Page 1

MMAC-Plus™

9C300-1 Environmental Module

User’s Guide

Page 2

Page 3

i

Notice

Notice

Cabletron Systems reserves the right to make changes in specifications and other information

contained in this document without prior notice. The reader should in all cases consult Cabletron

Systems to determine whether any such changes have been made.

The hardware, firmware, or software described in this manual is subject to change without notice.

IN NO EVENT SHALL CABLETRON SYSTEMS BE LIABLE FOR ANY INCIDENTAL, INDIRECT,

SPECIAL, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT NOT LIMITED

TO LOST PROFITS) ARISING OUT OF OR RELATED TO THIS MANUAL OR THE INFORMATION

CONTAINED IN IT, EVEN IF CABLETRON SYSTEMS HAS BEEN ADVISED OF, KNOWN, OR

SHOULD HAVE KNOWN, THE POSSIBILITY OF SUCH DAMAGES.

© Copyright November 1994 by:

Cabletron Systems, Inc.

35 Industrial Way

Rochester, NH 03867-0505

All Rights Reserved

Printed in the United States of America

Order Number: 9031155 November 1994

LANVIEW is a registered trademark and MMAC-Plus is a trademark of Cabletron Systems, Inc.

VT100 is a registered trademark of Digital Equipment Corporation.

Ethernet is a trademark of Xerox Corporation.

CompuServe is a registered trademark of CompuServe, Incorporated.

Page 4

ii

Notice

FCC Notice

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment uses, generates, and can radiate radio frequency energy and if not installed in

accordance with the operator’s manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which case the user

will be required to correct the interference at his own expense.

WARNING: Changes or modifications made to this device which are not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

DOC Notice

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage radioélectrique

édicté par le ministère des Communications du Canada.

Page 5

Chapter 1 Introduction

Using This Manual........................................................................................................ 1-1

The 9C300-1 Environmental Module ......................................................................... 1-1

Features ...................................................................................................................1-2

Related Manuals............................................................................................................ 1-3

Getting Help ..................................................................................................................1-4

Contents

Chapter 2 Installing the 9C300-1 Environmental Module

Installing the 9C300-1 Environmental Module......................................................... 2-1

Chapter 3 9C300-1 Environmental Module Operation

Monitoring Functions...................................................................................................3-1

External Ambient Temperature............................................................................ 3-2

Fan Speed................................................................................................................ 3-3

System Humidity................................................................................................... 3-4

System Voltages...................................................................................................... 3-4

Internal Operating Temperature.......................................................................... 3-4

LANVIEW LEDs.................................................................................................... 3-5

Out-of-Band Management........................................................................................... 3-6

COM1 and COM2 Ports........................................................................................3-7

The Ethernet™ Port Interface Module (EPIM).................................................. 3-8

LCD and Keypad ...................................................................................................3-8

Non-Interactive Mode .................................................................................................. 3-9

Non-Interactive Mode Screens............................................................................. 3-9

The System Screen.......................................................................................... 3-9

The Utilization Screen.................................................................................. 3-10

The Environment Screen.............................................................................. 3-10

The Power Screen ......................................................................................... 3-11

The System Banner Screen........................................................................... 3-11

Interactive Mode .........................................................................................................3-12

Interactive Mode Screens....................................................................................3-12

The Main Screen............................................................................................ 3-13

The Alarm Screen.......................................................................................... 3-13

The System Screen........................................................................................ 3-14

The Power Screen .........................................................................................3-15

The Power Supply Specific Screen ............................................................. 3-15

The Environment Screen.............................................................................. 3-16

The Communications Screen ......................................................................3-16

iii

Page 6

Contents

The Diagnostic Module Selection Screen ..................................................3-17

The Diagnostic Results Screen ....................................................................3-17

The BBU Screen.............................................................................................3-18

The Module Selection Screen ......................................................................3-18

The Module Specific Screen.........................................................................3-19

The Module Environment Screen............................................................... 3-20

The Module Memory Screen.......................................................................3-20

The Module Backplane Screen....................................................................3-21

The Environmental Module Specific Screen.............................................3-21

The Environmental Module Environment Screen ...................................3-22

The LCD Contrast Adjustment Screen.......................................................3-23

Chapter 4 Specifications

Safety...............................................................................................................................4-1

Service.............................................................................................................................4-1

Physical...........................................................................................................................4-2

Environmental ............................................................................................................... 4-2

Appendix A EPIM Specifications

Introduction ..................................................................................................................A-1

EPIM-T...........................................................................................................................A-1

EPIM-F1 and EPIM-F2.................................................................................................A-2

EPIM-F3 .........................................................................................................................A-4

EPIM-C...........................................................................................................................A-6

Connector Type .....................................................................................................A-6

Grounding..............................................................................................................A-6

EPIM-A and EPIM-X (AUI Port)................................................................................A-7

Appendix B Uninterruptible Power Supply (UPS)

Introduction ...................................................................................................................B-1

Connecting a UPS to an EM.........................................................................................B-1

Configuring COM Port for UPS..................................................................................B-2

Verifying Configuration ...............................................................................................B-3

Monitoring UPS.............................................................................................................B-3

iv

Page 7

Introduction

Using This Manual

Read through this manual to become familiar with its contents and to gain an

understanding of the features and capabilities of the Environmental Module prior

to installing and operating it.

Chapter 1

Chapter 1 Introduction, provides product descriptions and features, gives a brief

description of the 9C300-1 Environmental Module and ends with a list of related

manuals.

Chapter 2 Installing the 9C300-1 Environmental Module, contains detailed

information for unpacking and installing the Environmental Module.

Chapter 3 9C300-1 Environmental Module Operation, contains detailed

information about the Environmental Module operation.

Chapter 4 Specifications , provides detailed specifications for the 9C300-1

Environmental Module.

Appendix A EPIM Specifications , contains detailed information about the

various that can be used with the 9C300-1 Environmental Module.

Appendix B Uninterruptible Power Supply (UPS) , contains detailed information

about connecting, configuring, and monitoring a UPS.

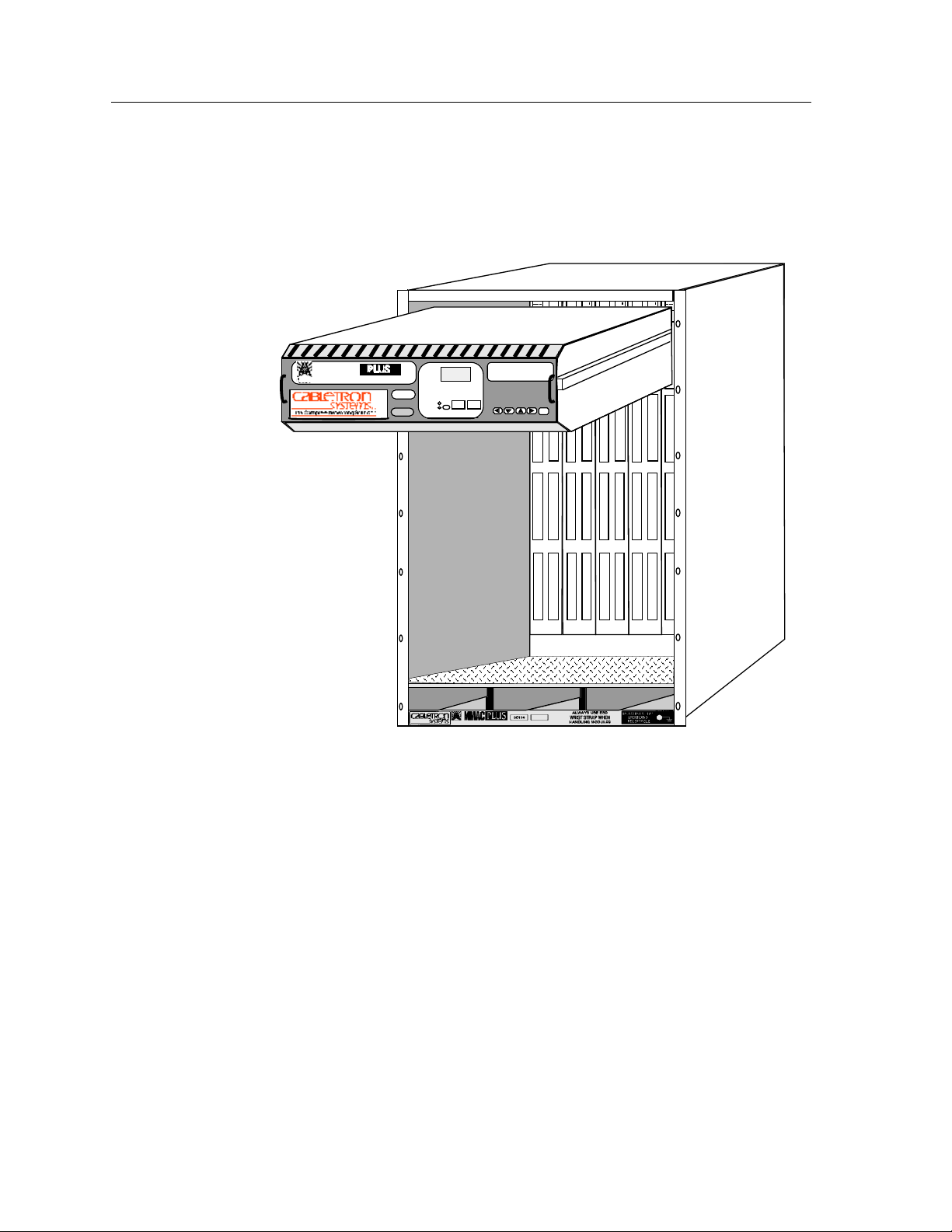

The 9C300-1 Environmental Module

The 9C300-1 Environmental Module, shown in Figure 1-1, provides system

cooling, out-of band management capabilities, and environmental/power

monitoring for the MMAC-Plus System. The Environmental Module is inserted in

the slot above the module card cage in the front of the MMAC-Plus chassis.

1-1

Page 8

Introduction

Features

MMAC

123

4 5 6 7 8 9 10 11 12 13 14

9C300-1

EPIM

STATUS

ALARM

COM 1

COM 2

ENTER

Figure 1-1. The 9C300-1 Environmental Module

System Cooling

The 9C300-1 Environmental Module houses the cooling fan subsystem. There are

four, high-air flow fans in the assembly to provide necessary chassis cooling. Any

one of these can fail without adversely affecting system operation. The fans’

operation and speed are continuously monitored, allowing network technicians

to be quickly notified if repairs are needed. Control of the fans’ operating speed is

also provided for maximum cooling efficiency and fan life. The fans are protected

from controller failure by a fail-safe circuit. In the event of a controller

malfunction, this circuit forces the fan subsystem to maximum speed and notifies

Network Management.

Out-of-Band Management

Out-of-band management refers to managing the MMAC-Plus via a Local

Management (LM) connection or an SNMP-based management application which

does not use the same network connection to the chassis as “user data.”

1-2

Four Out-of-band management interfaces are built into the 9C300-1

Environmental Module. One channel is the 4x40 character backlit LCD and

associated five button keypad. This interface provides a network manager or

technician with the capability to review system status, performance and

configuration information. Two interfaces are serial RS-232 ports. These ports

support local management via a VT100 session, SLIP, or PPP, or monitor an

American Power Conversion Smart UPS.

The remaining out-of-band management interface supports any standard

Cabletron Ethernet Port Interface Module (EPIM). This interface provides a direct

connection to the internal System Management Bus-10 (SMB-10).

Page 9

Related Manuals

Environmental/Power Monitoring

The 9C300-1 Environmental Module monitors and reports chassis power

parameters, ambient chassis temperature, chassis humidity, temperature of the

Environmental Module itself, as well as the status and speed of the chassis

cooling fans.

Flash EEPROM

The capability of downloading future firmware upgrades has been built into the

9C300-1 Environmental Module.

Hot Swapping

The 9C300-1 Environmental Module can be removed from the chassis while the

MMAC-Plus is running without interrupting network performance.

LANVIEW

Two LEDs, STATUS and ALARM, are built into the front of the 9C300-1

Environmental Module. These LEDs indicate the status of the Environmental

Module and the presence or absence of system alarms.

Related Manuals

The manuals listed below should be used to supplement the procedures and

technical data contained in this manual.

MMAC-Plus Installation Guide

MMAC-Plus Operations Guide

MMAC-Plus 9C214-AC Power Supply User’s Guide

In addition, each Interface Module has a user’s guide.

®

LEDs

1-3

Page 10

Introduction

Getting Help

If you need additional support related to the Environmental Module, or if you

have any questions, comments or suggestions concerning this manual, feel free to

contact Cabletron Systems Technical Support:

By phone: (603) 332-9400

By CompuServe

By Internet mail: support@ctron.ctron.com

By Fax: (603) 337-3075

By BBS: (603) 335-3358

By mail: Cabletron Systems, Inc.

®

: GO CTRON from any ! prompt

P.O. Box 5005

Rochester, NH 03866-5005

1-4

Page 11

Installing the 9C300-1 Environmental Module

Chapter 2

Installing the 9C300-1 Environmental Module

The 9C300-1 Environmental Module is installed in the slot above the module card

cage in the front of the MMAC-Plus chassis, as shown in Figure 2-1.

Install an Environmental Module by following the steps below:

1. Unpack the Environmental Module by removing it from the shipping box and

sliding the two foam end caps off the unit. (Save the shipping box and

packing materials in the event the Environmental Module must be

reshipped.)

2. Remove it from the protective plastic bag. Observe all precautions to prevent

damage from Electrostatic Discharge (ESD). (Save the bag in the event the

Environmental Module must be reshipped.)

3. Remove the plastic protective cap that covers the connector on the rear of the

Environmental Module.

4. Examine it carefully, checking for damage. If any damage exists, DO NOT

install it. Immediately contact Cabletron Systems Technical Support.

5. Hold the left and right sides.

6. Line up the rails on the left and right sides with the tracks on the left and right

inside panels of the chassis.

7. Slide the Environmental Module into the chassis until it is completely seated.

If the MMAC-Plus chassis has been powered up, the 9C300-1 Environmental

Module illuminates the STATUS and ALARM LEDs and displays the name

Cabletron on the LCD.

If the LEDs are any color other than green, refer to LANVIEW LEDs in Chapter 3.

If no keypad entries are made within 60 seconds, the LCD scrolls through various

non-interactive mode screens.

2-1

Page 12

Installing the 9C300-1 Environmental Module

If the MMAC-Plus chassis has not been powered up, make sure that all modules

have been properly installed; then power up the MMAC-Plus chassis by

following the steps in the MMAC-Plus Installation Guide .

MMAC

1 2 3 4 5 6 7 8 9 10 11 12 13 14

9C3001

EPIM

STATUS

ALARM

COM 1 COM 2

Figure 2-1. Installing the Environmental Module

ENTER

2-2

Page 13

Chapter 3

9C300-1 Environmental Module Operation

The 9C300-1 Environmental Module, as shown in Figure 3-1, performs three main

functions. It monitors several chassis environmental parameters, provides

multiple out-of-band management interfaces, as well as system cooling. The

Environmental Module also includes LANVIEW

diagnostics.

®

LEDs for at-a-glance

MMAC

123

4567891011121314

Figure 3-1. The 9C300-1 Environmental Module

Monitoring Functions

The 9C300-1 Environmental Module monitors the following MMAC-Plus

functions:

• External ambient temperature

• Fan speed

• System humidity

• System voltages

• Internal operating temperature

9C300-1

EPIM

STATUS

ALARM

COM 1 COM 2

ENTER

3-1

Page 14

9C300-1 Environmental Module Operation

External Ambient Temperature

The 9C300-1 Environmental Module includes an external ambient temperature

sensor. This sensor is located on the front of the Environmental Module, as shown

in Figure 3-2. The ambient temperature is monitored and the results of the

monitoring are available to the network manager via the LCD, as well as local and

remote management.

MMAC

1 2 3

9C300-1

4 5 6 7 8 9 10 11 12 13 14

EPIM

STATUS

ALARM

COM 1

COM 2

ENTER

External ambient temperature sensor

Figure 3-2. External Ambient Temperature Sensor

Table 3-1 lists the ambient temperature information available to the network

manager.

Table 3-1. External Ambient Temperature

Temperature Range

6

°

C/43

°

F and below COLD

7–12

°

13–32

C/44–54

°

C/55–90

°

F COOL

°

F NORM (normal)

LCD Display

3-2

33–38

39

°

C/102

°

C/91–101

°

°

F WARM

F and above HOT

Page 15

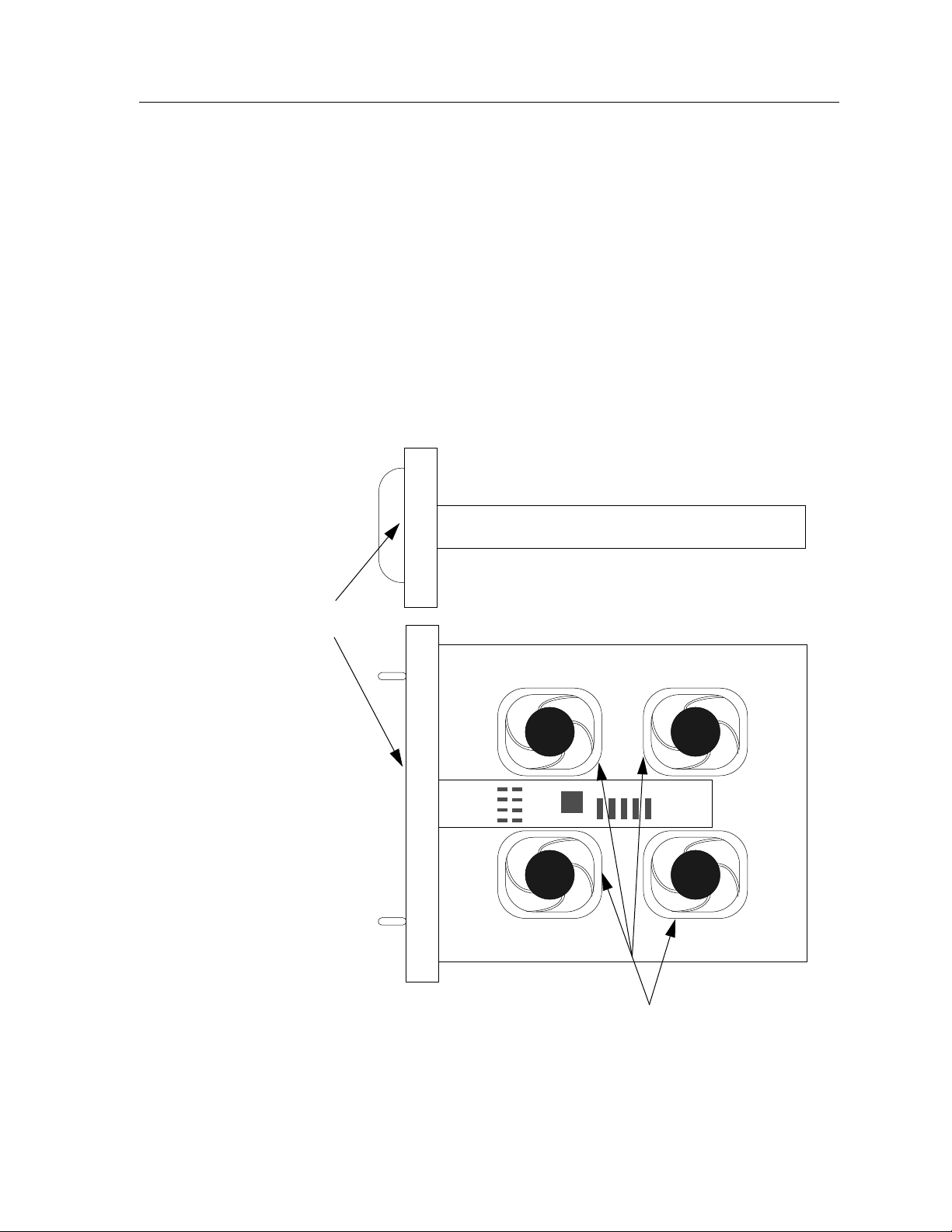

Fan Speed

Monitoring Functions

The 9C300-1 Environmental Module adjusts the speed of the system cooling fans

(Figure 3-3) based on the external ambient temperature. Fan speed increases as

ambient temperature rises to ensure adequate cooling for the system. Conversely,

fan speed decreases as ambient temperature decreases. In the event the ambient

temperature sensor, or the Environmental Module itself, fails, fan speed defaults

to maximum speed to ensure adequate cooling.

The ability to control fan speed is useful for two reasons:

• To increase the cooling level of the MMAC-Plus system to accommodate

changing operating environments.

• To prolong fan life and limit audible noise when full fan speed is not necessary

for cooling.

Front panel

Fan Tray Side View

Fan Tray Top View

System Cooling Fans

Figure 3-3. The 9C300-1 Environmental Module and Fan Tray

3-3

Page 16

9C300-1 Environmental Module Operation

System Humidity

The 9C300-1 Environmental Module monitors the non-condensing humidity level

of the MMAC-Plus. The results of the monitoring are available to the network

manager via LCD, as well as local and remote management. The humidity levels

are displayed as shown in Table 3-2.

Table 3-2. System Humidity

System V oltages

The 9C300-1 Environmental Module monitors specific system power parameters

to ensure that they are within acceptable limits. The power parameters monitored

from the backplane are the 48 volt DC System Power Bus and the INB

Termination Power Bus. The power parameter monitored within the

Environmental Module is the 12 volt internal line. The results of the monitoring

are available to the network manager via LCD, as well as local and remote

management. Voltages above or below the acceptable voltage limits cause an

alarm to be sent to the network manager. Table 3-3 summarizes these acceptable

voltage limits.

Humidity

0–45% STATIC RISK

46–94% NORM (normal)

95% and above MOIST

Table 3-3. Acceptable Voltage Limits

Description

LCD Display

Acceptable Voltage Limits

48 volt DC System Power Bus

INB Termination Power Bus

12 volt internal line

Internal Operating Temperature

The 9C300-1 Environmental Module monitors its own internal operating

temperature by comparing its current temperature to the ambient temperature

and programmed rise temperatures to determine current temperature status. If

the temperature of the Environmental Module exceeds normal operating limits,

an alarm is sent to the network manager. In addition, if the ambient temperature

sensor fails, pre-established temperature ranges have been programmed to ensure

proper internal temperature monitoring.

3-4

From 40 volts to 59 volts

From 3.1 volts to 5 volts

From 11 volts to 13 volts

Page 17

LANVIEW LEDs

The LANVIEW LEDs on the front of the 9C300-1 Environmental Module may be

used as an aid in troubleshooting.

There are two LEDs visible to the user (Figure 3-4): the STATUS LED and the

ALARM LED.

STATUS LED

Monitoring Functions

MMAC

1 2 3

9C300-1

4 5 6 7 8 9 10 11 12 13 14

EPIM

STA TUS

ALARM

COM 1

COM 2

ENTER

ALARM LED

Figure 3-4. 9C300-1 Environmental Module LANVIEW LEDs

The STATUS LED indicates the current status of the Environmental Module

processor and peripherals. The possible states and descriptions of the STATUS

LED are listed in Table 3-4.

Table 3-4. STATUS LED

LED Color

State Description

Green Functional Fully operational.

Yellow/Green Booting Flashes green and yellow while booting.

Yellow Testing Testing system.

Yellow (Flashing) Crippled Not fully operational.

Red Reset Normal power-up reset.

Red (Flashing) Failed Fatal error has occurred.

Off Power off Lack of 5 volt input to the Environmental

Module.

3-5

Page 18

9C300-1 Environmental Module Operation

The ALARM LED indicates the presence, or absence, of an unread system

alarm(s). Unread system alarms can be read using the LCD and five-function

keypad. The possible states and descriptions of the ALARM LED are listed in

Table 3-5.

Table 3-5. ALARM LED

LED Color

Green Functional No unread alarms.

Yellow Functional Pending unread system alarms, warning.

Red Functional Pending unread system alarms, critical.

State Description

Out-of-Band Management

Out-of-band management refers to managing the system via a Local Management

(LM) connection or an SNMP-based management application which does not use

the same network connection to the chassis as “user data.”

The 9C300-1 Environmental Module provides four out-of-band management

interfaces for managing the MMAC-Plus system. These interfaces are listed

below:

• Two serial communication ports, COM1 and COM2

• One standard Cabletron EPIM interface

• Liquid Crystal Display (4 lines by 40 characters) and an associated five button

keypad

3-6

Page 19

COM1 and COM2 Ports

The 9C300-1 Environmental Module front panel has two RJ-45 communication

ports for RS-232 serial communication to and from the MMAC-Plus. Figure 3-5

illustrates a single RJ-45 communication port connector. COM1 and COM2 can be

configured to run the Serial Line Internet Protocol (SLIP), Point-to-Point Protocol

(PPP), Local Management via a terminal or modem connection, or monitor an

American Power Conversion Smart UPS. Refer to the Local Management Manual

for detailed information on configuring the COM1 or COM2 port.

Pin 1

Out-of-Band Management

Figure 3-5. RJ-45 Communication Port Connector

Table 3-1 details the pinout connections for an RJ-45 communication port

connector.

Table 3-6. Pinout Connections RJ-45 Communication Port Connector

Pin

1 TRANSMIT

2 DATA CARRIER DETECT

3 DATASET READY

4 RECEIVE

5 SIGNAL GROUND

6 DATA TERMINAL READY

7 REQUEST TO SEND

8 CLEAR TO SEND

Description

3-7

Page 20

9C300-1 Environmental Module Operation

The Ethernet™ Port Interface Module (EPIM)

The 9C300-1 Environmental Module provides a port for Cabletron Systems

EPIMs. The EPIM provides a direct connection to the internal SMB-10 bus. This

connection can be used for out-of-band graphical SNMP management of the

MMAC-Plus system or a Telnet session into local management. Any standard

Cabletron EPIM can be installed. Refer to Appendix A for detailed information on

the EPIM.

LCD and Keypad

The LCD functions as a “window” into the MMAC-Plus System, allowing users

to navigate through various screens via the five-function keypad.

The LCD is a 4 line by 40 character, backlit liquid crystal visual display.

The five-function keypad is used to scroll through MMAC-Plus information

screens, and to select option fields within each menu and submenu. The keypad

consists of five buttons, four of which are directional to move the cursor; the fifth

is the Enter button, used to make menu selections. Figure 3-6 shows the LCD with

a System Banner Screen and the five-function keypad on the MMAC-Plus

Environmental Module front panel.

CABLETRON SYSTEMS, INC.

MMAC-PLUS

<ALARMS>

<SYSTEM> <MODULES> <SCREEN CONTRAST>

ENTER

Figure 3-6. The LCD and Five-Function Keypad

3-8

Page 21

Non-Interactive Mode

The LCD defaults to this mode if there is no user input within 60 seconds of

installation of the Environmental Module or system start-up.

Non-Interactive Mode Screens

This section describes the LCD screens that display in the non-interactive mode.

The LCD scrolls through different status screens (depending on MMAC-Plus

configuration), displaying each screen for a period of 7 seconds; or, until user

input is sensed on the keypad.

Line 4 of each screen displays any active alarm conditions that exist within the

system. If no alarm conditions exist, the line displays “SYSTEM STATUS

NORMAL.”

Non-Interactive Mode

The System Screen

If an alarm condition exists, line 4 displays a message describing the alarm for 5

seconds. The screen then displays a message stating how many alarms are present

in the alarm queue, “XX ALARMS PENDING” and the ALARM LED on the front

of the Environmental Module turns yellow or red indicating unread alarms in the

queue.

The System Screen, as shown in Figure 3-7, is the first screen of the

non-interactive mode.

Lines 1 and 2 display the MMAC-Plus chassis Internet Protocol (IP) address and

Media Access Control (MAC) address.

Line 3 displays the current chassis hardware revision and serial number.

Line 4 displays the system status.

CHASSIS IP ADDRESS xxx.xxx.xxx.xxx

CHASSIS MAC ADDRESS xx-xx-xx-xx-xx-xx

CHASSIS HW REV xxx SN xxxxxxxxxxxx

SYSTEM STATUS NORMAL

Figure 3-7. The System Screen

3-9

Page 22

9C300-1 Environmental Module Operation

The Utilization Screen

The Utilization Screen, as shown in Figure 3-8, is the second screen of the

non-interactive mode.

Line 1 displays the screen heading.

Line 2 displays the FDDI 1 and FDDI 2 bus utilization.

Line 3 displays the INB A and INB B bus utilization.

Line 4 displays the system status.

FDDI 1_ _ _ _ _ 100% FDDI 2 _ _ _ _ _100%

INB A _ _ _ _ _100%

SYSTEM UTILIZATION

INB B _ _ _ _ _ 100%

SYSTEM STATUS NORMAL

The Environment Screen

The Environment Screen, as shown in Figure 3-9, is the third screen of the

non-interactive mode.

Line 1 displays the screen heading.

Line 2 displays the external temperature of the chassis in both Fahrenheit and

Celsius and qualifies the temperature as COLD, COOL, NORM (normal), WARM

or HOT based on system parameters.

Line 3 displays the non-condensing humidity level of the chassis and qualifies it

as STATIC RISK, NORM (normal) or MOIST based on system parameters.

Line 4 displays the system status.

Figure 3-8. The Utilization Screen

CHASSIS ENVIRONMENT

EXTERNAL TEMP xxx˚F xx˚C NORM

HUMIDITY xxx% NORM

SYSTEM STATUS NORMAL

3-10

Figure 3-9. The Environment Screen

Page 23

The Power Screen

Non-Interactive Mode

The Power Screen, as shown in Figure 3-10, is the fourth screen of the

non-interactive mode.

Line 1 displays the screen heading.

Line 2 displays the percentage of power being used.

Line 3 displays the availability of power redundancy.

Line 4 displays the system status.

CHASSIS POWER

POWER LOAD_ _ _ _ _ _ _ _ _ _ 100%

POWER REDUNDANCY AVAILABLE

SYSTEM STATUS NORMAL

The System Banner Screen

The System Banner Screen, as shown in Figure 3-11, is the fifth screen of the

non-interactive mode. The information that displays is the default information

built into the system.

Lines 1 and 2 display the Cabletron name and the system name.

Line 3 displays the system uptime.

Line 4 displays the system status.

Figure 3-10. The Power Screen

CABLETRON SYSTEMS INC.

MMAC-PLUS

SYSTEM UPTIME hh:mm:ss

SYSTEM STATUS NORMAL

Figure 3-11. The System Banner Screen

3-11

Page 24

9C300-1 Environmental Module Operation

Interactive Mode

The LCD enters this mode upon installation. This mode allows user input

through the five-function keypad to navigate through MMAC-Plus status screens,

and to make menu selections.

Press any button on the keypad to enter this mode from the non-interactive mode.

Once past the Main screen, the Interactive Mode is maintained for three minutes

without a keypad entry before returning to the non-interactive mode.

Interactive Mode Screens

This section describes the LCD screens that display in the Interactive Mode. The

Interactive Mode screen flow, as shown in Figure 3-12, provides a representation

of the Interactive Mode screen structure hierarchy.

Pwr

Pwr

Supply

Specific

System

Environment

Figure 3-12. Interactive Mode Screen Flow

Diag

Results

Main Screen

Alarms

Com

BBU

Modules/Environmental Module Specific Screen

Environment

Modules

Modules Selection Screen

Memory Backplane

Screen Contrast

Screen Adjust

3-12

Page 25

The Main Screen

Interactive Mode

The Main Screen, as shown in Figure 3-13, is the initial screen of the Interactive

Mode. It allows access to all of the Interactive Mode screens. Interactive Mode

screens are distinguished by the display of option fields. Option fields are

designated with brackets (< >). To select an option, highlight the option field by

using the arrow function keys to place the cursor on the option; then press the

ENTER key.

Lines 1 and 2 display the screen heading.

Line 3 displays the <ALARMS> option field. Access information about any

current alarms by selecting this item.

Line 4 displays the <SYSTEM>, <MODULES> and <SCREEN CONTRAST>

options. Select the appropriate option to access information on the desired

category.

CABLETRON SYSTEMS INC

MMAC-PLUS

<ALARMS>

<SYSTEM> <MODULES> <SCREEN CONTRAST>

The Alarm Screen

Figure 3-13. The Main Screen

Select the <ALARMS> option field in line 3 of the Main Screen, as shown in

Figure 3-13, to access the alarm message queue. Unread alarms are present in the

message queue when the ALARM LED is red.

Line 1 of the Alarm Screen, as shown in Figure 3-14, displays the current alarm in

the queue as well as the date and time the alarm occurred.

Lines 2 and 3 show the description of the current alarm including the module and

parameter(s) causing the alarm.

If other alarms are in the queue (indicated by x > 1 on line 1), select <MORE> to

see the information screens for them.

ALARM y of x 11/05/94, 11:23

Alarm Description Field

Alarm Description Field

<MORE> <ACKNOWLEDGE> <EXIT>

Figure 3-14. The Alarm Screen

3-13

Page 26

9C300-1 Environmental Module Operation

Select <ACKNOWLEDGE> after reading all alarms to reset the front panel

ALARM LED (red to green). Selecting <ACKNOWLEDGE> deletes all alarms

and resets the alarm pending banner on line 4 of the non-interactive screens.

Select <EXIT> to return to the Main Screen.

The System Screen

Select the <SYSTEM> option field in line 4 of the Main Screen, as shown in

Figure 3-13, to access the System Screen as shown in Figure 3-15. This screen

displays information specific to the MMAC-Plus chassis. Lines 1 and 2 display the

MMAC-Plus chassis Internet Protocol (IP) address and Media Access Control

(MAC) address.

Line 3 displays the current chassis hardware revision and serial number.

Line 4 lists the following five submenus. Access a specific submenu by selecting it

on the screen.

<PWR> Displays general power supply configuration information,

with the option to view statistics on specific power supply

modules.

<ENV> Displays environmental information about the chassis.

<COM> Displays statistics and information about the front panel

COM ports and EPIM on the Environmental Module.

<DIAGS> Displays the results of power-up or restart diagnostic tests.

<BBU> Displays status of BBUs, if they are installed.

CHASSIS IP ADDRESS xxx.xxx.xxx.xxx

CHASSIS MAC ADDRESS xx-xx-xx-xx-xx-xx

CHASSIS HW REV xxx SN xxxxxxxxxxxx

<PWR> <ENV> <COM> <DIAGS> <BBU> <EXIT>

Figure 3-15. The System Screen

Select <EXIT> to return to the Main Screen.

3-14

Page 27

The Power Screen

Interactive Mode

Select <PWR> from the System Screen, as shown in Figure 3-15, to access

information about the chassis power supply configuration.

Line 1 of the Power Screen, as shown in Figure 3-16, displays the number of

power supplies currently configured and the availability of power redundancy.

Lines 2 and 3 display the power supply status as either ON, OFF DUE TO

MANAGEMENT, or FAULT.

Line 4 is used to access information about a specific power supply module by

selecting a power supply number.

SUPPLIES INSTALLED 2 PWR REDUNDANCY

STATUS 1 ON 2 ON

<1>

Select <EXIT> to return to the System Screen.

The Power Supply Specific Screen

Select a power supply number from line 4 of the Power Screen, as shown in

Figure 3-16, to learn about a specific power supply in the MMAC-Plus chassis.

There is an LCD screen available for each installed power supply, as shown in

Figure 3-17.

Line 1 identifies the power supply selected and its serial number.

Line 2 identifies the power supply’s hardware revision, firmware revision of the

diagnostic controller and power loading factor as a percentage of its capacity.

Line 3 provides the input and output voltages of the power supply.

HW REV xxx FW REV x.xx.xx LOAD xxx%

<EXIT><2>

Figure 3-16. The Power Screen

PWR SUPPLY 1 SN xxxxxxxxxxxx

PWR IN 110V PWR OUT 57.1V 5.1V 3.3V

<EXIT>

Figure 3-17. The Power Supply Specific Screen

Select <EXIT> to return to the Power Screen.

3-15

Page 28

9C300-1 Environmental Module Operation

The Environment Screen

Select <ENV> from the System Screen, as shown in Figure 3-15, to view

environmental parameters of the MMAC-Plus.

Line 1 of this screen, as shown in Figure 3-18, displays the external temperature of

the current chassis in both Fahrenheit and Celsius, and qualifies the temperature

as COLD, COOL, NORM (normal), WARM, or HOT, based on system parameters.

Line 2 displays the current system non-condensing humidity level, qualified as

STATIC RISK, NORM (normal), or MOIST, based on system parameters.

Line 3 displays the current fan speed of the Environmental Module cooling

system as a percentage of maximum rotational velocity.

CHASSIS EXTERNAL TEMP xxx°F xx°C NORM

CHASSIS HUMIDITY xxx% NORM

FAN SPEED 1 xxx% 2 xxx% 3 xxx% 4 xxx%

<EXIT>

Select <EXIT> to return to the System Screen.

The Communications Screen

Select <COM> from the System Screen, as shown in Figure 3-15, to access

MMAC-Plus chassis communication port status information.

Line 1, as shown in Figure 3-19, displays the status of the Ethernet Port Interface

Module (EPIM) as either ENABLED, DISABLED or N/A if not installed.

Line 2 displays the Port Administration status of COM port 1 (enabled or

disabled), the application in use (such as Local Management (LM), SLIP, PPP or

UPS), the baud rate of the attached device (a VT100 type terminal or modem) and

the port operational status (active or inactive).

Line 3 displays the Port Administration status of COM port 2 in the same manner

as described for line 2.

Figure 3-18. The Environment Screen

COMMUNICATIONS PORTS EPIM ENABLED

COM 1 ENABLED SLIP 9600 ACTIVE

COM 2 ENABLED

<EXIT>

3-16

Figure 3-19. The Communications Screen

Select <EXIT> to return to the System Screen.

Page 29

The Diagnostic Module Selection Screen

Select <DIAGS> from the System Screen, as shown in Figure 3-15, to view the

Diagnostic Module Selection screen.

Line 1, as shown in Figure 3-20, displays the screen heading.

Lines 2 and 3 show the chassis slot locations in which modules have been

installed in the MMAC-Plus.

Line 4 displays Power Supply Units and BBUs configured in the MMAC-Plus.

Diagnostic test results for these units can be viewed individually. The Diagnostic

Results Screen displays the diagnostic test results for the selected modules. It

provides an itemized list of failed tests only.

<EM> <1> <2> <3> <4> <5> <6> <7>

<8><9> <10> <11> <12> <13> <14>

Interactive Mode

VIEW DIAG RESULTS ON

<PS1> <PS2> <BBU1> <EXIT>

Select <EXIT> to return to the System Screen.

The Diagnostic Results Screen

The Diagnostic Results Screen, as shown in Figure 3-21, displays the results of

failed tests for the modules selected on the Diagnostic Screen.

Line 1 displays the module(s) selected for diagnostics.

Lines 2 and 3 display failed test results; or, if no failures occurred, the message

ALL DIAGNOSTICS TESTS HAVE PASSED.

or ALL MODULE DIAGNOSTICS TESTS HAVE PASSED

Select <MORE> to view more failed tests for the current module.

Figure 3-20. The Diagnostic Module Selection Screen

MODULE xx

Test Results (Left Blank if all pass)

<MORE> <EXIT>

Figure 3-21. The Diagnostic Results Screen

Select <EXIT> to return to the Diagnostic Module Selection Screen.

3-17

Page 30

9C300-1 Environmental Module Operation

The BBU Screen

Select <BBU> from the System Screen, as shown in Figure 3-15, to view the status

of the Battery Backup Units (BBUs). Figure 3-22 shows the BBU Screen.

Line 1 displays the screen heading.

Line 2 displays BBU status (CHARGING, STANDBY or DISCHARGING) if BBUs

are installed; however, if no BBUs are installed, the message NO BBU

INSTALLED displays.

Line 3 displays the estimated amount of system run time stored in the BBUs if the

system is running on a standard power source; or, if the system is running on

BBUs, the amount of system run time remaining in the BBUs at the current power

load.

SYSTEM RUN TIME AT PWR LOSS xxx MINUTES

BATTERY STATUS

BBU CHARGING

<EXIT>

Select <EXIT> to return to the System Screen.

The Module Selection Screen

Select <MODULES> from the Main Screen, as shown in Figure 3-13, to display

the chassis slot locations in which modules have been installed.

Line 1, as shown in Figure 3-23, displays the screen heading.

Lines 2 and 3 list all modules in the MMAC-Plus by slot number.

Figure 3-22. The BBU Screen

MODULE SELECTION

<EM> <1> <2> <3> <4> <5> <6> <7>

<8> <9> <10> <11> <12> <13> <14>

<EXIT>

Figure 3-23. The Module Selection Screen

3-18

Select <EXIT> to return to the main System Screen.

Page 31

The Module Specific Screen

Select a module on the Module Selection Screen, as shown in Figure 3-23, to

display configuration information on the Module Specific Screen, as shown in

Figure 3-24.

Line 1 identifies the selected module by chassis slot location, current status, and

hardware revision. A module’s status can be one of the following:

ON-LINE The host processor is operational.

DOWN The host processor is not operational.

FAULT The power-up diagnostic tests have failed.

Lines 2 and 3 display a firmware revision and SMB-1 firmware revision, along

with the BOOT PROM revision and the module serial number.

Line 4 lists the following three submenus. Access a specific submenu by selecting

it on the screen.

<ENV> accesses the Module Environment Screen, showing

Interactive Mode

environmental parameters for the selected module.

<MEMORY> accesses the Module Memory Screen, showing the amount of

various memory categories on the module.

<BACKPLANE> accesses the Module Backplane Screen, showing backplane

configuration parameters.

MODULE xx STATUS ON-LINE HW REV xxx

FW REV x.xx.xx SMB 1 FW REV x.xx.xx

BOOT PROM REV x.xx.xx SN xxxxxxxxxxxx

<ENV> <MEMORY> <BACKPLANE> <EXIT>

Figure 3-24. The Module Specific Screen

Select <EXIT> to return to the Module Selection Screen.

3-19

Page 32

9C300-1 Environmental Module Operation

The Module Environment Screen

Select <ENV> at the Module Specific Screen, as shown in Figure 3-24, to display

environmental parameters for the specific module.

Line 1 of the Module Environment Screen, as shown in Figure 3-25, identifies the

selected module by chassis slot location.

Line 2 displays the measured input voltage from the 48 volt system power bus to

the module’s DC-to-DC converter. The MMAC-Plus power supply provides

voltage to the module via a chassis backplane. The converter’s 5 volt output line

is also shown on line 2.

Line 3 displays the module’s current temperature in Fahrenheit and Celsius. The

temperature is qualified as either COLD, COOL, NORM (normal), WARM, or

HOT based on system parameters.

INPUT PWR: xx.xV, OUTPUT PWR x.xV

MODULE xx

TEMP: xxx°F, xx°C NORM

<EXIT>

Select <EXIT> to return to the Module Specific Screen.

The Module Memory Screen

Select <MEMORY> at the Module Specific Screen, as shown in Figure 3-24, to

view the memory configuration of a selected module.

Line 1 of the Module Memory Screen, as shown in Figure 3-26, identifies the

module, and its current CPU loading factor, expressed as a percent of capacity.

Line 2 displays the amount of FLASH memory (in megabytes) installed on the

module.

Line 3 displays the amount of SHARED DRAM and LOCAL DRAM (in

megabytes) installed on the module.

Figure 3-25. The Module Environment Screen

MODULE xx, CPU LOAD xxx%

FLASH xx MB

SHARED DRAM xx MB LOCAL DRAM xx MB

<EXIT>

Figure 3-26. The Module Memory Screen

3-20

Select <EXIT> to return to the Module Specific Screen.

Page 33

The Module Backplane Screen

Select <BACKPLANE> on the Module Specific Screen, as shown in Figure 3-24, to

access the Module Backplane Screen, as shown in Figure 3-27. The Module

Backplane Screen displays the current MMAC-Plus backplane configuration for a

selected module.

Line 1 identifies the selected module by chassis slot location.

Line 2 displays the module’s FNB connection (if applicable) and connection

status. Refer to the MMAC-Plus Operation Guide for further information about

FNB configuration.

Line 3 displays the module’s INB connection (if applicable) and connection status.

Refer to the MMAC-Plus Operation Guide for further information about the

INB.

Interactive Mode

MODULE xx

FDDI 1 INS PRI FDDI 2 BYP

INB A B/W ALLOC xxx MBPS

<EXIT>

Figure 3-27. The Module Backplane Screen

Select <EXIT> to return to the Module Specific Screen.

The Environmental Module Specific Screen

Select <EM> on the Module Selection Screen, as shown in Figure 3-23, to access

the Environmental Module Specific Screen, as shown in Figure 3-28.

Line 1 displays the Environmental Module’s current status (on-line or fault) and

the hardware revision.

Line 2 displays the Environmental Module’s firmware and boot prom revision.

Line 3 displays the Environmental Module serial number.

EM STATUS ON-LINE HW REV xxx

FW REV x.xx.xx BOOT PROM REV x.xx.xx

Figure 3-28. The Environmental Module Specific Screen

Select <ENV> to access the Environmental Module Environment Screen (used to

view Environmental Module electrical and environmental parameters).

SN xxxxxxxxxxxx

<ENV> <EXIT>

Select <EXIT> to return the display to the Module Selection Screen.

3-21

Page 34

9C300-1 Environmental Module Operation

The Environmental Module Environment Screen

Select <ENV> on the Environmental Module Specific Screen, as shown in

Figure 3-28, to access the Environmental Module Environment Screen, as shown

in Figure 3-29. This screen displays voltage, temperature, and non-condensing

humidity readings for the Environmental Module.

Line 1 displays the measured values for the 48 volt DC power bus and the 3.3 volt

bus for the Internal Network Bus (INB) terminator modules. The MMAC-Plus

power supply system provides these voltages as input to the Environmental

Module. The acceptable limits for the 48 volt line are between 40 and 59 volts. The

acceptable limits for the 3.3 volt line are between 3.1 and 5 volts.

Line 2 displays the temperature of the Environmental Module in Fahrenheit and

Celsius. The temperature is qualified as either COLD, COOL, NORM (normal),

WARM, or HOT based on system parameters.

Line 3 displays the Environmental Module’s non-condensing humidity level as

STATIC RISK, NORM (normal) or MOIST, based on system parameters.

INPUT PWR 56.1V 3.3V

TEMP: xxx°F, xx°C NORM

HUMIDITY: xx% NORM

<EXIT>

Figure 3-29. The Environmental Module Environment Screen

Select <EXIT> to return to the Environmental Module Specific Screen.

3-22

Page 35

The LCD Contrast Adjustment Screen

Select <SCREEN CONTRAST> from the Main Screen, as shown in Figure 3-13, to

access the LCD Contrast Adjustment Screen, as shown in Figure 3-30.

Select <LIGHTER> and press ENTER (repeat as necessary) to make the displayed

characters appear lighter on the screen.

Select <DARKER> and press ENTER (repeat as necessary) to make the displayed

characters appear darker on the screen.

SCREEN CONTRAST ADJUSTMENT

<LIGHTER> ___________ <DARKER>

Figure 3-30. LCD Contrast Adjustment Screen

Interactive Mode

<EXIT>

NOTE

Select <EXIT> to return to the Main Screen.

The LCD contrast setting reverts to the darkest setting at power-up or restart of the

Environmental Module.

3-23

Page 36

9C300-1 Environmental Module Operation

3-24

Page 37

Specifications

Safety

It is the responsibility of the person who sells the system to which the modules will be a

!

CAUTION

part to ensure that the total system meets allowed limits of conducted and radiated

emissions.

The 9C300-1 Environmental Module, when properly installed in the MMAC-Plus

chassis, complies with the following safety specifications and standards.

• UL 1950

• CSA C22.2 No. 950

• EN 60950

• IEC 950

• EMI requirements of FCC Part 15 Class A

• EN 55022 Class A

• VCCI Class I

• EMC requirements of

Chapter 4

Service

EN 50082-1

IEC 801-2 ESD

IEC 801-3 Radiated Susceptibility

IEC 8-1-4 EFT

The 9C300-1 Environmental Module is designed with the following service

capability:

MTBF (MIL-STD-217): >200,000 hours projected

MTTR: <.50 hour

4-1

Page 38

Specifications

Physical

Dimensions

12.7 H x 43.2 W x 44.5 D centimeters

(5 H x 17 W x 17.5 D inches)

Weight

Unit: 6.5 kilograms (14 pounds)

Shipping: 7.7 kilograms (17 pounds)

Environmental

Operating Temperature: 5–40°C, 43–100°F

Operating Humidity: 5% to 95% non-condensing

Cooling: 21.8 cubic meters of air per minute drawn through the

chassis

770 cubic feet of air per minute drawn through the

chassis

4-2

Page 39

EPIM Specifications

Introduction

The 9C300-1 Environmental Module provides a port for Cabletron Systems

EPIMs. EPIMs let you connect to the main network using different media types.

Cabletron Systems offers a variety of EPIMs whose specifications are explained in

the following sections.

EPIM-T

The EPIM-T is an RJ-45 connector supporting UTP cabling. It has an internal

Cabletron Systems TPT-T™ 10BASE-T Twisted Pair Transceiver.

Appendix A

The slide switch on the EPIM-T determines the crossover status of the cable pairs.

If the switch is on the X side, the pairs are internally crossed over. If the switch is

on the = side, the pairs are not internally crossed over. Figure A-1 shows the

pinouts for the EPIM-T in both crossover positions.

Position X

(crossed over)

1. RX+

2. RX-

3. TX+

4. NC

5. NC

6. TX-

7. NC

8. NC

Position =

(not crossed over)

1. TX+

2. TX-

3. RX+

4. NC

5. NC

6. RX-

7. NC

8. NC

Figure A-1. EPIM-T Pinouts

A-1

Page 40

EPIM Specifications

EPIM-F1 and EPIM-F2

The EPIM-F1 and EPIM-F2 support Multimode Fiber Optic cabling. Each EPIM

has an internal Cabletron Systems FOT-F™ Fiber Optic Transceiver. The EPIM-F1

is equipped with SMA Connectors and the EPIM-F2 is equipped with ST

Connectors. Figure A-2 shows both EPIMs. Specifications for the EPIMs are listed

in Table A-1.

Figure A-2. EPIM-F1 and EPIM-F2

Table A-1. EPIM-F1 & EPIM-F2 Specifications

Parameter Typical Value

Receive

Sensitivity

Peak Input

Power

Transmitter power parameters are listed Table A-2.

-30.5 dBm -28.0 dBm — —

-7.6 dBm -8.2 dBm — —

Worst

Case

Worst Case

Budget

Typical

Budget

A-2

Page 41

Table A-2. Transmitter Power

The transmitter power levels and receive sensitivity levels listed are Peak Power

es

EPIM-F1 and EPIM-F2

NOTE

Parameter Typical Value

50/125 µm

-13.0 dBm -15.0 dBm 13.0 dB 17.5 dB

Worst

Case

Worst Case

Budget

Typical

Budget

fiber

62.5/125 µm

-10.0 dBm -12.0 dBm 16.0 dB 20.5 dB

fiber

100/140 µm

-7.0 dBm -9.0 dBm 19.0 dB 23.5 dB

fiber

Error Rate Better than 10

-10

Levels after optical overshoot. A Peak Power Meter must be used to correctly

compare the values given above to those measured on any particular port. If

Power Levels are being measured with an Average Power Meter, then 3 dBm

must be added to the measurement to correctly compare those measured valu

to the values listed (i.e., -30.5 dBm peak = -33.5 dBm average).

A-3

Page 42

EPIM Specifications

Transmitter Power decreases as temperatures rise and increases as

al

EPIM-F3

The EPIM-F3 supports Single Mode Fiber Optic cabling. It has an internal

Cabletron Systems FOT-F™ Fiber Optic Transceiver and is equipped with ST

Connectors. Figure A-3 shows the EPIM-F3. Specifications for the EPIM-F3 are

listed in Figure A-4 and Table A-3.

Figure A-3. EPIM-F3

NOTE

Maximum Sensitivity (-36.0)

Receive

Sensitivity

Maximum

Receive

Input Power

Transmitter Power*

(At 25°C into

8.3/125µm fiber)

-40 -35 -30 -25 -20 -15 -10 -5 0

dBm

Less Power

* Transmit Power Typical Power Minimum Power Maximum Power

Coefficient

(See Note Below) -0.15dBm/°C -0.12 dBm/°C -0.18 dBm/°C

Typical Sensitivity (-31.0)

Minimum Sensitivity (-30.0)

Minimum Receive Input (-9.72)

Typical Receive Input (-7.5)

Maximum Receive Input (-6.99)

Maximum Transmit Power (-12.0)

Typical Transmit Power (-15.5)

Minimum Transmit Power (-21.0)

More Power

Figure A-4. EPIM-F3 Power and Sensitivity Specifications

temperatures fall. Use the Output Power Coefficient to calculate increased or

decreased power output for your operating environment. For example, the

typical power output at 25°C is -16.4 dBm. For a 4°C temperature increase,

multiply the typical coefficient (-0.15 dBm) by four and add the result to typic

output power (4 x -0.15 dBm + -16.4 = -17.0).

A-4

Page 43

EPIM-F3

The transmitter power levels given above are Peak Power Levels after optical

Table A-3. EPIM-F3 Specifications

Parameter Typical Minimum Maximum

NOTE

Transmitter Peak Wave

1300 nm 1270 nm 1330 nm

Length

Spectral Width 60 nm - 100 nm

Rise Time 3.0 nsec 2.7 nsec 5.0 nsec

Fall Time 2.5 nsec 2.2 nsec 5.0 nsec

Duty Cycle 50.1% 49.6% 50.7%

Bit Error Rate Better than 10

-10

overshoot. You must use a Peak Power Meter to correctly compare the values

given above to those measured on any particular port. If you are measuring

power levels with an Average Power Meter, add 3 dBm to the average power

measurement to correctly compare the average power values measured to the

values listed above (i.e., -33.5 dBm average + 3 dB = -30.5 dBm peak).

A-5

Page 44

EPIM Specifications

EPIM-C

The EPIM-C supports thin-net coaxial cabling and is equipped with an internal

Cabletron Systems TMS-3™ Transceiver. You can use the TERM switch on the

front of the EPIM-C to set the internal 50-ohm terminator. This eliminates the

need to connect the port to a tee-connector and terminator. Figure A-5 shows the

setting for the terminator switch.

Internal Termination Switch

= On (internally terminated)

= Off (need external termination)

Connector T ype

This connector type is a BNC receptacle, with gold center contact, for use with

BNC type tee-connectors and RG-58 thin-net cable.

Grounding

For safety reasons, only one end of a thin-net segment should be connected to

earth ground. Connection to earth ground at more than one point on the segment

may cause dangerous ground currents.

The BNC port of the Coaxial Interface Modules is not connected to earth ground.

Figure A-5. EPIM-C

A-6

Page 45

EPIM-A and EPIM-X (AUI Port)

The EPIM-A is a DB-15 female connector used to attach segments to an external

transceiver. The EPIM-X is equipped with dual internal transceivers. It has a

DB-15 male connector used to attach segments to an AUI cable. Figure A-6 shows

both modules.

Figure A-6. The EPIM-A and EPIM-X

Table A-4 lists the DB-15 pinouts.

EPIM-A and EPIM-X (AUI Port)

Table A-4. DB-15 Pinouts

Pin Number Represents Pin Number Represents

1 Logic Ref. 10 Transmit -

2 Collision + 11 Logic Ref.

3 Transmit 12 Receive -

4 Logic Ref. 13 Power (+12Vdc)

5 Receive 14 Logic Ref.

6 Power Return 15 No Connection

*

7 No Connection

9 Collision -

*

Connector Shell: Protective Ground

Connector Shell Positive Ground

A-7

Page 46

EPIM Specifications

A-8

Page 47

Appendix B

Uninterruptible Power Supply (UPS)

Introduction

The MMAC-Plus can be connected to a UPS to provide an uninterruptible source

of AC power. Two UPS models are available, the Matrix 3000 and the Matrix 5000.

Either can be monitored via remote SNMP Management after connecting the UPS

to the Environmental Module (EM).

Connecting a UPS to an EM

To connect a UPS to an EM, use the RJ-45/DB-9 adapter labeled “UPS”, the

RJ-45 cable included in the 9372089 kit shipped with the EM, and follow the steps

below.

1. Plug the RJ-45/DB-9 adapter labeled “UPS” into the receptacle on the rear of

the UPS (Figure B-1).

2. Plug one end of the cable with the RJ-45 connector into the RJ-45/DB-9

adapter labeled “UPS” on the rear of the UPS (Figure B-1).

3. Plug the other end of the cable with the RJ-45 connector into the COM2 port

on the front of the EM inserted in the MMAC-Plus Chassis (Figure B-1).

B-1

Page 48

Uninterruptible Power Supply (UPS)

9 Pin D Connector Receptacle

MMAC

1 2 3 4 5 6 7 8 9 10 11 12 13 14

EPIM

STATUS

COM 2

COM 1

ALARM

9C3001

ENTER

MMAC-Plus Chassis (Front View)

Figure B-1. Connecting EM to UPS

Configuring COM Port for UPS

After the UPS has been connected to the COM2 port, the COM2 port must be

configured for UPS Management. To configure the COM2 port for UPS

Management, follow the steps below.

Matrix UPS (Back View)

COM Ports

B-2

1. Connect the terminal or PC used for local management to the COM1 port on

the Environmental Module (EM) and press RETURN until the Slot Selection

Screen displays.

2. At the Slot Selection Screen, enter 0 (zero) to display the EM Configuration

Screen.

3. At the EM Configuration Screen, cursor to the Application Field for the

COM2 port.

4. Using the space bar, toggle to the UPS option.

5. Using the tab key, tab to the SAVE option and press RETURN.

If you need additional information about configuring the COM ports, refer to the

Local Management User’s Guide.

Page 49

Verifying Configuration

After configuring the COM port for a UPS, verify the configuration was done

correctly by checking the Communications Screen on the EM. Follow the steps

below to verify the configuration.

1. At the Main Screen select <SYSTEM> and press ENTER.

2. At the System Screen select <COM> and press ENTER.

3. At the Communications Screen, verify that the screen displays “ENABLED

UPS 2400 ACTIVE FOR COM PORT 2”.

Monitoring UPS

Information about the operation of the UPS is obtained via Remote SNMP

Management or locally by the LCD on the front of the UPS. Refer to the UPS

User’s Guide, provided by the vendor, for detailed information on the UPS LCD.

Verifying Configuration

B-3

Page 50

Uninterruptible Power Supply (UPS)

B-4

Loading...

Loading...