Page 1

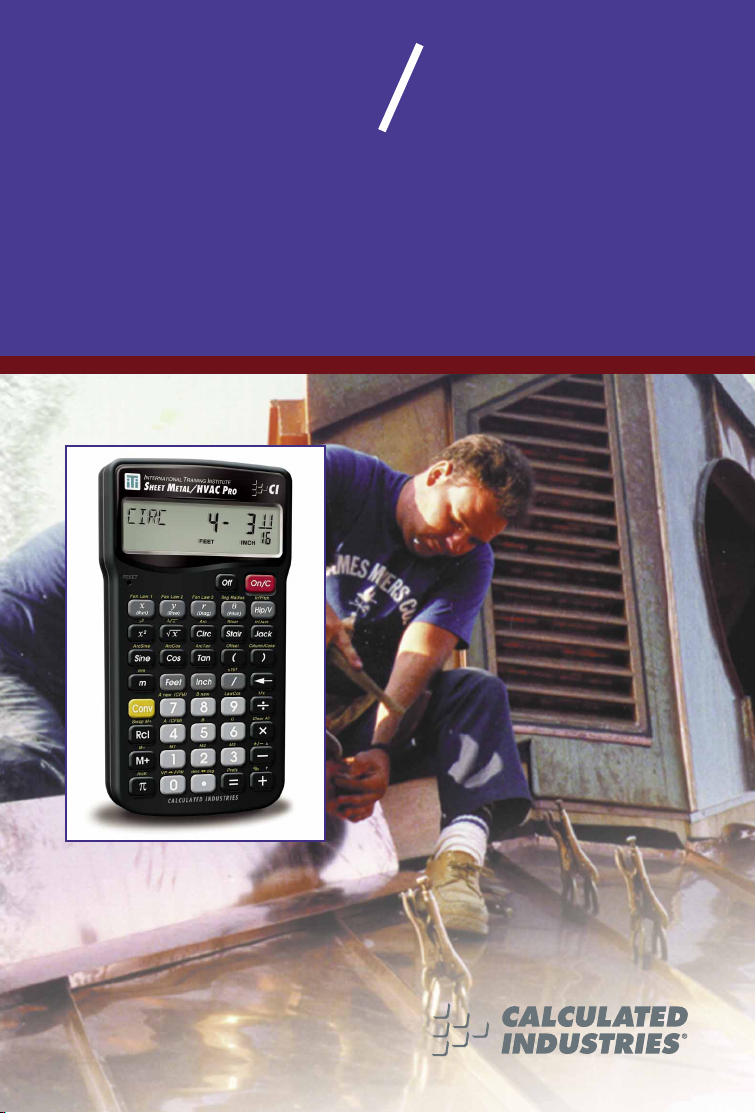

SHEET METAL HVAC PRO

Model 4090

User’s Guide

Page 2

INTRODUCTION

The custom-designed ITI Sheet Metal/HVAC Pro calculator was

specifically created for sheet metal pro’s to ease the task of performing mathematics on the job. It includes the most popular built-in formulas for sheet metal computations, so you’ll save time, increase

accuracy and eliminate errors.

Your Calculator Helps You Solve:

• Dimensional Math Problems

• Conversions Between Feet-Inch-Fractions, Decimal Feet,

Decimal Inches and Metric

• Problems Involving All Common Fractions – 1/2” to 1/64”

• Area/Volume Calculations

• Arc/Circle/Column/Cone Areas and Volumes

• D:M:S

• Scientific Notation, Cubed Root

• Offset Calculations

• Trigonometry

• Law of Cosines

• Fan Laws 1, 2 and 3

• Velocity/Velocity Pressure Conversions

• Right Angle/Rafter Solutions

• Stair Layout (Risers/Treads), and more!

It also includes handy construction math and material estimation

examples — such as right angle/rafter and stair calculations — that

will also help you build faster and more accurately.

USER’S GUIDE —1

Page 3

TABLEOFCONTENTS

KEY DEFINITIONS ............................................................................6

BASIC OPERATION KEYS .............................................................6

CONVERT Ç KEY—UNIT CONVERSIONS and

SECOND FUNCTIONS................................................................6

MEMORY and STORAGE FUNCTIONS ........................................7

RECALL ® KEY ..........................................................................8

FEET-INCH-FRACTION and METRIC KEYS .................................8

TRIGONOMETRIC KEYS ...............................................................9

PYTHAGOREAN THEOREM/RIGHT TRIANGLE KEYS ..............10

LAW OF COSINES/NON-90 DEGREE TRIANGLE KEYS ...........12

OFFSET KEYS..............................................................................13

FAN LAW KEYS ............................................................................14

VELOCITY PRESSURE/FPM KEYS ............................................15

CIRCULAR/ARC FUNCTION KEYS .............................................15

COLUMN/CONE KEY ...................................................................16

HIP/VALLEY and JACK RAFTER KEYS.......................................17

STAIR KEY....................................................................................19

GETTING STARTED........................................................................21

ORDER OF OPERATIONS ...........................................................21

USING PARENTHESES ...............................................................22

SETTING FRACTIONAL RESOLUTION.......................................23

Setting Fraction Resolution to Other Than 16ths —

Using the Preference Setting Mode .......................................23

Setting Fixed/Constant Fractional Resolution............................24

ENTERING DIMENSIONS............................................................25

Entering Linear Dimensions.......................................................25

Entering Square/Cubic Dimensions...........................................25

CONVERSIONS (LINEAR, AREA, VOLUME) ..............................27

Linear Conversions ....................................................................27

Converting Feet-Inch-Fractions to Decimal Feet.......................27

Converting Decimal Feet to Feet-Inch-Fractions.......................27

Converting Fractional Inches to Decimal Inches .......................27

Converting Decimal Inches to Fractional Inches .......................28

Square Conversions ..................................................................28

Cubic Conversions.....................................................................28

PERFORMING BASIC MATH WITH DIMENSIONS....................29

Adding Dimensions ....................................................................29

Subtracting Dimensions .............................................................29

Multiplying Dimensions ..............................................................29

2—ITISHEET METAL/HVAC PRO

Page 4

Dividing Dimensions ..................................................................29

Percentage Calculations ............................................................30

MEMORY OPERATION ................................................................31

EXAMPLES — USING THE SHEET METAL/HVAC PRO ..............33

BASIC EXAMPLES .......................................................................34

Adding Linear Measurements....................................................34

Converting Feet-Inch-Fractions to Decimal Feet and

Fractions of an Inch................................................................34

Converting Feet-Inches to Meters and Millimeters ....................34

Adding and Subtracting Fractions of an Inch.............................35

Converting Fractions to Decimals..............................................35

Converting Decimals to Fractions..............................................35

Finding Length (of Iron) Required..............................................35

Circumference of a Circle ..........................................................36

Circumference and Area of a Circle...........................................36

Square Area (x

2

).........................................................................36

Area of a Rectangle ...................................................................36

Area of a Triangle ......................................................................37

Volume of a Rectangular Box ....................................................37

Volume of a Rectangular Container, Converting to

Cubic Meters...........................................................................37

Volume of a Cylinder..................................................................38

Volume of a Cone ......................................................................38

Cubed Function..........................................................................39

Cubed Root Function.................................................................39

Scientific Notation ......................................................................39

TRIGONOMETRIC FUNCTIONS..................................................40

Finding Sine, Cosine, Tangent...................................................41

Finding “Angle A” (ArcSin, ArcCos, ArcTan) ..............................41

Using Trigonometry to Find Unknown Side ...............................41

Using Trigonometry to Find Unknown Angle or Side .................42

Converting Pitch to Angle/Tangent.............................................45

D:M:S EXAMPLE ..........................................................................45

Converting Degrees:Minutes:Seconds ......................................45

VELOCITY PRESSURE/VELOCITY EXAMPLES.........................46

Converting Velocity Pressure to FPM ........................................46

Converting FPM to Velocity Pressure ........................................47

OFFSET EXAMPLES ....................................................................48

Offset, Basic Example................................................................48

OGEE Offset in Feet-Inch-Fractions ..........................................49

OGEE Offset, in Millimeters .......................................................50

USER’S GUIDE —3

Page 5

Dividing Offset into Multiple Degreed Elbows for

Manageable Sections .............................................................51

Change OGEE Offset ................................................................53

LAW OF COSINES EXAMPLES ...................................................55

Field Measuring for Ductwork Using the Law of Cosines

Introduction .............................................................................55

Non-90 Degree Triangle Measurement Using Law of Cosines

and Heron’s Theorem .............................................................56

Using Law of Cosines and Pythagorean Theorem to

Calculate Offset, Length, and Angle.......................................58

Sheet Metal Panels for an Irregular Hip Roof............................59

Inline Duct, Single Offset (Computing Offset, Length,

and Angle)...............................................................................60

Inline Duct, Double Offset (Computing Offset, Length,

and Angle)...............................................................................62

Objects at Right Angles .............................................................65

Calculating Angles Between Objects (“Angle Between”)...........69

Calculating Angles Between Objects Example ..........................70

FAN LAW EXAMPLES ..................................................................75

Fan Law 1 ..................................................................................75

Fan Law 2 ..................................................................................76

Fan Law 3 ..................................................................................77

ARC/CIRCLE EXAMPLES ............................................................78

Arc Length — Degree and Diameter Known .............................78

Arc Length — Degree and Radius Known.................................78

Using ArcK to Calculate an Arc Length......................................78

Arc Calculations — Arc Length and Diameter Known...............79

Arched/Circular Rake-Walls — Chord Length and Segment

Rise Known.............................................................................80

Arched Windows ........................................................................81

CONCRETE/PAVING ....................................................................82

Squaring-up a Foundation .........................................................82

Volume of a Rectangle...............................................................82

Volume of Columns....................................................................83

RIGHT TRIANGLE and ROOF FRAMING EXAMPLES ...............84

Roof Framing Definitions ...........................................................84

Degree of Pitch ..........................................................................86

Percent Grade............................................................................86

Common Rafter Length..............................................................87

Common Rafter Length — Pitch Unknown................................87

Angle and Diagonal (Hypotenuse).............................................88

4—ITISHEET METAL/HVAC PRO

Page 6

Rise ............................................................................................88

Rise and Diagonal......................................................................88

Sheathing Cut ............................................................................89

Regular Hip/Valley and Jack Rafters .........................................89

Jack Rafters — Using Other Than 16 Inch On-Center

Spacing...................................................................................91

Irregular Hip/Valley and Jack Rafters — Descending, with

On-Center Spacing Maintained ..............................................92

STAIR LAYOUT EXAMPLES ........................................................94

Stair Layout Definitions ..............................................................94

Stairs — Given Only Floor-to-Floor Rise ...................................96

Stairs — Given Only the Run.....................................................98

Stairs — Given Rise and Run....................................................99

Baluster Spacing......................................................................100

APPENDIX A — TRIGONOMETRY FORMULAS .........................101

APPENDIX B — AREA/VOLUME FORMULAS............................102

AREA FORMULAS......................................................................102

SURFACE AREA/VOLUME FORMULAS ...................................103

APPENDIX C — OFFSET FORMULAS ........................................104

APPENDIX D — LAW OF COSINES/HERON’S THEOREM

FORMULAS ................................................................................105

APPENDIX E — FAN LAW FORMULAS ......................................106

APPENDIX F — DEFAULT SETTINGS.........................................106

APPENDIX G — PREFERENCE SETTINGS................................107

How to Set Preferences ..............................................................110

Accessing Preference Settings....................................................111

APPENDIX H — CARE INSTRUCTIONS......................................113

APPENDIX I — ACCURACY, AUTO SHUT-OFF, BATTERIES,

ERRORS .....................................................................................114

Accuracy/Errors ...........................................................................114

Auto Shut-Off...............................................................................115

Battery(ies) ..................................................................................115

Replacing the Battery(ies) ...........................................................115

Battery Replacement Instructions ...............................................115

Reset Key ....................................................................................115

REPAIR AND RETURN..................................................................116

WARRANTY...................................................................................117

INDEX.............................................................................................119

USER’S GUIDE —5

Page 7

KEY DEFINITIONS

BASIC OPERATION KEYS

o

O

+–x Arithmetic operation keys.

÷=

Ç+ Percent (%) — Four-function percent. See page 30

0 – 9 and • Keys used for entering digits.

B Backspace Key — Used to delete entries one key-

On/Clear — Turns power on. Pressing once clears the

display. Pressing twice clears all temporary values.

Turns all power off, clearing all non-permanent registers.

for examples.

stroke at a time (unlike the o function, which

deletes the entire entry).

CONVERT Ç KEY —

UNIT CONVERSIONS and SECOND FUNCTIONS

The Ç key is to convert between measurement units or to access

second functions, listed below:

Ç Convert — Used with the measurement keys to

convert between units or with other keys to access

special functions.

Çx Clear All — Clears all values, including Memory.

Resets all permanent entries to default values

(except Preference Settings, which are retained).

Note: Use only when necessary, as it deletes all stored values.

X Squares the value in the display. For example, to

Square the value ten, enter 10then press X.

ÇX x3— Cubes the value in the display. For example, to

Cube the value ten, enter 10then press ÇX.

√ Square Root Function — Used to find the Square

Root of a non-dimensional or area value

(e.g., 100√=10).

6—ITISHEET METAL/HVAC PRO

Page 8

Ç√ Cube Root Function — Used to find the Cube Root

of a non-dimensional or area value (e.g., 100

0Ç√= 10).

y

Ç/ x10

— Allows entry of an exponent. For example,

8Ç/14is 8 times 10 to the 14th power

(8x1014).

Ç÷ 1/x — Finds the reciprocal of a number (e.g., 8

Ç÷= 0.125).

Ç– Change(+/–)Sign— Changes the sign of the dis-

played value to negative or positive.

π Pi — Constant = 3.141593

Çπ ArcK — Constant = 0.017453. This value is equiva-

lent to the constant of a 1° arc angle for a one-unit

value. The formula for this constant is π ÷ 180.

Ç• Degrees:Minutes:Seconds — Converts between

D:M:S and Decimal Degree formats.

Note: Your calculator uses a floating d:m:s format (that is, displays decimal degrees to the maximum number of decimal points,

for greater accuracy). If you desire rounding to two decimal points

(0.00°), you must set your calculator via Preference Settings (see

page 107).

Ç= Access Preference Settings — Used to access

various customizable settings, such as dimensional

answer formats (see Preference Settings on page

107).

MEMORY and STORAGE FUNCTIONS

Your calculator has two types of Memory:

1) basic Memory or Semi-Permanent, Cumulative μ;

2) non-cumulative Storage Registers (M1-M3).

μ Semi-Permanent Memory — Adds any displayed

number, dimensioned or unitless, to the semi-permanent, accumulating Memory. Values can be subtracted from this Memory using Çμ. ®®

will recall and clear the Memory. Ǯwill swap

the value stored in accumulative Memory with the

value that is currently displayed.

USER’S GUIDE —7

Page 9

Ç1 Storage Register (M1) — Stores the displayed

value in non-cumulative, permanent Memory (e.g.,

10Ç1, ®1= 10). Good for storing a

single value, for future reference.

Note: Non-cumulative means it only accepts one value (does not

add or subtract) and a second entered value will replace the first.

Permanent means the value is stored even after the calculator is

shut off. To delete a stored value, enter a new value or perform a

Clear All (Çx).

Ç2 Storage Register (M2) — Same function as Ç

1. See above.

Ç3 Storage Register (M3) — Same function as Ç

1. See above.

RECALL ® KEY

The ® key is used to recall or review stored values (e.g., ®p

to recall a previously entered pitch value). It is also used in reviewing stored settings and Memory operation (see below).

®® Clear M+ — Displays and clears M+.

®μ Recall M+ — Displays value stored in M+.

®1 Recall M1 — Recalls the stored value in M1.

®2 Recall M2 — Recalls the stored value in M2.

®3 Recall M3 — Recalls the stored value in M3.

FEET-INCH-FRACTION and METRIC KEYS

The following keys are used for entering units of measure, with ease

and accuracy:

f Enters or converts to Feet. Also used with the i

and / keys for entering Feet-Inch values (e.g., 6

f9i1/2).

Note: Repeated presses after Ç toggle between Feet-Inches and

Decimal Feet (e.g., 6f9i1/2Çf= 6.791667

FEET; press f again to return to Feet-Inch-Fractions).

8—ITISHEET METAL/HVAC PRO

Page 10

i Enters or converts to Inches. Also used with the /

key for entering fractional inch values (e.g., 9i

1/2).

Note: Repeated presses after Ç toggle between Fractional

and Decimal Inches (e.g., 9i1/2Çi=9.5

INCH; press i again to return to Inch-Fractions).

/ Fraction Bar — Used to enter Fractions. Fractions

may be entered as proper (1/2, 1/8, 1/16) or improper

(3/2, 9/8). If the denominator (bottom) is not entered,

the calculator's fractional resolution setting is automatically used (e.g., entering 15/=or +

will display 15/16, based on the default fractional

resolution setting of 16ths.

m Meters — Enters or converts to Meters.

Çm Millimeters — Enters or converts to Millimeters.

TRIGONOMETRIC KEYS

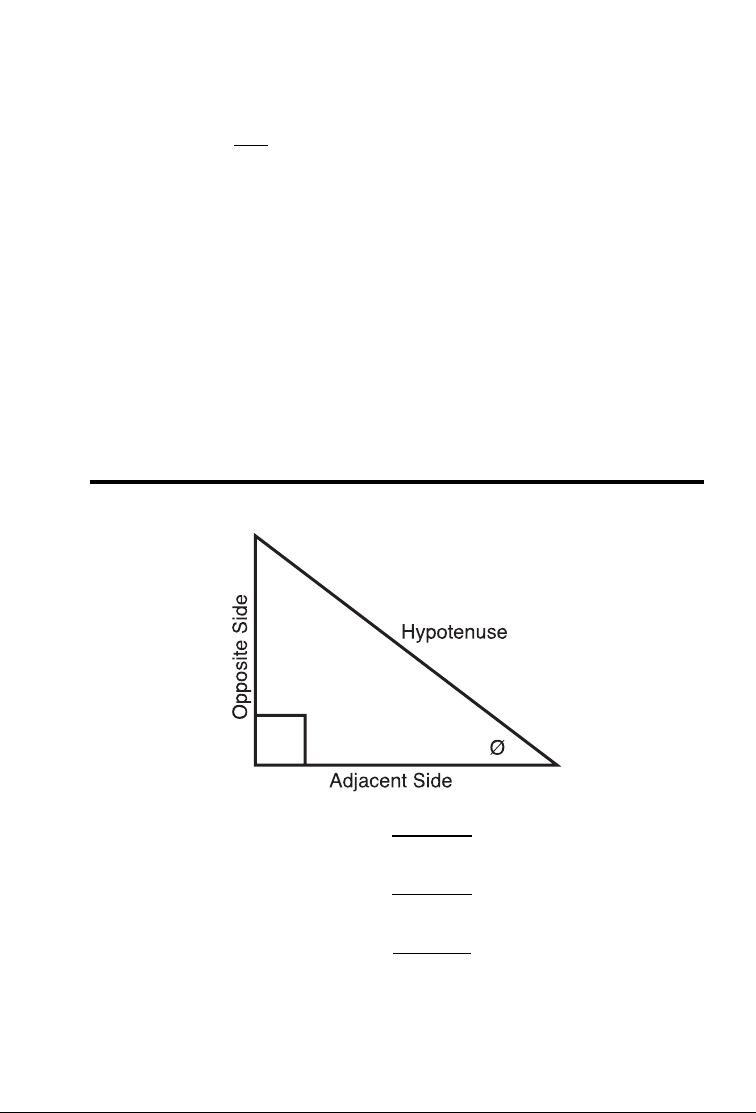

Tangent Ø = Opposite

Adjacent

Sine Ø = Opposite

Hypotenuse

Cosine Ø = Adjacent

Hypotenuse

USER’S GUIDE —9

Page 11

Your calculator has standard trigonometric keys, in addition to Right

Triangle keys (e.g., R, r, d and p), for advanced Right Triangle

mathematics.

The Sine, Cosine, and Tangent of an angle are defined in relation to

the sides of a Right Triangle.

Using the Ç key with the trigonometric function gives you the

Arcsine, Arccosine and Arctangent – all of which are used to find the

Angle for the Sine, Cosine, or Tangent value entered.

S Sine Function — Calculates the Sine of a Degree

or undimensioned* value.

ÇS Arcsine (sin

-1

) — Calculates the angle for the

entered or calculated Sine value.

ç Cosine Function — Calculates the Cosine of a

Degree or undimensioned* value.

-1

Çç Arccosine (cos

) — Calculates the angle for the

entered or calculated Cosine value.

t Tangent Function — Calculates the Tangent of a

Degree or undimensioned* value.

Çt Arctangent (tan

-1

) — Calculates the angle for the

entered or calculated Tangent value.

*Note: Cannot use on dimensioned values.

PYTHAGOREAN THEOREM / RIGHT TRIANGLE KEYS

10 — ITI SHEET METAL/HVAC PRO

Page 12

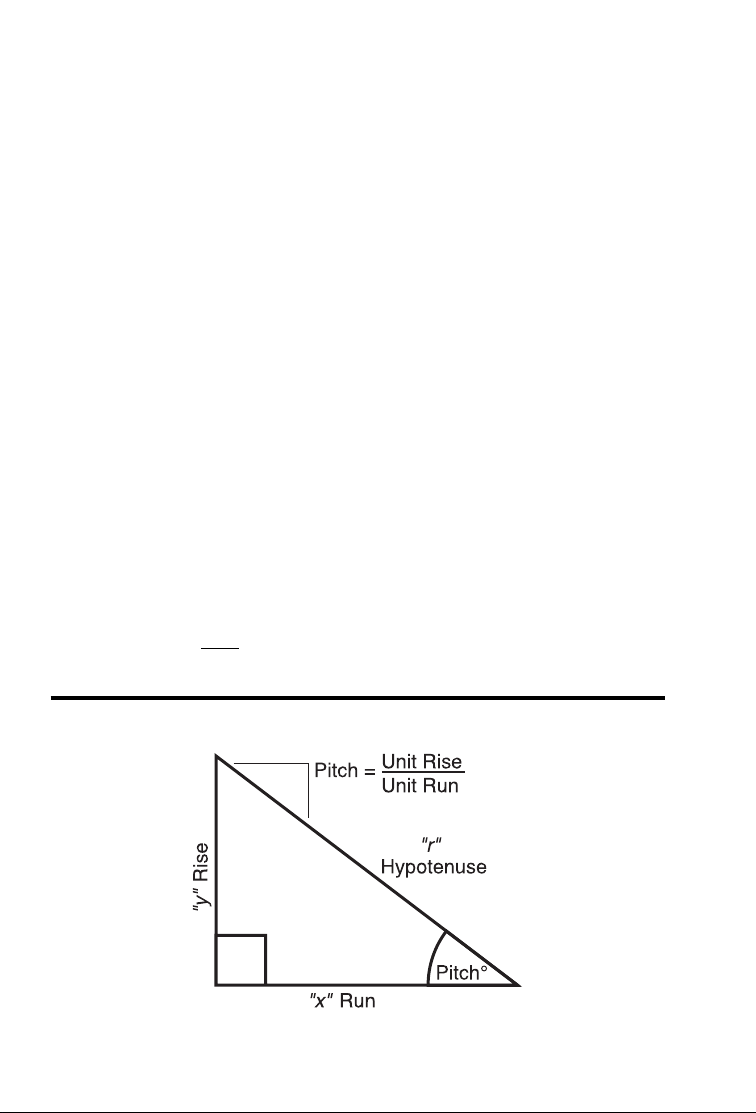

Using the Pythagorean Theorem, the top row of keys on your ITI

Sheet Metal/HVAC Pro provides instant solutions in dimensional format

to Right Triangle problems for sheet metal problems and roof framing.

The Right Triangle is calculated simply by entering two of four variables:

1) x (Run)

2) y (Rise)

3) r (Diagonal, or Hypotenuse); or

4) θ (Theta/Pitch).

R Run — Enters or calculates “x,” or the Run or hori-

zontal leg (base) of a Right Triangle.

r Rise — Enters or calculates “y,” or the Rise or verti-

cal leg (height) of a Right Triangle.

d Hypotenuse or Diagonal (for Roof Framing) —

Enters or calculates the Hypotenuse or diagonal leg

of a Right Triangle. Typical applications in construction/framing are “Squaring-up” slabs or finding

Common rafter lengths. Additional presses of the d

key will also display Plumb and Level cut angles in

degrees.

Note: The Common rafter calculation is the “point-to-point” length

and does not include the overhang or ridge adjustment.

p Theta — Enters or calculates the Pitch (slope) of a

roof (or Right Triangle). Pitch is the amount of “Rise”

over 12 Inches of “Run.” Pitch may be entered as:

• a Dimension: 9ip

• an Angle or Degrees: 30p

• a Percentage (percent grade): 75Ç+p

Once a Pitch in one of the above formats is entered,

consecutive presses of p will convert to the remaining pitch formats listed above (e.g., Pitch in Inches

will convert to Pitch Degrees, Percent Grade and

Pitch Ratio/Slope).

Note: An entered (vs. calculated) Pitch is a permanent entry. This

means that it will remain stored even after you turn the calculator

off. To change the Pitch, simply enter a new Pitch value.

In contrast, a calculated Pitch value is not permanently stored.

This means that the calculator will return to the Pitch value you

last entered when you press o twice.

USER’S GUIDE —11

Page 13

LAW OF COSINES / NON-90 DEGREE TRIANGLE KEYS

Ç9 Law of Cosines — These keys are used for non-90

degree triangle mathematics and are incorporated

with Right Triangle mathematics (using “Measured”

non-90 degree and “Calculated” Right Triangles),

particularly, for finding the dimensional relationship

of distance and alignment between two or more

objects. The overall purpose of these calculations is

to develop the duct and/or fittings required to fill a

space.

These keys calculate the opposite angles A, B, and

C given entry of Side a, b, and c using the Law of

Cosines (see Storage Registers a, b, and c below)

and triangle area using Heron’s Theorem. They also

enable the computation of Right Triangle lengths “x,”

“y,” “r ” and Theta, for determining Offset, Length,

and Angle.

Press

1 Angle A

2 Angle B

3 Angle C

4 Area (using formula for Heron’s Theorem)

5 Redisplays entered Side a

6 Redisplays entered Side b

7 Redisplays entered Side c

Ç4 Storage Register “a” — Enters Side “a” of a

Measured Triangle (e.g., if Side “a” is five feet, enter

5fÇ4).

Ç5 Storage Register “b” — Enters Side “b” of a

Measured Triangle.

Ç6 Storage Register “c” — Enters Side “c” of a

Measured Triangle.

12 — ITI SHEET METAL/HVAC PRO

Result

Page 14

Right Triangle Functions:

R Length of Unknown Side — Calculates Side “x” of

unknown Right Triangle.

r Length of Unknown Side — Enters Side “y” of

unknown Right Triangle.

d Hypotenuse — Enters “c” of Measured Triangle as

“r” of unknown Right Triangle, for final determination

of “x” and “y.”

p Theta — Finds unknown angle for determination of

“x” and “y.”

OFFSET KEYS

Ç( Offset — Calculates offset measurements, including

the Centerline Radius, Wrapper Length/Stretch-out,

Heel Radius, Throat Radius and Theta, given entry

of “x” (actual length), “y” (offset), and “a” (“end a”)

into the keys below:

Press

1 Centerline Radius (CR)

2 Wrapper Length/Stretch-out (WL)

3 Heel Radius

4 Throat Radius

5 Theta (THET)

6 Redisplays entered “x” (Actual Length)

7 Redisplays entered “y” (Offset)

8 Redisplays entered “a” (Storage

R Actual Length — Enters the actual length “x” for

offset calculations.

r Offset Length — Enters the offset “y.”

Ç4 Storage Register “a” — Enters length of “end a”

for offset calculations.

Result

Register “a” or End “a”)

USER’S GUIDE —13

Page 15

FAN LAW KEYS

Your calculator also has built-in formulas and keys that calculate Fan

Laws 1, 2 and 3, for air flow calculations. Each of these formulas

requires the entry of three variables in order to solve the fourth.

ÇR Fan Law 1 — Calculates the missing variable (e.g.,

“a-new” or “b-new” for CFM new or RPM new) for

Fan Law 1, given the three known variables into the

applicable Storage Registers (see below). See

page 75 for examples.

Çr Fan Law 2 — Calculates the missing variable (e.g.,

“a-new” or “b-new” for CFM new or SP new) for Fan

Law 2, given the three known variables into the

applicable Storage Registers (see below). See

page 76 for examples.

Çd Fan Law 3 — Calculates the missing variable (e.g.,

“a-new” or “b-new” for CFM new or BHP new) for

Fan Law 3, given the three known variables into the

applicable Storage Registers (see below). See

page 77 for examples.

Storage Registers Used For Fan Laws:

Ç4 Storage Register “a” — Enters “a-old” or current

“a” value.

Ç7 Storage Register “a-new” — Enters “a-new” or

new “a” value.

Ç5 Storage Register “b” — Enters “b-old” or current

“b” value.

Ç8 Storage Register “b-new” — Enters “b-new” or

new “b” value.

14 — ITI SHEET METAL/HVAC PRO

Page 16

VELOCITY PRESSURE / FPM KEYS

Ç0 VP

ß©

FPM — Converts entry to Velocity (Feet per

Minute - FPM), Velocity Pressure, Metric Velocity

(MPS) and Metric Velocity Pressure (kPA).

Press Result

1 Calculates Velocity (FPM) – assumes

entry is Velocity Pressure

2 Calculates Velocity Pressure – assumes

entry is Velocity (FPM)

3 Calculates Metric Velocity (MPS) –

assumes entry is kPA

4 Calculates Metric Velocity Pressure

(kPA) – assumes entry is MPS

See page 46 for examples.

CIRCULAR / ARC FUNCTION KEYS

The Circle key helps you quickly solve Circular Area, Volume or Arc

problems.

C Circle — Displays and calculates the following val-

ues, given an entered Circle Diameter* or Radius:

• Diameter

• Circumference

• Circle Area

*To enter a Diameter (e.g., ten feet), press 10fC.To

enter a radius, see below.

Çp Segment Radius — Enters or calculates the Circle

Radius (e.g., 5fÇp). Used to calculate

Diameter, Circumference and Circle Area (see

above).

ÇC Arc Length or Degree of Arc — A multi-function

key that enters or calculates Arc Length or Degree

of Arc, and further solves for additional Circular/Arc

values, including Arched Rake-Walls (based on the

stored on-center), listed on next page.

(Cont’d)

USER’S GUIDE —15

Page 17

(Cont’d)

If a Circle Diameter is entered into the C key and

Arc Degree (or Arc Length) entered into the Arc

function (ÇC), further presses of C will dis-

play and calculate the following:

Press

Result

1 Arc Length or Degree of Arc

2 Chord Length

3 Segment Area

4 Pie Slice Area

5 Segment Rise

6 Stored On-Center Spacing

7 Length of Arched Wall 1

8 Length of Arched Wall 2

9 Length of Arched Wall 3

(if applicable), etc.*

*Note: The calculator will calculate Arched Rake-Wall stud sizes

with consecutive presses of the C key until it reaches the last

stud.

R Run (Chord Length) — Used with r or Çpto

find the Chord Length or the Radius of a Circular

Segment. If the Segment Rise and Radius have

been entered, this key will display the Chord Length

of the Circular Segment.

r Rise — Used with R or Çpto find the Rise or

the Radius of a Circular Segment. If the Chord

Length and Radius have been entered, this key will

display the Segment Rise of the Circular Segment.

COLUMN / CONE KEY

The Column and Cone functions help you quickly estimate volume

and surface area of Columns or Cones.

Ç) Column and Cone — The first and second press of

) following Ç calculate the total volume and

surface area of a Column using the values stored in

C and r; the third and fourth consecutive presses of ) calculate the total volume and surface area

of a Cone.

16 — ITI SHEET METAL/HVAC PRO

Page 18

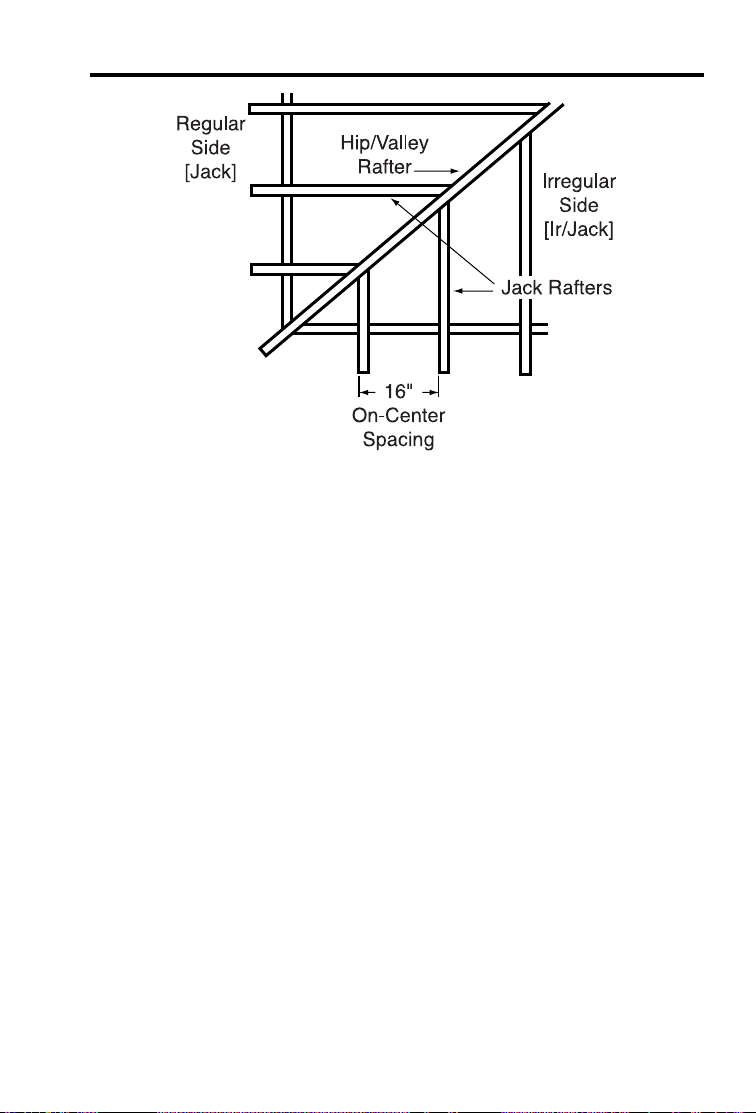

HIP/VALLEY and JACK RAFTER KEYS

Your calculator uses the y (rise), x (run), r (diagonal), θ (pitch), and

o.c. spacing values to calculate Regular (45°) and Irregular (non-45°)

Hip/Valley and Jack rafter lengths (excluding wood thickness, etc.).

When calculating Regular and Irregular Jack rafter lengths, you will

see the letters “JK” (Common Pitch side) or “IJ” (Irregular Pitch side)

and the corresponding Jack number to the left of your calculator display. This will help you keep track of the descending sizes and which

side the corresponding rafter is based on.

H Hip/Valley Rafter — Finds the Regular (45°) or

Irregular (non-45°) Hip/Valley rafter length.

• Regular Hip/Valley Length: After Right

Triangle/Rafter values are entered or calculated

(e.g., Pitch, Rise, Run), pressing H will calculate

the length of the Regular Hip/Valley rafter.

• Irregular Hip/Valley Length: If an Irregular Pitch is

entered via ÇH(see next page), pressing

H will calculate the Irregular Hip/Valley rafter

length. (An Irregular or “non-standard” roof has two

different Pitches/Slopes.)

(Cont’d)

USER’S GUIDE —17

Page 19

(Cont’d)

• Subsequent presses of the H key will also display Plumb, Level, and Cheek cut angle values in

degrees.

ÇH Irregular Pitch — Enters the Irregular or Secondary

Pitch value used to calculate lengths of the Irregular

Hip/Valley and Jack rafters.

You may enter the Irregular Pitch as:

• a Dimension: 9iÇH

• an Angle: 30ÇH

• a Percentage: 75Ç+ÇH

Note: An entered Irregular Pitch can be recalled by pressing ®

ÇH.

j Jack Rafters — Finds the descending Jack rafter

sizes for Regular pitched roofs, based on the stored

on-center spacing and previously entered or calculated Right Triangle/Rafter values (e.g., Pitch, Rise,

Run).

• The default On-Center spacing is 16 Inches. A new

On-Center spacing may be entered and permanently stored by entering an Inch value prior to performing the Jack Rafters function (e.g., 12i

j). The current On-Center spacing value can be

viewed by pressing ®j.

• Repeated presses of the j key will display all

the rafter sizes (on the regular pitch side) as well as

display the Plumb, Level, and Cheek cut angle values. Additional presses will display the rafter sizes

on the Irregular Pitch side (if an Irregular Pitch was

entered; see above), or repeat the previously displayed values.

Note: You may set your calculator to display the Jack rafter

lengths in either ascending or descending order (see Preference

Settings on page 107).

Note: You may program your calculator to “mate up” the Jack

rafters, rather than using the entered or default on center for both

sides (see Preference Settings on page 107).

18 — ITI SHEET METAL/HVAC PRO

Page 20

Çj Irregular Side Jacks — Operates same as j,

but displays the rafter values from the irregular

pitched side first.

STAIR KEY

Your calculator easily calculates stair layout solutions. Given values

for r (Rise) and/or R (Run), your calculator will calculate Riser, Tread,

Stringer and Angle of Incline values simply by pressing the s key.

s A multi-function key that uses a stored “desired”

Riser height, stored “desired” Tread width, stored

Headroom and Floor Thickness, and entered r

(Rise) and/or R (Run) values to calculate and display the following:

Press Result

1 Riser Height

2 Number of Risers

3 Riser Overage/Underage

4 Tread Width

5 Number of Treads

6 Tread Overage/Underage

7 Stairwell Opening

8 Stringer Length

9 Angle of Incline*

10 Run (entered or calculated)

11 Rise (entered or calculated)

12 Stored Riser Height

13 Stored Tread Width

14 Stored Headroom Height

15 Stored Floor Thickness

Note: Default values are 7-1/2 Inches for Desired Riser Height

and ten Inches for Desired Tread Width, ten Inches for Floor

Thickness and 6 Feet 8 Inches for Headroom.

Note: It is not possible for the calculator to include the Nose/

Overhang Measurement. Thus, you need to adjust for this measurement per local codes.

*Note: If the inclination angle exceeds the stored Rise and stored

Run ratio by 10%, the yield symbol (

steep incline.

will light, indicating a

)

USER’S GUIDE —19

Page 21

Çs Store Desired Riser Height — Stores a value other

than the default desired stair Riser height of

7-1/2 Inches (e.g., 8iÇsstores an

eight-inch desired stair Riser height). To recall the

stored setting, press ®s.

Ç== Store Desired Tread Width — Stores a value other

== than the default desired stair Tread width of ten inch-

es. See page 107 Preference Settings to view how

to use the + and – key to increase or decrease

stored Tread width.

Ç=== Store Headroom Height — Stores a value other

== than the default desired Headroom Height of six

Feet eight Inches, for calculation of stairwell opening. See page 107 Preference Settings to view how

to use the + and – key to increase or decrease

stored Headroom height.

Ç=== Store Floor Thickness — Stores a value other than

=== the default desired Floor Thickness of ten Inches.

See page 107 Preference Settings to view how to

use the + and – key to increase or decrease

stored Floor Thickness.

20 — ITI SHEET METAL/HVAC PRO

Page 22

GETTING STARTED

You may want to practice getting a feel for your calculator keys by

reading through the key definitions and learning how to enter basic

Feet-Inch-Fractions and Metric, how to store values in Memory, etc.,

before proceeding to the examples.

You may also want to glance at various formulas listed in the

Appendix, so you understand what mathematical calculations your

calculator is programmed to perform, or common formulas you can

refer to on the job. Also review specific default settings or

Preference Settings, listed in the Appendix.

ORDER OF OPERATIONS

Unlike other Calculated Industries’ calculators, which use the

Chaining Method of Operations, this calculator uses the Order of

Operation Method.

— Chaining Method (“as entered”): 10 +4x5=70

— Order of Operations: 10 + 4 x 5 = 30

The Order of Operations method of computing is based on the following order of preference:

1) Expressions inside of parentheses

2) Single-variable functions that perform the calculation and

display the result immediately (Trig functions, Square,

Square Root, Cube, Cube Root, Log, Percent, Reciprocal,

Angle Conversions)

3) Exponential function

4) Multiplication and Division

5) Addition and Subtraction

6) Equals (completes all operations)

If you need to calculate using the Chaining Method, you can change

this in your calculator Preference Settings. See page 107 for instructions.

USER’S GUIDE —21

Page 23

USING PARENTHESES

Your calculator has Parentheses keys ( and ) for performing

mathematical operations. (In the Order of Operations method,

expressions inside of parentheses are performed first.)

The calculator offers four levels of parenthesis:

1) First parenthesis level opened – press ( for one Right-

Sided Parenthesis.

2) Second level opened – press ( a second time for two

Right-Sided Parentheses ((.

3) Third level opened –press( a third time for three RightSided Parentheses (((.

4) Fourth level opened – press ( a fourth time for four RightSided Parentheses ((((.

As you close each level of Parenthesis, the displayed number of

Parentheses in the upper left corner of the LCD is reduced by one,

and the results of expression are displayed.

22 — ITI SHEET METAL/HVAC PRO

Page 24

SETTING FRACTIONAL RESOLUTION

Your calculator is set to display fractional answers in 16ths, and all

examples in this User Guide are, therefore, based on 1/16ths.

However, you may select the fractional resolution to be displayed in

other formats (e.g., 1/64ths, 1/32nds, etc.). Follow the two options

for selecting fractional resolution below.

Setting Fraction Resolution to Other Than 16ths —

Using the Preference Setting Mode

KEYSTROKE DISPLAY

1. Access Preference Settings:

Ç=(default setting = 1/16th of an Inch) FRAC 0-1/16 INCH

2. Access Next Fraction Sub-setting:

+ FRAC 0-1/32 INCH

+ FRAC 0-1/64 INCH

+ FRAC 0-1/2 INCH

+ FRAC 0-1/4 INCH

+ FRAC 0-1/8 INCH

+ (returns to 16ths) FRAC 0-1/16 INCH

3. To Permanently Set the Fraction Resolution You Have Selected

Above, Press o or Any Key to Exit:

o 0.

4. To Recall Your Selected Fraction Resolution:

®/ STD 0-1/16 INCH

USER’S GUIDE —23

Page 25

Setting Fixed/Constant Fractional Resolution

You can also program your calculator so that the displayed fraction

will always show in the fractional resolution you have set (following

the above instructions). That is, instead of solving for the closest

fraction, it will always display the chosen fractional resolution. For

example, if you have chosen 1/64ths, 1/2 will be displayed as 32/64.

If you do not use this feature, Standard Fractional Resolution will be

displayed. In other words, in the above example, 1/2 will be displayed as 1/2.

To change your calculator to Fixed (or Constant) Fractional Resolution:

KEYSTROKE DISPLAY

1. Access Preference Settings:

Ç= FRAC 0-1/16 INCH

2.

Press = 12 times to access Fixed/Constant Fractional Resolution setting:

= (twelfth press of = ) FRAC Std.

3. Change setting by pressing + :

+ FRAC COnSt

+ (returns to Standard) FRAC Std.

4. To permanently set the Fixed/Constant Fractional Resolution set-

ting, press o or any key to exit.

o 0.

5.

To recall your selected Fixed/Constant Fractional Resolution setting:

®/ (default settings) STD 0-1/16 INCH

24 — ITI SHEET METAL/HVAC PRO

Page 26

ENTERING DIMENSIONS

Entering Linear Dimensions

When entering Feet-Inch-Fraction values, enter dimensions from

largest to smallest — e.g., Feet before Inches, Inches before

Fractions. Enter Fractions by entering the numerator (top), pressing

/ (Fraction bar key) and then the denominator (bottom).

Note: If a denominator is not entered, the fractional setting value is used.

Examples (press o after each one):

DIMENSION KEYSTROKES

5Feet1-1/2Inch 5f1i1/2

17.5 Meters 17•5m

32 Millimeters 32Çm

Entering Square/Cubic Dimensions

Your calculator lets you easily enter Square and Cubic values.

Simply press a dimensional unit key two times to label a number as

a Square value, or three times to label a Cubic value.

Note: If you pass the desired dimensional format, keep on pressing the dimensional

unit key until the desired result is displayed.

Enter Square and Cubic dimensions in the following order:

(1) Enter numerical value (e.g., 100).

(2) Press desired unit key (e.g., f) to label value as “linear.”

KEYSTROKE DISPLAY

oo 0.

100f 100

(3) Second consecutive press of unit key (e.g., f) labels value as

“Square.”

KEYSTROKE DISPLAY

oo 0.

100ff 100 SQ FEET

(4) Third consecutive press of unit key labels value as “Cubic.”

KEYSTROKE DISPLAY

oo 0.

100fff 100 CU FEET

Note: Feet-Inch format cannot be used to enter Square or Cubic values.

FEET

USER’S GUIDE —25

Page 27

Examples of Square and Cubic Entry:

FEET

ff— Square Feet

(e.g., 5ffwill display 5.

SQ FEET).

fff— Cubic Feet

(e.g., 5fffwill display 5.

INCHES

CU FEET).

ii— Square Inches

(e.g., 5iiwill display 5. SQ INCH).

iii— Cubic Inches

(e.g., 5iiiwill display 5. CU INCH).

METERS

mm— Square Meters

(e.g., 5mmwill display 5. SQ M).

mmm— Cubic Meters

(e.g., 5mmmwill display 5. CU M).

MILLIMETERS

Çmm— Square Millimeters

(e.g., 5Çmmwill display 5. SQ MM).

Çmmm— Cubic Millimeters

(e.g., 5Çmmmwill display 5. CU MM).

26 — ITI SHEET METAL/HVAC PRO

Page 28

CONVERSIONS (LINEAR, AREA, VOLUME)

Linear Conversions

Convert 14 Feet to other dimensions:

KEYSTROKE DISPLAY

oo 0.

14f 14 FEET

Çi 168 INCH

m* 4.267 M

Çm(mm) 4267.2 MM

*Note: When performing multiple conversions, you only have to press the Ç key

once (except when accessing secondary functions (Millimeters), e.g., Çm).

Converting Feet-Inch-Fractions to Decimal Feet

Convert 15 Feet 9-1/2 Inches to Decimal Feet. Then convert back to

Feet-Inch-Fractions.

KEYSTROKE DISPLAY

oo 0.

15f9i1/2

15 FEET 9-1/2 INCH

Çf 15.79167 FEET

f 15 FEET 9-1/2 INCH

Converting Decimal Feet to Feet-Inch-Fractions

Convert 17.32 Feet to Feet-Inch-Fractions.

KEYSTROKE DISPLAY

oo 0.

17•32f 17.32 FEET

Çf 17 FEET 3-13/16 INCH

Converting Fractional Inches to Decimal Inches

Convert 8-1/8 Inches to Decimal Inches. Then convert to Decimal

Feet.

KEYSTROKE DISPLAY

oo 0.

8i1/8 8-1/8 INCH

Çi 8.125 INCH

f 0.677083 FEET

USER’S GUIDE —27

Page 29

Converting Decimal Inches to Fractional Inches

Convert 9.0625 Inches to Fractional Inches. Then convert to Decimal

Feet.

KEYSTROKE DISPLAY

oo 0.

9•0625i 9.0625

INCH

Çi 9-1/16 INCH

ff 0.755208 FEET

Square Conversions

Convert 14 Square Feet to other Square dimensions:

KEYSTROKE DISPLAY

oo 0.

14ffÇi 2016. SQ INCH

m 1.300643 SQ M

Çm(mm) 1300642.56* SQ MM

*For larger digit displays, the numerator section is utilized for decimal displays.

Cubic Conversions

Convert 14 Cubic Feet to other Cubic dimensions:

KEYSTROKE DISPLAY

oo 0.

14fffÇi 24192. CU INCH

m 0.396436 CU M

28 — ITI SHEET METAL/HVAC PRO

Page 30

PERFORMING BASIC MATH WITH DIMENSIONS

Adding Dimensions

KEYSTROKE DISPLAY

Add 11 Inches to 2 Feet 1 Inch:

11i+2f1i= 3 FEET 0 INCH

Add 5 Feet 7-1/2 Inches to 18 Feet 8 Inches:

5f7i1/2+18f8i=

Subtracting Dimensions

KEYSTROKE DISPLAY

Subtract 3 Feet from 11 Feet 7-1/2 Inches:

11f7i1/2–3f= 8

Subtract 32 Inches from 81 Inches:

81i–32i= 49 INCH

Multiplying Dimensions

KEYSTROKE DISPLAY

Multiply 5 Feet 3 Inches by 11 Feet 6-1/2 Inches:

5f3ix11f6i1/2=

Multiply 2 Feet 7 Inches by 10:

2f7ix10= 25 FEET 10 INCH

24 FEET 3-1/2 INCH

FEET 7-1/2 INCH

60.59375 SQ FEET

Dividing Dimensions

KEYSTROKE DISPLAY

Divide 30 Feet 4 Inches by 7 Inches:

30f4i÷7i= 52.

Divide 20 Feet 3 Inches by 9:

20f3i÷9= 2 FEET 3 INCH

USER’S GUIDE —29

Page 31

Percentage Calculations

Percent (Ç+) is used to find a given percent of a number or to

perform add-on, discount or division percentage calculations. You

may also perform percentage calculations with dimensional units

(Feet, Inch, etc.), in any format (Linear, Square or Cubic).

Examples:

KEYSTROKE DISPLAY

Find 18% of 500 Feet:

500fx18Ç+ 90 FEET 0 INCH

What is 15% of $250?

250x15Ç+ 37.5

Add 10% to 137 Square Feet:

137ff+10Ç+ 150.7

SQ FEET

Subtract 20% from 552 Feet 6 Inches:

552f6i–20Ç+ 442 FEET 0 INCH

Divide 350 Meters by 80%:

350m÷80Ç+ 437.500 M

30 — ITI SHEET METAL/HVAC PRO

Page 32

MEMORY OPERATION

Your calculator has two types of Memory operations:

1) A Standard, Cumulative, Semi-permanent Memory μ; and

2) Three Storage Registers [M1], [M2] and [M3], used to permanently store single, non-cumulative values.

Memory commands are listed below.

FUNCTION KEYSTROKES

M+:

Add value to M+ μ

Subtract value from M+ Çμ

Clear M+ (displays and clears M+) ®®

M+ Swap (swaps current value stored in M+

with displayed value) Ç®

Recall stored value ®μ

M1/M2/M3:

Store single value in M1 Ç1

Store single value in M2 Ç2

Store single value in M3 Ç3

Clear register M1 0Ç1

Clear register M2 0Ç2

Clear register M3 0Ç3

Recall stored value in M1 ®1

Recall stored value in M2 ®2

Recall stored value in M3 ®3

USER’S GUIDE —31

Page 33

i. Basic Cumulative Memory (M+)

Example 1:

Store 100 into M+, add 200, then subtract 50. Clear the Memory:

KEYSTROKE DISPLAY

100μ M+ 100.

200μ M+ 200.

50Çμ M– 50.

®® M+ 250.

Note: To Clear Memory (M+):

- press ®®;or

- turn off the calculator.

Example 2:

Store 100 into M+, then replace this value with 200 using Memory

Swap:

KEYSTROKE DISPLAY

100μ M+ 100.

®μ M+ 100.

STORED

200Ç® SWAP 100.

®μ M+ 200.

STORED

®® M+ 200.

ii. Permanent Storage Registers (M1, M2, and M3)

Examples:

Store a rate of $175 into M1 and recall the value:

KEYSTROKE DISPLAY

175Ç1 M-1 175.

Oo 0.

®1 M-1 175.

STORED

M

M

M

M

M

M

M

Store 1,575 Square Meters into M2 and recall the value:

KEYSTROKE DISPLAY

1575mmÇ2 M-2 1575. SQ M

Oo 0.

®2 M-2 1575. SQ M

Note: To Clear M1-M3: Values stored in M1-M3 will remain permanently stored, even

after you turn the calculator off. You will never need to clear the storage registers;

simply enter a new value. However, if you wish to clear M1-M3 to “zero”:

- Enter 0Ç1, 0Ç2or 0Ç3

STORED

32 — ITI SHEET METAL/HVAC PRO

Page 34

EXAMPLES — USING THE SHEET METAL/HVAC PRO

The ITI Sheet Metal/HVAC Pro calculator has keys and functions

labeled in common sheet metal/HVAC or construction terms. Just

follow the examples and adapt the keystrokes to your specific application.

Your calculator will save you time; you don’t need to remember common formulas, as they are built into timesaving keys.

The first examples that follow provide you with mathematical problems

seen in the sheet metal industry, such as computing triangle measurements using the Pythagorean Theorem or the Law of Cosines, as

well as dedicated Offset, Fan Law, and Velocity functions.

The remaining examples apply to the construction trades, especially

roof framing, which also depends on Right Triangle mathematics.

It is good practice to clear your calculator (press o twice) before

beginning each problem. And remember to use the Backspace

(B) key to correct entries one entry at a time.

USER’S GUIDE —33

Page 35

BASIC EXAMPLES

Adding Linear Measurements

Find the total length of the following measurements: 5 Feet 4-1/2

Inches, 8 Inches and 3.5 Meters.

KEYSTROKE DISPLAY

1. Add the measurements:

oo 0.

5f4i1/2+ 5 FEET 4-1/2 INCH

8i+ 6 FEET 0-1/2 INCH

3•5m 3.5 M

2. Find the total:

= 17 FEET 6-5/16 INCH

Converting Feet-Inch-Fractions to Decimal Feet and Fractions

of an Inch

Convert 5 Feet 7-1/2 Inches to Decimal Feet, then Decimal Inches

and Inch-Fractions:

KEYSTROKE DISPLAY

oo 0.

5f7i1/2 5 FEET 7-1/2 INCH

Çf 5.625 FEET

i 67.5 INCH

i 67-1/2 INCH

Converting Feet-Inches to Meters and Millimeters

Convert 8 Feet 6 Inches to Meters and Millimeters:

KEYSTROKE DISPLAY

oo 0.

8f6iÇm 2.591 M

Çm(mm) 2590.8 MM

34 — ITI SHEET METAL/HVAC PRO

Page 36

Adding and Subtracting Fractions of an Inch

Add 1/2 Inch, 3/8 Inch and 11/16 Inch. Then subtract 5/8 Inch.

KEYSTROKE DISPLAY

oo 0.

1/2+3/8+11/16= 1-9/16 INCH

–5/8= 0-15/16 INCH

Converting Fractions to Decimals

Convert 7/32 Inch and 1/3 Inch to Decimals, respectively (and round

answers):

KEYSTROKE DISPLAY

oo 0.

7/32Çi 0.21875 INCH

(Answer = 0.219”)

1/3Çi 0.333333 INCH

(Answer = 0.33”)

Converting Decimals to Fractions

Convert 5.875 Inches and 8.545 Inches to the nearest 16ths of an

Inch:

KEYSTROKE DISPLAY

oo 0.

5•875iÇi 5-7/8 INCH

8•545iÇi 8-9/16 INCH

Finding Length (of Iron) Required

What is the length of iron required if you need twenty (20) pieces

measuring 5-1/16 Inches each? If you allow 3/32 Inch for each cut,

what is the new length required?

KEYSTROKE DISPLAY

oo 0.

5i1/16x20= 101-1/4 INCH

μ M+ 101-1/4 INCH

3/32x19= 1-25/32 INCH

μ M+ 1-25/32 INCH

®μ M+ 103-1/32 INCH

STORED

®®(clear Memory) M+ 103-1/32 INCH

USER’S GUIDE —35

M

M

M

M

Page 37

Circumference of a Circle

Find the Circumference of a Circle if its Radius is 8 Feet 4 Inches:

KEYSTROKE DISPLAY

oo 0.

8f4iÇp RAD 8 FEET 4 INCH

C DIA 16 FEET 8 INCH

C CIRC 52 FEET 4-5/16 INCH

Circumference and Area of a Circle

Find the Area and Circumference of a Circle with a Diameter of 11

Inches:

KEYSTROKE DISPLAY

oo 0.

11iC DIA 11 INCH

C CIRC 34-9/16 INCH

C AREA 95.03318 SQ INCH

Square Area (x2)

What is the Area of a Square room with sides measuring 7 Feet 4

Inches?

KEYSTROKE DISPLAY

oo 0.

7f4iX 53.77778 SQ FEET

Area of a Rectangle

What is the Area of a room measuring 12 Feet 6 Inches by 15 Feet

8 Inches?

KEYSTROKE DISPLAY

oo 0.

12f6i 12 FEET 6 INCH

x15f8i= 195.8333 SQ FEET

36 — ITI SHEET METAL/HVAC PRO

Page 38

Area of a Triangle

Find the Area of a Triangle if its base is 45 Inches and Altitude/

Height is 30 Inches.

KEYSTROKE DISPLAY

oo 0.

45i÷2= 22-1/2

INCH

x30i= 675. SQ INCH

Volume of a Rectangular Box

Find the Volume of a rectangular box with Length of 15 Inches,

Width of 6 Inches and Height 9-1/2 Inches.

KEYSTROKE DISPLAY

oo 0.

15ix6ix9i1/2= 855. CU INCH

Volume of a Rectangular Container, Converting to Cubic Meters

What is the Volume of a rectangular container that measures 3 Feet

by 1 Foot 9-5/8 Inches by 2 Feet 4 Inches?

KEYSTROKE DISPLAY

1. Find Volume in Cubic Feet:

oo 0.

3f 3 FEET

x1f9i5/8 1 FEET 9-5/8 INCH

x2f4i= 12.61458 CU FEET

2. Convert to Cubic Meters:

Çm 0.357205 CU M

USER’S GUIDE —37

Page 39

Volume of a Cylinder

Calculate the Volume of a Cylinder with a Diameter of 2 Feet 4

Inches and a Height of 4 Feet 6 Inches:

*Note: For a Cylinder, use the Column ) function.

KEYSTROKE DISPLAY

1. First, enter Diameter to find Circle Area:

oo 0.

2f4iC DIA 2 FEET 4 INCH

CC AREA 4.276057 SQ FEET

2. Enter Height and find Volume of Column (or Cylinder):

4f6ir Y4FEET 6 INCH

Ç) COL 19.24226 CU FEET

Volume of a Cone

Calculate the Volume of a Cone with a Diameter of 3 Feet 6 Inches

and a Height of 5 Feet:

KEYSTROKE DISPLAY

1. Find Circle Area:

oo 0.

3f6iC DIA 3 FEET 6 INCH

CC AREA 9.621128 SQ FEET

2. Enter Height and find Volume:*

5fr Y5FEET 0 INCH

Ç)))* CONE 16.03521 CU FEET

*Note: To access Cone Volume, notice you must press the ) key three times after Ç.

38 — ITI SHEET METAL/HVAC PRO

Page 40

Cubed Function

What is the Cubed value of 10? What is 503?

KEYSTROKE DISPLAY

oo 0.

10ÇX 1000.

50ÇX 125000.

Cubed Root Function

Example 1:

What is the Cubed Root of 100? Then, find :

KEYSTROKE DISPLAY

oo 0.

100Ç√ 4.641589

5088Ç√ 17.1995

Example 2:

What are the three dimensions of a Cube with a Volume of 2028

Cubic Inches?

KEYSTROKE DISPLAY

oo 0.

2028Ç√ 12.65773 (Inches)

Alternate method of entry using Unit Keys:

KEYSTROKE DISPLAY

oo 0.

2028iii 2028 CU INCH

Ç√ 12-11/16 INCH

Çii 12.65773 INCH

Scientific Notation

Add1.78x1010and 3.90 x 109:

KEYSTROKE DISPLAY

oo 0.

1•78Ç/10+3•9Ç/9= 2.17000

USER’S GUIDE —39

10

Page 41

TRIGONOMETRIC FUNCTIONS

Trigonometric functions are available on the ITI Sheet Metal/HVAC

Pro calculator.

The drawing and formulas below list basic trigonometric formulas,

for your reference:

Given side A and angle a, find:

Side C A ÷ a ç=

(i.e., 3f÷53•13ç=)

Side B A x a t=

Angle b 90° – a =

Given side A and angle b, find:

Side B A ÷ b t=

Side C A ÷ b S=

Angle a 90° – b =

Given side B and angle a, find:

Side A B ÷ a t=

Side C B ÷ a S=

Given side C and angle a, find:

Side A C x a ç=

Side B C x a S=

Given side A and side C, find:

Angle a A ÷ C =Çç

Angle b A ÷ C =ÇS

Given side B and angle b, find:

Side C B ÷ b ç=

Side A B x b t=

40 — ITI SHEET METAL/HVAC PRO

Page 42

Finding Sine, Cosine, Tangent

Find Sine 12°, Cosine 33° and Tangent 75°:

KEYSTROKE DISPLAY

oo 0.

12S 0.207912

33ç 0.838671

75t 3.732051

Finding “Angle A” (ArcSin, ArcCos, ArcTan)

Find Angle A if Sine A = 0.57544, Cosine A = 0.06753 and Tangent

A = 0.87421 and round to the nearest whole angle:

KEYSTROKE DISPLAY

oo 0.

•57544ÇS 35.13045° (35°)

•06753Çç 86.12787° (86°)

•87421Çt 41.16028° (41°)

Using Trigonometry to Find Unknown Side

Using the Pythagorean Theorem (a2+b2=c2) keys, find Side a (“x”)

of a Right Triangle, if Side b (“y”) is 6-1/2 Inches and Side c (“r”), the

Hypotenuse, is 12-1/16 Inches.

Note: Use the calculator’s R, r and d keys; substitute triangle legs a, b and c for

[x], [y] and [r].

KEYSTROKE DISPLAY

oo 0.

6i1/2r Y6-1/2INCH

12i1/16d R 12-1/16 INCH

R X 10-3/16 INCH

USER’S GUIDE —41

Page 43

Using Trigonometry to Find Unknown Angle or Side

Example 1 — Cos A:

Solve for the unknown angle A if the two known sides are:

Side b = 15 mm

Side c = 35 mm

a) Longhand Method

: In this case, use the trigonometry formula:

Cos = Adjacent/Hypotenuse or cos A = b/c

KEYSTROKE DISPLAY

oo 0.

15* ÷35=Çç 64.62307°

(64.6°)

Ç• DMS 64.37.23

*Note: you do not have to label mm.

b) Alternative Method (Use Pythagorean Theorem Keys):

Insert values into x, y, or r keys to solve for Theta.

KEYSTROKE DISPLAY

oo 0.

15R X 15.

35d R 35.

p 64.62307°

(64.6°)

Ç• DMS 64.37.23

42 — ITI SHEET METAL/HVAC PRO

Page 44

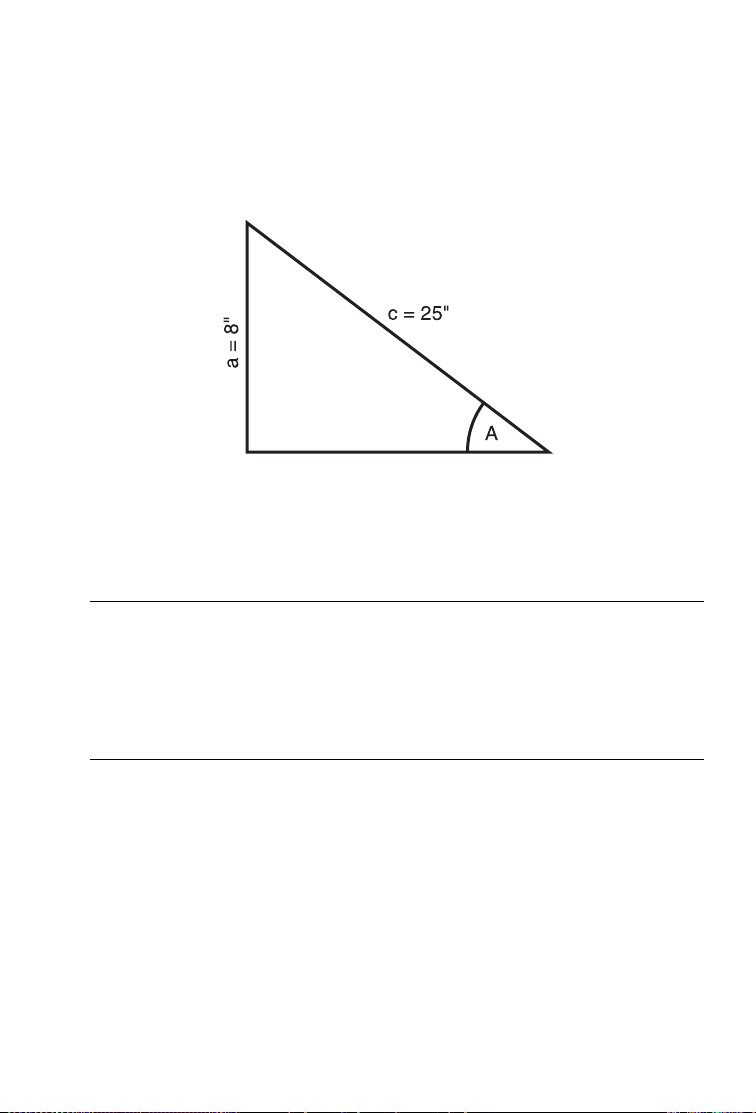

Trig Examples (Cont’d)

Example 2 — Sin A:

Solve angle A of the offset below, if the two known sides are:

Sidea=8Inches

Sidec=25Inches

In this case, use the trigonometry formula:

Sin = Opposite/Hypotenuse or Sin A = a/c

a) Longhand/Use Sine Formula:

KEYSTROKE DISPLAY

oo 0.

8÷25=ÇS 18.66292°

(18.7°)

b) Use Pythagorean Theorem Keys:

KEYSTROKE DISPLAY

oo 0.

8r Y8.

25d R 25.

p /_Ø 18.66292°

(18.7°)

USER’S GUIDE —43

Page 45

Trig Examples (Cont’d)

Example 3 — Tan A:

Find the length of the transition for a 20° angle:

Side a = 18 Inches

Side b = unknown

a) Longhand Method: Use Tan = Opposite/Adjacent

KEYSTROKE DISPLAY

1. First solve for Tan 20° to find ratio, then enter in Memory:

oo 0.

20tμ M+ 0.36397

M

2. Solve for Side b by dividing Side a by stored ratio:

18÷®μ= 49.45459

(49.5 inches)

3. Clear Memory and clear display:

®®o 0.

b) Use Pythagorean Theorem Keys:

KEYSTROKE DISPLAY

oo 0.

18r Y 18.

20p /_Ø 20.°

R X 49.45459

(49.5 inches)

44 — ITI SHEET METAL/HVAC PRO

M

Page 46

Converting Pitch to Angle/Tangent

Find the angle and corresponding Tangent for a roof with an 8/12

Pitch:

KEYSTROKE DISPLAY

1. Enter Pitch:

oo 0.

8ip PTCH 8

INCH

2. Convert Pitch to degrees:

p /_Ø 33.69007°

3. Find Tangent or slope:

pp 0.666667

D:M:S EXAMPLE

Converting Degrees:Minutes:Seconds

Convert 23°42’39” to Decimal Degrees:

KEYSTROKE DISPLAY

oo 0.

23•42•39 DMS 23.42.39

Ç•(degrees) 23.71083°

Convert 44.29° to degrees:minutes:seconds format:

KEYSTROKE DISPLAY

oo 0.

44•29Ç•(d:m:s) DMS 44.17.24

Note: Improperly formatted entries will be redisplayed in the correct convention after

any operator key is pressed. For example, 30°89’ entered will be corrected and displayed at 31°29’ 0” or 31.48333°.

USER’S GUIDE —45

Page 47

VELOCITY PRESSURE / VELOCITY EXAMPLES

The Velocity Pressure/Velocity function uses an entered value to

calculate these four values:

1. Velocity (FPM) Number entered is assumed to be

Velocity Pressure

2. Velocity (Pressure) Number entered is assumed to be

Velocity (FPM)

3. Metric Velocity (MPS) Number entered is assumed to be

Metric Velocity Pressure (kPA)

4. Metric Velocity Pressure Number entered is assumed to be

(kPA) Metric Velocity (MPS)

The first time you perform this function, the values are displayed in

the order identified above. Subsequent calculations begin with the

last displayed value.

Converting Velocity Pressure to FPM

After obtaining Velocity Pressures (VP) from taking a traverse, your

calculator easily converts to Feet per Minute (FPM).

For example, convert the following VPs to FPM:

0.049”

0.123”

0.027”

KEYSTROKE DISPLAY

1. Enter first VP and convert to FPM:

oo 0.

•049Ç0* FPM 886.5445

2. Enter second VP and convert to FPM:

•123Ç0 FPM 1404.608

3. Enter third VP and convert to FPM:

•027Ç0 FPM 658.0887

*The VPß©FPM function begins with the last displayed value. If FPM is not displayed

with the first press of Ç0, continue pressing 0 until FPM is displayed.

46 — ITI SHEET METAL/HVAC PRO

Page 48

Converting FPM to Velocity Pressure

Calculate the Velocity Pressure (Imperial and Metric) if the FPM is

500:

KEYSTROKE DISPLAY

1. Enter 500 FPM to calculate Velocity:

oo 0.

500Ç0 FPM 89554.52

2. Calculate Velocity Pressure (VP):

0* VP 0.015586

3. Calculate Metric Velocity (MPS):

0 MPS 29.06888

4. Calculate Metric Velocity Pressure (KPA):

0 KPA 147928.99

5. Re-display entered value:

0 500.

*The VPß©FPM function begins with the last displayed value. If FPM is not displayed with the first press of Ç0, continue pressing 0 until FPM is displayed.

: The entered value is used to calculate all four values; for calculation of Velocity

Note

(FPM), the entered value is assumed to be VP, and for calculation of VP, the entered

value is assumed to be FPM. For calculation of MPS, the entry is assumed to be kPA,

and for calculation of kPA, the entry is assumed to be MPS.

USER’S GUIDE —47

Page 49

OFFSET EXAMPLES

Offset, Basic Example

If an offset is 5 Feet, the actual Length 10 Feet, and the Height of

the “end A” equal to 7 Feet, calculate the Centerline Radius,

Wrapper Length, Heel Radius, Throat Radius, and Theta.

KEYSTROKE DISPLAY

1. Enter actual Length as “x”:

oo 0.

10fR X10FEET 0 INCH

2. Enter offset Length as “y”:

5fr Y5FEET 0 INCH

3. Enter Height of “end A” as “a”:

7fÇ4 A7FEET 0 INCH

STORED

4. Calculate Centerline Radius, Wrapper Length, Heel Radius,

Throat Radius and Theta:

Ç( RAD 6 FEET 3 INCH

( WL 11 FEET 7-1/8 INCH

( HEEL 9 FEET 9 INCH

( THRT 2 FEET 9 INCH

( THET 26.56505°

Note: If the calculated Throat Radius is less than zero, an error will be displayed (i.e.

“THRT Error”) when attempting to calculate the Offset.

48 — ITI SHEET METAL/HVAC PRO

Page 50

OGEE Offset in Feet-Inch-Fractions

If an offset is 12-5/8 Inches, the actual Length 45 Inches, and the

Height of the “end A” is 38 Inches, calculate the Centerline Radius,

Wrapper Length, Heel Radius, Throat Radius, and Theta.

KEYSTROKE DISPLAY

1. Enter actual Length as “x”:

oo 0.

45iR X45INCH

2. Enter offset Length as “y”:

12i5/8r Y 12-5/8 INCH

3. Enter Height of “end A” as “a”:

38iÇ4 A38INCH

STORED

4. Calculate Centerline Radius, Wrapper Length, Heel Radius,

Throat Radius and Theta:

Ç( RAD 43-1/4 INCH

( WL 47-5/16 INCH

( HEEL 62-1/4 INCH

( THRT 24-1/4 INCH

( THET 15.67176°

USER’S GUIDE —49

Page 51

OGEE Offset, in Millimeters

If an offset is 573 Millimeters (mm), the actual Length 2045 mm, and

the Height of the “end A” 1727 mm, calculate the Centerline Radius,

Wrapper Length, Heel Radius, Throat Radius, and Theta.

*Note: To save keystrokes, you do not have to label entries in mm.

KEYSTROKE DISPLAY

1. Enter actual Length as “x”:

oo 0.

2045ÇmR X 2045. MM

2. Enter offset Length as “y”:

573Çmr Y 573. MM

3. Enter Height of “end A” as “a”:

1727ÇmÇ4 A 1727. MM

STORED

4. Calculate Centerline Radius, Wrapper Length, Heel Radius,

Throat Radius and Theta:

Ç( RAD 1967.868 MM

(1968 MM)

( WL 2150.408 MM

(2150 MM)

( HEEL 2831.368 MM

(2831 MM)

( THRT 1104.368 MM

(1104 MM)

( THET 15.65264°

50 — ITI SHEET METAL/HVAC PRO

Page 52

Dividing Offset into Multiple Degreed Elbows for Manageable

Sections

Solve the offset using the given variables:

Actual Length “x”: 80-1/2 Inches

Offset Length “y”: 22-9/16 Inches

A: 68 inches

Then, divide Theta into four degreed elbows; double Theta for two

equal elbows.

KEYSTROKE DISPLAY

1. Enter actual Length as “x”:

oo 0.

80i1/2R X 80-1/2 INCH

2. Enter offset Length as “y”:

22i9/16r Y 22-9/16 INCH

3. Enter Height of “way end A” as “a”:

68iÇ4 A68INCH

STORED

(Cont’d)

USER’S GUIDE —51

Page 53

(Cont’d)

KEYSTROKE DISPLAY

4. Calculate Centerline Radius, Wrapper Length, Heel Radius,

Throat Radius and Theta:

Ç( RAD 77-7/16 INCH

( WL 84-5/8 INCH

( HEEL 111-7/16 INCH

( THRT 43-7/16 INCH

( THET 15.6571°

5. Convert Theta to degrees:minutes:seconds:*

Ç• DMS 15.39.26

6. Multiply by two to double offset:**

x2= DMS 31.18.51

*The angle of Theta can be used to divide the offset into degreed elbows for more

manageable sections. If the angle calculated is used, there would be four (4) elbows

each at 15°39’26”.

**If two (2) elbows were desired, the calculated angle can be doubled (each elbow

would be 31°18’51”). Doubling Theta provides the maximum elbow size for this offset

and radius combination. The total angle on either side of center can be divided into as

many elbows as is required to make the offset manageable. In the case above, the

maximum angle that can be divided is 31°18’51”.

52 — ITI SHEET METAL/HVAC PRO

Page 54

Change OGEE Offset

Solve the Change OGEE Offset below, with Wrapper Size transitions

from one end to another.

A) Solve Using:

a. Actual Length “x”: 52-5/8 Inches

b. Offset “y”: 15-3/16 Inches

c. End “a”: 34 Inches

KEYSTROKE DISPLAY

1. Enter actual Length as “x”:

oo 0.

52i5/8R X 52-5/8 INCH

2. Enter offset Length as “y”:

15i3/16r Y 15-3/16 INCH

3. Enter Height of “way end A” as “a”:

34iÇ4 A34INCH

STORED

4. Calculate Centerline Radius, Wrapper Length, Heel Radius,

Throat Radius and Theta:

Ç( RAD 49-3/8 INCH

( WL 55-1/2 INCH

( HEEL 66-3/8 INCH

( THRT 32-3/8 INCH

( THET 16.09806°

USER’S GUIDE —53

Page 55

B) Solve Using:

a. Actual Length “x”: 52-5/8 Inches

b. Offset “y”: 25-3/16 Inches

c. End “a”: 34 Inches

KEYSTROKE DISPLAY

1. Enter actual Length as “x”:

oo 0.

52i5/8R X 52-5/8 INCH

2. Enter offset Length as “y”:

25i3/16r Y 25-3/16 INCH

3. Enter Height of “end A” as “a”:

34iÇ4 A34INCH

STORED

4. Calculate Centerline Radius, Wrapper Length, Heel Radius,

Throat Radius and Theta:

Ç( RAD 33-13/16 INCH

( WL 60-5/16 INCH

( HEEL 50-13/16 INCH

( THRT 16-13/16 INCH

( THET 25.57682°

“WL”, or the Wrapper, corresponds to the side of the fitting associated with the offset dimension used for the calculation. The longest

Wrapper corresponds to the side with the largest offset (y).

Caution: When working with a “Change Transitional OGEE

Offset” (Wrapper size transitions from one end to other) the length

of a cheek having a slant length must be adjusted to include

that slant length prior to the calculations above taking place.

54 — ITI SHEET METAL/HVAC PRO

Page 56

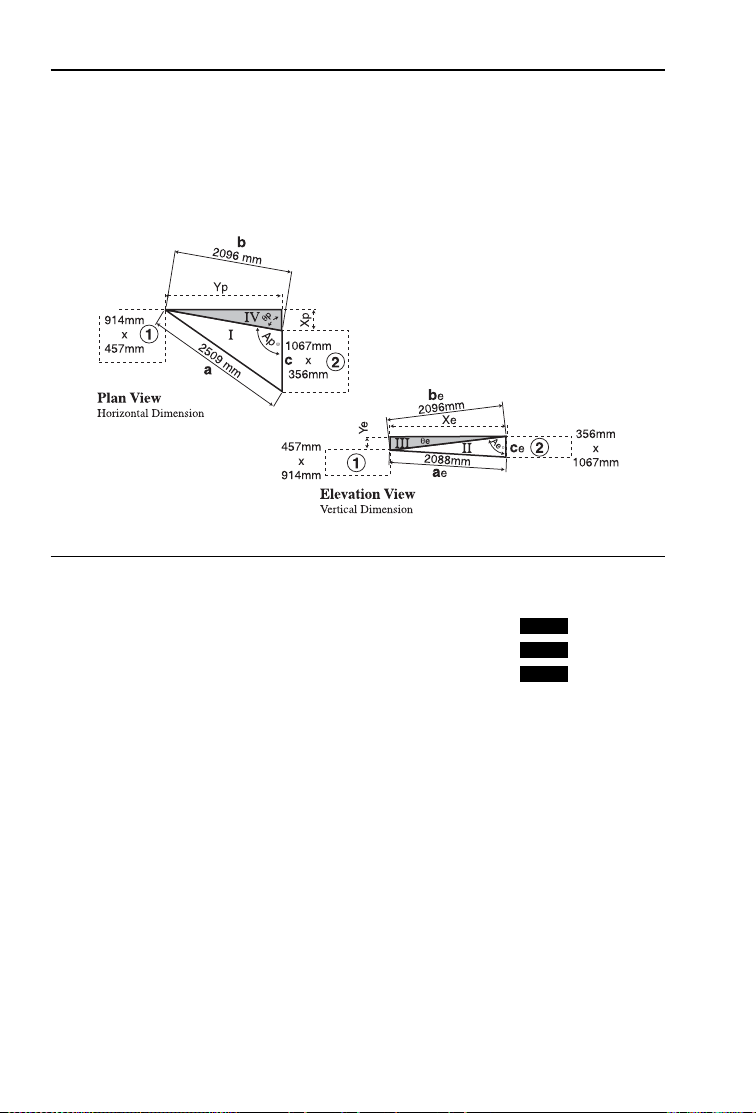

LAW OF COSINES EXAMPLES

Field Measuring for Ductwork Using the Law of Cosines —

Introduction

Dimensions taken when measuring objects in the field are taken

from the plan or horizontal plane and the elevation or vertical plane

of the objects. The purpose is to find the dimensional relationship of

distance and alignment between two or more objects. In the Sheet

Metal Industry, these specific dimensions are identified as Length,

Offset, and Angle.

Relationships can be established between any two objects such as

ductwork, structural, penetrations, units or terminal devices. The

objects are not as important as an understanding of the information

required to achieve the ultimate goal of “the ability to develop the

required fittings and/or parts for the system.”

Example:

Two duct lines, both 18 Inches x 12 Inches as shown in the sketch

on the next page, are to be measured for a fill-in piece. Measurements

of the plan view or horizontal plane are taken from both ducts to a

parallel stationary object such as a wall or a structural member. The

difference between these two measurements establishes the horizontal offset between the two duct lines, if any exists. The process is

repeated for the elevation measurements typically using the floor

below the objects (upper at 8 Feet 8 Inches, the lower 8 Feet 109/16 Inches). A measurement between the two duct lines will establish length. These measurements and calculations are used to develop the duct and/or fittings required to fill the space.

Using this method we find the fill-in piece will need to be 24 Inches

in length with a 9 Inch horizontal offset and a 2-9/16 Inches vertical

offset.

USER’S GUIDE —55

Page 57

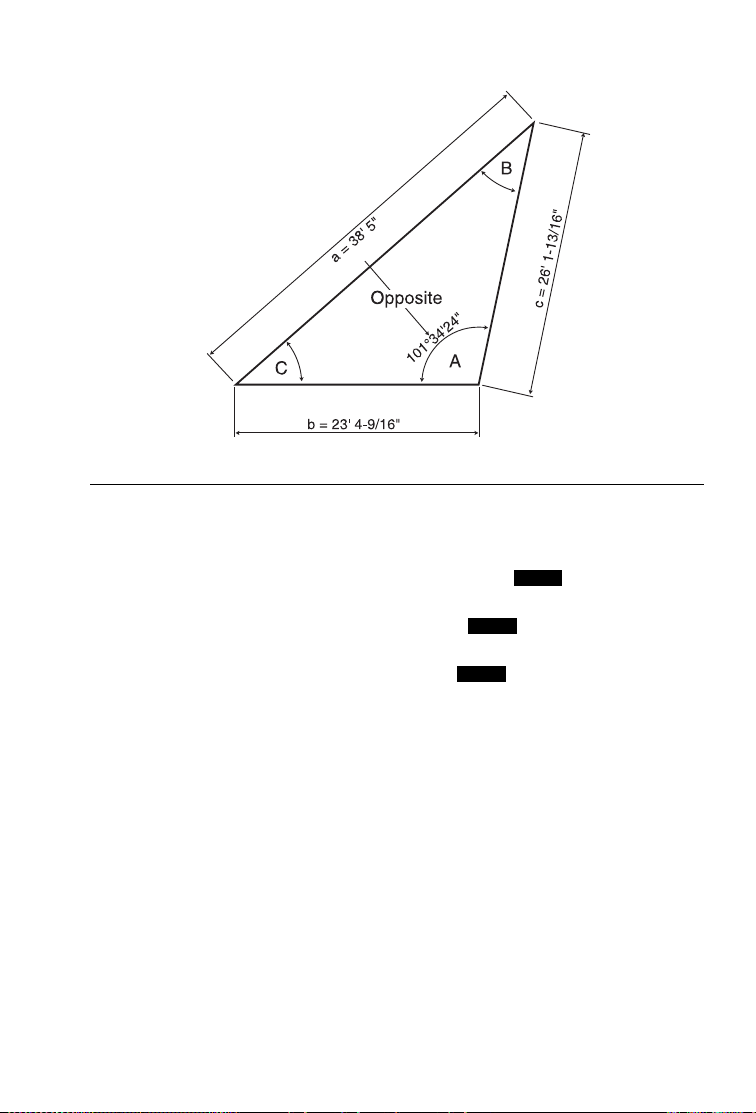

Non-90 Degree Triangle Measurement Using Law of Cosines

and Heron’s Theorem

The Law of Cosines keys calculate the unknown angles after

inputting the three known sides of a non-90 degree triangle. Triangle

area is also found given the built-in formula for Heron’s Theorem.

The relationship of any side to the included angle is identified as the

angles opposite the side having the same letter designation (see

diagram on next page). When using this method of measuring, the

user needs to keep the relationship of the sides to their included

angles in perspective at all times. Because your calculator displays

all three angles, the user has the discretion of identifying as they

choose.

Note: As a test, rotate the letters used to identify the sides and corresponding angles

clockwise on the triangle on next page, input the lengths in the appropriate key location for the new letter and display the included angles. You’ll find that the Degree of

Angles are still in the same location in relationship to the Length of Sides as before,

only the letters used to identify those lengths and angles changed positions.

Using the lengths given below designated as Side a, b and c, calculate the corresponding angles A, B and C.

Side a: 38 Feet 5 Inches

Side b: 23 Feet 4-9/16 Inches

Side c: 26 Feet 1-13/16 Inches

(Cont’d)

56 — ITI SHEET METAL/HVAC PRO

Page 58

(Cont’d)

KEYSTROKE DISPLAY

1. Enter side a, b and c:

oo 0.

38f5iÇ4

STORED

A38FEET 5 INCH

23f4i9/16Ç5

STORED

B23FEET 4-9/16 INCH

26f1i13/16Ç6

STORED

C26FEET 1-13/16 INCH

2. Calculate Angle A, B and C:

Ç9 /_A 101.5734°

9 /_B 36.59978°

9 /_C 41.8268°

3. Calculate Triangle area:

9 AREA 299.4929 SQ FEET

USER’S GUIDE —57

Page 59

Using Law of Cosines and Pythagorean Theorem to Calculate

Offset, Length, and Angle

In field measuring, Offset, Length and Angle are the essential dimensions to the design and fabrication of the components required to fill

in between objects. In some cases, no structural objects are within

reach or parallel to the objects to be measured, so other methods of

measuring are required. In this method, a Triangle is formed to

establish the relationship between the objects. For the sake of

identification, this Triangle, which is physically measured, will be called

“The Measured Triangle,” or Triangle “I” below, with given dimensions.

Length and Offset form a Right Angle to each other, so Triangle

“II”, a Right Triangle, is used to calculate these dimensions.

Note: “x” or “y” can represent either Offset or Length, the order dictated by the initial

setup and perspective. In the setup, placement of the Right Triangle should always

allow for the angle of “ θ” in Triangle “II” to be established by simple subtraction of

angle “A0” from a known angle like 180°, as in the example below.

Find Theta θ, “x,” and “y,” if the sides of the Measured Triangle “I”

are: 35 Feet 8-3/4 Inches, 21 Feet 8-15/16 Inches, and 24 Feet

3-7/8 Inches. See diagram below.

b = 21' 8-15/16"

58 — ITI SHEET METAL/HVAC PRO

(Cont’d)

Page 60

(Cont’d)

KEYSTROKE DISPLAY

1. Enter side a, b and c:

oo 0.

35f8i3/4Ç4 A35FEET 8-3/4 INCH

STORED

21f8i15/16Ç5

STORED

B21FEET 8-15/16 INCH

24f3i7/8Ç6 C24FEET 3-7/8 INCH

STORED

2. Calculate and input Theta by subtracting Angle “A” (found by the

Law of Cosines) from known angle of 180°:

180–Ç9 /_A 101.5687°

= 78.43128 (Theta θ)

p /_Ø 78.43128°

3. Recall stored “c” and input as “r” the Hypotenuse:

®6=d R24

FEET 3-7/8 INCH

4. Calculate “x”:

R X4FEET 10-9/16 INCH

5. Calculate “y”:

r Y23FEET 9-15/16 INCH

Sheet Metal Panels for an Irregular Hip Roof

A contractor is going to cover one end of an Irregular Hip Roof with

sheet metal panels. The length of the roof along the eave is 98 Feet

5-1/4 Inches, the length along the left hip is 38 Feet 10-11/16

Inches, and the length along the right hip is 73 Feet 1-1/8 Inches.

Find the angles between the roof edges.

KEYSTROKE DISPLAY

1. Enter lengths:

98f5i1/4Ç4 A98FEET 5-1/4 INCH

STORED

38f10i11/16Ç5

STORED

B38FEET 10-11/16 INCH

73f1i1/8Ç6 C73FEET 1-1/8 INCH

STORED

2. Calculate the angles between the roof edges:

Ç9 /_A 119.9081°

9 /_B 20.02713°

9 /_C 40.06473°

9 AREA 1232.046 SQ FEET

USER’S GUIDE —59

Page 61

Inline Duct, Single Offset (Computing Offset, Length, and Angle)

When working with the process of direct measure between two ducts

#1 and #2, as diagramed below, one leg of “The Measured Triangle”

“I” should use the larger horizontal dimension of the two ducts.

Therefore, in this scenario, the 42 Inches dimension of duct #2 is

used since it is the larger of the two ducts.

To calculate the angle A

0

in “The Measured Triangle” “I” and the

dimensions of θ1, X1, and Y1 in triangle “II,” follow the sequence of

input given below to solve for the dimensions in question.

Note: “x” or “y” can represent either Offset or Length, the order dictated by the initial

setup and perspective. In the setup, placement of the Right-Triangle should always

allow for the angle of “ θ” in triangle “II” to be established by simple subtraction of

angle “A0” from a known angle like 180°, as in the example below.

Find Theta θ, “x”, and “y” if the sides of the Measured Triangle “I”

are: 8 Feet 2-3/8 Inches, 42 Inches, and 6 Feet 10 Inches. See

diagram below.

60 — ITI SHEET METAL/HVAC PRO

(Cont’d)

Page 62

(Cont’d)

KEYSTROKE DISPLAY

1. Enter side a, b, and c:

oo 0.

8f2i3/8Ç4 A8FEET 2-3/8 INCH

42iÇ5 B42INCH

6f10iÇ6 C6FEET 10 INCH

STORED

STORED

STORED

2. Calculate and input Theta by subtracting Degree “A” (found by the

Law of Cosines) from known angle of 180°:

180–Ç9 /_A 99.94554°

= 80.05446 (Theta θ)

p /_Ø 80.05446°

3. Recall stored “c” and input as “r”:

®6=d R6FEET 10 INCH

4. Calculate “x”:

R X1FEET 2-3/16 INCH

5. Calculate “y”:

r Y6FEET 8-3/4 INCH

USER’S GUIDE —61

Page 63

Inline Duct, Double Offset (Computing Offset, Length and Angle)

This example (see diagrams below) depicts two ducts offsetting both

in the horizontal and vertical planes. Basic procedures are the same

as those followed in the previous example, except a correction to

the calculated length will be required at triangle “V”.

A) Input “Measured Triangle I” to find Triangle IV:

KEYSTROKE DISPLAY

1. Enter side a, b, and c:

oo 0.

2509ÇmÇ4 A 2509. MM

2096ÇmÇ5 B 2096. MM

1067ÇmÇ6 C 1067. MM

STORED

STORED

STORED

2. Calculate and input Theta by subtracting Degree “A” (found by the

Law of Cosines) from known angle of 180°:

180–Ç9 /_A 99.82668°

= 80.17332 (Theta θ)

p /_Ø 80.17332°

3. Recall stored “b”* and input as “r”:

®5=d R 2096. MM

4. Calculate “x”:

R X 357.7207 MM