Page 1

Price - $3.00

INSTALLATION, OPERATING AND

SERVICE INSTRUCTIONS FOR

LEDV SERIES DIRECT VENT

OIL FIRED BOILER

As an ENERGY STAR Partner, Burnham Corporation has determined that the LEDV-1, fired at the 0.60 GPH rate,

meets the ENERGY STAR guidelines for Energy efficiency established by the United States Environmental Protection

Agency (EPA).

For service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide

Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number

L EDV__ - __ ____ _

Heating Contractor Phone Number

Address

81433101R3-3/00

Boiler Serial Number

6 _ _ _ _ _ _ _

1

Installation Date

Page 2

IMPORTANT INFORMATION - PLEASE READ THIS PAGE CAREFULL Y

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to

important information concerning product life.

DA NGER

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of this or any

other appliance.

If you smell g as vapors, DO NOT try to op erate any ap pliance - DO NOT touch any electrical

switch or use any phone in the building. Immediately, call the gas supplier from a remotely

located phone. Follow the gas sup p lier's instru ctions o r if th e supplier is unavailab le, cont act th e

fire department.

WARN ING

Improper installation, adjustment, alteration, service or maintena nce can cause property damage,

personal injury or loss of li fe. Failure to fo llow all instructions in the proper order can cause

personal injury or death. Read and und erstand all instruction s, including all those contained in

component manufac turers manuals which are provided w ith the appliance before installing,

starting-u p , op erating, maintaining or servicing this ap pliance. Keep this manual and liter ature in

legib le conditio n and posted near appliance fo r reference by owner and service technician.

This boiler req uires regular maintenance and service to operate safely. Follow the instructions

contained in this manu al. Installatio n, maintenance, and service must be p erform ed on ly by an

ex perienced, skilled installer or servi ce agency. A ll he ating systems should be designed by

co mpetent contractor s and on ly person s kn o wled geable in the layout and installat ion of hydronic

heating sy stems s ho uld attemp t installa tion of any bo iler. It is the resp on sibility of the in stalling

contractor to see that all controls are correctly installed and are operating properly when the

inst allation i s comp leted . Inst allation is not comp lete u nles s a p res sure re lief va lve is in stalled

into the tapp ing loca ted on top of applian ce - S ee Se ction III o f t his m anua l for details.

2

Page 3

WARNING

Boiler materials of construction, products of combustion and the fuel contain alumina, silica,

heavy metals, carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful

substances which can cause death or serious inj ury and which are kno wn to th e state of California

to cause cancer, birth def ects and o ther repro ductive h arm . Always use proper safety clothing,

respirators and equipment when servicing or working near by th e boiler.

This boiler contains very hot water under high pressures. Do not unscrew any pipe fittin gs nor

attempt to disconnect any components of this boiler witho ut positively assur ing the water is cool

and has no pressure. Always wear p ro tective cloth ing and equipment when installing, starting

up or servicing this boiler to prevent scald injuries. Do not rely o n t h e pressure and temperatur e

gauges to determ ine the temp erature and pressure of the boiler. This boiler contains components

which become very hot when the boiler is operating. D o not touch any components unless they

are cool.

This boiler must be properly vented and connected to an approved vent system in goo d condition.

Serious p roperty dam age could result if the boiler is connected to an unapproved ven t system

This boiler needs fresh air for safe op eration and m ust be installed so there are provisio ns for

adequate combustion and ventilation air.

The interior of the venting an d air intake systems must b e inspected and cleaned before the start

of the heating season and should be inspected periodically throughout the heating season for

any obstructions. Clean and unobstructed venting an d air intake systems ar e necessary to allow

noxious fumes that could cause injury or loss of life to vent safely and will contribute toward

maintaining the boiler's efficiency.

This boiler is supplied with controls which may cau se the boiler to shut down and not re-start

withou t service - If d amage due to fro zen pipes i s a pos sibility, t he heating system should

not be left unatttended in cold weather; or appropriate safegu ards and alarms should be installed

on the h eating system to prevent damage if th e boiler is inoperative.

This boiler is desig ned to bur n No. 2 fu el oil only. D o not use gasoline, crankcase drainings, or

any oil containing gasoline. Never bu rn garb age or paper in thi s boiler. Do not convert to any

solid fuel (i. e. wood, coal) or gaseous fuel (i. e. natural gas, LP/propane). All flammable debr is,

rags, paper, wood scraps, etc., should be kept clear of the boiler at all times. K eep the boiler area

clean an d f ree of fire hazards.

All boilers equipped w ith Burner Swing Door have a potential hazard which can cause severe

property damage, personal injury or loss of life if ignored. B efore opening swing door, turn off

service switch to boiler and disconnect two halves o f Burner Swing Doo r Interlock wiring harness

to prevent accidental firing of b u rner ou tside the co mbustio n chamber. Be sure to tigh ten swing

door fastener completely and reconnect two halves of Burner Swing Door Interlock when service

is co mpleted.

.

NOTICE

Th is boiler has a limited warranty, a copy of which is printed o n the back of th is ma nua l.

It is the respons ibility of the in stalling cont ractor to see th at all controls are correctly in stalled

and are operat ing prop e rly when the installatio n is c omplete. T he warran ty for this boile r is valid

only if the boiler has been installed, maintain ed and operated in accor d ance with th ese

instr u ctions.

3

Page 4

NOTICE

All boilers must be installed in accordance with National, State and Local Plumbing, Heating

and Electrical Codes and the regulations of the serving utilities which may differ from this

manu a l. Authorities having jurisdic t ion should be con s ulted before installatio ns are made.

In all cases, r eferen ce sho uld b e made to th e following Standards:

USA BOILERS

C urr ent Edition of American Na t iona l Standard AN SI/NFPA 31, “Inst a llation of Oil Burning

A.

Equipment”, for recommen ded installation practices.

B.

Current Edition of American National Standard ANSI/NFPA 211, “Chimneys, Fireplaces,

Ven ts, a nd Solid Fuel Bu rning App lian ces”, F or Venting r equirem ents.

C.

Cu rrent Edition of American Society of Mechanical Engineers ASME CSD-1, "Contro ls and

Safety Devices for Automatically Fired Boilers", for assembly and operations of con trols

and safety devices.

CA NADIAN B OIL ERS

A. Current Edition of C anadian Standards Association CSA B139, "Installation Code for Oil

Burning Equipment", for recommended Installation Practices.

This boiler is suitable for installation on combustible flooring. Boiler cannot be installed on

carpeting.

For optimum performance and servi ceability from this unit adhere to the following

recommendations:

A.

Do not tamper w ith or alter the unit or controls. Retain your contractor or a competent

serviceman to assur e th at th e unit is properly adjusted and maintained.

B.

Clean firetub es at least once a year - p referably at the start of the heating season to remove

soot and scale. Inside of Combustion Chamber should also be cleaned at the same time.

C.

Have Oil Bu rner and Con tro ls checked at least once a year or as may b e necessitated.

D.

Do not operate unit with jumpered o r absen t con trols or devices.

E.

Do not op erate unit if any control, switch , com p onent, or device has been subject to w ater.

4

Page 5

T able of Contents

I. Pre-Installation ......................................... 6

II. Unpack Boiler........................................... 7

III. Water Piping and Trim ............................ 9

IV. Venting/Air Intake Piping ..................... 12

V. Electrical and Sequence of Operations .. 18

VI. Oil Piping ............................................... 20

VII. System Start-up ...................................... 22

VIII. Service and Cleaning .............................. 26

IX. Repair Parts ............................................ 29

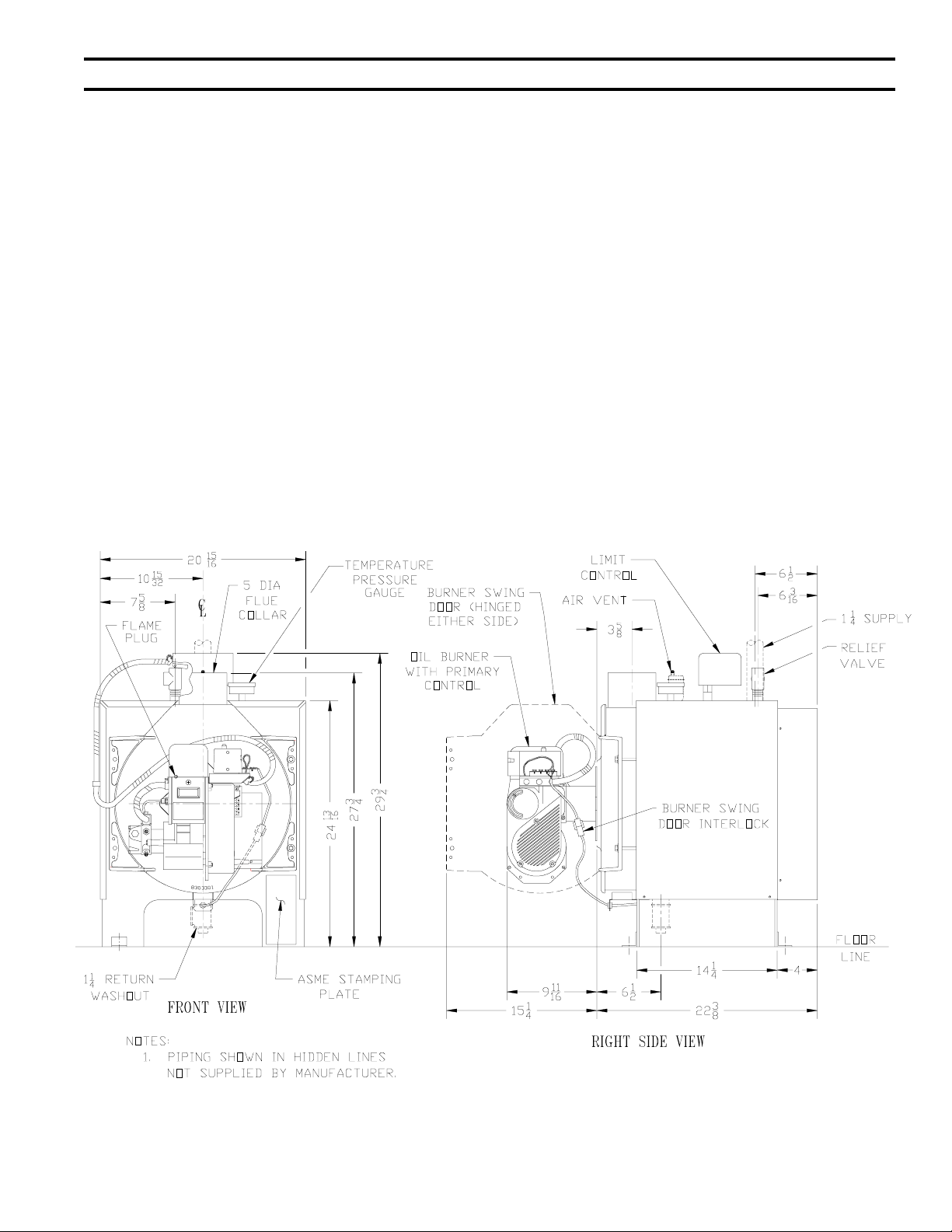

Figure 1: LEDV Packaged Boiler

5

Page 6

I. Pre-Installation

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated boiler to the carrier in good

condition.

2. ANY CLAIMS for damage or shortage in shipment

must be filed immediately against the carrier by the

consignee. No claims for variances from, or

shortage in orders, will be allowed by the

manufacturer unless presented within sixty (60)

days after receipt of goods.

B. LOCATE BOILER in front of final position before

removing crate. See Figure 1. Boiler's approximate

shipping weight is 325 pounds.

1. LOCATE so that vent pipe will be short and direct.

Refer to Section V. A., General Venting

Guidelines.

2. BOILER IS SUITABLE FOR INSTALLATION ON

COMBUSTIBLE FLOOR. Boiler cannot be installed

on carpeting.

3 . FOR BASEMENT INSTALLATION, provide a solid

base, such as concrete, if floor is not level, or if water

may be encountered on floor around boiler.

4. PROVIDE SERVICE CLEARANCE of at least 24” at

front of boiler for servicing.

5. For minimum clearances to combustible materials,

see Figure 2.

C. PROVIDE COMBUSTION AIR SUPPLY to

accommodate proper combustion of oil. Local and

national codes may apply and should be referenced.

1. In unconfined spaces (basement) in buildings of

conventional frame, brick, or stone construction,

infiltration normally is adequate to provide air for

combustion. An unconfined space is a space whose

volume is greater than or equal to 50 cubic feet per

1000 BTUH of the combined input of all air

consuming appliances in the space.

2. In a confined space, combustion air may be ducted

directly from the outdoors to the burner. Refer to

Section IV for installation of air intake duct to the

burner.

D. VENTILATION AIR must be provided to maintain the

ambient temperature at safe limits. Local and national

codes may apply and should be referenced.

1. In unconfined spaces (basement) in buildings of

conventional frame, brick, or stone construction,

infiltration normally is adequate to provide air for

ventilation.

2. In confined spaces (closet, etc.) two permanent

openings, one near the top of the enclosure and one

near the bottom, shall be provided. Each opening

shall have a free area of not less than 1 sq. inch per

1000 BTUH of the total input of all appliances in

the space.

E. Do not install boiler where gasoline or other

flammable vapors or liquids, or sources of

hydrocarbons (i.e. bleaches, cleaners, chemicals,

sprays, paint removers, fabric softeners, etc.) are used

or stored.

6

Page 7

II. Unpack Boiler

CAUTION

Do not drop boiler. Do not bump boiler jacket

against floor.

A. REMOVE CRATE

1. Remove all fasteners at crate skid.

2. Lift outside container and remove all other inside

protective spacers and bracing. Remove vacuum

relief valve and miscellaneous trim bag containing

safety/relief valve, and pipe fittings.

B. REMOVAL OF BOILER FROM SKID

1. Boiler is secured to base with 2 bolts, 1 at left front

and 1 at right rear. Remove both bolts.

2. Tilt boiler, "walk" boiler backward, and set rear

legs down on floor. Tilt boiler backward, pull skid

forward and set front legs down on edge of skid.

Install close nipple, tee, and plug in return

coupling. See Section III and Figure 5. Point tee

toward permanent return location.

3. Tilt boiler backward and remove skid. Be careful

not to damage Burner or Jacket.

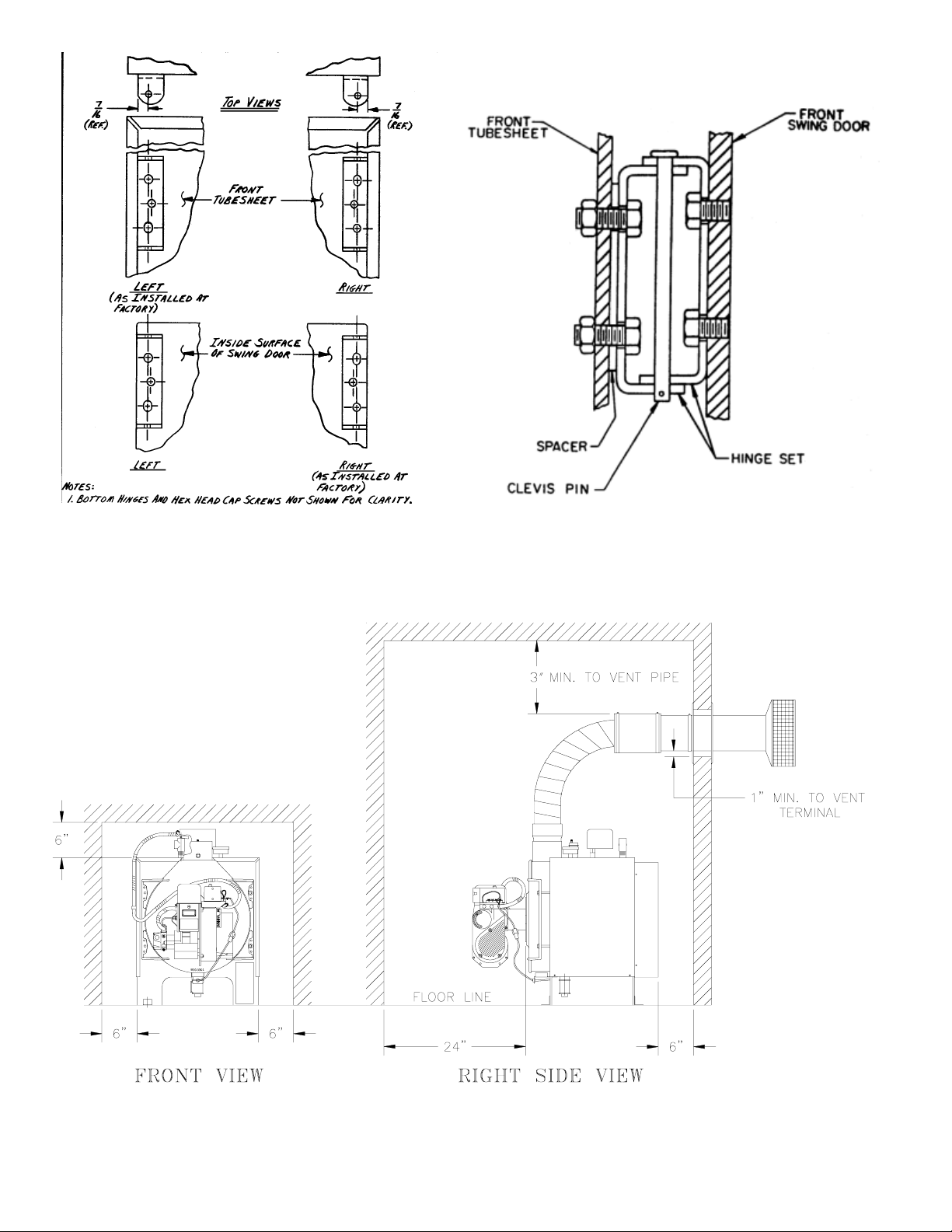

C. DETERMINE PROPER HINGE LOCATION FOR

BURNER SWING DOOR. Boiler is shipped with

hinges on left side. Approximately 12 inches are

required on the hinge side for burner clearance. If

there will be less than 12 inches from left side of boiler

to wall, move hinges to right side (refer to Paragraph

D).

D. HINGE LOCATION CHANGE (if required).

1. Pull 2 halves of Burner Swing Door Interlock apart.

Swing Door Interlock is connected to R-W

terminals on R8184P Control. Lift Honeywell

R8184P Control off of Burner Junction Box and

disconnect wiring harness from burner.

2. Remove 8 sheet metal screws from jacket. Remove

rear jacket box and bend both sides of Jacket

Wrapper up, see Figure 20.

3. Remove 2 (two) 5/16" - 18 x 3" long hex head cap

screws and flat washers from right side of door.

Remove 2 hairpin cotter pins and 2 hinge pins from

hinges on left side of door and remove Door

Assembly from boiler. Inspect Front and Rear Door

Insulation Pieces and Combustion Chamber Liner,

see Paragraph G.

4. Remove 4 hex nuts from bolts that attach hinges

and hinge spacers to left side of Tubesheet. Remove

4 hex head cap screws that attach hinges to door.

5. Attach 2 hinge brackets & spacers to Tubesheet and

2 hinge brackets to Door on right side of boiler. 3

Holes in each Hinge Bracket must line up with 3

matching holes in Spacer, Tubesheet or Door. See

Figure 3. Tighten hex nuts, bolts and screws by

hand only.

6. Replace door assembly. Hinge brackets attached to

door must rest on top of hinge brackets attached to

tubesheet. See Figure 4. Slide hinge pins through

hinges from top and install cotter pins. Close door

and install 5/16" - 18 x 3" long hex head cap

screws through flat washers and left side of door

and into tapped holes in tubesheet. Tighten all hex

nuts, bolts and screws. When door is installed

properly, it is parallel to Tubesheet when viewed

from top and sides.

7. Bend sides of Jacket Wrapper down and attach 2

Jacket Straps to 4 slots at bottom of Jacket Wrapper

sides with sheet metal screws. Install Rear Jacket

Box with 4 sheet metal screws. See Figure 20.

8. Connect wiring harness to burner Junction Box and

install Honeywell R8184P Control, see Wiring

Diagram, Figure 15.

Reconnect Swing Door Interlock.

E. INSTALL BOILER CONTROL.

1. Pull bulb and capillary tube out of hole in back of

control. Insert bulb in immersion well on top of

boiler and secure control with set screw in control.

2. Secure flexible conduit to Jacket Wrapper side with

conduit clamp and sheet metal screw. Conduit

must be on same side of boiler as Swing Door

hinges.

F. MOVE BOILER TO PERMANENT POSITION by

sliding or walking.

G. INSPECT FRONT AND REAR DOOR INSULATION

AND COMBUSTION CHAMBER LINER

1. OPEN BURNER SWING DOOR on front of boiler.

Use flashlight to inspect insulation secured to front

and rear doors. Inspect ceramic fiber blanket

secured to bottom of combustion chamber. Inspect

inner and outer door gaskets. Replace any damaged

pieces.

7

Page 8

TS-98-14-A

Figure 4: Hinge AssemblyFigure 3: Proper Hinge Bracket Installation

Figure 2: Minimum Clearances to Combustible Materials

8

Page 9

III. Water Piping and Trim

A. Design and install boiler and system piping to

prevent oxygen contamination of boiler water.

There are many possible causes of oxygen

contamination such as:

1 . Addition of excessive make-up water as a result of

system leaks.

2. Absorption through open tanks and fittings.

3. Oxygen permeable materials in the distribution

system.

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by

taking the following measures:

1. Repairing system leaks to eliminate the need for

addition of make-up water.

2. Eliminating open tanks from the system.

3. Eliminating and/or repairing fittings which allow

oxygen absorption.

4. Use of non-permeable materials in the distribution

system.

5 . Isolating the boiler from the system water by

installing a heat exchanger.

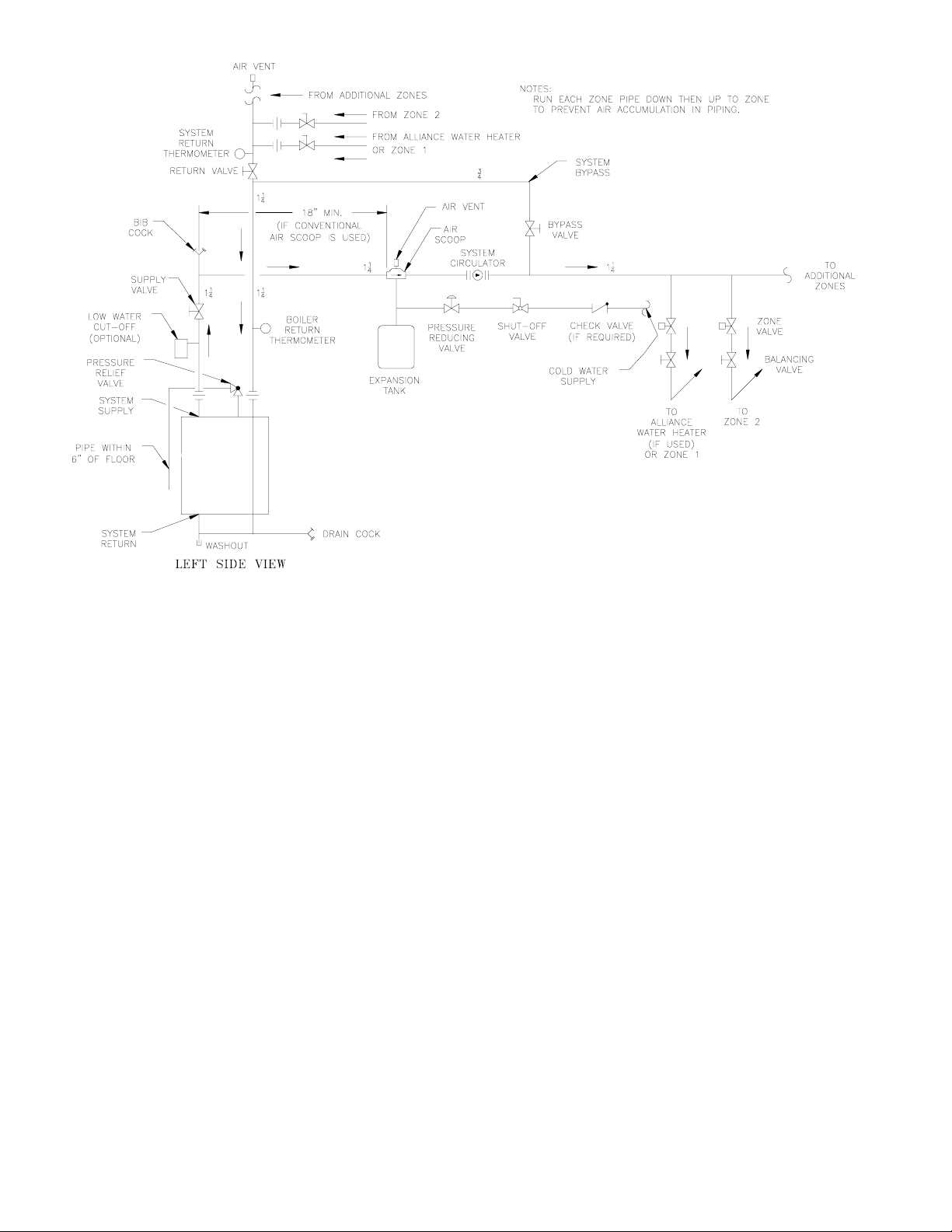

B. Connect System supply and return piping to boiler. See

Figures 5 and 7. Also consult I=B=R Installation and

Piping Guides. Maintain minimum ½ inch clearance from

hot water piping to combustible materials.

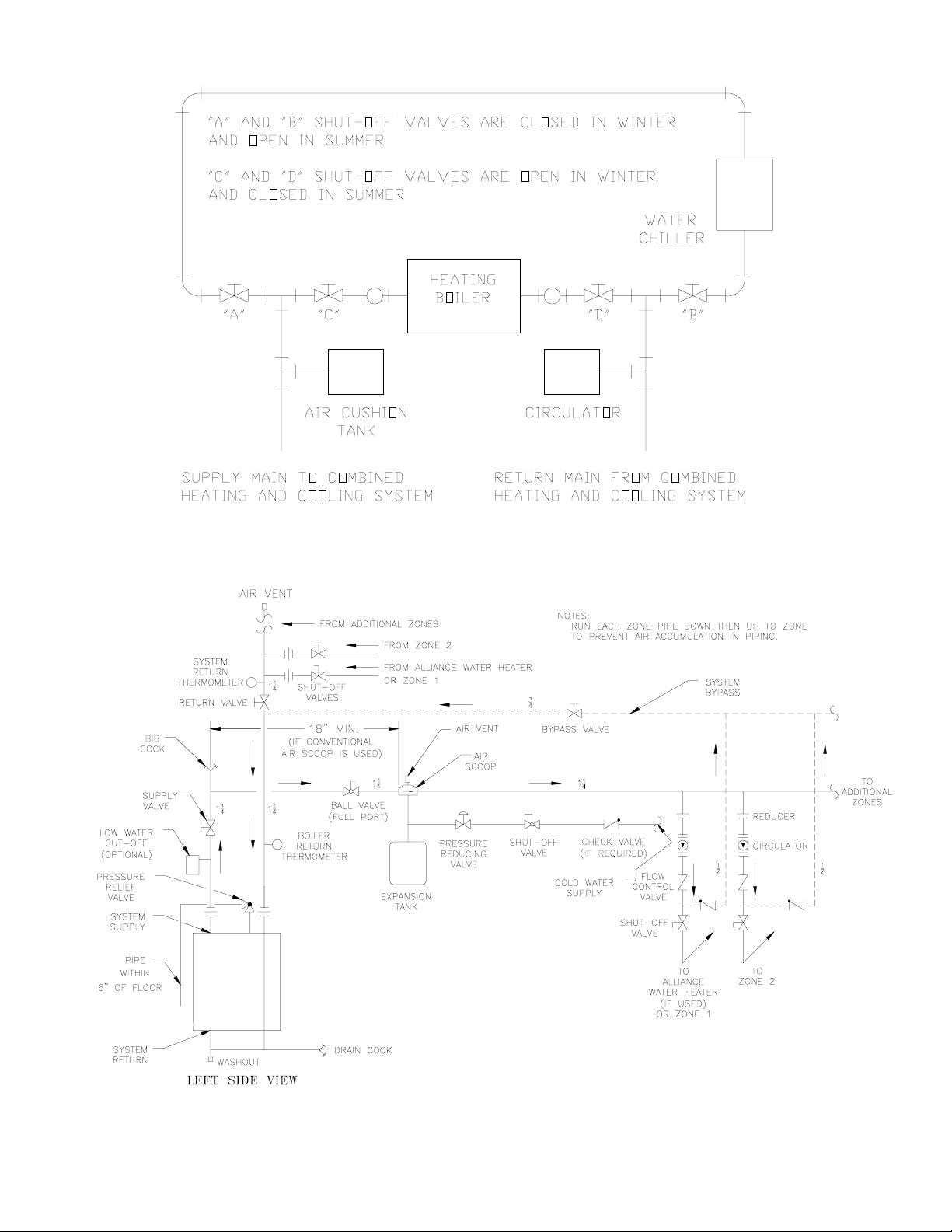

refrigerated air, the boiler piping must be equipped

with flow control valves to prevent gravity

circulation of boiler water during the operation of the

cooling system.

3 . If boiler is used with an Alliance Indirect-Fired

Domestic Water Heater, install the Alliance as a

separate heating zone. Refer to the Alliance

Installation, Operating, and Service Instructions for

additional information.

4. Use a system bypass if the boiler is to be operated in

a system which has a large volume or excessive

radiation where low boiler water temperatures may

be encountered (i.e. converted gravity circulation

system, etc.).

The bypass should be the same size as the supply

and return lines with valves located in the bypass

and return line as illustrated in Figures 5 and 7 in

order to regulate water flow for maintenance of

higher boiler water temperature.

Set the by-pass and return valves to a half throttle

position to start. Operate boiler until the system

water temperature reaches its normal operating

range.

Adjust the valves to maintain 180°F to 200°F boiler

water temperature and greater than 120°F return

temperature. Adjust both valves simultaneously.

Closing the boiler return valve while opening the bypass valve will raise the boiler return temperature.

Opening the boiler return valve while closing the bypass valve will lower the boiler return temperature.

5 . A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of the installation.

C. Install Safety Relief Valve. See Figures 5 and 7. Safety

Relief Valve must be installed with spindle in vertical

position. Installation of the relief valve must be

consistent with the ANSI/ASME Boiler and Pressure

Vessel Code, Section IV.

1 . If this boiler is used in connection with refrigeration

systems, the boiler must be installed so that the

chilled medium is piped in parallel with the heating

boiler using appropriate valves to prevent the chilled

medium from entering the boiler, see Figure 6. Also

consult I=B=R Installation and Piping Guides.

2. If this boiler is connected to heating coils located in

air handling units where they may be exposed to

WARNING

Safety (relief) valve dischar ge p iping must

be piped near floor to elim inate potential of

severe bur ns. D o not pipe in any ar ea where

freezing co uld occur. Do not install any shutoff valves, plugs or caps.

9

Page 10

Figure 5: Recommended Boiler Piping for Zoning with Valves

D. Install Drain Valve in return piping. See figure 5.

E. Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new or

reworked system should be boiled out, and then

thoroughly flushed. A qualified water treatment

chemical specialist should be consulted for

recommendations regarding appropriate chemical

compounds and concentrations which are compatible

with local environmental regulations.

F. After the boiler and system have been cleaned and

flushed, and before refilling the entire system add

appropriate water treatment chemicals, if necessary, to

bring the pH between 7 and 11.

G. Fill entire heating system with water and vent air

from system. Use the following procedure on a Series

Loop System equipped with zone valves. (See Figure

5).

1 . Close isolation valve in boiler supply piping.

2 . Isolate all circuits by closing zone valves or

balancing valves.

isolation valve in boiler supply piping. (Note Terminate hose in five gallon bucket at a suitable

floor drain or outdoor area).

4. Starting with one circuit, open zone valve.

5. Open bib cock.

6. Open fill valve (Make-up water line should be

located directly above isolation valve in boiler

supply piping).

7 . Allow water to overflow from bucket until dis charge

from hose is bubble free for 30 seconds.

8. Open zone valve to the second zone to be purged,

then close the first. Repeat this step until all zones

have been purged, but always have one zone open.

At completion, open all zone valves.

9. Close bib cock, continue filling the system until

the pressure gauge reads 12 psi. Close fill valve.

(Note - If make-up water line is equipped with

pressure reducing valve, system will automatically

fill to 12 psi.

10. Open isolation valve in boiler supply piping.

3. Attach a hose to bib cock located just below

11. Remove hose from bib cock.

10

Page 11

Figure 6: Recommended Piping for Combination Heating & Cooling (Refrigeration) Systems

Figure 7: Recommended Boiler Piping for Zoning with Circulators

11

Page 12

IV. Venting / Air Intake Piping

A. General Guidelines

1 . Vent system installation must be in accordance with

these instructions and applicable provisions of local

building codes. Contact local building or fire officials

about restrictions and installation inspection in your

area.

2 . The LEDV Series is designed as a Direct Vent boiler.

In this configuration, all air for combustion is

supplied directly to the burner from outdoors and

flue gases are vented directly outdoors (through

wall). See Figures 10 and 11. The LEDV may be

side-wall vented with combustion air supplied from

indoors. This configuration may be used in

installations where infiltration provides adequate air

for combustion and ventilation. Flue gases are still

vented directly outdoors (through wall).

3 . For minimum clearances to combustible materials

refer to Figure 2.

4 . Maximum wall thickness that vent terminal may be

installed through is 10 inches.

5 . Vent Terminal Location (see Figure 8). Locate vent

terminal so vent pipe is short and direct. The vent

terminal must be located:

a. Not less than 12 inches above grade plus snow

accumulation.

b. Not less than 4 feet below, 4 feet horizontally, or

1 foot above any door, window, or gravity air

inlet.

c. Not less than 3 feet above any forced air inlet

located within 10 feet.

d. Not less than 2 feet from an adjacent building.

e. Not less than 7 feet above a public walkway.

Figure 8: Vent Terminal Location

12

Page 13

6 . Intake Terminal Location (Direct Vent only) - Locate

Air Intake Terminal not less than 12 inches to the

left, right, or bottom of the vent terminal. Do not

locate air intake terminal above vent terminal. Intake

terminal must be at least 12 inches above grade plus

snow accumulation. See Figure 9.

7. The LEDV must be vented with 4" Z-Flex Direct

Oil™ Vent. 20 feet is the maximum vent length

allowed. The vent pipe is available in 5, 10, 15, and

20 foot lengths. Table 1 lists vent part numbers.

Components of this kit are listed in the Repair Parts

Section of this manual.

B. Vent Installation (Direct Vent and Side-Wall Vent)

1. Install Vent Terminal. See Figure 10.

Table 1: Vent Pipe Part Numbers

4" Direct Oi l™ Vent Pipe

Pipe Length Burnham Part No.

5 Ft. 8113302

10 F t. 8113303

15 F t. 8113304

20 F t. 8113305

8 . The vent system must be completed with the Direct

Oil™ Vent Kit, which is shipped with the boiler.

a. After determining the location from previous

Section, cut an opening in the wall for the vent

terminal.

• Combustible wall: 8 inches diameter hole is

required to maintain a 1 inch clearance to

combustible materials.

• Non-combustible wall: 6½ inches diameter

hole is required.

b. Secure trim plate to outside wall.

c. Insert the vent terminal through the opening

until the stop bead rest against the trim plate.

d. Slide the inside trim plate assembly (fitted with

gear clamp) onto the terminal pipe.

Figure 9: Intake Terminal Location

13

Page 14

Figure 10: Vent Installation

Figure 11: Vent Connector, Un-Assembled

14

Page 15

Figure 12: Vent Connector, Assembled

Figure 13: Air Intake Installation

15

Page 16

e. Secure the inside trim plate to inside wall.

f. Tighten the gear clamp to the terminal pipe.

g. Seal all external joints with a weatherproof caulk.

2 . Cut vent pipe to length with a hack saw.

3. Install Vent Connector/Appliance Adaptor. See

Figures 11 and 12.

a. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) around

outside of corrugated pipe of vent connector.

b. Twist vent connector into end of vent pipe.

Turn the connector counter-clockwise until it is

engaged approximately 4 inches into the inner

vent pipe and the outer collar of the connector

overlaps the outside of the vent pipe.

a. All horizontal runs must rise at least ¼ inch per

foot toward vent terminal.

b. Avoid any sags or dips in vent pipe.

C. Air Intake Installation (Direct Vent only)

See Figure 13.

1. General

c. Tighten the gear clamp on the outer collar of the

connector.

d. Repeat steps a. through c. with the appliance

adapter.

4. Connect vent pipe to boiler.

a. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) to inside

of appliance adapter (approximately ½ inch

from end).

b. Slip appliance adapter over boiler flue collar and

tighten gear clamp.

5. Connect vent pipe to terminal.

a. Carefully slide insulation sleeve over vent

connector and vent pipe until gear clamp on

small end of connector can be accessed.

a. Use 4 inch diameter single wall metal pipe and

fittings available at most heating distributors.

Maximum allowable air intake length is 40

equivalent feet. Each elbow is equal to 6

equivalent feet.

b. Start at Burner. Work toward air intake terminal.

c. Maintain minimum of ¼ inch per foot slope in

horizontal run to air intake terminal. Slope

down toward air intake terminal.

d. Seal all joints gas-tight, using silicone caulk or

self-adhesive aluminum tape.

2. After determining location, cut a hole in the wall to

accept 4 inch air intake pipe.

3. Remove the black plastic inlet cover from the right

side of the Beckett AFII burner.

4. Mount the vacuum relief valve tee assembly or 90°

elbow into the burner inlet ring. See Figure 13.

a. Secure with at least three (3) sheet metal screws

evenly spaced around the burner inlet ring.

b. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) on inside

of cent connector (approximately ½ inch from

end).

c. Clip connector over vent terminal until it is fully

engaged. Then tighten gear clamp.

d. Slide insulation sleeve over terminal connection

so that connector is completely covered.

e. Secure each end of insulation sleeve with the

gear clamps provided.

6. Secure vent pipe in position with pipe straps.

b. Assemble the vacuum relief valve balance

weight onto the gate. Refer to the vacuum relief

valve manufacturer's instructions.

c. Mount the vacuum relief valve into the tee and

fasten with a screw and nut in collar tabs. To

ensure proper operation, the gate must be level

across the pivot point and plumb. Refer to

vacuum relief valve manufacturer's instructions.

5 . Install remainder of air intake, securing each joint

with at least three (3) sheet metal screws evenly

spaced.

16

Page 17

6. Install air intake terminal. See Figure 13.

7. Seal all external joints with weatherproof caulk.

D. Air Intake Installation (Indoor Air for Combustion)

1 . Remove the black plastic inlet cover from the right

side of the Beckett AFII burner.

2 . Attach the Air Intake Terminal directly to the burner

intake collar.

3 . Discard the Vacuum Relief Valve.

Alternate to 1., 2. and 3.:

Keep the black plastic inlet cover in place and

discard the Air Intake Terminal and the Vacuum

Relief Valve.

17

Page 18

V. Electrical and Sequence of Operations

A. ELECTRICAL

1. Install wiring and ground boiler in accordance with

requirements of authority having jurisdiction, or in

absence of such requirements the National

Electrical Code, ANSI/NFPA 70, and/or the CSA

C22.1 Electric Code.

2. A separate electrical circuit should be run from the

main electrical service with a fused disconnect

switch in the circuit.

3. Wiring should conform to Figure 15.

B. SEQUENCE OF OPERATIONS

1. General. A call for heat by the thermostat

energizes the L8148A limit control which in turn

energizes the R8184P primary control to turn on

the burner. The circulator will operate as long as

there is a call for heat. If the call for heat is not

satisfied and the high limit setting is reached, the

circulator will continue to operate, and the burner

will stop until the high limit circuit is closed by a

drop in boiler water temperature.

2. L8148A Combination Limit control.

The switching action within the L8148A control

has one setting, the high limit. The switching relay

is controlled by the low voltage room thermostat.

On a call for heat, the relay contacts close to

complete the line voltage circulator circuit and also

the burner circuit if the boiler water temperature is

below the high limit setting. The high limit switch

shuts off the burner if boiler water temperature

exceeds the high limit setting. See Figure 14.

and ignition transformer.

b. After a 15 second pre-purge period, in which

time a draft is established in the flueways, the

oil valve is opened.

c. If the burner ignites within 15 seconds from the

time the oil valve opens and the CAD cell senses

a flame, the burner will operate until the call for

heat is satisfied or the setting of the high limit is

reached.

d. A manual reset button is provided to reset the

safety switch after lockout.

e. When the call for heat ends, or the CAD cell

fails to sense a flame, the oil valve will close.

The combustion blower will continue to operate

for a postpurge period of approximately two (2)

minutes.

4. CAD Cell.

The Beckett AFII burners used on the LEDV Series

are supplied with a C554A Cadmium Sulfide (cad

cell) Flame Detector to monitor the burner flame

and shut down the burner on ignition failure or on

flame failure during the run cycle. On either

failure, the manual reset button on the R8184P will

be tripped.

3. R8184P Oil Primary Control.

The R8184P operates the oil burner motor, solenoid

oil valve, and the ignition transformer in response

to a call for heat from the L8148A limit control.

a. A call for heat will energize the burner motor

Figure 14: Control Differential

18

Page 19

19

Figure 15: Schematic Wiring Diagram

Page 20

VI. Oil Piping

A. General

1. Use flexible oil line(s) so that Swing Door can be

opened without disconnecting oil supply.

2. A supply line fuel oil filter is recommended as a

minimum for all firing rates but a pleated paper

fuel oil filter is recommended for the lowest (.6

GPH) firing rate application to prevent nozzle

fouling.

3. Use Flared fittings only. Do not use compression

fittings.

4. Use of a high efficiency micron oil filter (Garber or

equivalent) in addition to conventional filter is

highly recommended.

B. Single-pipe Oil Lines.

1. Standard burners are provided with single-stage

3450 rpm fuel units with the bypass plug removed

for single-pipe installations.

2. The single-stage fuel unit may be installed singlepipe with gravity feed or lift. Maximum allowable

lift is 8 feet. See Figure 16.

TABLE 2: SINGLE-STAGE U NITS (3450 RPM)

TWO-PIPE SYSTEMS

Maximum Le ngth of Tubing

Lift "H"

(See Fig. 16)

0' 84' 100'

1' 78' 100'

2' 73' 100'

3' 68' 100'

4' 63' 100'

5' 57' 100'

6' 52' 100'

7' 47' 100'

8' 42' 100'

9' 36' 100'

10' 31' 100'

11' 26' 100'

"H" + "R" (Se e Figure 16)

3/8" OD

Tubing (3 GPH )

Tubing (3 GPH )

1/2" OD

12' 21' 83'

13' - -- 62'

14' - -- 41'

Figure 16: Single-Pipe Installation

20

Page 21

Figure 17: Two-Pipe Installation

C. Two-Pipe Oil Lines.

1. For two-pipe systems where more lift is required,

the two-stage fuel unit is recommended. Table 2

(single-stage) and Table 3 (two-stage) show

allowable lift and lengths of 3/8-inch and ½-inch

OD tubing for both suction and return lines. Refer

to Figure 17.

TABLE 3: T WO-STAGE U NITS (3450 RPM)

TWO-PIPE SYTEMS

Maximum Length of Tubing

Lift "H"

(See Fig. )

"H" + "R" (See Figure)

3/8" OD

Tu bin g (3 G P H)

1/2" OD

Tu bin g (3 G P H)

0' 93' 100'

2' 85' 100'

4' 77' 100'

6' 69' 100'

8' 60' 100'

10' 52' 100'

12' 44' 100'

14' 36' 100'

16' 27' 100'

18' --- 76'

21

Page 22

VII. System Start-up

WARNING

All boilers equipped with burner swing door have a potential hazard which can cause severe

property damage, personal injury or loss of life if ignored. Before opening swing door, turn off

ser vice switch to boiler to preven t accidental firing of burn er o utside the combustion chamber.

Be su re to tigh ten swin g d o o r fastener completely wh en service is completed.

A. ALWAYS INSPECT INSTALLATION BEFORE

STARTING BURNER.

B. FILL HEATING SYSTEM WITH WATER. Refer to

Section III, G.

C. CHECK CONTROLS, WIRING AND BURNER to be

sure that all connections are tight and burner is rigid,

that all electrical connections have been completed and

fuses installed, and that oil tank is filled and oil lines

have been tested.

D. LUBRICATION — Follow instruction on burner and

circulator label to lubricate, if oil lubricated. Most

motors currently used on residential type burners

employ permanently lubricated bearings and thus do

not require any field lubrication. Water lubricated

circulators do not need field lubrication.

Do not over-lubricate. This can cause as much trouble

as no lubrication at all.

E. SET CONTROLS with burner service switch turned

“OFF”.

1. SET ROOM THERMOSTAT about 10° above

room temperature.

2. PRESS RED RESET BUTTON on R8184P Oil

Primary Control and release.

F. BURNER START-UP

1 . VERIFY burner settings.

a. Refer to Table 4.

2. Open all shut-off valves in the oil supply line to the

burner.

3. Attach a plastic hose to fuel pump vent fitting and

provide a container to catch the oil.

4. REMOVE GAUGE PORT PLUG from fuel pump

and install pressure gauge.

5. REMOVE TEST PLUG IN FLUE COLLAR.

6. Close the service switch to start the burner. If the

burner does not start immediately, check the

manual overload switch on the motor, if so

equipped, and the safety switch of the burner

primary control.

3. Set high limit dial on L8148 at temperature to suit

requirements of installation.

TABLE 4: BE CKETT AFII BURNER

Boiler

Model

LEDV-1 0.60 AFII 85 HLX50HD 0. 50 x 70° B 2.5 #2 140

LEDV-2 1.00 AFII 150 HLX50HE 0.85 x 60° B 3.5 #3 140

LEDV-3 1.25 AFII 150 HLX50HE 1.00 x 60° B 4.0 #5 140

Firing Rate

(GPH)

Burner

Air Tube

Combination

Delavan No zzle

Air Head

(stop screw)

Setti ngs

Pump Pr essu re

(P SIG )

22

Page 23

Figure 18: Electrode / Head Setting

7. Bleed the fuel unit when the burner motor starts

rotating. To bleed, loosen the vent fitting (with

plastic hose attached) and catch the oil in an empty

container. Continue to bleed for 15 seconds after

oil is free of air bubbles. Tighten the vent fitting

when all the air is purged. NOTE: Bleeding might

not be necessary with a two pipe system. When

vent fitting is closed, burner flame should start

immediately.

8. ADJUST OIL PRESSURE

a. Locate oil pressure adjusting screw and turn

screw to obtain 140 PSIG pressure.

b. DO NOT REMOVE PRESSURE GAUGE until

later.

9. ADJUST AIR SETTING on burner for a light

orange colored flame. Use a smoke tester and

adjust air for minimum smoke (not to exceed

#1) with a minimum of excess air. Make final

check using suitable instrumentation to obtain a

CO2 of 11.5 to 12.5%. These settings will assure a

safe and efficient operating condition. If the flame

appears stringy instead of a solid fire, try another

nozzle of the same type. Flame should be solid and

compact.

10. TURN "OFF" BURNER BY OPENING SERVICE

SWITCH. Remove pressure gauge. Install gauge

port plug and tighten. Re-start burner.

11. HINTS ON COMBUSTION

a. NOZZLES — Although the nozzle is a

relatively inexpensive device, its function is

critical to the successful operation of the oil

burner. The selection of the nozzle supplied

with the microTEKDV boiler is the result of

extensive testing to obtain the best flame shape

and efficient combustion. Other brands of the

same spray angle and spray pattern may be used

but may not perform at the expected level of

CO2 and smoke. Nozzles are delicate and should

be protected from dirt and abuse. Nozzles are

mass-produced and can vary from sample to

sample. For all of those reasons a spare nozzle is

a desirable item for a serviceman to have.

b. FLAME SHAPE — Looking into the

combustion chamber through the flame plug

hole, the flame should appear straight with no

sparklers rolling up toward the top of the

chamber. If the flame drags to the right or left,

sends sparklers upward or makes wet spots on

the rear door insulation piece, the nozzle should

be replaced. If the condition persists look for

fuel leaks, air leaks, water or dirt in the fuel as

described below.

c. FUEL LEAKS — Any fuel leak between the

pump and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in the

air tube, under the transformer, and around the

air inlet. Any such leaks should be repaired as

they may cause erratic burning of the fuel and in

the extreme case may become a fire hazard.

d. AIR LEAKS — Any such leaks should be

repaired, as they may cause erratic burning of

the fuel and in extreme cases may become a fire

hazard.

There are many possible causes of air leaks in

oil lines such as:

23

Page 24

i. Fitting leaks due to mis-flared tubing or

damaged fitting.

ii. Fuel line leak due to crushed or bent tubing.

iii. Filter connection leaks.

iv. Tank connection leaks.

There are various test kits available to trace

air leaks, such as electronic sight glasses.

Follow the manufacturers' instructions to

find air leaks.

The following actions can eliminate air leaks:

i. Bleed pump as detailed in System Start-Up

Section of this manual.

ii. Replace flare fittings.

iii. Replace oil supply line.

iv. Repair oil filter leaks.

v. Replace or repair tank fittings.

e. GASKET LEAKS — If 11.5 to 12.5% CO2 with

a #1 smoke cannot be obtained in the breeching,

look for air leaks around the flue collar. Such air

leaks will cause a lower CO2 reading in the

breeching. The smaller the firing rate the

greater effect an air leak can have on CO

readings.

2

is to bury the tank and lines deep enough to

keep the oil above 40°F.

i. HIGH ALTITUDE INSTALLATIONS — Air

settings must be increased at higher altitudes.

Use instruments and set for 11.5 to 12.5% CO2.

j. START-UP NOISE — Late ignition is the cause

of start-up noises. If it occurs recheck for

electrode settings, flame shape, air or water in

the fuel lines.

k. SHUT DOWN NOISE — If the flame runs out

of air before it runs out of fuel, an after burn

with noise may occur. That may be the result of

a faulty cut-off valve in the fuel pump, or it may

be air trapped in the nozzle line. It may take

several firing cycles for that air to be fully

vented through the nozzle. Water in the fuel or

poor flame shape can also cause shut down

noises.

f. DIRT — A fuel filter is a good investment.

Accidental accumulation of dirt in the fuel

system can clog the nozzle or nozzle strainer

and produce a poor spray pattern from the

nozzle. The smaller the firing rate, the smaller

the slots become in the nozzle and the more

prone to plugging it becomes with the same

amount of dirt.

g. WATER — Water in the fuel in large amounts

will stall the fuel pump. Water in the fuel in

smaller amounts will cause excessive wear on

the pump, but more importantly water doesn’t

burn. It chills the flame and causes smoke and

unburned fuel to pass out of the combustion

chamber and clog the flueways of the boiler.

h. COLD OIL — If the oil temperature

approaching the fuel pump is 40°F or lower

poor combustion or delayed ignition may result.

Cold oil is harder to atomize at the nozzle.

Thus, the spray droplets get larger and the flame

shape gets longer. An outside fuel tank that is

above grade or has fuel lines in a shallow bury is

a good candidate for cold oil. The best solution

G. TEST CONTROLS

WARNING

Before installation of the boiler is considered

complete, the operation of the boiler controls

should be checked, particularly the primary

control and high limit control.

1. CHECK THERMOSTAT OPERATION. Raise and

lower thermostat setting as required to start and

stop burner.

2. VERIFY PRIMARY CONTROL SAFETY

FEATURES using procedures outlined in

Instructions furnished with control (See back of

Control Cover) or Instructions as follows:

24

Page 25

FOR HEATING SERVICEMAN ONLY

a. Simulate flame failure:

• Follow the starting procedure to turn on the

burner.

• Close the hand valve in the oil supply line.

• Safety switch should lock out in

approximately 15 seconds. Ignition should

stop and oil valve should close. Blower will

stop after postpurge period.

• Push red reset button to reset safety switch.

b. Simulate ignition failure:

• Follow the starting procedure to turn on the

burner, but do not open the oil supply hand

valve.

• Safety switch should lock out in

approximately 15 seconds. Ignition and

motor should stop and oil valve should

close.

• Push red reset button to reset safety switch.

c. Simulate power failure:

temperature. Burner should start.

d. Adjust thermostat to lowest setting. Adjust limit

to desired setting.

4. CHECK LOW WATER CUTOFF (if so equipped).

a. Adjust thermostat to highest setting.

b. With boiler operating, open drain valve and

slowly drain boiler.

c. Burner should stop when water level drops

below low water cutoff probe. Verify limit,

thermostat or other controls have not shut off

boiler.

d. Adjust thermostat to lowest setting. Refill

boiler.

H. Boiler is now ready to be put into service.

• Follow the starting procedure to turn on the

burner.

• With the burner running, turn off the power

to the system by tripping the circuit breaker

or removing the fuse.

• Burner should stop.

• Restore power. Burner should start.

d. If system does not operate as described, go to the

TROUBLESHOOTING AND MAINTENANCE

section.

3. VERIFY HIGH LIMIT OPERATION.

a. Adjust thermostat to highest setting.

b. Observe temperature gauge. When temperature

is indicated, adjust limit to setting below

observed temperature. Burner should stop.

c. Adjust limit to setting above observed

A leaky system will increase the volume of make-up

water supplied to the boiler which can significantly

shorten the life of the boiler. Entrained in make-up

water are dissolved minerals and oxygen. When the

fresh, cool make-up water is heated in the boiler the

minerals fall out as sediment and the oxygen escapes

as a gas. Both can result in reduced boiler life. The

accumulation of sediment can eventually isolate the

water from contacting the steel. When this happens

the steel in that area gets extremely hot and eventually

cracks. The presence of free oxygen in the boiler

creates a corrosive atmosphere which, if the concentration becomes high enough, can corrode the steel

through from the inside. Since neither of these failure

types are the result of a manufacturing defect the

warranty does not apply. Clearly it is in everyone’s

best interest to prevent this type of failure. The

maintenance of system integrity is the best method to

achieve this.

25

Page 26

Section VIII: Service and Cleaning

WARNING

All boiler service and cleaning must b e completed with burner service switch tu rned off. B o ilers

equipped with burn er swing door have a potential hazard which can cause severe prop erty

dam age, perso nal in jury or loss of life if igno red. Before o pening swing do or, turn off s ervice

switch to boiler to p revent accide ntal firing of b urner outside the combustion chamber. Be sure to

tighten swing do or fasteners completely when service is com p leted.

piece. Inspect front and rear door insulation

pieces, front door gaskets and combustion

chamber liner for damage. Replace any damaged

pieces.

4. CLOSE BOILER

CAUTION: Do not start burner unless burner swing

door is securely closed. Close door, install fasteners,

and tighten securely. Door should be parallel to

tubesheet when viewed from top and sides.

Reconnect two halves of Swing Door Interlock.

A. General. Inspection, service and cleaning should be

conducted annually. Turn off electric power and close

oil supply valve while conducting service or

maintenance.

B. Firetubes and Combustion Chamber.

1. CLEAN THE FIRETUBES

a. For access to fireside of boiler, pull two halves

of Burner Swing Door Interlock wiring harness

apart, remove fasteners holding door closed and

open swing door.

b. Prior to cleaning boiler, lay a protective cloth or

plastic over combustion chamber liner.

c. Using a 1 1/2" diameter wire brush (30"

handle), clean firetubes. Measure 15" from end

of brush opposite handle, and mark handle. DO

NOT allow this mark to go past front end of

firetube during cleaning, or brush will hit rear

door insulation piece.

2. CLEAN THE COMBUSTION CHAMBER

Using wire or fiber bristle brush, clean inside of

combustion chamber. DO NOT let brush hit rear

door insulation piece or combustion chamber liner.

C. Vent/Air Intake System. Inspect for obstructions,

soot accumulation, proper support, and deterioration of

pipe, fittings, and joints.

1. Inspect inside of vent pipe.

a. Disconnect appliance adapter from boiler flue

collar.

b. Remove any obstructions and clean with a wire

brush as required.

c. Reconnect appliance adapter to boiler flue collar

as detailed in Section IV: Venting/Air Intake

Piping.

2. Clean terminal screens. Terminals must be free of

obstruction, undamaged, with screens securely in

place.

3. Terminal and wall thimbles (if used) must be

weather-tight.

4. Pipe must be full round shape, and show no damage

from impact or excessive temperature.

5. Pipe must be supported at minimum 5 foot intervals

and must not sag.

6. All vent joints must be secure and watertight.

3. AFTER CLEANING

a. Vacuum debris inside bottom of rear door,

remove protective cloth, and vacuum remaining

fireside of boiler as necessary. BE CAREFUL

not to damage liner or rear door insulation

7. All air intake joints must be secure and airtight.

D. Burner.

1. Replace the oil supply line filter.

26

Page 27

2. Remove and clean the pump strainer (if applicable).

3. Replace the nozzle with an equivalent nozzle. See

Table 4.

4. Clean and inspect the electrodes for damage,

replacing any that are cracked or chipped.

5. Clean the combustion head of all lint and soot.

6. Inspect the transformer cables and connectors.

7. Remove and clean the cad cell.

8. Clean the blower wheel and the air control of any

lint.

9. Check all wiring for secure connections or

insulation breaks.

10. Re-adjust the burner as detailed in Section VII:

System Start-up, Paragraph F.

an external float type low water cutoff is on the

boiler, the blow off valve should be opened once

a month (use greater frequency where conditions

warrant), to flush out the sediment chamber so

the device will be free to function properly.

b. Annual Service. Float type low water cutoffs

should be dismantled annually by qualified

personnel, to the extent necessary to insure

freedom from obstructions and proper

functioning of the working parts. Inspect

connecting lines to boiler for accumulation of

mud, scale, etc., and clean as required.

Examine all visible wiring for brittle or worn

insulation and make sure electrical contacts are

clean and that they function properly. Give

special attention to solder joints on bellows and

float when this type of control is used. Check

float for evidence of collapse and check mercury

bulb (where applicable) for mercury separation

or discoloration.

E. Controls. Test Controls for proper operation as

detailed in Section VII: System Start-up, Paragraph G.

F. Low water cutoff (if so equipped).

1. Float Type

a. Monthly Blowoff. During the heating season, if

2. Probe Type (Annual Service). Probe type LWCO

should be removed once a year, examined and

cleaned of any dirt accumulations to assure proper

operations. Do not attempt to repair mechanisms in

the field. Complete replacement mechanisms,

including necessary gaskets and installation

instructions, are available from the manufacturer.

27

Page 28

Service Notes

28

Page 29

IX. Repair Parts

All LEDV Series Repair Parts may be obtained through your local Burnham Wholesale Distributor. Should

you require assistance in locating a Burnham Distributor in your area, or have questions regarding the availability of Burnham products or repair parts, please contact your Burnham Regional Sales Office as listed

below.

Burnham Corporation Regional Offices

A. B urnham Corporation - Centr al & Western Regions

P.O. Box 3079

La ncaster, PA 17604 -3079

Phone: (717) 481-8400

FAX: (717) 481-8408

B. B urnham Sal es Corporation - Northeast Region

19 -27 Mystic Avenue

Somerville, MA 02145

Phone: (617) 625-9735

FAX: (617) 625-9736

C. Burnham Corporation - M etropolitan Region

P.O. Box 3079

Lancas ter, PA 17604-3079

Phone: (717) 481-8400

FAX: (717) 481-8409

D. Burnham Corporation - Mid-Atlantic Region

P.O. Box 3079

La ncaster, PA 17604 -3079

Phone: (717) 481-8400

FAX: (717) 481-8409

29

Page 30

Figure 19: LEDV Boiler Trim & Controls

30

Page 31

31

Figure 20: LEDV Boiler Jacket & Insulation

Page 32

32

Figure 21: LEDV Bare Boiler Assembly

Page 33

33

Figure 22: Vent Kit Repair Parts

Page 34

34

Figure 23: Beckett AFII Oil Burner Repair Part

For replacement oil burner parts, contact your wholesaler or the burner manufacturer: R.W. Beckett Co., P.O. Box 1289, Elyria, OH 44036

(216) 327-1060 or (800) OIL BURN(645-2876)

Page 35

BECK ETT A FII BU RNER REPLACEMEN T PARTS

Part Description

Com plete Burner (without Primary Control) BCB5406 BCB5407 BCB5408

Air Tube Com bination HLX50HD HLX50HE

Air Tube Screws 4352

Blower Wheel 21439 21438

Coupling (Motor to Pump) 21437

Electrodes (Replacement Kit) 51484U

Escutcheon Plate 31623

Stop Screw 3166502 3166503 3166505

Fuel Line 5394

Fuel Pump (Si ngle Stage, with Sol enoid

Valve)

Fuel Pump (Two Stage, with Solenoid

Valve)

Gasket, Flange 31658

LEDV1 LEDV2 LEDV3

Becke tt Part Number

21757

2583

Head A ssembly (AFII 6 Slot) 51671 51672

Ho le Pl ug 2139

Inlet Air Scoop 51485

Splined Nu t 366 6

Main Housing Assembly 51584 51476

Motor 21444

Nozzle Adapter 213

Nozzle Line Heater 51621

Rear Access Door 5142 4GY

Transformer 51402

4 x 4 Electrical Box 31613BK

35

Page 36

36

Loading...

Loading...