Bunn Coffee Maker RL Installation Manual

Reach-in Merchandisers

®

Medium and Low Temperature

IMPORTANT

Keep in store for

future reference!

MANUAL- I/O REACH-IN

Installation &

Operation Manual

Shipped With Case Data Sheets

P/N 0387183_R

August 2015

English P/N 0387183

Spanish P/N 0517045

French P/N 0527085

P/N 0387183_R

Table of Contents

INSTALLATION

NSF Certification1-1

Location ....................................................... 1-1

Shipping Damage

Exterior Loading

Merchandisers Shipped With End Installed

Shipping Braces

Moving Through Narrow Entrances

Leveling

........................................................ 1-6

Joining

......................................................... 1-8

Splashguards

Installing Bumpers

........................................... 1-1

........................................... 1-2

......... 1-2

............................................. 1-2

.................. 1-3

............................................... 1-23

........................................ 1-24

REFRIGERATION / ELECTRICAL

Refrigerant .................................................... 2-1

Refrigerant Piping

Insulation

Branch Line Piping

Expansion Valve Adjustment

Refrigeration Thermostat

Defrost Termination Thermostat

Control Settings

Merchandiser Electrical Data

Field Wiring

Electrical Connections

Identification of Wiring

Wiring Color Code

.......................................... 2-1

...................................................... 2-2

........................................ 2-3

........................... 2-4

................................ 2-4

...................... 2-5

............................................ 2-7

........................... 2-9

................................................. 2-9

.................................... 2-9

.................................. 2-9

....................................... 2-10

START UP / OPERATION

Start up

.......................................................... 4-1

Stocking

Load Limits

Load Limit Profiles

Installing FDA/NSF Required Thermometer

........................................................ 4-1

.................................................... 4-1

.......................................... 4-1

..... 4-2

MAINTENANCE

Care and Cleaning ............................................ 5-1

Cleaning Honeycomb Assemblies

Cleaning Under Merchandisers

Removing Scratches from Bumper

........................ 5-2

......................... 5-2

...................... 5-2

SERVICE

Replacing Fan Motors and Blades ...................... 6-1

Replacing Electric Defrost Heaters

Replacing Drain Pan Heater

.................... 6-3

............................. 6-5

RLT with Gas Defrost Only: Replacing

Slave Plate Heater ........................................ 6-6

Servicing Vertical Lighting

Servicing Doors and Frames

Replacing Door or Door Frame Parts

Replacing Damaged Drain Fitting

Repairing Aluminum Coils

.............................. 6-7

............................. 6-7

................ 6-7

..................... 6-7

............................... 6-8

WARRANTY

DRIP PIPING AND SPLASHGUARDS

Waste Outlet and Water Seal ............................ 3-1

Installing Drip Piping

Drip Piping Lineup Arrangements

Installing Splashguards

Sealing Splashguard to Floor

..................................... 3-1

................... 3-4

................................... 3-5

........................... 3-6

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

This merchandiser is NSF® certified.

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900

www.hussmann.com

© 2015 Hussmann Corporation

iv Contents

INSTALLATION

TOOL LIST

Unloading From Trailer:

Lever Bar (also know as a Mule,

Johnson Bar, J-bar, Lever Dolly,

and pry lever)

Moving Dolly

Setting Case Line-Up:

Level, 4 ft suggested

Ratchet

¼ in. Socket

5

/16 in. Socket

½ in. Socket

Battery Drill/Screw Gun

Caulking Gun

10 in. Adjustable Crescent Wrench

ANSI Z535.5 DEFINITIONS

• DANGER – Indicate[s] a hazardous

situation which, if not avoided, will result

!

in death or serious injury.

• WARNING – Indicate[s] a hazardous

!

situation which, if not avoided, could

result in death or serious injury.

• CAUTION – Indicate[s] a hazardous sit-

!

uation which, if not avoided, could result

in minor or moderate injury.

• NOTICE – Not related to personal injury –

Indicates[s] situations, which if not avoided,

could result in damage to equipment.

REVISION HISTORY

REVISION R — JULY 2015

1.Replaced RLT drawings in Section 1; New Drawing

Page 2-6, 2-7, 4-2, wording on 6-2 and 6-4,

removed drawing 6-4.

P/N 0387183_R

REVISION Q — MAY 2015

1. Redesigned manual to 1/2 letter size

REVISION P — OCTOBER 2014

1. California Warning Statement, Page 1-2;

changed to 2 in. partition kit, Page 1-7; Shim

location, Page 1-6; End Caps, Page 1-8;

Removed screws, Page 2-2; Time Termination,

Page 2-8, 2-9; No thread sealer, Page 3-2, 3-3;

RLT load limit drawing, Page 4-2; Ammonia

cleaners, Page 5-3; Number 11, Page 6-1, 6-2;

Heater drawings, Page 6-4, 6-5; Removed number 2 teflon tape, Page 6-7.

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0387183_R

REVISION N — APRIL 2013

1. Inserted Joining Instructions,

Pages 1-8 - 1-22

REVISION M — MARCH 2013

1. Revised caution note on page 1-1; added to

Page 4-1.

REVISION L — AUGUST 2012

1. Updated instructions for moving case through

small doors, Section 1.

REVISION K — JULY 2012

1. Included instructions for clearing smaller store

entrances, Section 1. Ice cream note added to

Page 4-1.

REVISION J — APRIL 2012

1. Corrected Table of Contents, page iii.

REVISION I — NOT ISSUED

REVISION H — MARCH 2012

1. Amended Installing Drip Piping procedure,

Page 3-2.

REVISION G — MARCH 2010

1. Revised Installing Drip Piping procedure,

Pages 3-1 through 3-6.

REVISION E — JANUARY 2009

1. Added page division lines for thermometer,

Page 4-3.

2. Added heater front and rear drawing,

Page6-3.

3. Changed shimming drawing, Page 1-3.

REVISION D — SEPTEMBER 2007

1. Added front panel text and illustration, Page

1-2.

2. Clarified shimming directions, Page 1-3.

3. Added RLT information throughout.

4. Added note to remove bumper protective film,

Page 1-6.

5. Added information on Always*Clear™ glass,

page 5-1.

6. Removed reference to Anthony doors, Page

6-5.

7. Added repairing aluminum coil, Page 6-12.

8. Changed warranty page.

9. Added Installation Tool List, Page iv.

10. Added revision history, Page iv.

REVISION C — JUNE 2002

1. Added NSF information, Pages 1-1,4-2

through 4-4.

2. Sections 2 through 6 are completely

rewritten.

3. Changed warranty to March 15,2002.

REVISION F — DECEMBER 2009

1. Changed shimming drawing, Page 1-3.

2. Updated drip piping pitch, Page 3-1.

3. Added page division lines for thermometer,

Page4-3.

4. Added cleaning stainless steel rails,

Page5-2.

5. Added heater front and rear drawing,

Page6-3.

6. Updated warnings and cautions throughout

7. Added new back cover

HUSSMANN CORPORATION, BRIDGETON, MO 63044-2483 U.S.A.

Reach-In

P/N 0387183_R 1-1

INSTALLATION

NSF CERTIFICATION

These merchandisers are manufactured to meet ANSI

/ National Sanitation Foundation (NSF®) Standard

#7 requirements. Proper installation is required to

maintain certification. Near the serial plate, each case

carries a label identifying the type of application for

which the case was certified.

ANSI/NSF-7 Type I – Display Refrigerator / Freezer

Intended for 75°F / 55%RH Ambient Application

ANSI/NSF-7 Type II – Display Refrigerator / Freezer

Intended for 80°F / 55%RH Ambient Application

ANSI/NSF-7 – Display Refrigerator

Intended for Bulk Produce

LOCATION

These merchandisers are designed for displaying products in air conditioned stores where temperature is

maintained at or below the ANSI/NSF-7 specified level

and relative humidity is maintained at or below 55%.

Placing refrigerated merchandisers in direct sunlight,

near hot tables or near other heat sources could

impair their efficiency.

Like other merchandisers, these are sensitive to air disturbances. Air currents passing around merchandisers

will seriously impair their operation. Do NOT allow

air conditioning, electric fans, open doors or windows,

etc. to create air currents around the merchandisers.

Product should always be maintained at proper temperature. This means that from the time the product

is received, through storage, preparation and display,

the temperature of the product must be controlled to

maximize the life of the product.

SHIPPING DAMAGE

All equipment should be thoroughly examined for

shipping damage before and during unloading.

This equipment has been carefully inspected at our

factory. Any claim for loss or damage must be made

to the carrier. The carrier will provide any necessary

inspection reports and/or claim forms.

Apparent Loss or Damage

If there is an obvious loss or damage, it must be noted

on the freight bill or express receipt and signed by the

carrier’s agent; otherwise, carrier may refuse claim.

The carrier will supply necessary forms.

Concealed Loss or Damage

When loss or damage is not apparent until after

equipment is uncrated, a claim for concealed damage

is made. Upon discovering damage, make request in

writing to carrier for inspection within 15 days and

retain all packing. The carrier will supply inspection

report and required claim forms.

To prevent sweating on the exterior surfaces

of merchandisers, there must be

ance of 4 inch es (102 mm ) between the merchan-

a m inimum clear -

Do not store items or ammable

materials atop the unit.

disers and other fixtures or walls.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Do not walk on case.

Reach-In

1-2 InstallatIon

EXTERIOR LOADING

Do NOT walk on top of merchandisers or damage to

the merchandisers and serious personal injury could

occur.

They are noT sTrucTurally designed To supporT

excessive exTernal loading such as the weight of

a person. Do not store items or flammable materials

atop the unit.

For California Businesses:

This product may contain chemicals

known to the State of California to

cause cancer, birth defects, or other

This warning is the result of the California State law

known as the California Safe Drinking Water and Toxic

Enforcement Act of 1986, which is commonly referred

to as “Proposition 65.”

This warning does not mean that Hussmann products will cause cancer or reproductive harm, or is in

violation of any product-safety standards or requirements. As claried by the California State government,

Proposition 65 can be considered more of a ‘right to

know’ law than a pure product safety law. When used

as designed, Hussmann believes that our products are

not harmful. We provide the Proposition 65 warning

to stay in compliance with California State law. It is

your responsibility to provide accurate Proposition 65

warning labels to your customers when necessary. For

more information on Proposition 65, please visit the

California State government website.

reproductive harm.

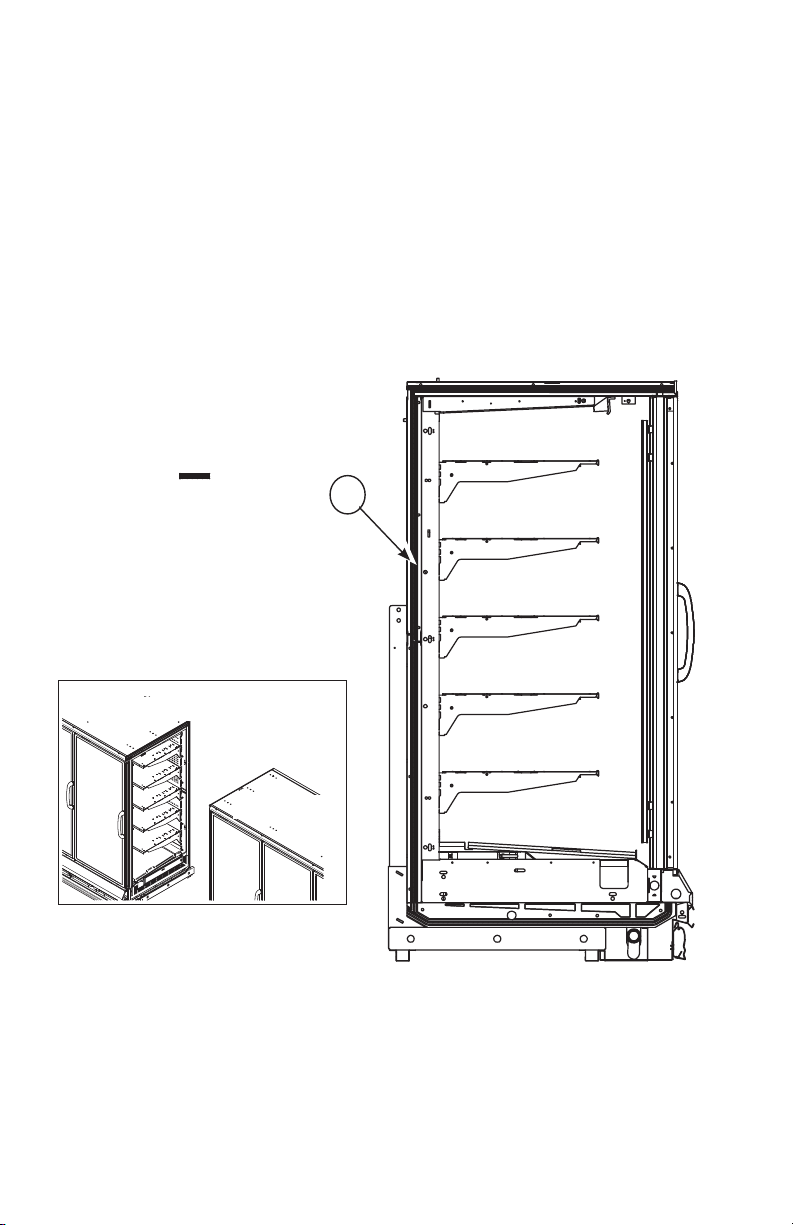

MERCHANDISERS SHIPPED WITH

END INSTALLED

If the case was shipped with the end installed, two

long bolts were used to hold the shipping brace to the

end. If the shipping bolts are reinserted after removing the brace, they will extend into the product area

and may damage the coil.

re pla ce The se bol Ts wi Th The sh or Ter bo lTs

pr ovi ded .

Th ere for e, be sur e T o

Be careful not to damage the factory-installed end

while moving the merchandiser. Make sure that tools

are positioned past the end and beneath the merchandiser’s support bar.

SHIPPING BRACES

Move the merchandiser as close as possible to its permanent location and then remove all packaging. Check

for damage before discarding packaging. Remove all

separately packed accessories such as kits and shelves.

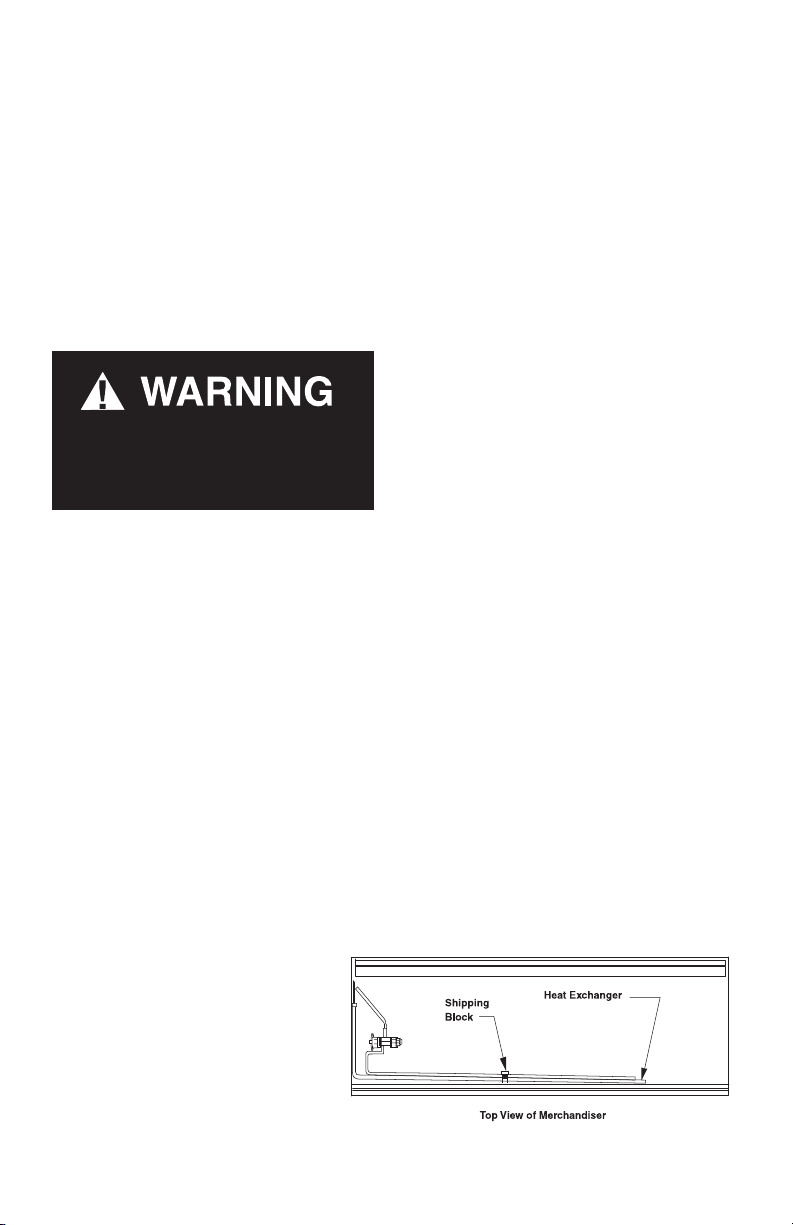

Locate the shipping block in the center of the heat

exchanger (see illustration), and remove it before

piping the merchandiser. This block was installed to

minimize shipping vibration.

P/N 0387183_R

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0387183_R 1-3

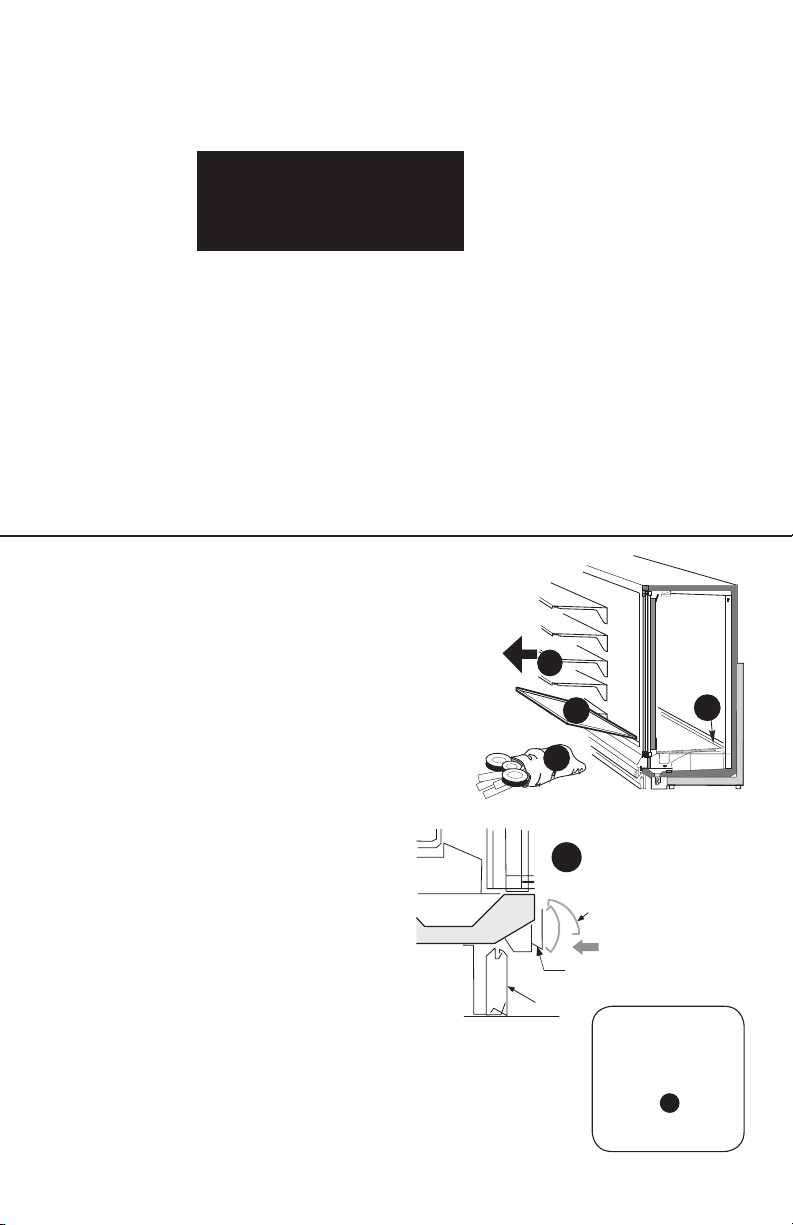

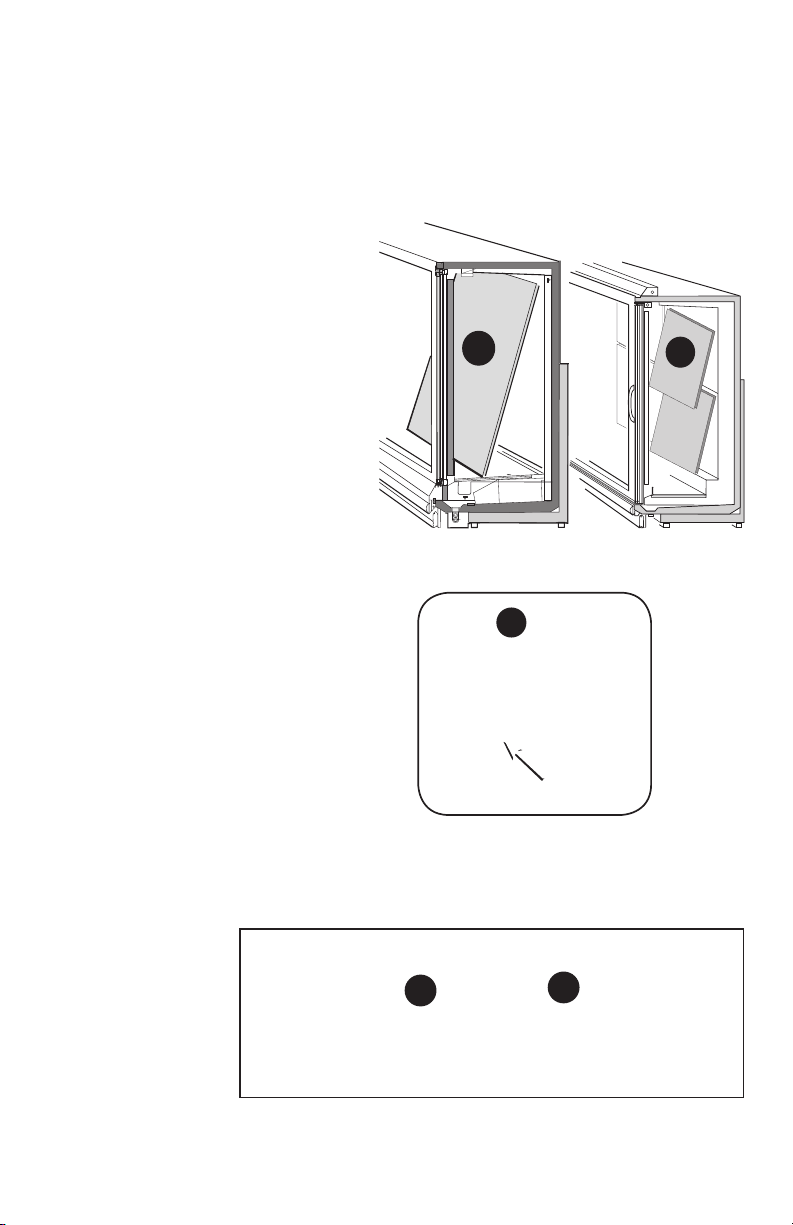

MOVING MERCHANDISER THROUGH

NARROW STORE ENTRANCES

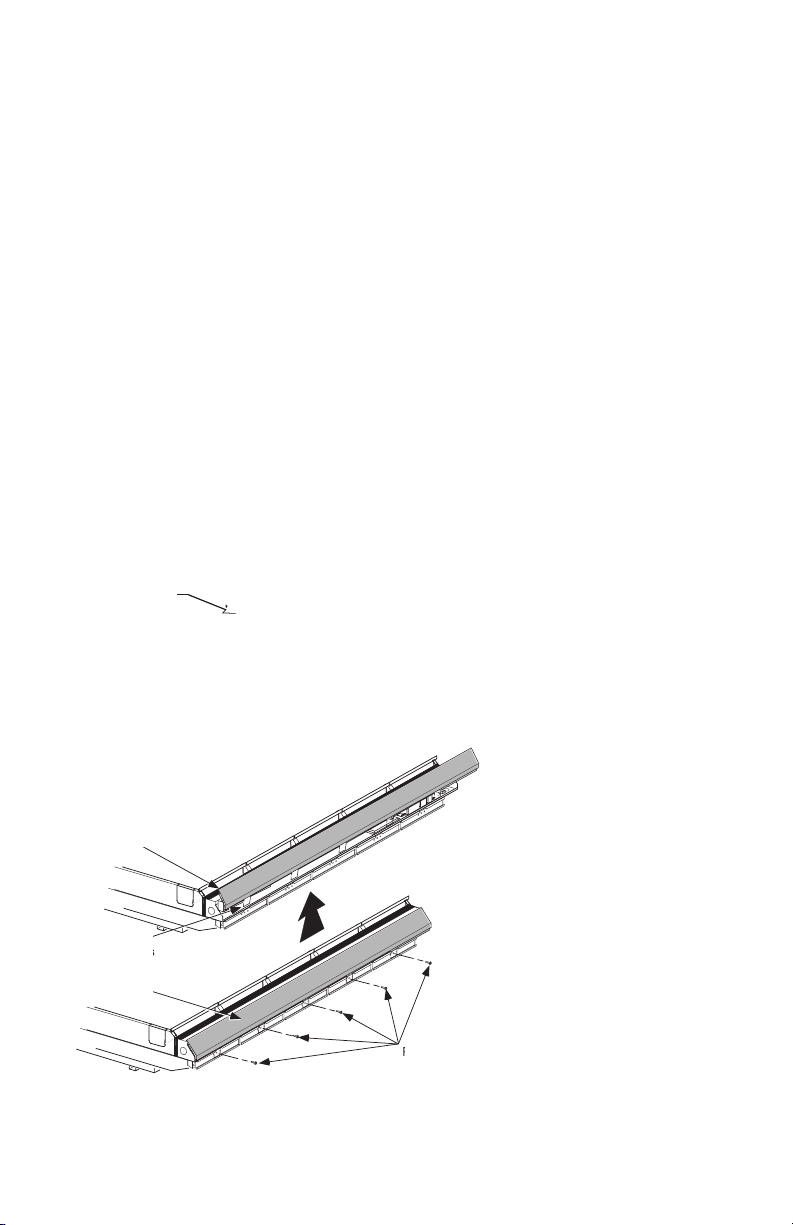

2. Remove the front bumper. Pull from the

Some exterior merchandiser parts may be disassembled

bottom and set aside.

for transit access through small doors or passage ways.

This procedure takes approximately 30 minutes to

disassemble and reassemble one case. Contact your

Hussmann representative to see if store merchandisers

have this kit option. The case height without these

components installed on top is 82.75 in. (2102 mm).

Case depth is 35.5 in. with handles, wireway pan and

external frames removed.

Follow the steps below to decrease the

merchandiser profile for narrow access:

1. Remove the door handles.

Remove

Screws from

Door Handle

Edge Fits over

Wireway

Tabs t in

Retainer Slots

Front Panel

3. Remove the lower front panel to access the

wireway.

Remove Screws

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Reach-In

1-4 InstallatIon

4. Remove the screws that attach the wireway pan to

the bottom assembly.

5. Detach the rubber and plastic gromets from the

wireway pan.

6. Remove the screws that attach the grounding lug to

the wireway pan.

7. Slide the wireway pan out, and remove it from the

case. Bumper brackets and supports are attached to

wireway pan. Removing the pan will remove the entire

assembly.

8. Remove the back, external braces from the rear of

the case as shown below. Braces will slide straight

back away from the case when nuts and screws are

removed.

6 nuts and 1

bottom screw per

external brace

P/N 0387183_R

Bottom screw is located approximately 10 inches inboard from the rear of

the case. Bottom screw location on

removed rear brace.

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0387183_R 1-5

Check the following before the rear of the case is positioned at its final location according to the store plan:

1. The external braces must be reinstalled

with (6) nuts per brace, torqued to 24 foot

pounds.

Do not walk on top of merchandiser.

Do not store items or

ammable materials atop the unit.”

FINAL LOCATION

Once the case reaches its final location, reassemble the

wireway and door handles as follows:

1. Reinstall wireway pan in reverse order of removal.

2. The ground lug must be reinstalled using the

screws provided.

3. Replace the conduit connectors and plastic gromets to the wireway pan.

LEVELING

Merchandisers must be installed level to ensure proper

operation of the refrigeration system and to ensure

proper drainage of defrost water. When leveling mer-

chandisers, use a carpenter’s level as shown.

Metal leveling shims or wedges are provided with each

merchandiser for use if needed.

Rear external frames must be

reinstalled securely before setting

or unloading shelves.

o not walk on top of the merchandIser.

D

do not place heavy objects on case.

4. Replace wireway cover, bumper and door handles.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Reach-In

1-6 InstallatIon

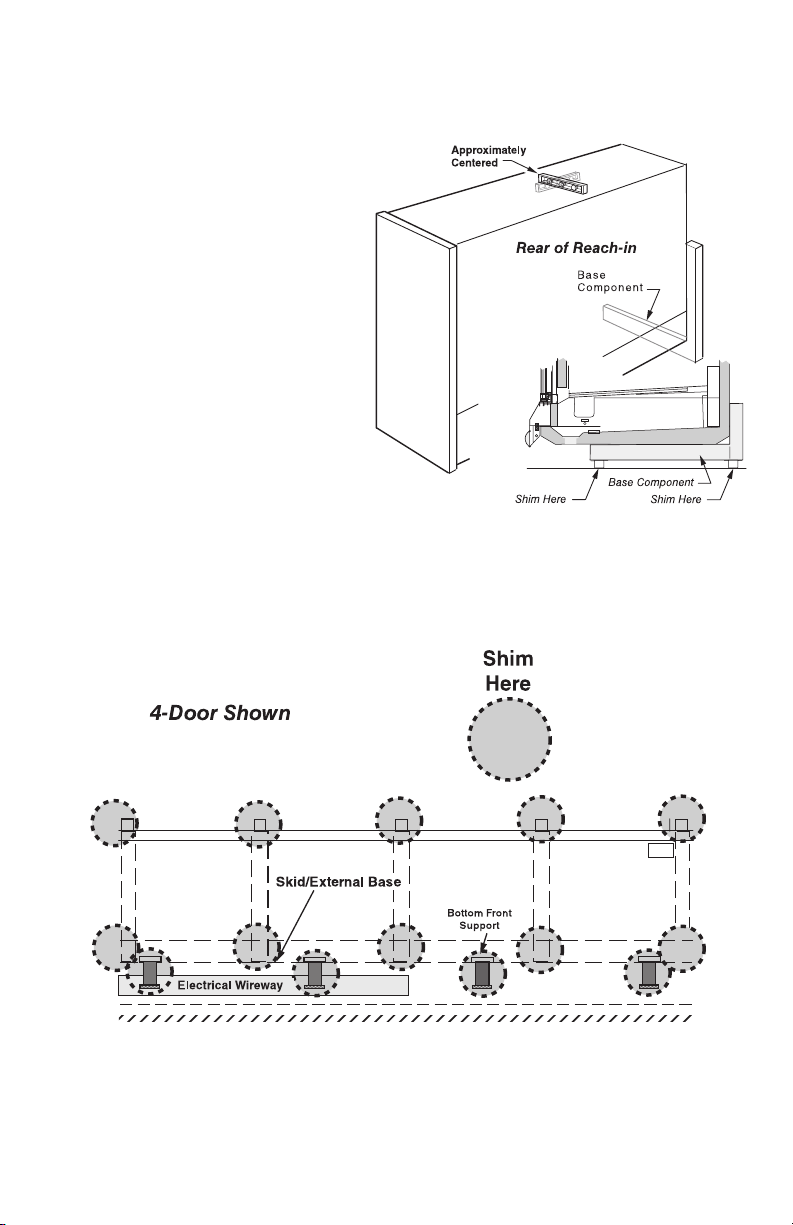

LEVELING

Merchandisers must be installed level to ensure

proper operation of the refrigeration system and

to ensure proper drainage of defrost water. When

leveling merchandisers, use a carpenter’s level as

shown.

Metal leveling shims or wedges are provided with

each merchandiser for use if needed.

NOTE:

Be gi n li neu p le ve li ng f ro m t he

hi gh es t po in t o f th e st ore f lo or .

Place shims under the rail and make sure that they

are positioned at a base component (crossbar).

This transfers the weight directly from the loaded

case through to the floor.

Placing shims at other locations will cause uneven

distribution of weight leading to piping leaks, as well

as sagging or wracked doors.

P/N 0387183_R

Back

Front

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0387183_R 1-7

DOOR ADJUSTMENT

After leveling and joining the merchandisers, adjust

and level doors according to manufacturer’s instructions

shipped with each product. Factory settings may be

lost due to vibration during shipment.

JOINING

Sectional construction means that two or more merchandisers may be joined in line yielding one long

continuous display requiring only one pair of ends.

Joining kits and instructions are shipped with each

merchandiser.

To join like fixtures, a joining kit is required. To

join unlike fixtures, or like fixtures operating at different temperatures, a 2inch (51mm) partition kit

is required. To join same temperature merchandisers

on different defrost cycles, a plexiglass partition kit is

required.

all jo inTs musT be air-Ti ghT To pre venT forma-

Tion o f ice or condensaTi on.

Refer to the instructions on the next page.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Reach-In

1-8 InstallatIon

Joining Instructions

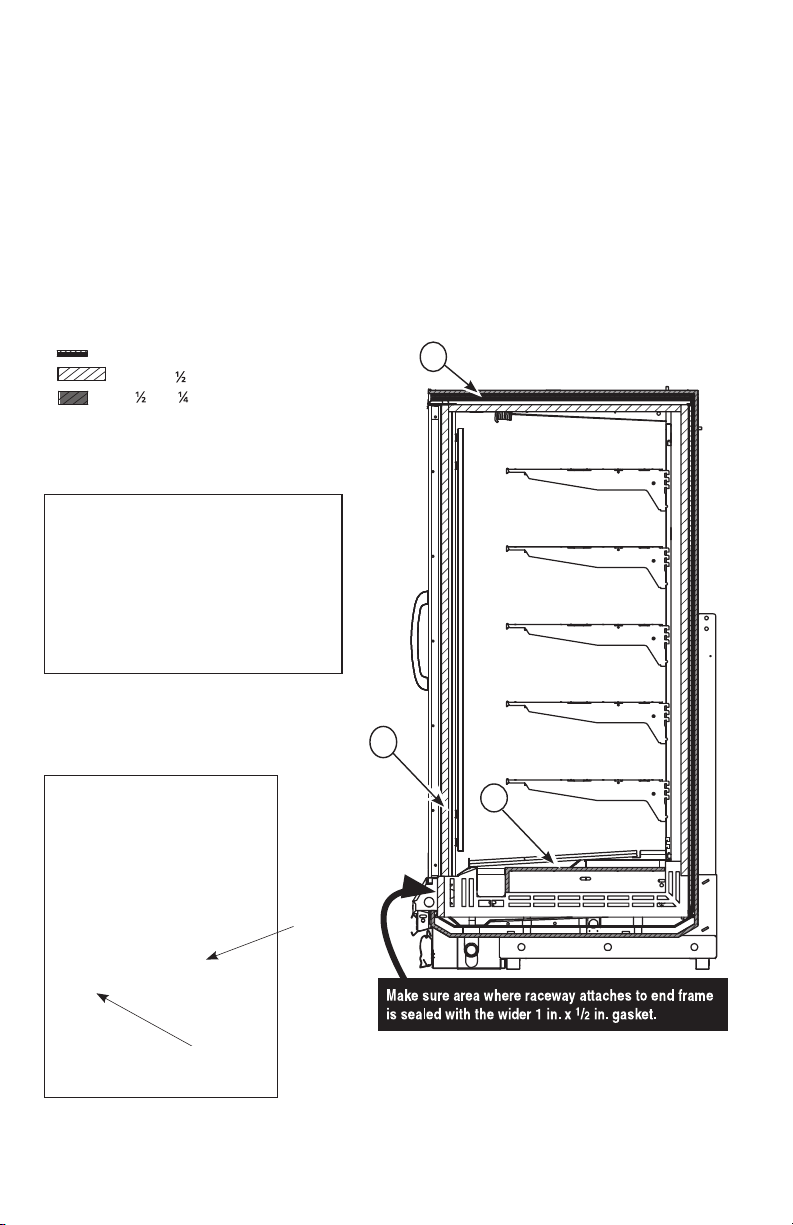

RL / RM / RMF, RLTM

RLN / RMN / RLNI / RLNIE

Splashguard brackets must

be installed before piping or

PARTS LIST

Item

Quantity Description

RL/RM RLN RLNI

RM/RMF RMN RLNIE RLTM

1. 2 2 4 2 Donut Gasket

2. 1 1 2 2 Gasket, 1 x

3. 1 1 2 1 Gasket,

4. 8 8 14 6 Cap Screw

5. 8 8 14 6 Split Lock Washers 5/16

6. 1 1 2 1 Joint Molding

7. 5 5 10 5 Binder Post and Screw

8. 1 1 2 1 Splice Connector

NOTE: Be sure first merchandiser has been leveled

according to the main installation instruction.

Carefully unpack and inspect the joining parts listed

above to verify completeness and that there is no

damage.

wiring case.

Joining Instructions

1

/2 x 180 in.

1

/2 x 1/4 x 180 in.

5

/16 -18 x 11/4

B

C

E

D

Prepare cases for joining (both sides of

1

islands) as shown in Figure 1.

A. Remove bumpers, rails, packing materials,

and splashguards from the both cases.

B. Remove shelves (if installed).

C. Remove display racks and pans from

ends to be joined.

D. Remove plenum covers

P/N 0387183_R

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

RLTM

Figure 1. Prepare Cases

SIDE VIEW

A

A

Bumper

Retainer

Splashguard

Bumper

C

P/N 0387183_R 1-9

RL / RM / RMF

RLN / RMN

and RLNI

E. Remove back panels from ends to be

joined by lifting up and out near the bottom. No tools are necessary. The RLTM

models have upper and lower back panels

that must be removed.

F. Remove joint molding from any door

frames that will be joined to another case.

G. RLNI Only: Remove screws and interior top panel on both sides of the island

case end to be joined (see Figure 1).

E

F

Alignment Pin

RLTM

E

G

RLNI Only

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

G

Reach-In

1-10 InstallatIon

Shipping

Block

Figure 2. Remove Shipping Block

(One From Each Side of Island Models)

Locate and remove the shipping block in the

2

center of the heat exchanger in the interior

bottom of each case, see Figure 2.

Snap a chalk line on the floor to use as a guide

for positioning the front of the cases in the

line-up. The front base frame should be on the

chalk line.

Once cases are close to final placement, remove

3

the shipping braces from the ends to be joined,

see Figure 3. Discard bolts and flat washers

used to hold shipping braces. Bolts are too

long to be used for joining.

Do not use shipping bolts to join cases!

RMN

P/N 0387183_R

Shipping Brace

RLNI / RLNI

Figure 3. Remove Shipping Braces

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0387183_R 1-11

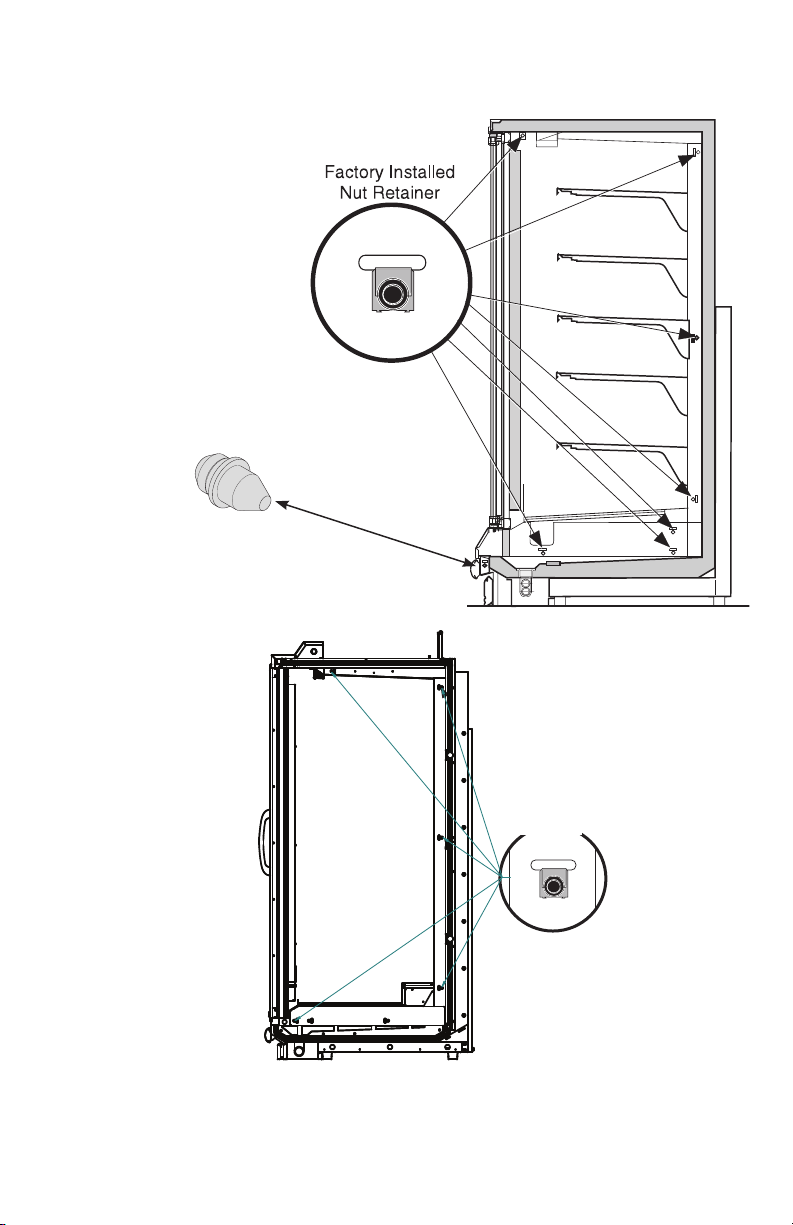

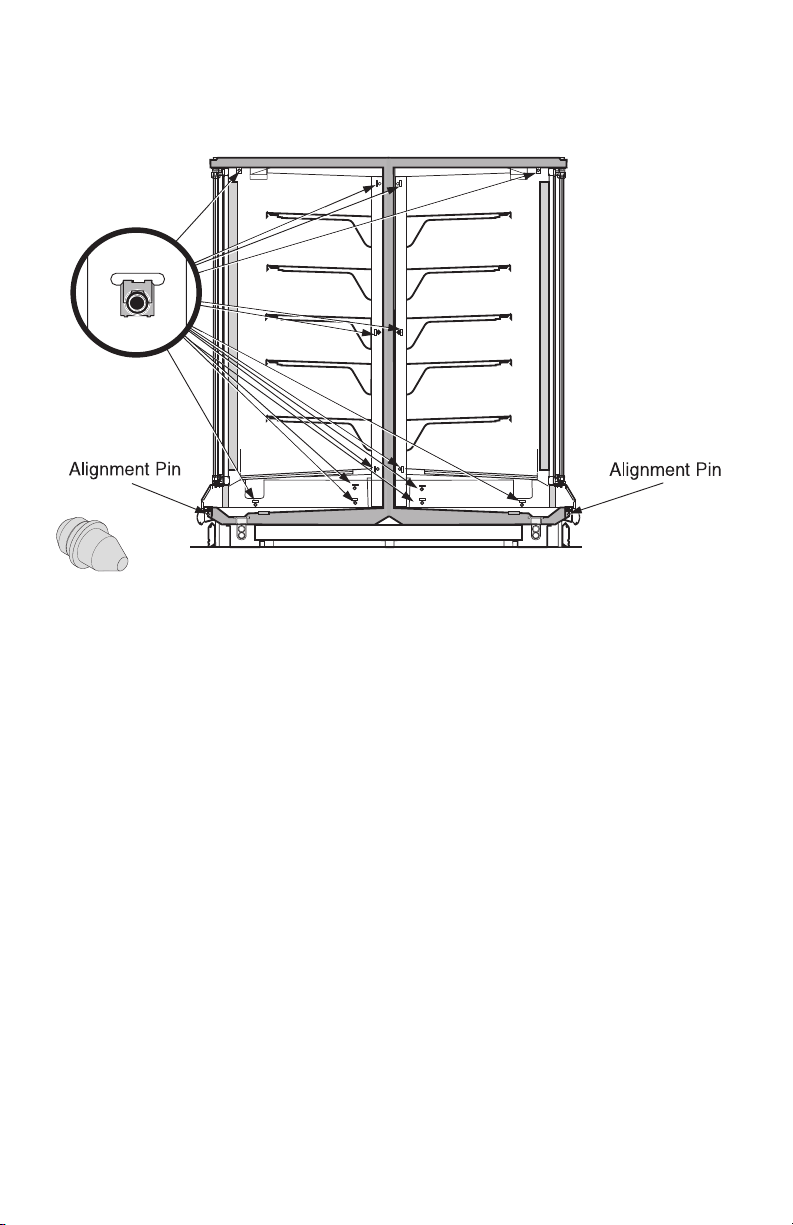

If not already installed make

sure NutRetainers and

4

Alignment Pins are in place in

the right end frame as shown

in Figure 4A or 4B.

RL / RM / RMF

and

RLN / RMN

Alignment Pin

RLTM

RLT has no

Alignment Pin

Figure 4A. Verify Nut Retainer Installation

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Factory Installed

Nut Retainer

Reach-In

1-12 InstallatIon

RLNI

P/N 0387183_R

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

P/N 0387183_R 1-13

Left End

PadShoeSealer

in

1- Donut

Apply Donut Gasket– 1 in recess around both

5

left end as shown in Figure 5A, Part 1; 5B or

5C, Part 1, and right end frames as shown in

Figure 5A, Part 2; 5B or 5C, Part 2.

RL / RM / RMF

and

RLN /

RMN

Right End Case

Apply the wider Foam Tape Gasket — 2

around the right end frame as shown in Figure

5A, Part 2, 5B or 5C, Part 2.

Left End Case

F

1

R

O

N

T

Left End Case

Figure 5A, Part 1. Apply Gasket to Left End of

RL/RM/RMF and RLN/RMN

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Reach-In

1-14 InstallatIon

Right End

Left End

F

R

O

N

T

1- Donut

2- 1 in x

in

3- in x in

Use all three gaskets

When applying an end

assembly.

assembly.

Apply Pad Shoe Sealer first,

then apply the narrower Foam

Tape Gasket — 3 around

the perimeter of the right end

frame outside of the donut

gasket as shown in Figure 5A,

Part 2, 5B or 5C, Part 2.

1- Donut

2- 1 in x

3- in x in

Use all three gaskets

When applying an end

notes:

1. The perimeter gasket, Item 3,

is required by NSF.

2. Butyl is NOT an acceptable

substitute for donut or foam

gasket.

in

• Lap gaskets at lower

corners.

• Check that there are no

gaps between gasket and case.

• Do not stretch gasket,

especially around corners.

To make sharp corners,paper

backing can be torn without

removing from gasket.

RL / RM /

RMF

and

RLN / RMN

F

R

O

N

T

2

1

Right End Case

ALL MODELS: Apply

gasket between

wipes.

3

• Do not butt gaskets; always

lap joints.

• Remove paper backing after

gasket is applied to keep gasket

free of debris.

• Gasket has high tack

adhesive and must be properly

placed the first time.

Figure 5A, Part 2. Apply Gaskets to Right End of RL/RM/RMF and RLN/RMN

P/N 0387183_R

Pad Shoe

Sealer

Overlap

Gasket

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • WWW.HUSSMANN.COM

Loading...

Loading...