Buhler 535, 435, 485 User Manual

::

435

Operator’s Manual

::

485

::

535

89002109 12/2007

Foreword

To the Owner

This manual contains information concerning the operation, adjustment, and maintenance of Buhler Versatile 4WD tractors. You

have purchased a dependable machine. With only proper care and operation can you expect to receive the performance and long

service built into this tractor.

HAVE ALL OPERATORS READ THIS MANUAL CAREFULLY AND KEEP IT AVAILABLE FOR READY REFERENCE.

The tractor was designed to pull agricultural equipment in agricultural applications at field speeds of 7.2 KPH (4.5 MPH) or greater.

Proper ballasting to provide equal traction to front and rear axles under moderate to heavy load will improve tractor performance

and life. Your Buhler Versatile dealer will instruct you in the general operation of your tractor. Your dealer’s staff of factory–trained

service technicians will be glad to answer any questions that may arise regarding the operation of your tractor.

For engine maintenance not covered in this manual, follow the instructions provided in the Cummins Engine Operator’s manual.

Before putting the tractor in service, become familiar with the procedures outlined in both manuals.

At this time biodiesel blends up to B5 are the only blends approved for use in all Cummins engines for both On highway and

Off highway markets. B5 which is a blend of 5 percent pure biodiesel (B100) and 95 percent standard petroleum diesel has

demonstrated to have no impact on engine performance, durablilty or maintenance. The industry standard known as ASTM D6751

defines the specification for B100. However, this standard currently lacks a specification for stability. Without a specification for

stability, the quality of the fuel blends higher than B5 could degrade to a point which could damaging to engines. Cummins is

supporting industry efforts to add a stability spec to the current ASTM standard, and continues to evaluate the impact of these

blends on the durability of engines. Until this spec is developed and tested, other blends of biodiesel will be unsuitable for use in

Cummins On highway and Off highway engines.

The warranty coverage that is extended to your Buhler Versatile 4WD tractor is explained in the Warranty and Limitation of Liability

Agreement form. Your dealer will provide you with a copy of the warranty and retain a copy which you have signed. After you read

the warranty, ask your dealer to explain any points that you may not understand.

Do not modify, alter, or permit anyone else to modify or alter this tractor or any of its components, or any tractor function, without

first consulting an authorized Buhler Versatile dealer. If you have any questions regarding tractor modifications, contact Buhler

Versatile Inc., 1260 Clarence Ave, Winnipeg MB, R3C 4E8.

Your safety, and the safety of those around you depends upon the care and good judgement you use while operating this equipment.

Read the safety precautions carefully.

For a complete list of the delivery service checks performed by your dealer, refer to the Delivery Report in this manual. The first

copy is your record of the service performed and the second copy, which is to be removed from the manual, is your dealer’s record.

MAKE SURE THAT BOTH COPIES ARE SIGNED BY YOURSELF AND YOUR DEALER.

After you have operated the tractor for 50 hours, have your dealer perform the factory recommended first 50–hour service. Return

this manual with your tractor to the dealer so the “First 50–Hour Service” checklist can be filled out. You will be responsible for the

cost of lubricants, fluids, filters and other items replaced as part of normal maintenance. Prior to taking the tractor to your selling

dealer for service, it is recommended that you contact them to determine any other charges for which you may be responsible.

All data given in this book is subject to production model variations. Dimensions and weights are approximations only, and the

illustrations do not necessarily show tractors in standard condition. For exact information about any particular tractor, please

consult your Buhler Versatile dealer.

CAUTION: THIS SYMBOL IS USED THROUGHOUT THIS BOOK WHENEVER PERSONAL SAFETY IS INVOLVED. TAKE TIME TO

READ AND FOLLOW THE INSTRUCTIONS.

CAUTION: PICTURES IN THIS MANUAL MAY SHOW PROTECTIVE SHIELDING OPEN OR REMOVED TO BETTER ILLUSTRATE

A PARTICULAR FEATURE OR ADJUSTMENT.

BE CERTAIN, HOWEVER, TO CLOSE OR REPLACE ALL SHIELDING BEFORE OPERATING THE MACHINE.

Improvements

Buhler Versatile Inc. is continually striving to improve its products. We reserve the right to make improvements or changes when

it becomes practical and possible to do so, without incurring any obligation to make changes or additions to the equipment sold

previously.

435/485/535

1-2

435/485/535

1-3

Operator’s Manual - Contents

Section 1 - Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Section 2 - General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Section 3 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Section 4 - Lubrication and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Section 5 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Section 6 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Delivery Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

435/485/535

1-4

435/485/535

1-5

Section 1 - Safety

Contents

Section 1 Contents - Safety Information

Introduction to the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Tractor Statement of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Precautionary Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Machine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

The Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Driving the Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Operating the Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Operating the PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Servicing the Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Diesel Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Safety Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Additional Safety Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Articulation Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Emergency Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Safety Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

ROPS Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Damage to the Cab/ROPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

435/485/535

1-6

F1-1

Foreword

Introduction to this manual

This manual has been prepared to assist you in the

correct procedure for breaking in, driving, operating,

and maintaining your tractor.

The manual is divided into 6 sections with contents

page at the beginning of each section itemizes the

section in detail. A detailed index is also provided at

the back of this manual.

The sections are:

Section 1 - Safety Information

Section 2 - General Information

Section 3 - Operation

Section 4 - Lubrication and maintenance

Section 5 - Troubleshooting Charts

1

Section 6 - Specifications

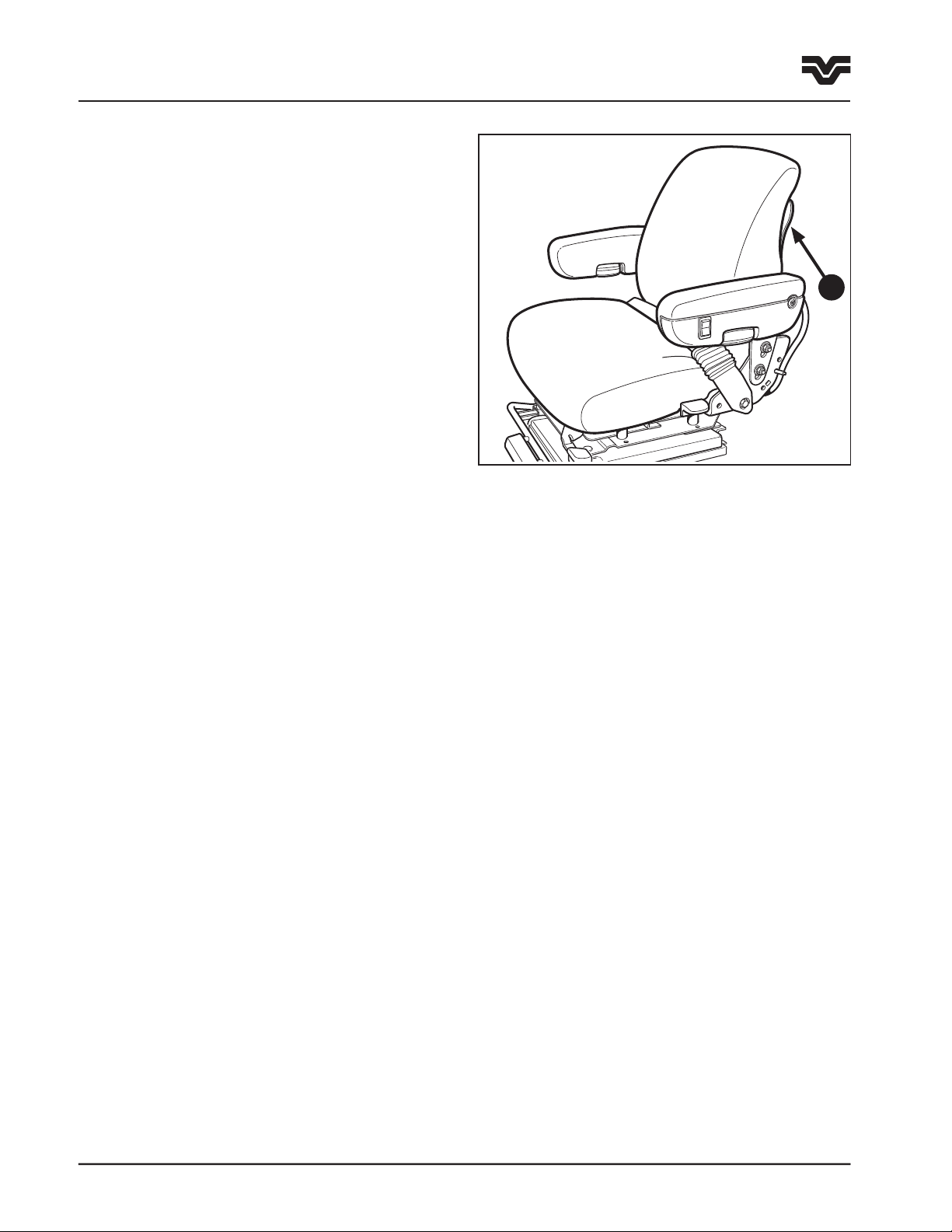

Read this manual carefully and keep it along with other

tractor information in the storage pocket attached to

the rear of the seat (1) for future reference. If at any

time you require advice concerning your tractor, do not

hesitate to contact your authorized Buhler Versatile

dealer. He has factory trained personnel, genuine

replacement parts, and the necessary equipment for

your service requirements.

Your tractor has been designed and built to give

maximum performance, economy and ease of operation

under a wide variety of operating conditions. Prior to

delivery, the tractor was carefully inspected, both at

the factory and by your dealer, to ensure that it reaches

you in optimum condition. To maintain this condition

and ensure trouble–free operation, it is important that

the routine services, as specified in this manual, are

carried out at the recommended intervals.

All data given in this book is subject to production

variations. Dimensions and weights are approximate

only, and the illustrations do not necessarily show

tractors in standard condition. For exact information

about any particular tractor, please consult your

authorized dealer.

Tractor Statement of Use

Buhler Versatile has designed the 435, 485 and 535

4WD articulated tractors to be used in customary

agricultural applications. Using the tractor in an

industrial only application (ie. road building) will not

be covered by warranty.

The machine is constructed to use specific tire

combinations along with additional ballast to properly

distribute weight and power for the operation of

agricultural equipment.

To obtain maximum performance and durability, the

tractor must be operated and maintained in a manner

as described in this manual. Failure to follow the

information contained in this manual may lead to

premature deterioration or personal injury.

You have made a substantial investment in this

agricultural tractor and it demands proper operation

and maintenance.

PLEASE FOLLOW YOUR OPERATOR’S MANUAL.

The company policy is one of continuous improvement,

and the right to change prices, specifications or

equipment at any time without notice is reserved.

Section 1 of this manual lists the precautions to be

observed to ensure your safety and the safety of others.

Read the safety precautions carefully and follow the

advice offered BEFORE operating the tractor.

435/485/535

1-7

Section 1 - Safety

Precautionary Statements

Precautionary Statements

Personal Safety

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION”, “WARNING”,

and “DANGER”) followed by specific instructions. These precautions are intended for the personal safety of you

and those working with you. Please take the time to read them.

CAUTION: THE WORD “CAUTION” IS USED WHERE A SAFE BEHAVIORAL PRACTICE ACCORDING TO

OPERATING AND MAINTENANCE INSTRUCTIONS AND COMMON SAFETY PRACTICES WILL PROTECT THE

OPERATOR AND OTHERS FROM ACCIDENT INVOLVEMENT.

WARNING: THE WORD “WARNING” DENOTES A POTENTIAL OR HIDDEN HAZARD WHICH HAS A POTENTIAL

FOR SERIOUS INJURY. IT IS USED TO WARN OPERATORS AND OTHERS TO EXERCISE EVERY APPROPRIATE

MEANS TO AVOID A SURPRISE INVOLVEMENT WITH MACHINERY.

DANGER: THE WORD “DANGER” DENOTES A FORBIDDEN PRACTICE IN CONNECTION WITH A SERIOUS

HAZARD.

FAILURE TO FOLLOW THE “CAUTION”, “WARNING”, AND “DANGER” INSTRUCTIONS MAY RESULT IN

SERIOUS BODILY INJURY OR DEATH.

Machine Safety

Additional precautionary statements (“ATTENTION” and “IMPORTANT”) are followed by specific instructions.

These statements are intended for machine safety.

ATTENTION: The word “ATTENTION” is used to warn the operator of potential machine damage if a certain

procedure is not followed.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of something he needs to know to prevent

minor machine damage if a certain procedure is not followed.

435/485/535

1-8

Section 1 - Safety

Precautionary Statements

Safety

Precautionary Statements

National Safety Council statistics indicate many people die or suffer serious injury each year as a result of farm

accidents.

Don’t become a statistic or victim.

Carefully review the procedures given in this manual with all operators ANNUALLY. It is important that all

operators be familiar with, AND FOLLOW, safety precautions.

Operating instructions must be given to everyone using the tractor before operation and at least once yearly

thereafter in compliance with OSHA Regulation 1928.57 (United States).

A careful operator is the best operator. Most accidents can be avoided by observing certain precautions. To help

prevent accidents, read and take the following precautions before operating the tractor. Equipment should be

operated only by those who are responsible and instructed to do so.

The Tractor

1. Read the Operator’s Manual carefully before

using the tractor. Lack of operating knowledge

can lead to accidents.

2. Only allow properly trained and qualified persons

to operate the tractor.

3. Do not permit anyone but the operator to ride on

the tractor, especially children. The instructional

seat (optional) is used for instructing or service

diagnosing only.

4. Keep safety decals free of dirt or grime.

Replace safety decals if missing, illegible or

damaged.

5. Do not modify, alter, or permit anyone else to

modify or alter the tractor or any of its components

or any tractor function without first consulting an

authorized Buhler Versatile dealer.

6. Install all shields before starting or operating the

tractor.

7. Always use the steps and handrails

when entering and exiting the tractor. Never

jump from the tractor. There is a danger of

catching clothing on protruding parts.

Driving the Tractor

1. Always sit in the driver’s seat while starting or

driving the tractor.

2. When driving on public roads always use hazard

lights (and extremity lights where applicable).

Have consideration for other road users by pulling

to the side of the road so that any following traffic

may pass.

3. Dim the tractor lights when meeting a vehicle at

night. Make sure the lights are adjusted to prevent

blinding the driver of an oncoming vehicle.

4. Reduce engine speed before turning or applying

the brakes.

5. Any towed vehicle whose total weight exceeds that

of the towing tractor must be equipped with

brakes for safe operation.

6. Never apply the differential lock when turning.

When engaged, the differential lock will increase

the effort required to turn the tractor and increase

the turning radius.

7. Always check overhead clearance, especially

when transporting the tractor. Watch where you

are going, especially at row ends, on roads, and

around trees and low overhanging obstacles.

435/485/535

8. To avoid overturns, drive the tractor with care and

at speeds compatible with safety, especially when

operating over rough ground, when crossing

ditches or slopes and when turning corners.

1-9

Section 1 - Safety

Precautionary Statements

9. Use extreme caution when operating on steep

slopes.

10. Keep the tractor in the same gear when going

down hill as would be used when going uphill.

Do not coast or freewheel down hills.

11. When descending steep grades, select a sufficiently

low gear to maintain control with minimum

braking.

12. Drive the tractor slowly on hillsides and curves to

eliminate the danger of tipping. Avoid slopes

which are too steep for safe operation. Avoid sharp

uphill turns.

13. When driving out of a ditch, gully or up a steep

hillside, engage the clutch slowly. Avoid sharp

uphill turns.

14. Use caution when driving near the edge of a ditch

or gully. It may cave in, causing the tractor to roll

over.

15. Use extreme caution when operating the tractor

on single wheels. The danger of tipping increases.

Do not travel at high speeds.

16. Before transporting the tractor and implement

on public roadways, check with authorities for

local regulations.

Operating the Tractor

1. Apply the parking brake, place the PTO control

in the “OFF” position, the lift control in the down

position, the remote control valve levers in the

neutral position and the transmission lever in

neutral before starting the tractor.

2. Do not start the engine or operate controls

while standing beside the tractor. Always sit in

the tractor seat when starting the engine or

operating the controls.

3. Do not bypass the transmission neutral start

circuit. Consult your authorized dealer if your

neutral start controls malfunction.

4. Use jumper cables only in the recommended

manner. Improper use can result in a tractor

runaway.

5. Avoid accidental contact with the gear shift

lever while the engine is running. Unexpected

tractor movement can result from such contact.

6. Do not get off the tractor while it is in motion.

7. Shut off the engine and PTO and apply the parking

brake before getting off the tractor.

8. Do not park the tractor on a steep incline.

17. Use the wide transport marker lights to clearly

indicate the full width of the tractor with those

tire options.

18. Ensure towed implements are equipped with slow–

moving vehicle (SMV) signs when traveling on

public roads.

19. Install additional lights on implement rear to

safeguard against rear–end collisions. Daybreak

and dusk are particularly dangerous. Buhler

Versatile tractors have seven–pin trailer connectors

to facilitate installation of extra lighting.

20. Be aware of the transport width of towed

implements. Install additional lights to the sides

of wide implements to alert passing traffic. Keep

clear of the approaching lane.

21. Use hazard warning flashers as required by law

when transporting or driving the tractor on public

roads. Use extremity lighting kit when required or

deemed necessary.

22. Use extreme caution when pulling heavy loads

at road speeds. Avoid hard application of the

tractor brakes at high speed.

9. Do not operate the tractor engine in an enclosed

building without adequate ventilation. Exhaust

fumes can cause death.

10. The cab air filter is designed to remove dust from

the air but will not exclude chemical vapor. Follow

the chemical manufacturer’s directions regarding

protection from dangerous chemicals.

11. Always wear a protective mask when working with

toxic spray chemicals. Follow the directions on

the chemical container.

12. If the power steering or engine ceases to operate,

stop the tractor immediately as the tractor will be

more difficult to control.

13. WARNING: RELIEVE PRESSURE BEFORE

STOPPING THE ENGINE TO CONNECT OR

DISCONNECT HYDRAULIC, STEERING, WATER,

OR FUEL LINES.

435/485/535

1-10

Section 1 - Safety

Precautionary Statements

14. Pull only from the drawbar. Use only a drawbar

pin that locks in place. Pulling from the tractor

rear axle or any point above the axle may cause

the tractor to overturn.

15. Be sure hydraulic couplers are properly mounted

and will disconnect safely in case of accidental

detachment of the implement.

16. Do not leave equipment in the raised position

when the vehicle is stopped or unattended.

17. Ensure any attached equipment or accessories

are approved for use and are correctly

installed. Maintained in accordance with the

instructions issued by the equipment or accessory

manufacturer.

18. Remember that your tractor, if abused or

incorrectly used, can be dangerous and become a

hazard both to the operator and to bystanders.

Do not overload or operate with attached equipment

which is unsafe, not designed for the particular task,

or is poorly maintained.

19. The cab is designed to meet and exceed

the applicable noise level standards (86dBA).

However, noise (sound pressure level)

in the workplace can exceed this level

when the cab window is open. Therefore, it

is recommended that the operators wear suitable

ear protectors when operating in high noise level

conditions.

20. Always keep sleeves, jackets or other clothing

relatively tight and belted. Loose clothing may

catch in moving parts and result in personal injury

or death.

21. Use steps and hand holds when mounting and

dismounting the tractor or for servicing

components too high to reach from the ground.

22. Lock the seat in position and buckle your safety

belt before operating the tractor.

23. Do not operate the tractor when you are tired,

sick, or impaired in any way.

24. Never operate the tractor in confined areas, or

when visibility next to the tractor is reduced. Injury

to bystanders or damage to the tractor or

equipment may result.

25. When hitching drawn equipment to the drawbar,

only allow an assistant between the tractor and

implement if the tractor is off, in neutral and the

brakes are engaged.

26. Do not leave implements with the hydraulic

cylinders fully extended or retracted where the

heat from the sun can cause the hydraulic fluid

to expand. Hydraulic pressure can rupture the

hoses, releasing high pressure oil causing personal

injury.

27. Be careful when turning with an implement. Lift

it from the ground if possible during turns. Side

thrust caused by the implement could damage

the tire and implement.

28. Use transport locks, lower the implement to the

ground and securely block the frame before

servicing the implement. Relieve pressure from

the hydraulic system and shut off the tractor.

Operating the PTO

1. When operating PTO–driven equipment, shut off

the engine and wait until the PTO stops before

getting off the tractor and disconnecting the

equipment.

2. Do not wear loose clothing when operating the

power take–off or when near rotating equipment.

3. When operating stationary PTO–driven equipment,

ensure that the park brake is set and the gearshift

lever is in neutral, block the rear wheels front and

rear and engage the articulation lock. Do not leave

the tractor unattended. If you must leave the

tractor for any reason, stop the engine and remove

the key.

4. To avoid injury, do not clean, adjust, unclog or

service PTO driven equipment when the tractor

engine is running.

5. Make sure all PTO shields are in position at all

times.

7. Take special care in hook–up of implements to

the PTO.

435/485/535

Servicing the Tractor

1-11

Section 1 - Safety

Precautionary Statements

Most accidents can be avoided by observing certain

precautions. To help prevent accidents, read and

take the following precautions before servicing the

tractor.

1. The cooling system operates under pressure which

is controlled by the radiator cap. It is dangerous

to remove the cap while the system is hot. Always

turn the cap slowly to the first stop and allow the

pressure to escape before removing the cap

entirely. Wear gloves when removing the cap.

2. Do not smoke while refueling the tractor. Keep

any type of open flame away.

3. Keep the tractor and equipment, particularly

brakes and steering, maintained in a reliable

and satisfactory condition to ensure your safety

and comply with legal requirements.

4. To prevent fire or explosion, keep open flames

away from the battery or cold– weather starting aids.

To prevent sparks which could cause explosion,

use jumper cables according to instructions.

5. Do not attempt to service the air conditioning

system. It is possible to suffer severe frost bite or

injury from escaping refrigerant. Special

equipment and instruments are required to

service the air conditioning system which uses

R134A refrigerant. See your authorized Buhler

Versatile dealer for service.

6. Stop the engine before performing any service on

the tractor.

7. Escaping diesel/hydraulic fluid under pressure

can penetrate the skin causing serious injury.

• DO NOT use your hand to check for leaks.

Use a piece of cardboard or paper to search

for leaks.

• Stop the engine and relieve pressure before

connecting or disconnecting lines.

• Tighten all connections before starting the

engine or pressurizing lines.

• If fluid is injected into the skin, obtain medical

attention immediately or gangrene may

result.

8. Do not modify, alter or permit anyone else to

modify or alter the tractor or any of its components

or any tractor function without first consulting an

authorized Buhler Versatile dealer.

9. Unqualified persons should not remove or attempt

to adjust a pump, injector, nozzle or any other

part of the fuel injection system. Failure to follow

these instructions can result in serious injury.

10. Continuous long–term contact with used engine

oil may cause skin cancer. Avoid prolonged

contact with used engine oil. Wash skin promptly

with soap and water.

11. Tractor wheels are very heavy. Handle with care

and ensure, when stored, they cannot fall and

cause injury.

12. Dispose of all drained fluids and removed filters

properly. Follow local laws governing disposal of

used engine oil.

13. Never oil, grease or adjust the tractor while it is

running. Do not leave the engine running while

the tractor or drawn equipment is being adjusted,

repaired or cleaned.

14. Be sure all connections are tight and lines and

hoses are undamaged. Before disconnecting

hydraulic lines, relieve all pressure. Do not overfill

the hydraulic tank.

15. Do not smoke and avoid open flames when

servicing batteries.

16. Starting fluid is highly flammable. Do not use

near fire, sparks, or open flames.

17. Remove mud, crop residue, chains and tools from

steps and operator’s platform. They may interfere

with pedal operation or entry/exit from the

tractor.

18. Never operate the tractor with a damaged tire.

The tire may explode.

19. Tighten all connections before starting the engine

or pressurizing lines.

435/485/535

1-12

Section 1 - Safety

Precautionary Statements

Diesel Fuel

1. Under no circumstances should gasoline, alcohol

or blended fuels be added to diesel fuel. These

combinations can create an increased fire or

explosive hazard. In a closed container, such as a

fuel tank, these blends are more explosive than

pure gasoline. Do not use these blends.

2. Do not smoke while refueling the tractor or when

standing near fuel. Keep any type of open flame

away.

3. Never remove the fuel cap or refuel with the

engine running. Allow the tractor to cool off before

fueling.

4. Use the proper fuel transfer hose and nozzle. Make

sure the nozzle and hose are grounded to dissipate

static electric charges.

5. When refueling, make sure the nozzle is in

contact with the filler neck of the tractor fuel tank

before fuel starts to flow and during the entire

time fuel is flowing.

6. Maintain control of the fuel filler pipe nozzle when

filling the tank.

7. Do not fill the fuel tank to capacity. Allow room for

expansion.

8. Wipe up spilled fuel immediately.

9. Always tighten the fuel tank cap securely.

Safety Cab

Your tractor is equipped with a safety cab which must

be maintained in a serviceable condition. Be careful

when driving through doorways or working in confined

spaces with low headroom.

1. Do not modify, drill, weld, or alter the safety cab

in any way. Doing so could render you liable to

legal prosecution in some countries.

2. Never attempt to straighten or weld any part of the

main frame or retaining brackets which have

suffered damage. By doing so you may weaken

the structure and endanger your safety. Replace

all damaged parts.

3. Never attach chains or ropes to the cab or main

frame for pulling purposes.

4. Never take unnecessary risks even though your

safety cab affords you the maximum protection

possible.

5. Do not carry harmful chemicals in the cab.

Chemicals may rupture the container, and the

fumes may poison the operator.

6. The tractor cab is not designed to provide a

“sprayer safe” environment for the operator. When

applying chemicals from a spray unit, do not rely

on the cab filter elements to provide protection to

the operator from the airborne chemicals.

10. If the original fuel tank cap is lost, replace it with

a genuine replacement cap. A non–approved cap

may not be safe.

11. Keep equipment clean and properly maintained.

12. Do not drive equipment near open fires.

13. Never use fuel for cleaning purposes.

14. Arrange fuel purchases so that summer grade

fuels are not held over and used in the winter.

15. Ground fuel storage tanks to prevent static

buildup.

435/485/535

F1-2

1-13

Section 1 - Safety

Safety Labels

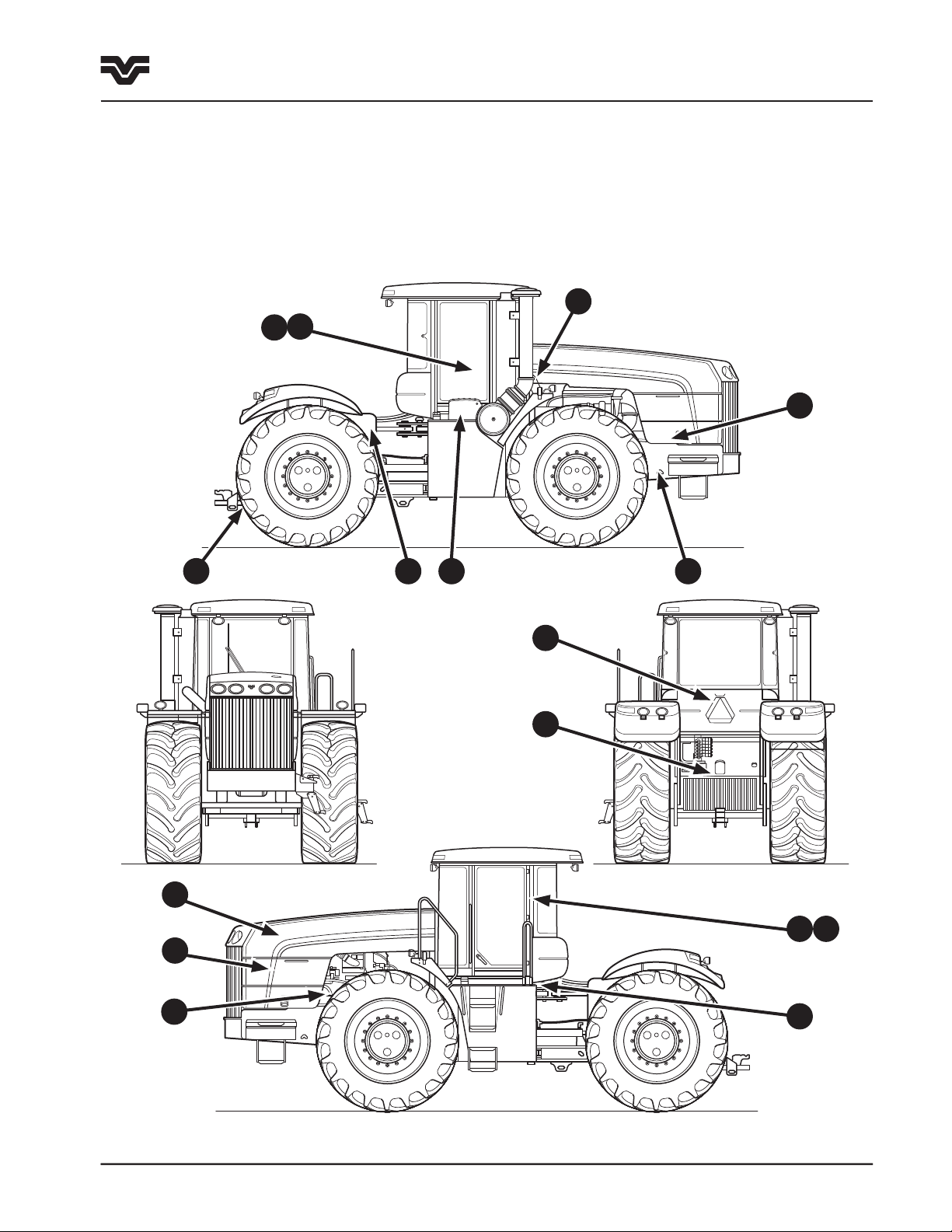

Safety Labels

The following warning signs are installed on the tractor in the areas indicated. They are intended for your safety

and for those working with you. Please become familiarized with the content and location of these warning

signs.

Make sure all warning signs are legible. Clean or replace where necessary. Replacements warning signs can be

obtained from your Buhler Versatile dealer.

6

15

4

11

10

12

7

3

9

8

3

2

5

13 14

1

435/485/535

CAUTION

ATTACH IMPLEMENTS PROPERLY

Attaching clevis

type tongues

Attaching clevis

type tongues

Pull only from drawbar or three

point hitch.

Use a safety chain when towing

implement.

•

•

•

•

86000550-C

WARNING

AVOID POSSIBLE

INJURY OR DEATH

Do not start engine by shorting

across starter terminals. Engine can

start and machine can move when

starting safety switch is by-passed.

Start engine only from operator’s

seat with transmission in neutral and

the parking brake applied

86000552-C

WARNING

CONTENTS UNDER PRESSURE

Accumulator charged to 69 bar (1000 psi).

Pump service brakes at least ten times

with engine off to release pressure before

loosening any fittings connected to the

accumulator.

86034047

WARNING

ENGAGE PARK BRAKE

BEFORE EXITING

TRACTOR

86034142

CAUTION

DO NOT CONNECT JUMPER CABLE TO NEGATIVE POST OF DISCHARGE BATTERY

BATTERY BOOST INSTRUCTIONS

86000551-D

•

Apply parkbr ake, set transmis sion in neutral a nd turn all elec trical connection s off

•

Connect one end of jumper cab le to positive te rminal of boosti ng battery and ot her

end to posit ive terminal of d ischarged battery

•

Connect one end of negative c able to negative post of battery and other end to

tractor fram e at least 300 mm (12") from dis charged battery

•

DO NOT LEAN OVER BATTERIES WHILE MAKING CONNECTIONS

•

DO ENSURE POSITIVE AND NEGATIVE CLAMOS ARE NOT IN CONTACT

•

DO ENSURE VEHICLES ARE NOT IN CONTACT

•

86001239

ROLL OVER PROTECTIVE STRUCTURE

FOR TRACTORS: 435/485/535

MEETS OSHA REGULATION

PROTECTIVE STRUCTURE

PART NO: 86031286

CERTIFIED TO CSA STANDARD

86033283

F1-3A

1-14

Section 1 - Safety

Safety Labels

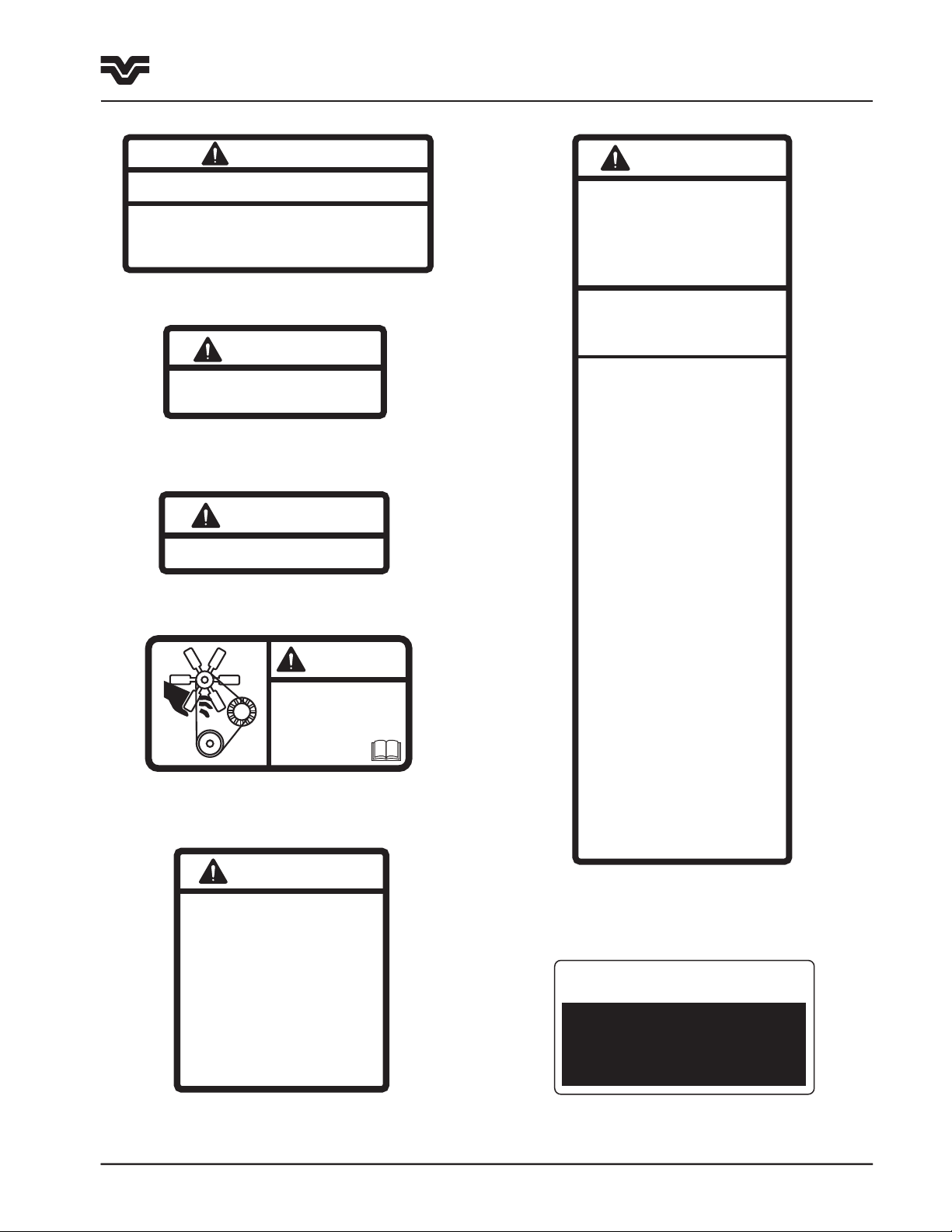

1. ROPS Certificate - Located left underside of cab.

2. Slow-Moving Vehicle - Located on rear of cab.

5. Implement Attaching - Located above the drawbar

at the rear of the tractor.

6. Accumulator Pressure - Located on the fender

support above the multifunction valve.

3. Tie down brackets

- Located on frames.

4. Park Brake - Located

inside cab on right hand window

8. Battery Boosting - Located on the underside of

the battery cover.

435/485/535

7. Jump starting - Located on the left

side frame next to the starter.

CAUTION

PRESSURIZED SYSTEM

Remove cap slowly

86000548-C

CAUTION

HOT EXHAUST SYSTEM COMPONENTS

86000549-C

WARNING

ARTICULATING JOINT

STAY CLEAR OF THIS AREA WHEN ENGINE IS RUNNING

TO PREVENT PERSONAL INJURY

Engage articulation lock before lifting tractor, transporting tractor on another vehicle,

performing maintenance in articulation area or operating stationary PTO equipment.

86000554-C

Shut off engine before servicing articulation area.

Disengage lock before driving the tractor,

•

•

•

CAUTION

This roll over protective structure meets

OSHA and other safety standards when

installed in accordance with approved

factory mounting instructions

The protection afforded may be impaired if it

has been subjected to alteration, structural

damage, or involved in an overturn accident.

In these cases the entire structure must be

replaced.

BE SURE OPERATION AND SAFETY

INSTRUCTIONS ARE GIVEN TO

ANYONE USING THIS TRACTOR AT

THE TIME OF INITIAL ASSIGNMENT

AND ANNUALLY THEREAFTER.

BEFORE STARTING:

WHEN OPERATING:

BEFORE DISMOUNTING, SERVICING,

CLEANING OR ADJUSTING TRACTOR

OR IMPLEMENT:

FAILURE TO FOLLOW ALL OF THE

ABOVE INSTRUCTIONS COULD LEAD

TO SERIOUS INJURY.

Read the operator’s manual provided.

Know all the operating and safety

instructions in the operator’s manual

and on the machine.

86000553-D

•

Securely fasten your seatbelt.

•

Be sure all shields are in place.

•

Hitch only to drawbar or three point

hitch lift points.

•

No riders should be permitted in the

cab or on the tractor.

•

Make sure everyone is clear of the

machinery.

•

Do not allow children to operate the

tractor.

•

Avoid operating tractor near holes,

ditches or steep slopes.

•

Bring tractor to a complete stop. Lower

implement, shift transmission to neutral,

set park brake.

•

Stop engine and wait for all moving parts

to come to a complete halt. Remove key

if leaving tractor.

•

Avoid jerky starts or stops.

•

Use flashers and extremity lights

when required.

•

Reduce speed when turning, crossing

slopes and on rough, slick, or muddy

surfaces.

•

Be sure the transmission is in neutral,

PTO is disengaged and implement

hydraulic levers are in neutral.

•

86033512

CAUTION

This instructional seat

has been provided only

for training operators

or diagnosing machine

problems.

Keep all other riders off

the tractor and equipment.

Always wear your seat belt.

WARNING

Ke ep ha nds a nd

cl oth in g a wa y f ro m

ro tat in g f an an d bel ts .

Fa ilu re to c omp ly co ul d

re sul t in de ath

or se ri ous i nju ry.

86501511-E

F1-3B

IMPORTANT

CLUTCH PEDAL MUST BE

DEPRESSED & TRANSMISSION

MUST BE IN NEUTRAL TO

START TRACTOR

86034143

1-15

Section 1 - Safety

Safety Labels

9. Pivoting Frames - Located on the right and left

sides.

1

0. Radiator Cap Pressure - Located on the left side

of the hood at the access hole for the radiator cap.

11. Hot Exhaust - Located on the right side frame

under engine hood.

12. Engine Cooling Fan - Located on both sides of

radiator under the engine side shields

14. ROPS Caution - Located inside cab on left hand

door post.

13. Instructional Seat - Located inside cab on left

hand door post.

15. Clutch Pedal operation - Located inside cab on

right hand window

435/485/535

F1-6

F1-4

F1-5

1-16

Section 1 - Safety

Additional Safety Items

Additional Safety Items

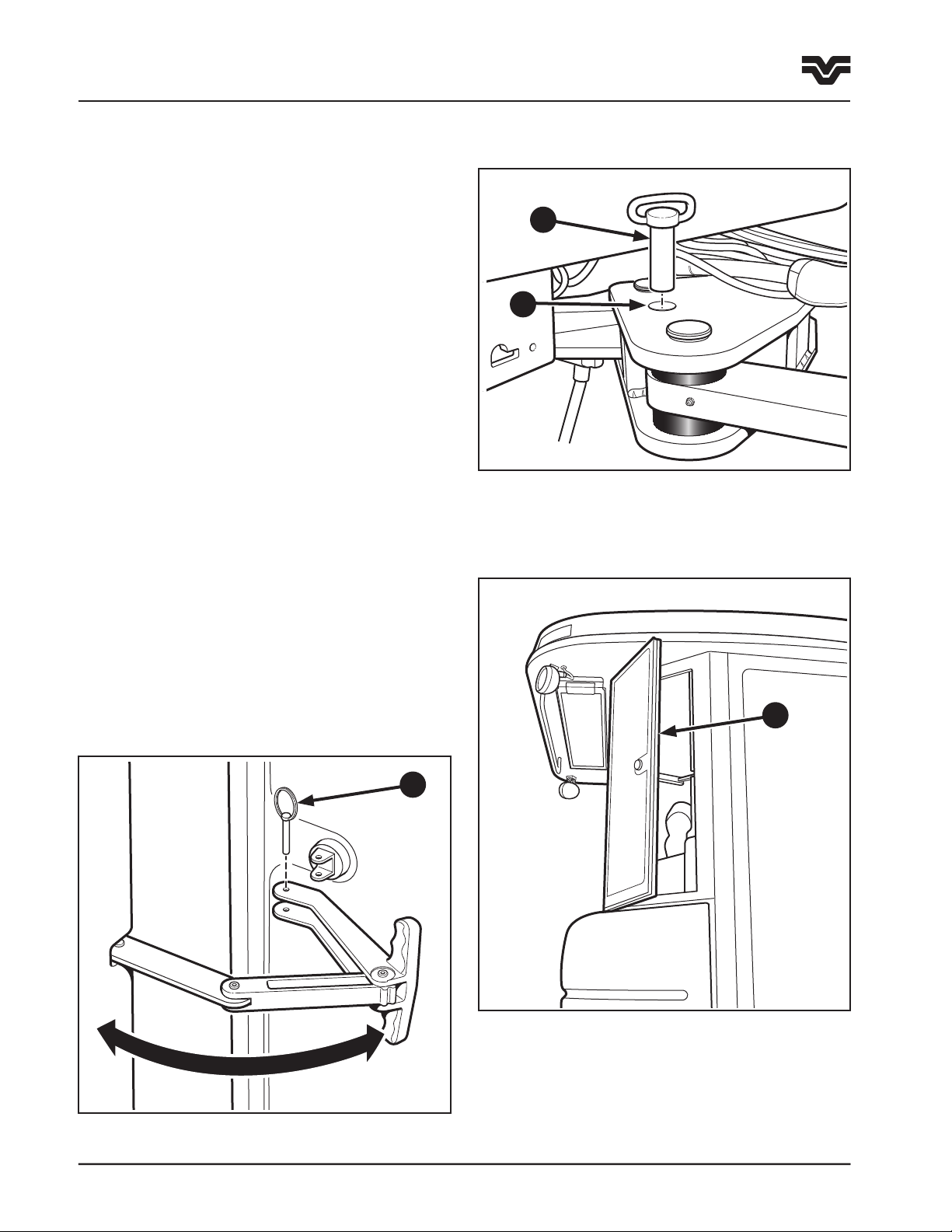

Articulation Locks

1. Use the articulation lock during stationary

applications, servicing, jacking or overhaul

operations. Do not use when the tractor is

operating.

1

2. Before engaging the lock, drive the tractor to a

level surface, put the steering straight, engage the

park brake, put the gearshift in neutral and stop

the engine.

3. Remove the pin (1) from the storage position

located on the right of the swing frame and insert

the pin through the hole on the left of swing

frame (2).

NOTE: It may be necessary to start the engine and

articulate the frame slightly to enable the

articulation pin to seat properly through the swing

frame and front frame.

Emergency Exit

1. The cab has an emergency exit located in the right

rear of the cab (3). To operate, pull out the

pin (4) attaching the lever to the glass window.

This will allow the window to open beyond

the latch. If greater access is required, the

silicone hinge/seal can be cut to remove the

window completely.

2

3

435/485/535

4

1-17

Section 1 - Safety

Safety Cab

Safety Cab

A safety cab incorporates a Roll Over Protective

Structure (ROPS). Safety belts are standard fitted

equipment for the tractor at the time of factory

assembly. The safety belt, when used by the operator,

maximizes the protection offered by the ROPS.

WARNING: ALWAYS USE YOU SAFETY BELT WITH

THE CAB/ROPS TO PREVENT BEING THROWN

FROM THE TRACTOR IN THE EVENT OF ROLLOVER.

SAFETY BELTS SAVE LIVES WHEN THEY ARE

USED.

Information regarding the safety cab/ROPS and safety

belt are available from your authorized Buhler Versatile

dealer.

ROPS Maintenance and Inspection

After the first 50 hours of operation and every 1500 of

operation (or yearly, whichever comes first):

Damage to the Cab/ROPS

If the tractor has rolled over or the cab has been

damaged (such as striking an overhead object during

transport), it must be replaced to provide the original

protection.

IMPORTANT: Do not try to weld or straighten the

cab/ROPS.

After an accident, check for damage to the cab/ROPS,

operator’s seat, safety belt and safety belt mountings.

Replace all damaged parts before operating the

tractor.

WARNING: NEVER ATTACH, CHAINS, ROPES

OR CABLES TO THE CAB/ROPS FOR PULLING

PURPOSES. ALWAYS PULL FROM THE TRACTOR

DRAWBAR. BE CAREFUL WHEN DRIVING THROUGH

DOOR OPENINGS OR UNDER LOW OVERHEAD

OBJECTS. MAKE SURE THERE IS SUFFICIENT

OVERHEAD CLEARANCE FOR THE CAB/ROPS.

1. Check the torque of the cab/ROPS mounting bolts,

as detailed in the lubrication and maintenance

section of this manual.

2. Check the operators seat mounting bolts and safety

belt mounting bolts. Tighten the seat mounting

bolts to 40 N

damaged parts.

·m (30 ft-lbs.). Replace any worn or

WARNING: IF THE CAB/ROPS IS REMOVED OR

REPLACED, MAKE CERTAIN THAT THE PROPER

HARDWARE IS USED AND THE RECOMMENDED

TORQUE VALUES ARE APPLIED TO THE ATTACHING

BOLTS. SEE YOUR AUTHORIZED BUHLER

VERSATILE DEALER.

435/485/535

1-18

435/485/535

2-1

Section 2 - General Information

Contents

Section 2 Contents - General Information

Tractor Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Overall Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Tractor Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Tractor Identification Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Vehicle Identification Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Tractor Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Engine Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Transmission Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Front & Rear Axle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Protective Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Engine Side Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Starter Solenoid Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Battery Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Break-In period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Towing the Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Transporting the Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

435/485/535

2-2

F2-3

F2-2

F2-4

F2-1

Section 2 - General Information

Tractor Orientation

Tractor Orientation

Overall Description

The Models 435, 485 and 535 tractors are

classified as 4–wheel drive articulating vehicles.

The tractors consist of front and rear frame assemblies

which steer by pivoting at the center articulation

joint.

The front frame, (1) incorporates the engine, fuel

tanks, transmission, front drive axle, and cab. The rear

frame, (2) incorporates the rear drive axle and supports

any implements that are operated by the tractor. This

type of design allows for greater flexibility of weight

distribution, depending upon operating conditions and

type of implement. The operator can ballast the tractor

to best suit the needs of the particular operation.

The construction of the tractor is a modular-type

construction. This means that the major components

are individual units which are supported within

the front and rear frames. This makes for easier

serviceability and longer life due to reduced structural

stress on components.

Tractor Terminology

This manual uses the following terms to describe

tractor function and directional relationships:

Front (1) - The engine end of the tractor. This direction

will also be referred to as the “Forward Direction

of Travel”.

Right (2) - The console side of the cab.

Rear (3) - The drawbar end of the tractor, which is

used for pulling implements.

Left (4) - The doorway side of the cab.

1

2

1

2 3

4

Articulation - The ability to steer by pivoting

between front and rear frame sections.

435/485/535

Oscillation - The ability of a vehicle to twist,

allowing travel over uneven terrain.

F2-7

F2-6

Tractor Identification Data

MODEL

TRANSMISSION

HYDRAULIC PUMP

FWD-FACTOR

BUHLER VERSATILE INC.

TRACTOR NUMBER

ENGINE

FRONT AXLE

UNIT

REAR AXLE

HYDRAULIC LIFT

SPECIAL ORDER

F2-5

The tractor and its major components are identified

using serial numbers and/or manufacturing codes.

These codes are recorded on the Vehicle Identification

Plate, (ID plate).

NOTE: Tractor identification data must be supplied

to the dealer when requesting parts or service.

Identification data is needed to aid in identifying the

tractor if it is ever stolen.

Please record the following identification data in the

sample ID plate, right.

The following information provides the locations of the

identification data.

2-3

Section 2 - General Information

Tractor Identification Data

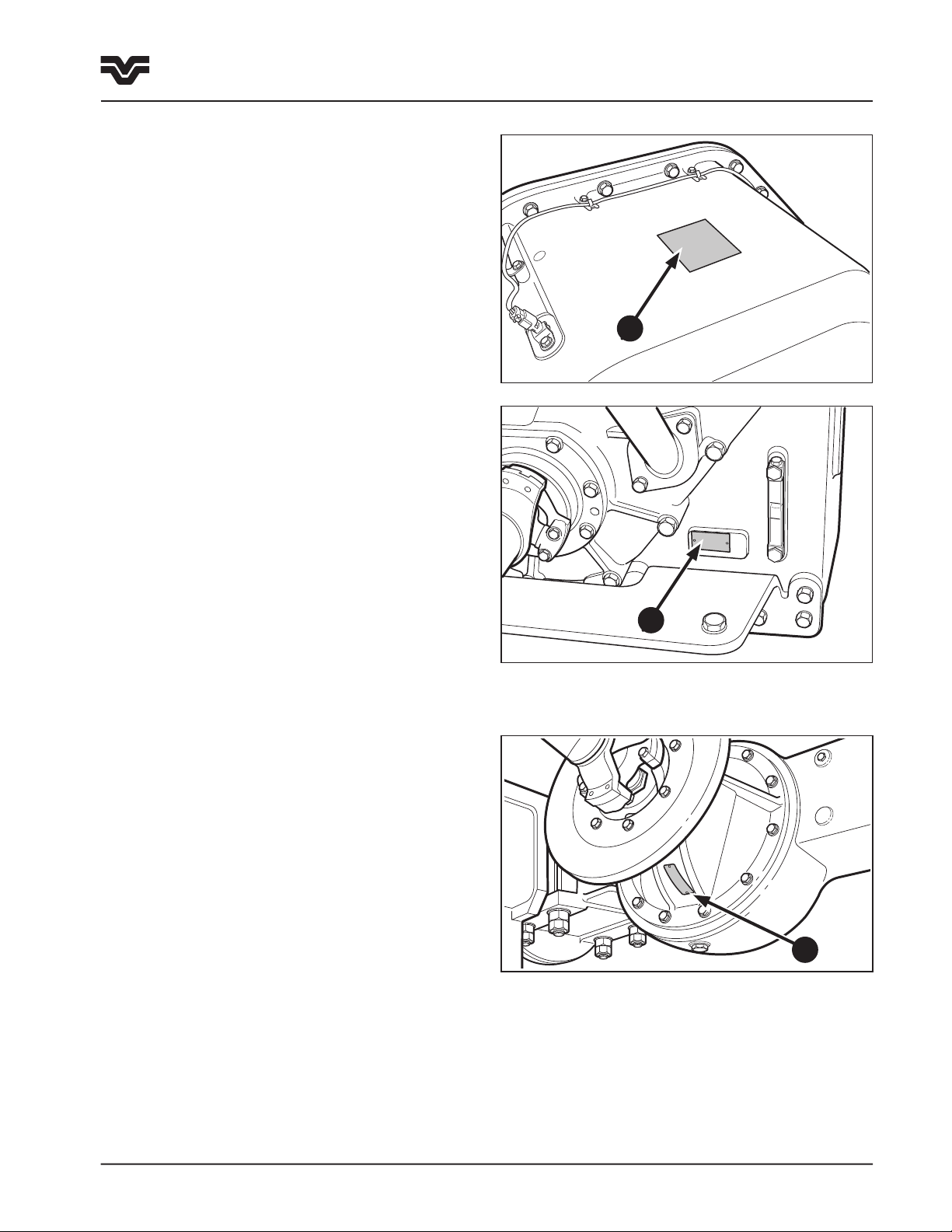

Vehicle Identification Plate

The Vehicle Identification Plate (1) is located on the

left rear underside corner of the cab.

The ROPS identification plate (2) is located adjacent

to it.

Tractor Identification

The tractor serial number (3) is stamped on the front

frame.

This serial number stamp is used in the event that the

Tractor Identification Plate is removed or mutilated.

1

2

3

435/485/535

2-4

F2-9S

F2-8

F2-9P

Section 2 - General Information

Tractor Identification Data

Engine Identification

The Cummins engine used in your Buhler Versatile

4WD tractor is serviced solely by the Cummins

Engine Company through its authorized dealers and

distributors. Many Buhler Versatile dealers are

authorized Cummins dealers. If your dealer is

not, he will arrange for the engine service on

your tractor to be carried out by an authorized

Cummins engine dealer or distributor.

For service, warranty, and parts information, contact

your Buhler Versatile dealer.

For the 435, 485 and 535 tractor (Cummins QSX15

engine), the Engine Identification Plate (1) is located

on the front left side of the engine block below the

valve cover.

Transmission Identification

Synchromesh Transmission (12 x 4 Synchronized)

The serial number plate is on the right rear of

the transmission case (2). This is a 6-digit alpha

numeric number.

1

1407 Twindisc Powershift Transmission

The serial number plate is located on the left rear of

the transmission case (3).

435/485/535

2

3

F2-10

CAT TA22 Powershift Transmission

F2-9C2

F2-9C1

There are two serial number plates, located on the top

of the transmission case (1) and on the bottom rear

right below the transmission oil level sight glass (2).

2-5

Section 2 - General Information

Tractor Identification Data

1

Front & Rear Axle Identification

On the underside (or topside) of the input shaft is

the Differential Identification Plate (3) containing

differential model information.

NOTE: Make a copy of the information recorded in the

preceding paragraphs and keep in a safe location in

the event your operator’s manual is lost or destroyed.

2

3

435/485/535

2-6

F2-13

F2-12

F2-11

Section 2 - General Information

Protective Shielding

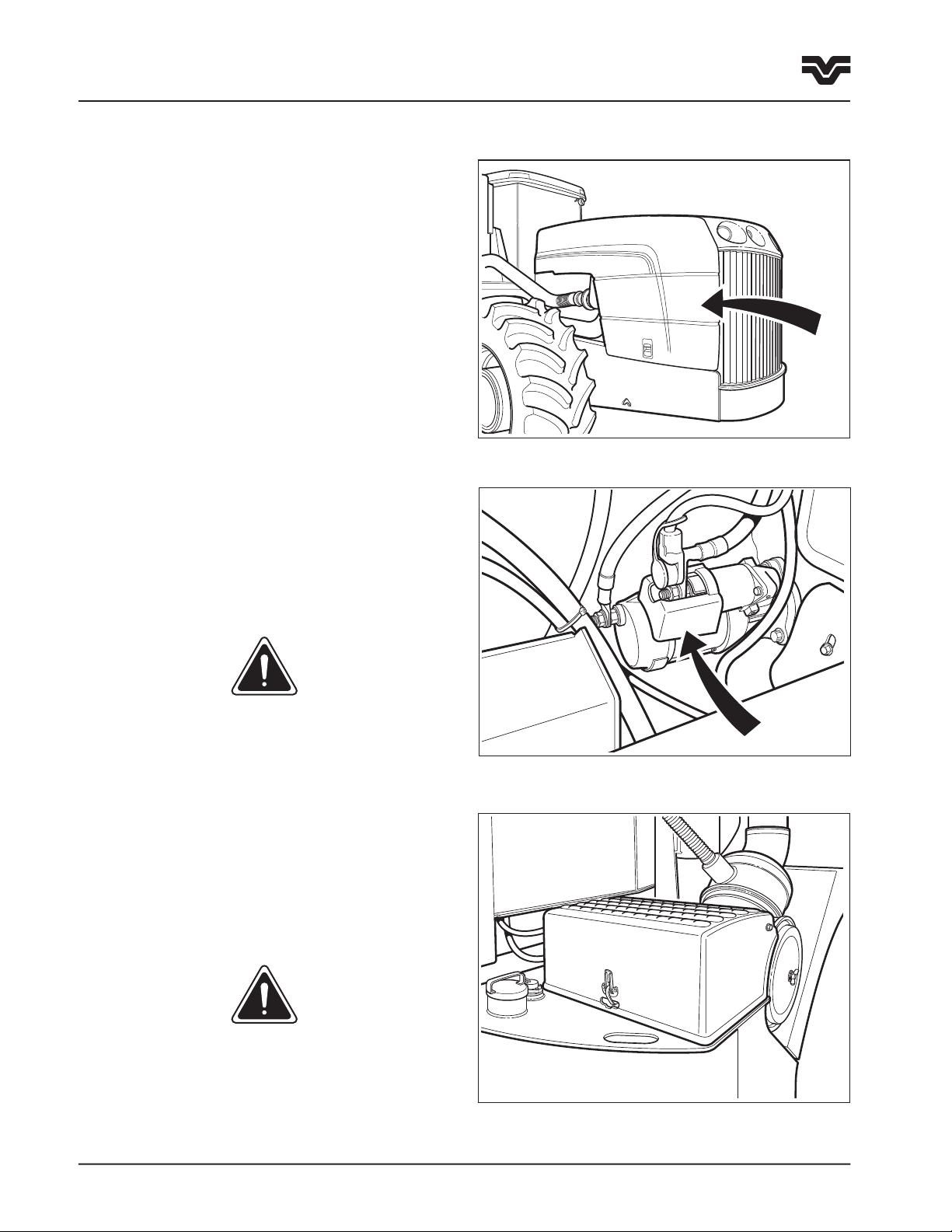

Protective Shielding

Engine Side Covers

The side covers protect the operator from hot and/or

moving parts. Do not operate the tractor unless the

engine side covers are in place and latched.

Starter Solenoid Shield

The shield covers the starter solenoid electrical

connections to prevent accidental contact. The

shield must be installed whenever the batteries are

connected to the electrical system. Always disconnect

battery before removing the shield.

DANGER: NEVER ATTEMPT TO START THE TRACTOR

BY BYPASSING THE WIRES TO THE STARTER

MOTOR.

Battery Cover

The battery cover protects the batteries from damage

and the electrical connections from accidental contact.

The battery cover must always be in place and latched

during operation.

WARNING: INSTALL ALL PROTECTIVE SHIELDS

BEFORE STARTING OR OPERATING THE TRACTOR.

435/485/535

Break-in Periods

2-7

Section 2 - General Information

Break-In Period

The first 50 hours of operation are the most critical for

insuring long and dependable tractor life. Please carry

out the following procedures:

1. Review the tractor Pre-delivery Checklist contained

in the assembly manual with your dealer. Be sure

all applicable items on the sheet have been

checked.

2. Check all fluid levels and be sure all systems are

filled with the correct fluids for your operating

conditions.

3. Check the engine, transmission, and hydraulic oil

levels hourly during the first 10 hours of

operation.

4. Inspect the tractor for leaks hourly during the first

10 hours of operation.

5. Torque the wheel bolts to 715 N

after the first hour of operation and after every three

hour of operation for the first day. Re-tighten to the

specified torque daily until wheel hardware

maintains the specified torque.

6. Operate the engine at 3/4 load as much as possible

during the first 50 hours (3/4 load is approximately

one gear lower than would be normally used to pull

a matched load).

·m (525 ft-lbs)

Engine Break-in

The Cummins engine used in Buhler Versatile 4WD

tractors has been run on a dynamometer before

installation but not enough to be considered broken

in.

1. Do not operate the engine at more than 3/4 load

for the first 24 hours of operation. Full load should

only be held for short intervals during the next 24

hours of operation.

2. Check the oil level every 8 to 10 hours for the first

100 hours of operation.

3. Follow the recommendations outlined in the

Cummins manual supplied with your tractor.

7. Do not operate the engine at idle speed or maximum

horsepower for more than 5 minutes at a time for

the first 50 hours.

8. Check the frame pivot pin, drag link and steering

cylinder cap screw torques after the first 10 hours

of operation. Torque the frame pivot pin to 1365

N

·m (1000 ft-lbs) and the remaining pins to 175

N

·m (130 ft-lbs).

9. Have your dealer complete the “First 50-Hour

Service” checklist at the end of this manual.

435/485/535

2-8

Section 2 - General Information

Towing the Tractor

Towing The Tractor

IMPORTANT: The tractor should only be towed a short

distance such as out of a building. Do not tow down

roadways or as a method of transport. Haul the tractor

on a trailer.

If towing the tractor is necessary, use a strong chain

or cable of sufficient strength to tow the vehicle.

Consult your Buhler Versatile Dealer. Tow the tractor

BACKWARD from the drawbar or FORWARD from both

of the front tie-down slots. Use the tie-down slots in

the front and rear frames to attach the chains to the

tractor.

WARNING: WHEN THE TRACTOR IS TOWED AND

THE ENGINE IS NOT RUNNING THERE WILL BE NO

BRAKES AVAILABLE ON THE TRACTOR RESULTING

IN A POSSIBLE COLLISION. ALWAYS USE A SOLID

TOWING BAR BETWEEN THE TRACTOR AND THE

TOWING VEHICLE. THE TOWING VEHICLE MUST

BE OF ADEQUATE SIZE TO STOP THE TOWED

TRACTOR.

IMPORTANT: Do not tow the tractor by hooking to the

engine cross brace.

1. Engage the parking brake, then shift transmission

in neutral. Attach the chain to the tractor.

2. If possible start the engine and let the engine run

so that full use can be made of the power steering

and brakes. If the engine cannot be run engage

the articulation lock. (see page 1-12)

IMPORTANT: If the engine is not operational, and

the transmission internal components are rotated by

the axle drive shafts for a long period of time,

possible transmission damage due to lack of

lubrication may result.

IMPORTANT: When the engine is running, the

clutch, transmission input shaft, and transmission

output shafts will also be driven. Be sure that

these components are functional prior to starting

the engine.

3. Release the parking brake and tow the tractor.

CAUTION: DO NOT TOW THE TRACTOR FASTER

THAN 8 KPH (5 MPH). ENGAGE THE ARTICULATION

LOCK WHEN IT IS NOT POSSIBLE TO STEER THE

TRACTOR (WITH THE ENGINE RUNNING).

WARNING: ONLY USE CABLES OF SUFFICIENT

STRENGTH TO TOW THE TRACTOR. IF A CABLE

BREAKS OR SLIPS, IT MAY WHIP WITH SUFFICIENT

FORCE TO CAUSE SERIOUS INJURY. WHEN USING

A CHAIN, ATTACH WITH THE HOOK OPEN SIDE

FACING UP; IF IT SLIPS, IT WILL DROP DOWN

INSTEAD OF FLYING UPWARD CAUSING SERIOUS

INJURY.

435/485/535

F2-14

F1-6

Transporting the Tractor

2-9

Section 2 - General Information

Transporting

1. Haul the tractor with all four wheels on to a flatbed

trailer.

2. Remove the outer duals or triples during

transporting unless special permits allow for over width hauling. Consult local authorities for

information on over-width hauling.

3. Make an accurate measurement of the highest point

on the tractor when it is loaded on the transporter.

Consult local authorities regarding over-height

hauling based on the measurements taken.

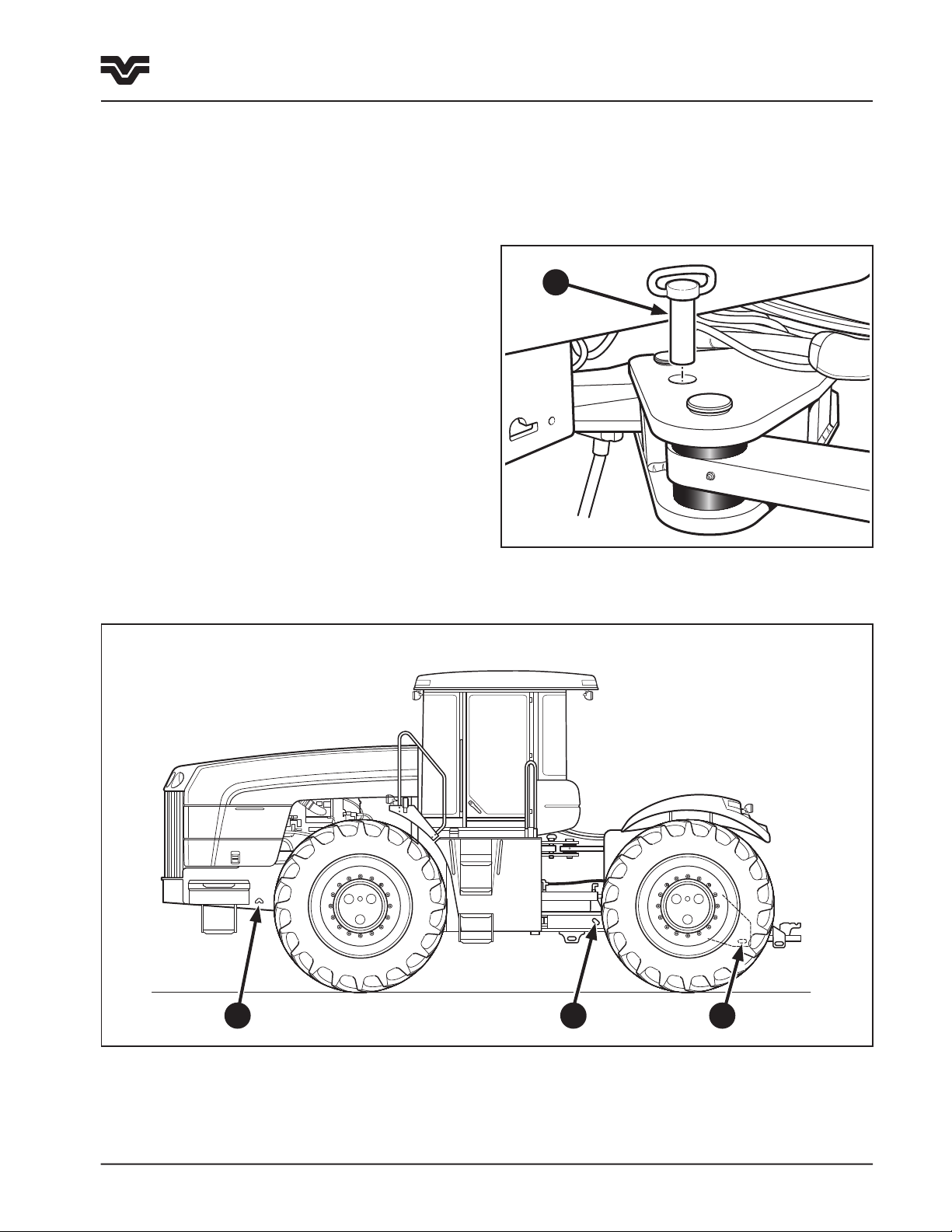

4. Tie-down brackets are located in the following

positions.

Cutout slots (1) are located on either side of the front

frame to allow a chain hook to be used to hold down

the front end of the tractor.

Tie-down brackets are located on either side of the rear

frame, in the articulation area (2) and on the drawbar

cage (3). Use a chain of adequate size, routed through

the brackets to hold down the tractor.

6. Always fully engage the park brake and install

the articulation lock pin (4) when transporting the

vehicle.

4

1

2 3

435/485/535

2-10

435/485/535

Section 3 Contents - Operation

3-1

Section 3 - Operation

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Pre-operation Checks . . . . . . . . . . . . . . . . . . 3-2

Precautionary Statements . . . . . . . . . . . . . . . 3-2

Welding & Battery Charging . . . . . . . . . . . . . . 3-3

The Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Entering the Cab . . . . . . . . . . . . . . . . . .

Cab Features . . . . . . . . . . . . . . . . . . . . .

Emergency Exit / Rear Window . . . . . . . .

Operator’s Seat . . . . . . . . . . . . . . . . . . . . . . . 3-6

Seat Belt . . . . . . . . . . . . . . . . . . . . . . . .

Standard Seat . . . . . . . . . . . . . . . . . . . .

Deluxe Seat . . . . . . . . . . . . . . . . . . . . . .

Instructional Seat . . . . . . . . . . . . . . . . 3-11

Controls & Instruments Overview . . . . . . . . . 3-12

Forward Operator Controls . . . . . . . . . . 3-12

Overhead Controls . . . . . . . . . . . . . . . . 3-13

Right Side Console Controls . . . . . . . . . 3-14

Steering Wheel and Column Adjustments . . . 3-16

Park Brake . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Foot Brake & Decelerator Pedal . . . . . . . . . . 3-17

Forward Operator Control Console . . . . . . . . 3-18

Overhead Control Details . . . . . . . . . . . . . . . 3-20

Climate Control & Air Conditioning . . . . . . . . 3-21

Electronic Instrument Cluster . . . . . . . . . . . 3-25

Indicator, Warning Lamps & Alarm . . . .

EIC Tractor Performance Monitor . . . . . .

Fault Codes . . . . . . . . . . . . . . . . . . . . .

EIC Calibration . . . . . . . . . . . . . . . . . . 3-41

Right Side Console Controls . . . . . . . . . . . . 3-46

Synchromesh Transmission . . . . . . . . . .

Powershift Transmission . . . . . . . . . . . .

Hand Throttle . . . . . . . . . . . . . . . . . . .

Cruise Control . . . . . . . . . . . . . . . . . . .

Autoshift (CAT TA22 Transmission) . . . .

Differential Lock . . . . . . . . . . . . . . . . .

Remote Hydraulic Controls - Manual . . . . . . 3-47

Remote Hydraulic Controls -

Electro-Hydraulic . . . . . . . . . . . . . . . . . . . . 3-49

Tractor Start-up and Engine Operation . . . . . 3-50

Cold Weather Starting. . . . . . . . . . . . . . 3-51

Tractor Boosting . . . . . . . . . . . . . . . . . .

3-4

3-4

3-5

3-6

3-7

3-9

3-27

3-36

3-40

3-46

3-46

3-46

3-47

3-47

3-47

3-53

Tractor Operation . . . . . . . . . . . . . . . . . . . . 3-54

Hand Throttle Operation . . . . . . . . . . . .

Decelerator Pedal . . . . . . . . . . . . . . . . .

Cruise Control Operation . . . . . . . . . . . .

Stopping the Tractor . . . . . . . . . . . . . . .

Transmission Operation . . . . . . . . . . . . . . . . 3-57

Synchromesh Transmission Operation . .

1407 Powershift Transmission Operation

CAT TA22 Powershift Transmission Operation

Drawbar Operation . . . . . . . . . . . . . . . . . . . 3-67

External Lighting . . . . . . . . . . . . . . . . . . . . 3-70

Hydraulic System Overview . . . . . . . . . . . . . 3-72

Hydraulic Schematic Diagram . . . . . . . .

Remote Control Valve Operation - Manual . . . 3-74

Lockout Levers . . . . . . . . . . . . . . . . . .

Hydraulic Flow Controls . . . . . . . . . . . .

Hydraulic Quick Couplers . . . . . . . . . . .

Operating Continuous Flow Hydraulic

Equipment . . . . . . . . . . . . . . . . . . . . . 3-80

Hydraulic Motor Applications . . . . . . . . 3-81

Remote Control Valve Operation Electro-Hydraulic . . . . . . . . . . . . . . . . . . . 3-82

Electro-Hydraulic Control Pods . . . . . . .

Engagement Switch . . . . . . . . . . . . . . .

Manual Operation . . . . . . . . . . . . . . . .

Programmable Operation . . . . . . . . . . .

Flow Control Adjustment . . . . . . . . . . .

Hydraulic Quick Couplers . . . . . . . . . . .

Connecting Single-Acting Cylinders . . . .

Connecting Double-Acting Cylinders . . .

Operating Continuous Flow Hydraulic

Equipment . . . . . . . . . . . . . . . . . . . . . 3-89

Hydraulic Motor Application . . . . . . . . .

Bleeding Remote Cylinders . . . . . . . . . .

Wheels, Tires & Articulation Blocks . . . . . . . 3-91

Wheel Installation-Single . . . . . . . . . . . 3-91

Wheel Installation-Dual . . . . . . . . . . . .

Wheel Installation-Triple . . . . . . . . . . . .

Tire Selection . . . . . . . . . . . . . . . . . . .

Articulation Blocks . . . . . . . . . . . . . . . .

Ballasting . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

Ballasting Weights . . . . . . . . . . . . . . . . . . 3-102

3-54

3-54

3-54

3-56

3-57

3-59

3-61

3-73

3-75

3-77

3-78

3-83

3-84

3-85

3-85

3-87

3-88

3-89

3-89

3-90

3-90

3-92

3-93

3-95

3-96

435/485/535

Loading...

Loading...