Page 1

Digital

ThermoFresh®

1.0 & 1.5 Gallon Server

with Countup Timer

USE & CARE INFORMATION

CAUTION: CLEAN AND SANITIZE YOUR SERVER BEFORE USING. SEE NOTE #1 of DAILY CLEANING.

BUNN-O-MATIC CORPORATION OF CANADA

280 INDUSTRIAL PARKWAY SOUTH,

AURORA, ONTARIO, L4G 3T9

PHONE: (905) 841-2866 FAX: (905) 841-2775

43240.7009B 11/12 ©2012 Bunn-O-Matic Corporation

Page 2

INTRODUCTION

This server is intended for use with a BUNN® DUAL® TF DBC®, SINGLE® TF DBC® or ICB family brewers.

When proper precautions are followed, 1.0 up to 1.5 gallons of coffee may be brewed directly into the server

and then transported to a remote serving location. The server must be placed on a sturdy counter or shelf.

NOTE: Calibration of the brewer is required prior to the use of the Digital TF Server.

USER NOTICES

The notices on this server should be kept in good condition. Replace unreadable or damaged labels.

WARNING

HOT LIQUID

35710.7000

AVERTISSEMENT

LIQUIDE CHAUD

D

O

N

O

T

N

E

P

A

S

I

45457.7000

E

G

R

E

M

B

S

U

M

M

R

E

G

R

E

39043.0000

39043.0001

39043.0002

DAILY CLEANING

CAUTION: CLEAN AND SANITIZE YOUR SERVER DAILY

NOTE: Bunn-O-Matic recommends the 3 step method for cleaning and sanitizing the server. The 3 step method

consists of hot soapy water using an approved detergent, a fresh water rinse, and an aqueous sanitizing

solution using an approved non-chlorine sanitizer. Do not submerge server.

1. Run a complete brew cycle of just hot water into the server and let it set for a minute. Empty the server

completely by opening the faucet.

2. Remove the sensor assembly, fill server with cleaning solution and thoroughly clean the inside of server.

3. Rinse server thoroughly using fresh water rinse.

4. Fill server with sanitizing solution and let the server set for 5 minutes, then drain through fully open faucet.

Thoroughly rinse server after sanitizing.

5. Remove the faucet handle/stem assembly by unscrewing the faucet nut just beneath the faucet handle.

6. Use enclosed cleaning brush to thoroughly clean the faucet body and tube.

7. Disassemble the faucet/stem assembly. Thoroughly wash all faucet parts in a mild detergent and water solution. Rinse the parts in hot water. Sanitize the parts for five minutes, thoroughly rinse, then air dry completely.

8. Use enclosed cleaning brush to thoroughly clean the fill tube of the sensor assembly.

NOTE: Never submerge the Digital ThermoFresh

®

Server Display or sensor assembly in water.

9. Wipe sensor assembly with a clean, damp cloth.

10. Reassemble the faucet and attach it to the dispenser.

11. Wash the entire outside surface of the server and display with a clean damp cloth.

PERIODIC CLEANING

1. Remove the sensor assembly from the server.

2. Remove the two thumb screws and slide display assembly from the server.

3. Wipe the surface of the display unit, area under the display unit, and sensor assembly with a clean damp

cloth.

4. Wash the entire outside surface of the sensor assembly with a mild detergent and water solution and rinse

with hot water. Do not submerse. NOTE: Thoroughly cleaning the sensor assembly fins will prevent inac-

curate level readings.

5. Replace the display unit and sensor assembly.

2

43240.9 030912

Page 3

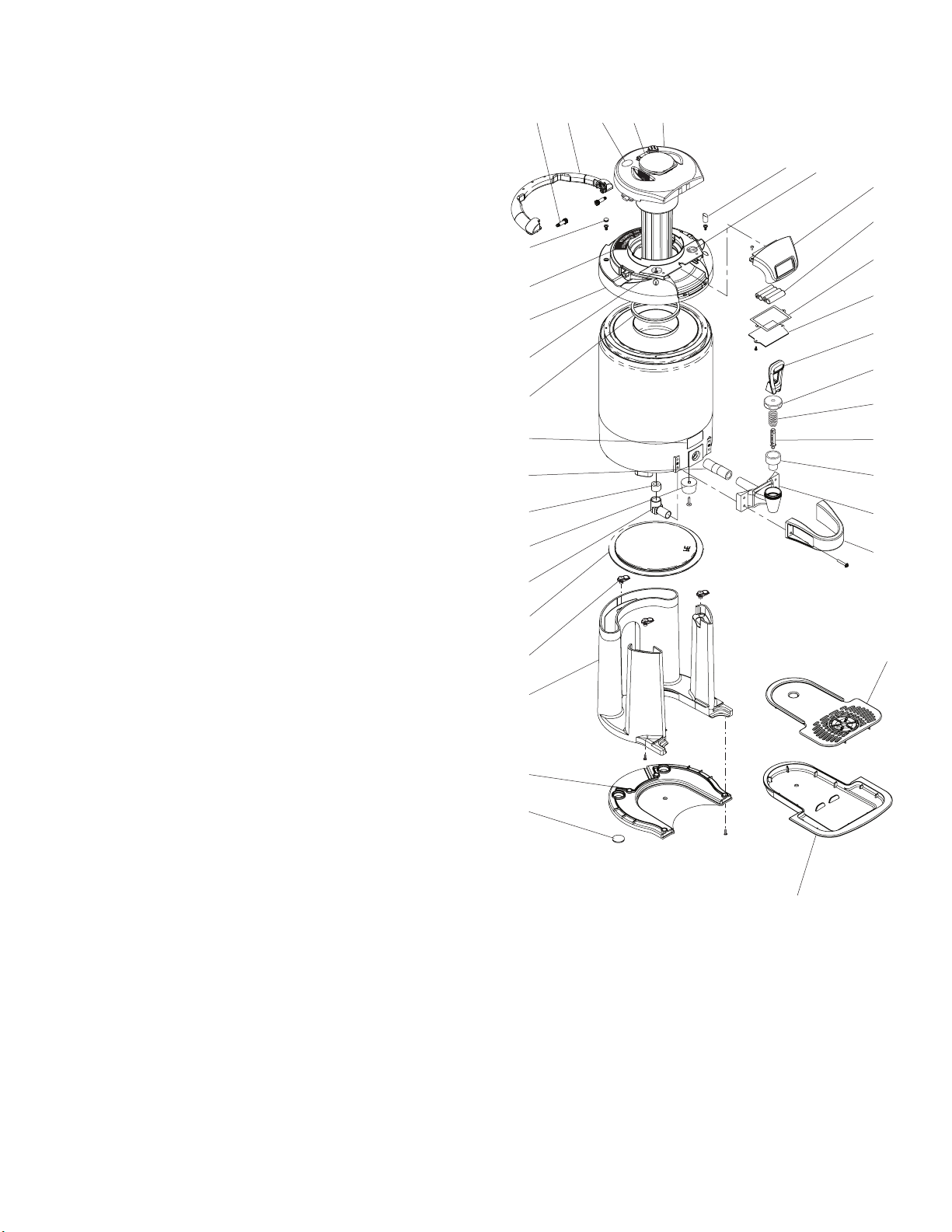

SERVER WITH STAND

REPLACEMENT PARTS

1. 42554.1001 Display Kit, Countup (Includes items 2 - 4)

42826.1000 Screw, Thumb #6-32 x .25"

2. 46247.1000 Batteries, 4 Pack AAA

3. 42546.0001 Gasket, Battery Cover

4. 42547.0001 Cover, Battery

02361.0000 Screw, Pan Head #4-40 x .25"

5. 43135.0000 Handle, Faucet

6. 29165.1002 Faucet Bonnet

7. 00601.1000 Faucet Spring (Package of 6)

8. 29164.1000 Faucet Stem (Package of 6)

9. 00600.1000 Faucet Seat Cup (Package of 6)

10. 42567.0000 Faucet Body

11. 42543.0000 Guard, Faucet

35074.1000 Screw, Pan Head M4 x .7 x .25

43231.0000 Washer, M4 x 9MM

12. 42584.1000 Plug, Front (Package of 10)

13. 42818.1001 Sensor Assy, 1.0 Gal (Includes items 14 &15)

42565.1000 Sensor Assy, 1.5 Gal (Includes items 14 &15)

14. 42563.1002 Cap, Sensor Assy (Package of 5)

15. 39043.0000 Decal, Do Not Submerge

16. 42562.0000* Handle, Server

17. 42758.0000* Shoulder Screw

18. 42585.1000 Plug, Rear (Package of 10)

19. 43246.1000 Cover Assy, Top

42761.0000* Screw, Pan Head M4 x 9

20. 35710.0000 Decal, Warning Hot Liquid

21. 32591.1000 Tube, Silicone .50" ID x 12.0" LG (cut to length)

22. 28526.1000 Tube, Silicone .31" ID x 12.0" LG (cut to length)

23. 42912.0000 Foot, Rubber

43163.0000 Screw, Pan Head #8 x .75"

24. 42295.0001 Elbow, 90°

25. 42890.1000 Base Cover

26. 35016.0001 Insert, Stand

27. 38929.0002 Stand, Server

39617.0000 Screw, Pan Hd Plastite #6 x .75"

28. 38930.0002 Base Plate, Stand

44010.0000 Screw, Pan Head #8 x .50"

29. 39443.1003 Pad, Adhesive Back .75" Dia.

30. 38931.1002 Kit, Drip Tray (Includes item 31)

31. 38932.0000 Cover, Drip Tray

32. 45457.0000* Decal, Do not Submerge

33. 39043.0002* Decal, Do not Spray

34. 39043.0001* Decal, Do not Submerge Server

35. 42889.0000 Seal

36. 35071.0000 Decal, Black Wrap 1.5 Gal. (Not Illustrated)

37974.0000 Decal, Black Wrap 1.0 Gal. (Not Illustrated)

37. 35301.0001 Brush, Cleaning (Not Illustrated)

* Components of item 19

17 16 15 14 13

18

32

19

33

35

20

21

22

23

24

25

26

27

28

29

12 34

1

2

3

4

5

6

7

8

9

10

11

31

P4166

30

3

43240.9 030912

Page 4

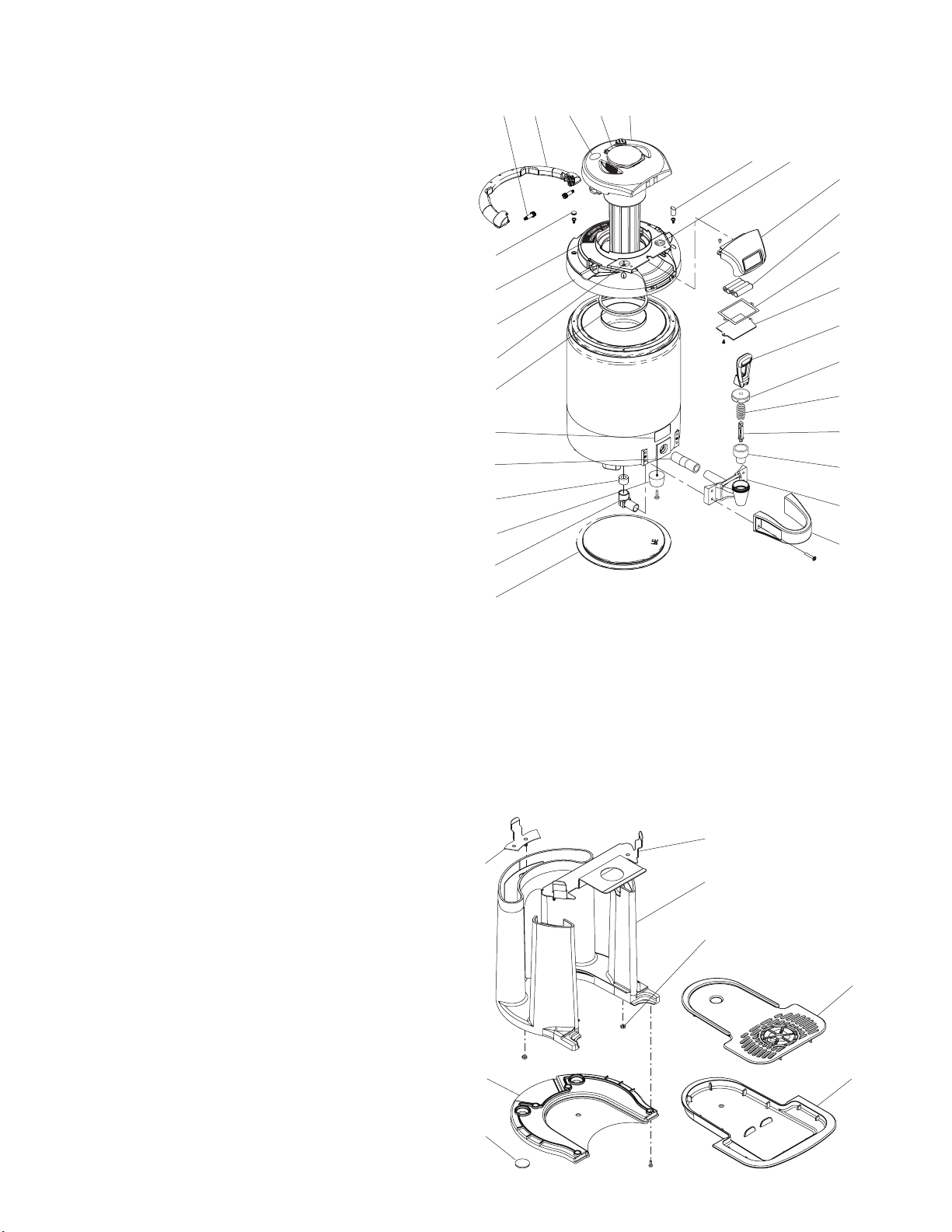

SERVER WITHOUT STAND

REPLACEMENT PARTS

1. 42554.1001 Display Kit, (Countup)(Includes items 2 - 4)

42826.1000 Screw, Thumb #6-32 x .25"

2. 46247.1000 Batteries, 4 Pack AAA

3. 42546.0001 Gasket, Battery Cover

4. 42547.0001 Cover, Battery

02361.0000 Screw, Pan Head #4-40 x .25"

5. 43135.0000 Handle, Faucet

6. 29165.1002 Faucet Bonnet

7. 00601.1000 Faucet Spring (Package of 6)

8. 29164.1000 Faucet Stem (Package of 6)

9. 00600.1000 Faucet Seat Cup (Package of 6)

10. 42567.0000 Faucet Body

11. 42543.0000 Guard, Faucet

35074.1000 Screw, Pan Head M4 x .7 x .25

43231.0000 Washer, M4 x 9MM

12. 42584.1000 Plug, Front (Package of 10)

13. 42818.1001 Sensor Assy, 1.0 Gal (Includes items 14 &15)

42565.1000 Sensor Assy, 1.5 Gal (Includes items 14 &15)

14. 42563.1002 Cap

15. 39043.0000 Decal, Do Not Submerge

16. 42562.0000* Handle, Server

17. 42758.0000* Shoulder Screw

18. 42585.1000 Plug, Rear (Package of 10)

19. 43246.1000 Cover Assy,

42761.0000* Screw, Pan Head M4 x 9

20. 35710.0000 Decal, Warning Hot Liquid

21. 32591.1000 Tube, Silicone .50" ID x 12.0" (cut to length)

22. 28526.1000 Tube, Silicone .313" ID x 12.0" (cut to length)

23. 42912.0000 Foot, Rubber

43163.0000 Screw, Pan Head #8 x .75"

24. 42295.0001 Elbow, 90°

25. 42890.1000 Base Cover

26. 45457.0000* Decal, Do not Submerge

27. 39043.0002* Decal, Do not Spray

28. 39043.0001* Decal, Do not Submerge Server

29. 42889.0000 Seal

30. 35071.0000 Decal, Black Wrap 1.5 Gal. (Not Illustrated)

37974.0000 Decal, Black Wrap 1.0 Gal. (Not Illustrated)

31. 35301.0001 Brush, Cleaning (Not Illustrated)

* Components of item 19

17 16 15 14 13

18

26

19

27

29

20

21

22

23

24

25

12 28

1

2

3

4

5

6

7

8

9

10

11

STAND FOR SERVERS WITHOUT STAND

REPLACEMENT PARTS

- 39795.0003 Stand, Assy (Includes items 1 - 8)

1. 39449.0005 Bracket, Rear

2. 39448.0003 Bracket, Front

3. 38929.0002 Stand, Server

4. 00970.0000 Nut, Keps #8-32

5. 38930.0002 Base Plate, Stand

44010.0000 Screw, Pan Head #8 x .50"

6. 39443.1003 Pad, Adhesive Back .75" Dia.

7. 38932.0000 Cover, Drip Tray

8. 38931.1002 Drip Tray Kit (Includes item 7)

2

1

5

6

4

3

4

7

8

43240.9 030912

Page 5

DIGITAL DISPLAY

The Digital ThermoFresh® Server is equipped with a digital probe and display called a Digital Sight Gauge. The probe

contains a circuit board designed to sense liquid levels & hold times. During the monitoring process, the probe sends

information to the display. The display then allows the user to monitor the liquid level and freshness (hold time) of the

beverage held in the server.

HORIZONTAL BAR

Using the Digital Sight Gauge display, the liquid level in the server can be

monitored by watching the horizontal bars. The 1.0 gallon display is equipped with

4 bars and the 1.5 gallon with 6 bars to represent the level inside the dispenser.

(each bar represents a quart, or one quarter of a gallon)

All four/six bars will be displayed when the server is full. When the level of

the liquid drops to a certain level, the highest bar on the display will no longer be

illuminated. These bars will continue to disappear as the level inside the dispenser drops. (See Fig. 1)

COUNT UP TIMER

FIG. 1

The Digital display is set to count up to 4:00 hours. The display counts up in one minute increments, flashing at 2:00

hours and continuing to flash once it reaches 4:00 hours. (See Fig. 1)

TIMER RESET

The display will reset to 0 when any of the following occurs:

• Theliquidlevelintheserverisincreasedby1barforasustainedperiodoftime.(brewinginto,oraddingadditional

liquid to existing beverage)

• Afreshnewbeverageisbrewedintotheserver.

• Whenthecontactpinsofthesensorassemblyaredisengagedfromthedisplayformorethan20seconds.

DISPLAY OFF

When the sensor assembly on the server is removed or loosened for more than 20 seconds, the display on the

Digital Sight Gauge breaks contact with the pins on the surface of the server. When this happens, the outline that

surrounds the Horizontal Level Bars will flash on and off and the time disappears. This indicates that the display has

been disengaged from the probe and cannot receive data.

When the display is in place and engaged, but the server is empty, the outline surrounding the Horizontal Level Bars

will be on but not flashing and the Freshness Time will not be displayed. All other portions of the display will not be

visible. This indicates the display is engaged and ready to receive data from the probe, but the server is empty.

The only time the display will be completely blank, is when the batteries have

been removed or have expired. (See the “Battery Replacement” section for additional

information.)

FRESHNESS TIME

This unit is factory set to count up to 2:00 hours, and begin flashing. If a reset condition

has not occurred, it will continue to flash and count up to a maximum of 4:00 hours.

Flashing notification is adjustable and can be set between 15 minutes and 3 hours 45

minutes in 15 minute increments. Setting changed by opening battery compartment and

positioning rotary switch using a small screwdriver. Settings are defined in the Flashing

Notification Table.

LOW BATTERY INDICATOR

When the batteries in the display unit are running low, the display is also equipped with

a battery icon. The upper most bar used in monitoring liquid levels, will begin to flash in the

shape of a battery to indicate that it is time to replace the batteries. (See FIG. 1)

5

Flashing Notification Table

Position Minutes

0 30

1 60

2 90

3 120 (Default)

4 150

5 180

6 210

7 240

8 15

9 45

A 75

B 105

C 135

D 165

E 195

F Disable Timer

43240.9 030912

Page 6

BATTERY REPLACEMENT

The Digital Sight Gauge display comes equipped with 4 AAA batteries. The batteries have

a use life of approximately 1 1/2 years under normal operating conditions.

NOTE: Batteries are not covered under product warranty.

To replace the batteries:

1. Remove the sensor assembly from the server.

2. Remove the two thumb screws and slide display assembly from the server.

3. Loosen the two screws on the bottom of the display, Fig 2 and rotate the cover approximately

180°.

4. Replace used batteries with 4 AAA alkaline batteries.

FIG. 2

SENSOR ASSEMBLY INSTALLATION

Proper installation of the sensor assembly is achieved by aligning the contacts of the sensor assembly (B) with the

contacts on the back of the sight gauge (A) when the sever handle is in the fully open position. Once the sensor assembly

is engaged into the server, it is locked in place by flipping the handle over approximately 180° as shown in Fig 3.

A B

FIG. 3

6

P4164

43240.9 030912

Page 7

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corporation of Canada (“Bunn”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCP/MCA pod brewers

thermal servers and Thermofresh servers (mechanical and digital) - 1 year parts and 1 year labour.

2) All other equipment - 2 years parts and 1 year labour plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labour for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labour.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve

analysis - parts and labour for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation. Bunn warrants that the equipment manufactured

by it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component

or part that was not manufactured by Bunn or that, in Bunn’s judgement, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, non periodic cleaning and descaling,

equipment failures related to poor water quality, damage or casualty. In addition, the warranty does not apply to

replacement of items subject to normal use including but not limited to user replaceable parts such as seals and

gaskets. This warranty is conditioned on the Buyer 1) giving Bunn prompt notice of any claim to be made under

this warranty by telephone at (905) 841-2866 or by writing to 280 Industrial Parkway South, Aurora, Ontario, L4G

3T9. 2) if requested by Bunn, shipping the defective equipment prepaid to an authorized Bunn service location;

and 3) receiving prior authorization from Bunn that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, CONDITION,

WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY

OF EITHER MERCHANTABILITY, MERCHANTABLE QUALITY OR FITNESS FOR A PARTICULAR PURPOSE.The

agents, dealers or employees of Bunn are not authorized to make modifications to this warranty or to make

additional warranties that are binding on Bunn. Accordingly, statements by such individuals, whether oral or

written, do not constitute warranties and should not be relied upon.

If Bunn determines in its sole discretion that the defective equipment is covered by warranty, Bunn, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labour (during the applicable parts and labour warranty periods specified above) to repair the defective

components, provided that this repair is done by a Bunn Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE

SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT

BUNN’S SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall Bunn be liable for any other damage or loss, including, but not limited to, lost profits, lost

sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental, consequential or punitive damages.

RETURN POLICY

CONTACT PLANT FOR RETURN MATERIAL AUTHORIZATION. ALL RETURNS MUST

BE AUTHORIZED BY BUNN-O-MATIC AND ARE SUBJECT TO A RETURN CHARGE.

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN

Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic,

Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design,

Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with

the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel,

Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh,

Titan, trifecta, Velocity Brew, A Partner You Can Count On, Air Brew, Air Infusion, Beverage Bar Creator, Beverage Profit

Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Daypart, Digital Brewer

Control, Nothing Brews Like a BUNN, Pouring Profits, Signature Series, Tea At Its Best, The Horizontal Red Line, Ultra are

either trademarks or registered trademarks of Bunn-O-Matic Corporation.

7

43240.9 030912

Page 8

43240.9 030912

7

Horizontal Red Line, Ultra sont des marques de commerce déposées de Bunn-O-Matic Corporation.

Heating System, Daypart, Digital Brewer Control, Nothing Brews Like a BUNN, Pouring Profits, Signature Series, Tea At Its Best, The

Brew, Air Infusion, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic

The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, Velocity Brew, A Partner You Can Count On, Air

Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard,

PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design,

Clear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew,

BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyGourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic,

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family

DOIVENT-ÊTRE PRÉCÉDEMMENT AUTORISÉS PAR BUNN-O-MATIC ET SONT SUJETS À DES FRAIS DE RETOUR.

COMMUNIQUEZ AVEC BUNN-O-MATIC POUR UNE AUTORISATION DE RETOUR. TOUS LES RETOURS

POLITIQUE DE RETOUR

touts autres dommages-intérêts spéciaux, accessoires, indirects ou punitifs.

des temps d’arrêt, le coût d’appareils de remplacement, de services de remplacement, ou des installations de remplacement, et

profits, les ventes perdues, la perte d’utilisation de l’appareil, les réclamations des clients de l’acheteur, le coût du capital, le coût

En aucun cas Bunn ne sera tenu responsable d’autres dommages ou pertes, y compris, mais sans y être limité à, la perte de

DISCRÉTION DE BUNN.

À LA RÉPARATION, AU REMPLACEMENT, OU AU REMBOURSEMENT DU PRIX D’ACHAT DE L’APPAREIL, À L’ENTIÈRE

VENTE DE CET APPAREIL, QU’IL RELÈVE OU NON DE GARANTIE, SERA LIMITÉ, TEL QUE PRÉCISÉ DANS LA PRÉSENTE,

LE RECOURS DE L’ACHETEUR CONTRE BUNN POUR LA VIOLATION DE TOUTE OBLIGATION DÉCOULANT DE LA

ou rembourser le prix d’achat de l’équipement.

condition que la réparation soit effectuée par un représentant de service autorisé par Bunn; soit 2) remplacer l’équipement

main-d’œuvre (pendant le délai applicable de garantie tel qu’indiqué ci-dessus) pour réparer les composants défectueux, à

exclusive, pendant que l’appareil est sous garantie, devra soit 1) fournir gratuitement des pièces de rechange et / ou de la

Si Bunn détermine à son entière discrétion que l’appareil défectueux est couvert par la garantie, Bunn, à sa discrétion

la responsibilité de Bunn.

Bunn. Ainsi, les déclarations de ces individus, orales comme écrites, ne constituent pas de garanties et n’engagent pas

ne sont pas autorisés à modifier cette garantie ou à apporter des garanties supplémentaires qui engageront ou affecteront

Les agents, concessionnaires ou employés de Bunn

MARCHANDE, OU DE CONFORMITÉ À UN USAGE PARTICULIER.

EXPRESSE OU IMPLICITE, Y COMPRIS MAIS NON LIMITÉE À TOUTE GARANTIE IMPLICITE DE QUALITÉ, DE QUALITÉ

LA GARANTIE CI-DESSUS EST EXCLUSIVE ET REMPLACE TOUTE AUTRE GARANTIE, CONDITION, ÉCRITE OU ORALE,

est sous garantie.

payé, à un centre de service autorisé par Bunn; et 3) reçoive une autorisation préalable de la part de Bunn que l’appareil défectueux

écrit au 280 Industrial Parkway South, Aurora, Ontario L4G 3T9; 2) fasse livrer, à la demande de Bunn, l’appareil défectueux, port

l’acheteur 1) avise Bunn ponctuellement de toute réclamation en vertu de cette garantie par téléphone au (905) 841-2866 ou par

n’est pas limité à des pièces remplaçables par l’utilisateur tels des joints d’étanchéité. Cette garantie est conditionnelle à ce que

remplacement des composantes des appareils devant être remplacées dans le cour normal de leur utilisation; cela comprend mais

d’équipement liées à une eau de mauvaise qualité, à des dommages ou à un accident. En outre, cette garantie ne s’applique pas au

ou un usage impropre, un entretien impropre ou une réparation impropre, un manque de nettoyage et détartrage, des défaillances

été fabriqués par Bunn ou qui, selon Bunn, auraient subi un usage abusif, une négligence, une altération, une installation impropre,

pendant la période couverte par la garantie. Cette garantie ne s’applique pas aux appareils, composants ou pièces qui n’ont pas

affectés d’aucun défaut commercial quant à leur matériel ou leur fabrication, existant au moment de fabrication, et se manifestant

Ces délais de garantie commencent à courir à partir de la date d’installation. Bunn garantit que les appareils fabriqués par elle ne sont

original de l’usine - 4 ans pièces et main-d’œuvre ou 40 000 livres de café, selon la première éventualité.

c) Bavures de mouture sur équipement de moulure de café pour mourde le café afin de répondre à l’analyse de passage au crible

b) Compresseurs inclus dans l’équipement de réfrigération - 5 ans pièces et 1 an main-d’œuvre.

a) Cartes de circuits électroniques et / ou de contrôle - 3 ans pièces et main-d’œuvre.

2) Tout autre appareil - 2 ans pièces et 1 an main-d’œuvre ainsi que les garanties additionnelles indiquées ci-dessous :

et 1 an main-d’œuvre.

nacelle de type MCP/MCA, serveurs thermiques et serveurs de type Thermofresh (mécanique et numérique) - 1 an pièces

1) Cafetières, carafes thermiques, carafes à décanter, serveurs GPR, distributrices de thé glacé / de café glacé, infuseursBunn-O-Matic Corporation of Canada (« Bunn ») garantit les appareils qu’elle fabrique ainsi :

BUNN-O-MATIC GARANTIE DE PRODUIT COMMERCIAL

Page 9

43240.9 030912

6

FIG. 3

P4164

FIG. 2

A B

nécessaire de service, verrouillez-le en place en faisant passer la poignée par-dessus, sur environ 180°, comme l’illustre la fig. 3.

(A) pendant que la poignée du nécessaire de service est dans la position ouverte. Lorsque le capteur est enclenché dans le

Pour installer le capteur, alignez les contacts du capteur (B) avec les contacts sur la partie arrière de la jauge visuelle

INSTALLATION DU CAPTEUR

4. Remplacez les 4 piles usagées par 4 nouvelles piles alcalines AAA.

d’environ 180°.

3. Desserrez les deux vis en bas de l’écran d’affichage (fig. 2) et faites tourner le couvercle

glisser.

2. Retirez les deux vis à oreilles, puis l’écran d’affichage du nécessaire de service en le faisant

1. Retirez le capteur du nécessaire de service.

Pour remplacer les piles :

NOTE: Les piles ne sont pas couvertes par la garantie.

une durée de vie d’environ une année et demie dans des conditions d’utilisation normales.

L’écran d’affichage de la jauge visuelle numérique est muni de 4 piles AAA, lesquelles ont

REMPLACEMENT DES PILES

Page 10

43240.9 030912

F Désactiver minuterie

E 195

D 165

C 135

B 105

A 75

9 45

8 15

7 240

6 210

5 180

4 150

3 120 (défaut)

2 90

1 60

0 30

Position Minutes

Tableau de réglage des clignotements

5

les piles (voir fig. 1).

service, une icône en forme de pile se mettra à clignoter pour indiquer qu’il faut remplacer

supérieure de l’écran, qui sert à indiquer le niveau de liquide dans le nécessaire de

Lorsque les piles sont presque entièrement déchargées, sur la barre horizontale

INDICATEUR DE DÉCHARGE

réglage des clignotements pour plus d’information.

piles et en ajustant l’interrupteur rotatif à l’aide d’un petit tournevis. Voir le tableau de

jusqu’à 3 heures 45 minutes. Le réglage est effectué en ouvrant le compartiment des

ajustables et peuvent être réglés par tranches de 15 minutes, allant de 15 minutes

et poursuivra son comptage progressif jusqu’à 4 heures. Les clignotements sont

et se mettre à clignoter. S’il n’y a pas eu de remise à zéro, il continuera de clignoter

Cet appareil est réglé en usine pour compter progressivement jusqu’à 2 heures

TEMPS DE MAINTIEN

périmées (voir la section « Remplacement des piles » pour plus d’information).

est complètement à blanc est lorsque les piles ont été enlevées ou lorsqu’elles sont

recevoir les données du nécessaire de service, mais que ce dernier est vide. Le seul moment où l’écran d’affichage

de l’écran ne sera visible, indiquant que l’écran d’affichage a été enclenché à la sonde et qu’il est dorénavant capable de

horizontales sera allumé mais non clignotant et le temps de maintien (l’heure) ne sera pas affiché. Aucune autre partie

Lorsque l’écran d’affichage est en place et enclenché, mais que le nécessaire de service est vide, le pourtour des barres

d’affichage a été débranché de la sonde et qu’il n’est plus capable de recevoir les données du nécessaire de service.

de faire clignoter le pourtour des barres horizontales (marche-arrêt) et de faire disparaître l’heure, indiquant que l’écran

de la jauge visuelle numérique coupe le contact avec les broches à la surface du nécessaire de service. Cela a pour effet

Lorsque le capteur du nécessaire de service est retiré ou desserré pendant plus de 20 secondes, l’écran d’affichage

ÉCRAN D’AFFICHAGE FERMÉ

FIG. 1

• lesbrochesdecontactducapteursontdébranchéesdel’écrand’afchagependantplusde20secondes.

• unenouvelleinfusionesteffectuéeàmêmelenécessairedeservice;

soutenue (soit en infusant à même le liquide présent ou en ajoutant du liquide à la boisson présente);

• leniveauduliquideàl’intérieurdunécessairedeserviceestrehausséd’unebarrependantunepériodedetemps

L’écran d’affichage se remet à 0 lorsque :

RÉINITIALIATION DE LA MINUTERIE

jusqu’à 4 heures, par tranche de 1 minute. Il clignote à 2 heures, et clignote encore lorsqu’il atteint 4 heures (voir fig. 1).

L’écran d’affichage numérique est programmé pour compter progressivement

COMPTEUR PROGRESSIF

s’éteignent une à une à partir du haut (voir fig. 1).

est plein. Au fur et à mesure que le niveau du liquide baisse, les barres horizontales

Les 4/6 barres horizontales sont toutes illuminées lorsque le nécessaire de service

volume de liquide présent (chaque barre représente une pinte, soit ¼ gallon.)

horizontales, et le modèle de 1,5 gallon affiche 6 barres, lesquelles indiquent le

barres horizontales. L’écran d’affichage du modèle de 1,0 gallon affiche 4 barres

déterminer le niveau du liquide que renferme le nécessaire de service à l’aide des

Grâce à l’écran d’affichage de la jauge visuelle numérique, il est possible de

BARRES HORIZONTALES

surveiller le niveau du liquide et la fraîcheur (temps de maintien) de la boisson contenue dans le nécessaire de service.

de maintien. À l’étape de surveillance, la sonde achemine l’information à l’écran d’affichage, qui permet à l’utilisateur de

jauge visuelle numérique. La sonde renferme un circuit imprimé conçu pour détecter les niveaux de liquide et le temps

Le nécessaire de service ThermoFresh numérique est muni d’une sonde numérique et d’un écran d’affichage appelé

ÉCRAN D’AFFICHAGE NUMÉRIQUE

Page 11

43240.9 030912

4

6

8. 38931.1002 Plateau perforé (comprend l’article 7)

7. 38932.0000 Couvercle de plateau perforé

8

5

6 x 0,375 po

o

8-32

o

6. 39443.1003 Semelle à envers adhésif 0,875 po dia.

44010.0000 Vis à tête cylindrique bombée n

5. 38930.0002 Plaque de base

4. 00970.0000 Écrou à rondelle dentée n

3. 38929.0002 Base pour nécessaire de service

2. 39448.0003 Support avant

7

1. 39449.0005 Support arrière

- 39795.0003 Base complète (comprend les articles 1-8)

4

PIÈCES DE RECHANGE

BASE POUR NÉCESSAIRE DE SERVICE SANS BASE

11

10

9

8

7

6

5

4

3

2

1

12

3

1

* Composantes de l'article item 19

2

31. 35301.0001 Brosse de nettoyage (non illustrée)

37974.0000 Décalcomanie enveloppante noire 1,0 gal (non illustrée)

30. 35071.0000 Décalcomanie enveloppante noire 1,5 gal (non illustrée)

29. 42889.0000 Tige

28. 39043.0001*Décalcomanie, N'immergez pas le serveur

27. 39043.0002*Décalcomanie, Ne pas vaporiser

26. 45457.0000*Décalcomanie, Ne pas immerger

25. 42890.1000 Couvercle inférieur

24. 42295.0001 Coude 90°

8 x 0,75 po

o

43163.0000 Vis à tête cylindrique bombée n

23. 42912.0000 Pied en caoutchouc

22. 28526.1000 Tube de silicone 0,313 po Di x 12,0 po (coupé à longueur)

21. 32591.1000 Tube de silicone 0,50 po Di x 12,0 po (coupé à longueur)

20. 35710.7000 Décalcomanie Avertissement! Liquide chaud

42761.0000* 4 vis à tête cylindrique bombée M4 x 9 mm

25

19. 43246.1000 Couvercle supérieur

18. 42585.1000 Bouchon arrière (lot de 10)

24

17. 42758.0000* Vis à épaulement

16. 42562.0000* Poignée du nécessaire de service

23

15. 39043.0000 Décalcomanie Ne pas immerger

14. 42563.0002 Capuchon

22

42565.1000 Capteur pour 1,5 gal (comprend les articles 14 et 15)

13. 42818.1001 Capteur pour 1,0 gal (comprend les articles 14 et 15)

21

12. 42584.1000 Bouchon avant (lot de 10)

43231.0000 Rondelle M4 x 9 mm

20

35074.1000 Vis à tête cylindrique bombée M4 x 0,7 x 0,25 po

11. 42543.0000 Protecteur de robinet

10. 42567.0000 Corps du robinet

9. 00600.1000 Cuvette de siège de robinet (lot de 6)

19

18

4-40 x 0,25 po

o

8. 29164.1000 Tige du robinet (lot de 6)

7. 00601.1000 Ressort du robinet (lot de 6)

6. 29165.1002 Capuchon du Robinet

5. 43135.0000 Poignée de robinet

02361.0000 Vis à tête cylindrique bombée n

4. 42547.0001 Couvercle du logement des piles

3. 42546.0001 Joint d’étanchéité du couvercle de logement des piles

2. 46247.1000 Piles AAA, lot de 4

6-32 x 0,25 po

o

42826.1000 Vis à oreilles n

articles 2 à 4)

1. 42554.1001 Trousse d'affiche, Progressif (Comprend les

17 16 15 14 13

PIÈCES DE RECHANGE

NÉCESSAIRE DE SERVICE SANS BASE

Page 12

31

11

10

9

8

7

6

5

4

3

2

1

P4166

43240.9 030912

30

12 34

3

29

6 x

o

28

27

26

25

24

23

22

21

20

35

33

19

32

18

17 16 15 14 13

8 x 0,50 po

o

8 x 0,75 po

o

4-40 x 0,25 po

o

6-32 x 0,25 po

o

* Composantes de l'article item 19

37. 35301.0001 Brosse de nettoyage (non illustrée)

illustrée)

37974.0000 Décalcomanie enveloppante noire 1,0 gal (non

illustrée)

36. 35071.0000 Décalcomanie enveloppante noire 1,5 gal (non

35. 42889.0000 Tige

34. 39043.0001*Décalcomanie, N'immergez pas le serveur

33. 39043.0002*Décalcomanie, Ne pas Vaporiser

32. 45457.0000*Décalcomanie, Ne pas immerger

31. 38932.0000 Couvercle de plateau perforé

30. 38931.1002 Trousse de plateau perforé (comprend l'article 31)

29. 39443.1003 Semelle à envers adhésif 0,875 po dia.

44010.0000 Vis à tête cylindrique bombée n

28. 38930.0002 Plaque de base

0,75 po

39617.0000 Vis à tête cylindrique bombée en Plastite n

27. 38929.0002 Base

26. 35016.0001 Isolant de la base

25. 42890.1000 Couvercle inférieur

24. 42295.0001 Coude 90°

43163.0000 Vis à tête cylindrique bombée n

23. 42912.0000 Pied en caoutchouc

longueur)

22. 28526.1000 Tube de silicone 0,31 po Di x 12,0 po (coupé à

longueur)

21. 32591.1000 Tube de silicone 0,50 po Di x 12.0 po (coupé à

20. 35710.7000 Décalcomanie Avertissement! Liquide chaud

42761.0000*4 vis à tête cylindrique bombée x 9 mm

19. 43246.1000 Couvercle supérieur

18. 42585.1000 Bouchon arrière (lot de 10)

17. 42758.0000*Vis à épaulement

16. 42562.0000*Poignée du nécessaire de service

15. 39043.0000 Décalcomanie Ne pas immerger

14. 42563.1002 Capuchon, capteur (lot de 5)

42565.1000 Capteur pour 1,5 gal (comprend les articles 14 et 15)

13. 42818.1001 Capteur pour 1,0 gal (comprend les articles 14 et 15)

12. 42584.1000 Bouchon avant (lot de 10)

43231.0000 Rondelle, M4 x 9 mm

35074.1000 Vis à tête cylindrique bombée M4 x 0,7 x 0,25 po

11. 42543.0000 Protecteur de robinet

10. 42567.0000 Corps du robinet

9. 00600.1000 Cuvette de siège de robinet (lot de 6)

8. 29164.1000 Tige du robinet (lot de 6)

7. 00601.1000 Ressort du robinet (lot de 6)

6. 29165.1002 Capuchon du Robinet

5. 43135.0000 Poignée de robinet

02361.0000 Vis à tête cylindrique bombée n

4. 42547.0001 Couvercle du logement des piles

des piles

3. 42546.0001 Joint d’étanchéité du couvercle du logement

2. 46247.1000 Piles AAA, lot de 4

42826.1000 Vis à oreilles n

articles 2 à 4)

1. 42554.1001 Trousse d'affiche, Progressif (Comprend les

PIÈCES DE RECHANGE

NÉCESSAIRE DE SERVICE AVEC BASE

Page 13

43240.9 030912

2

5. Remettez l’écran d’affichage et le capteur en place.

contre les erreurs de lecture de niveau.

à l’eau chaude. N’immergez pas les pièces dans l’eau. NOTE : Le nettoyage des ailettes du capteur préviendra

4. Nettoyez toute la surface extérieure du capteur à l’aide d’une solution détergente douce et de l’eau. Rincez

3. Nettoyez la surface de l’écran d’affichage, la zone sous l’écran et le capteur à l’aide d’un chiffon humide propre.

2. Retirez les deux vis à oreilles et enlevez l’écran d’affichage du nécessaire de service en le faisant glisser.

1. Retirez le capteur du nécessaire de service.

NETTOYAGE PÉRIODIQUE

humide propre.

11. Nettoyez la surface extérieure du nécessaire de service et l’écran d’affichage en entier à l’aide d’un chiffon

10. Remontez le robinet et remettez-le en place sur le distributeur.

9. Nettoyez le capteur à l’aide d’un chiffon humide propre.

dans l’eau.

®

ThermoFresh

NOTE: N’immergez pas l’écran d’affichage numérique ni le capteur du nécessaire de service numérique

8. À l’aide de la brosse de nettoyage fournie, nettoyez complètement le tube de remplissage du capteur.

cinq minutes, rincez à fond et séchez complètement à l’air.

solution détergente douce avec de l’eau. Rincez-les à l’eau chaude. Désinfectez toutes les pièces pendant

7. Démontez le robinet et la tige de robinet. Nettoyez complètement toutes les parties du robinet dans une

39043.0002

39043.0001

39043.0000

R

E

6. À l’aide de la brosse de nettoyage fournie, nettoyez complètement le tube de remplissage et le robinet.

5. Enlevez la poignée et la tige du robinet en dévissant l’écrou du robinet situé en dessous de la poignée.

vidangez par le robinet complètement ouvert. Rincez à fond le nécessaire de service après l’avoir désinfecté.

4. Remplissez le nécessaire de service de solution désinfectante et laissez la solution agir pendant 5 minutes, puis

3. Rincez complètement le nécessaire de service à l’eau froide.

du nécessaire de service complètement.

2. Enlevez le capteur électronique, remplissez le nécessaire de service de solution nettoyante et nettoyez l’intérieur

minute avant de le vidanger complètement en ouvrant le robinet.

1. Entamez un cycle d’infusion complet d’eau chaude seulement dans le nécessaire de service et attendez une

nécessaire de service dans l’eau.

à l’eau froide, et de l’usage d’une solution désinfectante à l’eau sans chlore approuvée. N’immergez pas le

service en trois étapes, qui consistent en l’usage d’une eau chaude et d’un détergent approuvé, d’un rinçage

NOTE: Bunn-O-Matic recommande d’effectuer le procédé de nettoyage et de désinfection du nécessaire de

ATTENTION! NETTOYEZ ET DÉSINFECTEZ VOTRE NÉCESSAIRE DE SERVICE QUOTIDIENNEMENT.

NETTOYAGE QUOTIDIEN

45457.7000

M

M

I

E

R

G

E

E

R

G

S

A

P

E

U

S

B

M

N

T

O

N

O

D

LIQUIDE CHAUD

AVERTISSEMENT

35710.7000

HOT LIQUID

WARNING

les décalcomanies si elles sont endommagées ou illisibles.

Les consignes qui figurent sur ce nécessaire de service doivent être conservées en bon état. Remplacez

AVIS À L’UTILISATEUR

NOTE: Il est nécessaire de calibrer le nécessaire de service numérique TF avant de l’utiliser.

de service doit être placé sur un plan de travail robuste.

directement dans le nécessaire de service, pour ensuite le transporter à un point de service distant. Le nécessaire

et ICB. En suivant les mesures de sécurité, il est possible d’infuser de 1,0 à 1,5 gallon de café

®

,

®

TF DBC

®

DUAL

®

TF DBC

®

SINGLE

Il est possible de combiner ce nécessaire de service aux familles d’infuseurs BUNN

INTRODUCTION

Page 14

43240.7009B 11/12 ©2012 Bunn-O-Matic Corporation

TÉLÉPHONE: (905) 841-2866 TÉLÉCOPIEUR: (905) 841-2775

AURORA, ONTARIO, L4G 3T9

280 INDUSTRIAL PARKWAY SOUTH,

BUNN-O-MATIC CORPORATION OF CANADA

SECTION QUI PORTE SUR LE NETTOYAGE QUOTIDIEN.

MISE EN GARDE : NETTOYEZ ET DÉSINFECTEZ VOTRE SERVEUR AVANT USAGE. VOIR LA NOTE DANS LA

GUIDE D’UTILISATION ET D’ENTRETIEN

®

compteur progressif

1,0 et 1,5 gallon muni d’un

ThermoFresh

numérique

service

Nécessaire de

Loading...

Loading...