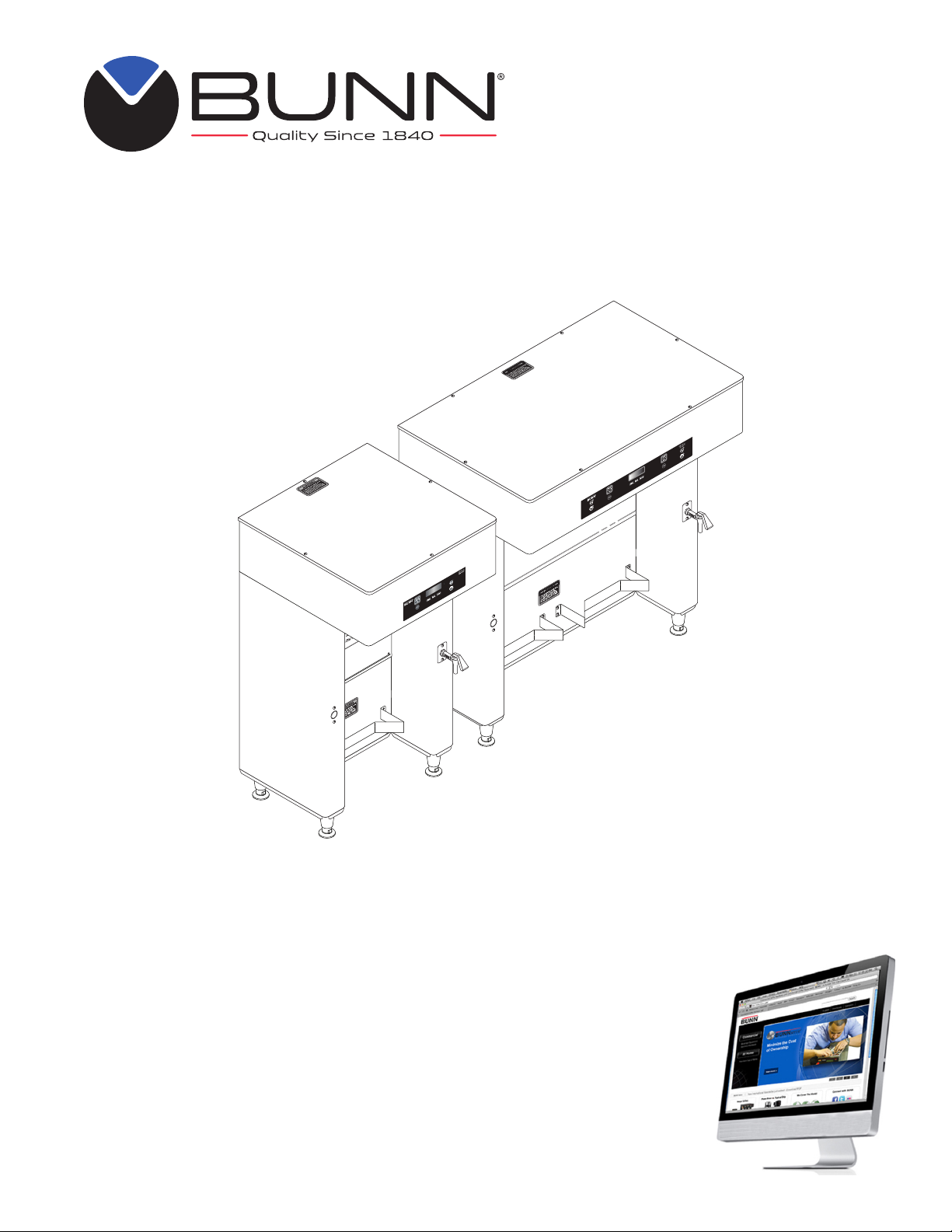

Bunn Titan Single, Titan Dual User Manual

TITAN DUAL

TITAN SINGLE

®

®

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

41747.0000C 02/17 ©2008 Bunn-O-Matic Corporation

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCR/MCP/MCA single cup brewers, thermal servers and ThermoFresh® servers (mechanical and digital) 1 year parts and 1 year labor.

2) All other equipment - 2 years parts and 1 year labor plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labor for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labor.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis - parts and

labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be

commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured

by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or operation,

improper maintenance or repair, non periodic cleaning and descaling, equipment failures related to poor water quality,

damage or casualty. In addition, the warranty does not apply to replacement of items subject to normal use including but

not limited to user replaceable parts such as seals and gaskets. This warranty is conditioned on the Buyer 1) giving BUNN

prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or by writing to Post Office Box

3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective equipment prepaid to an authorized

BUNN service location; and 3) receiving prior authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make

modifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by such

individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during the

applicable parts and labor warranty periods specified above) to repair the defective components, provided that this repair

is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase price for

the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION

AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of

use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities

or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with

the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design,

Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet

Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment

Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com,

Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in

Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, TRIFECTA (sylized logo), Velocity Brew, Air Brew, Beverage

Bar Creator, Beverage Profit Calculator, Brew better, not bitter., Build-A-Drink, BUNNSource, Coffee At Its Best, Cyclonic

Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN, Picture

Prompted Cleaning, Pouring Profits, Signature Series, Sure Tamp, Tea At Its Best, The Horizontal Red Line, Ultra are either

trademarks or registered trademarks of Bunn-O-Matic Corporation. The commercial trifecta® brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

Page 2

41747 031314

INTRODUCTION

This equipment will brew coffee into an awaiting server or airpot. The brewer may have an auxillary hot water

faucet. It is only for indoor use on a sturdy and level counter or shelf. Please install in an area where there are

no water jet devices.

This brewer can be programmed to adjust different functions of the brewing process, such as brew temperature, brew volumes, bypass percentages, pulse brew, etc. Other features are Energy Savings mode, Freshness

Timer and Clean Alert.

CONTENTS

Warranty .....................................................................................................................................2

Table of Contents ........................................................................................................................3

Troubleshooting ..........................................................................................................................4

Service Tools .............................................................................................................................15

Component Access ...................................................................................................................18

Control Board ......................................................................................................................18

Membrane Switch ................................................................................................................19

Dispense and Bypass Valves................................................................................................20

Refill Valves .........................................................................................................................21

Tank Heaters ........................................................................................................................22

Temperature Probe ..............................................................................................................23

Limit Thermostats ...............................................................................................................22

Contactor .............................................................................................................................23

Main Power Switch ..............................................................................................................24

Schematic (Wiring Diagram) .....................................................................................................25

Page 3

41747 112608

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

• All electronic components have 120-240 volt ac and low voltage dc potential on their terminals. Shorting of

terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If

an intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will

help to avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• This brewer is heated at all times. Keep away from combustibles.

WARNING – • Exercise extreme caution when servicing electrical equipment.

• Unplug the brewer when servicing, except when electrical tests are specified.

• Follow recommended service procedures.

• Replace all protective shields or safety notices.

Page 4

41747 112608

TROUBLESHOOTING (cont.)

PROBABLE CAUSE REMEDYPROBLEM

Temperature Too Low

Heating Time Too Long

Fill Time Too Long

Temp Sensor Out Of Range, Check

For Bad Connections

1. Water temperature in the tank

does not meet the ready temperature.

1. Tank Heater failure.

2. Control Board/Thermistor failure

1. Water shut off to brewer

2. Inlet Solenoid failure

3. Control Board failure

4. ON/OFF switch is OFF

1. Temperature Sensor Probe

wire(s) broken or not making connection

A) Wait for the brewer to heat to the

proper temperature.

B) Disable the BREW LOCKOUT

function. Refer to Programming

Manual for procedure.

Service required

Service required

Check water supply shut-off

Service Required

Service Required

Turn switch ON

Check wire and connection of both

black and white wires of temperature

probe.

Temp Sensor Out Of Range, Check

Wire For Shorts

Equipment will not operate

1. Temperature Sensor Probe

wire(s) shorted to housing or to

each other.

1. No power or incorrect voltage

Check to confirm that wire(s) are

not pinched between two surfaces

or connected to each other.

Measure the voltage at the terminal

block and confirm that it matches

the voltage specified on the brewer

data plate withing +/- 10%.

Page 5

41747 112608

TROUBLESHOOTING (cont.)

PROBLEM

Brew cycle will not start

PROBABLE CAUSE REMEDY

1. No water

Check plumbing and shut-off

valves

2. No power or incorrect voltage to

the brewer

3. ON/OFF switch

Check for voltage across the terminals at the terminal block.

Test the ON/OFF switch. Refer

to the test switch procedures on

page 17.

4. Brew switch

Test the BREW switch. Refer to the

test switch procedures on page

17.

5. Brew valve

Test the brew valve. Refer to the test

outputs procedures on page 15.

6. Control Board

Substitute a control board known

to be in good working order.

Page 6

41747 112608

TROUBLESHOOTING (cont.)

PROBLEM

Automatic refill will not operate

or display shows FILL TIME TOO

LONG

PROBABLE CAUSE REMEDY

1. No water

Check plumbing and shut-off

valves

2. Refill valve

Remove the strainer and check for

obstructions. Clear or replace.

3. Refill probe or Sensitivity setting

Check the sensitivity setting. Refer

to the REFILL function in Programmimg Manual. If the left three digit

number is less than the right number, the machine “thinks” it is full and

the refill valve should be off. If the left

number is larger than the right, then

the refill valve will automatically be

turned on to fill the tank. The right

number is the threshold setting and

can be adjusted to compensate for

extreme water conditions: very pure,

low conductance water requires a

higher setting, while high mineral

content, high conductance water

requires a lower setting. Note that

the left number changes from a high

value when water is NOT touching

the refill probe to a low valve when

water IS touching the probe. For

best operation, the right number

should be set to a value midway

between these low and high numbers. Before changing the setting,

confirm that the refill probe is free

of scale buildup and the connection

to it is secure. Test the refill valve.

Refer to the test outputs procedures

on page 15.

Page 7

41747 112608

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Automatic refill will not operate or

display shows FILL TIME TOO LONG

(Continued)

Refill valve – Disconnect the brewer

from the power source and remove

wires from refill valve coil. Check

for continuity across the terminals

of the solenoid coil. If continuity is

not present, replace the refill valve.

If continuity is present, the coil may

be stuck closed. Shut water off to

brewer. Press the ON/OFF switch to

turn off the brewer. Open the faucet

and drain water down in the tank

until flow stops or slows to a trickle.

Attach a voltmeter to the terminals

of the refill solenoid. Connect the

brewer to the power source. Press

the ON/OFF switch to turn the brewer

on. Within five seconds, voltage

should be present at the solenoid

terminals. If voltage is not present,

refer to the wiring schematic and

check the wiring harness.

4. Control Board

5. ON/OFF Switch

6. Overflow Safety Switch

Substitute a control board known

to be in good working order.

ON/OFF switch must be ON for the

refill circuit to operate. Turn ON.

When this condition occurs, the

brewer will display OVERFLOW

CUP FULL. EMPTY CUP. The reason

for overfilling could be a defective

refill valve, an incorrect sensitivity

setting, (see above) or boiling.

Page 8

41747 112608

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Water flows into tank continuously

with power removed from brewer.

1. Refill valve

2. Refill probe or sensitivity setting

Foreign material lodged in valve,

holding it in open state.

Check the sensitivity setting. Refer

to the REFILL function in Programming Manual. If the left three digit

number is less than the right number, the machine “thinks” it is full and

the refill valve should be off. If the

left number is larger than the right,

then the refill valve will automatically

be turned on to fill the tank. The right

number is the threshold setting and

can be adjusted to compensate for

extreme water conditions: very pure,

low conductance water requires a

higher setting, while high mineral

content, high conductance water

requires a lower setting. Note that

the left number changes from a high

value when water is NOT touching

the refill probe to a low valve when

water IS touching the probe. For

best operation, the right number

should be set to a value midway

between these low and high numbers. Before changing the setting,

confirm that the refill probe is free

of scale buildup and the connection

to it is secure.

3. Control Board

Page 9

Substitute a control board known

to be in good working order.

41747 112608

Loading...

Loading...