Page 1

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

TFARDDECROF"DF"

STINURENRUBRELIOBLEETS

FOR OIL, GAS

OR COMBINATION

OIL-GAS FIRING

sserddA

8143401R6-7/03

,reliobnonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp

rebmuNledoMrelioBrebmuNlaireSrelioBetaDnoitallatsnI

____________DF_______6

rotcartnoCgnitaeH rebmuNenohP

Price - $3.00

1

Page 2

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk

levels, or to important information concerning product life.

GNINRAW

nachcihwdrazahafoecneserpsetacidnI

rohtaed,yrujnilanosreperevesesuac

.derongifiegamadytreporplaitnatsbus

.derongifiegamad

NOITUAC

ECITON

nosnoitcurtsnilaicepssetacidnI

ecnanetniamro,noitarepo,noitallatsni

otdetalertontubtnatropmierahcihw

.sdrazahyrujnilanosrep

TABLE OF CONTENTS

INTRODUCTION TO "FD" SERIES STEEL BOILER-BURNER UNITS ...............................................................................3

DIMENSIONS AND RATING DATA.................................................................................................................................4 & 5

FURNACE FLOOR BLANKETS.........................................................................................................................................6 & 7

CERAMIC FIBER WARNING ...................................................................................................................................................8

CLEANING INSTRUCTIONS ....................................................................................................................................................9

BURNER DATA ...............................................................................................................................................................10 & 11

BECKETT BURNER SPECIFICATIONS .......................................................................................................................12 & 13

TANKLESS HEATER PERFORMANCE.................................................................................................................................14

COIL RATINGS.........................................................................................................................................................................15

INDIRECT WATER HEATER OPERATION ..........................................................................................................................16

COMBUSTION AND VENTILATION AIR REQUIREMENTS.............................................................................................16

VENTS—FAULTS AND SUGGESTIONS ..............................................................................................................................17

EXPANSION OR AIR CUSHION TANK ................................................................................................................................18

PIPING—FORCED HOT WATER HEATING ........................................................................................................................19

PIPING—DOMESTIC HOT WATER ......................................................................................................................................20

PIPING—FORCED HOT WATER HEATING AND DOMESTIC HOT WATER.................................................................20

PIPING—DOMESTIC HOT WATER WITH STORAGE TANK ...........................................................................................21

PIPING—RECIRCULATING DOMESTIC HOT WATER SYSTEM .................................................................................... 21

PIPING—MULTI-PURPOSE BOILER APPLICATION .........................................................................................................22

PIPING—MULTIPLE BOILER OPERATIONS (PARALLEL PIPING) ................................................................................22

ORDERING REPAIR PARTS ................................................................................................................................................... 23

JACKET PARTS IDENTIFICATION.......................................................................................................................................23

WARRANTY .............................................................................................................................................................. Rear Cover

rolliwhcihwdrazahafoecneserpsetacidnI

ytreporproyrujnilanosrepronimesuacnac

2

Page 3

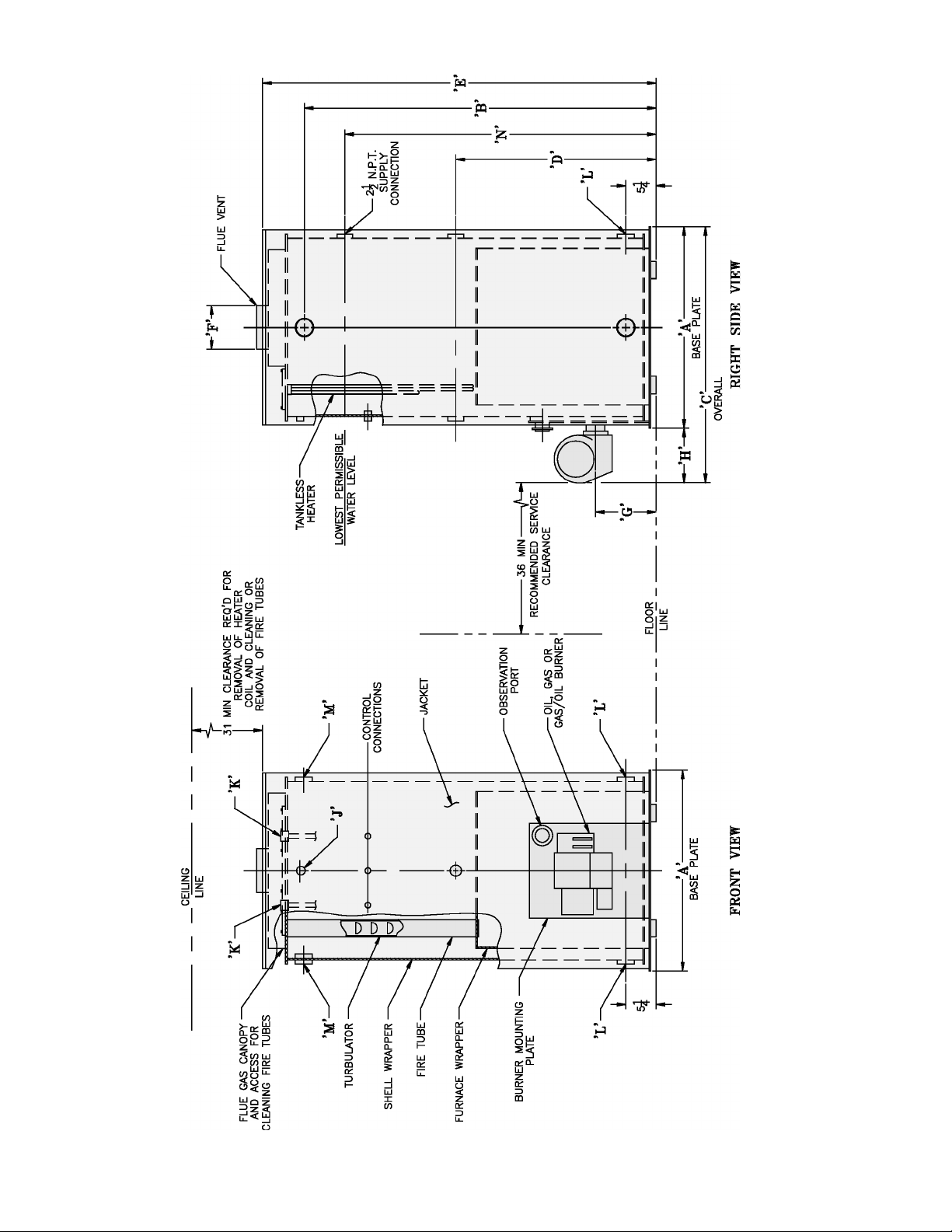

INTRODUCTION TO "FD" SERIES

STEEL BOILER BURNER UNITS

Due to an excellent combination of boiler and burner,

the "FD" Series boiler-burner units are capable of

developing the optimum in combustion and thermal

efficiencies. The burner provides 12½% CO

combustion efficiency in excess of 83% on #2 fuel oil.

Forced draft operation is accomplished by means of a

3450 RPM motor and blower wheel on the burner and a

factory sealed combustion chamber. The commonly

used refractory type combustion chamber is not

required.

Pressure is produced within the boiler by the "forced

draft" operation of the burner eliminating the need for a

chimney thus resulting in a substantial savings in

building costs. A vent to the outside of the building is

the only requirement. Boiler rooms can also be kept to

a minimum size since one boiler equipped with a

tankless heater can supply all of the heating

requirements for comfort heating and domestic hot

water.

For optimum performance and serviceability from these

units adhere to the following recommendations:

1) Clean boiler flueways (firetubes after removing

turbulator baffles) with a 3" OD flue brush, at least

once a year and preferably at the end of the heating

season, or as may be necessitated to remove all soot

and scale. See Page 10 for cleaning instructions.

2) Have burner and controls checked at least once a

year. See Pages 14, 15, 21 and 22 and burner

manual for burner adjustment specifications.

3) Retain your contractor or a competent service

agency to assure that the unit is properly adjusted

and maintained.

4) The interior of the venting must be inspected and

cleaned before the start of the heating season and

should be inspected periodically throughout the

heating season for any obstructions. A clean and

unobstructed vent is necessary to allow noxious

fumes that could cause injury or loss of life to vent

safely and will contribute toward maintaining the

boiler's efficiency.

for a

2

ECITON

noderiuqerebyamrepmadcirtemorabA

.noitidnoctfardhgihahtiwsnoitallatsni

FLUE DAMPER:

The boiler is provided with a breaching damper which

should be secured in the open position for initial start up

of the burner. The adjustable damper in the flue collar

at the boiler outlet is provided so that if the installer or

serviceman desires, he can easily introduce a flow

restriction at the boiler outlet and thereby increase the

pressure in the firebox. Normally, it is best to leave the

damper wide open and to control air flow to the burner

entirely by adjustments at the burner inlet. Flue

restrictions such as a partially closed damper tend to

make starts rougher. Boiler tests were run at 12½%

CO2 and 0.1 inches of water stack pressure to

demonstrate ample burner air capacity for good

performance up to this pressure. Boiler pressure drop

does not change measurably at different stack and

firebox pressures as long as the burner is adjusted to

maintain the same percent CO2.

MINIMUM INSTALLATION CLEARANCES TO

COMBUSTIBLE MATERIAL:

FRONT - 48 Inches ABOVE OR TOP - 18 Inches

SIDES - 18 Inches VENT CONNECTOR PIPE - 18 Inches

REAR - 18 Inches

NOTE:

1. Listed clearances comply with American National

Standard ANSI/NFPA 31, Installation of oil burning

equipment.

2. FD Series boilers can be installed in rooms with

clearances from combustible material as listed

above. Listed clearances can not be reduced for

alcove or closet installations.

3. For reduced clearances to combustible material,

protection must be provided as described in the

above ANSI/NFPA 31 standard.

4. Check dimensional data for boiler service

recommended clearances.

For additional information consult the service department.

GNINRAW

reliobehtfonoitarepoehtretfaerehtraeya

.evlav

GNINRAW

skcolbgnicalpybreliobtroppustonoD

.reliobehtfosrenroc)4(ruofehtta

ecnotsaeltadnareliobsihtfonoitallatsninopU

wolehtylralucitrap,dekcehcebdluohsslortnoc

feiler-ytefasdnalortnoctimilhgih,ffo-tucretaw

.esaberitnerednu

.erutsiomniatnoc

3

detroppusylneveebtsumesabrelioB

elbitsubmocnoreliobetarepotonoD

roolfdeilppusyrotcafatuohtiwroolf

sistsiojdoowrevoetercnoC.dleihs

tonoD.gniroolfelbitsubmocderedisnoc

yamhcihw,sroolfyrnosamnoetarepo

Page 4

456

Page 5

Page 6

FURNACE FLOOR BLANKETS

The furnace floor and the furnace wall below the mud

ring are not water backed. These surfaces must be

insulated from the intense heat in the furnace. The FD

Series boiler now employs precut, refractory ceramic

fiber (RCF) blankets to provide this insulation. They

are light weight, easy to handle and do not crack like the

poured refractory used heretofore.

The blankets must be replaced if they become water

logged or lose their thickness or shape for any other

reason, such as abuse during firetube cleaning.

BLANKET INSTALLATION

1. Confirm that the blankets are the appropriate size for

your FD boiler model using the chart opposite.

2. Unbolt the Burner Mounting Plate from the boiler

and set it aside.

GNINRAW

ytefaStcudorPtnatropmIehtdaeR

.gnideecorperofeb8egaPnonoitamrofnI

3. Remove the Burner Mounting Plate Insulation. It

may be poured-in-place refractory or precast,

lightweight RCF. In either case, it may be reused if

removed intact. Replacement, precast, lightweight

RCF Burner Mounting Door Insulation is available

from Burnham as Part No. 8203401 for Models FD7

through FD30 and as Part No. 8203402 for Models

FD38 and FD45.

4. Thoroughly clean any refractory or other insulation

out of the furnace.

5. On a flat surface, place the larger diameter 1" thick

Bottom Blanket.

6. Lay the smaller diameter 2" thick Top Blanket in the

center of the Bottom Blanket. Keep repositioning

the Top Blanket until you have equal Bottom

Blanket exposure all around the outside edge. See

dimension 'C' in the chart opposite and refer to the

illustration of blanket placement.

7. Fold the two (2) blankets in half, keeping the Top

Blanket centrally positioned on the Bottom Blanket.

8. Slide the folded blankets through the Burner

Mounting Plate opening and onto the furnace floor.

9. Unfold the blankets and position the blankets such

that the larger diameter 1" thick Bottom Blanket

curls up the wall of the furnace by at least 1½" all

around the furnace.

It is important that this curled edge of the Bottom

Blanket makes contact with the furnace wall all

around to protect the furnace wall from overheating

below the mudring. Refer to the illustration of

correctly installed blankets.

10. Reinsert the Burner Mounting Plate Insulation and

seal all gaps and cracks with ceramic caulking.

Ceramic caulking is available from Burnham in 10

ounce tubes (Part No. 9056081) and in gallon pails

(Part No. 9056982).

11. Reinstall the Burner Mounting Plate. Since neither

the blankets nor the ceramic caulk require cure

time, the boiler may be returned to service

immediately.

Page 7

7

Page 8

noitamrofnIytefaStcudorPtnatropmI

tcudorPrebiFcimareCyrotcarfeR

Warning:

This product contains refractory ceramic fibers (RCF). RCF has been classified as

a possible human carcinogen. After this product is fired, RCF may, when exposed

to extremely high temperature (>1800F), change into a known human carcinogen.

When disturbed as a result of servicing or repair, RCF becomes airborne and, if

inhaled, may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace previously fired RCF (combustion chamber insulation,

target walls, canopy gasket, flue cover gasket, etc.) or attempt any service or

repair work involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an air tight plastic bag.

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

8

Page 9

CLEANING INSTRUCTIONS

9

Page 10

FD BURNER SPECIFICATIONS

OGDF,GDF,ODF:REBMUNLEDOMRELIOB790121

denruBleuF&sledoMrenruB

)retteLebuT("FC"ttekceBliO2#005FC005FC005FC)A(008FC

"RC"emalFrewoPliO2#/saG01-OG-1-RC01-OG-1-RC01-OG-1-RC01-OG-1-RC

"RJ"emalFrewoPsaG01-A51-RJ01-A51-RJ01-A51-RJ01-A51-RJ

MPR0543-egatloV&PHrotoMrenruB

"FC"ttekceB 1/06/021,3/11/06/021,3/11/06/021,3/11/06/021,3/1

"RC"emalFrewoP 1/06/021,3/11/06/021,3/11/06/021,3/11/06/021,2/1

"RJ"emalFrewoP 1/06/021,4/11/06/021,4/11/06/021,4/11/06/021,4/1

)ISP(erusserP&epyT,).ged(elgnA,)HPG(eziS:elzzoNliO

"FC"ttekceB 051,P,54,57.1051,P,54,00.2051,P,54,05.2051,P,54,52.3

"RC"emalFrewoP 003,B,08,05.1003,B,08,05.1003,B,08,05.1582,B,07,05.2

SAGLARUTANEMALFREWOP

)#ezisllirdrosehcnI(eziS&rebmuN:secifirOsaG

steJsaG"RJ"61/5)02(61/5)02(61/5)02(61/5)02(

"RC"46/7)03(46/7)03(46/7)03(46/7)03(

gulPecifirOgnitimiL"RJ"23/1123/346/7223/51

"RC"23/118/323/3123/51

ecifirOsaG-renruBtoliP"RJ"84#84#84#84#

"RC"63#63#63#63#

.C.W"eeTecifirOtaderiuqeRerusserPsaG"RJ"5.31.36.39.3

"RC"3.32.37.37.3

.T.P.NsnoitcennoCniarTlortnoCsaGdradnatS"RJ"1 1 1 1

"RC"1 1 1 1

ENAPORPDIUQILEMALFREWOP

)#ezisllirdrosehcnI(eziS&rebmuN:secifirOsaG

steJsaG"RJ"61/5)02(61/5)02(61/5)02(61/5)02(

"RC"46/7)03(46/7)03(46/7)03(46/7)03(

gulPecifirOgnitimiL"RJ"23/1161/561/523/11

"RC"46/7123/961/523/11

ecifirOsaG-renruBtoliP"RJ"84#84#84#84#

"RC"84#84#84#84#

.C.W"eeTecifirOtaderiuqeRerusserPsaG"RJ"4.38.24.35.3

"RC"3.38.34.34.3

.T.P.NsnoitcennoCniarTlortnoCsaGdradnatS"RJ"1 1 1 1

"RC"1 1 1 1

10

Page 11

FD BURNER SPECIFICATIONS

41519142038354

)A(008FC)A(008FC)A(008FC)A(0041FC)A(0041FC)A(0032FC)A(0032FC

01-OG-1-RC01-OG-1-RC21-OG-1-RC21-OG-1-RC21-OG-1-RC51-OG-2-RC51-OG-2-RC

01-A51-RJ01-A03-RJ01-A03-RJ01-A03-RJ51-A05-RJ51-A05-RJ51-A05-RJ

1/06/021,3/11/06/021,3/11/06/021,3/11/06/021,2/11/06/021,2/11/06/021,4/31/06/021,4/3

1/06/021,2/11/06/021,2/11/06/021,2/11/06/021,2/11/06/032,4/31/06/032,4/31/06/032,4/3

1/06/021,4/11/06/021,3/11/06/021,3/11/06/021,3/11/06/021,3/11/06/021,3/11/06/021,2/1

051,P,54,57.3051,P,54,00.4051,P,06,05.4003,P,54,05.4003,P,54,05.5003,P,54,00.7003,P,54,00.8

003,B,08,05.2572,B,07,52.3003,B,07,05.3003,B,07,05.4042,B,07,05.6003,B,07,00.7003,B,07,05.8

61/5)02(61/5)02(61/5)02(61/5)02(7#)03(7#)03(7#)03(

46/7)03(46/7)03(46/9)03(46/9)03(46/9)03(8/1)04(8/1)04(

2/18/54/3ENON4/3ENONENON

2/123/714/3ENONENON61/51ENON

84#84#84#84#84#84#84#

63#63#63#63#63#63#63#

3.44.37.44.50.42.43.4

1.44.45.41.59.33.50.4

1111 2/1-12/1-12/1-1

1111 4/1-12/1-12/1-1

61/5)02(61/5)02(61/5)02(61/5)02(7#)03(7#)03(7#)03(

46/7)03(46/7)03(46/9)03(46/9)03(46/9)03(8/1)04(8/1)04(

8/323/3123/5123/7123/7161/1161/11

8/323/3123/512/18/58/54/3

84#84#84#84#84#84#84#

84#84#84#84#84#84#84#

6.34.39.32.41.45.34.4

5.34.38.37.44.33.42.6

1111 2/1-12/1-12/1-1

1111 4/1-12/1-12/1-1

11

Page 12

BECKETT CF500/800 OIL BURNER

2

renruB

relioB

ledoM

7DF1043206005FC3.26.5x4.2KK06FC05.3157.1º54P ogaH051

9DF1043206005FC57.26.5x4.2KK06FC0420.2º54P ogaH051

01DF1043206005FC1.36.5x4.2KK06FC0425.2º54P ogaH051

21DF1043206008FC0.43.6x4.2HK06FC05.55.152.3º54P ogaH051

41DF1043206008FC5.43.6x4.2HK06FC07257.3º54P ogaH051

51DF1043206008FC0.53.6x4.2HK06FC0820.4º54P ogaH051

91DF1043206008FC0.63.6x4.2HK06FC20145.4º06P ogaH051

gnitnuoM

.qeRetalP

renruB

ledoM

etaRgniriF

).H.P.G(

eziSnaF

ebuTriA

).nI(

*riA

noitanibmoC

gnitteS

OCdnaekomSybdeifirevebtsumdnaetamixorppaerasgnitteS*

*riA

rettuhS

dnaB

gnitteS

*daeH

gnitteS

.H.P.GelgnAepyT.gfM

ataDelzzoN

.yrassecenerehwtsujdaeR.stnemerusaem

12

pmuP

erusserP

)ISP(

Page 13

BECKETT CF1400 OIL BURNER

BECKETT CF2300 OIL BURNER

renruB

relioB

ledoM

42DF34432060041FC5.76.5x1.3DK06FC0.35.50.35.4º54P ogaH051003

03DF34432060041FC5.96.5x1.3EK06FC0.35.75.15.5º54P ogaH051003

83DF44432060032FC0.218.6x1.3GK06FC5.25.40.10.7º54P ogaH051003

54DF44432060032FC0.418.6x1.3GK06FC5.20.65.10.8º54P ogaH051003

gnitnuoM

.qeRetalP

renruB

ledoM

etaRgniriF

).H.P.G(

eziSnaF

).nI(

ebuTriA

*woL

*hgiH

eriF

eriF

noitanibmoC

riA

riA

OCdnaekomSybdeifirevebtsumdnaetamixorppaerasgnitteS*

2

*daeH

gnitteS

.H.P.GelgnAepyT.gfMeriFwoLeriFhgiH

ataDelzzoNerusserPpmuP

.yrassecenerehwtsujdaeR.stnemerusaem

13

Page 14

TANKLESS HEATER PERFORMANCE

Check and if necessary torque coil plate nuts to 25 ft.lb. max (Do Not Over Torque) before filling system and

again after the boiler has been up to operating temperature

for several hours.

Tankless heater ratings in the FD boiler are based on

continuous draw, temperature rise of 100°F (40-140°F) and

boiler water temperature of 200°F. Some of the items

effecting the coil performance are as follows:

ECITON

dewollofebdluohssenilediuggniwollofehT

:retaehsselknatehtgnipipnehw

1. Install Flow Regulator

If flow through the heater is greater than its rating,

the supply of adequate hot water may not be able to

keep up with the demand. For this reason a FLOW

REGULATOR matching the heater rating should be

installed in the cold water line to the heater. Refer

to figure below for piping recommendations. Locate

the flow regulator below the inlet (cold water side)

of the heater and a minimum of 36” away from the

inlet so that the regulator is not subjected to excess

temperatures during “off” periods when it is possible

for heat to be conducted back through the supply

line. The flow regulator will limit the flow of supply

water regardless of inlet pressure variations ranging

from 20 to 125 psi.

2. Install Water Temperature Mixing Valve

3. Flushing of Heater

All water contains some sediment which settles on

the inside of the coil. Consequently, the heater

should be periodically backwashed. This is

accomplished by installing hose bibs (as illustrated

below) and allowing water at city pressure to run

into hose bib A, through the heater, and out hose bib

B until the discharge is clear. The tees in which the

hose bibs are located should be the same size as

heater connections to minimize pressure drop.

4. Hard Water

A water analysis is necessary to determine the

hardness of your potable water. This is applicable to

some city water and particularly to well water. An

appropriate water softener should be installed based

on the analysis and dealer’s recommendation. This is

not only beneficial to the tankless heater but to

piping and fixtures plus the many other benefits

derived from soft water.

GNINRAW

gnidlacsrosnrubfoksirdiovaotteltuo

.serutxiftaretawtohylevissecxeoteud

deppiuqenehwreliobehtetarepotonoD

.ylreporpgnitareposi

a. Adjust and maintain the mixing valve in

accordance with manufacturers instructions.

b. Installation of a mixing valve will lengthen the

delivery of the available hot water by mixing

some cold water with the hot. In addition,

savings of hot water will be achieved since the

user will not waste as much hot water while

seeking desired water temperature.

c. Higher temperature hot water required by

dishwashers and automatic washers is possible by

piping the hot water from the heater prior to

entering the mixing valve.

d. The mixing valve should be “trapped” by

installing it below the cold water inlet to heater to

prevent lime formation in the valve.

retaehsselknatehttaevlavgniximallatsnI

evlavgniximsselnuretaehsselknatahtiw

Schematic Tankless Heater Piping

SGNINEPOLIOCRELIOB

ledoMrelioB

01DF21-01-9-8

21DF21-01-9-8

41DF61-21-01-9-8

51DF61-21-01-9-8

91DF61-21-01-9-8

42DF02-61-21-01-9-8

03DF02-61-21-01-9-8

03DF02-61-21-01-9-8

83DF82-42-02-61-21-01-9-8

54DF82-42-02-61-21-01-9-8

nidetaR(slioC

TIFLLIWHCIHWSLIOCRETAEH

)esiR°001@MPG

14

Page 15

SRELIOBTFARDDECROF"DF"-SGNITARRETAEH

ledoMrelioB.oNlioCssaPlioC

7DFA43-A2 0035.01

9DFA43-A2 0633.51

01DFB43-A2 0248.02

21DF8-32 0842.91

41DF9-32 0450.72

51DF01-33 0060.11

91DF21-33 0278.81

42DF61-35 0695.8

03DF02-35 00219.2

83DF42-36 04419.2

54DF82-36 08613.6

.dezis

retawtelniF°04htiwwardsuounitnocnodesaB*

ruoHrePsnollaG*

esiRF°001nOdesaB

tA).I.S.P(porDerusserP

esiRF°001roFetaRwolF

esirerutarepmetafiro,F°07fossecxeniserutarepmettelnirof"gnireenignEnoitacilppA"tcatnoC

-revoebnacsretaeh,evissecxeebotdnuoferasporderusserpfI.derisedsiF°001nahtrehto

15

Page 16

INDIRECT WATER HEATER OPERATION

The Forced Draft Boiler with a tankless heater coil for

domestic hot water supply is an efficient and easily

maintained system to provide large volumes of domestic

hot water. An indirect tankless water heater is one in

which domestic water is heated as it passes through a

copper coil immersed in hot boiler water. The boiler

water is maintained at 200°F or higher and circulates

around the outside of the coil transferring boiler water

heat to the domestic water in the coil. The domestic

water and boiler water are therefore separated, and the

domestic hot water provided is totally potable.

The tankless heater coil heats the domestic water

instantaneously as it passes through the coil. The coils

are designed for a predetermined flow of water in

gallons heated per minute. This flow rate should not be

exceeded, or the temperature of the domestic hot water

will be reduced.

If the domestic hot water demand will exceed the output

of the heater, then a storage tank should be considered

as illustrated on Page 21. It should be noted that a

circulating pump must be used with a storage tank

application since the design of a tankless coil prevents

the gravity flow of the water. The pump should be of an

all-bronze, corrosion-proof construction since continual

pumping of fresh water, which contains acids and

corrosive substances in varying amounts, frequently

causes rapid deterioration of circulator pumps. The

storage tank should be sized in accordance with that

required to provide the maximum amount of water over

a given period of time and allowance should be made

for that additional amount of hot water which the heater

will provide to replenish that in the tank.

An indirect tankless hot water heater is not

recommended for use with a hard water supply unless

the water is treated. Use of hard water in a tankless coil

results in internal mineral scaling and progressively will

build up to the point of total obstruction. It is

recommended that the local water supply be checked

and treated as may be recommended.

VENTILATION AND COMBUSTION AIR —

When the boiler is installed in an unconfined space in a

building of unusually tight construction, a single

opening in an outside wall shall be provided and

furnished with a properly louvered metal sleeve. This

opening shall have a free area of not less than one (1)

square inch for each five thousand (5000) Btu per hour

total input rating on all appliances.

When the Boiler is installed in a confined space, one of

the following provisions must be made to insure

adequate air for ventilation and combustion:

a. Two openings in a wall to an adjoining interior

area which has adequate air supply from

outdoors. One opening should be near the floor

and the other near the ceiling. Each shall have a

free area of not less than one (1) square inch for

each thousand (1000) Btu per hour input to all

appliances in the boiler room.

b. Two openings to outdoors or to spaces (crawl or

attic) that freely communicate with outdoors.

One opening should be in or near the ceiling and

one should be in or near the floor, and each shall

have a free area of not less than one (1) square

inch for each four thousand (4000) Btu per hour

total input. Horizontal ducts may be used if the

free area is not less than one (1) square inch for

two thousand (2000) Btu per hour total input and

minimum duct dimension is 3” or more.

c. Two openings through an interior wall (located

and sized as in provision (a) above) and an

additional opening to outdoors (as in provision

(b) above) in or near the floor having a free area

of not less than one (1) square inch for each five

thousand (5000) Btu per hour total input.

COMBUSTION AND VENTILATION AIR REQUIREMENTS

FOR BOILER ROOMS — MINIMUM AIR TO ACCOMMODATE

FORCED DRAFT BOILER-BURNER UNITS

The boiler room must have an adequate air supply to permit clean, safe combustion,

and to minimize soot formation. An unobstructed direct air opening of the sizes listed

below should be provided.

LIOROSAG

relioB

ledoM

7DF

9DF

01DF

21DF

41DF

51DF

91DF

42DF

03DF

83DF

54DF

76

08

09

611

031

541

371

712

472

643

404

edistuOotgninepOtceriD

.nI.qSteN-riA

16

Page 17

VENT SIZING - AREA MUST BE THE SAME AS OR GREATER THAN THE BOILER BREECHING

(Smoke outlet). A BAROMETRIC DAMPER MAY BE REQUIRED ON INSTALLATIONS WITH A

HIGH DRAFT CONDITION.

FAULTY BOILER BURNER OPERATION

1. IF IMPROPER VENT IS SUSPECTED, REMOVE PIPE AT BREECHING AND OPERATE

BOILER. THIS WILL DETERMINE IF EXCESSIVE DOWN DRAFT, BLOCKED OR

RESTRICTED FLUE, ETC. IS CAUSING PROBLEM.

2. IF USING TYPE SHOWN IN A. ABOVE, BE SURE CAP IS RAISED SUFFICIENTLY

ABOVE MAIN PIPE TO ALLOW FLUE GASES TO VENT UNIMPEDED.

3. A POPULAR TYPE CAP IS SHOWN IN B.

4. THE TEE IS FREQUENTLY USED AS SHOWN IN C.

5. D. AND E. SHOULD NOT BE USED DUE TO POSSIBLE FLUCTUATIONS IN BACK

PRESSURE.

17

Page 18

EXPANSION OR AIR CUSHION TANK

"

It is necessary to make provision for the increased

volume of water in the boiler and heating system caused

by thermal expansion. This is accomplished by

installing an expansion tank. The tank is usually located

above the boiler with a piping connection between the

bottom of the tank and the top of the boiler.

When the boiler and system is initially filled with water,

DF79012141519142038354

eziSknaTnoisnapxE*

)metsySgnitaeHoN(

knaTnoisnapxE*

.laG-emuloV

)metsySgnitaeHoN(

relioBniemuloVretaW

.laG-llehS

"03x"21"03x"21"63x"21"63x"21"84x"21"84x"21"84x"21"84x"21"06x"41"06x"41

5151818142424242040404

44250877491978901351981771

.ylnoretawcitsemodtaehotdesusireliobnehW*

a pocket or cushion of air is trapped within the tank.

This air cushion provides the additional space required

to accommodate the increased volume of water caused

by thermal expansion. The use of an expansion tank

permits operation through all ranges of boiler water

temperature, including temperatures above 212ºF

without opening the safety-relief valve.

GNIZISKNATNOISNAPXE

06x"41

NOTES:

1. If the boiler is used for space heating, the heating

system water volume must be added to the boiler

water volume in order to determine the expansion

tank requirements.

2. Before selecting expansion tank, consult local

authorities to determine ASME or State

requirements.

3. There are occasions in operation when the expansion

tank becomes “waterlogged” or filled with water.

When this occurs, it is necessary to close the stop

valve to the boiler and open the draw valve on the

tank. When the water is completely drained and the

tank is again filled with air, close the drain valve and

open the valve to the boiler.

4. It may be more economical to use the pressurized air

cushion tank rather than the conventional type

expansion tank listed above. When selecting a

pressurized air cushion tank, consult your dealer.

18

Page 19

OXYGEN CORROSION

Oxygen contamination of the boiler water will cause

corrosion of the iron and steel boiler components, which

can lead to failure. As such, any system must be

designed to prevent oxygen absorption in the first place

or prevent it from reaching the boiler. Problems caused

by oxygen contamination of boiler water are not

covered by Burnham’s standard warranty.

There are many possible causes of oxygen

contamination such as:

1. Addition of excessive make-up water as result of

system leaks.

2. Absorption through open tanks and fittings.

3. Oxygen permeable materials in the distribution

system.

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by

taking the following measures:

1. Repairing system leaks to eliminate the need for

addition of make-up water.

2. Eliminating open tanks from the system.

3. Eliminating and/or repairing fittings which allow

oxygen absorption.

4. Use of non-permeable materials in the distribution

system.

5. Isolating the boiler from the system water by

installing a heat exchanger.

19

Page 20

202122

Page 21

Page 22

Page 23

All FD Series Repair Parts may be obtained through your local Burnham Wholesale distributor.

Should you require assistance in locating a Burnham Distributor in your area, or have questions

regarding the availability of Burnham products or repair parts, please contact Burnham Customer

Service at (717) 481-8400 or Fax (717) 481-8408.

When ordering repair parts, refer to: (1) the part description on this page or page 4, (2) the Boiler Model Number and (3) the

Boiler Serial Number.

23

Page 24

Limited WarrantyLimited Warranty

Limited Warranty

Limited WarrantyLimited Warranty

FD SERIES™

Limited Warranty – Except as provided below with respect to products or parts not manufactured by

Burnham Commercial™, Burnham Commercial warrants to the original owner at the original installation site that

products manufactured by Burnham Commercial, America’s Boiler Company comply, at the time of manufacture,

with recognized Hydronics industry regulatory agency standards and requirements then in effect and will be free

from defects in materials and workmanship for a period of one year after the date of installation.

The remedy for breach of this warranty is expressly limited to the repair or replacement of any part found to be

defective under conditions of normal use and does not extend to liability for incidental, special or consequential

damages or losses such as loss of the use of the products, inconvenience, loss of time or labor expense involved

in repairing or replacing alleged defective product. Burnham Commercial shall have no responsibility for the

performance of any product sold by it under conditions varying materially from those under which such product is

usually tested under existing industry standards, nor for any damage to the product from abrasion, erosion,

corrosion, deterioration or the like due to abnormal temperatures or the influence of foreign matter or energy, nor

for the design or operation of any system of which any such product may be made a part or for the suitability of

any such product for any particular application.

For products or parts not manufactured by Burnham Commercial, the warranty obligation of Burnham

Commercial shall, in all respects, conform and be limited to the warranty actually extended to Burnham

Commercial by its vendors.

Warranty service can be obtained by contacting the original installer of the product and providing them with a

detailed description of any apparent defect. If this procedure fails to result in satisfactory warranty service, the

owner should notify Burnham Commercial, America’s Boiler Company, P.O. Box 3939, Lancaster, PA 17604.

Transportation to a factory or other designated facility for repairs of any products or items alleged defective shall,

in all events, be the responsibility and at the cost of the owner.

Not with standing any of the above provision, (1) failures resulting from misuse, improper installation or lack of

maintenance are not covered by this warranty, and (2) Burnham Commercial’s liability under this warranty shall

not exceed the selling price of the product found to be defective.

Equipment furnished by the Buyer, either mounted or unmounted, and when contracted for by the Buyer to be

installed or handled is not covered by this warranty. Burnham Commercial does not assume any responsibility in

connection with such equipment, operation, warranty, performance, or any other liability connected thereto.

Then foregoing provisions of this WARRANTY shall be effective to the maximum extent permitted by applicable

law, and, to the extent that any such provision would otherwise have an unconscionable result or would otherwise

be inconsistent with applicable law, such provision shall be limited in effect to the minimum extent necessary to

avoid such unconscionable result or inconsistency with applicable law.

Any implied warranties, including implied warranties of merchantability and fitness for a particular purpose shall,

to the extent permitted by applicable law, be limited in duration to a period of one year after the date of installation.

To the extent permitted by applicable law, the remedies for breach of any such implied warranty shall be limited to

the remedies set forth above with respect to a breach of the express limited warranty provided. With respect to

the limitations on implied warranties set forth above, Burnham Commercial hereby notifies each person to whom

such warranty is made as follows: Some states do not allow limitations on how long an implied warranty lasts or

the exclusion or limitation of incidental or consequential damages, so the above limitations, or exclusions may not

apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

24

03/03

Loading...

Loading...