Page 1

MRXI-22 AND MRXI-24

The Complete Networking Solution™

10BASE-T HUB

USER’S GUIDE

CABLETRON SYSTEMS, P. O. Box 5005, Rochester, NH 03867-5005

Page 2

Page 3

NOTICE

Cabletron Systems reserves the right to make changes in specifications and other information

contained in this document without prior notice. The reader should in all cases consult Cabletron

Systems to determine whether any such changes have been made.

The hardware, firmware, or software described in this manual is subject to change without notice.

IN NO EVENT SHALL CABLETRON SYSTEMS BE LIABLE FOR ANY INCIDENTAL,

INDIRECT, SPECIAL, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT

NOT LIMITED TO LOST PROFITS) ARISING OUT OF OR RELATED TO THIS MANUAL OR

THE INFORMATION CONTAINED IN IT, EVEN IF CABLETRON SYSTEMS HAS BEEN

ADVISED OF, KNOWN, OR SHOULD HAVE KNOWN, THE POSSIBILITY OF SUCH

DAMAGES.

© Copyright May 1993 by:

Cabletron Systems Inc.

P.O. Box 5005, Rochester, NH 03867-5005

All Rights Reserved

Printed in the United States of America

Order Number: 9030637-01 May 93

Remote LANVIEW, LANVIEW

Systems, Inc.

MRXI

and

MMAC

IBM

is a registered trademark of International Business Machines Corporation.

CompuServe

DEC, VT200

Ethernet

Hayes

Windows

is a trademark of Xerox Corporation.

is a trademark of Hayes Microcomputer Products Inc.

is a registered trademark of Microsoft Corporation

are trademarks of Cabletron Systems, Inc.

is a registered trademark of CompuServe.

, and

VT300

, and

SPECTRUM

are trademarks of Digital Equipment Corporation.

are registered trademarks of Cabletron

i

Page 4

NOTICE

FCC NOTICE

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

NOTE:

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment uses, generates, and can radiate radio frequency energy and if not installed in accordance

with the operator’s manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause interference in which case the user will be required

to correct the interference at his own expense.

WARNING

party responsible for compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

: Changes or modifications made to this device which are not expressly approved by the

DOC NOTICE

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage radioélectrique

édicté par le ministère des Communications du Canada.

ii

Page 5

CONTENTS

CHAPTER 1 INTRODUCTION

1.1 USING THIS MANUAL................................................................1-1

1.2 GETTING HELP..........................................................................1-2

1.3 THE 10BASE-T MRXI .................................................................1-2

1.4 LANVIEW LEDs AND LCD DISPLAY..........................................1-4

1.5 LOCAL MANAGEMENT..............................................................1-4

1.6 NETWORK MANAGEMENT CAPABILITIES..............................1-4

1.7 RELATED MANUALS..................................................................1-5

CHAPTER 2 INSTALLATION

REQUIREMENTS/SPECIFICATIONS

2.1 NETWORK REQUIREMENTS....................................................2-1

2.2 SELECTING A LOCATION FOR THE MRXI...............................2-1

2.3 NETWORK GUIDELINES ...........................................................2-2

2.3.1 10BASE-T Twisted Pair Network Requirements ............2-2

2.3.2 Multi Mode Fiber Optic Network Requirements..............2-3

2.3.3 Single Mode Fiber Optic Network Requirements............ 2-4

2.3.4 Thin-Net Network Requirements ....................................2-5

2.3.5 Transceiver Requirements.............................................. 2-6

2.3.6 AUI Cable Requirements................................................2-6

2.4 OPERATING SPECIFICATIONS ................................................2-7

CHAPTER 3 INSTALLATION

3.1 UNPACKING THE MRXI.............................................................3-1

3.2 ATTACHING THE STRAIN RELIEF BRACKET..........................3-1

3.3 INSTALLING THE MRXI .............................................................3-2

3.3.1 Rack Mounting the MRXI................................................3-2

3.3.2 Wall Mounting the MRXI.................................................3-3

3.3.3 Free-Standing Installation...............................................3-5

3.4 CONNECTING THE MRXI TO THE POWER SOURCE.............3-6

3.5 CONNECTING THE MRXI TO THE NETWORK.........................3-6

3.5.1 Connecting the Network Port Cabling............................. 3-7

3.5.2 Connecting a Twisted Pair Segment to an EPIM-T ........3-8

3.5.3 Connecting an AUI Cable to an EPIM-X.......................3-10

3.5.4 Connecting a Fiber Optic Link Segment to an

EPIM-F1, EPIM-F2, or EPIM-F3...................................3-11

3.5.5 Connecting a Thin-Net Segment to an EPIM-C............3-13

3.5.6 Connecting an AUI Cable to an EPIM-A.......................3-14

3.6 FINISHING THE INSTALLATION..............................................3-15

iii

Page 6

CONTENTS

CHAPTER 4 TESTING AND TROUBLESHOOTING

4.1 INSTALLATION CHECK-OUT.....................................................4-1

4.2 TESTING SEGMENTS ATTACHED TO THE MRXI....................4-2

4.3 USING LANVIEW ........................................................................4-5

4.4 THE LCD DISPLAY .....................................................................4-6

CHAPTER 5 LOCAL MANAGEMENT

5.1 TERMINAL CONFIGURATION....................................................5-1

5.1.1 Console Cable Configuration ..........................................5-3

5.1.2 Modem Cable Configuration............................................5-5

5.1.3 Cable Configuration for UPS...........................................5-5

5.2 ACCESSING LOCAL MANAGEMENT ........................................5-6

5.3 COMMUNITY NAME TABLE.......................................................5-7

5.3.1 Accessing the Community Name Table Screen..............5-8

5.3.2 Community Name Table Screen Fields...........................5-8

5.3.3 Editing the Community Name Table Screen...................5-9

5.4 CONFIGURING THE MRXI .......................................................5-10

5.4.1 Accessing the Configuration Screen.............................5-10

5.4.2 Configuration Screen Fields..........................................5-11

5.4.3 Setting the IP Address Table and SubNET Mask Field.5-12

5.4.4 Setting the Default Gateway..........................................5-13

5.4.5 Setting the UPS Option.................................................5-13

5.4.6 Using the Port LOCK Override Option ..........................5-14

5.4.7 Using the Port ENABLE Override..................................5-14

5.5 SETTING THE TRAP TABLE ....................................................5-15

5.5.1 MRXI Trap Table Screen...............................................5-15

5.5.2 Trap Table Screen Fields..............................................5-16

5.5.3 Configuring the Trap Table............................................5-16

5.6 SNMP TOOLS ...........................................................................5-17

5.6.1 Accessing the SNMP Tools Screen ..............................5-18

5.6.2 SNMP Tools Screen Fields...........................................5-18

5.6.3 Using SNMP Tools........................................................5-19

5.7 COMMAND LINE INTERFACE (CLI).........................................5-22

iv

Page 7

CHAPTER 1

INTRODUCTION

Welcome to the Cabletron Systems

HUB User’s Guide

. This manual provides installation instructions and

MRXI-22 and MRXI-24 10BASE-T

presents reference information for the MRXI-22 and MRXI-24

10BASE-T Hubs.

Note

: Throughout this manual the term MRXI is used to cover both the

MRXI-22 and MRXI-24 unless otherwise specified.

1.1 USING THIS MANUAL

Read through this manual completely to familiarize yourself with its

content and to gain an understanding of the features and capabilities of

the MRXI. A general working knowledge of Ethernet and IEEE 802.3

type data communications networks and their physical layer components

will be helpful when installing the MRXI.

Chapter 1,

Introduction

describes features of the MRXI, and concludes with a list of related

manuals.

, outlines the contents of this manual, briefly

Chapter 2,

Requirements/Specifications

, describes installation

requirements, network guidelines, and MRXI operating specifications.

Chapter 3,

Installation

, contains instructions for installing your MRXI

and connecting it to the network using the various media types.

Chapter 4,

Testing and T r oubleshooting,

contains procedures for testing

the MRXI after installation, a description of the LANVIEW ™ LEDs, and

explains the use of the front panel LCD display.

Chapter 5,

Local Management,

describes how to access Local

Management. It also describes each of the Local Management screens and

the available commands.

1-1

Page 8

INTRODUCTION

MRXI-24

10BASE-T HUB with LANVIEW

1.2 GETTING HELP

If you need additional support related to the MRXI-22 or MRXI-24, or if

you have any questions, comments, or suggestions concerning this

manual, feel free to contact Cabletron Systems Technical Support:

By phone ..........................(603) 332-9400

Monday-Friday; 8am - 8pm EST

®

By CompuServe

.............GO CTRON from any ! prompt

By Internet mail ...............support@ctron.com

1.3 THE 10BASE-T MRXI

The MRXI-22 and MRXI-24 are functionally identical. The MRXI-22

provides twelve RJ-45 connectors and the MRXI-24 provides twenty-four

RJ-45 connectors for network ports. Additional network connections are

made through the use of front panel EPIM modules (one module for the

MRXI-22, two modules for the MRXI-24). A variety of EPIMs are

available permitting the expansion of an Ethernet/802.3 network via:

• Unshielded Twisted Pair Cable from the 10BASE-T Twisted Pair

Interface Module (EPIM-T).

• Fiber Optic Cable, with SMA or ST connectors, from the Fiber Optic

Interface Modules (EPIM-F1, EPIM-F2 or EPIM-F3).

• Thin-Net Cable from the Coaxial Interface Module (EPIM-C).

• AUI Cable from the AUI Interface Module (EPIM-A or

EPIM-X).

The Complete Networking Solution

Figure 1-1 The MRXI-24

1-2

Page 9

INTRODUCTION

The MRXI fully conforms to the IEEE 802.3 Repeater, AUI, and

10BASE-T specifications, and provides the flexibility to connect

networks using IEEE 802.3, Ethernet Version 1 or Version 2 equipment. A

Repeater Interface Controller (RIC) in the MRXI provides full 802.3

repeater capabilities integrated into a single chip. The MRXI transmits

re-timed data packets, regenerates the preamble, extends fragments, and

arbitrates collisions.

The MRXI automatically partitions problem segments, and reconnects

non-problem segments to the network. This feature minimizes the impact

on network operation resulting from a problem on one segment by

isolating the problem segment. Only devices on the problem segment are

affected. When the problem is solved, the MRXI automatically reconnects

the isolated segment to the network.

Since the MRXI utilizes polarity detection and correction, the twisted pair

connections are not sensitive to signal polarity. The network will still

function properly with the (+) and (–) lines within a pair reversed.

Operating in this condition is not recommended and if this condition is

discovered, the segment should be removed from the network and wired

correctly by a technician. This reduces the potential for problems in the

future if equipment changes are made. Connector pinouts are provided in

Chapter 2,

Installation Requirements / Specifications

.

You can configure the two front panel serial ports to support an SNMP

proxy for Uninterruptible Power Supplies (UPS) or the Serial Line

Internet Protocol (SLIP). MIB II and RMON support are built into the

MRXI for network analyzer functionality. In addition, Cabletron’s

Distributed LAN Monitor (DLM), a software option for the MRXI,

provides a method for locally polling and monitoring devices on a LAN to

minimize network management traffic on an enterprise, campus, or wide

area network.

The MRXI uses Flash EEPROMs that allow you to download new and

updated firmware using Cabletron Systems Remote

LANVIEW/Windows, version 2.3 or later or any device using BOOTP or

TFTP protocols.

The front panel of the MRXI also has a reset switch to initialize the

processor.

1-3

Page 10

INTRODUCTION

1.4 LANVIEW LEDS AND LCD DISPLAY

Cabletron Systems’ LANVIEW Status Monitoring and Diagnostics

System is a convenient troubleshooting tool that helps you diagnose

power failures, collisions, cable faults, and link problems.

The front panel LCD display provides information about the MRXI such

as power up diagnostics, re vision lev els, MA C and IP addresses, and error

alerts.

1.5 LOCAL MANAGEMENT

There are two RJ-45 ports on the front panel of the MRXI that let you

™

access Local Management by connecting a DEC VT

PC using VT320 emulation software. Refer to Chapter 5,

Management

.

320 terminal or a

Local

1.6 NETWORK MANAGEMENT CAPABILITIES

The MRXI can be controlled and managed by any SNMP network

management system. These include:

• Cabletron Systems SPECTRUM

• Cabletron Systems Remote LANVIEW®/Windows

• Cabletron Systems Remote LANVIEW® for SunNet™ Manager

• Third Party SNMP compliant Network Management Packages

The MRXI network management capabilities provide the necessary

management tools for the MRXI to operate at its full capacity . Your ability

to set up parameters with network management ensures optimal

performance of the MRXI.

For example, you can gather a large amount of statistical information

about the MRXI, including the number of:

• Packets • Receive Collisions

• Transmit Collisions • Giant Packets

• Runt Packets • Misaligned Packets

• CRC Errors • Out of Window Collisions

• Bytes Received

®

™

1-4

Page 11

INTRODUCTION

For specific information, refer to the applicable network management

package user’s manual.

1.7 RELATED MANUALS

Use the following manual to supplement the procedures and other

technical data provided in this manual. The procedures contained in the

following manual are referenced where appropriate, but not repeated in

this manual.

Cabletron Systems

LAN-MD Portable Ethernet Tester

User's Manual.

1-5

Page 12

INTRODUCTION

1-6

Page 13

CHAPTER 2

INSTALLATION

REQUIREMENTS/SPECIFICATIONS

This chapter describes network guidelines, power requirements, and

operating specifications for the MRXI. Be sure that you read this chapter

before you install the MRXI. Your network must meet the requirements

and conditions specified in this chapter to obtain satisfactory performance

from this equipment. Failure to follow these guidelines could result in

poor network performance.

2.1 NETWORK REQUIREMENTS

When connecting a network segment to the MRXI, via a transceiver and

an AUI cable, the following network requirements must be met:

• The transceivers used to connect the MRXI meet Ethernet Version 2 or

IEEE 802.3 standards.

• The AUI cables connecting the MRXI to the transceivers on the

network match the transceiv er type on the netw ork se gment, Ethernet

Version 1, Version 2, or IEEE 802.3 type cables, and do not exceed 50

meters in length.

2.2 SELECTING A LOCATION FOR THE MRXI

You can mount the MRXI on a wall, a 19-inch rack, or place it on any

horizontal surface. If you choose not to install the MRXI in a 19-inch

rack, the location must be within reach of the network cabling and meet

the requirements listed below:

• An unrestricted free surface area at least 21 inches wide, 18 inches

deep, and 6 inches high is needed.

• A single phase 120 Vac, 15A, grounded power receptacle must be

located within 7 feet of the location.

• If you use a shelving unit, it must be able to support 30 pounds of static

weight.

• The temperature for the selected location must be maintained between

°

and 50°C, and fluxuate less than 10°C per hour.

5

2-1

Page 14

INSTALLATION REQUIREMENTS/SPECIFICATIONS

2.3 NETWORK GUIDELINES

Take care in planning and preparing the connections and the cables for

your network. The quality of the connections, the length of the cables, and

the location of the MRXI are critical factors in determining the reliability

of your network. The following sections describe the network guidelines

to operate this equipment.

2.3.1 10BASE-T Twisted Pair Network Requirements

The device at the other end of the twisted pair segment must meet IEEE

802.3 10BASE-T specifications. When you connect a 10BASE-T T wisted

Pair Segment to the MRXI’s 10BASE-T Twisted Pair Ports, the following

network requirements must be met:

Length

•

10BASE-T devices transmit over a

- The IEEE 802.3 10BASE-T standard requires that

100 meter

(328 foot) link using

22-24 AWG unshielded twisted pair wire. As a general rule, links up

to 130 meters in length for unshielded twisted pair and 200 meters in

length for shielded twisted pair are achiev able. For each connector or

patch panel in the link, subtract 12 meters from the 150 meter limit.

This allows for links of up to 126 meters using standard 24 AWG UTP

wire and two patch panels within the link. Higher quality low

attenuation cables may be required when using links of greater than

126 meters. Due to cable delay, the maximum link length is always

limited to 200 meters, regardless of the cable type.

Insertion Loss

•

- The maximum insertion loss allowed for a

10BASE-T link is 11.5 dB at all frequencies between 5.0 and 10 MHz.

This includes the attenuation of the cables, connectors, patch panels,

and reflection losses due to impedance mismatches in the link

segment.

Impedance

•

- Unshielded twisted pair cables typically have an

impedance of between 85 to 110 ohms. Shielded twisted pair cables,

such as IBM T ype 1 cable, can also be used. You should remember that

the impedance of IBM Type 1 cable is typically 150 ohms. This

increases the signal reflection caused by the cable, but since the cable

is shielded, this signal reflection has little effect on the received

signal’ s quality due to the lack of crosstalk between the shielded cable

pairs. Cabletron Systems 10BASE-T Twisted Pair products will work

on twisted pair cable with 75 to 165 ohms impedance.

2-2

Page 15

INSTALLATION REQUIREMENTS/SPECIFICATIONS

•

Jitter

- Intersymbol interference and reflections can cause jitter in the

bit cell timing, resulting in data errors. A 10BASE-T link must not

generate more than 5.0 nsec. of jitter. If your cable meets the

impedance requirements for a 10BASE-T link, jitter should not be a

concern.

•

Delay

- The maximum propagation delay of a 10B ASE-T link segment

must not exceed 1000 nsec. This 1000 nsec. maximum delay limits the

maximum link segment length to no greater than 200 meters.

Crosstalk

•

- Crosstalk is caused by signal coupling between the

different cable pairs contained within a multi-pair cable bundle.

10BASE-T transcei v ers are designed so that the user does not need to

be concerned about cable crosstalk, provided the cable meets all other

requirements.

•

Noise -

Noise can be caused by either crosstalk or externally induced

impulses. Impulse noise may cause data errors if the impulses occur at

very specific times during data transmission. Generally, the user need

not be concerned about noise. If noise-related data errors are

suspected, it may be necessary to either reroute the cable or eliminate

the source of the impulse noise.

Temperature

•

- Multi-pair PVC 24 AWG telephone cables typically

have an attenuation of approximately 8 to 10 dB/100m at 20

F). The attenuation of PVC insulated cable varies significantly with

°

temperature. At temperatures greater than 40

C (104° F), it is strongly

recommended that you use plenum-rated cables to ensure that cable

attenuation remains within specification.

°

C (78°

2.3.2 Multi Mode Fiber Optic Network Requirements

When you connect a Fiber Optic Link Segment to the MRXI with a Single Port

Fiber Optic Interface Module (EPIM-F1 or EPIM-F2), the following network

requirements must be met:

•

Cable T ype

one of the following multimode fiber optic media:

- 50/125

- 62.5/125

- 100/140

- The EPIM-F1 and EPIM-F2 are designed for use with

µ

m fiber optic cabling.

µ

µ

m fiber optic cabling.

m fiber optic cabling.

2-3

Page 16

INSTALLATION REQUIREMENTS/SPECIFICATIONS

•

Attenuation

- The fiber optic cable must be tested with a fiber optic

attenuation test set that is adjusted for an 850 nm wavelength. This test

verifies that the signal loss in a cable is within an acceptable level:

- 13.0 dB or less for 50/125 fiber cable segment.

- 16.0 dB or less for 62.5/125 fiber cable segment.

- 19.0 dB or less for 100/140 fiber cable segment.

Budget and Propagation Delay

•

- When determining the maximum

fiber optic cable length, the fiber optic budget delay and total network

propagation should be calculated and taken into consideration before

fiber optic cable runs are incorporated in any network design. Fiber

optic budget is the combination of the optical loss due to the fiber optic

cable, in-line splices, and fiber optic connectors. Propagation delay is

the amount of time it takes a packet to travel from the sending device

to the receiving device.

•

Length

- The maximum allowable fiber optic cable length is

2 km. Howe ver, IEEE 802.3 specifications allow for a maximum of 1

km.

2.3.3 Single Mode Fiber Optic Network Requirements

When you connect a Single Mode Fiber Optic Link Segment to the MRXI

with a Fiber Optic Ethernet Port Interface Module (EPIM-F3), the

following network requirements must be met:

µ

• The fiber optic link segment should consist of 8/125 - 12/125

µ

single mode

m fiber optic cabling. You can also use 62.5/125 µm

m

multi mode cable, howe ver optical loss will be greater with multi mode

cable and distances will be limited to 2 km.

• The fiber optic cable must be tested with a fiber optic attenuation test

set that is adjusted for a 1300 nm wave length. This test verifies that

the signal loss in a cable is within an acceptable level of 10.0 dB or less

for any given single mode fiber optic link.

• When determining the maximum fiber optic cable length, the fiber

optic budget (total loss of 10.0 dB or less between stations) and total

network propagation delay should be calculated and considered before

fiber runs are incorporated in any network design.

2-4

Page 17

INSTALLATION REQUIREMENTS/SPECIFICATIONS

• Fiber optic budget is the combination of the optical loss due to the fiber

optic cable, in-line splices, and fiber optic connectors (the loss for each

splice and connector is typically 1 dB or less).

• Propagation delay is the amount of time it takes a packet to trav el from

the sending device to the receiving device. Total propagation delay

µ

allowed for the entire network is 25.6

delay between any two nodes on the network e xceeds 25.6

sec. If the total propagation

µ

sec, then

bridges should be used.

• When using single mode fiber optic cable, segment lengths up to 10

km are possible if system budgets are met. However, IEEE 802.3

FOIRL specifications allow for a maximum length of 1 km.

2.3.4 Thin-Net Network Requirements

When you connect a Thin-net segment to the MRXI with a Coax Interface

Module (EPIM-C), the following network requirements must be met:

•

Cable T ype

- 50 ohm RG-58A/U type coaxial cable must be used

when making up a thin-net cable segment.

•

Length

•

Terminations

- The thin-net segment must be no longer than 185 meters.

- A 50 ohm terminator must be connected to the far end

of each thin-net segment.

•

Connections

- A maximum of 29 tee-connectors may be used

throughout the length of cable segment for host connections. If an

excessive number of barrel connectors are used within the cable

segment, such as finished wall plates with BNC feed-throughs, then a

reduced number of host connections may be required. For special

network design, contact Cabletron Systems Technical Support.

Grounding

•

- For safety, only one end of a thin-net segment should be

connected to earth ground. Connection to earth ground at more than

one point on the segment could produce dangerous ground currents.

The BNC ports of the Coaxial Interface Modules are not connected to

earth ground.

Warning

ground. Only one end of the shield should be connected to earth ground.

Multiple ground paths can introduce noise or a hazardous voltage

potential onto the cable.

: Do not connect the shield at both ends of a thin net segment to

2-5

Page 18

INSTALLATION REQUIREMENTS/SPECIFICATIONS

2.3.5 Transceiver Requirements

When you connect an external network segment, via a transceiver, to the

MRXI with an EPIM-A, the following requirements must be met:

• The transceiver or Ethernet Device to which the module will be

connected must meet IEEE 802.3 standards, and/or Ethernet Version

1.0 or Version 2.0 standards.

• The Signal Quality Error (SQE) test function on the transceiver must

be disabled if you connect it to a repeater or to an Ethernet Version 1.0

device. In addition, some Version 2.0 equipment does not support the

SQE test. Devices that do not support SQE test interpret the SQE test

pulse as a collision.

2.3.6 AUI Cable Requirements

When you connect an external network segment to the MRXI with an

EPIM-A or EPIM-X, the AUI cable must meet the following

requirements:

AUI Cable

•

- The AUI cable connecting the module to a device must

be IEEE 802.3 type cable.

•

Length - The AUI Cable must not exceed 50 meters in length. If 28

AWG thin office drop AUI cable is used, then the maximum cable

length is limited to 50 feet (15.24 meters).

• Grounding - The connector shell of the EPIM-A and the EPIM-X are

connected to ground.

2-6

Page 19

INSTALLATION REQUIREMENTS/SPECIFICATIONS

2.4 OPERATING SPECIFICATIONS

The operating specifications for the MRXI are described in this section.

Cabletron Systems reserves the right to change these specifications at any

time without notice.

GENERAL

Operating System Memory: 4 MB

Internal Processor: Intel 80C960CA operating at

24 MHz

Ethernet Controller: National Semiconductor

DP83932

Static RAM: 128 KB with battery back-up

EPROM: 128 KB

FLASH MEMORY: 2 MB

Delay Times (Start of Packets):

Twisted Pair to EPIM- A 900 nsec.

Twisted Pair to Twisted Pair 1 msec.

EPIM-A to Twisted Pair 750 nsec.

Delay Times (JAM):

Twisted Pair to EPIM-A 1.16 msec.

Preamble:

Input: Minimum of 40 bits required.

Output: 64 bits min. (last 2 bits are 1, 1).

2-7

Page 20

INSTALLATION REQUIREMENTS/SPECIFICATIONS

JAM Output: Collisions are propagated through the

network using the JAM signal of an

alternating pattern of 1's and 0's in

accordance with 802.3 specifications for a

repeater unit.

Fragment Extension: Packet fragments are extended to a

minimum of 96 bits using the JAM [1,0].

Fault Protection: Each segment will disconnect itself from

the other segments if 31 consecutive

collisions occur, or if the collision detector

of a segment is on for longer than

approximately 110 µs. This fault

protection will reset automatically after

one packet is transmitted/receiv ed onto the

fault protected segment without causing a

collision.

INTERFACE CONNECTORS

Network (Twisted Pair) Interface

Type: Internally Crossed Over RJ-45 Connector

Pin-out for RJ-45 Connector

Pin 1 RX+ 5 No Connection

2 RX- 6 TX3 TX+ 7 No Connection

4 No Connection 8 No Connection

2-8

Page 21

INSTALLATION REQUIREMENTS/SPECIFICATIONS

Ethernet Port - EPIM-T (10BASE-T Twisted pair Port)

Internal Cabletron Systems TPT-T™ 10BASE-T Twisted

Transcei v er: Pair T ranscei v er

Type: Pin RJ-45 Connector

The slide switch on the EPIM-T determines if the cable pairs are

internally swapped in the module. If the switch is on the X side, the

pairs are swapped. If the switch is on the II side, the pairs are not

internally swapped.

Pin-outs for RJ-45 connector

Position II (not crossed over) Position X (crossed over)

1 TX+ 5 NC 1 RX+ 5 NC

2 TX- 6 RX- 2 RX- 6 TX3 RX+ 7 NC 3 TX+ 7 NC

4NC 8NC 4NC 8NC

Ethernet Port - EPIM-F1 or EPIM-F2 (Fiber Optic Port)

Internal Cabletron Systems FOT-F™ Fiber Optic

Transceiver: Transceiver

Type: EPIM-F1 (SMA fiber optic ports)

EPIM-F2 (ST fiber optic ports)

Parameter Typical Worst Worst Case Typical

Value Case Budget Budget

Receive

Sensitivity: -30.5 dBm -28.0 dBm — —

Peak Input

Power: -7.6 dBm -8.2 dBm — —

2-9

Page 22

INSTALLATION REQUIREMENTS/SPECIFICATIONS

Parameter Typical Worst Worst Case Typical

Value Case Budget Budget

Transmitter Power

50/125 µm

fiber: -13.0 dBm -15.0 dBm 13.0 dB 17.5 dB

62.5/125 µm

fiber: -10.0 dBm -12.0 dBm 16.0 dB 20.5 dB

100/140 µm

fiber: -7.0 dBm -9.0 dBm 19.0 dB 23.5 dB

Error Rate: Better than 10

Note: The transmitter power levels and receive sensitivity levels listed

above are Peak Power Levels after optical overshoot. A Peak Power

Meter must be used to correctly compare the values giv en abo v e to those

measured on any particular port. If P o wer Le vels are being measured with

an Av erage Power Meter, then 3 dBm must be added to the measurement

to correctly compare those measured values to the values listed above

(i.e. -30.5 dBm peak=-33.5 dBm average).

-10

Ethernet Port - EPIM-F3

Internal

Transceiver: Cabletron Systems FOT-F3™ Fiber Optic Transceiver

Type: ST fiber optic ports.

Note: Transmitter Power decreases as temperatures rise and increases

as temperatures fall. Use the Output Power Coefficient to calculate

increased or decreased power output f or y our oper ating environment. For

example, the typical power output at 25° C is -16.4 dBm. For a 4° C

temperature increase, multiply the typical coefficient (-0.15 dBm) by four

and add the result to typical output power (4 x -0.15 dBm + -16.4 = -17.0).

2-10

Page 23

Receive

C

Sensitivity

Maximum

Receive

Input Power

INSTALLATION REQUIREMENTS/SPECIFICATIONS

Maximum Sensitivity (-36.0)

Typical Sensitivity (-31.0)

Minimum Sensitivity (-30.0)

Minimum Receive Input (-9.72)

Typical Receive Input (-7.5)

Maximum Receive Input (-6.99)

Transmitter Power*

(At 25°C into

8.3/125µm fiber)

* Transmit Power Typical Power Minimum Power Maximum Power

Coefficient

(See Note Below)-0.15dBm/ °C -0.12 dBm/ °C-0.18 dBm/ °

dBm

Less Power

-40 -35 -30 -25 -20 -15 -10 -5 0

Maximum Transmit Power (-12.0)

Typical Transmit Power (-15.5)

Minimum Transmit Power (-21.0)

More Power

Parameter Typical Minimum Maximum

Transmitter Peak

Wave Length 1300 nm 1270 nm 1330 nm

Spectral Width 60 nm - 100 nm

Rise Time/ 3.0 nsec 2.7 nsec 5.0 nsec

Fall Time 2.5 nsec 2.2 nsec 5.0 nsec

Duty Cycle 50.1% 49.6% 50.7%

Bit Error Rate: Better than 10

Note: The transmitter power levels given above are Peak Power Levels

after optical overshoot. You must use a Peak Power Meter to correctly

compare the values given above to those measured on any particular

port. If you are measuring power le v els with an A v er age P o wer Meter , add

3 dBm to the average power measurement to correctly compare the

average power values measured to the values listed above (i.e. -33.5

dBm average + 3 dB = -30.5 dBm peak).

-10

2-11

Page 24

INSTALLATION REQUIREMENTS/SPECIFICATIONS

Ethernet Port - EPIM-C (BNC Port)

Internal

Transcei v er: Cabletron Systems TMS-3™ Transceiv er.

Termination: The port on the module can be internally

terminated, to an internal 50 Ohm terminator,

utilizing the switch located to the left of the

port. This eliminates the need to connect the

port to a Tee Connector and terminator.

Type: BNC receptacle, with gold center contact, for

use with BNC type tee-connectors and RG-58

thin-net cable.

Grounding: For safety, only one end of a thin-net segment

should be connected to earth ground.

Connection to earth ground at more than one

point on the segment may cause dangerous

ground currents.

The BNC port of the Coaxial Interface

Modules is not connected to earth ground.

Ethernet Port - EPIM-A and EPIM-X (AUI Port)

Interface DB-15 Port (male connector for EPIM-A,

Connector: female connector for EPIM-X)

Type: 15 position D type receptacle

Pin 1 Logic Ref. 9 Collision -

2 Collision + 10 Transmit 3 Transmit 11 Logic Ref.

4 Logic Ref. 12 Receive 5 Receive + 13 Power (+12Vdc)

6 Power Return 14 Logic Ref.

7 No Connection 15 No Connection

Connector Shell: Protective Ground

2-12

Page 25

INSTALLATION REQUIREMENTS/SPECIFICATIONS

Console Port

The RJ-45 Console port supports access to a Local Management

Console. The Console port supports a Digital Equipment

Corporation, VT 320™ terminal or PC emulation of the VT 320™

terminal.

Type: 8 pin RJ-45 Port

Pin 1 Not Used 5 Signal Ground (SG)

2 Data Terminal Ready (DTR)6 Receive Data (RX)

3 Transmit Data (TX) 7 Data Set Ready (DSR)

4 Not Used 8 Not Used

Modem Port

The RJ-45 Modem Port supports access to Local Management via a

Hayes compatible modem. You can also use this port to support an

Uninterruptible Power Supply (UPS).

Type: 8 pin RJ-45 Port

Pin 1 Transmit Data 5 Signal Ground (SG)

2 Data Carrier Detect (DCD) 6 Data Terminal Read(DTR)

3 Not Used 7 Not Used

4 Receive Data (RX) 8 Ring Detect

LANVIEW INDICATORS

PWR (green): Indicates that the repeater is receiving

power.

LNK (green): Indicates that a link has been

established between the module and

the 10BASE-T device at the other end

of the twisted pair segment. This LED

remains lit as long as the link is

maintained.

2-13

Page 26

INSTALLATION REQUIREMENTS/SPECIFICATIONS

RCV (yellow): Indicates that the repeater is receiving

a data packet on that segment.

CPU (flashing green): This LED alternates from red to green

during power up. After the boot is

complete, the LED flashes green. A

flashing green LED indicates normal

operation. A red LED indicates a fault

in the processor.

POWER SUPPLY REQUIREMENTS

Note: The MRXI has a universal power supply. This unit allows y ou to use

an input power from 85 to 264 VAC, 47-63 Hz.

Parameter Typical Worst

Value Case

Input Current: 0.5 A 0.75 A

Overload Protection - Output: (1) 2AG 1 amp fuse.

ENVIRONMENTAL REQUIREMENTS

Operating Temperature: +5° to +50° C

Non-operating Temperature: -30° to +90° C

Operating Humidity: 5 to 95% (non-condensing)

SAFETY

Designed in accordance with UL478, UL910, NEC 725-2(b), CSA,

IEC, TUV, VDE class A. Meets FCC part 15, Class A limits.

Warning: It is the responsibility of the person who sells the system to

which the MRXI will be a part to ensure that the total system meets

allowed limits of conducted and radiated emissions.

2-14

Page 27

INSTALLATION REQUIREMENTS/SPECIFICATIONS

SERVICE

MTBF (MHBK-217D): >70,040 hrs. projected

MTTR: < 0.5 hr.

PHYSICAL

Dimensions: 2.8H x 17.0W x 13.5D inches

(7.2 x 43.6 x 34.6 cm)

Weight: 7 lbs.

2-15

Page 28

INSTALLATION REQUIREMENTS/SPECIFICATIONS

2-16

Page 29

CHAPTER 3

INSTALLATION

This chapter outlines the procedure for installing your MRXI and

connecting it to a network. Ensure that your network meets the

guidelines and requirements outlined in Chapter 2, Installation

Requirements/Specifications, before installing the MRXI.

3.1 UNP ACKING THE MRXI

Unpack the MRXI as follows:

• Remove the two plastic bags containing the accessories.

• Remove the MRXI from the shipping box.

• Slide the two foam end caps off the MRXI.

• Remove the MRXI from the protective plastic bag and set it aside to

prevent damage.

Before you install the MRXI visually inspect the unit and check the

contents of the accessory package. Contact Cabletron Systems Technical

Support immediately if you find any discrepancies.

3.2 ATTACHING THE STRAIN RELIEF BRACKET

Attach the strain relief bracket to the front of the MRXI as follows:

1. Locate the strain relief bracket and four 8-32 x 3/8” screws from the

MRXI installation kit.

Warning: Use of longer screws may cause damage to the unit or

electrical shock.

2. Attach the strain relief bracket to the bottom of the MRXI as shown in

Figure 3-1.

3-1

Page 30

INSTALLATION

MRXI

10 BASE-T HUB with LANVIEW

Figure 3-1 Attaching the Strain Relief

3.3 INST ALLING THE MRXI

You can mount the MRXI on a wall, a 19-inch rack, or place it

free-standing on any horizontal surface (i.e., shelf or desk, etc.). Select

one of the following subsections and perform the steps that are applicable

for your installation.

3.3.1 Rack Mounting the MRXI

Refer to Figure 3-2 and perform these steps to install the MRXI in a

19-inch rack.

1. Remove four cover screws (two from each side) located along the

front edges of each side of the MRXI.

2. Using the four cover screws removed in step 1, attach the rack

mounting brackets to each end of the MRXI.

3-2

Page 31

INSTALLATION

Rackmount

Brackets (2)

MRXI 10 BASE-T HUB with LANVIEW

Screws (4)

Figure 3-2 Rack Mount Brackets Installation

3. With the mounting brackets installed, position the MRXI between the

vertical frame members of the 19-inch rack and fasten it securely with

the mounting screws as shown in Figure 3-3.

19-Inch Rack

MRXI 10 BASE-T HUB with LANVIEW

Screws (4)

Figure 3-3 Installing the MRXI in the Rack

3.3.2 Wall Mounting the MRXI

When you wall mount the MRXI, the cable connections must face down.

Refer to Figure 3-4 and perform the following steps to wall mount the

MRXI.

3-3

Page 32

INSTALLATION

Note: 1/4-inch Molly screw anchors for wall mounting are not included

with the MRXI.

1. Use the supplied screws to attach the wall mounting brackets to the

bottom of the MRXI as shown in Figure 3-4. There are two brackets,

one for each side.

Figure 3-4 Installing the Wall Mounting Brackets

2. Select the wall location for the MRXI within 7 feet of a power outlet.

WARNING: There is a potential SHOCK HAZARD if there is electrical

wiring within the wall that interferes with drilling for pilot holes. Select a

wall location where drilling pilot holes for the Molly screws will not come in

contact with electrical wiring in the wall.

3. You will need a pencil for this step. With the wall mounting brackets

attached to the MRXI, position the MRXI against the wall where it

will be permanently mounted with the network port facing down. Use

the pencil to mark the wall location for the four pilot holes.

4. Set the MRXI aside and carefully drill four 1/4” pilot holes, one for

each of the Molly screw anchors and insert the four Molly screw

anchors into the holes just drilled.

3-4

Page 33

Molly Anchor

INSTALLATION

Figure 3-5 Wall Mounting the MRXI

5. Tighten each of the anchor screws until the anchor expands holding

the anchor firmly in the wall, then remove the screws completely.

6. Position the MRXI on the wall over the anchors and reinstall the four

anchor screws to attach the MRXI to the wall, as shown in Figure 3-5.

Tighten the four anchor screws.

3.3.3 Free-Standing Installation

For a free-standing shelf or tabletop installation, locate the MRXI within

7 feet of its power source and with an unrestricted free surface area 21

inches wide, 18 inches deep, and 6 inches high, as shown in Figure 3-6.

3-5

Page 34

INSTALLATION

B

MRXI 10 BASE-T HUB with LANVIEW

A

A = 15 cm (6 in)

B = 46 cm (18 in)

C = 53 cm (21 in)

D = 213 cm (7 ft)

Figure 3-6 Shelf or Table-top Installation

C

D

3.4 CONNECTING THE MRXI TO THE POWER SOURCE

Note: The MRXI has a universal power supply. This allows y ou to connect

the MRXI to power sources from 85 Vac to 264 Vac, 47-63 Hz.

To connect the MRXI to the power source, plug the power cord into a

grounded wall outlet. Turn on the power switch at the back panel of the

MRXI. Verify that the PWR LED is lit, this indicates that the MRXI is

receiving power. After the MRXI runs a self test, the CPU LED flashes

green indicating normal operation. If the LED remains red, the processor

is faulty.

3.5 CONNECTING THE MRXI TO THE NETWORK

The procedure for connecting Ethernet segments to the MRXI varies

depending on the media and ports being connected. Refer to the following

list and perform the procedure described in the subsections that apply to

your MRXI:

• Network Port (MRXI-22/24), refer to subsection3.5.1

• EPIM-T, refer to subsection 3.5.2

• EPIM-X, refer to subsection 3.5.3

• EPIM-F1, F2, F3, refer to subsection 3.5.4

• EPIM-C, refer to subsection 3.5.5

• EPIM-A, refer to subsection3.5.6

3-6

Page 35

INSTALLATION

3.5.1 Connecting the Network Port Cabling

You attach unshielded twisted pair segments to the RJ-45 Network Ports

on the front panel of the MRXI. Since the MRXI utilizes polarity

detection and correction, the twisted pair connections are not sensitive to

signal polarity. The network will still function properly with the (+) and

(–) lines within a pair reversed. Operating in this condition is not

recommended and if this condition is discovered, the segment should be

removed from the network and wired correctly by a technician.

1. Connect twisted pair segments to the MRXI Network Port (see Figure

3-7) by inserting the RJ-45 connector from each twisted pair segment

into the desired RJ-45 port number on the MRXI.

EPIM 1

24X

23X

22X

21X

12X

11X 10X

9X

20X 19X

8X 7X

18X

6X

17X

5X

16X

4X

15X

3X

14X

2X

13X

1X

EPIM 1

Figure 3-7 MRXI-24 Network Ports

2. Check that the associated LNK LED for the port is lit. If the LED is

not lit, perform each of the following steps until it is:

a. Check that the 10BASE-T device at the other end of the twisted

pair segment is powered up.

b. Verify that the RJ-45 connector on the twisted pair segment has

the proper pin-outs as shown in Figure 3-8.

3-7

Page 36

INSTALLATION

NOTE:

RX+/RX– and TX+/TX–

must share a common

color pair.

Figure 3-8 Cable Pin-outs - RJ-45 Network Ports

NETWORK

Port (1-12)

RX+

RX–

TX+

TX–

1

2

3

6

RJ-45 to RJ-45

10BASE-T

DevicePort

TX+

1

TX–

2

3

6

c. Check the cable for continuity.

d. Check that the twisted pair connection meets dB loss and cable

specifications outlined in 10BASE-T Twisted Pair Network

Requirements.

RX+

RX–

e. Check that the cross-over switch is in the correct position.

If a link still has not been established, contact Cabletron Systems

Technical Support.

3.5.2 Connecting a Twisted Pair Segment to an EPIM-T

Before connecting a segment to the EPIM-T, check each end of the

segment to determine if the wires have been crossed-over for the proper

connection (see Figure 3-11 for proper pin-outs). If the wires are not

crossed-over you can use the switch on the EPIM-T (Figure 3-9) to

internally cross-over the RJ-45 port, eliminating the need to rewire the

twisted pair segment going into the port. If the wire is crossed-over, set

the switch on the EPIM to the

switch to the X position.

= position. If not crossed-over, set the

3-8

Page 37

Switch

LNK

EPIM-T

INSTALLATION

EPIM-T

Front Panel

X

Figure 3-9 EPIM-T Cross-over Switch

II

To connect a EPIM-T to a Twisted Pair Segment:

1. Connect the twisted pair segment to the module by inserting the RJ-45

connector on the twisted pair segment into the RJ-45 port on the

module. See Figure 3-10.

2. Check that the LNK LED for the port is lit. If the LED is not lit,

perform each of the following steps until it is:

a. Check that the 10BASE-T device at the other end of the twisted

pair segment is powered up.

b. Verify that the RJ-45 connector on the twisted pair segment has

the proper pin-outs as shown in Figure 3-11.

c. Check the cable for continuity.

Figure 3-10 The EPIM-T

3-9

Page 38

INSTALLATION

d. Check that the twisted pair connection meets dB loss and cable

specifications outlined in 10BASE-T Twisted Pair Network

Requirements.

e. Check that the cross-over switch is in the correct position.

10BASE-T Device

Port

1

TX+

2

TX-

3

RX+

6

RX-

NOTE:

RX+/RX- and TX+/TXmust share a common

color pair.

Figure 3-11 Cable Pin-outs - EPIM-T RJ-45 Port

RX+

RX-

TX+

TX-

EPIM-T

Port

1

2

RJ-45 to RJ-45

3

6

If a link still has not been established, contact Cabletron Systems

Technical Support.

3.5.3 Connecting an AUI Cable to an EPIM-X

To connect an EPIM-X to an external network device, attach an AUI

cable, no longer than 50 meters in length, to the port located on the

EPIM-X. See Figure 3-12. You must also set the SQE switch to off.

CAUTION: Ensure that the external transceiver to which the MRXI will be

connected does not have the signal quality error (SQE or “heartbeat”) test

function enabled. The MRXI will not operate if the transceiver has the

SQE test function enabled, and the network will be unusable . Refer to the

applicable transceiver manual.

3-10

Page 39

INSTALLATION

SQE

EPIM-X

Figure 3-12 The EPIM-X

3.5.4 Connecting a Fiber Optic Link Segment to an

EPIM-F1, EPIM-F2, or EPIM-F3

When connecting a fiber optic link segment to an EPIM-F1, F2, or F3

keep the following in mind:

• If you are connecting a fiber optic link segment with SMA 906

connectors to an EPIM-F1 with SMA ports, ensure that half alignment

sleeves are in place on each connector. A full alignment sleeve will

damage the receive port. SMA 905 connectors do not need alignment

sleeves.

• If you are connecting a fiber optic link segment with ST connectors to

an EPIM-F2 with ST ports, keep in mind that ST connectors attach to

ST ports much like BNC connectors attach to BNC ports. The

connector is inserted into the port with the alignment key on the

connector inserted into the alignment slot on the port. The connector

is then turned to lock it down.

• The physical communication link consists of two strands of fiber optic

cabling: the T ransmit (TX) and the Receive (RX). The T ransmit strand

from the applicable port on the module will be connected to the

Receive port of a fiber optic Ethernet device at the other end of the

segment. For example, TX of the applicable port on the module will go

to RX of the other fiber optic device. The Receive strand of the

applicable port on the module will be connected to the Transmit port

of the fiber optic Ethernet device. For example, RX of the applicable

port on the module will go to TX of the other fiber optic device.

We recommend that you label the fiber optic cable to indicate which

fiber is Receive and which is Transmit. When you buy fiber optic

3-11

Page 40

INSTALLATION

LNK

EPIM-F1/F2

RX TX

LNK

EPIM-F3

RX TX

cable from Cabletron Systems, it is labeled so that: at one end of the

cable, one fiber is labeled 1, and the other fiber is labeled 2. This

pattern is repeated at the other end of the cable. If you did not

purchase your cable from Cabletron Systems, be sure you have

labeled your cable in the manner described above.

CAUTION: Do not touch the ends of the fiber optic str ands , and do not let

the ends come in contact with dust, dirt, or other contaminants.

Contamination of the ends can cause problems in data transmissions.

If the ends become contaminated, clean them with alcohol using a soft,

clean, lint free cloth.

To connect a fiber optic link segment to an EPIM-F1 or an EPIM-F2:

1. Remove the protective plastic covers from the fiber optic ports on the

applicable port on the module and from the ends of the connectors on

each fiber strand.

2. Attach the fiber labeled 1 to the applicable receive port, labeled RX,

on the module. See Figure 3-13.

Figure 3-13 The EPIM-F1/F2 and EPIM-F3

3. Attach the fiber labeled 2 to the applicable transmit port labeled TX,

on the module.

4. At the other end of the fiber optic cable, attach the fiber labeled 1 to

the transmit port of the device.

5. Attach the fiber labeled 2 to the receive port.

6. Check that the LNK LED on the applicable port on the module is lit.

If the LED is not lit, perform each of the following steps until it is:

a. Check that the power is turned on for the de vice at the other end of

the link.

b. Verify that the fiber strands are properly “crossed over” between

the applicable port on the module and the fiber optic device at the

3-12

other end of the fiber optic link segment.

Page 41

INSTALLATION

EPIM-C

c. Verify that the fiber connection meets the dB loss specifications

outlined in Fiber Optic Network Requirements.

If a link still has not been established, contact Cabletron Systems

Technical Support.

3.5.5 Connecting a Thin-Net Segment to an EPIM-C

To connect a thin-net segment to an EPIM-C:

1. Set the Internal Termination Switch (see Figure 3-14), located to the

right of the port and labeled TERM to:

• The on position (•) if the thin-net segment connected directly to

the port will be internally terminated at the port.

• The off position (o) if the thin-net segment will not be terminated

at the port or externally terminated.

2. If the Internal Termination switch is in the On position, connect the

thin-net segment directly to the BNC port.

3. If the Internal Termination switch is in the Off position:

a. Attach a BNC tee-connector to the BNC port on the module.

b. Attach the thin-net segment to one of the female connectors on the

tee-connector.

Note: You must terminate each segment attached to the tee-connector. If

you do not attach a segment to one of the female connections on the

tee-connector, then a terminator must be placed on that connection.

c. Attach another thin-coax segment or a terminator to the other

female connector on the tee-connector.

TERM

Figure 3-14 The EPIM-C

3-13

Page 42

INSTALLATION

PWR

EPIM-A

3.5.6 Connecting an AUI Cable to an EPIM-A

To connect an EPIM-A to an external network segment, via an AUI Cable:

1. Attach an external transceiver to the network segment that will be

connected to the AUI port. Refer to the applicable transceiver manual.

2. Attach an AUI cable, no longer than 50 meters in length, to the

transceiver connected to the network in step 1.

3. Connect the AUI cable to the AUI port located on the EPIM-A. See

Figure 3-15.

4. Lock the AUI connector into place using the slide latch on the

connector.

Figure 3-15 The EPIM-A

CAUTION: Ensure that the external transceiver to which the MRXI will be

connected does not have the signal quality error (SQE or “heartbeat”) test

function enabled. The MRXI will not operate if the transceiver has the

SQE test function enabled, and the network will be unusable . Refer to the

applicable transceiver manual.

5. Check that the PWR LED on the EPIM-A is lit. If the PWR LED is

not lit, contact Cabletron Systems Technical Support.

6. If the PWR LED is lit with the AUI cable disconnected, continue with

the following checks:

a. Check the AUI connections for proper pin-outs. The pin-outs for

the transceiver connection are listed in Chapter 2, Installation

Requirements/Specifications.

b. Check the cable for continuity.

c. Reconnect the AUI cable to the MRXI and the device.

If the LED is still not lit after reconnecting the segment, contact Cabletron

Systems Technical Support.

3-14

Page 43

INSTALLATION

3.6 FINISHING THE INST ALLATION

The MRXI is now ready for operation. Before placing the network into

service, test the installation thoroughly, making sure that you can address

all stations and that the MRXI and all stations are indicating normal

operation. Ensure that the networking software is configured properly to

match the installed network. If you encounter errors or abnormal

operation, proceed to Chapter 4, Testing and Troubleshooting.

3-15

Page 44

INSTALLATION

3-16

Page 45

CHAPTER 4

TESTING AND TROUBLESHOOTING

This chapter contains procedures for testing the MRXI after you connect

it to the network. It also describes LANVIEW and includes instructions

for using the LCD display to troubleshoot physical layer network

problems.

4.1 INSTALLATION CHECK-OUT

After you connect the MRXI to the network, verify that packets pass

between all Ethernet devices connected to the MRXI and any other

devices connected to the network. If you encounter difficulty with any of

the attached devices, check the link as follows:

1. Check that the LNK LED, if applicable, for the port is lit. If the LED

is not lit:

a. Check that the 10BASE-T device at the other end of the twisted

pair segment is powered up.

b. Verify that the connector on the twisted pair segment has the

proper pin-outs. Refer to Chapter 2 for the pin assignments for

twisted pair connectors.

For EPIM-F1/EPIM-F2 check that the TX and RX fibers are

properly connected.

For EPIM-A check that the PWR is lit.

c. Check the cable for continuity. A variety of tools are available for

this test, depending on the media you are using.

d. Check that the twisted pair segments meet cable specifications for

dB loss described in Chapter 2.

2. If the remote station is ready and the LNK LED is lit, but no data

passes through the port, one of two conditions may exist:

4-1

Page 46

TESTING AND TROUBLESHOOTING

• Network management has disabled the port.

• The port is segmented either because the collision detector was on

for more than 110 µsec or the MRXI detected more than 30

consecutive collisions on the attached segment. The af fected port

remains segmented until a good packet is transmitted/received

without collisions.

If the LNK LED is still not lit, contact Cabletron Systems Technical

Support.

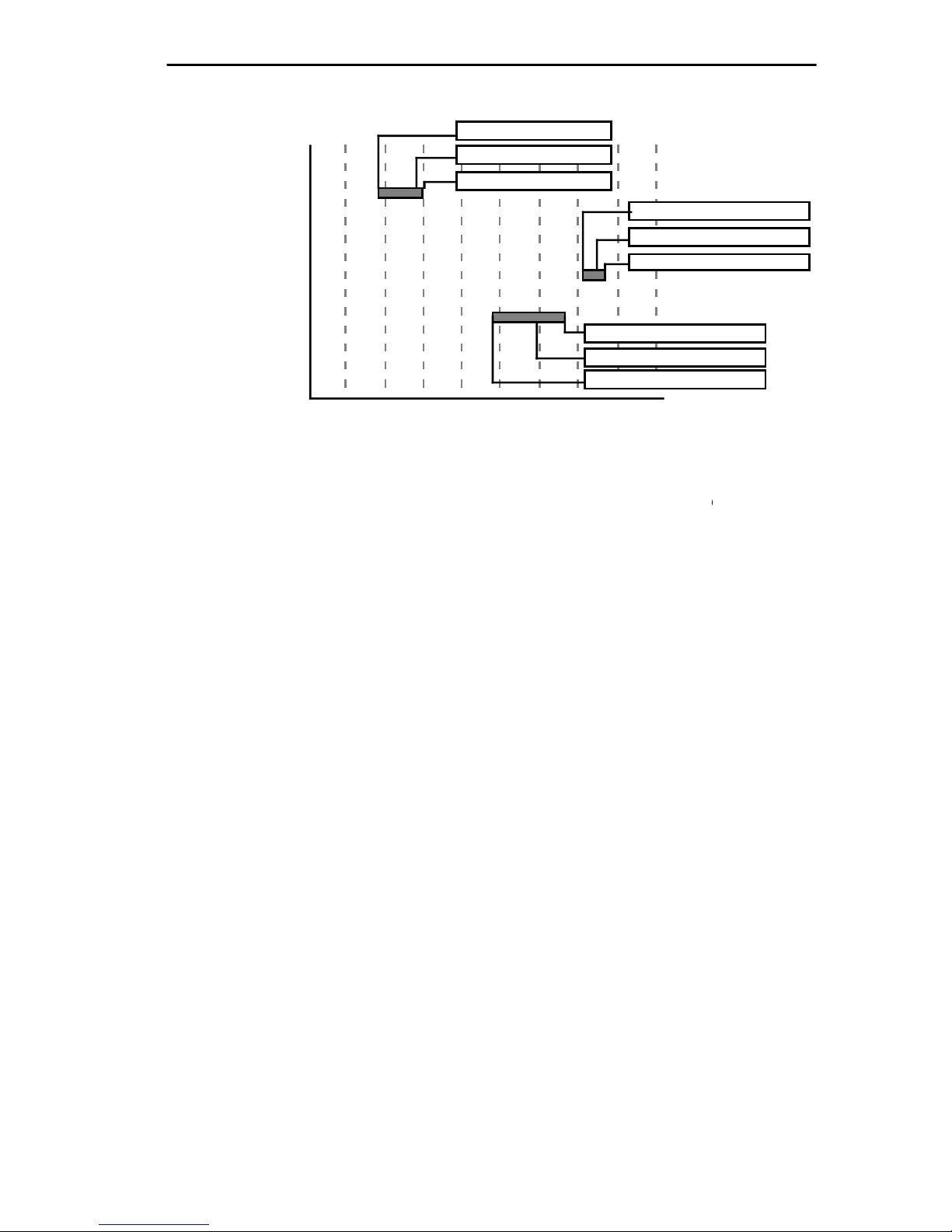

4.2 TESTING SEGMENTS ATTACHED TO THE MRXI

You can test the Ethernet segments connected to the MRXI to determine

if they comply with IEEE 802.3 specifications. To do this, use two

™

Ethernet node testers, such as Cabletron Systems LAN-MD

place of the Ethernet devices normally attached on any two links. Figure

4-1 shows several methods for connecting the LAN-MD to test different

media types and links connected to the MRXI. The LAN-MDs exchange

valid data packets for end-to-end testing.

attached in

To test any single link; select two links (the link you want to test and a

second link that you know operates properly), and perform the following

steps:

Note: The flexibility of the MRXI permits a variety of media combinations,

resulting in many possible test configurations. Since it is impossible to

cover e v ery combination of network media and MRXI configuration, minor

adjustments to the testing procedures given here may be necessary to

test your specific configuration.

1. Connect two LAN-MDs, one at the end of each of the Ethernet links

your are testing. If you connect one or both of the LAN-MDs to a

segment that is attached to:

4-2

Page 47

TESTING AND TROUBLESHOOTING

EPIM-T

9

TPT-T

FIBER OPTIC (EPIM-F1/F2) TO

LAN-MD

EPIM-F1/2

MRXI

FOT-F

UNSHIELDED TWISTED PAIR

AUI CABLE

AUI CABLE

LAN-MD

TPT-T

MRXI

COAX (EPIM-C) TO UNSHIELDED TWISTED PAIR

(NETWORK PORT)

AUI CABLE

LAN-MD

AUI CABLE

MRXI

EPIM-A

TPT-T

A

EPIM-T

AUI CABLE

LAN-MD

(EPIM-T)

AUI CABLE

EPIM-C

LAN-MD

AUI (EPIM-A) TO UNSHIELDED

TWISTED PAIR (EPIM-T)

AUI CABLE

LAN-MD

Figure 4-1 Test Connections for MRXI Segments

a. one of the unshielded twisted pair (Network) ports or EPIM-T

installed in the MRXI:

1.) Connect a properly functioning Cabletron Systems TPT-T

10BASE-T Twisted Pair Transceiver to the device end of the

Twisted Pair Segment coming from the applicable port on the

MRXI.

2.) Connect a LAN-MD to the TPT-T by using an AUI cable.

4-3

Page 48

TESTING AND TROUBLESHOOTING

b. EPIM-F1 or EPIM-F2 installed in the MRXI:

1.) Connect a properly functioning Cabletron Systems FOT-F

Fiber Optic Transceiver to the device end of the Fiber Optic

Link Segment coming from the EPIM-F1/F2.

2.) Connect a LAN-MD to the FOT-F by using an AUI cable.

c. EPIM-C installed in the MRXI:

1.) Connect a transceiver and an AUI cable to the Thin-net

segment.

2.) Connect a LAN-MD to the AUI cable.

d. EPIM-A installed in the MRXI:

1.) Attach an external transceiver to the segment coming from the

port on the EPIM-A.

2.) Connect a LAN-MD to the transceiver by using an AUI cable.

2. Select and run test 6 - SERVER on either LAN-MD connected to the

Ethernet network on either side of the wide area link.

3. Verify that the Test Status PASS LED is lit and that the Status Code

reads 000 or 001. If these two conditions exist, the LAN-MD is now

the SERVER unit and, when used with another LAN-MD, will echo

packets.

4. Select and run test 4 - NODE CHECK on the LAN-MD connected to

the Ethernet network on the other side of the wide area link.

5. Verify that this test passes by ensuring at least 100 packets are sent and

received between LAN-MDs with no errors. Packets are sent from this

LAN-MD to the LAN-MD at the other end of the wide area link, acting

as the Server, then echoed back.

After successfully completing these tests using the links, the MRXI is

ready for normal operation. If you note any failures, contact Cabletron

Systems Technical Support.

4-4

Page 49

TESTING AND TROUBLESHOOTING

10BASE-T HUB with LANVIEW

MRXI-24

4.3 USING LANVIEW

LANVIEW is Cabletron Systems’ built-in visual diagnostic and status

monitoring system. Using LANVIEW, your network troubleshooting

personnel can quickly scan the LANVIEW LEDs to observe network

status or diagnose network problems, and determine which node or

segment is faulty. Figure 4-2 shows the locations for each of the front

panel LANVIEW LEDs.

RCV

E

The Complete Networking Solution

24 23 22 21 1 18 17 16 15 14 13

2

E

1

LNK

CPU

12 11 10 9 8 7 6 5 4 3 2 1

PWR

Figure 4-2 LANVIEW LEDs

PWR (Green)

When this LED is lit, it indicates that the MRXI is receiving power. If

this LED is not lit, it indicates a loss of input power. Check the input

power source (circuit breaker, fuse, etc.). If the proper power source is

present, the problem could be with the MRXI.

RCV (Yellow)

When this LED flashes, it indicate that the MRXI is repeating data

packets received from the associated Network Port segment. The flash

of the LED is pulse stretched for viewing effect.

4-5

Page 50

TESTING AND TROUBLESHOOTING

LNK (Green)

When this LED is lit, it indicates an established link between the

associated twisted pair segment and the 10BASE-T device at the other

end of the segment. This LED will remain lit as long as a link is

maintained

If a port receives no data for 16 msec from the device at the other end

of the segment, a positive link test pulse of 100 nsec is sent onto the

transmit link of the twisted pair cable. The MRXI receives these link

test pulses and checks to determine if they occur at the correct rate,

polarity, and pulse shape. If the MRXI receives no link test pulses, or

the pulses are not correct, the transceiver enters the Link Fail State and

the LED will not be lit. The MRXI does not receive or transmit data

until it receives a correct link test pulse or a valid packet.

When the MRXI is powered-on, the LNK LED flashes if the MRXI

detects reversed polarity on the segment attached to the associated

port.

CPU (Flashing Green)

This LED alternates from red to green during power up. After the boot

is complete, the LED flashes green. A flashing green LED indicates

normal operation. A red LED indicates a faulty processor.

4.4 THE LCD DISPLAY

The MRXI is equipped with an LCD display as shown in Figure 4-3. The

LCD display is a diagnostic tool that gives you important status

information about the MRXI such as: Power up diagnostics, Revision

levels, MAC and IP Addresses, and Error Alerts.

4-6

Page 51

TESTING AND TROUBLESHOOTING

MRXI-24

10BASE-T HUB with LANVIEW

The Complete Networking Solution

DISPLAY RESET

Figure 4-3 LCD Display

The LCD displays four types of messages:

LCD Display

• Static System Messages

• Alarm Messages

• Unsaved Initialization Messages

• Saved System Messages

Static System Messages

These messages display MRXI configuration information. To view the

Static System Messages, momentarily press the display button at the side

of the LCD window. Press the display button to scroll through each

message. If you do not press the display button for 20 seconds, the display

defaults to the product name.

Displayed Messages Comments

IP Address Displays the current MRXI

xxx.xxx.xxx.xxx IP address. You can change this

through Local Management.

4-7

Page 52

TESTING AND TROUBLESHOOTING

MAC Address Displays the MAC address.

00001dxxxxxx

RAM Image Displays the revision number of the

Rev. xx.xx.xx Flash EEPROM. The revision

increments each time you download

new software to the Flash EEPROM.

Boot PROM Displays the revision number of the

Rev. xx.xx.xx internal Boot PROM. The revision

increments each time you change the

Boot PROM.

Flash Programmed Displays the number of times you

xx Times download new software to the Flash

EEPROM.

Console Port Displays the Baud Rate you set in

Baud Rate xxxxx Local Management.

Console Port This can be changed through

Function xxxxx Local Management.

Modem Port Displays the current baud rate for

Baud Rate xxxxx the modem port

Modem Port Displays the current function of the

Function xxxxxx modem port (OFFLINE, LIM, UPS).

Alarm Messages

Alarm messages pertain to events that occur within the MRXI. Press the

display button and hold for two seconds to view alarm messages. Press

the display button to scroll through each message. If you do not press the

display button for 20 seconds, the display defaults to the product name.

4-8

Page 53

TESTING AND TROUBLESHOOTING

Displayed Messages Comments

Port xxxxxx Displays segmentation status of

Segmented network ports 1-24, EPIM-1 or

EPIM-2.

Port xxxxxx Displays segmentation status of

UnSegmented network ports 1-24, EPIM-1, or

EPIM-2.

Port xxxxxx Displays link status of network

Link Established ports 1-24, EPIM-1 or EPIM-2.

Port xxxxxx Displays link status of network

Not Linked ports 1-24, EPIM-1 or EPIM-2.

EPIM-x Displays installation status of

Inserted EPIM-1 or EPIM-2.

EPIM-x Displays installation status of

Removed EPIM-1 or EPIM-2.

EPIM-x Indicates unauthorized access

Security Violation attempt at EPIM-1 or EPIM-2.

CableRedun Fail Indicates failure of redundant link

Port EPIM-x at EPIM-1 or EPIM-2.

CableRedun Enable Indicates redundant link enabled at

Port EPIM-x EPIM-1 or EPIM-2.

Port xxxxxx Indicates network ports 1-24,

Disabled EPIM-1, or EPIM-2 disabled.

Port xxxxxx Indicates network ports 1-24,

Enabled EPIM-1, or EPIM-2 enabled.

Port xx Security Indicates unauthorized access

Violation attempt at ports 1-24.

Cable Redundancy Indicates failure of redundant link

Port xx Failure at ports 1-24.

4-9

Page 54

TESTING AND TROUBLESHOOTING

Cable Redundancy Indicates redundant link enabled

Enable Port xx at ports 1-24.

No Messages in No Alarm messages.

Queue x

Unsaved Initialization Messages

These are power-up messages that appear on the LCD display as the e v ent

occurs but are not saved in a buffer for future recall. Unsaved

Initialization Messages include initializing unit, download, and unit ready

messages. If Failure or Error messages appear, call Cabletron Technical

Support.

ailure or Error Messages

F

Cabletron Cabletron

Ctrl. Reg. Err. BBRAM Failure

Cabletron Cabletron

SDRAM Failure Modem SCC Error

Cabletron Cabletron

SONIC Failure Bit Swap Failure

Cabletron Cabletron

Console SCC Error LDRAM Failure

Cabletron

82C54 Failure

Normal Unsaved Initialization Messages

Cabletron Cabletron

Hardware Init Boot From Flash

Cabletron Cabletron

BOOTP Discovery RARP Req. State

4-10

Page 55

TESTING AND TROUBLESHOOTING

Cabletron Cabletron

TFTP Req. State TFTP in Progress

Cabletron Cabletron

TFTP Complete Erasing Flash

Cabletron Cabletron

Programming Flash Flash Programmed

Cabletron Cabletron

Boot Complete Test in Progress

Saved System Messages

Saved System Message are device related startup or boot strap messages,

BOOTP/TFTP host, or startup error messages. To display Saved System

Messages, press the display button and hold for two seconds while in the

Alarm Messages display. The messages that may appear are shown

below:

Displayed Messages

TFTP Host TFTP File

xxx.xxx.xxx.xxx xxxxxxxxxxxxxxxx

Last Host Used Last File Used

xxx.xxx.xxx.xxx xxxxxxxxxxxxxxxx

4-11

Page 56

TESTING AND TROUBLESHOOTING

4-12

Page 57

CHAPTER 5

LOCAL MANAGEMENT

Local Management provides unique management and control capabilities

for the MRXI. Local Management supplies the tools to manage the MRXI

and all of its attached segments. You can:

• assign an IP address and subnet mask

• select a default gateway

• set interface parameters for both serial ports, Local Management, or

Uninterruptible Power Supply proxy (UPS)

• control access to the MRXI through the community names established

in the Community Names Table

• designate which Network Management Workstations receive trap

messages from the device

• navigate through the Management Information Base (MIB) and

manage the objects within it from a remote location. Given the

appropriate security level, the MIB is accessible from the MRXI

through either SNMP Tools or the Command Line Interface (CLI).

5.1 TERMINAL CONFIGURATION

You access Local Management by attaching a management terminal to

the RJ-45 CONSOLE port on the front panel of the MRXI as shown in

Figure 5-1. You can also use a Hayes compatible modem connected to the

RJ-45 MODEM port. The console connection supports a Digital

Equipment Corporation VT 320™ terminal or PC emulation of one of

these terminals.

5-1

Page 58

LOCAL MANAGEMENT

MRXI-24

CONSOLE

CABLE

MANAGEMENT

TERMINAL

Figure 5-1 Management Terminal Connection

Table 5-1 lists the setup requirements for the local management terminal.

If your terminal is a Digital Equipment Corporation VT 320™ terminal,

press F3 to access the Setup Directory. If you have a terminal emulation

of the Digital Equipment terminals, refer to your equipment user manual

for setup procedures.

5-2

Page 59

LOCAL MANAGEMENT

Table 5-1 Terminal Setup Requirements

MENU FUNCTION SELECTION

Display Setup: Columns 80 Columns

Controls Interpret Controls

Auto Wrap No Auto Wrap

Test Cursor Cursor

General Setup: Mode 7 Bit Control

Cursor Keys Normal Cursor Keys

Communications

Setup:

Keyboard Setup: Auto Repeat any option

Transmit Transmit = 9600

Receive Receive = Transmit

XOFF any option

Bits, Parity 8 Bits, No Parity

Stop Bit 1 Stop Bit

Local Echo No Local Echo

Port

Transmit any option

Auto Answerback No Auto Answerback

Keyclick any option

Margin Bell Margin Bell

Warning Bell Warning Bell

Auto Answerback No Auto Answerback

DEC-423,

Data Leads only

5.1.1 Console Cable Configuration

Cabletron Systems supplies a console cable kit with the MRXI. This kit

includes an unshielded twisted pair cable with RJ-45 connectors on both

ends, an RJ-45 to 25 pin adapter, and an RJ-45 to 9 pin adapter. Use this

kit to attach the terminal to the RJ-45 CONSOLE port on the front panel

of the MRXI. Figure 5-2 shows the pin-out for both cables.

5-3

Page 60

LOCAL MANAGEMENT

Pin 1

RJ-45 CONSOLE PORT

RECEIVE

TRANSMIT

SIGNAL GROUND

DATA SET READY

DATA TERMINAL READY

CONSOLE PORT

RJ-45

TRANSMIT

RECEIVE

SIGNAL GROUND

DATA SET READY

DATA TERMINAL READY

RJ-45 TO 25 PIN

CABLE

4

1

5

2

6

1

4

5

2

6

FEMALE - 25 Pin

"D" Shell Connector

2

TRANSMIT

3

RECEIVE

7

SIGNAL GROUND

DATA TERMINAL READY

20

CLEAR TO SEND

5

LOCAL MANAGENT

CONSOLE

RECEIVE

2

TRANSMIT

3

SIGNAL GROUND

5

READY TO SEND

7

CLEAR TO SEND

8

Figure 5-2 Console Cable Pin-outs

Connect the console cable to the MRXI as follows:

1. Attach the male RJ-45 connector to the CONSOLE port of the MRXI.

2. Attach the female end (25 pin or 9 pin, as applicable) to the COMM

port on the terminal.

5-4

RJ-45 TO 9 PIN

CABLE

FEMALE - DB-9

(9-Pin Connector)

Page 61

LOCAL MANAGEMENT

5.1.2 Modem Cable Configuration

To access Local Management with a modem use an RS-232 cable

available from Cabletron Systems. This cable connects the modem to the

MRXI Modem port. Figure 5-3 shows the pin-out for a cable and a RJ-45

connector at the MRXI end of the cable.

Pin 1

RJ-45 MODEM PORT

RJ-45

Female

TRANSMIT

RECEIVE

SIGNAL GROUND

DATA CARRIER DETECT

DATA TERMINAL READY

RING

RJ-45 TO 25 PIN

CABLE

1

4

5

2

6

8

2

TRANSMIT

3

RECEIVE

7

SIGNAL GROUND

DATA CARRIER DETECT

8

20 DATA TERMINAL READY

22

RING

FEMALE - 25 Pin

"D" Shell Connector

Figure 5-3 Modem Cable Pin-outs

5.1.3 Cable Configuration for UPS

To configure the cable connections for the Uninterruptible Power Supply

(UPS):

1. Plug a straight-through twisted pair, RS232, cable into the MRXI’s

RJ-45 Modem Port.

2. Plug the other end of the RS232 cable into the adapter (Part #9372066)

and connect the adapter to the UPS.

You can now use the UPS option in the Local Management.

5-5

Page 62

LOCAL MANAGEMENT

5.2 ACCESSING LOCAL MANAGEMENT

After ensuring that your terminal is properly configured, and that the

physical cable connections are correct, you can access the Local

Management interface.

To access Local Management:

1. Turn the terminal on. The MRXI Password screen, Figure 5-4,

appears.

MRXI-960 LOCAL

MANAGEMENTCabletron MRXI