Page 1

MMAC-Plus

™

9A000, SFCS-200BX,

SFCS-200WG and SFCS-1000

ATM SWITCH

User’s Guide

Page 2

Page 3

i

Notice

Notice

Cabletron Systems reserves the right to make changes in specifications and other information

contained in this document without prior notice. The reader should in all cases consult Cabletron

Systems to determine whether any such changes have been made.

The hardware, firmware, or software described in this manual is subject to change without notice.

IN NO EVENT SHALL CABLETRON SYSTEMS BE LIABLE FOR ANY INCIDENTAL, INDIRECT,

SPECIAL, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT NOT LIMITED

TO LOST PROFITS) ARISING OUT OF OR RELATED TO THIS MANUAL OR THE INFORMATION

CONTAINED IN IT, EVEN IF CABLETRON SYSTEMS HAS BEEN ADVISED OF, KNOWN, OR

SHOULD HAVE KNOWN, THE POSSIBILITY OF SUCH DAMAGES.

© Copyright April 1996 by:

Cabletron Systems, Inc.

35 Industrial Way

Rochester, NH 03867-0505

All Rights Reserved

Printed in the United States of America

Order Number: 9031473-03

LANVIEW is a registered trademark of Cabletron Systems, Inc.

MMAC-Plus is a trademark of Cabletron Systems, Inc.

CompuServe is a registered trademark of CompuServe, Inc.

Page 4

ii

Notice

FCC Notice

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment uses, generates, and can radiate radio frequency energy and if not installed in

accordance with the operator’s manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which case the user

will be required to correct the interference at his own expense.

WARNING: Changes or modifications made to this device which are not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

VCCI Notice

This equipment is in the 1st Class Category (information equipment to be used in commercial and/or

industrial areas) and conforms to the standards set by the Voluntary Control Council for Interference

by Information Technology Equipment (VCCI) aimed at preventing radio interference in commercial

and/or industrial areas.

Consequently, when used in a residential area or in an adjacent area thereto, radio interference may be

caused to radios and TV receivers, etc.

Read the instructions for correct handling.

Page 5

Preface

Technical Support.......................................................................................................vii

Typographical Styles..................................................................................................vii

Important Information Indicators ..........................................................................viii

Laser Warning............................................................................................................... x

Safety Agency Compliance........................................................................................ xi

Safety Precautions................................................................................................ xi

Symbols ................................................................................................................. xi

Modifications to Equipment.............................................................................. xii

Placement of a Cabletron Systems Product ....................................................xii

Power Cord Connection.....................................................................................xii

Chapter 1 Introduction

Table of Contents

1.1 Overview of the ATM Standard........................................................................ 1-1

1.2 Hardware Description......................................................................................... 1-2

1.2.1 Front Panel Description ...........................................................................1-4

1.2.2 9A000 and SFCS Series Hardware Configuration................................ 1-4

1.2.3 9A000 and SFCS Series Switch Board .................................................... 1-4

1.2.4 Switch Control Processor......................................................................... 1-5

1.2.5 9A000 and SFCS Series Network Modules ...........................................1-5

1.2.6 Environmental Information..................................................................... 1-5

1.2.7 Standards Compliance .............................................................................1-7

1.2.8 Safety Compliance .................................................................................... 1-7

1.2.9 Emissions Compliance .............................................................................1-7

1.2.10 Electromagnetic Compatibility (EMC) ................................................1-7

1.3 Software Description ........................................................................................... 1-7

1.3.1 Switch Control Software.......................................................................... 1-7

Chapter 2 Installing the 9A000

2.1 Installing the 9A000 ............................................................................................. 2-1

2.2 The Reset Switch ..................................................................................................2-3

Chapter 3 Switch Hardware

3.2 Switch Hardware Components.......................................................................... 3-5

3.2.1 Switch Board.............................................................................................. 3-5

3.2.2 Switch Control Processor......................................................................... 3-5

3.2.2.1 i960 Switch Control Processor .......................................................3-6

3.2.3 Network Modules..................................................................................... 3-9

3.2.3.1 Port Numbering............................................................................... 3-9

3.2.4 Power Supply Modules.......................................................................... 3-11

3.2.4.1 SFCS-200BX AC Power Supply ................................................... 3-11

iii

Page 6

Contents

3.2.4.2 SFCS-1000 AC Power Supply (Model A).................................... 3-12

3.2.4.3 SFCS-1000 AC Power Supply (Model B).................................... 3-15

3.2.5 SFCS-1000 Fan Tray ................................................................................ 3-18

3.2.6 SFCS-1000 Temperature Sensing........................................................... 3-18

3.2.7 SFCS-1000 Common Equipment Card (CEC)..................................... 3-19

3.2.7.1 CEC Front Panel............................................................................. 3-19

3.2.7.2 Alarm Relay Contacts....................................................................3-19

3.2.7.3 CEC Status LEDs............................................................................ 3-21

3.2.7.4 Ethernet Port................................................................................... 3-22

Chapter 4 Switch Setup

4.2 Unpacking .............................................................................................................4-1

4.2.1 Inventorying the Unit................................................................................4-2

4.3 Electrical Considerations.....................................................................................4-3

4.4 Rack-Mounting an SFCS-200BX......................................................................... 4-4

4.4.1 Required Tools............................................................................................ 4-4

4.4.2 Installing the Rack-mount Brackets.........................................................4-5

4.5 Rack-Mounting an SFCS-200WG....................................................................... 4-7

4.5.1 Required Tools............................................................................................ 4-7

4.5.2 Installing the Rack-mount Brackets.........................................................4-8

4.6 Rack-Mounting an SFCS-1000.......................................................................... 4-10

4.6.1 Installing the SFCS-1000.......................................................................... 4-11

4.7 Installing the Serial Cable .................................................................................4-12

4.8 Modem Configuration.......................................................................................4-13

4.8.1 Modem Parameters.................................................................................. 4-13

4.9 Configuring IP Addresses................................................................................. 4-14

4.10 AMI Security..................................................................................................... 4-15

4.11 Subsequent Operation .....................................................................................4-15

4.12 Verifying the Installation................................................................................. 4-16

4.13 Product Registration Information..................................................................4-16

Chapter 5 Hardware Maintenance Procedures

5.1.1 Overview.....................................................................................................5-1

5.1.2 Multicast Mode...........................................................................................5-2

5.1.3 Hot-swapping Network Modules ...........................................................5-3

5.2 Power Supply Module Replacement................................................................. 5-4

5.2.1 SFCS-200BX Power Supply Module Replacement................................5-4

5.2.1.1 Replacing an SFCS-200BX AC Power Supply..............................5-4

5.2.2 SFCS-1000 Power Supply Module Replacement................................... 5-6

5.2.2.1 Replacing an SFCS-1000 AC Power Supply (Model A).............. 5-6

5.2.2.2 Replacing an SFCS-1000 AC Power Supply (Model B).............. 5-9

5.3 SFCS-1000 Fan Tray Replacement.................................................................... 5-12

5.4 Switch Control Processor Replacement ..........................................................5-13

5.5 Switch Board Replacement ...............................................................................5-15

iv

Page 7

Chapter 6 Software Upgrade Instructions

6.1 Obtaining the Software Upgrade File via Diskette ......................................... 6-2

6.2 Performing the Software Upgrade ....................................................................6-4

6.3 Changing between Multiple Versions of Software.......................................... 6-7

6.4 Using bootp to Download Software to the Switch.......................................... 6-9

6.4.1 Overview..................................................................................................... 6-9

6.4.2 Setting Up Your bootp Server .................................................................. 6-9

6.4.3 Adding an Entry for Your Switch in the bootptab File....................... 6-10

6.4.4 Setting Up a tftpboot Server................................................................... 6-12

Appendix A Troubleshooting

A.1.1 Run Looptest ............................................................................................A-3

A.1.2 Check Self-Test (Automatically Performed) ........................................ A-4

A.1.3 Firmware Download (Automatically Performed) ..............................A-4

A.1.4 Hardware Detected by Driver ...............................................................A-5

A.1.5 Check Firmware.......................................................................................A-6

A.1.6 Check Physical Link ................................................................................A-7

A.2 Testing Network Connectivity Using PVCs................................................... A-8

A.2.1 Verifying the Outgoing ATM ARP Entry............................................A-11

A.2.2 atmstat..................................................................................................... A-12

A.2.2.1 No Cells Received by Remote End ...........................................A-13

A.2.2.2 Cells and VPI/VCI Errors Received by Remote .....................A-13

A.2.2.3 Cells and AAL* Errors Received by Remote ...........................A-13

A.2.2.4 Cells and No Errors Received by Remote and Transmitting No

Cells ........................................................................................................A-14

A.2.2.5 Cells and No Errors Received by Remote and Transmitting Cells

A-14

A.3 Collecting Additional Information................................................................ A-15

A.3.1 Basic Information...................................................................................A-15

A.3.2 Adapter Information .............................................................................A-15

A.3.3 Switch Information................................................................................ A-18

Contents

Appendix B SCP Diagnostics

B.1.1 Accessing the Monitor Mode...................................................................B-2

B.1.2 Running the Hardware Tests ...................................................................B-4

B.1.2.1 Clock Test .........................................................................................B-4

B.1.2.2 DRAM Test .......................................................................................B-4

B.1.2.3 DRAM Chip Test .............................................................................B-5

B.1.2.4 Ethernet Test.....................................................................................B-5

B.1.2.5 FLASH Test ......................................................................................B-5

B.1.2.6 FLASH Chip Test.............................................................................B-6

B.1.2.7 Serial Port Test .................................................................................B-7

B.1.2.8 SRAM Test ........................................................................................B-7

B.1.2.9 Timer Test .........................................................................................B-7

B.1.2.10 Hardware Test................................................................................B-7

B.1.2.11 Complete Hardware Test..............................................................B-8

v

Page 8

Contents

Appendix C Hardware Specifications

C.1.1 SFCS-200WG............................................................................................ C-2

C.1.2 SFCS-200BX.............................................................................................. C-3

C.1.3 SFCS-1000..................................................................................................C-4

C.2 ATM Network Modules.................................................................................... C-5

C.2.1 100 Mbps TAXI Module ..........................................................................C-5

C.2.2 155 Mbps OC-3c/STM-1 MM Module.................................................. C-6

C.2.3 155 Mbps STS-3c/STM-1 UTP Module................................................. C-7

C.2.3.1 155 Mbps UTP Pinout Specifications ..........................................C-8

C.2.3.2 Connecting Switches with 155 Mbps UTP Network Modules C-8

C.2.4 622 Mbps OC-12c/STM-4c MM Module ..............................................C-9

C.2.5 25 Mbps TP25 Module........................................................................... C-10

C.2.5.1 Connecting Switches with TP25 Network Modules............... C-11

C.2.5.2 Connecting Switches with Token Ring Pinouts to Cabletron

Switches ................................................................................................. C-11

C.2.5.3 Connecting Adapters with Token Ring Pinouts to Cabletron

Switches ................................................................................................. C-12

C.2.6 34 Mbps E3 Module ............................................................................... C-13

C.2.7 45 Mbps DS3 Module ............................................................................ C-14

C.2.8 155 Mbps OC-3c/STM-1 SM Module.................................................. C-15

C.2.9 155 Mbps OC-3c/STM-1 3MM/1SM Module.................................... C-16

C.2.10 622 Mbps OC-12c/STM-4c SM Module............................................ C-18

C.3 ATM Adapters.................................................................................................. C-19

C.3.1 Adapter Cabling Specifications............................................................ C-19

C.3.1.1 Fiber-Optic Cable Specifications................................................ C-19

C.3.1.2 UTP Cable Specifications ............................................................C-20

C.3.1.3 UTP Pinouts.................................................................................. C-20

C.3.2 ESA-200PC Technical Specifications.................................................... C-21

C.3.3 PCA-200PC Technical Specifications ................................................... C-22

C.3.4 PCA-200MAC Technical Specifications .............................................. C-23

C.3.5 NBA-200 Technical Specifications........................................................ C-24

C.3.6 GIA-200 Technical Specifications .........................................................C-25

C.3.7 HPA-200 Technical Specifications........................................................ C-26

C.3.8 MCA-200 Technical Specifications....................................................... C-27

C.3.9 SBA-200 Technical Specifications .........................................................C-28

C.3.10 ESA-200 Technical Specifications .......................................................C-29

C.3.11 VMA-200 Technical Specifications..................................................... C-30

vi

Page 9

PREFACE

This manual provides technical information needed to install and operate the

Cabletron

vides information for the 9A000 and SFCS-200BX switches and the userinstallable network modules offering both LAN and WAN interfaces. This

document also provides safety instructions, general product information, network configuration information and information on software administration

capabilities.

TM

9A000 and SecureFast Cell Switch-200BX ATM Switches. It pro-

Technical Support

In the U.S.A., you can contact Cabletron Systems’ Technical Support by any

By phone: Monday through Friday between 8 A.M. and

By CompuServe

By Internet mail: support@ctron.com

By mail: Cabletron Systems, Inc.

By FAX: (603) 335-4743

Technical support for non-U.S.A. customers should be handled through your

local distributor.

No matter which method is used for technical support, please be prepared to

provide your support contract ID number, the serial number(s) of the product(s), and as much information as possible describing your problem/question.

®

one of four methods:

8 P.M. Eastern Standard Time at (603) 3329400

: GO CTRON from any ! prompt

P.O. Box 5005

Rochester, NH 03867-0505

Typographical Styles

Throughout this manual, all specific commands meant to be entered by the

user will appear on a separate line in bold

tion, use of the

lowing example demonstrates this convention.

Enter

or

Return

Avant Garde typeface. In addi-

key will be represented as

<ENTER>

. The fol-

vii

Page 10

PREFACE

Important Information Indicators

cd /usr <ENTER>

Commands or file names that appear within the text of this manual will be

represented in the following style: “...the

distribution”.

As in the following example, any messages that appear on your screen during

software installation and network interface administration will appear in

Courier font to distinguish them from the rest of the text.

....

Are all four conditions true?

To call your attention to safety and otherwise important information that

must be reviewed to insure correct and complete installation, as well as to

avoid damage to the ForeRunner Switch or your system, Cabletron Systems

utilizes the following WARNING/CAUTION/NOTE indicators.

WARNING statements contain information that is critical to the safety of the

operator and/or the system. Do not proceed beyond a WARNING statement

until the indicated conditions are fully understood or met. This information

could prevent serious injury to the operator, damage to the ForeRunner

Switch, the system, or currently loaded software, and will be indicated as follows:

fore_install

program will install this

viii

WARNING!

Information contained in CAUTION statements is important for proper

installation/operation. CAUTION statements can prevent possible equipment damage and/or loss of data and will be indicated as:

CAUTION

Hazardous voltages are present. If the instructions are not heeded, there is a risk of electrical

shock and danger to personal health.

You risk damaging your equipment and/or

software if you do not follow these

instructions.

Page 11

PREFACE

Information contained in NOTE statements has been found important

enough to be called to the special attention of the operator and will be set off

from the text as follows:

NOTE:

Cabletron Systems strongly recommends that

you disconnect the serial cable once you have

configured the ATM switch and then access

the switch over the ATM network.

ix

Page 12

PREFACE

Laser Warning

Class 1 Laser Product:

This product conforms to

applicable requirements of

21 CFR 1040 at the date of

manufacture.

Class 1 lasers are defined as products which do not permit human access to

laser radiation in excess of the accessible limits of Class 1 for applicable wavelengths and durations. These lasers are safe under reasonably foreseeable

conditions of operation.

The following network modules contain Class 1 lasers:

NM-2/155SMSRA-1 NM-2/155SMSRB-1 NM-2OC3/SMSRA-1

NM-4/155SMSRA-1 NM-4/155SMSRB-1 NM-4OC3/SMSRA-1

NM-4OC3/SMSRA-1A NM-4OC3/SMSRB-1 NM-2/155SMSRC

NM-4/155SMSRC NM-2/155SMLRA-1 NM-2/155SMLRB-1

NM-2/155SMLRC-1 NM-2OC3/SMLRB-1 NM-2OC3/SMMRA-1

NM-4/155SMLRB-1 NM-4/155SMLRC-1 NM-4OC3/SMLRB-1

NM-4OC3/SMMRA-1 NM-1/622SMIRC NM-4/155LR3SCC

NM-4/155SR3SCC

x

Page 13

Safety Agency Compliance

This preface provides safety precautions to follow when installing a

Cabletron Systems, Inc., product.

Safety Precautions

For your protection, observe the following safety precautions when setting up

your equipment:

• Follow all warnings and instructions marked on the equipment.

• Ensure that the voltage and frequency of your power source matches

the voltage and frequency inscribed on the equipment’s electrical rating label.

• Never push objects of any kind through openings in the equipment.

Dangerous voltages may be present. Conductive foreign objects

could produce a short circuit that could cause fire, electric shock, or

damage to your equipment.

PREFACE

Symbols

The following symbols appear in this book:

WARNING!

CAUTION

Hazardous voltages are present. If the instructions are not heeded, there is a risk of electrical

shock and danger to personal health.

You risk damaging your equipment and/or

software if you do not follow these

instructions.

xi

Page 14

PREFACE

Modifications to Equipment

Do not make mechanical or electrical modifications to the equipment.

Cabletron Systems, Inc., is not responsible for regulatory compliance of a

modified product.

Placement of a Cabletron Systems Product

CAUTION

To ensure reliable operation of your Cabletron

Systems product and to protect it from overheating, openings in the equipment must not

be blocked or covered. A Cabletron Systems

product should never be placed near a radiator or heat register.

Power Cord Connection

WARNING!

WARNING!

Cabletron Systems products are designed to

work with single-phase power systems having a grounded neutral conductor. To reduce

the risk of electrical shock, do not plug

Cabletron Systems products into any other

type of power system. Contact your facilities

manager or a qualified electrician if you are

not sure what type of power is supplied to

your building.

Your Cabletron Systems product is shipped

with a grounding type (3-wire) power cord. To

reduce the risk of electric shock, always plug

the cord into a grounded power outlet.

xii

Page 15

CHAPTER 1

The Cabletron 9A000 and SFCS series ATM Switch brings ATM connectivity to

LAN workgroup, LAN backbone, and LAN/WAN internetworking applications. Together with the Cabletron series of ATM Computer Interfaces, the

9A000 and SFCS series meet the networking demands of today’s distributed,

time-critical applications.

The Cabletron 9A000 and SFCS series ATM high-performance ATM switches

deliver switching capacity and speed for ATM applications. A non-blocking

switching capacity of 2.5 Gbps is continually available for connectivity to 16

users or networking devices, each running at speeds up to 622 Mbps or 24

users or network devices running at 100 Mbps.

This chapter provides an overview of the ATM Standard and Cabletron Systems 9A000 and SFCS series Switches. It details the hardware and software

requirements necessary to use the 9A000 and SFCS series and also provides

information on the contents of the 9A000 and SFCS series Switch packages.

Introduction

1.1 Overview of the ATM Standard

Asynchronous Transfer Mode, or ATM, is a communication architecture

based on the switching of small fixed length packets of data called cells . In

ATM, all data is transferred in 53-byte cells. Each cell has a 5-byte header that

identifies the cell’s route through the network and 48-bytes containing user

data. This user data in turn carries any headers or trailers required by higher

level protocols.

The operation of an ATM switch is conceptually quite simple. The header of

each cell contains a virtual connection (VC) identifier, consisting of a virtual

path identifier (VPI) and a virtual channel identifier (VCI). On each incoming

link, an arriving cell’s VC identifier uniquely determines a new VC identifier

to be placed in the cell header, and the outgoing link over which to transmit

the cell. In the case of a multicast connection, the VC identifier maps to a set of

new VC identifiers and outgoing links.

Perhaps the single most important advantage offered by ATM, in addition to

the speed at which data is transferred, is its open-ended growth path. ATM is

not locked into a single physical medium or speed. The fixed-size ATM cell

allows traffic from multiple sources (simultaneous video, audio, and data

1-1

Page 16

Introduction

1.2 Hardware Description

communication) to be switched to multiple destinations by fast ATM switches

such as the Cabletron 9A000 and SFCS series (connecting up to 64 workstations

with an aggregate capacity of 2.5 Gbps or 96 workstations running at 100

Mbps). Larger LANs can be built by interconnecting multiple 9A000 and SFCS

series ATM switches.

Based upon international standards developed by the CCITT, ATM allows for

fast packet switching of cells, 53 bytes in length. By using small cells to transfer data, coupled with a low latency switch supporting isochronous timing,

ATM is able to support a wide range of audio, video, image, and data communications requirements.

Unlike shared-medium LAN technologies such as Ethernet and Token Ring,

in which users must contend for bandwidth, ATM switching provides dedicated, deterministic, high-speed connectivity. In addition, ATM is scalable

from 155 Mbps to 2.5 Gbps - to the desktop, or for the entire network.

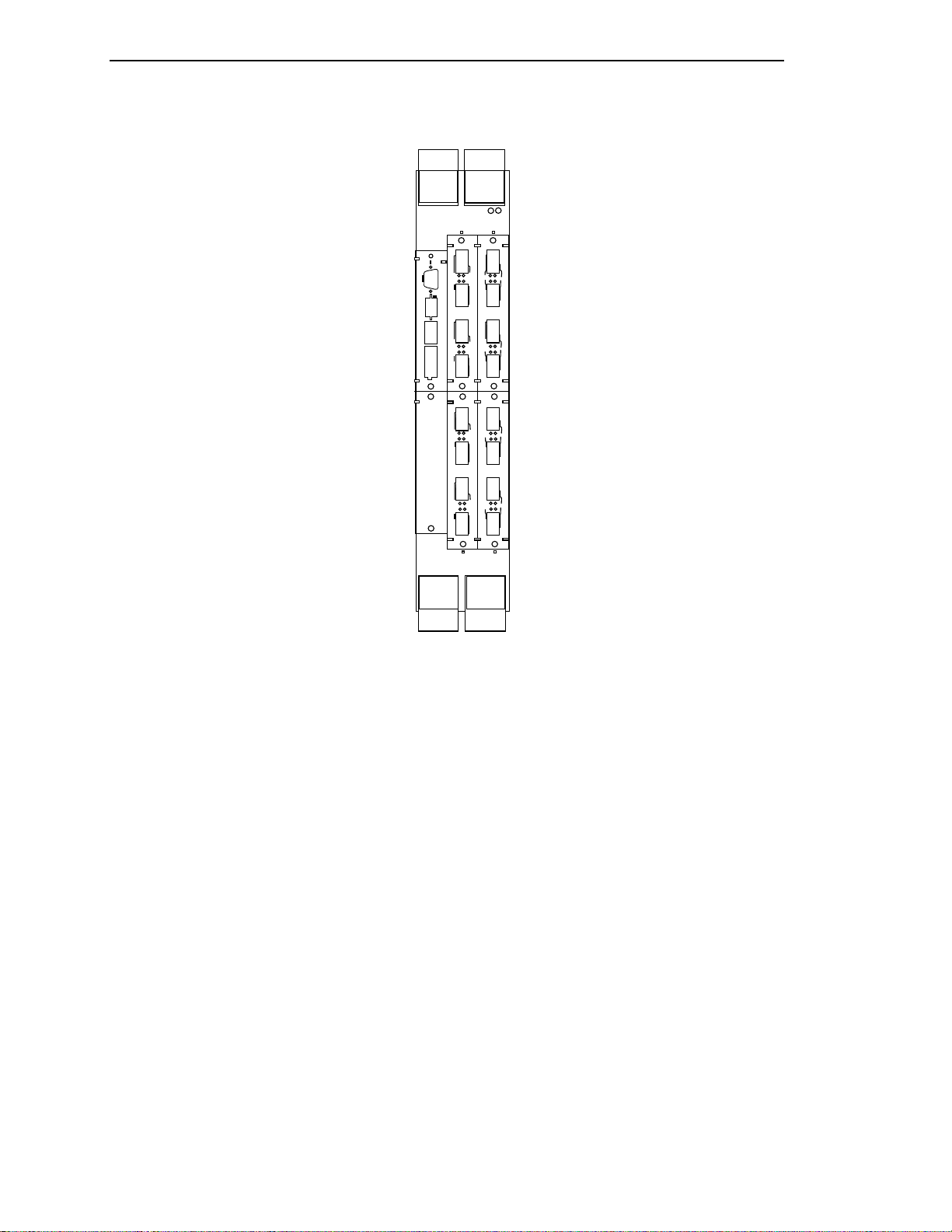

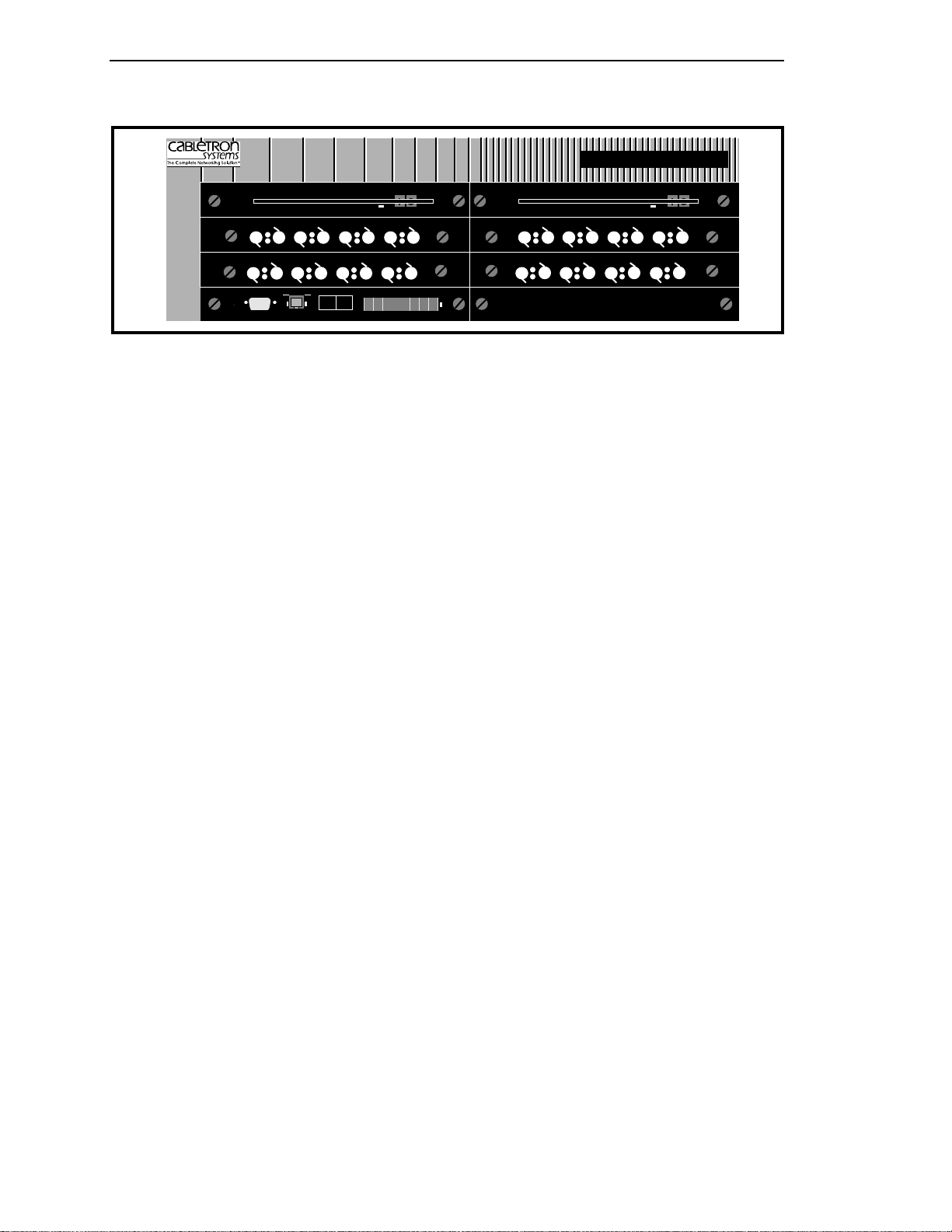

The 9Cabletron 9A000 and SFCS series ATM switches, as shown in Figure 1-1

and Figure 1-2, provide connectivity for up to 16 computer workstations,

hubs, or routers at rates operating up to 622 Mbps/sec (or 24 workstations

running at 100 Mbps) via dedicated fiber optic links and twisted pair links.

Wide-area network (WAN) connectivity is seamlessly integrated into the

9A000 and SFCS series for connection to private networks or ATM SONET,

DS-3, DS-1, E-3, or J-2 services.

Interconnecting multiple 9A000 and SFCS series switches at various speeds is

simple. Once a new 9A000 and SFCS series switch is added to the network,

all other switches recognize its presence and dynamically establish connections to ports on the new switch. Furthermore, scaling the network is accomplished without costly and time consuming address reconfiguration and LAN

segmentation.

The 9A000 and SFCS series is a self-contained ATM switch that includes an

Ethernet connection to provide network management access.

1-2

Page 17

Introduction

Figure 1.1 - 9A000 Switch Configuration

1-3

Page 18

Introduction

SecureFast Cell Switch

5 VOLT

RX2

RESET

RX2

RX1

TX2

TX1

RX2

RX1

TX1

Tx

C

ETH

SER

RX3

TX2

TX3

Rx

L

SELECT

NEXT

RX4

RX3

TX4

TX3

RX4

TX4

SFCS

PWR

RESET

RX1

TX2

TX1

RX2

RX1

TX2

TX1

Tx

Rx

L

C

SER

ETH

Figure 1.2 - SFCS-200BX Switch Configuration

1.2.1 Front Panel Description

The front panel of the 9A000 and SFCS series includes the following features:

a power switch, two power supply LEDs, a RESET button, an RS-232 serial

port, an Ethernet 10BaseT port, a NEXT pushbutton, a SELECT pushbutton, a

display LED, and a power LED. For more information about these features,

please refer to Appendix A of this manual.

1.2.2 9A000 and SFCS Series Hardware Configuration

The 9A000 and SFCS series hardware consists of a switch board, an i960

switch control processors, and network modules. These components work

together to provide ATM switching capabilities, as well as distributed connection set-up and management. A functional description for each component

follows.

NEXT

RX3

TX3

RX3

TX3

FORE - FORE

SELECT

-200BX

5 VOLT

RX4

TX4

RX4

TX4

PWR

1-4

1.2.3 9A000 and SFCS Series Switch Board

The 9A000 and SFCS series switch board contains the VPI/VCI lookup tables,

and routing circuitry to ensure that a cell received from an input port is correctly switched to one or more output ports. The 9A000 and SFCS series

switch board can accept up to four network modules, which themselves contain up to six ports each. The switch board also has an interface, controlled by

the switch control processor, that is functionally equivalent to an ATM host

interface. (See Switch Control Software for more information).

Page 19

1.2.4 Switch Control Processor

The i960 switch control processor provides the distributed connection set-up

for a network of ATM switches. The switch control processor primarily provides management access through SNMP and is responsible for storing and

updating all SNMP management information. Additionally, the switch control processor can access the ATM switch in-band in very much the same

manner as an ATM adapter in a workstation (such as the Fore SBA-200 SBus

Adapter). Since it has the ability to communicate over IP, the 9A000 and SFCS

series can route IP traffic from one given IP network to another. The switch

control processor, and associated software, manages the behavior of the

9A000 and SFCS series switch board (i.e., connection setup), but is not

involved in the actual cell switching.

1.2.5 9A000 and SFCS Series Network Modules

The network modules for the 9A000 and SFCS series act as the physical

input/output ports to the 9A000 and SFCS series switch. A network module

may have up to six physical ports, depending on its physical configuration.

There is also a logical control port located inside the SCP which is referred to

in the switch software as the Control Port (CTL). This control port is a logical

(not physical) location where cells that are directed to the SCP itself are sent.

(See section 1.4.1 for more information.)

Introduction

1.2.6 Environmental Information

In the 9A000 and SFCS series, there is a temperature sensor, located over the

switch fabric area of the enclosure, which ensures that the internal cabinet

temperature is not too high. This temperature is displayed on the Environmental Module LCD readout, within the MMAC Plus chassis. The power utilization for the 9A000 and SFCS series is also monitored and can be displayed

on the Environmental Module.

1-5

Page 20

Introduction

Table 1.1 - System Hardware and Environmental Specifications

Features SFCS Series/9A000

Switching Fabric

Traffic Policing

Number of Ports

Switch Transit Delay

Connection Setup Time < 10 milliseconds

Maximum Port Speed

Power (nominal) 90 - 270 VAC @ 47 - 63 Hz

Dimensions H: 4.75” (12.1 cm)

Weight 43 lbs (19.5 kg)

Operating Temperature 5˚C to 40˚C

2.5 Gbps

non-blocked

UNI 3.1 dual leaky

bucket support

up to 24 ports

< 10 microseconds

622 Mbps

(OC-12/STM-4)

2.2 amps maximum

W: 17.5” (44.5 cm)

D: 18” (45.7 cm)

up to 10,000 ft

1-6

Operating Humidity 10 to 90% RH

Storage Temperature -40˚C to 70˚C

up to 30,000 ft

Storage Humidity 5 to 95% RH

Page 21

1.2.7 Standards Compliance

• ITU I.361 ATM Layer

• ATM Forum UNI 3.0

1.2.8 Safety Compliance

• US: UL 1950

• Canada: CSA 22.2 No. 950-M89

• Europe: EN 60950

1.2.9 Emissions Compliance

• FCC Part 15, Class A

• CISPR 22, Class A

• VCCI, Class 1

1.2.10 Electromagnetic Compatibility (EMC)

The following all comprise EN 50082-1:

• ESD Susceptibility: IEC 801-2, Level 3

• Radiated Susceptibility: IEC 801-3, Level 2

• Electrical Fast Transient Compatibility: IEC 801-4, Level 2

Introduction

1.3 Software Description

The software for the 9A000 and SFCS series runs on a FLASH file system to

accomplish switch and connection management, IP connectivity, and SNMP

network management.

1.3.1 Switch Control Software

The Switch Control Software (SCS) is the “brains” of the 9A000 and

SFCS series switches. The SCS controls the 9A000 and SFCS series switch

board and handles connection set-up and tear-down duties. The SCS can also

communicate with other Cabletron Systems switches using the SPANS NNI

protocol to learn network topology and establish connections across multiple

switches. In addition, there is an SNMP agent built into the SCS to allow

SNMP management and control.

1-7

Page 22

Introduction

1-8

Page 23

CHAPTER 2 Installing the 9A000

This chapter contains the procedures for installing the 9A000. The installation

of the SFCS series is covered in Chapter 3.

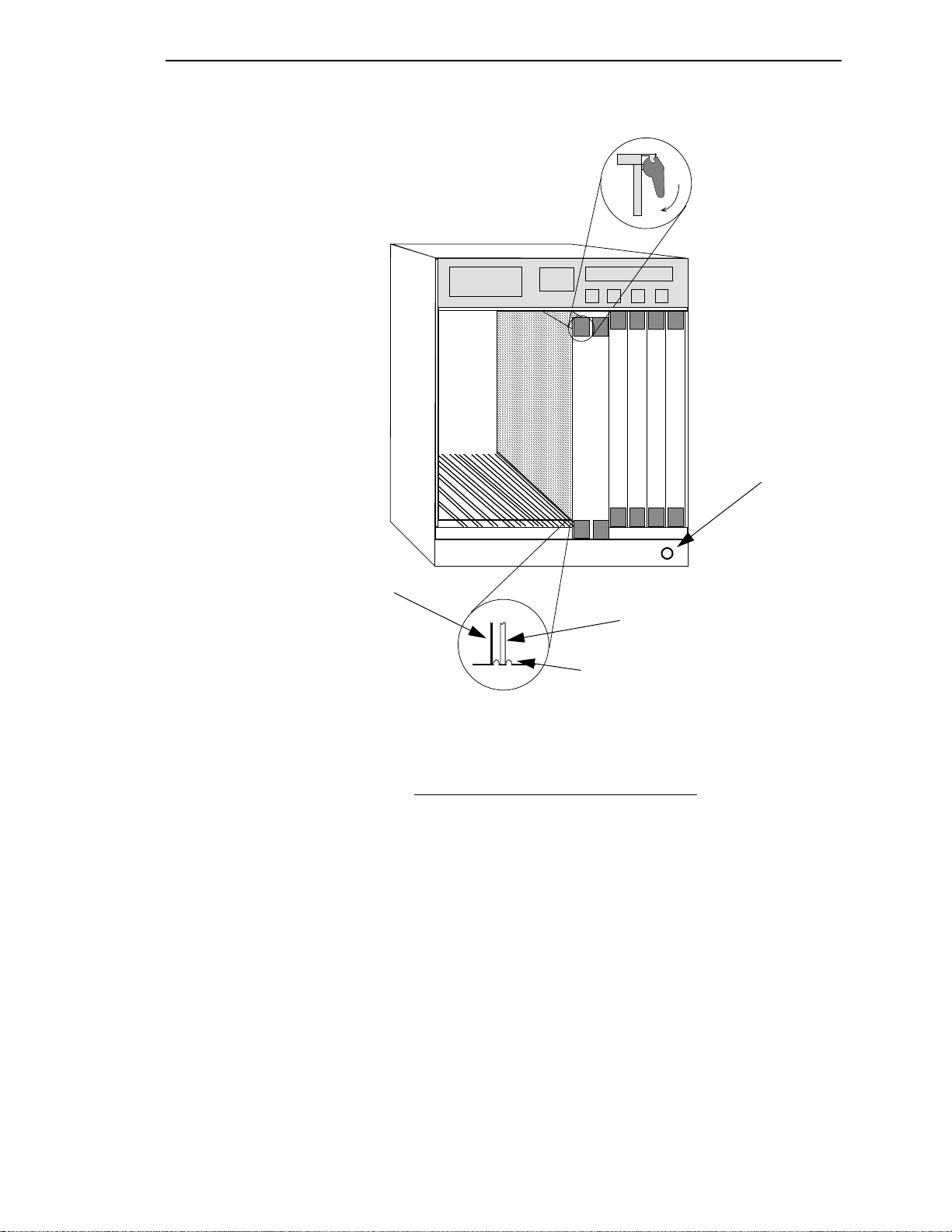

2.1 Installing the 9A000

To install the Cabletron 9A000, follow the steps below:

1. Switch off the power supplies and remove all power from the

MMAC-Plus chassis.

2. Remove the blank panels, covering the slots that the module is

being mounted in. All other slots must be covered, if modules are

not being installed, to ensure proper airflow and cooling.

3. Carefully remove the module from the shipping box. (Save the

box and packing materials in the event the module must be

reshipped.)

4. Attach one end of the ESD wrist strap packaged with the MMAC-

Plus chassis to your wrist. Plug the other end into the ESD Wrist

Strap Grounding receptacle in the lower right corner of the

MMAC-Plus Chassis shown in Figure 2.1.

5. Remove the module from the plastic bag. Observe all precautions

to prevent damage from Electrostatic Discharge (ESD).

6. Carefully examine the module, checking for damage. If any dam-

age exists, DO NOT install the module. Contact Cabletron

Systems Technical Support immediately.

7. The modules are installed into the chassis by sliding them into

slots and locking down both the top and bottom plastic tabs, as

shown in Figure 2.1. Take care that the module slides in straight

and engages the backplane connectors properly. When installing

the module, ensure that both circuit cards are between the card

guides, as shown in Figure 2.1. Check both the upper and lower

tracks of both cards.

2-1

Page 24

Installing the 9A000

7

FLNK

8

FLNK

FLNK

10

RX

FLNK

INS

TX

11

RX

FLNK

INS

TX

12

RX

Jack for ESD

wrist strap

2-2

Metal Back-Panel

Circuit Card

Card Guides

Warning:

Ensure that the circuit card is between the card guides.

Lock down the top and bottom plastic tabs

at the same time, applying even pressure.

Figure 2.1 - Installing the 9A000 Module

Page 25

2.2 The Reset Switch

SMB

CPU

The Reset switch is located on the rightmost front panel, under the top plastic

tab as shown in Figure 2.2. It serves two functions:

• Pressing the reset switch twice within three seconds causes the processor (i960) to reset.

• Pressing and holding the switch on for three or more seconds causes

the module to shutdown. Pressing and holding again for three seconds restarts the module.

SNMP management may be used to disable this switch to enhance module

security.

Installing the 9A000

Reset Switch

Figure 2.2 - The Reset Switch

2-3

Page 26

Installing the 9A000

2-4

Page 27

CHAPTER 3 Switch Hardware

Cabletron Systems offers a full line of ATM products that work together to

provide a complete ATM network solution. The Cabletron SFCS-200WG ATM

switch provide high-performance ATM connectivity for LAN workgroup and

desktop applications. The SFCS-200BX ATM switch and the SFCS-1000 ATM

switch offer high reliability and port density for LAN backbone and LAN/

WAN internetworking applications. Together with the Cabletron series of

ATM LAN and WAN Network Modules, these switches meet the networking

demands of today’s distributed, time-critical applications.

All of the Cabletron ATM switches deliver high-performance switching

capacity and speed for ATM applications. A non-blocking switching capacity

of 2.5 Gbps is continually available on the SFCS-200WG, and the SFCS-200BX.

Each switch provides up to 4 ports of connectivity, each running at speeds up

to 622 Mbps; or up to 16 ports, each running at speeds up to 155 Mbps; or up

to 24 ports, each running at speeds up to 100 Mbps. The

10 Gbps of switching capacity for up to 16 ports of connectivity, each running

at speeds up to 622 Mbps; or up to 64 ports, each running at speeds up to 155

Mbps; or up to 96 ports, each running at speeds up to 100 Mbps.

Wide-area network (WAN) connectivity is seamlessly integrated into the

SFCS-200BX and the SFCS-1000 for connection to private networks or ATM

SONET, DS3 and E3 services.

Interconnecting multiple Cabletron switches at various speeds is simple.

Once a new Cabletron switch is added to the network, all other switches recognize its presence and dynamically establish connections to ports on the

new switch. Furthermore, scaling the network is accomplished without costly

and time consuming address reconfiguration and LAN segmentation.

This chapter provides an overview of the Cabletron Systems’ family of ATM

switches. It details the hardware requirements necessary to use these switches

and also provides information on the contents of each of the switch packages.

SFCS-1000 provides

3-1

Page 28

Switch Hardware

3.1 Switch Hardware Configurations

The SFCS-200WG, as shown in Figure 3.1, is a self-contained ATM switch that

provides an Ethernet connection for network management access. The

SFCS-200WG ATM switch hardware consists of a single switch board with an

i960 SCP, network modules, and fans. These components work together to

provide ATM switching capabilities, as well as distributed connection setup

and management.

SYSTEMS

RESET

SecureFast

RX2

RESET

RX1

TX2

TX1

RX2

RX1

TX2

TX1

Tx

Rx

L

C

SER

NEXT

ETH

RX2

RX1

TX2

TX1

RX2

RX1

TX1

Tx

C

ETH

SER

RX3

TX2

TX3

Rx

L

SELECT

NEXT

RX4

RX3

TX4

TX3

RX4

TX4

PWR

RX3

SELECT

RX3

TX3

TX3

-

SFCS-200WG

5 VOLT

RX4

TX4

RX4

TX4

PWR

Figure 3.1 - SFCS-200WG Switch Configuration

The SFCS-200BX, as shown in Figure 3.2, is a self-contained ATM switch that

provides an Ethernet connection for network management access. The

SFCS-200BX hardware consists of a single switch board with an i960 SCP, network modules, redundant power supplies, and fans. These components work

together to provide ATM switching capabilities, as well as distributed connection setup and management.

3-2

Page 29

Switch Hardware

SYS

5 VOLT

RX1

TX1

RX1

TX1

RESET

SER

RESET

RX2

RX1

TX2

TX1

RX2

RX1

TX1

Tx

C

ETH

SER

RX3

TX2

TX3

Rx

L

SELECT

NEXT

RX4

RX3

TX4

TX3

RX4

TX4

PWR

SecureFast SFCS

RX2

TX2

RX2

TX2

Tx

Rx

L

C

NEXT

ETH

SELECT

RX3

TX3

RX3

TX3

SFCS-200BX

5 VOLT

RX4

TX4

RX4

TX4

PWR

Figure 3.2 - SFCS-200BX Switch Configuration

The SFCS-1000, as shown in Figure 3.3, is a self-contained ATM switch that

provides an Ethernet connection for network management access. The hardware for the SFCS-1000 consists of up to four switch boards, each with an i960

SCP; network modules; redundant power supplies; a Common Equipment

Card (CEC); and a removable fan tray. These components work together to

provide ATM switching capabilities, as well as distributed connection setup

and management.

3-3

Page 30

Switch Hardware

SYSTEMS

SFCS-1000

C

A

AL1 AL2

AL1 AL2

AL2

AL1

AL1

AL2

RX

LI

ETH

RX

LI

COL

POL

ETH

COL

POL

RESET

SER

Tx

C

ETH

Rx

L

NEXT SELECT

PWR

RX1

TX1

RESET

RX1

TX1

RX2

TX2

TX3

TX4

TX1

TX2

TX3

TX4

SER

RX2

TX2

Tx

C

ETH

Rx

L

NEXT SELECT

RX3

TX3

RX3

RX4

RX4

TX4

PWR

TX1 RX1 TX2 RX2 TX3 RX3 TX4 RX4

RX1

RX2

RX3

RX4

C

A

RX1

TX1

RX1

TX1

RX2

TX2

RX3

TX3

RX4

TX4

RX1

TX1

RX2

TX2

RX3

TX3

RX4

TX4

RESET

SER

RX2

TX2

Tx

C

ETH

Rx

L

NEXT SELECT

RX3

TX3

RX4

TX4

PWR

TX1 RX1 TX2 RX2 TX3 RX3 TX4 RX4

C

A

TX1

RX1

RESET

RX1

TX1

TX2

TX3

TX4

TX1

TX2

TX3

TX4

SER

RX2

TX2

RX2

Tx

C

ETH

Rx

L

NEXT SELECT

RX3

TX3

RX3

RX4

TX4

RX4

PWR

TX1 RX1 TX2 RX2 TX3 RX3 TX4 RX4

RX1

RX2

RX3

RX4

C

A

RX1

TX1

RX1

TX1

TX2

RX2

RX2

TX2

TX3

RX3

TX3

RX4

TX4

TX4

RX1

TX1

48V DC

48V DC

RX3

RX4

CB1

CB1

TX1 RX1 TX2 RX2 TX3 RX3 TX4 RX4

110

RX2

TX2

RX3

TX3

F12A/250V

RX4

TX4

F12A/250V

TB1TB1

3-4

D

B

D

B

D

B

B

Figure 3.3 - SFCS-1000 Switch Configuration

D

AC V olt. In

AC V olt. In

Page 31

3.2 Switch Hardware Components

3.2.1 Switch Board

The switch board (also referred to as the “switch fabric”) contains the VPI/

VCI lookup tables and routing circuitry to ensure that a cell received from an

input port is correctly switched to one or more output ports. The SFCS200WG, and the SFCS-200BX each come with one switch board. The

SFCS-1000 can be populated with as many as four switch boards. Each switch

board can accept up to four network modules, which themselves can contain

up to six ports each. The switch board also has an interface, controlled by the

SCP, that is functionally equivalent to an ATM host interface.

3.2.2 Switch Control Processor

The i960 SCP in the SFCS-200WG, SFCS-200BX, and the SFCS-1000 provide

the distributed connection setup for a network of ATM switches. The SCP primarily provides management access through SNMP and is responsible for

storing and updating all SNMP management information. Additionally, the

SCP has direct access to the switch board. The SCP, and associated software,

manages the behavior of the switch board (i.e., connection setup), but is not

involved in the actual cell switching.

Switch Hardware

3-5

Page 32

Switch Hardware

3.2.2.1 i960 Switch Control Processor

The front panel of an i960 SCP for the SFCS-200WG, SFCS-200BX, and the

SFCS-1000 includes the following features: a RESET button, an RS-232 serial

port, an Ethernet 10BaseT port, a NEXT pushbutton, a SELECT pushbutton, a

display LED, and a power LED. All of the features are illustrated in Figure 3.4

and are described in detail in the subsections that follow.

RESET

SER

Tx

C

ETH

Rx

L

NEXT SELECT

Figure 3.4 - i960 Switch Control Processor Front Panel

3.2.2.1.1 RESET Button

The RESET button allows the user to reset the switch control software on the

SCP. Using RESET “soft boots” the SCP and runs the initial power-on diagnostics. All open AMI sessions are ended by the SCP, and all ports lose any

active sessions and initially go off-line after a reset. The ports then return to

the configuration stored in the CDB. Because the RESET button is small (to

avoid accidental resets), it is recommended that you use a straightened paper

clip to push the RESET button.

3.2.2.1.2 RS-232 Serial Port

The RS-232 serial port provides terminal access for any VT100 (or similar) terminal or terminal emulation package to the SCP. The serial port has a standard DB-9 female connector as shown in Figure 3.5.

PWR

3-6

4

5

987

3

21

6

Figure 3.5 - RS-232 Serial Port Pinouts

Page 33

Switch Hardware

Table 1.1 describes the RS-232 serial port pinouts that are illustrated in

Figure 3.5.

Table 3.1 - RS-232 Serial Port Pinouts

Pin Number

1 DCD Data Carrier Detect

2 RXD Receive Data

3 TXD Transmit Data

4 DTR Data Terminal Ready

5 GND Signal Ground

6 DSR Data Set Ready

7 RTS Request to Send

8 CTS Clear to Send

9 Not Used

3.2.2.1.3 Ethernet 10BaseT Port

The Ethernet 10BaseT port on the front panel of the SCP has a standard RJ45

connector. There is a transmit LED to the left of this port and a receive LED to

the right of this port. Tables 1.2 and 1.3 describe the states of the LEDs and

their meanings.

Table 3.2 - Ethernet 10BaseT Transmit LED Description

Signal

Mnemonic

Signal Name

LED Color Meaning

red There is a collision on the port.

green The port is transmitting normally.

Table 3.3 - Ethernet 10BaseT Receive LED Description

LED Color Meaning

red The port is failing link integrity.

green The port is receiving normally.

3-7

Page 34

Switch Hardware

3.2.2.1.4 CTL Port

3.2.2.1.5 NEXT Pushbutton

3.2.2.1.6 SELECT Pushbutton

3.2.2.1.7 Display LED

A control port inside the SCP, referred to in the switch software as the CTL

port, is a logical (not physical) location where cells that are directed to the

SCP itself are sent. The CTL port has two roles, serving as both a host and a

switch board controller. All signalling from the switch host and every

attached host must interact with the switch board controller.

The NEXT pushbutton lets you scroll through the menu that is shown on the

display LED after the power is turned on or after the SCP is reset/rebooted.

The SELECT pushbutton lets you choose an option from the menu that is

shown on the display LED after the power is turned on or after the SCP is

reset/rebooted.

During the boot process and the initial power-on diagnostics, the display LED

shows messages about what is happening to the SCP. It is also used to show

the menu choices for the NEXT and SELECT pushbuttons after the power is

turned on or after the SCP is reset/rebooted. The choices shown on the display LED are as follows:

Flash ? When chosen, the SCP will attempt to boot from

the FLASH file.

Ethernet ? When chosen, the SCP boots from the network.

Monitor ? When chosen, the user can connect a terminal to

the serial port and run hardware self-diagnostics.

Auto ? When chosen, the SCP will attempt to boot from

the FLASH. If this is unsuccessful, then the SCP

will perform an Ethernet boot.

To access the modes listed above, press the NEXT pushbutton while the

switch is booting until the mode you want to access is shown on the display

LED. Then, press the SELECT pushbutton.

After the boot process and self-diagnostics are complete, the name of the SCP

is shown in the display LED during normal operations, if an SCP name has

been assigned. If an SCP name has not been assigned, it will display ATM

SWITCH. For information on creating or modifying the SCP name, please refer

to the section on configuring the SCP name in Appendix B, AMI Configuration Commands, in the Cabletron ATM Switch Configuration Manual.

3-8

Page 35

Switch Hardware

3.2.2.1.8 Power LED

The power LED that is located to the right of the display LED on the front

panel of the SCP reflects the current state of power to the SCP. Table 1.4 lists

the states of the power LED and their meanings.

Table 3.4 - Power LED Description

LED Color Meaning

red The SCP has power, but has failed. (The individual

SCP, not the entire switch, has not passed

self-diagnostics.)

green The SCP is powered up and is in good status.

off There is no power to the SCP.

A power switch is located on the upper right-hand corner of the SFCS200WG. When the power is turned on, the power LED, located to the right of

the display LED, illuminates green and the initial power-on diagnostics are

run. When the power is turned off, the power LED is extinguished.

3.2.3 Network Modules

The network modules in a Cabletron switch board act as the physical input/

output ports to the switch board. A network module may have one, two, four,

or six physical ports, depending on its configuration.

3.2.3.1 Port Numbering

The individual ports on a network module are numbered according to the

Board-Network Module-Port (BNP) notation.

Board Refers to the number of the switch board that

Network Module Refers to the slot (A, B, C, or D) in the switch

Port Refers to the physical port (1 - 6) being num-

contains the port being numbered. “Board” is

always 1 in an SFCS-200BX, or an SFCS-200WG,

since these switches each contain only one

switch board. “Board” can be 1, 2, 3, or 4 in an

SFCS-1000, depending on the number of the

physical switch board that contains the port

being numbered.

board that contains the port being numbered.

bered on the individual network module.

3-9

Page 36

Switch Hardware

For example, according to this notation, the fourth port on a network module

in slot B of switch board #2 is port 2B4.

Figure 3.6 illustrates how the ports of various network modules, located in

switch board #4 of an SFCS-1000, for example, would be numbered.

PORT

PORT PORT PORT PORT

4C1 4C2 4C3 4C4

RX1

C

AB

RX2

TX1

TX2

RX1

TX1

RX3

RX4

TX3

TX4

PORT

4A1

4D2

PORT

4D1

R1 R2 R3 R4 R5 R6T1 T2 T3 T4 T5 T6

RX1

TX1

PORT PORT

4B1 4B2

PORT

4D3

RX2

TX2

PORT

4D4

PORT

4D5

PORT

4D6

D

Figure 3.6 - Network Module Port Numbering

NOTE: For information about the technical and oper-

ating specifications for all of the Cabletron

ATM network modules, see Appendix C,

Hardware Specifications, in this manual.

3-10

Page 37

3.2.4 Power Supply Modules

The SFCS-200BX and the SFCS-1000 each come with two removable power

supply modules. In the event of a single power supply failure, the power supply indicator LED(s) on the front panel of the supplies will indicate the failed

supply. The failed power supply can be removed and replaced while the other

supply continues to provide power to the enclosure. In this manner, a single

power supply failure will not cause the switch to stop functioning.

WARNING! The SFCS-200WG comes with internal, non-

removable power supplies. Attempting to

remove these power supplies could result in

serious injury or may cause permanent damage to the unit.

3.2.4.1 SFCS-200BX AC Power Supply

The SFCS-200BX has two power supply LEDs, one for each removable, hotswappable power supply. Each LED is located to the left of the power switch

on the front panel for that supply. On the AC power supply for the

SFCS-200BX, the LED is green under normal circumstances, indicating that

the 5-volt supply coming from that particular power supply is functioning

properly.

Switch Hardware

CAUTION If the power supply LED is red, the faulty sup-

ply should be turned off as soon as possible,

using the single power switch which controls

power to that supply. The problem should

then be diagnosed and repaired. Please refer

to Chapter 3, Hardware Maintenance Procedures, for details about how to hot-swap a

power supply in the SFCS-200BX.

NOTE: A replacement AC power supply will not

function in a DC-equipped SFCS-200BX, and

vice-versa. However, no damage will be done

if this occurs.

3-11

Page 38

Switch Hardware

3.2.4.2 SFCS-1000 AC Power Supply (Model A)

The model A AC power supply for an SFCS-1000 is shown in Figure 3.7.

AC

48V DC

5VDC OK

SHUTDOWN

CAUTION: This unit has more than one

power cord. To reduce the risk of

electric shock, disconnect two power

supply cords b servicing.

ATTENTION: Cet appareil comporte plus

d’un cordon d’alimentation. Afin

de prevenir les chocs electriques,

debrancherles 2 cordons d’alimentation

avant de faire le depannage.

Retention

screws

CAUTION: Double pole/neutral fusing

F12A/250V

Ejection/insertion

handle

3-12

Figure 3.7 - Model A SFCS-1000 AC Power Supply

Page 39

Switch Hardware

3.2.4.2.1 Power Supply LEDs

There are four LEDs on the front panel of the model A SFCS-1000 AC power

supply which indicate the status of the power supply. The LEDs and their

functions are described in the following table:

Table 3.5 - SFCS-1000 Power Supply LED Descriptions

3.2.4.2.2 Shutdown Conditions

To avoid damaging itself or the switch, the model B SFCS-1000 AC power

supply shuts itself down under the following condition:

Overload The power supply is overloaded or the AC input

is out of specification, and the supply voluntarily

shuts down to avoid damage to the system.

NOTE: The SFCS-1000 CEC can not shut down the

model A power supply. Only the power supply can shut itself down in an overload state.

3-13

Page 40

Switch Hardware

If a model A power supply goes into shutdown, it will remain shut down

until the power switch is turned off and turned on again (power cycle). The

power switch must remain off long enough for the SHUTDOWN LED to

extinguish (this allows the capacitors to discharge).

WARNING! A replacement AC power supply should

never be placed in an SFCS-1000 that already

contains a DC power supply, and vice-versa. If

these instructions are not heeded, there is a

risk of electrical shock, danger to personal

health, and serious damage to the equipment.

If the power supply needs to be replaced, please refer to Chapter 3, Hardware

Maintenance Procedures, for hot-swap information.

3-14

Page 41

3.2.4.3 SFCS-1000 AC Power Supply (Model B)

The model B AC power supply for an SFCS-1000 is shown in Figure 3.8.

Switch Hardware

ON/OFF Switch

Handle

100 - 120V ~ T15A 250V

200 - 240V ~ T15A 250V

50 - 60Hz

PWR

OK

FAULT

TEMP

I LIM

CAUTION: This unit has more than one po wer cord. To reduce the risk

of electric shock, disconnect two power supply cords b servicing. ATTENTION: Cet appareil comporte plus d’un cordon d’alimentation. Afin de

prévenir les chocs électriques, débrancher les 2 cordons d’alimentation avant de faire le dépannage.

Figure 3.8 - Model B SFCS-1000 AC Power Supply

Captive

fasteners

3-15

Page 42

Switch Hardware

3.2.4.3.1 Power Supply LEDs

3.2.4.3.2 Shutdown Conditions

There are four LEDs on the front panel of the model B SFCS-1000 AC power

supply which indicate the status of the power supply. The LEDs and their

functions are described in the following table:

Table 3.6 - SFCS-1000 Power Supply LED Descriptions

To avoid damaging itself or the switch, the model B SFCS-1000 AC power

supply shuts itself down under the following error conditions:

Input undervoltage The AC line voltage is below 87 ±5VAC RMS.

Output undervoltage Output 1 is 42 ±2 VDC or Output 2 is below 4.5

±0.25 VDC. Shutdown from undervoltage is

defeated during power-up period (2 seconds

maximum) to allow slow-start.

Output overvoltage The voltage at Output 1 or Output 2 is above

125% ±8% of the nominal voltage.

Overtemperature Any power semiconductor has reached 90% of

its maximum junction temperature.

3-16

NOTE: The SFCS-1000 CEC can not shut down the

model B power supply. Only the power supply can shut down and restart itself.

Page 43

Switch Hardware

If a model B power supply goes into shutdown, it remains turned off until the

fault condition is rectified. At that point, the power supply restarts itself,

except in the case of an overvoltage condition.

To recover from a shutdown caused by an overvoltage state, the AC line input

must be turned off for at least one second.

WARNING! A replacement AC power supply should

never be placed in an SFCS-1000 that already

contains a DC power supply, and vice-versa. If

these instructions are not heeded, there is a

risk of electrical shock, danger to personal

health, and serious damage to the equipment.

If the power supply needs to be replaced, please refer to Chapter 3, Hardware

Maintenance Procedures, for hot-swap information.

3-17

Page 44

Switch Hardware

3.2.5 SFCS-1000 Fan Tray

3.2.6 SFCS-1000 Temperature Sensing

The SFCS-1000 comes with a removable fan tray. The speed of each fan is

monitored by circuitry in the CEC, and is available via SNMP. In this manner,

the failure of any fan can be detected immediately. The fan tray is hot-swappable, and the entire tray may be replaced in the event of a single or multiple

fan failure. Please refer to Chapter 3, Hardware Maintenance Procedures, for

information about how to hot-swap a fan tray.

NOTE: The fans in the SFCS-200WG, and the SFCS-

200BX are not removable.

In the SFCS-1000, a built-in thermal temperature sensor resides on each

switch board and reads out the board’s local temperature. By default, the

switch control software will trigger an alarm at 65˚C and will reset the alarm

when the temperature drops back down to 60˚C. However, the user can configure these alarm and reset thresholds in the software on an individual board

via AMI. Please refer to Appendix C, AMI Operation Commands, in the

Cabletron ATM Switch Configuration Manual for more information about

configuring these thresholds. If the temperature of an individual switch board

were ever to reach 75˚C, the switch board would shut itself down immediately.

3-18

Page 45

3.2.7 SFCS-1000 Common Equipment Card (CEC)

The CEC provided with the SFCS-1000 performs several functions. Because

each SCP contains an Ethernet port, a major function of the CEC is to provide

a single, unified Ethernet port connection for all of the SCPs. The CEC is also

responsible for monitoring the environmental conditions of the switch and

reporting this information to the SCPs. The CEC reports conditions such as

malfunctioning fans, overheated power supplies, and an overheated enclosure.

3.2.7.1 CEC Front Panel

The front panel of the SFCS-1000 CEC includes the following features: alarm

relay contacts, CEC status LEDs, and an Ethernet port with four LEDS. These

features are illustrated in Figure 3.9. Refer to the following subsections for

detailed descriptions of these features.

AL1 AL2

Switch Hardware

AL1

AL2

Figure 3.9 - CEC Front Panel Status Indicators

3.2.7.2 Alarm Relay Contacts

Pins 1 and 2 are the contacts for AL1, and pins 3 and 4 are the contacts for

AL2. Although the pins are not actually labeled on an SFCS-1000 CEC, they

will be referred to as shown in Figure 3.10.

RX

LI

ETH

AL1 AL2

Pin 1 Pin 2 Pin 3 Pin 4

Figure 3.10 - Alarm Relay Contacts for AL1 and AL2

COL

POL

3-19

Page 46

Switch Hardware

Table 3.7 - Alarm Relay Contact Status During Major and Minor Alarms

Switch Powered OFF Jumped Jumped

During Boot Indeterminate Indeterminate

Normal Operation Open Open

Minor Alarm Only Jumped Open

The alarm relay contacts are normally closed when there is no power to the

switch. The user can attach alarm circuits to these contacts to trigger an external alarm in the case of an alarm condition on the switch.

The user can define AL1 and AL2 as major and minor alarm indicators and

can display which condition is alarming through the use of AMI. For more

information, please refer to the alarm configuration section in Appendix B,

AMI Configuration Commands, in the Cabletron ATM Switch Configuration

Manual.

Condition Pins 1 and 2 Pins 3 and 4

Major Alarm Only Open Jumped

Major and Minor Alarms Jumped Jumped

NOTE: In Table 1.7, “Jumped” indicates that the cir-

cuit between the indicated pins has been

closed (i.e., an external alarm would be triggered if connected to the pins).

3-20

Page 47

Switch Hardware

3.2.7.3 CEC Status LEDs

This subsection discusses the meaning of the status LEDs on the CEC of the

SFCS-1000 switch. The LEDs have been designed to provide information pertaining to the state of the switch at a glance.

SW4PS2

AL1

AL2

SW3PS1

Figure 3.11 - CEC Status LEDs

There are eight status LEDs located on the front panel of the CEC in a 2 row x

4 column arrangement. The only LEDs that are actually labeled are AL1 and

AL2, but for the purposes of discussion, the other LEDs will be referred to as

labeled in Figure 3.11. The LEDs have been broken down into the following

function groups: alarm LEDs, power supply LEDs, and switch board LEDs.

3.2.7.3.1 Alarm LEDs

The LEDs labeled AL1 and AL2 are alarm relay LEDs. During boot-up, AL1

and AL2 are in an indeterminate state. During normal operation, they will be

off. During a state of alarm, they will illuminate red. By default, AL1 is the

major alarm indicator for SPANS failure and for link failure. By default, AL2

is the minor alarm indicator for fan failure, an overtemperature condition, or

a power supply failure. The user may display and/or change these configurations through the use of AMI. For more information, please refer to the alarm

configuration section in Appendix B, AMI Configuration Commands, in the

Cabletron ATM Switch Configuration Manual.

SW2

SW1

3-21

Page 48

Switch Hardware

3.2.7.3.2 Power Supply LEDs

3.2.7.3.3 Switch Board LEDs

There are two power supply LEDs on the front panel of the CEC, one for each

power supply. The LEDs for the two power supplies should be illuminated

yellow, indicating that the CEC is on and that the power supply corresponding to that LED is functioning correctly. The LED for a failed power supply

will be extinguished. On an SFCS-1000, power supply “1” is in the slot labeled

PS1 on the enclosure, while power supply “2” is in the slot labeled PS2 on the

enclosure.

There are four switch board LEDs on the front panel of the CEC, one for each

possible switch board. These LEDs should be blinking, indicating that the

switch has booted and is operating correctly. If the SCP is removed, the LEDs

may remain in a steady-on or steady-off state. Even if the SCP has booted correctly, the LEDs will not illuminate if the SCP is running a software version

prior to 3.2.0. If the switch board in the slot corresponding to the LED is not

intended for an SFCS-1000 (e.g., it is an SFCS-200BX board), or if the entire

switch board corresponding to that LED is removed, then that LED will be

extinguished. On an SFCS-1000, the SW1 LED corresponds to switch board

“1,” which is in the slot labeled 1 on the enclosure, and so on.

3-22

3.2.7.4 Ethernet Port

The Ethernet port located on the CEC of the SFCS-1000 has a standard RJ-45

female connector and is designed to provide a single, unified Ethernet connection. It is connected via the backplane and simple Ethernet repeater to

each SCP’s Ethernet port, thus eliminating the need to attach each SCP individually. This Ethernet port has four LEDs which indicate its current status as

shown in Figure 3.12. These LEDs are described in Tables 1.8 through 1.11.

RX

LI

Figure 3.12 - CEC Ethernet Port and LEDs

COL

POL

ETH

Page 49

Table 3.8 - CEC Receive (RX) LED Description

LED Color Meaning

green The Ethernet port is receiving traffic normally.

off The Ethernet port is NOT receiving traffic.

Table 3.9 - CEC Link Integrity (LI) LED Description

LED Color Meaning

green The status of the twisted pair cable connected to

the CEC Ethernet port is OK.

off The Ethernet port is NOT receiving link integrity

pulses. Check the integrity of the connection.

Table 3.10 - CEC Collision (COL) LED Description

LED Color Meaning

Switch Hardware

red An Ethernet collision has been detected on the

CEC Ethernet port.

off No Ethernet collisions have been detected.

Table 3.11 - CEC Polarity (POL) LED Description

LED Color Meaning

amber A reverse polarity condition has been detected on

the twisted pair cable connected to the CEC Ether-

net port. The polarity is automatically corrected,

but the amber light will remain illuminated until a

corrected twisted pair cable is inserted into the

Ethernet port.

off The polarity of the twisted pair cable connected to

the CEC Ethernet port is OK.

3-23

Page 50

Switch Hardware

3-24

Page 51

CHAPTER 4 Switch Setup

This chapter describes how to handle and set up a Cabletron ATM switch

prior to its operation.

4.1 Introduction

Before installing a Cabletron ATM switch, there are several important factors

that must be taken into consideration, depending on the type of installation

site. The following sections discuss in detail how to install a Cabletron ATM

switch and any prerequisites to the installation.

NOTE: It is important to read through the ENTIRE

installation procedure before attempting to

turn on the power to the unit.

4.2 Unpacking

Upon receipt of, and before opening your Cabletron ATM switch, inspect the

package for any damage that may have occurred during shipping. If the package shows any signs of external damage or rough handling, notify your carrier’s representative.

When unpacking your Cabletron ATM switch, be sure to keep all original

packing materials. They may be needed for storing, transporting, or returning

the product.

4-1

Page 52

Switch Setup

4.2.1 Inventorying the Unit

A complete inventory of the Cabletron ATM switch package should be performed before any power is supplied to the unit.

The Cabletron ATM switch package should contain the following:

• Cabletron ATM switch

• Cabletron ATM Switch User’s Manual (this manual)

• Cabletron ATM Switch Configuration Manual

• Power cords

• International power cords (optional)

1

1

• Modem serial cable

• Anti-static grounding strap

• Product registration card

• Rack-mount kit (standard with an SFCS-200BX)

2

The rack-mount kit should contain the following:

• 1 left rack-mount bracket

• 1 right rack-mount bracket

• 1 cable strain relief rail

• 6 Phillips-head screws

If any of the items listed above are missing or damaged, please contact

Cabletron Systems’ Technical Support immediately.

1. The SFCS-200WG comes with one power cord (or international power cord). The SFCS200BX and the SFCS-1000 each come with two power cords (or international power

cords).

2. The rack-mount kit is not applicable to the SFCS-1000. The rackmount kit is optional for

the SFCS-200WG and may be purchased separately.

4-2

Page 53

4.3 Electrical Considerations

The following items should be considered when setting up the switch:

CAUTION Consideration should be given to the connec-

tion of the equipment to the supply circuit and

the effect that the overloading of circuits could

have on overcurrent protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when

addressing this concern.

CAUTION Reliable grounding of rack-mounted equip-

ment should be maintained. Particular

attention should be given to supply connections other than direct connections to the

branch (i.e., use of power strips).

Switch Setup

4-3

Page 54

Switch Setup

4.4 Rack-Mounting an SFCS-200BX

The SFCS-200BX is designed to be installed either as a stand-alone unit placed

on the desktop, or as a rack-mounted unit using the included rack-mount kit

(refer to section 4.2.1). The following items should be addressed when rackmounting this switch:

WARNING! When rack-mounting equipment, make sure

that a hazardous condition is not created due

to uneven weight distribution.

CAUTION To prevent damage to your equipment,

Cabletron Systems recommends that the maximum operating temperature not exceed 40˚C.

Consideration must be made if the switch is to

be installed in a closed or multi-unit rack

assembly, because the ambient temperature of

the rack environment may be greater than the

room ambient temperature.

4-4

CAUTION Take care not to block the air vents of the

switch, as this would compromise the amount

of air flow required for proper cooling.

4.4.1 Required Tools

A set of rack-mount brackets, a cable relief strain rail, and 6 Phillips-head

screws are supplied with each SFCS-200BX for rack-mounting the unit. You

will need to supply a Phillips screwdriver.

WARNING! To prevent user injury and possible damage to

equipment, Cabletron Systems recommends

that at least two people be present when rackmounting the SFCS-200BX.

Page 55

4.4.2 Installing the Rack-mount Brackets

To install the rack-mount brackets and cable relief strain rail, use the following procedure:

1. Carefully place the SFCS-200BX unit upside down on a clean, flat,

sturdy work surface with the front of the unit still facing front.

2. Using a Phillips screwdriver, remove the four feet from the bottom

of the unit.

3. Each rack-mount bracket has three screws that secure the bracket

to the bottom of the unit. The screw closest to the front of the unit

is used to secure the bracket to the bottom of the unit as well as

secure the cable relief strain rail to the front of the unit. Tighten the

three screws to secure the left bracket, marked HWST0027-0001,

and the left side of the cable relief strain rail to the left side of the

unit. Tighten the three screws to secure the right bracket, marked

HWST0027-0002, and the right side of the cable relief strain rail to

the right side of the unit.

CAUTION When attaching the rack-mount brackets, the

use of screws other than those provided could

result in damage to the unit.

Switch Setup

4. Once the brackets and the cable relief strain rail are secure, choose

a rack position for the SFCS-200BX. The SFCS-200BX should be

placed right side up in the rack with the front of the unit facing

forward.

CAUTION When it is mounted in the equipment rack, do

not use the SFCS-200BX chassis to support

other equipment. This could overload the