Page 1

Operating Instructions (from serial number 3000)

Bedienungsanleitung (ab Serien-Nummer 3000)

Manuel d‘utilisation (à partir du numéro de série 3000)

Type 8222 ELEMENT neutrino

Conductivity meter

Leitfähigkeits-Messgerät

Conductivimètre

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2010-2017

Operating Instructions 1708/03_EU-ML 00561659 Original_FR

Page 3

3

Type 8222 ELEMENT neutrino

1. ABOUT THE OPERATING INSTRUCTIONS ......................................5

1.1. Symbols used ......................................................................................5

1.2. Definition of the word "device" ...................................................5

1.3. Validity of these Operating Instructions ................................ 6

2. INTENDED USE ..............................................................................................6

3. BASIC SAFETY INFORMATION ...............................................................6

4. GENERAL INFORMATION ..........................................................................8

4.1. Contact ....................................................................................................8

4.2. Warranty conditions ...........................................................................8

4.3. Information on the internet ............................................................8

5. DESCRIPTION .................................................................................................8

5.1. Area of application ............................................................................8

5.2. General description ..........................................................................8

5.2.1. Design .....................................................................................8

5.2.2. Conductivity sensor .............................................................9

5.3. Description of the rating plates .................................................9

6. TECHNICAL DATA ....................................................................................... 10

6.1. Operating conditions .................................................................... 10

6.2. Conformity to standards and directives ............................. 10

6.2.1. Conformity to the pressure equipment directive ..........10

6.2.2. UL certification ....................................................................10

6.3. Mechanical data ..............................................................................11

6.4. Dimensions ........................................................................................ 11

6.5. Fluid data ..............................................................................................12

6.6. Electrical data ....................................................................................14

6.7. Electrical data specific to the UL devices ......................... 14

6.8. Probe data .......................................................................................... 14

7. ASSEMBLY ..................................................................................................... 15

7.1. Safety instructions ......................................................................... 15

7.2. Unscrewing the cover on the connection box ................ 15

7.3. Fitting the cover to the connection box .............................. 16

8. INSTALLATION AND WIRING ................................................................ 17

8.1. Safety instructions ......................................................................... 17

8.2. Installation onto the pipe ............................................................ 18

8.2.1. Installation of a device with a G 1 1/2" nut ..................18

8.2.2. Installation of a device with a G 3/4" external

threaded sensor .................................................................19

English

Page 4

4

Type 8222 ELEMENT neutrino

8.3. Wiring ....................................................................................................20

8.3.1. Electrical connections .......................................................20

8.3.2. Wiring a version with cable gland ..................................20

8.3.3. Assembling and wiring the female connector,

order code 917116 ...........................................................22

8.3.4. Wiring a version with an M12 fixed connector ............23

9. ADJUSTMENT AND COMMISSIONING ...........................................24

9.1. Safety instructions ......................................................................... 24

9.2. Description of the connection box ....................................... 25

9.3. Choosing the conductivity or temperature range

associated with the 4...20 mA output ................................... 26

9.4. Checking the cell constant of the conductivity

sensor ................................................................................................... 28

10. MAINTENANCE AND TROUBLESHOOTING .............................. 28

10.1. Safety instructions .........................................................................28

10.2. Device and conductivity sensor maintenance ................ 29

10.3. Replacing the cover seal on the connection box ........... 29

10.4. Replacing the seal of the G 3/4'' threaded sensor .......31

10.5. If you encounter problems ........................................................32

11. SPARE PARTS AND ACCESSORIES .............................................33

12. PACKAGING, TRANSPORT ................................................................. 33

13. STORAGE .....................................................................................................33

14. DISPOSAL OF THE DEVICE .................................................................34

English

Page 5

5

About the Operating Instructions

Type 8222 ELEMENT neutrino

1. ABOUT THE OPERATING

INSTRUCTIONS

These Operating Instructions describe the entire life cycle of the

device. Please keep these Operating Instructions in a safe place,

accessible to all users and any new owners.

These Operating Instructions contain important safety

information.

Failure to comply with these instructions can lead to hazardous

situations.

▶ These Operating Instructions must be read and understood.

1.1. Symbols used

DANGER

Warns you against an imminent danger.

▶ Failure to observe this warning can result in death or in serious

injury.

WARNING

Warns you against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or

even death.

CAUTION

Warns you against a possible risk.

▶ Failure to observe this warning can result in substantial or minor

injuries.

NOTICE

Warns you against material damage.

▶ Failure to observe this warning may result in damage to the

device or system.

Indicates additional information, advice or important

recommendations.

Refers to information contained in these Operating Instructions or in other documents.

▶ Indicates an instruction to be carried out to avoid a danger, a

warning or a possible risk.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

The word "device" used within these Operating Instructions refers to

the conductivity meter type 8222 ELEMENT neutrino.

English

Page 6

6

Basic safety information

Type 8222 ELEMENT neutrino

1.3. Validity of these Operating

Instructions

These Operating Instructions are valid for the devices type 8222

ELEMENT neutrino with a series number equal or higher than 3000.

2. INTENDED USE

Use of the device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

The device is intended solely for the measurement of the

conductivity.

▶ This device must be protected against electromagnetic interfer-

ence, ultraviolet rays and, when installed outdoors, the effects of

climatic conditions.

▶ This device must be used in compliance with the characteristics

and commissioning and use conditions specified in the contractual documents and in the Operating Instructions.

▶ Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

▶ Only use the device as intended.

3. BASIC SAFETY INFORMATION

This safety information does not take into account any contingencies

or occurrences that may arise during installation, use and maintenance of the product.

The operating company is responsible for the respect of the local

safety regulations including for the staff safety.

Danger due to high pressure in the installation.

Danger due to electrical voltage.

Danger due to high fluid temperatures.

Danger due to the nature of the fluid.

Various dangerous situations.

To avoid injury take care:

▶ to prevent any power supply switch-on.

▶ to carry out the installation and maintenance work by qualified

and skilled staff with the appropriate tools.

▶ to guarantee a set or controlled restarting of the process after a

power supply interruption.

▶ to use the device only if in perfect working order and in

compliance with the instructions provided in the Operating

Instructions.

English

Page 7

7

Basic safety information

Type 8222 ELEMENT neutrino

Various dangerous situations.

To avoid injury take care:

▶ to observe the general technical rules during the planning and

use of the device.

▶ not to use the device in explosive atmospheres.

▶ not to use this device in an environment incompatible with the

materials from which it is made.

▶ not to use fluid that is incompatible with the materials the device

is made of.

▶ not to subject the device to mechanical loads.

▶ not to make any external or internal modifications to the device.

NOTICE

The device may be damaged by the fluid in contact with.

▶ Systematically check the chemical compatibility of the compo-

nent materials of the device and the fluids likely to come into

contact with it (for example: alcohols, strong or concentrated

acids, aldehydes, alkaline compounds, esters, aliphatic com-

pounds, ketones, halogenated aromatics or hydrocarbons,

oxidants and chlorinated agents).

NOTICE

Elements / Components sensitive to electrostatic discharges

This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they are touched by an

electrostatically charged person or object. In the worst case scenario, these components are instantly destroyed or go out of order

as soon as they are activated.

▶ To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 norm.

▶ Do not touch any of the live electrical components.

English

Page 8

8

General information

Type 8222 ELEMENT neutrino

4. GENERAL INFORMATION

4.1. Contact

To contact the manufacturer of the device use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the

internet at: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use

of the device in observance of the operating conditions specified in

these Operating Instructions.

4.3. Information on the internet

You can find the Operating Instructions and technical data sheets

regarding the type 8222 ELEMENT neutrino at: www.burkert.com

5. DESCRIPTION

5.1. Area of application

The device is intended solely for the measurement of the conductivity.

The device is used to transmit the conductivity measured to a

4...20 mA loop.

5.2. General description

5.2.1. Design

The device comprises:

• A sensor for measuring physical parameters, comprising:

- 2 electrodes which measure an impedance in Ohm

- a Pt1000 temperature probe which converts the temperature

of the fluid into resistance (in W).

• an acquisition / conversion module of measured physical data:

- acquisition of the impedance measured in Ohm

- conversion of the measured impedance into conductivity units

- acquisition of the resistance measured and conversion into

temperature.

The device operates on a 2 wire system and needs a 12...36 V DC

power supply. Electrical connection is made:

- Either by one M12 5-pin male fixed connector

- Or via a cable gland on a 5-pin terminal block.

English

Page 9

9

Description

Type 8222 ELEMENT neutrino

5.2.2. Conductivity sensor

The sensor is pined together with the electronic module and cannot

be dismantled.

The sensor itself comprises a Pt1000 temperature sensor and 2

electrodes.

An alternating voltage is applied to the electrode terminals: the

current measured is directly proportional to the conductivity of the

solution.

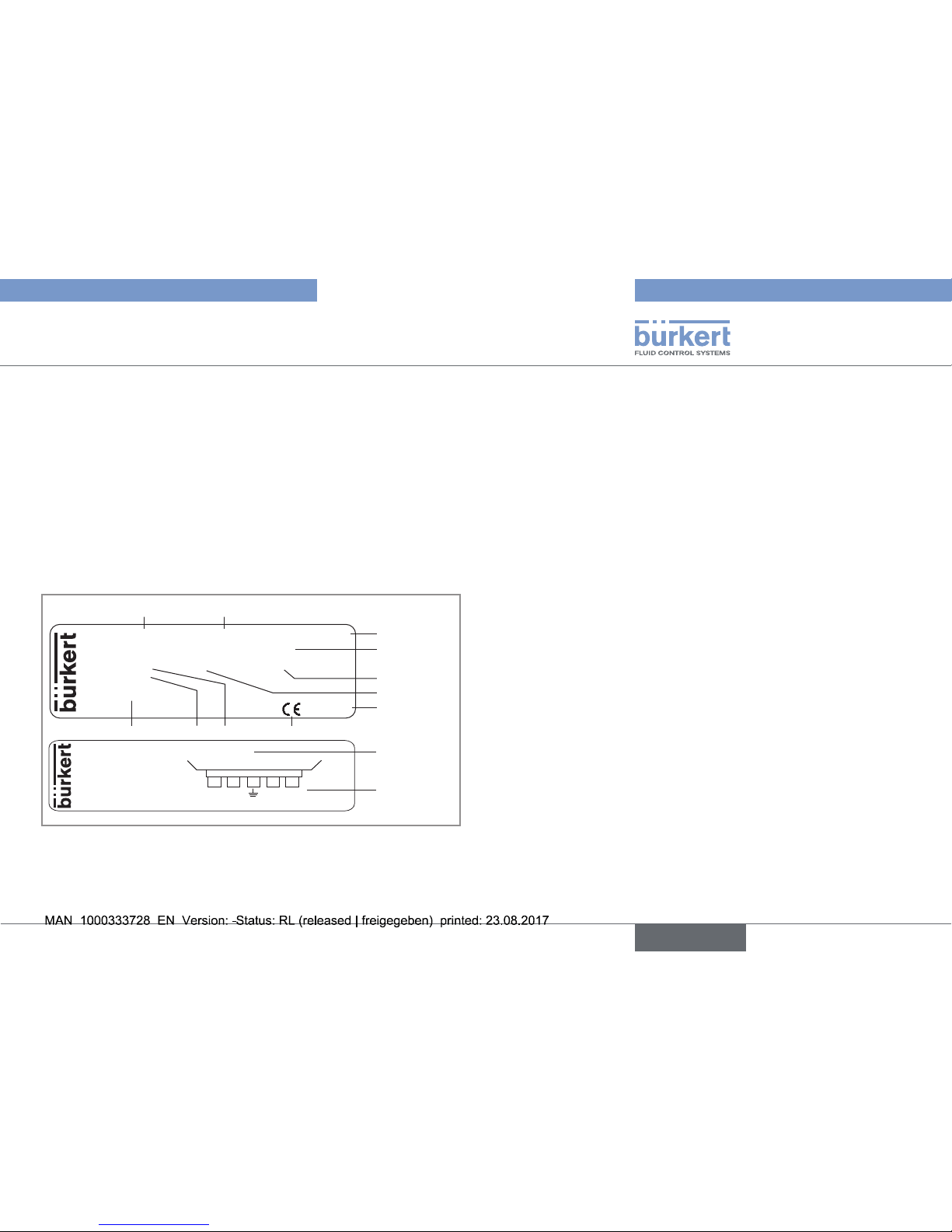

5.3. Description of the rating plates

Supply: 12-36VDC Max1W Output: 1x4-20mA

Cell: C 1,00 Range 5-10000 µS/cm

Fluid: 16Bar Temp -20/100°C IP65-67

S/N 1009

00561672

Made in France

3

4

5

6

7

8911

8222 Conductivity-Transmitter

Made in France

12

13

W43ML

1 2

10

+V

0V

NC

NC

Fig. 1: Name plates of the device (example)

1. Power supply

2. Power consumption

3. Type of output

4. Sensor specifications

5. Protection rating

6. Temperature range of the fluid

7. Construction code

8. Conformity marking

9. Nominal pressure of the fluid

10. Serial number

11. Order code

12. Type of the device and measured value

13. Pin assignment of the M12 fixed connector or the terminal block

English

Page 10

10

Technical data

Type 8222 ELEMENT neutrino

6. TECHNICAL DATA

6.1. Operating conditions

Ambient temperature –10...+60 °C

Air humidity < 85 %, non condensated

Protection rating, with connector

or cable plugged in and cable

gland tightened and cover of the

connecting box fully tightened

and locked

• IP67 and IP65

• NEMA 250, 4X and 6P

6.2. Conformity to standards and

directives

The applied standards, which verify conformity with the EU directives, can be found on the EU-type examination certificate and/or the

EU declaration of conformity (if applicable).

6.2.1. Conformity to the pressure

equipment directive

The device conforms to article 4§1 of the Pressure Equipment

Directive 2014/68/EU under following conditions.

The device can only be used in the following cases (depending on

the max. pressure, the DN of the pipe and the fluid):

Type of fluid Conditions

Fluid group 1, art. 4 §1.c.i DN25 only

Fluid group 2, art. 4 §1.c.i

DN ≤ 32

or PNxDN ≤ 1000

Fluid group 1, art. 4 §1.c.ii

DN ≤ 25

or PNxDN ≤ 2000

Fluid group 2, art. 4 §1.c.ii

DN ≤ 200

or PN ≤ 10

or PNxDN ≤ 5000

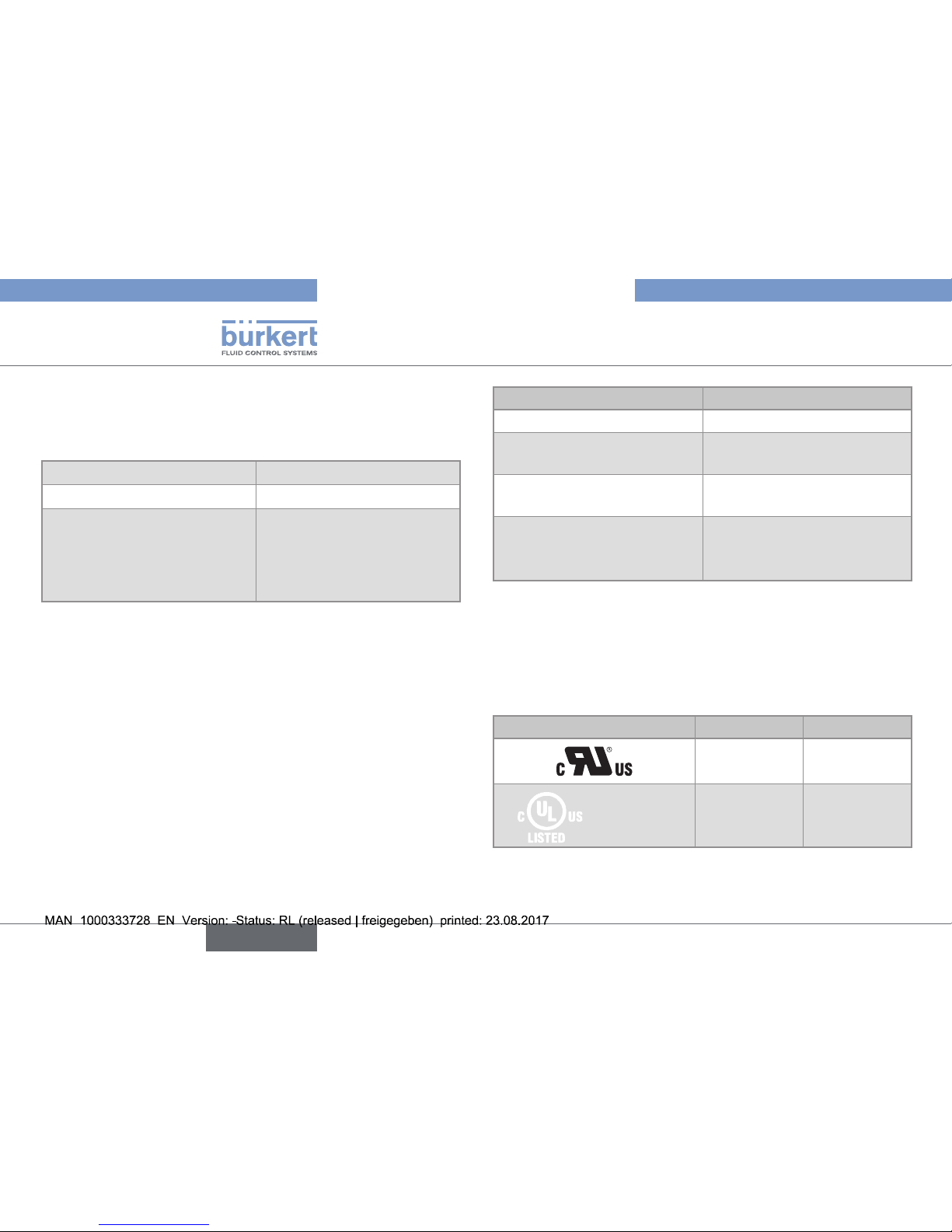

6.2.2. UL certification

Products with variable key PU01 or PU02 are UL-certified products

and comply also with the following standards:

• UL 61010-1

• CAN/CSA-C22.2 n°61010-1

Identification on the device Certification Variable key

UL-recognized PU01

Measuring

Equipment

EXXXXXX

®

UL-listed PU02

English

Page 11

11

Technical data

Type 8222 ELEMENT neutrino

6.3. Mechanical data

Part Material

Box / seals stainless steel, PPS / EPDM

Cover / seal PPS / EPDM

M12 fixed connector / Seal PA66 / EPDM

Cable gland / Seal PA66 / EPDM

Nut PVC (or PVDF on request)

Conductivity sensor PVDF

Pt1000 stainless steel 1.4571 (316Ti)

Electrodes

• probe C=1

• probe C=0,1 or C=0,01

• graphite

• stainless steel 1.4571 (316Ti)

• Materials in contact with the fluid:

PVDF, stainless steel 1.4571 (316Ti), graphite, EPDM (only

version with G 3/4'' external threaded sensor)

Stainless steel 316Ti

(C=0,1 ou 0,01)

Stainless steel

316Ti (C=1)

Graphite (C=1)

PVC or

PVDF

PVDF

PPS

EPDM

PA66 / EPDM

Stainless steel

Fig. 2: Materials of the device

6.4. Dimensions

→ Please refer to the technical data sheets regarding the pH- or

redox-meter type 8222 ELEMENT neutrino, available at:

www.burkert.com

English

Page 12

12

Technical data

Type 8222 ELEMENT neutrino

6.5. Fluid data

Process connection

• Version with a G 1 1/2'' nut

• Version with a G 3/4''

external threaded sensor

• Adapter or fitting S022

• Adapter with G 3/4" internal

thread

Fluid pressure

PN16

The max. fluid pressure may be

restricted by the fluid temperature,

the material of the nut and the material

from which the S022 is made (see

Fig. 3, Fig. 4, Fig. 5 and Fig. 6)

Fluid temperature

The max. fluid temperature may be

restricted by the fluid pressure, the

material of the nut and the material

from which the S022 is made (see

Fig. 3, Fig. 4, Fig. 5 and Fig. 6)

Conductivity measurement

• Measurement range

• Internal resolution

• Measuring error

• 0,05 µS/cm to 10 mS/cm

• 1 nS/cm

• ±3 % of the measured value

Temperature probe

Pt1000 integrated in the conductivity sensor

Temperature measurement

• Measurement range

• Accuracy

• –40...+130 °C

• ±1 °C

Temperature compensation

• Automatic (integrated Pt1000)

according to the position of the

selector on the electronic board

(see chap. 9.3)

• Reference temperature = 25 °C

-20 0 +20 +40 +60 +80 +100+120T (°C)

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

P (bar)

A

A

B

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

P (psi)

A: with a PVDF nut or a G 3/4" external threaded sensor;

B: with a PVC nut

The measures have been made at an ambient temperature of 60 °C.

Fig. 3: Fluid temperature / pressure dependency, for the device

with a PVC or a PVDF nut or with a G 3/4'' external

threaded sensor

English

Page 13

13

Technical data

Type 8222 ELEMENT neutrino

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100

T (°C)

P (bar)

+120

PVC

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

P (psi)

Metal

The measurements have been made at an ambient temperature of 60 °C.

Fig. 6: Fluid temperature / pressure dependency, for the device

with a G 3/4" external threaded sensor and an adapter in

PVC or metal.

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

0 +20 +40 +60

T (°C)

P (bar)

PVC + PP

-20

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

P (psi)

Metal

Fig. 4: Fluid temperature / pressure dependency, for the device

with a PVC nut and an S022 in metal, PVC or PP.

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100

PVC

PP

T (°C)

P (bar)

PVC + PP

+120

232

217.6

203

188.6

174

159.6

145

130.6

116

101.6

87

72.5

58

43.5

29

14

0

P (psi)

Metal

Fig. 5: Fluid temperature / pressure dependency, for the device with

a PVDF nut and an S022 in metal, PVC or PP.

English

Page 14

14

Technical data

Type 8222 ELEMENT neutrino

6.6. Electrical data

Power supply 12...36 V DC, filtered and regulated

Current consumption ≤ 25 mA (12...36 V DC)

Protection against polarity

reversal

yes

Protection against voltage

spikes

yes

Current output

• Accuracy

• Response time

(10 % - 90 %)

• max. loop impedance

4...20 mA

• ±1 % (0,16 mA)

• 5 s

• 1100 W at 36 V DC, 610 W at

24 V DC, 100 W at 12 V DC

6.7. Electrical data specific to the UL

devices

Characteristics of the power

source (not supplied)

• limited energy source (in

accordance to UL 61010-1, § 9.4

• or Low Power Source in

accordance to UL 60950-1

• or Class 2 source in accordance

to UL 1310 or UL 1585

6.8. Probe data

Probe C=0,01

• Measurement range

• Type of fluid

• 0,05...20 µS/cm

• ultra-pure water, pure water

Probe C=0,1

• Measurement range

• Type of fluid

• 0,5...200 µS/cm

• for example: pure water, industrial

wastewater

Probe C=1

• Measurement range

• Type of fluid

• 0,005...10 mS/cm

• for example: industrial wastewater, wastewater

English

Page 15

15

Assembly

Type 8222 ELEMENT neutrino

7. ASSEMBLY

7.1. Safety instructions

DANGER

Risk of injury due to electrical voltage.

▶ If a 12...36 V DC powered version is installed either in a wet

environment or outdoors, all the electrical voltages must be of

max. 35 V DC.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

WARNING

Risk of injury due to nonconforming assembly.

▶ The device must only be assembled by qualified and skilled staff

with the appropriate tools.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

▶ Avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subse-

quent to any intervention on the device.

7.2. Unscrewing the cover on the

connection box

NOTICE

The tightness of the device is not guaranteed when the cover

is removed.

▶ Take all the precautions to prevent the projection of liquid inside

the housing.

The connection box is fitted

with a locking system.

→ Using a screwdriver with

a suitable head, turn

the latch to the unlock

position to unlock the

connection box.

English

Page 16

16

Assembly

Type 8222 ELEMENT neutrino

→ Unscrew the cover on

the connection box by

hand.

Fig. 7: Unscrewing the cover on the connection box

7.3. Fitting the cover to the

connection box

B

→ Check that seal

"B" on the cover is

in good condition.

Replace it if necessary

(see chap. 11 and

chap. 10.3).

slots

polarising slots

→ Position the polarising

slots on the cover in

the axis of the slots on

the box: 3 positions

are possible.

→ Tighten the cover on

the connection box.

→ Using a screwdriver

with a suitable head,

turn the latch to the

lock position to lock

the cover.

Fig. 8: Fitting the cover on the connection box

English

Page 17

17

Installation and wiring

Type 8222 ELEMENT neutrino

WARNING

Risk of injury due to nonconforming installation.

▶ The electrical and the fluid installation can only be carried out by

qualified and skilled staff with the appropriate tools.

▶ Install appropriate safety devices (correctly rated fuse and/or

circuit-breaker).

▶ Respect the assembly instructions for the fitting or the adapter

used.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

▶ Avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subse-

quent to any intervention on the device.

WARNING

Risk of injury if the fluid pressure/ temperature dependency

is not respected.

▶ Take into account the fluid pressure/ temperature dependency

according to the materials from which the fitting is made (see

chap. 6.5).

▶ Comply with the Pressure Equipment Directive 2014/68/EU.

8. INSTALLATION AND WIRING

8.1. Safety instructions

DANGER

Risk of injury due to high pressure in the installation.

▶ Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

▶ If a 12...36 V DC powered version is installed either in a wet

environment or outdoors, all the electrical voltages must be of

max. 35 V DC.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Risk of injury due to the nature of the fluid.

▶ Respect the regulations on accident prevention and safety relat-

ing to the use of aggressive fluids.

Risk of injury due to the high temperature of the fluid.

▶ Use safety gloves to handle the device.

English

Page 18

18

Installation and wiring

Type 8222 ELEMENT neutrino

Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of

the climatic conditions.

8.2. Installation onto the pipe

If the conductivity is measured in liquids containing solids

that may leave deposits in the bottom of the pipe, use installation position 1 (see Fig. 9)

The device is available with an external threaded sensor or with a

G 1 1/2'' nut. The device with a nut can be installed on a pipe by

means of an S022 adapter or fitting. The device with an external

threaded sensor can be installed on a pipe or a tank wall by means

of an internal threaded adapter.

8.2.1. Installation of a device with a

G 1 1/2" nut

Prefer mounting position “1” to install a device with probe

C=0,1 or C=0,01.

→ Choose an appropriate position in the pipe to install the fitting

(see Fig. 9).

→ Install the adapter or the fitting on the pipe according to the

Operating Instructions of the adapter or fitting used.

1 2

Direction of the fluid

Fig. 9: Mounting positions of the fitting/device unit in the pipe

→ Install the device on the fitting (see Fig. 10).

B

→ Check that

seal B is on

the fitting and

that it is not

damaged.

Replace

the seal if

necessary.

→ Carefully insert

the device into

the fitting.

English

Page 19

19

Installation and wiring

Type 8222 ELEMENT neutrino

Ø 24 min.

21,5

1)

Ø 27,5

H8

G3/4''

R 0,25 min.

3,3

1x45°

0,5 x 45°

1)

minimal internal thread depth

Fig. 11: Threading jig for the adapter [mm]

→ Install the device into the adapter.

→ Position the device in such a way that the markings (see zoom in

Fig. 10) located on either side of the electronics box are parallel

to the pipe.

→ Position the

device in such

a way that the

markings (see

zoom) located

on either side

of the electronics box are

parallel to the

pipe.

→ Tighten by hand

the nut G 1 1/2"

on the fitting.

Fig. 10: Installation of the device into a fitting

8.2.2. Installation of a device with a G 3/4"

external threaded sensor

→ Check that the seal is on the threaded sensor.

→ Check the condition of the seal and replace it if necessary (see

chap. 10.4)

→ Install the device on the pipe or the tank wall by means of an

adapter that respects the threading jig from Fig. 11

English

Page 20

20

Installation and wiring

Type 8222 ELEMENT neutrino

8.3. Wiring

DANGER

Risk of injury due to electrical voltage.

▶ If a 12...36 V DC powered version is installed either in a wet

environment or outdoors, all the electrical voltages must be of

max. 35 V DC.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

• Use a high quality electrical power supply (filtered and

regulated).

• Make sure the installation is equipotential.

8.3.1. Electrical connections

Version Type of connection

with a male M12 fixed

connector

5-pin female M12 connector (not

supplied).

For the M12 connector with order code

917116, use a shielded cable:

• diameter: 3...6.5 mm

• wire cross section: max. 0.75 mm

2

Version Type of connection

With a 5-pin terminal

block and a cable

gland

Shielded cable (not provided):

• diameter: 4...8 mm

• wires in compliance with the characteristics of the Table 1

Table 1 : Specifications of the wires composing the cable for a

version with cable gland

Wire specifications Dimensions

• Max clamping area 0.14...1.5 mm

2

• Single core H05(07) V-U 0.25...1.5 mm

2

• Flexible wire H05(07) V-K 0.25...1.5 mm

2

• With non-insulated end connection 0.25...1.5 mm

2

• With insulated end connection 0.25...0.75 mm

2

8.3.2. Wiring a version with cable gland

→ Select a cable that meets the specifications detailed in

chap. "8.3.1. Electrical connections".

75-85 mm

8-9 mm

→ Strip 75 to 85 mm of the

cable.

→ Expose 8 to 9 mm of the wires

on the stripped cable.

Fig. 12: Stripping the cable and exposing the wires

English

Page 21

21

Installation and wiring

Type 8222 ELEMENT neutrino

12...36 V DC

+ -

out 2

out 1

0V

+V

+ -

Power supply

4...20 mA input at external

instrument

12...36 V DC

+

-

out 2

out 1

0V

+V

+

-

Power supply

4...20 mA input at external

instrument

Fig. 14: Possible connections of the 4...20 mA current output on a

version with cable gland

→ Fit the cover to the connection box (see chap. 7.3).

A B

→ Unscrew and remove the

cable gland nut [A].

→ Remove the stopper [B] from

the cable gland.

→ Unscrew the cover on

the connection box (see

chap. 7.2)

→ Thread the cable through the

cable gland nut and the cable

gland.

→ Pull the cable inside the box

until the end of the stripped

part of the cable sticks out of

the cable gland by 5 to 6 mm.

→ Roll a cable clamp around the

cable jacket (twice).

→ Tighten the cable clamp.

→ Pull the cable from the

outside of the box to check

that it is secure.

Fig. 13: Threading the cable into the cable gland

→ Tighten the cable gland.

→ Connect the 4...20 mA output (see Fig. 14).

English

Page 22

22

Installation and wiring

Type 8222 ELEMENT neutrino

8.3.3. Assembling and wiring the female connector, order code 917116

See chap. "11. Spare parts and accessories"

1 2

→ Completely unscrew nut [1].

→ Remove the rear section of connector [2].

5,5

11,5

20

→ Thread the cable through the nut and the rear part of the

connector.

→ Strip 20 mm of the cable.

→ Cut the central wire (earth) so that its length is equal to

11.5 mm.

→ Expose 5.5 mm of the wires on the stripped cable.

→ Insert each wire into the appropriate pin (see pin allocation

in chap. 8.3.4).

→ Tighten the connector nut.

Fig. 15: M12 multi-pin connector (not provided)

English

Page 23

23

Installation and wiring

Type 8222 ELEMENT neutrino

8.3.4. Wiring a version with an M12 fixed

connector

1

2

3

4

V+ (12...36 V DC)

Not connected

0 V

Not connected

Fig. 16: Pin assignment of the M12 fixed connector

Pin of the M12 female cable

available as an accessory

(order code 438680)

Signal Colour of the wire

1 V+ brown

2 NC white

3 0 V blue

4 NC black

5

green/yellow or grey

The M12 fixed connector of the device is adjustable:

→ Unscrew the locknut.

→ Turn the fixed connector to the desired position, by 360° max. so

as not to twist the cables inside the housing.

→ Tighten the locknut using a spanner, while keeping the fixed con-

nector in the desired position.

12...36 V DC

+ -

+ -

1

2

3

4

4...20 mA input at

external instrument

Power supply

brown

green/yellow or

grey

blue

+ -

1

2

3

4

12...36 V DC

+ -

Power supply

brown

green/yellow or

grey

blue

4...20 mA input at

external instrument

Fig. 17: Possible connections of the 4...20 mA current output on a

version with M12 fixed connector

English

Page 24

24

Adjustment and commissioning

Type 8222 ELEMENT neutrino

Internal wiring of the M12 fixed connector on the terminal block

Terminals Colour of the wire connecting the fixed

connector to the terminal block

V+ red

0 V black

green

OUT1 grey

OUT2 orange

9. ADJUSTMENT AND

COMMISSIONING

9.1. Safety instructions

DANGER

Risk of injury due to electrical voltage.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Risk of injury due to the nature of the fluid.

▶ Respect the regulations on accident prevention and safety relat-

ing to the use of aggressive fluids.

WARNING

Risk of injury due to nonconforming adjustment.

Nonconforming adjustment could lead to injuries and damage the

device and its surroundings.

▶ The operators in charge of adjustment must have read and

understood the contents of these Operating Instructions.

▶ In particular, observe the safety recommendations and intended

use.

▶ The device/installation must only be adjusted by suitably trained

staff.

English

Page 25

25

Adjustment and commissioning

Type 8222 ELEMENT neutrino

WARNING

Danger due to nonconforming commissioning.

Nonconforming commissioning could lead to injuries and damage

the device and its surroundings.

▶ Before commissioning, make sure that the staff in charge

have read and fully understood the contents of the Operating

Instructions.

▶ In particular, observe the safety recommendations and intended

use.

▶ The device/installation must only be commissioned by suitably

trained staff.

9.2. Description of the connection box

The box contains the terminal block for electrical connection and

elements used for adjustment:

• a selector of the conductivity or temperature range associated

with the 4...20 mA output

• a green LED to indicate that the device is energized

• a red LED to:

- indicate the type of probe that is fitted on the device (see chap. 9.3)

- indicate a problem (see chap. 10.5)

• a push-button (not used).

Selector

Push-button (not

used)

Red LED

Green LED

Red mark

Fig. 18: Connection box

English

Page 26

26

Adjustment and commissioning

Type 8222 ELEMENT neutrino

9.3. Choosing the conductivity or

temperature range associated

with the 4...20 mA output

The following procedure is valid for the devices with a series

number equal or higher than 3000. See the name plate of

the device.

Upon power-up and every ten seconds afterwards, the red LED flashes:

• once if the device is equipped with a probe C=1

• twice if the device is equipped with a probe C=0,1

• three times if the device is equipped with a probe C=0,01

The selector (see Fig. 18) allows for choosing the conductivity

or temperature range associated with the 4...20 mA output . The

following tables give, depending on the cell constant and on the

position of the selector (from 0 to 9 and A to F, the uneven positions being marked by a full stop), the conductivity or temperature

range associated to the 4...20 mA output, the applied temperature

compensation and the measuring range of the recommended

conductivity.

The compensation graph “NaCl” is valid for the 10 to 90 °C temperature range and a concentration of 0,2 %.

Table 2 : Sensor C=0,01

Selector

position

4...20 mA

output range

Temperature

compensation

acc. to

Recommended

conductivity

measurement

range

0 (default

position)

0...20 µS/cm NaCl 2...20 µS/cm

1 0...20 µS/cm none 2...20 µS/cm

2 0...10 µS/cm NaCl 1...10 µS/cm

3 0...10 µS/cm none 1...10 µS/cm

4 0...5 µS/cm NaCl 0,5...5 µS/cm

5 0...5 µS/cm none 0,5...5 µS/cm

6 0...2 µS/cm NaCl 0,2...2 µS/cm

7 0...2 µS/cm none 0,2...2 µS/cm

8 0...1 µS/cm ultra pure

water

0,05...1 µS/cm

9 0...1 µS/cm none 0,05...1 µS/cm

A 0...0,5 µS/cm ultra pure

water

0,05...0,5 µS/cm

B 0...0,5 µS/cm none 0,05...0,5 µS/cm

C, D, E 0...0 µS/cm

1)

- -

F –40...+130 °C - -

English

Page 27

27

Adjustment and commissioning

Type 8222 ELEMENT neutrino

Table 3 : Sensor C=0,1

Selector

position

4...20 mA

output range

Temperature

compensation

acc. to

Recommended

conductivity

measurement

range

0 (default

position)

0...200 µS/cm NaCl 20...200 µS/cm

1 0...200 µS/cm none 20...200 µS/cm

2 0...100 µS/cm NaCl 10...100 µS/cm

3 0...100 µS/cm none 10...100 µS/cm

4 0...50 µS/cm NaCl 5...50 µS/cm

5 0...50 µS/cm none 5...50 µS/cm

6 0...20 µS/cm NaCl 2...20 µS/cm

7 0...20 µS/cm none 2...20 µS/cm

8 0...10 µS/cm NaCl 1...10 µS/cm

9 0...10 µS/cm none 1...10 µS/cm

A 0...5 µS/cm NaCl 0,5...5 µS/cm

B 0...5 µS/cm none 0,5...5 µS/cm

C 0...2 µS/cm NaCl 0,5...2 µS/cm

D 0...2 µS/cm none 0,5...2 µS/cm

E 0...0 µS/cm

1)

- -

F –40...+130 °C - -

1)

When these positions are selected, the 4...20 mA current output is

not used. Its value is always 4 mA.

Table 4 : Sensor C=1

Selector

position

4...20 mA

output range

Temperature

compensation

acc. to

Recommended

conductivity

measurement

range

0 (default

position)

0...10 mS/cm NaCl 1...10 mS/cm

1 0...10 mS/cm none 1...10 mS/cm

2 0...5 mS/cm NaCl 0,5...5 mS/cm

3 0...5 mS/cm none 0,5...5 mS/cm

4 0...2 mS/cm NaCl 0,2...2 mS/cm

5 0...2 mS/cm none 0,2...2 mS/cm

6 0...1 mS/cm NaCl 0,1...1 mS/cm

7 0...1 mS/cm none 0,1...1 mS/cm

8 0...500 µS/cm NaCl 50...500 µS/cm

9 0...500 µS/cm none 50...500 µS/cm

A 0...200 µS/cm NaCl 20...200 µS/cm

B 0...200 µS/cm none 20...200 µS/cm

C 0...100 µS/cm NaCl 10...100 µS/cm

D 0...100 µS/cm none 10...100 µS/cm

E 0...50 µS/cm NaCl 5...50 µS/cm

F –40...+130 °C - -

→ Position the red mark of the selector on the desired range (see

Fig. 18). In the example in Fig. 18, the selector is placed on

position 5.

English

Page 28

28

Maintenance and troubleshooting

Type 8222 ELEMENT neutrino

9.4. Checking the cell constant of the

conductivity sensor

Each sensor is delivered calibrated.

Take the temperature compensation into account.

The following procedure makes it possible to check the exactness of

the device:

→ Prepare a calibration solution adapted to your process or the

sensor (see chap. "11. Spare parts and accessories").

→ Place the sensor into the calibration solution.

→ Wait for the temperature to stabilise.

→ Check the exactness of the measured value transmitted by the

transmitter to the acquisition system (PLC,...).

→ If necessary, correct the measure on the acquisition system

(PLC, ...).

10. MAINTENANCE AND

TROUBLESHOOTING

10.1. Safety instructions

DANGER

Risk of injury due to high pressure in the installation.

▶ Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Risk of injury due to the nature of the fluid.

▶ Respect the regulations on accident prevention and safety relat-

ing to the use of dangerous fluids.

Risk of injury due to the high temperature of the fluid.

▶ Use safety gloves to handle the device.

English

Page 29

29

Maintenance and troubleshooting

Type 8222 ELEMENT neutrino

WARNING

Risk of injury due to nonconforming maintenance.

▶ Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

▶ Ensure that the restart of the installation is controlled after any

interventions.

10.2. Device and conductivity sensor

maintenance

• During cleaning of the sensor, take care not to scratch its

surface.

• Store the sensor dry.

The device can be cleaned with a cloth dampened with water or a

detergent compatible with the materials the device is made of.

→ Regularly check if the conductivity sensor is dirty; clean it if nec-

essary using a compatible product.

Please feel free to contact your Bürkert supplier for any additional

information.

10.3. Replacing the cover seal on the

connection box

→ Using a screwdriver

with a suitable head,

turn the latch to

the unlock position

to unlock the connection box.

→ Unscrew the cover

by hand.

English

Page 30

30

Maintenance and troubleshooting

Type 8222 ELEMENT neutrino

out 2

out 1

0V

+V

→ On a version with

cable gland, locate

the colours of the

wires connected to

the terminal block.

→ Disconnect the

wires from the

terminal block by

pressing the plugs

on the terminal block

with a screwdriver.

B

→ Remove the worn

seal "B" from the

cover.

→ Put the new seal "B"

in place in the cover.

→ Reconnect the wires

to the terminal block

(for a version with

M12 fixed connector, see table,

chap. 8.3.4 for the

references).

→ Put the cover in

place.

→ Fully tighten the

cover by hand to

guarantee tightness.

→ Using a screwdriver

with a suitable head,

turn the latch to the

lock position to lock

the cover.

Fig. 19: Replacing the cover seal on the connection box

English

Page 31

31

Maintenance and troubleshooting

Type 8222 ELEMENT neutrino

10.4. Replacing the seal of the G 3/4''

threaded sensor

C

→ Remove the worn seal "C"

without damaging the groove

nor the threads.

→ Put the new seal "C" in place

in the groove.

English

Page 32

32

Maintenance and troubleshooting

Type 8222 ELEMENT neutrino

10.5. If you encounter problems

Red LED status 4...20 mA output value Possible cause Recommended action

flashes (once per

second)

4...20 mA Fluid temperature outside

the operating range

(–20...+100 °C).

→ Check the fluid temperature.

→ Put the fluid temperature back to within the operating

range (–20...+100 °C).

ON 22 mA • Connection with temper-

ature probe interrupted.

• Parameters of the device

cannot be read.

→ Power off the device.

→ Power on the device.

→ If the fault persists, contact your Bürkert retailer.

flashes (once to three

times every 10 s)

4 mA, whatever the

measured conductivity or

temperature value.

The position of the selector of

the electronic board may be

incorrectly set.

→ Adjust the position of the selector depending on the

fluid conductivity (or temperature): see chap. 9.3.

flashes (once to three

times every 10 s)

20 mA, whatever the

measured conductivity or

temperature value.

The position of the selector of

the electronic board may be

incorrectly set.

→ Adjust the position of the selector depending on the

fluid conductivity (or temperature): see chap. 9.3.

English

Page 33

33

Spare parts and accessories

Type 8222 ELEMENT neutrino

11. SPARE PARTS AND

ACCESSORIES

CAUTION

Risk of injury and/or damage caused by the use of unsuitable

parts.

Incorrect accessories and unsuitable replacement parts may

cause injuries and damage the device and the surrounding area.

▶ Use only original accessories and original replacement parts

from Bürkert.

Spare part Order code

EPDM seal for the G 3/4'' external threaded

sensor

561955

EPDM seal for the tightness between the

cover and the housing

561752

Accessories Order code

5-pin female M12 connector, to be wired 917116

5-pin female M12 female connector, moulded

on shielded cable (2 m)

438680

Calibration solution, 300 ml, 5 µS 440015

Calibration solution, 300 ml, 15 µS 440016

Calibration solution, 300 ml, 100 µS 440017

Calibration solution, 300 ml, 706 µS 440018

Calibration solution, 300 ml, 1413 µS 440019

12. PACKAGING, TRANSPORT

NOTICE

Damage due to transport

Transport may damage an insufficiently protected device.

▶ Transport the device in shock-resistant packaging and away

from humidity and dirt.

▶ Do not expose the device to temperatures that may exceed the

admissible storage temperature range.

▶ Protect the electrical interfaces using protective plugs.

13. STORAGE

NOTICE

Poor storage can damage the device.

▶ Store the device in a dry place away from dust.

▶ Storage temperature: –10...+60 °C.

English

Page 34

34

Disposal of the device

Type 8222 ELEMENT neutrino

14. DISPOSAL OF THE DEVICE

→ Dispose of the device and its packaging in an environmentally-

friendly way.

NOTICE

Damage to the environment caused by products contaminated by fluids.

▶ Keep to the existing provisions on the subject of waste disposal

and environmental protection.

English

Page 35

Page 36

www.burkert.com

Loading...

Loading...