Page 1

<THESE INSTRUCTIONS MUST BE GIVEN TO THE END USER>

B&W Trailer Hitches

1216 Hawaii Rd / PO Box 186

Humboldt, KS 66748

P:800.248.6564

F:620.869.9031

Turnoverball Gooseneck Hitch Installation Instructions

®

See Limited Lifetime Warranty at

bwtrailerhitches.com/warranty

Call or Email us for

Installation Support

hitches@turnoverball.com

bwtrailerhitches.com

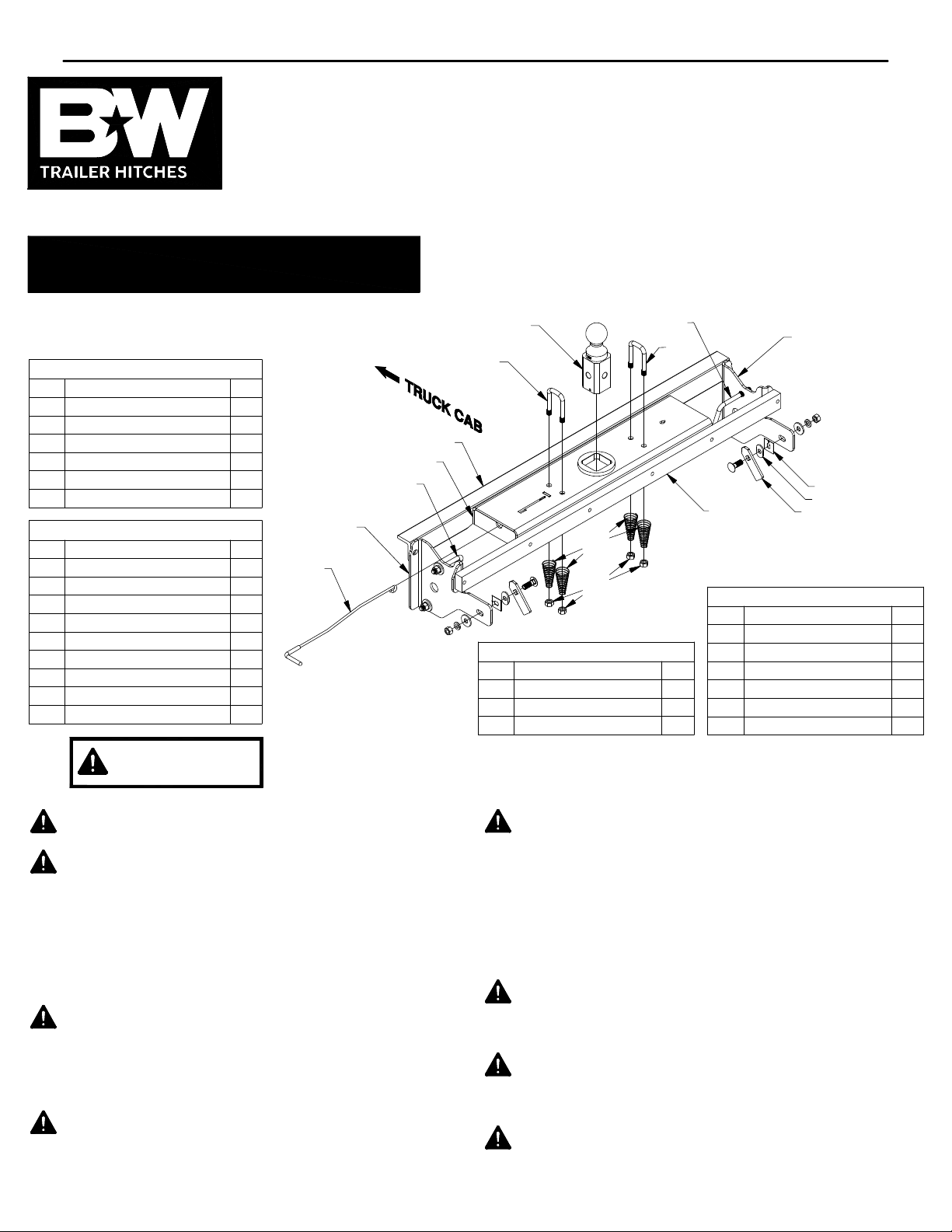

MODEL 1019

2019 CHEVROLET & GMC 1500 Short Bed Trucks

12

5

3

Safety Chain Kit Bolt Bag

ITEM

12

1/2" U−Bolt

13

Conical Springs

14

1/2" Lock Nut

1

1

1

5/16" X 3/4" Carriage Bolt

5/16" X 3/4" Cap Screw

5/16" Lock Nut

Excludes 2019 Chevy LD & GMC Limited 1500 Trucks.

(call B&W for details concerning other bed sizes.)

Mounting Kit Box (GNRM1019)

ITEM

1

2

3

4

5

Fish Wire

ITEM

6

7

8

1/2" X 1−1/2" Carriage Bolt

1/2" X 1−1/2 Cap Screw

1/2" Finish Nut

1/2" Lock Washer

1/2" Flat Washer

O−Ring

DESCRIPTION QTY

Driver Side Plate

Passenger Side Plate

Rear Cross Member

Front Cross Member

1/2" X 5−1/2" X 4−1/4" U−Bolt

Mounting Kit Bolt Bag

DESCRIPTION QTY

1/2" Retainer

1/2" Frame Bushing

1/2" Locking Strap

12

12

18

14

1

1

1

1

2

2

1

2

2

2

2

1

11

10

12

4

9

5

13

14

Center Box (GNRC919)

ITEM DESCRIPTION QTY

9

Center Section

10

2−5/16" Ball

11

Latch Pin Handle

2

6

7

8

DESCRIPTION QTY

2

4

4

1

1

1

Failure to comply with the safety information in these

WARNING

Read all installation and operating instructions along with all labels

before using this product.

Adding components such as a Turnoverball hitch to the chassis of

any vehicle can be hazardous. There is potential for unexpected

combustion of fuel, electric shock, burns, shifting or falling of

unstable vehicle, damage to vehicle, injury from tool usage and

many other hazards. This installation must be completed by

someone who is aware of the hazards involved. This person must

be knowledgeable of proper safety procedures for a vehicle

modification of this nature, and for usage of the equipment

required to perform the installation.

Without proper knowledge, towing can be a dangerous activity.

Understand all the risks involved with towing before proceeding.

For information on towing safety, see

Guide to Understanding Trailer and Towing Safety"

National Association of Trailer Manufacturers, www.NATM.com

and your trailer manufacturer’s owner’s manual.

Do not exceed tow or tongue rating of coupler, tow or tongue

rating of hitch, or tow or weight ratings of truck or trailer. See

vehicle and trailer manufacturer information for ratings. Exceeding

these ratings may cause damage to towing components or loss of

attachment between the trailer and truck.

instructions could result in serious injury or death.

"The Trailer Handbook: A

from the

Additional caution must be used when towing a wedge car trailer.

Towing stability greatly depends on keeping the center of gravity

as low as possible. Load heavy cars over the axles. Never tow

with a single car on the front of the trailer. When towing a wedge

car trailer, never exceed speeds that are reasonable for the

roadway conditions (e.g. turns, going around a curve, etc.). Failure

to account for proper trailer center of gravity and speeds that are

reasonable for the roadway conditions may cause damage to the

truck, trailer, towing components, and loss of attachment between

the truck and trailer.

This product was designed to fit vehicles in their original, "as

manufactured" condition. Compatibility with vehicles having

replacement parts, or other modifications is not guaranteed.

Inspect vehicle for modifications before installation of this product.

The Turnoverball hitch comes equipped with a 2−5/16" ball.

Trailers towed with the ball provided must have a 2−5/16" coupler.

Towing with a larger coupler could cause loss of attachment

between the trailer and the tow vehicle.

Do not modify this product in any manner. Doing so could alter its

integrity and lead to a loss of attachment between the trailer and

the tow vehicle.

PAGE 1 of 7

Page 2

PREPARE TO INSTALL

NOTE: Remove all parts from the packaging and

familiarize yourself with all the parts and tools

required. Use the parts list on the front page to verify

that all parts and hardware are present.

Installation of the Turnoverball hitch requires several

common tools and a few specialized tools. Below is a

listing of equipment used during a typical installation.

TOOLS REQUIRED

Impact wrench or ratchet with 3/4",

10mm, & 13mm sockets.

1/2" & 3/4" Box end wrenches

Marking tool ( pencil or permanent marker)

4" hole saw Flashlight

Drill with 1/2" bit Eye protection

Ear protection

Pry Bar

Tape measure

Lifting Device Pilot hole Bit

Screw driver with T15 and T25 bits.

1.

Determine cab clearance. The Turnoverball hitch is

designed so that the ball can be inverted and stored

below the surface of the truck bed while not in use.

The ball location is determined by this design feature

and the truck geometry. Measure the trailers to be

towed with this hitch to be sure that the location of the

2−5/16" ball listed in Step 11 will provide ample turning

clearance between the nose of the trailers and the cab

of the truck.

Cab clearance on short bed trucks is very limited

when towing certain trailers. Failure to ensure that

there will be adequate clearance, may result in

significant property damage, or serious injury.

2.

Position the vehicle.

Installation of the hitch requires

the installer to be under the truck bed in the area of

the rear axle. Lifting the vehicle makes this area more

accessible to the installer, and improves the

installation process.

WARNING: Lift vehicle using only equipment

designed for lifting and positioning vehicles for

service. Failure to do so may result in property

damage, serious injury, or death.

Remove the spare tire.

3.

Following the vehicle

manufacturer’s instructions, remove the spare tire.

4.

Remove the spare tire heat shield.

bolts attaching the spare tire heat shield to the frame

of the truck with a 13mm socket or wrench. Set the

heat shield aside for later re−installation.

5.

Prepare a lifting device (optional).

of the device is to safely hold the hitch in position

during part of the installation.

See Figure A1 for an example.

A simple mechanical

lifting device is available

for purchase from B&W.

Torque wrench

Remove the six

The purpose

Figure A1.

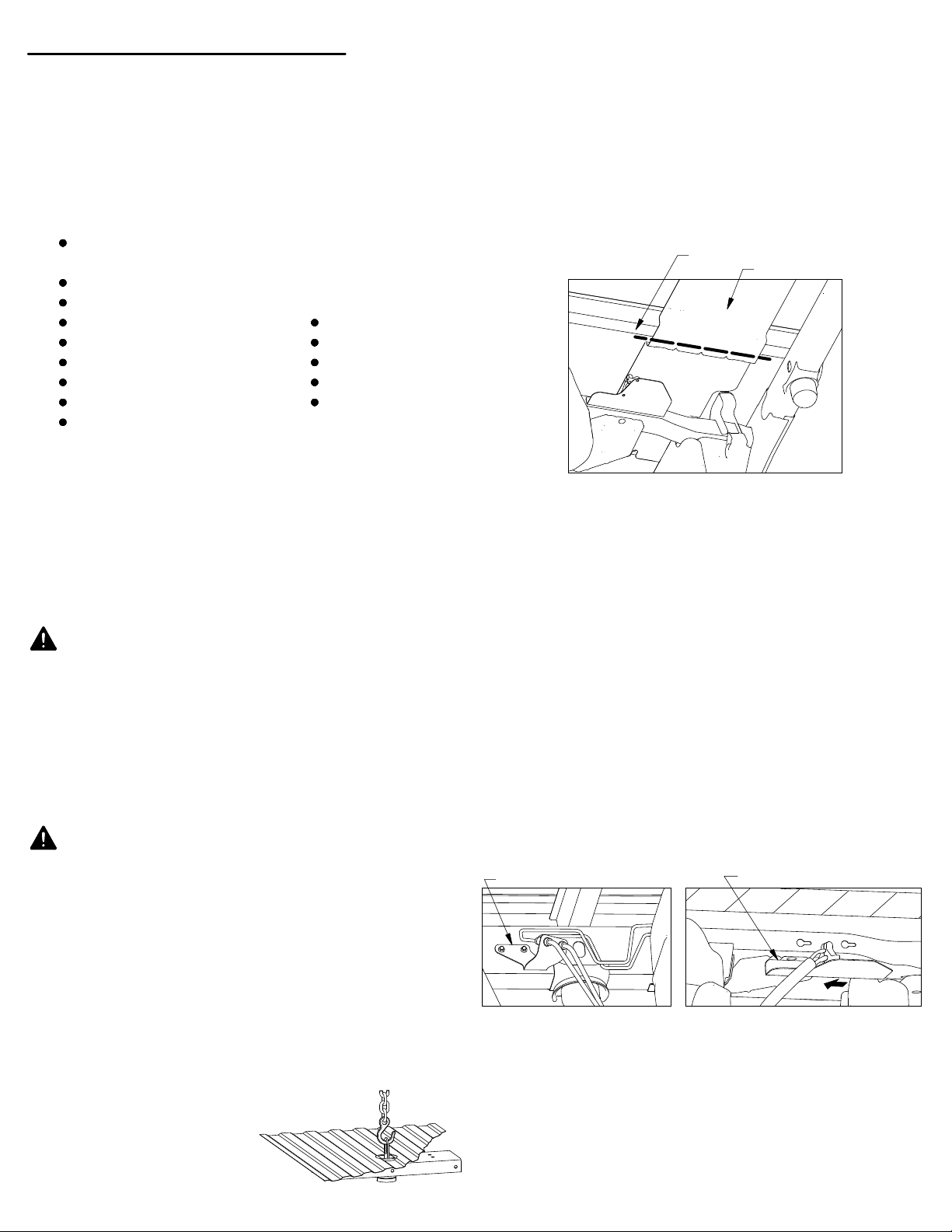

6.

Remove and discard the heat shield above the

rear axle.

A section of the exhaust heat shield will

need to be removed. Locate the bed cross member

that is directly over the axle, see Figure A2. The

section of heat shield in front of this cross member

will have to be removed. Cut along the cross member

with tin snips or another suitable tool. Make sure that

none of the heat shield is protruding past the front of

the cross member. Remove the T25 Torx screws

holding the front of the heat shield to the truck.

Discard the forward section of the heat shield when it

has been removed.

Figure A2: View looking up at bottom of bed above axle.

7.

Lower the exhaust (Optional).

CROSS MEMBER

C

U

T

L

I

N

E

HEAT SHIELD

To ease in the

installation of the center section, un−attach the rear

most tail pipe hangers from the frame and allow the

exhaust to hang freely. Re−attach the exhaust

brackets after installation is complete.

Un−attach brake and wiring brackets.

8.

Two brackets

are attached to the frame in locations that will interfere

with the installation. Using a 10mm socket or wrench

un−attach these brackets and allow to hang during

installation. These brackets will be re−attached when the

installation is complete. The first bracket holds two

brake lines on the inside of the driver side frame just

behind the rear axle, see Figure A3. The second

bracket holds wiring and is attached to a rectangular

frame cross member in front of and above the

differential. Loosen the connection and slide the bracket

to the driver side and unhook from frame. Allow to hang,

see Figure A4.

BRAKE LINE BRACKET (FIRST)

Figure A3.

9.

Disconnect wiring harness.

WIRING BRACKET (SECOND)

Figure A4.

Locate the wiring

harness running along the top of the passenger side

frame rail above the rear axle. Detach the plastic

connector closest to the shock bracket from the

frame. Pull the wiring down off the top of the frame,

towards the inside, to make space for the forward

cross member to sit on top of the frame. This wiring

will be left loose during and after the installation.

PAGE 2 of 7

Page 3

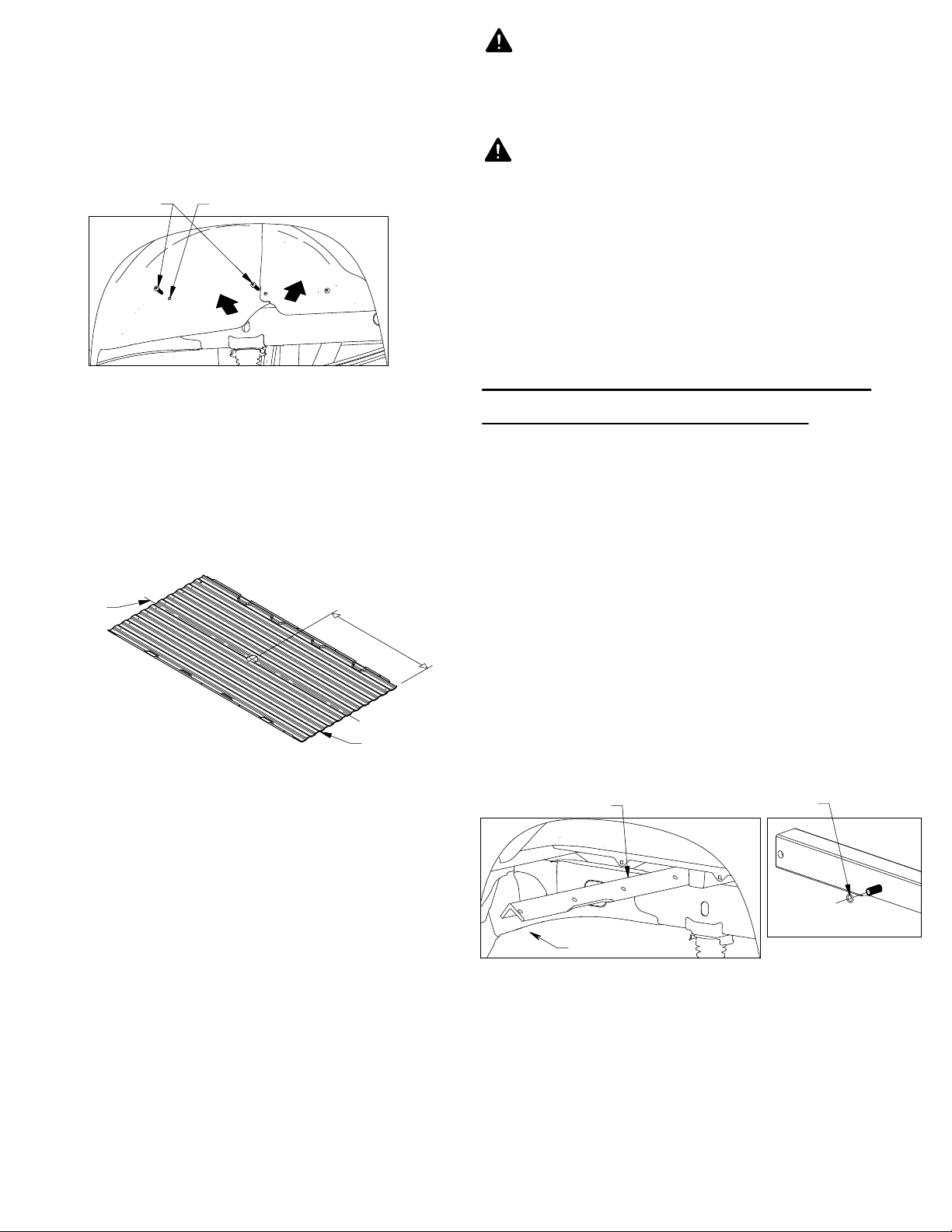

10.

Un−attach the wheel well liners.

Check for the

presence of flexible wheel well liners in the truck

wheel wells. If present, two T15 Torx screws will need

to be removed so that the liners can be folded up and

allow the cross members and side plates to be

installed, see Figure A5. Remove the screw retainer

from forward most hole using a screw driver. It will be

replaced after the hitch is installed.

T−15 SCREWS

SCREW RETAINER LOCATION

Turnoverball hitch components are heavy and

may be cumbersome to handle. Failure to use

proper lifting techniques and caution when

handling these items could result in serious

injury.

Most trucks have fuel lines, brake lines, electrical

wires or other vehicle systems located along the

frame rails or in the general area where B&W

Turnoverball hitches install. Carefully examine the

locations of these systems before installation.

Make certain that these are not damaged during

positioning hitch components, drilling holes, or

tightening fasteners. Damage to these systems

may result in property damage, serious injury, or

death.

Figure A5: View looking into driver side wheel well.

11.

Mark the 4" hole location. Using a tape measure

hooked over the rear edge of the bed (at tailgate end),

measure the location for the hole as shown in Figure

A6. Next, locate the center of the bed by measuring

the distance between the wheel wells and dividing by

two. The center of the hole will be at the intersection

of the center of the bed and the first distance

measured.

CENTER OF

TRUCK BED

FIGURE A6

4" HOLE LOCATION

SHORT BED (BED LESS THAN 8’ LONG) − 44 1/8"

4

"

H

O

L

E

L

O

REAR OF

TRUCK BED

IMPORTANT: The hitch is designed to install only at

the described location. Failure to place the 4" hole

precisely may result in added difficulty during

installation or property damage.

IMPORTANT: If the bed is equipped with a plastic bed

liner, the hole may be cut through both the liner and

the bed. However, the center of truck bed may be

more difficult to locate, and the mark may be harder to

hit if the liner slides or moves. Failure to cut the hole in

the correct location may adversely affect the install

and may result in property damage.

INSTALL CROSS MEMBERS

AND CENTER SECTION

1.

Install front cross member.

side wheel well, orient the front cross member (angle

iron) so that the heel of the angle is up and the flange

with the holes is towards the back of the truck, see

Figure B1. Pass the cross member between the bed

and the frame until it rests on the passenger side

frame. Roll the cross member so that the flange with

the holes is vertical. Install a 1/2" X 1−1/2"cap screw

into the second hole from the driver side of the cross

C

A

T

I

O

N

member with the threads towards the back of the

truck. Install the rubber O−Ring onto this bolt to keep

it in place during installation, See Figure B2. Push

the passenger side of cross member forward until it

hits the shock bracket. Push the driver side of the

cross member forward to make extra room for the

center section to be installed.

HEEL OF THE ANGLE

FRONT OF TRUCK

Figure B1: View looking into wheel well.

Starting in the driver

O−RING

Figure B2.

IMPORTANT:

If your truck has a spray−in bed liner

you will need to take this into account when you are

measuring, and add the thickness of the applied liner

that has been sprayed over the end of the bed.

12.

Cut the 4" diameter hole.

Cut the hole in the marked

location using a 4" hole saw or by marking out the 4" hole

and using a saber saw equipped with a metal cutting

blade. Remove any burrs created while cutting hole.

Continued on next page...

PAGE 3 of 7

Page 4

2.

Install center section. Starting behind the differential

under the truck, hold the center section so that the top

of the center section is facing towards the back of the

truck and the latch pin handle is on the driver side,

see Figure B3. Position the center section over the

differential and axle and move it towards the driver

side between the frame and the axle. Move the

center towards the driver side far enough that the

passenger side of the center can be lifted up past the

exhaust, see Figure B4. Roll and lift the center up

towards the passenger side of the truck so that the top

of the center is towards the bed and the passenger

side of the center is over the exhaust. Lift the driver

side of the center up and forward so that it is

positioned over the fuel tank.

4.

Attach the center to the cross members.

center section so that the raised portion on the top of

the center is through the 4" hole drilled in the bed

earlier. Secure with a lifting device if available. Slide

the front cross member back against the center

section so that the bolt installed previously in the front

cross member goes into the center section slot directly

across from it. Line up the rest of the holes and attach

the two members with 1/2" x 1−1/2" long cap screws,

flat washers, lock washers, and nuts. Insert four 1/2" x

1−1/2" bolts, with flat and lock washers installed,

through the rear leg of the center section into the

threaded holes of the rear cross member, see Figure

B5. Leave these bolted connections loose, engaging

only 3−4 threads, for the time being

.

Lift the

Figure B3: View looking up over axle.

CAUTION:

Plastic components located on top of the

Figure B4: View looking up over axle.

fuel tank can be easily damaged during the installation

of the hitch components. Care must be taken when

positioning the front crossmember and center section.

3.

Install rear cross member. Starting in the driver side

wheel well, orient the cross member so that the bar is

vertical, and the threaded holes are closer to the top

of the bar. Pass the cross member between the bed

and the frame until it rests on the passenger side

frame, see Figure B5. Center the cross members

between the bed flanges on either side of the truck.

Push the cross member back against the bed cross

member to make room for the center section.

BED FLANGE

Figure B5: View looking under the truck bed.

INSTALL SIDE PLATES

1.

Position the U−bolts. Each side plate will utilize a

U−bolt for attachment to the frame. On the driver side,

the U−bolt will need to be passed under the brake lines

on the side of the frame, see Figure C1. On the

passenger side the U−bolt will need to be positioned

under the wiring that runs over the top of the frame,

see Figure C2. Move the U−bolts so that they hang

roughly 8 inches in front of the axle center line.

U−BOLT

BRAKE LINES

WIRING HARNESS

U−BOLT

Figure B5: View looking into driver side wheel well.

View looking at driver side of frame

Figure C1:

View looking at passenger side of frame

Figure C2:

Continued on next page...

PAGE 4 of 7

Page 5

2.

Install frame studs. Locate the oval hole on the

outside of the frame directly over the center line of the

axle. To begin, place a 1/2" x 1−1/2" carriage bolt

through a locking strap. Next, thread a fish wire onto

the end of the carriage bolt. From the inside of the

frame pass the fish wire though the oval hole located

earlier. While holding the fish wire on the outside of

the frame push the locking strap and carriage bolt into

the frame, see Figure C3. Continue pulling on the fish

wire until the threaded portion of the bolt is sticking out

of the frame. Turn the carriage bolt until the square

shoulder engages the square hole of strap. Before

removing the fish wire, thread the oval frame spacer

on the carriage bolt and into the oval slot. Remove

the fish wire and thread a bolt retainer on the carriage

bolt to hold the bolt in place. Repeat this step on other

side of the truck.

SECURE HITCH

1.

Square the hitch. Start by hand tightening each of

the bolts attaching the center section to the cross

members. Next, with a tape measure, check the

distance between the Turnoverball hitch and the

nearest bed cross member. The distance between the

hitch and the cross member should be consistent on

the driver side and the passenger side of the hitch,

see Figure D1.

BED CROSS MEMBER

REAR CROSS MEMBER

Figure D1: View looking at driver side plate.

Figure C3: View looking at driver side frame.

3.

Install the side plates.

Pass the side plates over the

U−bolts and stud placed in the frame. Secure each

side plate with flat washers, lock washers, and nuts,

see Figure C4. Attach the front flange of the side

plate to the front angle cross member by placing a

1/2" X 1−1/2" bolt though the front cross member, then

secure to the side plate with a lock washer and nut.

Next, attach the side plate to the rear bar by placing a

1/2" X 1−1/2" bolt with a lock washer through the side

plate flange and threading it into the rear cross

member, see Figure C5. Leave these bolted

connections loose for the time being.

IMPORTANT:

The hitch must be square in the truck.

If the center section is not parallel with the axle,

certain accessories to the Turnoverball hitch will not

be square with the truck.

2.

Tighten the center section bolts. Tighten each of

the eight bolts attaching the center section to the

cross members. Torque each bolt to 110 ft. lbs.

Tighten the side plate bolts.

3.

With the hitch squared

and firmly against the frame, tighten each of the

bolted connections in the side plates until snug in this

order: 1st, tighten the hardware attaching the side

plates to the cross members. 2nd, tighten the nuts

attaching the side plates to the frame studs installed

inside the frame. 3rd, tighten the U−bolt nuts to the

frame. Once all the hardware is snug, torque the

bolts in the side plate ears 110 ft. lbs. Tighten the

side plate frame stud connection to 110 ft. lbs.

Tighten both side plate U−bolts alternating between

the top and bottom threads so that the U−bolt is

secured evenly. Torque nuts on U−bolts to 40 ft. lbs.

Figure C4: View looking is driver side wheel well.

Figure C5.

PAGE 5 of 7

Page 6

INSTALL LATCH PIN RELEASE

INSTALL SAFETY CHAIN U−BOLTS

HANDLE

IMPORTANT: The latch pin will not function properly

if handle is not installed correctly.

1.

Cut access hole though liners. If truck is equipped

with wheel well liners, an access hole needs to be cut

in the liner. Draw a line on the liners, between the two

holes of the screws that were removed. Drill a pilot

hole on the line 8−3/4" forward of the rear hole. Make

sure this pilot hole lines up with the latch pin

mechanism on the center. Use a hole saw or other

method to cut a 1" to 1.5" diameter hole in this

location.

2.

Install handle. Install the latch pin release handle by

inserting it , from the outside of the truck, through the

slot in the end of the center section on the driver side

of the truck. Align the handle eyelet with the square

hole in the latch pin so the handle is in line with the

latch as shown in Figure E1.

3.

Secure Handle. Secure the handle to the pin with the

5/16" X 3/4" carriage bolt and 5/16" locking flange,

see Figure E2. Note: The included 5/16" cap screw

can replace the carriage bolt if wrench access on the

"cab side" of the handle is limited. Tighten the nut until

it is secure. When tightening the handle, position it so

that it will not rub on the center, the side plate, the bed

flange, or the liner. Retract and release the handle

slowly to make sure it will not hang up on any

obstacles that may prevent the latch pin from fully

engaging the socket. Do not over−tighten and deform

the handle eyelet.

1.

Drill the holes. To install the safety chain brackets, it

is necessary to drill four 1/2" holes through the truck

bed floor. Drill the holes so that they match up with the

two sets of holes on each side of the center. This may

be done by drilling the 1/2" holes from the bottom

using the center as a guide, or by drilling a smaller

pilot hole from the bottom and drilling the 1/2" holes

from the top side of the bed.

2.

Install the U−bolts. From the top side of the truck

bed, drop a U−bolt in each set of holes.

3.

Add Springs.

Place a conical spring over each leg of

the U−bolts and secure with a 1/2" lock nut. see

Figure F1. Tighten the lock nut until the nut is flush

with the end of the U−bolt.

Figure F1: View looking up at center.

Figure E1.

TAB

LATCH

PIN

DRIVER SIDE

IN−LINE

Figure E2.

PAGE 6 of 7

Page 7

PREPARE FOR TOWING

1.

Replace truck components. Replace the wire

bracket, brake line bracket, and spare tire heat shield

which were removed in the PREPARE TO INSTALL

section. If the exhaust was lowered re−attach the tail

pipe hangers. If wheel well liners were present,

re−install the T−15 Torx screws and screw retainer that

were removed earlier.

2.

Replace spare tire If the spare tire was removed

prior to installing the hitch, replace it at this time.

3.

Retract the pin. Pull the handle out all the way until it

stops then slide it toward the cab. The handle should

stay in this position. The latch should only be put in

this open position when inverting the 2−5/16" ball or

installing a B&W towing accessory.

The handle operates in a very tight space within the

wheel well of the truck. Use caution when operating

the handle so that your hands and fingers do not

get injured on the sharp edges of the truck, or by

getting pinched against the frame due to the force

of the spring loaded latch pin.

Operating the tow vehicle while the latch is in the

open position may allow the handle to come into

contact with the rear tire. This may damage the tire

or the handle and could lead to serious injury or

death.

OPERATION & MAINTENANCE

Always be sure that latch pin is fully engaged in the

socket before towing.

Inspect hardware connections before towing to be

sure that they are secure.

Measure and determine turning clearance with cab

before towing unfamiliar trailers. Additional products

for increasing turning clearance are available from

B&W.

When inverting the ball, inspect the ball’s relationship

with the truck’s differential and drive line to ensure

proper clearance. DO NOT INVERT THE BALL

WHEN HAULING HEAVY LOADS ON 2 WHEEL

DRIVE TRUCKS. A plug for the socket is available

from B&W so that the ball may be removed and the

socket may be covered when hauling heavy loads.

Periodically grease the corners on the square shank of

the 2−5/16" ball.

4.

Lubricate 2−5/16" ball.

to the corners on the square shank of the 2−5/16" ball.

5.

Engage pin.

handle retracts and engages the 2−5/16" ball.

When installed properly the latch pin will pass

through the 2−5/16" ball and fully engage through

both walls of the hitch receiver. Failure of the pin to

engage the ball and hitch properly could result in a

loss of attachment between the trailer and the tow

vehicle.

Move handle toward rear of truck until the

Apply a light coating of grease

Copyright 2019, B&W Custom Truck Beds, Inc. ALL RIGHTS RESERVED

1019 (pn1019−1−1021) 03 13 2019

PAGE 7 of 7

Loading...

Loading...