Page 1

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

®

NAMETUNIM

II

TNEVTCERID

RETAEHRETAW/RELIOBDERIF-SAG

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp

rebmuNledoMrelioB

__-_____IIMM

rotcartnoCgnitaeH

sserddA

rebmuNlaireSrelioB

_______6

etaDnoitallatsnI

rebmuNenohP

,reliobnonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

81404025R13-1/07 Price - $3.00

Page 2

The New York City Department of Buildings has approved the Minuteman® II boiler: Approval No. MEA 332-93-E.

The City of New York requires either a Licensed Master Plumber or a Fire Suppression Piping Contractor supervise the

installation of this product.

The Massachusetts Board of Plumbers and Gas Fitters has approved the Minuteman® II boiler. See the Massachusetts Board of

Plumbers and Gas Fitters website, http://license.reg.state.ma.us/pubLic/pb_pre_form.asp for the latest Approval Code or ask

your local Sales Representative.

The Commonwealth of Massachusetts requires this product to be installed by a Licensed Plumber or Gas Fitter.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk

levels, or to important information concerning product life.

REGNAD

nisuoires

.egamad

ytreporplaitnatsbusroyruj

GNINRAW

ytreporplaitnatsbusroyrujnisuoires

.egamad

Table of Contents

I. Pre-Installation ...............................4

II. Unpack Boiler ................................ 5

NOITUAC

noitautissuodrazahyltnenimminasetacidnI

,htaednitluserlliw,dediovatonfi,hcihw

.

egamad

nitluseryam,dediovatonfi,hcihw

ytreporproyrujnironimroetaredom

noitautissuodrazahyllaitnetopasetacidnI

ECITON

noitautissuodrazahyllaitnetopasetacidnI

,htaednitluserdluoc,dediovatonfi,hcihw

.sd

razahyrujnilanosrep

VI. Venting/Air Intake Piping ............. 11

VII. Electrical ....................................... 17

nosnoitcurtsnilaicepssetacidnI

ecnanetniamro,noitarepo,noitallatsni

otdetalertontubtnatropmierahcihw

III. Boiler Water Piping .........................5

IV. Domestic Hot Water Piping ............ 8

V. Gas Piping ......................................9

2

VIII. System Start-up ............................. 18

IX. Service Instructions ....................... 22

X. Repair Parts ..................................29

NOITUAC

itaeheht,ytilibissopasisepipnezorfoteudegamadfI.ecivres

.evitareponisireliobehtfiegamadtneverpotmetsysgnitaeh

tuohtiwtratsertondnanwodtuhsotreliobehtesuacyamhcihwslortnocsniatnocreliobsihT

tfelebtondluohsmetsysgn

ehtnodellatsniebdluohssmraladnasdraugefasetairporpparo;rehtaewdlocnidednettanu

Page 3

GNITAEHESUOH

GNIPIP

NOITCENNOC

)SEHCNI(

RELIOB

LEDOM

07-4IIMM

501-4IIMM

501-5IIMM

041-5IIMM

YLPPUS

)TPN(

4

/1-14/1-12/12/12/143

NRUTER

)TPN(

RETAW

)TPN(NI

RETAWCITSEMOD

NOITCENNOCLIOC

)SEHCNI(

RETAW

)TPN(TUO

YLPPUSSAG

NOITCENNOC

)SEHCNI(

NOI

TSUBMOC

EKATNIRIA

NOITCENNOC

)SEHCNI-.AID(

TNEVEULF

NOITCENNOC

)SEHCNI-.AID(

RELIOB

)SNOLLAG(

2/1-2

38/1-5.BL543

YTICAPACRETAW

'A'

KNAT

)SNOLLAG(

8/7-5.BL703

6.71

.XORPPA

GNIPPIHS

THGIEW

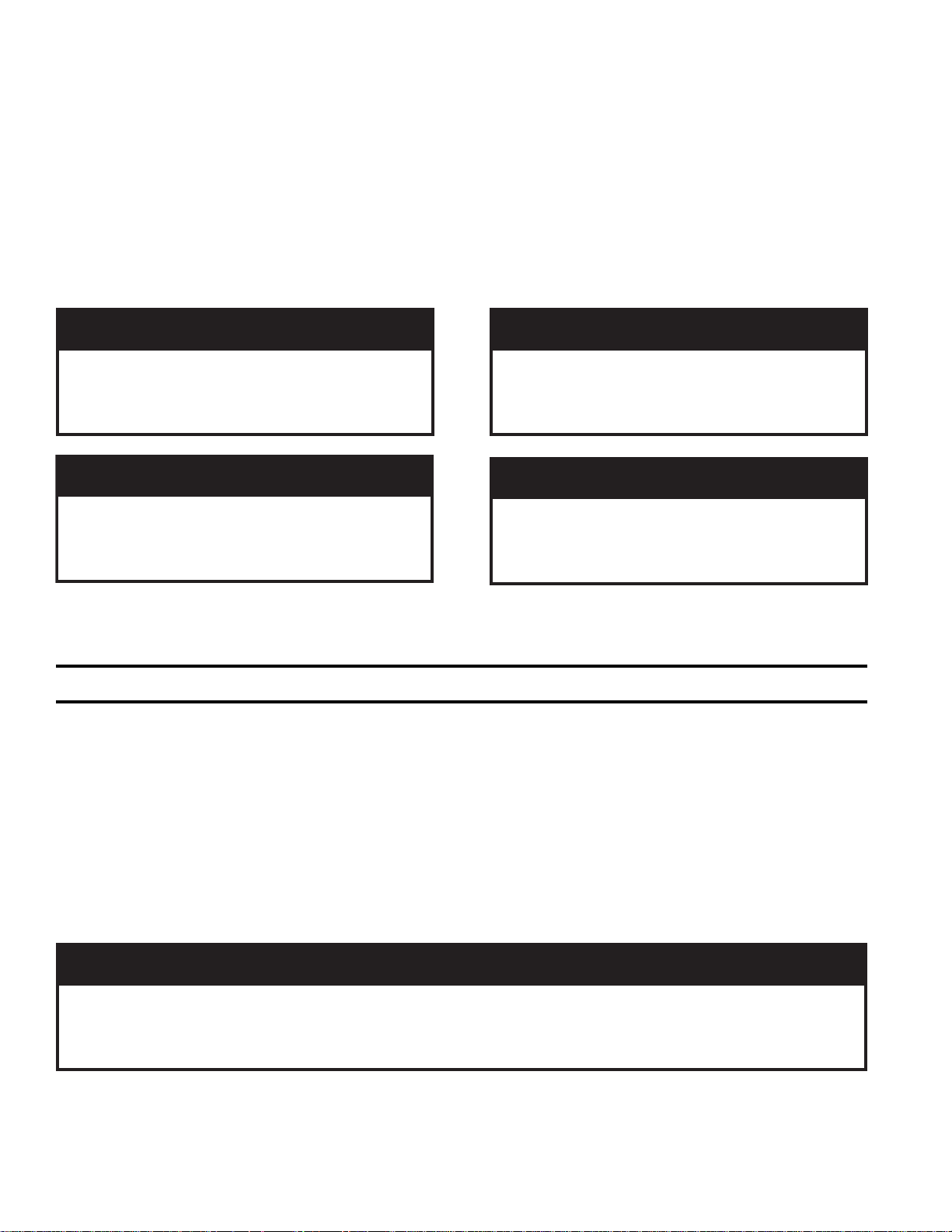

Figure 1: Dimensional Drawing

3

Page 4

I. Pre-Installation

GNINRAW

erofebsnoitcurtsnilladaerylluferaC

llawollofoteruliaF.reliobgnillatsni

esuacnacredroreporpnisnoitcurtsni

.htaedroyrujnilanosrep

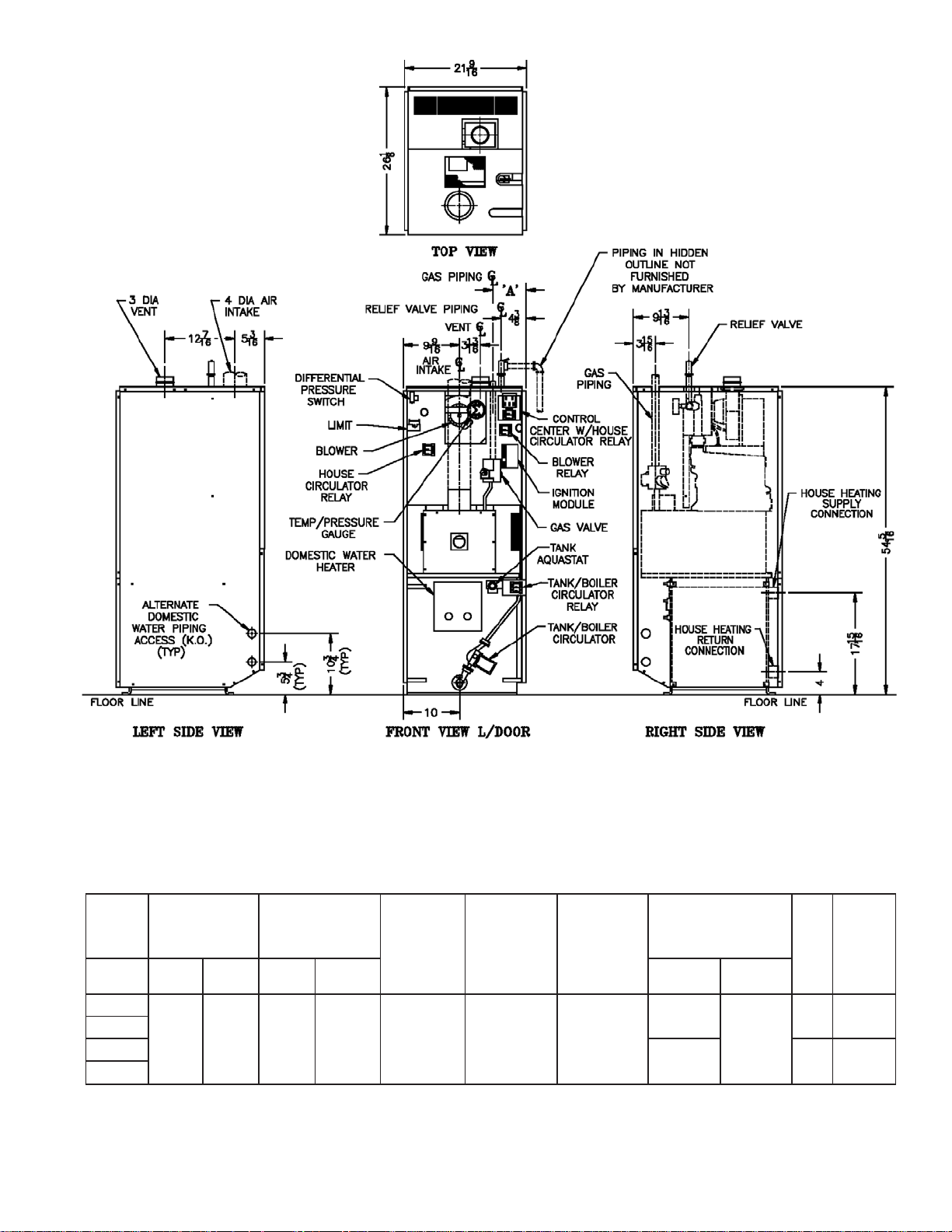

A. Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to:

USA ANSI Z223.1, National Fuel Gas Code.

Where required by the authority having

jurisdiction, the installation must also conform to

ANSI/ASME CSD-1 Standard for Controls and

Safety Devices for Automatically Fired Boilers.

CANADA CAN/CGA B149.1 or .2 Installation Codes

for Gas Burning Appliances and Equipment,

and CSA C22.1 Canadian Electrical Code,

Part I.

B. Appliance is design certifi ed for installation on

combustible fl ooring. The boiler must not be installed

on carpeting.

C. Provide clearance between boiler jacket and

combustible material in accordance with local fi re

ordinance. Refer to Figure 2 for minimum listed

clearance from combustible material. Recommended

service clearance is 24 inches from left side, right side,

front and rear. Service clearances may be reduced to

minimum clearances to combustible materials.

D. Install on level fl oor. For basement installation provide

concrete base if fl oor is not perfectly level or if water

may be encountered on fl oor around boiler.

E. Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during boiler operation

and service (circulator replacement, condensate trap,

control replacement, etc.).

Figure 2: Minimum Clearances to Combustible Surfaces

4

Page 5

F. Provide combustion and ventilation air in accordance

with applicable provisions of local building codes, or

National Fuel Gas Code, ANSI Z223.1, Section 5.3, Air

for Combustion and Ventilation.

GNINRAW

rianoitalitnevdnanoitsubmocetauqedA

reporperussaotdedivorpebtsum

.noitsubmoc

II. Unpack Boiler

This boiler is equipped with a fan which produces an

induced draft through the unit. 100% of combustion air

is pulled in from outdoors and the fl ue gases are

exhausted to the outdoors through the intake air/vent

system. Refer to Section VI.

G. Do not install boiler where gasoline or other fl ammable

vapors or liquids, or sources of hydrocarbons (i.e.

bleaches, cleaners, chemicals, sprays, paint removers,

fabric softeners, etc.) are used or stored.

NOITUAC

.roolftsniagatekcaj

A. Move boiler to approximate installed position.

B. Remove all crate fasteners.

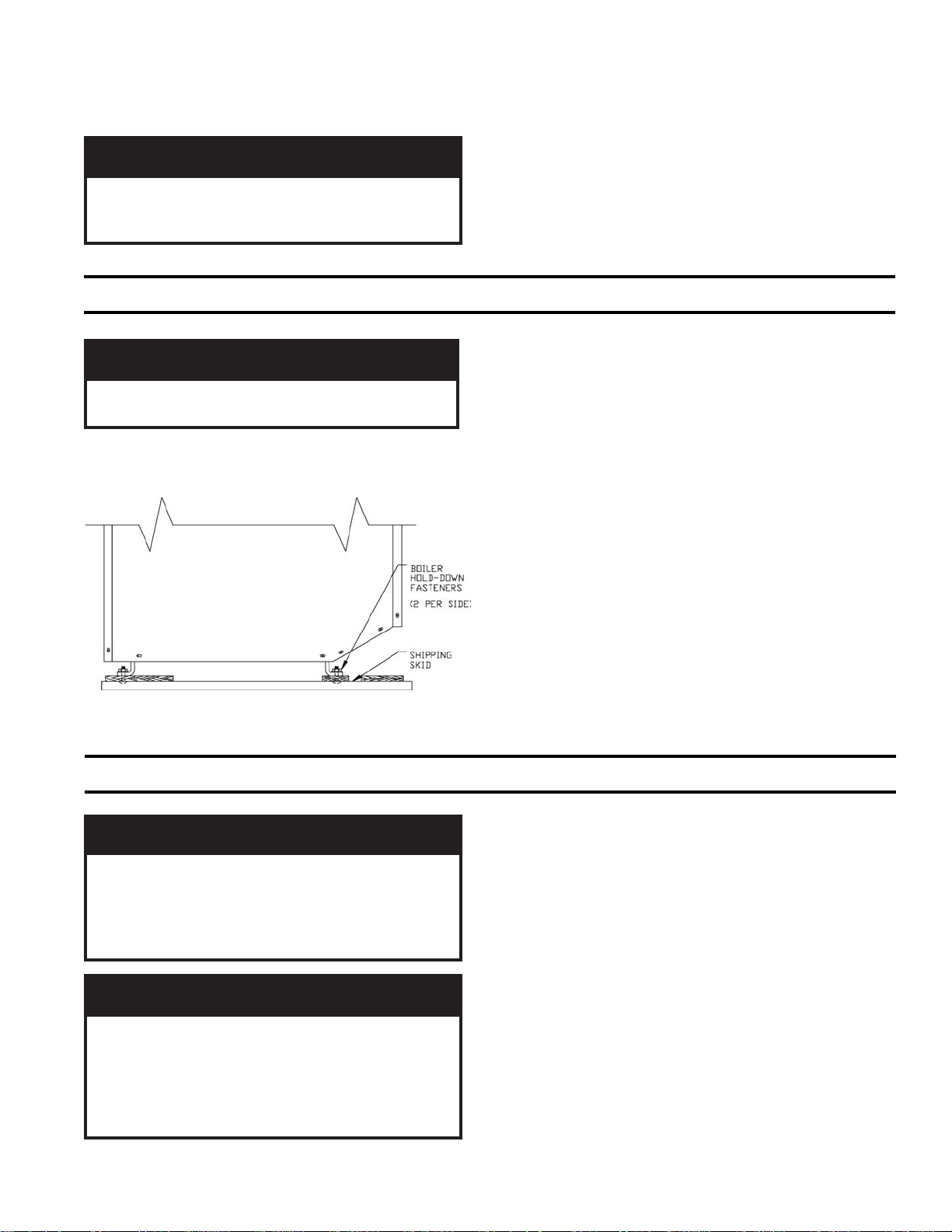

Figure 3: Removal From Skid

III. Water Piping and Trim

C. Remove outside container with all other inside

protective spacers and bracing. Save two of the

reliobpmubtonoD.reliobpordtonoD

wooden slats from the container sleeve for use in Steps

E and F.

D. Remove four (4) boiler hold-down fasteners. See

Figure 3.

E. Tilt the boiler to one side and slide a wooden slat under

the two nylon glides.

F. Tilt the boiler to the other side and slide another

wooden slat under the two nylon glides.

G. Slide the boiler forward or backward off the skid using

the two wooden slats as runners.

H. Move boiler to its permanent location.

NOITUAC

nitluseryamreliobepipylreporpoteruliaF

roreliobotegamaddnanoitareporeporpmi

.gnidliub

REDEEFRETAWCITAMOTUAESUTONOD

.RELIOBSIHTHTIW

NOITUAC

lliwretawreliobfonoitanimatnocnegyxO

reliobleetsdnanorifonoisorrocesuac

.eruliafreliobotdaelnacdna,stnenopmoc

tonseodytnarrawdradnatss'mahnruB

negyxoybdesuacsmelborprevoc

.retawreliobfonoitanimatnoc

A. Design and install boiler and system piping to

prevent oxygen contamination of boiler water.

Oxygen contamination sources are system leaks

requiring addition of makeup water, fi ttings, and

oxygen permeable materials in distribution system.

Eliminate oxygen contamination by repairing system

leaks, repairing fi ttings, and using nonpermeable

materials in distribution system.

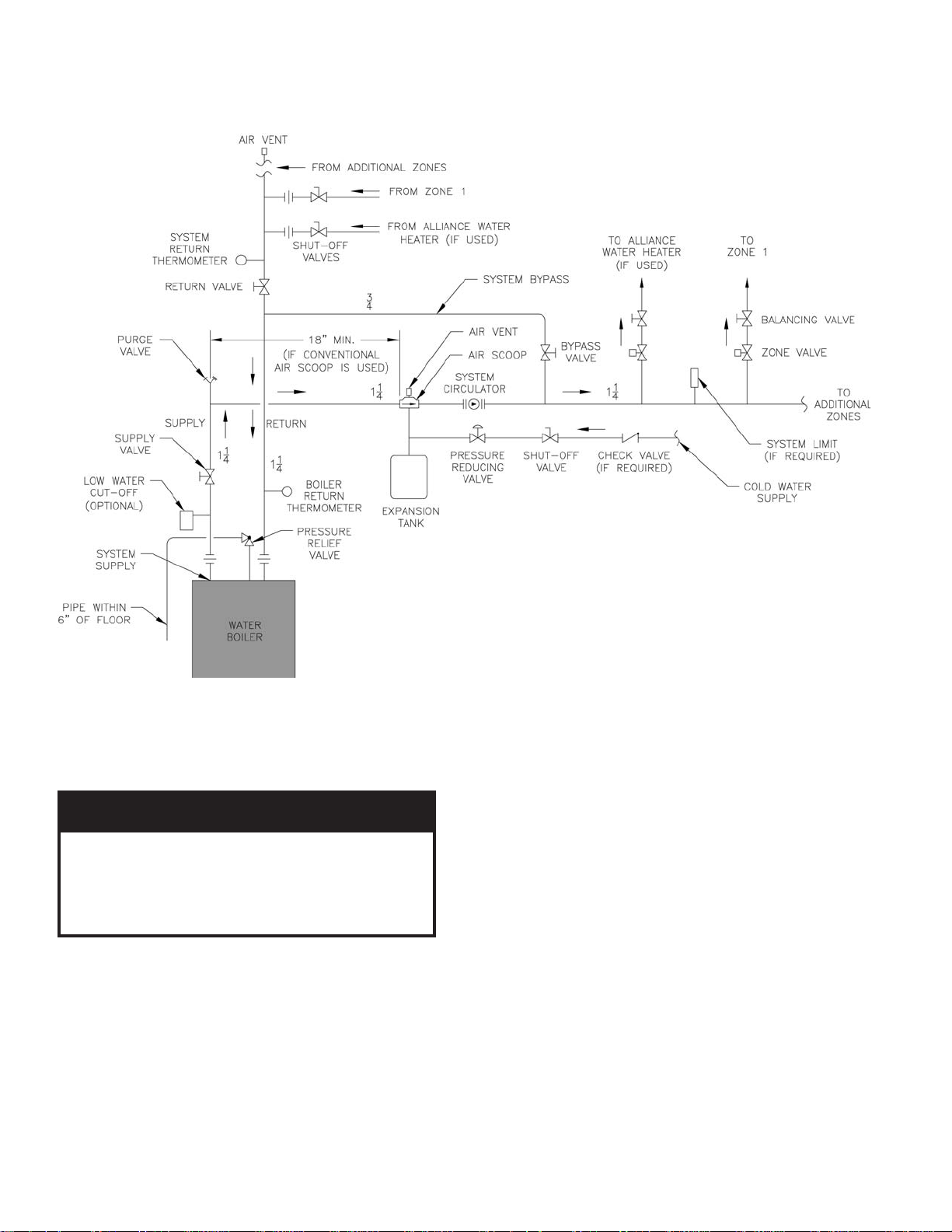

B. Connect system supply and return piping to boiler.

See Figure 4. Also consult I=B=R Installation and

Piping Guides. Maintain a clearance between hot water

piping and combustible construction as required by

local codes. In the absence of local codes, ½" clearance

should be used. Note that a system circulator is

required and is not supplied with the Minuteman II.

5

Page 6

C. Install Safety Relief Valve. See Figure 4. Safety Relief

Valve must be installed with spindle in vertical position.

Installation of the relief valve must be consistent with

the ASME Boiler and Pressure Vessel Code, Section IV.

Figure 4: Recommended Water Piping for Zone Valve Zoned Heating Systems

GNINRAW

folaitnetopetanimileotroolfraendepip

ves

.sevlavffo-tuhsyna

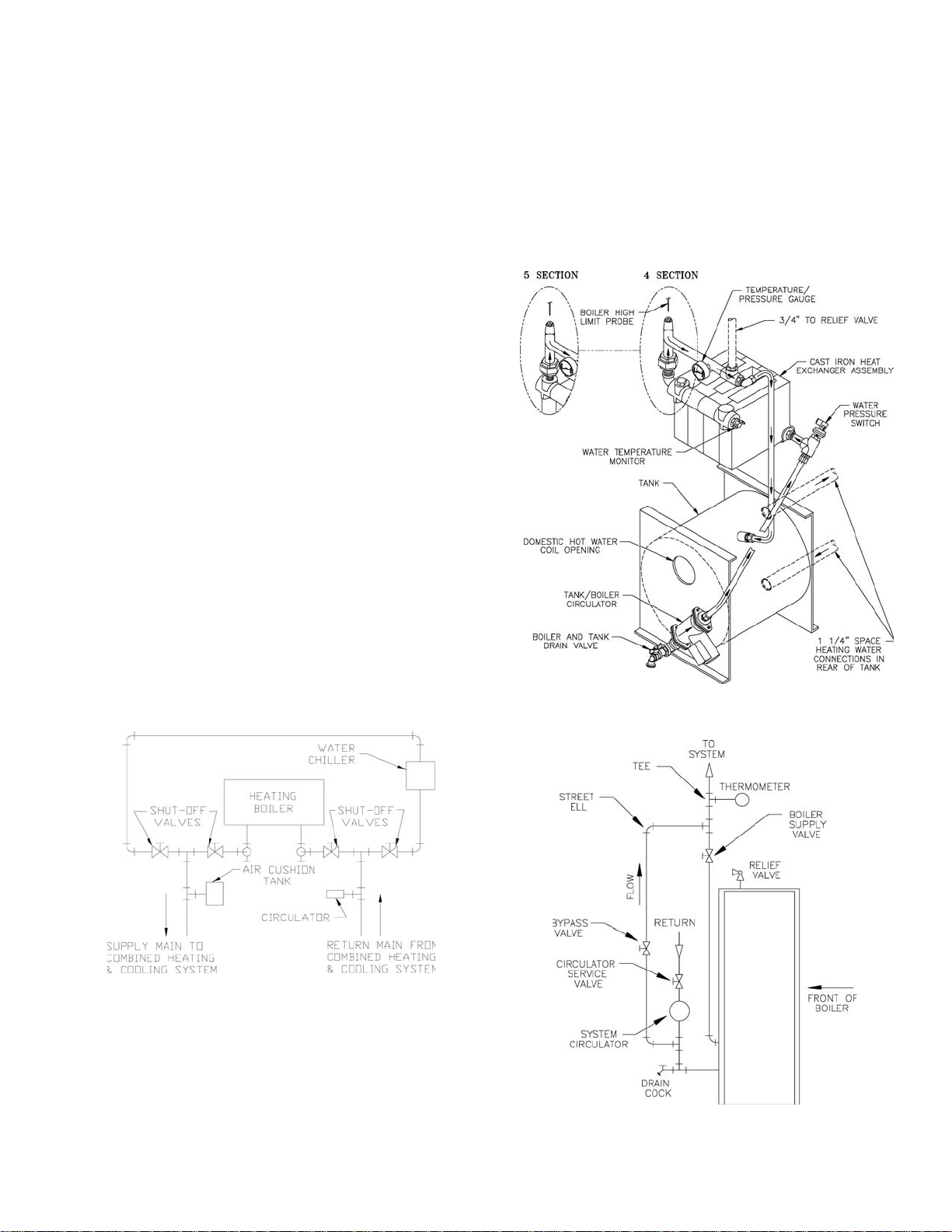

D. If boiler is used in connection with refrigeration

systems, boiler must be installed with chilled medium

piped in parallel with the heating boiler using

appropriate valves to prevent chilled medium from

entering boiler, see Figure 5. Also consult I=B=R

Installation and Piping Guides.

aeraynaniepiptonoD.snrubere

Refer to Figure 5a for a diagram of the water piping

system inside the Minuteman

ebtsumgnipipegrahcsidevlavfeilerytefaS

llatsnitonoD.ruccodluocgnizeerferehw

E. If boiler is connected to heating coils located in air

handling units where they may be exposed to

refrigerated air, boiler piping must be equipped with

fl ow control valves to prevent gravity circulation of

boiler water during operation of cooling system.

®

II's jacket.

F. Use a boiler bypass if the boiler is to be operated in a

system which has a large volume or excessive radiation

where low boiler water temperatures may be

encountered (i.e. converted gravity circulation system,

etc.).

6

Page 7

Install pipe tee between circulator and boiler return

along with second tee in supply piping as shown in

Figure 4. Bypass should be same size as the supply and

return lines with valves located in bypass and supply

outlet as illustrated in Figure 4 in order to regulate

water fl ow to maintain higher boiler water temperatures.

After the boiler is operational (reference Section VII.

System Start-Up) set by-pass and boiler supply valves

to half throttle position to start. Operate boiler until

system water temperature reaches normal operating

range.

Adjust valves to provide 180° to 200°F supply water

temperature. Opening the boiler supply valve will raise

system temperature, while opening the by-pass valve

will lower system supply temperature.

G. A hot water boiler installed above radiation level

must be provided with a low water cut-off device as

part of installation.

If a low water cut-off is required, it must be mounted in

the system piping above the boiler.

The minimum safe water level of a hot water boiler is

just above the highest water containing cavity of the

boiler; that is, a hot water boiler must be full of water to

operate safely.

It is required to perform a long term pressure test of the

hydronic system, the boiler should fi rst be isolated to

avoid a pressure loss due to the escape of air trapped in

the boiler.

To perform a long term pressure test including the

boiler, ALL trapped air must fi rst be removed from the

boiler.

A loss of pressure during such a test, with no visible

water leakage, is an indication that the boiler contained

trapped air.

H. Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new or

reworked system should be boiled out, and then

thoroughly fl ushed. A qualifi ed water treatment

chemical specialist should be consulted for

recommendations regarding appropriate chemical

compounds and concentrations which are compatible

with local environmental regulations.

Figure 5: Recommended Piping for Combination

Heating & Cooling (Refrigeration)

Systems

Figure 5a: Internal Water Piping System Diagram

I. After the boiler and system have been cleaned and

fl ushed, and before refi lling the entire system add

appropriate water treatment chemicals, if necessary, to

bring the pH between 7 and 11.

Figure 6: Recommended Bypass Piping

7

Page 8

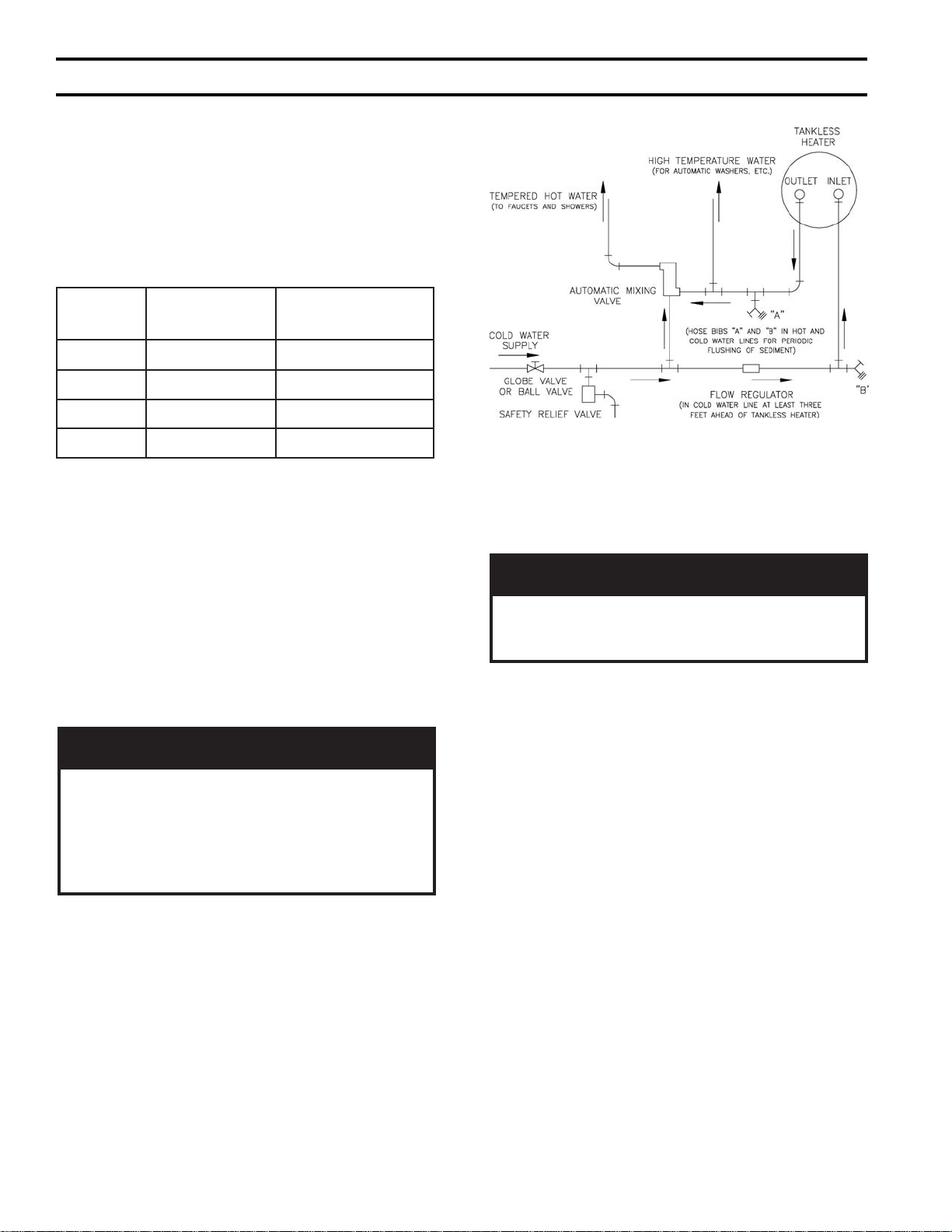

IV. Domestic Hot Water Performance and Piping

A. Domestic hot water ratings for the Minuteman

based two 5 minute draws with 10 minute recovery

period at 100°F average temperature rise. Refer to

Table 1 for ratings.

Table 1: Domestic Hot Water Ratings

RELIOB

LEDOM

07-4IIMM9.241

501-4IIMM1.361

501-5IIMM1.361

041-5IIMM3.381

WARDRETAW

)MPG(

B. Drain domestic water system.

1. Shut off cold water supply at main shutoff valve.

2. Open 1 or more system faucets to relieve pressure.

Open system drain valve, leaving faucets open to

relieve vacuum.

3. Disconnect exiting domestic hot water heating

system ( if applicable).

®

)ISP(

II are

PORDERUSSERP

Figure 7: Domestic Hot Water Piping

ECITON

ehtsaherutarepmetretawcitsemoD

erutarepmetderisedehtdeecxeotlaitnetop

.elcycgnitaehecapsagnirud

C. Connect hot water piping to ½" NPT outlet of heater.

See Figure 7.

GNINRAW

gnirepmet(evlavgniximcitamotuanallatsnI

ksirdiovaotteltuoretaehsselknatehtta)evlav

tohylevissecxeoteudgnidlacsrosnrubfo

ehtniatniamdnatsujdA.serutxiftaretaw

ehthtiwecnadroccanievlavgnixim

tcafunam

.snoitcurtsnis'reru

D. Connect cold water piping to ½" NPT inlet of heater.

See Figure 7.

E. Fill domestic hot water system.

1. Open all faucets to allow air to purge from heater

and piping.

2. Open domestic hot water shutoff valve (if used).

3. Open cold water inlet shutoff valve.

4. Purge air from domestic water system. Close

faucets.

5. Check system for leaks. Repair as necessary.

8

Page 9

V. Gas Piping

A. Size gas piping. Design system to provide adequate gas

supply to boiler. Consider these factors:

1. Allowable pressure drop from point of delivery to

boiler. Maximum allowable system pressure is ½

psig. Actual point of delivery pressure may be less;

contact gas supplier for additional information.

Minimum gas valve inlet pressure is stamped on the

rating label located in the boiler's vestibule

compartment.

2. Maximum gas demand. Table 2 lists boiler input

rate. Also consider existing and expected future gas

utilization equipment (i.e. cooking equipment).

3. Length of piping and number of fi ttings. Refer to

Table 3 for maximum capacity of Schedule 40 pipe.

Table 4 lists equivalent pipe length for standard

fi ttings.

Table 2: Rated Input

relioB

ledoM

rebmuN

07-4IIMM0782½

501-4IIMM50124½

501-5IIMM50124½

041-5IIMM04165½

larutaN

saG

etaRtupnI

]ruohrepteefcibuc[

saGPL

saG

noitcennoC

4. Specifi c gravity of gas. Gas piping systems for gas

with a specifi c gravity of 0.70 or less can be sized

directly from Table 3, unless authority having

jurisdiction specifi es a gravity factor be applied. For

specifi c gravity greater than 0.70, apply gravity

factor from Table 5. If exact specifi c gravity is not

shown choose next higher value.

For materials or conditions other than those listed

above, refer to National Fuel Gas Code, NFPA 54/

ANSI Z223.1, or size system using standard

engineering methods acceptable to authority having

jurisdiction.

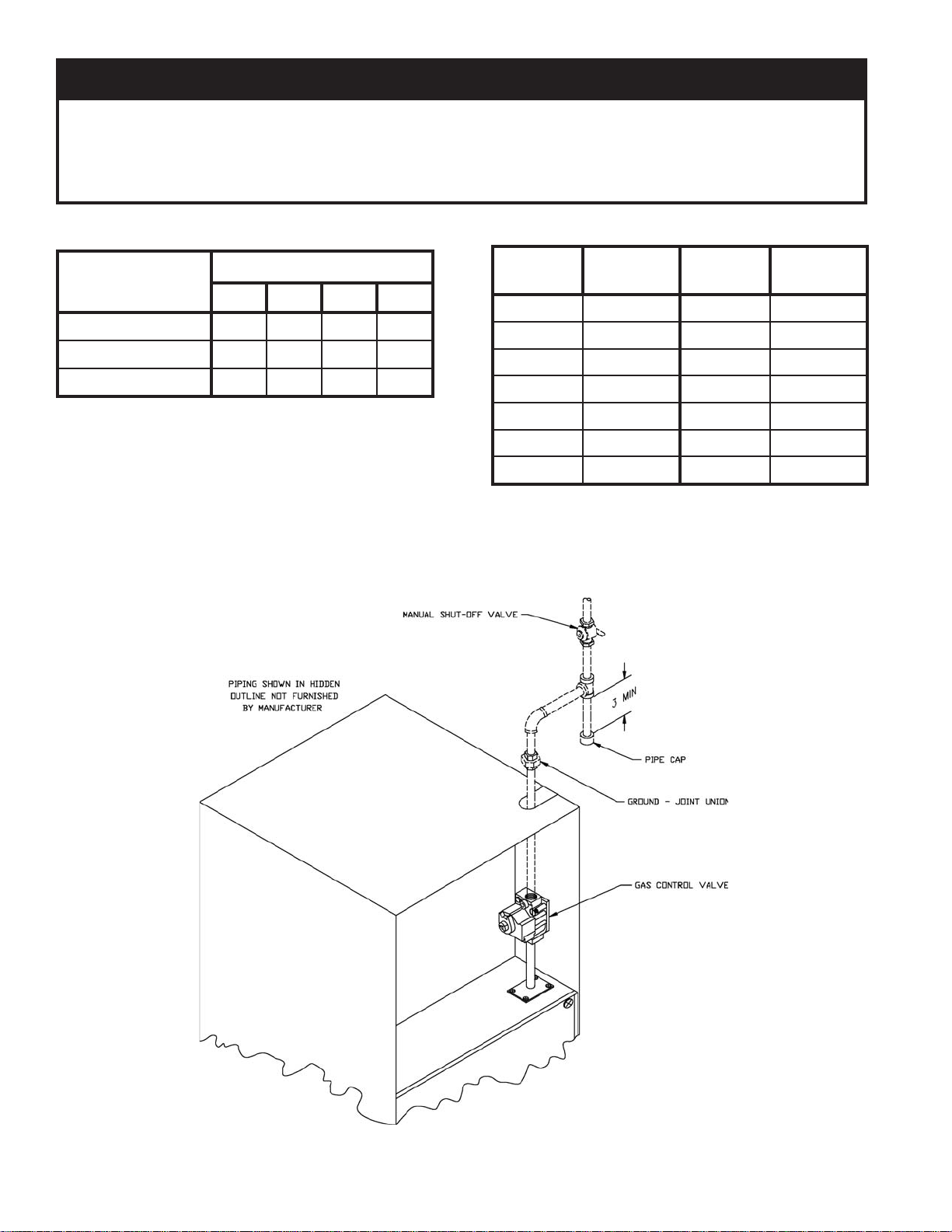

B. Connect boiler gas valve to gas supply system.

1. Use methods and materials in accordance with local

plumbing codes and requirements of gas supplier. In

absence of such requirements, follow National Fuel

Gas Code, ANSI Z223.1.

2. Use thread (joint) compounds (pipe dope) resistant

to action of liquefi ed petroleum gas.

3. Install sediment trap, ground-joint union and manual

)sehcnI(eziS

shut-off valve upstream of boiler gas control valve

and outside of jacket. See Figure 8.

4. All above ground gas piping upstream from manual

shut-off valve must be electrically continuous and

bonded to a grounding electrode. Do not use gas

piping as grounding electrode. Refer to National

Electrical Code, ANSI/NFP A 70.

Table 3: Maximum Capacity of Schedule 40 Pipe in CFH For Gas Pressures of 0.5 psig or Less

htgneL

]teeF[

01231872025050,1571063086004,1

0229091053037021052564059

033725158209579002573077

043603154200528071023066

056551151204437151582085

0605501591004668310620

07646908107316521042094

08340907105375811022064

09044806102335011502034

001839705150305301591004

½¾ 1 ¼1½¾1¼1

porDerusserP.c.whcni3.0 porDerusserP.c.whcni5.0

35

9

Page 10

ECITON

neebevahlevelaesevobateef000,2nahtretaergsedutitlatanoitallatsniroftliubsreliobASU

ehtreplevelaesevobateef000,1reptnecrep4etartupnisagecuderotdecifiroyllaiceps

tceS,1.322ZISNA,edoCsaGleuFlanoitaN

.lebalgnitarehtno"H"xiffusrebmun

ecifiro'sreliobnaidanaC.FxidneppAdna2.1.8noi

ledomehtybelbaifitnedierasledomreliobedutitlahgiH.lebalgnitarehtnodetacidnisignizis

Table 4: Fitting Equivalent Lengths

eziSepiPlanimoN

gnittiF

½¾ 1 ¼1

llE°547.012.16.1

llE°096.11.26.25.3

)woblEsA(eeT1.31.42.59.6

C. Pressure test. The boiler and its gas connection must be

leak tested before placing boiler in operation.

1. Protect boiler gas control valve. For all testing over

½ psig, boiler and its individual shutoff valve must

be disconnected from gas supply piping. For testing

at ½ psig or less, isolate boiler from gas supply

piping by closing boiler's individual manual shutoff

valve.

Table 5: Specifi c Gravity Correction Factors

cificepS

ytivarG

05.001.103.170.1

55.040.104.140.1

06.000.105.100.1

56.069.006.179.0

07.039.007.149.0

57.009.0

08.078.0

noitcerroC

rotcaF

cificepS

ytivarG

2. Locate leaks using approved combustible gas

detector, soap and water, or similar nonfl ammable

solution. Do not use matches, candles, open fl ames,

or other ignition source.

noitcerroC

rotcaF

10

Figure 8: Recommended Gas Piping

Page 11

VI. Venting / Air Intake Piping

:swollofsaerasnoitcurtsnieseht

stnenopmoctnevfogniniojynA)1

saeltasevlovnitaht

enot

tnenopmoctnevssel-teksag

tnalaesehtseriuqersyawla

.noitacilppa

ehT)2

.tnenopmoc

ssel-teksagafodneelamef

seriuqersyawlatnenopmoctnev

ehtfosseldrager,dnabpmalca

tnevelamgnitamehtfongised

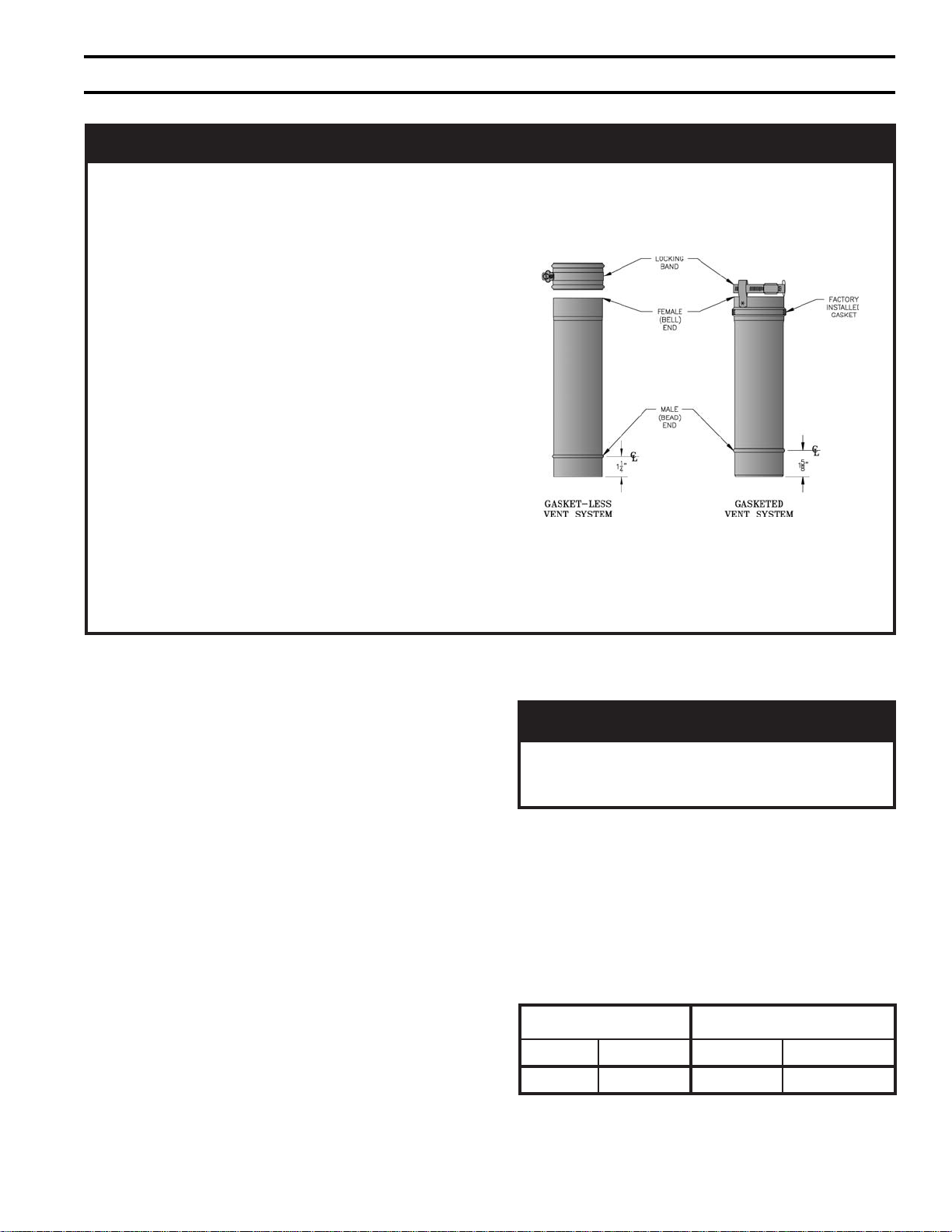

ECITON

hcaednanidesahpgnieberaAerugiFniwolebderutcipstnenopmocmetsystnevdeteksagehT

gnitnevssel-teksagdeilppusylsuoiverpehthtiwelbaegnahcretnisitnenopmoctnev

odyehtsa,niojotreisaednarekciuqyllarenegerastnenopmoctnevrewenehT.stnenopmoc

.dehcattaerasdnabpmalcriehtdnanoitacilppatnalaesehteriuqerton

adnatnenopmoctnevdeteksagatneveehtnI

-nocretniebtsumtnenopmoctnevssel-teksag

htiwdetaicossasnoitcurtsniehtwollof,detcen

f

oselpicnirpgnidiugowtehT.C01roB01erugiF

Figure A: Burnham Vent

.tnalaesfoebutecnuo

A. General Guidelines.

1. Vent system installation must be in accordance with

National Fuel Gas Code, ANSI Z223.1, Venting of

Equipment, or applicable provisions of local

building codes. Contact local building or fi re

offi cials about restrictions and installation inspection

in your area.

2. This appliance requires a Special Gas Vent. The

product is designed to use Burnham supplied

AL 29-4C® Stainless Steel vent system components.

The following manufacturer's offer similar AL 294C® components and are approved for use with this

product: Heat-Fab Inc. - Saf-T-Vent, Flex-L

International Inc. - Star-34, Protech Systems, Inc. FasNSeal™, and Z-Flex U. S., Inc. - Z-Vent. The

use of these alternate manufacturer's venting

systems will require adapters to connect to the

Burnham supplied vent connector and vent terminal.

These adapters are not supplied with this unit and

should be obtained from the supplier of the alternate

manufacturer's venting system. See Table 7 for

complete parts list.

.tnalaesdnadnabpmalcahtiwdeilppussitnenopmoctnevssel-teksaghcaE

GNINRAW

®

C4-92LA

3. Vent length restrictions are based on equivalent

length of vent pipe (total length of straight pipe plus

equivalent length of fi ttings). Maximum vent length

is listed in Table 6. Do not exceed maximum vent/

air intake lengths. Table 7 lists equivalent length for

fi ttings. Do not include Vent Terminal or Vent

Connector in equivalent feet calculation.

Table 6: Vent/Air Intake Length

).tF.viuqE(epiPtneV"3"4epiPekatnIriA).tF.viuqE(

.niM.xaM.niM.xaM

8078 07

.smetsystnevdesab

3enodnadnabpmalcenosniatnoctahtelbaliavasi,2036116rebmuntrap,tiKnoitisnarTtneVA

403,dezinavlaghtiwreliobsihtesutonoD

nonrehtoynaroleetssselniats613ro

11

Page 12

Table 7: Burnham Vent System Components

mahnruB

metsyStneV

tnenopmoC

tF1xepiP.aiD"3U69261181

tF3xepiP.aiD"3U89261183

tF5xepiP.aiD"3U00361185

elbatsujdAxepiP.aiD"3U9136118

woblE°09.aiD"3U49261185

woblE°54.aiD"3U29261185

eeTniarDlatnoziroH.aiD"3U2036118½

eeTn

iarDlacitreV.aiD"3U4036118½7

elbmihTllaWelgniS"36116118---

elbmihTllaWelbuoD"35116118---

mahnruB

traP

rebmuN

otlauqE

neLdellatsnI

4. Do not install venting system components on the

exterior of the building except as specifi cally

required by these instructions.

5. Thickness of exterior walls through which vent-air

intake system may be installed: Minimum: 3",

Maximum: 12".

B. Removal of Existing Boiler. For installations not

involving the replacement of an existing boiler, proceed

to Step C.

When an existing boiler is removed from a common

venting system, the common venting system is likely to

be too large for proper venting of the remaining

appliances. At the time of removal of an existing boiler,

the following steps shall be followed with each

appliance remaining connected to the common venting

system placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion, and other

defi ciencies which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn

on any exhaust fans, such as range-hoods and

bathroom exhausts, so they will operate at maxi mum

speed. Do not operate a summer exhaust fan. Close

fi replace dampers.

4. Place in operation the appliance being inspected.

Follow the Lighting (or Operating) Instructions.

tnelaviuqE

epiPfoteeF

Adjust thermo stat so appliance will operate

continuously.

5. Test for spillage at the drafthood relief opening after

5 minutes of main burner operation. Use the fl ame

of a match or candle, or smoke from a cigarette,

cigar or pipe.

6. After it has been determined that each appliance

remain ing connected to the common venting system

htg

)46.1ot60.1(

properly vents when tested as outlined above, return

doors, win dows, exhaust fans, fi replace dampers and

any other gas burning appliance to their previous

conditions of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code,

ANSI Z223.1 and/or CAN/CGA B149, Installation

Codes. When resizing any portion of the common

venting system, the common venting system

should be resized to approach the minimum size as

determined using the appropriate tables in Part 11 in

the National Fuel Gas Code, ANSI Z223.1 and/or

CAN/CGA B149, Installation Codes.

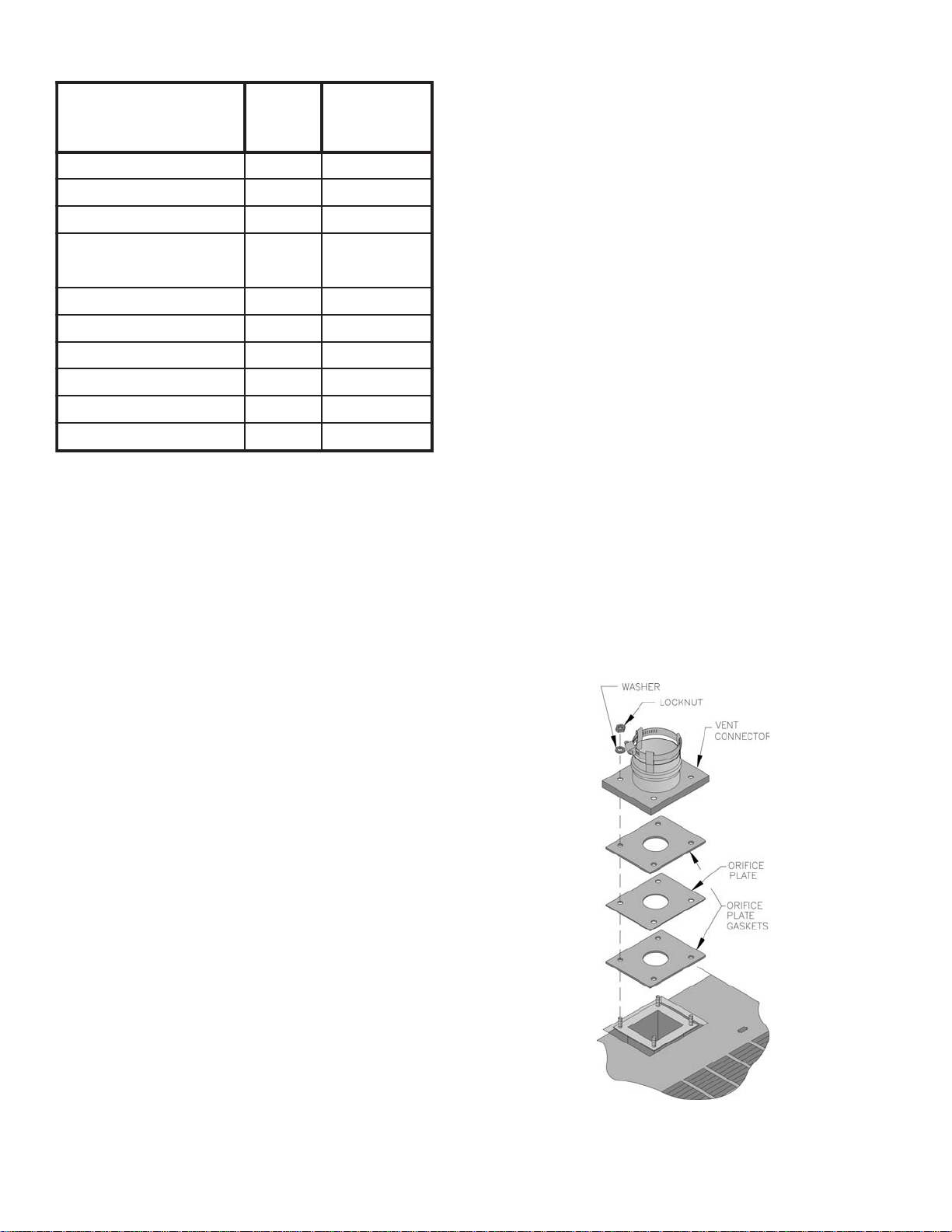

C. Install Vent Connector.

1. Remove vent connector from vent accessory carton.

2. Remove gaskets, orifi ce plate and hardware from

blower outlet fl ange.

3. Assemble orifi ce plate gaskets, orifi ce plate, and

vent connector. See Figure 9.

Figure 9: Vent Connector Installation

12

Page 13

4. Secure vent connector with washers and locknuts.

Do not overtighten.

D. Install Vent Pipe, General.

1. Plan venting system to avoid possible contact with

plumbing or electrical wires. Start at vent connector.

Work toward vent terminal.

2. Use non-combustible ¾ inch pipe strap to support

horizontal runs and maintain vent location and slope

while preventing sags in pipe. Do not restrict

thermal expansion or movement. Maximum support

spacing is 5 feet. Do not penetrate any part of the

vent system with fasteners.

3. Provide and maintain minimum 5 inch clearance to

combustible materials. Use double wall thimble

(Burnham Part No. 8116115) when penetrating

combustible wall. Other wall thimble manufacturers

are American Metal Products, Hart & Cooley, and

Metal Fab.

4. Once a vent pipe manufacturer and system is chosen

never mix and match vent systems.

5. If a non-standard length pipe is required:

The use of the adjustable length pipe (P/N

8116319U) is recommended to complete a nonstandard pipe length. This pipe requires a minimum

installed length of 12¾ inch and can adjust across a

7 inch gap up to a maximum of 19¾ inch long.

(Note for the adjustable pipe the installed length

should be measured from the centerline of the bead

on the male end of the fi rst pipe to the end of the

female pipe excluding the locking band of the

second pipe with a single gasket.) Only in the event

the adjustable length pipe is not suffi cient a standard

length pipe may be cut using the procedure outlined

below .

GNINRAW

.epiphtgnelelbatsujdarofsehcni¾91

.elbissopsiegakaelsageulffoksiR

Carefully cut pipe to length using a hacksaw with

minimum 32 teeth per inch or circular saw with

metal abrasive wheel. Remove male (bead) end

only – female (bell) end accepts next fi tting or pipe.

ECITON

e

.launamsihtnideificeps

6. Seal all Burnham Gasket-Less vent, Burnham mixed

vent (Gasket-Less and Gasketed) and fi eld cut joints

using Dow Corning Silastic 732 RTV, Dow Corning

Silastic 736 RTV, GE RTV106, Polybac #500 RTV,

Sil-bond RTV 4500 (Acetoxy) and Sil-bond RTV

6500. Do not use other adhesives or sealants.

E. Install Vent Pipe, Burnham Gasket-Less Vent System.

1. Procedure for Joining Burnham Gasket-Less Vent

Pipe and Fittings. See Figure 10A.

Figure 10A: Burnham Gasket-Less Vent Joint

a. Clean joints of pipe or fi ttings using an alcohol

pad to remove any dirt and grease.

b. Slip a locking band over female (bell) end of

pipe/fi tting.

c. Apply a continuous ¼ inch bead of sealant

around male end of joint no more than 1/8 inch

from end.

d. Align weld seams and use a slight twisting

motion to FULLY insert male end into female

end of joint. Ensure bead in male end rest against

the end of the female pipe.

e. Smooth sealant around joint for a continuous

seal. Reapply sealant if necessary.

fohtgneldellatsnimumixamdeecxereveN

rodelifdnaepiphtiwerauqsebtsumtuC

ylluferaC.gniniojerofebhtoomsdednas

htiwdnahybepiptucfossendnuorerusn

VTRhtiwtniojlaeS.gnillatsnierofebsevolg

F. Install Vent Pipe, Burnham Gasketed Vent System.

f. Slip the locking band over joint and align closest

bead in locking band with bead in male end of

pipe.

g. Tighten locking band by HAND with a 5/16" nut

driver until snug plus ¼ turn. DO NOT

SECURE JOINTS WITH SHEET METAL

SCREWS OR POP RIVETS. DO NOT

PUNCTURE THE VENT SYSTEM!

h. Once the installation is complete, operate

appliance and inspect all joints to ensure that fl ue

gases and/or liquid condensate will not escape.

1. Procedure for Joining Burnham Gasketed Vent Pipe

and Fittings. See Figure 10B.

a. Wipe the male end of each joint using an alcohol

pad to remove any dirt and grease.

13

Page 14

Figure 10B: Burnham Gasketed Vent Joint Detail

b. Align weld seams in pipes and use a slight

twisting motion to FULLY insert male end into

female end of joint. Ensure bead in male end of

pipe is below locking band and rest against the

end of the female pipe. Verify the factoryinstalled gasket is not dislodged or cut.

c. Tighten locking band by HAND with a 5/16" nut

driver until snug plus ¼ turn. DO NOT

SECURE JOINTS WITH SHEET METAL

SCREWS OR POP RIVETS. DO NOT

PUNCTURE THE VENT SYSTEM!

d. Once the installation is complete, operate

appliance and inspect all joints to ensure that fl ue

gases and/or liquid condensate will not escape.

G. Install Vent Pipe, Burnham Gasket-Less & Gasketed

Vent System.

1. Procedure for joining the male end of Burnham

Gasket-Less Vent with the female end of Burnham

Gasketed Vent. See Figure 10C.

Figure 10C: Burnham Gasket-Less Male and

Gasketed Female Vent Joint Detail

a. Clean the male end of each joint using an alcohol

pad to remove any dirt and grease.

b. Apply a continuous ¼ inch bead of sealant

around male end of joint no more than 1/8 inch

from end.

c. Align weld seams in pipes and use a slight

twisting motion to FULLY insert male end into

female end of joint. Ensure bead in male end of

pipe is below locking band and rest against the

end of the female pipe. Verify the factoryinstalled gasket is not dislodged or cut.

d. Smooth sealant around joint for a continuous

seal. Reapply sealant if necessary.

e. Tighten locking band by HAND with a 5/16" nut

driver until snug plus ¼ turn. DO NOT

SECURE JOINTS WITH SHEET METAL

SCREWS OR POP RIVETS. DO NOT

PUNCTURE THE VENT SYSTEM!

f. Once the installation is complete, operate

appliance and inspect all joints to ensure that fl ue

gases and/or liquid condensate will not escape.

2. Procedure for joining the female end of Burnham

Gasket-Less Vent with the male end of Burnham

Gasketed Vent. See Figure 10D.

Figure 10D: Burnham Gasket-Less Female and

Gasketed Male Vent Joint Detail

a. Clean joints of pipe or fi ttings using an alcohol

pad to remove any dirt and grease.

b. Slip a locking band over female (bell) end of

pipe/fi tting.

c. Apply a continuous ¼ inch bead of sealant

around male end of joint no more than 1/8 inch

from end.

d. Align weld seams in pipes and use a slight

twisting motion to FULLY insert male end into

female end of joint.

e. Smooth sealant around joint for a continuous

seal. Reapply sealant if necessary.

f. Slip the locking band over joint and align closest

bead in locking band with bead in male end of

pipe.

g. Tighten locking band by HAND with a 5/16" nut

driver until snug plus ¼ turn. DO NOT

SECURE JOINTS WITH SHEET METAL

SCREWS OR POP RIVETS. DO NOT

PUNCTURE THE VENT SYSTEM!

h. Once the installation is complete, operate

appliance and inspect all joints to ensure that fl ue

gases and/or liquid condensate will not escape.

H. Horizontal (Through Wall) Vent Installation.

1. Maintain minimum ¼ inch per foot slope in

horizontal runs. Position weld seams in vent pipes

in all horizontal runs at the top to avoid condensate

from lying on the seams.

14

Page 15

a. Recommended Installation: slope toward vent

terminal. See Figure 11.

b. Alternate Installation (where recommended

installation is not practical): slope toward boiler.

Horizontal vent drain tee (see Table 7 for part

number) required. See Figure 12.

NOITUAC

secafrusnomrofyamecidnaerutsioM

tneverpoT.lanimrettnevdnuora

doogniebdluohssecafrus,noitaroireted

etniap,delaes(riaper

).cted

2. Vent terminal location restricted per following:

a. Minimum 12 inches above grade or normally

expected snow accumulation level, or 7 feet

above grade if located adjacent to public

walkway. Do not install over public walkways or

areas where local experience indicates

condensate or vapor from Category III

appliances creates a nuisance or hazard .

b. Minimum 3 feet above any forced air inlet

located within 10 feet.

c. Minimum 1 foot below, 1 foot horizontally from,

or 1 foot above any door, openable window,

gravity air inlet, or building opening through

which fl ue gases could enter any building

(including adjacent buildings).

Figure 11: Recommended Horizontal Vent Installation

Figure 12: Alternate Horizontal Vent Installaltion

15

Page 16

d. Minimum 4 feet (6 feet in Canada) horizontally

from electric meters, gas meters, regulators, and

relief equipment.

e. Minimum 12 inches from overhang or corner.

3. Use double wall thimble when passing through

combustible outside wall (thimble use optional for

noncombustible wall). Insert thimble through wall

from outside. Secure outside fl ange to wall with

nails or screws, and seal OD, ID and vent holes with

sealant material. Install inside fl ange to inside wall,

secure with nails or screws, and seal with sealant

material.

4. For noncombustible wall when thimble is not used,

size opening such that female (bell) end with

locking band attached cannot pass through.

5. Join vent terminal to vent pipe. Locate vent terminal

between 3" and 6" from wall when joined to inside

vent piping. See Figure 13.

6. Insert vent pipe through thimble/opening from

outside and join to vent system. Apply sealant

between vent pipe and opening/thimble to provide

weathertight seal.

Figure 15: Vent/Air Intake Terminal Relationship

Horizontal (thru wall) or Vertical (thru roof)

Figure 13: Horizontal Vent Pipe Wall Penetration

I. Vertical (Through Roof) Vent Installation

1. Install vertical vent drain tee (see Table 7 for part

number). See Figure 16. Attach tee directly to

elbow or horizontal pipe from elbow.

2. Install condensate drain line. Use 3/8 inch i.d. high

temperature fl exible tubing such as silicone rubber

or EPDM. See Figure below.

a. Form condensate trap with 6 inch diameter loop.

Secure loop with plastic cable tie. Fill with

water.

Figure 14: Horizontal Air Intake Pipe Wall

Penetration

16

Page 17

Figure 16: Vertical Vent Installation

b. Secure to vertical vent tee with hose clamp or

plastic cable tie.

c. Run condensate drain line to fl oor drain or

condensate pump. Condensate disposal must be

acceptable to authority having jurisdiction.

3. Slope horizontal runs minimum ¼ inch per foot.

Slope toward vertical vent drain tee. Position weld

seams in vent pipes in all horizontal runs at the top

to avoid condensate from lying on the seams.

4. Install fi restops at fl oor and ceiling where vent

passes through fl oor, ceiling, or framed wall. The

fi restop must close the fl oor or ceiling opening

between vent pipe and structure. Firestop

manufacturers are Air-Jet, American Metal Products,

Metal-Fab, and Simpson Dura-Vent.

5. Enclose vent passing through unoccupied or

occupied spaces above the appliance with materials

having a fi re resistance rating at least equal to the

rating of adjoining fl oor or ceiling. Maintain 5 inch

minimum clearance to combustible materials. Note:

For one-or two-family dwellings fi re resistance

rating requirement may not need to be met, but is

recommended.

6. Whenever possible install vent straight through roof.

Refer to Figure 17 if offset is necessary. Maintain 5

inch minimum clearance to combustible materials.

7. Install Vent Terminal. See Figure 18.

a. Locate roof opening to allow vertical vent

penetration. Size opening to maintain 5 inch

minimum clearance from combustible materials.

b. Vertical venting requires use of roof fl ashing

(available from Burnham - P/N 8116250) and

storm collar (available from Burnham - P/N

8116251) to prevent moisture from entering the

structure.

c. Extend vent pipe to maintain minimum vertical

and horizontal distance of 12 inches from roof

surface. Allow additional vertical distance for

expected snow accumulation. Provide brace as

required. Refer to Figure 18.

d. Install storm collar on vent pipe immediately

above roof fl ashing. Apply Dow Corning

Silastic 732 RTV Sealant between vent pipe and

storm collar to provide weathertight seal..

e. Attach Vent Terminal.

J. Install Air Intake Pipe.

1. Locate air intake termination on the same wall or

roof location as the vent termination if possible, to

prevent nuisance boiler shutdowns. However, boiler

Figure 17: Attic Offset

Figure 18: Vertical Vent Termination

Extend Vent/Air Intake Piping to maintain minimum vertical ("X") and minimum horizontal ("Y") distance

of twelve (12) inches from roof surface. Allow additional vertical ("X") distance for expected snow

Figure 19: Vertical Air Intake Termination

17

Page 18

may be installed with vertical venting and sidewall

combustion air inlet if installation conditions do not

allow alternate arrangement.

2. Use 4 inch diameter single wall metal pipe, fi ttings,

fi restop(s), roof fl ashing and storm collar available

at most heating distributors.

3. Start at air intake connector. Work toward air intake

terminal.

VII. Electrical

4. Maintain minimum of ¼ inch per foot slope in

horizontal runs to air intake terminal. Slope down

toward air intake terminal.

5. Seal all joints gas-tight, using silicone caulk or selfadhesive aluminum tape.

6. Install air intake terminal. See Figures 14 and 19.

A. General. Install wiring and ground boiler in accordance

with requirements of authority having jurisdiction, or in

absence of such requirements the National Electrical

Code, ANSI/NFPA 70, and/or the CSA C22.1 Electric

Code.

B. Install thermostat. Locate on inside wall

approximately 4 feet above fl oor. Do not install on

outside wall, near fi replace, or where infl uenced by

drafts or restricted air fl ow, hot or cold water pipes,

lighting fi xtures, television, or sunlight. Allow free air

movement by avoiding placement of furniture near

thermostat.

C. Wire thermostat. Provide Class II circuit between

thermostat and boiler. Set thermostat heat anticipator to

0.6 amps. See Figure 20.

D. Wire boiler. Boiler is rated for 120 VAC, 60 hertz, less

than 12 amperes. A separate electrical circuit must be

run from the main electrical service with an overcurrent device/disconnect in the circuit. A service

switch is recommended and may be required by some

local jurisdictions. Connect circuit to black and white

wires and green ground screw. See Figure 20.

18

Figure 20: Wiring Diagram

Page 19

VIII. System Start-up

A. Safe operation and other performance criteria were

met with gas manifold and control assembly provided

on boiler when boiler underwent tests specifi ed in

American National Standard for Gas-Fired LowPressure Steam and Hot Water Boilers, ANSI Z21.13.

B. FILL ENTIRE HEATING SYSTEM WITH WATER

and vent air from system. Use the following procedure

on a Series Loop System equipped with zone valves.

(See Figure 4).

1. Close isolation valve in boiler supply piping.

2. Isolate all circuits by closing zone valves or

balancing valves.

3. Attach a hose to hose bib located just below

isolation valve in boiler supply piping. (Note Terminate hose in fi ve gallon bucket or at a suitable

fl oor drain or outdoor area).

4. Starting with one circuit, open zone valve.

5. Open hose bib.

6. Open manual fi ll valve (Make-up water line should

be located directly above isolation valve in boiler

supply piping).

7. Allow water to overfl ow from bucket until discharge

from hose is bubble free for 30 seconds.

8. Open zone valve to the second zone to be purged,

then close the fi rst. Repeat this step until all zones

have been purged, but always have one zone open.

At completion, open all zone valves.

9. Close hose bib, continue fi lling the system until the

pressure gauge reads between 12 and 15 psi. Close

fi ll valve.

GNINRAW

.reliob

10. Open isolation valve in boiler supply piping.

11. Remove hose from hose bib.

C. Prepare to check operation.

sihthtiwevlavllifcitamotuanallatsniTONOD

1. Obtain gas heating value (in BTU per cubic foot)

from gas supplier.

2. Connect manometer to pressure tap on gas valve.

Use 1/8 NPT tapping provided.

3. Temporarily turn off all other gas-fi red appliances.

Figure 21: Sequence of Operation

19

Page 20

Figure 22: Operating Instructions

D. Follow Operating Instructions to place boiler in

operation. See Figure 22.

E. Sequence of Operation. See Figure 21. If boiler fails

to operate properly, see Troubleshooting Tree on pages

26-27.

F. Check pilot burner fl ame. See Figure 24. Flame

should be steady, medium hard blue enveloping 3/8 to

½ inch of sensing probe.

20

G. Check main burner fl ame. See Figure 23. Flame

should have clearly defi ned inner cone with no yellow

tipping. Orange-yellow streaks should not be confused

with true yellow tipping.

H. Check thermostat operation. Raise and lower

temperature setting to start and stop boiler operation.

I. Check domestic hot water (tank) aquastat operation.

Raise and lower temperature setting to start and stop

boiler operation. Tank aquastat should be set at least

Page 21

Figure 23: Main Burner Flame

Figure 24: Pilot Burner Flame

20°F below boiler high limit setting to allow tank water

to reach desired temperature before boiler water reaches

the high limit setting.

J. Ignition system safety device test. Disconnect ignitor/

sensor cable from Terminal 9 (SPARK). Gas valve

should close and pilot and main burners should

extinguish.

K. Check water pressure switch.

1. Adjust thermostat to highest setting.

2. Connect hose to drain valve and run to bucket or

fl oor drain. With boiler operating, partially open

drain valve and slowly drain boiler.

3. Main burners and pilot burner will extinguish and

blower stop when water pressure drops below 10

psi. Verify limit, thermostat or other controls have

not shut off boiler.

4. Close drain valve.

5. Adjust thermostat to lowest setting. Refi ll boiler.

L. Check Boiler High Limit.

1. Adjust thermostat to highest setting.

2. Observe temperature gauge. When temperature is

indicated, adjust limit to setting below observed

temperature. Main burners and pilot burner should

extinguish, and blower stop.

3. Adjust limit to setting above observed temperature.

Ignition sequence should begin.

4. Adjust thermostat to lowest setting. Adjust limit to

desired setting, at least 20°F above the tank aquastat

setting.

M. Adjust gas input rate to boiler.

1. Adjust thermostat to highest setting.

2. Check manifold gas pressure. Pressure should be

stamped on the rating label located in the boiler's

vestibule compartment. Adjust gas valve pressure

regulator as necessary (turn adjustment screw

counterclockwise to decrease manifold pressure, or

clockwise to increase manifold pressure). If pressure

cannot be attained, check gas valve inlet pressure. If

less than minimum indicated on the boiler's rating

label, contact gas supplier for assistance.

3. Clock gas meter for at least 30 seconds. Use Table 9

to determine gas fl ow rate in Cubic Feet per Hour.

21

Page 22

4. Determine Input Rate. Multiply gas fl ow rate by gas

heating value.

Table 9: Gas Flow Rate in Cubic Feet per Hour

5. Compare measured input rate to input rate stated on

rating plate.

a. Boiler must not be overfi red. Reduce input rate

by decreasing manifold pressure. Do not reduce

more than 0.2 inch w.c. If boiler is still overfi red,

contact your Burnham distributor or Regional

Offi ce for replacement Gas Orifi ces.

b. Increase input rate if less than 98% of rating

plate input. Increase manifold gas pressure no

more than 0.2 inch w.c. If measured input rate is

still less than 98% of rated input:

i. Remove Main Burners per procedure in

Section IX: Service.

ii. Remove gas orifi ces. Drill one (1) drill size

larger (drill size is stamped on orifi ce, or see

Key No. 4C in Section X: Repair Parts).

iii. Reinstall gas orifi ces and main burners.

Measure input rate.

6. Recheck Main Burner Flame.

sdnoceS

enOrof

noituloveR

0306021042

2365311522

4335601212

6305001002

837459981

045409081

243468271

441428461

649387751

847357051

056327441

255396831

453376331

652346921

flaH-enO

.tF.uC

enO

.tF.uC

laiDreteMsaGfoeziS

owT

.tF.uC

7. Return other gas fi red appliances to previous

conditions of use.

N. Review User's Information Manual and system

operation with owner or operator.

851326421

060306021

22

Page 23

IX. Service

A. General. Inspection and service should be conducted

annually. Turn off electrical power and gas supply while

conducting service or maintenance. Follow instructions

TO TURN OFF GAS TO APPLIANCE. See Figure 22.

NOITUAC

nehwnoitcennocsidotroirpseriwllalebaL

esuacnacsrorregniriW.slortnocgnicivres

yfireV.noitareposuoregnaddnareporpmi

.gnicivresretfanoitareporeporp

B. Inspect domestic hot water coil gasket for water

leakage. Tighten nuts or replace gasket if leakage is

evident.

C. Low water cut-off (if so equipped).

1. Float Type

a. Monthly Blowoff. During the heating season, if

an external fl oat type low water cut-off is on the

boiler, the blow off valve should be opened once

a month (use greater frequency where conditions

warrant), to fl ush out the sediment chamber so

the device will be free to function properly.

b. Annual Service. Float type low water cutoffs

should be dismantled annually by qualifi ed

personnel, to the extent necessary to insure

freedom from obstructions and proper

functioning of the working parts. Inspect

connecting lines to boiler for accumulation of

mud, scale, etc., and clean as required. Examine

all visible wiring for brittle or worn insulation

and make sure electrical contacts are clean and

that they function properly. Give special

attention to solder joints on bellows and fl oat

when this type of control is used. Check fl oat for

evidence of collapse and check mercury bulb

(where applicable) for mercury separation or

discoloration.

2. Probe Type (Annual Service). Probe type LWCO

should be removed once a year, examined and

cleaned of any dirt accumulations to assure proper

operations. Do not attempt to repair mechanisms in

the fi eld. Complete replacement mechanisms,

including necessary gaskets and installation

instructions, are available from the manufacturer.

D. Vent/Air Intake System. Inspect for obstructions, soot

accumulation, proper support, and deterioration of pipe,

fi ttings, and joints.

1. Clean terminal screens. Terminals must be free of

obstruction, undamaged, with screens securely in

place.

2. Terminal and wall thimbles (if used) must be

weathertight.

3. Pipe must be full round shape, and show no damage

from impact or excessive temperature.

4. Pipe must be supported at minimum 5 foot intervals

and must not sag.

5. All vent joints must be secure and watertight.

6. All air intake joints must be secure and airtight.

Horizontal vent tee drain (if used) must have

minimum 6 inch trap and allow condensate to fl ow

freely. To Clean:

a. Disconnect drain tube from drain fi tting.

b. Flush drain tube with water. Fill trap with water.

c. Securely fasten drain tube to drain fi tting,

providing gas-tight and watertight seal.

7. If pipe must be disassembled for removal of

obstructions or resealing of joint:

a. Remove locking band (vent pipe only).

b. Break skin of sealant with utility knife. Do not

cut or score pipe.

c. Pull pipe from fi tting.

d. Clean pipe and fi tting of all cured sealant.

e. Join pipe and fi tting as described in Section VI:

Venting/Air Intake Piping.

E. Boiler Flue Passages. Inspect for blockage or soot

accumulation.

1. Remove Main Burners. See Figure 25.

a. Remove jacket front door.

b. Remove combustion air enclosure cover.

c. Remove Burner Access Panel by lifting up and

out.

d. Disconnect Ignitor/Sensor Wire from pilot

burner.

e. Mark location of Main Burner with Pilot Bracket

on gas manifold.

f. Remove External Hitch Pin Clips.

g. Hold Main Burner on throat. Lift slightly while

pushing toward rear of boiler to disengage from

Burner Tray and to clear Gas Orifi ce. Pull Main

Burner from combustion chamber.

2. Remove four (4) locknuts securing vent connector.

23

Page 24

See Figure 9. Disconnect vent connector and vent

pipe from blower outlet.

5. Install main burners by reversing procedure to

remove burners.

3. Remove Jacket Top Panels.

4. Disconnect Red and Black Silicone Tubing from

Canopy. Pull tubing through Blower Access panel

into vestibule.

5. Disconnect wiring harness from Blower Motor.

6. Remove Canopy/Blower Assembly.

a. Remove four (4) machine screws securing

canopy to heat exchanger.

b. Remove ceramic fi ber gasketing from top of heat

exchanger.

c. Pry canopy from boiler sections.

7. Inspect fl ue passages. Clean with fl ue brush. See

Figure 25.

8. Inspect heating surface in combustion chamber.

Clean with straight handle wire brush.

9. Replace Canopy/Blower Assembly and seal using

ceramic fi ber gasketing. Refer to Key No. 2 in

Repair Parts Section for quantity and part number.

10. Connect Silicone Tubing between Pressure Fittings

on Canopy Assembly and Pressure Switch. See

Figure 26.

11. Install Jacket Top Panels.

12. Connect vent system. See Figure 9.

13. Connect Blower Motor Wiring Harness.

F. Main Burners and Combustion Chamber.

1. Vacuum combustion chamber. Exercise care - do

not damage base insulation.

2. Clean main burners. Brush top of burners with soft

bristle brush. See Figure 25. Vacuum to remove any

dirt and lint.

a. Pilot burner must be installed in original

location. See Table 10.

b. Main burners must be properly secured in burner

tray slot at rear of combustion chamber and over

gas orifi ce with hitch pin in place. See Figure 25.

c. Burner access panel must be securely in place.

d. Verify that Combustion Air Diffuser is securely

in place.

e. If Flame Roll-out Switch wires were

disconnected, they must be reconnected.

f. Air Intake Box Cover must be installed.

G. Check operation. Follow steps C through L from

Section VIII: System Start-up.

H. Procedure for Measuring Fan Differential Pressure.

(See Figure 27).

1. With boiler off, remove gray and black hoses at

differential pressure switch.

2. With tees, connect water manometer as shown with

additional tubing.

3. Start boiler and read pressure on manometer when

boiler water temperature reaches operating

temperature. Refer to Table 11 for minimum

readings.

NOTE: If switch drops-out before boiler reaches

temperature or if differential pressure readings are

below minimums shown in Table 11, check for

cracks in hoses or contact your nearest Burnham

representative.

4. Stop boiler, remove manometer and reconnect hoses

to pressure switch. See Figure 26.

I. Lubrication

3. Vacuum tip of pilot burner.

4. Check gas orifi ces for lint and dirt. Clean as

necessary.

24

There are no parts requiring lubrication on the part of

the Service Technician or the User. Circulator bearings

are water lubricated. Combustion blower motor uses

sealed bearings.

Page 25

Figure 25: Burner and Flueway Cleaning

25

Page 26

Figure 26: Silicone Tubing Assembly

Table 10: Pilot Burner Location

relioB

ledoM

07-411MM

&

501-411MM

501-511MM

&

041-511MM

.reliob

34&3

45&4

htiwrenruBniaM

*tekcarBtoliP°06

Figure 27: Differential Pressure Measurement

detacoLrenruBtoliP

*srenruBniaMneewteB

fotnorfmorfdeweivsathgirottfelderebmunsrenrubniaM*

Table 11: Differential Pressure Switch Settings

RELIOB

LEDOM

07-4IIMMcw"08.0

501-4IIMMcw"08.0

501-5IIMMcw"96.0

041-5IIMMcw"96.0

MUMINIM

ERUSSERP

26

Page 27

noitamrofnIytefaStcudorPtnatropmI

tcudorPrebiFcimareCyrotcarfeR

Warning:

This product contains refractory ceramic fi bers (RCF). RCF has been

classifi ed as a possible human carcinogen. After this product is fi red, RCF

may, when exposed to extremely high temperature (>1800F), change into a

known human carcinogen. When disturbed as a result of servicing or repair,

RCF becomes airborne and, if inhaled, may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace previously fi red RCF (combustion chamber

insulation, target walls, canopy gasket, fl ue cover gasket, etc.) or attempt

any service or repair work involving RCF without wearing the following

protective gear:

1. A National Institute for Occupational Safety and Health

(NIOSH) approved respirator

2. Long sleeved, loose fi tting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after

contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an air tight plastic bag.

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes.

Seek immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and

water. Seek immediate medical attention if irritation persists.

• If breathing diffi culty develops: Leave the area and move to a

location with clean fresh air. Seek immediate medical attention

if breathing diffi culties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

27

Page 28

282930

Page 29

Page 30

X. Repair Parts

All Minuteman® II Repair Parts may be obtained through your local Burnham Wholesale distributor.

Should you require assistance in locating a Burnham Distributor in your area, or have questions regarding the availability of Burnham products or repair parts, please contact Burnham Customer Service at (717) 481-8400 or Fax (717) 481-8408.

rebmuNtraP]ytitnauQ[

.oNyeKnoitpircseD

07-4IIMM501-4IIMM501-5IIMM041-5IIMM

.1ylbmessAregnahcxEtaeH

24040716]1[2

ylbmessArewolB/yponaC.2

A2yponaC44040116]1[34040116]1[35040116]1[45040116]1[

B21013-2607#ocsaF,rewolB 5171116]1[

C2rotinoMeulF 22606108]1[

D2rotcennoCtneV 11.oNyeKeeS

E2teltuOnaF,etalPecifirO55040117]1[65040117]1[75040117]1[85040117]1[

F2)B2/wdedul

G2)B2/wdedulcni(gnitnuoMrewolB,teksaG 9406028]1[

H2gnoL"22x.D.I"61/3,gnibuT

J2gnoL"81x.D.I"61/3,gnibuTenociliS )htgneLyficepS(7006109

K2803A#reywD,gnit

L242-"8/3,lenaPleetSxeH,tuN 67406808]1[

M2"8/3talF,rehsaW 65606808]1[

N2.gl"1x02-"

P2detalP,EAS,"4/1talF,rehsaW 33606808]21[

enociliS )htgneLyficepS(6006109

cni(teltuOnaF,teksaG 5306028]2[

tiFerusserPcitatS 756228]2[

4/1,.dHxeH,wercSpaC 85316808]4[

5040716]1[

Q202-"4/1stuNkcoL 65406808]4[

R2)B2/

wdedulcni(02-"4/1,xeHssarB,tuN 42406808]4[

)detcipedton(gniteksaGtlefareC.3

regnahcxEtaeHotyponaC

6106027]1[

Page 31

313233

Page 32

Page 33

yeK

.oN

noitpircseD

07-4IIMM501-4IIMM501-5IIMM041-5IIMM

ylbmessAesaB.3

A3)noitalusnIo/w(repparWesaB 134040817]1[135040817]1[

1A3noitalusnIediSthgiR&tfeLesaB 42040027]2[

rebmuNtraP]ytitnauQ[

2A3noitalus

B3)dehcattanoitalusni(ylbmessAetalPesaB 64040816]1[65040816]1[

C3yarTrenruB

D3

1D3le

2D3reniateRsneLtroPnoitavresbO 9106817]1[

3D3teksaGsneLtroP

4D3sneLtroPnoitavresbO 2806208]1[

E3ylbmessAlenaPsseccArenruB 54040126]1[55040126]1[

1E

3lenaPsseccArenruB 114040127]1[115040127]1[

2E3tekcarBgnitnuoM/whctiwStuO-lloRemalF 0606106]1[

F3resuffiDriAn

G3)dehcattanoitalusni(ylbmessAlenaPtnorFesaB 44040816]1[45040816]1[

H3laeSdl

J3laeSdlofinaM,teksaG 2040818]1[

nIraeResaB 22040027]1[32040027]1[

44040127]1[45040127]1[

ylbmessAlenaPtnorFerusolcnErenruB

)4D3urht1D3sedulcni(

naPtnorFerusolcnErenruB 124040127]1[125040127]1[

noitavresbO 9306028]2[

oitsubmoC 54040127]1[55040127]1[

ofinaM,etalPgnikcaB 01040817]1[

64040126]1[65040126]1[

K3)dehcattanoitalusni(lenaPpoTerusolcnEren

M3seriWSRF,teksaG 3040818]1[

N3.gL.tF01x"2x"

P3.gL.tF01x"1x"8/1,teksaGepaTssalgrebiF 4006026]1[

Q3.gL"2/1x8#,wercSlate

R3.gL"2/1x02-"4/1,wercSgnippaT-fleS 00706808]01[

S3.gL"4/1-1x81-"61/5,wercSgnippaT-fleS

U381-"61/5,tuNkcoL 46406808]4[

ruB 44040126]1[45040126]1[

L3teksaGeriWSRF,etalPgnikcaB 2006907]1[

2/1,teksaGrebiFcimareC 2006026]1[

MteehS 00006808]02[

T3talF"61/5,rehsaW 10606808]4[

71706808]4[

Page 34

34

Page 35

yeK

.oN

noitpircseD

07-4IIMM501-4IIMM501-5IIMM041-5IIMM

rebmuNtraP]ytitnauQ[

A4evlaVsaG

B4dlofinaMsaG 1404022

larutaN

niaM

C4

D4pilCniP

E4.gL"03x.D.O"8/1,gnibuTtoliP 0116328]1[

F42-308493#llewyenoH,elbaCrosneS/noitingI 12

G4

H4tekcar

J4tekcarBtoliPsselrenruBsaGniaM 5116328]4[5116328]6[

K4.gL"61/3x23-01#,werc

renruB

secifirO

hctiH406228]5[406228]7[

toliP

ylbmessA

SenihcaM 00806808]2[

saG

75#656228]5[------------

PL

BtoliP/wrenruBsaGniaM 6116328]1[

0006C4028RVllewyenoH).taN( 67106618]1[

8106C4028RVllewyenoH)PL(08106618]1[A/N

8]1[15040228]1[

)wolleY(llirD94#556228]5[----556228]7[----

)deR(llirD34#----4362

)egnarO(llirD44#------------046228]7[

)kcalB(45#----536228]5[--------

3331A843QllewyenoH,)saG.taN( 4016328]1[

1431A843QllewyenoH)PL(7016328]1[A/N

28]5[--------

16328]1[

L4.gL"1x02-"4/1,wercSgnippaT-fleS 02706808]2[

MM:A/N

ecivressagPLrofelbaliavAtoNerasledoM5II

35

Page 36

.oNyeKnoitpircseD

07-4IIMM501-4IIMM501-5IIMM041-5IIMM

ylbmessAtekcaJ.5

5ylbmessAtekcaJetelpmoC 20040406]1[

A5lenaPpoTtnorF 5140406]1[

B5lenaPpoTraeR 19040407]1[

rebmuNtraP]ytitnauQ[

C5duorhSnaF 40040117]1

D5lenaPraeRreppU 4140406]1[

E5lenaPraeRrewoL 3140406]1[

F5lenaPediSthgiR 1140406]1[

G5lenaPelubitseV 7140406]1[

H5lenaPkciK 1110407]1[

J5lenaPediStfeL 2140406]1[

K5lenaPtnorFrewoL 12040407]1[

L5rooDelbavomeR 14040407]1[

M5gnih

N5.gL"2/1x8#,wercSlateMteehS 00006808]75[

suBpanS 7526318]3[

[

36

Page 37

.oNyeKnoitpircseD

07-4IIMM501-4IIMM501-5IIMM041-5IIMM

ylbmessAknaTretaWcitsemoD.6

6ylbmessAknaTdetalusnI 23040306]1[

A6ylbmessAknaT 13040306]1[

B6tekcarBtnemhcattAtekcaJ 11040407]8[

rebmuNtraP]ytitnauQ[

C6.gL"2/1x0

D6noitalusnItnorF 76040027]1[

E6lioCretaWtoHcitsemoD 1040306]1[

F661-"8/

G6teksaGlioC 6306028]1[

H6noitalusnIrepparWknaT 96040027]1[

J6noitalusnIraeR 86040027]1[

3,tuN,xeH 32406808]01[

2-"4/1,wercSgnippaT-fleS 00706808]61[

37

Page 38

.oNyeKnoitpircseD

07-4IIMM501-4IIMM501-5IIMM041-5IIMM

slortnoCdnamirTsuoenallecsiM.7

A750-804-01ocarbnoC,evlaVfeileR 91306618]1[

B71005D5828RllewyenoH,retneClortnoC U55106108]1[

rebmuNtraP]ytitnauQ[

C7hctiwSlamrehT

D7hctiwSerusserPretaW 19106108]1[

E77001E0768SllewyenoH,eludoMnoitingI 80106108]1

F72902A9816LllewyenoH,tatsauqAknaT 99406108]1[

G79201V2228RllewyenoH,yaleRTSPD 53106108]1[

H7700ocaT,rotalu

J730-203-53#ocarbnoC,evlaVniarD 160306608]1[

K76001U2228RllewyenoH,yaleRTSPD U69006108]1[

L7eg

M72102B9814LllewyenoH,timiLhgiHrelioB 06406108]1[

N7hctiwSerusserPlaitne

P70001B2228RllewyenoH,yaleRTSPS 78606108]1[

criC 7006508]1[

reffiD 58806106]1[78806106]1[

gnitcA-esreveR 62106108]1[

uaGerutarepmeT/erusserP 5326508]1[

[

38

Page 39

.oNyeKnoitpircseD

rebmuNtraP]ytitnauQ[

07-4IIMM501-4IIMM501-5IIMM041-5IIMM

notraCyrosseccAtneV.11

A11rotcennoCtneV 7036118]1[

B11lanimreTtneV 0136118]1[

lanimreTekatnIriA.21

92101116]1[

2040118]1[

39

Page 40

Limited WarrantyLimited Warranty

Limited Warranty

Limited WarrantyLimited Warranty

FOR MINUTEMAN® II BOILER/WATER HEATER

Subject to the terms and conditions set forth below, U.S. Boiler™ Co., Inc.,

Lancaster, Pennsylvania (“U.S. Boiler Co., Inc.”) hereby extends the following

limited warranties to the original owner of a Minuteman® II Boiler/Water Heater

manufactured and shipped on or after July 1, 1996:

ONE YEAR LIMITED WARRANTY ON

MINUTEMAN® II BOILER/WATER HEATER

U.S. Boiler Co., Inc. warrants to the original owner that its Minuteman® II

Boiler/Water Heater complies at the time of manufacture with recognized

hydronic industry standards and requirements then in effect and will be free of

defects in material and workmanship under normal usage for a period of one

year from the date of original installation. If any part of a water boiler is found to

be defective in material or workmanship during this one year period, U.S. Boiler

Co., Inc. will, at its option, repair or replace the defective part.

FIVE YEAR LIMITED WARRANTY

ON WATER HEATER RESERVOIR

U.S. Boiler Co., Inc. warrants to the original owner that the water heater

reservoir of its Minuteman® II Boiler/Water Heater will remain free from defects

in material and workmanship under normal usage for five years from the date of

original installation. If the water heater reservoir is found to be defective in

material or workmanship during this five year period, U.S. Boiler Co., Inc. will, at

its option, repair or replace the defective water heater reservoir.

LIFETIME LIMITED WARRANTY

ON CAST IRON HEAT EXCHANGER

U.S. Boiler Co., Inc. warrants to the original owner that the cast iron heat

exchanger of its Minuteman® II Boiler/Water Heater will remain free from defects

in material and workmanship under normal usage for the lifetime of the original

owner at the original place of installation. If a claim is made under this warranty

during the first ten years from the date of original installation, U.S. Boiler Co.,

Inc. will, at its option, repair or replace the cast iron heat exchanger. If a claim is

made under this warranty after the expiration of ten years from the date of

original installation, U.S. Boiler Co., Inc. will, at its option and upon payment of

the pro-rated service charge set forth below, repair or replace the cast iron heat

exchanger. The service change applicable to a cast iron heat exchanger

warranty claim is based upon the number of years the cast iron heat exchanger

has been in service and will be determined as a percentage of the retail price of

the cast iron heat exchanger model involved at the time the warranty claim is

made as follows:

sraeY

ecivreSnI

fo%sa

ecirPliateR

sraeY

ecivreSni

fo%sa

ecirPliateR

NOTE: If the cast iron heat exchanger model involved is no longer available due

to product obsolescence or redesign, the value used to establish the retail price

will be the published price as shown in the Burnham Hydronics Repair Parts

Price Sheet where the cast iron heat exchanger last appeared or the current

retail price of the then available nearest equivalent cast iron heat exchanger.

only to the original owner at the original place of installation within the United

States and Canada. This warranty is applicable only to the Minuteman® II Boiler/

Water Heater installed in a single or two-family residence and does not apply to

any commercial installations.

limited warranty on the Minuteman® II Boiler/Water Heater, all boiler components

manufactured by others but furnished by U.S. Boiler Co., Inc. (such as oil

burner, circulator and controls) will be subject only to the manufacturer’s

warranty, if any.

conditioned upon the installation of the Minuteman® II Boiler/Water Heater in

1. Applicability: The limited warranties set forth above are extended

2. Components Manufactured by Others: Upon expiration of the one year

3. Proper Installation: The warranties extended by U.S. Boiler Co., Inc. are

01-111213141516171

egrahCecivreS

oN

5015102520353

egrahC

81910212223242

egrahCecivreS

0454055506560757

ADDITIONAL TERMS AND CONDITIONS

dna52

evoba

strict compliance with U.S. Boiler Co., Inc. installation instructions. U.S. Boiler

Co., Inc. specifically disclaims liability of any kind caused by or relating to

improper installation.

4. Proper Use and Maintenance: The warranties extended by U.S. Boiler

Co., Inc. are conditioned upon the use of the Minuteman

for its intended purposed and its maintenance in accordance with U.S. Boiler

Co., Inc.’s recommendations and hydronics industry standards. These warranties will be inapplicable if the Minuteman

operated over its rated capacity, is subjected to unauthorized modification, or is

damaged as a result of being otherwise improperly operated or serviced

including, but not limited to, damage from any of the following: operation with

insufficient water, allowing the boiler to freeze, subjecting the boiler to flood

conditions, and operation with unapproved water or fuel additives which cause

deposits or corrosion.

5. Removal and Installation: These warranties do not cover expenses of

removal or reinstallation. The owner is responsible for the cost of removing and

reinstalling any defective part and its replacements and all labor and material

connected therewith.

6. Exclusive Remedy: U.S. Boiler Co., Inc.’s obligation for any breach of

these warranties is limited to the repair or replacement of its parts in accordance

with the terms and conditions of these warranties.

7. Limitation of Damages: Under no circumstances shall U.S. Boiler Co.,

Inc. be liable for incidental, indirect, special or consequential damages of any

kind whatsoever under these warranties, including, but not limited to, injury or

damage to persons or property and damages for loss of use, inconvenience or

loss of time. U.S. Boiler Co., Inc.’s liability under these warranties shall under no

circumstances exceed the purchase price paid by the owner for the Minuteman

II Boiler/Water Heater involved. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

8. Limitation of Warranties: These warranties set forth the entire obligation

of U.S. Boiler Co., Inc. with respect to any defect, in a Minuteman® II Boiler/

Water Heater and U.S. Boiler Co., Inc. shall have no express obligations,

responsibilities or liabilities of any kind whatsoever other than those set forth

herein. These warranties are given in lieu of all other express warranties.

ALL APPLICABLE IMPLIED WARRANTIES, IF ANY, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE ARE EXPRESSLY LIMITED IN DURATION TO A PERIOD OF ONE

YEAR, EXCEPT THAT IMPLIED WARRANTIES, IF ANY, APPLICABLE TO THE

CAST IRON HEAT EXCHANGER IN A MINUTEMAN® II BOILER/WATER

HEATER SHALL EXTEND TO THE ORIGINAL OWNER FOR THE LIFETIME OF

THE ORIGINAL OWNER AT THE ORIGINAL PLACE OF INSTALLATION. Some

states do not allow limitation on how long an implied warranty lasts, so the

above limitation may not apply to you.

PROCEDURE FOR OBTAINING WARRANTY SERVICE

In order to assure prompt warranty service, the owner is requested to

complete and mail the attached Warranty Card within ten days after the

installation of the boiler, although failure to comply with this request will not void

the owner’s rights under these warranties.

Upon discovery of a condition believed to be related to a defect in material or

workmanship covered by these warranties, the owner should notify the installer

who will in turn notify the distributor, if this action is not possible or does not

produce a prompt response, the owner should write to: Burnham Hydronics,

P.O. Box 3079, Lancaster, PA 17604, giving full particulars in support of this

claim.

The owner is required to make available for inspection by

U.S. Boiler Co., Inc. or its representative the parts claimed to be defective and,

if requested by U.S. Boiler Co., Inc., to ship these parts prepaid to Burnham

Hydronics at the above address for inspection or repair. In addition, the owner

agrees to make all reasonable efforts to settle any disagreement arising with a

claim before resorting to legal remedies in the courts.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY

ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

®

II Boiler/Water Heater is used or

®

II Boiler/Water Heater

03/03

®

Loading...

Loading...