Page 1

600 Series

www.bowers-wilkins.com

Page 2

It’s that time again. When B&W unveils the latest

edition of its 600 Series. It’s been going on since the

mid-1990s. Even on its debut the 600 Series swept up

five star reviews and product of the year awards for its

affordable, audible brilliance. Every three years or so since

then, as new editions have appeared, it’s been the same

story. The new 600 Series – the fourth generation – has

been a little longer coming, so the heat’s been off the

competition. But it’s back. And it’s better, sharing more

leading-edge technologies with our top-of-the-range 800

Series. There’s a wider choice of finishes, a fresh new look

and a step forward in sound quality that raises the bar to

a whole new level. It’s been a wait, but it’s worth it.

www.bowers-wilkins.com

Page 3

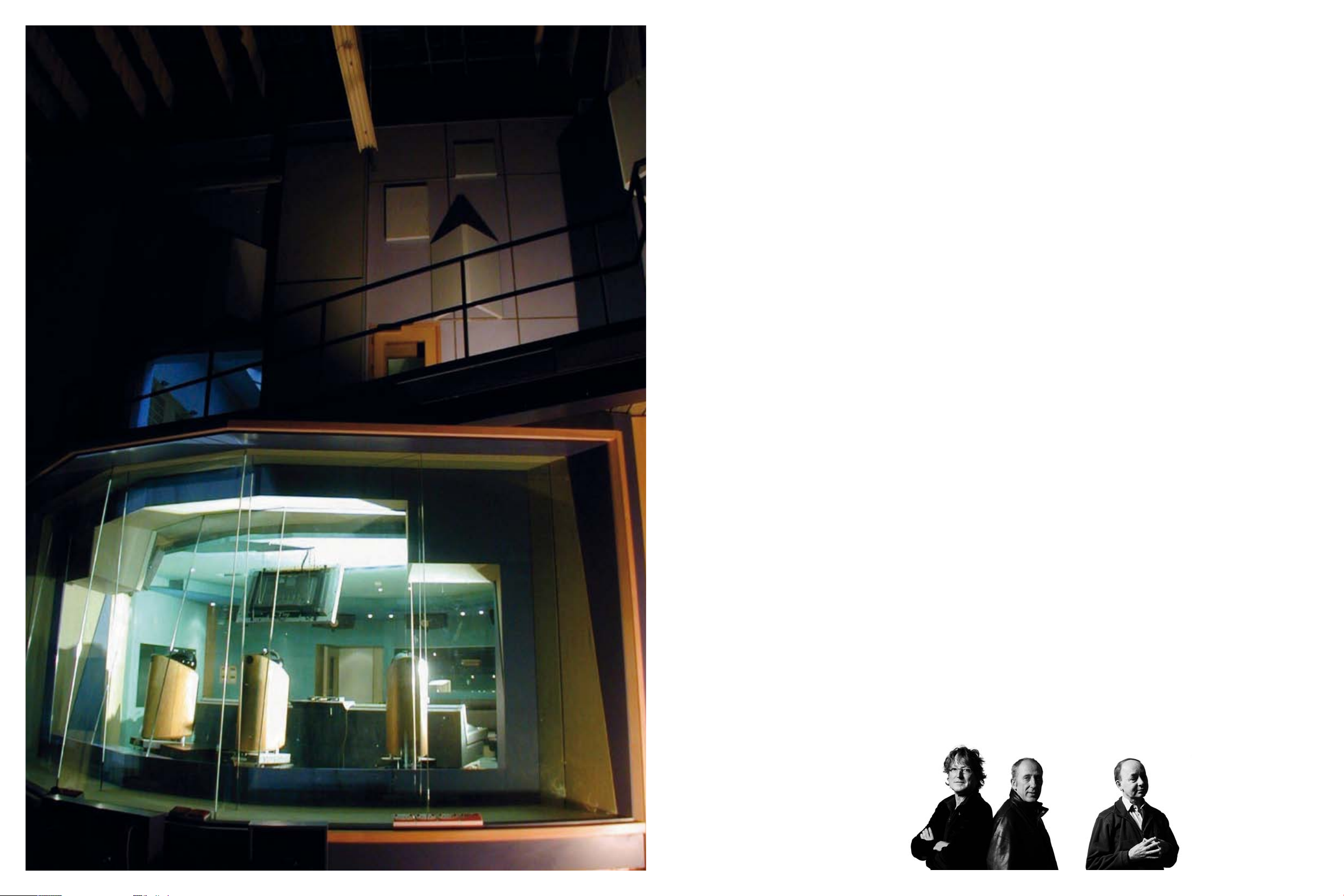

There’s no room for dreams in business. That’s

what we’re told. B&W is different. Its success stems from

the dream of founder John Bowers to create the perfect

loudspeaker – one that neither adds to nor takes away from

the recorded performance. And, in the laboratories and

listening rooms of our dedicated Research Establishment in

southern England, that’s been our goal from day one. The

design breakthroughs we’ve made and the technologies

we’ve developed along the way have helped to create

award-winning loudspeakers at every level of the market.

By working with respected studios like Abbey Road, we’ve

satisfied the world’s most demanding listeners. The dream

is our business. And today, through networks such as our

newly-founded Society of Sound, we’re finding performers,

technicians and customers who share it. We’re getting

closer all the time.

From left to right: Michael Gleason

and Peter van Hooke, Live from

Abbey Road. John Dunkerley, Decca

Recording Engineer.

www.bowers-wilkins.com

Page 4

You might think that seeing a movie at home can

never compare to seeing it at the cinema. Well,

that’s what the B&W 600 Series is here for: to

bring the big screen experience into your home.

With a sound system that can deliver every word,

whisper, pin drop and tyre screech in super-sharp

clarity, from any point in your room, you’ll find

yourself living every moment. And, when you’re

winding down from that experience, switch the

system to audio to enjoy your favourite music in

revelatory sound quality.

The 683 Theatre is one of three suggested

packages designed for different roomscapes.

It’s the reference 600 Series home theatre system,

put together to fill large, open spaces effortlessly

with rich, deep, detailed sound. Prepare yourself

for the big sound experience, fronted by a pair of

uncompromising 683 floorstanders. Think you

saw and heard it all at the cinema? Think again.

www.bowers-wilkins.com

Page 5

www.bowers-wilkins.com

Page 6

Behind the scenes. The creation of the 600 Series has

engaged just about everyone at Bowers & Wilkins in some

way. Here’s a look at some of the detail and thinking from

two of the people involved.

Mike Gough, Senior Product Manager

When you are faced with creating a new

600 Series, how does your approach differ

from that for a reference level range?

In one respect, surprisingly little. After all, our

customers’ passion for music is governed by their

hearts not wallets. And from an execution point

of view we’re tied by the same laws of physics at

every level. Of course, the challenges are different

but we expend just as much energy solving them.

Can you explain how the challenges differ?

Normally, new technologies are developed for

high-end products. There the challenge is all about

pushing absolute boundaries and there’s usually a

good deal of heartache in the perfecting process.

It may be learning about new materials or getting

to grips with a new manufacturing process. It’s

very time consuming and can be very expensive

to perfect. Once that part of the process is over,

however, you don’t have to go through it again

when you want to apply it to another product.

The challenge with value products is how to apply

what may be an expensive feature more cost

effectively. Interestingly, they’re not all expensive to

manufacture. Take Flowport™, for example. It costs

no more to mould a dimpled port than it does a

plain one, so that feature made its way into most of

our products across the board very quickly.

Give me an example of how you cost

engineered an expensive technology.

I’ll give you two that are related. For many years,

because of the cost of manufacture, Kevlar® cones

were restricted to 800 Series products and the first

two 600 Series did not feature them except for the

midrange driver of the largest floorstander. We then

considerably slicked up our production methods

and not only made the cones more affordable but

more consistent in performance. This time round,

we have used our FST™ midrange driver for the first

time in 600 Series. This is a really great driver - lots

of detail and resolution - and has helped make

the reputation of 800 Series products. This time

though, we already had the optimum production

methods in place, so nothing to gain there. What

we did was use a much simpler mounting method

than the single point tension method of the 800

Series. You can do that sort of stuff at the high

end but that you can get a big chunk of the benefit

at 600 Series level is a pretty good deal for the

customer.

A lot of what makes a great speaker is

down to the final voicing. Do the 600 Series

engineers go about this in a different way

from the 800 Series engineers?

If I say at the outset that it’s the same team across

the board, you’ll realise that the answer is no. One

of the advantages of this is that you get the same

dedication to performance targets. Once you have

worked on high end products, you can’t lower your

standards. I’ve stopped counting the number of

times I have sat in on listening sessions and been

amazed at the level of performance those guys can

wring out of speakers.

Dr. Gary Geaves, Head of Research

One of the important acoustic changes in

this new 600 Series is in crossover design.

Why is this area of acoustic design so

crucial?

Sufficient coverage of the full audible spectrum

requires at least two drive units, covering the low,

mid and high frequency bands. It is necessary to

filter out the high and low frequencies respectively,

in order that the two drivers combine in the correct

manner. This filter is known as the crossover, and

it is just as critical to the overall sound as any other

element in the system. Experience has shown that

the simpler we can make the crossover filter, the

better the sound. And the better the drivers, the

simpler the crossover required. In this new 600

Series we have really done a lot of work in this area

which has resulted in just one capacitor for the high

frequency part of the crossover - as uncomplicated

a format as it gets.

B&W also talks about the selection of these

crossover components as being in itself

crucial.

Yes. With a loudspeaker design where the drive

units are very high resolution, it is often the case

that filter components which appear to have

identical stated specifications can sound drastically

different. We’re researching this to find out why

but we can definitely hear huge differences that we

currently don’t really know how to measure. The

ear is a remarkably sensitive device!

How do you choose these components

then?

The final selection of components and therefore

the overall ‘tuning’ of the loudspeaker must, of

necessity, be done by subjective analysis i.e.

listening to music. And not just in one room with

one type of equipment - in as many rooms as

possible with all manner of different partnering

equipment. This aspect of acoustics is actually

as much of a skill as the more obviously scientific

areas like material science and it’s why B&W has

always dedicated a large portion of a loudspeaker’s

development time to listening. It’s also the area

of development where we’ll involve our friends at,

say, Abbey Road Studios to get as broad a set of

opinion as we can.

www.bowers-wilkins.com

Page 7

www.bowers-wilkins.com

Page 8

Treble. Mobile phones, DVD players, car navigation

systems… Sooner or later, most technological advances

become accessible. Few, though, will generate as much

sheer pleasure as the innovations now found in the 600

Series.

When we develop a breakthrough technology for

one of our studio-standard ranges, every other

B&W product feels the benefit. What was state-ofthe-art in the high-end series becomes state-ofthe-art in more affordable ranges. Everything that

goes into a B&W speaker has a pedigree. The

600 Series tweeter is a case in point. Its tubeloaded design, which spirits away unwanted sonic

radiation from behind the dome, first appeared in

our convention-busting Nautilus™ speaker. The

aluminium dome itself, bonded resolutely to the

voice coil, achieves truer-than-ever frequencies well

past the upper limit of human hearing.

Neodymium magnets similar to the kind used in

the tweeter of the 800 Series replace the ceramic

magnets of the previous 600 Series tweeter. More

compact, they allow the separation between the

centres of the midrange and tweeter to be reduced,

which makes for a more focused sound ‘image’.

Other refinements, to the magnet pole and the

surround material, have lowered distortion and

further sharpened the imaging. All of which adds up

to a tweeter of such high quality that it requires only

a 1st-order filter, whose simplicity helps to preserve

the full purity of the signal.

www.bowers-wilkins.com

Page 9

Midrange. Owners of earlier 600 Series speakers will

be wondering how we could improve on the clarity and

detail of a midrange drive unit that’s already in a class of

its own. That’s just the kind of challenge we like.

In all our 600 Series midrange/bass units the

distinctive yellow woven Kevlar® cone snuffs out

the kind of concentric standing waves that build

up in standard, homogeneous cones, while a light,

airy ‘open’ chassis cuts down echo from behind

the cone. But, to the midrange of the three-way

683 speaker, we’ve been able to add something

even more special. We call it a ‘fixed suspension

transducer’, or FST™ for short. It sounds complex,

but it’s not. It’s simple, and it sounds wonderful, but

until now it has only been seen in B&W’s audiophile

ranges, such as the 800 Series.

The FST™ is a ring of foam whose mechanical

properties exactly match those of the woven

Kevlar® cone, which gives it magical properties

over the bending waves that travel outwards

through the cone, to its edge. With a conventional

roll surround, these energies would be reflected

back into the cone and smudge the sound.

The FST™ soaks them up, like a circular shock

absorber around the cone’s edge. What you hear is

a cone moving even more freely and responsively: a

midrange that’s top of the range.

www.bowers-wilkins.com

Page 10

Bass. When push comes to shove, you have to be serious

about bass. At B&W, it’s a science. We test materials,

structures and circuits to their limit to get better bass for

your buck.

You might not think a material like paper would

tie in very well with a B&W bass driver. Turn the

volume up on one of our 600 Series subwoofers,

for instance, and you could probably shake

wallpaper off walls. So it might surprise a lot of

listeners to find that paper plays a vital part in

what they’re hearing. In our ASW608, ASW610

and ASW610XP subs, the bass driver diaphragms

are constructed from a finely-tuned mix of paper

pulp, Kevlar® fibres and resin, which provides

the stiffness needed to withstand the tremendous

physical forces exerted by the voice coil and

pressures inside the cabinet.

For the 683 bass drivers, which operate to

higher frequencies than the subwoofers, that

paper/Kevlar® mix is closely bonded to an

aluminium front skin and the unit features our novel

‘mushroom’ construction in which the cone, dust

cap and voice coil bobbin are bonded together

like a ring girder. Extra measures to extend the

performance.

Ultra-solid construction - that’s the key to slamming

bass, drum kicks and special movie effects.

Deformation is minimised; bass precision, power

and enjoyment are maximised.

www.bowers-wilkins.com

Page 11

Finishes. We don’t believe in spoiling your enjoyment of

what you hear by designing speakers that you don’t want

to see. Choose from a wider-than-ever set of finishes and

tailor your 600 Series speakers to their setting.

Speakers, after all, are furniture. They have a form

as well as a function. You’ll find the craftsmanship

and quality of finish on B&W 600 speakers reflect

the high standard of engineering and innovation

inside them. For the new series, we have widened

the choice of cabinet finishes and remodelled the

speaker facades to echo currents in contemporary

furniture design.

A matt, soft-touch front surface and elimination

of visible screws around the drivers creates an

understated, seamless appearance, complemented

by a new, brushed aluminium, diamond-cut logo

plate that encompasses the tweeter. There are

three cabinet veneers available: our traditional

Black Ash; the Light Oak that proved popular for

the 600 Series 3 and a smooth Red Cherry.

www.bowers-wilkins.com

Page 12

Want to ride with Hopper and Fonda in Easy Rider?

Fly into the Death Star with Luke? Or eavesdrop

on the neighbours in Rear Window with James

Stewart? If your requirements from a home theatre

system don’t run to maximum power, but you’d

still like sound that can drop you headfirst into the

action, we suggest the 684 Theatre. Featuring a

pair of 2½-way, floorstanding 684s, two 686s in

the rear position, an HTM62 centre speaker and an

ASW610 subwoofer, it can recreate movie sound

and music in totally believable 3D detail and power.

www.bowers-wilkins.com

Page 13

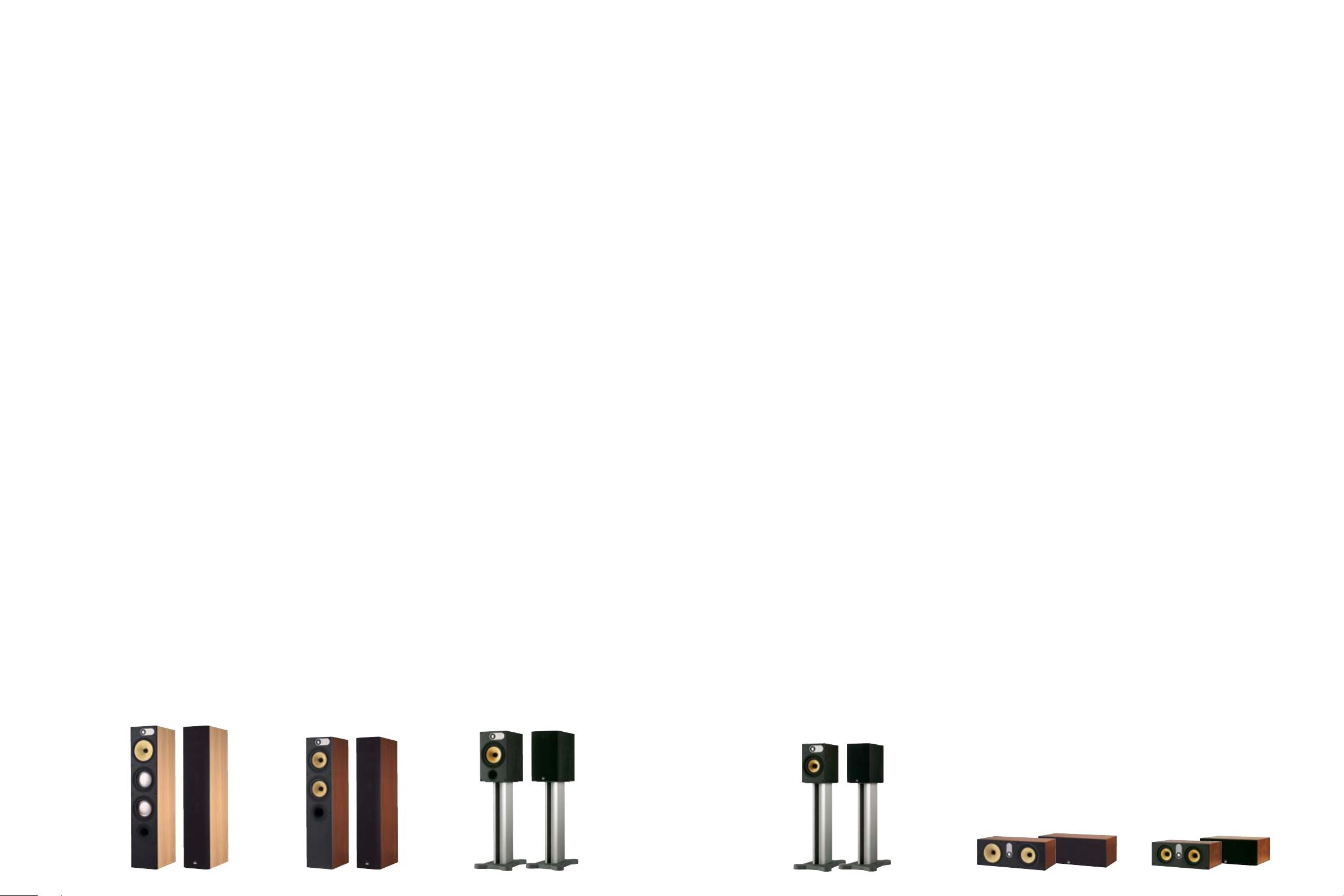

Home theatre packages. With two bookshelf speaker

models, two floorstanders, two centre speakers and three

subwoofers in the 600 Series, there’s a lot of potential

ways to assemble a home theatre system. Here are three

groups that, to our ears, go together as harmoniously as

the Beach Boys or Ladysmith Black Mambazo.

685 Theatre

The most compact of the three set-ups, the 685

Theatre is a bookshelf-based arrangement for more

enclosed listening environments. With an ASW608

subwoofer bringing bass aplenty, it still packs all the

punch you’ll need.

Main: 685

Centre: HTM62

Surround: 686

Subwoofer: ASW608

684 Theatre

For maximum detail and impact in medium-sized to

large rooms, team up a pair of 2½-way 684s with a

larger subwoofer, an HTM62 centre speaker and a

pair of 686s in the rear position.

Main: 684

Centre: HTM62

Surround: 686

Subwoofer: ASW610

683 Theatre

If you’re watching movies and listening to music

in a large, open space, you need a system with

authority as well as attention to detail. The 683

Theatre will command the largest domestic spaces

with ease.

Main: 683

Centre: HTM61

Surround: DS3

Subwoofer: ASW610XP

www.bowers-wilkins.com

Page 14

So, that’s it. Or is it? At B&W, the pursuit of perfect

sound continues. For over 40 years, we’ve been dedicated

to creating a loudspeaker that neither adds nor takes away

from the recorded sound. In the process, we’ve become

a world leader, developing award-winning speakers

like the 600 Series. It’s a passion. Thankfully, we’re not

alone. There are others – musicians, technicians, critics,

customers – who are as dedicated as we are. And now,

we’re coming together to share knowledge, insights

and our love of sound. You can join this global network,

too, and get closer to your movies and music. Come to

www.bowers-wilkins.com to find out more and to join

the Society of Sound.

www.bowers-wilkins.com

Page 15

Main

Centre

Technical fe atures

Descri ption

Drive units

Frequen cy range

Frequen cy respon se

Disper sion

Sensit ivity

Harmon ic disto rtion

Nomina l impeda nce

Crossov er freque ncy

Recomm ended am plifier p ower

Max. re commende d cable

impeda nce

Dimens ions

Net Wei ght

Finish es

683

Nautilus™ tube loaded aluminium

dome tweeter

®

brand fibre cone FST™ midrange

Kevlar

Aluminium/Paper/Kevlar

™

Flowport

3-way vented-box system

1x ø25mm (1 in) aluminium dome highfrequency

1x ø150mm (6 in) woven Kevlar

™

midrange

FST

2x ø165mm (6.5 in)

Aluminium/paper/Kevlar

-6dB at 30Hz and 50kHz

38Hz - 22kHz ± 3dB on re ference a xis

Withi n 2dB of reference response

Horizo ntal: over 60º a rc

Vertical: over 1 0º arc

90dB s pl (2.83 V, 1m)

2nd an d 3rd har monics ( 90dB, 1m )

<1% 90 Hz - 22k Hz

<0.5% 120Hz - 20kHz

8V (mi nimum 3. 0V)

350Hz, 4kHz

25W - 200W into 8V on unclipped programme

0.1V

Height: 985mm (38.8 in)

(not including plinth or feet)

Width: 198mm (7.8 in)

Depth: 340mm (13.4 in)

26kg (57.3 lb)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

cone bass driver

®

cone

®

cone bass

684 685

™

tube loaded aluminium

Nautilus

dome tweeter

®

brand fibre cone bass/midrange

Kevlar

®

brand cone bass driver

Kevlar

™

Flowport

2½-way vented-box system

1x ø25mm (1 in) aluminium dome highfrequency

1x ø165mm (6.5in) woven Kevlar

midrange

1x ø165mm (6.5in) woven Kevlar

®

cone bass /

®

cone bass

-6dB at 34Hz and 50kHz

44Hz–22kHz ±3dB on reference axis

Within 2dB of reference response

Horizontal: over 60° arc

Vertical: over 10° arc

90dB spl (2.83V, 1m)

2nd & 3rd harmonics (90dB, 1m)

<1% 90Hz - 22kHz

<0.5% 120Hz - 20kHz

8V (minimum 3.0V)

150Hz, 4kHz

25W–150W into 8V on unclipped programme

0.1V

Height: 910mm (35.8 in)

(not including plinth or feet)

Width: 198mm (7.8 in)

Depth: 300mm (11.8 in)

18.2kg (40.1lb)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

Nautilus™ tube loaded aluminium

dome tweeter

Kevlar

Flowport

2-way vented-box system

1x ø25 mm (1 in ) alumin ium dome highfrequen cy

1x ø16 5mm (6.5 in) wov en Kevla r

midra nge

-6dB a t 42Hz a nd 50kHz

49Hz - 22kHz ± 3dB on re ference a xis

Withi n 2dB of reference response

Horizo ntal: over 60º a rc

Vertical: over 1 0º arc

88dB s pl (2.83 V, 1m)

2nd an d 3rd har monics ( 90dB, 1m )

<1% 10 0Hz - 22 kHz

<0.5% 150Hz - 20kHz

8V (mi nimum 3. 7V)

4kHz

25W - 100W int o 8V on unclippe d program me

0.1V

Height: 340mm (13.4 in)

Width: 198mm (7.8 in)

Depth: 331mm (12.3 in)

7.0kg (15.4 lb)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

brand fibre cone bass/midrange

™

®

cone bass /

Technical fe atures

Descri ption

Drive units

Frequen cy range

Frequen cy respon se

Disper sion

Sensit ivity

Harmon ic disto rtion

Nomina l impeda nce

Crossov er freque ncy

Recomm ended am plifier p ower

Max. re commende d cable

impeda nce

Dimens ions

Net Wei ght

Finish es

686

™

tube loaded a luminium

Nautil us

dome t weeter

®

brand fibre co ne bass/ midrange

Kevlar

™

Flowpo rt

2-way vented-b ox syste m

1x ø25 mm (1 in ) alumin ium dome highfrequen cy

1x ø13 0mm (5 i n) woven Kevlar

midran ge

-6dB a t 45Hz a nd 50kHz

55Hz - 22kHz ± 3dB on re ference a xis

Withi n 2dB of reference response

Horizo ntal: over 60º a rc

Vertical: over 1 0º arc

84dB s pl (2.83 V, 1m)

2nd an d 3rd har monics ( 90dB, 1m )

<1% 11 0Hz - 22 kHz

<0.5% 150Hz - 20kHz

V (minimum 5.1V)

8

4kHz

25W - 100W int o 8

V on u nclipped programm e

V

0.1

Height : 265mm (10.5 in )

Width : 170mm (6.7 in)

Depth: 284mm (11.2 in )

4.9kg (10.8 lb)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

cone bass /

HTM61

Nautilus™ tube loaded aluminium

dome tweeter

®

brand fibre cone FST™ midrange

Kevlar

®

brand fibre cone bass

Kevlar

™

Flowport

Magnetic shielding

3-way vented-box system

1 x ø2 5mm (1 i n) alumi nium dom e highfrequen cy

1 x ø1 50mm (6 in) wove n Kevlar

midran ge

1 x ø1 65mm (6. 5 in) wo ven Kevl ar

-6dB a t 30Hz a nd 50kHz

38Hz - 22kHz ± 3dB on re ference a xis

Withi n 2dB of reference response

Horizo ntal: over 20º a rc

Vertical: over 6 0º arc

90dB s pl (2.83 V, 1m)

2nd an d 3rd har monics ( 90dB, 1m )

<1% 90 Hz - 22k Hz

<0.5% 120Hz - 20kHz

V (minimum 3.0V)

8

350Hz, 4kHz

30W - 150W into 8

V on unclipped programme

V

0.1

Height: 198mm ( 7.8 in)

Width: 545mm ( 21.5 in)

Depth: 339mm ( 13.4 in)

15.4kg (34 lb)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

cone FST™

®

cone bass

HTM62

Nautilus™ tube loaded aluminium

dome tweeter

®

brand fibre cone bass/midrange

Kevlar

™

Flowport

Magnetic shielding

2-way vented-box system

1x ø25 mm (1 in ) alumin ium dome highfrequen cy

2x ø13 0mm (5 i n) woven Kevlar

midran ge

-6dB a t 45Hz a nd 50kHz

55Hz - 22kHz ± 3dB on re ference a xis

Withi n 2dB of reference response

Horizo ntal: over 20º a rc

Vertical: over 6 0º arc

85dB s pl (2.83 V, 1m)

2nd an d 3rd har monics ( 90dB, 1m )

<1% 10 0Hz - 22 kHz

<0.5% 150Hz - 20kHz

V (minimum 4.3V)

8

4kHz

25W - 120W into 8

V on unclipped programme

V

0.1

Height: 170mm (6.7 in)

Width: 438mm (17.3 in)

Depth: 308mm (12.2 in)

9.1kg (20.1 lb)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

cone bass /

www.bowers-wilkins.com

Page 16

Subwoofer

Surround

Technical fe atures

Descri ption

Drive units

Frequency range

Frequency response

Bass Extension

Amplifier

Low-pa ss filte r

Dimens ions

Net we ight

Finish es

ASW610XP

Dual voice coil drive unit Paper/Kevlar

stiffened cone

200W + 200W ICEpower

Active closed-box subwoofer system

ø250mm (10 in) dual voice coil

paper/Kevlar

-6dB at 18Hz and 25/140Hz adjustable (EQ at A)

±3dB 2 5Hz – 40 /140Hz a djustabl e (EQ at A)

-6dB at 18Hz (position A)

-6dB at 23Hz (position B)

-6dB at 28Hz (position C)

Power output: 200W + 200W

Rated power

Consum ption: 80W/ 1W stand by

Input impedanc e: 33k

Signal / noise : >90dB

Functi ons: Input level (line in)

Input level (speaker in)

Low-pass filter

frequency (line in only)

Low-pass filter bypass

Bass extension

Bass roll-off alignment

Auto sense on/

standby

Phase switch

Inputs : Line I n (RCA P hono)

Speake r in (Bi nding po st)

12v tr igger (3 .5mm jac k)

Active 4th -ord er, variable cut-off frequency

Height : 310mm (12.2 in ) not in cluding feet

Width : 310mm (12.2 in )

Depth: 375mm ( 14.8 in)

includ ing gril le and c ontrols

15.5kg (34.4 l b)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

cone long-throw

V

®

amplifier

®

ASW610

Paper/Kevlar® cone drive unit

200W ICEpower

Active closed- box subw oofer sy stem

ø250mm (10 in) paper/Ke vlar

-6dB a t 20Hz a nd 25/14 0Hz adju stable ( EQ at A)

±3dB 2 7Hz – 40 /140Hz a djustabl e (EQ at A)

-6dB a t 20Hz ( position A)

-6dB a t 25Hz ( position B)

-6dB a t 30Hz ( position C)

Power output: 200W

Rated power

Consum ption: 40W/ 0.5W sta ndby

Input impedanc e: 33k

Signal / noise : >90dB

Functi ons: Input level (line in)

Input level (s peaker i n)

Low-pass filter frequency

(line in only)

Low-pa ss filte r bypass

Bass e xtension

Bass ro ll-off al ignment

Auto s ense on/ standby

Phase switch

Inputs : Line I n (RCA P hono)

Speake r in (Bi nding po st)

12v tr igger (3 .5mm jac k)

Active 4th -ord er, variable cut-off frequency

Height : 310mm (12.2 in ) not in cluding feet

Width : 310mm (12.2 in )

Depth: 375mm ( 14.8 in)

includ ing gril le and c ontrols

12.5kg (27.6 l b)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

amplifier

V

®

cone long-thro w

ASW608

Paper/Kevlar® cone drive unit

200W ICEpower

Active closed- box subw oofer sy stem

ø200mm (8 in) p aper/Kev lar

-6dB at 23Hz and 25/140Hz adjustable (EQ at A)

±3dB 3 2Hz – 40 /140Hz a djustabl e (EQ at A)

-6dB a t 23Hz ( position A)

-6dB a t 28Hz ( position B)

-6dB a t 36Hz ( position C)

Power output: 200W

Rated power:

Consum ption: 40W/ 0.5W sta ndby

Input impedanc e: 33k

Signal / noise : >90dB

Functi ons: Volume le vel (lin e in)

Volume le vel (spe aker in)

Low-pass filter frequency

(line in only)

Low-pa ss filte r bypass

Bass e xtension

Bass ro ll-off al ignment

Auto s ense on/ standby

Phase switch

Inputs : Line I n (RCA P hono)

Speake r in (Bi nding po st)

12v tr igger (3 .5mm jac k)

Active 4th -ord er, variable cut-off frequency

Height : 260mm (10.2 in ) not in cluding feet

Width : 260mm (10.2 in )

Depth: 330mm ( 13 in)

includ ing gril le and c ontrols

8.85kg (19.5 l b)

Black Ash Viny l

Light Oak Viny l

Red Ch erry Vin yl

®

amplifier

V

®

cone long-thro w

Technical fe atures

Description

Drive units

Frequency range

Frequency response

Dispersion

Sensitivity

Harmonic distortion

Nominal impedance

Crossover frequencies

Power handling

Max. recommended

cable impedance

Dimensions

Net Weight

Finishes

DS3

Nautilus™ tube loaded aluminium dome tweeter

®

brand fibre co ne bass/ midrange

Kevlar

2-way closed-b ox selec table di pole/mon opole

surroun d system

1x ø25mm (1 in) aluminium dome high-frequency

2x ø80 mm (3 in ) midran ge / hig h frequen cy

1x ø13 0mm (5 i n) woven Kevlar

midran ge

-6dB a t 63Hz a nd 42kHz (monopo le mode)

-6dB a t 63Hz a nd 15kHz (dipole mode)

85Hz – 22kHz ± 3dB on re ference a xis

(monop ole mode )

85Hz – 10kHz ± 3dB powe r averag ed over front

hemisp here (dip ole mode )

Monopole mode: within 2dB of reference response

Horizontal: over 40º arc

Vertical: over 10º arc

Dipole mode: horizontal figure of eight

Effective null zone ±20º (250Hz – 15kHz)

89dB s pl (2.83 V, 1m)

2nd an d 3rd har monics ( 90dB, 1m )

<1% 13 0Hz – 20 kHz

V (min imum 3.3 V)

8

4kHz ( monopole mode)

250Hz (dipole mode)

25W – 100W int o 8

V

0.1

Height : 249mm (9.8 in)

Width : 380mm (15 in)

Depth: 1 53mm (6 in)

5.2kg (11.5 lb )

Black cabinet and gril le

White cabinet and gril le

V on u nclipped programm e

®

cone bass /

www.bowers-wilkins.com

Page 17

03/07. PU16575

B&W Group Ltd

Dale Road

Worthing West Susse x

BN11 2BH Englan d

T +44 (0) 1903 221800

F +44 (0) 1903 221801

info@b wgroup.co m

www.bower s-wilkin s.com

B&W Gro up (UK S ales)

T +44 (0) 1903 221 500

E uksa les@bwgro up.com

B&W Gro up North America

T +1 9 78 664 2 870

E mark eting@bw groupusa. com

B&W Gro up Asia

T +852 2 790 8 903

E info @bwgroup. hk

Nautilus and Flowport are trademarks of B&W Group Ltd.

Kevlar is a registered trademark of DuPont.

ICEpower is a registered trademark of B&O ICEpower A/S.

Copyright © B&W Group Ltd. stands featured within this

brochure are not supplied with the speakers. E&OE.

Design Thomas Manss & Company. Printed in U.K.

B&W Group Ltd reserve the right to amend details of the

specification without notice in line with technical developments.

Loading...

Loading...