Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

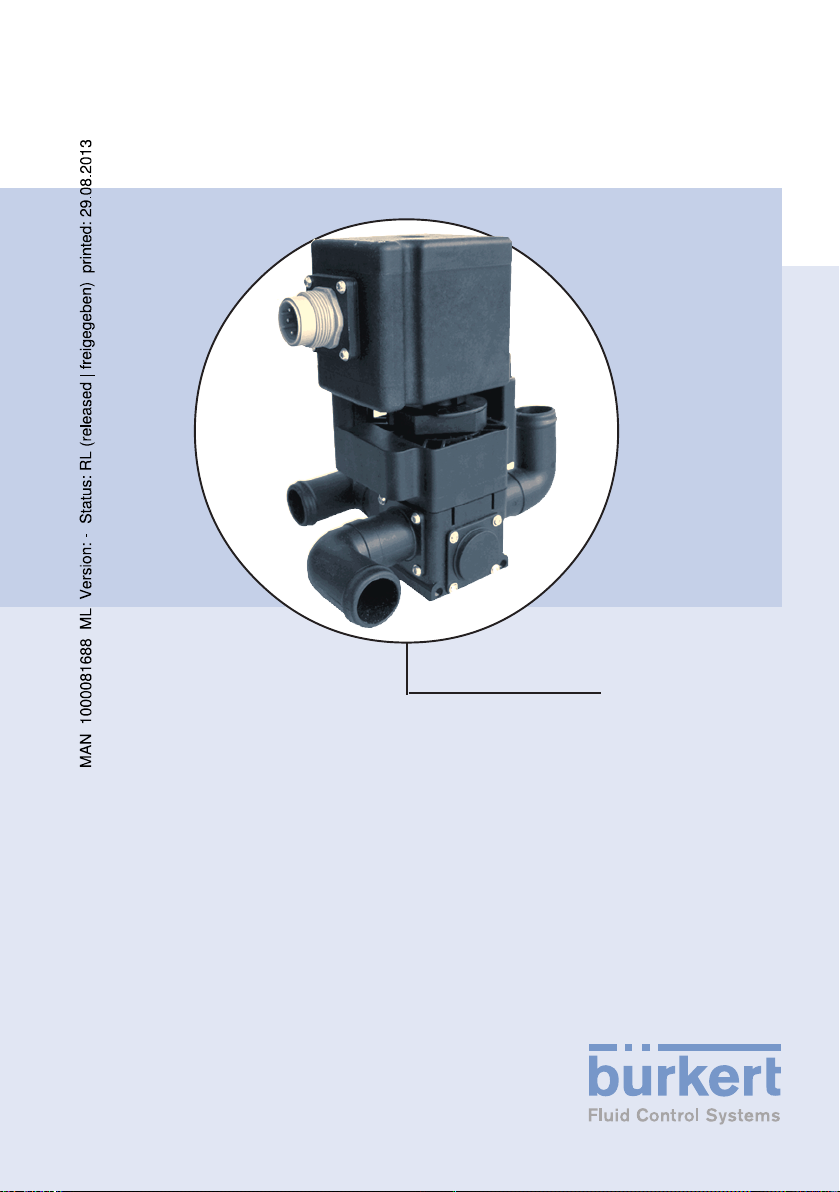

Type 0258

Modular 2 and 3-way motor control valve

Modulares 2- und 3-Wege-Motorregelventil

Vanne de régulation motorisée

modulaire à 2 et 3 voies

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2004 Bürkert Werke GmbH & Co. KG

Operating Instructions 0601/00_EU-EN_00804858

Page 3

Modular 2 and 3-way

motor control valve

GENERAL NOTES ....................................................................................... 3

Symbols ...................................................................................................... 3

Trademarks ................................................................................................ 3

Safety notes .............................................................................................. 3

Application Guidelines............................................................................ 4

Scope of delivery ..................................................................................... 4

Warranty conditions ................................................................................ 4

Approval ..................................................................................................... 5

SYSTEM DESCRIPTION ............................................................................ 6

Application area ....................................................................................... 6

Design......................................................................................................... 6

Function ..................................................................................................... 6

Control functions of the valves............................................................. 7

Flow characteristic curves ..................................................................... 7

Marking....................................................................................................... 8

Basic module ............................................................................................ 9

Filter module ....................................................................................................... 9

2-way flow valve ................................................................................................. 9

3-way mixing or distribution valve ............................................................... 10

Check valve ...................................................................................................... 10

Shut-off valve ................................................................................................... 10

english

TECHNICAL DATA ...................................................................................... 11

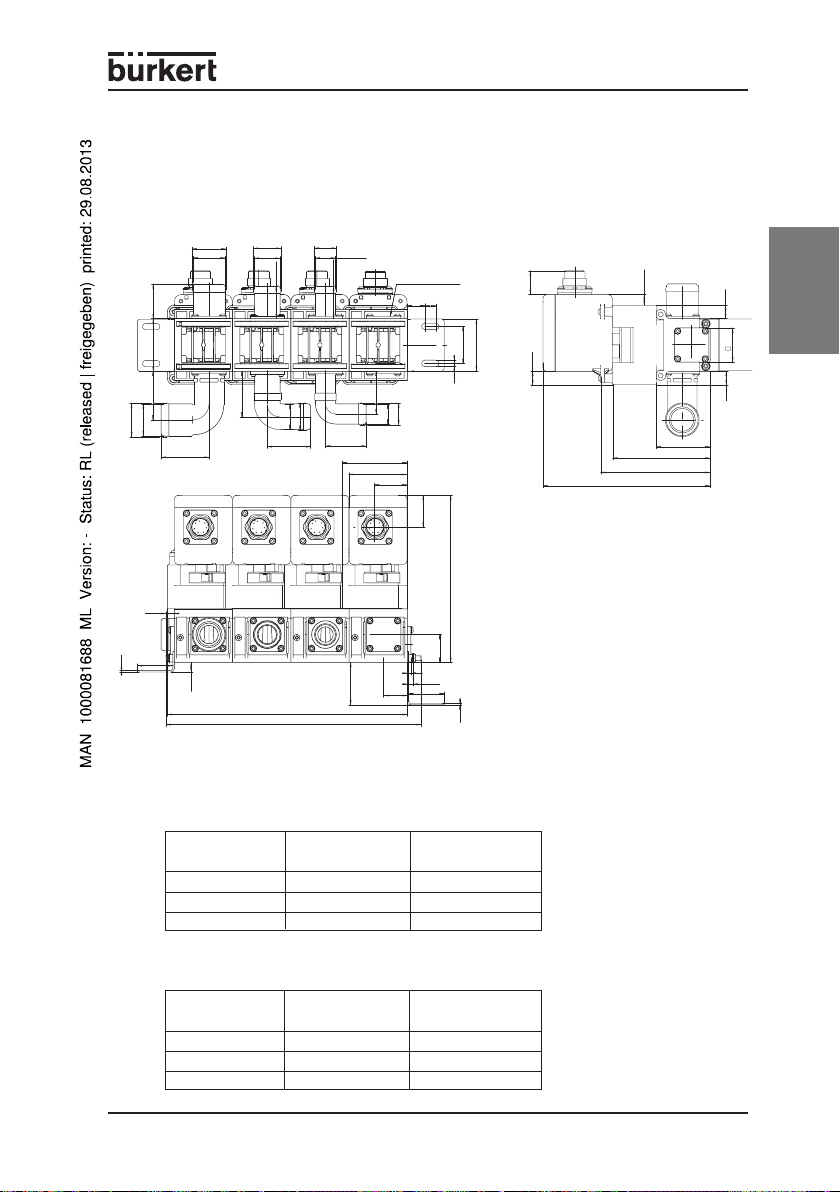

Dimensions .............................................................................................. 11

4-way block ...................................................................................................... 11

Port connections (hose)............................................................................... 11

General data ........................................................................................... 12

Mechanical data .................................................................................... 12

Electrical data.........................................................................................13

Electrical connections .......................................................................... 14

Plug configuration Mod ................................................................................ 14

Plug configuration LC .................................................................................... 14

OPERATING AND DISPLAY ELEMENTS ............................................. 15

Emergency manual override ................................................................15

0258 - 1

Page 4

Optical position indicator..................................................................... 15

PUTTING INTO OPERATION...................................................................16

Safety notes ............................................................................................ 16

Installation ............................................................................................... 16

OPERATION AND FUNCTION ................................................................ 16

Safety notes ............................................................................................ 16

english

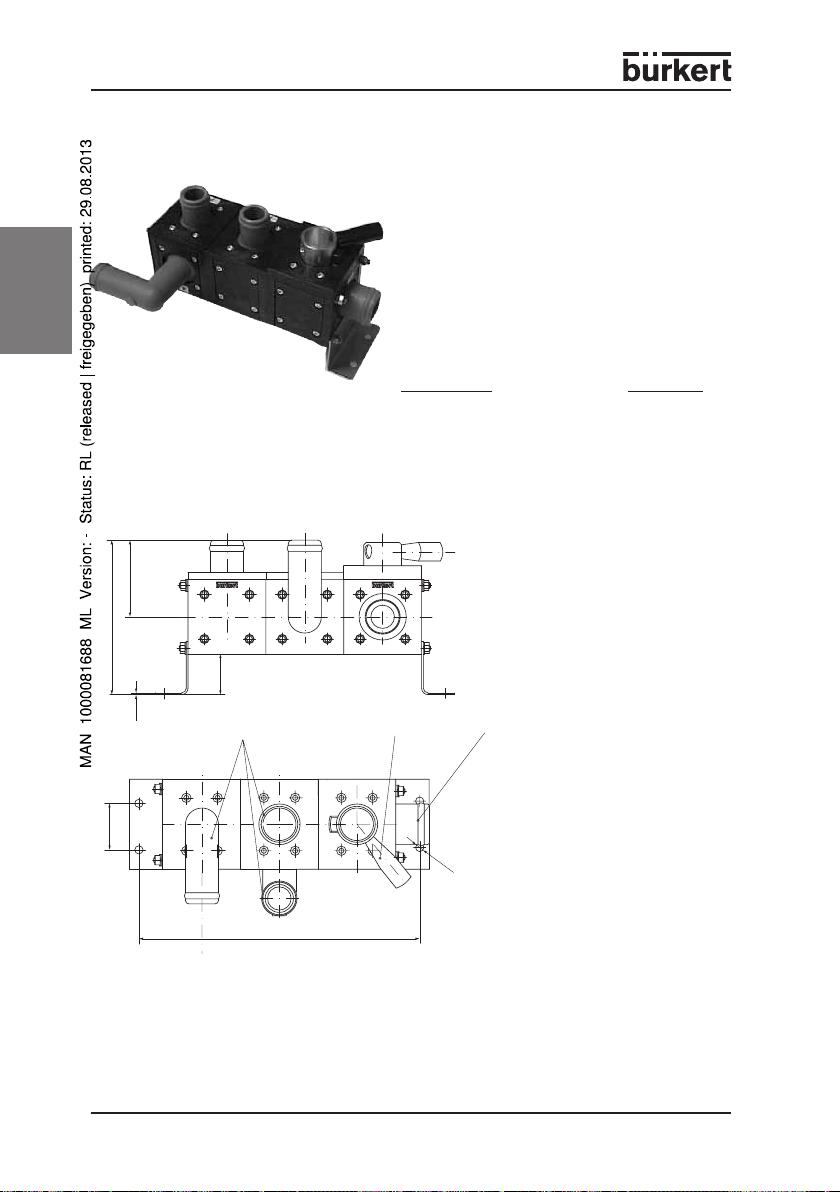

ACCESSORY ............................................................................................. 17

MAINTENANCE ........................................................................................... 19

TRANSPORT AND STORAGE................................................................ 20

DISPOSAL ................................................................................................... 20

Modular filter type 250, solo ............................................................... 17

Dimensional drawings for modular filter type 250, solo ............... 17

3-way check valve block with shut-off valve .................................. 18

Dimensional drawings for 3-way check valve block

with shut-off valve .................................................................................18

Safety notes ............................................................................................ 19

Service ..................................................................................................... 19

Service intervals..................................................................................... 19

Correction of faults ............................................................................... 19

2 - 0258

Page 5

GENERAL NOTES

Symbols

The following symbols are used in these operating instructions:

Marks a work step that you must carry out.

ATTENTION!

NOTE

marks notes on whose non-observance your health or the

functioning of the device will be endangered.

marks important additional information, tips and

recommendations.

Trademarks

Ultramid® is a registered Trademark of BASF.

Grivory® is a registered Trademark of EMS-Grivory.

Safety notes

Please observe the notes in these operating instructions together with the

conditions of use and permitted data that are specified in the data sheet, in

order that the devices will function perfectly and remain operable for a long

time:

• Keep to standard engineering rules in planning the use of and operating

the device!

• Only use the device as intended, for the application agreed with the

Bürkert company.

• Interference with the device is only allowed by specialist personnel using

suitable tools!

• Observe the current regulations on accident prevention and safety for

electrical devices during operation, maintenance and repair of the device!

• Before interfering with the system, always switch off the voltage!

• Avoid undue mechanical force and stress when installing the motor control

valve and when connecting the lines to the hose connections.

• Take suitable precautions to prevent unintended operation or damage by

unauthorized action!

• Only use the device in its original configuration!

• On non-observance of this note and unauthorized interference with the

device, we will refuse all liability and the guarantee on device and

accessories will become void.

english

0258 - 3

Page 6

Application Guidelines

The modular 2 and 3-way motorized regulating valve of Type 0258 is

preferably used as a control element for hot water or coolant circuits in buses,

goods vehicles, floating and rail vehicles, as well as in machine tool

construction. The configuration that is required for your special application

will be drawn up by our Field Service employees. Only use the Type 0258

modular 2 and 3-way motor control valve for the applications agreed with the

Bürkert company. Any other use will have to be agreed with the Customer

Service of the Bürkert company.

english

Scope of delivery

Immediately after receipt of a shipment, make sure that the contents are

undamaged and match the scope of delivery stated on the packing slip.

In case of any discrepancies, please contact our Call Center:

or your local Bürkert Sales Centre immediately.

Bürkert Fluid Control Systems

Call Center

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

Fax: 07940-10448

E-mail: info@de.buerkert.com

Warranty conditions

This document contains no warranty statements. In this connection we refer

to our general sales and business conditions. A prerequisite for validity of the

warranty is use of the device als intended with observance of the specified

conditions of use.

ATTENTION!

4 - 0258

The warranty only extends to the freedom from faults of the

motor control valve and its components.

No liability will be accepted for consequential damage of any

kind that may arise from failure or malfunctioning of the

device.

Page 7

Approval

Devices that carry the e1 marking have been approved by the Federal Office

for Motorised Transport under the type approval number

e1*72/245*95/54*3187*00

and will be brought into circulation with the indicated approval designation.

1

e

023187

You can obtain an excerpt from the type approval from the address below

Bürkert Werke GmbH & Co KG

Zulassungsbeauftragter

Christian Bürkert Str.13-17

74653 Ingelfingen

english

0258 - 5

Page 8

SYSTEM DESCRIPTION

Application area

The modular 2 and 3-way motorized regulating valve of Type 0258 is

preferably used as a control element for hot water or coolant circuits in buses,

goods vehicles, floating and rail vehicles, as well as in machine tool

construction.

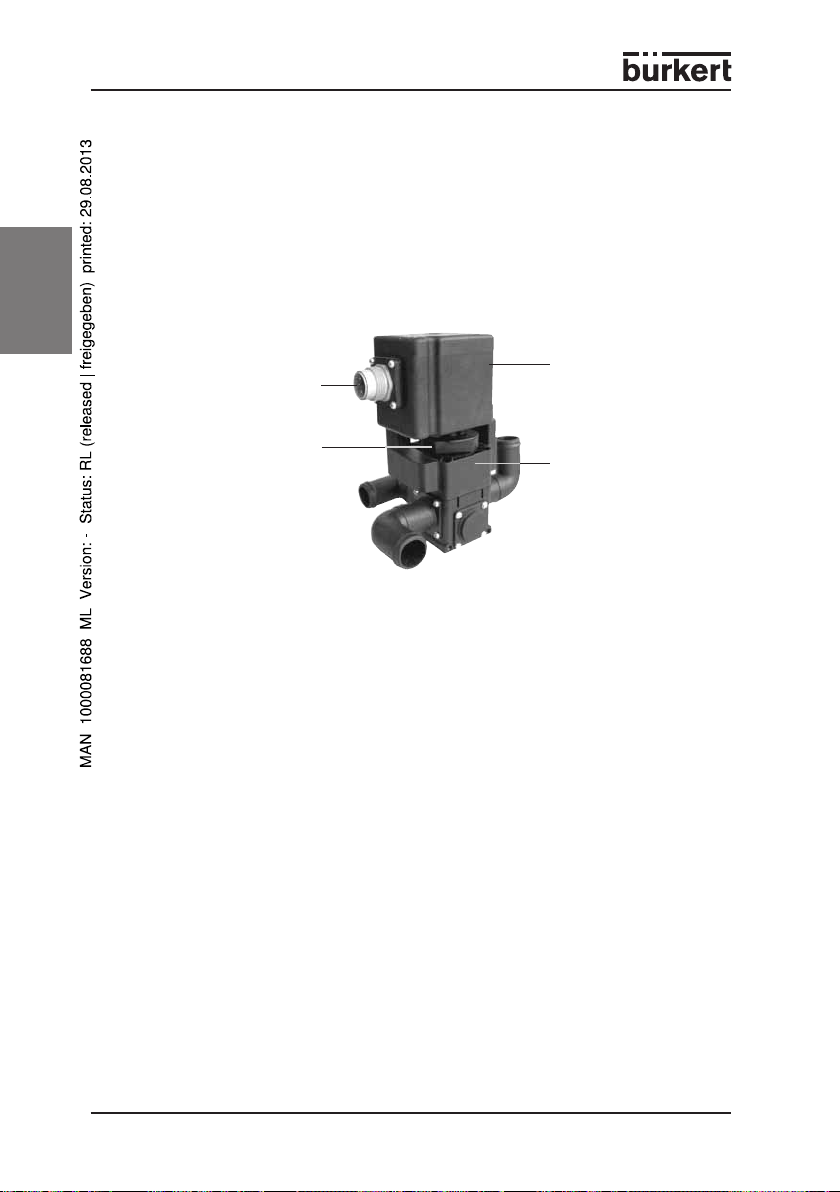

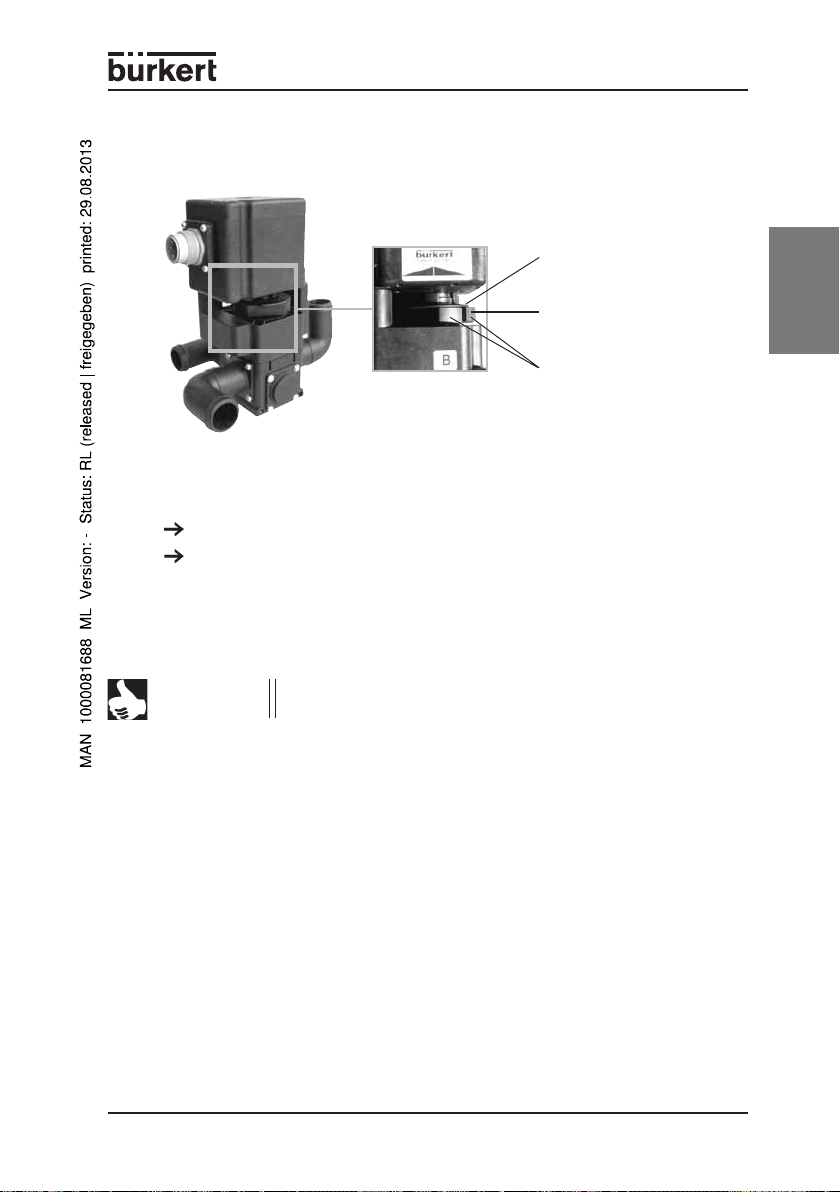

Design

english

Emergency manual override

(optical position indicator)

The Type 0258 motorised regulating valve has a modular design, and is

mounted individually or assembled into blocks. Up to 4 valves can be

combined in one block. It can be used as either 2 or 3-way valve, as desired,

and contains ceramic sealing elements, while the valve body is made from

plastic.

The electrical rotary actuator with d.c. motor that is used here consists of

either a maintenance-free flat drive1) (LC) with an AMP plug, or of a powerful,

maintenance-free spur drive2) (Mod) with a magnetic clutch coupling and

Hirschmann plug (options possible), an emergency manual override with an

optical position indicator and one or more valve modules.

In connection with the emergency manual override, the drives have a rotation

angle of 180°. The drives may not be operated without emergency manual

override, as the position feedback can otherwise become maladjusted.

1)

2)

Electrical connection

(AMP or circular

connector according

to DIN 43651,

Hirschmann)

Flat drive (LC): referred to as "LC" in the following text

Spur drive (Mod): referred to as "Mod" in the following text

Motor drive powerful spur drive with

magnetic coupling (Mod) or

flat drive (LC), with

position feedback in each

case

Valve module

Function

By means of a shaft, the drive moves a regulating disk over a fixed disk made

from ceramic oxide, and thereby alternately closes the valve seats A and B

with a sliding transition.

The flow values (2-way), mixing or distribution ratios (3-way) are continually

variable depending on the rotation angle.

The position feedback takes places using a potentiometer.

6 - 0258

Page 9

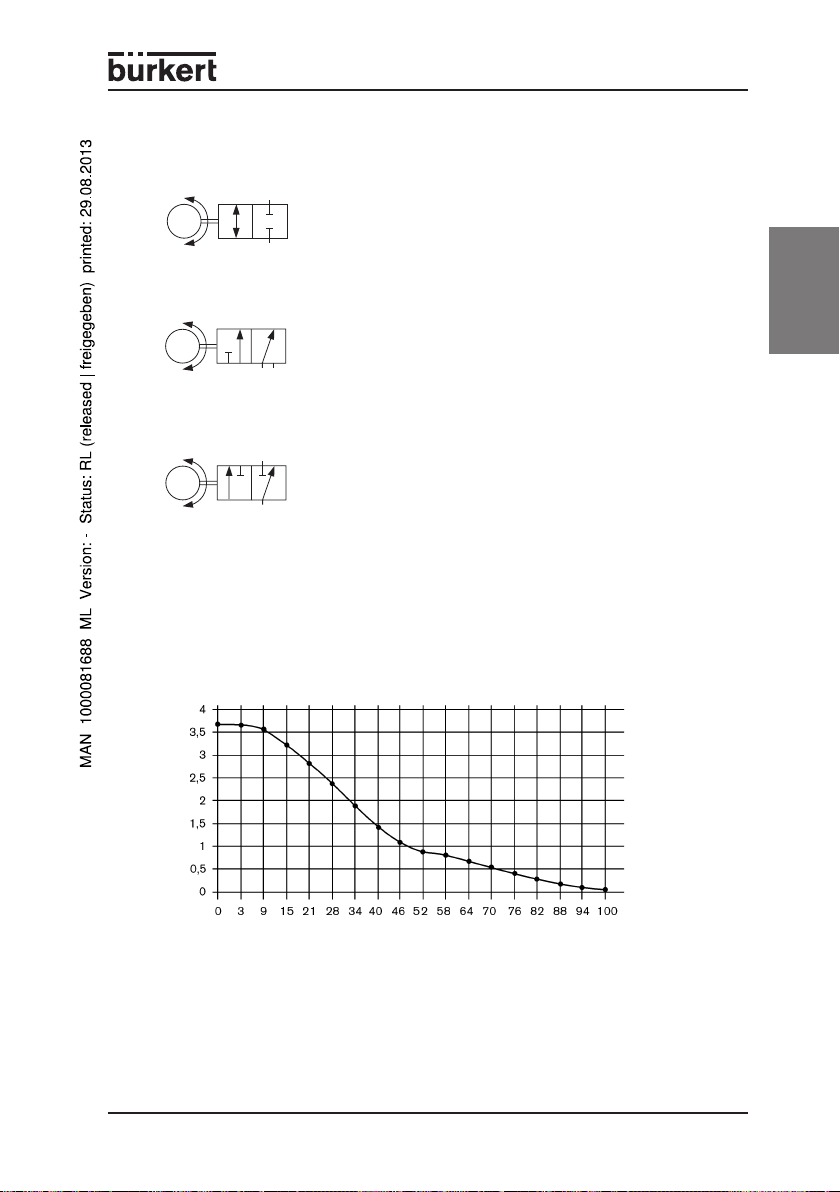

Control functions of the valves

Control function I

A

2-way valve for continuous control of the flow rate in

M

outlet port A,

motor-driven, holds position with no power

P

Control function E

P

3-way valve for continuous mixing of the incoming flows A

M

and B to the port P,

motor-driven, holds position with no power

A B

Control function F

B

A

3-way valve for continuous distribution of the incoming

M

flow P to the outlet ports A and B,

motor-driven, holds position with no power

P

Flow characteristic curves

The flow

shown in the following diagrams. The Kv set-value of 1 m 3 is being prepared.

1)

characteristic curves for the Kv set-values of 3 m3 and 6 m3 are

english

Flow characteristic curves2) Kv-Sollwert = 3 m

/h]

3

Kv value [m

Potentiometer3) [%]

1)

Flow: Kv value water [m³/h],

port.

2)

only Mod drive type

3 )

in relation to the total stroke of the potentiometer = 100 %

4 )

Pressure quoted in [bar]: over-pressure with regard to atmospheric pressure

measurement at +20 °C, 1 bar

3

3 )

pressure at valve inlet port and free outlet

0258 - 7

Page 10

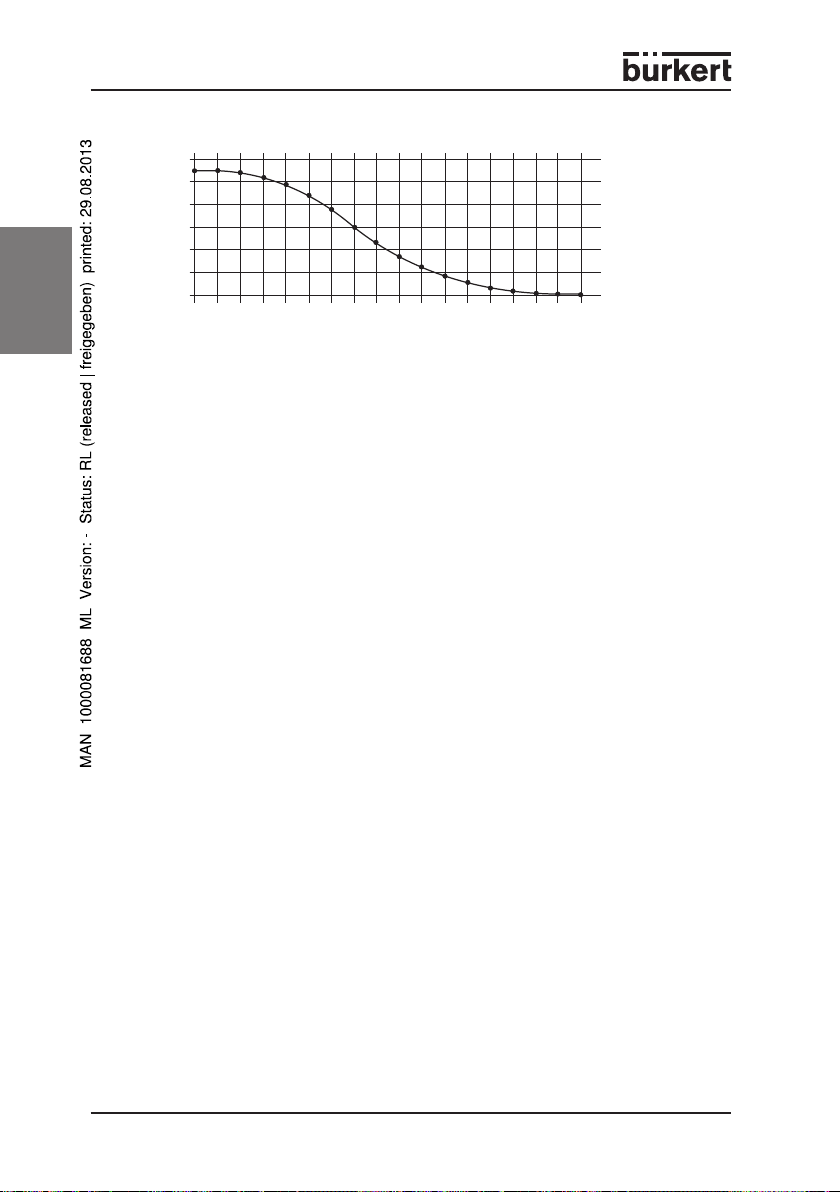

Flow characteristic curves1) Kv set-value = 6 m

english

1)

2)

Marking

The motorised regulating valve is marked with two labels.

The rating label for the complete device (valve block) is located on the lower

left side. The upper line gives the device specification key "SYST-0258", while

the lower line gives the identity number and the encoded date of

manufacture.

Every drive also has its own rating plate with the following content:

• Specification key/Drawing No. e.g.: 0258-G665-205-00,

• Voltage and type of voltage: 24 V DC,

• Power consumption: e.g. 3.0 W,

• Rotation angle: e.g.: 28 s / 180°,

• Rated pressure: e.g.: 0 ... 2.5 bar,

• Identity number and the encrypted date of construction.

6

6

/h]

3

5

5

4

4

3

3

Kv value [m

2

2

1

1

0

0

0

9

0

9

33

33

45

57 70 82 94

45

21

21

57 70 82 94

Potentiometer2) [%]

only Mod drive type

in relation to the total stroke of the potentiometer = 100 %

3

8 - 0258

Page 11

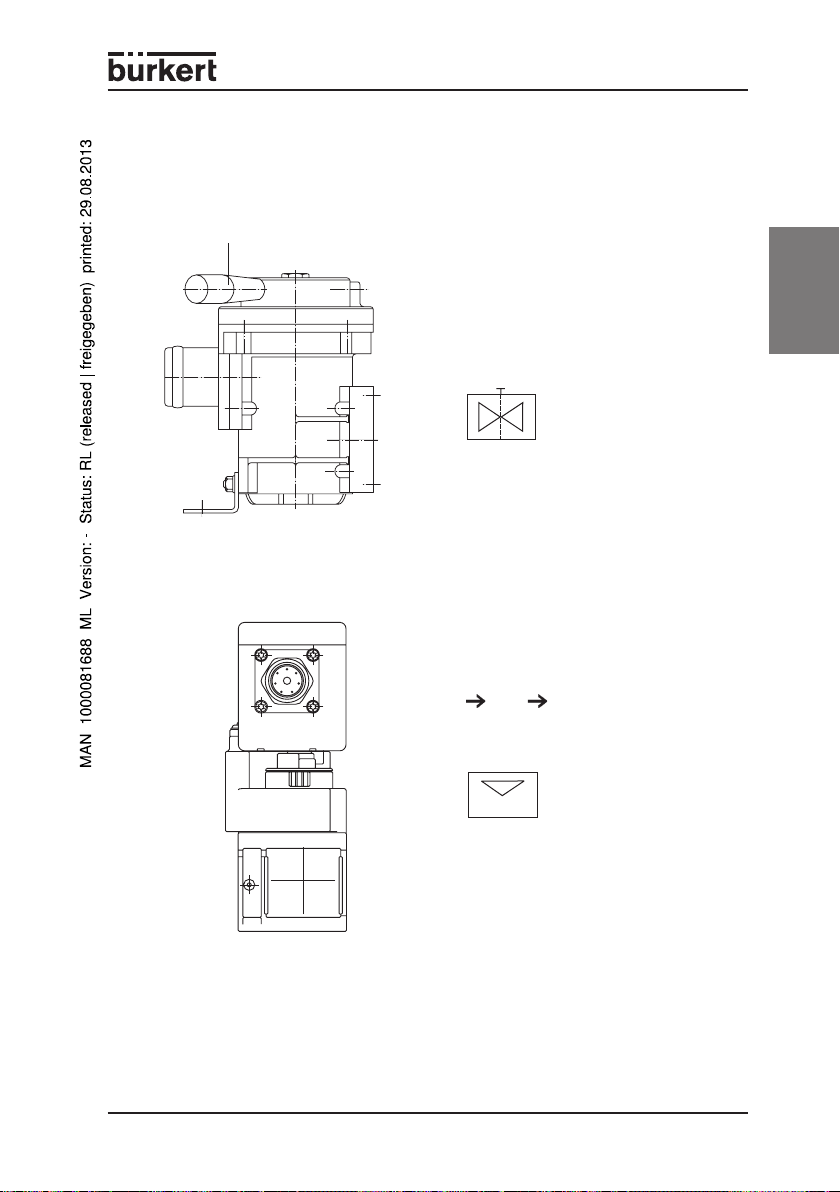

Basic module

4

2

1

3

You can use all basic modules individually or in a block.

Filter module

manual lever

Description

The filter module can be shut off by

hand. Note the direction of flow.

As an option, the filter module can be

fitted with a magnetic insert.

Block symbol

english

2-way flow valve

4

Description

The 2-way flow valve is continuously

operated.

The direction of flow:

P A, P B

Block symbol

2

0258 - 9

Page 12

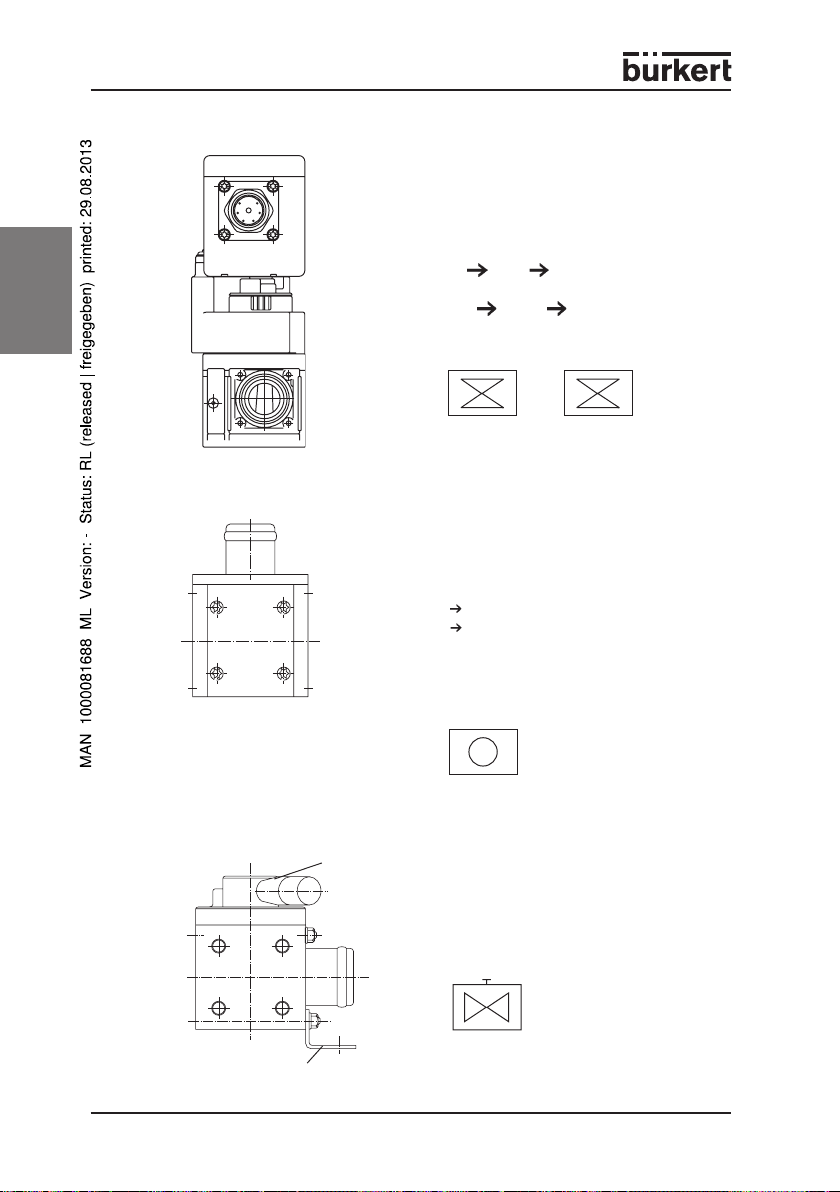

3-way mixing or distribution valve

english

Check valve

Description

The 3-way mixing or distribution valve is

continuously operated.

The directions of flow

• in the distribution valve:

P A, P B

• in the mixing or distribution valve:

P1 A, P2 A

Block symbols

1

4

2

E

3

1

4

2

F

3

Mixing Distribution

Description

The check valve has a collection

function. Manual override is possible.

Manual lever at the left stop:

P A closed

P B open

Note the direction of flow.

Block symbol

1

4

R

2

3

Shut-off valve

10 - 0258

Mounting angle

Hand lever

Description

The shut-off valve is operated

manually. The direction of flow is freely

selectable.

Block symbol

4

2

Page 13

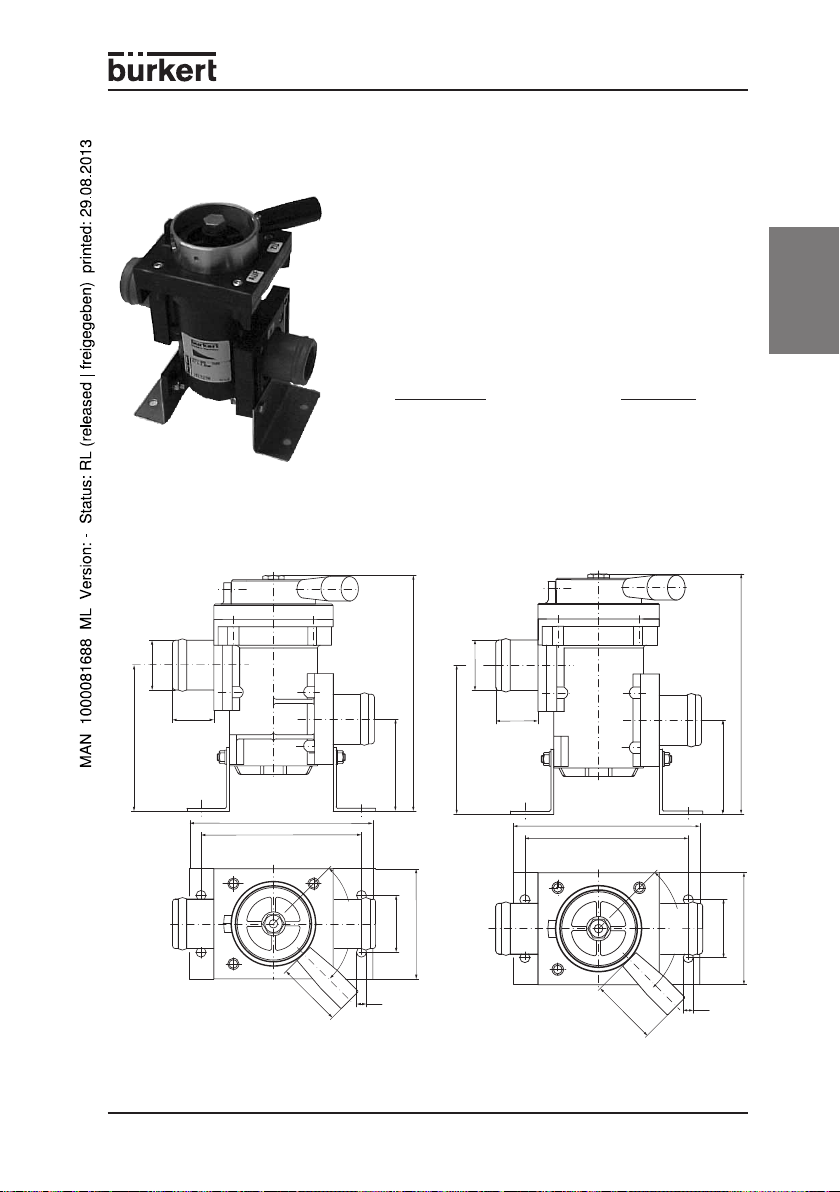

TECHNICAL DATA

Dimensions

4-way block

Ø36,5

Ø34,5

TU35

37,6

57

TU35

52,5

Ø 34,5

Ø 36,5

51,85

8,88

38,5

1,5

49,1

10,5

Ø29,8

Ø27,8

35,6

TU28

TU28

47

259,5

Ø 27,8

276

Ø 29,8

Ø23,4

35,6

Ø

TU22

TU22

44

21,8

70,1

46,1

63

35,2

Abschlussplatte

19

Ø23,8

Ø21,8

34,5

12

40

7

25,7

56

14,44

180,7

11,44

105,2

118,2

58,2

14,5

14,5

37

english

This assembly drawing is

( 180,7 )

an overview of the different

constructive possibilities of

the motorised control valve.

30

4

25,5

6,4

38,5

1,5

46

Port connections

Hose connection, straight

DesignationDesignation

Designation

DesignationDesignation

TU22L 22 47.5

TU28L 28 50.5

TU35L 35 53.85

Hose connection, angled

DesignationDesignation

Designation

DesignationDesignation

TU22 22 37

TU28 28 37

TU35 35 39

DiameterDiameter

Diameter

DiameterDiameter

(mm)(mm)

(mm)

(mm)(mm)

DiameterDiameter

Diameter

DiameterDiameter

(mm)(mm)

(mm)

(mm)(mm)

Installed heightInstalled height

Installed height

Installed heightInstalled height

(mm)(mm)

(mm)

(mm)(mm)

Installed heightInstalled height

Installed height

Installed heightInstalled height

(mm)(mm)

(mm)

(mm)(mm)

0258 - 11

Page 14

General data

Ambient temperature -20 ... +80 °C

Operating temperature -20 ... +95 °C

Storage temperature 0 ... +60 °C

Relative humidity max. 80 %

Weight approx. 900 g / module,

english

Duty cycle

Protection class IP 65

Approval Type approval from Federal Office for Motorised

Mechanical data

Materials

Media

Port connection Tube hose connections,

Motor torque LC nom./max.: 0.35 Nm / 0.7 Nm

Block assembly with mounting plates and adapters

Fixation with fixing angles and tie rods

Installation position any, preferably with drive above

Basic module 2- and 3-way valves

depending on the design

1) 2)

Valve body Ultramid® T KR 4355 G5 black,

Valve internals Ultramid® T KR 4355 G5 black,

Seal material FKM / Al2O3

3)

Media temperature -20 ... +95 °C

Viscosity max. 40 mm²/s

continuous operation ED 100 %

e1*72/245*95/54*3187*00

Grivory® HTV black

Grivory® HTV black and VA

neutral gases and liquids, e.g., air, water,

glycol, cooling water with additives

either TU 22, TU28, TU35,

straight or angled

Mod. nom./max.: 1.2 Nm / 2.1 Nm

Check valve

Filter module, lockable

Hand shut-off valve

4)

12 - 0258

Page 15

Electrical data

Direction of rotation depending on polarity

Rotation time LC: approx. 4 ... 8 s at 24 V DC

for 100%

Electrical connection LC: for AMP socket 967066-1

Position feedback LC: 5 kΩ lin

Resistance change ca. 55 ... 75 % (at 100 % rotation path)

of potentiometer

max. slider current Standard design:

of potentiometer Conduction plastic design:

max. power in LC: 7.5 V (Potentiometer terminals 1 and 3)

potentiometer Mod: 10 V (Potentiometer terminals 4 and 6)

max. power in LC: 0.25 W / 40 °C

potentiometer

Rated operating 24 V DC

voltage

Voltage tolerance ±10 %

Power consumption LC: 4.8 W

5)

Mod: approx. 28 s at 24 V DC

and AMP contact 962885-1

Mod: circular plug according to DIN 43651

(6-pole and earth)

Mod: Potentiometer 1 kΩ linear (optional 5 kΩ

linear and models in conducting plastic)

Protective resistance Rs = 6.8 kΩ

≤≤

≤4 mA

≤≤

8)

))

9

)

))

Mod: 0.5 W / 40 °C

≤≤

≤65 µA

≤≤

Mod: 3 W

6)

english

7)

LCLC

NOTE LCLC

LC: Max. number of operations (at nominal torque) = 100,000

under laboratory conditions, 20 °C and 1 s drive time in each

case over the complete adjustment range.

ModMod

Mod: Max. number of operations = 400,000 under laboratory

ModMod

conditions, 20 °C and 1 s drive time in each case over the

complete adjustment range.

1 )

Pause time with change of rotation 0.4 s.

2 )

Increased wear with continuous operation of the motor.

3 )

limited gas seal

4 )

Impurities (e.g., fluff etc.) should be pre-filtered, otherwise the function of the valve could be impaired.

5 )

At 24 V DC smoothed. Pulsed drive increases the rotation time (see also 8) )

6 )

dependent on pressure/load

7 )

Higher currents considerably reduce the service life!

8 )

Higher temperatures limit the max. power loss of the potentiometers.

9 )

min. pulse length (the min. pulse length increases at no-load/ at pressure/load):

for LC: approx. 100 ms / for Mod.: approx. 100 ms

0258 - 13

Page 16

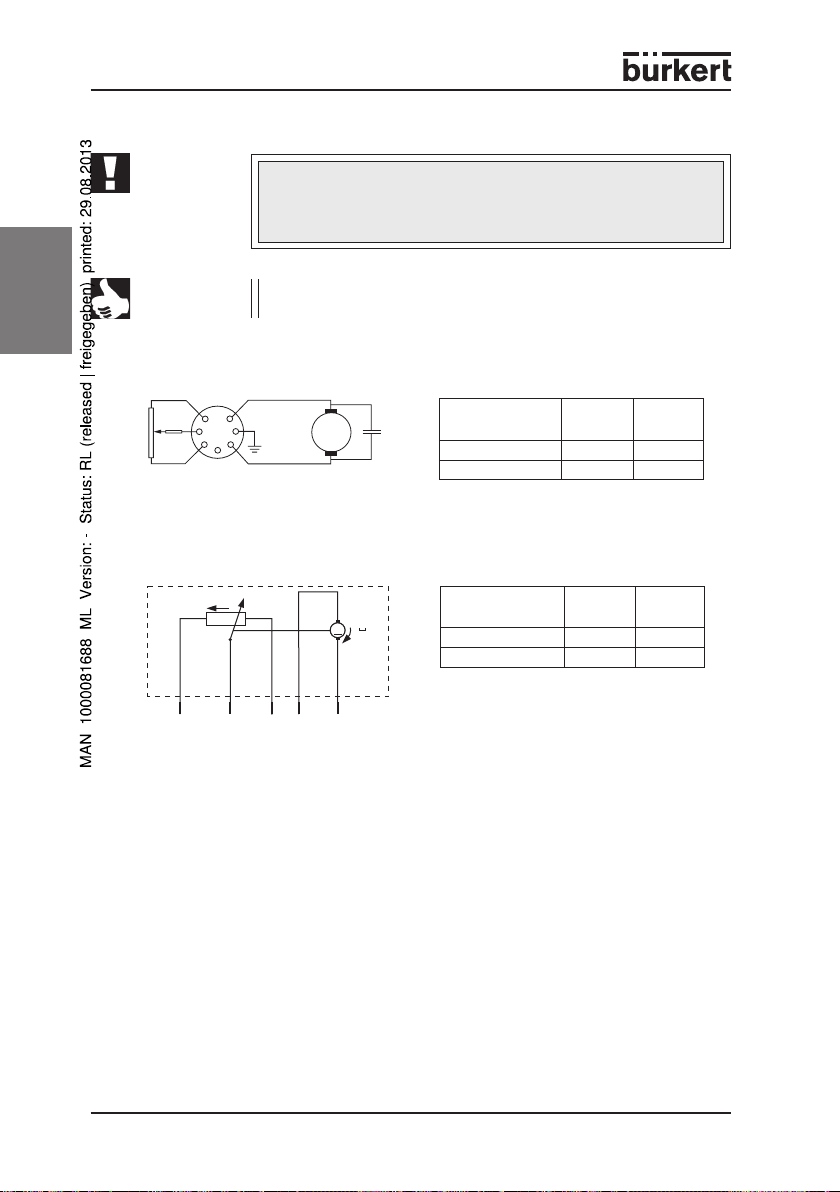

Electrical connections

ATTENTION!

NOTE

english

Plug configuration Mod

Rs = 6.8 kΩ

P1 = 1.0 kΩ / 5.0 kΩ

Plug configuration LC

P1

6

1

5

2

4

R

3

s

1234

The operating voltage and frequency of the electrical supply

must be the same as quoted on the rating plate of the drive.

The voltages and currents must not lie outside the permitted

operating range.

With a pulsed drive and nominal voltage, the pulse duration

should not fall below 100 ms.

PolePole

Pole

PolePole

M

configurationconfiguration

configuration

configurationconfiguration

left running plus minus

Pin 1Pin 1

Pin 1

Pin 1Pin 1

Pin 2Pin 2

Pin 2

Pin 2Pin 2

right running minus plus

PolePole

Pole

PolePole

configurationconfiguration

configuration

M

M

configurationconfiguration

left running minus plus

Pin 4Pin 4

Pin 4

Pin 4Pin 4

Pin 6Pin 6

Pin 6

Pin 6Pin 6

right running plus minus

65

P1 = 5.0 kΩ

14 - 0258

Page 17

OPERATING AND DISPLAY ELEMENTS

Emergency manual override

Coupling bell, firmly

connected to the

drive

Button, separates

the drive from the

valve when pressed

in

Emergency manual

override, adjustable,

connected to the

rotatable valve

With the emergency manual override, you can adjust the valve regardless of

the position of the drive.

Press the button in (see illustration) to separate the drive from the valve.

Turn the emergency manual override into the desired position while holding

the button in.

If the drive is driven over the complete rotary range, the emergency manual

override latches in again in the neutral position.

english

NOTE

The position query generally takes place on the basis of the

drive position, and not on the position of the valve.

Optical position indicator

The optical position indicator results from the position of the emergency

manual override.

Turn the emergency manual override the the right: outlet port A closes and

outlet port B opens at the same time.

Turn the emergency manual override to the left, outlet port B closes and

outlet port A opens.

The transition is flowing.

0258 - 15

Page 18

PUTTING INTO OPERATION

Safety notes

ATTENTION!

english

Before putting the motorised control valve into operation,

ensure that

• the electrical power supply corresponds to the voltage

• the electrical connections have been carried out as

• the motorised regulating valve is only used in its original

• all hoses are securely connected to the hose

ASSEMBLY

NOTE

You can install the motor control valve in any position, but preferably with

the drive at the top.

Single blocks are secured with tie rods or angle brackets, and dual and quad

blocks with angle brackets.

If connection sizes or angled connections other than those set

up in the factory are required, the valve must be converted by

the factory. This also applies to changes to the serial

connection of the modules.

OPERATION AND FUNCTION

quoted on the rating plate,

described in the TECHNICAL DATA chapter.

configuration and must not be dismantled,

connections. Danger of scalding!

Safety notes

ATTENTION!

16 - 0258

Observe the following during operation

• compliance with the general technical rules!

• the valid accident prevention and safety regulations for

electrical device.

Page 19

ACCESSORY

Modular filter type 250, solo

english

DescriptionDescription

Description

DescriptionDescription

Filter shut-off module 191 327

Filter magnet shut-off module 198 066

Dimensional drawings for modular filter type 250, solo

103

Ö35

P

DN 25

29

129

113

DN 25

Zu

Auf

A

°

90

(Stellbereich)

166

103

65

40

77,5

Ö35

P

DN

25

29

129

113

Order no.Order no.

Order no.

Order no.Order no.

A

DN

25

Zu

90° (Stell-

bereich)

Auf

166

65

40

77,5

46

Ö7

46

Ö7

0258 - 17

Page 20

3-way check valve block with shut-off valve

english

DescriptionDescription

Description

DescriptionDescription

Order no.Order no.

Order no.

Order no.Order no.

Check valve block with 192 218

shut-off cock

Dimensional drawings for 3-way check valve block with shut-off

valve

33

132

35

1.5

40

TU 28

238

Open

manual lever

Closed

TU 35

Ö7

18 - 0258

Page 21

MAINTENANCE

Safety notes

ATTENTION!

During maintenance and service work, ensure that:

• work on the devices may only be carried out by persons

who have been authorised and have received the

corresponding training.

• the devices must be switched free of electrical voltage

before the start of the maintenance work.

• the national regulations valid in the country of use are

complied with.

Service

Check the following within the context of the service work:

• that the lines are firmly seated,

• the plastic body for cracks and other visible damage,

• the maintenance of the permitted temperatures (see the TECHNICAL

DATA chapter),

• the proper functioning of the device.

Service intervals

Check the correct condition of the motorised control valve with regard to

assembly, installation, and operation at regular intervals.

Take the following factors into consideration when determining the inspection

intervals:

• Operating conditions (loading level, incorrect operation),

• The manufacturer's data in the technical documentation (mechanical and

electrical service life),

• Major changes in the system.

english

Correction of faults

If you detect faults that have an effect on the functionality of the motorised

control valve, these must be corrected immediately:

• Place the device out of operation, and switch it free of voltage!

• Correct the fault.

• Put the device back into operation.

0258 - 19

Page 22

TRANSPORT AND STORAGE

Transport and storage are only permitted in the original packaging.

DISPOSAL

NOTE

english

Observe the national regulations for the disposal of waste in

the respective country of use.

20 - 0258

Page 23

Modulares 2- und 3-Wege-

Motorregelventil

ALLGEMEINE HINWEISE......................................................................... 23

Darstellungsmittel .................................................................................. 23

Warenzeichen .........................................................................................23

Sicherheitshinweise .............................................................................. 23

Bestimmungsgemäßer Gebrauch....................................................... 24

Lieferumfang ........................................................................................... 24

Garantiebestimmungen ........................................................................ 24

Zulassung ................................................................................................ 25

SYSTEMBESCHREIBUNG...................................................................... 26

Einsatz ...................................................................................................... 26

Aufbau ...................................................................................................... 26

Funktion.................................................................................................... 26

Wirkungsweisen des Ventils ................................................................ 27

Durchfluss-Kennlinien ........................................................................... 27

Kennzeichnung ....................................................................................... 28

Grundmodule .......................................................................................... 29

Filtermodul ....................................................................................................... 29

2-Wege-Durchlassventil ................................................................................ 29

3-Wege-Misch- oder Verteilerventil ............................................................ 30

Rückschlagventil .............................................................................................. 30

Absperrventil ................................................................................................... 30

deutsch

TECHNISCHE DATEN ............................................................................... 31

Abmessungen ......................................................................................... 31

4fach Block ...................................................................................................... 31

Leitungsanschlüsse (Schlauch) ................................................................... 31

Allgemeine Daten ................................................................................... 32

Mechanische Daten .............................................................................. 32

Elektrische Daten ................................................................................... 33

Elektrische Anschlüsse ......................................................................... 34

Steckerbelegung Mod ................................................................................... 34

Steckerbelegung LC ...................................................................................... 34

BEDIEN- UND ANZEIGEELEMENTE..................................................... 35

Handnotbetätigung ................................................................................35

0258 - 21

Page 24

INBETRIEBNAHME .................................................................................... 36

BEDIENUNG UND FUNKTION................................................................ 36

ZUBEHÖR.................................................................................................... 37

deutsch

INSTANDHALTUNG.................................................................................... 39

TRANSPORT UND LAGERUNG ............................................................40

ENTSORGUNG .......................................................................................... 40

Optische Stellungsanzeige .................................................................. 35

Sicherheitshinweise .............................................................................. 36

Montage ................................................................................................... 36

Sicherheitshinweise .............................................................................. 36

Modularer Filter Typ 250, solo ............................................................ 37

Maßzeichnung Modularer Filter Typ 250, solo ................................ 37

3fach Rückschlagventilblock mit Absperrventil .............................. 38

Maßzeichnung 3fach Rückschlagventilblock

mit Absperrventil..................................................................................... 38

Sicherheitshinweise .............................................................................. 39

Wartung.................................................................................................... 39

Wartungsintervalle ................................................................................. 39

Beseitigung von Fehlern....................................................................... 39

22 - 0258

Page 25

ALLGEMEINE HINWEISE

Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre

Gesundheit oder die Funktionsfähigkeit des Gerätes

gefährdet ist.

kennzeichnet wichtige Zusatzinformationen,

Tipps und Empfehlungen.

Warenzeichen

Ultramid® ist ein geschütztes Warenzeichen der Firma BASF.

Grivory® ist ein geschütztes Warenzeichen der Firma EMS-Grivory.

Sicherheitshinweise

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten, die im Datenblatt spezifiziert sind, damit

das Gerät einwandfrei funktioniert und lange einsatzfähig bleibt:

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an

die allgemeinen Regeln der Technik!

• Verwenden Sie das Gerät bestimmungsgemäß nur für den mit der Fa.

Bürkert vereinbarten Einsatz.

• Installation und Wartungsarbeiten dürfen nur durch Fachpersonal und mit

geeignetem Werkzeug erfolgen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte während des Betriebs und der Wartung

des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Vermeiden Sie beim Einbau des Motorregelventils und beim Anschluss der

Leitungen an die Schlauchanschlüsse unzulässige mechanische Kräfte

und Spannungen.

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder

unzulässige Beeinträchtigung auszuschließen!

• Verwenden Sie das Gerät nur in seiner Originalkonfiguration!

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das

Gerät entfällt jegliche Haftung unsererseits, ebenso erlischt die Garantie

auf Geräte und Zubehörteile!

deutsch

0258 - 23

Page 26

Bestimmungsgemäßer Gebrauch

Das modulare 2- und 3-Wege-Motorregelventil vom Typ 0258 ist vorzugsweise als Stellglied für Heizwasser- oder Kühlmittelkreisläufe in Omnibussen,

Nutz-, Schwimm- und Schienenfahrzeugen sowie im Werkzeugmaschinenbau

einsetzbar. Die für Ihren speziellen Anwendungsfall erforderliche Konfiguration wird von unseren Mitarbeitern im Außendienst zusammengestellt. Verwenden Sie das modulare 2- und 3-Wege-Motorregelventil vom Typ 0258 nur für

diesen mit der Fa. Bürkert vereinbarten Anwendungsfall. Eine anderweitige

Verwendung muss mit dem Kundenservice der Fa. Bürkert abgesprochen

werden.

Lieferumfang

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung, dass der Inhalt

nicht beschädigt ist und mit dem auf dem beigelegten Packzettel angegebenen Lieferumfang übereinstimmt.

deutsch

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an unser Call-Center:

oder an Ihr Bürkert Vertriebs-Center.

Bürkert Fluid Control Systems

Call-Center

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

Fax: 07940-10448

E-mail: info@de.buerkert.com

Garantiebestimmungen

Diese Druckschrift enthält keine Garantiezusagen. Wir verweisen hierzu auf

unsere allgemeinen Verkaufs- und Geschäftsbedingungen. Voraussetzung für

die Garantie ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der spezifizierten Einsatzbedingungen.

ACHTUNG!

24 - 0258

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit

des Motorregelventils und seiner Bauteile.

Es wird jedoch keine Haftung übernommen für Folgeschäden jeglicher Art, die durch Ausfall oder Fehlfunktion des

Gerätes entstehen könnten.

Page 27

Zulassung

Geräte, die das Typgenehmigungszeichen tragen müssen, wurden beim Kraftfahrtbundesamt unter der Typgenehmigungsnummer

e1*72/245*95/54*3187*00

genehmigt und werden mit dem gezeigten Typgenehmigungzeichen in den

Verkehr gebracht.

1

e

023187

Einen Auszug der Typgenehmigung erhalten Sie unter der unten stehenden

Adresse.

Bürkert Werke GmbH & Co KG

Zulassungsbeauftragter

Christian Bürkert Str.13-17

74653 Ingelfingen

deutsch

0258 - 25

Page 28

SYSTEMBESCHREIBUNG

Einsatz

Das modulare 2- und 3-Wege-Motorregelventil vom Typ 0258 ist vorzugsweise als Stellglied für Heizwasser- oder Kühlmittelkreisläufe in Omnibussen, Nutz-, Schwimm- und Schienenfahrzeugen sowie im Werkzeugmaschinenbau einsetzbar.

Aufbau

deutsch

(optische Stellungsanzeige)

Das Motorregelventil Typ 0258 ist modular aufgebaut und wird einzeln oder

zu Blöcken angereiht montiert. In einem Block sind bis zu 4 Ventile

kombinierbar. Es kann wahlweise als 2- oder 3-Wege-Ventil eingesetzt

werden. Es enthält keramische Dichtelemente, das Ventilgehäuse besteht

aus Kunststoff.

Der eingesetzte elektrische Drehantrieb mit Gleichspannungsmotor besteht

entweder aus einem wartungsfreien Flachantrieb1) (LC) mit AMP-Stecker

oder aus einem wartungsfreien, leistungsstärkeren Stirnradantrieb2) (Mod)

mit Magnetkupplung und Hirschmann-Stecker (Optionen möglich), einer

Handnotbetätigung mit optischer Stellungsanzeige und einem oder mehreren

Ventilmodulen.

Die Antriebe haben in Verbindung mit der Handnotbetätigung einen Stellwinkel von 180°. Die Antriebe dürfen ohne Handnotbetätigung nicht betrieben werden, da sonst der Stellungsrückmelder dejustiert werden kann.

1)

2)

elektrischer Anschluss

(AMP oder Rundstecker

nach DIN 43651,

Hirschmann)

Handnotbetätigung

Flachantrieb (LC): im folgenden Text immer "LC"

Stirnradantrieb (Mod): im folgenden Text immer "Mod"

Motorantrieb leistungsstarker Stirnradantrieb mit Magnetkupplung

(Mod) oder Flachantrieb

(LC), jeweils mit Stellungsrückmeldung

Ventilmodul

Funktion

Der Antrieb bewegt über eine Welle eine Regelscheibe über eine Fixscheibe

aus Oxyd-Keramik und verschließt somit die Ventilsitze A und B wechselseitig

bei gleitendem Übergang.

In Abhängigkeit vom Stellwinkel sind die Durchflusswerte (2 Wege), Mischoder Verteilungsverhältnisse (3 Wege) stetig veränderbar.

Die Stellungsrückmeldung erfolgt über ein Potentiometer.

26 - 0258

Page 29

Wirkungsweisen des Ventils

Wirkungsweise I

A

2-Wege-Ventil zur stetigen Steuerung des Durchflusses

M

im Ausgang A,

motorgetrieben, stromlos verharrend

P

Wirkungsweise E

P

3-Wege-Ventil zur stetigen Mischung der Zuströme A und B

M

auf den Anschluss P,

motorgetrieben, stromlos verharrend

A B

Wirkungsweise F

B

A

3-Wege-Ventil zur stetigen Verteilung des Zustromes P

M

auf die Ausgänge A und B,

motorgetrieben, stromlos verharrend

P

Durchfluss-Kennlinien

Die Durchfluss1)-Kennlinien für die Kv-Sollwerte von 3 m3 und 6 m3 sind in

den folgenden Diagrammen dargestellt. Der Kv-Sollwert von 1 m 3 ist in Vorbereitung.

Durchflusskennlinie2) Kv-Sollwert = 3 m

3

deutsch

/h]

3

Kv-Wert [m

Potentiometer3) [%]

1)

Durchfluss: Kv-Wert Wasser [m³/h],

Ausgang.

2)

nur Antriebsart Mod

3 )

relativiert auf den Gesamthub des Potentiometers = 100 %

4 )

Druckangabe in [bar]: Überdruck zum Atmosphärendruck

Messung bei +20 °C, 1 bar

4 )

Druck am Ventileingang und freiem

0258 - 27

Page 30

Durchflusskennlinie1) Kv-Sollwert = 6 m

6

6

/h]

3

5

5

4

4

3

3

Kv-Wert [m

2

2

1

1

0

0

0

9

0

9

33

33

21

21

Potentiometer2) [%]

1)

nur Antriebsart Mod

2)

relativiert auf den Gesamthub des Potentiometers = 100 %

Kennzeichnung

3

45

57 70 82 94

45

57 70 82 94

deutsch

Das Motorregelventil ist durch zwei Typenschilder gekennzeichnet.

Das Typenschild für das Komplettgerät (Ventilblock) befindet sich unten auf

der linken Seite. Es bezeichnet in der oberen Zeile den Geräteschlüssel

"SYST-0258", in der unteren Zeile die Identnummer sowie das verschlüsselte

Baudatum.

Jeder Antrieb verfügt außerdem über ein eigenes Typenschild mit folgendem

Inhalt:

• Geräteschlüssel/ZeichNr. z. B.: 0258-G665-205-00,

• Spannung und Spannungsart: 24 V DC,

• Aufnahmeleistung: z. B. 3 W,

• Drehwinkel: z. B.: 28 s / 180°,

• Nenndruck: z. B.: 0 ... 2,5 bar,

• Identnummer und verschlüsseltes Baudatum.

28 - 0258

Page 31

Grundmodule

4

2

1

3

Alle Grundmodule können Sie einzeln oder im Block einsetzen.

Filtermodul

Handhebel

Beschreibung

Das Filtermodul kann von Hand abgesperrt werden. Beachten Sie die

Durchflussrichtung.

Optional kann das Filtermodul mit

einem Magneteinsatz ausgerüstet sein.

Blocksymbol

2-Wege-Durchlassventil

4

Beschreibung

Das 2-Wege-Durchlassventil ist

stetigwirkend.

Die Durchflussrichtung:

P A, P B

Blocksymbol

2

deutsch

0258 - 29

Page 32

3-Wege-Misch- oder Verteilerventil

deutsch

Rückschlagventil

Beschreibung

Das 3-Wege-Misch- oder Verteilerventil ist stetigwirkend.

Die Durchflussrichtungen

• im Verteilerventil: P A, P B

• im Mischventil: P1 A, P2 A

Blocksymbole

1

4

2

E

3

1

4

2

F

3

Mischen Verteilen

Beschreibung

Das Rückschlagventil hat

Sammelfunktion. Handbetätigung ist

möglich. Handhebel in Linksanschlag:

P A geschlossen

P B offen

Beachten Sie die Durchflussrichtung.

Blocksymbol

1

4

R

2

3

Absperrventil

30 - 0258

Befestigungswinkel

Handhebel

Beschreibung

Das Absperrventil wird von Hand betätigt. Die Durchflussrichtung ist beliebig.

Blocksymbol

4

2

Page 33

TECHNISCHE DATEN

Abmessungen

4fach Block

Ø29,8

Ø36,5

Ø34,5

Ø27,8

TU35

37,6

35,6

TU28

Ø23,4

35,6

Ø

TU22

21,8

Abschlussplatte

19

12

25,7

11,44

14,5

57

TU35

52,5

Ø 34,5

Ø 36,5

51,85

8,88

38,5

1,5

10,5

49,1

TU28

47

259,5

Ø 27,8

276

Ø 29,8

Leitungsanschlüsse

Schlauchanschluss, gerade

BezeichnungBezeichnung

Bezeichnung

BezeichnungBezeichnung

TU22L 22 47,5

TU28L 28 50,5

TU35L 35 53,85

DurchmesserDurchmesser

Durchmesser

DurchmesserDurchmesser

(mm)(mm)

(mm)

(mm)(mm)

TU22

44

37

14,5

58,2

deutsch

70,1

46,1

63

Ø21,8

35,2

Ø23,8

34,5

56

40

7

14,44

180,7

105,2

118,2

Diese Zusammenstellungs-

( 180,7 )

zeichnug ist eine Übersicht

über die verschiedenen

konstruktiven Möglichkei-

30

4

25,5

BauhöheBauhöhe

Bauhöhe

BauhöheBauhöhe

(mm)(mm)

(mm)

(mm)(mm)

6,4

38,5

1,5

46

ten des Motorregelventils.

Schlauchanschluss, abgewinkelt

BezeichnungBezeichnung

Bezeichnung

BezeichnungBezeichnung

DurchmesserDurchmesser

Durchmesser

DurchmesserDurchmesser

(mm)(mm)

(mm)

(mm)(mm)

TU22 22 37

TU28 28 37

TU35 35 39

BauhöheBauhöhe

Bauhöhe

BauhöheBauhöhe

(mm)(mm)

(mm)

(mm)(mm)

0258 - 31

Page 34

Allgemeine Daten

Umgebungstemperatur -20 ... +80 °C

Betriebstemperatur -20 ... +95 °C

Lagertemperatur 0 ... +60 °C

rel. Luftfeuchte max. 80 %

Gewicht ca. 900 g / Modul, abhängig von der Ausführung

Nennbetriebsart

Schutzart IP 65

Zulassung Typgenehmigung beim Kraftfahrtbundesamt

Mechanische Daten

deutsch

Werkstoffe

Ventilgehäuse Ultramid® T KR 4355 G5 schwarz,

Ventilinnenteile Ultramid® T KR 4355 G5 schwarz,

Dichtwerkstoff FKM / Al2O3

Medien

Medientemperatur -20 ... +95 °C

Viskosität max. 40 mm²/s

Leitungsanschluss Schlauchanschlüsse,

Motordrehmoment LC nom./max.: 0,35 Nm / 0,7 Nm

Blockaufbau mit Klemmblechen und Zwischenadaptern

Befestigung mit Haltewinkeln und Zugstangen

Einbaulage beliebig, vorzugsweise Antrieb nach oben

Grundmodule 2- und 3-Wege-Ventile

1) 2)

3)

Dauerbetrieb ED 100 %

e1*72/245*95/54*3187*00

Grivory® HTV schwarz

Grivory® HTV schwarz und VA

neutrale Gase und Flüssigkeiten, z. B. Luft,

Wasser, Glykole, Kühlwasser mit Additiven

wahlweise TU 22, TU28, TU35,

gerade oder gewinkelt

Mod. nom./max.: 1,2 Nm / 2,1 Nm

Rückschlagventil

Filtermodul, absperrbar

Hand-Absperrventil

4)

32 - 0258

Page 35

Elektrische Daten

Stellrichtung je nach Polarität und Antriebstyp

Stellzeit für 100 %

Elektrischer Anschluss LC: für AMP-Buchse 967066-1

Stellungsrückmelder LC: 5 kΩ lin

Widerstandsänderung ca. 55 ... 75 % (bei 100 % Stellweg)

Potentiometer

max. Schleifstrom Standardausführung:

Potentiometer Leitplast-Ausführung:

max. Spannung LC: 7,5 V (Potentiometer-Klemmen 1 und 3)

Potentiometer Mod: 10 V (Potentiometer-Klemmen 4 und 6)

max. Leistung LC: 0,25 W / 40 °C

Potentiometer

Nennbetriebs

spannung

))

9

)

))

Spannungstoleranz ±10 %

Leistungsaufnahme LC: 4,8 W

5)

LC: ca. 4 ... 8 s bei 24 V DC

Mod: ca. 28 s bei 24 V DC

und AMP-Kontakt 962885-1

Mod: Rundstecker nach DIN 43651

(6polig und Masse)

Mod: Potentiometer 1 kΩ lin (optional 5 kΩ lin

sowie Leitplast-Ausführungen)

Schutzwiderstand Rs = 6,8 kΩ

8)

--

- 24 V DC

--

Mod: 0,5 W / 40 °C

Mod: 3 W

≤≤

≤4 mA

≤≤

≤≤

≤65 µA

≤≤

7)

6)

deutsch

HINWEIS

LC: Max. Anzahl der Ansteuerungen (bei Nominaldrehmo-

ment) = 100 000 unter Laborbedingungen, 20 °C und je

1 s Ansteuerzeit durch den gesamten Stellbereich.

Mod: Max. Anzahl der Ansteuerungen = 400 000 unter Laborbedingungen, 20 °C und je 1 s Ansteuerzeit durch den gesamten Stellbereich.

1 )

Pausenzeit bei Drehumkehr 0,4 s.

2 )

Bei permanenter Ansteuerung des Motors erhöhter Verschleiss.

3 )

eingeschränkte Gasdichtheit

4 )

Verschmutzungen (z. B. Flusen usw.) sollten vorgefiltert werden, sonst eventuell Beeinträchtigung der

Ventilfunktion.

5 )

Bei 24 V DC geglättet. Gepulste Ansteuerung verlängert die Stellzeit (siehe auch 9) )

6 )

abhängig vom Druck/Last

7 )

Höhere Ströme schränken die Lebensdauer stark ein!

8 )

Höhere Temperaturen schränken die max. Verlustleistung des Potentiometers ein.

9 )

min. Pulsdauer (im Leerlauf / bei Druck/Last erhöht sich die min. Pulsdauer):

bei LC: ca. 100 ms / bei Mod.: ca. 100 ms

0258 - 33

Page 36

Elektrische Anschlüsse

ACHTUNG!

HINWEIS

Steckerbelegung Mod

deutsch

Rs = 6,8 kΩ

P1 = 1,0 kΩ / 5,0 kΩ

Steckerbelegung LC

P1

6

1

5

2

4

R

3

s

1234

Die Betriebsspannung und Frequenz der Versorgung müssen

mit den Typschildangaben des Antriebs überein stimmen.

Die Spannungen und Ströme dürfen nicht außerhalb des

zulässigen Betriebsbereichs liegen.

Bei getaktetem Antrieb und Nennspannung soll die Impulsdauer von 100 ms nicht unterschritten werden.

M

65

PolbelegungPolbelegung

Polbelegung

PolbelegungPolbelegung

Linkslauf plus minus

Rechtslauf minus plus

PolbelegungPolbelegung

Polbelegung

PolbelegungPolbelegung

M

M

Linkslauf minus plus

Rechtslauf plus minus

Pin 1Pin 1

Pin 1

Pin 1Pin 1

Pin 4Pin 4

Pin 4

Pin 4Pin 4

Pin 2Pin 2

Pin 2

Pin 2Pin 2

Pin 6Pin 6

Pin 6

Pin 6Pin 6

P1 = 5,0 kΩ

34 - 0258

Page 37

BEDIEN- UND ANZEIGEELEMENTE

Handnotbetätigung

Kupplungsglocke,

fest mit dem Antrieb

verbunden

Taste, trennt durch

Eindrücken den

Antrieb vom Ventil

Handnotbetätigung,

verstellbar, mit dem

verdrehbaren Ventil

verbunden

Mit der Handnotbetätigung verstellen Sie das Ventil unabhängig von der

Antriebsstellung.

Drücken Sie die Taste (siehe Abbildung) ein, um den Antrieb vom Ventil

zu trennen.

Drehen Sie die Handnotbetätigung mit eingedrückter Taste in die

gewünschte Position.

Wird der Antrieb über den gesamten Stellbereich verfahren, rastet die Handnotbetätigung wieder in Neutralstellung ein.

HINWEIS

Die Positionsabfrage erfolgt generell anhand der Antriebsstellung und nicht nach der Stellung des Ventils.

Optische Stellungsanzeige

Die optische Stellungsanzeige resultiert aus der Lage der Handnotbetätigung.

Drehen Sie die Handnotbetätigung nach rechts, schließt sich Ausgang A und

Ausgang B wird gleichzeitig geöffnet.

Drehen Sie die Handnotbetätigung nach links, schließt sich Ausgang B und

Ausgang A wird geöffnet.

Der Übergang ist fließend.

deutsch

0258 - 35

Page 38

INBETRIEBNAHME

Sicherheitshinweise

ACHTUNG!

deutsch

Montage

HINWEIS Sind andere als die vom Werk eingestellten Anschlussgrößen

Einfach-Blöcke werden durch Zugstangen oder Winkel, 2fach- bis 4fachBlöcke durch Winkel befestigt.

Das Motorregelventil können Sie in beliebiger Lage einbauen, bevorzugt

vertikal mit Antrieb nach oben.

Beachten Sie vor der Inbetriebnahme des Motorregelventils, dass

• die Stromversorgungsspannung der auf dem Typenschild

angegebenen Spannung entsprechen muss,

• die elektrischen Anschlüsse wie in Kap. TECHNISCHE

DATEN ausgeführt werden müssen,

• das Motorregelventil nur in seiner Originalkonfiguration

verwendet und nicht demontiert werden darf,

• alle Schläuche sicher mit den Schlauchanschlüssen

verbunden sind. Verbrühungsgefahr!

oder Anschlusswinkelstellungen erforderlich, muss das Ventil

vom Werk umgebaut werden. Das betrifft auch Änderungen an

der Anreihung der Module.

BEDIENUNG UND FUNKTION

Sicherheitshinweise

ACHTUNG!

36 - 0258

Beachten Sie bei der Bedienung und im Betrieb

• die Einhaltung der allgemeinen Regeln der Technik!

• die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte.

Page 39

ZUBEHÖR

Modularer Filter Typ 250, solo

BezeichnungBezeichnung

Bezeichnung

BezeichnungBezeichnung

Filter-Absperrmodul 191 327

Filter Magnet Absperrmodul 198 066

Maßzeichnungen Modularer Filter Typ 250, solo

Ö35

P

DN

25

29

103

Ö35

P

DN 25

29

129

113

A

DN 25

Zu

°

90

(Stellbereich)

Auf

46

166

103

65

40

77,5

Ö7

Bestell-Nr.Bestell-Nr.

Bestell-Nr.

Bestell-Nr.Bestell-Nr.

129

113

46

Zu

Auf

A

DN

25

90° (Stell-

bereich)

Ö7

deutsch

166

65

40

77,5

0258 - 37

Page 40

3fach Rückschlagventilblock mit Absperrventil

BezeichnungBezeichnung

Bezeichnung

BezeichnungBezeichnung

Rückschlagblock mit Ab- 192 218

sperrhahn

deutsch

Maßzeichnung 3fach Rückschlagventilblock mit Absperrventil

33

132

35

1,5

40

TU 28

238

Handhebel

ZU

AUF

TU 35

Ö7

Bestell-Nr.Bestell-Nr.

Bestell-Nr.

Bestell-Nr.Bestell-Nr.

38 - 0258

Page 41

INSTANDHALTUNG

Sicherheitshinweise

ACHTUNG!

Beachten Sie bei der Instandhaltung und Wartung, dass

• die Arbeiten an den Geräten nur von dazu befugtem und

entsprechend geschultem Personal durchgeführt werden

dürfen.

• die Geräte vor Beginn der Wartungsarbeiten spannungsfrei zu schalten sind.

• die geltenden nationalen Bestimmungen im Einsatzland

eingehalten werden müssen.

Wartung

Überprüfen Sie im Rahmen der Wartung:

• die Leitungen auf festen Sitz,

• das Kunststoffgehäuse auf Rissbildung und andere sichtbare Schäden,

• die Einhaltung der zulässigen Temperaturen (siehe Kap. TECHNISCHE

DATEN),

• die bestimmungsgemäße Funktion.

Wartungsintervalle

Prüfen Sie die Motorregelventile auf ihren ordnungsgemäßen Zustand hinsichtlich der Montage, der Installation und des Betriebes regelmäßig.

Berücksichtigen Sie die folgenden Faktoren bei der Festlegung der Prüfintervalle:

• Betriebsbedingungen (Auslastungsgrad, Fehlbedienung),

• Herstellerangaben in der technischen Dokumentation (mechanische und

elektrische Lebensdauer),

• größere Veränderung im System.

deutsch

Beseitigung von Fehlern

Haben Sie Fehler festgestellt, die sich auf die Funktionsfähigkeit des Motorregelventils auswirken, müssen diese sofort beseitigt werden:

• Setzen Sie das Gerät außer Betrieb, schalten Sie es spannungsfrei!

• Beseitigen Sie den Fehler.

• Nehmen Sie das Gerät wieder in Betrieb.

0258 - 39

Page 42

TRANSPORT UND LAGERUNG

Transport und Lagerung sind nur in Originalverpackung gestattet.

ENTSORGUNG

HINWEIS

deutsch

Beachten Sie die nationalen Vorschriften zur Abfallentsorgung im jeweiligen Einsatzland.

40 - 0258

Page 43

Vanne de régulation motorisée

modulaire à 2 et 3 voies

IDENTIFICATIONS GENERALES ........................................................... 43

Symboles utilisès ................................................................................... 43

Marque déposée .................................................................................... 43

Consignes de sécurité .......................................................................... 43

Utilisation conforme aux instructions ................................................ 44

Fourniture ................................................................................................. 44

Clauses de garantie ..............................................................................44

Homologation .......................................................................................... 45

DESCRIPTION DU SYSTEME ................................................................. 46

Mise en oeuvre ....................................................................................... 46

Construction ........................................................................................... 46

Fonctionnement...................................................................................... 46

Mode d'action de la vanne .................................................................. 47

Courbes caractéristiques de débit ..................................................... 47

Marquage ................................................................................................. 48

Modules de base.................................................................................... 49

Module filtrant.................................................................................................. 49

Vanne d'admission à 2 voies ........................................................................ 49

Vanne de mélange ou de répartition à 3 voies ......................................... 50

Clapet antiretour ............................................................................................ 50

Vanne d'arrêt .................................................................................................... 50

français

CARACTERISTIQUES TECHNIQUES .................................................. 51

Dimensions .............................................................................................. 51

Bloc quadruple ................................................................................................ 51

Raccords de conduites (tuyau) .................................................................. 51

Caractéristiques générales .................................................................. 52

Caractéristiques mécaniques ............................................................. 52

Caractéristiques électriques ............................................................... 53

Branchements électriques ...................................................................54

Affectation des connecteurs Mod .............................................................. 54

Affectation des connecteurs LC ................................................................. 54

ORGANES DE COMMANDE ET D'AFFICHAGE ...............................55

Commande de secours manuelle....................................................... 55

0258 - 41

Page 44

MISE EN SERVICE .................................................................................... 56

COMMANDE ET FONCTIONNEMENT................................................. 56

ACCESSOIRES ......................................................................................... 57

MAINTENANCE ........................................................................................... 59

français

TRANSPORT ET STOCKAGE ................................................................60

MISE AU REBUT ........................................................................................ 60

Affichage de position optique ............................................................. 55

Consignes de sécurité .......................................................................... 56

Montage ................................................................................................... 56

Consignes de sécurité .......................................................................... 56

Filtre modulaire type 250, solo ........................................................... 57

Dessins dimensionnels du filtre modulaire type 250, solo ........... 57

Bloc de 3 clapets antiretour avec robinet d'arrêt........................... 58

Dessin dimensionnel du bloc de 3 clapets antiretour

avec robinet d'arrêt ................................................................................ 58

Consignes de sécurité .......................................................................... 59

Entretien................................................................................................... 59

Intervalle d'éntretien ..............................................................................59

Elimination des défauts ........................................................................ 59

42 - 0258

Page 45

INDICATIONS GENERALES

Symboles utilisés

Les symboles utilisés dans cette notice d'instructions sont les suivants:

désigne une opération à exécuter.

ATTENTION!

REMARQUE

désigne une mise en garde dont l'inobservation pourrait

mettre en danger votre santé ou l'intégrité de l'appareil.

désigne des informations supplémentaires, conseils et

recommandations importantes.

Marque déposée

Ultramid® est une marque déposée de la société BASF.

Grivory® est une marque déposée de la société EMS-Grivory.

Consignes de sécurité

Veuillez tenir compte des directives figurant dans ces instructions de service

de même que des conditions d'utilisation et des données autorisées

spécifiées dans la fiche technique pour que l'appareil fonctionne parfaitement

et reste longtemps opérationnel:

• S'en tenir lors de la mise en oeuvre prévue et du service de l'appareil aux

règles techniques générales reconnues!

• Utiliser uniquement l'appareil conformément à sa destination pour les

inserts convenus de la maison Bürkert..

• L'installation et les interventions nécessitées par la maintenance ne

doivent être effectuées que par un personnel qualifié équipé des outils

adéquats!

• Respecter les dispositions en vigueur de prévention des accidents et de

sécurité pour appareils électriques pendant le service, la maintenance de

l'appareil!

• Toujours couper la tension d'allimentation avant toute intervention dans le

systeme!

• Eviter lors du montage de la vanne motorisée et lors du branchement des

conduites aux raccords des tuyaux souples des forces et tension

mécaniques non admises.

• Prendre les mesures qui s'imposent pour éviter un actionnement par

inadvertance de l'appareil ou une mise en cause inadmissible de son

fonctionnement!

• N'utiliser l'appareil que dans sa configuration originale!

• Nous déclinons toute responsabilité en cas d'inobservation des ces

recommandations et d'intervention non autorisée à l'intérieur de l'appareil.

Il en résulterait par ailleurs l'extinction de la garantie sur l'appareil et les

accessoires!

français

0258 - 43

Page 46

Utilisation conforme aux instructions

La vanne modulaire de régulation motorisée de type 0258 est mise en oeuvre

de préférence comme composant de réglage pour circuits d'eau chaude ou

de réfrigérant dans des omnibus, véhicules utilitaires, flottants et sur rails de

même que dans la construction de machines-outils.

La configuration nécessaire à votre application spéciale sera assemblée par

nos collaborateurs du service de visite à la clientèle. Utiliser uniquement la

vanne de régulation motorisée modulaire à 2 et 3 voies du type 0258 pour le

cas d'application convenu avec la maison Bürkert. Une autre emploi doit être

convenu avec le service après-vente de la maison Bürkert.

Fourniture

S'assurer immédiatement après réception de la fourniture si le contenu est

conforme à ce qui a été indiqué.

En cas de désaccord, veuillez contacter au plus vite notre centre d'appel:

Bürkert Fluid Control Systems

Chr.-Bürkert-Str. 13-17

français

ou votre revendeur Bürkert.

E-mail: info@de.buerkert.com

Centre d'appel

D-76453 Ingelfingen

Tel. : 07940-10111

Fax: 07940-10448

Clauses de garantie

Ce document ne constitue aucun assentiment de garantie. Nous vous

renvoyons à cet effet à nos conditions générales de vente et commerciales.

La condition préalable au consentement de la garantie est l'utilisation

conforme de l'appareil à l'usage auquel il est destiné, compte tenu de

l'observation des conditions d'emploi spécifiées.

ATTENTION!

44 - 0258

La garantie ne s'étend que jusqu'à l'absence de défaut de la

vanne de régulation motorisée et de ses composants.

Nous déclinons, par contre, toute responsabilité pour des

dégâts consécutifs de toute nature susceptibles de survenir

par suite de défaillance ou défaut de fonctionnement de

l'appareil.

Page 47

Homologation

Les appareils portant la marque e1 ont été homologués au Service fédéral de

la circulation automobile (Kraftfahrtbundesamt) sous le numéro

e1*72/245*95/54*3187*00

et seront mis en circulation avec la marque d'homologation indiquée.

1

e

023187

Vous recevrez un extrait de l'homologation à l'adresse ci-dessous:

Bürkert Werke GmbH & Co KG

Zulassungsbeauftragter

Christian Bürkert Str.13-17

74653 Ingelfingen

français

0258 - 45

Page 48

DESCRIPTION DU SYSTEME

Mise en oeuvre

La vanne modulaire de régulation motorisée de type 0258 est mise en oeuvre

de préférence comme composant de réglage pour circuits d'eau chaude ou

de réfrigérant dans des omnibus, véhicules utilitaires, flottants et sur rails de

même que dans la construction de machines-outils.

Construction

Branchement électrique

(AMP ou connecteur

rond selon DIN 43651,

Commande de secours

(indication optique de position)

français

Le vanne de régulation motorisée de type 0258 est de construction modulaire

et se monte, isolée ou rangée en bloc. Dans un bloc, jusqu'à 4 vannes

peuvent être combinées. On peut utiliser au choix des vannes à 2 ou 3 voies.

Il contient des éléments d'étanchéité en céramique, le corps de soupape est

en matière plastique.

L'entraînement rotatif électrique utilisé, à moteur à courant continu, est

constitué soit d'un entraîtement plat sans entretien1) (LC) à connecteur AMP,

soit d'un entraînement puissant à roue droite, sans entretien2) (Mod), à

accouplement magnétique et connecteur Hirschmann (options possibles),

commande de secours manuelle à indication optique de position et un

plusieurs modules de soupapes.

En liaison avec la commande de secours manuelle, les entraînements ont un

angle de positionnement de 180°. Les entraînements ne doivent pas être

utilisés sans commande de secours manuelle, car les dispositifs de réponse

seraient sinon déréglés.

1)

Entraînement plat (LC): ci-après toujours "LC"

2)

Entraînement à roue droite (Mod): ci-après toujours "Mod"

Fonctionnement

Hirschmann)

manuelle

Entraînement par moteur entraînement puissant à

roue droite avec

accouplement magnétique

(Mod) ou entraînement plat

(LC), chacun avec réponse

de position

Vanne modulaire

Par l'intermédiaire d'un axe, l'entraînement déplace un disque de réglage

au-dessus d'un disque fixe en céramique oxydée et ferme ainsi alternativement les sièges de soupape A et B en transistion glissante.

En fonction de l'angle de réglage, les valeurs de débit (2 voies), les rapports

de mélange ou de répartition (3 voies) peuvent constamment être changés.

La réponse de position a lieu par un potentiomètre.

46 - 0258

Page 49

Mode d'action de la vanne

Mode d'action I

A

Vanne à 2 voies pour commande constante du débit

M

dans la sortie A,

motorisée, restant dans le même état sans courant

P

Mode d'action E

P

Vanne à 3 voies pour le mélange constant des courants

M

d'amenée A et B au raccord P,

motorisée, restant dans le même état sans courant

A B

Mode d'action F

B

A

Vanne à 3 voies pour la répartition constante de courants

M

d'amenée P aux sorties A et B,

motorisée, restant dans le même état sans courant

P

Courbes caractéristiques de débit

Les courbes de débit1) des valeurs de consignes Kv de 3 m3 et de 6 m3 sont

représentées dans les diagrammes suivants. La valeur de consigne de 1 m

est en préparation:

Courbe caractéristique de débit

2)

de la valeur de consigne Kv = 3 m

3

français

3

/h]

3

Valeur Kv [m

Poatentiomètre3) [%]

1)

Débit valeur Kv eau [m³/h],

2)

uniquement entraînement Mod

3 )

référencé à la course totale du potentiomètre = 100 %

4 )

Indication de pression en [bar]: surpression par rapport à la pression atmosphérique

measure à +20 °C, 1 bars

4 )

pression à l'entrée de la vanne et sortie libre

0258 - 47

Page 50

Courbe caractéristique de débit1) de la valeur de consigne Kv = 6 m

1)

2)

Marquage

La vanne de régulation motorisée est marquée par deux plaques

signalétiques.

La plaque signalétique pour l'appareil complet (bloc de vannes) se trouve en

bas du côté gauche. Elle désigne sur la ligne suérieure la clé de l'appareil

"SYST-0258", sur la ligne inférieure le numéro d'identification de même que la

date de construction codée.

français

Chaque entraînement dispose, en outre, d'une propre plaque signalétique

comportant ce qui suit:

• Clé de l'appareil / n° de dessin p. ex.: 0258-G665-205-00,

• Tension et type de tension: 24 V DC,

• Puissance consommée: p. ex. 3 W,

• Ecart angulaire, p. ex.: 28 s / 180°,

• Pression nominale, p. ex.: 0 ... 2,5 bars,

• Numéro d'identification et date de construction codée.

6

6

5

5

4

4

/h]

3

3

3

2

2

1

1

Valeur Kv [m

0

0

0

9

0

9

33

33

45

57 70 82 94

45

21

21

57 70 82 94

Potentiomètre2) [%]

uniquement entraînement Mod

référencé à la course totale du potentiomètre = 100 %

3

48 - 0258

Page 51

Modules de base

4

2

1

3

Tous les modules de base peuvent être employés isolés ou en bloc.

Module filtrant

Manette

Description

Le module filtrant peut être bloqué à la

main. Faire attention au sens du débit.

Le module filtrant peut être équipe en

option d'un insert magnétique.

Symbol fonctionnel

Vanne d'admission à 2 voies

4

Description

La vanne d'admission à 2 voies est à

action continue.

Le sens du débit:

P A, P B

Symbol fonctionnel

2

français

0258 - 49

Page 52

Vanne de mélange ou de répartition à 3 voies

Clapet antiretour

français

Vanne d'arrêt

Description

La vanne de mélange et de répartition

à 3 voies est à action continue.

Le sens de débit

• dans la vanne de répartition:

P A, P B

• dans la vanne de mélange:

P1 A, P2 A

Symboles fonctionnels

1

4

2

E

3

1

4

2

F

3

Mélange Répartition

Description

Le clapet antiretour a une fonction

collectrice. La manœuvre manuelle est

possible. Manette dans butée de

gauche:

P A fermé

P B ouvert

Faire attention au sens du débit.

Symbole fonctionnel

1

4

R

2

3

50 - 0258

Equerre de fixation

Manette

Description

La vanne d'arrêt est manœuvrée à la

main. Le sens de débit est quelconque.

Symbole fonctionnel

4

2

Page 53

CARACTERISTIQUES TECHNIQUES

Dimensions

Bloc quadruple

Ø23,4

Ø29,8

Ø36,5

Ø34,5

37,6

TU35

Ø27,8

35,6

TU28

35,6

Ø

TU22

21,8

Abschlussplatte

19

12

25,7

11,44

14,5

57

TU35

52,5

Ø 34,5

Ø 36,5

51,85

8,88

38,5

1,5

10,5

49,1

TU28

47

259,5

Ø 27,8

276

Ø 29,8

Raccords de conduites

Raccord de tuyau, droit

DésignationDésignation

Désignation

DésignationDésignation

TU22L 22 47,5

TU28L 28 50,5

TU35L 35 53,85

DiamètreDiamètre

Diamètre

DiamètreDiamètre

(mm)(mm)

(mm)

(mm)(mm)

TU22

44

37

14,5

58,2

70,1

46,1

63

Ø21,8

35,2

Ø23,8

34,5

56

40

7

14,44

180,7

105,2

118,2

Ce dessin d'assemblage

( 180,7 )

donne une vue d'ensemble

des diverses possibilités de

français

construction de la vanne

30

4

25,5

6,4

38,5

1,5

HauteurHauteur

Hauteur

HauteurHauteur

(mm)(mm)

(mm)

(mm)(mm)

46

de régulation motorisée.

Raccord de conduite, coudé

DésignationDésignation

Désignation

DésignationDésignation

DiamètreDiamètre

Diamètre

DiamètreDiamètre

(mm)(mm)

(mm)

(mm)(mm)

TU22 22 37

TU28 28 37

TU35 35 39

HauteurHauteur

Hauteur

HauteurHauteur

(mm)(mm)

(mm)

(mm)(mm)

0258 - 51

Page 54

Caractéristiques générales

Température ambiante -20 ... +80 °C

Température de service -20 ... +95 °C

Température de stockage 0 ... +60 °C

Humidité rel. de l'air max. 80 %

Poids env. 900 g / module, en fonction de la version

Mode de service

nominal

Protection IP 65

Homologation Homologation de type au Bureau fédéral

1) 2)

Caractéristiques mécaniques

Matière

Boîtier de vanne Ultramid® T KR 4355 G5 noir,

Pièces intérieures

français

de la vanne Ultramid® T KR 4355 G5 noir,

Matière d'étanchéité FKM / Al2O3

3)

Fluides

Température des fluides -20 ... +95 °C

Viscosité max. 40 mm²/s

Raccord de conduite Raccords par tuyaux souples,

Couple moteur LC nom./max.: 0,35 Nm / 0,7 Nm

Structure du bloc avec tôles à griffes et adaptateurs intermédiaires

Fixation par équerres de soutien et barres de traction

Position de montage quelconque, de préférence avec l'entraînement

Modules de base Vannes à 2 et 3 voies

Service permanent ED 100 %

du trafic automobile e1*72/245*95/54*3187*00

Grivory® HTV noir

Grivory® HTV noir et VA

Gaz et liquides neutres, p. ex. air, eau, glycols,

eau de refroidissement avec additifs

au choix TU 22, TU28, TU35,

droit ou coudé

Mod. nom./max.: 1,2 Nm / 2,1 Nm

dirigé vers le haut

Clapet antiretour

Module filtrant, pouvant être bloqué

Vanne d'arrêt manuelle

4)

52 - 0258

Page 55

Caractéristiques électriques

Sens de réglage selon la polarité et le type d'entraînement

Temps de réglage LC: env. 4 ... 8 s à 24 V DC

pour 100 %

5)

Mod: env. 28 s à 24 V DC

Branchement électrique LC: pour prise AMP 967066-1

et contact AMP 962885-1

Mod: connecteur rond selon DIN 43651

(6 pôles et masse)

Dispositif de réponse LC: 5 kΩ lin

Mod: potentiomètre 1 kΩ lin (en option 5 kΩ lin