Page 1

ESTATE

COMMERCIAL

SERIES

Zero Turn Riding Mower

Published 01/13 Part No. 50068108

OPERATOR’S MANUAL

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ,

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

UNDERSTAND, and FOLLOW the Safety

BUSH HOG

®

2501 Griffin Ave.

Selma, AL 36703

334-874-2700

www.bushhog.com

©2010 Alamo Group Inc.

$0.00

Page 2

CONGRATULATIONS!

You have invested in the best implement of its type on the market today.

The care you give your Bush Hog implement will greatly determine your satisfaction with its performance and its service life. We urge a careful study of this manual to provide you with a thorough understanding of your new implement before operating, as well as suggestions for

operation and maintenance.

If your manual should become lost or destroyed, Bush Hog will be glad to provide you with a new

copy. Order from Bush Hog, 2501 Griffin Ave. Selma, Al. 36703. Most of our manuals can also

be downloaded from our website at www.servis-bushHog.com.

As an authorized Bush Hog dealer, we stock genuine Bush Hog parts which are manufactured

with the same precision and skill as our original equipment. Our trained service personnel are well

informed on methods required to service Bush Hog equipment,

and are ready and able to help you.

Should you require additional information or assistance, please contact us.

YOUR AUTHORIZED

BUSH HOG DEALER

BECAUSE BUSH HOG MAINTAINS AN ONGOING

PROGRAM OF PRODUCT IMPROVEMENT, WE RESERVE THE RIGHT TO MAKE IMPROVEMENTS IN

DESIGN OR CHANGES IN SPECIFICATIONS WITH

OUT INCURRING ANY OBLIGATION TO INSTALL

THEM ON UNITS PREVIOUSLY SOLD.

BECAUSE OF THE POSSIBILITY THAT SOME PHOTOGRAPHS IN THIS MANUAL WERE TAKEN OF PROTOTYPE MODELS, PRODUCTION MODELS MAY

VARY IN SOME DETAIL. IN ADDITION, SOME PHOTOGRAPHS MAY SHOW SHIELDS REMOVED FOR

PURPOSES OF CLARITY. NEVER OPERATE THIS IM-

PLEMENT WITHOUT ALL SHIELDS IN PLACE.

Page 3

EC SERIES

ZERO TURN RIDING MOWER

TABLE OF CONTENTS

SECTION PAGE

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dealer Preparation Check List . . . . . . . . . 3

Safety Alert Symbols . . . . . . . . . . . . . . . . 4

Safety Precautions . . . . . . . . . . . . . . . . . . 5

Federal Laws and Regulations. . . . . . . . . 8

I INTRODUCTION AND DESCRIPTION . . 9

Introduction. . . . . . . . . . . . . . . . . . . . . . . . 9

Description . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications . . . . . . . . . . . . . . . . . . . . . 10

II OPERATION . . . . . . . . . . . . . . . . . . . . . 11

General Safety . . . . . . . . . . . . . . . . . . . . 11

Pre-Operation Checklist . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . 12

Mowing Recommendations . . . . . . . . . . 14

III MAINTENANCE. . . . . . . . . . . . . . . . . . . 15

Maintenance Schedule. . . . . . . . . . . . . . 15

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tachometer / Hour Meter . . . . . . . . . . . 16

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SECTION PAGE

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Mower Blades . . . . . . . . . . . . . . . . . . . . .16

Cleaning Grass Buildup . . . . . . . . . . . . .16

Motion Control Adjustment . . . . . . . . . . .17

Drive Adjustments . . . . . . . . . . . . . . . . .17

Test Drive Operations . . . . . . . . . . . . . .17

Leveling The Deck and Setting

the Counter Balance Spring Tension . . .18

Deck Belt Adjustment . . . . . . . . . . . . . .18

Deck Belt Replacement . . . . . . . . . . . . .18

Start Up Maintenance . . . . . . . . . . . . . . .19

Parking Brake Adjustment . . . . . . . . . . .19

Parking Brake Cable Replacement . . . .20

Troubleshooting . . . . . . . . . . . . . . . . . . .21

IV ASSEMBLY . . . . . . . . . . . . . . . . . . . . . .22

Wiring Schematics . . . . . . . . . . . . . . . . .24

Safety Decals . . . . . . . . . . . . . . . . . . . . .25

Torque Specifications . . . . . . . . . . . . . . .27

Optional Equipment List . . . . . . . . . . . . .28

Slope Angle Guide . . . . . . . . . . . . . . . . .29

RETAIL CUSTOMER’S RESPONSIBILITY

UNDER THE BUSH HOG WARRANTY

It is the Retail Customer and/or Operator’s responsibility to read the Operator’s Manual, to operate, lubricate, maintain and store the product in accordance with all instructions and safety

procedures. Failure of the operator to read the Operator’s Manual is a misuse of this equipment.

It is the Retail Customer and/or Operator’s responsibility to inspect the product and to have any

part(s) repaired or replaced when continued operation would cause damage or excessive wear

to other parts or cause a safety hazard.

It is the Retail Customer’s responsibility to deliver the product to the authorized Bush Hog

Dealer, from whom he purchased it, for service or replacement of defective parts which are covered by warranty. Repairs to be submitted for warranty consideration must be made within

forty-five (45) days of failure.

It is the Retail Customer’s responsibility for any cost incurred by the Dealer for traveling to or

hauling of the product for the purpose of performing a warranty obligation or inspection.

1

Page 4

EC ZERO TURN RIDING MOWER LIMITED WARRANTY

OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

Bush Hog warrants to the original purchaser of this new Zero Turn Riding Mower, purchased from an authorized

Bush Hog dealer, that the equipment be free from defects in material and workmanship for a period of three (3) years from

date of retail sale. The three year limited warranty (third year parts only) includes drive train, electromagnetic clutch, deck and

cutter spindles. See dealer for complete details. The obligation of Bush Hog to the purchaser under this warranty is limited to

the repair or replacement of defective parts. NOTE: This warranty covers parts and labor for the first two years and

parts only during the third year.

Replacement or repair parts installed in the equipment covered by this limited warranty are warranted for ninety (90)

days from the date of purchase of such part or to the expiration of the applicable new equip-ment warranty period, whichever

occurs later. Warranted parts shall be provided at no cost to the user at an authorized Bush Hog dealer during regular working hours. Bush Hog reserves the right to inspect any equipment or parts which are claimed to have been defective in material or workmanship.

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Bush Hog’s obligation under this limited warranty, to the extent allowed by law, is in lieu of all warranties, implied or

expressed, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PUR-

POSE and any liability for incidental and consequential damages with respect to the sale or use of the items warranted. Such

incidental and consequential damages shall include but not be limited to: transportation charges other than normal freight

charges; cost of installation other than cost approved by Bush Hog; duty; taxes; charges for normal service or adjustment; loss

of crops or any other loss of income; rental of substitute equipment, expenses due to loss, damage, detention or delay in the

delivery of equipment or parts resulting from acts beyond the control of Bush Hog.

THIS LIMITED WARRANTY SHALL NOT APPLY:

1. To transportationto and from dealership or servicecalls made bydealers,ie, driving time, towing, pickup and delivery.

2. To vendor items which carry their own warranties, such as engines, batteries, tires, and tubes.

3. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

4. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgement of Bush

Hog such use affects its performance, stability or reliability.

5. If the unit has been altered or repaired outside of an authorized Bush Hog dealership in a manner which, in the sole

judgement of Bush Hog, affects its performance, stability or reliability.

6. To normal maintenance service and normal replacement items such as gearbox lubricant, hydraulic fluid, worn blades,

or to normal deterioration of such things as belts and exterior finish due to use or exposure.

7. To expendable or wear items such as teeth, chains, sprockets, belts, springs and any other items that in the company’s

sole judgement is a wear item.

NO EMPLOYEE OR REPRESENTATIVE OF BUSH HOG IS AUTHORIZED TO CHANGE THIS LIMITED WARRANTY IN

ANY WAY OR GRANT ANY OTHER WARRANTY UNLESS SUCH CHANGE IS MADE IN WRITING AND SIGNED BY BUSH

HOG’S SERVICE MANAGER, 2501 GRIFFIN AVE., SELMA, ALABAMA 36703

OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

Record the model number, serial number and date

purchased. This information will be helpful to your

dealer if parts or service are required.

MAKE CERTAIN THE WARRANTY REGISTRATION

HAS BEEN FILED ON LINE WITH BUSH HOG / SELMA

ALABAMA

MODEL NUMBER

SERIAL NUMBER

DATE OF RETAIL SALE

2

Page 5

DEALER PREPARATION CHECK LIST

EC ZERO TURN RIDING MOWER

BEFORE DELIVERING MACHINE — The following check list should be completed.

Use the Operator’s Manual as a guide.

r 1. Engine has been serviced.

r 2. Battery fluid level is checked.

r 3. Low oil pressure light checked for operation.

r 4. Operator interlock switches checked for operation.

r 5. Assembly completed.

r 6. All fittings lubricated.

r 7. Hydraulic Reservoir filled to appropriate level with oil.

r 8. All shields in place and in good condition.

r 9. Roll-over Protective Structure is installed and retractable seat belt functions

properly.

r 10. All fasteners torqued to specifications given in Torque Chart.

r 11. All decals in place and readable. (See decal page.)

r 12. Overall condition good (i.e. paint, welds)

r 13. Parking brake checked and adjusted, if necessary.

r 14. Steering checked and adjusted, if necessary.

r 15. Check tire pressure.

r 16. Warranty information has been registered on line with Bush Hog.

r 17. Operators manual has been delivered to owner and he has been instructed

on the safe and proper use of the cutter.

Dealer’s Signature

Purchaser’s Signature

THIS CHECKLIST TO REMAIN IN OWNER’S MANUAL

It is the responsibility of the dealer to complete the procedures listed

above before delivery of this implement to the customer.

3

Page 6

Safety Alert Symbol

This Safety Alert Symbol means: “ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!”

This symbol is used to call attention to safety

precautions that should be followed by the operator to avoid accidents. When you see this symbol, carefully read the message that follows and

heed its advice. Failure to comply with safety precautions could result in death or serious bodily

injury.

Safety Signs Signal Words

The signal words DANGER, WARNING, AND CAUTION are used on the equipment safety signs. These words

are intended to alert the viewer to the existence and the degree of hazard seriousness.

White letters on RED

Black letters on ORANGE

Black letters on YELLOW

This signal word indicates a potentially hazardous situation which,

if not avoided, will result in death or serious injury.

This signal word indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury

It may also be used to alert against unsafe practices.

This signal word indicates a potentially hazardous situation exist

which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

4

Page 7

IMPORTANT SAFETY PRECAUTIONS

This symbol is used to call attention to safety precautions that should be followed by

the operator to avoid accidents. When you

see this symbol, carefully read the message

that follows and heed its advice. Failure to

comply with safety precautions could result

in serious bodily injury.

In addition to the design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and proper training of personnel in the operation,

transport, maintenance and storage of equipment. Lack of attention to safety can result in accident, personal injury, reduction of efficiency and worst of all—loss of life. Watch for safety hazards and correct deficiencies promptly. Use the following safety precautions as a general guide to safe operations when using this

machine. Additional safety precautions are used throughout this manual for specific operating and maintenance procedures. Read this manual and review the safety precautions often until you know the limitations.

ACCIDENT PATTERNS TO AVOID

1. CONTACT WITH THE ROTATING BLADE - This accident usually happens when the operator is

clearing the discharge chute of grass, (especially when the grass is wet), or when the operator adjusts

the machine without turning it off and waiting for the blades to completely stop.

2. PROPELLED OBJECTS - Sticks, rocks, wires, and other objects can be propelled out through the discharge chute or from under the mower housing. Bystanders are particularly vulnerable.

3. GRASS DISCHARGE CHUTE - The mower shall not be operated without the grass discharge chute

in its lowered position.

4. OVERTURNING - This happens when riding mowers are used on steep slopes, embankments or hills.

The operator in these cases can come in contact with blades or sustain injuries during a fall.

5.

MOWER RUNNING OVER THE VICTIM - This usually happens when a riding mower is driven in reverse.

The accident victims are most often young children whom, unseen by the operator of the mower, were

in the area being mowed.

WE SHARE YOUR DESIRE TO PROTECT YOURSELF, YOUR FAMILY, YOUR FRIENDS AND YOUR

NEIGHBORS FROM ACCIDENTAL INJURY. OBSERVING AND ENFORCING THE FOLLOWING GUIDE

LINES WILL HELP TO INSURE THE SAFETY OF EVERYONE.

SAFETY INSTRUCTIONS AND RECOMMENDATIONS

1. PEOPLE WHO OPERATE, SERVICE, OR ARE OTHERWISE ASSOCIATED with the Zero Turning

Riding Mower should be trained in its proper use and warned of its dangers. Before operating, adjusting,

or servicing the Zero Turning Riding Mower they should read and understand this entire manual and the

engine manual.

2. AVOID CONTACT WITH MOVING PARTS. Keep hands and feet from under mowing deck and away

from blades at all times. Turn engine (motor) off if you must unclog the chute.

3. AVOID HILLS AND SLOPES. Use EXTREME caution when mowing and/or turning on slopes as loss of traction

and/or tip-over could occur. Drive slower on slopes. DO NOT mow slopes greater than 15 degrees. Watch for

ditches, holes, rocks, dips and rises, which change the operating angle. Keep away from drop-offs and steep

banks. Avoid sudden starts when mowing uphill - mower may tip backwards. Loss of traction may occur going

downhill - weight transfer to the front wheels may cause drive wheels to slip and cause loss of braking. DO NOT

mow slopes when grass is wet - slippery conditions affect steering and reduce traction and braking. The operator

is responsible for safe operation on slopes.

4. DISENGAGE POWER TO MOWER BEFORE BACKING UP. Do not mow in reverse unless absolutely

necessary and then only after turning around and observing the entire area behind the mower. Go slowly.

Most “running over victim” accidents occur in reverse.

5. BEGINNING OPERATORS SHOULD LEARN HOW TO STEER the Zero Turning Riding Mower before

attempting to mow. Start with slow engine speed and drive without the blades engaged in open area until

comfortable with the machine.

5

Page 8

SAFETY CONTINUED

6. KNOW HOW TO STOP QUICKLY. Know the location and operation of every control, especially how to brake and

how to disengage the mower blades.

7. DO NOT MOVE THE CONTROL LEVERS from forward position to reverse position rapidly. The speed

and/or direction of travel is affected instantly by movement of the Control Levers.

8. DO NOT ALLOW CHILDREN TO OPERATE MOWER. Do not allow others who have not had instructions to operate mower. Do not operate the mower when children or others are in the area.

9. ALWAYS TURN ENGINE OFF AND REMOVE KEY before leaving mower to prevent children and

inexperienced operators from starting the engine. Never leave the mower unattended with engine running. Always wait for all moving parts and all sounds to stop before leaving operator’s seat. Always set

the parking brake on an unattended mower.

10. WEAR STURDY, ROUGH-SOLED WORK SHOES AND CLOSE-FITTING TROUSERS AND SHIRTS.

Never operate mower in bare feet, sandals or sneakers.

11. WEAR PERSONAL PROTECTIVE EQUIPMENT such as, but not limitied to, protection for eyes, ears, feet, hands

and head when operating or repairing equipment. Do not wear loose clothing or jewelry that may catch on equipment moving parts.

12. NEVER CARRY PASSENGERS.

13. KNOW THE AREA YOU ARE TO MOW. Watch for hidden dangers such as rocks, roots, sticks, holes,

bumps, and drop-offs, etc. Before mowing, pick up all debris in area to be mowed. Sharp and hard

objects can be propelled at a high speed and can act like shrapnel. Walk through tall grass BEFORE

MOWING to make sure there are no hidden dangers. Mow higher than desired in tall grass to expose

any hidden objects and/or obstacles, clean the area, and then mow to the desired height.

14. BE SURE THE AREA IS CLEAR of other people before mowing. Stop machine if anyone enters the area.

15. NEVER REFUEL A MOWER INDOORS. Allow the engine time to cool before refueling. Unseen vapors may be

ignited by a spark. Always clean up spilled gasoline. Never run the engine indoors in a garage

or any other closed building. Allow engine to cool before storing in any enclosure. The engine exhaust

and gasoline fumes are dangerous.

16. NEVER REMOVE THE FUEL CAP or add gasoline to a running or hot engine or an

engine that has not been allowed to cool for several minutes after running. Always make sure the gas

cap is in place.

17. DO NOT SMOKE AROUND THE MOWER or the gasoline storage container. Gasoline fumes can easily ignite.

18. KEEP GASOLINE IN A WELL-VENTILATED AREA away from your living quarters and in tightly

capped safety cans. Never store mower with gasoline in the tank inside a building where fumes may

reach open flame or spark.

19. DISENGAGE BLADES, STOP ENGINE, ENGAGE PARKING BRAKE AND REMOVE IGNITION KEY before any

servicing. Be sure all moving parts and all sounds have stopped. Let engine cool and disconnect the spark plugs

so the engine cannot start by accident.

20. KEEP ALL NUTS, BOLTS, AND SCREWS TIGHT to be sure equipment is in safe working condition, especially blade bolts.

21. VEHICLE SHOULD BE STOPPED AND INSPECTED FOR DAMAGE after striking a foreign object and

the damage should be repaired before restarting and operating the equipment. Stop immediately and

check for damage or loose parts if mower should start vibrating.

22. DISENGAGE BLADES BEFORE DRIVING ACROSS WALKS or projecting objects or transporting.

23. KEEP SAFETY DEVICES AND GUARDS IN PLACE. If any of the safety switches become inoperable,

have them repaired immediately.

24. DO NOT STEP OR STAND ON THE MOWER HOUSING. Step or stand only on the tread areas on the deck.

25. WATCH OUT FOR TRAFFIC near roadways and when crossing roads.

26. THIS MACHINE IS NOT MEANT FOR HIGHWAY OR STREET USE. It is not a recreational vehicle and it should

not be operated as such.

27. WHEN FEASIBLE, DO NOT USE MOWER WHEN GRASS IS WET OR SLIPPERY.

28. MOW ONLY IN DAYLIGHT OR GOOD ARTIF ICIAL LIGHT.

6

Page 9

SAFETY CONTINUED

29. ALWAYS DISENGAGE THE MOWER BLADE CLUTCH when transporting.

30. Do not operate the mower under influence of drugs or alcohol.

31. Do not change the engine governor settings or overspeed the engine. Operating an engine at excessive speed may

increase the hazard of personal injury.

TOWING

1. Use for towing only if equipped with a Bush Hog hitch kit. Do not attach towed equipment except at the hitch point.

2. Never allow children or others in or on towed equipment.

3. On slopes, the weight of the towed equipment may cause loss of traction and loss of control.

4. Travel slowly and allow extra distance to stop.

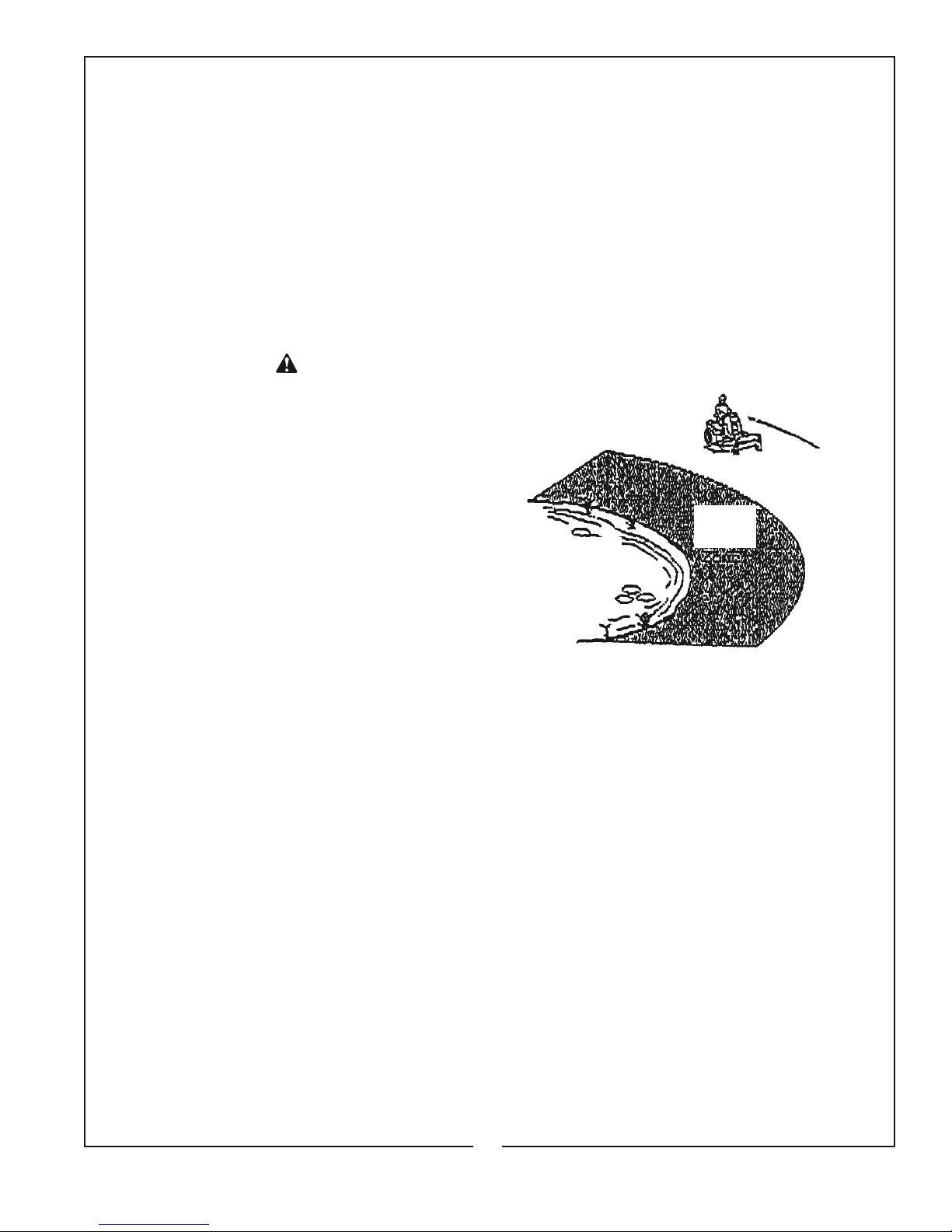

SLOPE OPERATION

DANGER

POTENTIAL HAZARD

Mowing on wet grass or steep slopes can cause

sliding and loss of control.

WHAT CAN HAPPEN

Wheels dropping over edges, ditches, steep banks,

or water can cause injury, or death by drowning.

HOW TO AVOID THE HAZARD

Do not mow slopes when grass is wet.

Do not mow near drop-offs or near water.

Do not mow slopes greater than 15 degrees.

Reduce speed and use extreme caution on slopes.

Avoid sudden turns or rapid speed changes.

Do not ride or operate the ZTR if the mower head

has been removed.

1. Use EXTREME caution when mowing and/or turning on slopes as loss of traction and/or tip-over could occur. The

operator is responsible for safe operation.

2. See inside of the back cover to determine the approximate slope angle of the area to be mowed.

3. Use a walk behind mower and/or a hand trimmer near drop-offs, ditches, steep banks or water. This area can be dangerous.

4. Progressively greater care is needed as the slope increases.

5. Always avoid sudden starting or stopping on a slope. If tires lose traction, disengage the blades and proceed slowly down the

slope.

6. Avoid sudden starts when mowing uphill. Mower may tip backwards.

7. Be aware that loss of traction may occur going downhill. Weight transfer to the front wheels may cause drive wheels to slip and

cause loss of braking and steering.

8. Watch for ditches, holes, rocks, dips, and rises that change the operating angle, as rough terrain could overturn the machine.

Tall grass can hide obstacles.

Water

Danger

Zone

Safe

Zone

9. Remove or mark obstacles such as rocks, tree limbs, etc. from the ,mowing area. Tall grass can hide obstacles.

10. Use extreme care with grass catches or attachments. These can change the stability of the machine and cause loss of control.

11. Follow the manufacturer’s recommendations for counterweights to improve stablity.

12.. Check carefully for overhead clearances (ie. branches, doorways, and electrical wires) before driving under objects and do

not contact them.

SLOPE ANGLE GUIDE LOCATED INSIDE REAR COVER

7

Page 10

IMPORTANT FEDERAL LAWS AND REGULATIONS* CONCERNING

EMPLOYERS, EMPLOYEES AND OPERATIONS.

*(This section is intended to explain in broad terms the concept and effect of the following federal laws and

regulations. It is not intended as a legal interpretation of the laws and should not be considered as such).

U.S. Public Law 91-596 (The Williams-Steiger Occupational and Health Act of 1970) OSHA

This Act Seeks:

“...to assure so far as possible every working man and woman in the nation safe and healthful working

conditions and to preserve our human resources...”

DUTIES

Sec. 5 (a) Each employer—

(1) shall furnish to each of his employees employment and a place of employment

which are free from recognized hazards that are causing or are likely to cause

death or serious physical harm to his employees;

(2) shall comply with occupational safety and health standards promulgated under

this Act.

(b) Each employee shall comply with occupational safety and health standards

and all rules, regulations and orders issued pursuant to this Act which are

applicable to his own actions and conduct.

OSHA Regulations

Current OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the

employer shall instruct every employee in the safe operation and servicing of all equipment with which the

employee is, or will be involved.” These will include (but are not limited to) instructions to:

Keep all guards in place when the machine is in operation;

Permit no riders on equipment;

Stop engine, disconnect the power source, and wait for all machine movement to stop before

servicing, adjusting, cleaning or unclogging the equipment, except where the machine must be

running to be properly serviced or maintained, in which case the employer shall instruct employees

as to all steps and procedures which are necessary to safely service or maintain the equipment.

Make sure everyone is clear of machinery before starting the engine, engaging power, or operating

the machine.

Child Labor Under 16 Years Old

Some regulations specify that no one under the age of 16 may operate power machinery. It is your

responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of

Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.)

8

Page 11

SECTION I

INTRODUCTION AND DESCRIPTION

INTRODUCTION

We are pleased to have you as a Bush Hog customer.

Your Bush Hog Zero Turn Riding Mower has been

carefully designed to give maximum service with minimum down time. This manual is provided to give you

the necessary operating and maintenance instructions for keeping your mower in top operating condition. Please read this manual thoroughly. Understand

what each control is for and how to use it. Observe all

safety precautions decaled on the machine and noted

throughout the manual for safe operation of the implement. If any assistance or additional information is

needed, contact your authorized Bush Hog dealer.

NOTE:

All references made to right, left, front, rear, top or bottom is as viewed facing the direction of forward travel.

DESCRIPTION

The Zero Turn riding mower is intended for use on

lawns and other frequently maintained areas where a

smooth, even cut is desired and superior maneuverability is needed. The tractor unit consists of a

Kawasaki or Kohler twin cylinder engine. The engine

has a pressurized oil lubrication system with spin-on type

filter, fused electronic ignition, electric start and an 8 gallon fuel system.

Two hydrostatic transaxles are used for propelling and

steering. The pumps are belt driven by the engine output shaft. One lever for each drive controls both speed

and direction. This independent control of each drive

wheel coupled with continuously variable speed selection gives the Zero Turn mower exceptional maneuverability.

The mower attachment is available in 55” or 61” cutting widths. The mower has three cutting blades, driven

by an electromagnetic clutch through a single v-belt.

9

Page 12

CONTROLS

CONTROL LOCATIONS

OPERATOR INTERLOCK SYSTEM

Your Bush Hog Zero Turn Riding Mower is equipped

with an Operator Interlock System that is designed to

help prevent possible serious injuries. Understanding

and maintaining this system is vital for safe operation.

To Start Engine:

1. Blades (PTO) must be disengaged.

2. Control levers in neutral (swung out).

3. Parking brake set.

The Engine Will Kill If:

1. The operator leaves the seat with:

a. The control levers out of neutral (swung in).

b. The blades are engaged.

c. The parking brake is off.

d. All of the above.

2. The park brake is on before the control levers

are swung out.

DO NOT OPERATE MOWER IF SAFETY SWITCHES

ARE NOT OPERATING PROPERLY.

WARNING

DO NOT OPERATE MACHINE UNLESS INTERLOCK SYSTEM FUNCTIONS PROPERLY. FAILURE TO HEED THIS WARNING

MAY RESULT IN SERIOUS INJURY, DEATH

OR EQUIPMENT DAMAGE.

1 Ignition Key -Starts and stops engine.

2 Engine Throttle - Controls engine speed.

3 Two Steering/Speed Control Levers - In front of

seat at side.

4 PTO Switch - Engages electric clutch which

engages mower blades.

5 Parking Brake Lever - Engages parking brake.

(See page 22)

6 Cutting Height Adjust Pin - Sets cutting height to

desired position. (See page 12)

7 Choke - Aids in starting engine.

8 Light Switch (Optional)

9 Hour Meter / Tachometer

0

1

Warning Light for oil pressure.

33

99

11

44

EC ZERO TURN SPECIFICATIONS

Tread Width - ( Outside Tires) . . . . . . . . . . . . . . . . . . . 49”

Height - To top of seat back (Standard Seat) . . . . . . . 47”

(Suspension Seat) . . . . . 51”

Fuel Capacity (In Twin Tanks) . . . . . . . . . . . . . . 8 gallons

Hydrostatic Transaxles - All Models . . . . (2) Hydro- Gear

ZT3400

Engines - 26 hp Kawasaki FX Twin

25 hp Kohler Courage Pro SV830

27 hp Kohler Courage Pro SV840

Tires - All Models - Front . . . . . . . . . . . . . . . . 13 x 5.0 - 6

Drive . . . . . . . . . . . . . . 22 x 10.5 - 12

23 x 10.5 -12 Bar Tire - Optional

88

77

22

DECK SPECIFICATIONS

ITEM

Cutting width 55” 61”

Cutting Height ------ 1-1/2” to 4-1/2” in 1/4” increments

Blades 19” 21”

Overall width

with chute down 69” 75”

Material thickness - Deck -------------10 GA.-----------------

Spindle bearings ----------------------25 mm-------------------

10

Page 13

GENERAL SAFETY

SECTION II

OPERATION

7. Check battery fluid level.

Only qualified people familiar with this operator’s manual should operate this machine. Operator should

wear hard hat, safety glasses, and safety shoes.

Avoid loose fitting clothing or jewelry. The operator

should read, understand and practice all safety messages shown on the caution, warning and danger decals affixed to the machine to avoid serious injury or

death. Before beginning operation, clear work area of

any objects that may be picked up and thrown by

mower. Check for ditches, stumps, holes or other obstacles that could upset power unit or damage mower.

Tall grass can hide obstacles. Always push steering

levers apart, set parking brake, disengage PTO, turn

off engine, and allow blades to come to a complete

stop before leaving operator’s seat. Do not operate

without all shields in place and in good condition.

PRE-OPERATION CHECKLIST

1. Make sure fuel tank is full. Use regular unleaded

gasoline. See engine manual for more details.

WARNING

AVOID SERIOUS INJURY OR DEATH:

GASOLINE IS EXTREMELY FLAMMABLE AND EXPLOSIVE UNDER CERTAIN CONDITIONS.

ll

REFUEL IN A WELL VENTILATED AREA WITH

ENGINE STOPPED.

ll

DO NOT SMOKE OR ALLOW FLAMES OR

SPARKS IN THE REFUELING AREA OR

WHERE GASOLINE IS BEING STORED.

ll

DO NOT OVERFILL FUEL TANK. AFTER

REFUELING, MAKE CERTAIN THE TANK CAP

IS CLOSED PROPERLY AND SECURELY.

ll

BE CAREFUL NOT TO SPILL FUEL WHEN

REFUELING. FUEL VAPOR OR SPILLED FUEL

MAY IGNITE. IF ANY FUEL IS SPILLED, MAKE

SURE THE AREA IS DRY BEFORE STARTING

THE ENGINE.

ll

KEEP OUT OF REACH OF CHILDREN

2. Make sure dirt and foreign matter are kept out of

fuel tank. Use a clean funnel and fuel can.

3. Do not mix oil with gasoline.

8. Inspect V-belts

9. Check tire pressure (Use low pressure gauge):

Front & Drive Tires -15 psi. (Rear tires may

be inflated to 12 psi if additional ride comfort

is desired.)

10. Make sure underside of mower deck is free of

grass.

11. Make sure mower blades are sharp and secured

tightly.

12. Clean the air intake screen on the engine if

necessary.

13. Perform any other maintenance as it becomes

necessary. (See “Maintenance” section)

14. Check parking brake operation by disengaging

hydrostatic transaxles (freewheeling position),

and placing the brake lever in the “on” position.

Attempt to rock tractor by hand. Both drive wheels

should be locked. When the brake handle is in the

“off” position, both drive wheels should turn freely.

If there is a problem in either position, refer to

adjustment procedure in the maintenance sec

tion.

15. Seat Adjustments: The high-back full suspension

seat has a variable rate suspension system,

adjustable lumbar support and sliding seat to

accomodate different operators.

Operator Weight Adjustment Knob - Turn the

knob until the indicator position closely matches

your weight to give the most comfortable ride.

Adjustable Lumbar Knob (Under left arm rest) Turn knob clockwise or counter-clockwise to

achieve desired support.

Back Angle Adjustment Knob (Under right arm

rest) -Turn knob clockwise or counter-clockwise to

achieve desired support.

4. Do not use white, high test or premium gasoline.

Do not use de-icers, carburetor cleaners or other

such additives.

5. Check the crankcase oil level. Make sure the

engine is off. The mower should be parked on a

level area. Do not overfill. (See your engine

manual for more detailed instructions.)

6. Check the hydrostatic transaxle oil level. (See

“Maintenance” section of this manual.)

11

Lever Release Seat Slides - Pull the lever outward

to release the latch. Slide the seat forward or rearward to your most comfortable position and release

the lever.

WARNING

ENGINE EXHAUST GASES CONTAIN

ll

ll

POISONOUS CARBON MONOXIDE.

NEVER RUN ENGINE IN A CLOSED BUILDING OR

CONFINED AREA.

AVOID INHALING EXHAUST GASES.

Page 14

OPERATION

1. OPEN FUEL TANK SELECTOR VALVE left or

right tank.

2. MOVE CONTROL LEVERS TO neutral “OUT”

position by pushing each one straight sideways.

3. SET PARKING BRAKE. Pull rearward to set.

4. DISENGAGE MOWER BLADE CLUTCH by

moving clutch switch to “OFF” (down) position.

WARNING

AVOID SERIOUS INJURY OR DEATH:

DO NOT MOVE STEERING LEVERS FROM FOR

WARD TO REVERSE OR REVERSE TO FOR

WARD POSITION RAPIDLY. A SUDDEN CHANGE

IN DIRECTION MAY CAUSE LOSS OF CONTROL

AND/OR DAMAGE TO EQUIPMENT. FOR

SMOOTH, SAFE OPERATION, MOVE THE CON

TROL LEVERS IN A GENTLE, SLOW MOTION,

ESPECIALLY ON GRADES.

5. SET ENGINE CHOKE CONTROL for cold starts

to full position.

6. SET ENGINE THROTTLE TO 1/2 throttle.

7. TURN IGNITION KEY to “START” position and

release to “RUN” as soon as engine starts.

NOTE: Prolonged cranking will damage starter

motor and shorten the battery life.

8. ADJUST ENGINE THROTTLE AND CHOKE for

desired engine smoothness and speed. NOTE:

When mowing, always run engine at full throttle.

9. RELEASE PARKING BRAKE. Push brake lever

forward to release.

CAUTON

If the operator is inexperienced with the zero turn

mower lever steering/speed control, he/she

should follow these recommendations: Disengage

the mower blades. Go very slowly until thoroughly

familiar with the machine. Keep away from fences,

buildings, and other obstructions. While becom

ing familiar with the machine, move the Control

Levers smoothly and slowly. Practice until opera

tion is smooth and efficient.

11. BRAKING: To brake mower, gently move

Control Levers in the direction opposite to travel.

If the parking brake is engaged with the Control

Levers in the “IN” position the engine will stop.

12. CUTTING HEIGHT ADJUSTMENT:

1. Stop engine and move the control levers to

the neutral position and engage the parking brake.

2. Disengage the blades.

3. Depress the deck lift foot pedal raising the

deck to the transport position and place the pedal in

the locked position.

4. Insert height adjustment pin into the hole cor-

responding to the desired cutting height. See

decal on the top of the deck lift plate.

5. Depress the deck lift pedal and lower the deck to

the selected mowing height.

6. To transport, depress the lift foot pedal and lock in

position, then move the height adjustment pin to the 41/2” position.

7. The cutting height adjustment is only a recom

mended guide. During normal mowing cut only 1/3 of the

grass blade. Set cutting height to achieve your desired results.

10. TO DRIVE: Adjust seat forward or backward for

operator comfort. Move the Control Levers to the

“IN” position. Move Control Levers forward to

move forward. Move levers slowly forward to

increase speed. To reverse direction, move the

Control Lever on the side to which you want to

turn slightly rearward of the other Control Lever.

To turn on a zero radius axis, go slowly and pull

one Control Lever back and push the other

Control Lever forward, depending on which

direction you wish to turn.

CUTTING HEIGHT ADJUSTMENT DECAL

12

Page 15

ANTI-SCALP ROLLER OR CASTER ADJUSTMENT:

1. Stop engine and move the control levers to the

neutral position and engage the parking brake.

2. Disengage the blades.

3. The Anti-Scalp deck rollers are adjustable up and

down to provide improved deck flotation and scalping protection at various cutting heights. They are not intended

to ride continously on the ground. Rollers should maintain

.375” minimum clearance to ground. DO NOT adjust rollers

to support deck. (Refer to photographs)

14. ENGAGE MOWER BLADES by pulling

up on the PTO clutch switch. The engine will not

start if the PTO switch is engaged. If the engine

is running while the PTO clutch is engaged and

the operator leaves the seat, the engine will stop.

15. TO STOP:

A. Slow engine speed with throttle to slowest

position

B. Disengage the mower blade clutch by mov-

ing the PTO clutch switch to the “OFF” position.

C. Move Control Levers to neutral position and

then to the “OUT” position.

D. Set the parking brake.

WARNING

Use EXTREME caution when mowing and/or

turning on slopes as loss of traction and/or

tip-over could occur. Drive slower on slopes.

DO NOT mow slopes greater than 15 degrees.

Watch for ditches, holes, rocks, dips and

rises, which change the operating angle.

Keep away from drop-offs and steep banks.

Avoid sudden starts when mowing uphill mower may tip backwards. Loss of traction

may occur going downhill - weight transfer to

the front wheels may cause drive wheels to

slip and cause loss of braking. DO NOT mow

slopes when grass is wet - slippery conditions affect steering and reduce traction and

braking. The operator is responsible for safe

OPERATION ON SLOPES.

E. Turn ignition key to “OFF” position.

F. Remove the key and wait for all movement

and sound to cease before dismounting.

ANTI-SCALP ROLLER

CASTER ASSEMBLY (Optional on 61” Decks Only)

Roller Height Adjustment Holes

Spacers may be positioned above and/or below the

caster arm to adjust position.

13

Page 16

WARNING

AVOID SERIOUS INJURIES TO OTHERS:

ALWAYS REMOVE THE KEY FROM THE IGNITION SWITCH WHENEVER THE MOWER IS UNATTENDED TO PREVENT CHILDREN OR

UNAUTHORIZED PERSONS FROM STARTING

THE ENGINE.

15. HYDRAULIC COMPONENTS BYPASS-TO

MOVE THE TRACTOR WITHOUT POWER: The

bypass levers are located on the rear of the

engine plate. NOTE: Exhaust muffler can be

extremely hot. Use extreme caution when

engaging or disengaging bypass levers to

prevent severe burns. Pull both the RH & LH

levers to the rear and lock out in the keyway

slot to disengage for freewheeling. Reverse

this procedure for operation.

NOTE: To move the tractor without power, the pumps

must be unlocked and in the free wheel position. Failure to do so could possibly damage the hydraulic components. Never pull at more than 2 MPH.

16. FUEL SHUT-OFF VALVE: Located on the front

panel below the operator is the fuel directional

valve. This valve has three positions for operations and each position is made in 1/4 turn increments. This directional valve has a shut off position and can be used when the machine will not

be used for a few days or when the unit is transported to and from a work site.

Fuel Flow Valve Position

Off Down

Right Tank Right

Left Tank Left

Fuel Shut-Off Handle

Oil Drain RH side (Kawasaki) Bypass Lever

(RH Shown)

Oil Drain LH side (Kohler)

Bypass Lever (LH Shown)

MOWING RECOMMENDATIONS

1. Keep mower blades sharp.

2. Make sure deck and discharge chute are clean.

WARNING

TO AVOID SERIOUS INJURY FROM BLADE

CONTACT, POWER MUST BE OFF TO

CLEAN DISCHARGE CHUTE

DANGER

KEEP HANDS AND FEET AWAY FROM UNDERNEATH MOWER TO AVOID SERIOUS INJURY

OR DEATH.

WARNING

ROTARY MOWERS CAN DISCHARGE OBJECTS

AT HIGH SPEEDS. TO AVOID SERIOUS INJURIES

OR DEATH:

ll

OPERATE ONLY WITH SIDE BANDS IN

GOOD REPAIR AND CHUTE OR GRASS

CATCHER ATTACHMENT INSTALLED.

ll

KEEP CHILDREN, PETS, AND

BYSTANDERS AWAY FROM THE WORK

AREA.

ll

DO NOT OPERATE MOWER IN THE VICINITY OF OTHER PERSONS.

ll

DISCHARGE AWAY FROM BUILDINGS,

WALLS OR OTHER STRUCTURES.

14

Page 17

SECTION III

MAINTENANCE

CAUTION

BEFORE PERFORMING ANY MAINTENANCE, TURN OFF ENGINE, REMOVE KEY AND DISCONNECT SPARK

PLUGS. USE EXTREME CARE WHEN WORKING ON MACHINERY. DO NOT WEAR WATCH OR JEWELRY. DO

NOT WEAR LOOSE FITTING CLOTHES, AND OBSERVE ALL COMMON SAFETY PRACTICES WITH TOOLS.

BEFORE PERFORMING ANY SERVICE, MAINTENANCE OR REPAIR ON THE ENGINE, REFER TO THE RESPECTIVE ENGINE MANUFACTURERS’ MANUAL FOR SPECIFIC INFORMATION CONCERNING YOUR PARTICULAR BRAND OF ENGINE.

MAINTENANCE SCHEDULE

SERVICE WHEN

Check crankcase oil level before each use

Check air intake screen after each use

Clean grass from under deck after each use

Check tire pressure every 10 hours

Sharpen mower blades every 10 hours

Clean air filter element every 8 hours

IMPORTANT:

Check 20W50 motor oil

in hydrostatic system every 10 hours

Check drive belts every 50 hours

(20 hr break-in)

Grease blade spindles every 50 hours

Grease front wheels every 50 hours

Change engine every 50 hours

crankcase oil and filter (5 hrs break-in)

Change hydrostatic oil filter (See your Bush Hog Dealer)

Important: Substitution of an improper filter will cause every 500 hours

hydrostatic failure which will not be covered under warranty (50 hrs break-in)

Replace air

filter element annually or 500 hours

Check spark plugs annually or 100 hours

Service battery annually or 500 hours

Perform these maintenance procedures more frequently under extremely dusty, dirty conditions.

Replace decals when illegible. Write parts dept. for free replacement.

WARNING: Your mower is equipped with a ROPS, make sure seat frame retention click-pins are in place

after lifting seat pan for service.

15

Page 18

1. ENGINE:

For complete maintenance and operating information for your engine, please refer to your

engine operating and maintenance instructions

furnished by the engine manufacturer and

included in your Zero Turn mower information packet.

NOTE

Air intake screen must be kept clean. If

plugged, engine may be seriously damaged by over heating.

2. TACHOMETER / HOURMETER

The tachometer / hourmeter includes a

Flash Alert feature to remind you to change

engine oil and filter at recommended intervals. The tachometer displays engine rpm

when the engine is running and elapsed time

in hours when the engine is turned off.

Oil Change Flash Alert Break In:

Service Alert will be CHG OIL: Period is 5 HRS

with 1 hour gentle reminder. Alert fr equency

every 10 seconds, occurs when en gine is running or off. Service Alert will automaticly reset

after CHG OIL...now has flashed for 1 hour of engine run time (resets to normal interval).

4. TIRES:

Correct tire pressure is essential for efficient

operation of the mower. Check tire air pres-

sure periodically. Inflate front and rear tires to 15 psi.

(Rear tires may be inflated to 12 psi if additional ride

comfort is desired)

Lug bolts should be checked regularly for

tightness. Torque lug bolts to 59 ft./lbs.

5. MOWER BLADES:

Check sharpness of mower blades after every 10

hours of operation. To sharpen blades proceed as

follows:

WARNING

WHEN IT IS NECESSARY TO RAISE THE DECK

OR MOWER FOR SERVICE OR MAINTENANCE,

TO AVOID SERIOUS INJURY OR DEATH, STOP

ENGINE, SET PARKING BRAKE, REMOVE IGNITION KEY AND SPARK PLUG WIRES AND SECURELY SUPPORT THE DECK OR MOWER

BEFORE WORKING UNDERNEATH.

A. Lift deck and secure in raised position.

B. Remove bolt, cup washer, and blade from shaft.

New Blade

Normal:

Service Alert will be CHG OIL: Perid with 1 hour

gentle reminder, Alert frequency is every 10 seconds, occurs when engine is running or off.

Service Alert will automatically reset after CHG

OIL... now has flashed for 1 hour of engine run

time.

3. BATTERY:

When taking the battery out of the mower for

servicing, make sure to reconnect the cables to

the battery exactly as they were prior to removal.

Keep the battery clean. Remove the corrosion

around the battery terminals by applying a solution of one part baking soda to four parts water.

Coat all exposed terminal surfaces with a light

layer of grease or petroleum jelly to prevent corosion.

NOTE

At temperatures below 32 degrees F (0 deg

C) the full charge state must be maintained to

prevent cell electrolyte from freezing and

causing permanent battery damage.

WARNING

ll

ll

ll

AVOID SERIOUS INJURY OR DEATH:

THE BATTERY CONTAINS SULFURIC ACID.

AVOID CONTACT WITH SKIN, EYES OR CLOTHING.

EYES - FLUSH WITH WATER AND GET PROMPT MEDICAL ATTENTION.

ANTIDOTE: INTERNAL - DRINK LARGE QUANTITIES

OF WATER OR MILK. FOLLOW WITH MILK OF MAGNESIA, BEATEN EGG OR VEGETABLE OIL. CALL A

PHYSICIAN IMMEDIATELY.

BATTERIES PRODUCE EXPLOSIVE GASES.

KEEP SPARKS, FLAMES AND SMOKING MATERIALS AWAY. VENTILATE WHEN CHARGING IN AN

ENCLOSED SPACE. WEAR EYE PROTECTION

WHEN WORKING NEAR BATTERIES.

KEEP OUT OF REACH OF CHILDREN.

25 Degrees

When Notch Starts

Discard Blade

Dangerous!

C. Blades should be discarded when worn excessively. See sketch.

D. Sharpen blade with a hand file, electric grinder

or blade sharpener. Wear gloves and eye protec

tion when sharpening. Grind blade at original bevel.

E. Check balance of blade by positioning the blade

on a nail or blade balance pedestal. Grind the blade

on the end that is heavier until both sides balance.

F. Install blades with the concave side of the cup

washer against blade. Be sure blades are installed

with uplifts and cutting edges in the proper directions. Tighten retaining bolt to 76 ft./lbs.

WARNING

WHEN IT IS NECESSARY TO RAISE THE DECK

OR MOWER FOR SERVICE OR MAINTENANCE,

TO AVOID SERIOUS INJURY OR DEATH, STOP

ENGINE, SET PARKING BRAKE, REMOVE IGNITION KEY AND SPARK PLUG WIRES AND SECURELY SUPPORT THE DECK OR MOWER

BEFORE WORKING UNDERNEATH.

6. CLEANING GRASS BUILD UP UNDER DECK

Depress the deck lift foot pedal and lock in position, then

move the height adjustment pin to the 4-1/2”

position.

Lift the front of the unit and support unit securely.

Clean out any grass build up from underside of deck and

in deck discharge chute.

16

Page 19

MOTION CONTROL LEVER ADJUSTMENT

1. There are three lever height positions available.

Place the levers in the position that provides the

most confortable operating position for you.

2. Align the levers front/rear position. With the

levers in the neutral position, loosen the hardware and adjust the levers by tilting forward or

backward until properly aligned. tighten hardware.

6. Re-tighten the nuts at the end of the hex

turnbuckles and repeat the procedure for

the opposite side of the unit.

7. Shut the unit off. Remove the jumper wire from

the wiring harness and replace the connectors

into the seat switch. Never operate the mower

unless all safety switches are operating properly.

DRIVE ADJUSTMENTS

Steering and motion controls should be uniform in all

forward and reverse speeds. From the reverse position the levers should automatically return to neutral

when released.

CAUTION

STOP THE ENGINE BEFORE MAKING ADJUSTMENTS.

TEST DRIVE OPERATIONS

Check air pressure in tires. Equal tire pressure is critical for proper drive operation.

1. Raise drive wheels off ground. Safely block

the frame in this position.

Lever Position Adjustment Bolts

MOTION CONTROL STEERING ADJUSTMENT

1. Raise the drive wheels of the Zero Turn

off of the ground. Safely block the frame

in this position so it is secure. This

adjustment must be made with the drive

wheels turning.

2. Remove the electrical connection from

the seat switch and temporarily install a

jumper wire across the terminals of the

wiring harness.

3. Loosen the jamnuts on the hex turnbuckle,

which connects the lever control arm to

the pump control arm. Note: The nuts to

the front of the hex turnbuckle have lefthanded threads.

4. Start the engine. Run the engine at full

throttle and release brake.

2. Put control levers in neutral lock position

(control levers swung outward).

3. Start engine. Wheels should not rotate. If one or

both drive wheels are turning, perform procedures under “Motion Control Adjustment” for

side(s) that wheel turns.

Control Arm

Hex Turnbuckle

Jamnut

5. Position the control levers in the neutral

position. If the drive wheels creep

(rotate) in the neutral position then

lengthen or shorten the turnbuckle

assembly. Make the adjustment to stop

the wheel from rotating.

Control Arm Lever

Pump

Control Arm

17

Page 20

LEVELING THE DECK AND SETTING THE

COUNTERBALANCE SPRING TENSION

CAUTON

STOP THE ENGINE, SET PARKING BRAKE, REMOVE IGNITION KEY AND SPARK PLUG WIRES

FOR SAFETY.

55” Deck-Spring length of 16”. 61” DeckSpring length of 15-1/2” for 3” cutting height. For

lower cutting heights loosen springs at 1/4” intervals until stop hits adjusting pin in correct

height location. If deck floats, loosen springs at

1/4” intervals until deck stops floating. (Measure

from back of flatwasher to back of flatwasher)

1. Set all tire pressures to the correct specifications.

2. Rest machine on a level slab of concrete.

3. Depress the deck lift pedal to raise the deck to the

full lift height position and move the height adjust

pin to the 4.5” position.

4. Take all the force off the two deck lift springs by

loosening the nut at the front of each spring.

5. Place a level on the deck, from front to rear. If the

level is too short to reach all the way from front to

rear, lay a straight edge on the deck first, then

place the level on the straight edge.

6. Lay a .12” spacer beneath the front level. this will

automatically set the rear of the deck higher than

the front.

7. Adjust the bolts in the slot to raise the rear of the

deck (Shown below) until the level’s bubble is centered. Repeat for the other side.

8. Check to verify the deck is leveled side-to-side. To

do this, lay a 2” x 4” x 30” piece of wood under

each side of the deck and lower the deck to rest

freely on the top of these boards. Inspect the (4)

lift chains to see if tension is on each of them. If

any of the chains appear slack, adjust the bolt in

the slot to remove the slack from the chain.

9. Raise the deck up to the transport position and

lock in place.

10. Remove the 2” x 4”s from under the deck.

11. Tighten each of the counterbalance spring nuts

until springs are to the following lengths:

DECK BELT ADJUSTMENT

Belt adjustment should be checked every 50 hours to

get maximum life and cutting performance from the

mower. Belt tension is adjusted by increasing or decreasing the length of the spring on the movable idler.

For proper belt tension on the 55” and 61” mowers,

the spring length should be set to 7” inside hook to inside hook with the deck in 3” cutting height position.

To adjust the spring length, loosen or tighten the 3/8”

hex nuts on the eye bolt until the correct spring length

is reached.

DECK BELT REPLACEMENT

SE ONLY GENUINE Bush Hog REPLACEMENT PARTS

U

A. Remove the deck shield assembly.

B. Relieve the spring tension by loosening the two

3/8” hex nuts on the eye bolt.

C. Remove old belt.

D. Install new belt. Be sure that the belt is properly

positioned in all sheave grooves.

E. Adjust tension on the belt by adjusting the length

of the spring on the moveable idler. The correct

spring length is 7” for the 55” and 61” decks.

F. Replace the deck shield assembly.

DECK SPINDLE BELT ROUTING DIAGRAM

Front Of Deck

.12” Spacer At Front End

Height

Adjustment Pin

Deck

Lift Pedal

Deck Lift Spring Adjustment Nut

Bolt In Slot

Level on

Mower Deck

Upper

Chain Fastener

Deck

Shield

Deck

”

7

(Measure from inside of

Spring Loaded

Idler Assembly

Engine/Clutch Pulley

WARNING

TO AVOID SERIOUS BURN INJURIES:

ll

ALLOW ENGINE, OIL AND HYDRAULIC FLUIDS TO COOL BEFORE SERVICING TRANSMISSION OR ENGINE SYSTEM

CAUTION

TO AVOID CLEANING SOLVENT FIRES:

ll

AVOID USING FLAMMABLE SOLVENTS.

ll

AVOID AREAS WITH IGNITION SOURCES

18

WHEN USING FLAMMABLE SOLVENTS.

hook to inside of hook)

Page 21

WARNING

HIGH PRESSURE HYDRAULIC FLUID LEAKS

CAN PENETRATE SKIN CAUSING SERIOUS INJURY AND GANGRENE.

INJECTED FLUID MUST BE SURGICALLY REMOVED WITHIN A FEW HOURS BY A DOCTOR

FAMILIAR WITH THIS TYPE OF INJURY.

TO AVOID SERIOUS INJURY FROM

PRESSURE LEAKS:

l USE CARDBOARD AND NOT HANDS TO

SEARCH FOR LEAKS.

l RELIEVE HYDRAULIC PRESSURE BEFORE

WORKING ON SYSTEM.

l CHECK HYDRAULIC HOSES, LINES, AND

CONNECTIONS FOR TIGHTNESS AND

GOOD CONDITION BEFORE APPLYING

SYSTEM PRESSURE.

Place the steering levers in the neutral position and

open the bypass valve. Slowly move the steering

levers in both the forward and reverse directions to

purge the air from the closed circuit.

Close the bypass valve and run the unit in both directions for several minutes until any remaining air is

purged from the unit. Refill the reservoir as necessary.

Stop the engine, check for and correct any fluid leaks,

and check the reservoir level. Add fluid if necessary.

The transmission is now ready for operation.

HYDROSTATIC MAINTENANCE

Check the reservoir daily for proper fluid level. Oil level

should be to the cold fill line on the reservoir baffle.

START-UP MAINTENANCE

HYDROSTATIC FLUID

Bush Hog recommends the use of 20W50 motor oil in

the hydrostatic reservoir.

START-UP PROCEDURE

WARNING

TO AVOID INJURY FROM EQUIPMENT GROUND

TRAVEL AND MOVEMENT DURING

START-UP PROCEDURE:

DO NOT START OR JOG ENGINE UNTIL:

l PUMP IS IN NEUTRAL POSITION

l DRIVE WHEELS ARE RAISED OFF THE

GROUND.

l EQUIPMENT IS SECURELY BLOCKED-UP TO

KEEP WHEELS FROM GROUND CONTACT.

l PTO AND OTHER WORK FUNCTIONS ARE

DISCONNECTED.

l KEEP HANDS, HAIR AND CLOTHING AWAY

FROM ROTATING BLADES.

The following start-up procedure should always be followed when starting a new installation or when restarting an installation in which the transaxle has been

removed from the system or when oil has been

changed in the transaxle.

The hydrostatic transaxle units normally do not require

regular fluid changes. The system filter should be

changed after the first 50 hours of break-in, then every

500 hours thereafter. The fluid and filter should be

changed and the system cleaned if the fluid becomes

contaminated with foreign matter (water, dirt, etc.)

.Refer to illustration on page 20.

PARKING BRAKE ADJUSTMENT

(Refer to next page for illustration and instructions for Parking

Brake Cable Replacement / Installation)

Check to make sure brake is adjusted properly.

Force on the brake handle to lock the brake in place

should be 15 pounds. To adjust the brake tension,

shorten or lengthen the brake cable linkage.

If further adjustment is needed at each individual wheel

brake:

1. Engage the brake lever (lever up).

2. Remove the wheel from the side needing adjusting.

Loosen brake adjusting nuts, remove excess slack from

cable and retighten nuts.

3. Reinstall the wheel and torque the lug nuts.

Prior to starting the transaxle, make certain all system

components (reservoir, fittings, etc.) are clean prior to

filling with fluid.

Fill the reservoir with recommended fluid which should

be filtered prior to entering the reservoir.

Start the engine and idle at the lowest possible RPM.

With the bypass valve closed, slowly move the displacement control in both the forward and reverse directions. As air is purged from the unit, the oil level in

the reservoir will drop and bubbles may appear in the

fluid. Refill the reservoir as necessary.

Pump Drive Belt Tension Adjustment

1. Stop engine and remove key.

2. The pump drive belt tension is adjusted through a

spring loaded idler pulley.

3. Adjust the eye bolt so the spring length is 7” (measured to the inside of the spring loops).

19

Page 22

PARKING BRAKE CABLE REPLACEMENT / INSTALLATION

OUTSIDE BRAKE ARMS

1. The outside brake arms are to remain in the position as received from the factory. (Horizontal and

rearward)

2. Install brake cables finger tight and position the brake handle in the “vertical” position.

3. Open left and right relief valves on the pumps by pulling the RH and LH levers to the rear and lock

out in the keyway slot to disengage for free wheeling. (See photo on page 14)

4. Install the brake cable spring onto the brake arm. (Note: the spring should be positioned to the outside of the brake arm.)

RH Brake Cable

RH Outside Brake Arm

Brake Handle

(Shown in Horizontal Position)

Tension Rod

LH Brake Cable

Brake Cable

Adjusting Nuts

Hydrostatic Oil Filter

LH Outside Brake Arm

Brake Cable

Adjusting Nuts

20

Page 23

TROUBLESHOOTING CHECK LIST

1. ENGINE IDLES POORLY:

Carburetor maladjustment readjust carburetor

Improper spark plug gap check and re-gap plug

2. ENGINE BACKFIRES:

Carburetor maladjustment readjust carburetor

3. ENGINE RUNS BUT POWER UNIT WON’T MOVE FORWARD

Drive belt loose or broken re-tension or replace

Pump shift arm disconnected reconnect

Hydrostatic reservoir oil low add oil

Pump bypass valve open put in closed position

Hydrostatic oil filter plugged replace filter

Bad transaxle consult dealer

4. POWER UNIT LOSES POWER OR HYDROSTAT SYSTEM OVERHEATS

Hydrostatic oil reservoir too low add oil

Transaxle damaged consult dealer

Hydrostatic oil reservoir blowing oil out cap overfilled or water contaminated

5. ENGINE STALLS WHEN BLADES ARE ENGAGED

Operator not on seat sit on seat

Faulty interlock system consult dealer

Bad blade spindle bearing consult dealer

Deck drive belt not properly routed reroute

Blades blocked by foreign material clean under deck

•See engine manual for engine adjustments

ENGINE ELECTRICAL TROUBLE

1. ENGINE WILL NOT TURN OVER:

Dead battery

Bad ground connection

Bad terminal connection at battery

Wiring harness plugs are not attached properly at

the key switch or the PTO switch

Bad parking brake switch

Bad PTO switch

2. ENGINE WILL TURN OVER,

BUT WILL NOT START:

A. If there is spark at the plug:

No fuel

Bad fuel solenoid in engine

B. If there is no spark at the plug:

Make sure safety interlock system is sequenced:

PTO switch is off

Control levers in neutral position

Parking brake is on

Operator in seat

Check safety interlock switches:

Seat switch

Neutral switch

Bad ignition module on engine

POOR CUTTING PERFORMANCE

* ENGINE SPEED IS TOO SLOW:

Always mow at full throttle.

* BELT SLIPPAGE:

Tighten deck adjusting spring on the 55” or 61”

deck to 7”.

* DECK IS PLUGGED WITH GRASS:

Clean underneath the mower.

* BLADES ARE NOT SHARP:

Sharpen the blades or replace.

* CUTTING HEIGHT:

Normal mowing - cut only 1/3 of the grass blade.

* FINISHED CUT IS UNEVEN:

Groundspeed is too fast.

* BLADES ARE WORN DOWN TOO FAR:

Replace your blades.

21

Page 24

SECTION IV

ASSEMBLY

MOUNTING THE REAR TIRES

Position the rear tire rims over the axle hubs and fasten with the 1/2” lug nuts. Torque to 59 ft. lbs.

Control Lever

MOUNTING THE CONTROL LEVERS

Mount the control levers to the 3/4” x 3/4” square bars

positioning the control levers to the preferred height

and mount with 3/8” x 1” fasteners, lock washers, and

flat washers. Move the control levers forward or rearward for operator comfort.

ROPS

Insert the ROPS frame into the channels in the ZT

frame so the upper folding portion angles forward

above the operators seat. Attach with the 1/2” x 3-1/4”

fasteners and locknuts.

MOUNTING THE SEAT

Mount seat and mounting plate assembly to the mainframe using the fasteners installed in the seat mount

lugs on the mainframe. Attach the seat limit rod to the

left side of the seat mounting plate, use the cotter pin

and flatwasher supplied.

Seat and Mounting Plate Assembly

Seat

Limit

Rod

ROPS

Upper folding

portion angles

forward above

the operators

seat.

Park Brake Lever

Seat

Safety

Wires

Battery

Attach the seat safety wires to the seat switch.

BATTERY

Attach the positive lead to the battery.

Additional wire tie straps are shipped to secure the

wiring harness as needed.

ITEMS TO CHECK:

Check oil level in the engine (see engine manual)

Check the fluid level in the hydrostatic oil reservoir.

Check tightness of all fasteners, including bolts, lug

nuts, and setscrews.

Check tire pressure.

Seat Mount Lugs and Fasteners

22

Page 25

Models with Kohler Engines require Harness adapter 50068129

WIRING DIAGRAM FOR TORNADO SERIES ZERO TURN MOWERS

Note: Models with Kawasaki Engines require Harnes adapter 50068725

23

Page 26

50068725 HARNESS ADAPTER

KAWASAKI ENGINES

50068133 Oil Pressure Lead for Kawasaki Engines

To Main

Harness

50068129 HARNESS ADAPTER

KOHLER ENGINES

To Engine Harness

To Solenoid

To Main Harness

24

Page 27

To promote safe operation, Bush Hog supplies safety decals on all products manufactured. Because damage can

SAFETY DECALS

occur to safety decals either through shipment, use or reconditioning, Bush Hog will, upon request, provide safety

decals for any of our products in the field at no charge. Contact your authorized Bush Hog dealer for more information.

83056

50043277

25

94132

50012615

D859

Page 28

50043279

SERIOUS INJURY

OR DEATH MAY

RESULT FROM

MACHINE ROLLOVER

•

Failure to follow these

instructions could result

in serious injury or death.

• Do not operate machine on

steep slopes or near drop offs.

• Avoid sharp and/or quick turns.

• Do not exceed the machine

weight rating of the rops.

• Always use seat belt.

• Do not jump if machine tips.

• If ROPS is foldable

°

Always keep the ROPS fully extended.

°

WHEN ROPS MUST BE DOWN-

°

Do not use seat belt.

°

Drive with extra care.

•

If equipped with seat platform,

Do not operate machine without

seat platform pins in place.

50048632

50029501

50048632

50043280

94134

26

Page 29

Wrench

Size “A”

AMERICAN

Bolt Head Markings

SAE Grade 2

(No Dashes)

SAE Grade 5

(3 Dashes)

SAE Grade 8

(6 Dashes)

TORQUE SPECIFICATIONS

Proper toque for American fasteners used on Bush Hog equipment.

Recommended Torque in Foot Pounds (Newton Meters).*

BOLT DIAMETER

Bolt

Diameter “B”

WRENCH (IN.) “B” AND SAE SAE SAE

SIZE (IN.) “A” THREAD SIZE GRADE 2 GRADE 5 GRADE 8

7/16 1/4 2O UNC 6 (7) 8 (11) 12 (16)

7/16 1/4 28 UNF 6 (8) 10 (13) 14 (18)

1/2 5/16 18 UNC 11 (15) 17 (23) 25 (33)

1/2 5/16 24 UNF 13 (17) 19 (26) 27 (37)

9/16 3/8 16 UNC 20 (27) 31 (42) 44 (60)

9/16 3/8 24 UNF 23 (31) 35 (47) 49 (66)

5/8 7/16 14 UNC 32 (43) 49 (66) 70 (95)

5/8 7/16 20 UNF 36 (49) 55 (75) 78 (106)

3/4 1/2 13 UNC 49 (66) 76 (103) 106 (144)

3/4 1/2 20 UNF 55 (75) 85 (115) 120 (163)

7/8 9/16 12 UNC 70 (95) 109 (148) 153 (207)

7/8 9/16 18 UNF 79 (107) 122 (165) 172 (233)

15/16 5/8 11 UNC 97 (131) 150 (203) 212 (287)

15/16 5/8 18 UNF 110 (149) 170 (230) 240 (325)

1 1/8 3/4 10 UNC 144 (195) 266 (360) 376 (509)

1 1/8 3/4 16 UNF 192 (260) 297 (402) 420 (569)

1 5/16 7/8 9 UNC 166 (225) 430 (583) 606 (821)

1 5/16 7/8 14 UNF 184 (249) 474 (642) 668 (905)

1 1/2 1 8 UNC 250 (339) 644 (873) 909 (1232)

1 1/2 1 12 UNF 274 (371) 705 (955) 995 (1348)

1 1/2 1 14 UNF 280 (379) 721 (977) 1019 (1381)

1 11/16 1 1/8 7 UNC 354 (480) 795 (1077) 1288(1745)

1 11/16 1 1/8 12 UNF 397 (538) 890 (1206) 1444 (1957)

1 7/8 1 1/4 7 UNC 500 (678) 1120 (1518) 1817 (2462)

1 7/8 1 1/4 12 UNF 553 (749) 1241 (1682) 2013 (2728)

2 1/16 1 3/8 6 UNC 655 (887) 1470 (1992) 2382 (3228)

2 1/16 1 3/8 12 UNF 746 (1011) 1672 (2266) 2712 (3675)

2 1/4 1 1/2 6 UNC 870 (1179) 1950 (2642) 3161 (4283)

2 1/4 1 1/2 12 UNF 979 (1327) 2194 (2973) 3557 (4820)

METRIC

Bolt

Diameter “B”

Wrench

Size “A”

*Use 75% of the specified torque value for plated fasteners. Use 85% of the specified torque values for lubricated fasteners.

8.8

Numbers appearing on bolt heads

indicate ASTM class.

Proper torque for metric fasteners used on Bush Hog equipment.

Recommended torque in foot pounds (Newton Meters).*

WRENCH BOLT

SIZE DIA. ASTM ASTM ASTM ASTM

(mm) “A” (mm) “B” 4.6 8.8 9.8 10.9

851.8 (2.4) 5.1 (6.9) 6.5 (8.8)

10 6 3 (4) 8.7 (12) 11.1 (15)

13 8 7.3 (10) 21.1 (29) 27 (37)

16 10 14.5 (20) 42 (57) 53 (72)

18 12 25 (34) 74 (100) 73 (99) 93 (126)

21 14 40 (54) 118 (160) 116 (157) 148 (201)

24 16 62 (84) 167 (226) 181 (245) 230 (312)

30 20 122 (165) 325 (440) 449 (608)

33 22 443 (600) 611 (828)

36 24 211 (286) 563 (763) 778 (1054)

41 27 821 (1112) 1138 (1542)

46 30 418 (566) 1119 (1516) 1547 (2096)

27

Page 30

EC SERIES

ZERO TURN RIDING MOWERS

Optional Equipment:

Canopy Kit

Light Kit

Rear Hitch Kit

Mulching Kit 55”

Mulching Kit 61”

Deck Caster Wheel Kit (61” Deck)

28

Page 31

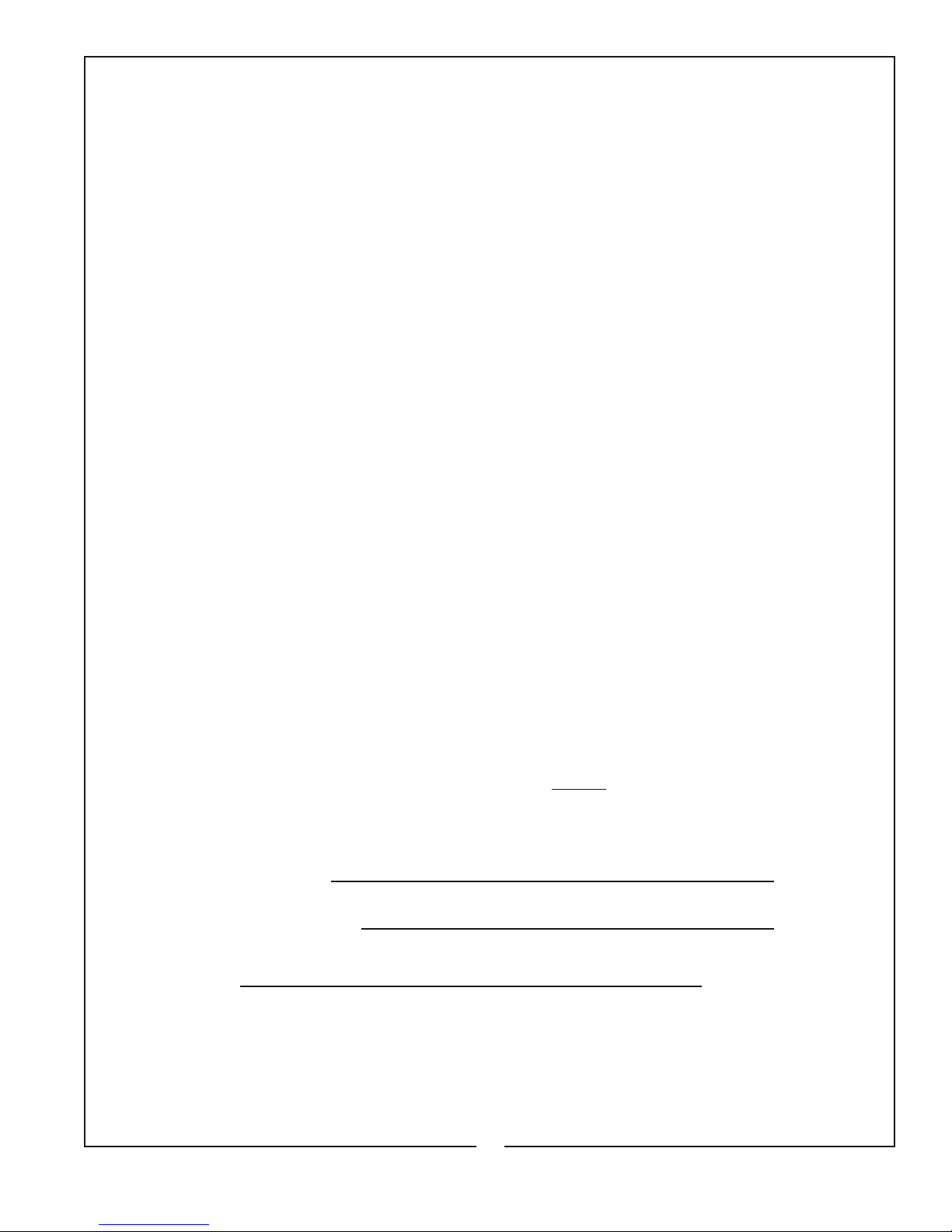

SLOPE ANGLE GUIDE

ALIGN THIS EDGE WITH A VERTICAL SURFACE

(TREE. BUILDING, FENCE POST. POLE, ETC.)

THIS I

S A 5°

SLOPE

THIS I

S

A 10° SLOPE

T

H

I

S

I

S

A

1

5

°

SL

O

P

E

FOLD ALONG APPROPRIATE LINE

EXAMPLE: COMPARE

SLOPE WITH FOLDED

EDGE

29

Page 32

Page 33

TO THE OWNER/OPERATOR/DEALER

To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions

and the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can

easily find the information you need.

The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety

requirements of tractor operators:

REQUIRED OF THE OWNER:

1. Provide a Roll-Over-Protective Structure that meets the requirements of this Standard; and

2. Provide Seat belts that meet the requirements of this paragraph of this Standard and SAE J4C; and

3. Ensure that each employee uses such Seat belt while the tractor is moving; and

4. Ensure that each employee tightens the Seat belt sufficiently to confine the employee to the protected

area provided by the ROPS

REQUIRED OF THE OPERATOR:

1. Securely fasten seat belt if the tractor has a ROPS.

2. Where possible, avoid operating the tractor near ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going - especially at row ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly - no jerky turns, starts, or stops.

8. Hitch only to the drawbar and hitch points recommended by the tractor manufacturer.

9. When the tractor is stopped, set brakes securely and use park lock, if available.

x Keep children away from danger all day, every day...

x Equip tractors with rollover protection (ROPS) and keep

all machinery guards in place...

x Please work, drive, play and live each day with care

and concern for your safety and that of your family and

fellow citizens.

Page 34

Loading...

Loading...