BUSHMASTER XM15 OPERATION INSTRUCTION

BFI OP. MANUAL

PDF Version

get help from someone qualified in the safe handling of firearms.

WARNING: BEFORE USING THlS FIREARM,

READ AND FOLLOW THESE INSTRUCTIONS.

If there is anything you do not understand,

®

For all

BUSHMASTER

XM15 Models

OPERATING AND SAFETY

INSTRUCTION MANUAL

A1 & A2 Sight Systems

All Rifles & Carbines

including V Match

PLEASE PRACTICE SAFE FIREARMS HANDLING!

This instructional manual should always accompany your Bushmaster firearm.

WARNING: IF THIS FIREARM IS CARELESSLY OR IMPROPRERLY HANDLED,

UNINTENTIONAL DISCHARGE COULD RESULT AND COULD CAUSE INJURY,

DEATH, OR DAMAGE TO PROPERTY.

CAUTION: CAREFULLY READ THIS INSTRUCTION MANUAL PRIOR TO LOADING

AND FIRING THIS FIREARM. FOLLOW ALL INSTRUCTIONS ON THE PROPER

HANDLING AND SAFE USE OF THIS FIREARM - LIVES MAY DEPEND ON IT! If

unfamiliar with firearms, seek further advice through safe handling courses run by your

local gun clubs, NRA approved instructor, or similar qualified organizations.

CAUTION: USE ONLY CLEAN, DRY, HIGH QUALITY COMMERCIALLY

MANUFACTURED AMMUNITION IN GOOD CONDITION which is appropriate to the

.223 Rem. caliber of your firearm. We do not recommend the use of remanufactured or

hand loaded ammunition because it may damage your rifle. Use of improper ammunition

will invalidate your warranty.

WARNING: THIS WEAPON COULD CHAMBER A ROUND if it is dropped or jarred with

a loaded magazine in place - either with the Bolt Carrier Assembly locked to the rear, or in

its forward position.

PLEASE PRACTICE SAFE FIREARMS HANDLING!

FUNDAMENTAL RULES FOR SAFE GUN HANDLING

FUNDAMENTAL RULES FOR SAFE GUN HANDLING

ALWAYS KEEP THE GUN POINTED IN A SAFE DlRECTlON.

NEVER LOAD THE GUN UNTIL READY TO USE.

KEEP YOUR FINGER OFF THE TRIGGER UNTIL READY TO SHOOT.

WARNING: BEWARE OF DANGEROUS PROCEDURES

• Be sure cam pin is installed in the bolt group. If it isn't, your rifle can still fire and will

explode.

• If you are using a blank firing attachment, never fire anything except blank

rounds (for safety, we recommend the visible military style blank firing attachment).

• If your rifle stops firing with a live round in the chamber of a hot barrel (a misfire),

remove the round fast. However, if you cannot remove it within 10 seconds, remove

magazine and wait 15 minutes with the rifle pointing in a safe direction. This way you

won't get hurt by a possible round “cooking-off” (i.e. the round detonating just from the

heat of the barrel). In any event, keep your face away from the ejection port while

clearing a hot chamber.

• If your bolt fails to unlock, and you try to free it by banging the buttstock on the ground,

keep yourself clear of the muzzle.

• If there's water in the barrel, do not fire the rifle. It could explode.

• If a noticeable difference in sound or recoil is experienced, STOP FIRING. Either

condition could indicate an incomplete powder burn and/or a bullet stuck in the bore.

ALWAYS PRACTICE SAFE FIREARMS HANDLING!

FACTS ABOUT YOUR BUSHMASTER XM15 E2S RIFLE…

The Bushmaster XM15 E2S rifle system consists of a rifle, a magazine, and a sling. It

is a lightweight, gas operated, air-cooled, magazine-fed, shoulder-fired weapon that can

be fired in a semi-automatic mode - i.e., a single shot each time the trigger is pulled.

• The upper receiver and barrel assembly has a fully adjustable rear sight.

• The upper and lower receivers are easily opened for cleaning and inspection.

• The bolt group and barrel extension are designed with locking lugs that lock the bolt

group to the barrel extension.

• The forged aluminum upper and lower receivers reduce the weight of the rifle.

• The bore and chamber are chrome plated for long life and ease of maintenance.

• Caliber: .223 Remington / 5.56 mm

• Weight: (depends upon model) 20" Bbl. Rifle = 8.27 Ibs. / 3.75 kg

• Length: (depends upon model) 20" Bbl. Rifle = 38.25" / 97cm

• Barrel Rifling: R.H. twist; 1 in 9"; 6 lands & grooves

• Firing characteristics: muzzle velocity approx. 3,260 fps; chamber pressure 52,000 psi

• Maximum effective rate of fire: 45 rounds per min. / semi-automatic

• Max effective range: 550 meters (individual/point targets) / 800 meters (area targets)

• Maximum range: 3534 meters

2

1

TABLE OF CONTENTS

Rifle Parts and Where To Find Them……… 4

Clearing Your Rifle……… 6

Disassembling Your Rifle……… 8

Cleaning / Inspection / Lubrication……… 13

Detailed Cleaning Techniques……… 14

Cleaning the Upper Receiver……… 15

Cleaning the Lower Receiver……… 16

Cleaning the Ejector……… 17

Inspection before Lubrication……… 18

Lubrication / Upper Receiver……… 19

Lubrication / Lower Receiver……… 19

Lubrication / Bolt Carrier Group……… 20

Lubrication / Adjustable Rear Sight……… 21

Reassembly……… 22

Magazine Disassembly / Reassembly……… 28

WARNING: BEFORE USING THIS FIREARM, READ AND

FOLLOW THESE INSTRUCTIONS. If there is anything you do

not understand, get help from someone qualified in the safe

handling of firearms.

Preventative Maintenance Checks……… 29

Safety Function Checks……… 30

Adjustable Front Sight Post……… 32

Dual Aperture Rear Sight……… 32

Zeroing Your Sights……… 33

Zeroing Adjustments……… 34

25 Meter Zeroing Procedure……… 34

A1 Sights - Differences / Adjustments……… 36

Operation of Your Rifle / Loading……… 38

Operation / Inserting a Magazine……… 39

Operation / Chambering a Round……… 40

Immediate Action in Case of Trouble……… 42

Remedial Action……… 44

Bullet Stuck in the Bore……… 45

Troubleshooting……… 46

Parts Illustration……… 54

Limited Warranty……… 55

RIFLE PARTS AND WHERE TO FIND THEM (Right Side)…

REAR SIGHT

ELEVATION KNOB

CHARGING HANDLE

FORWARD ASSIST

ASSEMBLY

REAR SLING

LOOP

4

TRIGGER

MAGAZINE

RELEASE

BUTTON

REAR SIGHT

WINDAGE KNOB

SPENT BRASS

DEFLECTOR

EJECTION PORT

COVER

MAGAZINE

(RIFLE ACCEPTS ALL

CAPACITY AR15 / M16 TYPE)

FRONT SIGHT

ASSEMBLY

FRONT SLING

SWIVEL

HANDGUARDS

BARREL

MUZZLE

RIFLE PARTS AND WHERE TO FIND THEM (Left Side)…

A2 “SQUARE” FRONT

SIGHT POST

(A Round Post can be

found on some A1

models. Bushmaster

only uses the A2)

SLIP RING

(DELTA RING)

CARRYING HANDLE

(A3 Removeable type is

illustrated at lower left.)

BOLT

CATCH

B.F.I.

WINDHAM, ME.

®

U.S.A.

BUSHMASTER

L099999

CAL.223-5.56MM

MOD. XM15-E2S

WITH ”TRAPDOOR”

A2 TYPE

UPPER RECEIVER

TAKEDOWN PIN

BUTTPLATE

ASSEMBLY

STORAGE

Above, A Bushmaster

V Match “Flat-Top” Style

Upper Receiver And A3 Type

Removeable Carry Handle.

Right, an early A1 Upper Receiver

(note the rear sight differences).

CLEARING YOUR RIFLE…

PIVOT

PIN

SAFETY

SELECTOR

LEVER

PISTOL

GRIP

BUTTSTOCK

5

Point Rifle in a SAFE DIRECTION!

1.)

Place Safety Selector Lever on SAFE.

(If the rifle is not cocked, the Selector

Lever cannot be pointed toward SAFE.)

6

Press Magazine Catch Button and pull

2.)

Magazine down to remove.

CLEARING YOUR RIFLE (continued)…

To Lock Bolt Open, Pull Charging

3.)

Handle rearward. Press bottom of

Bolt Catch and allow Bolt to move

forward until it engages Bolt Catch.

Return Charging Handle to forward.

If you haven't before, place Safety

Selector Lever on SAFE.

Check Receiver and

4.)

Chamber to ensure there is

no ammunition in the rifle.

With Selector Lever pointing

5.)

toward SAFE, allow Bolt to

go forward by pressing upper

portion of Bolt Catch.

7

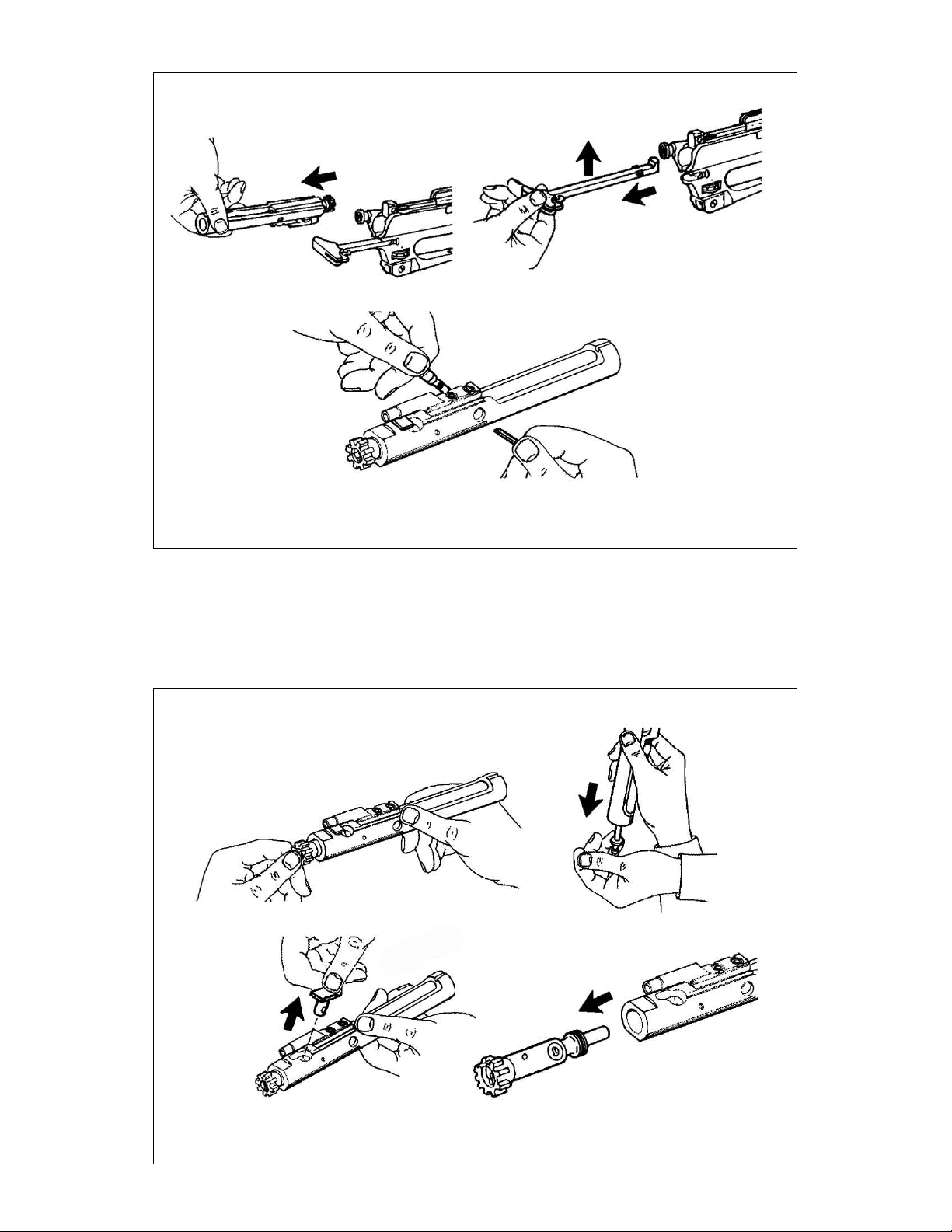

DISASSEMBLING YOUR RIFLE…

1.) Clear your Rifle and disconnect the Sling.

3.) Push in Front Pivot Pin.

2.) Push in Takedown Pin as far as it will go.

Pivot Upper Receiver away from Lower.

4.) Separate Upper and Lower Receivers. 5.) Pull back Charging Handle and Bolt Carrier

8

DISASSEMBLING YOUR RIFLE (continued)…

6.) Remove Bolt Carrier and Bolt 7.) Remove Charging Handle by pulling

back and up

DO NOT OPEN

OR CLOSE

SPLIT END

OF PIN

8.) Remove Firing Pin Retaining Pin.

9

DISASSEMBLING YOUR RIFLE (continued)…

9.) Push Bolt in to locked position.

PUSH BOLT IN

10.) Drop Firing Pin out rear of Bolt Carrier.

11.) Remove

Bolt Cam Pin.

GIVE CAM

PIN A 1/4

TURN AND

LIFT OUT

12.) Remove Bolt Assembly from Carrier.

10

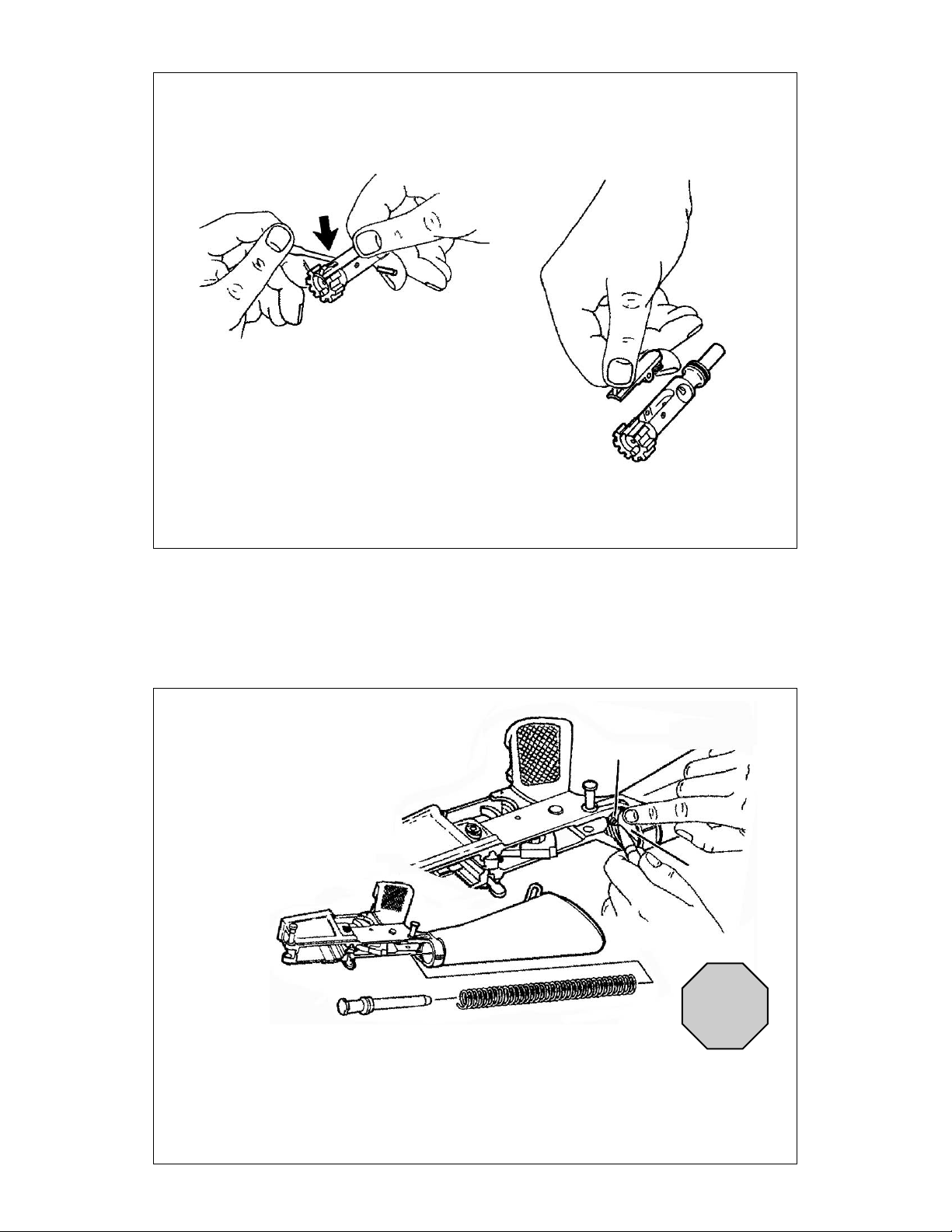

DISASSEMBLING YOUR RIFLE (continued)…

DISASSEMBLE USING STEPS 13 THRU 16 ONLY WHEN DIRTY OR DAMAGED

PUSH

EXTRACTOR

PIN OUT

NOTE: Press rear

of extractor to check

spring function.

13.) Remove Extractor Pin by pushing out

with a punch or the tip of a bullet.

14.) Remove Extractor and Spring.

CAUTION: Extractor Spring may

pop out and get lost!

11

DISASSEMBLING YOUR RIFLE

(continued)…

15.) Press in Buffer, depress Retainer,

and release Buffer.

16.) Remove Buffer and

Action Spring.

The Handguards may be disassembled at any point in your cleaning

procedures as necessary (see Pg. 27 - “Buddy System” instructions).

If your Rifle is equipped with the A3 Type Removeable Carry Handle,

that may be removed for cleaning by loosening the 2 thumbnuts. Clean as

per instructions for aluminum Upper and Lower Receivers (see Pg. 16).

Lightly lubricate the thumbnut threads and the Rear Sight mechanism (as

described on Pg. 21 - Lubrication - Adjustable Rear Sight).

12

BUFFER

RETAINER

BUFFER

STOP

BUSHMASTER

DOES NOT

RECOMMEND

ANY FURTHER

DISASSEMBLY

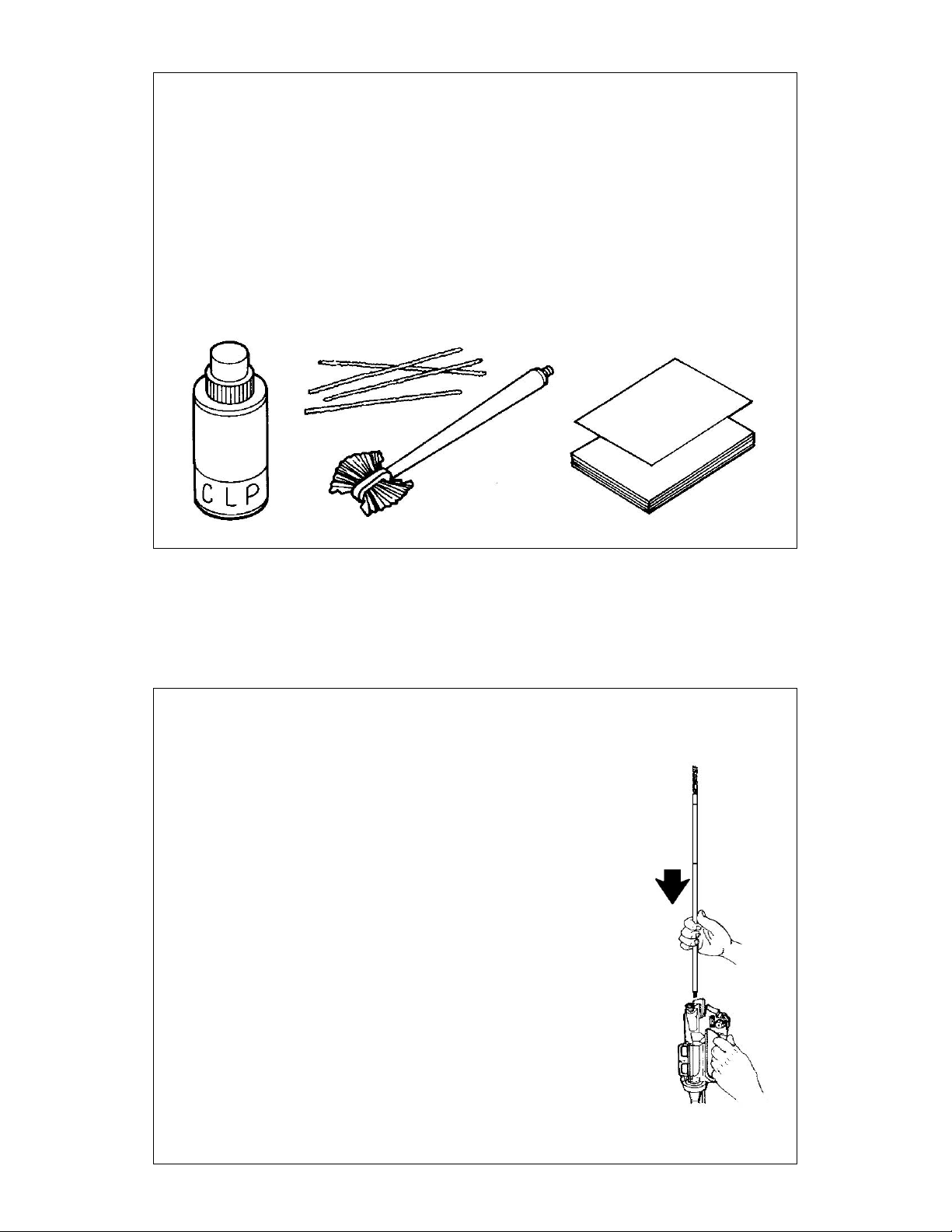

CLEANING • INSPECTION • LUBRICATION…

After firing, clean your rifle as soon as possible to make the job easier and to avoid allowing

the development of any corrosion.

When your firearm has not been fired, you should clean it at least once or twice a year if

you live in a temperate climate, or as often as once a week in a tropical climate.

If you get your firearm wet, clean it as soon as possible.

Use a high quality rifle cleaning kit that includes a cleaning rod; swab holder; cotton flannel

bore patches; pipe cleaners; a small toothbrush; brass wire bristle bore and chamber brushes

and a Cleaner/Lubricant/Preservative (CLP in Army terminology).

After you have disassembled the rifle, thoroughly clean, inspect and lubricate all parts

according to the techniques described on following pages.

13

DETAILED CLEANING TECHNIQUES…

NOTE: The procedures below describe cleaning with a standard military

issue multi-piece rod cleaning kit. Other commercial cleaning kits may

include alternate cleaning instructions which may be just as effective.

CLEANING THE BORE: The bore of your Bushmaster rifle has lands and

grooves called rifling. Rifling makes the bullet spin very fast as it moves

down the bore and down range. It is difficult to push a new, stiff bore brush

through the bore. You will find it much easier, and more effective, to pull

your bore brush through the bore. Also, because the brush will clean

better if the bristles follow the grooves (this is called tracking), you want the

bore brush to be allowed to turn as you pull it through. Always clean from

from chamber toward the muzzle. This is how you do it:

1.) Swab out the bore with a patch moistened with “CLP”.

2.) Attach three rod sections together but leave each one about two turns

short of being tight.

3.) Attach the bore brush but leave it two turns short also.

4.) Point muzzle down. Hold the upper receiver in one hand while inserting

the end of the rod without the brush into the chamber. Guide the rod

carefully through the bore. CAUTION - do not let the rod or its threaded

end scratch the Chrome Lining of the Bore or Firing Chamber.

About 2 - 3 inches of the rod should protrude out of the muzzle.

14

BORE

BRUSH

AND

THREE

ROD

SECTIONS

DETAILED CLEANING TECHNIQUES (continued)…

5.) Attach the handle section of the cleaning rod to the end of the rod sticking

out of the muzzle.

6.) Pull the brush through the bore and out the muzzle. You should be able to

see the rod twisting as you pull it - this is the brush "tracking" in the rifling. Never

reverse the direction of the bore brush while it is in the bore.

7.) After one pull, take off the handle section and repeat the process. After

three or four pulls, the three rod sections and the bore brush may become

screwed tightly together. Loosen them up and repeat the process.

8.) Send a patch through the bore occasionally to help clean out the crud that

the brush is getting loose. Just replace the bore brush with the rod tip (patch

holder) and a wet patch. Pull it through. If you leave the rods loose again, the

patch will "track" in the rifling as before. But remember, always have the bore

wet with cleaner before trying to pull a brush through.

CLEANING THE UPPER RECEIVER…

NOTE: Check to ensure that there is no looseness between the Barrel

and the Upper Receiver - if you detect any movement by twisting with your

hands, the barrel nut must be retorqued. Bring the Rifle to a qualified

gunsmith.

1.) Using a “CLP“ type product, clean all areas of Powder Fouling,

Corrosion, Dirt and Rust. Never use a wire brush or any type of abrasive to

clean the Aluminum Upper Receiver - you'll scratch and damage the finish.

AND PULL THROUGH

ATTACH HANDLE

FROM CHAMBER

TO MUZZLE

15

CLEANING THE UPPER RECEIVER (continued)…

2.) Clean the Firing Chamber - dip the larger chamber cleaning brush in CLP and use at least

five plunge strokes and three 360 clockwise rotations. Then swab out the bore as described

previously to remove any contaminated solution or loosened crud.

3.) Use the bore cleaning brush, still wet with CLP, and clean carbon and powder residue from

around the gas tube, run a pipe cleaner into the gas tube, clean the bolt locking lugs, bolt rings,

firing pin, bolt cam pin, lip of the extractor, and inside the bolt carrier from both front and rear.

4.) Wipe all components clean and dry, and inspect

for excessive wear, corrosion or mechanical damage.

Replace any defective parts before firing again (call

us at 1-800-998-SWAT for any parts needs.)

A SMALL TOOTHBRUSH

WILL REMOVE BUILT-UP

DIRT

CLEANING THE LOWER RECEIVER…

1.) Clean all areas of Powder Fouling, Corrosion, Dirt

and Rust. Again, never use a wire brush or any type of

abrasive to clean the Aluminum Lower Receiver.

2.) Wipe any dirt from the Trigger Mechanism. Clean

the Buffer, Action Spring, and inside

the Lower Receiver Extension

(the Buffer Tube).

WIPE INSIDE OF BUFFER

16

TUBE CLEAN

CLEAN THE DRAIN HOLE IN

THE BUTTPLATE SCREW

PIPE

CLEANER

Loading...

Loading...