Page 1

nonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp,reliob

rebmuNledoMrelioB

2SE

rebmuNlaireSrelioB etaDnoitallatsnI

rotcartnoCgnitaeH rebmuNenohP

sserddA

INSTALLATION, OPERATING AND

SERVICE INSTRUCTIONS FOR

ES2™

ENHANCED SERIES 2

Gas - Fired Boiler

As an ENERGY STAR

STAR® guidelines for energy efciency established by the United States Environmental Protection Agency (EPA).

102538-01R4-2/10

®

Partner, Burnham Hydronics has determined that this boiler meets the ENERGY

Page 2

WARNINGS FOR THE HOMEOWNER

FOLLOW ALL INSTRUCTIONS and warnings

printed in this manual and posted on the boiler.

INSPECT THE BOILER ANNUALLY. To keep your

boiler safe and efcient, have a service technician

follow the Service checklist near the end of this

manual.

IF YOU ARE NOT QUALIFIED to install or service

boilers, do not install or service this one.

THE BOILER MAY LEAK WATER at the end of

its useful life. Be sure to protect walls, carpets,

and valuables from water that could leak from the

boiler.

PROTECT YOUR HOME IN FREEZING

WEATHER. A power outage, safety lockout, or

component failure will prevent your boiler from

lighting. In winter, your pipes may freeze and cause

extensive property damage. If you must leave

your home unattended for an extended time when

outdoor temperatures are below 32°F, rst turn off

your home’s main water supply and drain the water

from all pipes.

DO NOT BLOCK AIR FLOW into or around the

boiler. Insufcient air may cause the boiler to

produce carbon monoxide or start a re.

KEEP FLAMMABLE LIQUIDS AWAY from the

boiler, including paint, solvents, and gasoline.

The boiler may ignite the vapors from the liquids

causing explosion or re.

KEEP CHILDREN AND PETS away from hot

surfaces of the boiler, boiler piping, and vent pipe.

CARBON MONOXIDE (CO) is an odorless, deadly

gas that may be introduced into your home by

any malfunctioning fuel-burning product or vent

system failure. Consider installing CO alarms near

bedrooms in all levels of the building to warn you

and your family of potential CO exposure.

WARNINGS FOR THE INSTALLER

READ THIS ENTIRE MANUAL before attempting

installation, start-up, or service. Improper

installation, adjustment, alteration, service, or

maintenance may cause serious property damage,

personal injury, or death.

DO NOT DISCONNECT PIPE FITTINGS on the

boiler or in the heating system without rst verifying

that the system is cool and free of pressure and

that your clothing will protect you from a release

of hot water or steam. Do not rely solely on the

boiler’s temperature and pressure gage when

making this judgment.

USE PROPER PERSONAL PROTECTION

EQUIPMENT when servicing or working near the

boiler. Materials of construction, ue products, and

fuel contain alumina, silica, heavy metals, carbon

monoxide, nitrogen oxides, and/or other toxic or

harmful substances that can are hazardous to

health and life and that are known to the State of

California to cause cancer, birth defects, and other

reproductive harm.

INSTALL ALL GUARDS, cover plates, and

enclosures before operating the boiler.

SIZE THE BOILER PROPERLY relative to the

design heat load or, if using domestic hot water

priority, the peak hot water load, whichever

is larger. A grossly oversized boiler will cycle

excessively and this will lead to premature failure

of the boiler and its components. Our warranty

does not apply to damage from excessive cycling.

ADHERE TO ALL LOCAL CODE

REQUIREMENTS. Contact your local code

inspector prior to installation. In the absence of

a local code, adhere to the National Fuel Gas

Code ANSI Z223.1/NFPA 54 or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

ALL WIRING must comply with the National

Electrical Code ANSI/NFPA 70 (in the USA) or the

Canadian Electrical Code CSA C22.1 (in Canada)

and any local regulations.

2

Page 3

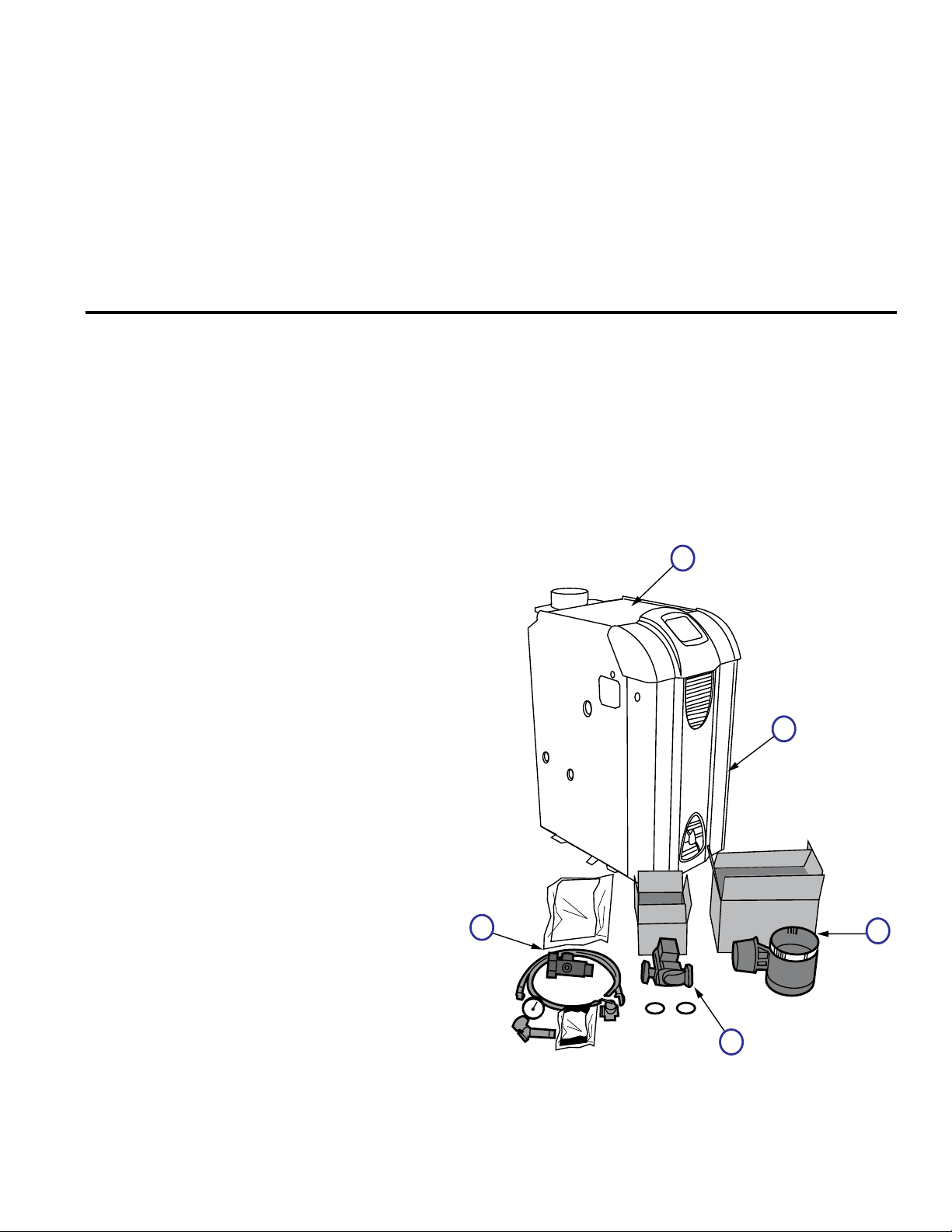

5

2

1

3

4

Congratulations on your purchase of a new Burnham® boiler—designed and constructed to provide you

with years of reliable service.

•

•

ENERGY STAR™ efficiency – friendly on the environment and your wallet.

Cast iron heat exchanger – for reliability and durability, nothing beats a cast iron heat exchanger.

Ours is made proudly by our foundry in Zanesville, Ohio.

•

IQ Control™ – the most advanced and easiest to use control available.

• System-friendly – built-in protection from condensation and thermal shock.

What's in the crate?

1. q ES2™ Boiler

q Vent Damper w/ Carton

2.

4” Damper ES23 (102284-01)

5” Damper ES24 (102284-02)

6” Damper ES25 & ES26 (102284-03)

7” Damper ES27 & ES28 (102284-04)

8” Damper ES29 (102284-05)

3. q

Taco 007-2 (8056170)

4.

q Temperature/Pressure Gage; ¼” NPT

(100282-01)

Circulator & Gasket Kit

Grundfos UP-15 (8056173)

B & G NRF-22 (8056174)

q Miscellaneous Parts Bag (102627-01)

5. q Instruction Envelope (102625-01)

q

Instruction & Operation Manual

(102538-01)

q

Hydronics Institute Instructions

(81460061)

q Boiler Warranty Sheet (102198-01)

q Equipment List (102620-01)

q Circulator Mounting Hardware Kit, 1-

1/4” NPT (6056007)

q Circulator Wiring Harness (6130701)

q

Drain Valve; ¾” NPT (806603012)

q Pressure Relief Valve; 30 psi

(81660363)

q Water Manifold for Pressure Relief/

Temp. Gage (80607001)

3

Page 4

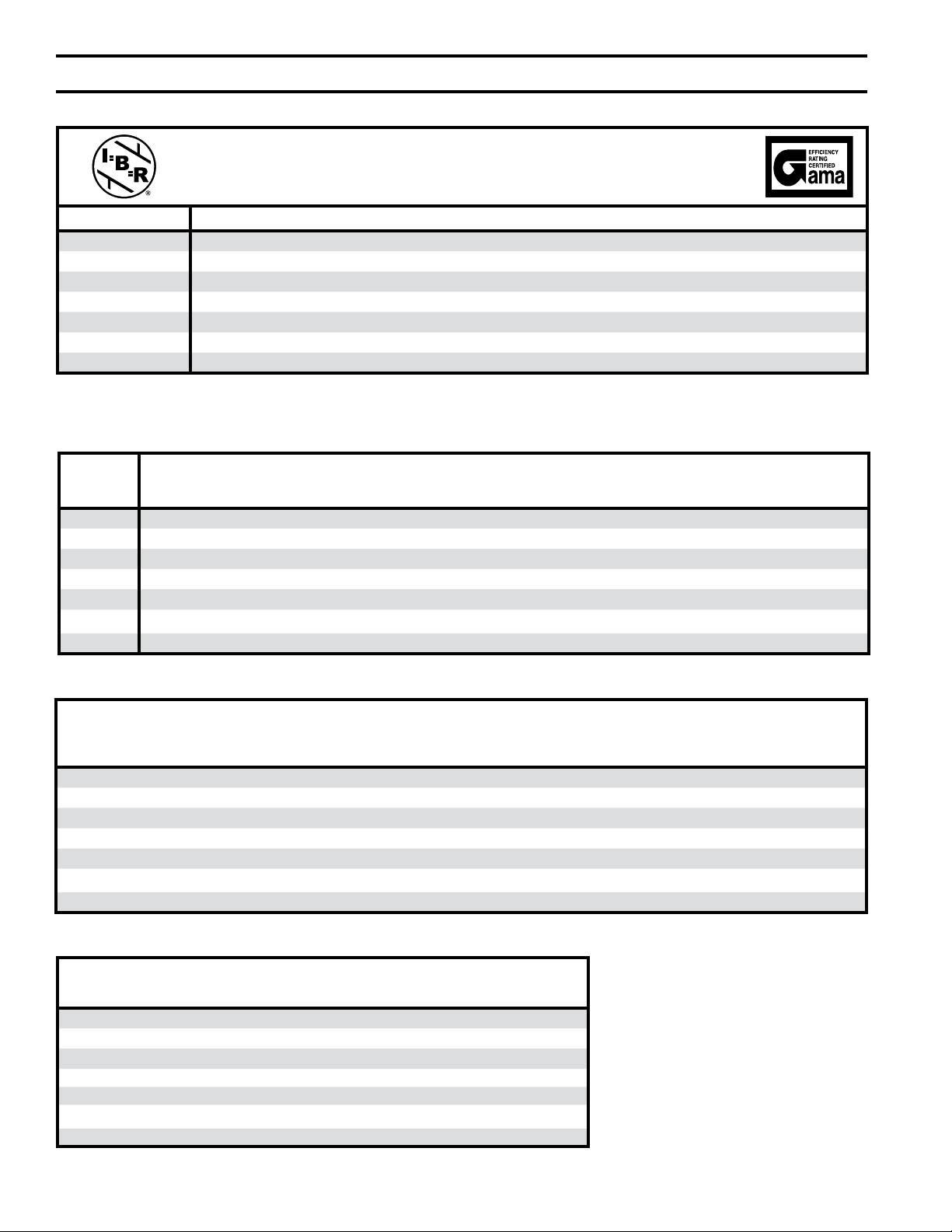

Ratings

SPECIFICATIONS

ES2 Series

Boiler Model

ES23 70 59 51 85

ES24 105 88 77 85

ES25 140 118 102 85

ES26 175 147 128 85

ES27 210 176 153 85

ES28 245 206 179 85

ES29 280 235 205 85

Input (MBH) DOE Heating Capacity (MBH) Net I=B=R Rating (MBH) AFUE (%)

Electrical Requirements: 120VAC, 60 Hz, 1-ph, 15A

Dimensions and Connections

Boiler

Model

ES23 33 12¾ 41 1¼ 1¼ 4 ½ ¾ ¾

ES24 33 15½ 41 1¼ 1¼ 5 ½ ¾ ¾

ES25 33 18½ 41 1¼ 1¼ 6 ½ ¾ ¾

ES26 33 21½ 41 1¼ 1¼ 6 ½ ¾ ¾

ES27 33 24¾ 41 1¼ 1¼ 7 ¾ ¾ ¾

ES28 33 27¾ 41 1¼ 1¼ 7 ¾ ¾ ¾

ES29 33 30¾ 41 1¼ 1¼ 8 ¾ ¾ ¾

Depth Width Height

Supply NPT

(inch)

Return NPT

(inch)

Vent

(inch)

Gas NPT

(inch)

Relief Valve

NPT (inch)

Drain

NPT (inch)

Water Temperatures and Flows

Allowable Supply

Boiler Model

Water Temperature

(°F)

ES23 130-220 110 None <1

ES24 130-220 110 None <1

ES25 130-220 110 None <1

ES26 130-220 110 None <1

ES27 130-220 110 None <1

ES28 130-220 110 None <1

ES29 130-220 110 None <1

Minimum Return

Water Temperature

(°F)

Weights and Volume

Boiler

Model

ES23 250 170 2

ES24 300 220 3

ES25 350 270 4

ES26 410 320 5

ES27 460 370 5

ES28 510 420 6

ES29 560 470 7

4

Shipping Weight

(lbs)

Empty Weight

(lbs)

Minimum Flow

Water Content

(gal)

(GPM)

Waterside Pressure Drop

at 20°F DT

(Ft. of Head)

Page 5

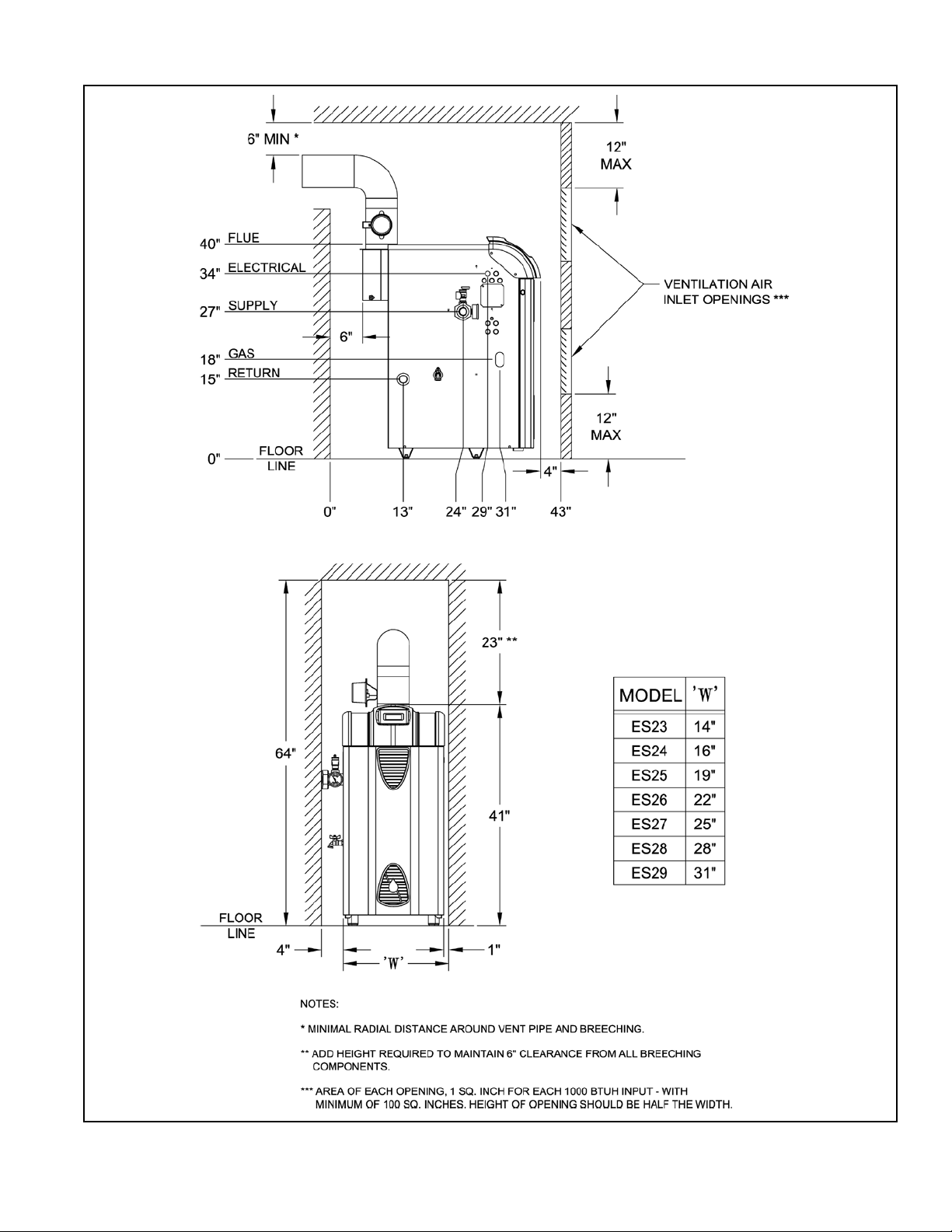

SPECIFICATIONS (continued)

Figure S-1: Minimum Clearances to Combustibles and Closet Dimensions

5

Page 6

Boiler Quick-Start

Installation:

1. Unpack the crate ............................................................................................. 7

2. Position the boiler ............................................................................................ 7

3. Provide combustion air .................................................................................... 8

4. Connect venting ............................................................................................... 8

5. Connect gas piping ........................................................................................ 10

6. Connect boiler water piping ........................................................................... 10

7. Connect electrical wiring ................................................................................ 12

8. Program the controls ..................................................................................... 13

9. Check for gas and water leaks ...................................................................... 15

10. Perform startup checks and adjustments ...................................................... 16

Annual Maintenance Checklist ............................................................................ 17

Troubleshooting ....................................................................................

Repair Parts List ................................................................................................... 21

Internal Wiring ....................................................................................

................ 18

................... 27

Appendices:

A – Combustion Air.................................................................................................. 32

B – Venting ..............................................................................................................33

C – Gas Piping ........................................................................................................36

D – System Piping ...................................................................................................37

E – Filling the System and Checking for Leaks .......................................................43

F – Adjusting Gas Input Rate ..................................................................................44

G – Checking Draft and Combustion ....................................................................... 46

H – IQ Control System............................................................................................. 47

Warranty ....................................................................................

.............. Back Cover

6

Page 7

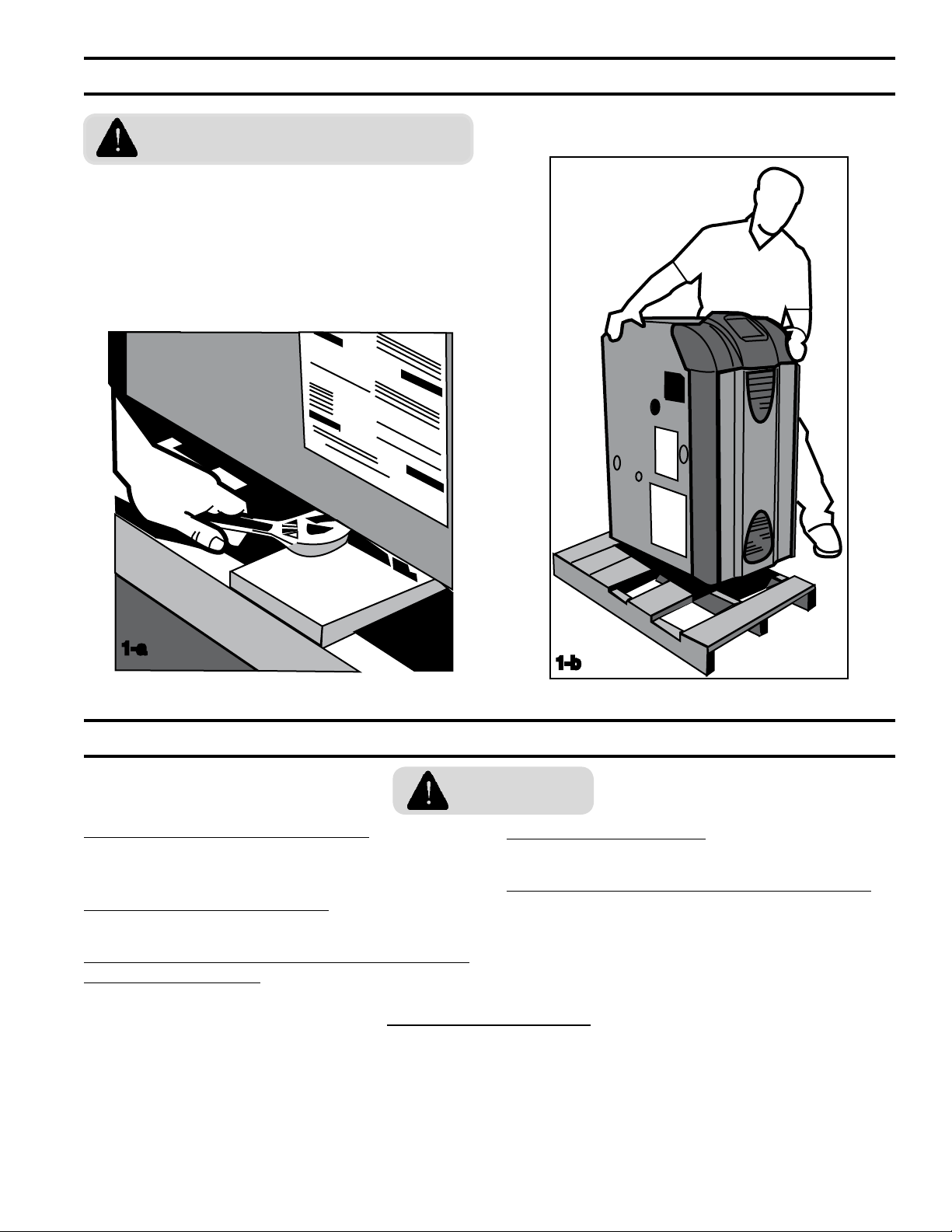

1. UNPACK THE CRATE

THE BOILER IS TOP-HEAVY. Do not

allow it to tip over.

1. Remove the sleeve.

2. Remove the contents from the skid, except

the boiler.

3. Remove the four (4) hex-drive lag screws

holding the boiler to the skid (Figure 1-a).

4. Tip the boiler and shimmy it off the skid.

1-a

2. POSITION THE BOILER

WARNINGS

OBSERVE MINIMUM CLEARANCES to

combustible walls and ceilings to avoid potential

re hazard.

DO NOT INSTALL ON CARPET. This may cause

a re.

INSTALLING THE BOILER NEAR A SOURCE OF

FLAMMABLE LIQUIDS or gases may cause re or

explosion.

1. Slide the boiler into desired location.

2. Meet the minimum clearances to

combustible construction per the

Specification Section of this manual.

1-b

CLEAN BURNERS DAILY if operating the boiler in

a dusty environment.

PROTECT IGNITION SYSTEM COMPONENTS

from sources of water that may spray, drip, or rain

on them during installation or service.

3. Allow 24" service clearance in front and on

the left side of the boiler.

4. Level the boiler, using shims as necessary.

7

Page 8

3. PROVIDE COMBUSTION AIR

INSUFFICIENT COMBUSTION AIR

SUPPLY may result in the production and

release of deadly carbon monoxide (CO) into the

home which can cause severe personal injury or

death.

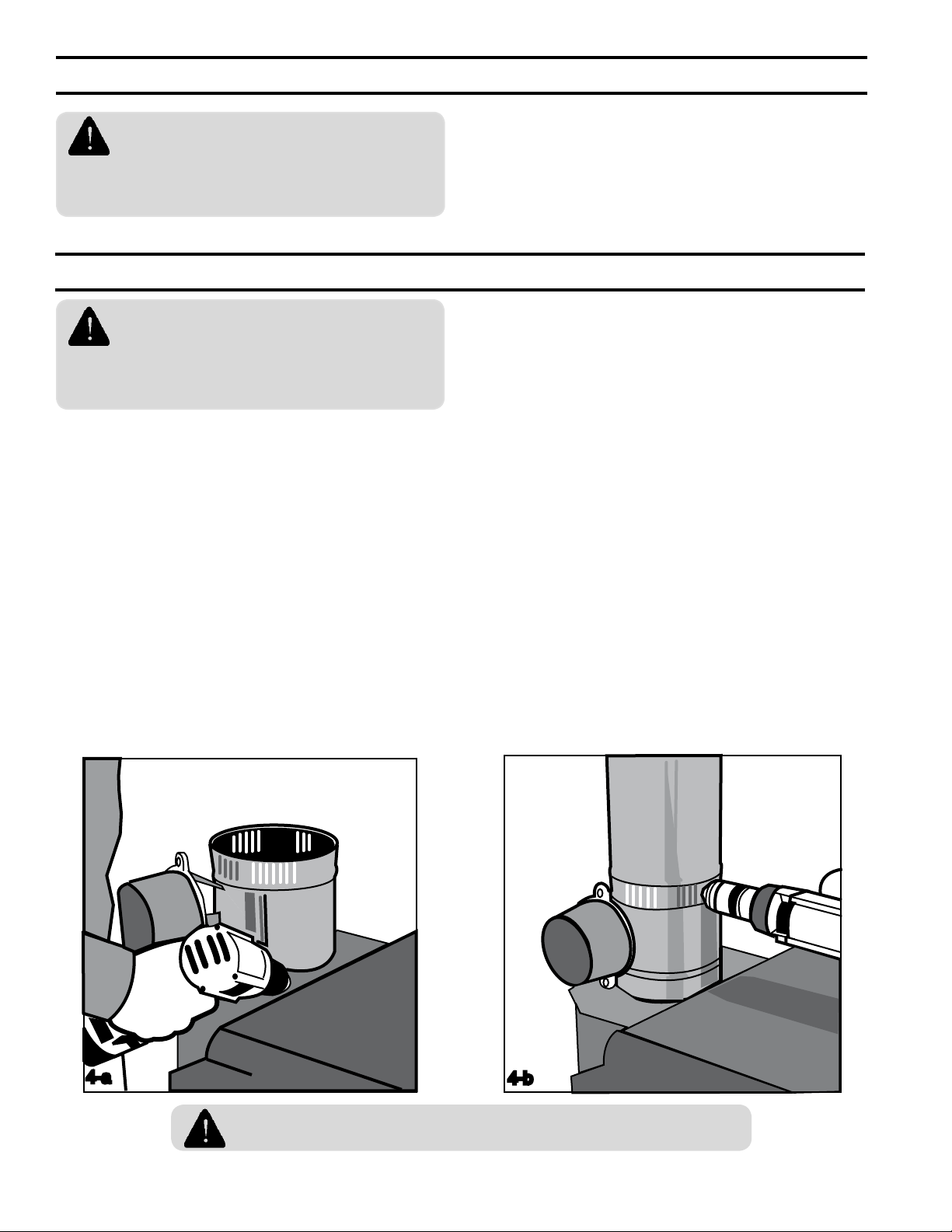

4. CONNECT VENTING

IMPROPER VENTING may result in

property damage and the release of ue

gases which contain deadly carbon monoxide (CO)

into the home, which can cause severe personal

injury, death or substantial property damage.

The vent system shall be designed and

constructed in accordance with NFPA 54 and

applicable local codes to develop a positive ow

adequate to convey ue or vent gases to the

outdoors, while ensuring that ue gases do not

cool prematurely.

Observe all general venting guidelines provided in

Appendix B—Venting. Additionally:

1. This appliance shall be vented into a listed

gas vent, masonry, metal, or factorybuilt chimney as required by NFPA 54

and applicable local codes for Category I

appliances. If venting this appliance into

a masonry chimney, the chimney must be

lined with a listed chimney lining system

Like all fuel-burning appliances, boilers need air to

operate reliably and safely.

Provide combustion air using the instructions in

Appendix A—Combustion Air.

(i.e. Type B gas vent or exible metal) as

required by NFPA 54 and applicable local

codes. Clay ue lined masonry chimneys do

not meet the venting requirements for this

appliance.

2. Attach the vent damper with three

sheetmetal screws around the perimeter of

the ue collar (Figure 4-a), oriented so that

the position indicator is visible. The vent

damper may also be mounted anywhere

between the ue outlet and the chimney

within reach of the electrical harness.

3. Vent connector shall be double-wall

insulated gas vent as supplied with this

boiler or Type B (double-wall) gas vent only.

Using sheetmetal screws, attach the vent

connector between the vent damper and

the vertical chimney (Figure 4-b). Do not

exceed the maximum vent connector length

in Table 4.1.

4-a

DAMPER MUST BE OPEN when the main burner is ring.

8

4-b

Page 9

4. CONNECT VENTING (continued)

Table 4.1: ES2 Vent Connector - Horizontal Length Restrictions (ft)

Model ES23 ES24 ES25 ES26 ES27 ES28 ES29

Input (MBH) 70 105 140 175 210 245 280

Minimum Vent

Diameter (in)

Vent Height (ft) With B-Vent (double wall) Vent Connector

6 0 0 6 0 4 0 2

8 8 8 8 2 8 2 8

10 10 10 10 10 10 10 10

15 15 15 15 15 15 15 15

20 20 20 20 20 20 20 20

30 20 30 30 30 30 30 30

50 20 30 30 30 30 30 30

100 20 30 30 30 50 50 50

4 5 6 6 7 7 8

9

Page 10

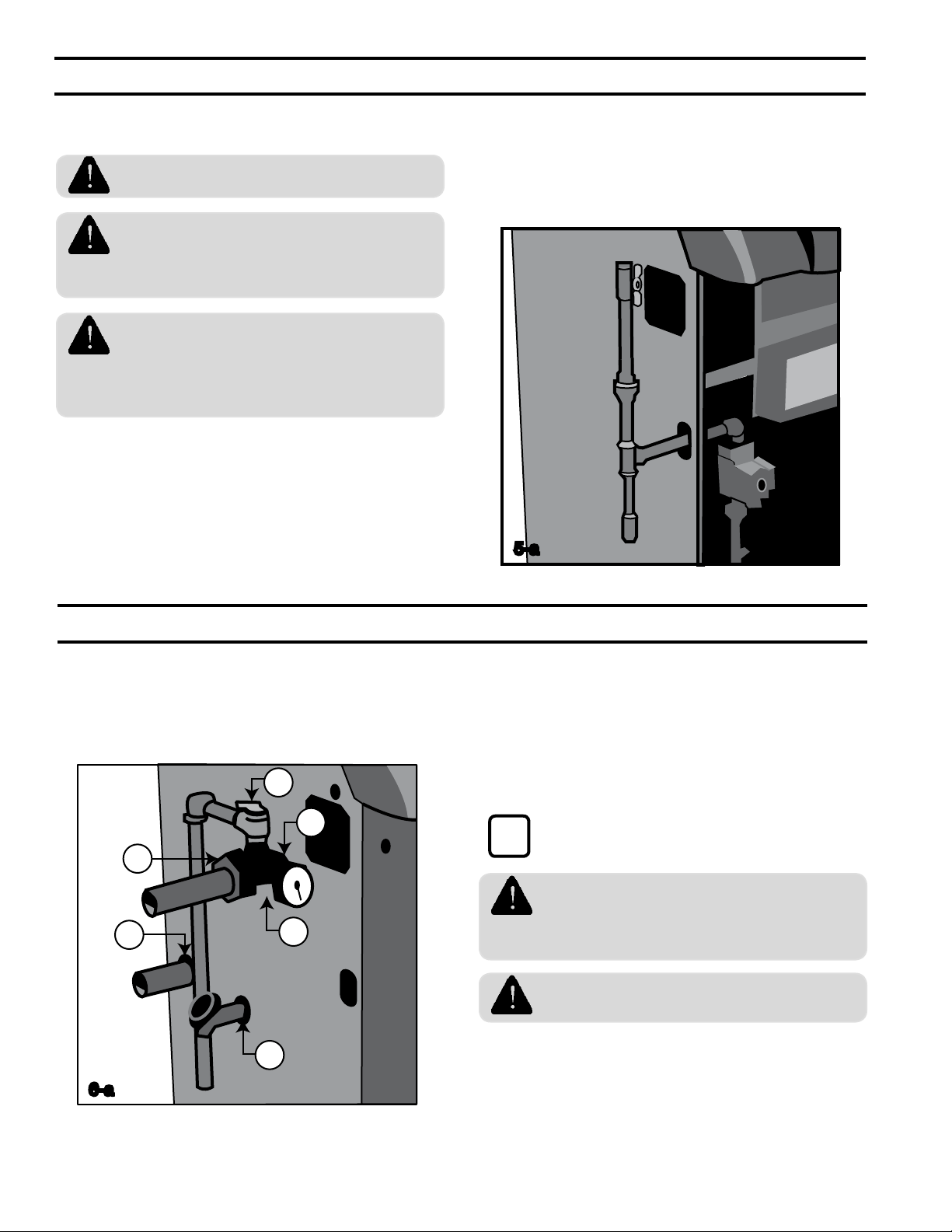

5. CONNECT GAS PIPING

RV

S

R

O

G

D

Size gas piping according to Appendix C – Gas

Piping

SHUT OFF GAS SUPPLY before

servicing the boiler.

ALL GAS PIPING MUST BE GAS

TIGHT. Use gas rated thread compound

on all threaded joints to avoid leaks, which may

result in re or explosion.

SIZE GAS PIPING, regulators, valves,

and meters so as to provide an adequate

gas ow and pressure to the boiler during

operation. Failure to do so may cause poor

combustion, noise, injury, or death.

1. Remove boiler door, locate gas valve and

remove plastic shipping plug.

2. Thread a ¾" x 1½" nipple, a 90° street

elbow, or a Honeywell ange onto the gas

valve and pipe through the slot in the left

jacket panel (Figure 5-a). In Canada, close

nipples and street ells are not approved for

use as gas piping.

3. Pipe through the left jacket panel, and

complete drip leg as shown (Figure 5-a).

5-a

6. CONNECT BOILER WATER PIPING

General system piping guidelines are included in

Appendix D—System Piping.

Additionally, for this particular boiler install piping

shown below (Figure 6-a).

6-a

1. Apply sealant to all threads.

10

2. Screw the water supply manifold into the

boiler outlet tapping “O.”

3. Orient the manifold with the relief valve on

top.

4. Screw the relief valve into manifold tapping

“RV”.

relief valve is installed.

to a location where it will not harm

people or damage property. The relief valve may

discharge scalding hot water or steam.

result in boiler explosion.

This installation is not complete until the

i

PIPE THE RELIEF VALVE DISCHARGE

BLOCKING THE RELIEF VALVE may

5. Screw the temperature-pressure gage into

manifold tapping “G”.

6. Connect the system supply to the open end

of the manifold "S" using a 1¼” male NPT

tting.

Page 11

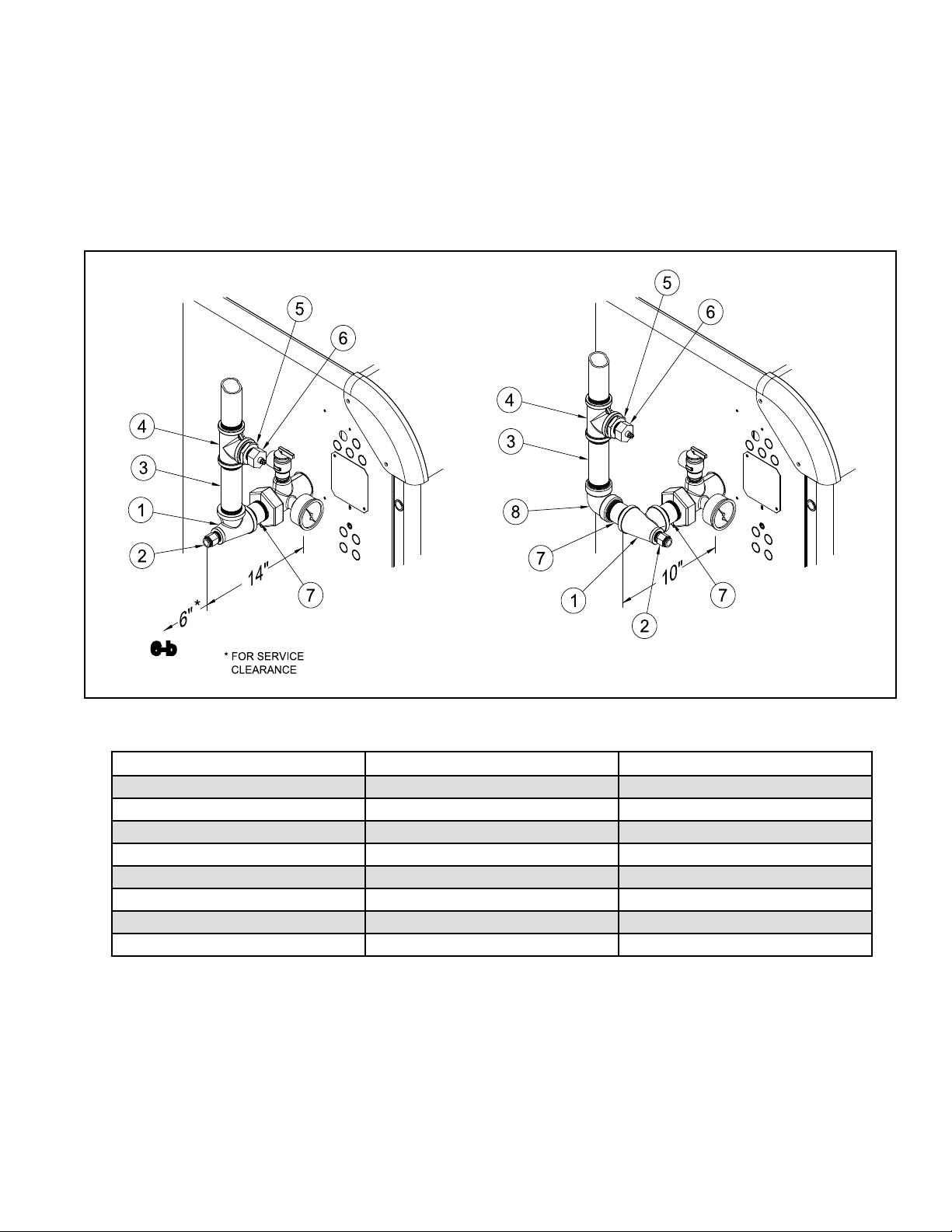

6. CONNECT BOILER WATER PIPING (continued)

7. Screw an installer-supplied 1¼” pipe or

nipple into the water return tapping “R”.

8. Screw the supplied drain valve into tapping

“D”.

9. See Figure 6b for suggested near boiler

piping of IQ Options.

6-b

Item Description Burnham Part Number

1 1¼ x 1¼ x ½ Tee 806601021

2 Immersion Well, ½ NPT 80160456

3 1¼ x 6 Nipple 806600029

4 1¼ Tee 806601030

5 1¼ x ¾ Bushing 806600504

6 LWCO Sensor, ¾ NPT 102305-01

7 1¼ x 3 Nipple 806600005

8 1¼ Elbow 806601528

11

Page 12

7. CONNECT ELECTRICAL WIRING

1

1

2

3 T

T

DISCONNECT ELECTRICAL POWER

to the boiler and heating system before

servicing. Positively assure that no voltage is

present. Lock electrical boxes to prevent someone

from inadvertently restoring power before the

heating system is safe to operate.

NEVER DEFEAT OR JUMP OUT safety

devices.

PROTECT EACH BOILER circuit with a

properly sized over-current protection

device.

MAKE ELECTRICAL CONNECTIONS

CAREFULLY according to the boiler’s

wiring diagram and instructions

Refer to the Internal Wiring diagrams later in this

manual.

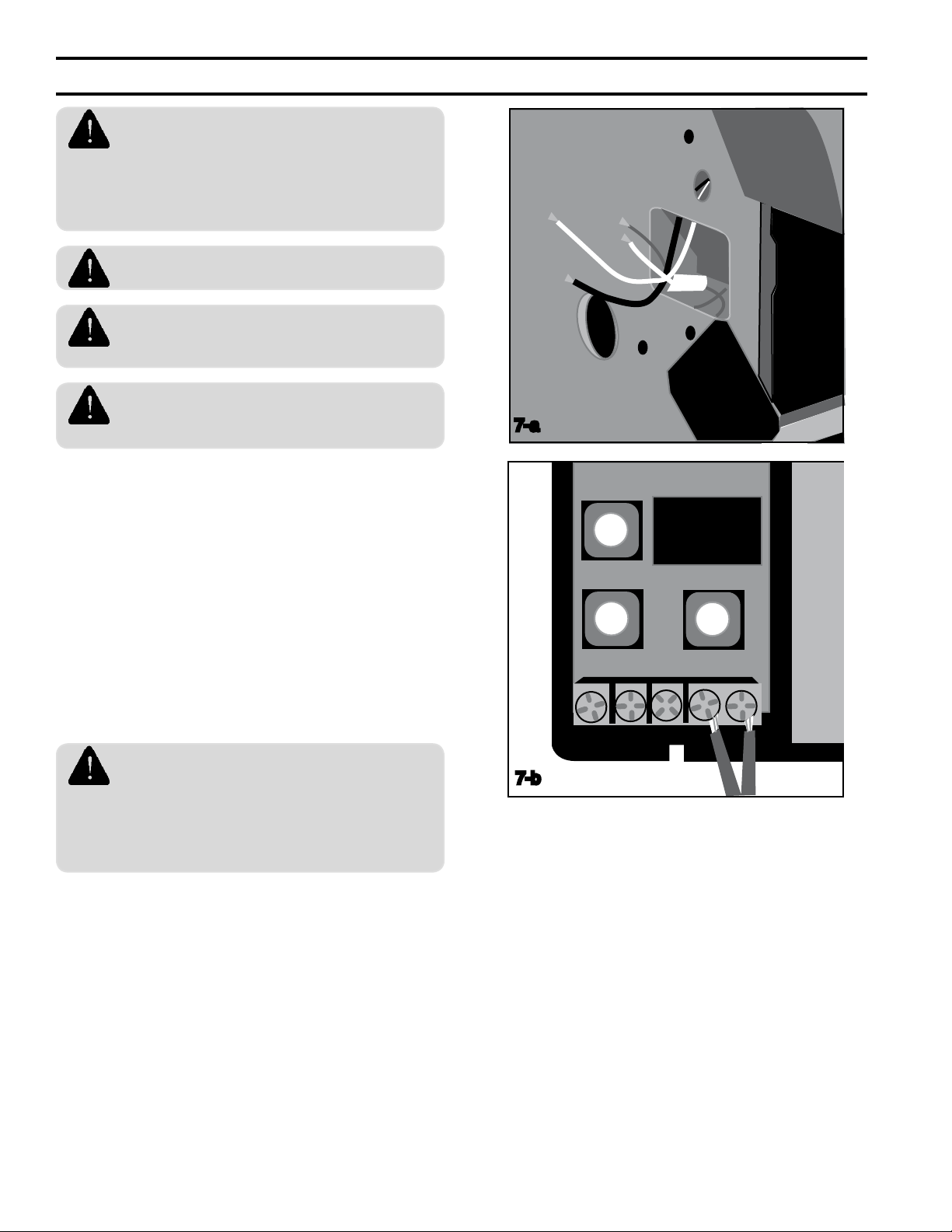

1. Locate the wiring box on the left side of the

boiler and open the cover (Figure 7-a).

2. Install a 120V disconnect near the boiler.

3. Connect the 120V wiring from the disconnect

to the boiler's white (neutral), black (hot),

and green (ground) labeled "120VAC Power

supply". Do not reverse polarity.

4. Connect the 120V wiring from the circulator

to the white (neutral) yellow (hot) wires

marked "circulator".

7-a

WIRE AN ADDITIONAL SAFETY LIMIT

such as a low water cutoff or temperature

limit device, other than an IQ™ Control device,

in series with the 120V circuit used to power the

boiler. Do not alter the boiler’s factory wiring when

adding an additional limit.

12

7-b

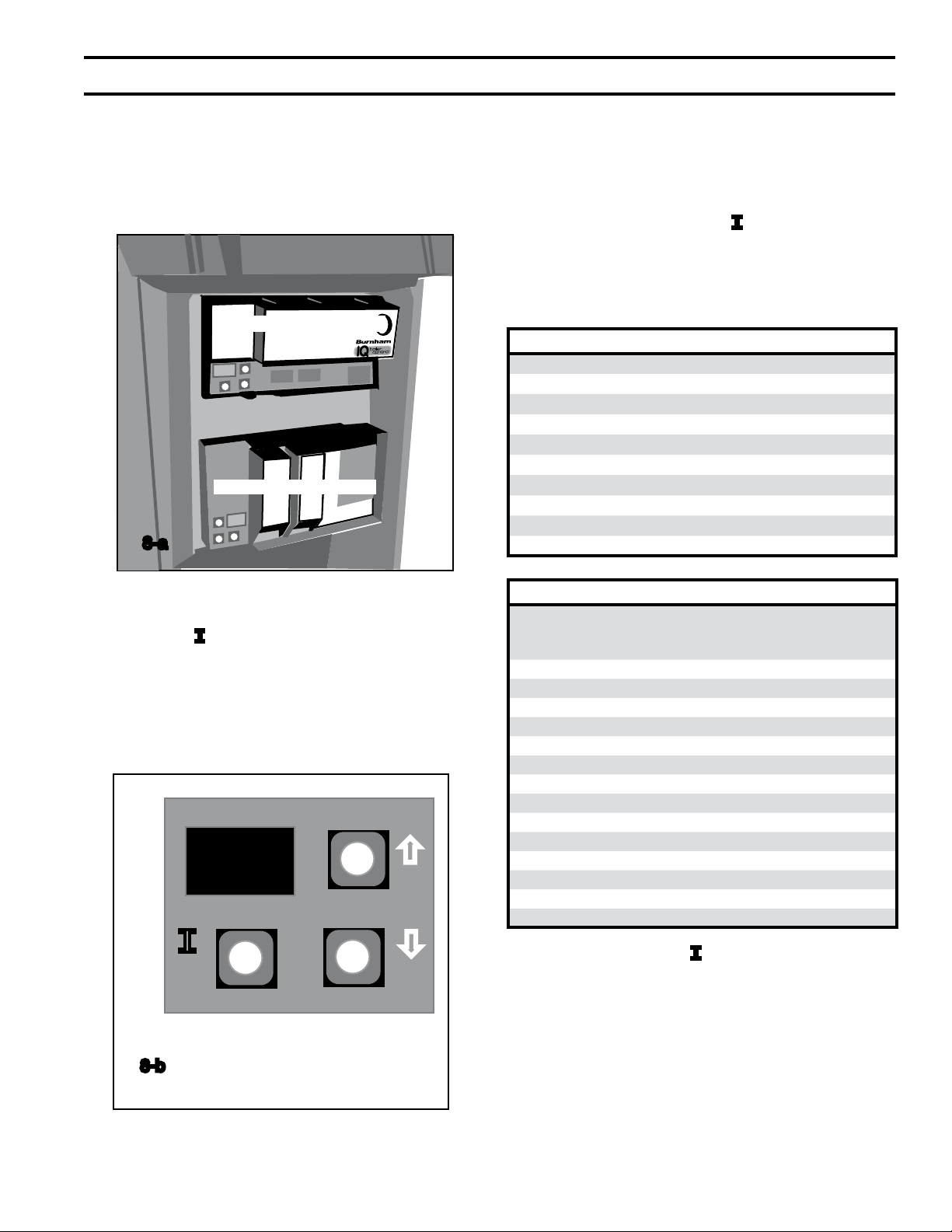

5. Connect the 24V wiring from the thermostat

to the "T-T" terminals on the Option Control

Panel.

6. To connect other external devices, refer to

the instructions included with these devices.

Page 13

8. PROGRAM THE CONTROLS

1

Using IQ Boiler Control Display

The IQ Boiler Control is located inside the boiler

front door, just above the IQ Option Panel (Figure

8-a).

IQ Boiler Control

IQ Option Panel

8-a

Viewing the Operating Mode Options

In operating mode the user may view (but not

change) boiler operating status, settings and

troubleshooting information. To view IQ Boiler

Control display information:

1. Press and release the “I” key on the IQ

Boiler Control to change from one parameter

to the next. Each setting will alternately ash

between the relevant display code and its

corresponding value.

Operating Mode Options

StA Status

bt Boiler Temperature

SP Operating Setpoint (Outdoor Reset)

HL High Limit Setting

HdF High Limit Differential

hr Heat Request Status

FLA Flame Current

rUn Run Time Hours

CYC Boiler Cycles

Err Error (see Error Numbers)

The IQ Boiler Control display, along with Up ñ,

Down ò, and “I” keys may be used to view boiler

operating status (Figure 8-b). Please note that

these keys look similar to the keys on the IQ

Option Panel but are in a different orientation, and

they perform different functions.

ñ

I

ò

IQ Boiler Control

8-b

Status Code Displayed in STA Mode

1 Standby:

Either TT Open or TT Closed and Boiler Temperature

within Setpoint & Differential with circulator running.

4 Prepurge

6 Spark

7 Flame Proving

8 Running

10 Retry/Recycle Delay

13 Soft Lockout

14 Hard Lockout

15 Waiting for Limit to Close

16 Flame Present Out of Sequence

17 Self Test

18 Waiting for Damper to Open

19 Waiting for Damper to Close

20 Damper Failure to Open

21 Damper Failure to Close

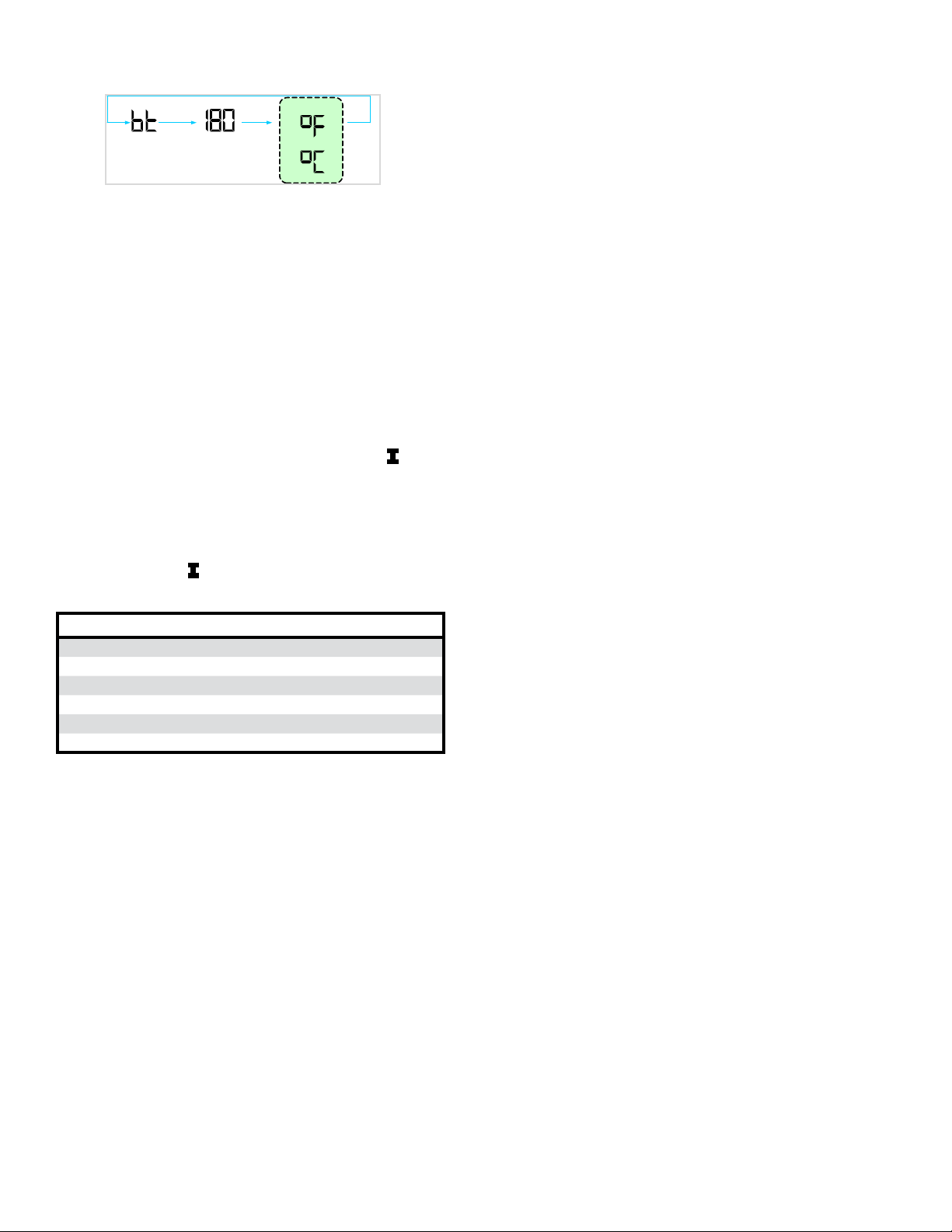

For example, when the “I” key is pressed on the

IQ Boiler Control until “bt” is displayed, it will then

ash a three digit number (such as “180”) followed

by either “F” (or “C”). This indicates that the boiler

water temperature is 180°F. Other operating

parameters display the information in a similar

fashion.

13

Page 14

Unit D isplay

OR

Sample

Display

1 sec

1 sec

1 sec

8. PROGRAM THE CONTROLS (continued)

Please note that in operating mode to hold the

display on the value the user can press and hold

either the Up ñ or Down ò keys and the value

will be continuously shown. This may be helpful in

watching a value “live”.

Changing the Adjustable Parameters

To adjust the High Limit setpoint, High Limit

Differential or Pump Overrun time settings or

setting the display for either °F or °C temperature

readings:

1. Access the adjustment mode by pressing

and holding the Up ñ, Down ò, and “I”

keys simultaneously for three (3) seconds.

This procedure is intended to discourage

unauthorized changes or accidental changes

to limit settings.

2. Press the "I" key to display available

Adjustment Mode options. Select an option.

Adjustment Mode Options

HL_ Adjust High Limit Setting

dF_ Adjust High Limit Differential

Or_ Pump Overrun Time (minutes)

rst Reset Lockout

f-C Select degrees F or C Mode

bac Back to Operating Mode

3. Press the Up ñ and Down ò keys to adjust

the displayed setpoint to the desired value.

4. To return to the normal operating mode

from the Adjustment Mode, when the "bAc”

option is displayed, press either the Up ñ or

Down ò key. If no keys are pressed, after

ve (5) minutes the IQ Boiler Control will

automatically return to the Operating Mode.

More Information about Adjustable Parameters

1. High Limit (HL_)

The IQ Control is factory programmed

with a High Limit Setpoint of 180°F. The

boiler turns "off" when the supply water

temperature is above this value. The High

Limit setpoint is adjustable between 130°

and 220°F. The Operating Setpoint (SP) will

equal the High Limit Setpoint unless an IQ

Outdoor Reset IQ Option Card is installed.

The Outdoor Reset IQ Option Card reduces

the Operating Setpoint to regulate heat

delivery, increase home comfort and

save energy. Refer to the Appendix H for

additional information.

2. Differential (df_)

The IQ Boiler Control is factory programmed

with a Differential of 15°F. The Differential

is the number of degrees the supply

temperature must decrease below the

Operating Setpoint before the boiler can

restart. The differential is adjustable

between 10° through 30°F.

3. Pump Overrun Time (OR_)

The IQ Boiler Control is factory programmed

with a Pump Overrun Time of 0 minutes.

Pump Overrun Time (also called “off delay”

or “post purge”) continues pump operation

after a call for heat has ended, sending

excess heat from the boiler into the priority

zone. Ensure system piping and zone panel

settings allow water ow to the priority zone

after the call for heat ends. The Pump

Overrun Time is adjustable between 0

through 10 minutes.

Using the IQ Option Panel

IQ Option Cards are available from Burnham

distributors and are the simplest way to add

functionality, safety and efciency to your heating

system. The IQ Option Panel provides an easy and

convenient means to "plug-in" an Auxiliary High

Limit, Low Water Cut-off and/or Outdoor Reset

function.

For installation, programming, and troubleshooting

instructions, refer to the instructions supplied with

those cards.

14

Page 15

8. PROGRAM THE CONTROLS (continued)

Using the Optional LCD Display Kit

The LCD Display is an easy to use touch screen

type display that allows a technician to monitor

and adjust the IQ Boiler Control and connected

IQ Option Cards. All boiler settings, status and

error codes are displayed in full text. All Outdoor

Reset IQ Option Card parameters are adjustable

with graphic and help information screens. The

LCD Display Kit includes a mounting bracket

and wiring harness to allow mounting in the ES2

plastic hood above the front door. For installation,

programming, and troubleshooting instructions,

refer to the instructions supplied with the display.

GAS LEAKS may result in re or

explosion.

WATER LEAKS may cause extensive

property damage.

9. CHECK FOR GAS AND WATER LEAKS

Refer to Appendix E – Filling the System and

Checking for Leaks

15

Page 16

10. PERFORM STARTUP CHECKS AND ADJUSTMENTS

FAILURE TO PERFORM THESE

CHECKS of the boiler's combustion and

safety systems may result in serious property

damage, injury, or death.

IF YOU SMELL GAS, STOP and repair

the leak. Lighting the boiler when gas is

leaking may cause explosion or re.

Follow the checklist below:

1. Verify that the venting, water piping, gas

piping, and electrical systems are properly

installed and checked.

2. Apply power to the boiler.

3. Adjust zone thermostat to maximum setting.

4. Allow gas line to purge of air.

10-b

q Boiler lights cleanly within 60 seconds.

5. Adjust gas input rate. See Appendix F

– Adjusting Gas Input Rate

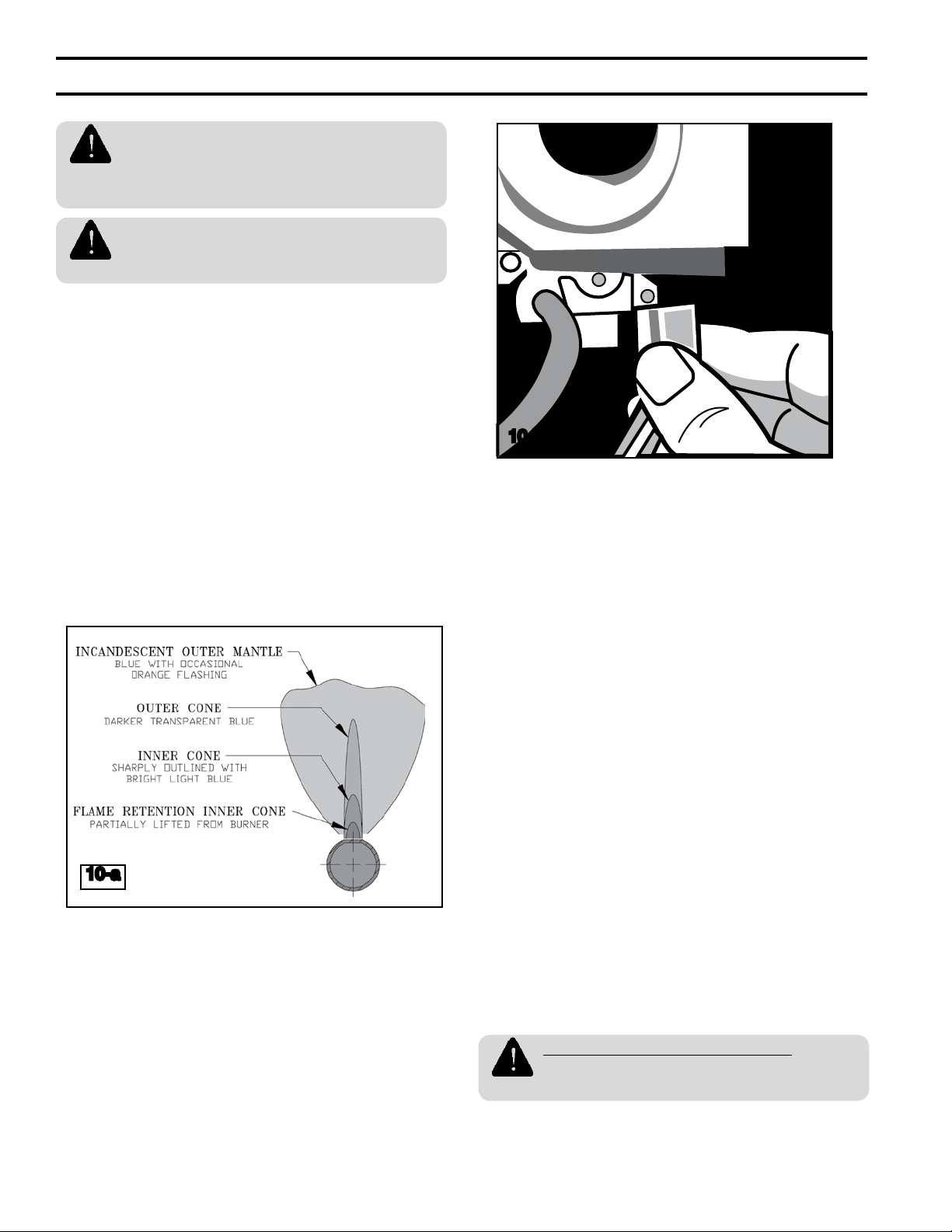

10-a

q Pilot and main burner flames appear

clean and blue.

6. Disconnect pilot lead wires from gas valve

(Figure 10-b).

q Boiler shuts off.

7. Reconnect pilot lead wires to gas valve.

q Boiler restarts.

8. Adjust zone thermostat to minimum setting.

q Boiler shuts off.

9. Adjust zone thermostat to maximum setting.

10. Observe temperature gage as boiler heats.

11. Adjust the high limit setting to its minimum

level (see "Programming High Limit" in

Section 8).

q Boiler shuts off when temperature gage

reads within 15°F of high limit setting.

12. Return high limit to the desired setting (see

"Programming High Limit" in Section 8).

13. Check draft. See Appendix G

– Checking Draft and Combustion.

q No spillage observed.

14. Check combustion in the vent stack and

record results in the spaces provided below.

_____ CO

_____ O

(less than 7%)

2

(more than 9%)

2

_____ CO (less than 100 ppm, air free)

ANY FAILED STARTUP CHECK

Must be corrected before placing the

boiler in service.

16

Page 17

ANNUAL MAINTENANCE CHECKLIST

WARNINGS

THE BOILER CONTAINS REFRACTORY

CERAMIC FIBER, a possible human carcinogen

Use a NIOSH approved respirator when servicing

high-temperature insulation and gasket materials.

Wash exposed skin gently with soap and water

after contact Wash exposed clothing separate

from normal laundry.

LABEL ALL WIRES prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation

FAILURE TO MAINTAIN THE BOILER in proper

working condition may lead to re, explosion,

Equipment you will need:

q Soft bristle brush

q Bristle ue brush

q Vacuum with brush attachment

Perform these tasks each year:

1. Clean low water cutoff probe (if applicable).

personal injury or death, and extensive property

damage.

TURN OFF ALL GAS AND ELECTRIC power

supplies to the boiler before servicing. Contact with

or release of dangerous ammable gas, electrical

voltage, moving parts, and very hot water under

pressure may cause serious personal injury,

property damage, or death.

LOCK ELECTRICAL BOXES AND GAS VALVES

CLOSED to prevent someone from inadvertently

restoring power or gas before the heating system is

safe to operate.

(7) Hold burner at throat. Lift front of burner

to clear orice (Figure AM-1). The

burner that holds the pilot can only be

removed by rst lifting the burner

adjacent to its right.

6. Perform Startup Checks and Adjustments

described earlier in this manual.

2. Inspect vent for obstruction and signs of

condensation, distortion, overheating or gas

leakage.

3. Clean vent terminal and air intake screens.

4. Inspect boiler ue passages:

(1) Remove vent pipe, damper.

(2) Remove top panel and hood.

(3) Remove blocked vent switch and

canopy.

(4) Examine all ue passageways. Using

bristle ue brush and vacuum,

remove any soot or obstructions.

5. Remove and clean main burners:

(1) Remove jacket front panel.

(2) Disconnect pilot tubing at gas valve.

(3) Disconnect pilot lead wires at gas valve.

(4) Remove wires from ame roll-out switch.

(5) Remove burner access panel.

(6) Mark location of the pilot main burner on

the manifold if the marking on manifold

is missing or obliterated.

7. Check operation of airow sensing switches.

8. Check for water leaks on the boiler or water

pooling around boiler.

9. Manually operate the relief valve. If the

water is grey or black, there is excessive

oxygen in the system. Oxygen is corrosive

to boilers. Eliminate any source of oxygen.

10. Verify proper operation after servicing.

AM-1

17

Page 18

TROUBLESHOOTING

When a problem occurs with the boiler operation, the Burnham IQ Control System easily provides specic,

valuable information to help resolve the issue quickly. The display on the IQ Boiler control should be the

rst place to check.

If "Err" IS NOT displayed on the IQ Boiler Control: Use the following table to determine the problem

and possible causes.

IQ Boiler Control Status Codes (when "Err" is not displayed)

Display Status Boiler / Control Action(s)

Blank

Boiler and

Circulator off

Boiler not

responding to

1

Heat Request

Boiler Running

but Circulator

8

is not Running

10

10

13

14

15

16

18

19

Retry Delay

Recycle Delay

Soft Lockout

Hard Lockout

Wait for Limit

to Close

Flame Out of

Sequence

Waiting for

Damper to Open

Waiting for

Damper to Close

No 120 Vac power at boiler, check breaker and wiring between breaker panel and boiler.

Boiler is not seeing Heat Request. Check thermostat or zone wiring for loose connection,

miswiring, or defective thermostat or zone control.

Check wiring for loose connection, miswiring. When there is a Domestic Hot Water Heat Request

wired to the Outdoor Air Reset card the Circulator will be off for the duration of the priority time.

This to allow all of the boiler output to be provided for fast Indirect Water Heater recovery. Check

Priority Time (pt_) function using Outdoor Air Reset IQ Option Card Adjustment Mode (see Reset

Card Adjustment Mode instructions).

The burner failed to light (no ame signal).

After a 5 minute delay, IQ Control will attempt to light the burner again.

There is no limit to the number of retries.

The burner loses ame during running mode ( code "8").

After a 10 second delay, IQ Control will attempt to light the burner again.

If the burner loses ame during running mode ( code "8") during the next six recycles, IQ

Control will progress to a soft lockout.

When a soft lockout occurs, boiler will shut down.

Boiler automatically restarts once condition that caused the lockout is corrected and the one-hour

time delay is completed.

Boiler can be restarted sooner than the time delay by using Adjustment Mode function and

manually resetting boiler (see Adjustment Mode instructions).

When a hard lockout occurs boiler shuts down.

Boiler will NOT automatically restart once the condition that caused the lockout is corrected.

It will be necessary to go to Adjustment Mode function to manually reset the boiler (see

Adjustment Mode instructions).

Heat Request occurs and start of operating sequence is halted due to an open limit.

Open limits may include Flame Roll Out Switch, Blocked Vent Switch, or Auxiliary.

Limit or Low Water Cutoff IQ Option Cards (when installed), refer to IQ Option Panel display for

additional information.

Flame Signal is still present when expected to be 0 (no ame).

Heat Request occurs and the IQ control is waiting for the damper to open (end switch to close).

The damper end switch is closed and the control waits for the damper end switch to open (*end

switch is open when damper is closed). This is checked at the beginning of a heat cycle before

opening the damper. If the damper doesn't close in 60 seconds, the IQ Control goes to Status 21.

18

Page 19

TROUBLESHOOTING (continued)

IQ Boiler Control Status Codes (when "Err" is not displayed) - continued

Display Status Boiler / Control Action(s)

Damper Failed

20

Damper Failed

21

Open

Closed

The damper end switch has not closed (damper end switch is open) at the beginning of

the heat cycle. An alarm message is sent but the control is not in lockout.

The damper end switch has not opened (damper end switch is closed) at the

beginning of the heat cycle. An alarm message is sent but the control is not in lockout.

If "Err" IS displayed on the IQ Boiler Control: "Err" ashes on the IQ Boiler control display followed

by a number. Use the following table along with this error number to determine the problem and possible

causes:

IQ Boiler Control Error Codes (when "Err" is ashing)

Display Status Boiler / Control Action(s)

Blank

Err

Err

Err

Err

Err

Err

Err

Err

Err

Err

Err

Err

Err

Err

Boiler and Circulator off No 120 Vac power at boiler, check breaker and wiring between breaker panel and boiler.

Flame Current Lower

4

6

18

24

32

55

56

57

58

59

60

61

63

64

than Threshold

Flame Sensed Out of

Normal Sequence

Electronics Failure Replace Control .

Flame Sensed During

Post-Purge

Temperature Sensor

Failure

Damper Failed

to Open

Damper Failed to Close Atmospheric Damper End Switch failed to open (end switch contacts stuck closed).

Flame Rod Shorted to

Burner Ground

AC Line Frequency Error AC Signal is too noisy or frequency is incorrect.

Line Voltage Error AC voltage out of specication high or low.

Thermostat Input Higher

than Threshold

Line Voltage Unstable Possibly too many heavy loads switching on and off cause erratic supply voltage.

Soft Lockout - Maximum

Recycles Exceeded

Soft Lockout - Internal

Failure

Check pilot assembly.

Flame sensed out of normal sequence (before opening gas valve or after closing gas

valve).

Flame sensed during post-purge (after gas valve signaled closed).

Temperature sensor or interface failure (open or short connection, increased connection

resistance, dual sensor mismatch) or control hardware failure.

Atmospheric Damper End Switch failed to close (end switch contacts stuck open).

Flame Rod shorted to burner ground, this can result from excessive ue gas

condensation.

Check thermostat wiring.

Maximum number of recycles exceeded.

Caused by general electronics failure such as relay open or shorted contacts, ame

sensing circuit error, or A to D error.

19

Page 20

TROUBLESHOOTING (continued)

If IQ Boiler Control Shows Status Code “STA 15": The IQ Boiler Control is “Waiting for Limit to Close”

and the display on the IQ Option Panel should be the rst place to check. The IQ Option Panel display

(lower display) will show one of the following status codes:

IQ Option Panel Display Shows “ERR"

Display Status Boiler / Control Action(s)

Err 1 Low Input Voltage AC voltage is too low

Whenever a new IQ Option Card is rst installed into the IQ Option Panel, the IQ Option

Panel automatically “Learns” the card. This means it detects the specic card and lists

it as a card number (C1, C2, or C3). However, to help avoid errors or unauthorized

IQ Option Card

Err 2 - card #

Err 3 - card #

Err 4 - card #

Err 5

Err 6 Incorrect Wiring Check boiler wiring.

Err 7

Err

8

8

Type Change

without Re-Learn

IQ Option Card

Communications

Error

IQ Option Card

Hardware

Interface Error

Limit Output OFF

in ON State

Limit Output ON

in OFF State

Internal IQ Option

Panel Error

option card changes, once an IQ Option Card is initially installed, the IQ Option Panel

will not automatically “Learn” a different card in the same slot. In this situation, the IQ

Option Panel has to “Learn” about the new card manually. To have the IQ Option Panel

recognize or “Learn” about a different card, the user must press the “I” key on the IQ

Option Panel until “Lrn” is displayed. Then press and hold either the Up ñ or Down ò

key for at least three (3) seconds. The IQ Option Panel will then recognize and “Learn”

the new IQ Option Card.

The IQ Option Card is not installed properly or has an internal fault. Remove the card

and check for bent IQ Option Panel card interface pins. Straighten bent or misaligned

pins or choose another card slot and reinstall card. If problem persists, replace card.

The IQ Option Card is not installed properly, there is a option card or IQ Option Panel

fault. Remove the card and check for bent IQ Option Panel card interface pins.

Straighten bent or misaligned pins or choose another card slot and reinstall card. If

problem persists, replace card.

Check limit string wiring, replace the IQ Option Panel.

Check limit string wiring, replace the IQ Option Panel.

Replace the IQ Option Panel.

If IQ Option Panel Display Shows “OL": The OL- “card number” indicates the card slot causing the Open

Limit. For example, “OL-C1" means open limit in the card located in card slot 1. To determine the cause

of the open limit the user must switch the display on the IQ Option Panel to show the view mode of the IQ

Option Card installed in Slot 1.

For example, if, while the boiler has a Heat Request, and the Aquastat IQ Option Card installed in Slot 1

has a sensor failure the IQ Option Panel displays OL-C1 (Open Limit Card Slot 1). To investigate the status

of option card C1:

1. Press the “I” key on the IQ Option Panel. The display will go from “OL-C1” to C1 .

2. When the display shows C1, press either the Up ñ or Down ò keys to switch the display to show the

view mode of the Aquastat Limit Control IQ Option Card inserted in Slot 1. The display will now read

Err -119, Sensor Failure.

3. Check the sensor connections and when required replace the sensor.

4. When the sensor failure is corrected the IQ Option Panel will return to the “O.C.P" display and the IQ

Boiler Control start sequence will continue.

For additional information refer to the instruction manual supplied with the IQ Option Card.

If IQ Option Panel Display Shows “

O.C.P": The Option Panel is in normal run or operating mode, the IQ

Option Panel display will show “O.C.P" (Option Card Panel) along with a oating decimal point that ashes

on and off (the “heartbeat” ash indicating the panel is functioning properly and there are no open limits or

errors). The Option Panel or the card installed in the option panel are not causing the open limit.

1. Check for loose boiler wiring and check ame roll out & blocked vent switches.

20

Page 21

REPAIR PARTS LIST

Key

No.

1A Block Assembly 102287-03 102287-04 102287-05 102287-06 102287-07 102287-08 102287-09

1B Canopy Gasket Kit 6206001

1C Canopy Assembly 102554-03 102554-04 102554-05 102554-06 102554-07 102554-08 102554-09

1D Flue Bafe

Description

Blocked Vent Switch

(not shown)

ES23 ES24 ES25 ES26 ES27 ES28 ES29

[2]

102678-01

[3]

102678-01

[Quantity] Part Number

[4]

102678-01

[5]

102678-01

80160157

[6]

102678-01

[7]

102678-01

[8]

102678-01

21

Page 22

REPAIR PARTS LIST (continued)

Key

No.

2A Base Wrapper 71807031 71807041 71807051 71807061 71807071 71807081 71807091

2B Base Tray 102543-03 102543-04 102543-05 102543-06 102543-07 102543-08 102543-09

2C Burner Tray Assembly 61807031 61807041 61807051 61807061 61807071 61807081 61807091

2D Base Front Panel 71807035 71807045 71807055 71807065 71807075 71807085 71807095

2E Burner Access Panel 71807036 71807046 71807056 71807066 71807076 71807086 71807096

2F Base Gasket Kit 6206002

2G Base Side Insulation [2] 72007001

2H Base Rear Insulation 72007031 72007041 72007051 72007061 72007071 72007081 72007091

2J Base Front Insulation 72007032 72007042 72007052 72007062 72007072 72007082 72007092

2K Base Leg Assembly [4] 6186001

2L Flame Roll-out Switch 80160044

2M Manifold Support Bracket 71807001

Description

ES23 ES24 ES25 ES26 ES27 ES28 ES29

[Quantity] Part Number

22

Page 23

REPAIR PARTS LIST (continued)

Key

No.

Gas Valve (Natural Gas),

Honeywell VR8204P1171

Gas Valve (Natural Gas),

Honeywell VR8304P4496

3A

Gas Valve (LP Gas), Honeywell

VR8204C3015

Gas Valve (LP Gas), Honeywell

VR8304P4314

½" Gas Manifold 82207031 82207041 82207051 82207061 N/A

3B

¾" Gas Manifold N/A 82207071 82207081 82207091

Burner Orices - Natural Gas #47

3C

Burner Orices - LP Gas 1.20mm

3D Pilot Burner 100147-01

Pilot Assembly - Natural Gas 102592-01

3E

Pilot Assembly - LP Gas 102593-01

3F Main Burner

3G Pilot Tubing 8236122

Description

ES23 ES24 ES25 ES26 ES27 ES28 ES29

81660282 N/A

N/A 81660283

81660146 N/A

N/A 81660160

[4]

822710

[4]

822792

[3]

100146-01

[6]

822710

[6]

822792

[5]

100146-01

[Quantity] Part Number

[8]

822710

[8]

822792

[7]

100146-01

[10]

822710

[10]

822792

[9]

100146-01

[12]

822710

[12]

822792

[11]

100146-01

[14]

822710

[14]

822792

[13]

100146-01

[16]

822710

[16]

822792

[15]

100146-01

23

Page 24

REPAIR PARTS LIST (continued)

Key

No.

4A IQ Boiler Control 102289-01

4B IQ Option Panel 102291-01

4C Transformer 102516-01

4D Temperature Sensor 102411-01

Description

ES23 ES24 ES25 ES26 ES27 ES28 ES29

[Quantity] Part Number

24

Page 25

REPAIR PARTS LIST (continued)

Key

No.

5A Jacket Left Side Panel 102566-01

5B Jacket Right Side Panel 102567-01

5C Jacket Rear Panel 102569-03 102569-04 102569-05 102569-06 102569-07 102569-08 102569-09

5D Jacket Vestibule Panel 102565-03 102565-04 102565-05 102565-06 102565-07 102565-08 102565-09

5E Jacket Top Panel 102568-03 102568-04 102568-05 102568-06 102568-07 102568-08 102568-09

5F Jacket Front Door 102576-03 102576-04 102576-05 102576-06 102576-07 102576-08 102576-09

5G Jacket Rear Discharge 102549-03 102549-04 102549-05 102549-06 102549-07 102549-08 102549-09

5H Jacket Poly Front Cover 102600-03 102600-04 102600-05 102600-06 102600-07 102600-08 102600-09

5J Upper Poly Grille 102621-01

5K Lower Poly Grille 102622-01

Description

ES23 ES24 ES25 ES26 ES27 ES28 ES29

[Quantity] Part Number

25

Page 26

REPAIR PARTS LIST (continued)

Key

No.

6A Supply Water Manifold 80607001

6B Temperature/Pressure Gauge 100282-01

6C Circulator Wiring Harness 6130701

6D 30 PSI Relief Valve 81660363

6E Drain Valve 806603012

6F Vent Damper 102284-01 102284-02 102284-03 102284-04 102284-05

Circulator (not shown):

Taco 007-2 8056170

Grundfos UP-15 8056173

B & G NRF-22 8056174

Description

ES23 ES24 ES25 ES26 ES27 ES28 ES29

[Quantity] Part Number

26

Page 27

INTERNAL WIRING

Figure IW-1: Wiring Diagram

27

Page 28

INTERNAL WIRING (continued)

28

Figure IW-2: Wiring Schematic

Page 29

INTERNAL WIRING (continued)

Figure IW-3: Single Zone System with Domestic Hot Water Tank

Figure IW-4: Multiple Zone System with Zone Circulators

29

Page 30

INTERNAL WIRING (continued)

Figure IW-5: Multiple Zone System with Zone Valves

30

Figure IW-6: Multiple Zone System with Zone Circulator Panel

Page 31

T STAT 1

VALVE 1

T STAT 2

VALVE 2

T STAT 3

OFF

ON

ZONE 4PRIORITY

TACO ZVC 404 (OR EQIV.)

FOUR ZONE ZONE VALVE CONTROL

WITH OPTIONAL PRIORITY

THERMOSTAT

BOILER JACKET

PANEL

1 23T T

1

1

4

2

3

5

6

7

8

2

3

LINE VOLTAGE FACTORY WIRINGSIZE 14 AWG TYPE TWOR TEW/AWM WIRE

LINE VOLTAGE FIELDWIRING

VALVE 3

T STAT 4

VALVE 4

POWER

POWER IN

T T

ZONE 1

T T

ZONE 2

T T

ZONE 3

T T

ZONE 4

MODE

NORMAL

RESET

THERMOSTAT THERMOSTAT

ZONE 1

1 2 3 4

ZONE 2

1 2 3 4

ZONE 3

1 2 3 4

ZONE 4

1 2 3 4

N/O COM N/C

ZONE 4RELAY

DHW

CIRCULATOR

(SUPPLIED BY

OTHERS)

JUMPER

3 &4

2 WIREZONE

VALVE

(NO ENDSWITCH)

2 WIREZONE

VALVE

(NO ENDSWITCH)

1

4 WIREZONE

VALVE

(POWER OPEN,

SELF CLOSING)

JUMPER

3 &4

PRIORITY

ZONE

FUSE (3AMP MAX.)

24V

TRANSFORMER

L1

POWER

SUPPLY

120/60/1

L2

DHW AQUASTAT

(L4006, L4080)

(SUPPLIED BY OTHERS)

DOMESTIC HOT WATER PRIORITY IS

SELECTED USING ZONE PANEL SWITCH

SYSTEM

CIRCULATOR

(SUPPLIED BY OTHERS)

WIRING USED WHEN DOMESTIC

HOT WATER PRIORITY ISDESIRED

N/O COM N/C

ZONE 4RELAY

MAIN

END

SWITCH

EXTRA

END

SWITCH

DHW

CIRCULATOR

(SUPPLIED BY

OTHERS)

L1

L2

SYSTEM

CIRCULATOR

(SUPPLIED BY OTHERS)

WIRING USED WHEN DOMESTIC

HOT WATER PRIORITY NOTDESIRED

IQ OPTION PANEL

MAIN

END

SWITCH

EXTRA

END

SWITCH

2

3

INTERNAL WIRING (continued)

Figure IW-7: Multiple Zone System with Zone Valve Panel

31

Page 32

APPENDIX A – COMBUSTION AIR

PROVIDE ENOUGH AIR to ventilate the

boiler room, dilute the ue gases, and

sustain combustion. Ignition failure, overheating,

re, carbon monoxide, and spillage of ue gases

may result from poor air supply.

If the boiler is a Direct Vent boiler and exchanges

all combustion air and combustion products

directly with the outdoors, there are no special

requirements for providing combustion, ventilation,

and dilution air.

If the boiler is chimney vented, power vented or

induced draft and draws combustion air from within

the building, follow the steps below to determine

how to provide air to the boiler.

Is the boiler located in a conned space?:

1. Calculate the oorspace (in square feet) of

the boiler room and all rooms connected

to the boiler room by passageways not

furnished with doors.

___________ floorspace (sq. ft.)

2. Add up the input rates of all the combustion

appliances installed in the same oorspace.

combined appliance

___________ input (BTU/hr)

3. In the table below, nd the Minimum

Allowable Floorspace based on the

Combined Input Rate from Step 2 and the

ceiling height. If the Combined Input Rate

is between two rates, use the next highest

rate.

minimum allowable

___________ floorspace (sq. ft.)

Minimum Allowable Floorspace in the Boiler Room

and Freely Connected Rooms (sq. ft.)

Ceiling Height

7’ 8’ 9’ 10’

50,000 357 313 278 250

Combined

Appliance

Input Rate

(see Step 2)

(BTU/hr)

100,000 714 625 556 500

150,000 1071 938 833 750

200,000 1429 1250 1111 1000

250,000 1786 1563 1389 1250

300,000 2143 1875 1667 1500

350,000 2500 2188 1944 1750

400,000 2857 2500 2222 2000

32

4. If the Floorspace from Step 1 is less than the

Minimum Floorspace from Step 3, then you

must provide outdoor air to the boiler room.

Proceed to Step 6.

Is the boiler located in a building of unusually tight

construction?

5. If the answer to all of the three questions

below is “yes”, then you must provide

outdoor air to the boiler room.

Do the walls and ceilings exposed to the

outside atmosphere have a continuous

water vapor retarder with a rating of 1 perm

or less, with openings gasket or sealed?

Yes No

Are operable windows and doors

weatherstripped?

Yes No

Are exterior wall joints caulked or sealed?

Yes No

6. If you must provide outdoor air to the boiler

room, the top of the permanent opening

into the boiler room must be within 12” of

the ceiling, and the free area of the opening

(sq. in.) must be no less than the Combined

Appliance Input (from Step 2) divided by

3000 BTU/hr/sq. in.

combined appliance

__________ input (Step 2)

÷ 3000 BTU/hr/sq. in.

Minimum Opening Size

_____ (sq. in.)

7. Duct this opening vertically or horizontally

directly to the outdoors, or directly to a

space that communicates directly with the

outdoors, such as an attic or crawlspace.

For more details and options, refer to your local

building code, the National Fuel Gas Code (NFPA

54 and ANSI Z223), and the Canadian Natural Gas

Installation Code CAN/CGA-B149.1 or Propane

Installation Code CAN/CGA-B149.2.

Page 33

APPENDIX B – VENTING

VENT THIS BOILER according to the instructions. Failure to do so may cause products of

combustion to enter the building resulting in severe property damage, personal injury or death.

Install this boiler according to this manual and the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

i

the Natural Gas and Propane Installation Code, CAN/CSA B149.1, or applicable provisions of the

local building codes. Contact local building or fire officials about restrictions and installation

inspection in your area.

If you are removing an existing boiler from a gas

vent or chimney that is also used to vent other gas

appliances:

1. Seal any unused openings in the

common venting system.

2. Visually inspect the venting system

for proper size and horizontal pitch

and determine there is no blockage or

restriction, leakage, corrosion, and other

deciencies which could cause an

unsafe condition.

3. Resize the common venting system

to approach the minimum size as

determined using the National Fuel Gas

Code, ANSI Z223.1 and/or CAN/CSA

B149.1, Installation Codes.

4. Check the draft of each remaining

appliance using the procedure described

in Appendix G, checking draft and

combustion.

5. Correct any draft problems before

placing the gas appliances back into

service.

In addition to previously mentioned vent

i

codes of the main general guidelines,

atmospheric vented installations must

also be in accordance with the Standard for

Chimneys, Fireplaces, Vents and Solid Fuel

Burning Appliances, ANSI/NFPA 211. For Canada

installations, refer to the Natural Gas and LP

Installation Code, CAN/CSA- B149.1.

33

Page 34

APPENDIX B1 – ATMOSPHERIC VENTING

GENERAL WARNINGS FOR ATMOSPHERIC VENTING SYSTEMS

USE ATMOSPHERIC VENTING only with

boilers approved for atmospheric venting as

noted in the Specifications Section of this

manual.

INSPECT EXISTING CHIMNEY for obstructions

and deterioration and repair or line the chimney

prior to placing the boiler in service.

UNLINED MASONRY CONSTRUCTION is

prohibited for use as a chimney.

FIREPLACES AND FAN-ASSISTED GAS

APPLIANCES must not be vented into the same

chimney space as this boiler.

Install vent and vent connector (Figure B-1). Comply with all design and installation requirements in the

Connect Venting Section of this manual, local code, and the National Fuel Gas Code or Can/CSA B149.1.

Clay ue lined masonry chimneys do not meet the venting requirements for this appliance.

DO NOT REDUCE THE DIAMETER of the vent

connector between the boiler and the chimney.

It must not be smaller than the outlet on the

drafthood, damper, or vent reducer supplied with

the boiler.

UNLISTED VENT DAMPERS AND

OBSTRUCTIONS in the vent pipe are prohibited.

THE VENT DAMPER supplied with the boiler

shall not be used to block the vent of any other

appliance.

34

Figure B-1: Typical Atmospheric Vent Installation

Page 35

THIS PAGE INTENTIONALLY LEFT BLANK

35

Page 36

APPENDIX C – GAS PIPING

ASSURE GAS PIPING IS LEAK FREE

AND OF PROPER SIZE and type for the

connected load.

SHUT OFF MAIN GAS SUPPLY prior to

installing or servicing boiler gas piping.

1. Determine the boiler’s maximum gas

demand and minimum gas supply pressure

(printed on the boiler’s rating label) and the

demand of other gas appliances served by

the same gas meter.

2. Ensure that gas piping, ttings, and gas

meter capacities can supply the maximum

gas demand of all appliances at pressures

above their minimum allowable gas

pressure. Tables C-1 and C-2 provide typical

capacities of gas pipes and ttings.

3. Derate the gas ow through pipes by

multiplying by a correction factor in Table

C-3 based on the specic gravity of the gas.

4. For materials or conditions other than those

listed above, refer to the National Fuel Gas

Table C-3: Specic Gravity Correction Factors For

Natural Gas

Specic

Gravity

0.50 1.10 0.85 0.81

0.55 1.04 0.90 0.82

0.60 1.00 1.00 0.78

0.65 0.96 1.10 0.74

0.70 0.93 1.20 0.71

0.75 0.90 1.30 0.68

0.80 0.87 1.40 0.66

Correction

Factor

Specic

Gravity

Correction

Factor

Code, NFPA54/ANSI Z223.1, or size the

system using standard engineering methods

acceptable to authority having jurisdiction.

USE PROPER THREAD COMPONENTS

on all gas connectors.

USE THREAD (JOINT) COMPOUNDS

(pipe dope) rated for liqueed petroleum

gas.

Table C-1: Maximum Capacity of Schedule 40 Pipe in Cubic Feet Per Hour (CFH)

Length

(Feet)

10 132 278 520 1050 175 360 680 1400

20 92 190 350 730 120 250 465 950

30 73 152 285 590 97 200 375 770

40 63 130 245 500 82 170 320 660

50 56 115 215 440 73 151 285 580

60 50 105 195 400 66 138 260 530

70 46 96 180 370 61 125 240 490

80 43 90 170 350 57 118 220 460

90 40 84 160 320 53 110 205 430

100 38 79 150 305 50 103 195 400

½ ¾ 1 1¼ ½ ¾ 1 1¼

0.3” w.c. Pressure Drop 0.5” w.c. Pressure Drop

*

*1 CFH of Natural Gas is approximately equal to 1000 BTU/hr; 1 CFH of LP is approximately equal to 2500 BTU/hr.

Table C-2: Equivalent Lengths (ft) Of Standard Pipe Fittings & Valves

Pipe

Size

½” 0 19 9 4 2 1 1 3

¾” 0 23 12 5 2 1 1 4

1” 1 29 15 7 3 1 2 5

1 ¼” 1 39 20 9 4 2 2 7

1 ½” 1 45 22 11 5 3 3 8

Gate Globe Angle

Swing

Check

90°

Elbow

45°

Elbow

90° ‘T’, Flow

Through Run

90° ‘T’, Flow

Through Branch

36

Page 37

APPENDIX C – Gas Piping (continued)

5. Bond all above-ground gas piping to a

grounding electrode and ensure the piping is

electrically continuous.

DO NOT USE GAS PIPING AS A

GROUNDING ELECTRODE. Refer to

National Electrical Code, NFPA 70.

6. Install sediment trap, ground-joint union and

manual shut-off valve upstream of boiler gas

control valve and outside jacket.

7. When the piping is completed, test it for

leaks.

(1) When testing over ½ psig, disconnect

(2) When testing at ½ psig or less, isolate

boiler from gas supply piping by closing

boiler’s individual manual shut-off valve.

(3) Locate leaks using approved

combustible gas detector or

nonammable, non-corrosive leak

detection solution.

DO NOT CHECK FOR LEAKS USING

OPEN FLAMES such as matches or

candles or devices that spark.

8. Repair any detected leaks.

the boiler and its individual shut-off valve

from the gas supply piping.

APPENDIX D – SYSTEM PIPING

USE PROPER DESIGN AND INSTALLATION PRACTICES and observe all local codes when

installing system piping. Property damage and injury may result from an improperly piped or

designed heating system.

Boiler damage caused by flawed system design or operation is excluded from our warranty.

i

Training and experience is required to design and install a piping system that will protect the boiler and

provide many years of comfort to the building occupants. Be sure to protect the boiler from the following

problems:

1. Corrosion

(1) Comply with the boiler’s specic

water quality requirements. See the

Specifications Section of this manual.

(2) Pressurize the system above the highest

net positive suction head (NPSH)

required for each circulator and ensure

positive pressure at the uppermost point

in the system.

(3) Maintain a closed boiler system using

heat exchangers to transfer heat to

open systems, such as domestic hot

water systems.

(4) Purge the system completely of

dissolved oxygen by bleeding all

radiators and installing a properly

(5) Repair leaking pipes, ttings, and vents

to minimize the need to add makeup

water.

(6) Do not ll the boiler with softened water

unless makeup water is extremely hard

and it is not possible to eliminate all

system leaks. If lling the boiler with

softened water, test regularly the water

softener regularly to ensure that brine

solution is not entering the boiler’s water

supply.

2. Lime scale

(1) Repair leaking pipes, ttings, and vents

to minimize the need to add makeup

water.

installed air scoop or air vent.

37

Page 38

APPENDIX D – System Piping (continued)

(2) Comply with the boiler’s specic

water quality requirements. See the

Specifications Section of this manual.

(3) Comply with the boiler’s specic

requirements for minimum water ow

through the boiler, installing a system

bypass or primary-secondary loop if

necessary to maintain ow through the

boiler when serving small zones.

3. Overpressure

(1) Install a properly sized expansion tank.

(2) Do not exceed the boiler’s specic

requirements for maximum allowable

working pressure.

(3) Do not plug or block the relief valve.

4. Freezing

(1) Run all portions of the system piping

inside a heated space unless the system

is properly protected with an inhibited

antifreeze solution.

5. Overheating

(1) Comply with the boiler’s specic

requirement for minimum water ow

through the boiler. See the

Specifications Section of this manual.

(2) Install a low-water cutoff device

whenever the boiler is installed above

the level of the lowest heat emitter

or radiator. Also add a low-water

cutoff when required by local code

requirements.

6. Thermal shock

(1) Do not over-pump. Adhere to the design

ow requirements for each zone.

(2) Install a boiler bypass, system bypass,

or primary-secondary loop when needed

to avoid returning large volumes of cold

water directly to a hot boiler.

7. Condensation

(1) Do not over-pump. Adhere to the design

ow requirements for each zone.

(2) Adhere to the boiler’s specic

minimum return water and supply water

temperature requirements. Install a

boiler bypass, system bypass, or

primary-secondary loop when needed to

maintain water temperatures and ows

within the specied limits.

(3) Do not allow chilled water to enter the

boiler during the heating cycle, or heated

water to enter chilled water coils during

the cooling cycle.

8. Dry Fire

Install a low-water cutoff when the boiler

is installed above the level of the lowest

radiator and when required by local code.

The following system diagrams are intended to provide a minimum level of guidance for a

successful and trouble-free installation of the boiler in common applications. They do not substitute

i

for proper design, evaluation, and installation by a trained and qualified installer using the proper

tools, techniques, and design expertise. Not all options are available with every boiler.

Hot Water Boilers, Non-Condensing

See

Diagram

Indirect Tank?

D-W1

D-W2

D-W3 Tankless Coil

D-W4

D-W5

D-W6

Two or more

zones of

the same

temperature?

Two or more

zones of

different

temperatures?

Two or

more

boilers?

38

Page 39

APPENDIX D – System Piping (continued)

Figure D-0: Piping Schematic Symbols

39

Page 40

APPENDIX D – System Piping (continued)

Figure D-W1: Water Boiler, Series Loop

40

Figure D-W2: Water Boiler, Two or More Zones

Page 41

APPENDIX D – System Piping (continued)

Figure D-W3: Water Boiler, Tankless Coil, Two or More Zones

Figure D-W4: Water Boiler, Indirect Water Heater, Two or More Zones

41

Page 42

APPENDIX D – System Piping (continued)

Figure D-W5: Water Boiler, Indirect Water Heater

42

Figure D-W6: Multiple Water Boilers, Indirect Water Heater, Two or More Zones

Page 43

APPENDIX E – FILLING THE SYSTEM AND CHECKING FOR LEAKS

Fill entire heating system with water and vent air from system. Use the following procedure on a

Series Loop or multi-zoned system installed as per the gure below. Remove air from system when lling.

1. Close full port ball valve located between

vertical hose bib and air scoop in boiler

supply piping (see Appendix D – System

Piping.

2. Isolate all zones by closing zone valves or

shut-off valves in supply and return of each

zone(s).

3. Attach a hose to the vertical hose bib located

prior to the full port ball valve in the system

supply piping.

Terminate hose in five-gallon bucket at

a suitable floor drain or outdoor area.

i

4. Starting with one circuit at a time, open zone

valve or shut-off valve in system supply and

return piping.

5. Open hose bib.

6. Open ll valve (Make-up water line should

be located directly after full port ball valve in

system supply piping between air scoop and

expansion tank).

7. Allow water to overow from bucket until

discharge from hose is bubble free for 30

seconds.

8. Close hose bib, continue lling the system

until the pressure gauge reads 12 psi. Close

ll valve.

9. Starting with the rst convector in the loop,

open air vent to purge air until a steady

stream of water ows into container for

approximately 5 seconds. Proceed to next

convector and repeat procedure until all

convectors in the loop are purged of air

10. Close the opened zone valve or shut-

off valve for the zone being purged of

air.

11. Open the zone valve or shut-off valve

for the next zone to be purged. Repeat

the previous steps until all zones have

been purged. At completion, open all

zone valves or shut-off valves.

12. Close hose bib, continue lling the system

until the pressure gauge reads 12 psi.

Close ll valve.

If make-up water line is equipped

i

with pressure reducing valve, system

will automatically fill to 12 psi. Follow fill

valve manufacturer’s instructions.

13. Open isolation valve in boiler supply piping.

14. Remove hose from hose bib.

Confirm that the boiler and system have no

water leaks.

1. Check Rating Label for maximum operating

pressure of this boiler. Never exceed this

pressure during leak test. Do not plug or

change pressure relief valve. Perform visual

inspection for leaks or weeping joints after

initial ll and during boiler warm-up period.

Repair all leaks before placing boiler into

permanent operation.

2. If it is required to perform a long-term

pressure leak test of the hydronic system,

the boiler should rst be isolated to avoid

a pressure loss due to the escape of air

trapped in the boiler.

3. To perform a long-term pressure test

including the boiler, all trapped air must

be removed from the boiler and system as

prescribed above. A loss of pressure during

such a test, with no visible leakage, is an

indication that the boiler or system contained

trapped air.

43

Page 44

APPENDIX F – ADJUSTING GAS INPUT RATE

Natural Gas Boilers:

1. Turn off gas supply to all appliances other

than gas-red boiler.

2. Note the rated manifold gas pressure listed

on the boiler’s rating label.

3. Connect Manometer to manifold pressure

tapping on Gas Valve (Figure F-1).

F-2

8. Determine gas ow rate in Cubic Feet

per Hour based on elapsed time for two

revolutions. (Example: 70 Seconds for (2)

Revolutions = 102.8 Cu. Ft.

F-1

4. Light main burners by adjusting thermostat

to highest setting.

5. If required, adjust gas manifold pressure to

the rated setting by turning the gas valves

adjustment screw clockwise to decrease

manifold pressure or counterclockwise to

increase manifold pressure (Figure F-2).

Several turns may be required.

Do not force the adjustment screw.

6. On models using more than one gas valve,

turn “off” the gas valve not having pilot

control and rst adjust the gas valve with

pilot control. Then, turn “on” both gas valves

and adjust the gas valve without pilot control.

7. Clock gas meter for at least two (2)

revolutions of the dial typically labeled ½ or

1 cubic foot per revolution on a residential

gas meter.

44

9. When the clocked time falls between two

table values (Table F-1), add the table

values shown above and below your clocked

reading and divide by 2 (Example: 68

Seconds for (2) Revolutions = (110.7+102.8)

/2 = 106.7 Cu. Ft./Hr.).

10. Obtain gas-heating value (Btu per cubic

foot) from gas supplier or use nominal

value of 1000 Btu per cubic foot.

11. Multiply gas ow rate by gas heating value.

(Example: 70 Seconds for (2) Revolutions

= 120.8 Cu. Ft./Hr. X 1027 Btu/Cu. Ft. =

124,061 Btu/ Hr.

12. Compare measured input rate to input rate

stated on rating label.

DO NOT EXCEED the boiler’s rated gas

input.

13. If input is too high, reduce input rate by

decreasing manifold pressure. Do not

reduce more than 0.3” w.c. Instead, contact

Burnham for an orice replacement kit.

14. If input is below 98% of Rating Label input,

increase manifold gas pressure no more

than 0.3 inches w.c. If measured rate is still

less than 98% of rated input, replace or re drill existing main burner gas orices:

Page 45

APPENDIX F – Adjusting Gas Input Rate (continued)

Table F-1: Gas Flow Rate in Cu. Ft. / Hr.

Size of Gas Meter Dial

Seconds for Two

(2) Revolutions

24 150.0 300.0 450.0

26 138.4 276.9 415.3

28 128.5 257.1 385.7

30 120.0 240.0 360.0

34 105.8 211.7 317.6

38 94.7 189.4 284.2

42 85.7 171.4 257.1

46 78.2 156.5 234.7

50 72.0 144.0 216.0

55 65.4 130.9 196.3

60 60.0 120.0 180.0

65 55.3 110.7 166.1

70 51.4 102.8 154.2

80 45.0 90.0 135.0

90 40.0 80.0 120.0

100 36.0 72.0 108.0

120 30.0 60.0 90.0

140 25.7 51.4 77.1

160 22.5 47.0 67.5

180 20.0 40.0 60.0

200 18.0 36.0 54.0

One-Half

Cu. Ft.

One

Cu. Ft.

Two

Cu. Ft.

15. Recheck Main Burner Flame.

16. Return other gas-red appliances to

previous condition of use.

LP/Propane Gas Boilers:

1. Follow the procedure for gas boilers, except:

2. Adjust tank regulator for gas valve inlet

pressure of 13.5 inches w.c. or less, but not

less than 11.5 inches w.c.

3. Gas valve has step-opening regulator, which

initially opens to 1.4 to 2.5 inches w.c. and

steps to full pressure after approximately 30

seconds. Check manifold pressure after step

has occurred.

Leak Test Gas Piping:

THE BOILER AND ITS GAS

CONNECTIONS must be leak tested and

leak free before placing boiler in operation.

FOR LEAK TESTING OVER ½ PSIG,

disconnect boiler and its individual shutoff valve from gas supply piping.

1. For testing at ½ psig or less, isolate boiler

from gas supply piping by closing boiler’s

individual manual shut-off valve.

(1) Remove Main Burners per procedure in

Boiler Service instructions in Section (X).

(2) Remove gas orices. Drill each orice

one (1) drill size larger (drill size is

stamped on orice).

(3) Reinstall gas orices and main burner.

Repeat procedure to measure input rate.

2. Check for gas leaks in all piping joints,

valves, and ttings using a non-corrosive

leak detection solution or an electronic leak

detector.

3. Repair any leaks.

45

Page 46

APPENDIX G – CHECKING DRAFT AND COMBUSTION

CHECK DRAFT (GAS BOILERS WITH DRAFT HOODS)

1. Insofar as is practical, close all doors and

windows in the building.

2. Turn on all appliances not connected to the

same venting system as the boiler being

checked.

3. Turn on all exhaust fans (such as range

hoods and bathroom exhausts) to their

maximum speed. Do not turn on any

summer exhaust fans.

4. Close all replace dampers.

5. Operate the appliance being checked.

Follow lighting instructions.

CHECK DRAFT (OIL BOILERS)

1. Use a manometer precise to 0.01” water

column.

2. Fire the boiler until the chimney/vent reaches

normal operating temperature.

3. Locate the pressure sensing tapping on the

boiler.

6. After 5 minutes of main burner operation,

test for spillage at the draft hood relief

opening, using a lighted match, candle,

cigarette, etc.

7. Repeat this test for each appliance

connected to the common venting system.

8. If any appliance does not vent properly, per

the above test, make corrections, so that the

installation conforms to the National Fuel

Gas Code, NFPA 54/ANSI Z223.1, and/or

Installation Codes, CAN/CSA B149.1.

9. Return doors, windows, exhaust fans,

replace dampers, and any other gasburning appliance to their previous condition

of use.

4. While the boiler is still ring, use the

manometer to measure the draft at the

pressure tapping.

5. Conrm that the draft measurement matches

the required draft specied for the boiler.

6. If the required draft is not present, make any

necessary adjustments and check again.

1. Use a ue gas analyzer that accurately

measures CO2, O2, CO, and ue gas

temperature.

2. For oil boilers, also use a smoke tester with

smoke test paper.

3. Operate the boiler at its rated (high re)

input.

4. With the analyzer, check the CO

(or O2),

2

CO and temperature of the ue gases

exiting the boiler.

5. For two-stage or modulating boilers, also

check the CO2 (or O2), CO and temperature

of the ue gases at low re.

6. Conrm that the measured CO

(or O2)

2

matches the required CO2 (or O2) specied

for the boiler.

46

CHECK COMBUSTION

7. For oil boilers, also take a smoke

measurement of the ue gases. Smoke

should not exceed #1.

If CO2, O2, or CO fall outside of the

range specied for the boiler, review the

installation and startup instructions and make

any necessary adjustments to the boiler or

associated venting or piping systems.

Note the gross flue gas temperature for

future reference. Significant changes in

i

flue gas temperature can indicate changes

in the boiler’s operating efficiency.

Page 47

APPENDIX H – IQ CONTROL SYSTEM

IQ Control System Overview

The “IQ Control System” consists of an IQ Boiler

Control and an IQ Option Panel with optional “plug

in” cards:

• Fully integrates both factory and eld

installed components, simplifying installation

and troubleshooting.

• Efciently operates the entire boiler system

to save energy.

IQ Boiler Control:

The heart of Burnham’s IQ Control System is the

IQ Boiler Control. The IQ Boiler Control replaces

the traditional separate ignition control, primary

boiler aquastat, as well as the fan and circulator

relays.

The IQ Boiler Control stores two boiler supply

temperature setpoints in its memory; one setpoint

is for the High Limit Setting and the second is for

the Operating Setpoint.

• Ensures adequate heat and supply of

domestic hot water.

• UL / CSA Listed or Recognized and tested

as part of a complete system.

• Communicate with other EnviraCom™

enabled components to provide a complete

system solution to maximize comfort and

energy efciency.

When the optional Outdoor Air Reset Card is

installed in the IQ Option Panel, the Operating

Setpoint temperature is automatically adjusted

according to the outdoor temperature. For

example, as the outdoor temperature increases

the Operating Setpoint temperature is reduced

from the High Limit Setting to save energy

while improving home comfort. By better

matching boiler heat supply to actual home

heat demand, room air temperatures are more

closely maintained. In addition, when there is

a domestic hot water (DWH) heat request, the