% response)

Spectral Range 8 to 14 μm 2.0 to 2.6 μm

Supply Voltage 24 V DC ± 5%

Maximum Current Draw 100 mA

Maximum Loop Impedance -CB and -CRT models: 900 Ω (4 to 20 mA output)

Alarm Relays (-CRT

models)

2 x Single Pole Changeover alarm relays rated

24 V DC, 1 A, isolated 500 V DC

Page 4

4

MECHANICAL

Sensing head Electronics Module

Construction Stainless Steel

316

Die-cast Aluminium

Major Dimensions

Ø18 x 45 mm

98(w) x 64(h) x 36(d) mm

Mounting M16 x 1 mm

thread

Two M4 screws for wall mounting (see

diagram)

Cable Length (sensing head

to electronics module)

1 m (standard), up to 30 m (optional)

Weight with 1 m Cable 390 g (approx)

Cable Connections Removable screw terminal blocks (see Connections).

Conductor size: 28 AWG to 18 AWG

Output Cable Gland Suitable for cable diameters 3.0 to 6.5 mm

ENVIRONMENTAL

Sensing Head Electronics

Module

(without touch

screen)

Electronics

Module (with

touch screen)

Environmental Rating IP65 (NEMA 4) IP65 (NEMA 4) –

Ambient Temperature

Range

See table of

Model Numbers

0°C to 60°C 0°C to 60°C

Relative Humidity Ma ximum 95%

non-condensing

Ma ximum 95%

non-condensing

Maximum 95%

non-condensing

CE Marked Yes Ye s Ye s

RoHS Compliant Yes Ye s Ye s

The PyroMini series conforms to EMC Directive EN61326-1:2006 (Electrical equipment for

measurement, control and laboratory use – Industrial) as well as industrial standards for

electromagnetic immunity and emissions.

Page 5

5

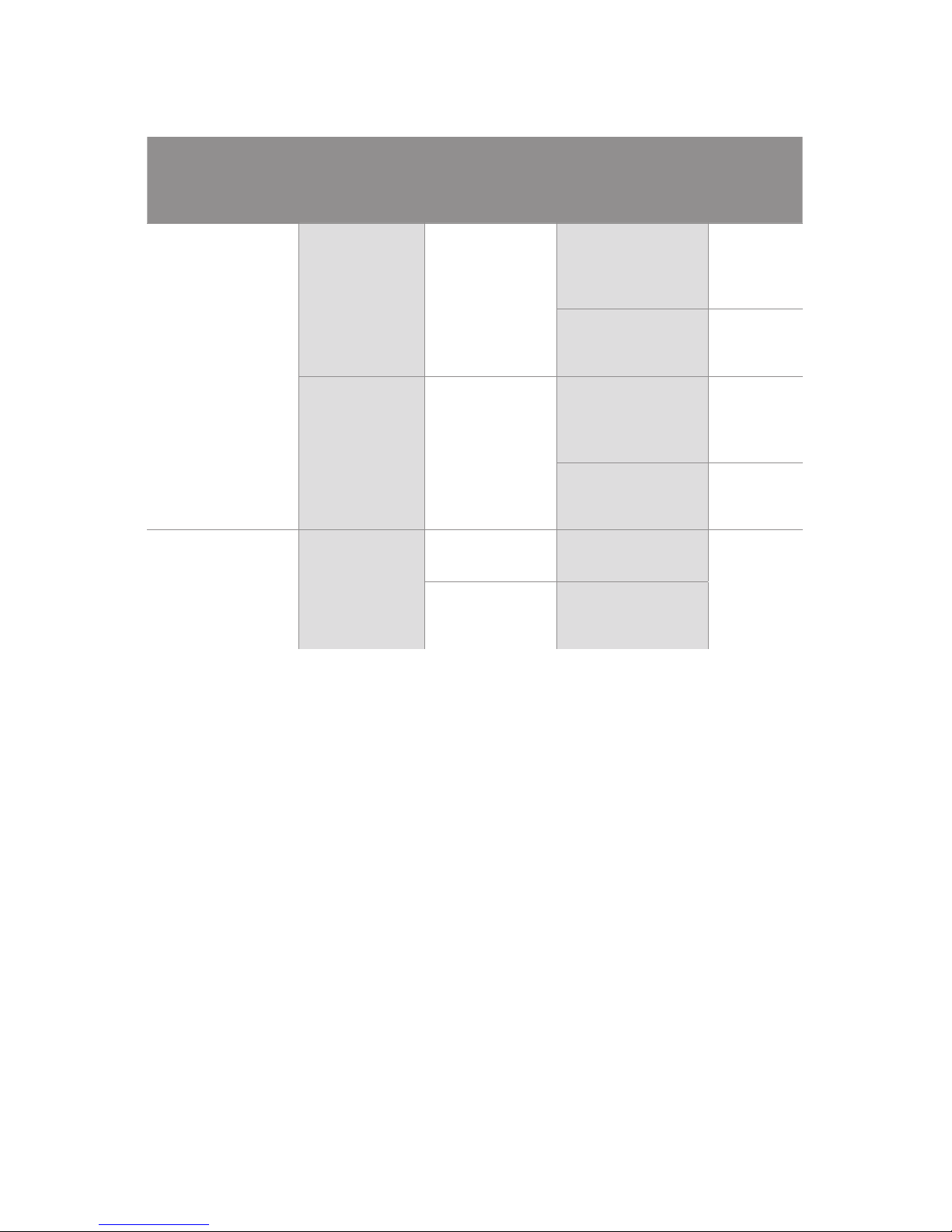

MODEL NUMBERS

The following combinations of ambient temperature range, optics, measured temperature

range, output and interface are available:

Series

Sensing Head

Operating

Temperature

Range

Field of View

Temperature

Range

Output

and

Interface

PM

General Purpose

(8-14 μ m )

MA (0-60°C)

21 (2:1)

151 (15:1)

301 (30:1)

CF (close focus)

LT (-20 - 100°C)

MT (0 - 250°C)

HT (0 - 500°C)

XT (0 - 1000°C)

CB

CT (-20 - 1000°C)

CRT

BB

BRT

HA (0 -18 0 °C)

JA (0-12 0 °C)

201 (2 0:1)

LT (-20 - 100°C)

MT (0 - 250°C)

HT (0 - 500°C)

XT (0 - 1000°C)

CB

CT (-20 - 1000°C)

CRT

BB

BRT

PM 2.2

High Temperature

(2.2 μm)

(all models

0-70°C)

151 (15:1) PT (100 - 400°C)

CB

CRT

BB

BRT

251 (25:1)

751 (75:1)

CF (close focus)

MT (250 - 1000°C)

HT (450 - 2000°C)

SENSING HEAD OPERATING TEMPERATURE RANGE

-JA and -HA models withstand high ambient temperatures without cooling. They are available

with -201 (20:1) optics only.

There is no need to supply cooling air or water, and the miniature sensing head is much smaller

than bulky, cooled sensors.

Page 6

6

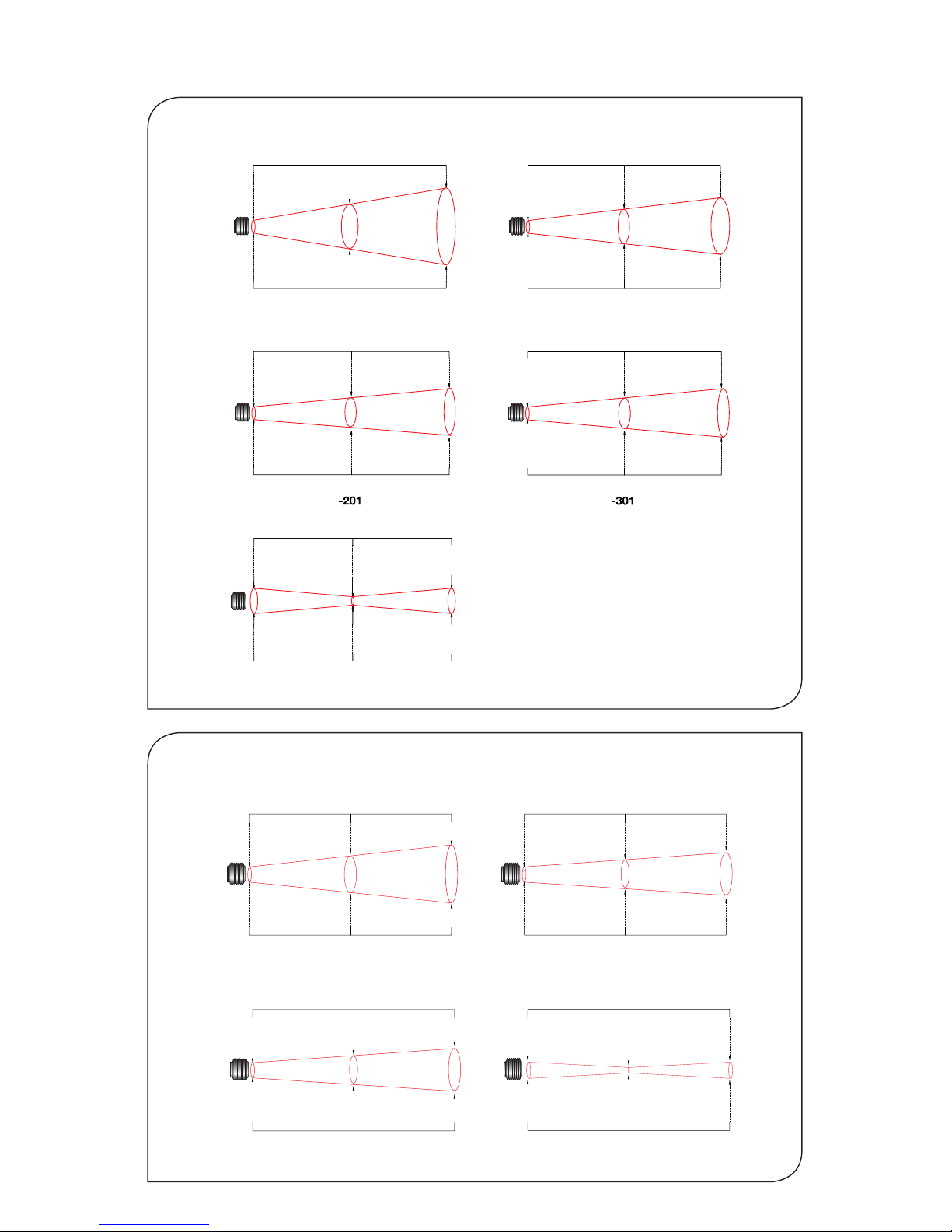

(PyroMini 2.2 - High Temperature)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

12

60

135

0.6

2.4

5.3

0 59.1 118.1

0 1500 3000

Spot Dia.

(inches)

Spot Dia.

(mm)

Spot Dia.

(inches)

Spot Dia.

(mm)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

12

100

215

0.6

3.9

8.5

0 59.1

118.1

59.1

118.1

0 1500 3000

015003000

D:S 25:1D:S 15:1

-251

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

12

20

55

0.6

0.8

2.2

0

Spot Dia.

(inches)

Spot Dia.

(mm)

D:S 75:1

-751

-151

Spot Dia.

(inches)

Spot Dia.

(mm)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

12

7.5

30

0.6

0.3

1.2

019.

73

9.4

0500 1000

-CF

(PyroMini - General Purpose)

FIELD OF VIEW

11.9

0

Spot Dia.

(inches)

Spot Dia.

(mm)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

61.9

111.9

0.5

2.4

4.4

048

100200

D:S 2:1

-21

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.9

45.2

78.6

0.5

1.8

3.1

019.

73

9.4

0500 1000

Spot Dia.

(inches)

Spot Dia.

(mm)

D:S 15:1

-151

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.9

36.9

61.9

0.5

1.5

2.5

019.739.4

0500 1000

Spot Dia.

(inches)

Spot Dia.

(mm)

D:S 20:1

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.9

28.6

45.2

0.5

1.1

1.8

019.

73

9.4

0500 1000

Spot Dia.

(inches)

Spot Dia.

(mm)

D:S 30:1

Spot Dia.

(inches)

Spot Dia.

(mm)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.9

0.5

0

0

5.0

0.20

100

3.9

12.5

0.49

200

7.9

-CF

Diameter of target spot measured

versus distance from sensing

head at 90% energy. Sensors may

be used at longer distances than

these diagrams show. There is no

maximum measurement distance

in clean air.

Page 7

7

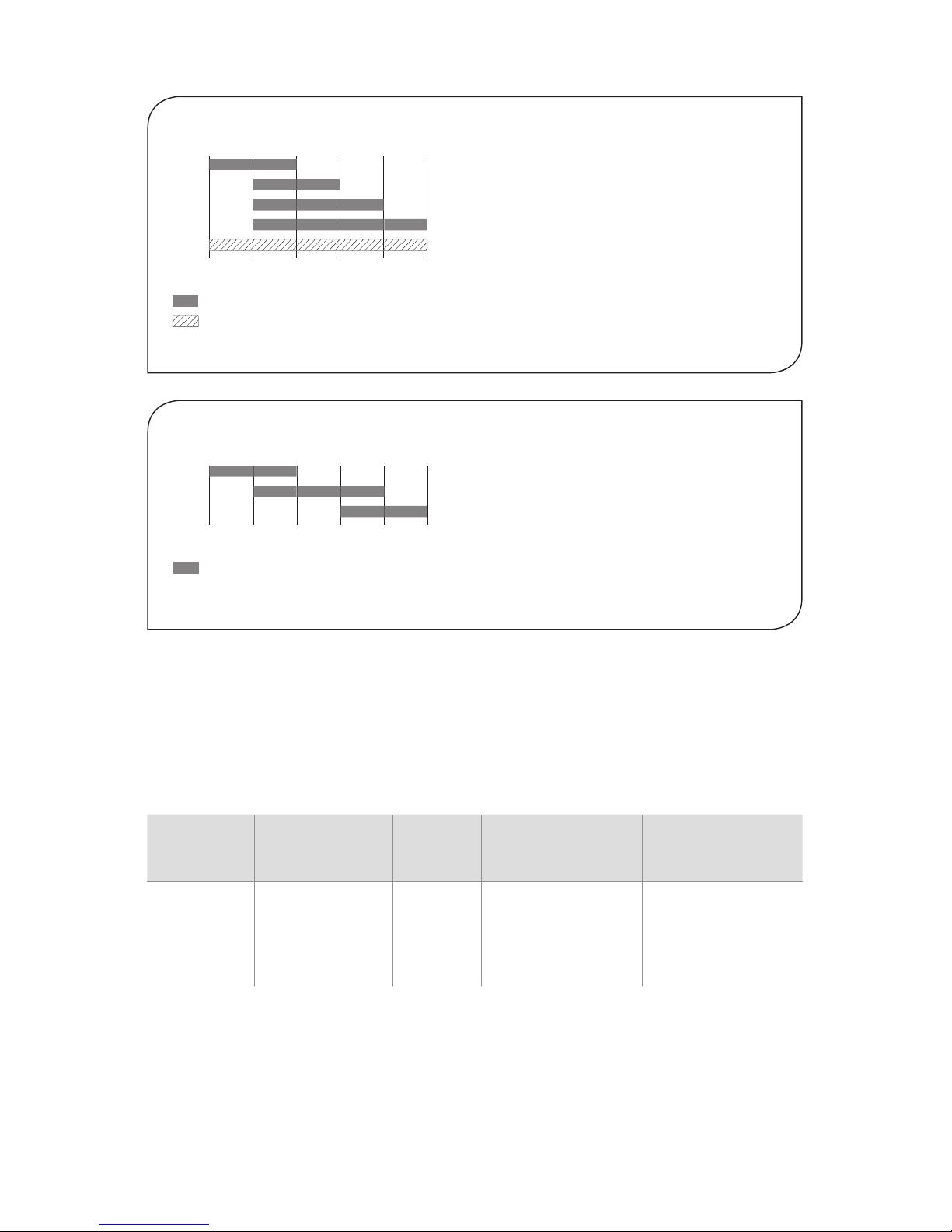

MEASUREMENT TEMPERATURE RANGE (°C)

-20

-LT

-MT

-HT

-XT

-CT

0 100

Fixed (e.g. -MT: 0°C @ 4 mA, 250°C @ 20 mA)

-CRT models: 4 to 20 mA output configurable within this range

-BRT and -BB models: Digital output, full temperature range

250 500 1000

OUTPUT AND INTERFACE

-CB 4 to 20 mA output, no touch screen

-CRT 4 to 20 mA output and two alarm relay outputs, with touch screen

-BB RS485 Modbus output, no touch screen

-BRT RS485 Modbus output and two alarm relay outputs, with touch screen

EXAMPLE: PM-MA-301-CT-BRT

Series

Sensing Head

Operating

Temperature

Optics

Temperature

Range

Output and

Interface

PM

PyroMini

-MA 0°C to 60°C -301 3 0:1

divergent

-CT configurable

within the limits: -20

to 1000 °C

-BRT RS485

Modbus output

and two alarm relay

outputs, with touch

screen

(PyroMini - General Purpose)

(PyroMini 2.2 - High Temperature)

100

-PT

-MT

-HT

250 400

-CB models: Fixed 4 to 20mA output scale (e.g. -MT: 250

o

C @ 4mA,1000oC @ 20 mA)

-CRT models: 4 to 20 mA output configurable within this range

-BRT and -BB models: Digital output, full temperature range

450 1000 2000

Page 8

8

EMISSIVITY ADJUSTMENT (-CB MODELS)

The emissivity setting on -CB models may be adjusted via two rotary switches inside the electronics

box. To adjust the emissivity setting:

Set the left switch to the first digit after the decimal point (0.1).

Set the right switch to the second digit after the decimal point (0.01).

To enter an emissivity setting of 1.00, set both switches to 0.

If the selected emissivity setting is lower than the minimum, the sensor will default to an emissivity

setting of 0.95.

For example:

Left switch Right switch Emissivity setting

6 3 0.63

0 0 1.00

TOUCH SCREEN (-CRT AND -BRT MODELS)

The optional backlit touch screen interface mounted in the lid of the electronics module provides

a large, bright display of the measured temperature, as well as options for full configuration of

the sensor. The graph view shows the history of the measured temperature.

In alarm conditions, the display changes colour to provide an immediate and obvious alarm

indication. Alarm modes and levels can be configured via the touch screen.

TOUCH SCREEN SPECIFICATIONS

Touch Screen

Display Format

2.83” (72 mm) resistive touch TFT, 320 x 240 pixels, backlit

Configurable

Parameters

Temperature range, temperature units, emissivity setting, reflected energy compensation, alarms, signal processing, Modbus

address (-BRT models), date and time, data logging

Temperature Units °C or °F configurable

Temperature

Resolution

0.1°

Alarm Configuration Two alarms with adjustable level, individually configurable as HI

or LO. Alarm 2 can be set to target temperature or sensing head

internal temperature

Signal Processing Average, peak hold, valley hold, minimum, maximum

EXAMPLE: PM2.2-251-MT-BRT

Series

Sensing Head

Operating

Temperature

Measurement

Temperature

Range Optics

Output and

Interface

PM2.2

PyroMini 2.2

251

25:1 divergent opticsMT250°C to 1000°C

-BRT RS485

Modbus output

and two alarm relay

outputs, with touch

screen

Page 9

9

User Interface

Default View

Temperature View

Displays a large indication of the measured temperature. The background

turns bright red when an alarm is activated.

Setting Temperature

Press “°C” to switch to °F and vice versa. The units are changed throughout the interface.

Selecting Displayed Temperature

Press the temperature display to select which reading is shown:

Filtered Temp

The measured temperature, with averaging and hold processing. This temperature is output

by the sensor on the 4 to 20 mA output (-CB and -CRT models).

Average Temp

The measured temperature with averaging but without hold processing.

Unfiltered Temp

The unprocessed measured temperature.

MicroSD Card status.

This icon is displayed when a MicroSD card is inserted, and flashes when

data logging is in progress.

This icon is displayed when scheduled data logging is enabled and has yet

to begin.

List View

Displays a list of the measured temperatures, alarm state and data logging

state.

Filtered Temp: The measured temperature, with averaging and hold processing.

Unfiltered Temp: The unprocessed measured temperature.

Average Temp: The Unfiltered Temperature averaged over the period specified in “Output

Pro c es s in g ”.

Maximum Temp: The highest temperature measured during the hold period, with averaging.

Minimum Temp: The lowest temperature measured during the hold period, with averaging.

Sensor Temp: The internal temperature of the sensing head.

Reflected Temp: The reflected energy compensation temperature, as specified in “Emis-

sivity and Compensation”.

Page 10

10

Lock/Unlock

Prevents settings being changed via a four-digit numerical code.

The default password is 1234.

Change Password

Enter, confirm and save a new four-digit code.

Start/Stop Logging

GO

Manually begins or ends data logging (requires MicroSD Card, available

separately).

If Scheduled Start is enabled in Settings > Data Logging, then logging cannot

be started manually.

To manually start logging, you must first disable Scheduled Start.

Graph

Displays the recent history of the Filtered Temperature and the Sensor

Temperature. To scroll backwards and forwards in time, touch the graph and

drag it. The graph stores the most recent 24 hours of temperature data.

Reset Graph

Clears and restarts the graph.

Real-Time Scrolling View

Returns the graph to the real-time scrolling view, showing the most recent

measurements.

STOP

Acknowledge Alarms

Switches the relay outputs for triggered alarms to their normal, untriggered

state. The background of the Temperature View, List View and Graph View will

stay red, and the alarms will not be triggered again, until the alarms are reset

(see “Alarms” below). Alarms can be acknowledged when the display is locked.

Settings

Access the configuration parameters. Press Apply

to save the settings, or Exit to leave the screen

without saving.

If Settings icon is grey, the interface is locked.

See “Lock/Unlock”.

Page 11

11

Settings

Date & Time

Change the date and time for data logging purposes.

The clock is reset when the power is switched off, unless a battery is fitted.

Output Processing

f

(x)

AVERAGING PERIOD

Set the time, in seconds, over which the measured temperature is averaged.

Note: averaging prevents the sensor from following rapid temperature

changes. Minimum: 0 (no averaging). Maximum: 60.

HOLD MODE

Peak

The sensor holds the maximum temperature steady for the Hold Period. After

this, the sensor responds normally. If the sensor detects a higher temperature,

it holds this temperature steady for the Hold Period.

Valley

Similar to Peak Hold mode except that the sensor outputs the minimum

detected temperature steady for the Hold Period.

Off

Disables hold processing.

HOLD PERIOD

Set the time, in seconds, for the sensor to hold the temperature as above.

Minimum: 0 (no hold processing). Maximum: 1200.

Data Logging

Sample Period

The time, in seconds, between samples. Minimum: 1. Maximum: 86,400

(1 day).

Number of Samples

The number of samples to collect before logging stops. Minimum: 0

(continuous logging). Maximum: 86,400 (1 day of data if Sample Period = 1

second).

Enable Scheduled Start

The sensor begins logging at the Date and Time specified. Logging can also

be started and stopped manually.

Date and Time

The date and time for scheduled logging to start.

Emissivity and Compensation

Emissivity and Compensation

Enter the emissivity of the target. Target emissivity can be determined

experimentally, or estimated using an emissivity table. For more information,

contact Calex.

Enable Reflected Energy Compensation

If enabled, compensates for errors caused by reflected energy from hotter or

colder objects.

Reflected Temperature

Enter the temperature of the surroundings of the target for Reflected

Energy Compensation.

Page 12

12

4 to 20 mA Output (-CRT models)

mA

Set the temperature range limits for the 4 to 20 mA output.

Temperature at 4 mA

The lower temperature range limit.

Temperature at 20 mA

The upper temperature range limit.

Please note

The difference between the temperatures at 4 mA and at 20 mA must be at

least 100°C. The temperature at 20 mA must be greater than the temperature

at 4 mA.

Modbus Address (-BRT models)

The current Modbus address of the sensor is displayed. Enter a new address,

then press Apply to save it to the sensor. Cycle the power to use the new

address.

Minimum: 1. Maximum: 247.

Alarms

Configure the settings for Alarm 1 and Alarm 2 separately, and configure alarm

logging settings.

Manually Reset Alarms

If an alarm has been triggered, allows both alarms to be triggered again.

Alarms will not be triggered again until they are reset, either automatically or

manually.

Alarm settings

Alarm 1 and Alarm 2

Alarm Set Point

The temperature at which the alarm is triggered.

Hysteresis

The temperature difference between the Alarm Set Point and the reset

temperature. Hysteresis is only used when Automatic Reset is enabled. Please

see the Alarm Operation diagrams below for more information.

Minimum: 0°C (hysteresis disabled).

Filtered Temperature or Sensor Temperature (Alarm 2 only)

Select the temperature monitored by Alarm 2.

Alarm Type

High

The alarm is triggered when the temperature rises above the Alarm Set Point.

Low

The alarm is triggered when the temperature drops below the Alarm Set Point.

Off

The alarm is disabled.

Page 13

13

ALARM OPERATION WITH HYSTERESIS & AUTOMATIC RESET

Alarm triggered Alarm reset

A

larm Set Point

Hysteresis

Temperature

Time

Alarm triggered Alarm reset

Alarm Set Point

Hysteresis

Temperature

Ti

me

High Alarm with Automatic Reset

Low Alarm with Automatic Reset

The PyroMini can be used as a standalone data logger.

PyroMini models -CRT and -BRT include a MicroSD card slot for data logging, which can be

configured via the touch screen interface. The user can select the sample rate and the number

of samples to be taken and schedule the data logging to start at a certain time.

With a 2 GB card, the user can store 28.4 million readings, which provides almost 1 year’s

worth of data at the fastest possible sample rate of 1 per second.

Data is stored on the MicroSD card in .csv format and can be viewed and edited easily using

spreadsheet software.

A MicroSD card with SD card adapter is available as an optional accessor y.

The MicroSD card slot and battery holder are located on the touch screen circuit board in the

lid of the electronics module. Readings are time and date stamped using the sensor’s internal

clock. The clock is reset when the power is disconnected, or it will continue if the optional

battery is fitted.

Reset

Automatic

The alarm is acknowledged and reset automatically when the temperature

reaches the reset temperature (see Hysteresis). It can also be acknowledged or

reset manually.

Manual

The alarm is acknowledged by pressing Acknowledge on the Temperature

View or List View, and reset by pressing Reset on the Alarms screen.

Alarm Logging

Alarm events can be logged to the MicroSD Card. Alarm log files and settings

are independent from Data Logging.

Log Trigger Time

The time that an alarm is triggered will be logged.

Log Data While Triggered

Data logging will start when an alarm is triggered. 1 sample is logged per

second. Logging stops when both alarms are reset.

Log Acknowledge Time

The time that the alarm is acknowledged will be logged.

Log Reset Time

The time that the alarm is reset will be logged.

Acknowledge

Reset

Page 14

14

DATA LOGGING SPECIFICATIONS

Data Logging Interval 1 to 86,400 seconds (1 day)

MicroSD Card Max. capacity: 32 GB (not included)

Internal Clock Battery 1 x BR 1225 3V (not included)

Variables Logged Target temperature, sensing head temperature, electronics

module temperature, max, min, average, emissivity setting,

reflected energy compensation temperature

File format .csv

Configurable

Parameters

Sample period, number of samples, scheduled start date and

time

Modbus address range 1 to 247

USING THE PYROMINI AS A DATA LOGGER

1. Insert a MicroSD card into the holder on the circuit board inside the lid of

the electronics module.

2. To retain the date and time when the sensor is switched off, fit a battery to

the holder on the circuit board inside the lid.

3. Replace the lid and connect the sensor power supply.

4. To set the number of samples to be logged, the time period between

samples, and, if required, to schedule data logging to automatically start,

press Settings to access the Settings menu, then press Data Logging to

access the Data Logging options.

5. To save data logging settings, press Apply

GO

6. To manually star t data logging, press Go on the Temperature View or List

Vi ew.

7. While logging is in progress, the Logging Icon flashes on the Temperature

View and List View.

STOP

8. To stop data logging, press Stop.

9. To transfer data to a computer, remove the MicroSD Card from the sensor,

insert the card into the SD Card adapter (supplied with MicroSD Card,

accessory model MSD) and insert the adapter into an SD Card reader.

Page 15

15

Data is saved to the MicroSD Card in .csv format. This file format can be opened or imported by

spreadsheet software such as Microsoft Excel.

A new folder is created on the MicroSD Card for each day that data is logged.

A new log file is created every time logging is started. The start time is used as the file name.

DIMENSIONS & ACCESSORIES

Thread M16 x 1 mm

Standard length

18

48

18

64

86

98

20

36

10004513

12

Ø 18.6

Air Purge Collar

Sensing Head

4

18

Ø 40

Ø 29

25

50

1/8" BSP

air fitting

Removable spigot fitted to

type APSN for use with

all optics except 2:1. Not fitted

to type APSW for -21 models.

Mounting Nut

(included)

Ø 18

Electronics Module

Touch screen

(optional)

72 mm (2.83")

Cable glands:

14 mm AF

Mounting

holes: use M4

CSK screws

(supplied)

36

Touch screen

(optional)

72 mm (2.83”)

MicroSD Card

Battery

(use 1 x BR 1225 3V)

INSTALLATION OF MICROSD CARD AND BATTERY

Page 16

16

10.0

40.0

50.0

50.0

40.0

9.0

15.0

25.0

25.0

Ø16.0

60° Rotation 60° Rotation

60° Rotation

9.0

48.0

Fixed Bracket (FBS) Adjustable Bracket (ABS)

2 x Mounting Holes M4 Clearance 2 x Mounting Holes M4 Clearance

Material: Stainless steel

Bracket thickness: 2 mm

9.0

24.024.0

A range of accessories to suit different applications and industrial environments is available.

These may be ordered at any time and added on-site. The following accessories are available

from Calex:

Fixed mounting bracket (see above for dimensions): Allows rotational adjustment in one

dimension. Model number: FBS.

Adjustable mounting bracket (see above for dimensions): Allows rotational adjustment in two

dimensions. Model number: ABS.

Air purge collar (see above for dimensions): The air purge collar is used to keep dust, fumes,

moisture, and other contaminants away from the lens. It must be screwed fully onto the sensing

head. Air flows into the 1/8” BSP fitting and out of the front aperture. Air flow should be 5 to 15

l/min. Clean or ‘instrument’ air is recommended. Model APSW is for use with sensors with 2:1

optics. Model APSN is for use with all other models.

Laser sighting tool: When fitted to the sensor during installation or re-alignment, the laser

sighting tool pinpoints the centre of the measured spot. Model number: LSTS.

MicroSD Card: Stores logged data. For use with -BRT and -CRT models. Includes SD Card

adapter. Model number: MSD.

Protective plastic or silicon windows: Helps protect the lens from mechanical or chemical

damage. Quick and easy to replace. For use with general-purpose models only. Model number:

PWS / SIWS.

Dual laser sighting bracket: Allows continuous laser sighting at the same time as using the

sensor. Model number: DLSBFS (fixed), DLSBAS (adjustable)

6-sensor touch screen hub (-BB and -BRT models): Multi-channel temperature display,

configuration and logging for up to 6 Modbus sensors. Model number: PM180.

OPTIONS

The following options are available. Options are factory installed and must be ordered with the

sensor.

Calibration Certificate: UKAS traceable certificate showing the measured temperature at

three points across the sensor’s temperature range. Model number: CALCERTA.

Extended Cable (30 m maximum total cable length): 1 m cable is supplied with each sensor

as standard. Extra cable can be added to this in increments of 1 m. Model number: PMCE (-MA

models), PMCEHT (-HA models), PM2.2CE (PM2.2 models).

Page 17

17

INSTALLATION

The installation process consists of the following stages:

Preparation

Mechanical installation

Electrical installation

Please read the following sections thoroughly before proceeding with the installation.

PREPARATION

Ensure that the sensor is positioned so that it is focused on the target only.

DISTANCE AND SPOT SIZE

Sensor

CORRECT

INCORREC

T

Background

T

arget larger

than spot size

T

arget smaller

than spot size

The size of the area (spot size) to be measured determines the distance between the sensor and

the target. The spot size must not be larger than the target. The sensor should be mounted so

that the measured spot size is smaller than the target.

AMBIENT TEMPERATURE

The sensing head withstands up to 60°C, 70°C, 120°C, or 180°C, without cooling, depending

on the choice of model. See “Model Numbers” for more information.

Avoid thermal shock. Allow 20 minutes for the unit to adjust to large changes in ambient

temperature.

ATMOSPHERIC QUALITY

Smoke, fumes, dust or steam can contaminate the lens and cause errors in temperature

measurement. In these types of environment the air purge collar should be used to help keep

the lens clean.

Page 18

18

INTERFERENCE FROM MOVEMENT

The low-noise sensing head cable on -HA models is resistant to interference caused by

movement. The sensing head may be mounted on moving machinery such as robot arms

without affecting the accuracy of the measured temperature.

ELECTRICAL INTERFERENCE

The PyroMini is tested to industrial standards for electromagnetic compatibility (EMC) as shown

in Specifications at the beginning of this manual.

To minimise electromagnetic interference or ‘noise’, the sensor should be mounted away from

motors, generators and such like.

POWER SUPPLY

Be sure to use a 24 V DC (100 mA) power supply.

MECHANICAL INSTALLATION

All sensors come with a 1 m cable and a mounting nut as standard. Longer cables are available

to order. The sensor can be mounted on brackets or cut-outs of your own design, or you can

use the fixed or adjustable mounting bracket accessories.

Note: The sensor housing must be connected to earth at one point, either the housing

of the sensing head, the electronics module, or the output cable shield termination. To

avoid ground loops, please ensure the sensor is grounded at only one of these points.

Page 19

19

ELECTRICAL INSTALLATION

CONNECTIONS

Sensing Head Cable Colour Codes

Depending on the sensing head type, there will be 4 or 5

wires, with the following combinations of colour codes:

Terminal label Colours

TP+ Yellow Blue with white line

TP- Green White with blue line

TH+ Brown/Red Blue

GND White White

VCC Grey (PyroMini 2.2 only)

OP+

OP-

PWR-

PWR+

NO1

COM1

NC1

NO2

COM2

NC2

A

24 V DC

100 mA

4 to 20

mA

x 0.10

x 0.01

Emissivity

adjustment

switches

(-CB models)

Relay outputs

(-CRT models)

Sensing head

-CB and -CRT models

+

-

Removable

screw terminals

OP+

OP-

PWR-

PWR+

NO1

COM1

NC1

NO2

COM2

NC2

A

24 V DC

100 mA

4 to 20

mA

x 0.10

x 0.01

Emissivity

adjustment

switches

(-CB models)

Relay outputs

(-CRT models)

Sensing head

OP-

NO1

COM1

NC1

NO2

COM2

NC2

24 V DC

100 mA

Relay outputs

(-BRT models)

Sensing head

Modbus

Master

GND

RS-

RS+

-CB and -CRT models

-BB and -BRT models

+

-

OP+

PWR-

PWR+

Removable

screw terminals

Removable

screw terminals

+

-

When reconnecting the sensing head to

the electronics module, ensure the

shield drain wire is terminated to the

inside of the cable gland.

Page 20

20

WIRING (ALL MODELS)

Check the distance between the sensing head and the electronics module, and between the

electronics module and the instrumentation. If necessary, the sensor can be ordered with a

longer cable between the sensing head and the electronics module.

Do not extend or shorten the sensing head cable. The head and electronics module are

calibrated as a pair, and modifying the sensing head cable can affect the measurement

accuracy. Contact Calex for assistance.

The output cable from the electronics module should have an outer diameter between 3.0 and

6.5 mm, with conductors of size 28 to 18 AWG.

The terminal blocks in the electronics module may be removed from the circuit board for easy wiring.

Do not connect or disconnect the touch screen circuit board from the main circuit board while

the sensor is on.

WIRING (-BB AND -BRT MODELS)

When connecting several sensors in a single Modbus network, all of the sensors should be

connected via a junction box to a single network bus cable, running from the furthest sensor to

the Modbus Master.

Up to 247 sensors may be connected to a single Modbus network. Each sensor must have a

unique Modbus address. The Modbus address may be changed via the touch screen interface

on -BRT models, or via Modbus.

To help prevent data reflections, please ensure the cable between each sensor and the main

network bus is as short as possible. The network bus should be terminated with a resistor of

120 Ω between the RS+ and RS- wires. The PWR- wire of the bus should be connected to the

signal ground of the Modbus Master.

MODBUS OVER SERIAL LINE (RS485)

Interface

Baud rate 9600

Format 8 data, No parity, 1 stop bit

Reply delay (ms) 20

Supported functions

Read register 0x03, 0x04

Write single register 0x06

Write multiple register 0x10

Mask write register 0x16

Read/write 0 x 17

Page 21

21

The list below includes all available addresses:

R = Read W = Write (single, multiple or read/write) MW = Mask write

Address Length (words) Description R/W/MW

0x00 1 MODBUS slave address R/W*

0x02

2

Sensor identification register

Bits 0..19 - Serial number

Bits 20..23 - Sensor type

(12 = PyroMini, 14 = PyroMini 2.2)

Bits 24..26 - Sensor field-of-view

For PM-MA : 0 = 2:1, 1 = 15:1, 2 = 30:1

For PM-HA : 0 = 20:1

For PM2.2: 0 = x51-MT, 1 = x51-HT,

2 = 151-LT, 3 = 151-PT

Bits 28..32 - Reserved

R

0x06 1 Unfiltered object temperature R

0x08 1 Sensor temperature R

0x0A 1 Maximum temperature over hold period R

0x0C 1 Minimum temperature over hold period R

0x0E 1 Average temperature over hold period R

0x10 1 Filtered object temperature R

0x12 1 PCB temperature R

0x14

1

Emissivity (1 LSB = 0.0001)

Minimum 0.2000, Maximum 1.0000

R/W

0x16 1 Reflected temperature R/W

0x18

1

Sensor status register

Bits 0..1 - Reserved

Bit 2 - Hold processing on (1)/off (0)

Bit 3 - Hold peaks (1)/valleys (0)

Bits 4..6 - Reserved

Bit 7 - Reflected energy compensation

on (1)/off (0)

Bits 8..15 - Reserved

R/ W/MW

0x1A

1

Average period (1 LSB = 0.05 seconds)

Minimum 0.05 seconds, Maximum 60.00

seconds

R/W

0x1C

1

Hold period (1 LSB = 0.05 seconds)

Minimum 0.05 seconds, Maximum 1200.00

seconds

R/W

0x1E 1 Temperature at 4 mA

PM: Minimum -20°C, Maximum 900°C

PM2.2: Minimum 100°C, Maximum 1900°C

R/W

0x20 1 Temperature at 20 mA

PM: Minimum 80°C, Maximum 1000°C

PM2.2: Minimum 200°C, Maximum 2000°C

R/W

Page 22

22

Address Length (words) Description R/W/MW

0x22 1 Alarm 1 setpoint

Minimum -20°C, Maximum 1000°C

Minimum 100°C, Maximum 2000°C

R/W

0x 24 1 Alarm 1 hysteresis

PM: Minimum 0°C, Maximum 1000°C

PM2.2: Minimum 0°C, Maximum 1550°C

R/W

0x26 1 Alarm 1 status register

Bit 0 – Relay triggered (R)

Bit 1 – Visible alarm active (R)

Bit 2 – Alarm triggered (R)

Bit 3 – Auto reset (1)/manual reset (0)

(R/ W/MW)

Bit 4 – Alarm acknowledge (R/W/MW)

Bit 5 – Alarm reset (R/W/MW)

Bits 6..7 – Reserved

Bit 8 – High alarm (1)/low alarm (0) (R/W/MW)

Bit 9 – Alarm enabled (1)/disabled (0)

Bits 10..15 – Reser ved

R/ W/MW

0x28 1 Alarm 2 status register

Bit 0 – Relay triggered (R)

Bit 1 – Visible alarm active (R)

Bit 2 – Alarm triggered (R)

Bit 3 – Auto reset (1)/manual reset (0)

(R/ W/MW)

Bit 4 – Alarm acknowledge (R/W/MW)

Bit 5 – Alarm reset (R/W/MW)

Bit 6 – Reserved

Bit 7 – Filtered object temperature

(1)/head temperature (0) (R/ W/MW)

Bit 8 – High alarm (1)/low alarm (0) (R/W/MW)

Bit 9 – Alarm enabled (1)/disabled (0)

Bits 10..15 – Reser ved

R/ W/MW

0x2A 1 Alarm 2 setpoint

PM: Minimum -20°C, Maximum 1000°C

PM2.2: Minimum 100°C, Maximum 2000°C

R/W

0x2C 1 Alarm 2 hysteresis

PM: Minimum 0°C, Maximum 1000°C

PM2.2: Minimum 0°C, Maximum 1550°C

R/W

* Single register writes only. New address will not take effect until next power on.

Notes:

1. All temperatures are in tenths of degrees C

2. Writing to unlisted registers could cause malfunction

3. All write and mask operations are saved to non-volatile memory

4. For further information please refer to http://www.modbus.org/specs.php

5. Use address 255 to communicate with any connected sensor. Use address 0 to broadcast

to all connected sensors (no response expected)

Page 23

23

OPERATION

Once the sensor is in position and the appropriate power, air and cable connections are secure, the system is ready for continuous operation by completing the following simple steps:

1. Turn on the sensor power supply

2. Turn on the connected instrumentation

3. Read, monitor or log the temperature

IMPORTANT

Be aware of the following when using the sensor:

1. If the sensor is exposed to significant changes in ambient temperature (hot to cold, or

cold to hot), allow 20 minutes for the temperature to stabilise before taking or recording

measurements.

2. Do not operate the sensor near large electromagnetic fields (e.g. around arc welders or

induction heaters). Electromagnetic interference can cause measurement errors.

3. Wires must be connected only to the appropriate terminals.

VIEWING THROUGH A WINDOW

The sensor is capable of measuring the temperature of a target through a window made of a

material that is transmissive to infrared radiation at 8-14 microns (PM models) or 2.0-2.6 microns (PM2.2 models). The emissivity setting of the sensor should be adjusted to compensate

for the presence of the window. Please contact Calex for more information on using the sensor

with a window.

MAINTENANCE

Our customer service representatives are available for application assistance, calibration,

repair, and solutions to specific problems. Contact our Service Department before returning

any equipment. In many cases, problems can be solved over the telephone. If the sensor is not

performing as it should, try to match the symptom below to the problem. If the table does not

help, call Calex for further advice.

Troubleshooting

Symptom Probable Cause Solution

No output No power to sensor Check power supply

Erroneous temperature Incorrect wire connection Check wire colour codes

Erroneous temperature Field of view obstruction Remove obstruction

Erroneous temperature

(analogue output)

Output temperature scale

mismatch

Re-scale input temperature

range on measurement

instrument to match sensor

LENS CLEANING

Keep the lens clean at all times. Any foreign matter on the lens would affect measurement

accuracy. Blow off loose particles (if not using the air purge accessory) with an air ‘puffer’.

GUARANTEE

Calex guarantees each instrument it manufactures to be free from defect in material and

workmanship under normal use and service for the period of two years from the date of

purchase. This guarantee extends only to the original buyer according to Calex terms and

conditions of Sale.

Page 24

Calex Electronics Limited

PO Box 2, Leighton Buzzard, Bedfordshire, England LU7 4AZ

Tel: +44 (0)1525 373178 Fax: +44 (0)1525 851319 Email: mail@calex.co.uk

Online: http://www.calex.co.uk

Issue E - Mar 2018

Loading...

Loading...