Page 1

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

EERF-ERAC

RELIOBCIRTCELE

4ELEDOM

nonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp,reliob

rebmuNledoMrelioBrebmuNlaireSrelioBetaDnoitallatsnI

_____-__4E_______6

rotcartnoCgnitaeH rebmuNenohP

sserddA

8143606R7-2/06 Price - $3.00

Page 2

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY BEFORE PROCEEDING WITH THE

INSTALLATION OF BOILER. POST INSTRUCTIONS NEAR BOILER FOR REFERENCE BY

OWNER AND SERVICE TECHNICIAN. MAINTAIN INSTRUCTIONS IN LEGIBLE CONDITION.

NOTE: — The equipment shall be installed in accordance with those installation regulations in force in the area where the

installation is to be made. These shall be carefully followed in all cases. Authorities having jurisdiction shall be consulted before

installations are made.

All wiring shall be made in accordance with the National Electrical Code and/or local regulations.

SECTION I - INSTALLATION INSTRUCTIONS ...........................................................Page 3

SECTION II - OPERATING AND SERVICE INSTRUCTIONS .....................................Page 5

STNEMERIUQERECNARAELC

EDISTFEL"81"81

EDISTHGIR"6"0

POT"9"9

MOTTOB"9"51

RAER"0"0

TNORF"42-lavomeRrooDroFtesolC"2

relioB

ledoM

V042V022V802

214000,14000,53000,130012105WK3-4GWA6#06551½31.45.31.3

614000,55000

024000,86000,85000,250010258WK5-4GWA2#09551½38.68.52.5

GNITAEHEOD

RH/UTB,YTICAPAC

%

,64000,140016107

.tnemeriuqergnitaehlatoteht

WK

EUFA

spmA

gnitaR

)V042(

)V042(

ytilibisseccAecivreSroF

OnoitalitneVowTseriuqeRnoitallatsnItesolC*

eziSdna.oN

stnemelEfo

.edoclacirtcelelanoitanrolacoltlusnoc.tf05fossecxenisnurroF*

)ylnOretaW(ISP03:erusserPgnikroWelbawollAmumixaM

*.niM

eziSeriW

)pot(WK3-2

GWA4#08551½35.56.42.4

)mottob(WK5-2

evoclA&tesolCrofdevorppA

muminimhtiwnoitallatsnI

*lairetamelbitsubmocotecnaraelc

evoclA"81

tadetacoleno,sgninep

.aeraeerften.ni.qs52evahotgninepohcae,mottobtaenodnapot

-etaRwolFretaW

rewoPdednemmoceR

relioBotylppuS

esuF.xaM

.spmA-eziS

retaW

.tW.xppA

).laG(

htnodetcelesebyamreliobeht,ecapsdetaehehtnieragnipipdnareliobehterehW.nwohseraseiticapaCgnitaeHEOD

stnetnoC

V042V022V802

ehtfosisabe

gnitaehlatotehtenimretedotssolgnidliubehtotssolsihtdda,tsixelliwssolpukciparo/dnassolgnipipaerehW.yticapaCgnitaeHEOD

).bL(lluF

F°02nodesaB)MPG(

relioBdnaesiR.pmeT

tAyticapaC

enimretedotrotcaf51.1aybssolgnidliubdetaluclacehtylpitlum,detaluclacebtonnactubtsixelliwylnossolgnipipaerehW.stnemeriuqer

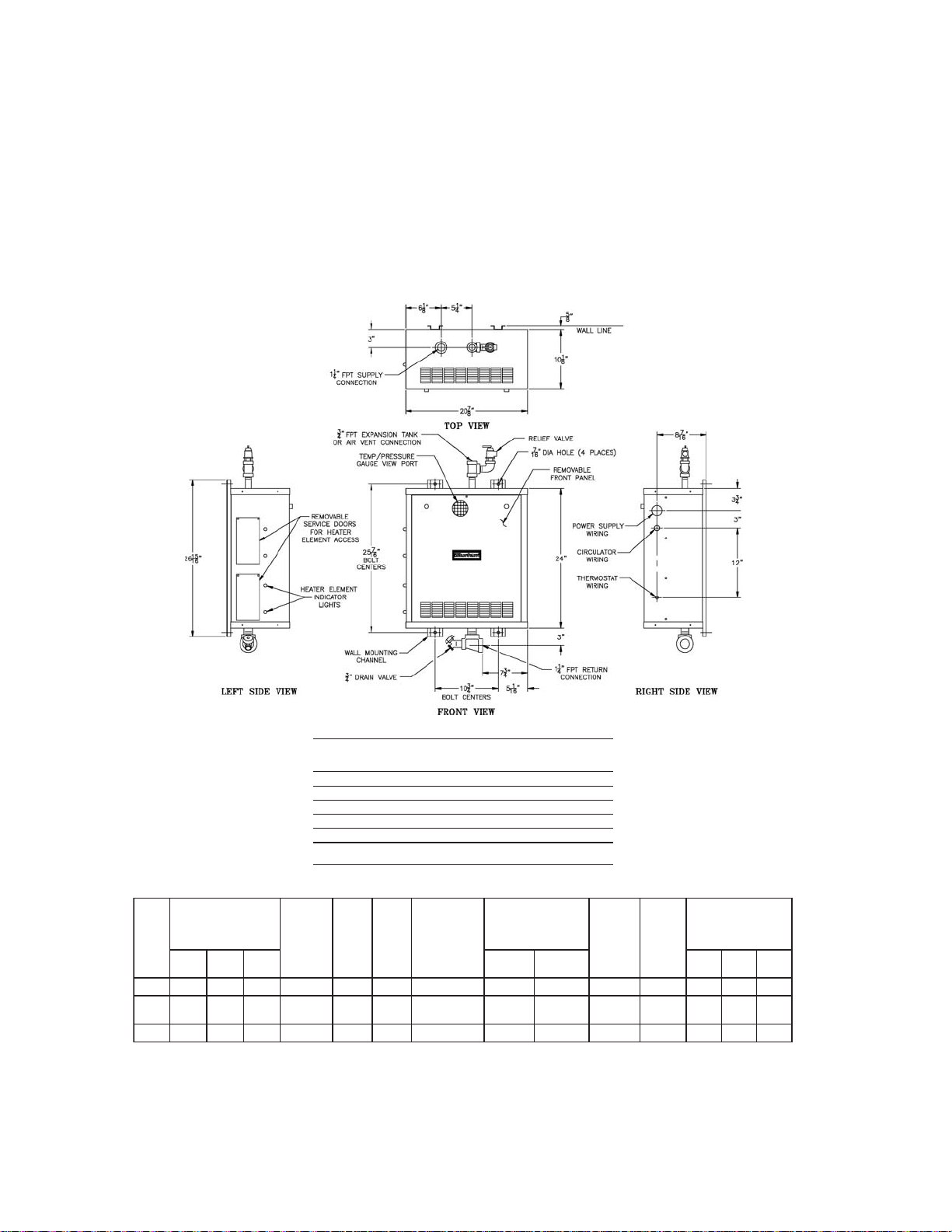

Figure 1: Dimensions and Specifi cations

2

Page 3

SECTION I: INSTALLATION INSTRUCTIONS

A. Inspect Shipment carefully for any signs of damage.

1. All equipment is carefully manufactured, inspected

and packed. Our responsibility ceases upon delivery

of Boiler to the carrier in good condition.

2. Any claims for damage or shortage in shipment

must be fi led immediately against the carrier by

the consignee. No claims for variances from,

or shortage in orders, will be allowed by Boiler

Manufacturer, unless presented within sixty (60)

days after receipt of goods.

B. Read These Instructions Carefully before proceeding

with installation and operation of the “CARE-FREE”

Electric Boiler.

1. The “CARE-FREE” is U.L. listed, constructed

and tested in accordance with the requirements of

the ASME Boiler and Pressure Vessel Code and

designed for use in any conventional hydronic

system except steam and gravity hot water.

2. The “CARE-FREE” Electric Boilers are shipped

completely assembled less circulator. All electrical

controls are mounted and wired in a compartment

immediately behind the Front Door of the Boiler

Jacket, see Figure 1.

C. Locate Boiler in or adjacent to the space to be heated

with consideration given to the location of the electrical

service. Although its compactness will allow the

“CARE-FREE” Electric Boiler to be mounted almost

anywhere – closet, alcove, or other small area, see

CLEARANCE REQUIREMENTS on Page 2.

D. Mount Boiler to wall using four 3/8" lag screws

or anchor bolts (depending upon wall construction)

passing through the holes provided in the wall

mounting channels. Figure 1 shows bolt center

dimensions. It is recommended that 1/2" plywood

be used as a base for mounting the boiler so that the

structure is adequate to carry the weight imposed upon

it – see Figure 1 for weight of boiler when full of water.

Boiler should be level for proper operation of BUILTIN AIR SEPARATOR.

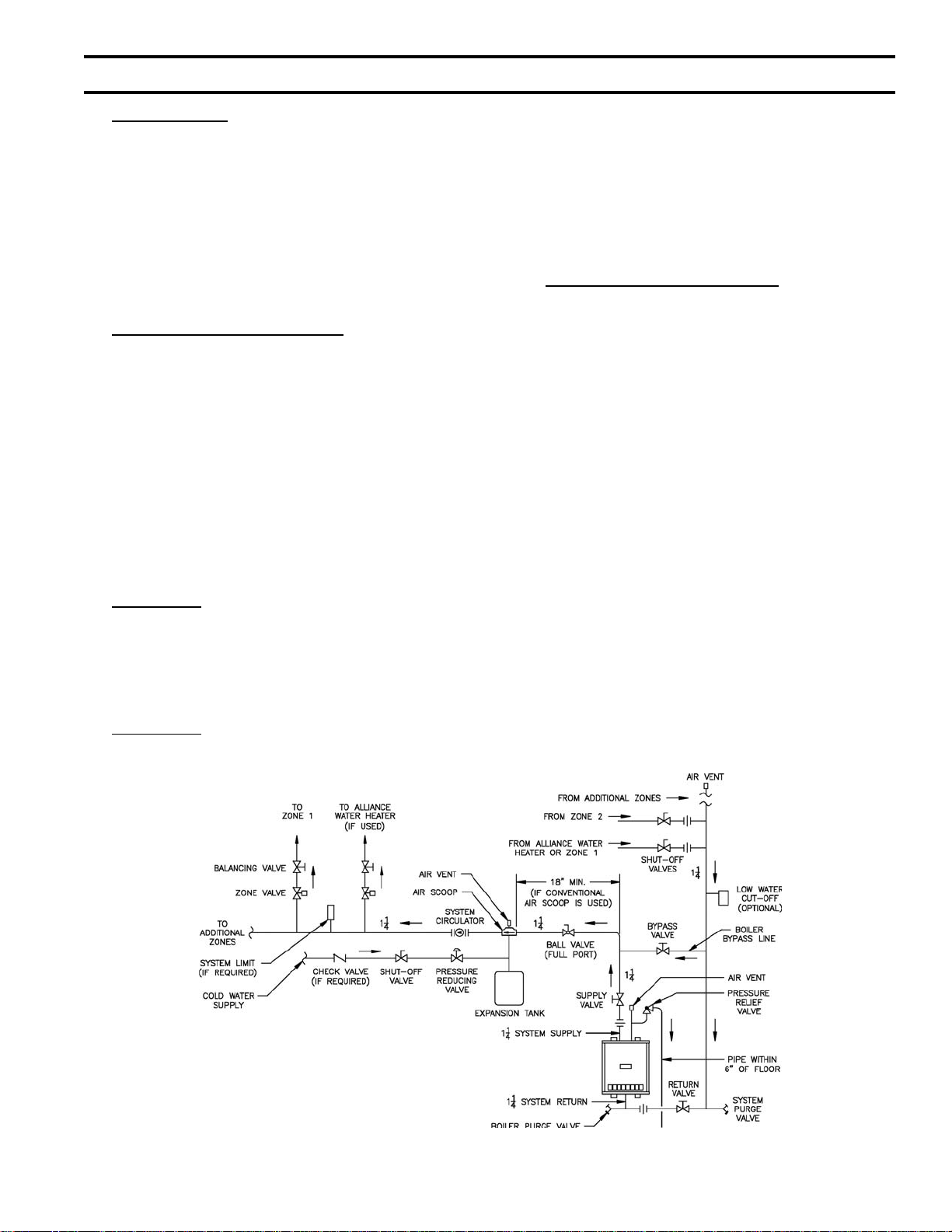

E. Connect Supply and Return Piping to Heating

System using standard recognized practices. See Figure

2. Install an appropriate size expansion tank in system

as per Figure 2. Do not connect into the 3/4" tee on top

of the boiler; instead install an automatic fl oat type air

vent at this point. Water content of the boiler is given

in Figure 1.

The relief valve outlet should be piped full size to a

drain or near the fl oor.

The heating elements are NOT compatible with

ethylene glycol based antifreeze.

If a low water cut-off is required, it must be mounted in

the system piping above the boiler.

The minimum safe water level of a hot water boiler is

just above the highest water containing cavity of the

boiler; that is, a hot water boiler must be full of water to

operate safely.

If it is required to perform a long term pressure test of

the hydronic system, the boiler should fi rst e isolated to

avoid a pressure test including the boiler, ALL trapped

air must fi rst be removed from the boiler.

A loss of pressure during such a test, with no visible

water leakage, is an indication that the boiler contained

trapped air.

Figure 2: Recommended Boiler Piping

3

Page 4

F. Install Electric Wiring in accordance with

NATIONAL ELECTRICAL CODE and Local

Regulations. The Burnham “CARE-FREE” Electric

Boilers may be used with 208 and 240 volt, 60 cycle,

single phase power and one 3 wire power supply. Since

the heaters are rated at 240 volts, however, any input

voltage less than this affects boiler capacity, see Figure

3.

To remove Front Door for access to terminal blocks and

controls:

1. CAUTION – make sure Electrical Service to Boiler

is disconnected.

2. Remove retaining screw at top of door.

3. Lower Door as far as possible, then push forward

until Hinge Pins in lower corners slide out of the

slots.

4. Raise one side of Door until Door will clear opening

– pull forward for removal.

Repeat above in reverse for replacing Door.

Provisions are provided in the right side of the boiler

jacket for power input, circulator, and thermostat

wiring, see Figure 1.

The power input legs are connected to the L1 and

L2 terminals on the terminal board on the control

compartment of the boiler. The neutral leg is connected

to the terminal marked N. Minimum recommended

wire sizes are shown in Figure 1. A separate grounding

conductor of at least #6AWG copper must be run to the

fi eld grounding lug on the control panel.

The Circulator is to be connected from its housing to

the terminals marked N and M on the Main Terminal

Block using Flexible Conduit, see Figures 2 and 4.

If the “QUICK CONNECT CIRCULATOR-PAK”

is ordered as Optional Equipment from the Boiler

Manufacturer, the Flexible Conduit for connecting the

circulator will be furnished.

G. A Prewired Low Voltage Control System is furnished

with every “CARE-FREE” boiler.

1. All controls are furnished in a compartment at the

front of the boiler for easy accessibility. In addition

to the Transformer used to power the system, are

the following: Circulator Relay, Heating Element

Sequencers (one per Heating Element), Dual High

Limit Control, Circulator Operation Selector Switch,

Circulator Fuse and Heating Element Relays.

2. If the Circulator Fuse is blown, power is interrupted

to the Transformer and hence, the control system

de-energized. This action prevents the Heating

Elements from coming on while the Circulator is

inoperative.

A Circulator Operation Selector Switch provides for

either Continuous or Intermittent Circulator operation.

With the switch in the “CONT.” position the Circulator

Delay Control will be bypassed and the Circulator will

operate continuously. The room Thermostat regulates

only the operation of the Heating Elements in the boiler.

With the Circulator Switch in the “INT.” position, the

Thermostat will operate both the Circulator and the

Heating Elements. Timing and wiring of the bimetal

heaters in the Circulator Relay and Sequencers assures

Circulator operation before and after Heating Elements

are energized and de-energized, respectively. The

Sequencers permit only one Heating Element at a time

(from bottom to top) to be energized thus preventing

a sudden inrush of electrical current. More detailed

operation is described in subsequent pages.

Wiring of a one zone system is shown in Figure 4.

Figures 5 and 6 show wiring for zoned systems, the

former when Zone Valves are used and the latter when

multiple Circulators are used.

Figure 3: Boiler Capacity at Various Voltages

4

Page 5

SECTION II: OPERATING AND SERVICE INSTRUCTIONS

A. Intermittent Circulator Operation

1. ROOM THERMOSTAT CLOSES

2. CIRCULATOR MOTOR ENERGIZED

a. As the thermostat closes its contacts, a low

voltage circuit (24V.) is completed to the bimetal

heater in the circulator relay (24A51). After

a time delay of 15 seconds, the main contacts

(120V.) of the circulator relay close to start the

circulator.

3. HEATING ELEMENT #1 ENERGIZED

a. Simultaneous with the completing of the circuit

for the circulator relay, two additional circuits

are completed.

b. The fi rst circuit is for the Heating Element

Relays which pull in immediately and the

second is for the bimetal heater in the #1 Heating

Element Sequencer (24A54).

c. These two circuits will be energized only if the

boiler is not “OFF” on limit.

d. After a time delay of 45 seconds (30 seconds

after the circulator has started) the main and

auxiliary contacts of the #1 Sequencer close;

the main contacts (240V.) energizing heating

element #1 and its pilot light (located at the

bottom of the side panel), the auxiliary contacts

(24V.) energizing the bimetal heater in the #2

Heating Element Sequencer.

4. HEATING ELEMENT #2 ENERGIZED

a. 45 seconds after bimetal heater in #2 Heating

Element Sequencer is energized, its main

contacts (240V.) and auxiliary contacts close;

the main contacts energizing heating element #2

and its pilot light (3

auxiliary contacts (24V.) energizing the bimetal

heater in the #3 Heating Element Sequencer.

5. HEATING ELEMENT #3 ENERGIZED

a. 45 seconds after bimetal heater in the #3 Heating

Element Sequencer is energized, its main

contacts and auxiliary contacts close; the main

contacts (240V.) energizing heating element #3

and its pilot light (2nd lowest in the boiler), the

auxiliary contacts (24V.) energizing the bimetal

heater in the #4 Heating Element Sequencer.

6. HEATING ELEMENT #4 ENERGIZED

a. 45 seconds after bimetal heater in #4 Heating

Element Sequencer is energized, its main

contacts and auxiliary contacts close, the main

contacts (240V.) energizing heating element #4

and its pilot light (highest in the boiler) – nothing

is connected to the auxiliary contacts.

rd

lowest in the boiler), the

7. ROOM THERMOSTAT OPENS

8. HEATING ELEMENTS DE-ENERGIZED

When the thermostat is satisfi ed and opens its

contacts, the low voltage circuits to the Heating

Element Relay and the Heating Element Sequencers

are broken. The Heating Element Relays “drop-out”

immediately and totally de-energize the Heating

Elements and pilot lights. After a time delay of 45

seconds, the main contacts of all the Sequencers

“break” thus resetting the Heating Element Relays.

9. CIRCULATOR MOTOR DE-ENERGIZED

Simultaneous with the breaking of the low voltage

circuit to the Heating Element Sequencers is the

breaking of the low voltage circuit to the Circulator

Relay by the opening of the thermostat contact.

After a time delay of 90 seconds after all Heating

Elements are “off” the bimetal heater opens the

main contacts in the Circulator Relay thus stopping

the circulator. When the boiler is zoned with

circulator and switching relays as illustrated in

Figure 6 on Page 8 the circulator switch must be in

the “constant” position; therefore the circulator will

not have any delay when the thermostat(s) closes or

opens its contacts.

B. Continuous Circulator Operation

If the Circulator Switch (located in the control portion

of the Boiler Jacket) is placed in the “CONT.” position,

the Circulator will run continuously and the Heating

Elements will sequence as in steps 3-6 and 8 above.

C. Dual Limit Operation

The Dual Limit Control consists of two independently

adjustable temperature limits. The left hand adjustment

is for the safety limit and should be set initially for

220°F. The lower right hand adjustment is for the

operating limit and should be set for 210°F with a

differential setting (upper right hand adjustment) of 10º.

These adjustments may be varied to suit the individual

installation, with minimum of 10° difference between

the limit settings. If the setting of the operating Limit

or the safety limit is reached, the Heating Elements only

will be de-energized; the Circulator will continue to

run. If the Circulator Switch is in the “INT.” position,

the Circulator runs until the thermostat is satisfi ed and

the main contacts on the Circulator Relay open.

GNINRAW

sireliobehtfonoitallatsnierofeB

ehtfonoitarepoeht,etelpmocderedisnoc

,dekcehcebdluohsslortnocreliob

timiLytefaS&gnitarepOehtylralucitrap

.slortnoC

5

Page 6

Figure 4: Wiring Diagram - Model E-4 Boilers

6

Page 7

D. Indicator Lights

There is an indicator light for each heating element.

If an indicator light is “on” it indicates its respective

heating element is energized. If the light is “off” it

indicates:

1. The heating element has not been energized.

2. The heating element sequencer is malfunctioning.

E. Built-In Air Eliminator

An air eliminator has been built into the top of the

electric boiler and a 3/4" tapping is provided with

nipple and tee for connection of Relief Valve and a fl oat

type Air Vent. See Figure 1.

Figure 5: Wiring Diagram - 3 Zone System

White-Rodgers 2 Wire Zone Valves

Figure 6: Wiring Diagram - 2 Zone System

Multiple Circulators

7

Page 8

Limited Warranty

FOR RESIDENTIAL CAST IRON WATER BOILERS

Subject to the terms and conditions set forth below, U.S. Boiler™

Co., Inc. Lancaster, Pennsylvania hereby extends the following limited

warranties to the original owner of a residential grade water boiler

manufactured and shipped on or after July 1,1991:

ONE YEAR LIMITED WARRANTY

ON RESIDENTIAL GRADE WATER BOILERS

U.S. Boiler Co., Inc. warrants to the original owner that its residential

grade water boilers comply at the time of manufacture with recognized

hydronic industry standards and requirements then in effect and will be

free of defects in material and workmanship under normal usage for a

period of one year from the date of original installation. If any part of a

water boiler is found to be defective in material or workmanship during

this one year period, U.S. Boiler Co., Inc. will, at its option, repair or

replace the defective part.

LIFETIME LIMITED WARRANTY ON HEAT EXCHANGER

U.S. Boiler Co., Inc. warrants to the original owner that the heat

exchanger of its residential grade water boilers will remain free from

defects in material and workmanship under normal usage for the

lifetime of the original owner at the original place of installation. If a

claim is made under this warranty during the fi rst ten years from the

date of original installation, U.S. Boiler Co., Inc. will, at its option, repair

or replace the heat exchanger. If a claim is made under this warranty

after the expiration of ten years from the date of original installation,

U.S. Boiler Co., Inc. will, at its option and upon payment of the pro-rated

service charge set forth below, repair or replace the heat exchanger.

The service charge applicable to a heat exchanger warranty claim is

based upon the number of years the heat exchanger has been in service

and will be determined as a percentage of the retail price of the heat

exchanger model involved at the time the warranty claim is made as

follows:

sraeY

ecivreSnI

egrahCecivreS

fo%sa

ecirPliateR

sraeY

ecivreSnI

egrahCecivreS

fo%sa

ecirPliateR

NOTE: If the heat exchanger model involved is no longer available due to

product obsolescence or redesign, the value used to establish the retail

price will be the published price as shown in the Burnham Hydronics

Repair Parts Price Sheet where the heat exchanger last appeared or the

current retail price of the then nearest equivalent heat exchanger.

ADDITIONAL TERMS AND CONDITIONS

1. Applicability: The limited warranties set forth above are extended

only to the original owner at the original place of installation within the

United States and Canada. These warranties are applicable only to

water boilers designated as residential grade by U.S. Boiler Co., Inc. and

installed in a single or two-family residence and do not apply to steam

boilers of any kind or to commercial grade boilers.

2. Components Manufactured by Others: Upon expiration of the

one year limited warranty on residential grade water boilers, all boiler

components manufactured by others but furnished by U.S. Boiler Co.,

Inc. (such as oil burner, circulator and controls) will be subject only to the

manufacturer’s warranty, if any.

3. Proper Installation: The warranties extended by U.S. Boiler Co., Inc.

are conditioned upon the installation of the residential grade water boiler

in strict compliance with U.S. Boiler Co., Inc. installation instructions. U.

S. Boiler Co., Inc. specifi cally disclaims liability of any kind caused by or

relating to improper installation.

4. Proper Use and Maintenance: The warranties extended by U.S. Boiler

Co., Inc. conditioned upon the use of the residential grade water boiler for

its intended purposes and its maintenance

01-111213141516171

oN

5015102520353

egrahC

81910212223242

0454055506560757

evoba

accordance with U. S. Boiler Co., Inc. recommendations and hydronics

industry standards. These warranties will be inapplicable if the residential

grade water boiler is used or operated over its rated capacity, is

subjected to unauthorized modifi cation, or is damaged as a result of

being otherwise improperly operated or serviced including, but not limited

to, damage from any of the following: operation with insuffi cient water,

allowing the boiler to freeze, subjecting the boiler to fl ood conditions, and

operation with unapproved water or fuel additives which cause deposits

or corrosion.

5. Removal and Installation: These warranties do not cover expenses

of removal or reinstallation. The owner is responsible for the cost of

removing and reinstalling any defective part and its replacements and all

labor and material connected therewith.

6. Exclusive Remedy: U.S. Boiler Co., Inc. obligation for any breach of

these warranties is limited to the repair or replacement of its parts in

accordance with the terms and conditions of these warranties.

7. Limitation of Damages: Under no circumstances shall U.S. Boiler Co.,

Inc. be liable for incidental, indirect, special or consequential damages

of any kind whatsoever under these warranties, including, but not limited

to, injury or damage to persons or property and damages for loss of use,

inconvenience or loss of time. U.S. Boiler Co., Inc. liability under these

warranties shall under no circumstances exceed the purchase price paid

by the owner for the residential grade water boiler involved. Some states

do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

8. Limitation of Warranties: These warranties set forth the entire

obligation of U.S. Boiler Co., Inc. with respect to any defect in a

residential grade water boiler and U.S. Boiler Co., Inc. shall have no

express obligations, responsibilities or liabilities of any kind whatsoever

other than those set forth herein. These warranties are given in lieu of all

other express warranties.

ALL APPLICABLE IMPLIED WARRANTIES, IF ANY, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSLY LIMITED IN DURATION TO

A PERIOD OF ONE YEAR EXCEPT THAT IMPLIED WARRANTIES, IF

ANY, APPLICABLE TO THE HEAT EXCHANGER IN A RESIDENTIAL

GRADE WATER BOILER SHALL EXTEND TO THE ORIGINAL OWNER

dna52

FOR THE LIFETIME OF THE ORIGINAL OWNER AT THE ORIGINAL

PLACE OF INSTALLATION. SOME STATES DO NO ALLOW LIMITATION

ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

PROCEDURE FOR OBTAINING WARRANTY SERVICE

In order to assure prompt warranty service, the owner is requested to

complete and mail the attached Warranty Card within ten days after the

installation of the boiler, although failure to comply with this request will

not void the owner’s rights under these warranties.

Upon discovery of a condition believed to be related to a defect in

material or workmanship covered by these warranties, the owner should

notify the installer, who will in turn notify the distributor. If this action is

not possible or does not produce a prompt response, the owner should

write to U.S. Boiler Co., Inc., Burnham Hydronics, at P.O. Box 3079,

Lancaster, PA 17604, giving full particulars in support of the claim.

The owner is required to make available for inspection by U.S.

Boiler Co., Inc. or its representative the parts claimed to be defective

and, if requested by U.S. Boiler Co., Inc. to ship these par ts prepaid to

U.S. Boiler Co., Inc. at the above address for inspection or repair. In

addition, the owner agrees to make all reasonable efforts to settle any

disagreement arising in connection with a claim before resorting to legal

remedies in the courts.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU

MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO

STATE.

03/03

Loading...

Loading...