Page 1

ASSEMBLY ● OPERATION ● MAINTENANCE

1006 $4.00

50054971

Operator’s Manual

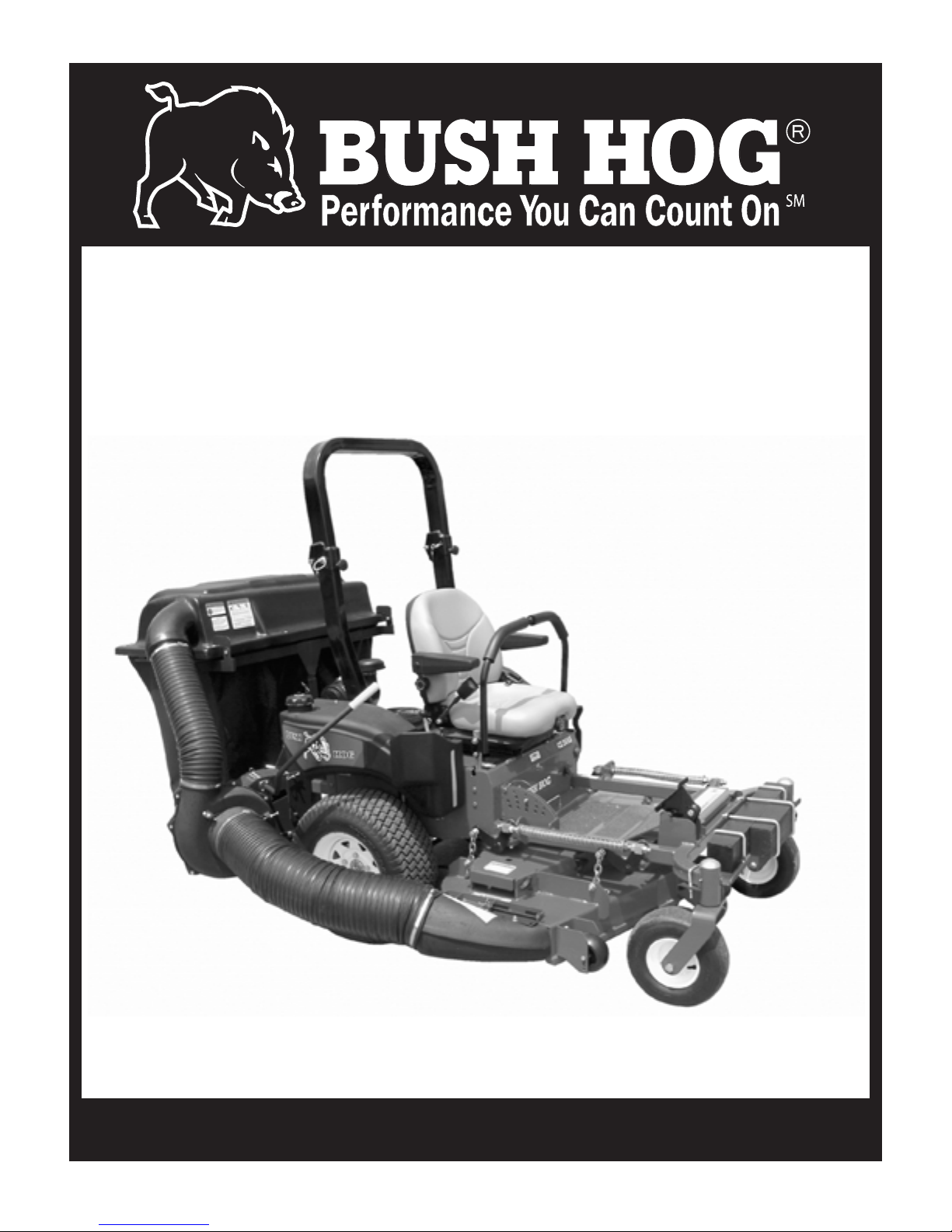

PZ & CZ ZER O TURN MOWER

MAX VAC

GRASS COLLECTION SYSTEM

Models

GC-350 &

GC-350CZ

Page 2

CONGRATULATIONS!

You have invested in the best implement of its type on the market today.

The care you give your Bush Hog implement will greatly determine your satisfaction

with its performance and its service life. We urge a careful study of this manual to provide

you with a thorough understanding of your new implement before operating, as well as

suggestions for operation and maintenance.

If your manual should become lost or destroyed, Bush Hog will be glad to provide you with

a new copy. Order from Bush Hog, P. O. Box 1039, Selma, Alabama 36702-1039. Most of our

manuals can also be downloaded from our website at www.bushhog.com.

As an authorized Bush Hog dealer, we stock genuine Bush Hog parts which are

manufactured with the same precision and skill as our original equipment. Our trained

service personnel are well informed on methods required to service Bush Hog equipment,

and are ready and able to help you.

Should you require additional information or assistance, please contact us.

YOUR AUTHORIZED

BUSH HOG DEALER

BECAUSE BUSH HOG MAINTAINS AN ONGOING

PROGRAM OF PRODUCT IMPROVEMENT, WE

RESERVE THE RIGHT TO MAKE IMPROVEMENTS IN

DESIGN OR CHANGES IN SPECIFICATIONS WITHOUT INCURRING ANY OBLIGATION TO INSTALL

THEM ON UNITS PREVIOUSLY SOLD.

BECAUSE OF THE POSSIBILITY THAT SOME

PHOTOGRAPHS IN THIS MANUAL WERE TAKEN OF

PROTOTYPE MODELS, PRODUCTION MODELS MAY

VARY IN SOME DETAIL. IN ADDITION, SOME

PHOTOGRAPHS MAY SHOW SHIELDS REMOVED

FOR PURPOSES OF CLARITY. NEVER OPERATE

THIS IMPLEMENT WITHOUT ALL SHIELDS IN PLACE.

Page 3

PZ & CZ ZERO TURN MOWER

GRASS CATCHER

TABLE OF CONTENTS

SECTION PAGE

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Federal Laws and Regulations . . . . . . . . . . . . 3

Safety Alert Symbols. . . . . . . . . . . . . . . . . . . . 4

I INTRODUCTION AND DESCRIPTION . . . . . 5

1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . 5

1-2 Description . . . . . . . . . . . . . . . . . . . . . . . . 5

II PREPARATION FOR USE . . . . . . . . . . . . . . . 5

2-1 Modification Of ZT. . . . . . . . . . . . . . . . . . . 5

2-2 Attaching Frame Mount Brackets . . . . . . . 6

2-3 Belt Installation . . . . . . . . . . . . . . . . . . . . . 6

2-4 Cam Assembly Adjustment. . . . . . . . . . . . 7

2-5 Attachemnt Of Upper Frame. . . . . . . . . . . 7

Assembly To The Lower Frame

2-6 Attachment Of Top Assembly To The. . . . 7

Upper Frame Assembly

2-7 Attachment Of The Boot To . . . . . . . . . . . 7

The Mower Deck

2-8 Adjustment Of The Lengths Of Hoses . . . 8

SECTION PAGE

2-9 Attachment of The Upper Hose . . . . . . . . . . 8

2-10 Attachment Of The Upper Hose To. . . . . . . . 8

The Lower Cone

2-11 Attachment Of The Lower Hose To . . . . . . 8

The Boot

2-12 Front Weight Assembly . . . . . . . . . . . . . . . 8

2-13 Installation/Removal Of Collection Bags . . 8

III OPERATING INSTRUCTIONS . . . . . . . . . . . . 10

3-1 General Safety . . . . . . . . . . . . . . . . . . . . . . 10

3-2 Operation & Tips On Mowing. . . . . . . . . . . 10

3-3 Disengagement Of The Blower . . . . . . . . . 10

IV MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . 10

4-1 Maintenance Checklist . . . . . . . . . . . . . . . . . . . 10

4-2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Torque Specifications . . . . . . . . . . . . . . . . . . . . 13

1

RETAIL CUSTOMER’S RESPONSIBILITY

UNDER THE BUSH HOG WARRANTY

It is the Retail Customer and/or Operator’s responsibility to read the Operator ’s Manual, to

operate, lubricate, maintain and store the product in accordance with all instructions and

safety procedures. Failure of the operator to read the Operator’s Manual is a misuse of this

equipment.

It is the Retail Customer and/or Operator’s responsibility to inspect the product and to have

any part(s) repaired or replaced when continued operation would cause damage or excessive wear to other parts or cause a safety hazard.

It is the Retail Customer’s responsibility to deliver the product to the authorized Bush Hog

Dealer, from whom he purchased it, for service or replacement of defective parts which are

covered by warranty. Repairs to be submitted for warranty consideration must be made within forty-five (45) days of failure.

It is the Retail Customer’s responsibility for any cost incurred by the Dealer for traveling to or

hauling of the product for the purpose of performing a warranty obligation or inspection.

Page 4

LIMITED WARRANTY

✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯

Bush Hog warrants to the original purchaser of any new Bush Hog equipment, purchased from an

authorized Bush Hog dealer, that the equipment be free from defects in material and workmanship for a period

of one (1) year from date of retail sale. The obligation of Bush Hog to the purchaser under this warranty is limited to the repair or replacement of defective parts.

Replacement or repair parts installed in the equipment covered by this limited warranty are warranted

for ninety (90) days from the date of purchase of such part or to the expiration of the applicable new equipment warranty period, whichever occurs later. Warranted parts shall be provided at no cost to the user at an

authorized Bush Hog dealer during regular working hours. Bush Hog reserves the right to inspect any equipment or parts which are claimed to have been defective in material or workmanship.

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Bush Hog’s obligation under this limited warranty, to the extent allowed by law, is in lieu of all warranties, implied or expressed, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE and any liability for incidental and consequential damages with respect to

the sale or use of the items warranted. Such incidental and consequential damages shall include but not be

limited to: transportation charges other than normal freight charges; cost of installation other than cost

approved by Bush Hog; duty; taxes; charges for normal service or adjustment; loss of crops or any other loss of

income; rental of substitute equipment, expenses due to loss, damage, detention or delay in the delivery of

equipment or parts resulting from acts beyond the control of Bush Hog.

THIS LIMITED WARRANTY SHALL NOT APPLY:

1. To vendor items which carry their own warranties, such as engines, tires, and tubes.

2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judge-

ment of Bush Hog such use affects its performance, stability or reliability.

4. If the unit has been altered or repaired outside of an authorized Bush Hog dealership in a manner

which, in the sole judgement of Bush Hog, affects its performance, stability or reliability.

5. To normal maintenance service and normal replacement items such as gearbox lubricant, hydraulic fluid,

worn blades, or to normal deterioration of such things as belts and exterior finish due to use or

exposure.

6. To expendable or wear items such as teeth, chains, sprockets, belts, springs and any other items that in the

company’s sole judgement is a wear item.

NO EMPLOYEE OR REPRESENTATIVE OF BUSH HOG IS AUTHORIZED TO CHANGE THIS LIMITED WARRANTY IN ANY WAY OR GRANT ANY OTHER WARRANTY UNLESS SUCH CHANGE IS MADE

IN WRITING AND SIGNED BY BUSH HOG’S SERVICE MANAGER, POST OFFICE BOX 1039, SELMA,

ALABAMA 36702-1039.

✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯✯

Record the model number, serial number and date

purchased. This information will be helpful to your

dealer if parts or service are required.

MAKE CERTAIN THE WARRANTY REGISTRATION

CARD HAS BEEN FILED WITH BUSH/

SELMA, ALABAMA

MODEL NUMBER

SERIAL NUMBER

DATE OF RETAIL SALE

2

Page 5

IMPORTANT FEDERAL LAWS AND REGULATIONS* CONCERNING

EMPLOYERS, EMPLOYEES AND OPERATIONS.

*(This section is intended to explain in broad terms the concept and effect of the following federal laws and

regulations. It is not intended as a legal interpretation of the laws and should not be considered as such).

U.S. Public Law 91-596 (The Williams-Steiger Occupational and Health Act of 1970) OSHA

This Act Seeks:

“...to assure so far as possible every working man and woman in the nation safe and healthful working

conditions and to preserve our human resources...”

DUTIES

Sec. 5 (a) Each employer—

(1) shall furnish to each of his employees employment and a place of employment

which are free from recognized hazards that are causing or are likely to cause

death or serious physical harm to his employees;

(2) shall comply with occupational safety and health standards promulgated under

this Act.

(b) Each employee shall comply with occupational safety and health standards

and all rules, regulations and orders issued pursuant to this Act which are

applicable to his own actions and conduct.

OSHA Regulations

Current OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the

employer shall instruct every employee in the safe operation and servicing of all equipment with which the

employee is, or will be involved.” These will include (but are not limited to) instructions to:

Keep all guards in place when the machine is in operation;

Permit no riders on equipment;

Stop engine, disconnect the power source, and wait for all machine movement to stop before

servicing, adjusting, cleaning or unclogging the equipment, except where the machine must be

running to be properly serviced or maintained, in which case the employer shall instruct employees

as to all steps and procedures which are necessary to safely service or maintain the equipment.

Make sure everyone is clear of machinery before starting the engine, engaging power, or operating

the machine.

Child Labor Under 16 Years Old

Some regulations specify that no one under the age of 16 may operate power machinery. It is your

responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of

Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.)

EMPLOYEE TRACTOR OPERATING INSTRUCTIONS:

1. Securely fasten your seat belt if the tractor has a

ROPS.

2. Where possible, avoid operating the tractor near

ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and

on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going, especially at row

ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly - no jerky turns,

starts, or stops.

8. Hitch only to the drawbar and hitch points recom-

mended by tractor manufacturers.

9. When tractor is stopped, set brakes securely and

use park lock if available.

3

Page 6

Safety Alert Symbol

This Safety Alert Symbol means: “ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!”

This symbol is used to call attention to safety

precautions that should be followed by the

operator to avoid accidents. When you see this

symbol, carefully read the message that follows

and heed its advice. Failure to comply with safety precautions could result in death or serious

bodily injury.

Safety Signs Signal Words

The signal words DANGER, WARNING, AND CAUTION are used on the equipment safety signs. These words

are intended to alert the viewer to the existence and the degree of hazard seriousness.

This signal word indicates a potentially hazardous situation

which, if not avoided, will result in death or serious injury.

White letters on RED

This signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury

It may also be used to alert against unsafe practices.

Black letters on ORANGE

This signal word indicates a potentially hazardous situation exist

which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Black letters on YELLOW

4

Page 7

5

SECTION I

INTRODUCTION AND DESCRIPTION

1-1 Introduction

We are pleased to have you as a return Bush Hog

customer. Your GC-350 or GC-350CZ has been

designed to give you a low maintenance, simple,

and effective way to collect the grass clippings or

perform spring/fall clean-up with your Bush Hog

Professional or Commercial ZT mower. This manual

is provided to give you the necessary instructions to

properly mount and operate the GC-350 or GC350CZ on your ZT mower. Please read this manual

thoroughly. Understand what each control is for and

how to use it. Observe all safety decal precautions

on the machine and noted throughout the manual.

Note: all references made to right, left, front, rear,

top or bottom are as viewed from the normal operator's position on the ZT mower.

Note: All work must be performed with the engine

off and the parking brake locked.

1-2 Description

The GC-350 & GC-350CZ Grass Catcher, Figure 1,

are designed for turf maintenance where there is a

need to collect the grass clippings as the ZT mower

cuts the turf. It is also good for picking up leaves

and twigs in pre-season and post-season clean-up.

The blower, mounted on the right side of the unit,

uses a belt and gearbox system from the engine

PTO shaft. Drive train protection comes through belt

slippage. The blower draws grass clippings from the

discharge area of the cutter deck up to the collection

bags mounted over the rear portion of the ZT frame.

The operator can engage the blower with a push of

the over-center linkage on the right side of the unit.

Once the bags are full of clippings, the top of the

unit can be pivoted up and each of the three bags

can be removed individually for emptying.

Figure 1

SECTION II

PREPARATION FOR USE

2-1 Modification Of Zero Turn

Carefully remove wrapping from around shipping

crate and open boxes. Remove and sort all parts for

easy identification.

NOTE: Before each step of assembly it will help to

study the exploded drawings on pages7, 8, and 9.

From the underside of the ZT engine remove the

bolt and bushing from the electric clutch assembly.

Replace these parts with the pulley and 7/16”-20 x

3-3/4” bolt that will power the grass catcher blower.

Note that the center of the hub that is extended

should be upward toward the engine. (Figure 3)

Torque the bolt to 55 ft./lbs.

Figure 2

Complete Machine

In Shipping Crate

Figure 3 Electric Clutch Assy. Grass Catcher Pulley

7/16”-20 x 3-3/4” Bolt

Page 8

6

2-3 Belt Installation

Loosen the two bolts that secure the gear box

assembly to the PTO mount plate. (Figure 6) Loosen

the adjustment bolt until the gear box assembly is at

its far left adjustment (the gear box is moved

towards the mower’s engine pully). Install the Kevlar

cord belt from the engine pulley to the lower gear

box pulley. To tension the drive belt, turn the adjustment bolt clockwise until there is 1” of deflection,

with 10-11 lbs. of pressure between the engine pulley and the gear box pulley. Once the correct tension on the belt is achieved, tighten the (2) bolts that

secure the gear box assembly and re-attach the

shield. (Figures 6 and 7)

Figure 6 Gear Box Attaching Bolts

2-2 Attaching Frame Mount Brackets

Mount the lower frame weldment, which supports

the bagger unit, to the rear bumper as shown in

Figure 4 below using 3/8” -16 x 3” bolts, flatwashers

and 3/8” Nylock nuts.

Figure 4 Lower Frame Weldment

Figure 5 Bracket Mounted on Right Side ZT Frame

U-Bolt PTO Assembly 3/8” x 1-1/4” Bolt

Belt Tension Adjustment Bolt

Figure 7 Engine Pulley

Blower

Fasten the mounting bracket to the rear frame as

shown using 3/8” x 2-1/8” x 2-1/4” long U-bolts and

Nylock nuts. NOTE: Remove 3/8” x 7/8” bolt and nut

and replace with 3/8” x 1-1/4” bolt and Nylock nut.

Position the PTO Assembly pivot pins into mounting

bracket slots and insert pin to fasten into place.

Secure with hair pin clip.

3/8 - 16 x 3” Bolts

Page 9

7

2-4 Cam Assembly Adjustment

The cam assembly, which controls the blower belt

tension, comes from the factory pre-adjusted. If the

belt is too tight, or becomes too loose, remove the

hair pin clip from the belt tension rod and pull the “L”

end of the rod out of its hole in the cam assembly .

The tension rod may then be screwed out to tighten

the belt or screwed in to loosen the belt. Replace

the “L” end into the top hole in the cam and replace

the hair pin clip. Adjust the cam stop bolt to allow

the cam to rotate slightly over center when the blower is disengaged. (Figure 8) Attach PTO handle to

it’s mount at your desired position using three 1/4” x

3/4” bolts and Nylock nuts.

Figure 8 Belt Tension Rod Cam Stop Bolt Is Below

The Cam Assembly

2-5 Attachment Of Upper Frame

Assembly To The Lower Frame

NOTE: During this step it is suggested that two

people install the Top Frame to the Lower Frame

Using two people to raise the top frame, lift the top

frame above the lower frame making sure the bag

frames are located away from the engine as shown in

Figure 9. Slide the top frame vertical tube into the

lower frame vertical tube aligning the holes. Insert the

1/2’ X 2-1/2” clevis pin through the holes and fasten

with a hair pin clip.

Figure 9 Top Frame Clevis Pin Lower Frame

2-6 Attachment Of Top Assembly To The

Upper Frame Assembly

Align the pivot brackets of the top assembly to the

pivot points on either side of the upper frame

asssembly. Place a fender washer between each

pivot point and fasten each side by using a 5/16” 18 x 3/4” bolt and nyloc nut. When fastening, leave

the nut slightly loose so that the top can pivot freely.

(Figure 10)

Figure 10 Top Assembly Locates Here

2-7 Attachment Of The Boot To The

Mower Deck

Remove the mower’s discharge chute from the cutter

deck. The boot rod will replace the discharge chute

pin and create a mounting surface for the deck boot.

Slide the boot rod through the lugs on the cutter

deck and fasten into place with a hair pin clip as

shown in Figure 11.

Attach the boot plate to the boot using 3/8 x 1” carriage bolts inserted from the inside of the boot. This

will prevent grass from building up on the bolts. Use

3/8” serated, flanged lock nuts on the bolts, but do

not tighten at this time. With the rod in place, slide

the boot plate tabs under the rod. Allow the boot to

rotate down and rest against the cutter deck opening. Adjust the boot location to cover the deck opening and tighten the lock nuts. (Figure 11)

Figure 11 Boot Hair Pin Clip Rod

Boot Plate

Lower Hose

Nyloc Nut

Fender Washer

5/16” - 18 x 3/4” Bolt

PTO Handle

Page 10

2-12 Front Weight Assembly

NOTE: Before installing front weights on PZ models, install the locking pins in the front axle for

either the pivoting or fixed position.

Loosely bolt the right hand caster mounting bracket

and the right hand weight mounting bracket together

with a 1/2” x 1” serrated flanged locknut.

Mount this assembly as shown with a 3/8” x 3-1/2” x

2-9/16” U-bolt and a 3/8” serrated flanged locknut.

Repeat this same procedure on the left hand side.

NOTE: Location of the U-bolts will vary slightly from

the picture below with different model mowers.

Using a jack, center the 3” x 4” x 27” weight between

the casters as shown. Fasten the weight to the

mounting brackets using 1/2” x 5-1/4” x 3-5/16” Ubolts and 1/2” serrated flanged locknuts. After positioning the weight, tighten all fasteners to the

required torque.

On the CZ units, add a 3” x 4” x 16” long weight kit

as shown. Lift weight with a jack and center on the

larger weight that was previously mounted. Fasten

with two 1/2” x 5-5/16” x 7” U-bolts and 1/2” Nylock

hex nuts.

2-13 Installation / Removal Of Collection Bags

To install the bag onto the ring, first install ring end caps

onto both ends of the ring. Place the seam openings of

8

2-8 Adjustment Of The Lengths Of Hoses

The hoses in steps 2-9 and 2-10 must be cut to fit

your machine. Follow the steps and do not cut the

hoses until you have tried them on your particular

machine. Remember that the hoses must be long

enough to allow for enough clamping surface

between the inlet, blower assembly and the deck

boot.

2-9 Attachment Of The Upper Hose

Fasten the inlet to the plastic top by sliding the inlet

from the inside of the top to the outside and snap

into place. Slide a 5” - 6” upper hose clamp onto

both ends of the 6” upper hose, then slide one end

of the hose onto the inlet. Make sure there is about a

2” overlap between the hose end and the container

inlet. Proceed to slide the opposite end of the hose

onto the outlet of the blower assembly as shown in

Figure 12. Make sure both ends of the hose are

clearly attached to the inlet and the blower assembly

inlet. Tighten the hose clamps.

Figure 12 Inlet Hose Clamp 6” Upper Hose

2-10 Attachment Of The Lower Hose To

The Blower Cone

Fasten the blower cone to the blower housing by

using two 5/16” - 18 x 2-1/2” bolts and jam nuts.

Slide a 7”-8” hose clamp over each end of the lower

hose, then proceed to slide the lower hose onto the

blower cone. Tighten the hose clamps. (Figure 12)

2-11 Attachment Of The Lower Hose To

The Boot

Take the unattached end of the lower hose and slide

it over the circular end of the boot. Use the lower hose

clamp to secure the hose to the boot. (Figure 12) Tip:

Before securing the clamp, rotate the hose

counter-clockwise (away from yourself) approximately 1” to aid in retaining boot to mower deck.

Blower Outlet

Blower Cone

8” Lower Hose Boot

Bag Ring

Slot Bracket

Bag Ring

End Caps

(Under Fabric)

Cloth Bag

CZ Weight

Weight Bracket

3/8” U-Bolt

1/2” Bolt

1/2” x 5-5/16” U-Bolt

1/2” x 5-1/4” U-Bolt

Figure 14 Bag Installation

Figure 13 Caster Bracket Front Weight

Page 11

9

Figure 15 One Bag Removed

Figure 16

Hood

Draw Latches

Bags With Bag Rings Installed

Upper Frame Assembly

Inlet

the bag onto the bag ring openings and slide the bag

around the ring until the slot bracket in the bag ring is

protruding through the opening in the bag. Do this for

each of the three bags. (Figure 14)

Install the completed assemblies onto the support

frame and close the hood. Fasten both draw latches to

hold the hood closed. (Figures 15 & 16)

NOTE: After bags have been installed, the engine

exhaust outlet may need to re-directed downward to

prevent over heating the bags.

To empty the bag, remove the bag ring by lifting and

sliding rearward. Grasp the loop on the bottom of the

bag, turn it upside down and empty the collected

debris. Repeat for the other bags. Reinstall all bags,

close the hood and reattach the draw latches.

Plastic lawn and leaf bags, 55 gallon size, may be

used inside the cloth bags. Be sure to leave enough

plastic bag hanging over the frame so the plastic bag

can be twist tied before emptying.

Engine Exhaust Outlet Pipe

Lower Frame Assembly

Page 12

10

SECTION III

OPERATING INSTRUCTIONS

3-1 General Safety

Only qualified people familiar with this operator’s

manual and the mower’s operator’s manual should

operate this machine.

3-2 Operation And Tips On Mowing

A. Perform BEFORE EACH USE maintenance list

in paragraph 4-1.

B. Start mower engine.

C. While seated in the operator’s seat, rotate the

engagement handle of the collection system

away from the mower. Continue to rotate the

handle until it stops in an over center position.

With the blower engaged, you can proceed to

operate the control levers of the mower.

D. With the mower engine at high rpm, engage the

mower deck.

NOTE: If the collection system does not appear to

be collecting the grass clippings, disengage the deck

and blower, then engage the parking brake and turn

the engine off. proceed to Section 3-3 and review

Section 2-6 in this manual.

To obtain the maximum effectiveness from your collection system the tips listed below should be

followed:

* Watch your speed - Normal conditions will allow

a speed of up to approximately 5 mph, but thick,

heavy damp conditions will require reduced

ground speed.

* Mow with sharp blades - A sharp blade cuts

cleaner.

* Wet grass and leaves will decrease effective-

ness and will increase horsepower require-

ments.

* Mow at higher cutting heights - Remove and

mulch no more than 2” of grass length with each

mowing. (Experts recommend not cutting off

more than 1/3 of the grass blade length at any

given time.)

* Mow twice, at different height settings, (high,

then low), if grass is extra tall.

* Remember that horsepower requirements will

vary with the mowing conditions such as type

and height of turf grass, moisture content,

amount of leaves, whether the terrain is flat or

hilly, etc.

3-3 Disengagement Of The Blower

A. To disengage the blower, rotate the engage-

ment handle towards the mower.

WARNING: To determine when the collection bags

are full, follow the following steps:

A. Stop the forward movement of the mower.

B. Disengage the mower deck.

C. Disengage the blower.

D. Engage the parking brake.

E. Once the parking brake has been engaged, and

only then, walk behind the mower and check the

collection bags by lifting the hood.The load

in the bags should not exceed the height of the

installed bags.

F. To release bags from the frame, lift the bag ring

from the tab on the bagger frame, slide the bag

out and turn the bag over to deposit the clippings.

G. Follow steps on page 9 to re-attach the bags

to the bagger.

NOTE: Do not allow collection bags to become over

filled as potential damage may occur to your equipment. Also, be sure to clean the hood screen as

needed.

SECTION IV

MAINTENANCE

4-1 Maintenance Checklist

Before each use:

1. Check blades and spindles to be sure that no foreign objects, such as wire or steel strapping

bands, are wrapped around them.

2. Inspect blades for wear. Replace if necessary. If it

is necessary to sharpen blades, remove the

blades from the spindles before sharpening. DO

NOT sharpen blades while still attached to the

mower.

3. Make sure all shields are in place and in good

condition. Repair or replace any missing or damaged shields.

4. Perform lubrication per paragraph 4-2.

5. Listen for abnormal sounds, which might indicate

loose parts, damaged bearings, or other damage.

Correct any deficiency before continuing operation.

6. With the engine off, engage the blower assembly.

Check the belt tension and inspect the pulley belt

for cracks or tears.

7. Check for wear or deterioration of the upper or

lower hoses and the bags.. If there are any portions of the hoses or bags that have been torn or

worn through, replace with genuine BUSH HOG parts.

After Each Use:

1. Clean all debris from machine especially from the

bags, underneath the belt shields and off of

safety decals. Replace any missing or illegible decals.

Page 13

11

2. Inspect the unit for worn or damaged components. Repair or replace before next use. Any

replacement component installed during repair

shall include the component’s current safety

decal specified by the manufacturers to be

affixed to the component.

3. Check belt for proper tension.

4-2 Lubrication

NOTE: Use only white lithium base grease for lubri-

cation of the shaft on the blower assembly.

1. On the initial use: Grease the fitting on the blower shaft.

2. Every 25 hours of use: Re-grease the grease fitting.

3. Every 200 hours of use: Check oil levels in gear

box. Oil in gear box should cover the gears. If

not, fill using an EP90 weight oil. 6 oz. will fill

the gear box from empty.

Removal Of The Collection System For

Non-Collection Mowing

If it is decided that a particular mowing area does not

require that the grass clippings be collected, most of

the collection system may be removed while allowing

the lower frame weldment, PTO mounting bracket,

and the engine pulley to remain on the ZT.

(Refer to instructions and photographs on pages 5-8)

1. Loosen the belt tension adjustment bolt to allow

removal of the drive belt from the engine pulley.

2. Remove the hair pin clip and rod from the boot.

After disconnecting the boot from the deck,

store the pin and clip in the lugs on the boot for

safe keeping. NOTE: The original grass

chute must be re-installed on the deck

before operating the ZT.

3. Loosen the upper hose clamp from the hood

inlet and slide the hose free from the inlet.

4. Remove the hair pin clip and pin from the PTO

assembly and pull the assembly up and out of

the mounting slots. Replace the pin and clip in

the PTO assembly for safe keeping.

5. Remove the hair pin clip and pin that secures

the top frame to the lower frame and lift the top

frame and bags from the ZT. Store the hair pin

clip and pin in the top frame.

Parts And Service Information

Bush Hog collection system owners should record

the name and telephone number of their dealer.

Your dealer will be happy to supply replacement

parts, accessories and do any service or repairs to

your collection system. If for any reason your dealer

is unable to service your collection system or supply

replacement parts, contact Bush Hog and include

the following information from the serial number

plate:

Model Number_______________

Serial Number_______________

Page 14

SAFETY DECALS

To promote safe operation, Bush Hog supplies safety decals on all products manufactured. Because damage

can occur to safety decals either through shipment, use or reconditioning, Bush Hog will, upon request, provide

safety decals for any of our products in the field at no charge. Contact your authorized Bush Hog dealer for

more information.

12

50031301

50031304

50031303

50031302

50052915

50052916

Page 15

TORQUE SPECIFICATIONS

Proper toque for American fasteners used on Bush Hog equipment.

Recommended Torque in Foot Pounds (Newton Meters).*

BOLT DIAMETER

WRENCH (IN.) “B” AND SAE SAE SAE

SIZE (IN.) “A” THREAD SIZE GRADE 2 GRADE 5 GRADE 8

7/16 1/4 - 2O UNC 6 (7) 8 (11) 12 (16)

7/16 1/4 - 28 UNF 6 (8) 10 (13) 14 (18)

1/2 5/16 - 18 UNC 11 (15) 17 (23) 25 (33)

1/2 5/16 - 24 UNF 13 (17) 19 (26) 27 (37)

9/16 3/8 - 16 UNC 20 (27) 31 (42) 44 (60)

9/16 3/8 - 24 UNF 23 (31) 35 (47) 49 (66)

5/8 7/16 - 14 UNC 32 (43) 49 (66) 70 (95)

5/8 7/16 - 20 UNF 36 (49) 55 (75) 78 (106)

3/4 1/2 - 13 UNC 49 (66) 76 (103) 106 (144)

3/4 1/2 - 20 UNF 55 (75) 85 (115) 120 (163)

7/8 9/16 - 12 UNC 70 (95) 109 (148) 153 (207)

7/8 9/16 - 18 UNF 79 (107) 122 (165) 172 (233)

15/16 5/8 - 11 UNC 97 (131) 150 (203) 212 (287)

15/16 5/8 - 18 UNF 110 (149) 170 (230) 240 (325)

1-1/8 3/4 - 10 UNC 144 (195) 266 (360) 376 (509)

1-1/8 3/4 - 16 UNF 192 (260) 297 (402) 420 (569)

1-5/16 7/8 - 9 UNC 166 (225) 430 (583) 606 (821)

1-5/16 7/8 - 14 UNF 184 (249) 474 (642) 668 (905)

1-1/2 1 - 8 UNC 250 (339) 644 (873) 909 (1232)

1-1/2 1 - 12 UNF 274 (371) 705 (955) 995 (1348)

1-1/2 1 - 14 UNF 280 (379) 721 (977) 1019 (1381)

1-11/16 1-1/8 - 7 UNC 354 (480) 795 (1077) 1288(1745)

1-11/16 1-1/8 - 12 UNF 397 (538) 890 (1206) 1444 (1957)

1-7/8 1-1/4 - 7 UNC 500 (678) 1120 (1518) 1817 (2462)

1-7/8 1-1/4 - 12 UNF 553 (749) 1241 (1682) 2013 (2728)

2-1/16 1-3/8 - 6 UNC 655 (887) 1470 (1992) 2382 (3228)

2-1/16 1-3/8 - 12 UNF 746 (1011) 1672 (2266) 2712 (3675)

2-1/4 1-1/2 - 6 UNC 870 (1179) 1950 (2642) 3161 (4283)

2-1/4 1-1/2 - 12 UNF 979 (1327) 2194 (2973) 3557 (4820)

Proper torque for metric fasteners used on Bush Hog equipment.

Recommended torque in foot pounds (newton Meters).*

WRENCH BOLT

SIZE DIA. ASTM ASTM ASTM ASTM

(mm) “A” (mm) “B” 4.6 8.8 9.8 10.9

8 5 1.8 (2.4) 5.1 (6.9) 6.5 (8.8)

10 6 3 (4) 8.7 (12) 11.1 (15)

13 8 7.3 (10) 21.1 (29) 27 (37)

16 10 14.5 (20) 42 (57) 53 (72)

18 12 25 (34) 74 (100) 73 (99) 93 (126)

21 14 40 (54) 118 (160) 116 (157) 148 (201)

24 16 62 (84) 167 (226) 181 (245) 230 (312)

30 20 122 (165) 325 (440) 449 (608)

33 22 443 (600) 611 (828)

36 24 211 (286) 563 (763) 778 (1054)

41 27 821 (1112) 1138 (1542)

46 30 418 (566) 1119 (1516) 1547 (2096)

*Use 75% of the specified torque value for plated

fasteners. Use 85% of the specified torque

values for lubricated fasteners.

Numbers appearing on bolt heads

indicate ASTM class.

METRIC

AMERICAN

Bolt Head Markings

Wrench

Size “A”

Bolt

Diameter “B”

SAE Grade 8

(6 Dashes)

SAE Grade 2

(No Dashes)

SAE Grade 5

(3 Dashes)

Wrench

Size “A”

8.8

Bolt

Diameter “B”

13

Page 16

P.O. Box 1039 ● Selma, AL 36702-1039

Telephone (334) 874-2700

● www.bushhog.com

Loading...

Loading...