Page 1

OMNI

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

35352.0000B 12/05 ©2003 Bunn-O-Matic Corporation

WARNING:

HOT LIQUID

NING:

WAR

HOT LIQUID

www.bunnomatic.com

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specifi ed below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis:

parts and labor for 3 years or 30,000 pounds of coffee, whichever comes fi rst.

These warranty periods run from the date of installation. BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component or

part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, damage or casualty. This warranty is

conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone

at (217) 529-6601 or by writing to Post Offi ce Box 3227, Springfi eld, Illinois 62708-3227; 2) if requested by

BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior

authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN

are not authorized to make modifi cations to this warranty or to make additional warranties that are binding on

BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labor (during the applicable parts and labor warranty periods specifi ed above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profi ts, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

2

35352 121405

Page 3

INTRODUCTION

This equipment has two dispense stations that blend powdered product and hot water on one side and two

dispense stations of coffee with four strength selections each on the other side. It also dispenses plain hot water.

This equipment is for indoor use only and should be placed on a sturdy table or counter top.

Machine weight: 125 lbs. (56.7 kg.) dry

and 190 lbs. (86.2 kg.) wet

USER NOTICES

00656.0000

00986.0000

3

35352 121405

Page 4

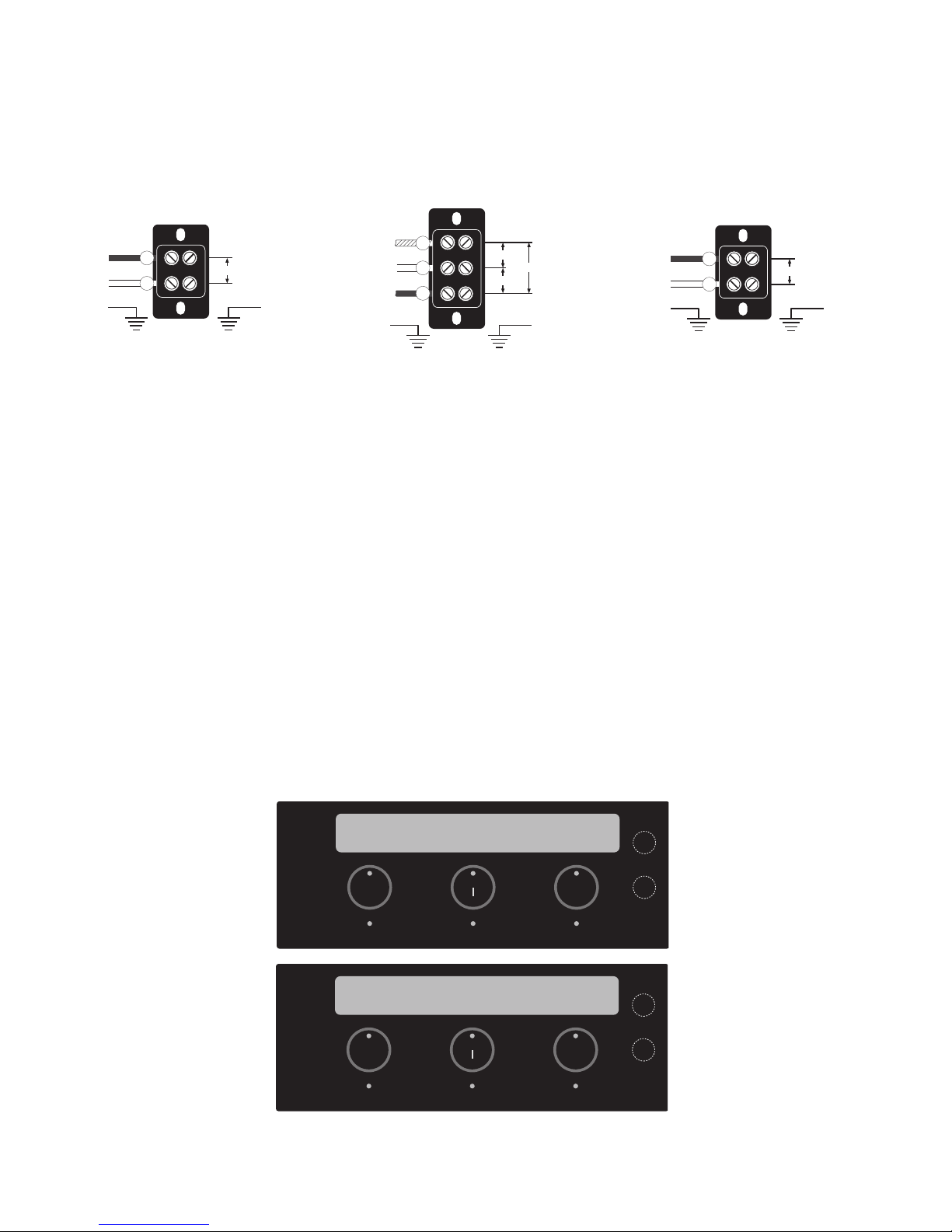

ELECTRICAL REQUIREMENTS

WARNING - The dispenser must be disconnected from the power source until specifi ed in Electrical Hook-Up.

The 120 volt version of this dispenser has an attached cordset. NOTE: If the power cord is damaged, it must be

replaced by the manufacturer or its service agent or a similarly qualifi ed person in order to avoid a hazard.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

LOAD

BLK

L1

WHI/VIO

L2

GREEN GREEN

200 or 240V. A.C.

200 & 240V AC

single phase models

Note: This electrical service

consists of 2 current carrying

conductors (L1 and L2) and a

separate conductor for earth

ground.

LOAD LOADLINE LINE LINE

WHI/VIO

L2

WHI

N

BLK

L1

GREEN GREEN

120V. A.C.

208 or 240V. A.C.

120V. A.C.

120/208 & 120/240V AC

single phase models

Note: This electrical service

consists of 3 current carrying

conductors (Neutral, L1 and

L2) and a separate conductor

for earth ground

BLK

L1

WHI

N

GREEN GREEN

120V. A.C.

120V AC

single phase models

Note: This electrical service

consists of 2 current carrying

conductors (Neutral and L1)

and a separate conductor for

earth ground.

ELECTRICAL HOOK-UP

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service as specifi ed.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3. Remove the right side access cover.

4. Feed the cord through the strain relief in the bottom right and connect it to the terminal block.

5. Connect the ground wire to the stud next to the terminal block and secure with #8-32 nut.

6. Connect the brewer to the power source and verify the voltage at the terminal block before proceeding. Replace the right side access cover.

7. A qualifi ed Service Technician should now enter the Service Program mode under SELECT MACHINE VOLTAGE screen and choose “YES” (RIGHT) only if supplied voltage is above 220V.

NOTE: If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing has been hooked up, the brewer is ready for Initial Set-Up.

SELECT MACHINE VOLTAGE

NO NEXT YES

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

IS MACHINE 240 VOLTS

NO NEXT YES

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

4

RIGHT

RIGHT LOW

RIGHT

RIGHT LOW

35352 121405

Page 5

PLUMBING REQUIREMENTS

This brewer must be connected to a cold water system with operating pressure between 20 and 90 psi (138

and 620 kPa) from a

Install a regulator in the line when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345 kPa).

The water inlet fi tting is

NOTE – Bunn-O-Matic recommends 1⁄4” copper tubing for installations of less than 25 feet and 3⁄8” for more

than 25 feet from the

the brewer to clean the countertop. Bunn-O-Matic does not recommend the use of a saddle valve to install the

brewer. The size and shape of the hole made in the supply line by this type of device may restrict water fl ow.

Building Codes in some areas require the installation of a back fl ow prevention device on branch water lines

that directly feed food and beverage equipment. The presence of a back fl ow prevention device can result in an

increase in water pressure that prevents the proper operation of the machine’s water inlet solenoid. When a back

fl ow prevention device is present, Bunn-O-Matic recommends the installation of a water hammer arrester on

the incoming water line between the back fl ow prevention device and the machine. Water hammer arresters are

available through a local plumbing supply house or directly from Bunn-O-Matic by ordering Bunn-O-Matic Part

Number 29350.0000 or 28919.0000.

1

⁄2” or larger supply line. A shut-off valve should be installed in the line before the brewer.

1

⁄4” fl are.

1

⁄2” water supply line. A tight coil of copper tubing in the water line will facilitate moving

This equipment must be installed to comply with the Basic Plumbing Code of the Building

Offi cials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the Food and Drug Administration (FDA). For models installed outside the

U.S.A., you must comply with the applicable Plumbing/Sanitation Code for your area.

PLUMBING HOOK-UP

1. Attach the fl ow control to fl are fi tting on bottom left side of brewer with copper tube assembly provided.

2. Flush the water line and securely attach it to the fl are fi tting on the water fl ow control.

3. Turn on the water supply.

4. Connect drain per instructions in the provided Drain Plumbing Kit.

5. The drip tray may also be connected to a drain. Run a 3/8” or 13/32” drill through the fi tting in the back of

the drip tray to open up the drain hole. Connect drain line to the fi tting and run the line to the drain.

5

35352 121405

Page 6

INITIAL SET-UP

1. Connect the brewer to the power source. The brewer will automatically begin to fi ll the tanks. After both tanks

are fi lled, the tank heaters will automatically turn on, one at a time. The dilution tank will heat fi rst, then the

brew tank. The tanks are fully heated when the BREWER READY indicator light is illuminated.

2. About 5 seconds after the brewer is connected to the power source, the LEFT/RIGHT LOW indicator lights

will illuminate. If a funnel is in place, the DISPOSE GROUNDS indicator will also be illuminated. Removing

the funnel for at least two seconds will reset this indicator.

OPERATING CONTROLS

1. BREWER READY INDICATOR

Indicates the water in the brew tank has reached the acceptable target temperature for brewing coffee. The

machine will not allow brewing until the indicator is illuminated. This is known as “brew Lockout” and cannot

be disabled. (Heating times are longer for 120V machines)

2. SERVICE INDICATOR

Indicates the machine has malfunctioned and requires service or clean. View the display screen for the actual

fault code. To reset any fault, remove the funnel and press both LEFT and RIGHT start switches. If the fault

returns, refer to the service decal (typically located on inside panel of door).

3. DISPOSE GROUNDS INDICATOR

Indicates that a brew or clean cycle is completed. Pull the funnel out and dump the used fi lter/grounds (or

Cleaning Packet). The indicator resets when the funnel is removed.

4. AUTOBREW ON INDICATOR

Indicates that the brewer is in the autobrew mode and will automatically start another brew cycle when a

reservoir reaches a low level. When brew cycle is completed, DISPOSE GROUNDS indicator will illuminate.

6

35352 121405

Page 7

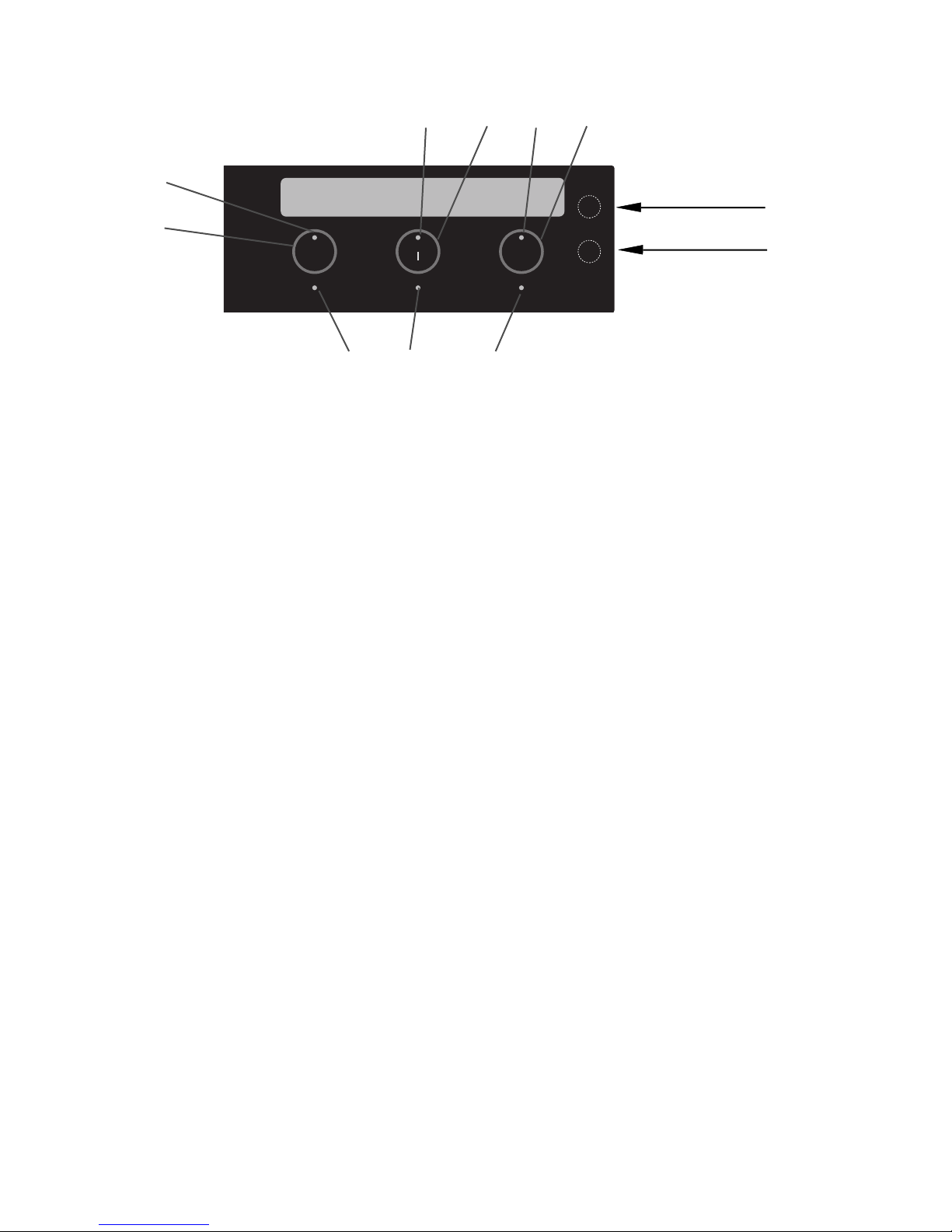

OPERATING CONTROLS (Continued)

4

8 7 6 5

3

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

“HIDDEN” Buttons

2 1 2

NOTE: In order for the REGULAR, DECAF, and CLEAN switch to actuate on the Manual Control machines, the

lower “Hidden” switch to the right of the “RIGHT” switch must be pressed and held.

1. CLEAN TONIGHT INDICATOR

Indicates that the brewer has missed a mandatory clean or rinse cycle.

2. LEFT/RIGHT LOW INDICATORS

Indicates the left or right reservoir has run low or out of coffee.

3. LEFT SWITCH

Momentarilly pressing and releasing this switch will start a brew cycle into the rear reservoir. Pressing the

switch after a brew cycle has started will terminate the brew.

4. LEFT BREW INDICATOR

Part of the LEFT switch, indicates that the brewer is brewing into the rear reservoir.

5. RIGHT SWITCH

Momentarilly pressing and releasing this switch will start a brew cycle into the front reservoir. Pressing the

switch after a brew cycle has started will terminate the brew.

6. RIGHT BREW INDICATOR

Part of the RIGHT switch, indicates that the brewer is brewing into the front reservoir.

7. CLEAN ON/OFF SWITCH

Momentarilly pressing and releasing this switch will set the brewer in a clean cycle mode. Pressing the switch

twice after a clean cycle has started will terminate the clean cycle.

8. CLEAN INDICATOR

Part of the CLEAN ON/OFF switch, indicates that the brewer is in a clean or rinse cycle.

7

35352 121405

Page 8

COFFEE BREWING

1. Insert a fi lter into the funnel. BUNN® part number 20138.0000 (Gourmet) or equivalent.

2. Pour the proper amount of fresh ground coffee into the fi lter and level the bed of grounds by gently shaking.

3. Slide the funnel into the funnel rails, the arrow on the funnel handle towards the front of the brewer pointing

towards the left, for brewing into the rear reservoir, or with the arrow pointing to the right, for brewing into

the front reservoir.

4. Press the appropriate button, either LEFT or RIGHT to start the brew cycle.

5. When the brew cycle is complete, the DISPOSE GROUNDS indicator light will be illuminated. Dispose of used

grounds to reset the indicator. The (red) LEFT or RIGHT LOW indicator for the reservoir brewed into should

be extinguished.

NOTE: In order for the LEFT, RIGHT, and CLEAN switch to actuate on the Manual Control machines, the lower

“Hidden” switch to the right of the “RIGHT” switch must be pressed and held.

AUTOBREW

The brewer can be staged to automatically start a brew cycle when a reservoir reaches a low level.

1. Repeat steps one through three above. When the appropriate button is pushed to start the brew cycle, the

green AUTOBREW ON indicator will light.

2. When the reservoir for which the brew cycle has been selected reaches the low level, the brew cycle will

automatically start, and the AUTOBREW ON indicator will reset.

3. To cancel the AUTOBREW mode before the brew cycle begins, remove the funnel from the brewer.

LEFT READY TO BREW

PRESS LEFT TO BEGIN

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

“HIDDEN” Buttons

DUMPING THE RESERVOIRS

Either or both reservoirs can be dumped of coffee by pressing and holding the corresponding or both BREW

switch(es) for fi ve seconds without a funnel in place.

NOTE: In order for the LEFT and RIGHT switches to actuate on the Manual Control machines, the lower “Hidden” switch to the right of the “RIGHT” switch must be pressed and held.

LEFT 50 (% FULL) 5 RIGHT

LOW

LEFT

CLEAN

ON OFF

RIGHT

“HIDDEN” Buttons

LEFT LOW

CLEAN TONIGHT

8

RIGHT LOW

35352 121405

Page 9

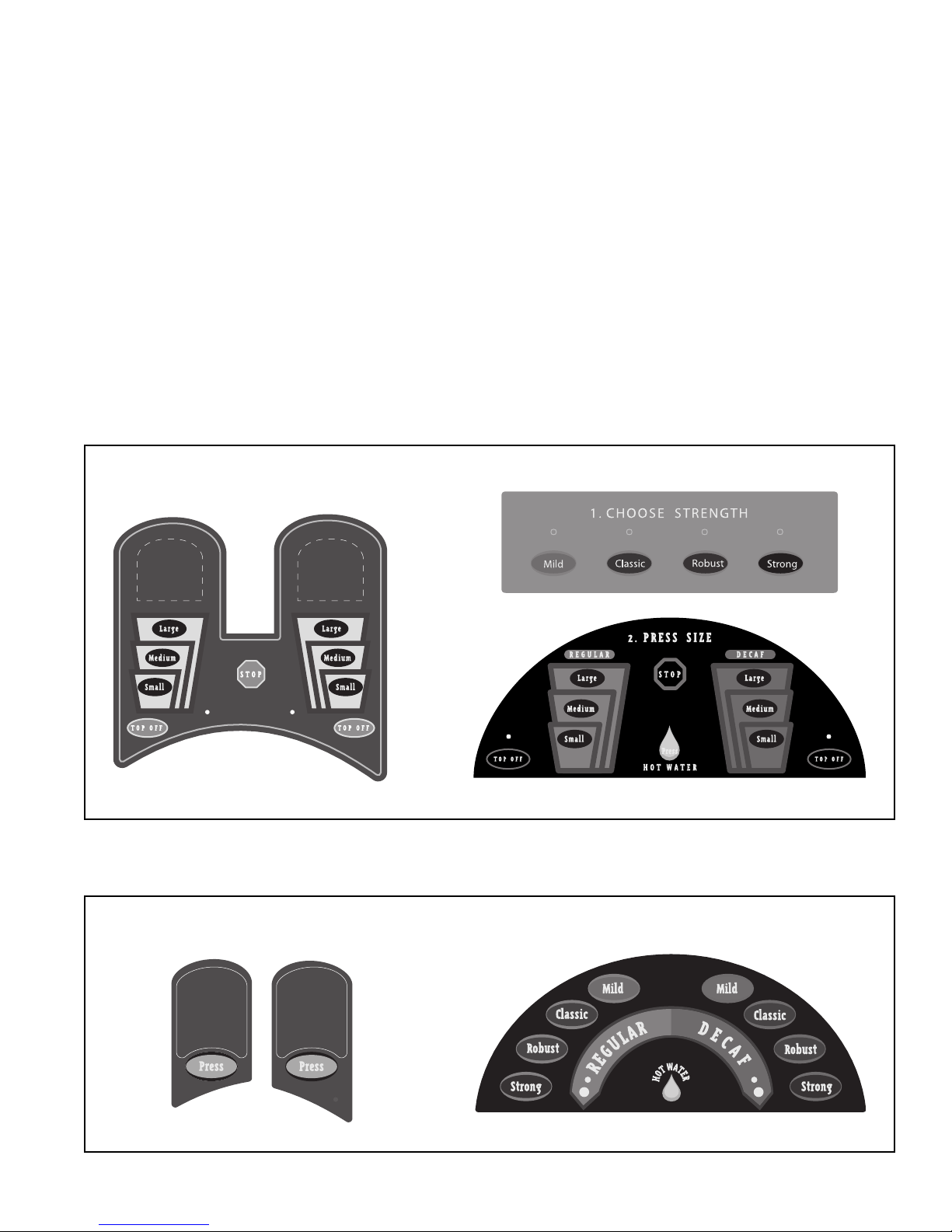

DISPENSER USE

PORTION CONTROL

1. Place cup on drip tray beneath desired dispensing tip.

2. Press button to select coffee strength desired.

3. Press appropriate cup size button. Cup will automatically fi ll and stop.

4. Automatic cup fi lling cycle may be stopped at any time by pressing the STOP button.

5. If cup did not fi ll to the desired level, press and hold the TOP-OFF button until the cup is full.

SELF SERVE

1. Place cup on drip tray beneath desired dispensing tip.

2. Press and hold button for type and strength desired until cup is full.

HOT WATER

1. Place cup on drip tray beneath hot water dispensing tip.

2. Press and hold HOT WATER button until desired amount of hot water is attained.

PORTION CONTROL

CAPPUCCINO

COFFEE

SELF SERVE

CAPPUCCINO

COFFEE

9

35352 121405

Page 10

CLEANING

CLEAN CYCLE

The clean cycle should be run daily to keep the brewer clean and in optimum operating condition. The clean

cycle is about an hour and twenty minutes total cleaning time. It is best to run the clean cycle at closing or during

off peak hours.

If at any time the CLEAN TONIGHT indicator is ON or Service light is ON, a message will appear on the display

screen.

1. Place pouch pack of cleaner fl at in the Cleaning Funnel.

2. Insert the Cleaning Funnel into the brewer. Press the “CLEAN ON/OFF” button once, to begin the cleaning

cycle.

NOTE: On Self Serve units, fi rst press and hold the lower hidden button before pressing the CLEAN button.

3. The remainder of the cleaning cycle is fully automatic. The green “CLEAN” light will remain lit during the

remainder of the cycle (which lasts about 60 minutes).

4. After the clean cycle is complete, the “Dispose Grounds” indicator will be lit. Remove the funnel and discard

the cleaner pouch pack. The unit is now ready for brewing.

NOTE: It is normal for the pumps to purge coffee from the lines during this cycle.

SOAP CLEAN RECOMMENDED - INSERT

THE FUNNEL AND PRESS THE CLEAN SWITCH

SOAP CLEAN FUNNEL

PRESS CLEAN TO BEGIN CLEAN

LEFT

CLEAN

ON OFF

RIGHT

“HIDDEN”

Button

LEFT LOW

10

CLEAN TONIGHT

RIGHT LOW

35352 042803

Page 11

PREPROGRAMMED RINSE CYCLE

The rinse cycle may be preprogrammed for automatic overnight run in case the clean cycle is ignored. Use of

a clean empty Brew funnel is required. In the event that preprogrammed rinse cycle was not complete, “RINSE

REQUIRED” will appear on the display. Brewing is disabled until the rinse cycle is complete.

MANUAL RINSE CYCLE

1. Insert a clean, empty Brew funnel into the brewer.

2. On portion control units, press and hold the “CLEAN” button for 5 seconds.

NOTE: On Self Serve units, press and hold the lower Hidden button before pressing the CLEAN button.

After the 30 minute rinse cycle is completed, the unit will be ready for brewing.

NOTE: It is normal for the pumps to purge coffee from the lines during this cycle.

RINSE REQUIRED - PLEASE INSERT

THE FUNNEL AND PRESS THE CLEAN SWITCH

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

RINSE REQUIRED - PRESS CLEAN

FOR 3 SECONDS TO BEGIN RINSE

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

“HIDDEN”

Button

EXTERIOR CLEANING

1. The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all

surfaces on Bunn-O-Matic equipment.

2. Check and clean sprayhead. The sprayhead holes must always remain open.

NOTE: In hard water areas, this may need to be done daily. It will prevent problems in the brewer and takes

less than a minute.

11

35352 042803

Page 12

RUNNING A RINSE SEQUENCE - CAPPUCCINO

RINSE REMINDER MESSAGE

CAPPUCCINO RINSE RECOMMENDED

Procedure

1. Open the cappuccino door.

2. Place the rinse switch in the upper “RINSE” position.

3. Close the cappuccino door.

4. Place a container capable of capturing 10 ounces or

more of hot water under the dispense tips.

5. Press and release each cappuccino dispense switch

(on Portion Control models any cup size will work)

and the corresponding fl avor will rinse for 10 seconds automatically.

6. After rinsing is complete, return the rinse switch to

the lower “RUN” position. The unit is now ready for

normal operation.

This counter can be set from 0 to 100

hours. (0 = disabled)

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

LOCKOUT MESSAGE (no cappuccino dispensing)

CAPPUCCINO RINSE REQUIRED

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

When this reminder message appears on

the display screen, a cappuccino rinse

cycle should be performed.

This counter can be set from 0 to 200

hours. (0 = disabled)

When this reminder message appears

on the display screen, the unit will not

dispense cappuccino until a rinse cycle

is performed. With this counter disabled,

the reminder only message will be displayed and the unit will still be allowed

to dispense.

12

35352 042803

Page 13

CAPPUCCINO PARTS CLEANING

Removal

1. Open the cappuccino door.

2. Remove hoppers.

14

13

19

3. Lift off steam collector (1).

4. Lift off mixing chamber (2).

18

17

16

15

5. Remove dispense tip (4) from whipper chamber (3).

6. Remove whipper chamber (3) with 1/4 turn in the clockwise direction.

7. Pull frother (6) off motor shaft.

8. Use the whipper chamber (3) as a tool to twist receptacle

(8) 1/4 turn in the clockwise direction and remove from

the studs.

9. Pull plastic slinger (9) off motor shaft.

12

10. Remove rubber seal (7) and o-ring (5) from receptacle

(8).

11

11. Lift the front edge of hopper assy (12) over the tab on

hopper support plate and slide hopper assembly out the

10

front of the dispenser.

12. Remove hopper lid (19) and empty product.

13. Pull off the ejector elbow (10).

14. Remove auger disc assy (17) by spreading the hopper

side walls, lifting agitator disc assy from hopper (12).

15. Remove auger (11) by pulling it out the front of the hopper

1

(12).

16. Remove auger drive shaft (15) by turning the auger drive

2

bracket clockwise.

17. Slide auger drive shaft (15) from auger drive shaft bushing

(16) and remove from hopper (12).

18. Remove locknut (13) from auger drive shaft bushing

9

8

7

6

5

3

(16) and remove auger drive shaft bushing from hopper

(12).

19. Wash all loose parts with a mild detergent, sanitze, rinse

4

and dry thoroughly.

Identifi cation

1. Steam collector

2. Mixing chamber

3. Whipping chamber

4. Dispense tip

5. O-ring

6. Frother

7. Rubber seal

8. Receptacle

9. Slinger

10. Ejector elbow

11. Auger spring

12. Hopper

13. Locknut

14. Drive bracket

15. Drive shaft

16. Bushing

17. Agitator disk

18. Mixing blade

19. Hopper lid

NOTE: These parts are dishwasher safe in most dishwashers however, sanitizing and cleaning is recommended in a

three compartment sink with a mild detergent using a bristle

brush.

20. Reassemble parts in reverse order.

NOTE: Make sure rubber seal (7) is installed properly in receptacle (8) and when installing receptacle to unit, verify the

seat has no gaps with the shaft.

Ensure spring is fully seated into drive shaft

before fi lling hopper.

13

35352 042803

Page 14

CLEANING/MAINTENANCE SCHEDULE

Daily Weekly Semi Annually Annually

Clean Cycle/Brush Tanks √

Rinse Sequence (Cappuccino) √

Wipe Exterior of Dispense Nozzles √

Empty/Rinse Drip Tray √

Wipe Splash Guard √

Clean Sprayhead √

Cappuccino Parts Clean √

(see below) (see below)

PREVENTIVE MAINTENANCE

Bunn-O-Matic Corporation recommends that preventive maintenance service be performed at 6 month intervals. Maintenance should be performed by a qualifi ed service technician according to the OMNI Preventive

Maintenance checklist instructions (part number 34123.0001).

14

35352 121405

Page 15

NOTES

15

35352 042803

Page 16

PROGRAMMING

Using the display on the front of the dispenser, the operator has the ability to review valuable log information and to set the Date and Time. Also, a qualifi ed Service Technician has the ability to alter or modify various

parameters such as service testing, set-up and calibration, cleaning and brew times .... all of which is password

protected.

1. Home screens: One Home Screen option displays the status of the coffee holding reservoirs in %FULL. The

indicator lights draw the operators’ attention to the display. The other Home Screen option will toggle between

four screens which display Home Screen, Date, Time and Tank Temperatures. To change the Home Screen

options, press and hold the CLEAN button for 5 seconds with no funnel in place.

Spanish displays: Press and hold the upper “Hidden” button for 5 seconds. Display will then toggle between

English/Spanish for all messages displayed. (Repeat to revert back to English)

Home screen

Option 1

LEFT 5 (%FULL) 0 RIGHT

LOW EMPTY

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

“HIDDEN” Buttons

16

35352 121405

Page 17

PROGRAMMING (Continued)

2. Unit data screens: To view the software version, serial number, and (if programmed) the asset number,

remove funnel, press and hold the lower “Hidden” button for 5 seconds. This screen will be displayed for 10

seconds, then will automatically change to the “View Log” screen.

SOFTWARE VERSION ##.##

SERIAL # OMNI001234 ASSET # 123456

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

DO YOU WISH TO VIEW LOG INFORMATION?

NO NEXT YES

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

Selecting NO (Left) will exit to Home Screen.

Selecting NEXT (Clean) will exit to Home Screen.

Selecting YES (Right) will allow the operator to scroll through the log information.

REAR BREW = OLDER LOG INFO ANY KEY TO

FRONT BREW = NEWER LOG INFO CONTINUE

Select LEFT to begin with the oldest info toward the most recent.

Select RIGHT to begin with the newest info back toward the oldest.

Press the CLEAN button to scroll through the log information.

Pressing both “Hidden” buttons will return to the Home Screen.

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

EVENT = POWER UP

B = 200° C = 190° 1/1/03 8:00AM

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

17

35352 121405

Page 18

PROGRAMMING (Continued)

3. Set Date and Time screens: Access by holding both “Hidden” buttons for 5 seconds with funnel removed.

Once in any screen other than home screen, Top hidden button to always select previous screen and bottom

“Hidden” button to always select next screen.

DO YOU WISH TO SET DATE AND TIME?

NO YES

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

Select YES (Right) to continue to set date per screens below.

Select NO (Left) to return to Home Screen.

Press RIGHT for (-) to decrease values, or

Press LEFT for (+) to increase values.

Press CLEAN for (Next) to advance to the next screen.

SET PRESENT YEAR 2003

(-) NEXT (+)

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

RIGHT

RIGHT LOW

LEFT LOW

LEFT LOW

SET PRESENT MONTH JANUARY

(-) NEXT (+)

LEFT

CLEAN

ON OFF

CLEAN TONIGHT

SET PRESENT DAY OF MONTH 1

(-) NEXT (+)

LEFT

CLEAN

ON OFF

CLEAN TONIGHT

18

RIGHT

RIGHT LOW

RIGHT

RIGHT LOW

35352 121405

Page 19

PROGRAMMING (Continued)

Set Date and Time (Continued)

Press RIGHT for (-) to decrease values, or

Press LEFT for (+) to increase values.

Press CLEAN for (Next) to advance to the next screen.

SET PRESENT HOUR 12:00 AM

(-) NEXT (+)

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

SET PRESENT MINUTE 01

(-) NEXT (+)

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

RIGHT

RIGHT LOW

If a password was entered during set-up, it will be needed to proceed beyond this point.

It is recommended to install a password and record it for use by a qualifi ed Service Technician.

ENTER PASSWORD 0

(-) NEXT (+)

LEFT

LEFT LOW

CLEAN

ON OFF

CLEAN TONIGHT

19

RIGHT

RIGHT LOW

35352 121405

Page 20

BASIC TROUBLESHOOTING

• Inspection, testing, and repair of electrical equipment should be performed only by qualifi ed service personnel.

• All electronic components have 208/240 or 120 volt ac and low voltage dc potential on their terminals. Shorting of terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If

an intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized without a supply of water.

• The use of two wrenches is recommended whenever plumbing fi ttings are tightened or loosened. This will

help to avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• This unit is heated at all times. Keep away from combustibles.

WARNING – • Exercise extreme caution when servicing electrical equipment.

• Unplug the dispenser when servicing, except when electrical tests are specifi ed.

• Follow recommended service procedures

• Replace all protective shields or safety notices

Problem

Dispenser will not operate

Service Indicator Flashing

Service Indicator On

Probable Cause

No power or incorrect voltage

Machine has detected a fault.

Three days have expired sinse last

clean cycle.

Remedy

1. Ensure power cord is properly

connected to wall receptacle.

2. Check circuit breakers or fuses.

See LCD Display for details.

Run a complete clean cycle.

20

35352 042803

Page 21

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

Dispenser will not brew

1. No indications

2. “Autobrew On” indicator lights

steadily

3. “Dispose Grounds” indicator

lights steadily

4. “Clean Tonight” indicator on

steady

5. “Brewer Ready” indicator not

on

6. “Clean Cycle” indicator lights

No water

Reservoir is not empty

Used grounds have been left in the

brew funnel

Time limit has expired between clean

cycles

Brewer not to temperature (brew lock

out selected)

Clean or rinse cycle is running

Check plumbing and shut-off

valves.

Dispenser will brew automatically

when the reservoir empties.

(A) Remove grounds and re-load

with fresh coffee.

(B) Make sure funnel is seated

properly in the funnel rails.

Run a complete clean cycle.

Wait for “Brewer Ready” indicator

to light.

Wait for “Clean Cycle” indicator to

extinguish.

7. “Clean Tonight” indicator fl ashing

Preprogrammed Rinse cycle not

completed

Ensure brew funnel is in place and

initiate a “Rinse Cycle”.

21

35352 042803

Page 22

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

“Autobrew ON” indicator extinguishes without brewing

Brew funnel cannot be removed

Left/Right coffee will not dispense

1. “Left/Right Low” indicator lit

2. No indication

Brew funnel was removed prior to

the start of the brew cycle

Funnel lock engaged

Reservoir contents are low

Two or more dispense strengths have

been selected

(A) Replace the brew funnel and

press the appropriate brew start

switch.

(B) Make sure funnel is seated properly in the funnel rails.

(A) Allow the “Dispose Grounds”

indicator to light before removing

brew funnel.

(B) Allow the “Clean Cycle” indicator

to extinguish before removing brew

funnel.

Brew fresh coffee.

Select only one dispense strength

at a time.

3. “Clean Tonight” indicator fl ash-

ing

4. “Clean Cycle” indicator lights

Time limit has expired between rinse

cycles

Clean or rinse cycle is running

Run a complete rinse cycle.

Wait for “Clean Cycle” indicator to

extinguish.

22

35352 121405

Page 23

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

Coffee is “weak” or “watery”

1. Type of paper fi lters

2. Coffee

3. Sprayhead

4. Funnel loading

5. Water temperature

®

Bunn

paper fi lters should be used

for proper extraction.

A suffi cient quantity of coffee should

be used for proper extraction.

B.O.M. sprayhead #01082.0000

should be used to properly wet the

bed of ground coffee.

The Bunn

®

paper fi lter should be

centered in the funnel and the bed

of coffee should be leveled by gentle

shaking.

Check the water temperature immediately below the sprayhead with

a thermometer during a brew cycle.

The reading should not be less than

F (90.5°C).

195°

Coffee is too strong

Rinse cycle will not run

1. “Clean Tonight” indicator lit

Brew tank will not fi ll

Cappuccino tank will not fi ll

6. Incorrect dispense strength selected

Incorrect dispense strength selected

Brew funnel is not in place

No water

No water

Select the correct dispense

strength.

Select the correct dispense

strength.

Place an empty brew funnel in the

rails, press Clean ON/OFF button.

Check plumbing and shut-off

valves.

Check plumbing and shut-off

valves.

23

35352 042803

Page 24

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

Inconsistent beverage level in concentrate reservoirs

Short cup (portion control)

Cup overfi lls (portion control)

Consistently high or low beverage

level in concentrate reservoirs

Water overfl ows fi lter

Coffee overfl ows concentrate reservoir

Improper water pressure

Incorrect cup size selected

Incorrect cup size selected

Incorrect brew time

1. Type of paper fi lters

2. No sprayhead

Incorrect brew time

Check the operating water pressure

to the dispenser. It must be between

20 and 90 psi (138 and 620 kPa).

Select the correct cup size.

Select the correct cup size.

Refer to Set-up.

BUNN-O-MATIC

®

paper fi lters should

be used for proper extraction.

Check Sprayhead.

Refer to Set-up.

24

35352 042803

Page 25

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

CAPPUCCINO

Cappuccino will not dispense

Weak cappuccino product

1. No water

2. No power or incorrect voltage to

the dispenser

1. Incorrect water temperature

2. Auger spring installed improperly

3. Rinse/Run switch in Rinse position

Water lines and valves to the dispenser must be open.

(A1) Ensure power cord is properly

connected to wall receptacle.

(A2) Check circuit breakers or

fuses.

Place an empty container beneath

the dispense tip. Initiate a dispense

cycle and check the water temperature below the dispense tip with a

thermometer.

Ensure spring is fully seated into

drive shaft before fi lling hopper.

Open cappuccino door and check

that the switch is in the Run position.

25

35352 042803

Page 26

ELECTRICAL WIRING DIAGRAM

L1- BREWER READY

L2- SERVICE

L3- DISPOSE GROUNDS

L4- AUTOBREW ON

DOT MATRIX DISPLAY

CAPPUCCINO PORTION

CONTROL TOUCHPAD

A1- LEFT TOP-OFF

A2- LEFT SMALL

A3- LEFT MEDIUM

A4- LEFT LARGE

A5- STOP

A6- RIGHT LARGE

A7- RIGHT MEDIUM

A8- RIGHT SMALL

A9- RIGHT TOP-OFF

L1- LEFT LED

L2- RIGHT LED

3

L4

4

L3

5

L2

6

L1

7

RIGHT CAPPUCCINO

SELF SERVE

LEFT CAPPUCCINO

SELF SERVE

A3

A4

A5

A2

A1

A7

A6

L2

A9

A8

L1

J18

1

5

10

J19

1

5

7

J23

BRN

1

RED

ORN

YEL

GRN

5

BLU

VIO

C

GRY

WHI

O

BLK

10

BRN

RED

ORN

GRN

N

YEL

T

BLU

R

16

Static Shield

1

RS232

PORT

1

4

8

12

16

O

L

1

ORN

GRN

WHI/RED

RED

4

1

ORN

WHI/ORN

3

WHI/ORN

WHI/RED

RED

ORN

GRN

C

I

R

C

U

I

T

7

8

4

9

10

6

5

3

Static Shield

1

5

11

Door Switch

RED/WHI

WHI/BLK

ORN/BLK

RED/BLK

GRN/BLK

1

BLU/WHI

BLU/BLK

J26

B

BLK

1

O

RED

GRN

5

ORN

A

R

D

10

13

A1- REGULAR BREW

A2- CLEAN

A3- DECAF. BREW

B1- BOTTOM HIDDEN

B2- TOP HIDDEN

L1- REGULAR LED

L2- REGULAR LOW LED

L3- CLEAN LED

L4- CLEAN TONIGHT LED

L5- DECAF. LED

L6- DECAF LOW LED

MANUAL COFFEE TOUCHPAD

HW- HOT WATER

D1- RIGHT STRONG

D2- RIGHT ROBUST

D3- RIGHT CLASSIC

D4- RIGHT MILD

R1- LEFT STRONG

R2- LEFT ROBUST

R3- LEFT CLASSIC

R4- LEFT MILD

PORTION CONTROL

SELECT STRENGTH TOUCHPAD

A1, L1- MILD

A2, L2- CLASSIC

A3, L3- ROBUST

A4, L4- STRONG

SWITCH & LED POSITIONS

A1

A2 A3 B2B1

R4

D4HW

D1

R1

D3

R3

D2

R2

Static Shield

L1

L2

L3

L4

A4

A3

A1

A2

L5 L3

L6

120 VOLTS AC 2 WIRE

120/208-240 VOLTS AC 3 WIRE

208-240 VOLTS AC 2 WIRE

60Hz SINGLE PHASE

L4

Static Shield

L1

Static Shield

L2

1

5

11

1

5

11

J27

1

5

10

13

J28

1

5

11

J29

1

5

11

26

35352 042803

Page 27

C

O

N

T

R

O

L

C

I

R

C

U

I

T

B

O

A

R

D

Loud

Soft

J1

WHI/RED

1

RED/BLK

WHI/BLU

BLU/BLK

J8

ORN-22

1

WHI/ORN-22

WHI/BLK-22

BLK-22

PNK-22

BLU-22

J2

PNK-20

1

WHI/BLU

BLK

WHI/RED

WHI/BLU

5

WHI/VIO

WHI/GRN

WHI/BLK

WHI/BLK

BRN/WHI

10

BRN/BLK

WHI

TAN-20

BLU/BLK

WHI/VIO

15

VIO

ORN

YEL

RED

BLU

20

GRY

WHI/ORN

WHI/ORN

WHI/YEL

24

J3

BLK

1

BLK-208/240V WHI-120V

YEL

YEL

5

J41

BLK

1

WHI

J42

ORN 5VDC+

1

GRN 5VDCTAN

BLU

J5

WHI

1

BLK

J6

BLK

1

WHI

J9

WHI/VIO-22

1

GRN-22

RED

RED/BLK

BLU/BLK

5

GRN-22

VIO-22

BLU

10

J13

RED

1

BLK

J16

TAN-20

1

ORN-20

BLU

WHI/RED VDC+

WHI/ORN VDC+

6

WHI

WHI

BLK

GRN VDCGRN VDC-

12

J17

1

5

WHI

8

J7

1

Right Dispense

1

Brew Refill

Left Dilution Low

Right Dilution High

1

+

BEEPER

-

Left Dispense

SOL

BLK

BLK

Funnel Lock

Hot Water

BLK

BLK

1

1

WHI/RED

RED/BLK

WHI/BLU

BLU/BLK

ORN-22

ORN-22

BLK-22

BLK-22

BLU-22

PNK-22

10

TAN

BLU BLU

1

WHI

SOL

WHI

Front Reservoir Drain

SOL

SOL

SOL

SOL

SOL

Brew

SOL

Transformer

120/24V

or

240/24V

TAN-20

ORN-20

RINSE/RUN

SWITCH

Closed-RUN

Static Shield

1

TAN

BLU

1

Dilution Refill

Left Dilution High

Right Dilution Low

Rear Reservoir Drain

1

Funnel

Sensor

Brew

Clean

Open-RINSE

BLKBLK

BLK

SOL

SOL

Left Tube Heater

Right Tube Heater

1

RED

-+

M

Left

BLK

RED

-+

M

Right

BLK

BLU-14

WHI

SOL

SOL

SOL

Brew Tank

Temp. Sensor

t

Clock

Left Whipper

M

Left Dispense

SOL

Right Whipper

M

Right Dispense

SOL

RED

M

RED BLK

Dilution

Tank Heater

Dilution Tank

Temp. Sensor

t

Left Hopper

M

WHI

WHI

WHI

WHI

WHI

WHI

WHI

WHI

WHI

WHI

WHI

WHI

Right Hopper

BLK-22

WHI

BLK

BLK-14

Left

1

Pump

Speed

Sensor

Right

1

Pump

Speed

Sensor

GRN

120VAC 2 WIRE

208-240VAC 2 WIRE

N (120V, 2-WIRE)

L1

L2 (208/240V, 2-WIRE)

BLK

WHI

20 Amp

Fuse

20 Amp

Fuse

WHI/VIO

BLK

WHI

ABC

Triac

Dilution Limit

BLK-14

Brew Tank

Heater

BLU-14 BLK-14

Front

Reservoir

GRN

Keep Warm

Heater

GRN

WHI

WHI

BLU

1

4

WHI

GRN

BLU/BLK

WHI/BLU

WHI WHI WHI

Brew Tank

Level Sensing

Dilution Tank

Level Sensing

WHI

WHI WHI

GRN

BLU

BLK-14

GRN

TAN

Rear

Reservoir

GRN

Keep Warm

Heater

Fan

M

120/208-240 VAC 3 WIRE

20 Amp

Fuse

Triac

Brew Limit

GRN

WHI

WHI

1

WHI

GRN

WHI/RED

Rear

Conductance Chamber

Front

Conductance Chamber

BLK

L1

BLK

BLK

ABC

BLU

4

RED/BLK

N

WHI

WHI/VIO

WHI/VIO

L2

WHI

20 Amp

WHI/VIO

Fuse

GRN

ABC

BLK

WHI

WHI/VIO

5

11

6

11

L1- LEFT LED

L2- RIGHT LED

R1- LEFT TOP-OFF

R2- LEFT SMALL

R3- LEFT MEDIUM

R4- LEFT LARGE

HW- HOT WATER

STOP- STOP

D1- RIGHT TOP-OFF

D2- RIGHT SMALL

D3- RIGHT MEDIUM

D4- RIGHT LARGE

R2

D1R3R1HWD2

STOPD3

D4

COFFEE PORTION CONTROL TOUCHPAD

27

R4

L1

L2

35352 042803

Loading...

Loading...