BW Technologies GasAlertQuattro 3, GasAlertQuattro 2, GasAlertQuattro 1, GasAlertQuattro 4 Operator's Manual

1, 2, 3, and 4-Gas Detector

Operator’s Manual

GasAlertQuattro

Introduction

The operator’s manual provides basic information to operate

the GasAlertQuattro gas detector. For complete operating

instructions, refer to the GasAlertQuattro Technical Reference

Guide provided on the CD-ROM. The GasAlertQuattro gas

detector (“the detector”) is designed to warn of hazardous gas

levels above user-defined alarm setpoints.

The detector is a personal safety device. It is your responsibility

to respond properly to the alarm.

The detector is shipped with English as the default

displayed language. Additional languages provided

are French, German, Portuguese, and Spanish. The

screens for the additional languages are displayed on

the detector and in the corresponding operator s

manual.

Note

Zeroing the Sensors

To zero the sensors, refer to steps #1-3 in Calibration on

page 8.

Safety Information - Read First

Use the detector only as specified in this operator’s manual and

the technical reference guide, otherwise protection provided by

the detector may be impaired. Read the following Cautions

before using the detector.

a

Cautions

• Warning: Substitution of components may impair Intrinsic

Safety.

• Before using the detector, refer to Sensor Poisons

and Contaminants.

• Protect the combustible sensor from exposure to lead

compounds, silicones, and chlorinated hydrocarbons.

Although certain organic vapors (such as leaded gasoline

and halogenated hydrocarbons) may temporarily inhibit

sensor performance, in most cases the sensor will recover

after calibration.

• Caution For safety reasons, this equipment must be

operated and serviced by qualified personnel only. Read

and understand the technical reference guide completely

before operating or servicing.

1

GasAlertQuattro

Operator’s Manual

• Charge the detector before first-time use. BW Technologies

by Honeywell recommends the detector be charged after

every workday.

• Calibrate the detector before first-time use and then on a

regular schedule, depending on use and sensor exposure

to poisons and contaminants. BW recommends that the

sensors must be calibrated regularly and at least once

every 180 days (6 months).

• Calibrate only in a safe area that is free of hazardous gas

in an atmosphere of 20.9% oxygen.

• The combustible sensor is factory calibrated to 50% LEL

methane. If monitoring a different combustible gas in the

% LEL range, calibrate the sensor using the appropriate

gas.

• Only the combustible gas detection portion of this

instrument has been assessed for performance by CSA

International.

• BW recommends that the combustible sensor be checked

with a known concentration of calibration gas after any

exposure to contaminants/poisons such as sulfur

compounds, silicon vapors, halogenated compounds, etc.

• BW recommends to bump test the sensors before each

day’s use to confirm their ability to respond to gas by

exposing the detector to a gas concentration that exceeds

the alarm setpoints. Manually verify that the audible, visual,

and vibrator alarms are activated. Calibrate if the readings

are not within the specified limits.

• Caution High off-scale LEL readings may indicate an

explosive concentration.

2

• Any rapid up scaling reading followed by a declining or

erratic reading may indicate a gas concentration beyond

upper scale limit, which can be hazardous.

• For use only in potentially explosive atmospheres where

oxygen concentrations do not exceed 20.9% (v/v).

• Extended exposure of the GasAlertQuattro to certain

concentrations of combustible gases and air may stress

the detector element that can seriously affect its

performance. If an alarm occurs due to a high

concentration of combustible gases, a calibration should

be performed, or if needed, the sensor replaced.

• Warning: The lithium battery (QT-BAT-R01) may present

a risk of fire or chemical burn hazard if misused. Do not

disassemble, heat above 212°F (100°C), or incinerate.

• Warning: Do not use any other lithium batteries with the

GasAlertQuattro detector. Use of any other cell can cause

fire and/or explosion. To order and replace the QT-BAT-R01

lithium battery, contact BW Technologies by Honeywell.

• Warning: Lithium polymer cells exposed to heat at 266°F

(130°C) for 10 minutes can cause fire and/or explosion.

• ec Warnin g: This instrument contains a lithium polymer

battery. Dispose of used lithium cells immediately. Do not

disassemble and do not dispose of in fire. Do not mix with

the solid waste stream. Spent batteries must be disposed

of by a qualified recycler or hazardous materials handler.

• Keep lithium cells away from children.

• Deactivating the detector by removing the battery pack

may cause improper operation and harm the detector.

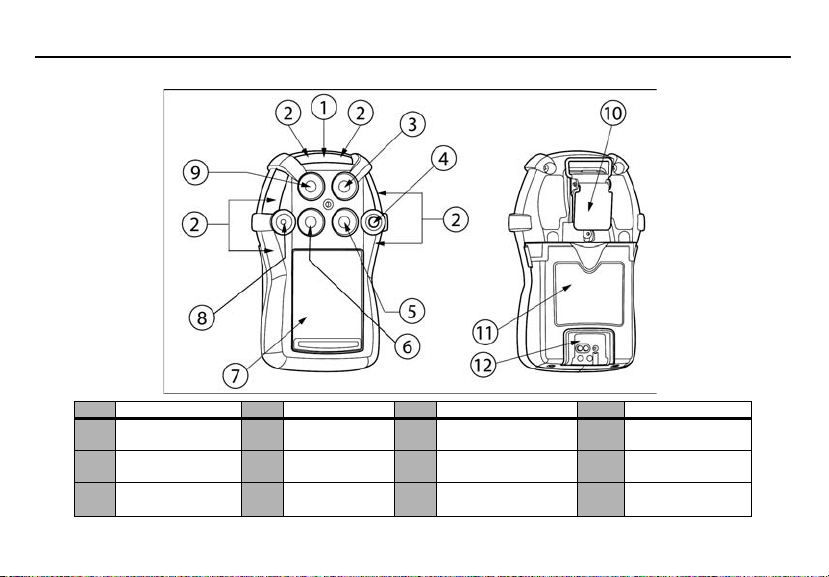

Parts of the GasAlertQuattro

Parts of the GasAlertQuattro

Item Description Item Description Item Description Item Description

Confidence/compliance

1

indicator (green LED)

Visual alarm indicator

2

(red LED)

Hydrogen sulfide

3

(H2S) sensor

4

Pushbutton

Combustible (LEL)

5

sensor

Carbon monoxide

6

(CO) sensor

Liquid crystal display

7

(LCD)

8

Audio alarm

9

Oxygen (O2) sensor

10

11

12

GasAlertQuattro

Alligator clip

Battery pack

Charging connector

and IR interface

3

GasAlertQuattro

Operator’s Manual

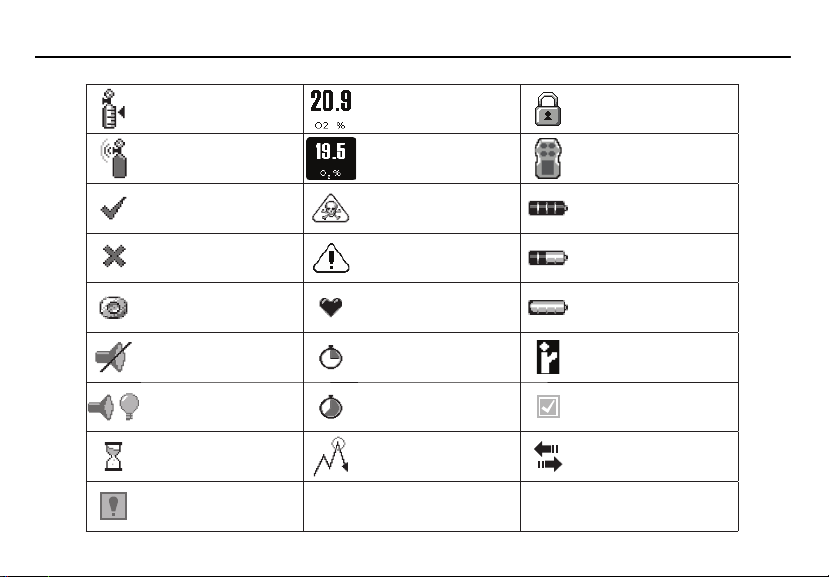

Screen Elements

Calibration gas cylinder

Bump test gas cylinder

Indicates pass for startup,

sensors, calibrations, and

bump tests

Indicates fail for startup, sensors, calibrations, and bump

tests

Pushbutton displays when

screen provides an option to

end or skip

Displays when the Stealth

option is enabled

Display during startup to

indicate audio and visual alarm

pass or fail during a MicroDock

II bump test

Displays during an operation

such as charging or autozeroing

Displays when the most recent

calibration failed but a previous

calibration is still valid within

the calibration due interval

4

Reading displays with white

background during normal

operation

Reading displays with black

background when the sensor

is in alarm

Displays when the detector

is in alarm (not applicable to

TWA and STEL)

Displays when there is a

warning, failure, error, or low

battery

Heartbeat pulses continually

during normal operation to

verify the detector is operating

correctly

Displays for STEL alarms and

setpoints

Displays for TWA alarms and

setpoints

Displays when maximum

concentration encountered

during work shift displays

Displays if calibration is initiated and the IR Lock option

is enabled

Displays during calibration

and when startup is complete

Battery — full charge

Battery — half charge

Low battery warning

Displays when the detector is

connected to an IR Link

Grey check box displays during bump tests or calibration

when a gas is not due

Displays when the detector’s

fi rmware is being updated

Pushbutton

Pushbutton Description

• To activate the detector, press and hold C in a safe area that is free of hazardous gas and

in an atmosphere of 20.9% oxygen.

• To deactivate the detector, press and hold C during the powering off countdown. Release

C when OFF displays.

• To view the date/time, current battery power, calibration due date, bump test due date,

TWA, STEL, and peak readings, press C twice rapidly. To clear the TWA, STEL, and

peak readings, press C when the LCD displays Hold C to reset peaks, TWA, STEL.

C

• To initiate calibration, press and hold C while the detector performs the OFF countdown.

Continue holding C while the LCD briefly deactivates and then reactivates to begin the

calibra ion countdown. Release C when Calibration started displays.

• To activate the backlight, press C and release.

• To acknowledge latching alarms, press C.

• To acknowledge a low alarm and disable the audible alarm, press C. The Low Alarm

Acknowledge option must be enabled in Fleet Manager II.

• To acknowledge any of the “due today” messages (calibration and bump test) press C.

If enabled, the force calibration and force bump features cannot be bypassed.

GasAlertQuattro

Pushbutton

5

GasAlertQuattro

Operator’s Manual

Sensor Poisons and Contaminants

Several cleaners, solvents, and lubricants can contaminate and

cause permanent damage to sensors. Before using cleaners,

solvents, and lubricants in close proximity to the detector sensors, read the following caution and table.

a

Caution

Use only the following BW Technologies by Honeywell

recommended products and procedures

• Use water based cleaners.

• Use non-alcohol based cleaners.

• Clean the exterior with a soft, damp cloth.

• Do not use soaps, polishes, or solvents.

6

The following table lists common products to avoid using

around sensors.

Cleaners and

Lubricants

Brake cleaners

Lubricants

Rust inhibitors

Window and glass

cleaners

Dishsoaps Mold releasing agents

Citrus based

cleaners

Alcohol based

cleaners

Hand sanitizer

Anionic

detergents

Methanol

(fuels and

antifreezes)

Silicones Aerosols

Silicone cleaners

and protectants

Silicone based

adhesives, sealants,

and gels

Hand/body and

medicinal creams that

contain silicone

Tissues containing

silicone

Polishes

Bug

repellents

and sprays

Lubricants

Rust

inhibitors

Window

cleaners

Loading...

Loading...