Page 1

Development of the B&W 800D

Page 2

Development of the B&W 800D

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Project brief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drive units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Crossover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Industrial Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Appendices

I Diamond Dome Tweeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

II The FST Midrange Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

III The use of Rohacell® in loudspeaker cones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

IV Tapered tube theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

V Sphere/tube midrange enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

VI Matrix™ cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

VII Decoupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

VIII Finite Element Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

IX Laser Interferometry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page 3

3

Bowers and Wilkins’ 800 Series first saw the

light of day in 1979 with the introduction of

the original Model 801. Its radical shape,

composed of separate enclosures for each

drive unit, was to remain relatively constant for

almost 20 years, proving, like so many concepts

to come from the R&D division at Steyning, that

good ideas, based on sound principles stand

the test of time.

The development of the flagship Nautilus

speaker, launched in 1993, introduced a raft of

new ideas that clearly warranted adaptation to

a broader range of products, the result of which

was the Nautilus 800 Series. That Series was to

redefine the high-end audio speaker market and

the development of the then top model in the

range – the Nautilus 801 – was covered in a

previous paper. The subsequent development of

the Signature 800, which refined and extended

some of the principles used in the Nautilus 801,

was also the subject of a paper.

This paper describes the development of a new

generation 800 Series, using the top model

800D to describe the principles and techniques

to be found in the range. There are significant

new developments, but there is much in the

new models that carries over from the old.

These existing techniques are discussed here

once more, so that this paper may be read in

isolation, without reference to the previous

publications.

Project Brief

High-end audio products are about performance.

The investigation of new ideas, materials and

processes is a continual process, sometimes

coming as small steps and sometimes as

significant leaps. In this case, our engineers

had been pursuing several projects that

promised a significant improvement in

performance and the brief was simply to

incorporate the results into products.

Overview

A loudspeaker system can be divided into three

basic constituent parts:

• The drive units

• The crossover

• The enclosures and supporting structure

In an ideal situation, the drive units, seamlessly

blended by the crossover, should transmit

a perfect audio replica of the electrical input

signal. The rest of the structure should remain

perfectly stationary and serve only to support

the drive units, absorb the unwanted radiation

radiated from the rear side of each drive unit

diaphragm and be shaped to aid even

distribution of the sound away from the

loudspeaker. How good a speaker sounds

can be measured by how close the designer

can get to this ideal. In the real world, of

course, we fall somewhat short. Drivers suffer

from distortions of all kinds and enclosures

vibrate and add their own coloration to the

sound. Crossover components add unwanted

artifacts to the electrical signal before it even

reaches the drivers.

We shall examine our design philosophy to all

these categories separately, but in fact, in the

design process, they must be treated as a

whole, because they all interact. The choices

the designer makes in one area are affected

by what he has to work with in another.

Inevitably, choices have to be made and it is

down to the skill of the design engineer to

make a balanced judgement and optimise the

whole. It is a skill that combines science with

art. The science provides understanding and

points the way forward. For as long as the

scientific understanding is incomplete, however,

an understanding of the art of music is essential.

In high-end audio, it is not sufficient simply to

achieve a pleasant sound, the designer must

strive to recreate as closely as possible the

impression of being at an event, of being able

to imagine performers in front of the listener,

of raising the goose bumps on the skin and

hair on the back of the neck. That is the target,

and virtually impossible to describe by a set

of numbers.

The listener must be the final arbiter of how

well the target has been met. All we can do

within the scope of this paper is to examine

the science. In the sections immediately

following there is a general overview of each

of the techniques used and they are covered

in greater detail in the Appendices at the end

of the paper.

Introduction

Page 4

4

Perhaps the most radical of the new

technologies used in the speaker is the

diamond dome of the tweeter. The acoustic

development is covered in detail in Appendix I.

One of the surprising outcomes of the new

design when compared with the existing

aluminium dome design is that the –6dB

frequency is lower (The blue horizontal line in

figure 4 represents the -6dB level after the

tweeters are equalised flat to 90dB by the

crossover). This may at first glance seem

strange, considering that diamond is much

stiffer and has a significantly higher break-up

frequency than aluminium. The answer is

simply to be found in the ‘ideal’ response of

an infinitely stiff dome of the same shape,

which suffers a deep dip in the response

around 70kHz because of the difference in

arrival times of sound generated at different

parts of the dome (Represented by the green

shaded area in figure 1). At 70kHz, the

wavelength of sound in air is 4.9mm (0.19 in)

at 20C, which is comparable with the height

of the dome. That the aluminium dome has

the higher –6dB frequency is simply because

the response is on the way down from a high

amplitude resonance at 30kHz.

We took the view that the diamond dome

should follow this ideal as closely as possible

and we should not attempt to achieve a flatter

acoustic response through various devices that

would either cause the total radiating area to

deliberately deviate from piston-like behaviour

at a lower frequency or by engineering cavity

effects in front of the diaphragm.

Our listening experience had repeatedly and

consistently shown that the most important

criterion affecting the sound quality was how

closely the radiating surface remained pistonlike in the accepted range of human hearing

below 20kHz. We were therefore not tempted

by any perceived marketing need to follow

popular (mis)conceptions of what is required

to properly convey the improvements offered

by high sampling rate digital recording formats.

We kept the acoustic response of the infinitely

stiff dome as our target. If one removes the

acoustic time delay effects by examining the

structural acceleration response of the dome,

one sees that it is flatter and more extended,

as expected (see Appendix I).

It should be remembered that deviation from

piston-like behaviour does not suddenly happen

when the break-up resonance frequency is

reached. It builds up from a much lower

frequency. It is similar to the effect of antialiassing filters used in digital recording. Those

used in the standard 44.1kHz CD format may

have cut-off frequencies above the accepted

limit of human hearing, but deviations in the

phase and associated group delay begin well

below 20kHz. It is the shifting of these build

up effects well above the limit of hearing that

is most important, not necessarily maintaining

a flat acoustic amplitude response to 100kHz

or whatever, although, of course, the two

are related.

That it is possible to produce a diamond dome

at all is due to relatively recent developments in

the production of industrial diamonds.

The standard technique for synthesising

diamond is to simulate the conditions that

occur in nature, ie the high pressures and

temperatures that are found inside a volcano.

The technical difficulty in achieving temperatures

as high as 2,100C (3,800ºF) and pressures

exceeding 50 kbar limits the size and shape

of the diamond components that can be

manufactured by this process.

In the 1980s, the invention of a chemical

vapour deposition (CVD) technique for

growing diamond overcame this limitation:

the deposition temperature was halved and,

more critically, growth could now be achieved

at sub-atmospheric pressures. The technique

succeeds in producing diamond under

conditions for which graphite is the thermodynamically stable form of carbon by creating

a carefully balanced chemical environment

that stabilises the diamond surface as it

grows; in effect, the kinetics win over the

thermodynamics. This very specific environment

is generated by exciting a gas mixture of

hydrogen with a small percentage of an alkane

(carbon source gas) and other gases (such

as argon and oxygen). The resultant plasma

contains alkyl radicals, hydrogen atoms and

5

Drive Units Tweeter

30

20

10

0

-10

-20

-30

10000 20000 100000Frequency (Hz)

Simulated acoustic Frequency response

30

20

10

0

-10

-20

-30

10000 20000 100000Frequency (Hz)

Simulated acoustic Frequency response

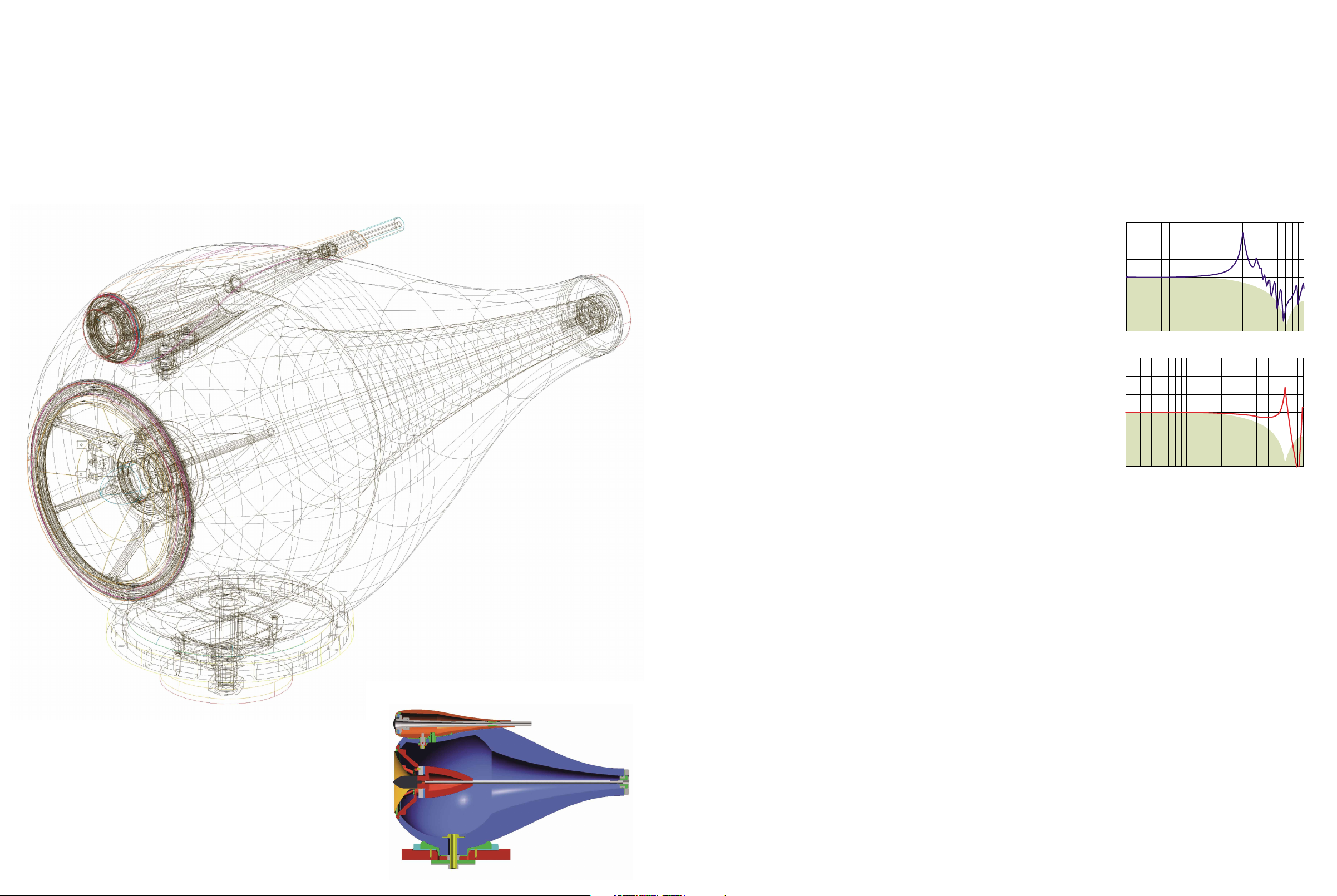

1 FEA simulated acoustic responses of aluminium (top) and

diamond (bottom) domes. The response of an ‘ideal’ dome

is shown shaded in each case.

Page 5

6 7

high-energy electrons. A range of power

sources can be used to excite the plasma,

the most common being microwaves, heated

filaments and arc discharges. The diamond is

deposited directly onto a suitable substrate

material, for instance tungsten, molybdenum

or silicon. This substrate can be removed after

deposition to leave a freestanding diamond

layer. The layers produced can be millimetres or

microns thick with areas greater than 100 cm2.

It is also possible to replicate complex shapes

machined into the substrate. The diamond itself

is polycrystalline and of high purity and,

because the properties are selected and

controlled, diamond materials grown by the

CVD process can actually outperform natural

diamond in many applications.

In developing the tweeter dome, B&W worked

closely with one of the world’s foremost

producers of industrial diamonds, Element 6,

based in Ascot, UK. As in so many industrial

applications, although the basic process was

well established, there were practical difficulties

peculiar to this application that had to be

overcome. Depositing diamond to the profile

of the spherical section of the dome itself

was fairly straightforward, but the vertical ring

location for the voice coil (see figure 3) proved

particularly tricky. Forming and ejecting with

parallel sides and maintaining material thickness

at the sharp corner were difficult. This part of

the profile is crucial both in ensuring repeatable

accurate location of the voice coil and also in

increasing the dome's stiffness to raise the first

break-up frequency. This is the first time such

a profile has been manufactured and the design

is patented.

The dome itself does not constitute the whole

of the radiating surface. The supporting surround

plays an important role in determining the

tweeter’s response.

During the development of the Nautilus 800

Series, deficiencies in the plastic film half roll

surround used on the then standard tweeter

design were ameliorated by using a flat foam

polymer surround. Its motion remained better

phase matched to that of the aluminium

dome and gave a smoother overall response.

However, in the new systems, we wanted to

use crossover filters with more gradual roll-off

2a

Tweeter continued

3 Diamond dome profile

5 Tweeter impedance with (red) and without (blue) a silver

layer on the magnet centre pole.

rates (see the subsequent section on the

crossover) and this necessitated lowering the

tweeter’s fundamental resonance frequency.

This could only be achieved by reverting to a

half roll profile to increase compliance, but we

were able to take advantage of a new synthetic

rubber material that avoided the shortcomings

of the original plastic film. We were thus able

to achieve good phase coherence with the

dome and usefully lower the fundamental

resonance frequency.

Frequency response deviations from the ideal

are not dependent solely on the dome and

surround. Any moving coil drive unit is a current

driven device, with the force on the voice coil

represented by the formula:

F = Bli

where F = force, B = magnetic flux density,

l = length of coil in the magnetic gap and

i = current.

Yet for various reasons, mainly to do with

controlling bass response, amplifiers are

voltage sources. The high frequency response

of a drive unit is therefore affected by the

inductance of the voice coil and, in order

to maintain high frequency response, the

inductance should be minimised. To that

end, not only does the tweeter employ a single

layer ribbon wire voice coil to minimise the

number of turns, it also uses a silver plated

centre pole in the magnet structure.

Copper is more usually used for this purpose.

The electrically conducting layer acts as a

shorted turn in the secondary windings of

what is in effect a transformer and reduces

the inductance of the primary windings (the

voice coil). Accommodating a layer of nonmagnetic material widens the magnetic gap,

with a resultant decrease in flux density and

hence drive unit sensitivity. Silver, having a

higher conductivity than copper, is effective

with a thinner layer and is used here to

maximise sensitivity.

Both the tweeter and bass drive unit diaphragms

of the 800D are designed following the ‘stiff is

good’ principle. However, good reproduction in

the midrange has a particular requirement that

precludes this approach if a single drive unit

is to be used to cover the whole range. With

stiff diaphragms, the dispersion progressively

narrows as the frequency increases and the

wavelength becomes similar to or smaller than

the diameter of the diaphragm. With bass units,

this factor is never a problem, because the

wavelength is always significantly greater

than the size of the drive unit. At 400Hz,

the wavelength is just under 860mm (34 in),

compared to, say, 380mm (15 in) or 250mm

(10 in) or less for the bass drive unit. At 4kHz,

the wavelength is 86mm (3.4 in) and so with

any drive unit of a size large enough to give

high output levels with low distortion at the

bass-to-midrange crossover frequency,

beaming is likely to be a problem. Off centre

listeners are going to hear a sound with a

significantly different balance from that on axis,

and image precision will suffer.

Having established that we do want to achieve

high sound levels and do not want to use more

than one drive unit, the best option is to use a

drive unit with a more flexible cone material.

That does mean that the cone is virtually certain

to be operating in its break-up region for much

of its usable range, but the usual deleterious

effect of this (delayed resonances colouring

the sound) is ameliorated greatly if the correct

material is chosen.

Woven Kevlar®has been used by B&W since

1974. For the Nautilus 800 Series, the way we

used Kevlar in midrange-only (as opposed to

bass/midrange) drive units was improved by the

use of a new design of outer cone support or

surround. Such drive units go under the name

FST, standing for Fixed Suspension Transducer.

Midrange

For the Signature 800 and Nautilus 800, the

magnet structure was improved by using a

Neodymium-Iron-Boron (NeFeB) magnet driving

a thicker top plate. The use of a short coil in a

long magnetic gap lowered harmonic distortion

and improved detail retrieval. The reduced bulk

of the magnet had a minor secondary benefit

in reducing the bulk of obstructions behind the

cone and hence the amount of sound energy

from the rear of the cone being reflected back

through the cone to add delayed coloration.

This approach is carried over to all models in

the new 800 Series. Completely new to this

Series is the chassis (basket), which provides

greater strength than before without compromising the open area of the original. The use

of Kevlar®in the FST drive unit is discussed

in detail in Appendix II.

2b

2c

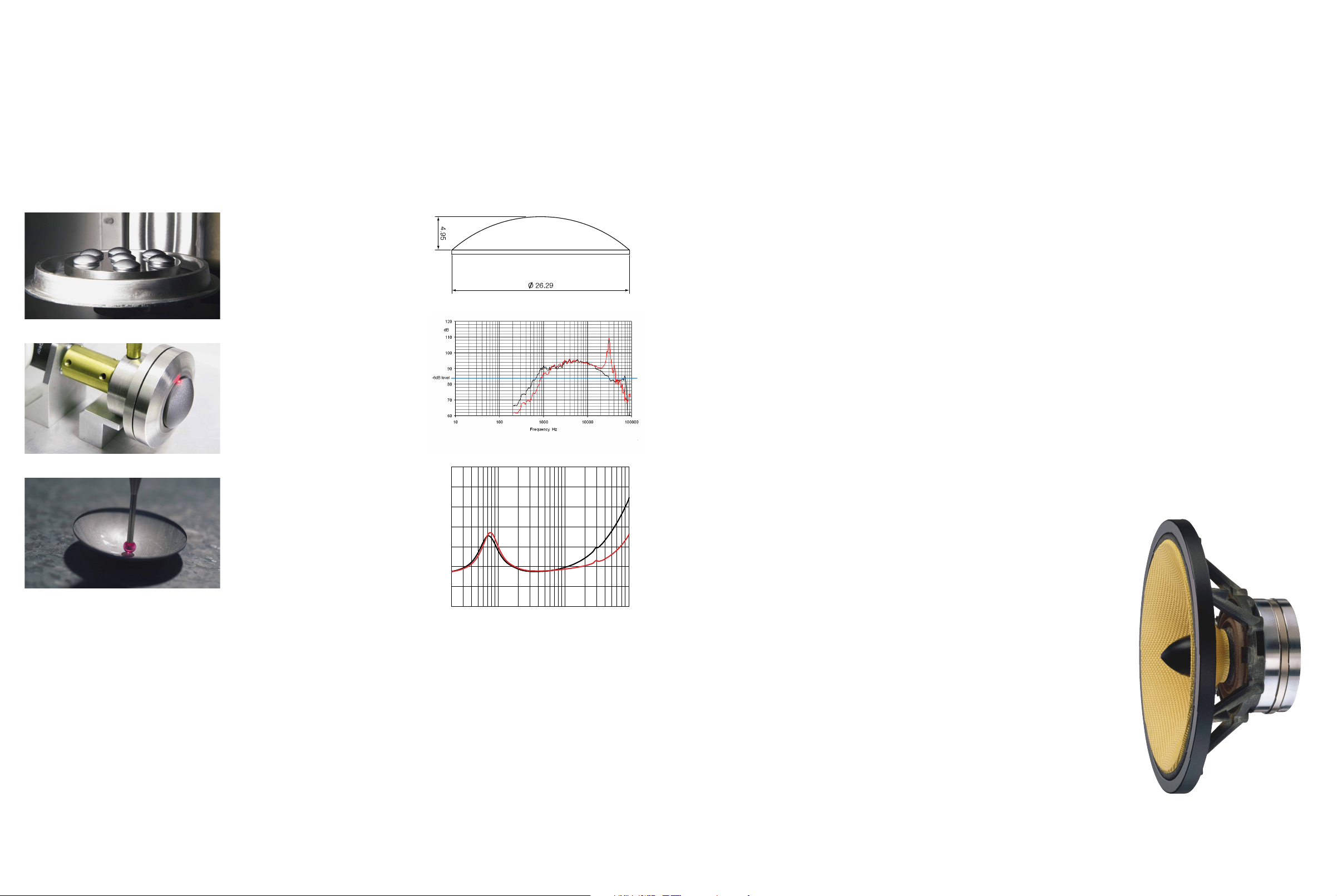

2 Diamond dome manufacture.

a Domes awaiting removal from the forming substrate.

b Laser cutting the outside diameter.

c Checking material thickness.

4 Responses of new diamond dome tweeter (black) and

Nautilus 800 Series tweeter (red)

14

12

10

8

6

4

Impedance magnitude (Ohms)

2

0

3

10

Frequency (Hz)

4

10

Page 6

8 9

The midrange enclosure is carried over from the

Nautilus 800 Series with a small change to the

exterior design where the tweeter is mounted.

The tweeter is more enveloped, but this is an

aesthetic development with no acoustic

significance, except that the tweeter is mounted

further forward (see the section Crossover).

The unique sphere/tube design overcomes the

bandwidth limitations of simple tube loading and

is described in Appendix VI.

Because tube loading results in an overdamped

high-pass alignment, it is not applicable to

passive system bass cabinets because of the

inability to add boost equalisation. Therefore,

like the Nautilus™800 Series products, the 800D

employs a Matrix™-braced vented-box enclosure

(see appendix II).

The inertness of the cabinet is further enhanced

by using 38mm thick panels, also contributing

significant mass. In addition, smoothly curving

the rear surface greatly adds to the stiffness of

the cabinet and gives an interior shape that

modifies the internal acoustic resonance modes,

since there are fewer parallel surfaces. The

combination of an internal Matrix™construction,

together with both a massive and stiff external

‘skin’, makes the combination uniquely

resistant, not only to sound transmission from

inside to outside, but also to intrinsic cabinet

structural modes.

Bending thin wood laminations under heat and

pressure is widely used in the furniture industry

for the manufacture of chairs. However the

ability to accurately match and join two such

curved panels together without a witness

groove and to maintain the accuracy required

to fit the Matrix™panels inside is beyond the

capability of many suppliers. Special storage

conditions for the raw laminations, with

controlled temperatures and humidity are

essential and sophisticated CNC 5-axis routing

machines are required to shape the edges and

cut-outs of the curved panels.

The Tweeter incorporates Nautilus™technology

through the use of a tapered tube, filled with

wadding attached to the rear of the unit and

matching the hole through the pole (See

appendix V). The exponential profile has been

designed to ensure that the cut-off frequency

of the tube is low enough to absorb all the

energy in the operational bandwidth of the

tweeter, but allowing a shorter tube than in the

Nautilus™. It also allows the absorptive wadding

to be packed loosely at the mouth of the tube

and to become gradually compressed towards

the end. This allows the sound energy radiating

from the rear of the dome to pass through the

pole piece and into the tube without being

reflected back up towards the dome. This

variation in packing density ensures that the

acoustic impedance is varied smoothly, and

that there are no sudden changes that would

cause such a reflection of energy. As the

passband of the tweeter is similar to that in

Nautilus™, the onset of cross modes in the

tube is not a problem, occurring well above

audibility in the human ear.

A secondary use for the tube is as a heat sink.

The small dimensions of the magnet assembly

result in a low thermal mass. Making the tube

of zinc alloy and ensuring a good thermal bond

to the magnet back plate significantly reduced

the operating temperature of the unit. When

fed music from a 600W amplifier run just below

clipping, the operating temperature is reduced

by around 20C. In fact the tweeter was found

to be capable of withstanding unclipped high

frequency peaks from an amplifier rated up to

1kW, without the coil burning out. The tweeter/

tube combination is housed in an outer die-cast

shell which defines the outer housing of the

unit. The tweeter diaphragm only moves a

maximum of 0.5mm. Therefore, it is crucial

Bass Unit Enclosures Tweeter Bass

restricted and one cannot make up for lost

sensitivity by adding amplifier power, as is the

case with a powered subwoofer. So, work

began on finding a material that would add

further stiffness, increase inherent damping and

act as a better sound barrier than the materials

we had used in the past.

The material chosen has a composite sandwich

construction. Sandwich construction cones are

not new. The famous Leak Sandwich speaker

of the 1960s used a bass cone having an

expanded polystyrene core bounded by thin

aluminium skins, as did the flat fronted, oval

B139 from KEF that followed shortly after. Both

these diaphragms were thick and were a better

sound barrier than the paper cones common at

the time. However, they were fairly heavy and

expanded polystyrene as a core material can

now be improved on in terms of stiffness and

internal damping to achieve higher break-up

frequencies and better-controlled resonances.

The core material chosen was Rohacell®, again

an expanded foam material and one that is

commonly used in aircraft construction, due

to its light weight and relatively high strength.

This is bounded on both sides by carbon fibre

skins in woven mat form with a high level of

resin to add stiffness. Neither Rohacell®on its

own nor a Rohacell®/carbon fibre sandwich is

a new cone material, although the introduction

of both is relatively recent. What is novel in

the 800 Series is the cone thickness that has

been achieved through improvements in the

manufacturing process. Most Rohacell®cones

are in the 1-2mm thickness range. In the 800

Series, the core thickness is 8mm, which aids

the suppression of sound transmission

considerably.

The audible result of the new cone material,

with its enhanced stiffness and reduced sound

transmission is to improve what is referred to

as bass attack or dynamic bass. Most bass

lines in music do not consist of steady tones.

The waveforms have an extended frequency

range and the reduction in coloration in the

upper bass/lower midrange cleans up the

presentation significantly.

A detailed discussion of Rohacell®/carbon fibre

sandwich cones is to be found in Appendix III.

Midrange

to isolate it from mechanical energy arising

elsewhere in the system. To this end, the

tweeter and tube are held in the housing

with rings moulded with a Shore 1A hardness

elastomer. The housing in turn is decoupled

from the midrange enclosure below by the

use of two isolator pads of high compliance

gel material.

The top isolator has been shaped to sit in the

scallop of the midrange head enclosure and

cradle the underside of the tweeter housing.

Raised ribs have been designed into this

isolator to create maximum compliance at

this interface, in order to absorb any energy

transmission between the midrange head

enclosure and tweeter body. The bottom

isolator sits between the connector and the

underside of the midrange head enclosure

to ensure that both the sections of the Molex

cable connector are isolated from the midrange

head enclosure. The tweeter is allowed to float

free and reproduce the input signal without any

external interference.

The 800D uses two 250mm (10-in) diameter

bass drive units. At B&W, we have long

promoted the use of stiff, rigid cones for bass

drivers. Bass/midrange drivers are a different

matter, because of the same bandwidth

conditions that apply to the FST midrange

driver, but for bass-only drivers in 3-way

systems, the ability to withstand deformation

when subjected to the high pressure differences

inside and outside the cabinet is the best way

of achieving that dynamic performance often

described as ‘slam’. The stiffness also pushes

the onset of break-up to higher frequencies,

extending this piston-like behaviour.

At B&W, we have commonly used two materials

for this application – aluminium and a fibre pulp

mix of kraft paper and Kevlar, further stiffened

by resins. Both materials are stiff, but metals

in particular suffer high Q resonances outside

their working range, due to their low inherent

damping. They must be well attenuated by the

time the break-up region is reached to avoid

intrusive coloration. In the Nautilus 800 Series,

the paper/Kevlar®mix was chosen over

aluminium for two reasons:

• It was difficult in practice to form aluminium

cones of large diameter that fulfilled the bass

alignment criteria. Either they split during

forming or the thickness had to be increased

such that they became too heavy.

• Paper/Kevlar®has higher internal

damping and break-up resonances were

better controlled.

However, even paper/Kevlar®is fairly dense

and results in relatively thin section cones if a

reasonable sensitivity is to be achieved. This

can allow a certain amount of sound energy

from inside the cabinet to pass through and

cause low levels of coloration. As general

driver, cabinet and crossover quality has

improved in recent times, even this very low

level of coloration deserves corrective attention

and the sandwich construction of our PV1

subwoofer driver has shown that a thick cone

construction can have benefits in this area.

Simply adding thickness, however, is not a

universal panacea. In a passive speaker, we

cannot afford to add mass at the same time.

The choice of alignments becomes too

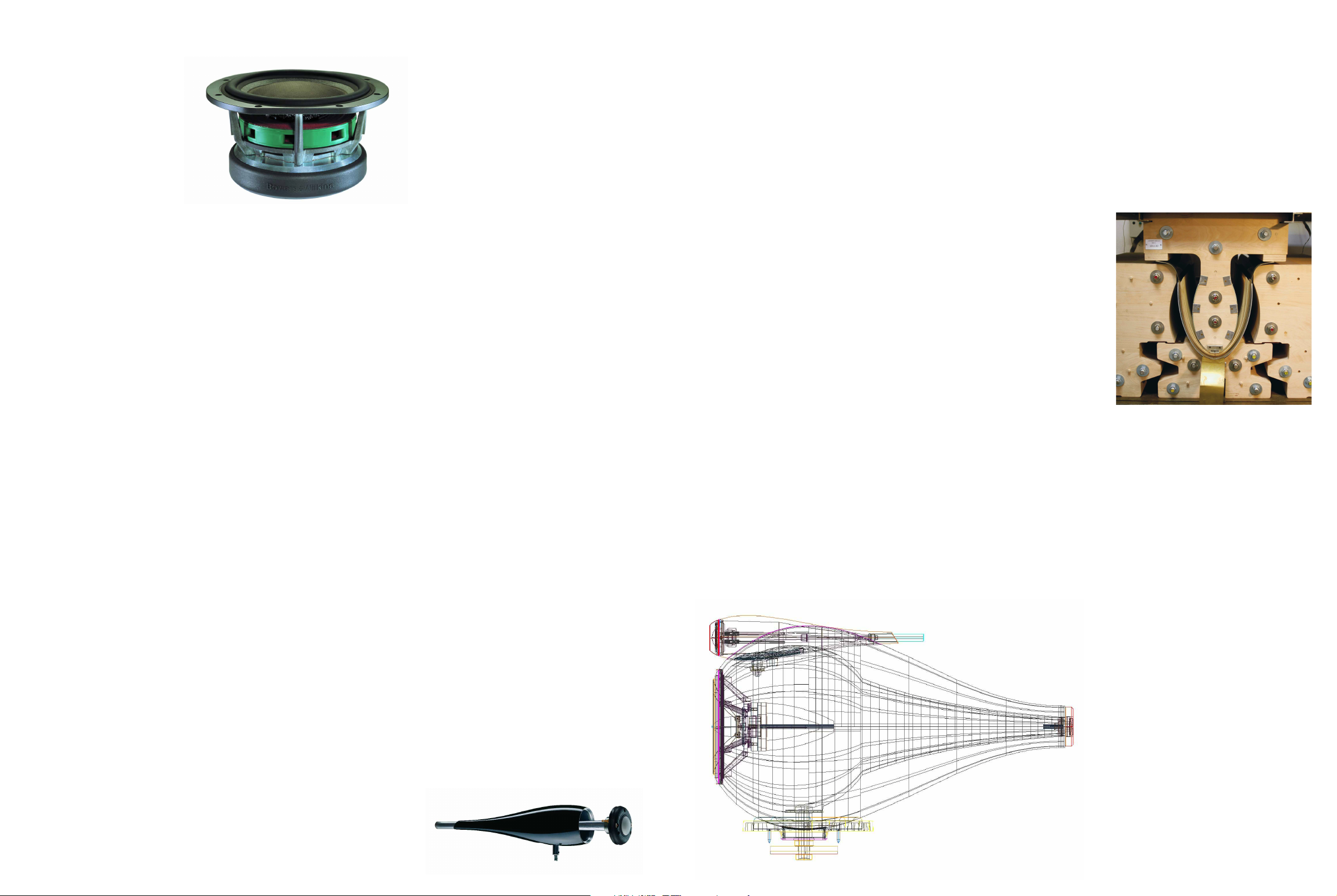

6 Forming curved cabinet sides at B&W Denmark

Page 7

10

make it turbulent, which may be heard as wind

noise, particularly because it can excite the

organ-pipe resonances of the tube.

Far more serious problems occur when laminar

airflow tries to leave the tube at high velocities.

If the curvature of the diffuser (flare) is too

sharp, the minimal momentum of the air at the

base of the laminar boundary layer is insufficient

to pass the resulting sharp, adverse pressure

gradient without stopping or stagnation. Slightly

downstream, the pressure gradient (higher

velocity with lower pressure to lower velocity

with higher pressure) causes the flow at the

base of the boundary to reverse and a turbulent

eddy is created in the form of a rotating torus

(this is how smoke rings can be blown). The

boundary layer now becomes the region that is

between the eddy and the main flow, but it has

now separated from the surface of the diffuser.

It tries to follow the pressure gradient formed by

the turbulence, but may form more eddies trying

to do so, and so on.

The turbulent wake thus created is responsible

for the ‘chuffing’ noises that even gently flared

ports can produce under some conditions.

The separation can sometimes be so extreme

that a turbulent jet can hit a listener at some

distance from a speaker. The aerodynamics

of reflex ports is actually rather complex and

somewhat unusual in that it involves alternating

flow in two different pressure regimes (at and

below port resonance), three octaves of the

frequency spectrum (different systems have

different tunings), completely indeterminate

starting conditions and well over 100dB of

level difference.

Aerodynamics research into reflex ports at B&W

is still in its infancy. Classical wind tunnel work

is very difficult because the alternating flow

makes a mockery of smoke trails. Recent work

with Computational Fluid Dynamics has shown

that ports are very difficult to model accurately.

This is partly because of the large number of

variables, and also because the flow regime is

influenced so heavily by small-scale turbulence

creation, which is less well understood than

large-scale fully-developed turbulence (more

is known about how aircraft stay in the air than

how midge flies do). Therefore, work has been

largely empirical, using comparative rather than

11

The movement of air in and out of tuning ports,

which may represent quite a considerable

physical displacement, often causes ‘chuffing’

noises as the air interacts with the discontinuities

found at the internal and external ends of the

port tube. These noises occur as turbulence is

formed at the discontinuities. Even when the

inside and outside ends of the tube are given

smoothly rounded profiles, the problem is not

totally cured, though it is mollified.

The reflex port is a well-established device to

improve the bass response of a transducer in

an otherwise sealed box of finite dimensions.

As the power handling, excursion and linearity

of bass drivers have steadily improved over the

years, the limitations of a simple tuned port

have become apparent. At low levels the

behaviour of the air in the tube can be correctly

approximated to a solid piston bouncing on

a known air volume and at a specific tuning

frequency; a readily predictable and essentially

acoustic problem. At higher levels, aerodynamic

effects become increasingly important and the

associated loss means that a given rise in bass

driver input level will yield a smaller rise in clean

port output level. This also means that the port

is not reducing the excursion of the bass driver

as effectively and the system will thus behave

increasingly like a lossy sealed box design; the

combined effect is known as ‘port compression’

and can often create an ultimate ceiling to

achievable bass levels.

Well before any ceiling is reached, the energy

losses associated with port compression cause

problems and it is the way energy is lost rather

than the amount lost that causes serious

acoustic problems. At very low velocities, and

with a perfect entry, air travelling through a real

port tube will pass smoothly along streamlines,

which do not interfere with one another. Close

to the walls of the tube is a thin boundary layer

caused by skin friction, with a relatively high

velocity gradient. It provides the transition

between the stationary walls and the moving air.

Laminae of air rub against each other causing

pressure drag through noiseless viscous losses.

These are minimal at low levels but increase at

a geometric rate in proportion to velocity. At

high enough velocities, if the tube is excessively

long and rough (or just very rough), the high

shearing energies in the boundary layer can

Flowport

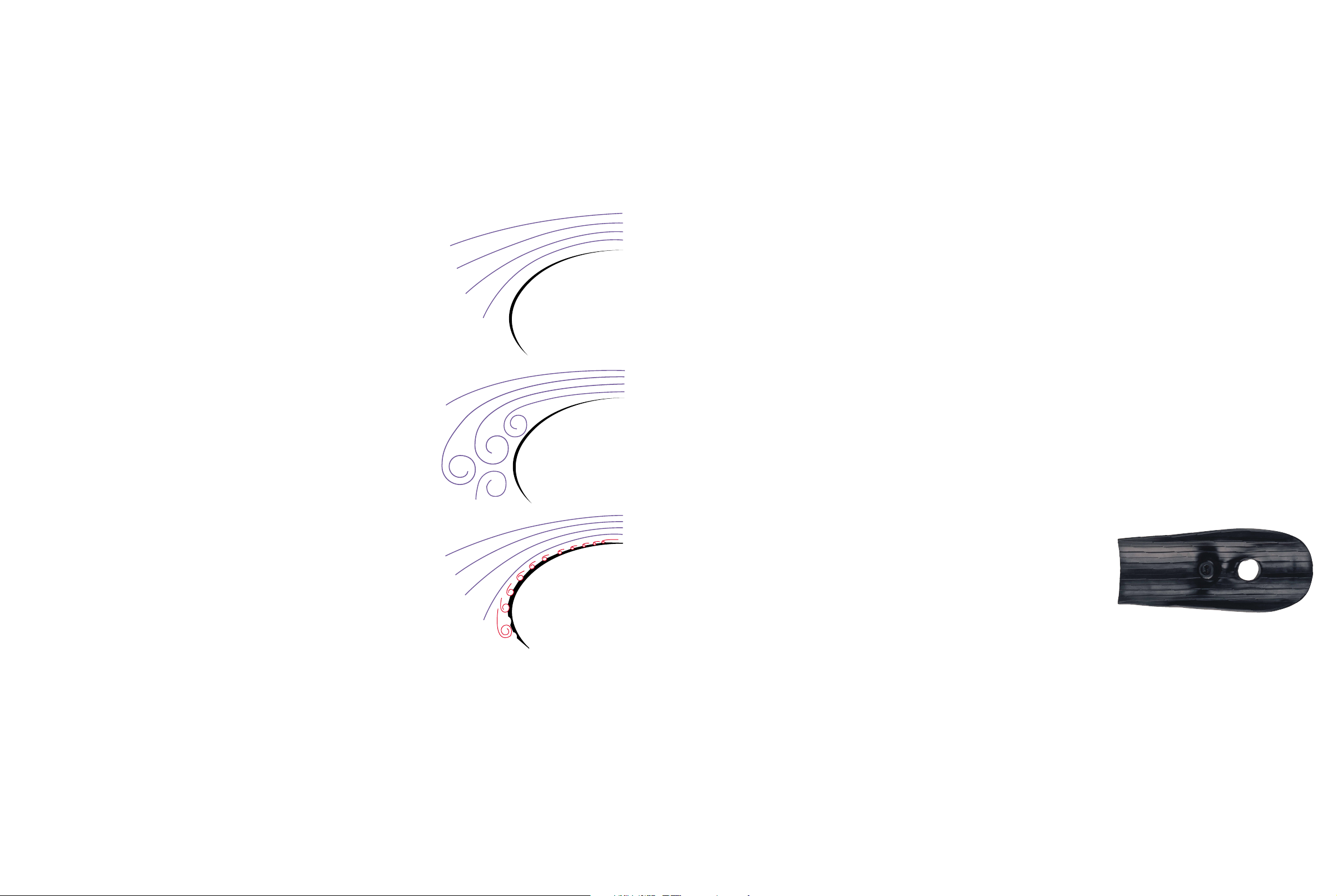

7 Representation of streamlines exiting port flare.

a Laminar airflow following curvature of flare

b Higher velocity turbulent airflow separates from surface

of flare causing large scale eddy formation

c Small scale turbulence due to dimples encourages

laminar streamlines to remain attached to boundary

a

b

c

absolute benchmarks, because it is difficult to

make reliable measurements of turbulent noise.

Theoretical predictions of air velocities down

the port were checked with a new Doppler

measurement system, to establish the kind of

flow regime operating around chuffing levels in

terms of the Reynolds number (a dimensionless

indicator of turbulence levels). This showed that,

with care, it was possible to maintain laminar

flow down the port tube, but that air could

detach from the flares at fairly modest levels.

Simply making the flares more gentle would

not guarantee silence.

Anyone studying aerodynamics will soon learn

that turbulence is not always a problem. In fact,

many aerodynamicists engineer turbulence to

their advantage (indeed, some aircraft would

not stay in the air without it). If a boundary layer

is turbulent prior to the stagnation point it will

be less inclined to separate because the base

layer has increased kinetic energy. This means

that the surface flow can be swept further

downstream before pressure conditions

stagnate it and the lower pressure in the layer

that results from the higher velocities within the

eddies adheres the main flow to the surface

profile better. Thus, small-scale turbulence can

be used to delay the large-scale turbulence

caused by separation.

Artificially creating turbulence in the air moving

down the tube can delay the onset of chuffing

to higher bass unit input levels, but problem

wind noise happens far earlier, especially when

turbulent air is sucked back in to the port as the

flow alternates. In addition, the thickened boundary layer effectively constricts the flow, causing

pressure drag and thus airflow compression.

This constriction also alters the effective area

of the port, which in turn affects the Helmholtz

tuning. Thus it is otherwise desirable to delay

the onset of turbulent flow down the tube to as

high a level as possible. A more optimal solution

would thus be to use a smooth tube and limit

artificial turbulence creation to the problematic

stagnation area. (figure 7)

It is quite easy to produce turbulence where

it is needed; aircraft use vortex generators,

(vertical strakes) ahead of separation points.

These strakes project into the main flow and

are very effective, but when the same technique

is applied to port flares it creates too much

wind noise at lower levels.

Enter the golf ball. It can travel twice as far

as an equivalent smooth ball because of its

distinctive dimpled surface. The dimples are

very carefully shaped to produce tiny separation

points and favourable conditions for the creation

of vortices within them. The ball is thus covered

by a thin turbulent boundary layer that moves

the separation point further round the ball. This

decreases the ball’s wake and hence its drag,

and it was this technology that was used to

improve the performance of the port flares.

Because a round port flare is axisymmetric,

it was first thought that a series of rings with

the cross section of a dimple might work (and

be easier to prototype). However, the regular

vortices formed simply became the new separation points and at lower levels there was audible

wind noise because they were so abrupt. So

real, pseudo random dimples were tried on

the surface of the flare. These immediately

improved the chuffing phenomenon as

predicted, but there was still wind noise caused

by deep dimples at the edge of the tube where

flow velocities were highest. These were filled

but at the expense of earlier separation levels.

A process of experimentation refined the size,

shape and distribution of the dimples to

maximise headroom and minimise wind noise.

Small, smooth dimples are thus used where

velocities are highest and larger, more abrupt

dimples are used where velocities are lower.

This greatly refines the exit flow regime and also

ensures that a minimum of turbulence is carried

back down the tube when the flow is reversed.

It was found unnecessary to make the dimples

totally random over the whole flare, but as long

as they are locally irregular, perceptible wind

noise is incoherent and unobtrusive.

In the case of the 800D, the port is down firing,

so more wind noise is acceptable and the

dimples are optimised for maximum high level

flow. In use, the dimpled ports delay the

nuisance chuffing noise to significantly higher

levels. However, and perhaps of even greater

importance, when large-scale separation does

occur the resulting turbulence is far more

incoherent and thus less apparent. A reduction

of 6dB in certain regions of the noise spectrum

was measured, particularly around the problem

organ pipe frequencies. Port compression is

also decreased and the tuning frequency is

more stable at higher levels.

Having achieved excellent cabinets for each of

the drive units independently, it is important that

vibrations and radiation from each driver do not

leak into the enclosures of others. Decoupling

has been used extensively in the 800D to isolate

drive units, apart from bass units, from their

enclosures and the individual enclosures from

one another. A discussion of the technique can

be found in Appendix VIII.

Decoupling was not used for bass or bass/

midrange units in the Series. While it has the

potential for reducing vibration in cabinet walls,

listening tests have always confirmed that

this is more than offset by a reduction in the

speaker’s ability to portray ‘slam’. A similar

effect is noticed if the bass cabinet is not firmly

anchored to the floor, for example using spikes.

It should be noted that it is only bass drive units

that are required to operate in the stiffness

region, below their fundamental resonance

frequency. All others operate entirely in the

mass controlled region.

Decoupling

8 Gel gasket used for vibration isolation between tweeter and

midrange enclosures

Page 8

12

that theoretical shape and with the units

nominally time aligned, it required the tweeter

to be connected in reverse polarity for the units

to be acoustically in phase with one another.

Reverse polarity connection of drive units has

always been avoided at B&W in recent years,

it being felt that the sound lacked coherence

and focus. There is inevitably phase distortion

and its associated group delay through any

practical crossover, but it has been deemed

preferable to restrict waveform distortion to the

limited frequency range immediately each side

of the crossover frequency rather than impose

a broadband change through polarity reversal

of any drive unit. In this case, positive polarity

connection would have led to a sharp null at

crossover, so this was avoided by realigning

the relative time delay of the drive units. Rather

than them being truly time aligned, the tweeter

is advanced by half a wavelength at the upper

crossover point of 4kHz to bring it in phase

with the midrange unit when fed with the simple

filter configuration. The addition of the drive

units is illustrated in figure 12. The tweeter sits

noticeably further forward than on the previous

series models. (figure 13)

It was strongly felt that this approach –

sacrificing true time alignment for a less

complex crossover – gave superior results

in terms of definition and imaging.

However, the bass drive unit’s high voice coil

inductance and the fact that the midrange drive

unit’s fundamental resonance frequency was

fairly close to the desired crossover frequency

meant that a higher component count was

the best solution for the bass to midrange

crossover. Nevertheless, the same in-phase

drive unit relationship and positive polarity

connection was followed.

13

Crossover Performance Industrial design

and, even though the drive units’ natural cut-off

frequencies may be well removed from the

crossover frequency, the phase response

associated with the drive unit magnitude

response usually intrudes through the frequency

range of the crossover to disrupt the way the

outputs of the two units add together.

In any case, a true 1st-order filter (assuming

one had drive units with perfectly flat responses)

is not particularly desirable. The two parts add

together in quadrature (constant 90º phase

difference) and, while this is of no consequence

in the one-dimensional world of current flowing

in a wire, when you have two drive units

separated in space, things are rather different.

On the reference axis, the responses add

together to give perfectly flat amplitude and

phase response. (figure 9)

As you change the measuring axis to move

downwards towards the lower drive unit, the

upper unit becomes delayed in time. The two

units become more in phase at crossover and

there is a peak in the response of up to 3dB.

(figure 10)

As the measuring position is moved up, the

lower unit becomes delayed and the units

become more out of phase, with a corresponding

dip in the response at crossover that reaches a

complete null when a 180º phase difference is

realised. (figure 11)

In both off-axis cases, the response oscillates

as the units go in and out of phase due to linear

time delay.

This situation of a lobe asymmetrically placed

around the reference axis is not ideal, leading

as it does to rapid changes in response with

relatively little height change. A preferable

situation is created when the units are in

phase at crossover. The lobe is aligned with

the reference axis and the same changes in

listening height result in much smaller changes

in response shape.

In the case of the midrange to tweeter crossover,

we were able to use a single capacitor in series

with the tweeter and achieve a response shape

very close to a 2nd-order Linkwitz-Riley. Like

Every effort was made to specify crossover

components of the highest calibre. The science

behind why certain crossover components

sound better than others is not fully understood.

That polypropylene capacitors sound better

than electrolytics is well accepted and can

be explained by the behaviour of the dielectric

properties as the signal changes. What is not

so clear-cut is why different capacitors, with

ostensibly the same specification, can sound

so different from one another. The difficulty in

mapping physical properties to the perceived

performance characteristics further compounds

this problem. Whilst we understand some of the

criteria, extensive listening tests are virtually

the only tool at our disposal to ensure that the

final choice of components is correct.

For the new 800 Series, we worked closely

with one of the foremost European capacitor

manufacturers to further optimise one of their

existing designs. All inductors are air core for

minimal distortion and thin film non-inductive

resistors were used in critical applications.

Where necessary for increased power handling,

the resistors are thermally bonded to the cast

aluminium plinth, which houses the crossover.

One of the notable things that comes from

critical listening tests is that, no matter how

good the crossover components are, all other

things being equal, the fewer of them there are

the better. That statement should be tempered

by the qualification that the response of the

speaker should be relatively flat with a good

phase relationship between the drive units,

but basic signal quality is never enhanced by

putting in an extra component. To that end,

one should try to minimise the component

count whenever possible.

The simplest filter configuration is 1st-order,

with a single series inductor for the low-pass

and a single series capacitor for the high-pass.

The fact of the matter is, however, that it is nigh

impossible to have a truly 1st-order crossover

in a passive loudspeaker system. One cannot

simply look at the component count. Drive units

themselves are inherently bandpass devices.

They have a 2nd-order high-pass characteristic

and usually a very high-order low-pass

characteristic. These shapes must be added

to the transfer function of the electrical network

10

dB

0

-10

-20

20 Hz 50 100 200 500 1000 2000 5000 10000 20000 50000

-30

-30

180°

Phase

0°

-180°

10

dB

0

-10

-20

20 Hz 50 100 200 500 1000 2000 5000 10000 20000 50000

-30

-30

180°

Phase

0°

-180°

10

dB

0

-10

-20

20 Hz 50 100 200 500 1000 2000 5000 10000 20000 50000

-30

-30

180°

Phase

0°

-180°

9 1st-order filter on axis

10 1st-order filter below axis

Several aspects of the speaker’s performance

are shown in figures 14 and 15, but many aspects

of performance cannot be represented simply

by a series of numbers or graphs; they can be

assessed only through careful listening tests.

The Nautilus 800 Series products always had

exceptional imaging, especially the ‘headed’

Nautilus 800, Nautilus 801 and Nautilus 802,

which was in no small measure a function of

the geometry of the enclosures. It is, for

example, quite easy to locate a central image

from a stereo pair, even when listening from

outside the area between the speakers. The

new 800 Series improves on this by adding still

better stability with a better impression of height

information. This last first became noticeable

when the simple electrical filter between

midrange and tweeter was incorporated.

The new Rohacell®sandwich cone material

delivers cleaner bass from a combination of

its higher transmission loss blocking sound

escaping from inside the cabinet more effectively

and having a more extended piston range.

However, no matter what other features the

new products employ, it is the diamond dome

tweeter that captures the imagination. What

it does not do is capture one’s attention when

listening. Rather it is an awareness that things

simply sound more natural. Bright sounds do

not become harsh, just bright. Everything is

there in correct proportion and the nuances in

the finest of detail in the input signal can be

discerned and appreciated.

Certainly the simple crossover design coupled

with the improvement in component quality

has helped bring out the full potential of the

diamond dome tweeter. It has also helped

combine the component parts of the speaker

into a coherent whole.

The styling of the 800D follows closely that of

its predecessor, the Nautilus 800. That latter

system’s bass cabinet was in fact styled

somewhat differently to the other two ‘headed’

products, the Nautilus 801 and Nautilus 802

in that the front baffle was curved round to

the base and the cabinet was supported on

the cast aluminium plinth by short pillars. That

general style has now been carried through

to the 801D and 802D. The bass grille has a

more sculpted outline compared to the original

Nautilus 800.

The Marlan ‘head’ design has altered slightly

in the way the tweeter is more enclosed by

the midrange cavity and, as mentioned above,

the tweeter is mounted further forward for

acoustic reasons.

12 graph of midrange (blue), tweeter (red) and sum (green)

responses

13 side view of tweeter on head.

14 800D – Horizontal responses and total harmonic distortion

15 800D – Modulus of impedance

11 1st-order filter above axis

10

2

10

3

10

4

30

40

50

60

70

80

90

10

0

11

0

Frequency (Hz)

Magnitude SPL (dB)

Frequency Response

Page 9

Appendix I

Diamond Dome Tweeter

Introduction

B&W’s standard 26mm diameter aluminium

dome tweeter has gradually evolved over the

years to give a higher and higher break-up

frequency. The original tweeters had the first

break-up at a frequency of approximately 26kHz

whereas the latest tweeters, as used on the

Signature 800 Series, have a 30kHz break-up.

This improvement in break-up frequency has

resulted from minor modifications in the design

of the voice coil former (bobbin) such as

swaging the top edge inwards to follow the

dome profile (often referred to as crowning)

or changing its length.

There are, of course, various different flavours of

the standard tweeter in production, for example

those using neodymium-iron-boron (NeFeB) and

those using barium ferrite magnets, those with

silver coating to the pole and those without,

those with short and those with long rear

tapered tubes. Also over the years we have

used different surrounds (half roll plastic film

and flat section foam polymer), different leadouts (beryllium copper strip and tinsels) and

a host of other variations in the quest to make

the most revealing tweeter possible.

Thus the increase in subjective performance

resulting from any increase in break-up

frequency had to be judged against a

background of many changing factors.

However, it is generally accepted within

B&W that a tweeter having its first resonance

at 30kHz sounds better than one having its

first resonance at 26kHz. This is perhaps

a little surprising when the normal audible limit

is generally considered to be 20kHz. However,

as discussed throughout this paper, there are

good reasons for pushing the break-up to very

high frequencies.

So, within B&W, there has always been a

motivation to increase the break-up frequency

of tweeters. However, over recent years,

provoked by high resolution audio formats

such as SACD and DVD-A with effective

sampling rates of 192kHz, the market has

started to demand so called Super Tweeters,

tweeters that are capable of reproducing

frequencies up to 96kHz.

The area of ultra high frequency audio in general

is somewhat controversial and debates rage

over which format is more accurate, whether

and why either format is better than standard

44.1kHz sampling rate CD, whether humans

can hear above 20kHz and so on. The resulting

lack of clarity has led the market to believe that

humans can hear above 20kHz and that a

supertweeter is therefore required to do this.

There is no credible scientific evidence at

present, that the author knows of, that proves

that frequencies above much 20kHz are audible,

and experiments to clarify this area are very

difficult to carry out.

Materials

In recent times, all B&W tweeters have used

aluminium domes. Aluminium is a comparatively

light and stiff material. This is beneficial

because, for simple structures such as domes

without formers, the break-up frequency is

directly proportional to √(E/), where E =

Young’s Modulus and = density. Clearly

the stiffer or lighter a material is the better.

Although aluminium and titanium are good,

better materials are available. A comparison

of some relevant materials is shown below.

Material E (GPa) (kgm-3) √(E/) Relative

Aluminium 71 2700 5128 1.0

Titanium 120 4500 5164 1.0

Beryllium 318 1850 13111 2.6

Diamond 1000 3500 16903 3.3

Aluminium and titanium will give similar

performance, but beryllium is approximately

2.6 times better than aluminium and diamond

3.3 times better than aluminium in terms of

break-up frequency. To qualify this claim the

simulated (using Finite Element Analysis, FEA)

first break-up mode shape and frequency

for a 50µm aluminium and diamond dome

is compared in figure AI.1.

It is clear from the table above that diamond is

a better material to use than beryllium from a

break-up point of view. In fact diamond is the

best material to use from this point of view.

Beryllium does have the advantage, though,

of being almost half the density of diamond.

It is also claimed that beryllium has quite high

damping for a metal, though at present data

are not available to verify this claim.

Basic Tweeter Simulations

In Section 1, the superiority of diamond over

any other material from a break-up point of

view was discussed and simple simulations of

domes were used to illustrate the performance

improvements. However, what happens when

diamond is used in tweeters?

The Model

In figure AI.2 the Finite Element Model of a

tweeter is shown. In this case the surround

is not included in the model to simplify the

analysis and interpretation. Addition of a

surround generally causes a small and

consistent decrease in break-up frequency

and therefore for comparative purposes this

simplified model is justified. In addition the

surround may introduce features in the SPL

response caused by pure surround resonances

(that are largely decoupled from the rest of the

tweeter). These surround resonances will be

common, regardless of the material used

in the dome.

Modal Analysis

In figure AI.3, the first break-up frequency and

mode shape for an aluminium tweeter and a

diamond tweeter are compared. Taking each in

turn, the aluminium tweeter is shown to have

a break-up of approximately 28.5kHz. This is

a little lower than for the best current tweeters

used on the 700 Series mainly because a crown

has not been modelled. However, the result is

broadly representative of what is to be expected

of aluminium tweeters.

The diamond tweeter has a first break-up

frequency of approximately 80.8kHz. Here

the diamond tweeter is modelled with a 40µm

dome and ‘Skirt’. A 40µm thickness design

(cf 50µm aluminium dome) was chosen so

as to compensate for the increase in density

of diamond compared to aluminium ( 3500kgm

-3

cf 2700kgm-3).

In Section 1 it was discussed that the break-up

frequency of a diamond dome should be 3.3

times higher than an aluminium dome. Clearly

for the complete diamond tweeter, less of an

improvement has been achieved (approx 2.8

times). This compromised improvement results

partly because the dome thickness is less in the

diamond than the aluminium. However, a more

important factor is that the vibrational behaviour

of a complete tweeter is more complex than

for a simple dome and is partly dictated by

the former, which in this case is common to

both designs.

However, diamond domes clearly offer a means

of considerably increasing the break-up frequency

of a tweeter (at least in a virtual world).

Sound Pressure Level Response

Before comparing the aluminium and diamond

tweeters, some justification for the simulation

method will be made. Two approaches are

available: the Simple Source Method (SSM)

and the Boundary Element Method (BEM).

The SSM is the simpler, computationally cheap

technique that relies upon the assumption that

the vibrating surface is composed of a number

of simple sources, each set in an infinite baffle.

The BEM gives an approximate solution to

Helmholtz’ equation and is therefore a more

complete solution than the SSM, but at

increased computational expense. When using

the BEM there is no infinite baffle assumption,

so some kind of enclosure is required and in

this work a sphere of radius 100mm was used.

In figure AI.4, a comparison is made between

the SPL response from 1-100kHz of a standard

aluminium tweeter calculated using the SSM

and the BEM. The first thing to note is that,

with both methods, the low frequency response

is clearly wrong, as the surround and interior

acoustics have not been modelled. Secondly,

below 10kHz the BEM and SSM differ because

only the BEM incorporates the effects of the

enclosure. However, at higher frequencies,

although there are small differences between

the responses, use of the SSM is justified at

least for comparative purposes.

In figure AI.5, three tweeter responses are shown.

These are the responses of the aluminium and

diamond tweeters (with first break-up modes

corresponding to those shown in figure AI.3)

together with the response of an infinitely rigid

tweeter. The rigid response shows a characteristic roll off and deep null at approximately

70kHz caused by the interference effects owing

to path length differences, commonly referred

to as phase loss. The response of the diamond

tweeter is much closer to that of the perfect

1514

Mode 2 , 38785.9 Hz

Mode 2 , 128084.0 Hz

AI.1 First break-up mode shape and frequency for a 50µm Al

(top) and diamond (bottom) dome.

Note: In all simulations, the red profile represents the

dome’s static shape.

Mode 2 , 28556.0 Hz

Mode 2 , 80819.1 Hz

AI.2 Finite Element Model of a simplified tweeter

AI.3 Break-up frequency and mode shape for a standard Al

tweeter and a diamond tweeter

Page 10

10

2

10

3

10

4

10

5

20

40

60

80

100

120

10

2

10

3

10

4

10

5

-200

-100

0

100

200

10

4

60

70

80

90

100

10

4

-60

-4

0

-2

0

0

2 2.2 2.4 2.6 2.8 3 3.2 3.4 3.6

x 10

3

-1

-0.5

0

0.5

1

1.5

2

2.5

3

3.5

4

Time (s)

Velocity re. m/s

Structural impulse response

AI.6 Diamond (red) versus aluminium (blue) magnitude (upper)

and phase (lower) responses

AI.7 Zoomed version of figure 6. Diamond (red) versus

aluminium (blue) magnitude (upper) and phase

(lower) responses

AI.8 Diamond (red) versus aluminium (blue) Structural

Impulse Response

Appendix I continued

Diamond Dome Tweeter

rigid tweeter below 20kHz than the aluminium

tweeter. More specifically, at 10kHz, the response

of the aluminium tweeter is approximately

0.8dB higher than the rigid tweeter whereas

the diamond tweeter's response differs by only

0.1dB. At 20kHz, the difference is increased to

approximately 4.6dB for the aluminium tweeter

but is less than 0.5dB for the diamond tweeter.

As discussed latter in the report, this absence

of coloration in the diamond tweeter when

compared to the perfect tweeter with a rigid

response is thought to be the reason for the

improved subjective performance.

Structural Acoustic Measurements

In the Section 2, the FEA was used to compare

the performance of aluminium and a diamond

tweeter. In this section structural measurements

are presented.

Structural Acceleration

In figure AI.6 the magnitude and phase response

for the diamond and aluminium tweeter measured

at the centre of the dome is shown and in figure

AI.7 a zoomed version is shown. The aluminium

tweeter, as expected, breaks up at 30kHz and

above this frequency a number of resonances

are apparent. The diamond tweeter’s magnitude

response is flat to approximately 40kHz before

rising to a break-up frequency of approximately

74kHz.

Note: this flatness of acceleration response is

really what should be quoted in specifications;

it indicates a purity in real performance which is

not obscured by acoustic effects such as phase

roll-off. A flat acoustic frequency response can

only be achieved by utilizing break-up.

Before 74kHz a number of small features are

evident, the most pronounced being a small

peak at approximately 65kHz. The cause

of these secondary features is not clear

though they could be as a result of surround

resonances, tube resonances, rocking of the

dome, etc.

The phase responses of the two tweeters start

to deviate from approximately 15kHz (figure AI.7)

with approximately 4 degrees difference at

20kHz. Though the phase responses are similar

to 15kHz, the magnitude responses for the two

tweeters show a far greater difference (approx

0.5dB at 10kHz and 3dB at 20kHz) and differences are evident from approximately 10kHz. As

the simulations show in figure AI.5, we expect

the output of the diamond tweeter to be lower

than the aluminium tweeter – though care must

be taken as here we are comparing an acoustic

simulation with a structural measurement.

Structural Impulse Response

Figure AI.8 shows the structural impulse

response of a point at the centre of the two

types of tweeter (sampling rate 204.8kHz).

Both responses show approximately the same

rise time and overall low frequency response (to

be expected) but the response of the aluminium

tweeter is characterised by a high frequency

ripple which results from the 30kHz resonance

of the structure. When both responses are low

pass filtered to exclude information above

20kHz no significant difference is evident

(not shown). This makes sense because,

as has been shown in Section 3.1, below 20kHz

the phase responses show only very small

differences at relatively high frequencies

(though there is some magnitude difference).

Structural Time-Frequency Plots

In figure AI.9 the time-frequency responses

(created using a Wavelet transform) for diamond

and aluminium and tweeters are shown. There

are obvious differences in the transforms above

20kHz owing of course to the change in

frequency of the break-up frequency. However

below 20kHz the responses are largely the same.

Note: the apparent small resonant tails below

20kHz are thought to artefacts of the analysis

method. It is uncertain whether the resonant

tails between 20kHz and 60kHz in the diamond

tweeter are artefacts or not. The increased

amplitude of these tails compared to those

below 20kHz suggests they are genuine. It is

possible that like the small features apparent

in the structural frequency response they are

caused by surround or tube resonances.

Acoustic Measurements

In section 3, structural measurements were

presented that highlight the differences between

diamond and aluminium tweeters. In this section

acoustic measurements are presented.

On-Axis SPL response

In figure AI.10, the on-axis SPL response for an

aluminium and diamond tweeter are compared.

The aluminium tweeter breaks-up at approximately

30kHz as expected. However, it is not so clear

from this plot at what frequency the diamond

breaks-up. The response of the diamond rolls

off smoothly to approximately 45kHz owing

to ‘phase loss’ (this effect is apparent in the

simulations). Above this frequency the response

rises before exhibiting two small peaks at

approximately 63kHz and 74kHz. Above

74kHz the response of the diamond tweeter

rolls off sharply.

As was shown in section 3 the actual break-up

frequency of the diamond tweeter is at 74kHz,

which compares to approximately 80kHz in

the simulation (see figure AI.3). The lower

frequency in the real tweeter is due to the effect

of the surround and uncertainty of the material

properties of the former/dome glue joint.

The peak in practice is much lower than in

the simulation. This is thought to be in part

because damping properties of the surround

at any frequency but especially high frequencies

are not known. Another explanation may be

that the peak is superimposed on a sharply

falling response so it appears to be lower than

it is. Another factor is likely to be the effect of

air absorption.

The degree of absorption is highly dependent

on factors such has humidity, temperature

and, of course, frequency. However, to illustrate

the effect, at 80kHz, 70% humidity and at

20 degrees, attenuation is approximately

3dB/metre. See (1) for a detailed discussion

of the effect of air absorption.

In figure AI.11 the acoustic phase response

of the aluminium and diamond tweeters are

compared. Below 20kHz the two responses

are similar but the aluminium shows anomalies

above this frequency. The phase differences

apparent in the structural measurements

(figures AI.6 and 7) are not so obvious in the

acoustic response.

The acoustic impulse response

Finally in figure AI.12, the acoustic impulse

response for aluminium and diamond tweeters

is shown. Whilst at first glance this looks like

convincing evidence that the diamond is better

than the aluminium; the leading edge of the

main pulse seems to be steeper than that of the

aluminium that could be equated with a ‘faster’

sound. The faster rise time would also equate

with more HF information. However when

considering figure AI.10, it might be concluded

then that the aluminium tweeter would have the

fastest rise time.

When the responses shown in figure AI.12

are low pass filtered to 20kHz (not shown) the

resulting impulses look largely the same. The

conclusion then is that the differences in rise

times are the result of ultrasonic frequencies –

though it is possible to argue that this result

is curious looking at figure AI.11. Thus the

responses in figure AI.12 are misleading and

are shown here just for completeness.

Distortion Measurements (an aside)

Other than the removal of the distortion features

that result from the 30kHz aluminium tweeter

break-up, there is no real reason that diamond

should be more linear than aluminium. THD+N

measurements for diamond and aluminium are

shown in figure AI.13, for reference. Below

3kHz, which is better depends on the frequency

considered and this variability is thought to be

more to do with manufacturing differences than

anything else (and this manufacturing variability

confounds all detailed comparisons of distortion).

1716

10

3

10

4

10

5

-25

-20

-15

-10

-5

0

5

10

15

20

25

Frequency (Hz)

Sound pressure level (dB)

Acoustic frequency response

AI.4 The SPL response of an Al tweeter calculated using

the SSM and the BEM

AI.9 Time-Frequency plots of aluminium and diamond

AI.5 The SPL response of aluminium, diamond and perfect,

rigid tweeters

110

100

90

80

70

Sound pressure level (dB)

60

50

3

10

Acoustic frequency response

Frequency (Hz)

4

10

BEM

SSM

5

10

Page 11

there is no known credible evidence that

airborne sound can be perceived above 25kHz.

Against this background, there are a number of

controversial works that challenge the established

conclusions. In particular in (7), it is concluded

that ultrasonic information modifies measurable

brain response. This is not the same as normal

auditory perception. Instead it is postulated that

ultrasound could have a direct impact on the

brain. This work is the subject of debate.

Undoubtedly further experiments will be carried

out in this area, although convincing conclusions

will be difficult to make. Such experiments are

very difficult to carry out owing to the problem

of keeping a like-for-like comparison before and

after addition of ultrasonic information. One big

problem is that of intermodulation resulting from

speaker nonlinearity. Remember, another issue

that confounds this debate is the fact that the

ear is not linear (see figure AI.16) and therefore

does not perform a perfect Fourier transform.

So far, the bandwidth of the ear has been

discussed. Although related in a linear system

at least, there is some debate over whether

our hearing system can resolve very small time

differences. Two cases are to be considered.

Firstly, events that are closely separated in

time, implying fine monaural resolution and

consequently high bandwidth. Secondly,

binaural time difference errors, such as

differential dispersion or delay between

channels that help build up the auditory scene.

A number of investigations conclude that the

lowest limit of temporal resolution for both

monaural and binaural events is approximately

10µs (8-10).

So, on the one hand the audibility of ultrasonic

frequencies is not accepted by the audio

community, but on the other, 10µs time

discrimination is, which in a linear system

(which the ear is not) would imply a 50kHz

audible bandwidth.

As an aside, could the 10µs time discrimination

limit be an explanation as to why the diamond

tweeter sounds better than the aluminium

tweeter? In section 3.1 it was discussed that,

19

Appendix I continued

Diamond Dome Tweeter

However both the aluminium and diamond

tweeters have greatly improved distortion

compared to the Nautilus 800 tweeters or even

the Signature 800 tweeters. This is thought to

be firstly because the coil position has been

adjusted slightly to be correctly centred in the

gap and secondly because of the use of the

new roll surround. Over the important range,

from 3kHz –10kHz the distortion maximum is

0.4%, with dips as low as approximately 0.26%.

On standard CD programme, there is little information above 20kHz and almost none at 22kHz.

However, with high definition audio, information

up to 96kHz can be present. Thus considerable

effort was made to differentiate between diamond

and aluminium when applying a multitone

excitation from 20-40kHz and measuring the

resulting intermodulation distortion. Unfortunately,

without applying excessive power, little

difference could be found.

However, in figure AI.14, the distortion resulting

from a 20-40kHz multitone excitation applied

to a Nautilus 800 Series tweeter with a foam

surround and a new aluminium tweeter with roll

surround. The new tweeter gives up to 12dB

lower distortion at some frequencies.

On High Frequency Audibility

An excellent paper that touches on the issues

of high frequency audibility and high sampling

rates and which is also a good source of

references is (2, especially117-132). Much of

the following is paraphrased from this paper:

The advent of higher sampling rate formats

such as DVD-A and SACD have provoked

a debate over high frequency audibility. It is

generally accepted that higher sampling rate

formats sound better. Is this really because

high frequency components (above 20kHz)

are directly audible or because the increased

sampling rate gives a bigger gap than 44.1kHz

sampling, between 20kHz and the sampling

frequency, thus allowing for less severe filters

and/or less aliassing?

It is undoubtedly true that musical instruments

contain ultrasonic components. For example a

cymbal, which is said to have more content

above 20kHz than any other instrument, has

40% of its power in this range (3). However is

this audible?

It is worth first recalling briefly the function of

the ear. See figure AI.15 for a cross section of

an ear showing the three main sections; the

outer, middle and inner ear. The frequency

response of the outer and middle ear has a fast

cut-off rate owing to the combined action of

the acoustics of the ear canal and mechanical

transmission loss (4), typified by the well-known

Fletcher-Munson Curves (note the non-linearity).

The cochlear, the main structure of the inner

ear, behaves as a bank of mechanical filters

with the highest frequency filter closest to the

eardrum (the membrane separating the middle

from the outer ear). The centre frequency of the