BUNN

®

DG-2

WDG-2

02328.0000(4)

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

10854.0000 3/00 ©1995 Bunn-O-Matic Corporation

CONTENTS

Introduction .............................................................................. 2

Warranty ................................................................................... 2

User Notices ............................................................................. 3

Electrical Requirements ............................................................ 4

Operating Controls .................................................................... 4

Initial Set-Up .............................................................................5

Cleaning .................................................................................... 6

Coffee Grinding .........................................................................6

Adjustments .............................................................................. 7

Trouble Shooting ...................................................................... 9

Service ....................................................................... 12 thru 23

Wiring Diagrams ................................................................24,25

INTRODUCTION

This equipment will store up-to six pounds of whole bean coffee in each of two hoppers and grind it to a preset

grind and amount into an awaiting funnel and filter from most commercial drip coffee brewers. The equipment is only

for indoor use on a sturdy counter or shelf. Adequate space must be available above the grinder to raise the lids when

adding beans. Use only with whole bean coffee.

The grind is preset at the factory to drip specifications as set forth by the United States Department of Commerce

and adopted by the Coffee Brewing Center of the Pan American Coffee Bureau. Adjustments may be made to alter both

the amount and grind from the factory setting.

WARRANTY

Bunn-O-Matic Corp. (“Bunn”) warrants the equipment manufactured by it to be commercially free from

defects in material and workmanship existing at the time of manufacture and appearing within one year from the

date of installation. In addition:

1.) Bunn warrants electronic circuit and/or control boards to be commercially free from defects in material

and workmanship for two years from the date of installation.

2.) Bunn warrants the compressor on refrigeration equipment to be commercially free from defects in mate-

rial and workmanship for two years from the date of installation.

3.) Bunn warrants that the grinding burrs on coffee grinding equipment will grind coffee to meet original

factory screen sieve analysis for three years from date of installation or for 30,000 pounds of coffee, whichever

comes first.

This warranty does not apply to any equipment, component or part that was not manufactured by Bunn or

that, in Bunn’s judgement, has been affected by misuse, neglect, alteration, improper installation or operation,

improper maintenance or repair, damage or casualty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Bunn are not

authorized to make modifications to this warranty or to make additional warranties that are binding on Bunn.

Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not

be relied upon.

The Buyer shall give Bunn prompt notice of any claim to be made under this warranty by telephone at (217)

529-6601 or by writing to Post Office Box 3227, Springfield, Illinois, 62708-3227. If requested by Bunn, the

Buyer shall ship the defective equipment prepaid to an authorized Bunn service location. If Bunn determines, in

its sole discretion, that the equipment does not conform to the warranty, Bunn shall repair the equipment with no

charge for parts during the warranty period and no charge for labor by a Bunn Authorized Service Representative

during the warranty period. If Bunn determines that repair is not feasible, Bunn shall, at its sole option, replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE

SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AS

SPECIFIED HEREIN, TO REPAIR OR, AT BUNN’S SOLE OPTION, REPLACEMENT OR REFUND.

In no event shall Bunn be liable for any other damage or loss, including, but not limited to, lost profits, lost

sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages.

2

10854 030300

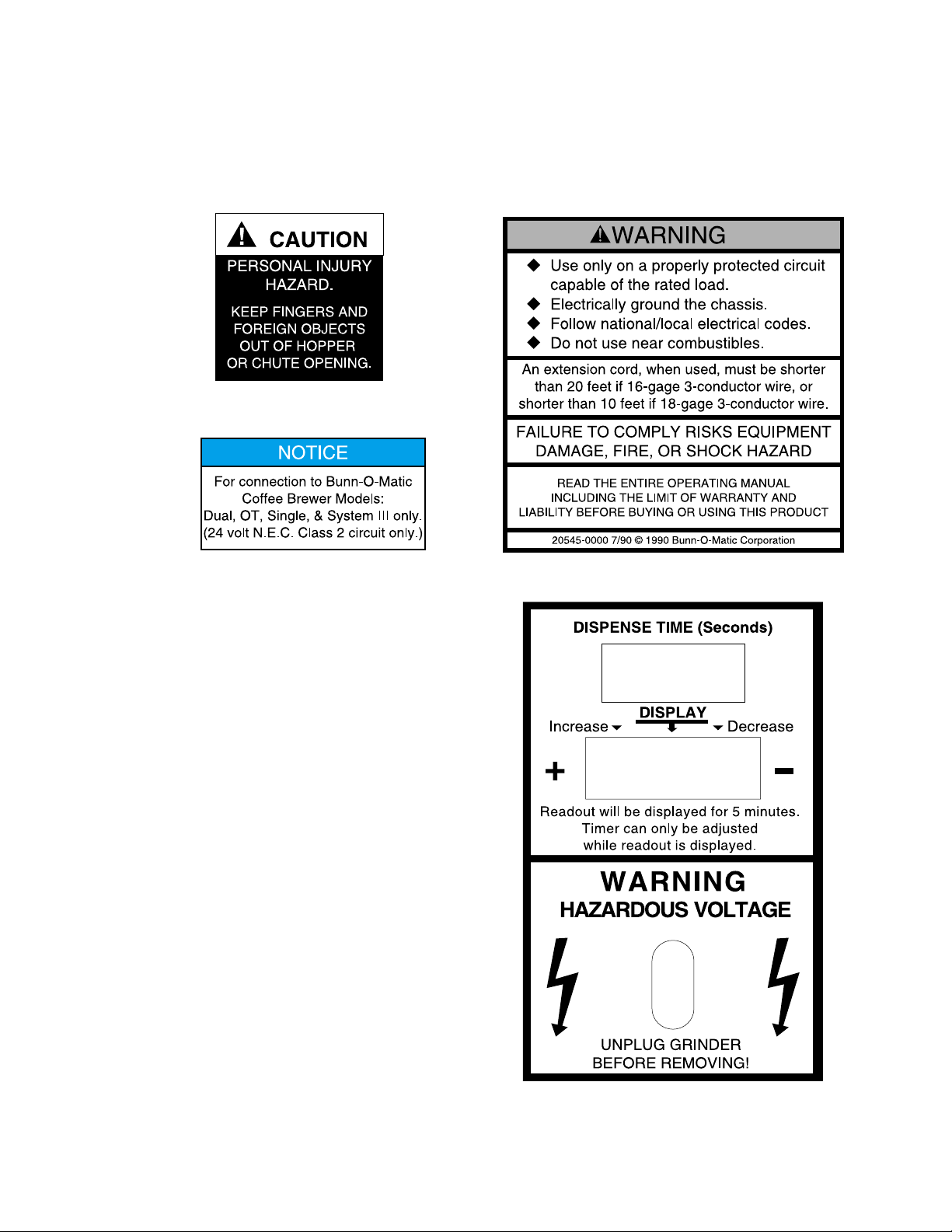

USER NOTICES

Carefully read and follow all notices on the grinder and in this manual. They were written for your protection. All notices on the

grinder are to be kept in good condition. Replace any unreadable or damaged labels.

#05876.0000

#24237.0000

#20545.0000

#05942.0000

DG-2 ONLY

3

10854 030300

ELECTRICAL REQUIREMENTS

This grinder has an attached cordset and requires 2-wire, grounded service rated 120 volts ac, 15 amp,

single phase, 60 Hz.

OPERATING CONTROLS

Off/On/Start Switch

OFF - (upper position) Switching to this position stops all operation of the grinder.

ON - (middle position) The switch will return to this position after a grind cycle has begun and

will remain in this position after grinding has ceased.

START - (lower, momentary position) Pressing the switch to this position and releasing initiates

a grind cycle.

Hopper Selector Switch

LEFT - Switching to this position allows beans to be ground from the left

hopper.

RIGHT - Switching to this position allows beans to be ground from the

right hopper.

P734

Dispense Timer - DG-2

The dispense timer controls the amount of beans that will be ground in a cycle. The timer can be adjusted

to dispense a different amount from each hopper. The scale is from 0.1 to 60.0 seconds. Refer to the

Adjustments section for timer setting chart. See page 7.

+/Increase - (left momentary push-button)

DISPENSE TIME (Seconds)

I 0.0

DISPLAY

Increase Decrease

+

Readout will be displayed for 5 minutes.

Timer can only be adjusted

while readout is displayed.

WARNING

HAZARDOUS VOLTAGE

Pressing this button will increase the dispense interval on the timer while

the readout is displayed. The interval will change slowly for the first second’s

indication, then speed-up for the next fifteen second’s indication, and increase

very fast after that until it reaches the limit on the scale.

DISPLAY - (center momentary push-button)

Pressing this button will display the current timer readout. The timer can

only be adjusted while the readout is displayed. The indication on the display

will last for five minutes.

UNPLUG GRINDER

BEFORE REMOVING!

–/Decrease - (right momentary push-button)

P595

Pressing this button will decrease the dispense interval on the timer while

the readout is displayed. The interval will change slowly for the first second’s

indication, then speed-up for the next fifteen second’s indication, and increase very fast after that until it reaches

the limit on the scale.

4

10854 030300

NOTICE

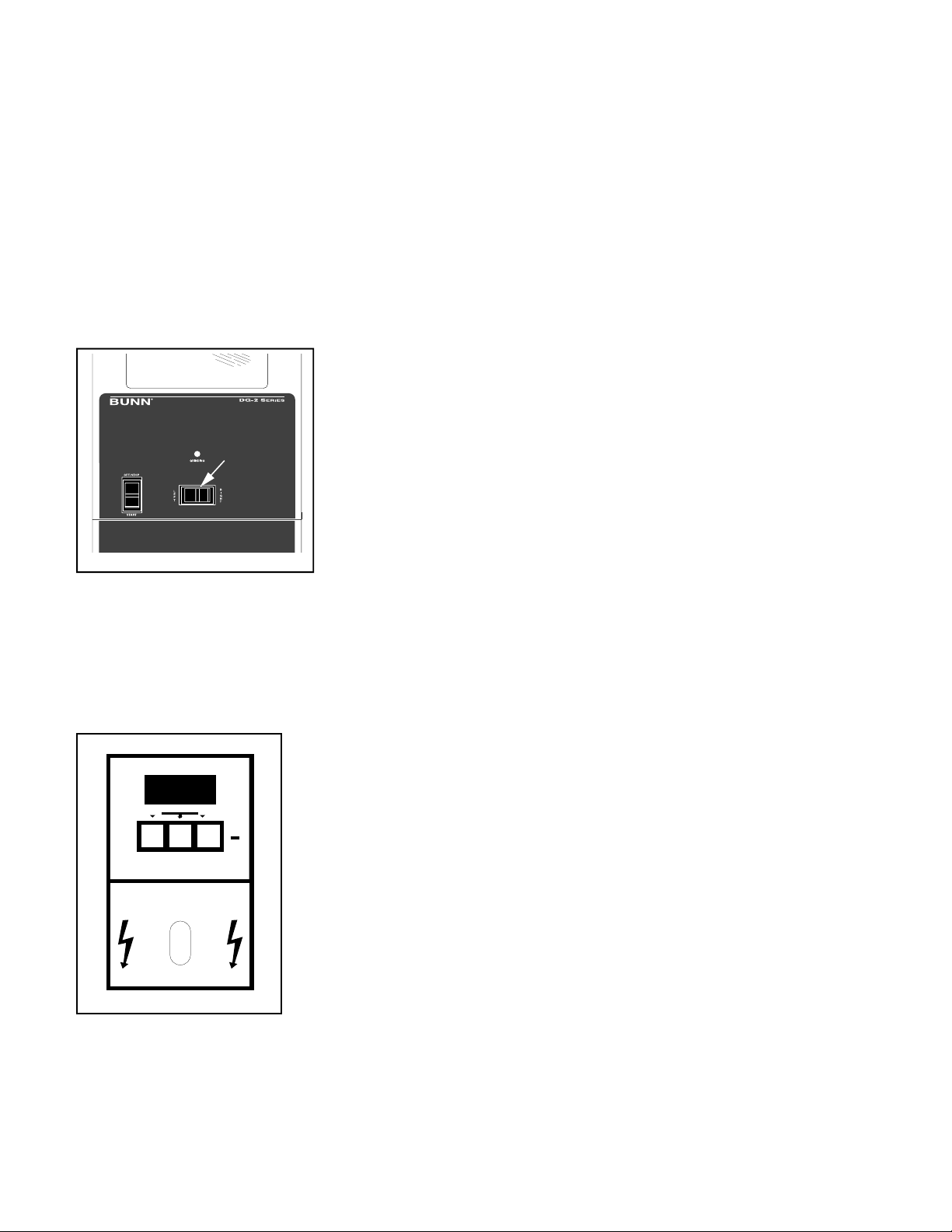

DG-2 INITIAL SET-UP

1. WARNING - Unplug grinder before removal of any panel.

2. Read NOTICE attached to upper front inspection panel.

3. Remove upper front inspection panel located below control switches and

the rear panel.

4. Remove shipping bracket, materials and discard.

5. Reinstall upper front inspection panel and rear panel.

6. Open the top lid(s). Clear all foreign objects and shipping material from the

hopper compartments and the entrance to the grind chambers.

7. Remove the lower front inspection panel.

8. Plug-in the grinder.

9. Select either the left or right hopper with the selector switch. Do not press

the start switch.

10. The dispense timer panel readout will indicate the present timer setting in

seconds and will remain displayed for five minutes.

11. Increase or decrease the timer setting to obtain the desired amount of coffee for the hopper selected by pressing the appropriate button (+ or –).

12. Repeat steps 9 thru 11 for the other hopper. The display will go out on its

own. Reinstall lower front inspection panel.

13. Fill the hopper compartments with whole bean coffee. (Capacity 6 pounds

each). The grinder is now ready for use.

DISPENSE TIME (Seconds)

I 0.0

DISPLAY

Increase Decrease

+

Readout will be displayed for 5 minutes.

Timer can only be adjusted

while readout is displayed.

WARNING

HAZARDOUS VOLTAGE

UNPLUG GRINDER

BEFORE REMOVING!

P734

WDG-2 INITIAL SET-UP

1. WARNING - Unplug grinder before removal of any panel.

2. Read NOTICE attached to the upper front inspection panel.

3. Remove upper front inspection panel located below control switches and

the rear panel.

4. Remove shipping bracket, materials and discard.

5. Reinstall upper front inspection panel and rear panel.

6. Open the top lid(s). Clear all foreign objects and shipping material from the

hopper compartments and the entrance to the grind chambers.

7. Remove the four screws securing the lower front inspection panel and carefully pull out far enough to view and operate the digital control display

assembly.

8. Plug-in the grinder.

9. Select either the left or right hopper with the selector switch. Do not press

the start switch.

10. The digital control display assembly screen displays selected weight when

idle. When grinding - display resets to 0.00 and shows increasing weight.

Display shows final weight for ten seconds and returns to selected weight.

11. Use (+) or (-) buttons and left or right hopper selector switch to set selected

weights, .50 oz minimum - 16 oz maximum.

NOTE: Refer to function list on page 8 for recalibration of weigh control

assembly if necessary.

NOTICE

The Shipping Bracket and

All Packing Material

Behind This Panel

MUST be Discarded

Before Using Grinder!

(Refer to the Operating & Service Manual for

Additional Set-up Information.)

NOTICE

For connection to Bunn-Omatic

Coffee Brewer Models:

Dual, OT, Single, & System III only.

(24 volt N.E.C. Class 2 circuit only.)

B

U

N

N

N

IO

T

A

R

O

P

R

O

C

IC

T

A

-M

-O

N

N

U

B

Y

B

D

E

R

U

T

C

A

F

U

N

A

M

.

.A

.S

, U

IS

O

IN

L

, IL

D

L

IE

F

G

IN

R

P

S

/N

S

L

E

M

D

O

S

T

T

A

W

M

P

. A

.C

A

S

T

L

O

V

Z

T

R

E

H

E

IR

W

E

S

A

H

P

:

S

T

N

E

T

A

P

G

IN

W

O

L

L

O

F

E

H

T

F

O

E

R

O

M

R

O

E

N

O

R

E

D

N

U

D

E

R

E

V

O

C

G

IN

D

N

E

P

E

B

Y

A

M

S

T

N

E

T

A

P

R

E

H

T

O

E

R

O

M

R

O

E

N

O

P928

-

+

+

F

F

U

U

N

N

C

C

+

F

U

N

C

PP927

P927

5

10854 030300

SPECIAL SET-UP FOR FLAVORED COFFEE BEANS

1. WARNING - Unplug grinder before removal of

any panel.

2. Select the hopper to be used for flavored coffee

beans.

3. Remove upper front inspection panel located

below control switches.

4. Locate dechaffer blade lever for hopper(s) selected in step #2.

5. Rotate lever clockwise approximately 90°.

6. Remove clip(s) from bag inside of grinder housing and clip to the right of the lever. This will

hold the dechaffer open.

7. Reinstall upper front inspection panel.

25705.0000

02311.0000(4)

S

S

R

R

A

A

O

O

C

C

T

H

E

M

O

P

R

T

O

Y

U

O

H

N

G

O

P

H

R

P

O

E

F

L

R

E

B

Y

C

L

D

E

N

I

A

R

N

G

01384.0000

E

E

IN

IN

F

F

E

E

S

S

R

R

A

A

Y

O

O

L

C

C

B

.

R

S

A

O

M

C

R

E

E

S

V

S

O

A

C

U

E

E

E

B

R

S

IN

IN

I

E

H

T

F

F

E

E

C

I

T

E

R

E

M

A

H

C

R

O

G

T

F

H

N

E

E

I

E

M

O

V

B

Y

C

P

R

O

I

L

T

R

O

M

Y

T

E

B

E

U

.

O

H

N

B

R

R

S

A

G

O

O

M

E

C

M

P

R

H

R

P

A

O

E

F

L

R

E

E

B

H

Y

E

C

C

S

L

D

E

V

N

I

A

R

N

G

S

O

A

C

U

E

B

R

S

I

E

H

T

R

O

G

F

N

E

I

E

V

B

O

R

M

E

B

01384.0002

P1178

6

10854 030300710854 030300

CLEANING

EXTERIOR SURFACES

The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning all

surfaces on Bunn-O-Matic equipment. Care should be taken not to scratch the hopper or windows with any

abrasive material. Regular cleaning will keep your grinder looking new for years.

GRIND CHAMBER

1. WARNING - Unplug grinder before removal of any panel or grind chamber housing parts.

2. Empty all beans from both hoppers.

3. Remove upper front inspection panel located below control switches.

4. Remove the two nuts holding dispense chute cover. Carefully wipe inside surface of dispense chute and

cover with a dry clean cloth.

5. Select a grind chamber to clean first. Each grind chamber should be disassembled, cleaned and reassembled

before cleaning the opposite side.

6. Remove the two screws holding front cover to burr housing. Carefully remove burr housing front cover.

Clean the inside surface with a dry stiff nonmetallic bristle brush and wipe with a dry clean cloth.

7. Carefully remove rotor button, rotor, brass bushing and steel washer from grinder. Clean all parts with a dry

stiff nonmetallic bristle brush and wipe with a dry clean cloth.

8. Clean the grind chamber with a dry stiff nonmetallic bristle brush and wipe with a dry clean cloth. Use a small

screw driver to dislodge coffee packed in the discharge chute at the base of the grind chamber and wipe

clean. Use care not to damage dechaffer blade.

9. Reinstall steel washer, brass bushing (flanged end first), rotor, rotor button and front cover to burr housing.

10. Repeat steps 6 through 9 on remaining grind chamber.

11. Reinstall dispense chute cover.

12. Reinstall upper front inspection panel.

13. Refer to adjustments section below to vary the grind dispensed from each grind chamber.

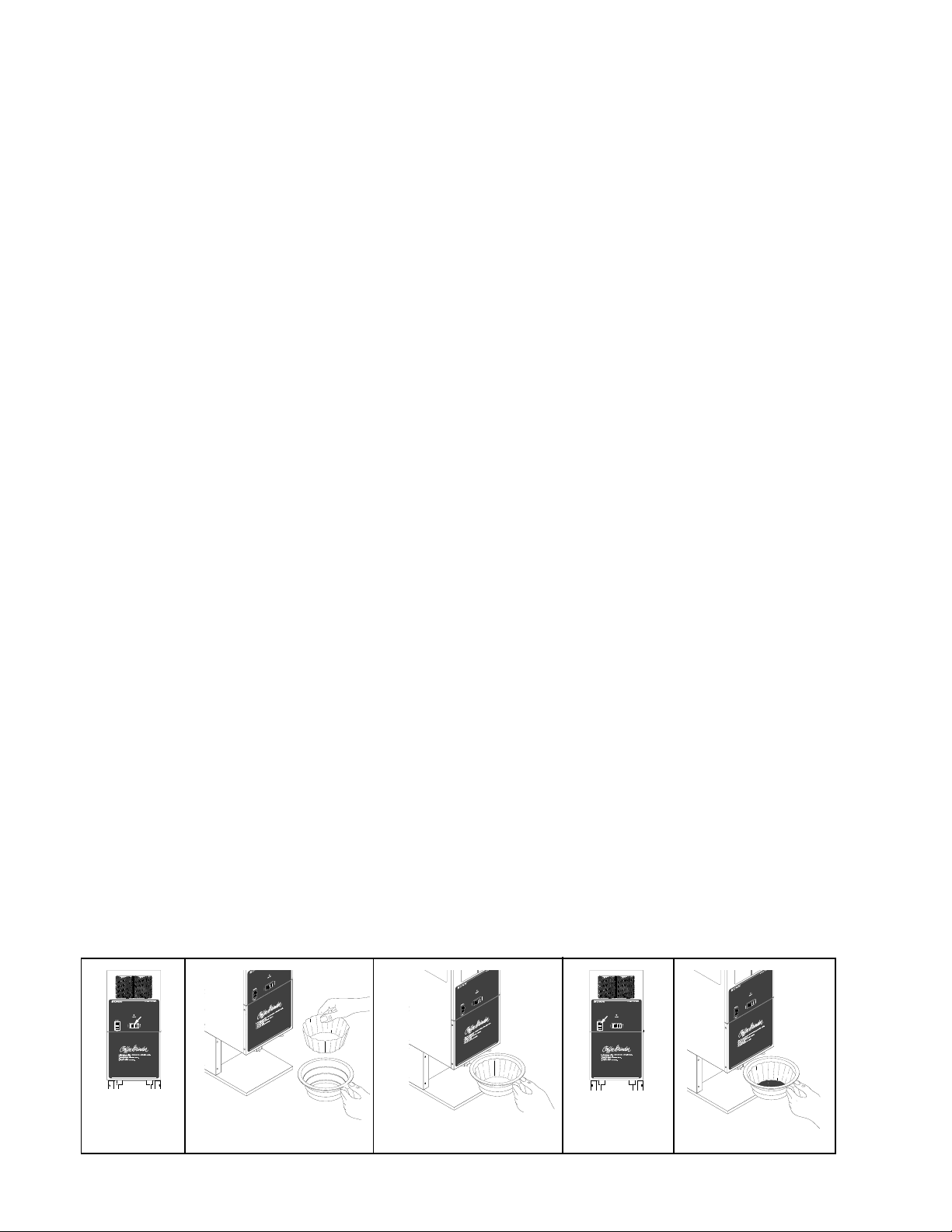

COFFEE GRINDING

1. Select (either left or right hopper) with selector switch and visually inspect the desired hopper for an ample

supply of whole bean coffee.

2. Place a paper filter into the brew funnel. The filter must not be folded-over or tilted to one side.

3. Insert the funnel into the funnel rails and push until it stops.

4. Momentarily press off/on/start switch to the "START" lower position and release. The grinding action will stop

automatically after the preset amount of ground coffee is dispensed into the funnel.

5. Remove the funnel from the grinder and level the bed of grounds by gently shaking.

6. The loaded funnel is now ready for use in any commercial drip coffee brewer according to the manufacturer’s

instructions.

P934

STEP #5

P935

STEP #1

P931

STEP #2

P932 P933

STEP #3

STEP #4

8

10854 030300

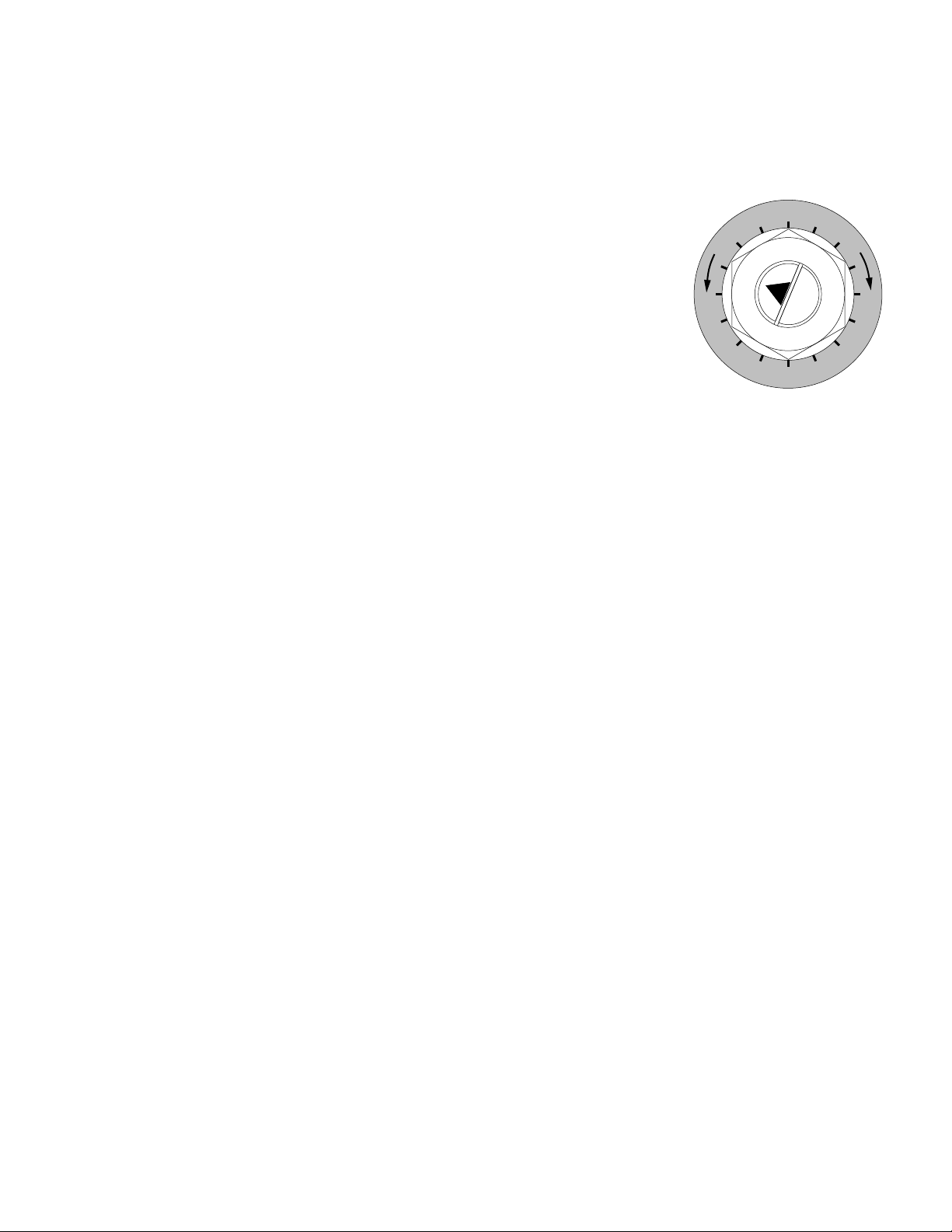

ADJUSTMENTS

The grind can be set from fine to very coarse. The grind may be adjusted for use in most commercial coffee

brewers. The following procedures should be used to make adjustments.

NOTE - On DG-2 grinders a change in the burr adjustment will also change the amount dispensed. Any adjustment to the burrs should be followed by an adjustment of the timer,

Burr Adjustment

1. Unplug the grinder and empty all beans from the hopper(s).

2. Plug-in the grinder, place funnel with filter into the funnel rails. Momentarily

O

C

-

F

I

E

S

R

A

N

E

press the off/on/start switch to the “START” (lower) position (with desired

hopper selected) and release, run a few grind cycles until all of the coffee in the

grind chamber is dispensed.

3. Remove the upper front inspection panel.

4. Loosen the burr adjustment screw from its locked position.

B

N

U

5. Hand loosen the adjustment locking nut around the screw approximately one

turn.

N

P581

P581

6. Make sure funnel with filter is still in place in the funnel rails. Press the off/on/start switch to the “START”

(lower) position and release,slowly turn the adjusting screw in a clockwise direction until a metallic whine is

heard due to the rubbing of the grinding burrs. (It may be necessary to start more than one grind cycle to

obtain this sound.)

7. Make a mark with a pen on the decal to note the position of the arrow on the grind adjustment screw.

8. The following settings approximately correspond to the CBC recognized grinds. All are referenced from the

arrow position marked in step #7.

FINE GRIND: Rotate the adjusting screw 7 hash marks in a counterclockwise direction.

DRIP GRIND: Rotate the adjusting screw 8 hash marks in a counterclockwise direction.

REGULAR (COARSE) GRIND: Rotate the adjusting screw 12 hash marks in a counterclockwise direction.

NOTE: Exact adjustment will vary according to bean roast or added flavoring.

9. Hold the adjusting screw in its set position with a screwdriver while tightening the lock nut to a snug position

by hand. The lock nut should now be tight against the burr housing front cover.

10. Repeat steps 1 thru 9 for remaining hopper if desired.

11. Reinstall upper front inspection panel.

Timer Adjustment - DG-2

1. Unplug the grinder and remove the lower front inspection panel.

2. Determine the grind setting. (The factory setting is drip, to determine other settings, refer to the previous

section.)

3. Use the instructions below to find the approximate timer setting for the grind and amount of coffee desired.

4. Plug-in grinder and select (left or right) desired hopper. Momentarily press the “DISPLAY” (center) button.

The display will indicate the current timer setting and will allow adjustment. Press the “+” or “-” buttons as

required to obtain the desired grind time. The interval will change slowly for the first second’s indication,

then speed-up for the next fifteen second’s indication, and increase very fast after that until it reaches the

limit on the scale. Set the timer for the desired amount of coffee to be ground.

5. Verify the setting by weighing a few samples. Use the chart on page 10 as an approximate guide only.

9

10854 030300

Coffee Weight/Timer Settings

Approx. 4.0 seconds per ounce, Medium Roast, Drip Grind.

Approx. 5.5 seconds per ounce, Dark Roast, Drip Grind.

Time will vary depending on bean density & grind size.

Check samples by weight.

DIGITAL CONTROL DISPLAY ASSEMBLY FUNCTION LIST - WDG-2

FUNCTION NO. FUNCTION RANGE

Place funnel with filter into rails, press (Func) button to advance to Function

One.

MIN. MAX.

1. When entering this function, load sensor is tared. To gain access to remaining

functions, press (+) or (-) button once to enter password(0). Display will read

(0) now press (Func).

2. Set weight offset, right grinder. Press (+) or (-) to adjust if necessary. Press

(Func).

3. Set weight offset, left grinder. Press (+) or (-) to adjust if necessary. Press

(Func).

4. Enter calibration mode? If yes, press (+) display will read (1) then press (Func).

If no, press (Func).

NOTE - Pressing (Func) will return to idle display.

5. Use present weight as tare for calibration? If yes, press (+). Display will read

(1) then press (Func). If no, press (Func).

6. To calibrate by grinding coffee, press (+) display will then read (1) then press

(Func).

7. Enter desired calibration weight using (+) and (-) buttons. Then press start

switch on grinder. Display changes to 0.00 and shows increasing weight as

coffee is ground. When grinding stops and 7 has reappeared in left corner of

the display. Push (Func) to advance to Function 8

before removing funnel.

0000 9999

0.00 9.99

0.00 9.99

0 = No 1 = Yes

0 = No 1 = Yes

1 = Grind

3.00 16.00

8. Weigh sample grind and enter actual weight onto the display by pressing (+)

or (-) if necessary. To abort and retain old calibration enter 0.00. Press (Func)

when complete.

10. Enter new password. To keep same password press (Func), to change password press (+) or (-), press function to enter new password and return to

function 0, normal operation.

NOTE: Display shows "----" when taring. Do not disturb while this is shown.

NOTE: WDG2 Models can be converted from weight based settings to timed

settings by pressing the (+) and (-) buttons for 10 seconds. Repeating the

process will convert back to weight based settings.

10

0.00 16.00

0000 9999

10854 030300

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified

service personnel.

• All electronic components have 120 volt ac and low voltage dc potential on their terminals.

Shorting of terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be

permanent. If an intermittent condition is encountered, the cause will likely be a switch contact

or a loose connection at a terminal or crimp.

• Make certain that all electrical connections are tight and isolated.

WARNING

• Exercise extreme caution when servicing electrical equipment.

• Turn power OFF when servicing, except when electrical tests are specified.

• Follow recommended service procedures.

• Replace all protective shields or safety notices.

Problem

Grinder will not start.

Probable Cause

1. No power or incorrect voltage

2. Off/On/Start switch

3. (A) Timer - DG-2

(B) Weigh Control Board WDG-2

4. Motor overload protector

Remedy

(A) Plug-in the grinder.

(B) Check the voltage at the wall

outlet with a voltmeter. It must

be 120 volts ac.

(A) Momentarily press the Off/On/Start

switch to the “START” (lower) position.

(B) Refer to

switch for testing procedures. See page

13.

Refer to

cedures. See page 16.

Refer to

for testing procedures. See page 18.

Remove Grinder rear cover. Press the

red “Reset” button, one located on rear

of each motor. Listen carefully for a

“click”. This resets the motor protection circuit and indicates that an overload may have been encountered by the

motor. (An overload can occur when

something other than coffee is inserted

into the hopper for grinding.) Refer to

Service -

cedures. See page 14.

Service

Service

Service

- Timer for testing pro-

- Weight Control Board

Motors for disassembly pro-

- Off/On/Start

11

10854 030300

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

Grinder will not start. (cont.)

Grinder will not shut off.

Grinder starts, but will not dispense from

either hopper.

Timer will not display or displays

incorrectly.

5. Motors

6. Fuse

1. Off/On/Start switch

2. Timer

1. Hoppers

2. Blockage of hoppers

1. Timer

Refer to

cedures. See page 14.

Refer to

cedures. See page 20.

A) Place the switch in the “OFF" upper

position.

(B) Refer to

for testing procedures. See page 13.

Refer to

cedures. See page 16.

Begin each grind cycle by visually inspecting the hoppers for ample supplies of whole

bean coffee.

Foreign materials must not block the openings at the bottom of the hoppers..

(A) Unplug the grinder. Wait a few seconds and plug it in again.

Service

Service -

Service

- Motors for testing pro-

Fuse for testing pro-

Service

- Off/On/Start Switch

- Timer for testing pro-

Incorrect amount of coffee. DG-2

Incorrect coffee grind dispensed.

Cooling fan not running.

1. Volume adjustment

2. Motor circuit assembly

1. Burr adjustment

1. Off/On/Start switch

2. Fan

(B) Refer to

cedures. See page 16.

Refer to the

7.

Refer to

bly replacement procedures. See page

16.

Refer to the

7.

Switch must be in the "ON" (middle)

position

Refer to

Service

Adjustments

Service

- Motor Circuit Assem-

Adjustments

Service -

- Timer for testing pro-

section. See page

section. See page

Fan. See page 20.

12

10854 030300

TROUBLESHOOTING (cont.)

Problem

LED will not come on when motor is

running.

Weigh control assembly leaking oil.

WDG-2

Incorrect amount of coffee. WDG-2

Probable Cause Remedy

1. No power

2. Faulty LED

WDG-2 DIGITAL DISPLAY CONTROL FAULT CODES

NOTE:

the fault code. The fault will also show on the digital display.

If the grinder stops or fails to start, the green L.E.D. should be flashing. The number of flashes corresponds to

Check timer and for loose connections.

Refer to

Replace - See removal and replacement

page 23

Check function list on setting the weight

to be ground (page 8), if settings are

ok replace weigh control assembly. See

page 23 for removal and replacement.

Service -

LED. See page 21.

FAULT

1

2

4

PROBLEM

Grinder on for three

seconds without a

weight increase.

Tare error.

Grinder motor shutting off

in middle of grind.

PROBABLE CAUSE

Selected hopper ran out

of whole bean coffee.

Foreign objects in motor

grinding burrs causing

motor to shut off.

Scale cannot find tare due

to excess vibration.

Power or hopper selector

switch changed during

grind.

REMEDY

Fill selected hopper with

whole bean coffee.

Clear motor gringing burs

of all foreign objects and

press the red "RESET"

button on rear of motor.

Move grinder to solid,

vibration free counter.

Do not change switches

during grind.

13

10854 030300

SERVICE

01311.0001(10)

02328.0004(4)

25713.0000

25716.0000(2)

PERSONAL INJURY

HAZARD.

KEEP FINGERS AND

FOREIGN OBJECTS

OUT OF HOPPER

OR CHUTE OPENING.

CAUTION

This section provides procedures for testing and

replacing various major components used in this

grinder should service become necessary. Refer to

Troubleshooting

cause of any problem.

WARNING - Inspection, testing, and repair of electrical equipment should be performed only by qualified

service personnel. The grinder should be unplugged

when servicing, except when electrical tests are required and the test procedure specifically states to

plug-in the grinder.

for assistance in determining the

WARNING

Use only on a properly protected circuit

capable of the rated load.

Electrically ground the chassis.

Follow national/local electrical codes.

Do not use near combustibles.

An extension cord, when used, must be shorter

than 20 feet if 16-gage 3-conductor wire, or

shorter than 10 feet if 18-gage 3-conductor wire.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE, OR SHOCK HAZARD

READ THE ENTIRE OPERATING MANUAL

INCLUDING THE LIMIT OF WARRANTY AND

LIABILITY BEFORE BUYING OR USING THIS PRODUCT

20545-0000 7/90 © 1990 Bunn-O-Matic Corporation

NOTICE

For connection to Bunn-Omatic

Coffee Brewer Models:

Dual, OT, Single, & System III only.

(24 volt N.E.C. Class 2 circuit only.)

B

U

N

N

N

O

A

I

R

O

T

C

P

R

T

C

O

N

A

M

I

-

N

O

U

-

D

Y

B

B

E

T

R

F

C

U

U

A

N

A

M

A

.S

.

U

S

.

IN

L

I

O

,

I

D

L

IE

L

,

IN

F

S

R

G

P

N

/

S

E

D

O

M

L

T

S

T

W

A

P

M

A

C

.

A

.

S

L

O

T

V

T

H

R

Z

E

IR

E

W

S

A

E

H

P

S

:

E

T

P

N

T

G

A

L

N

W

F

O

I

L

O

F

T

O

E

H

E

R

R

O

O

N

M

O

D

E

R

N

U

E

E

V

R

O

D

C

E

IN

D

G

P

N

B

E

E

Y

S

A

M

E

T

P

E

N

T

H

O

A

R

E

T

R

R

O

O

M

O

E

N

P737

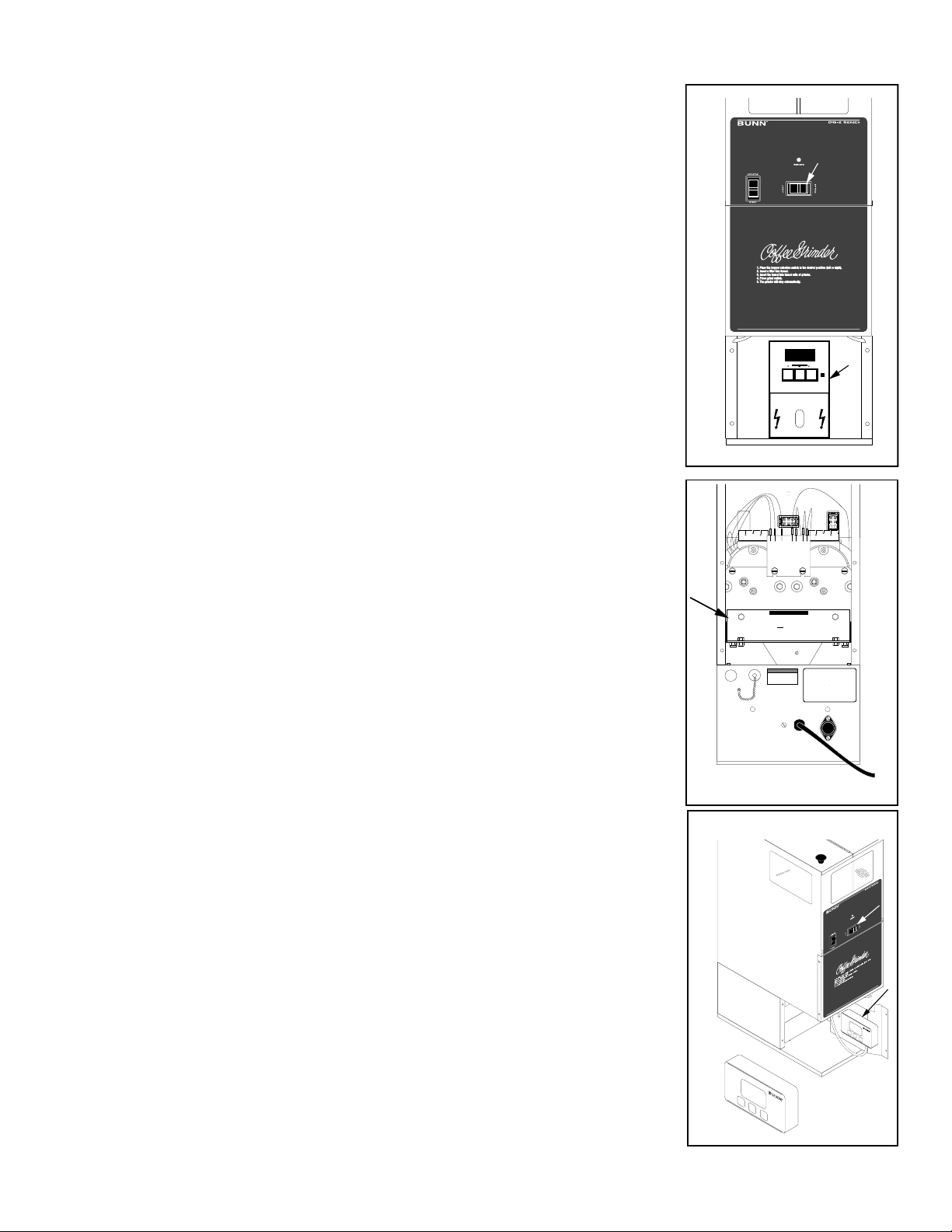

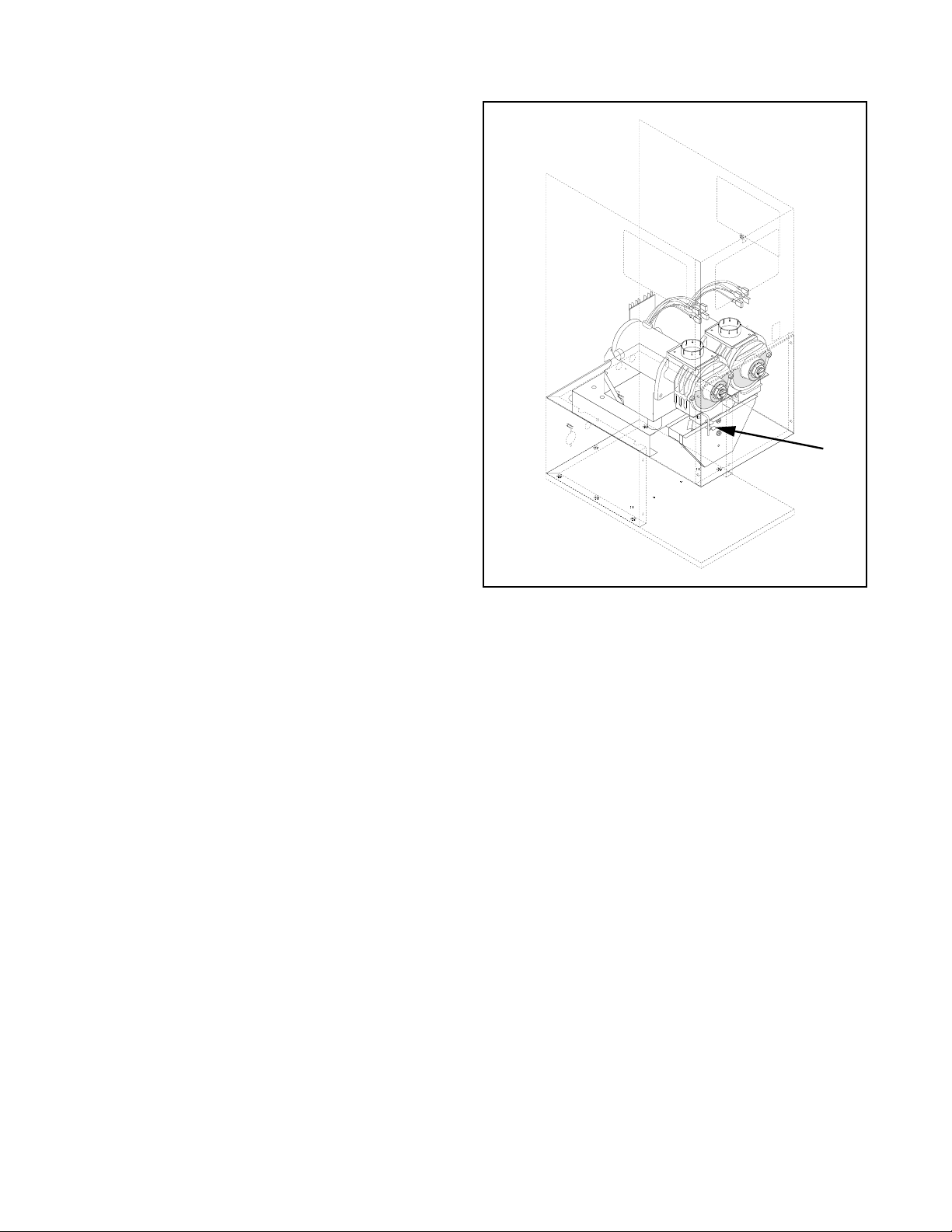

Component Access

WARNING - Unplug the grinder before the removal of

any panel or the replacement of any component.

All components are accessible by the removal

of the upper and lower front inspection panels, hopper assembly, and rear panel.

P735

The upper front inspection panel is attached with

four 8-32 slotted head screws.

The rear panel is attached with eight 8-32 slot-

ted head screws.

NOTE: Disconnect fan motor leads from main wiring

harness.

P738

The lid is attached to hopper divider with four

6-32 slotted head screws. Hopper dividers attached

to hopper and housing with two 6-32 slotted head

screws. Remove lid and hopper divider as an assembly.

The lower front inspection panel is attached with

four 6-32 slotted head screws.

P736

14

CONTENTS

Fan............................................................. 20

Fuse ........................................................... 20

Hopper Selector Switch ............................. 13

LED ............................................................ 21

Motors ....................................................... 14

Motor Circuit Assembly ............................. 16

Off/On/Start Switch.................................... 13

Timer ......................................................... 16

Weigh Control Board ................................. 18

Weigh Control Assembly ........................... 21

10854 030300

SERVICE (cont.)

25716.0000(2)

02328.0004(4)

The hopper is attached with ten #8-32 x .25” slotted head locking screws. Remove hopper by lifting

up and swing out the rear of the grinder to avoid

scratching of windows.

Off/On/Start Switch

25713.0000

01311.0001(10)

P739

the switch.

4. Check for continuity across the terminals on the

left side of the switch when it is in the center

"ON" position. Continuity must not be present in

the upper "OFF" position.

If continuity is present as described, reconnect the

wires, the switch is operating properly.

If continuity is not present as described, replace the

switch.

Removal and Replacement:

1. Remove all wires from the switch terminals.

2. Compress the clips inside the front of the housing and gently push the switch through the opening.

3. Push the new switch into the opening and spread

the clips to retain the switch in the housing.

4. Refer to the following illustration when reconnecting the wires.

P740

Location:

The Off/On/Start switch is located to the left side

on the front of the housing above the upper front

inspection panel.

Test Procedure:

1. Unplug the grinder.

2. Remove all wires from the switch terminals.

3. Check for continuity across the terminals on the

right side of the switch when it is held in the

lower "START" position. Continuity must not be

present across these terminals in the center or

upper position.

If continuity is present as described, proceed to #4.

If continuity is not present as described, replace

RED TO J1 - 1

PNK TO SELECTOR SWITCH

REAR VIEW

ORA TO J4 - 7

ORA TO J4 - 6

WHI/RED TO FAN

P741

Hopper Selector Switch

P734

Location:

The Hopper Selector Switch is located in the

center on the front of the housing above the upper

front inspection panel.

15

10854 030300

SERVICE (cont.)

Hopper Selector Switch (cont.)

Test Procedure:

1. Disconnect grinder from the power supply.

2. Remove all wires from the switch terminals.

3. Place the selector switch in the left position.

4. Check for continuity across the center and right

terminals on the rear of the switch.

5. Continuity must not present across the center

and left terminals on the rear of the switch.

6. Check the bottom row, then the top row of terminals.

If continuity is present as described proceed to #7.

If continuity is not present as described, replace the

switch.

7. Place the selector switch in the right position.

8. Check for continuity across the center and left

terminals on the rear of the switch.

9. Continuity must not be present across the center and right terminals on the rear of the switch.

10. Check the bottom row , then the top row of terminals.

Motors

PNK TO OPTIONAL MULTISET SWITCH

PNK TO OFF/ON/ START SWITCH

YEL TO J1- 1

BLU TO RIGHT MOTOR

VIO TO J4 - 3

WHI/ BLU TO LEFT MOTOR

REAR VIEW

4

P742

If continuity is present as described, reconnect the

wires, the switch is operating properly.

If continuity is not present as described, replace the

switch.

Removal and Replacement:

1. Remove all wires from the switch terminals.

2. Compress the clips inside the front of the housing and gently push the switch through the opening.

3. Push the new switch into the opening and spread

the clips to retain the switch in the housing.

4. Refer to the following illustration when re- connecting the wires.

1

2

5

3

NOTICE

For connection to Bunn-Omatic

Coffee Brewer Models:

Dual, OT, Single, & System III only.

(24 volt N.E.C. Class 2 circuit only.)

REAR VIEW

BUNN

M

F

U

N

A

S

M

L

O

E

D

O

R

E

D

N

U

D

E

R

E

O

C

V

M

O

R

O

O

E

N

N

IO

O

T

A

R

O

P

R

C

IC

T

A

O

M

-

-

N

N

U

B

Y

B

D

E

R

U

T

C

A

.

.A

.S

, U

O

IS

IN

L

, IL

D

L

IE

G

F

IN

R

P

/N

S

S

T

T

A

W

P

M

. A

.C

A

S

T

O

L

V

Z

T

R

E

H

E

IR

W

E

S

A

H

P

:

S

T

N

E

T

A

G

P

IN

O

W

L

O

L

F

E

H

T

O

F

O

E

R

M

R

O

E

N

G

IN

D

N

E

P

E

B

Y

M

A

S

T

N

E

T

A

P

R

E

H

T

O

E

R

P743

1. Motor Circuit Assembly

2. Motor & Circuit Assembly Mounting Screws

3. Motor Mounting Screws

4. Hopper Selector Switch

5. Motor Mounting Bracket

16

Location:

The motors are located in the center part of the

housing just below the hopper.

10854 030300

SERVICE (cont.)

Motor (cont.)

Test Procedure:

1. Disconnect grinder from the power supply.

2. Remove upper front inspection panel.

3. Remove the two 1/4"-20 screws (A) holding the

front cover (B).

4. Remove load disc (C) from burr auger rotor/assembly (D).

5. Remove burr auger rotor/spring assembly

(D) from the burr housing (H).

6. Remove rear panel.

7. Disconnect the red, black and blue wires from

the left or right motor to the motor circuit assembly (1).

8. (A) Left Motor - Disconnect blue wire on

the left motor from the blue wire to the

hopper selector switch.

(B) Right Motor- Disconnect the blue wire

on the right motor from the white/blue

wire to the hopper selector switch.

9. Connect leads of an ohm meter to the blue

wires from the left or right motor. Check

for continuity.

If continuity is present the motor overload is good.

If continuity is not present press the red "RESET" button. Listen carefully for a "click". This resets the motor overload. Recheck for continuity. If continuity is

now present the motor overload is reset. If motor overload does not reset replace motor.

10. Set an ohm meter to read at least 10 ohms.

Connect leads from ohm meter to the black

and red wires from the left or right motor.

The ohm reading should be approximately

10 ohms. Rotate the motor shaft approxi mately 1/8 turn through one full rotation. If

ohm readings are consistent motor wind ings are good. If reading vary more than

±1 ohm, replace motor.

Removal and Replacement:

1. Disconnect red, black and blue wires from the

motor to be removed from the motor circuit assembly (1).

2 Loosen the two #10-32 slotted head screws (2)

attaching motor circuit assembly (1) to motor

mounting bracket (5).

3. Remove motor circuit assembly (1) with wires

from harness and the opposite motor connected.

4. Right Motor - Disconnect blue wire on motor

from blue wire on hopper selector switch (4).

Left Motor - Disconnect blue wire on motor from

white/blue wire on hopper selector switch (4).

5. Using a 7/16" socket, extension and rachet remove two 1/4"-20 hex head capscrews and

lockwashers (3) attaching front of motor to front

of mounting bracket (5).

6. Remove two #10-32 slotted hex head screws (2).

7. Lift motor out of mounting bracket (5) and remove through the rear of grinder with hopper

collar and discharge chute assembly attached.

8. Remove four #10-24 slotted hex head screws

attaching discharge chute to motor. Remove discharge chute. Set discharge chute and screws

aside for reassembly.

9. On new motor assembly with hopper collar install discharge chute assembly using four #1024 slotted hex head screws.

10. Mount new motor, hopper collar and discharge

chute assembly on mounting bracket using two

1/4"-20 hex head capscrews and lockwashers

(3) and two #10-32 slotted hex head screws (2)

and one external tooth lockwasher.

11. Install motor circuit assembly (1) between head

of the two #10-32 slotted hex head screws (2)

and external tooth lockwashers. Tighten screws

(2).

12. Refer to wiring diagram (pages 24 & 25) and

connect wires from motor to motor circuit assembly (1) and hopper selector switch (4).

17

10854 030300

SERVICE (cont.)

Motor (cont.)

Removal and Replacement - GRIND CHAMBER

H

G

D

COARSE FINE

COARSE FINE

T

H

E

M

O

P

R

T

O

Y

U

H

G

O

P

H

P

L

Y

C

L

E

Y

L

B

.

E

N

I

F

M

R

-

E

E

E

S

S

R

V

A

S

O

O

A

C

C

E

R

S

I

E

H

T

R

O

G

F

N

E

I

E

V

N

B

N

C

O

U

I

B

R

M

T

E

E

O

N

B

R

E

M

R

A

O

E

F

R

E

B

H

C

D

N

I

A

R

N

G

C

B

20667.0000

20666.0000

F E A

T

H

E

M

O

P

R

T

O

Y

U

H

G

O

H

L

Y

C

COARSE FINE

COARSE FINE

T

O

N

E

P

R

P

O

E

F

R

E

B

H

C

L

D

E

N

I

A

R

N

G

Y

L

B

.

E

N

I

F

M

R

-

E

E

E

S

S

R

V

A

S

O

O

A

C

C

E

R

S

I

E

H

T

R

O

G

F

N

E

I

E

V

N

B

N

C

O

U

I

B

R

M

E

E

B

R

M

A

P744

1. Remove the two 1/4"-20 screws (A) holding the

front cover (B) to the burr housing (H). Carefully

remove the burr housing front cover with adjusting screw and nut. Inspect adjusting screw to

see if worn.

Replace if excessively worn or

damaged.

2. Remove load disc (C) from burr auger rotor/

spring assembly (D). Inspect disc to see if worn.

Replace if excessively worn or damaged.

3. Carefully remove burr auger rotor/spring assembly (D) from burr housing (H). Inspect burr for

wear.

Replace if excessively worn or damaged.

4. Remove bushing (E) and washer (F) from motor

shaft.

5. Remove the two 1/4"-20 screws attaching stationary burr (G) to burr housing (H). Remove

and inspect burr for wear.

Replace if excessively worn or damaged.

6. Inspect the grind chamber and remove any foreign materials. The burrs will not properly seat

in the chamber if any material or coffee particles

remain.

7. Reinstall the stationary burr (G), washer (F),

bushing (E), burr auger rotor/spring

assembly(D), load disc(C) and burr housing front

cover(B) with adjusting screw and nut to the burr

housing(H).

8. Refer to

Adjustments

section (page 7) to vary

the grind dispensed.

Motor Circuit Assembly

P750

Location:

The motor circuit assembly is located on the

rear of motor mounting bracket.

Test Procedure:

1. The motor circuit assembly is a line filter for

motor electrical noise.

2. If the timer settings are erratic or change replace

the motor circuit assembly board.

Removal and Replacement:

1. Remove all wires.

2. Loosen the two #10-32 slotted hex head screw

and lift motor circuit assembly off.

3. Install new motor circuit assembly between head

of screws and external tooth lockwashers.

Tighten screws.

4. Refer to

Wiring Diagram

(pages 24 & 25) and

reinstall wires.

Timer - DG-2

nds)

E (Seco

DISPENSE TIM

Decrease

DISPLAY

.

s

e

t

u

in

m

5

r

Increase

d

o

f

e

t

d

s

e

ju

.

y

d

d

a

l

a

e

p

y

e

is

la

b

p

d

ly

e

is

n

d

+

o

ill b

n

t is

a

w

t

u

u

o

r c

o

d

e

E

G

d

a

a

im

G

e

re

T

A

IN

R

ile

T

h

N

L

w

O

R

V

A

S

U

W

O

D

R

A

Z

A

H

DER

G

IN

GR

OVIN

01516.0000

REM

UNPLUG

RE

BEFO

P745

Location:

The timer is located on the grinder base, behind

the lower front inspection panel.

18

10854 030300

SERVICE (cont.)

Timer - DG-2 (cont.)

Test Procedure:

1. Disconnect grinder from the power source.

2. Slide timer with wires connected from housing.

3. Place the hopper selector switch in the left position.

4. Disconnect eight pin plug J4 from timer board.

5. Check the voltage between J4-1 and J4-2 with

a voltmeter. Connect the grinder to the power

source. The indication must be 120 volts AC.

6. Disconnect grinder from the power source.

10. Disconnect grinder from the power source.

If voltage is present as described, proceed to #11.

If voltage is not present as described, replace timer

and motor circuit board with part number

25725.1000.On grinders prior to S/N DG00002660

also order main wiring harness 25762.0001.

11. Reconnect the wires.

12. Place the hopper selector in the right position.

13. Repeat steps #4 thru 10.

If voltage is present as described, proceed to #7.

If voltage is not present as described, refer to the

wiring diagram and check grinder wiring harness.

7. Check the voltage between J4-2 and J4-6 with

a voltmeter when the "OFF/ON/START" switch is

in the "ON" position.Connect the grinder to the

power source. The indication must be 120 volts

AC.

8. Disconnect grinder from the power source.

If voltage is present as described, proceed to #9.

If voltage is not present as described, refer to the

wiring diagram and check the grinder wiring harness.

9. Grinders prior to S/N DG00002660:

Check the voltage between J4-3 (+) and J4-5 () with a voltmeter set to read DC voltage when

the "OFF/ON/START" switch is in the "START" position. The indication must be 110 volts DC minimum.

Grinders S/N DG00002660 - UP

Check the voltage between J4-3 and J4-5 with a

voltmeter when the "OFF/ON/START" is in the

"START" position. The indication must be 120

volts AC.

Grinders with One or Two Brewer Optional Interface

1. Set the brewer selector switch on one third batch

with grinder "OFF/ON/START" switch in the "ON"

position.

2. Select the two third's batch, if the readout is not

different then adjust the settings and return selector switch to one third batch. The readout

should now be different.

3. Select full batch, if the readout is not different

then adjust the settings and return selector switch

to two third's batch. The readout should be different.

4. Repeat steps 1 thru 3 for the opposite side.

NOTE: Each brew selection has its own readout. If

readouts do not differ with each brew selection after

adjusting settings, check interface cable. If interface

cable is ok replace timer and motor circuit board

with part number 25725.1000. On grinders prior to

S/N DG00002660 also order main wiring harness

part number 25762.0001.

Removal and Replacement:

1. Separate the grinder wiring harness connectors

from the timer circuit board.

2. Refer to the illustration on next page when reat-

taching the connectors.

3. Refer to the

Adjustments

(page 7) section to re-

set the volume dispensed.

19

10854 030300

SERVICE (cont.)

Timer - DG-2 (cont.)

RED TO MOTOR CIRCUIT BOARD

(Prior to S/N DG00002660)

WHI TO MOTOR CIRCUIT BOARD

(S/N DG00002660 - UP)

ORA TO OFF/ON/START SWITCH

ORA TO OFF/ON/START SWITCH

BLK TO FUSE HOLDER

WHI TO POWER CORD

VIO TO SELECTOR SWITCH

5

1

2

6

7

3

8

4

J4

1

2

678

RED TO OFF/ON START SWITCH

YEL TO SELECTOR SWITCH

GRN TO OPTIONAL MULTISET SWITCH

TAN TO OPTIONAL INTERFACE CONNECTOR

GRY TO OPTIONAL INTERFACE CONNECTOR

4

5

3

J1

10

9

Weigh Control Board - WDG-2

TAN TO INTERFACE CONNECTOR

GRY TO INTERFACE CONNECTOR

BLK TO GRINDING LED

PNK TO INTERFACE CONNECTOR

P746

Test Procedure:

1. Disconnect grinder from the power source.

2. Slide the weigh control board with wires connected from housing.

3. Place the hopper selector switch in the left position.

4. Disconnect eight pin plug J4 from weigh control

board.

5. Check the voltage between J4-1 and J4-2 with a

voltmeter. Connect the grinder to the power

source. The indication must be 120 volts AC.

6. Disconect grinder from the power source.

If voltage is present as described, proceed to #7.

If voltage is not present as described, refer to the wiring diagram and check grinder wiring harness.

P929

Location

The weigh control board is located on the grinder base

behind the lower front inspection panel.

20

7. Check the voltage between the J4-2 and J4-6

with a voltmeter when the "OFF/ON/START"

switch is in the "ON" position.Connect grinder to

the power source. The indication must be 120

volts AC.

10854 030300

SERVICE (cont.)

Weigh Control Board - WDG-2 (cont.)

Grinders with One or Two Brewer Optional Interface

8. Disconnect grinder from the power source.

If voltage is present as described, proceed to #9.

If voltage is not present as described, refer to the wiring diagram and check the grinder wiring harness.

9. Check the voltage between J4-3 and J4-5 with a

voltmeter when the "OFF/ON/START" is in the

"START" position. Connect grinder to the power

source. The indication must be 120 volts AC.

10. Disconnect grinder from the power source.

If voltage is present as described, proceed to #11.

If voltage is not present as described, replace weigh

control board.

11. Reconnect the wires.

12. Place the hopper selector in the right position.

13. Repeat steps #4 thru 10.

1. Set the brewer selector switch on one third

batch with grinder "OFF/ON/START" switch in the

"ON" position.

2. Select the two third's batch, if the readout is not

different then adjust the settings and return selector switch to one third batch. The readout

should now be different.

3. Select full batch, if the readout is not different

then adjust the settings and return selector switch

to two third's batch. The readout should be different.

4. Repeat steps 1 thru 3 for the opposite side.

NOTE: Each brew selection has its own readout. If

readouts do not differ with each brew selection after

adjusting settings, check interface cable. If interface

cable is ok replace weigh control board.

Removal and Replacement:

1. Separate the grinder wiring harness connectors

from the weigh control board.

2. Refer to the illustration below when re- attach-

ing the connectors.

3. Refer to the

Adjustments

(page 7) section to re-

set the volume dispensed.

VIO TO SELECTOR SWITCH

WHI TO POWER CORD

BLK TO FUSE HOLDER

WHI TO MOTOR CIRCUIT BOARD

ORA TO OFF/ON/START SWITCH

ORA TO OFF/ON/START SWITCH

2

3

1

4

J4

7

8

556

TAN TO INTERFACE CONNECTOR

GRY TO INTERFACE CONNECTOR

BLK TO GRINDING LED

PNK TO INTERFACE CONNECTOR

RED TO OFF/ON/START SWITCH

YEL TO SELECTOR SWITCH

GRN TO OPTIONAL MULTISET SWITCH

TAN TO OPTIONAL INTERFACE CONNECTOR

GRY TO OPTIONAL INTERFACE CONNECTOR

J5

DIGITAL CONTROL DISPLAY

ASSEMBLY CORD CONNECTION

GRY TO WEIGH CONTROL ASSEMBLY

BLK TO WEIGH CONTROL ASSEMBLY

112

3

J1

49

6

7

8

10

2

J3

3

4

RED TO WEIGH CONTROL ASSEMBLY

ORA TO WEIGH CONTROL ASSEMBLY

P930

21

10854 030300

SERVICE (cont.)

Fan

WARNING

Use only on a properly protected circuit

capable of the rated load.

Electrically ground the chassis.

Follow national/local electrical codes.

Do not use near combustibles.

P747

Fuse

Location:

NOTICE

For connection to Bunn-Omatic

Coffee Brewer Models:

Dual, OT, Single, & System III only.

(24 volt N.E.C. Class 2 circuit only.)

BUNN

M

A

N

U

M

O

D

E

L

C

O

V

E

R

E

D

U

N

D

E

O

N

E

O

R

M

A

F

C

U

T

R

E

D

B

Y

B

U

N

N

-O

-

M

A

IC

C

O

T

R

P

O

R

A

IO

T

N

S

P

R

N

I

G

D

E

L

, I

I

F

IN

O

L

L

IS

.A

U

.

.S

,

S

/N

A

C

V

O

.

S

.

T

L

A

M

P

S

A

T

W

T

P

H

A

S

E

W

R

I

E

H

E

R

Z

T

R

O

N

E

O

R

M

O

R

E

H

O

T

E

F

F

O

O

L

L

IN

G

W

P

A

E

:

N

S

T

T

O

R

O

E

H

T

E

R

P

A

E

N

S

T

M

T

A

B

Y

E

N

E

P

D

N

I

G

P748

Location:

The fan is mounted on upper part of the rear in-

spection panel.

Test Procedure:

1. Unplug the grinder.

2. To gain access remove the rear panel with fan

attached.

3. Disconnect fan motor leads from the main harness.

4. Check voltage across the WHT/RED and WHT

leads to the main harness with a voltmeter. Plugin the grinder. With the "OFF/ON/START" switch

in the center "ON" position the indication must

be 120 volts AC.

5. Unplug the grinder.

If voltage is present as described, replace the fan.

If voltage is not present as described, refer to wiring

diagrams and check the wiring harness.

The fuse is located in the fuse holder on the rear

of grinder near the bottom next to the power cord.

Test Procedure:

1. Unplug the grinder.

2. Remove cap and fuse from fuse holder.

3. Remove fuse from the cap.

4. Check for continuity through the fuse.

If continuity is present as described, reinstall the fuse,

the fuse is operating properly.

If continuity is not present as described, replace the

fuse.

Removal and Replacement:

1. Remove cap from fuse holder.

2. Remove fuse from fuse holder, inspect, if

blown discard.

3. Install a new SC 10 x .312" fuse in fuse

holder.

4. Reinstall fuse holder cap.

Removal and Replacement:

1. Remove rear panel with fan attached.

2. Disconnect fan motor leads from main harness

3. Remove four #6-32 flat head screws and locknuts attaching fan and fan guard to rear inspection panel. Discard fan and set guard, screws and

locknuts aside for reinstallation.

4. Reinstall fan guard and new fan to the rear

panel making sure the air flow direction

is away from rear panel.

5. Connect leads from fan to the main wiring

harness.

6. Reinstall rear panel.

22

10854 030300

SERVICE (cont.)

L.E.D

P749

Location:

The L.E.D is located on the front of the grinder

just above hopper selector switch.

Test Procedure:

1. Unplug the grinder.

2. Remove the wire nuts from both sets of wires.

3. With a voltmeter set to read DC volts. Attach the

positive (+) lead to the black and pink wires and

the negative (-) lead to the gray wires.

4. Connect grinder to the power supply.

5. Initiate a grind cycle. Voltage should be approximately 2 volts DC.

Weigh Control Assembly - WDG-2

00718.0000

01593.0000

If the voltage is present as described the L.E.D. is

operating properly.

If the voltage is not present as described proceed to

#6.

6. After initiating a grind cycle in step #5 the voltage was approximately 5 volts DC. Replace the

L.E.D. If the voltage is approximately 0 volts refer to wiring diagrams and check the wiring harness.

Removal and Replacement:

1. Remove upper front inspection panel.

2. Disconnect PNK and GRY wires from L.E.D.

3. Using a 5/16" open end wrench remove nut on

back of front housing securing L.E.D. Remove

L.E.D and discard.

4. Install new L.E.D through front of grinder housing and secure with nut.

5. Connect PNK and GRY wires from L.E.D. Refer

to wiring diagram on pages 24 & 25.

P941

Location:

The weigh control assembly is located behind

the lower front inspection panel just under and

behind the funnel rails.

23

10854 030300

SERVICE (cont.)

Weigh Control Assembly - WDG-2 (cont.)

00718.0000

01593.0000

5

3

4

2

1. Front Inspection Panel

2. Weigh Control Board and Mounting Bracket

3. Weigh Control Mounting Bracket

4. Weigh Control Assembly

6

8

1

7

5. Pivot Arm

6. Funnel Rails Mounting Bracket

7. Funnel Tab

8. Slot in Housing Assembly

P941

24

10854 030300

SERVICE (cont.)

Weigh Control Assembly - WDG-2 (cont.)

Removal and Replacement

1. Disconnect grinder from the power source.

2. Remove the four #6-32 truss head screws securing lower front inspection panel (1). Remove

panel with digital control display assembly attached.

3. Remove the one #6-32 truss head screw securing the weigh control board mounting bracket

(2) to the weigh assembly mounting bracket (3).

4. Slide weigh control board mounting bracket and

control board (2) out of weigh assembly mounting bracket (3) far enough so the connectors on

the grinders main wiring harness and the connector on the weight assembly leads can be disconnected.

5. Disconnect connectors.

6. Remove weigh control board mounting bracket

and weigh control board (2) from the grinder.

7. Remove the two #10-32 slotted head screws

securing weigh control mounting bracket (3) to

the base of the grinder and the two #10-32 keps

nuts securing the weigh control mounting

bracket (3) to the rear of the grinder housing.

8. Slide weigh control mounting bracket (3) from

grinder housing far enough to have access to

weigh control assembly (4).

9. Holding pivot arm w/overload assembly (5) up

remove the four #8-32 pan head screws securing weigh control assembly (4). Remove and discard weigh control assembly (4).

10. Holding pivot arm w/overload assembly (5) up

install the new weigh control assembly (4) to the

mounting bracket (3) using four #8-32 pan head

screws.

11. Slide weigh control assembly mounting bracket

(3) on to the two studs on the rear of the grinder

housing and secure with two #10-32 keps nuts.

NOTE - Carefully guide all wires while installing the

weigh mechanism. The funnel tab (7) on the funnel rails mounting bracket (6) must be in clearance slot (8) in the grinder housing and must

move freely up and down.

12. Secure weigh control assembly mounting bracket

(3) to grinder base with two #10-32 slotted head

screws.

13. Slide the weigh control bracket and weigh control board (2) into the weigh control mounting

bracket (3) far enough to reconnect the eight and

ten pin connectors from the main wiring harness

and the four pin connector from the weigh control assembly. Connect the wiring.

14. Refer to the illustration on page 19 when reattaching the connectors.

NOTE - Inspect for pinched wires.

15. Slide weigh control bracket and weigh control

board (2) the rest of the way into the weigh control mounting bracket (3) and secure with one

#6-32 truss head screw.

16. Reinstall lower front inspection panel with digital control display assembly attached using four

#6-32 truss head screws.

17. Connect the grinder to the power source and follow the function list on page 8 for information

on setting the weight to be ground.

25

10854 030300

WIRING DIAGRAMS

TIMER

J4-1

BLK

WHI

VIO

SCHEMATIC WIRING DIAGRAM DG2

L1

N

10 AMP

GRN

ORA

WHI/RED

RED

OFF/ON

START SW

ORA

PNK

J4-8

J1-1

J1-10

(OPTIONAL)

BREWER

INTERFACE

CONNECTOR

BREWER

INTERFACE

CONNECTOR

4

3

2

1

4

3

2

1

120 VOLTS AC

2 WIRE

SINGLE PHASE

60 HZ

WHI

ORA

ORA

RED

YEL

GRN

TAN

GRY

TAN

GRY

BLK

PNK

GRY

PNK

TAN

GRY

PNK

TAN

10856.0000B 6/97 © 1995 BUNN-O-MATIC CORPORATION

WHI/RED

WHI

BLK

BLK

WHI/BLU

BLU

SELECTOR

YEL

BLU

WHI/BLU

GRN

GRINDING

BLK GRY

FAN

PNK

MOTOR

CIRCUIT

ASSY

T2

SW

(OPTIONAL)

MULTI-SET SW

GRY

BLU

BLU

T1

BLK

RED

T3

WHI

T4

RED

T5

BLK

T6

BLU

T7

BLU

PNK

VIO

MOTOR

(D.C.)

MOTOR

(D.C.)

PNK

PNK

RT

LT

26

10854 030300

WIRING DIAGRAMS

SCHEMATIC WIRING DIAGRAM WDG2

J4-1

CIRCUIT

BOARD

J4-8

J1-1

J1-10

J3-1

J3-4

J5-1

J5-6

J1-1

CONTROL

ASSY

J1-6

TRANSDUCER

ASSY

10 AMP

BLK

WHI

VIO

WHI

ORA

ORA

RED

YEL

GRN

TAN

GRY

TAN

GRY

BLK

PNK

BLK

RED

GRY

ORA

ORA

GRY

RED

BLK

120 VOLTS AC

2 WIRE

SINGLE PHASE

60 HZ

L1

N

GRN

ORA

WHI/RED

RED

SELECTOR

YEL

BLU

WHI/BLU

(OPTIONAL)

MULTI-SET SW

GRN

GRINDING

PNK

MOTOR

CIRCUIT

ASSY

FAN

GRY

PNK

TAN

GRY

PNK

TAN

BLU

BLK

RED

WHI

RED

BLK

BLU

4

3

2

1

4

3

2

1

(OPTIONAL)

BREWER

INTERFACE

CONNECTOR

BREWER

INTERFACE

CONNECTOR

BLU

WHI/BLU

WHI/RED

WHI

BLK GRY

BLK

BLK

10874.0000C 1/96 © 1995 BUNN_O_MATIC CORPORATION

OFF/ON

START SW

SW

GRY

BLU

BLU

MOTOR

BLK

RED

WHI

RED

BLK

MOTOR

BLU

BLU

ORA

PNK

PNK

VIO

PNK

PNK

RT

(D.C.)

LT

(D.C.)

27

10854 030300

Loading...

Loading...