Page 1

ExTemp Series

Intrinsically Safe Infrared Temperature Sensor

and LCT Loop Configuration Tool

Operator’s Guide

Page 2

2

INTRODUCTION

ExTemp intrinsically safe non-contact infrared temperature sensors measure the temperature

of an area of the surface of a solid or liquid, and transmit this as a two-wire, linear 4-20 mA

output.

Temperature ranges from -20°C to 1000°C are available. All models have an adjustable

emissivity setting, and may be used to measure a wide variety of target materials, including

food, paper, textiles, plastics, leather, tobacco, pharmaceuticals, chemicals, rubber, coal,

asphalt and paint.

A choice of precision optics is available to measure small or large targets at short or long

distances.

The optional LCT Loop Configuration Tool (USB adapter) and free software allow the

ExTemp to be connected to a PC for temperature indication, sensor configuration and data

acquisition.

These sensors are designed primarily for use in hazardous areas in conjunction with a

suitable safety barrier or isolator. All models have been certified Intrinsically Safe for use

in gas and dust hazardous areas by Certification Management Ltd. They comply with the

European ATEX Directive 2014/14/EU and are covered by certificates for IECEx (international)

and TIIS (Japan).

IMPORTANT INFORMATION FOR USE:

Voltage MUST be supplied by a suitably rated safety barrier or isolator.

For re-configuration of the sensor, the LCT MUST be connected in the safe area, behind the

protection of a safety barrier or isolator.

The ExTemp dust certification relies upon the ingress protection provided by the device

enclosure and therefore the device MUST NOT be opened. Care should be taken to avoid

inadvertently loosening the cable gland when tightening locknuts.

Do not attempt to repair a faulty unit. Contact the vendor to arrange a return.

CONFORMANCE TO REQUIREMENTS

This product has passed a high voltage withstand test up to 700 VDC.

This product utilises the reduced creepage and clearance distances of ANNEX F by meeting

the requirements of IP65 and an Overvoltage Category I.

SAFETY PARAMETERS:

The device must not be used outside of the ambient temperature range (Ta) or subjected to

voltages, current or power greater than those listed below, in order to ensure safe operation

of the device:

Ui = 28 V Ta = -20°C to +70°C

Ii = 93 mA Ci = 8 nF

Pi = 650 mW Li = 0 mH

INTRINSIC SAFETY CERTIFICATION

All models of the ExTemp have been issued an ATEX (CML 14ATEX2079) Certificate for use in

both gas and dust explosive atmospheres in above ground installations.

Given the ExTemp conforms to the highest level of protection ‘ia’, it is suitable for use in all

Zones. The maximum energy stored in the device and the maximum surface temperature in

both normal operation, and under fault conditions, also make the ExTemp suitable for use

within all Gas and Dust Groups with a temperature rating of T4 or lower.

Tables 1, 2 and 3 describe the ATEX Gas and Dust Groups, Gas and Dust Zones, and gas

ignition temperature classifications in which the ExTemp is suitable:

Page 3

3

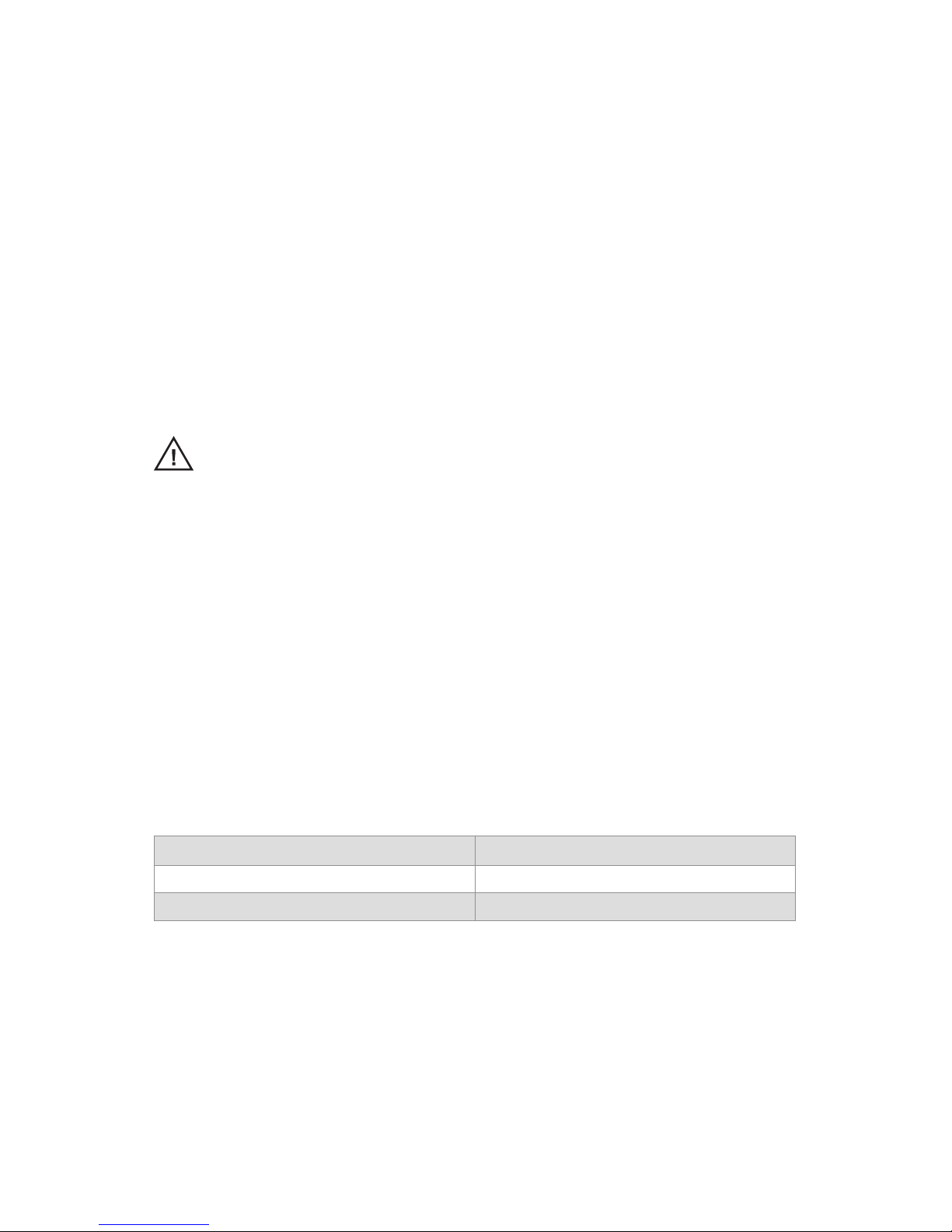

Zone Description Supported?

Gas 0 Explosive gas air mixture continuously present.

1 Explosive gas air mixture likely to occur in normal

operation.

2 Explosive gas air mixture not likely to occur, and if it does

it will only exist for a short time.

Dust 20 Explosive atmosphere in the form of a cloud of

combustible dust in air is continuously present, or for long

periods or frequently.

21 Explosive atmosphere in the form of a cloud of

combustible dust in air is likely to occur occasionally in

normal operation.

22 Explosive atmosphere in the form of a cloud of

combustible dust in air is not likely to occur in normal

operation, but if it does occur, will only persist for a short

period.

Group Definition Supported?

Gas IIA e.g. Propane

IIB e.g. Ethylene

IIC e.g. Hydrogen

Dust IIIA Combustible flyings

IIIB Non-conductive dusts

IIIC Conductive dusts

Table 1: Gas and Dust Zones in which the ExTemp may be used

Table 2: Gas and Dust Groups in which the ExTemp is suitable for use

Table 3: Gas ignition temperature classifications to which the ExTemp conforms

Gas Ignition Temperature Classification Supported?

450 °C T1

300 °C T2

200 °C T3

135 °C T4

100 °C T5 NO

85 °C T6 NO

Page 4

4

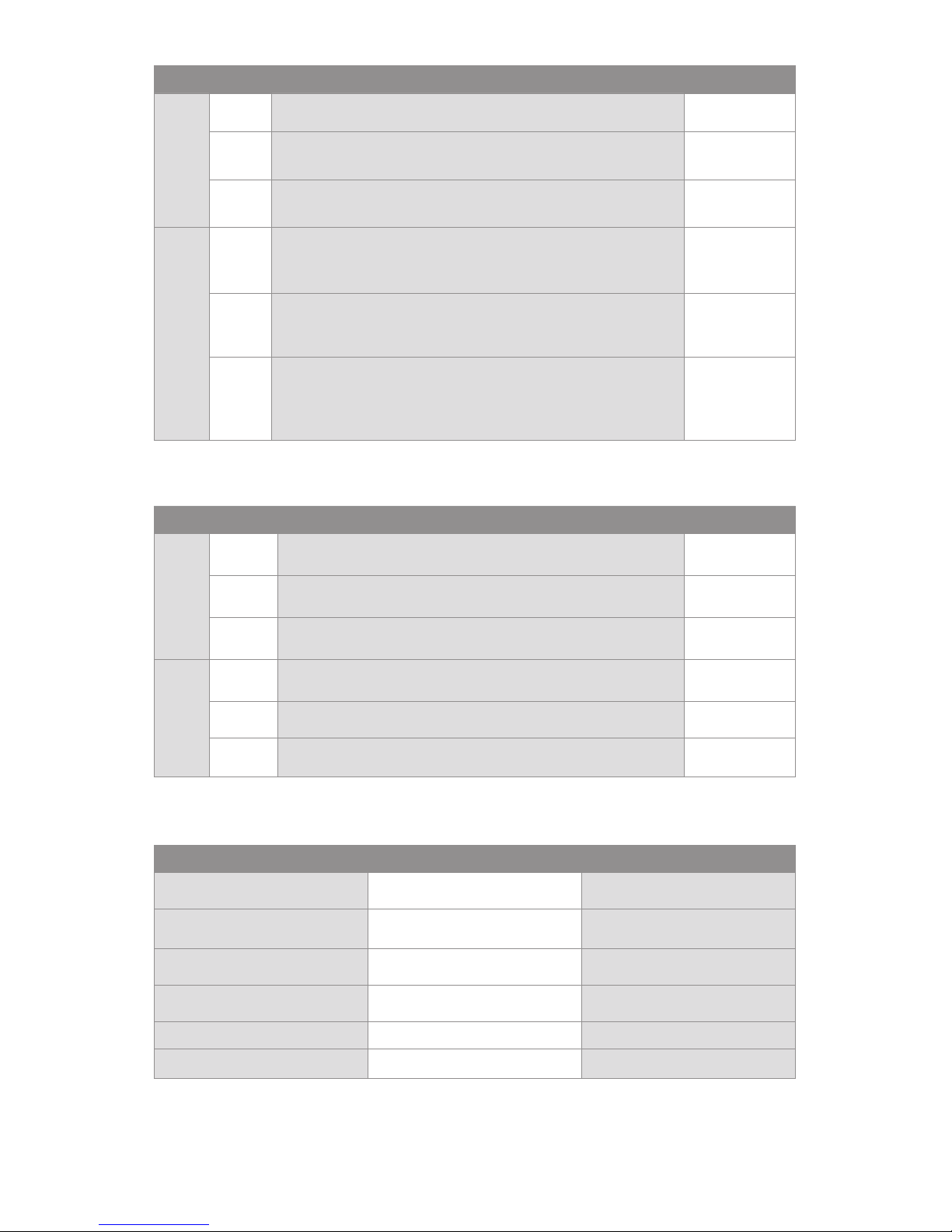

MODEL NUMBERS

SPECIFICATIONS

EX

----

FFF

CTT LL

Field of view

21 = 2:1 divergent optics

151 = 15:1 divergent optics

301 = 30:1 divergent optics

CF = Close focus optics

(Spot Ø 5 mm at distance 100 mm)

Temperature Range

LT = -20°C to 100°C

MT = 0°C to 250°C

HT = 0°C to 500°C

XT = 0°C to 1000°C

ST = Special temperature range

Temperature range may be re-scaled

between limits -20°C and 1000°C via optional

USB adapter and software

Cable Length

5 = 5 m

10 = 10 m

25 = 25 m

User Configurable

C = Configurable via optional USB adapter

General

Temperature Range -20°C to 1000°C (see table of Model Numbers)

Output 4 to 20 mA

Minimum Temperature Span 100°C

Maximum Temperature Span 1000°C

Field of View See table of Model Numbers

Accuracy ± 1°C or 1%, whichever is greater

Repeatability ± 0.5°C or 0.5%, whichever is greater

Emissivity Setting Range 0.20 to 1.00 (pre-set to 0.95)

Emissivity Setting Method User configurable via optional LCT Loop Configuration

Tool (USB adapter)

Response Time, t90 240 ms (90% response)

Spectral Range 8 to 14 μm

Supply Voltage 12 to 24 V DC ± 5%

Minimum Sensor Voltage 11.4 V DC

Maximum Current Draw 25 mA

Page 5

5

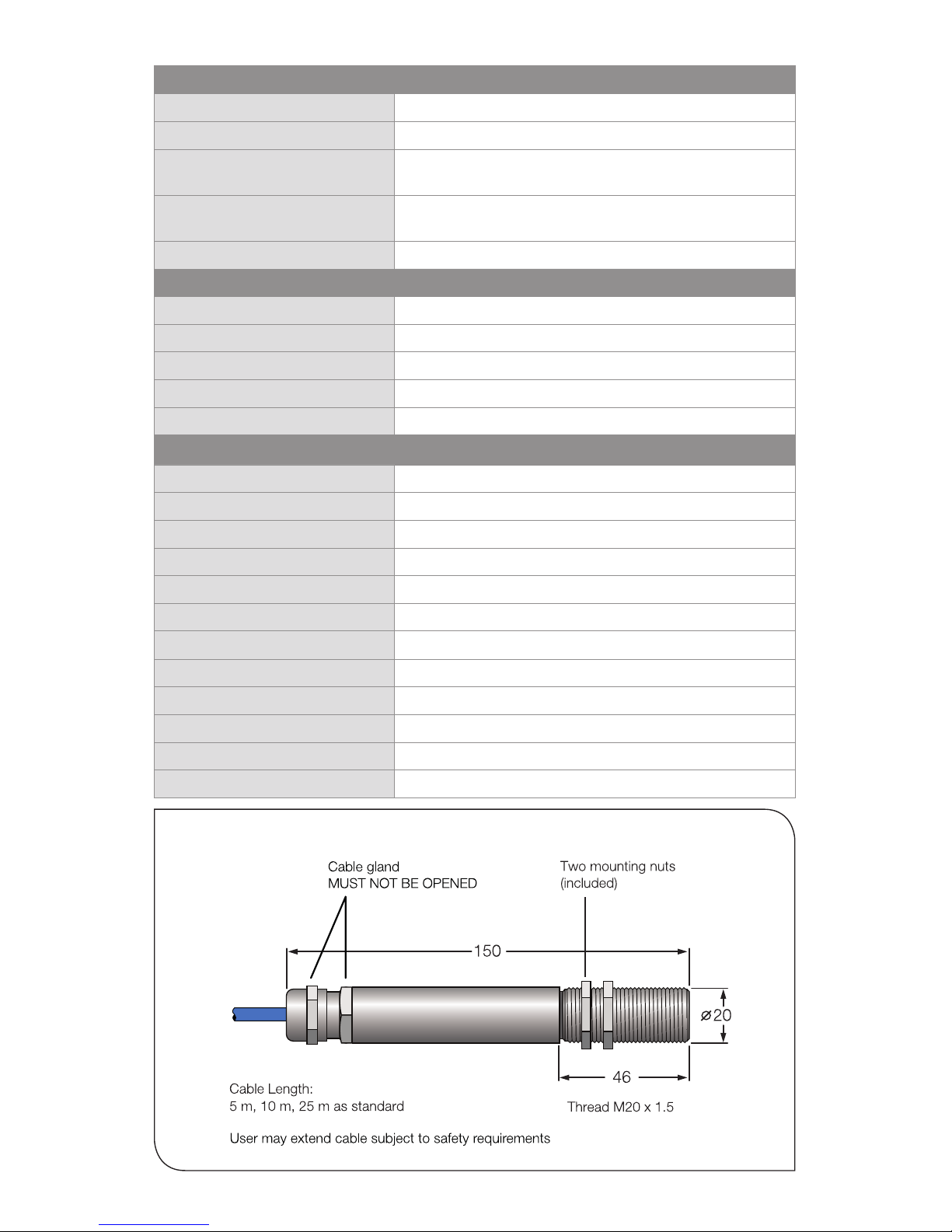

Mechanical

Construction Stainless Steel 316

Major Dimensions Ø 20 x length 150 mm (see Dimensions)

Mounting M20 x 1.5 mm thread, length 46 mm, supplied with two

mounting nuts

Cable Length Choice of 5 m, 10 m or 25 m factory-fitted. Contact

Calex for information about extending cable.

Weight with 5 m Cable 475 g

Environmental

Environmental Rating IP65 (NEMA 4)

Ambient Temperature Range 0°C to 70°C (Operating range)

Relative Humidity Max. 95% non-condensing

CE Marked Yes

RoHS Compliant Yes

Hazardous Area Classification

ATEX Classification Ex II 1GD

IECEx Classification (Gas) Ex ia IIC T4 Ga

IECEx Classification (Dust) Ex ia IIIC T135°C IP65 Da

Ambient Temperature Rating -20°C ≤ Ta ≤ 70°C

Maximum DC Input Voltage Ui = 28 V

Maximum Input Current Ii = 93 mA

Maximum Input Power Pi = 650 mW

Maximum Internal Capacitance Ci = 8 nF

Maximum Internal Inductance Li = 0 mH

ATEX Certificate Number CML 14ATEX2079

IECEx Certificate Number IECEx CML 14.0032

TIIS Certificate Number TC21097

DIMENSIONS (MM)

Page 6

6

ACCESSORIES

A range of accessories to suit different applications and industrial environments is available as

follows. These may be ordered at any time and added on-site:

• LCT Loop Configuration Tool (USB adapter)

• Fixed and adjustable mounting brackets

• Air purge collar

OPTIONS

The following options are available. Options are factory installed and must be ordered with

the sensor.

• Certificate of calibration

• Extended cable (25 m max. factor y-fitted; contct Calex for information about

extending the cable)

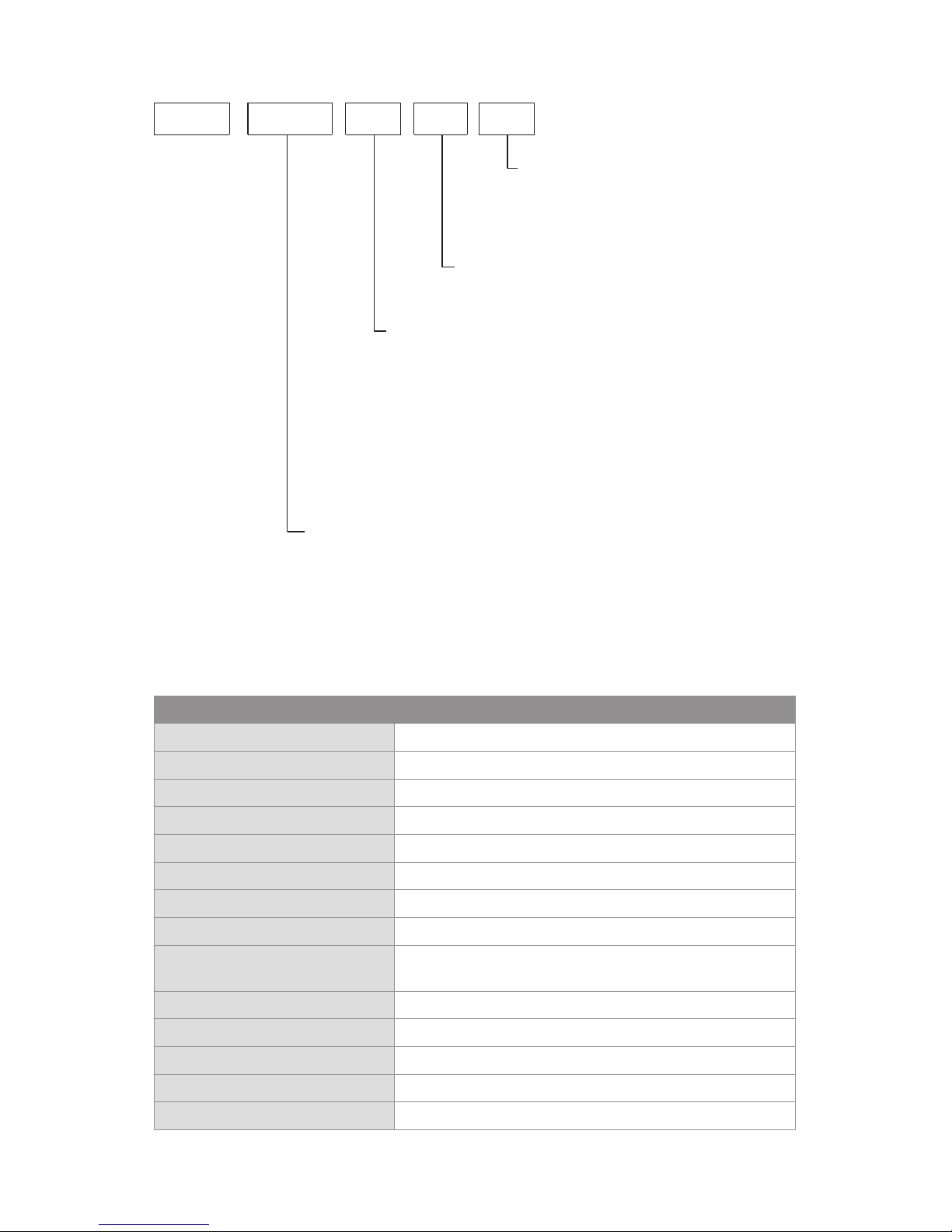

OPTICS

The below chart shows the measured spot diameter at the given distances from the sensing

head and assumes 90% energy. The sensor may be used at longer distances than shown

below, with a larger measured spot size.

INSTALLATION AND MAINTENANCE

The installation process consists of the following stages:

1 Preparation

2 Mechanical installation

3 Electrical installation

Please read the following sections thoroughly before proceeding with the installation.

11.0

0

Spot Dia.

(inches)

Spot Dia.

(mm)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

61.9

111.9

0.5

2.4

4.4

0 4 8

100 200

D:S 2:1

-21

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.0

45.2

78.6

0.5

1.8

3.1

0 19.7 39.4

0 500 1000

Spot Dia.

(inches)

Spot Dia.

(mm)

D:S 15:1

-151

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.0

28.6

45.2

0.5

1.1

1.8

0 19.7 39.4

0 500 1000

Spot Dia.

(inches)

Spot Dia.

(mm)

D:S 30:1

-301

Spot Dia.

(inches)

Spot Dia.

(mm)

Distance: Sensor to object (inches)

Distance: Sensor to object (mm)

11.0

0.5

0

0

5.0

0.20

100

3.9

12.5

0.49

200

7.9

-CF

Page 7

7

Distance and Spot Size

Ensure the sensor is positioned

so that it can only detect infrared

radiation from the target.

The size of the area (spot size)

to be measured determines the

distance between the sensor and

the target. The spot size must

not be larger than the target.

The sensor should be mounted

so that the measured spot size is

smaller than the target.

We normally recommend the

target is at least twice the size

of the given measured spot for

maximum accuracy.

PREPARATION

Ambient Temperature

The sensor is designed to operate in ambient temperatures from 0°C to 70°C.

Avoid thermal shock. Allow 20 minutes for the unit to adjust to large changes in ambient

temperature.

Atmospheric Quality

Smoke, fumes or dust can contaminate the lens and cause errors in temperature

measurement. In these types of environment the air purge collar should be used to help keep

the lens clean.

Electrical Interference

To minimise electromagnetic interference or ‘noise’, the sensor should be mounted away from

motors, generators and such like.

Wiring

Check the distance between the sensor and the indicating/controlling device. If necessary,

the sensor can be ordered with a longer cable attached. Contact Calex for information about

extending the cable.

Power Supply

A suitable intrinsically safe barrier or isolator must be used. See Specifications for the supply

voltage, current and safety requirements.

MECHANICAL INSTALLATION

Mounting

All sensors come with a hard-wired cable and 2 mounting nuts. The sensor can be mounted

on brackets or cut outs of your own design, or you can use the fixed and adjustable mounting

bracket accessories, which are shown in the following diagram.

Note: The sensor must be connected to earth at one point, either the cable shield

termination or the sensor housing.

Page 8

8

MOUNTING BRACKETS

AIR PURGE COLLAR

The lens must be kept clean and dry for an accurate reading. The optional air purge collar is

used to keep dust, fumes, moisture, and other contaminants away from the lens. It must be

screwed on fully.

Air flows into the hose barb fitting and out of the front aperture. Air flow should be no more

than 5 to 15 litres/min. Clean or ‘instrument’ air is recommended.

Page 9

9

An alternative certified Intrinsically Safe isolator or safety barrier may be used. The

connections shown above are for the suggested isolator, model MTL 5541.

WIRE IDENTIFICATION - EXTEMP SENSOR

Identification tags are attached to the PWR+ and PWR- wires. If the tags are removed, the

wires can be identified by the numbers marked on the black insulation:

Wire Markings Wire Identity

1 PWR+

2 PWR-

Table 4: Wire Identification

CONFIGURATION

All models are configurable via the optional USB adapter (Loop Configuration Tool, model LCT)

and free CalexConfig configuration software.

The LCT has hook-type connectors and may be connected to the 4-20 mA loop as shown

above.

The LCT (USB adapter) is not certified for use in hazardous areas. It must

only be connected on the safe side of the safety barrier or isolator.

For information about installing and using the LCT, please see the LCT section of this manual.

ELECTRICAL INSTALLATION

Page 10

10

CONFIGURABLE PARAMETERS

The following settings can be configured via CalexConfig.

Configuration settings are password protected. To access the Settings menu, go to the Unlock

screen and enter the password. The default password is 1234.

Temperature Units

On the temperature display screen, click °C or °F to switch between temperature units.

Output Processing

Go to the Settings screen, then Output Processing.

• 4 to 20 mA Output Scale

Set the temperature range limits for the 4 to 20 mA output, between the limits of

-20°C and 1000°C.

The difference between the temperatures at 4 mA and at 20 mA must be at least

100°C. The temperature at 20 mA must be greater than the temperature at 4 mA.

Default setting: Depends on model, e.g. LT = -20°C to 100°C (see Model Numbers)

• Averaging Period

Set the time, in seconds, over which the measured temperature is averaged.

Note: averaging prevents the sensor from following rapid temperature changes.

Default setting: 0

• Peak/Valley Hold Processing

If required, hold processing can be applied by setting Hold Mode to “Peak” or “Valley”

and setting the hold period. This is useful if the temperature reading is interrupted by

gaps between moving objects, or by an obstruction.

Default setting : OFF

Emissivity and Compensation

From the Settings menu, go to Emissivity and Compensation.

• Emissivity Setting

Enter the emissivity of the target. Target emissivity can be determined experimentally,

or estimated using an emissivity table. For more information, contact Calex.

Default setting: 0.95

• Reflected Energy Compensation On/Off

If enabled, compensates for errors caused by reflected energy from hotter or colder

objects. This should generally be kept OFF in most applications.

Default setting: OFF

• Reflected Temperature

Enter the temperature of the surroundings of the target for Reflected Energy

Compensation. Changing this has no effect if Reflected Energy Compensation is OFF.

OPERATION

Once the sensor is in position, a suitable safety barrier or isolator is connected and

configured, and the appropriate power and cable connections are secure, the system is ready

for continuous operation by completing the following simple steps:

1 Turn on the power supply

2 Turn on the meter, chart recorder or controller

3 Read or monitor the temperature

Page 11

11

IMPORTANT

Be aware of the following when using the sensor:

• If the sensor is exposed to significant changes in ambient temperature (hot to cold,

or cold to hot), allow 20 minutes for the temperature to stabilise before taking or

recording measurements.

• Do not operate the sensor or configuration tool near large electromagnetic fields (e.g.

around arc welders, generators or induction heaters). Electromagnetic inter ference

can cause measurement errors.

• Wires must be connected only to the appropriate terminals.

• Do not damage the cable, as this could provide a path for moisture and vapour to

enter the sensor.

• Do not open the sensor housing. This will damage the sensor and invalidate the

warranty.

MAINTENANCE

Our customer service representatives are available for application assistance, calibration,

repair, and solutions to specific problems. Contact our Service Department before returning

any equipment. In many cases, problems can be solved over the telephone. If the sensor is

not performing as it should, try to match the symptom below to the problem. If the table does

not help, contact us for further advice.

LENS CLEANING

Keep the lens clean and dry at all times. Any foreign matter on the lens would affect

measurement accuracy. Blow off loose particles (if not using the air purge accessory) with an

air ‘puffer’.

If dust or condensation continuously forms on the lens, consider fitting an air purge collar.

TROUBLESHOOTING

Symptom Probable Cause Solution

No output No power to sensor Check power supply and wiring

Inaccurate

measured

temperature

Target too small for

sensor’s field of view

Ensure the sensor’s view is completely filled

by the target. Position the sensor closer to

the target to measure a smaller area.

Ensure the target is at least twice the size of

the given measured spot.

Target is a reflective

metal surface

Measure a non-reflective area, or paint or

coat a measurable area of the target to

make it non-reflective

Field of view

obstruction

Remove obstruction; ensure sensor has a

clear view of target

Dust or condensation

on lens

Ensure lens is clean and dry. Clean gently

with a soft lens cloth and water. If problem

recurs, consider using an air purge collar.

Incorrect wire

connections

Check wire markings - see Table 4: Wire

Identification

Output temperature

scale mismatch

Re-scale input temperature range on

measurement instrument to match sensor

Page 12

12

LOOP CONFIGURATION TOOL (LCT)

The Loop Configuration Tool model LCT is a configuration

adapter for ExTemp infrared temperature sensors.

It is designed to be connected to the 4 to 20 mA current loop on

the safe side of an Intrinsically Safe barrier or isolator, and to a

Windows PC via USB.

This manual describes how to connect the LCT and use it to

configure the sensor. For information on connecting and using

the sensor itself, please refer to the previous sections of this

manual.

WARNING

This device MUST NOT be used in hazardous areas. It is not cer tified for use

in explosive atmospheres and may only be connected on the safe side of a

suitable, certified Intrinsically Safe barrier or isolator.

Do not attempt to repair a faulty unit. Contact the vendor to arrange a return.

ELECTRICAL CONNECTION

Connect the device to the 4 to 20 mA measurement loop via the hook-type connectors. For

reliable communications, the total resistance RL on the 4 to 20 mA loop should be within the

range specified on the connection diagrams. You may need to connect a resistor in series with

the existing measurement instrumentation on the 4 to 20 mA loop to ensure this.

WIRE IDENTIFICATION - LCT

The LCT connectors are colour coded as follows:

Colour of Wire and Hook Connector Polarity

Red +

Black -

Measurement

instrumentation

LCT

PC with

software

Power supply

Hazardous Area

(All Zones IIC and IIIC)

Safe Area

(Non-Hazardous)

Intrinsically Safe

isolator or barrier

To the sensor

Page 13

13

EXAMPLE ISOLATOR: MODEL MTL5541

This isolator has an internal resistance of 220Ω. Two wiring configurations are possible,

depending on whether or not this internal resistance is used.

Configuration A: 400 Ω ≤ RL ≤ 800 Ω (not using the internal resistance)

11

12

R

L

LCT

-+-

+

4/20 mA

MTL5541

11

12

R

L

LCT

-

+

MTL5541

10

220 Ω

-

+

4/20 mA

+

2

R

L

LCT

-

+

MTL7706+

1

+

Earth pin

Configuration B: 180 Ω ≤ RL ≤ 580 Ω (using the internal resistance)

EXAMPLE BARRIER: MODEL MTL7706+

200 Ω ≤ RL ≤ 800 Ω

Page 14

14

SOFTWARE

The latest version of the software is available for download from the Calex website at the

following URL:

www.calex.co.uk/software

Install the software before connecting the LCT to a Windows PC. This will ensure the driver is

properly installed.

USING THE SOFTWARE

See Configurable Parameters and the Configuration Software diagram opposite.

If the Settings icon is greyed out, the software is locked. Unlock the software to allow access to

the Settings menu. The default password is 1234.

MAINTENANCE AND TROUBLESHOOTING

Our technical support engineers are available for application assistance, calibration, repair,

and solutions to specific problems. Contact our Service Department before returning any

equipment. In many cases, problems can be solved over the telephone. Contact us for further

advice.

GUARANTEE

Calex guarantees each instrument it manufactures to be free from defect in material and

workmanship under normal use and service for the period of two years from the date of

purchase. This guarantee extends only to the original buyer according to the Calex Terms and

Conditions of Sale.

Page 15

15

CONFIGURATION SOFTWARE

Unlock

Clear graph

Exit

Unlock Graph

Change Password

Settings

Apply (save and exit)

Select connected sensor

Emissivity &

Compensation

Temperature List

Temperature Display

4 to 20 mA

Output

Processing

Default

Password:

1234

Connection List

Page 16

Issue O - Aug 2018

Calex Electronics Limited

PO Box 2, Leighton Buzzard, Bedfordshire, England LU7 4AZ

Tel: +44 (0)1525 373178 Fax: +44 (0)1525 851319

Email: mail@calex.co.uk Online: www.calex.co.uk

Loading...

Loading...