Page 1

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

SEIRESA9V RELIOB

nonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp,reliob

rebmuNledoMrelioB rebmuNlaireSrelioB etaDnoitallatsnI

A__9V_ _______6

rotcartnoCgnitaeH leuFfoepyT

sserddA rebmuNenohP

Commercial Boilers

3050579

8142958R19-2/11

www.burnhamcommercialcastiron.com

Price - $5.00

1

Page 2

2

Page 3

IMPORTANT INFORMATION - READ CAREFULLY

All boilers must be installed in accordance with National, State and Local Plumbing, Heating

and Electrical Codes and the regulations of the serving utilities. These Codes and Regulations

may differ from this instruction manual. Authorities having jurisdiction should be consulted

before installations are made.

In all cases, reference should be made to the following Standards:

USA BOILERS

A. Current Edition of American National Standard ANSI/NFPA 31, “Installation of Oil

Burning Equipment”, for recommended installation practices.

B. Current Edition of National Fuel Gas Code, NFPA 54/ANSI Z223.1.

C. Current Edition of American National Standard ANSI/NFPA 211, “Chimneys, Fireplaces,

Vents, and Solid Fuel Burning Appliances”, For Venting requirements.

D. Current Edition of American Society of Mechanical Engineers ASME CSD-1, “Controls and

Safety Devices for Automatically Fired Boilers”, for assembly and operations of controls

and safety devices.

E. All wiring on boilers installed in the USA shall be made in accordance with the National

Electrical Code and/or Local Regulations.

CANADIAN BOILERS

A. Current Edition of Canadian Standards Association CSA B139, “Installation Code for Oil

Burning Equipment", for recommended Installation Practices.

B. The equipment shall be installed in accordance with the current Installation Code for Gas

Burning Appliances and Equipment, CSA B149, and applicable Provincial Regulations for

the class; which should be carefully followed in all cases.

Authorities having jurisdiction should be consulted before installations are made.

C. All wiring on boilers installed in Canada shall be made in accordance with the Canadian

Electrical Code and/or Local Regulations.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death, serious

injury or substantial property damage.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

Indicates special instructions on installation,

operation, or maintenance which are important

but not related to personal injury hazards.

CAUTION

NOTICE

NOTICE

This boiler has a limited warranty, a copy of which is printed on the back of this manual.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are operating

properly when the installation is complete. The warranty for this boiler is valid only if the boiler has been

installed, maintained and operated in accordance with these instructions.

3

Page 4

DANGER

DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this or any other

appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal

injury or loss of life. Failure to follow all instructions in the proper order can cause personal injury or

death. Read and understand all instructions, including all those contained in component manufacturers

manuals which are provided with the appliance before installing, starting-up, operating, maintaining or

servicing this appliance. Keep this manual and literature in legible condition and posted near appliance

for reference by owner and service technician.

This boiler requires regular maintenance and service to operate safely. Follow the instructions contained

in this manual. Installation, maintenance, and service must be performed only by an experienced, skilled

and knowledgeable installer or service agency. All heating systems should be designed by competent

contractors and only persons knowledgeable in the layout and installation of hydronic heating systems

should attempt installation of any boiler. It is the responsibility of the installing contractor to see that all

controls are correctly installed and are operating properly when the installation is completed. Installation

is not complete unless a pressure relief valve is installed into the specied tapping located at the rear of

appliance - See Section III of this manual for details.

This boiler is suitable for installation on combustible ooring. Do not install boiler on carpeting. Do not

operate on oors where heat affected material is below.

Do not tamper with or alter the boiler or controls. Retain your contractor or a competent serviceman to

assure that the unit is properly adjusted and maintained.

Clean boiler at least once a year - preferably at the start of the heating season to remove soot and scale.

The inside of combustion chamber should also be cleaned and inspected at the same time.

Have Burner and Controls must be checked at least once a year or as may be necessitated.

Do not operate unit with jumpered or absent controls or safety devices.

Do not operate unit if any control, switch, component, or device has been subject to water.

Return water cannot be lower than 135°F for prolonged periods of time. Operation under these conditions will

result in sustained condensing within the combustion chamber and potentially reduce boiler longevity.

In addition, the return water cannot be introduced into the boiler if it is more than 40°F less than the idle

boiler temperature. Continued operation under these conditions may result in premature boiler failure

through thermal shock.

Example: A boiler that has been idle for some time since the last heat demand cycle may have it’s boiler

water temperature reduced to 150°F. The return temperature from the next zone activation cannot be

less than 110°F.

If the above conditions exist, an RTC (or similar type of control) system must be installed to protect

the boiler from sustained condensing operation and thermal shock. See separate RTC Manual, P/N

8146382.

4

Page 5

WARNING

Appliance materials of construction, products of combustion and the fuel contain alumina, silica, heavy

metals, carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful substances which

can cause death or serious injury and which are known to the state of California to cause cancer, birth

defects and other reproductive harm. Always use proper safety clothing, respirators and equipment when

servicing or working nearby the appliance.

This boiler contains very hot water under high pressures. Do not unscrew any pipe ttings nor attempt

to disconnect any components of this boiler without positively assuring the water is cool and has no

pressure. Always wear protective clothing and equipment when installing, starting up or servicing this

boiler to prevent scald injuries. Do not rely on the pressure and temperature gauges to determine the

temperature and pressure of the boiler. This boiler contains components which become very hot when

the boiler is operating. Do not touch any components unless they are cool.

This appliance must be properly vented and connected to an approved vent system in good condition.

Do not operate boiler with the absence of an approved vent system.

This boiler needs fresh air for safe operation and must be installed so there are provisions for adequate

combustion and ventilation air.

The interior of the venting and air intake systems must be inspected and cleaned before the start of the

heating season and should be inspected periodically throughout the heating season for any obstructions.

Clean and unobstructed venting and air intake systems are necessary to allow noxious fumes that could

cause injury or loss of life to vent safely and will contribute toward maintaining the boiler's efciency.

This boiler is supplied with controls which may cause the boiler to shut down and not re-start without

service. If damage due to frozen pipes is a possibility, the heating system should not be left unattended in

cold weather; or appropriate safeguards and alarms should be installed on the heating system to prevent

damage if the boiler is inoperative.

This boiler is designed to burn No. 2 fuel oil, natural and/or LP gas only. Do not use gasoline, crankcase

drainings, or any oil containing gasoline. Never burn garbage or paper in this boiler. Do not convert to

any solid fuel (i.e. wood, coal). Do not convert to any gaseous fuel (i.e. natural gas, LP). All ammable

debris, rags, paper, wood scraps, etc., should be kept clear of the boiler at all times. Keep the boiler area

clean and free of re hazards.

Always keep the oil supply valve shut off if the burner is shut down for an extended period of time.

Probe and oat type low water cutoff devices require annual inspection and maintenance. Refer to

instructions in Section V, Paragraph C for inspection and cleaning instructions.

NOTICE

All V9A Series cast iron boilers are designed, built, marked and tested in accordance with the ASME Boiler

and Pressure Vessel Code, Section IV, Heating Boilers. An ASME Data Label is factory applied to each V9A

jacket, which indicates the boiler Maximum Allowable Working Pressure (MAWP). Each cast iron section is

permanently marked with the MAWP listed on the boiler’s ASME Data Label. Those values for the V9A are as

follows:

MAWP, Steam - 15 psi

MAWP, Water (USA) - 80 psi

MAWP, Water (Canada) - 45 psi

It is common and acceptable practice to install these boilers in lower pressure systems, below the boiler

MAWP. Therefore, Burnham offers safety relief valves set at or below the MAWP of the boiler. See Table 1 for

available safety relief valve set pressures.

5

Page 6

TABLE OF CONTENTS

SECTION I - GENERAL INFORMATION

Dimensional Information ............................................................................................................................................... 8

Ratings/Data .................................................................................................................................................................. 9

Locating the Unit . ........................................................................................................................................................ 10

Air Supply/Venting ....................................................................................................................................................... 11

SECTION II - CAST IRON BLOCK ASSEMBLY (Knockdown Only)

Assembly of Sections, Manual Draw-up ..................................................................................................................... 14

Assembly of Sections, Hydraulic Draw-up ................................................................................................................. 17

Hydrostatic Test ........................................................................................................................................................... 18

SECTION III - INSTALLATION INSTRUCTIONS

Knockdown

Canopy ......................................................................................................................................................................... 20

Flue Cover Plates ......................................................................................................................................................... 23

Rear Observation Port Cover ........................................................................................................................................ 24

Inspect All Boiler Seals ................................................................................................................................................ 24

Jacket Assembly .......................................................................................................................................................... 24

Burner Mounting Plate / Burner Adapter Plate ........................................................................................................... 26

Steam Trim .................................................................................................................................................................. 27

Water Trim . .................................................................................................................................................................. 27

Burner Installation ....................................................................................................................................................... 28

Package Boilers

Preparation for Installation ........................................................................................................................................... 28

Common Installation Requirements

Boiler Piping - Water Heating Applications ................................................................................................................ 29

Boiler Piping - Steam Heating Applications ................................................................................................................ 30

Boiler Piping - Domestic Hot Water (DHW) Applications .......................................................................................... 39

Tankless Heater Piping ................................................................................................................................................ 40

Electric Wiring .............................................................................................................................................................. 44

SECTION IV - OPERATING INSTRUCTIONS

Filling System ............................................................................................................................................................... 45

Adjusting Controls ....................................................................................................................................................... 45

Adjusting Burner ......................................................................................................................................................... 46

Test Controls ................................................................................................................................................................ 46

Initial Cleaning, Steam Boilers .................................................................................................................................... 46

Initial Cleaning, Water Boilers ....................................................................................................................................47

Frequent Water Addition .............................................................................................................................................. 48

Oxygen Corrosion ........................................................................................................................................................ 48

SECTION V - SERVICE INSTRUCTIONS

Cleaning Boiler Heating Surfaces ............................................................................................................................... 49

Maintenance of Low Water Cutoff Devices ................................................................................................................ 50

Checking Burner & Controls ........................................................................................................................................ 51

Lubrication ................................................................................................................................................................... 51

General Maintenance Considerations ........................................................................................................................... 51

Attention to Boiler While Not in Operation ................................................................................................................. 51

6

Page 7

TABLE OF CONTENTS - CONTINUED

SECTION VI - BURNER SPECIFICATIONS

Beckett Burners (Table V) ............................................................................................................................................ 52

Power Flame Burners (Table VI) .................................................................................................................................. 53

Webster Burners (Table VII) ........................................................................................................................................54

Carlin Burners (Table VIII) .......................................................................................................................................... 55

SECTION VII - REPAIR PARTS

Customer Service Contact Information ........................................................................................................................ 55

Jacket Assembly .......................................................................................................................................................... 56

Bare Boiler Assembly ................................................................................................................................................... 58

Steam/Water Trim ......................................................................................................................................................... 61

WARRANTY ....................................................................................................................................................... REAR COVER

7

Page 8

8

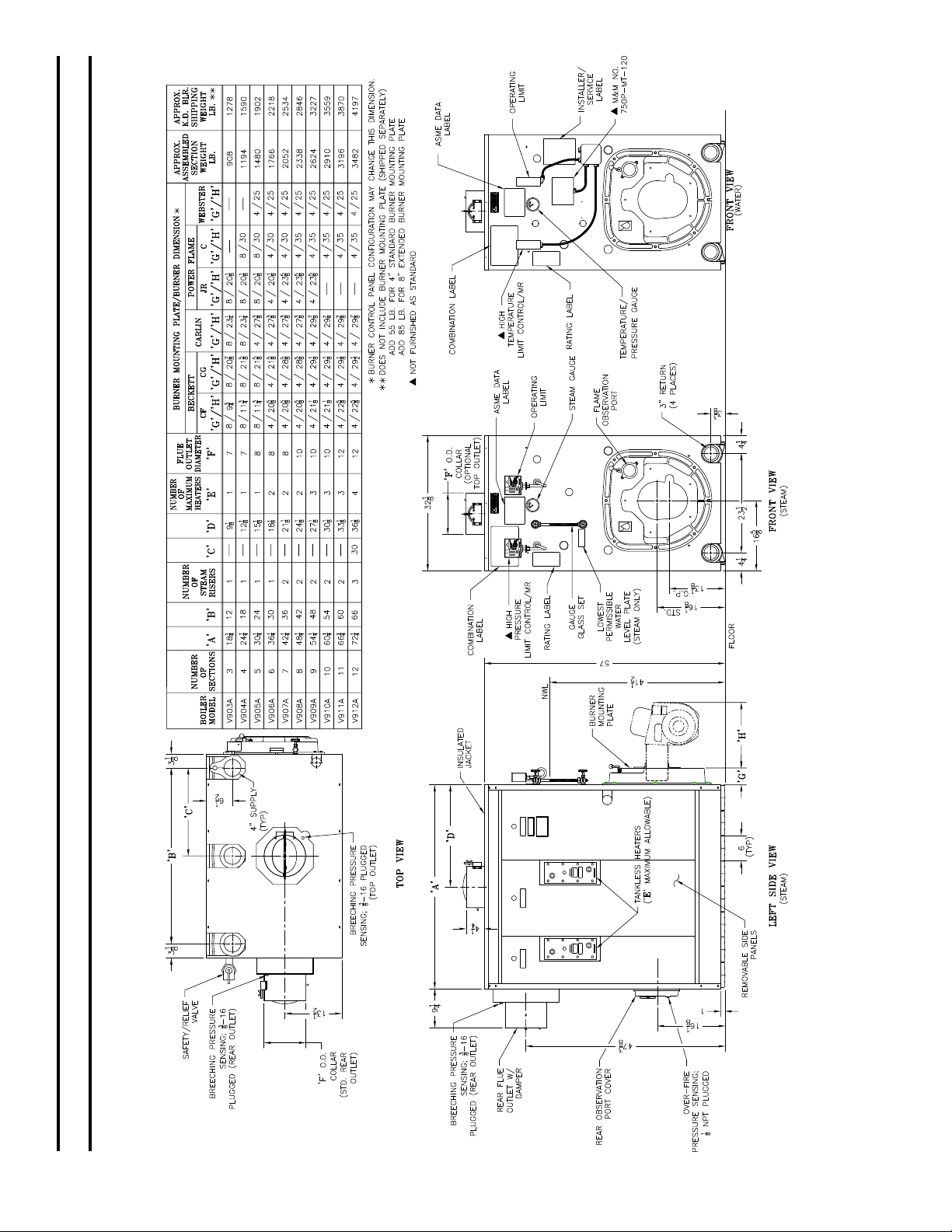

Figure 1: Dimensional Information

SECTION I - GENERAL INFORMATION

Page 9

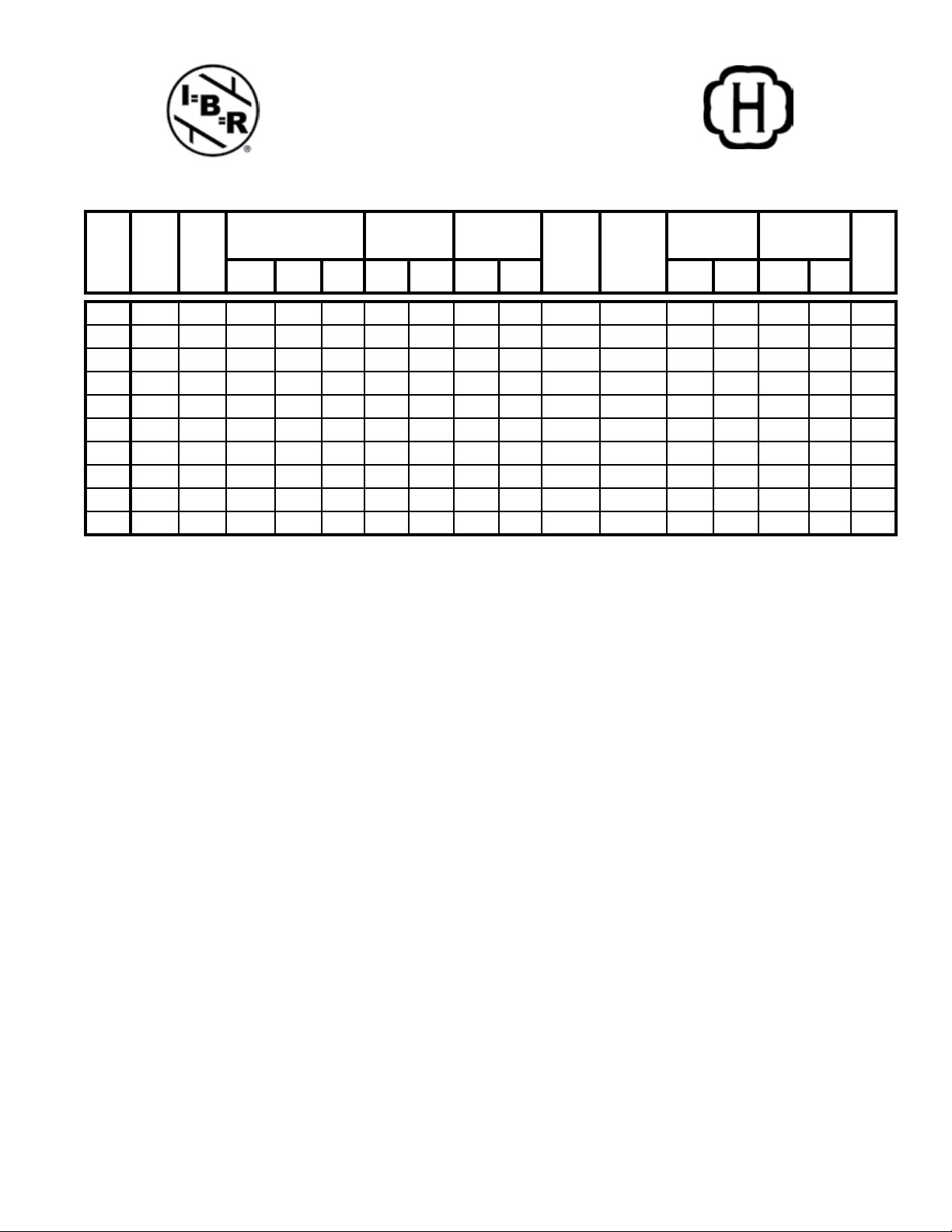

Table I: Boiler Ratings / Data

(1) (2) (3) (4)

Boiler

Model

HorsePower

Gross

Output

(MBH)

V903A 10.3 347 1083 260 302 3.1 447 34.2 37.0 3.2 .33 44.5 66.0 1439 1618 7

V904A 14.4 483 1508 362 420 4.2 606 48.6 54.3 4.8 .38 53.0 75.0 1811 1995 7

V905A 19.3 646 2021 485 562 5.6 808 63.0 71.5 6.4 .31 61.5 84.0 2184 2372 8

V906A 24.1 808 2525 606 703 7.0 1010 77.5 88.8 7.9 .38 70.0 93.0 2557 2749 8

I=B=R

V907A

V908A 33.2 1110 3471 833 965 9.6 1386 106.3 123.3 11.0 .35 87.0 111.0 3303 3503 10

V909A 10.1 1342 4225 1014 1167 11.6 1674 120.7 140.5 12.6 .35 95.5 120.0 3676 3880 10

V910A

V911A

V912A

(1) Type of Build Prex: K = Knockdown, A = Knockdown w/Assembled Sections, P = Packaged, F = Packaged and Firetested

Trim Sufx: S = Steam Boiler, W = Water Boiler

Fuel Sufx: N = Natural Gas, P = LP Gas, O = Oil, C = Natural Gas/Oil, D = LP Gas/Oil, M - Less Burner

Burner Sufx: B = Beckett, C = Carlin, J = Power Flame JR, P = Power Flame C, W = Webster, L = Less Burner

(2) I=B=R net ratings shown are based on piping and pick-up allowances which vary from 1.333 to 1.289 for steam and 1.15 for water. Consult manufacturer for

installations having unusual piping and pick-up requirements, such as intermittent system operation, extensive piping systems, etc. The I=B=R burner capacity in

GPH is based on oil having a heat value of 140,000 BTU per gallon.

(3)

listed above.

(4) Boiler ratings are based on 12.5% CO2 (oil) and 9.7% CO2 (natural gas), + .10” (inches) water column pressure at boiler ue outlet. Ratings shown above apply at

altitudes up to 1000 feet on oil and 2000 feet on gas.

For altitudes above those indicated, the ratings should be reduced at the rate of 4% for each 1000 feet above sea level.

Safety (Relief) Valve Set Pressure: USA Steam Boiler - 15 PSI, USA Water Boiler - 50 PSI

Optional USA Water Boiler - 30 PSI, 80 PSI (special order)

Canadian Steam Boiler - 15 PSI, Canadian Water Boiler - 45 PSI

Optional Canadian Water Boiler - 30 PSI (special order)

28.6 959 2996 719 834 8.3 1198 91.9 106.0 9.5 .36 78.5 102.0 2930 3126 8

45.6 1528 4867 1168 1329 13.2 1905 135.1 157.8 14.2 .40 104.0 129.0 4048 4257 10

51.2 1714 5513 1323 1490 14.8 2136 149.5 175.0 15.7 .45 112.5 138.0 4421 4634 12

56.8 1900 6142 1474 1652 16.4 2367 164.0 192.3 17.3 .49 121.0 147.0 4794 5011 12

Firebox volume does not include added volume of 8” extended burner mounting plate (BMP). If 8” BMP is specied (refer to Figure 1), add 0.7 cu. ft. to volume

Net I=B=R Rating

Sq. Ft.

Steam

MBH

Steam

MBH

Water

I=B=R

Burner Input

Oil

(GPH)

(MBH)

Gas

Heating

Surface

(Sq. Ft.)

Steam Water Steam Water Steam Water

New

Firebox

Volume

(Cu. Ft.)

Pressure

in Firebox

(In. Wtr.

Clmn.)

Water Content

(Gal.)

Boiler Weight

w/Water (Lbs.)

I=B=R

Vent

Dia.

(In.)

9

Page 10

SECTION I - GENERAL INFORMATION (Continued)

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated boiler to the carrier in good

condition.

2. ANY CLAIMS for damage or shortage in shipment

must be led immediately against the carrier by the

consignee. No claims for variances from, or shortage in orders, will be allowed by the manufacturer

unless presented within sixty (60) days after the

receipt of goods.

B. LOCATE THE UNIT

1. RECOMMENDED SERVICE CLEARANCE

- Locate the unit in the boiler room so as to

provide ease of venting and adequate clearance

for maintenance, serviceability, and installation of

piping. Refer to Figure 1 for boiler dimensional

data.

FRONT — Provide 43” service clearance for

removal, maintenance, and servicing of burner and

controls.

REAR — Provide a minimum clearance from the

boiler jacket for access to ame observation port,

rear ue damper and vent piping, relief valve, and

boiler return piping. See Table III.

LEFT SIDE — Provide a minimum clearance from

the boiler jacket of 26” for cleaning of ueways and

installation and removal of tankless heater(s).

RIGHT SIDE — Provide a minimum clearance from

the boiler jacket of 12”.

TOP — Provide a minimum clearance from the

boiler jacket of 24”

NOTICE

Recommended clearance for service may be

reduced to minimum clearance to combustible

material. However, increased service and

maintenance difculty will result.

WARNING

Boiler is suitable for installation on combustible

oor. Do not install boiler on carpeting.

Floor construction should have adequate load

bearing characteristics to bear the weight of

the boiler lled with water (see Table 1). A

boiler foundation similar to the one shown in

Figure 2 is recommended if the boiler room

oor is weak or uneven or if a water condition exists.

2. FOR MINIMUM CLEARANCES to combustible

materials, See Table II.

3. PROVIDE ADEQUATE FOUNDATION for the

unit. Refer to Figure 2.

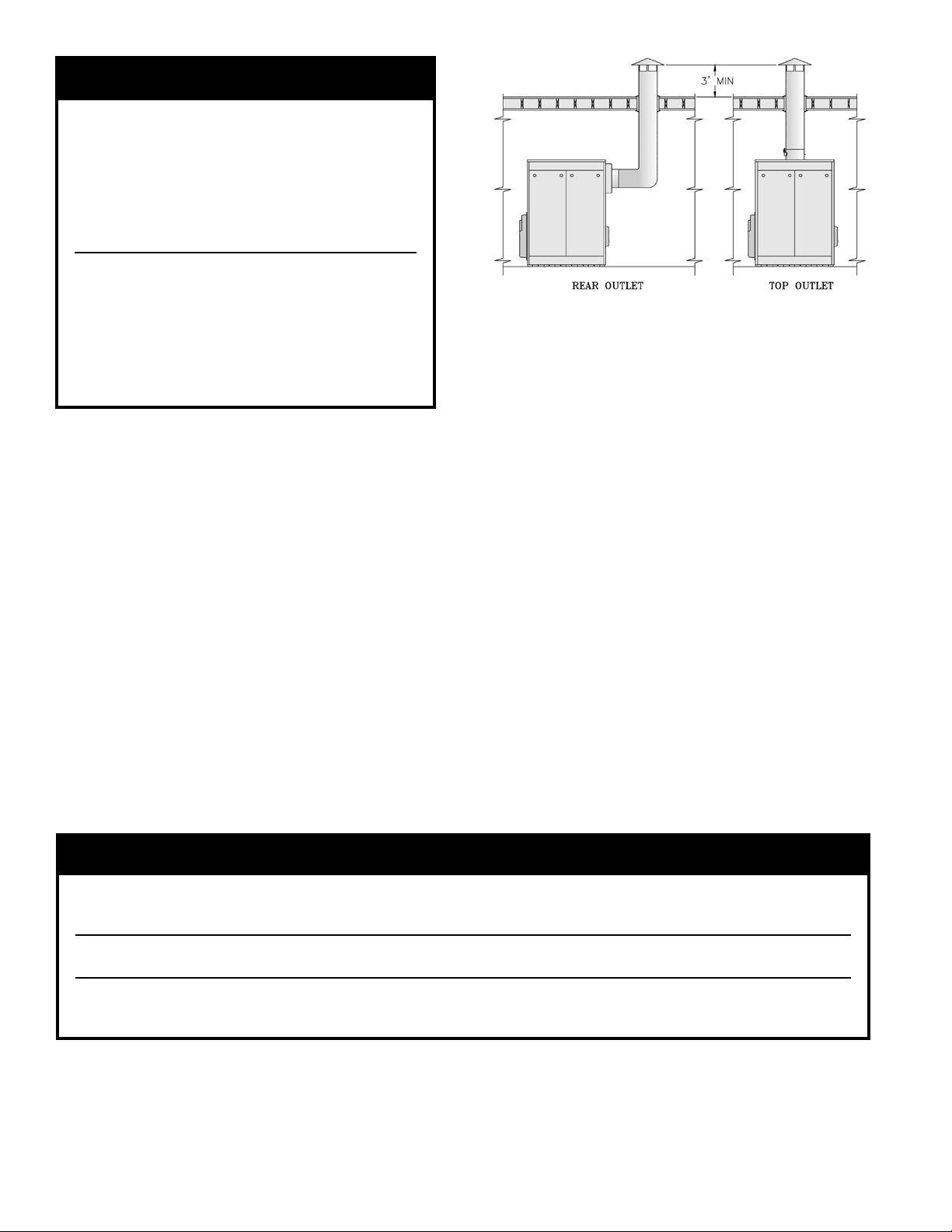

Table II: Minimum Clearances To Combustible

Materials (Inches)

Boilers with Top Flue Outlet

Boilers with Rear Flue Outlet

A B C D E

Above Front Rear Sides Vent Connector

6 24 6 6 18

* See Table III for Recommended Service Clearance to

access rear of boiler

NOTES:

1. Listed clearances comply with American

National Standard ANSI/NFPA 31, Installation of

Oil Burning Equipment.

2. V9A Series boilers can be installed in rooms with

clearances from combustible material as listed

above. Listed clearances cannot be reduced for

alcove or closet installations.

3. For reduced clearances to combustible material,

protection must be provided as described in the

above ANSI/NFPA 31 Standard.

Table III: Recommended Rear Service Clearance

Flue

Outlet

Size

7” Dia. 18” 37” 22”

8” Dia. 38” 23”

10” Dia. 40” 25”

12” Dia. 43” 28”

Top

Flue

Outlet

Combustible

Surfaces

Rear Flue Outlet

Non-Combustible

Surfaces

10

Page 11

Figure 2: Boiler Foundation

WARNING

Failure to supply adequate air to the boiler will

result in unsafe boiler operation.

C. PROVIDE AIR SUPPLY AND VENTILATION to

accommodate proper combustion.

For commercial and industrial equipment, permanent

facilities for supplying an ample amount of outside air

shall be provided in accordance with the following.

For boiler rooms adjacent to outside walls, and where

combustion air is provided by natural ventilation from

the outside, there shall be a permanent air supply inlet

having a total free area of not less than 1 sq. inch per

4,000 Btu per hr. (35 sq. inch per gallon per hour)

(5.5 cm2 per kw.) of total input rating of the burner or

burners and in no case less than 35 sq. inch (0.425m2).

For boiler rooms not adjacent to outside walls, the

combustion air shall be supplied in a manner acceptable

to the authority having jurisdiction.

1. In the absence of local requirements, the conned

space shall be provided with two permanent

openings, one in or near the top of the room and one

near the bottom. The openings shall communicate

by means of ducts, with the outdoors or to such

spaces (crawl or attic) that communicate with the

outdoors.

a. Where communicating by means of vertical

ducts, each opening shall have a free area of not

less than 1 sq. inch per 4,000 Btuh (35 sq. inch

per gph) (5.5 cm2 per kw) of total input rating of

all appliances in the enclosure.

b. If horizontal ducts are used, each opening shall

have a free area of not less than 1 sq. inch

per 2,000 Btuh (70 sq. inch per gph.) (11 cm2

per kw) of total input of all appliances in the

enclosure.

D. CHIMNEY OR VENT

NOTICE

When a V9A gas red boiler is connected to

a venting system that is designed so that it

will operate under a negative pressure, the

use of Type C, B, or other manufactured vent

systems designed for negative pressure is

acceptable.

When a V9A oil red or combination gas/oil

red boiler is connected to a venting system

that is designed so that it will operate under

a negative pressure, the use of Type C, L or

other manufactured vent systems designed

for negative pressure is acceptable.

Unlined masonry chimneys are not acceptable. Lined masonry chimneys are acceptable

with the appropriate vent connectors using

materials described above.

11

Page 12

WARNING

When a V9A gas red boiler is connected

to a venting system that is designed so that

it will operate under a positive pressure,

manufactured vent systems, designed and

approved for positive pressure application per

UL1738, must be used (for example, Van-Packer

model CS, Protech Model FasNSeal / FasNSeal

W2, Heatfab Saf-T-Vent or equivalent).

When a V9A oil red or combination gas/oil

red boiler is connected to a venting system

that is designed so that it will operate under a positive pressure, manufactured vent

systems, designed and approved for positive pressure application, must be used (for

example, Selkirk Metalbestos Model PS / IPS,

Van-Packer Model ES or equivalent).

The V9A Series boiler is designed for forced draft

ring and may be used with a conventional natural draft

stack (15’ minimum height) or a stub vent, sometimes

called a diesel stack (see Figure 3a). See Table I for

the proper vent outlet size. For low silhouette vent

terminations, see Figure 3b. Draft controls are not

normally required, although they may be used on

installations where a natural draft stack is used or on

multiple boiler installations with a common stack. The

boiler is provided with a breeching damper, which

should be adjusted to maintain a positive pressure of

0.1” W.C. in the vent connector box during burner high

re operation (see breeching pressure sensing port in

Figure 1).

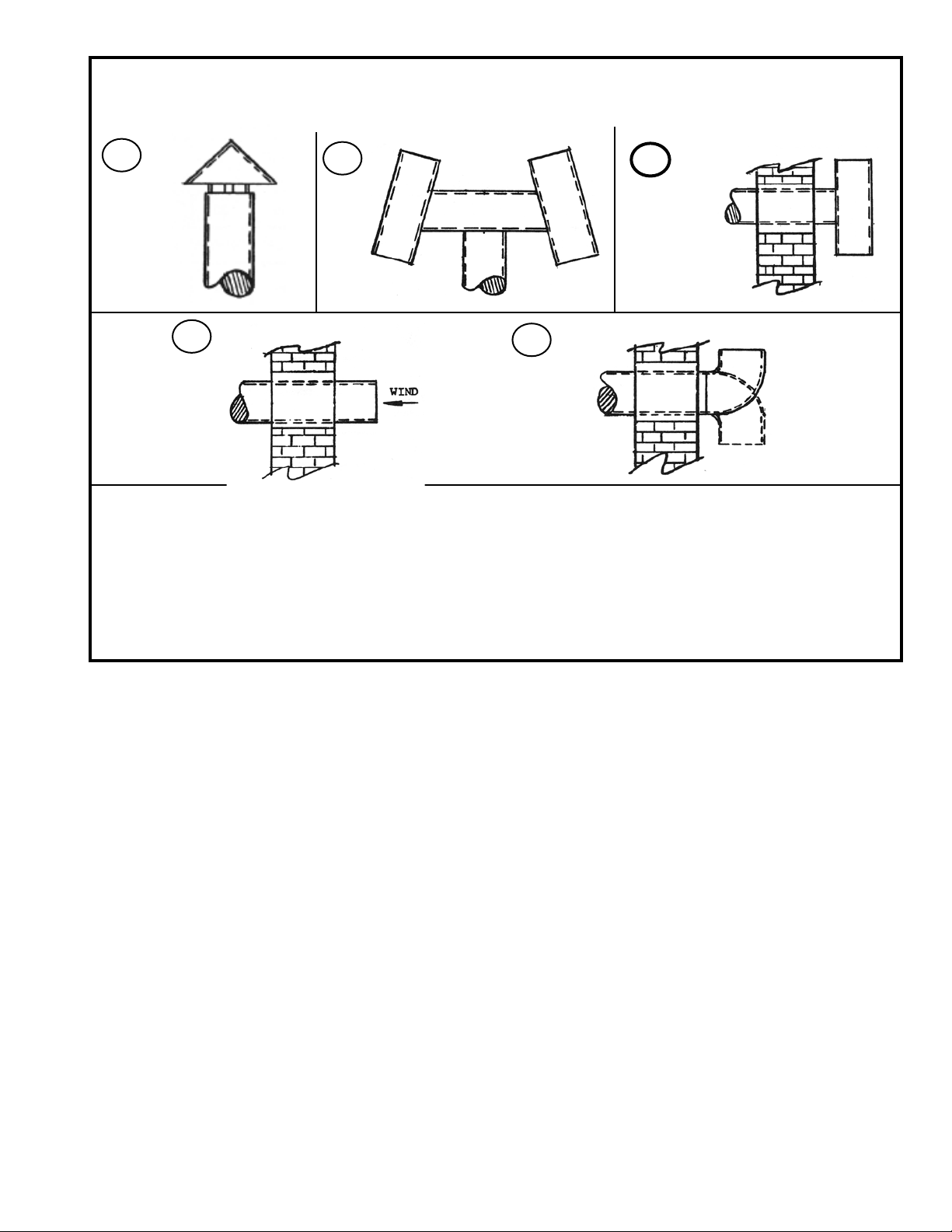

Figure 3a: Typical Arrangement for Stub Vent

If the venting system is designed for positive or forced

draft venting, the boiler, vent connector and stack will

operate under positive pressure. Gas tight vent systems

designed for pressure systems must be used to prevent

ue by-product leakage. The vent height is usually

limited to prevent negative draft, typically three (3)

feet above the roof line (see Figure 3a). The damper

shall be adjusted to maintain a positive pressure of

0.1” W.C. in the vent connector box during burner high

re operation (see breeching pressure sensing port in

Figure 1).

If the venting system is designed for negative pressure

(natural draft), the boiler still operates with positive

pressure in the chamber and up to the xed damper on

the ue collar. However, if the venting system is larger

than what is required, the stack will provide a surplus

draft (or negative pressure) that may require the use of

a barometric damper to maintain the positive 0.1” W.C.

pressure at the ue outlet. Multiple forced draft boiler

stacks should always be designed as negative to ensure

the products of combustion do not exit a boiler that is

not ring.

WARNING

Venting instructions are recommendations only. Consult a venting expert on the design of a specic

vent system for your application. The ASHRAE Venting Guide and The National Fuel Gas Code, NFPA

54 should be considered in all venting systems.

Conventional vent material may not be suitable for the application. Flue gases can leak carbon

monoxide from the joints on these materials and can result in severe personal injury or death.

Installations having long horizontal runs or an excessive amount of tees or elbows will restrict the ow

of combustion gases and can result in condensation, ue gas leakage of carbon monoxide, resulting in

severe personal injury or death.

12

Page 13

A

B

C

RAIN CAP

RIGHT

D

WRONG

VENT SIZING - Area must be the same as or greater than the boiler breeching (Smoke Outlet). A barometric damper may be required on

installations with a high draft condition.

1. If improper vent is suspected, remove pipe at breeching and operate boiler. This will determine if excessive down draft,

blocked or restricted ue, etc. is causing the problem.

2. If using type shown in A above, be sure cap is raised sufciently above main pipe to allow ue gases to vent unimpeded.

3. A popular type cap is shown in B.

4. The tee is frequently used as shown in C.

5. D and E should not be used due to possible uctuations in back pressure.

“A” CAP

RIGHT

E

WRONG

FAULTY BOILER BURNER OPERATION

TEE TYPE

RIGHT

90°

ELBOW

UP or DOWN

Figure 3b: Vents — Faults & Suggestions

Typical Vents that are used on Forced Draft Boilers, on Low Silhouette Buildings

13

Page 14

SECTION II - CAST IRON BLOCK ASSEMBLY

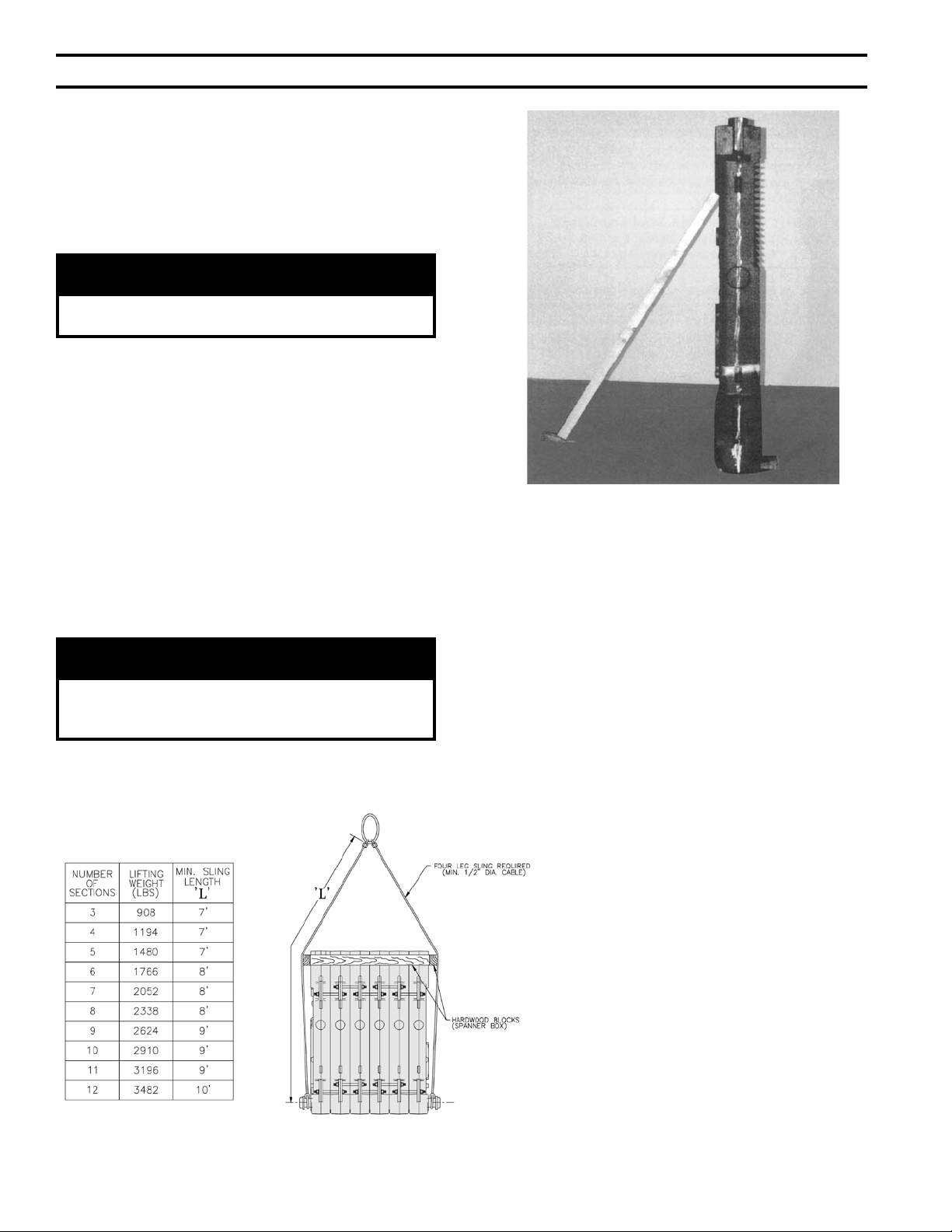

A. FACTORY ASSEMBLED SECTIONS — If the

boiler was ordered with factory assembled sections,

the assembly should be set in the proper location as

outlined in Section I. Lifting arrangement and weights

are given in Figure 4.

1. Proceed to Paragraph C of this Section,

“HYDROSTATIC TEST”.

CAUTION

Boiler sections must be drawn-up on perfectly

level surface or improper assembly may result.

B. FIELD ASSEMBLED SECTIONS — If the boiler

was ordered to be eld assembled, follow the assembly

procedure outlined on the following pages.

1. ASSEMBLY OF SECTIONS (MANUAL DRAWUP)

These sections are designed to be drawn together,

one section at a time, using the 9¾” long draw-up

rods (provided) and ordinary hand tools.

Tools required:

(1) ¾” Drive Ratchet

(1) 1-1/16” Socket

(1) 1-1/16” Combination or Open End Wrench

(1) Container of grease, oil or other appropriate

lubricant.

CAUTION

When assembling sections without hydraulic

draw-up equipment, never assemble more than

one section at a time.

a. Place the rear section in its approximate nal

position, as outlined in Section I, and support it

with a suitable prop and wedges. See Figure 5.

Figure 4: Lifting Instruction

Figure 5: Positioning of Back Section

b. On size V903A only— Open target wall carton,

apply Silastic to back of target wall and secure

target wall to rear section.

c. Clean the groove in the ground joint along the

edge of the section with the wire brush.

d. Open the Boiler Assembly Carton(s) and remove

the bottle of adhesive. Using the dauber supplied

in the bottle, apply the adhesive to the groove.

Be sure to use enough adhesive to sufciently

coat the entire groove surface. If so desired,

a multi-purpose spray adhesive (supplied by

others) may be used instead. HOWEVER,

GREAT CARE MUST BE TAKEN TO

ENSURE THAT THE ADHESIVE DOES

NOT COME IN CONTACT WITH THE

NIPPLES OR NIPPLE PORTS.

e. While the adhesive is becoming tacky, clean

nipples and nipple ports thoroughly with a degreasing solvent. Use the Loctite #592 provided

to lubricate the nipples and nipple ports. Apply

the lubricant to the nipples and nipple ports,

then use a brush to disperse it evenly around the

nipples and the nipple ports. Use approximately

25 ml of Loctite #592 per ueway [(1) 7” and

(2) 3” nipples and their (6) corresponding nipple

ports].

f. Drive nipples squarely into section using

block of wood and hammer, or preferably, an

aluminum head hammer. (Burnham offers a

Polyethylene Block for setting the nipples, part

number 8052601). Place block over entire

nipple edge and hit the wood with the hammer.

14

Page 15

WARNING

Nipples must be driven in evenly and to the

proper depth to assure tight joints. Most

nipple leaks are caused by tilted or cocked

nipples.

DO NOT use steel/iron head hammer to drive

nipples without using a wood block. Nipple

damage may result.

g. A special nipple setting gauge is provided for the

nipples. Gauge nipple at 90° angles to insure

that it is driven to the proper depth into the

nipple opening (nipple port). Cut-out in gauge

must rest on nipple, with legs of gauge touching

nished face of section, when nipple is properly

driven. See Figure 6.

Figure 7: Afxing the Fiberglass Rope

Figure 6: Setting of Nipples

h. Remove a 96” length of berglass rope from

the assembly carton. Starting with the area

around the upper 7” nipple port, rmly press

the rope into the groove, so that the adhesive

holds it in place. (If more than 25 minutes have

passed since the adhesive was applied, it may

be necessary to reapply.) Continue to afx the

rope to the groove in this fashion around the

perimeter of the section. Make sure that the rope

does not droop or hang outside of the groove.

When the end of the groove is reached, cut off

the excess rope. Push the length of excess rope

into the groove at the top corner of the section

face (opposite of the 7” nipple port.) Cut off and

discard any remaining rope after groove is lled.

See Figure 7.

NOTICE

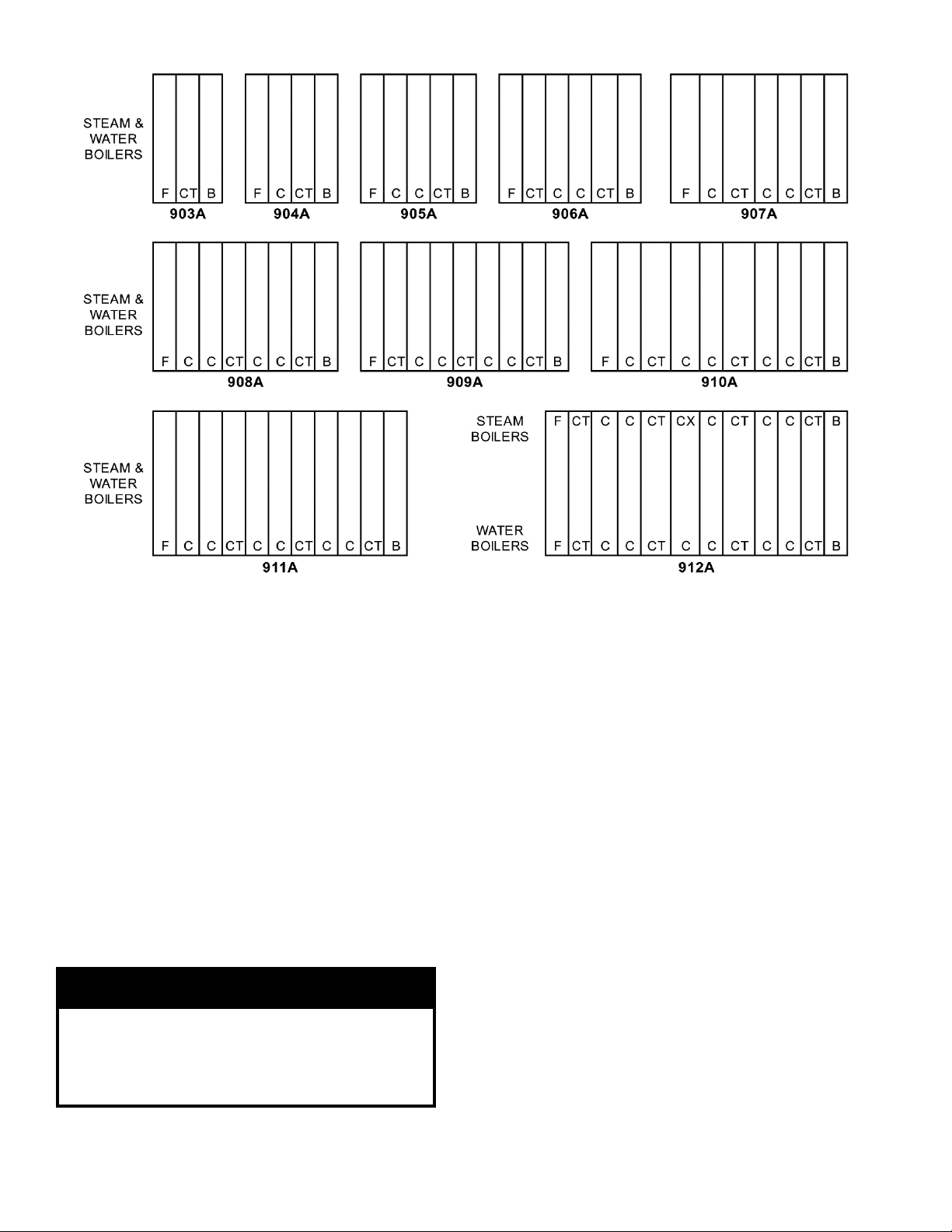

The sections must be assembled according to the

arrangement shown to ensure proper operation,

proper assembly of canopy, jacket and alignment

of piping and tankless heaters with jacket

knockouts. Start with the back section and work

towards the front.

i. From the “Section Arrangement” chart, select

the next section according to the “Identication

Code” at the top of the chart. See Figure 8. Use

a wire brush to clean the groove in the face

of the next section. Then, using a cartridge of

RTV 6500 or RTV 736 sealant in a caulking gun,

ll the groove in this section with silastic sealant.

Touch-up any missed spots before draw-up.

Touch-up after draw-up has no value.

WARNING

Sections must be drawn-up tight immediately

after properly applying sealant for best results.

Although sections may be joined within two

(2) hours of applying sealant, humidity and

temperature affect cure time. If a “thick skin”

has been formed on the sealant bead, remove

and re-apply sealant.

Sealant must be properly applied to ALL boiler

joints. Failure to properly seal the boiler joints

will result in combustion gas leaks through the

joint. DO NOT operate boiler with combustion

gas leaks.

15

Page 16

NOTES: FOR BOILERS LESS TANKLESS HEATER, REPLACE THE "CT" SECTIONS WITH "C" SECTIONS.

Figure 8: V9A Section Arrangement

j. Clean and lubricate nipple ports on next section

to be assembled and place on nipples previously

installed in rear section. To facilitate assembly,

it is advisable to enter the upper nipple rst in

its port. Then enter the lower nipples in their

respective ports. If necessary, place a lifting bar

(crowbar) under the center of the section and lift

the nipple port onto the upper nipple.

k. Drive sections in place with a heavy block of

wood, striking blows as squarely as possible over

nipple port.

l. The large draw-up rod lugs with dual holes

are cast in the four (4) corners of each casting.

STARTING WITH THE UPPER HOLES,

install four (4) 5/8” x 9¾” long draw-up rods

along with washers and nuts (see Figure 9).

CAUTION

To avoid damage to the draw-up rod threads while

drawing up sections, apply oil or other lubricant

to tie rod threads while assembling sections to

prevent stripping of threads on rod and to make

assembling easier.

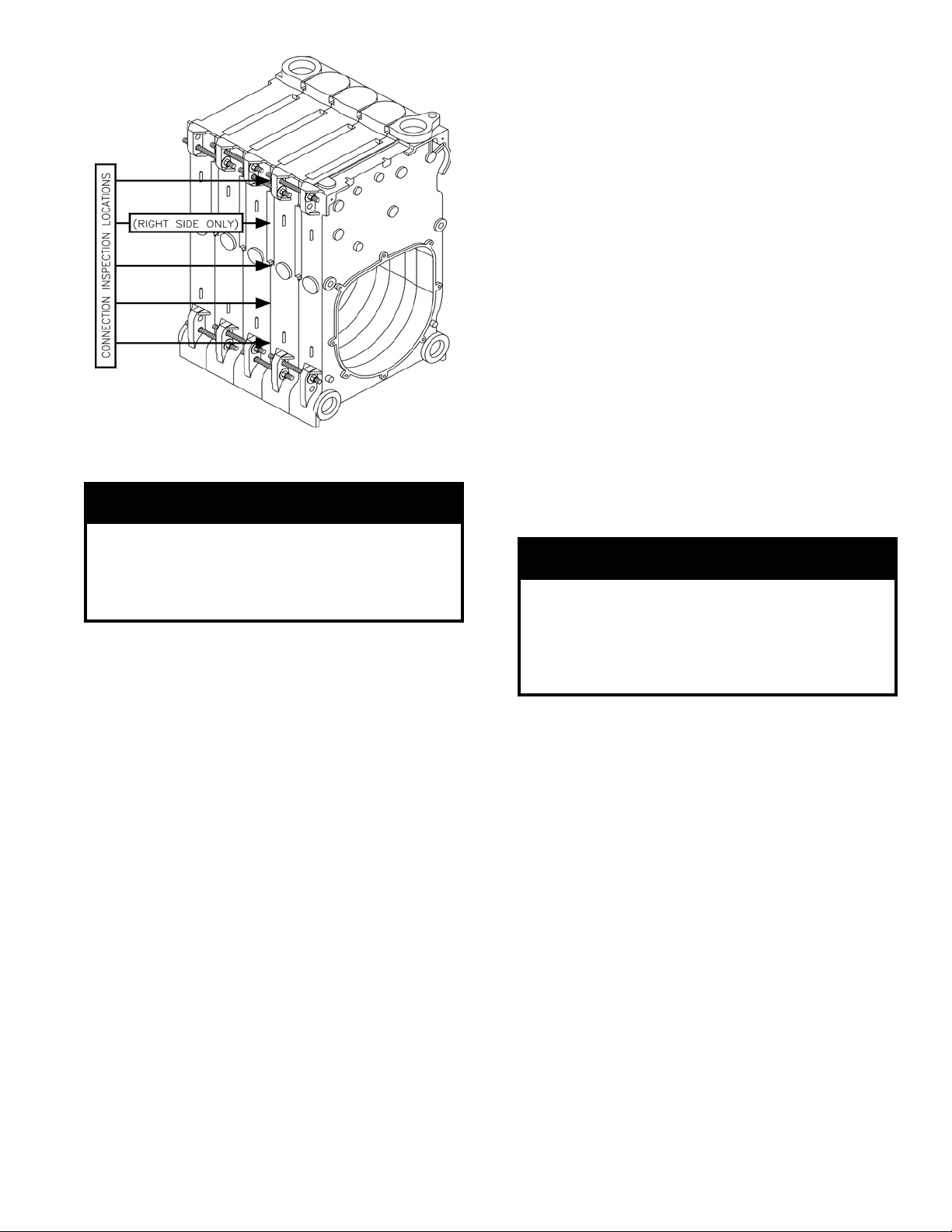

m. DRAW UP SECTION SLOWLY AND

EVENLY using an alternating pattern starting

with the upper right lug (closest to the 7” port)

and proceeding to the lower left , lower right

and nishing with upper left lug. When you

start, grind surfaces between adjoining sections

should be approximately 3/8” apart. Use

three (3) or four (4) passes at tightening the

four (4) draw-up rods a little at a time so that

sections are pulled up evenly. During the last

pass, pay close attention to the silastic sealant

as it squeezes when the sections come in close

contact. The silastic sealant should continue

to squeeze out wafer thin until the sections are

connected metal to metal. If the silastic has

stopped squeezing out from the connection and

the sections still do not appear to be drawn metal

to metal, use a feeler gauge to measure any gaps

at the locations identied in Figure 9. (Unless

specied otherwise, gaps should be measured at

these locations on both sides of the sections.) A

maximum gap of .025” is acceptable. Measure

gaps at the outer edge of the connection only,

making sure not to puncture the gasket created

by the silastic and rope.

16

Page 17

Figure 9: Connection Inspection Locations and

Manual Draw-Up Tie Rod Pattern

WARNING

When tightening the draw-up nuts, DO NOT

EXCEED 150 FT-LB OF TORQUE. If the maximum

torque limit has been reached and a gap greater

than .025” still exists between the sections,

consult the regional ofce.

KEEP NIPPLES ALIGNED WITH NIPPLE

PORTS. If necessary, tap edge of nipples lightly

with a blunt tool or rod to keep nipples from

cocking while sections are being drawn-up. DO

NOT DRAW UP SECTION WHEN NIPPLES

ARE COCKED. If the torque required becomes

excessive, periodically place a heavy block of

wood over each nipple port and strike as squarely

as possible with several blows to relieve tension

on the draw-up rods.

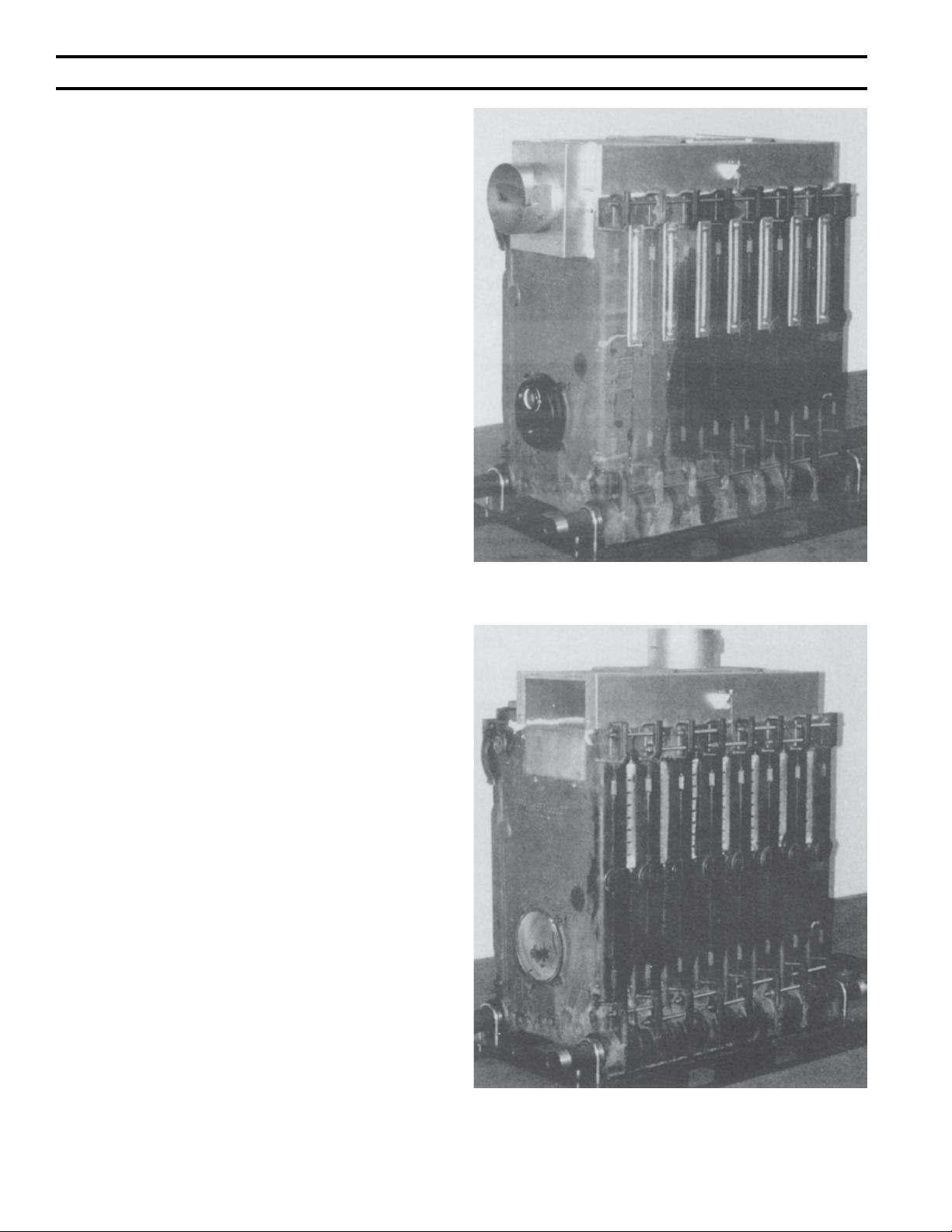

n. CONTINUE ASSEMBLING SECTIONS IN

THEIR RESPECTIVE ORDER alternating

draw-up rods from the upper to lower set of

holes in draw-up lugs (see Figure 13). Be certain

that all sections are drawn up iron-to-iron at all

three (3) nipple ports.

BE SURE TO APPLY THE SEALANT to

the groove in the ground joints between

adjacent sections as the boiler operates with a

positive pressure in the rebox and products of

combustion will escape between sections unless

the sections are properly sealed. The sealant

should be applied before each section is placed

on the assembly.

o. If a joint springs apart it must be redrawn tight

within four (4) hours of the time of application of

Silastic to that joint.

p. EXCESS LENGTH OF DRAW-UP RODS must

not extend beyond front and rear section to

ensure proper t of jacket, adjust accordingly.

q. After all sections have been drawn up, the

draw-up rod nuts should be loosened until

nger tight and then tightened ½ turn with a

wrench.

r. Now Proceed to Paragraph C of this Section,

Hydrostatic Test.

2. ASSEMBLY OF SECTIONS (HYDRAULIC

DRAW-UP)

The entire boiler assembly may be drawn up at one

time using hydraulic draw-up equipment providing

the operation is completed within two (2) hours after

application of the sealant.

a. Repeat steps 1a through 1k under “Field

Assembled Sections (Manual Draw-Up).”

b. Continue driving sections in place (in their

respective order) until all sections are in the

assembly. Ground surfaces between adjoining

sections should be spaced 1/4” to 3/8” apart.

Spacing of more than 3/8” will limit number of

sections that can be drawn up in one unit and

could indicate cocked nipples.

WARNING

Sealant must be properly applied to ALL boiler

joints. Failure to properly seal the boiler joints

will result in combustion gas leaks through to

joint. DO NOT operate boiler with combustion

gas leaks. The sealant should be applied before

each section is placed on the assembly.

On long boiler assemblies, it may be necessary to

draw-up a partial block if the entire boiler is not

ready to be drawn-up tight within two (2) hours

of the rst application of Silastic. If the block

assembly time extends overnight, the partial

block completed must be drawn-up tight before

leaving the boiler overnight. If a joint springs

out, it must be redrawn tight within four (4)

hours of rst application of Silastic to the joint.

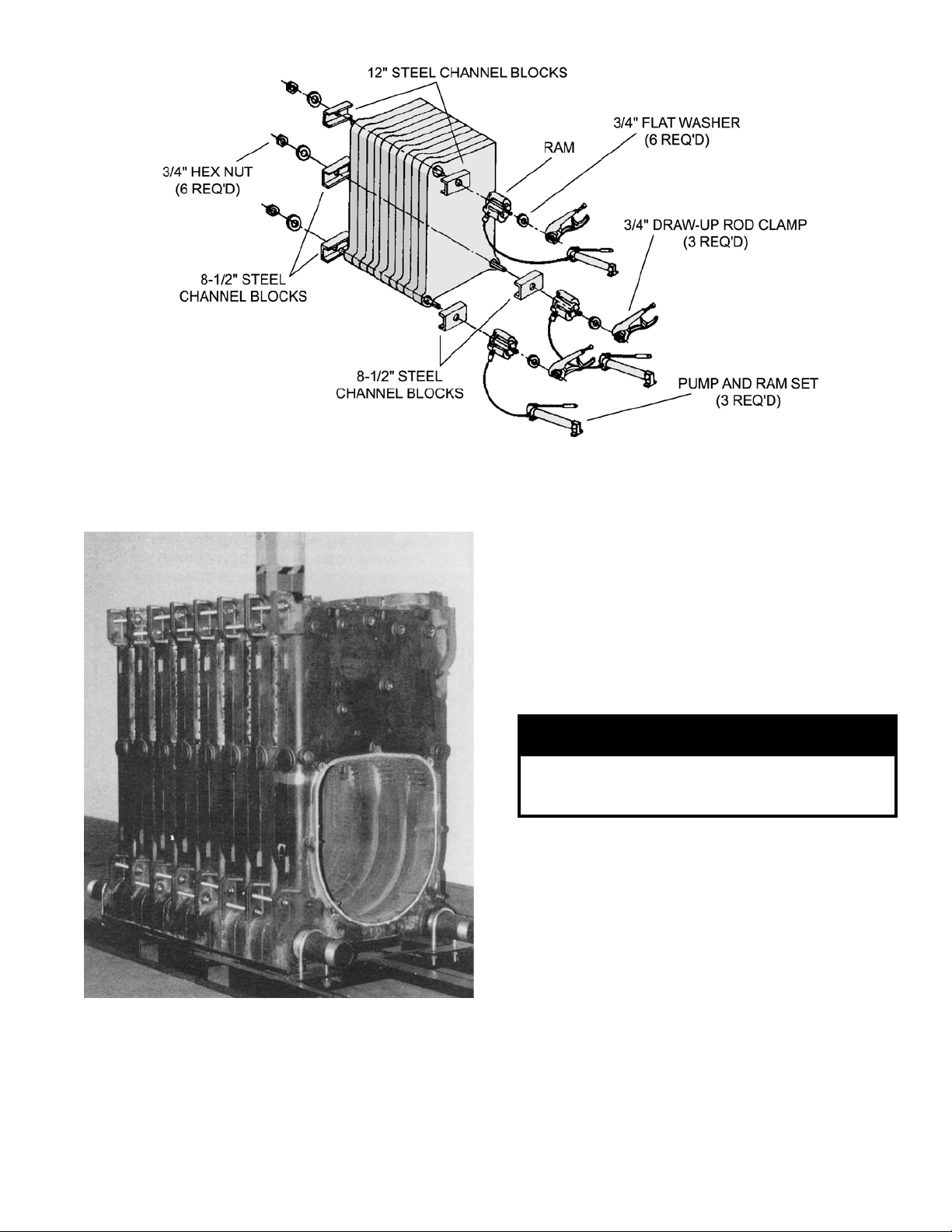

c. Insert the three (3) ¾” draw-up rods (and

couplings, if appropriate) through the tapped

holes in the rear section extending them through

the tapped holes in the front section. Be sure to

screw draw-up rods into couplings far enough to

prevent stripping threads.

d. Place a 3” x 12” lg. steel channel on each end of

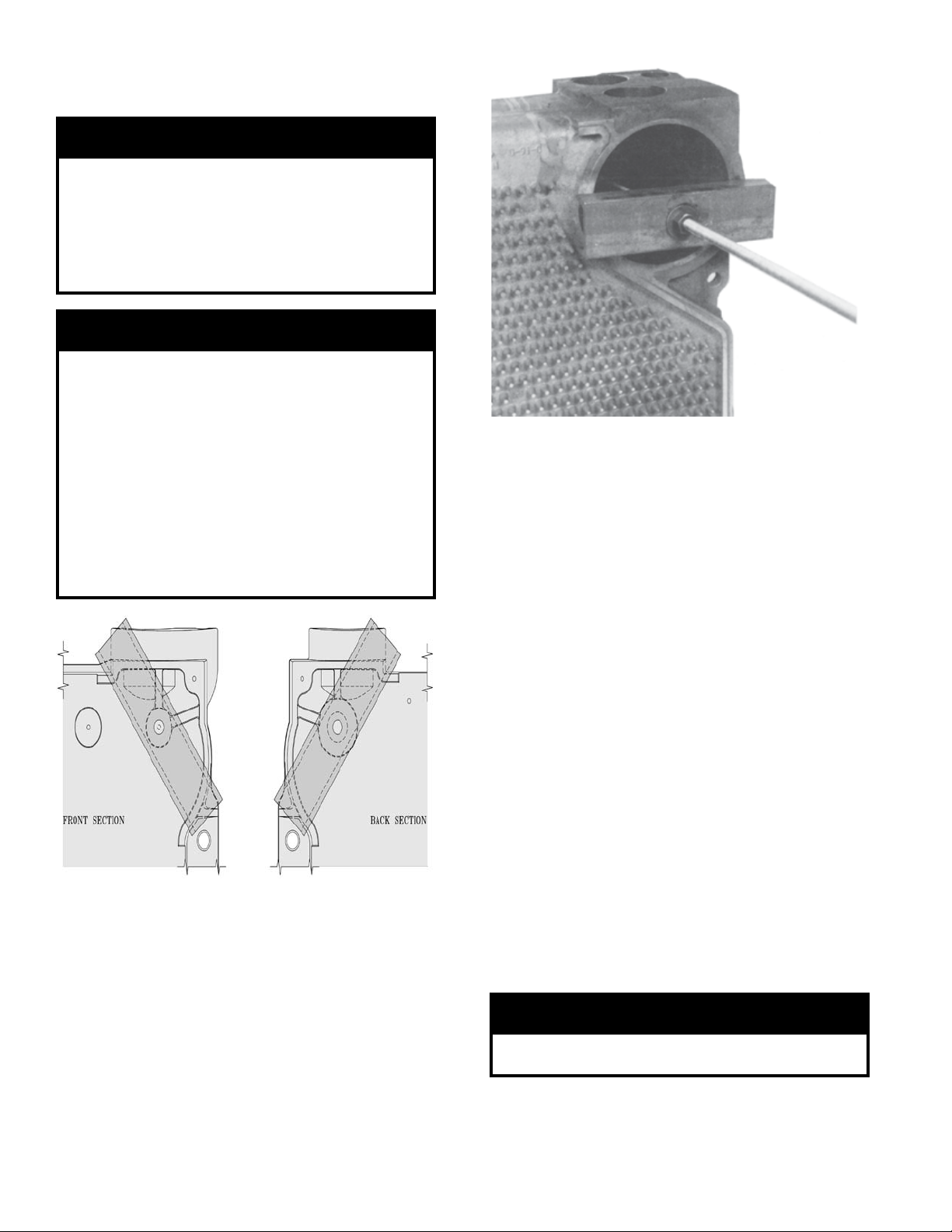

the upper draw-up rod and a 3” x 8½” lg. steel

channel on each end of the lower draw-up rods.

Refer to Figures 10 and 11 for proper placement

of channel block during assembly procedures.

Install nuts and washers on one end of the drawup rods and the hydraulic rams, washers and

17

Page 18

draw-up rod clamps on the other. These items

are all located in the Draw-Up Kit.

See Figure 12.

CAUTION

Do not apply pressure directly on threaded

tappings on front and rear sections with draw-up

channels during assembly procedures.

Rods should be approximately centered in

openings so that rods and couplings (when

used) do not drag on pipe thread in end section

tappings.

WARNING

READ THE STATEMENTS BELOW BEFORE

ATTEMPTING TO USE HYDRAULIC EQUIPMENT.

• Release pressure in ram pumps before

attempting to remove clamps.

• Do not stand in line with draw-up rods at either

end when hydraulic pressure is being applied.

As a safety measure, ends of draw-up rods

should be covered while sections are being

drawn in case rods should snap while under

tension.

• Do not operate ram against draw-up coupling.

• Do not operate pump after ram has reached

stroke limit.

Figure 11: Center Section Channel Block Position

(Partial Block Draw-Up)

The large draw-up rod lugs with dual holes cast

in the four (4) corners of each casting. Starting

with the upper holes in the back section, install

four (4) 5/8” x 9¾” long tie rods along with

washers and nuts. Continue installing the tie

rods alternating from the upper to lower set

of holes in draw-up lugs until front section is

secured. Be certain that all sections are drawn

up IRON TO IRON at all three nipple ports.

h. Excess length of draw-up rods must not extend

beyond front and rear section to ensure proper t

of jacket, adjust accordingly. Tighten all tie rod

nuts until nger tight. Then tighten them an

additional ½ turn with a wrench.

Figure 10: Front and Rear Section Channel

Block Positions (Hydraulic Draw-Up)

e. Draw-Up Sections

Use hydraulic rams to draw up sections by

applying pressure alternately on the draw-up

rods. When rams reach stroke limit, release

pressure in ram pumps and then move clamps to

new position.

f. Continue to draw-up until all sections make

contact at the ground joints.

g. After all sections have been drawn up, but before

removing the hydraulic rams and draw-up rods,

the 9¾” long tie rods must be installed.

18

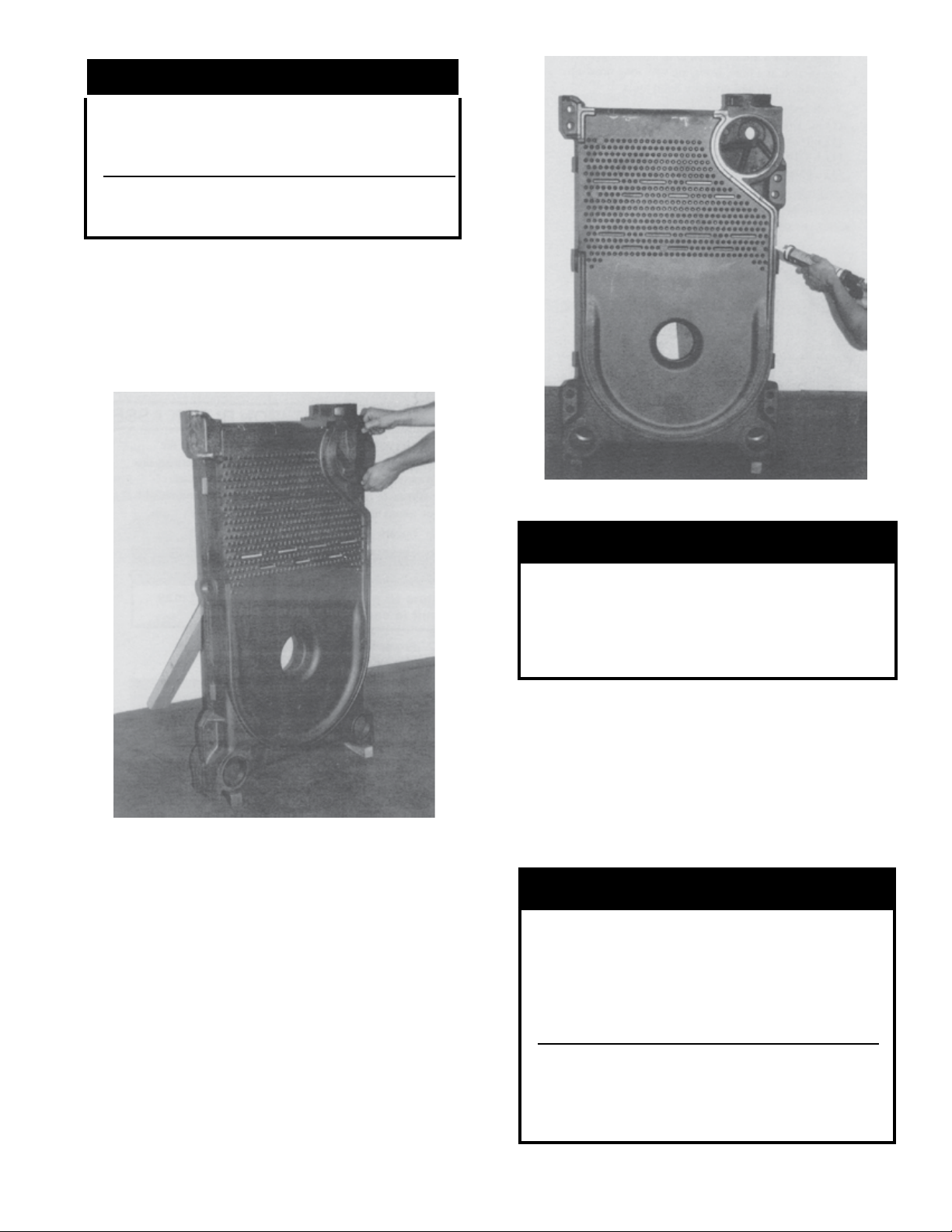

C. HYDROSTATIC TEST — After the boiler sections

have been assembled, it is essential that the boiler be

hydrostatically tested before the canopy, ue cover

plates, jacket, or piping is installed.

1. Tankless Heater Installation

If boiler is ordered with tankless heaters, install

heaters with the gaskets provided. Table IV gives

the maximum number of heaters permissible per

assembly and the heater ratings.

2. Plug all boiler tappings and ll boiler completely

with cold water.

CAUTION

DO NOT install gauge until after hydrostatic

testing the boiler. Gauge failure may result.

3. All completed boilers must satisfactorily pass the

prescribed hydrostatic test.

Page 19

Figure 12: Hydraulic Draw-Up Sections

Figure 13: Boiler Section Assembly

a. STEAM BOILERS: The assembled boiler must

be subjected to a hydrostatic test of 45 psig to 55

psig.

b. HOT WATER BOILERS: The assembled boiler

must be subjected to a hydrostatic test of not less

than 1½ times the maximum allowable working

pressure, as established by the relief valve

provided with the boiler. For example, a boiler

with a 50 psi relief valve must be subjected to a

test pressure of 75 psig to 85 psig.

WARNING

Failure to properly hydrotest all boilers at the

correct pressure may result in section assembly

failure in operation.

4. EXAMINE BOILER CAREFULLY, INSIDE AND

OUTSIDE, to insure against leaks from cocked

nipples or through concealed breakage caused in

shipping and handling. This precaution is for your

protection and will simplify handling of necessary

replacements and adjustment claims.

5. After making certain that there are no leaks, drain

boiler and remove plugs for boiler trim and other

connections.

19

Page 20

SECTION III - INSTALLATION INSTRUCTIONS

A. INSTALL CANOPY/FLUE OUTLET ASSEMBLY,

Refer to Figures 14, 15 and 16.

1. Open canopy carton.

2. Attach the two (2) canopy brackets to the front end

cap of canopy with four (4) #10 x 1/2” sheet metal

screws each.

3. Across the top of the front section and along the top

ledges running back each side of the sections, place

continuous 2” wide strips of cerafelt and overlap

joints at front corners. Cerafelt strip should extend

1/4” beyond rear surface of back section. Cut off

excess.

4. Place the canopy on the sections.

5. Position rear ange (end with studs) of canopy ush

with rear surface of back section.

6. Loosely attach the canopy brackets to the lugs on

the front section of the block assembly with 5/16”

carriage bolts, at washers and locknuts.

7. Check to see if rear ange of canopy is still ush

with raised ange on back section.

8. Open either the rear ue outlet carton (standard) or

top ue outlet carton (optional).

9. Attach the 1/8” x 1” wide self-adhesive ber gasket

to the surface of either the rear ue outlet damper

assembly or rear ue outlet cover that mounts

against the canopy and back section. Gasket must

be centered over all attachment holes. Do not

overlap corners, cut butt joints.

10. Attach either the rear ue outlet damper assembly

or rear outlet canopy cover to the canopy with the

5/16” at wasters, lock-washers and brass

nuts and tighten securely. Attach the rear ue

outlet damper assembly or cover to the back section

with the four (4) 5/16” at washers and cap screws

and tighten securely.

11. Tighten front canopy carriage bolt until canopy is

secure.

12. On the longer canopy sizes, Intermediate Mounting

Brackets are provided, two (2) are required on sizes

V907A thru V909A and four (4) are required on

sizes V910A thru V912A. Refer to Figures 17 and

18.

a. Intermediate brackets are shipped at. Bend

side anges down approximately 90° as shown.

Adjust bends until holes in bracket match hole

pattern on canopy.

b. Secure brackets to both sides of canopy with

three (3) #10 x ½” sheet metal screws per

bracket.

c. Secure canopy left side bracket(s) with

appropriate canopy ‘J’ bolt(s). Insert threaded

20

end through holes in brackets and hook ‘J’ bolt

Figure 14: Canopy with Rear Flue Outlet Damper

Assembly (Shown on optional steel shipping skid)

Figure 15: Canopy with Top Flue Outlet Damper

(Shown on optional steel shipping skid)

Assembly (Rear Cover Removed)

Page 21

Figure 16: Bare Boiler Assembly

21

Page 22

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Repair Parts list designates parts that contain refractory ceramic fibers

(RCF). RCF has been classified as a possible human carcinogen. When

exposed to temperatures about 1805°F, such as during direct flame contact,

RCF changes into crystalline silica, a known carcinogen. When disturbed as a

result of servicing or repair, these substances become airborne and, if inhaled,

may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures

:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

22

Page 23

Figure 17: Left Side Canopy Intermediate Bracket

on center section draw-up rod (hooks should

face outward). Secure canopy with 5/16” at

washers, lock washers and brass nuts. See

Figure 17.

d. Secure canopy right side bracket(s) with ¼ - 20

x 5” lg. carriage bolts. Insert head of carriage

bolt between canopy body and casting. Slide

carriage bolt into slot provided between castings.

Lower carriage bolt until threaded end will pass

through hole in bracket. Secure canopy with ¼”

at washers, lock washers and brass nuts. See

Figure 18.

13. Attach the 1/8” x 1” wide self-adhesive ber gasket

to the surfaces of either the top ue outlet damper

assembly or top outlet canopy cover that mounts

against the canopy. Gasket must be centered over

all attachment holes. Do not overlap corners, cut

butt joints.

14. Secure either the top ue outlet damper assembly

or top outlet canopy cover with #10 x 1/2” sheet

metal screws.

B. INSTALL FLUE COVER PLATES over cleanout

openings on left side of boiler as shown in Figure 19.

See Important Product Safety Information on Page

21 of this manual, regarding refractory ceramic

ber product warning.

Figure 18: Right Side Canopy

Intermediate Bracket

4. Install ue cover plates over studs with insulation

against boiler and secure with washers and nuts.

Tighten until insulation on cover plate provides a

tight seal to casting. If after tightening, a gap is still

evident where the sections join, apply silastic along

top and bottom edge of insulation board.

5. Repeat steps 3 through 6 for mounting remaining

ue cover plates.

1. Locate the cover plates, carriage bolts, nuts and

washers in the boiler assembly carton(s).

2. Remove insulation from two (2) 3/8” diameter holes

in ue cover plates using a 3/8” drill bit. Rotate bit

through insulation by hand.

3. Attach the carriage bolts to the top and bottom of the

ue openings with washers and hex nuts to provide

a xed stud.

Figure 19: Flue Cover Plate Attachment

23

Page 24

C. MOUNT REAR OBSERVATION PORT COVER

Refer to Figure 16.

1. With the silastic sealant, secure the 3/16” diameter

rope gasket into the groove around the perimeter of

the rear observation port cover.

2. Mount the rear observation port cover onto the rear

section (with the word “Top” in the upright position)

using the four (4) 5/16” - 18 x 1” lg. cap screws and

at washers provided.

D. INSPECT ALL BOILER SEALS

1. A visual inspection should be made of all sealed

joints and repairs made as necessary. Darken

the boiler room and place a light source in the

combustion space and canopy to observe any gaps

or open seals. Poor seals must be repaired and

rechecked before continuing.

E. JACKET ASSEMBLY - See Figure 22 for Jacket

Assembly Details.

1. Open jacket carton and jacket hardware package.

Unless otherwise stated, all jacket components are

fastened with #8 x ½” hex head sheet metal screws.

Do not drive sheet metal screws tight until jacket

assembly is complete.

2. On boilers with rear ue outlet damper assembly,

remove square knockout from jacket rear panel. To

remove knockout, use a single hacksaw blade with

handle or aviation snips to cut metal tabs between

slotted holes.

3. Attach jacket front panel to front section and jacket

rear panel to back section using the eight (8) #10

x ½” self tapping screws. Tighten these screws

securely.

4. Attach jacket lower tie bar panel (approximately

5-5/8” high) to the bottom of the jacket front and

rear panels using four (4) sheet metal screws.

Repeat for opposite side.

5. Attach jacket upper tie bar panel (approximately

4-1/8” high) to the top of the jacket front and rear

panels using four (4) sheet metal screws. Repeat for

opposite side.

6. Jacket Top Panel Attachment

a. On boilers with top ue outlet damper assembly,

remove octagon shaped knockout. To remove

knockout, use a single hacksaw blade with

handle or aviation snips to cut metal tabs

between slotted holes.

b. Remove knockout(s) for necessary supply piping

in a similar manner.

c. Attach jacket top panel to the front panel, rear

panel and upper tie bar panels with sheet metal

screws.

7. Install Jacket side Panels

a. Snap black thumb hole bushings into all side

panel holes.

b. Use the left side panel and right side panel usage

charts to determine correct positions of side

panels. The three (3) digit panel identication

numbers shown in the charts are also stamped

along the bottom edge of each panel. Refer to

Figures 20 and 21.

c. Rearward and Intermediate panels have reverse

bend anges on one side of panel. These panels

must be installed prior to forward panels.

NOTICE

To install multiple side panels, start at the rear

of boiler and work forward. To remove panels,

reverse order of assembly.

d. If boiler is equipped with tankless heaters they

should be installed at this time if they were not

installed for hydrostatic test outlined on Page 18.

e. Install right side panels into position by inserting

top of panel into ‘U’ shaped channel, pushing

bottom of panel in toward boiler, and sliding

panel down into ‘J’ shaped channel. Repeat

procedure until all right side panels are in place.

f. Remove the knockouts necessary for tankless

heater operation on left side panels.

g. Install left side panels, using the same procedure

used to install the right side panels.

Boiler

Model

V903A

V904A L10 L11 --- --- --V905A L10 L17 --- --- --V906A L10 L18 L5 --- --V907A L10 L18 L11 --- --V908A L10 L18 L17 --- --V909A L10 L18 L18 L5 --V910A L10 L18 L18 L17 --V911A L10 L18 L18 L17 --V912A L10 L18 L18 L18 L5

To remove panels, reverse order of assembly.

JACKET LEFT SIDE PANEL USAGE CHART

MULTIPLE SIDE PANELS*

Panel No. 1 Panel No. 2 Panel No. 3 Panel No. 4 Panel No. 5

L10 L5 --- --- ---

REAR OF BOILER

* NOTE: To install multiple side panels, start at the rear and work forward.

Figure 20: Left Side Panel Usage Chart

24

FRONT OF BOILER

JACKET RIGHT SIDE PANEL USAGE CHART

Boiler

Model

V903A

V904A --- --- R21 (Single)

V905A --- --- R27 (Single)

V906A --- --- R33 (Single)

V907A --- R15 R24

V908A --- R21 R24

V909A --- R27 R24

V910A --- R27 R30

V911A --- R33 R30

V912A R21 R24 R24

* NOTE: To install multiple side panels, start at the rear and work

forward. To remove panels, reverse order of assembly.

SINGLE OR MULTIPLE SIDE PANELS*

Panel No. 3 Panel No. 4 Panel No. 5

--- --- R15 (Single)

FRONT OF BOILER

Figure 21: Right Side Panel Usage Chart

REAR OF BOILER

Page 25

Figure 22: V9A Series Jacket Assembly (Boiler Models V903A thru V912A)

25

Page 26

8. Combination Label and Burnham Logo Plate were

attached to jacket front panel at time of manufacture.

If loose or peeling, apply pressure to reset adhesive.

9. On steam boilers, attach lowest permissible water

level plate (from steam trim carton) to the front

panel using sheet metal screws.

10. Tighten all sheet metal screws to complete jacket

assembly.

F. BURNER MOUNTING PLATE - Refer to Figures 16

and 23.

1. Using silastic sealant, secure the 3/16” diameter

rope gasket to the groove along the mounting plate

opening in the front section.

2. Install 5/16” x 1” lg. cap screw in lower tapping on

front section to carry weight of burner mounting

plate.

3. Engage bottom slot on burner mounting plate with

matching bolt in bottom tapping of front section.

Align mounting holes and fasten the mounting plate

to the boiler sections with seven (7) remaining 5/16”

cap screws and washers. Fully tighten all bolts.

G. MOUNT BURNER ADAPTER PLATE TO

BURNER MOUNTING PLATE.

Refer to Figures 16 and 23. ALSO, REFER TO

BURNER INSTALLATION MANUAL FOR

INSTRUCTIONS SPECIFIC TO EACH BURNER.

1. In all cases, the burner adapter plate carton for the

specied burner will be provided by Burnham.

2. Open Adapter Plate carton and remove contents.

Apply four (4) small dabs of silastic on rear surface

of adapter plate to temporarily hold gasket in

place. Hold adapter plate in position against burner

mounting plate, align holes and secure with ve (5)

3/8” lock washers and 3/8” x 7/8” lg. cap screws.

3. USE A HOLE SAW OR KNIFE TO CUT

BURNER MOUNTING PLATE INSULATION

TO MATCH HOLE SIZE ON BURNER

ADAPTER PLATE. After cutting, remove any and

all loose pieces of insulation which may become

lodged or interfere with the head of a burner air tube

after insertion.

4. Conrm that hole in insulation ts snugly around

burner blast tube. If hole is oversized, remove

burner mounting plate (with burner attached) from

boiler. Use additional berglass rope gasket

provided with burner to ll in any space between

26

Figure 23: Burner Mounting Plate/Burner Adapter Plate Options

Page 27

insulation and blast tube. If additional rope gasket

is not provided with the burner, use 3/8” berglass

rope rated for 2300°F (provided by others).

Reinstall burner mounting plate when nished.

CAUTION

6. Install the safety valve as shown in Figure 38a.

Safety valve must be installed in vertical position.

7. For boilers with tankless heaters, install the

operating control in an unused tapping through one

of the heater plates.

Failure to properly ll all gaps between the

insulation and burner blast tube may result in

damage to the burner.

5. For boilers without tankless heaters, proceed to

Paragraph H (Install Steam Trim) or I (Install Water

Trim).

6. For boilers with tankless heaters, install the tankless

heater manifolds according to Figure 36.

H. STEAM BOILERS — INSTALL STEAM TRIM

Items for steam trim are located in the steam trim carton

(except for the separately ordered low water cutoff and

tankless heater control). Figure 24 shows the proper

tappings for each item.

1. Install the gauge glass set.

2. Install the low water cut-off. Follow manufacturers

instructions furnished with control.

3. Install the pressure limit control using the ¼” x 90

(1-7/8” x 4”) extended leg syphon and the ¾” NPT x

¼” FPT hex bushing.

NOTICE

The L404 Pressure Limit contains mercury in a

sealed tube. Do not place limit in the trash at the

end of its useful life.

If this limit is replacing a limit that contains

mercury in a sealed tube, do not place your old

limit in the trash.

Contact your local waste management authority

for instructions regarding recycling and the

proper disposal of this limit, or of an old limit

containing mercury in a sealed tube.

If you have questions, call Honeywell Inc. at

1-800-468-1502.

4. Level the pressure limit control by carefully bending

the syphon until the control’s leveling indicator

hangs freely with its pointer directly over the index

mark inside the back of the case.

5. Install the steam gauge using the ½” NPT x ¼” FPT

hex bushing.

WARNING

Safety valve discharge piping must be piped to

within six (6) inches of oor, or to oor drain

to eliminate potential of severe burns. Do not

pipe in any area where freezing could occur. Do

not install any shut-off valves, plugs or caps in

discharge piping.

8. Plug extra boiler tappings.

9. Install required bottom blowoff/drain valve and

connecting piping (supplied by others) per minimum

piping requirements for steam boilers. See Figure

32.

I. WATER BOILERS - INSTALL WATER TRIM

Items for water trim are located in the water trim

carton (except for the separately ordered low water

cutoff and tankless heater control). Figure 24 shows

the proper tappings for each item.

1. Install the temperature pressure gauge.

2. Install the low water cutoff. Follow manufacturers

instructions furnished with control.

3. Install the immersion well and mount the aquastat

(limit control) onto the well.

4. Install the pressure relief valve as shown in Figure

38b. Relief valve must be installed in vertical

position.

5. Plug extra boiler tappings.

6. Install required bottom blowoff/drain valve

(supplied by others) per minimum piping

requirements for water boilers, see Figure 26.

WARNING

Relief valve discharge piping must be piped to

within six (6) inches of oor, or to oor drain

to eliminate potential of severe burns. Do not

pipe in any area where freezing could occur. Do

not install any shut-off valves, plugs or caps in

discharge piping.

27

Page 28

Figure 24: Purpose of Tappings

J. BURNER INSTALLATION

Refer to burner manufacturer’s installation manual

for proper installation, fuel piping, wiring, burner

adjustment, burner start-up and service instructions.

Consult Section VI of this manual for burner

specications and burner settings.

K. PACKAGED BOILER

1. The packaged boiler comes on it’s own shipping

skid (see Figure 25) and the assembled block is

hydrostatically tested at the factory. Once the boiler

is in it’s nal position, perform another hydrostatic

test at 1½ times the working pressure of the boiler.

Before boiler is put into service, all draw up rod nuts

should be loosened and then retighten to nger tight

plus 1/2 turn. The shipping skid can be used as a

housekeeping pad unless local codes say otherwise.

All controls are pre-wired down to the burner. If

burner is equipped with a lead lag panel, lead lag

controls will be shipped loose for header mounting.

The power can be supplied to the burner if equipped

28

with a control panel. If burner has no panel, the

power is supplied to the J-box on the front jacket.

2. SUPPLY CONNECTIONS - Removal of top

jacket is not required to connect the supply riser(s),

however one may nd it easier. Refer to Figure

26 or 27 for water boilers and Figure 32 for steam

boilers.

3. RETURN CONNECTIONS - The boiler is secured

to the shipping skid with U bolts and 3” shipping

nipples. Remove the bolts and nipples. Using

3” plugs and an appropriate pipe sealant, plug

the unused return connections according to the

minimum piping recommendations. Refer to Figure

26 or 27 for water boilers and Figure 32 for steam

boilers.

4. If the boiler burner unit was factory re tested, the

burner was adjusted to approximately 10% CO2

(gas) or 12% CO2 (oil) with an over re pressure as

listed in the Burner Specications, Section VI of this

manual. Final adjustments should be made once the

unit is installed and adjusted.

Page 29

Number

Boiler

Model

Sections

V903A 3 63-5/8 34-1/2 61 17-1/2 1478

V904A 4 69-5/8 34-1/2 61 20-1/2 1790

V905A 5 75-5/8 34-1/2 61 23-1/2 2102

V906A 6 81-5/8 34-1/2 61 27-1/2 2418

V907A 7 87-5/8 34-1/2 61 30-1/2 2734

V908A 8 93-5/8 34-1/2 61 33-1/2 3071

V909A 9 105-5/8 34-1/2 61 37-1/2 3452

V910A 10 111-5/8 34-1/2 61 40-1/2 3809

V911A 11 117-5/8 34-1/2 61 43-1/2 4120

V912A 12 123-5/8 34-1/2 61 46-1/2 4447

* Width can vary with gas train conguration.

If the V9A packaged boiler must pass through a 36” doorway, please

specify.

** Add 6-1/2” to dimension C when equipped with optional top outlet.

*** Varies slightly with burner and gas train conguration and with or without RTC.

1. Do not tilt. Exercise caution when lifting to avoid damage.

2. This boiler can be lifted by fork truck. Do not truck from front.

3. When lifting from rear, forks must extend beyond center of gravity and second skid

cross bar.

4. When lifting from side, forks must extend to opposite skid rail and straddle center

of gravity.

5. Cable spreader is to prevent jacket damage. Spreader width should equal B (width

of skid) + 12”. Adjust cable lengths to lift at approximate center of gravity per chart.

Figure 25: Shipping Information

Length AWidth B*Height

of

C**

Approx.

Center of

Gravity

D***

Approx.

Shipping

Weight

LBS***

L. BOILER PIPING - HEATING APPLICATIONS

CONNECT SUPPLY AND RETURN PIPING TO

HEATING SYSTEM

Connect supply and return piping to heating system (see

Figures 26 through 32). Flow direction for hot water

boilers must be from the rear return out through the top

front supply. Steam boilers can pipe return to the front

as an alternate location. Some boiler sizes may require

the use of additional supply and return tappings. Check

Figure 24 and applicable piping diagram for the boiler

size you are installing.

WARNING

Failure to properly pipe boiler may result in

improper, unsafe system operation and void

manufacturer’s warranty.

DO NOT improperly pipe boiler.

WARNING

All steam and hot water pipes must have

clearances of at least 1/2” from all combustible

construction.

WARNING

A hot water boiler installed above radiation level

must be provided with a low water cutoff device

as part of the installation.

1. HOT WATER HEATING - This boiler must be

installed in strict accordance with this installation

manual Deviations from these installation

instructions may void manufacturer’s warranty.

Also consult I=B=R Installation and Piping Guides.

WARNING

Continued boiler operation for prolonged periods

of time under conditions when temperature

differential across the system exceeds 40°F and/

or, return water temperature stays below 135°F,

may result in premature boiler failure due to ue

gas condensation and/or thermal shock.

a. If the boiler is used in connection with

refrigeration systems, boiler must be installed

with chilled medium piped in parallel with

heating boiler using appropriate valves to prevent

chilled medium from entering boiler. See Figure

35.

b. If the boiler is connected to heating coils

located in air handling units where they may be

exposed to refrigerated air, boiler piping must

be equipped with ow control valves to prevent

gravity circulation of boiler water during cooling

system operation.

c. Burnham Commercial recommends maintaining

temperature differential (drop) across the system

at 40°F or less, and return water temperature at

minimum of 135°F for optimum operation and

long-term reliability.

29

Page 30

i. If minimum return water temperature can

be maintained at 135°F and temperature

differential across the system is at 40°F

or less, refer to Figure 26 or 27 for

recommended minimum boiler piping

details.

ii. If minimum return water temperature cannot

be maintained at 135°F or the temperature

differential across the system varies, a blend

pump is recommended as a minimum to help

protect the boiler from ue gas condensation

and/or thermal shock. See piping details in

Figure 28. Primary secondary piping with

a by-pass is an alternate to the blend pump

method and is shown in Figure 29.

d. If conditions exist where the boiler is subjected

to prolonged periods of operating conditions

below 135°F, other mixing methods such as three

or four way valves or variable speed injection

should be used. Burnham Commercial offers an

RTC Return Temperature Control kit to protect

the boiler. See separate RTC manual.

e. Multiple Boilers - Recommended minimum

multiple boiler piping is shown in Figure 30 as

primary secondary with a by-pass. The boiler

circulator will maintain a constant ow through

the boiler during every heat demand while the

by-pass diverts a portion of hot water back to

the return. Alternate minimum multiple boiler

piping is shown in Figure 31. The blend pump

will maintain constant ow through the boiler

during every heat demand and provide a hot

water blend back to the return.

f. Glycol Antifreeze Solutions - Many systems

today use ethylene or propylene glycol antifreeze

solutions as a measure for freeze protection, as

well as a pump lubricator and corrosion inhibitor.

The properties of the glycol mixture have an

impact on valve and pump sizing. All glycol

solutions have a lower specic heat than water.

This means that the glycol solution cannot

transfer heat as well as pure water, resulting in

the need for higher ow rates. In addition, the

viscosity of the glycol solution is usually higher

than water, requiring a higher pump head for the

same given ow. Consult factory for specic

applications, pump selection and ow rate.

WARNING

A properly constructed Hartford Loop must be

installed on all gravity return steam systems.

Hartford Loop is not required on pumped return

systems.

2. STEAM HEATING, consult I=B=R Installation

and Piping Guide No. 200. For piping details,

see Figure 32. Figure 33 shows a typical pumped

return/boiler feed unit arrangement. Figure 34

illustrates the required elevations for McDonnell and

Miller 150 and 63 oat low water cut-offs.

30

Page 31

Figure 26: V9A Series Minimum Piping - Parallel - Water Boiler

31

Page 32

32

Figure 27: V9A Series Minimum Piping - Primary Secondary - Water Boiler

Page 33

Figure 28: V9A Series Minimum Piping Details, Bypass with Blend Pump - Water Boiler

33

Page 34

34

Figure 29: V9A Series Minimum Piping - Primary Secondary/with Bypass - Water Boiler

Page 35

Figure 30: Minimum Piping Details - Multiple Boiler Application, Primary/Secondary Piping With Bypass

35

Page 36

36

Figure 31: Minimum Piping Details - Multiple Boiler Application, Parallel Piping With Blend Pump

Page 37

Figure 32: Minimum Piping Requirements For Gravity Return V9A Series Steam Boilers

37

Page 38

38

Figure 33: Typical Steam Piping Arrangement for Boilers with Pumped Condensate Return and Boiler Feed Unit

Page 39

M. BOILER PIPING, DOMESTIC HOT WATER

(DHW) APPLICATION – The V9A boiler can be

used in many different piping applications to produce

Domestic Hot Water (DHW). In some applications,

depending on the control strategy (outdoor reset,

setpoint operation, etc.) and size of boiler, it is

recommended to isolate the space heating load from

the DHW load. For example, if the domestic load is

more than the space heating load, it is benecial to

dedicate one or more boilers solely to DHW production