Burr Brown Corporation DDC101U Datasheet

20-BIT ANALOG-TO-DIGITAL CONVERTER

DDC101

DESCRIPTION

The DDC101 is a precision, wide dynamic range, charge

digitizing A/D converter with 20-bit resolution. Low

level current output devices, such as photosensors, can be

directly connected to its input. The most stringent accuracy requirements of many unipolar output sensor applications occur at low signal levels. To meet this requirement, Burr-Brown developed the adaptive delta modulation architecture of the DDC101 to provide linearly

improving noise and linearity errors as the input signal

level decreases. The DDC101 combines the functions of

current-to-voltage conversion, integration, input programmable gain amplification, A/D conversion, and digital

filtering to produce precision, wide dynamic range results. The input signal can be a low level current connected directly into the unit or a voltage connected

through a user selected resistor. Although the DDC101 is

optimized for unipolar signals, it can also accurately

digitize bipolar input signals. The patented delta modula-

tion topology combines charge integration and digitization functions. Oversampling and digital filtering reduce

system noise dramatically. Correlated Double Sampling

(CDS) captures and eliminates steady state and conversion cycle dependent offset and switching errors that are

not eliminated with conventional analog circuits.

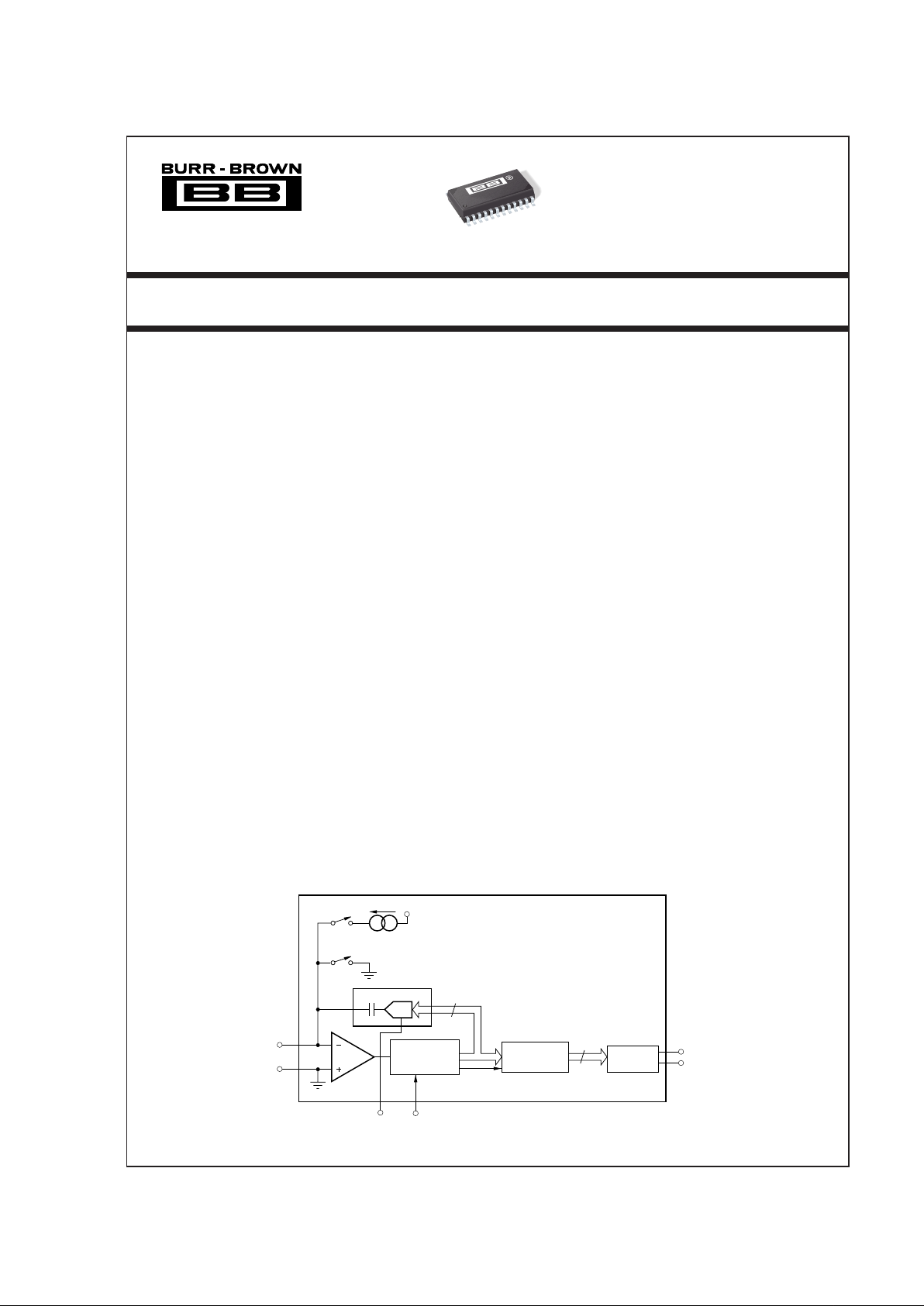

The DDC101 block diagram is shown below. During

conversion, the input signal is collected on the internal

integration capacitance for a user determined integration

period. A high precision, autozeroed comparator samples

the analog input node. Tracking logic updates the internal

high resolution D/A converter at a 2MHz rate to maintain

the analog input at virtual ground. A user programmable

digital filter oversamples the tracking logic’s output. The

digital filter passes a low noise, high resolution digital

output to the serial I/O register. The serial outputs of

multiple DDC101 units can be easily connected together

in series or parallel if desired to minimize interconnections.

● MONOLITHIC CHARGE INPUT ADC

● DIGITAL FILTER NOISE REDUCTION:

0.9ppm, rms

● DIGITAL ERROR CORRECTION: CDS

● CONVERSION RATE: Up to 15kHz

● USER FRIENDLY EVALUATION FIXTURE

APPLICATIONS

FEATURES

● DIRECT PHOTOSENSOR DIGITIZATION

● PRECISION INSTRUMENTATION

● INFRARED PYROMETRY

● PRECISION PROCESS CONTROL

● CT SCANNER DAS

● CHEMICAL ANALYZERS

C

INT

Digital Integration,

Tracking and

Control Logic

Digital Filter and

Error Correction

Serial I/O

Register

Serial In

Serial Out

Reset

DAC

CDAC

DDC101 Integrated Circuit

Comparator

V

REF

Analog

Input

Ground

Setup

Oversampled

Digital Out

18 Bits

20 Bits

Test In

+V

S

Test Current

©

1993 Burr-Brown Corporation PDS-1211E Printed in U.S.A. March, 1998

®

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111 • Twx: 910-952-1111

Internet: http://www.burr-brown.com/ • FAXLine: (800) 548-6133 (US/Canada Only) • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

DDC101

®

DDC101

2

TABLE OF CONTENTS

Section 1 ............. Basic Theory of Operation

2 ............. Specifications

3 ............. Pin Descriptions

4 ............. Timing Diagrams

5 ............. Discussion of Specifications

6 ............. Detailed Theory of Operation

7 ............. Applications Information

8 ............. Mechanical

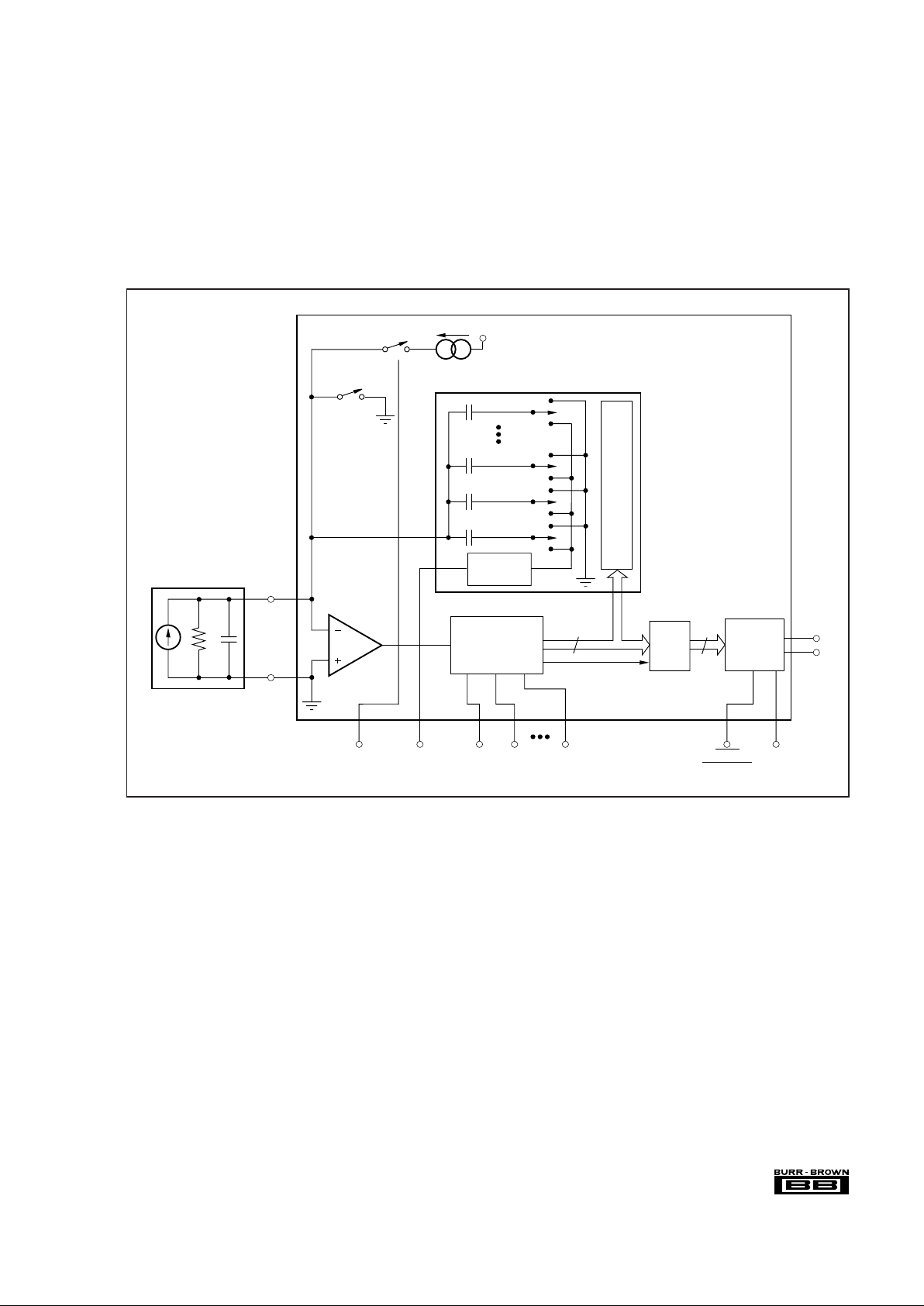

The second block diagram, Figure 2, shows the DDC101

circuit architecture which implements these functions

monolithically. During each conversion, the input signal

current is collected on the internal integration capacitance,

C

INT

, as charge for a user determined integration period, T

INT

.

As the integration capacitor collects input charge, the tracking logic updates the internal high resolution D/A converter

at a 2MHz rate to maintain the analog input node at virtual

ground.

The digital filter oversamples the tracking logic’s output at

the beginning and end of each integration period to produce

two oversampled data points. The DDC101 measures the

charge accumulated in the integration and performs correlated double sampling (CDS) by subtracting these two data

points. CDS eliminates integration cycle dependent errors

such as charge injection, offset voltage, and reset noise since

these errors are measured with the signal at each of the two

data points. The number of oversamples, and thus the frequency response of the digital filter, is user programmable.

The digital filter passes a low noise, high resolution digital

output to the serial I/O register. Since the timing control of

the serial I/O register is independent of the DDC101 conversion process, the outputs of multiple DDC101 units can be

connected together in series or parallel to minimize interconnections.

SECTION 1

BASIC THEORY OF OPERA TION

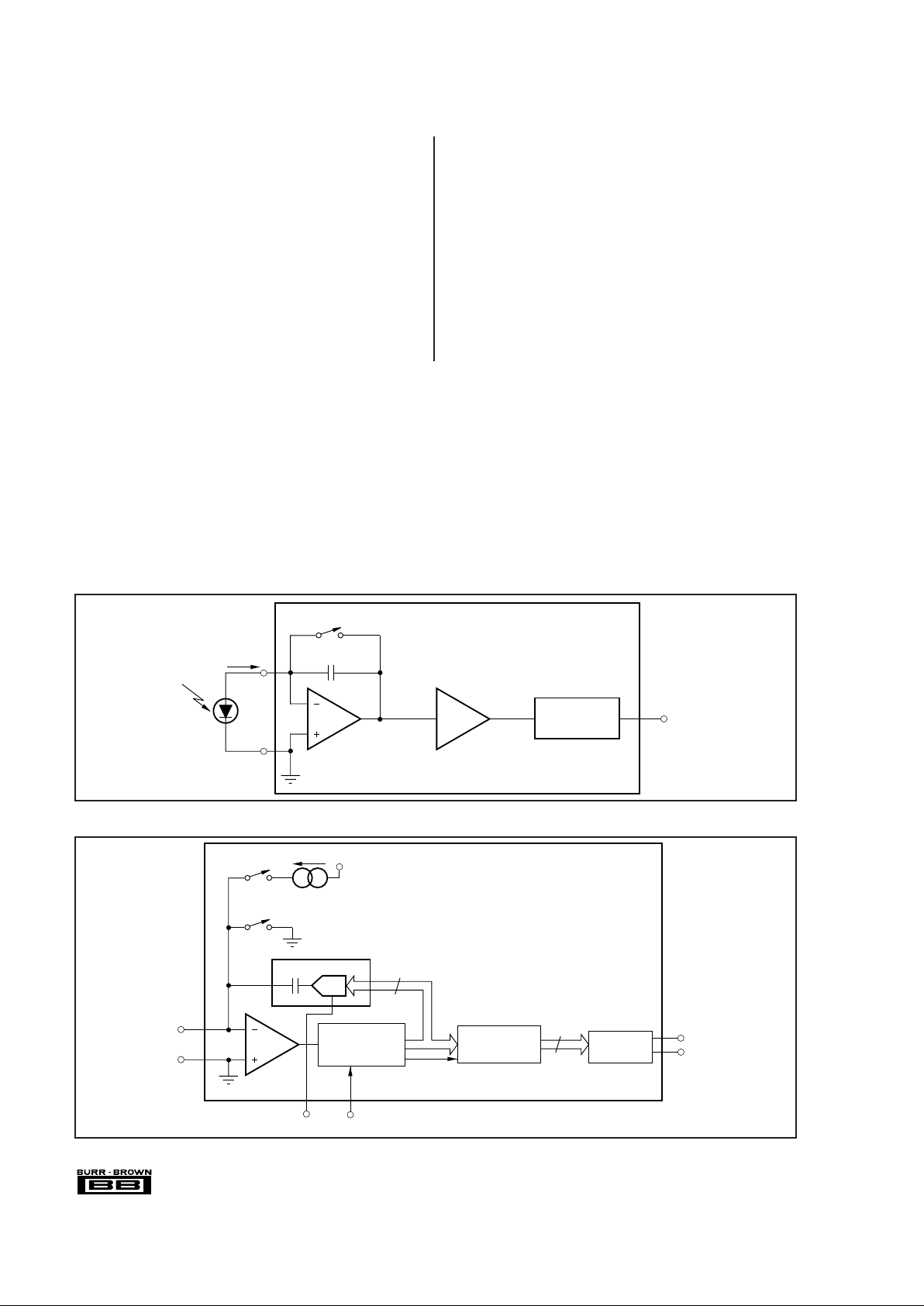

The basic function of the DDC101 is illustrated in the

Simplified Equivalent Circuit shown in Figure 1. The operation is equivalent to the functions performed by a very high

quality, low bias current switched integrator followed by a

precision floating point programmable gain amplifier and

ending with a high resolution A/D converter.

FIGURE 1. Simplified Equivalent Circuit of DDC101 to Illustrate Function.

FIGURE 2. DDC101 Block Diagram.

C

INT

Digital Integration,

Tracking and

Control Logic

Digital Filter and

Error Correction

Serial I/O

Register

Serial In

Serial Out

Reset

DAC

CDAC

DDC101 Integrated Circuit

Comparator

V

REF

Analog

Input

Ground

Setup

Oversampled

Digital Out

18 Bits

20 Bits

Test In

+V

S

Test Current

C

INT

Data Out

Reset

Switched Integrator

Programmable Gain

Amplifier

A/D Converter

and Control Logic

Sensor

i Signal

3

DDC101

®

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN

assumes no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject

to change without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not

authorize or warrant any BURR-BROWN product for use in life support devices and/or systems.

An internal test current source is provided for basic functionality testing and diagnostics. This approximately 100nA

current source is pin activated and sums with the external

input current.

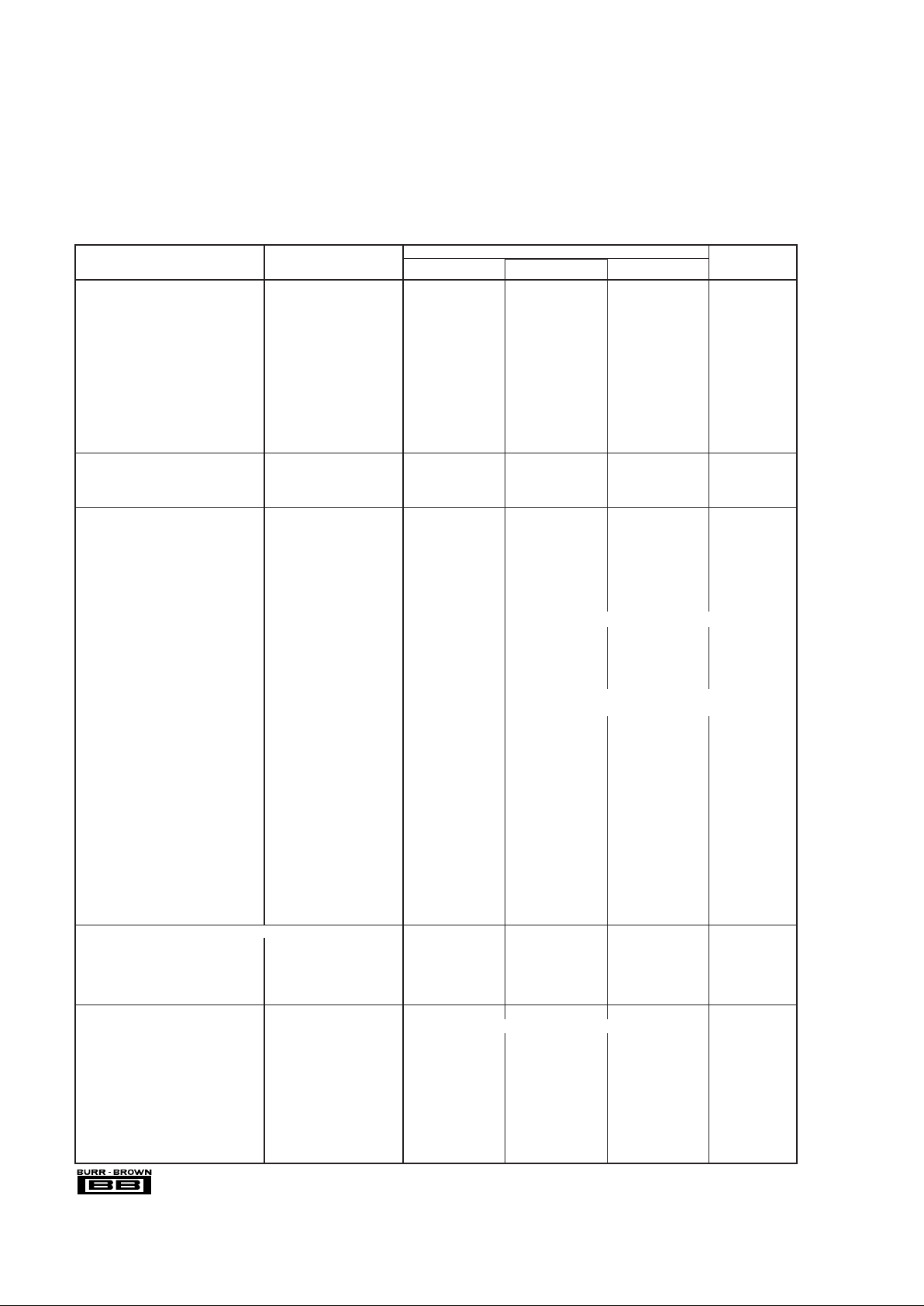

Figure 3 shows a more detailed circuit configuration of the

DDC101. The single integration capacitor, C

INT

, and the

D/A converter have been replaced with a high resolution

Capacitor Digital-to-Analog Converter (CDAC). By switching between ground and V

REF

the binary weighted capacitor

array of the CDAC accumulates the input signal’s charge to

keep the comparator input at virtual ground.

FIGURE 3. DDC101 Detailed Circuit Diagram.

Reset

Comparator

Sensor

Serial I/O

Register

DATA

INPUT

DATA

OUTPUT

High

Resolution

Digital Out

3rd Order Digital

Integration,

Tracking and

Control Logic

Digital

Filter

Oversampled

Digital Out

C

INT

Buffer

V

REF

SYSTEM

CLOCK

System Control DATA

CLOCK

DATA

TRANSMIT

CDAC

DDC101

+V

S

Test Current

TEST

In

ANALOG

In

ANALOG

COMMON

18 Bits

20 Bits

®

DDC101

4

SECTION 2

SPECIFICATIONS

ELECTRICAL

All specifications with unipolar current input range, T

INT

= 1ms, correlated double sampling enabled, System Clock = 2MHz, V

REF

= –2.5V, TA = +25°C and VS = ±5VDC,

unless otherwise noted.

DDC101

PARAMETER CONDITIONS MIN TYP MAX UNITS

INPUTS

Charge Input

(6)

Unipolar Input Range BTC Output Code –1.95 500 pC/Integration

Bipolar Input Range BTC Output Code –251.95 250 pC/Integration

Input Current Unipolar or Bipolar Range 7.8 µA

Current Input Range Examples

(10)

Unipolar Input Range T

INT

= 100µs –0.0195 5 µA

Unipolar Input Range T

INT

= 1ms –1.95 500 nA

Bipolar Input Range T

INT

= 100µs –2.5195 2.5 µA

Bipolar Input Range T

INT

= 1ms –251.95 250 nA

Voltage Input Examples

(10)

Unipolar Input Range

(2)

RIN = 10MΩ, T

INT

= 1ms –0.0195 5 V

Bipolar Input Range

(2)

RIN = 10MΩ, T

INT

= 1ms –2.5195 2.5 V

DYNAMIC CHARACTERISTICS

Conversion Time 64 256 x 10

6

µs

Integration Time 64 10

6

µs

System Clock Input 0.5 2 MHz

ACCURACY

Unipolar Mode Noise

Noise, Low Level Current Input

(1)

C

SENSOR

= 0pF, L = 8 0.9 ppm of FSR, rms

(3)

Noise, Low Level Current Input

(1)

C

SENSOR

= 0pF, L = 1 1.6 ppm of FSR, rms

Noise, Low Level Current Input

(1)

C

SENSOR

= 100pF, L = 1 2.1 3 ppm of FSR, rms

Noise, Low Level Current Input

(1)

C

SENSOR

= 500pF, L = 1 4.2 ppm of FSR, rms

Noise, Voltage Input

(1, 2)

RIN ≥ 20MΩ 1.9 ppm of FSR, rms

Differential Linearity Error

Unipolar Input Range Entire Range ±0.005% Reading ±0.5ppm FSR, max

0.1% FSR Input ±0.00006 % of FSR

1% FSR Input ±0.00010 % of FSR

10% FSR Input ±0.00055 % of FSR

Unipolar or Bipolar Input Range ±0.0015 % of FSR

Integral Linearity Error

Unipolar Input Range

(11)

0 to 500 pc/Integration ±0.0244% Reading ±2.5ppm FSR, max

–1.95 to 0 pc/Integration ±0.0244% Reading ±3.0ppm FSR, max

0.1% FSR Input ±0.00028 % of FSR

1% FSR Input ±0.00050 % of FSR

10% FSR Input ±0.0027 % of FSR

Unipolar or Bipolar Input Range

(11)

±0.003 % of FSR

No Missing Codes

Unipolar Input Range 18 Bits

Bipolar Input Range 16 Bits

Input Bias Current T

A

= +25°C310pA

DC Gain Error ±0.5 ±2 % of FSR

Output Offset Error

(8)

±0.5 ppm of FSR

Input Offset Voltage

(8)

±0.5 ±2mV

External Voltage Reference, V

REF

–2.5 VDC

Internal Test Signal 100 nA

Internal Test Signal Accuracy ±20 nA

Gain Sensitivity to V

REF

V

REF

= 2.5V ±0.1V 1:1

PSRR 80 90 dB

PERFORMANCE OVER TEMPERATURE

Output Offset Drift

(8)

not including bias current drift 0 µV/°C

Input Offset Voltage Drift

(8)

1 µV/°C

Input Bias Current Drift +25°C to +45°C 0.1 0.5 pA/°C

Input Bias Current T

A

= +85°C840pA

Gain Drift

(4)

±15 ppm/°C

DIGITAL INPUT/OUTPUT

Logic Family TTL Compatible CMOS

Logic Level: V

IH

IIH = +5µA +2.0 +V

CC

V

V

IL

IIL = +5µA –0.3 +0.8 V

V

OH

IOH = 2 TTL Loads +2.4 +V

CC

V

V

OL

IOL = 2 TTL Loads 0.0 0.4 V

Data Clock

Data I/O 8 MHz

SETUP Code I/O

(9)

4 MHz

Data Format

Straight Binary Unipolar or Bipolar Range 20 Bits

Two’s Complement Unipolar or Bipolar Range 21 Bits

5

DDC101

®

SPECIFICATIONS (CONT)

ELECTRICAL

All specifications with unipolar current input range, T

INT

= 1ms, correlated double sampling enabled, System Clock = 2MHz, V

REF

= –2.5V, TA = +25°C and VS = ±5VDC,

unless otherwise noted.

DDC101

PARAMETER CONDITIONS MIN TYP MAX UNITS

POWER SUPPLY REQUIREMENTS

Operation

(5)

±4.75 ±5 ±5.25 VDC

Quiescent Current, Positive Supply V

S

+ = +5VDC, VDD+ = +5VDC 15.6 19.5 mA

Analog, V

S

+ 8.9 mA

Digital, V

DD

+ 6.7 mA

Quiescent Current, Negative Supply V

S

– = –5VDC 18.0 22.5 mA

Operating Power 170 mW

TEMPERATURE RANGE

Operating –40 +85 °C

Storage –60 +100 °C

NOTES: (1) Input = low level (less than 1% of Full Scale); Full Scale I

IN

= 500nA; T

INT

= 1ms; Unipolar Input Range; Acquisition Time = 16 clock cycles, Oversampling = 128. (2) Voltage input is converted through user

provided input resistor, R

IN

. (3) FSR is Full Scale Range. (4) Gain Drift does not include the drift of the external reference. (5) V

DD

+ must be less than or equal to VS+. See Section 7 for recommended connections. (6)

Straight Binary output code has slightly different Charge Range. See Section 6. (8) Input offset voltage is nulled by autozero circuitry and causes no output error. See Section 6 (Internal Error Correction). (9) This is

the maximum clock frequency at which SETUP codes can be written to and read from the DDC101. (10) For other input current and voltage configurations, see Discussion of Specifications and Detailed Theory of Operation

sections. (11) A best-fit straight line method is used to determine linearity. Two different best-fit straight lines are used for the two unipolar integral linearity specifications. Acquisition Time = 16 clock cycles, Oversampling

= 128.

Analog Inputs

Input Current ............................................................ 100mA, momentary

Input Current .............................................................. 10mA, continuous

Input Voltage ................................................... V

S

+ +0.5V to VS– –0.5V

Power Supply

V

S

+ .................................................................................................. + 7V

V

S

– ....................................................................................................–7V

V

DD

+ ................................................................................. must be ≤ VS+

Maximum Junction Temperature ................................................... +165°C

ABSOLUTE MAXIMUM RATINGS

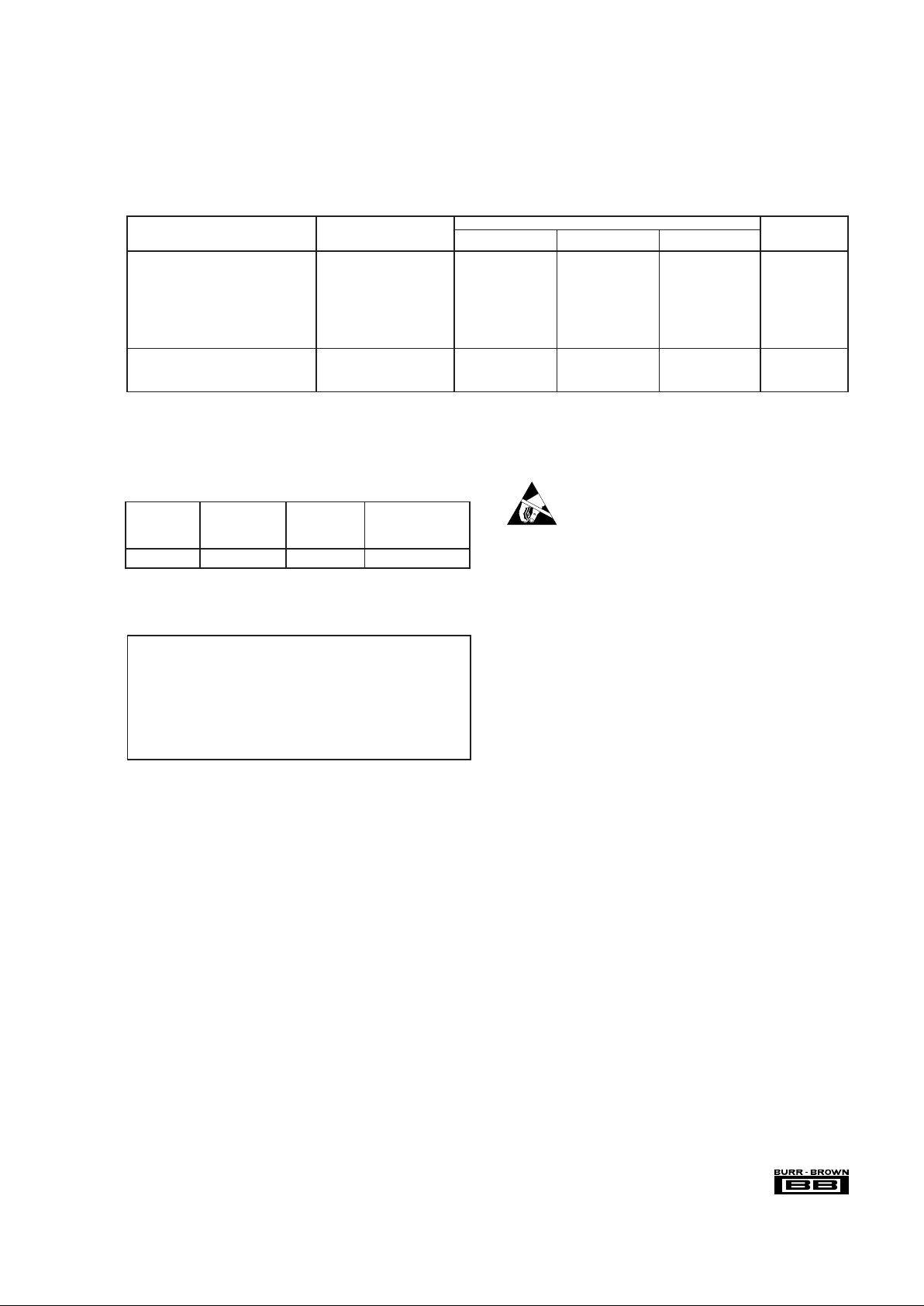

PACKAGE/ORDERING INFORMATION

PACKAGE THERMAL

DRAWING RESISTANCE (

θ

JA

)

PRODUCT PACKAGE NUMBER

(1) (°C/W)

DDC101U 24-Lead SOIC 239 100

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix C of Burr-Brown IC Data Book.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with appropriate precautions. Failure to observe proper handling and

installation procedures can cause damage.

ESD damage can range from subtle performance degradation

to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric

changes could cause the device not to meet published

specifications.

®

DDC101

6

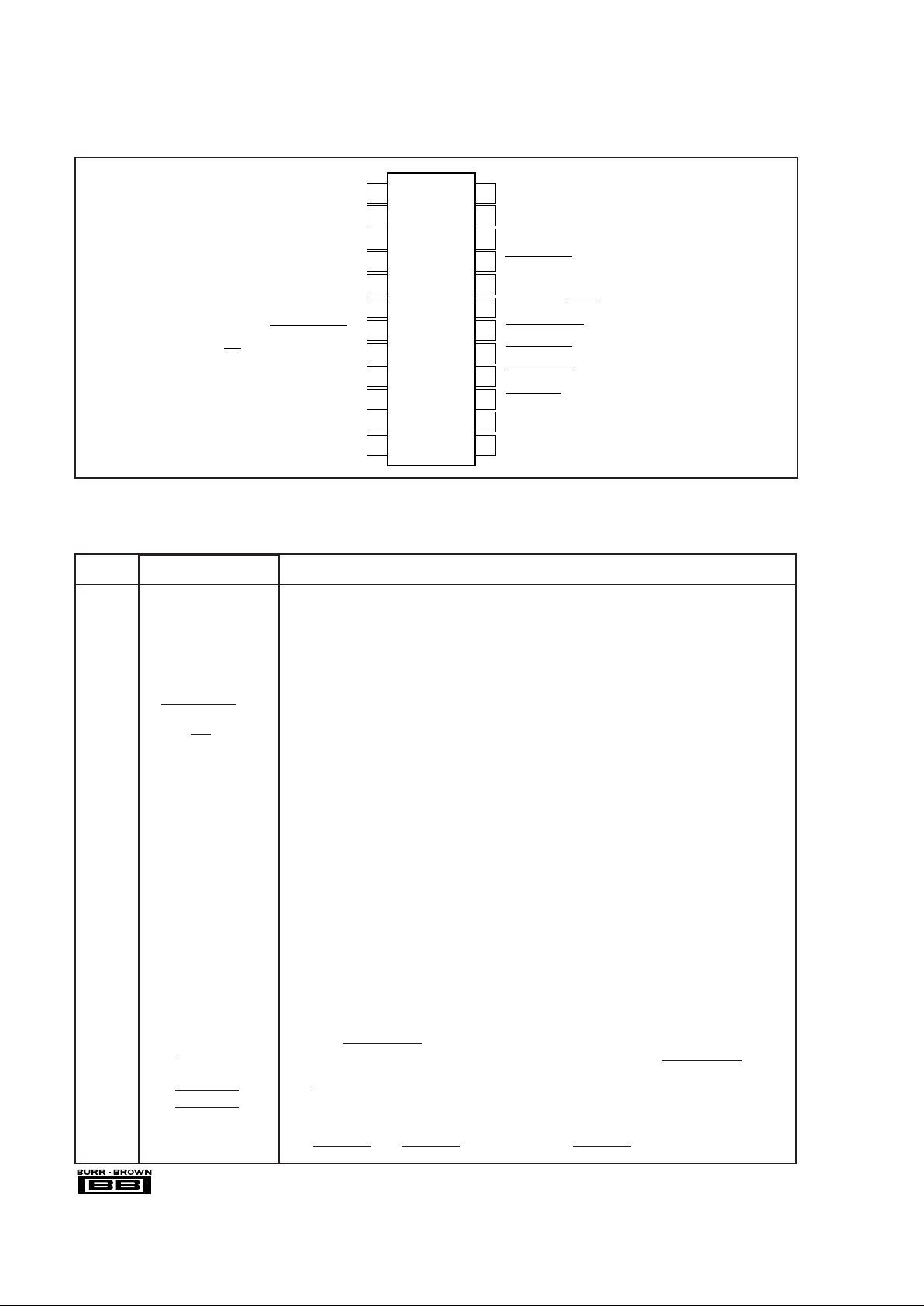

PIN CONFIGURATION

Top View 24-Lead SOIC

SECTION 3

PIN DESCRIPTIONS

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

REFERENCE BUFFER BYPASS

V

REF

TEST In

RESET SETUP In

SETUP

READ DATA/SETUP

DATA TRANSMIT In

OVERFLOW + Out

OVERFLOW – Out

DATA VALID Out

DATA OUTPUT

DIGITAL GROUND

V

S

–, ANALOG

ANALOG COMMON

ANALOG In

ANALOG COMMON

V

S

+, ANALOG

V

S

+, ANALOG

RESET SYSTEM In

FDS (Final Data Point Start) In

SYSTEM CLOCK

DATA CLOCK

DATA INPUT

V

DD

+, DIGITAL

PIN

NUMBER NAME DESCRIPTION

1V

S

–, ANALOG Negative analog power supply voltage, –5VDC.

2 ANALOG COMMON Analog ground point.

3 ANALOG INPUT Input for low level current signal. Photosensor can be directly connected to this input. With a resistor in series,

DDC101 will convert a voltage input.

4 ANALOG COMMON Analog ground point.

5V

S

+, ANALOG Positive analog power supply voltage, +5VDC. Hardwire to pin 6.

6V

S

+, ANALOG Positive analog power supply voltage, +5VDC. Hardwire to pin 5.

7 RESET SYSTEM In This input resets DDC101, but does not reset the SETUP register. The DDC101 system is reset when this pin

is active; reset action is removed when the pin is inactive.

8 FDS In This is Final Data point Start input. This input is the basic user control of the integration and conversion timing.

When it becomes active, the DDC101 starts collection of the M, final data point samples. The beginning of the

next integration time is exactly M system clock periods after the Final Data point Start command when operating

in the continuous mode.

9 SYSTEM CLOCK This clock input sets the basic sampling rate of the DDC101. The DDC101 is specified with a clock speed of

2MHz. The clock speed can be 0.5MHz to 2.0MHz.

10 DATA CLOCK This clock input controls the data transfer rate for the serial DATA INPUT and DATA OUTPUT ports. The DATA

CLOCK is independent of the SYSTEM CLOCK. This allows the DATA CLOCK to be operated at higher or lower

speeds than the SYSTEM CLOCK. For best noise performance, data should not be transmitted and the DATA

CLOCK should not be active during the initial and final data point collection. If data is being transmitted during

the initial and final data point collection periods, the DATA CLOCK should be synchronized to the SYSTEM

CLOCK, to minimize added noise. DATA CLOCK can be connected to SYSTEM CLOCK, so that the same clock

is used for both; however, for best noise performance, the DATA CLOCK input should be active only when data

is transmitted.

11 DATA INPUT This input can be used to “daisy chain” the output of several DDC101s together to minimize wiring. The output

register of the DDC101 acts as a shift register to pass through the output of previously connected DDC101 units.

In this way, multiple DDC101 units can convert simultaneously then sequence the data out serially on the same

data line with one common control line and one common data line for all DDC101 units.

12 V

DD

+, DIGITAL Digital power supply, +5VDC. VDD+ must be less than or equal to VS+.

13 DIGITAL GROUND Digital ground point.

14 DATA OUTPUT This output provides serial digital data clocked out at user controlled DATA CLOCK rate. Output data format

is a 21-bit Binary Two's Complement word or a 20-bit Straight Binary word. The data word is transmitted MSB

first. When DATA TRANSMIT is not active DATA OUTPUT tri-states.

15 DATA VALID This output is activated when conversion is complete and remains active until the DATA TRANSMIT input is

activated.

16 OVERFLOW– The OVERFLOW output signals each provide an open collector output so that the overflow outputs from several

17 OVERFLOW+ DDC101s can easily be connected (wire ORed) together to a common pull-up resistor. They are activated when

the input is beyond the acceptable range during conversion. Specifically, they are activated when the internal

D/A converter input or digital filter exceeds full scale. They are Cleared at the end of conversion 1/2 clock cycle

after DATA VALID high. DATA VALID can be used to capture OVERFLOW data into an external register.

7

DDC101

®

PIN DESCRIPTIONS (CONT)

PIN

NUMBER NAME DESCRIPTION

18 DATA TRANSMIT In This input controls the transmission of data from the serial I/O register of the DDC101. It can be activated

anytime after DATA VALID out becomes active. It must remain active until all data has been collected from the

serial I/O register(s) of all DDC101s in the data path.

19 READ DATA/ This input can be used to read back the current SETUP data. When this input is held high, the output from DATA

SETUP In OUTPUT is the data collected by the DDC101. When this input is pulled low, an internal shift register is loaded

with the current SETUP data on the rising edge of DATA CLOCK. This SETUP data shift register is logically

connected between DATA INPUT and DATA OUTPUT pins and can be read in the same way that the data

output is read. SETUP data read back does not invalidate data already stored in the DDC101's serial I/O register

or data being collected by the DDC101, although digital noise concerns should be considered as

discussed in DATA CLOCK.

20 SETUP In This input pin controls the DDC101 SETUP. A 12-bit digital word transmitted into this pin controls Acquisition

Time, K, Oversampling, M, Multiple Integrations, L, Input Range and Output Data Format. The DDC101 reads

the SETUP code at this pin after the RESET SETUP input transitions from active to inactive. The SETUP code

is read into the SETUP register on the 12 positive data clock transitions following that transition.

21 RESET SETUP Resets SETUP register only, does not reset balance of DDC101. The DDC101 reads SETUP input data after

this input transitions from active (reset) to inactive.

22 TEST In This is a digital input that controls the connection of an internal DC current source to the DDC101's input. TEST

In exercises the DDC101 and is intended to test for functionality only. The typical test input current is 100nA

±20nA. The quiescent current of the DDC101 increases by approximately 1mA when TEST In is active. When

TEST is HIGH, the internal current source is ON and current is flowing into the DDC101 input. When TEST is

LOW, the current source is disconnected from the input.

23 V

REF

An external –2.5V reference must be connected to the REFERENCE In pin. Use of an external reference allows

multiple DDC101s to use the same system reference for optimum channel matching. The external reference

should be filtered to minimize noise contribution (see Figure 24).

24 REFERENCE An external capacitor of 10µF should be connected to this node to provide proper operation of the internal

BUFFER BYPASS D/A converter. The REFERENCE In pin is connected to an internal reference buffer

amplifier. The internal reference buffer drives the internal CDAC. This buffer output is not intended for external

use.

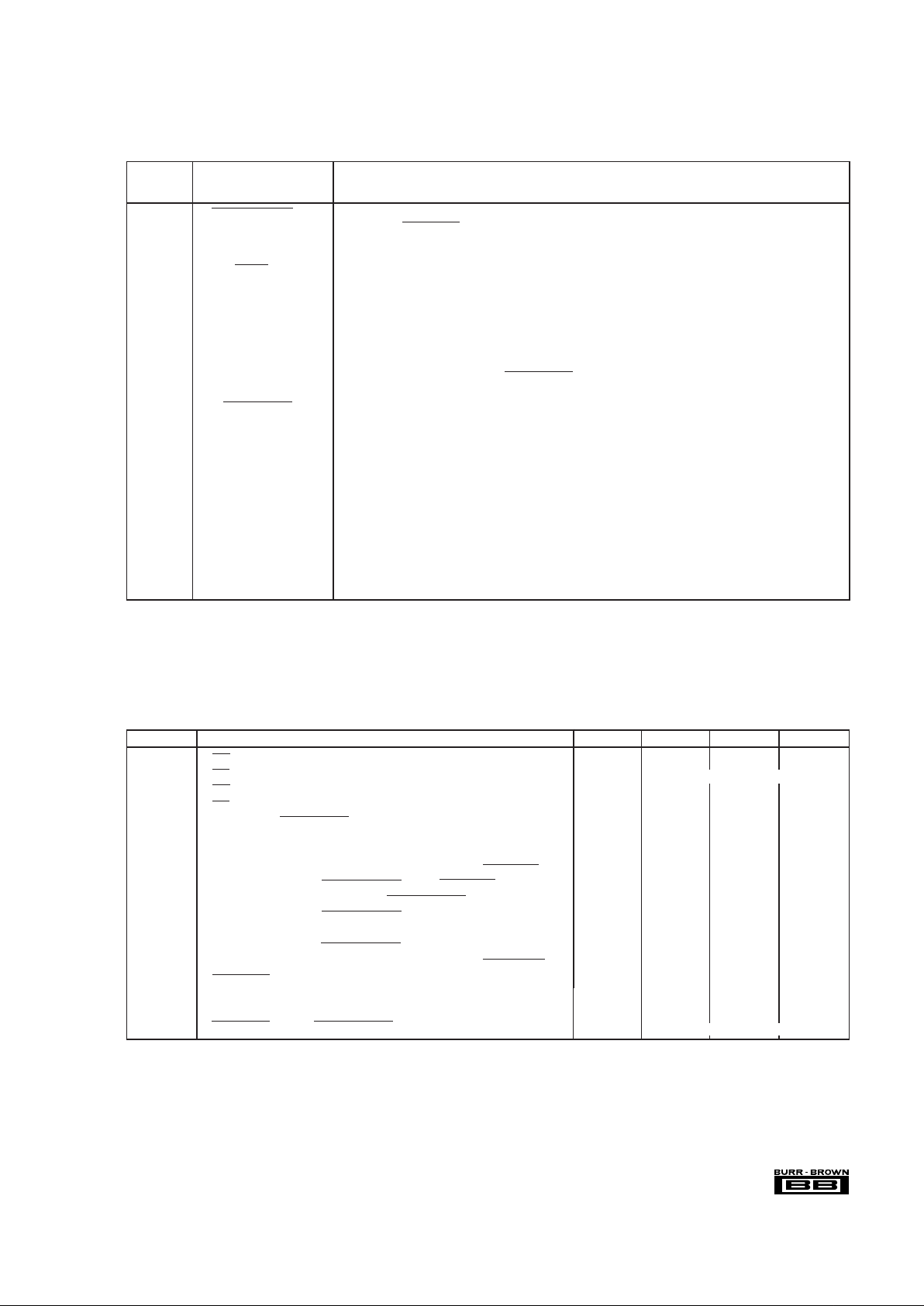

SECTION 4

TIMING CHARACTERISTICS

All specifications with Unipolar input range, T

INT

= 1ms, Current Input, Correlated Double Sampling enabled, Sys Clock = 2MHz, V

REF

= –2.5V, TA = +25°C and

V

S

= ±5VDC, unless otherwise noted.

SYMBOL DESCRIPTION MIN TYP MAX UNITS

t

1

FDS Setup 30 ns

t

2

FDS width, Continuous Conversion 50 (M–1) Clocks+t1+100ns ns

t

3

FDS width, Asynchronous Conversion M Clocks+t

1

ns

t

4

FDS HIGH to start of next integration, Asynchronous Conversion 50 ns

t

5

Setup time for RESET SETUP HIGH to DATA CLOCK HIGH 60 ns

t

6

Setup time for Setup Codes data valid before rising edge of DATA Clock 30 ns

t

7

Hold time for Setup Codes data valid after rising edge of DATA Clock 30 ns

t

8

Propagation delay from rising edge of SYSTEM CLOCK to DATA VALID LOW 50 ns

t

9

Propagation delay from DATA TRANSMIT LOW to DATA VALID HIGH 35 ns

t

10

Setup time for DATA CLOCK LOW to DATA TRANSMIT LOW 30 ns

t

11

Propagation delay from DATA TRANSMIT LOW to valid data out 30 ns

t

12

Hold time that Data output is valid after falling edge of DATA CLOCK 10 ns

t

13

Propagation delay from DATA TRANSMIT HIGH to Data Output tri-stated 40 ns

t

14

Propagation delay from falling edge of SYSTEM CLOCK to OVERFLOW+ and 25 ns

OVERFLOW–cleared

t

15

SYSTEM CLOCK pulse width HIGH 240 ns

t

16

SYSTEM CLOCK pulse width LOW 240 ns

t

17

DATA VALID LOW to DATA TRANSMIT LOW, Single DDC101 30 (LxN–21) Clocks ns

®

DDC101

8

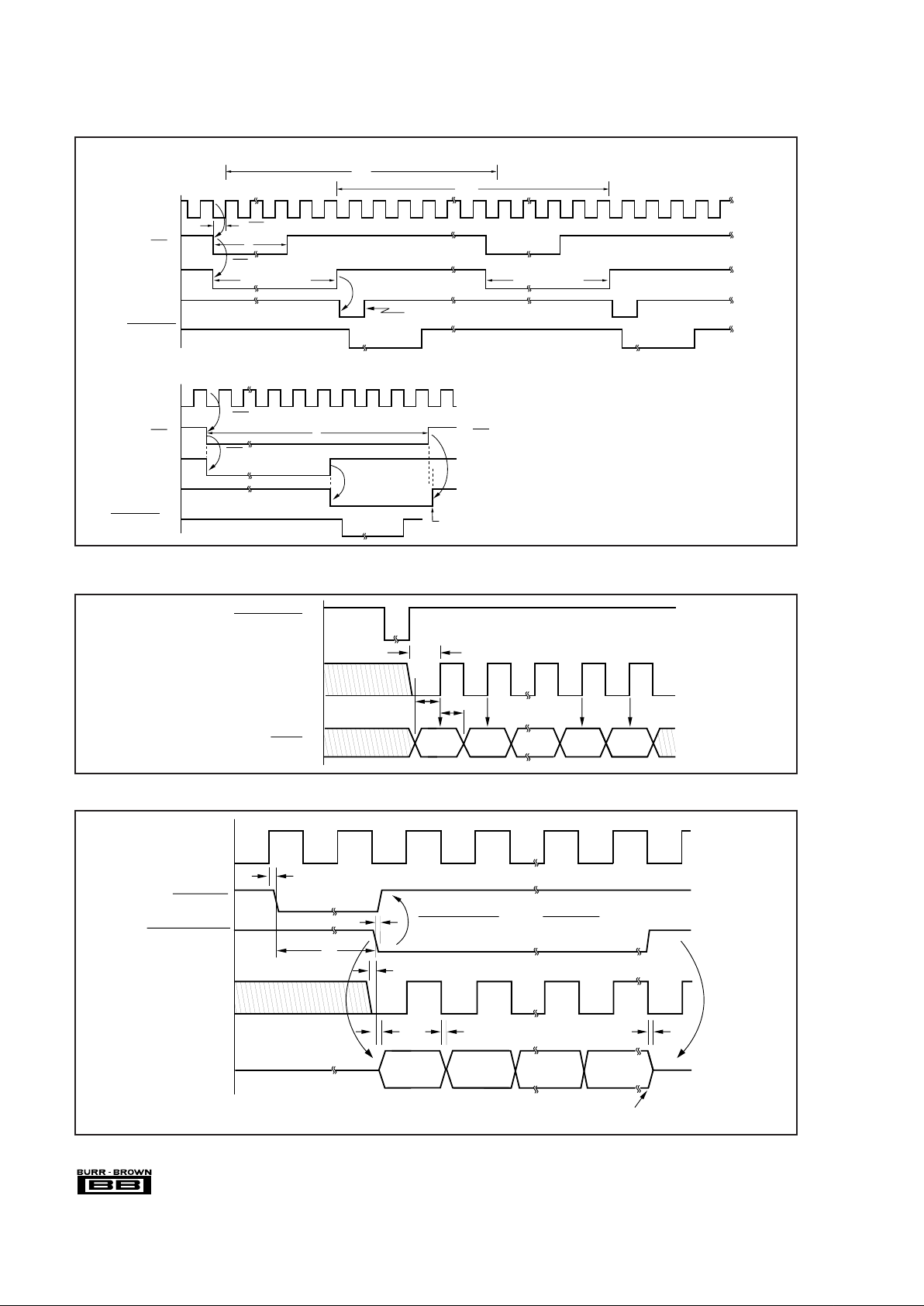

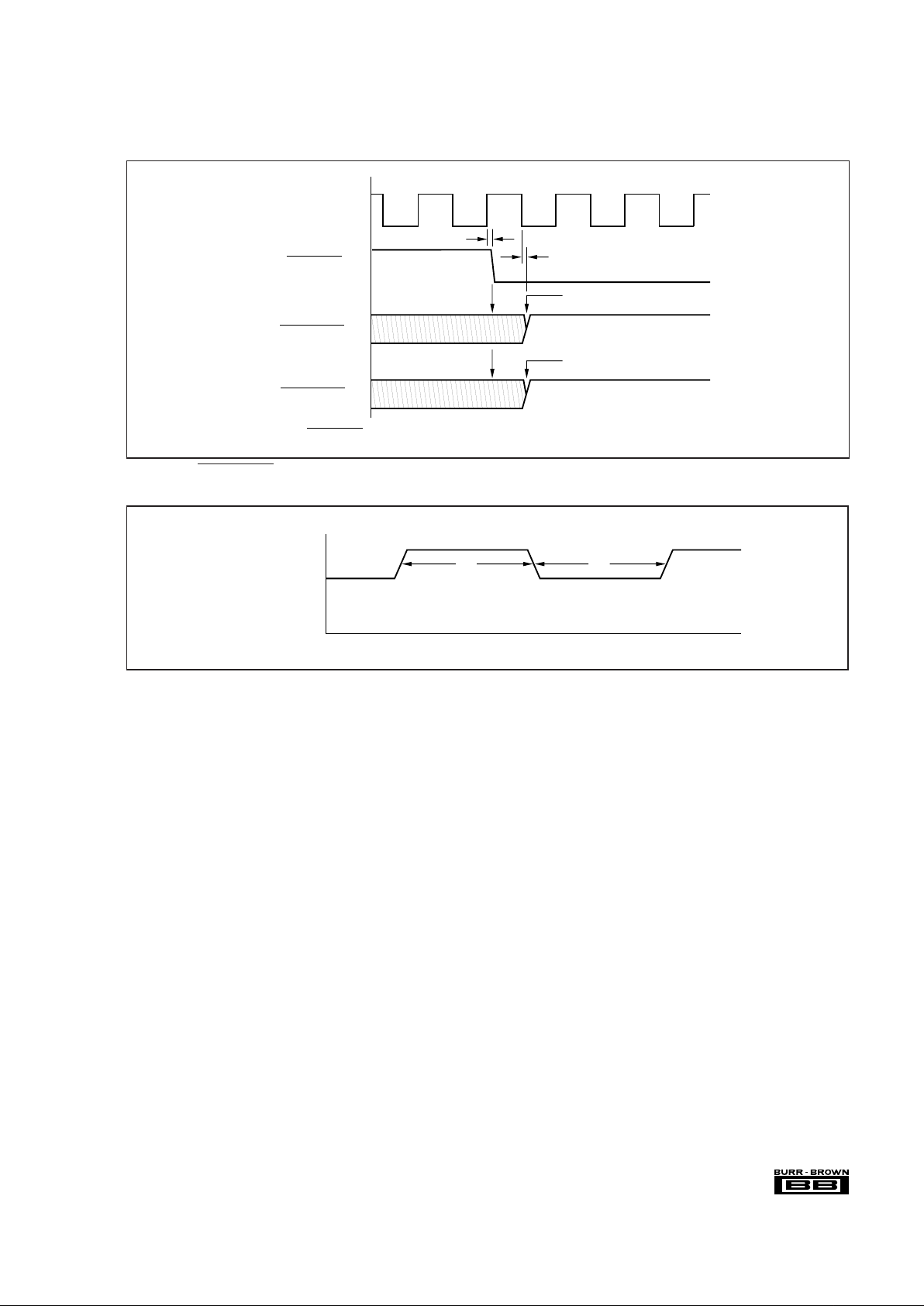

FIGURE 6. DATA TRANSMIT Timing Diagram.

FIGURE 4. Conversion Timing Diagrams.

Input

Range

Output

Format

SETUP In

DATA CLOCK

(4MHz, max for setup)

ACQ

LSB

t

5

RESET SETUP In

ACQ

MSB

Read Read Read Read

t

6

t

7

FIGURE 5. Input/Output Timing Diagram—SETUP Timing Diagram.

SYSTEM

CLOCK

DATA VALID

Out

DATA TRANSMIT

In

DATA OUTPUT

DATA CLOCK

(8MHz, max for data)

t

10

DDC(1)

Bit 1, MSB

DDC(n)

Bit 21, LSB

DDC

(n+1)

Bit 1

Output Disabled

Last DDC

Bit 21

Output Enabled

Output Disabled

t

12

Data can be read on rising or falling edge of Data Clock

DATA TRANSMIT In resets DATA VALID Out.

t

9

t

11

t

13

t

17

t

8

Continuous Integration Timing

Non-Continuous Integration Timing

SYSTEM

CLOCK

FDS In

Internal

Oversampling

Interval

Internal

Reset

SYSTEM

CLOCK

FDS In

Internal

Oversampling

Interval

Internal

Reset

FDS In should be coincident with negative clock.

FDS initiates oversampling period.

M Clock Periods

End of oversample period

initiates reset for next integration.

FDS In should be coincident with negative clock.

FDS initiates oversampling period.

End of FDS In

initiates end of Internal Reset.

End of oversample

period initiates

reset.

When Internal Reset period ends,

next integration begins.

DATA VALID

Out

t

2

t

1

t

3

DATA VALID Out

Next integration begins when 1 clock

period wide Internal Reset ends.

M Clock Periods

t

4

T

INT

'

T

INT

9

DDC101

®

TIMING DIAGRAMS (CONT)

FIGURE 7. OVERFLOW Out Monitoring Timing Diagram.

OVERFLOW – Out

OVERFLOW + Out

t

8

DATA VALID Out

Read

Read

Clear

SYSTEM CLOCK In

t

14

DATA VALID Out can be used to latch data from the overflow status outputs.

Clear

FIGURE 8. System Clock Timing.

t

15

SYSTEM CLOCK In

SYSTEM CLOCK

t

16

Loading...

Loading...