BW Technologies GasAlertMicroClip XT Instruction Manual

1, 2, 3, and 4-Gas Detector

Operator’s Manual

Limited Warranty and Limitation Liability

BW Technologies LP (BW) warrants the product to be free from defects in material and workmanship under normal use and service for a period of

two years, beginning on the date of shipment to the buyer. This warranty extends only to the sale of new and unused products to the original buyer.

BW’s warranty obligation is limited, at BW’s option, to refund of the purchase price, repair or replacement of a defective product that is returned to

a BW authorized service center within the warranty period. In no event shall BW’s liability hereunder exceed the purchase price actually paid by the

buyer for the Product.

This warranty does not include:

a) fuses, disposable batteries or the routine replacement of parts due to the normal wear and tear of the product arising from use;

b) any product which in BW’s opinion, has been misused, altered, neglected or damaged, by accident or abnormal conditions of operation,

handling or use;

c) any damage or defects attributable to repair of the product by any person other than an authorized dealer, or the installation of unapproved

parts on the product; or

The obligations set forth in this warranty are conditional on:

a) proper storage, installation, calibration, use, maintenance and compliance with the product manual instructions and any other applicable

recommendations of BW;

b) the buyer promptly notifying BW of any defect and, if required, promptly making the product available for correction. No goods shall be

returned to BW until receipt by the buyer of shipping instructions from BW; and

c) the right of BW to require that the buyer provide proof of purchase such as the original invoice, bill of sale or packing slip to establish that the

product is within the warranty period.

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. BW SHALL NOT BE LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL, OR BASED ON CONTRACT, TORT OR RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential

damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this warranty is held invalid or

unenforceable by a court of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Contacting BW Technologies by Honeywell

USA: 1-888-749-8878 Canada: 1-800-663-4164

Europe: +44(0) 1295 700300 Other countries: +1-403-248-9226

Email us at: info@gasmonitors.com

Visit BW Technologies by Honeywell’s website at: www.gasmonitors.com

GasAlertMicroClip XT

Introduction

The operator’s manual provides basic information for the

GasAlertMicroClip XT. For complete operating instructions,

refer to the GasAlertMicroClip XT Technical Reference Guide

provided on the CD-ROM. The GasAlertMicroClip XT (“the

detector”) warns of hazardous gas at levels above user-defined

alarm setpoints. The detector is a personal safety device. It is

your responsibility to respond properly to the alarm.

Note

The detector is shipped with English as the default

displayed language. Additional languages provided are

Portuguese, Spanish, German, and French. The screens

for the additional languages are displayed on the detector

and in the corresponding operator’s manuals.

Zeroing the Sensors

To zero the sensors, refer to steps #1-3 in Calibration on page 7.

ec Warning

This instrument contains a lithium polymer battery. Dispose

of lithium cells immediately. Do not disassemble and do not

dispose of in fire. Do not mix with the solid waste stream.

Spent batteries should be disposed of by a qualified

recycler or hazardous materials handler.

Safety Information - Read First

Use the detector only as specified in this manual and the reference guide, otherwise the protection provided by the detector

may be impaired. Read the following cautions before using the

detector.

Cautions

a

• Warning: Substitution of components may impair

Intrinsic Safety.

• Caution: For safety reasons, this equipment must be

operated and serviced by qualified personnel only.

Read and understand the user manual completely

before operating or servicing.

• Charge the detector before first time use. BW

recommends the detector be charged after every

workday.

• Before using the detector, refer to Sensor Poisons and

Contaminants.

1

GasAlertMicroClip XT

Operator’s Manual

• Calibrate the detector before first-time use and then

on a regular schedule, depending on use and sensor

exposure to poisons and contaminants. BW

recommends calibrating at least once every 180 days

(6 months).

• The combustible sensor is factory calibrated to 50%

LEL methane. If monitoring a different combustible

gas in the %LEL range, calibrate the sensor using

the appropriate gas.

• Only the combustible gas detection portion of this

instrument has been assessed for performance by

CSA International.

• Calibrate only in a safe area that is free of hazardous

gas and in an atmosphere of 20.9% oxygen.

• It is recommended that the combustible sensor be

checked with a known concentration of calibration

gas after any exposure to contaminants/poisons such

as, sulfur compounds, silicon vapors, halogenated

compounds, etc.

• BW recommends to bump test the sensors before each

day’s use to confirm their ability to respond to

gas by exposing the detector to a gas concentration

that exceeds the alarm setpoints. Manually verify that

the audible and visual alarms are activated. Calibrate

if the readings are not within the specified limits.

• Caution: High off-scale readings may indicate an

explosive concentration.

• Any rapid up scaling reading followed by a declining

or erratic reading may indicate a gas concentration

beyond the upper scale limit, which can be hazardous.

• Extended exposure of the GasAlertMicroClip XT to

certain concentrations of combustible gases and

air may stress a detector element that can seriously

affect its performance. If an alarm occurs due to a

high concentration of combustible gases, calibrate

the detector. If necessary, replace the sensor.

• Protect the combustible sensor from exposure to lead

compounds, silicones, and chlorinated hydrocarbons.

• Sensor exposure to certain organic vapors (such as

leaded gasoline and halogenated hydrocarbons) may

temporarily inhibit sensor performance. After exposure,

a bump test or calibration is recommended.

• For use only in potentially explosive atmospheres

where oxygen concentrations do not exceed

20.9% (v/v).

2

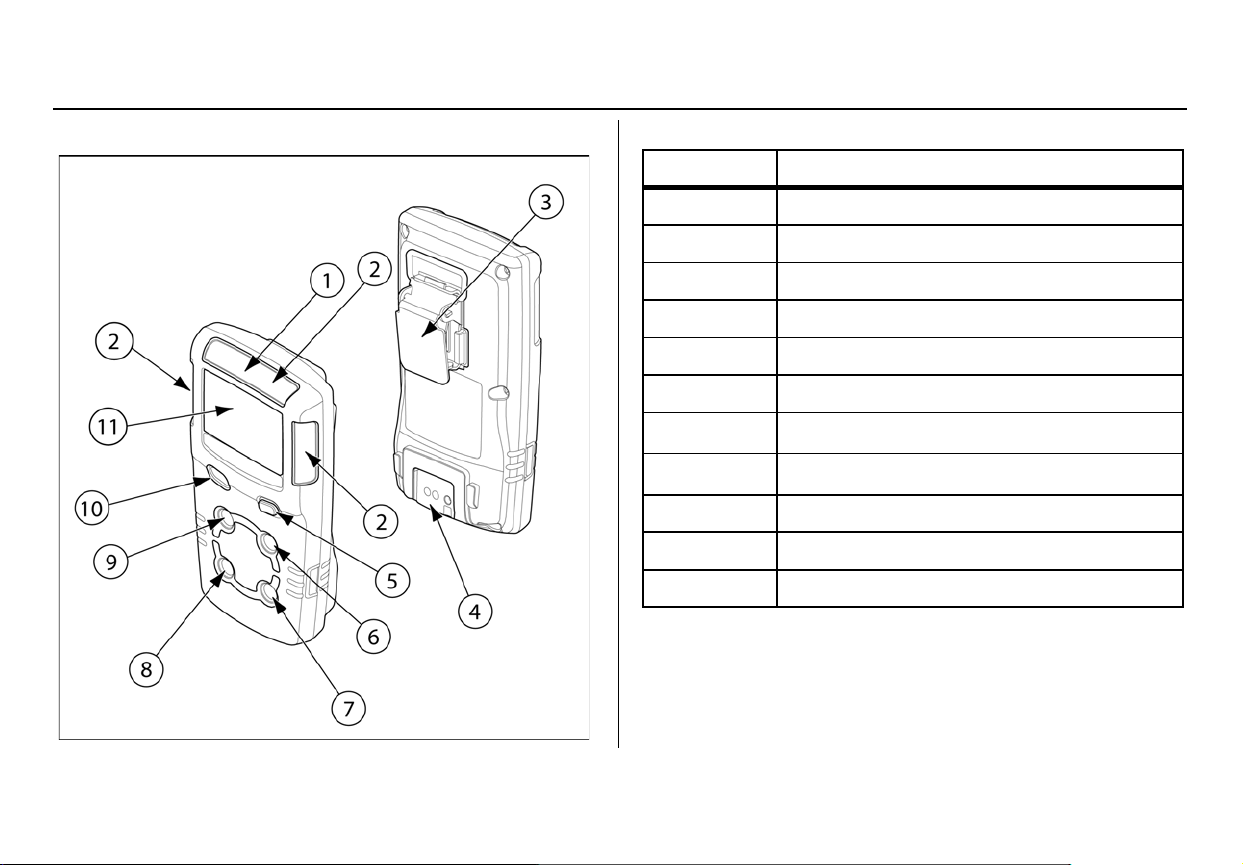

Parts of the GasAlertMicroClip XT

GasAlertMicroClip XT

Parts of the GasAlertMicroClip XT

Item Description

1 IntelliFlash

2 Visual alarm indicators (LEDs)

3 Alligator clip

4 Charging connector / IR interface

5 Pushbutton

6 Carbon monoxide (CO) sensor

7 Hydrogen sulfide (H

8 Oxygen (O

9 Combustible (LEL) sensor

10 Audible alarm

11 Liquid crystal display (LCD)

) sensor

2

S) sensor

2

3

GasAlertMicroClip XT

1

8

7

6

5

4

3

2

Operator’s Manual

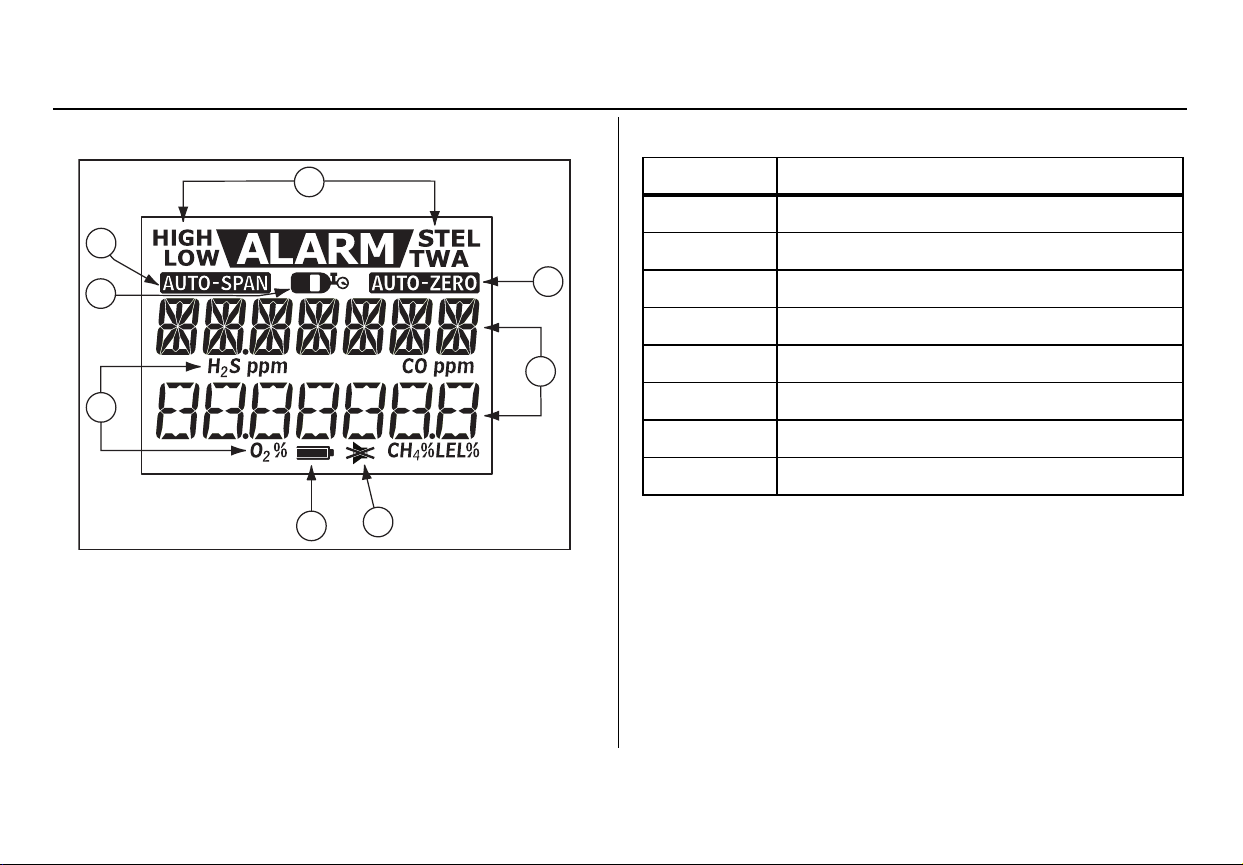

Display Elements

Item Description

1 Alarm condition

2 Automatically zero sensor

3 Numeric value

4 Stealth mode

5 Battery life indicator

6 Gas identifier bars

7 Gas cylinder

8 Automatically span sensor

4

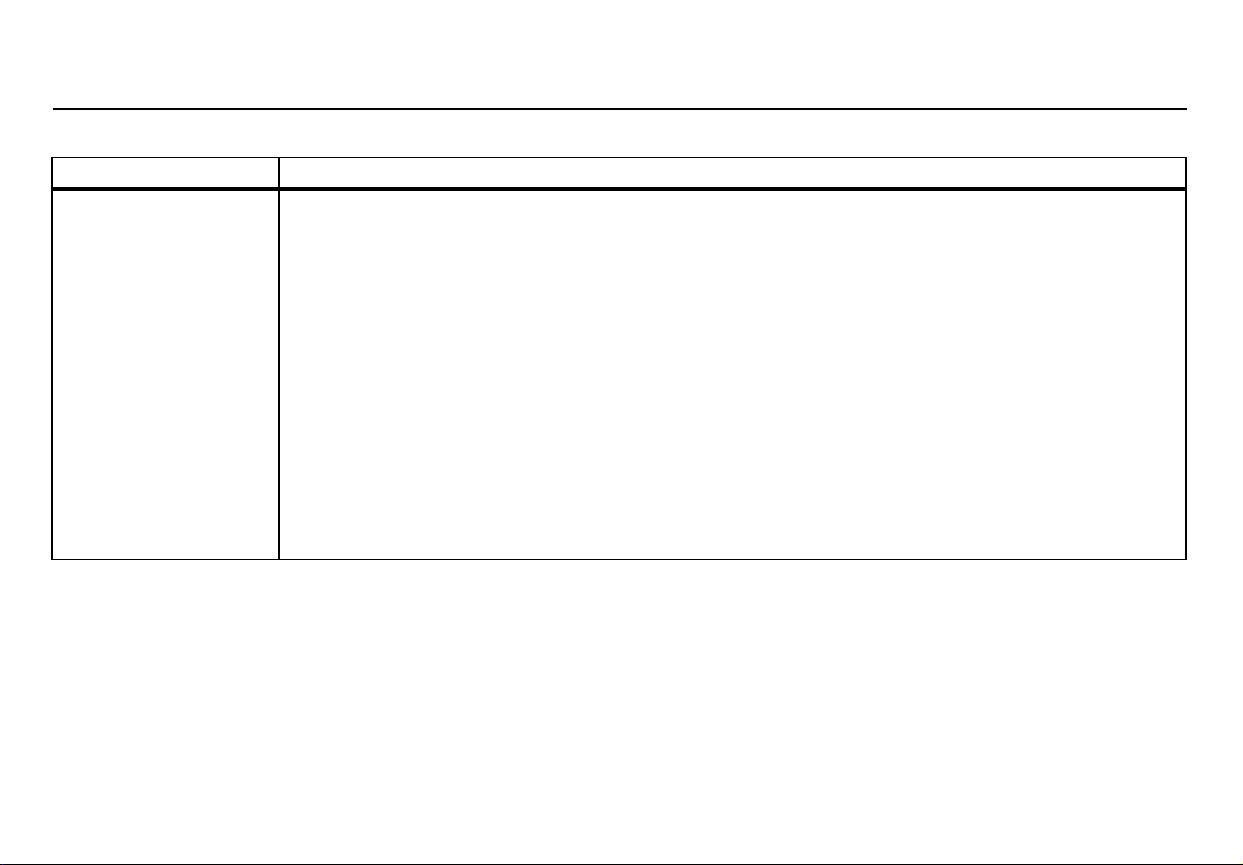

Pushbuttons

Pushbutton Description

• To activate the detector, press C.

• To deactivate the detector, press and hold C until the OFF countdown is complete and the LCD

deactivates.

• To view the TWA, STEL, and MAX (maximum) readings, press C twice. To clear the TWA, STEL,

and MAX readings, press C when the LCD displays RESET.

C

• To initiate calibration, deactivate the detector. Press and hold C while the detector performs the

OFF countdown. Continue holding C while the LCD briefly deactivates and then begins the CAL

countdown. Release C when the CAL countdown is complete.

• To activate the backlight while in normal operation, press C.

• To acknowledge latched alarms, press C.

• To acknowledge a low alarm and disable the audible alarm, press C (if the Low Alarm Acknowl-

edge option is enabled).

GasAlertMicroClip XT

Pushbuttons

5

Loading...

Loading...