Page 1

MHG

Multi-Hopper Grinder and Storage System for use with Smart Funnel

®

ICB Twin SH, ICB SH, ICBA SH Infusion Series

®

PROGRAMMING MANUAL

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts Catalog, Programming Manual, or

Service Manual, please visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain

the latest catalog and manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

Bunn-O-Matic Corporation

Post Office Box 3227, Springfield, Illinois 62708-3227

Phone (217) 529-6601 | Fax (217) 529-6644

53669.0000 B 4/20 © 2017 Bunn-O-Matic Corporation

www.bunn.com

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCR/MCP/MCA single cup brewers,

thermal servers and ThermoFresh® servers (mechanical and digital) 1 year parts and 1 year labor.

2) All other equipment - 2 years parts and 1 year labor plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labor for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labor.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis - parts

and labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be

commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured

by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or

operation, improper maintenance or repair, non periodic cleaning and descaling, equipment failures related to poor

water quality, damage or casualty. In addition, the warranty does not apply to replacement of items subject to normal

use including but not limited to user replaceable parts such as seals and gaskets. This warranty is conditioned on the

Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or by

writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective

equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from BUNN that the

defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make

modifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by

such individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive

option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor

(during the applicable parts and labor warranty periods specified above) to repair the defective components, provided

that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the

purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION

AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss

of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment,

facilities or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter,

BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with

the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool

Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice,

High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment Worldwide,

Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver

Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in Beverage Equipment

Worldwide, ThermoFresh, Titan, trifecta, TRIFECTA (stylized logo), Velocity Brew, Air Brew, Beverage Bar Creator, Beverage

Profit Calculator, Brew better, not bitter., Build-A-Drink, BUNNSource, Coffee At Its Best, Cyclonic Heating System, Daypart,

Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN, Picture Prompted Cleaning, Pouring Profits,

Signature Series, Sure Tamp, Tea At Its Best, The Horizontal Red Line, Ultra are either trademarks or registered trademarks of

Bunn-O-Matic Corporation. The commercial trifecta® brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

2

Page 3

INTRODUCTION

ICB SH & ICB TWIN SH

This equipment will brew coffee into an awaiting dispenser. The brewer has an auxiliary hot water faucet. It is only for

indoor use on a sturdy counter or shelf.

The Infusion Series combines BrewWISE and CDBC into one. ICB SH and ICB Twin SH are able to brew coffee with recipe

settings. They have an LCD for digital readout and programming along with the Smart Funnel options for coffee. Other

features include: Pre-Infusion, Pulse Brew, and BrewWISE, Energy Savings mode, BUNNLink compatible, Smart Reader

compatible, Freshness Timer, Sanitation Alert, USB Flash Drive Programming Port, and SH Server Recipe Setting.

CONTENTS

Warranty ...............................................................................................................................2

Introduction ..........................................................................................................................3

Factory Defaults ....................................................................................................................4

Programming Flow Chart ......................................................................................................5

Programming With Ad Card ................................................................................................12

Programming ......................................................................................................................13

Troubleshooting ..................................................................................................................31

3

Page 4

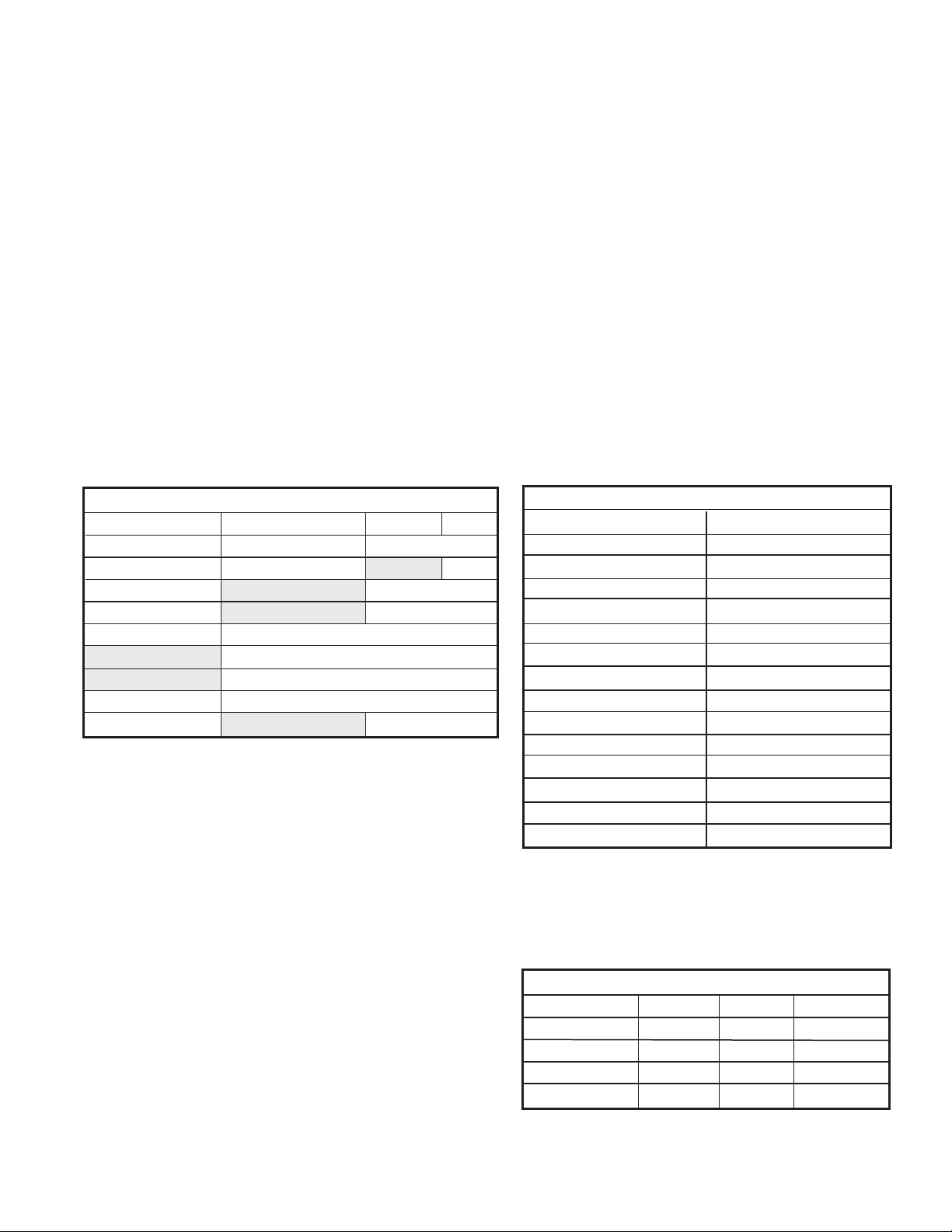

FACTORY DEFAULTS

ICB ICB TWIN

Brew Lockout Enabled Enabled

Set Language English English

Units English English

Review Recipes √ √

Assign Recipes √ √

Set New Recipe √ √

Set (Master) Temp 200° 200°

Ready Degree 5° 5°

Enable Ads Disabled Disabled

Enable Sanitation Disabled Disabled

Enable Energy Saver Disabled Disabled

Enable Fresh Timer Disabled Disabled

Refill 155 155

Left Spray Oz. X 40.0

Right Spray Oz. X 41.0

Spray Oz. 40.0 X

Left Bypass Oz. X 41.0

Right Bypass Oz. X 38.0

Bypass 38.0 X

Calibrate Flow Reset Reset

Set Recipes Temps X X

Funnel Detect Enabled Enabled

4

Page 5

FACTORY DEFAULTS (cont.)

ICB ICB TWIN

Server Detect Enabled Enabled

SH Empty Detect Enabled Enabled

SH Heat Auto Off Disabled Disabled

Server Preheat Enabled Enabled

Server Indicators Enabled Enabled

5

Page 6

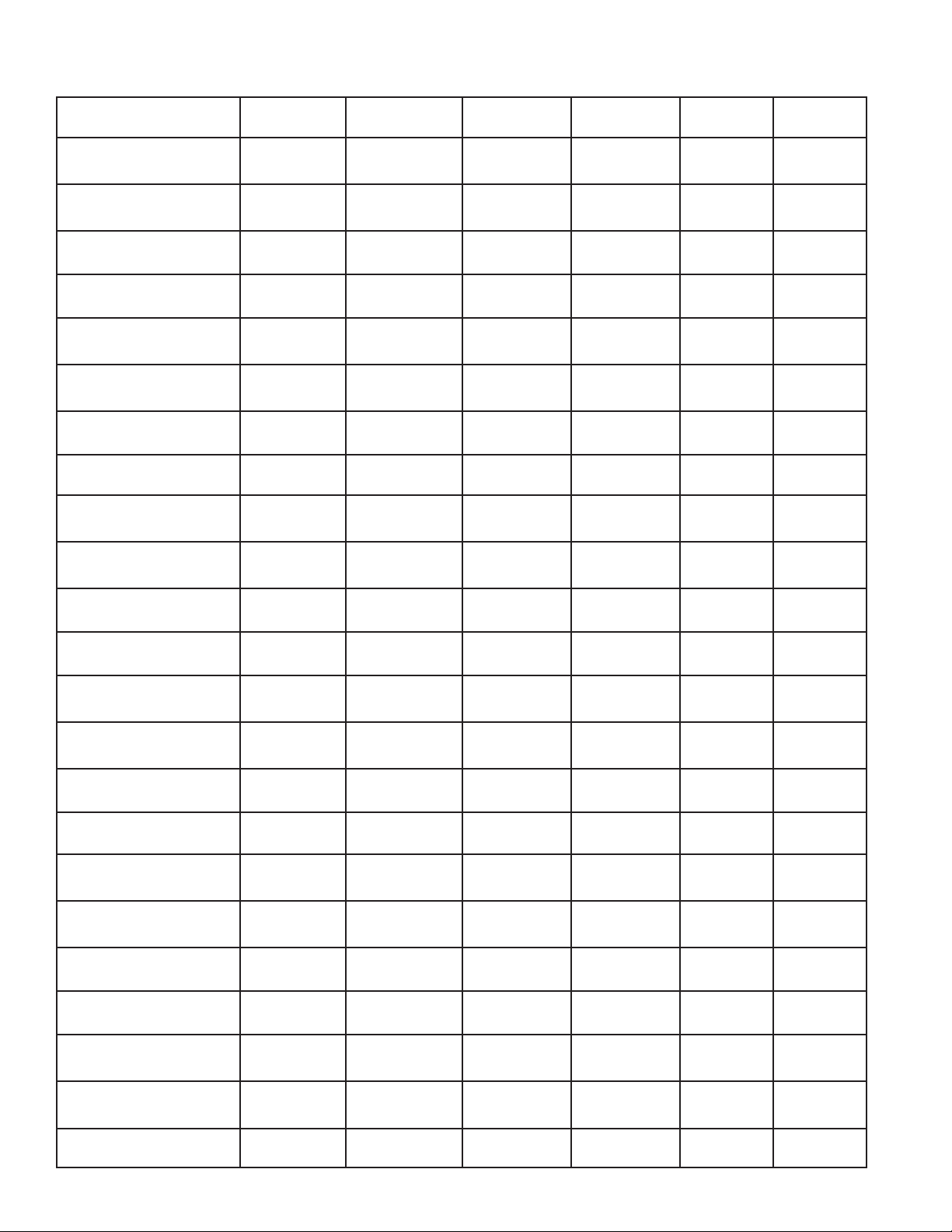

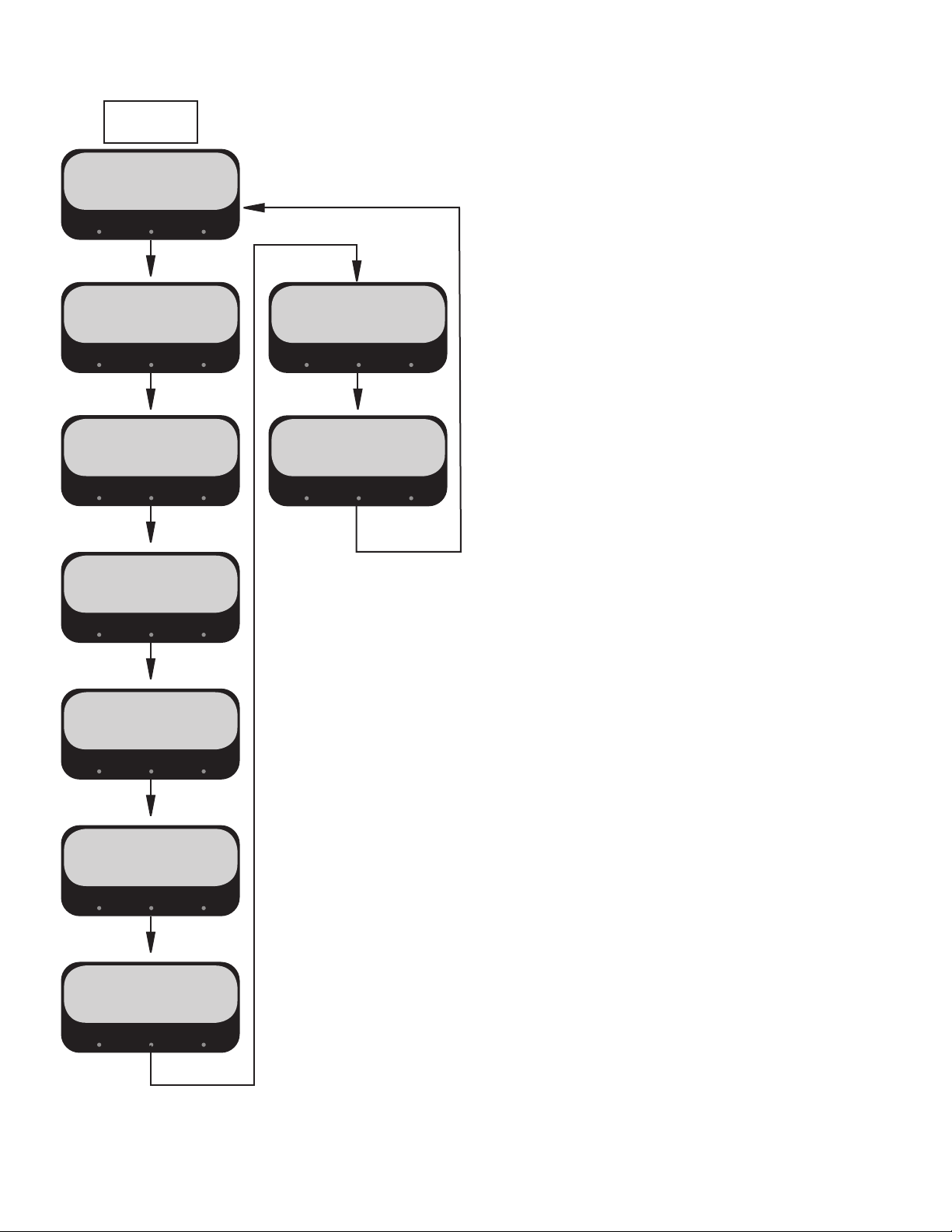

PROGRAMMING FUNCTIONS - FLOW CHART

RECIPES

<< SELECT >>

REVIEW RECIPES

<< SELECT >>

ASSIGN RECIPES

<< SELECT >>

SET NEW RECIPE

<< SELECT >>

CALIBRATION

<< SELECT >>

L SPRY OZ/M XX.X

(-) DONE (+)

R SPRY OZ/M XX.X

(-) DONE (+)

SPRY HEAD CAL

<< SELECT >>

SETTINGS SERVICE

<< SELECT >> << SELECT >>

PROCEED TO

COLUMN A

NEXT PAGE

PROCEED TO

COLUMN B

NEXT PAGE

L BYPS OZ/M XX.X

(-) DONE (+)

R BYPS OZ/M XX.X

(-) DONE (+)

BYPASS CAL

<< SELECT >>

6

Page 7

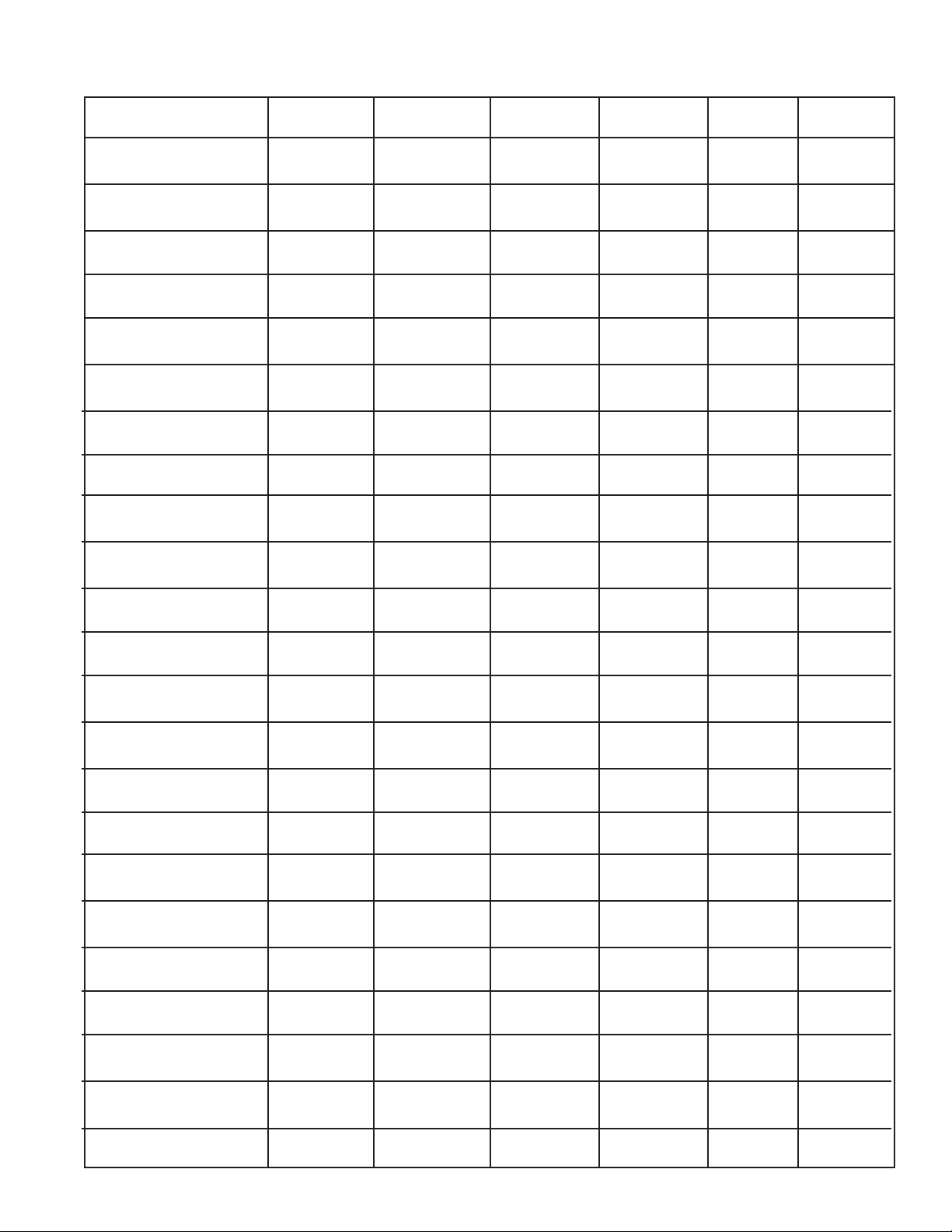

COLUMN A

PROGRAMMING FUNCTIONS - FLOW CHART (cont.)

SETTINGS

<< SELECT >>

SET LANGUAGE

<< SELECT >>

UNITS

METRIC DONE ENG

SET TEMP: 200°

(-) DONE (+)

SERVER DETECT

NO DONE YES

SH EMPTY DETECT

NO DONE YES

SH HEAT AUTO OFF

NO DONE YES

ENABL ENERGYSAVR

NO DONE YES

ENABL ADS ?

NO DONE YES

BREW ALERT

NO DONE YES

SERVICE

<< SELECT >>

PROCEED TO

COLUMN B

NEXT PAGE

READY DEGREE 5°

(-) DONE (+)

BREW LOCKOUT

NO DONE YES

FUNNEL DETECT

NO DONE YES

SERVER PREHEAT

NO DONE YES

SERVER INDICATORS

NO DONE YES

ENABLE FRESH TIMER

NO DONE YES

7

Page 8

COLUMN B

SERVICE

<< SELECT >>

PROGRAMMING FUNCTIONS - FLOW CHART (continued)

TEST OUTPUTS

<< SELECT >>

TEST SWITCHES

<< SELECT >>

TEST FREQUENCY

<< SELECT >>

ENTER ASSET #

<< SELECT >>

X REFILL XXX

(-) DONE (+)

FACTORY DEFAULTS

NO YES

ENTER SERVICE #

<< SELECT >>

BREW COUNTERS

<< SELECT >>

8

Page 9

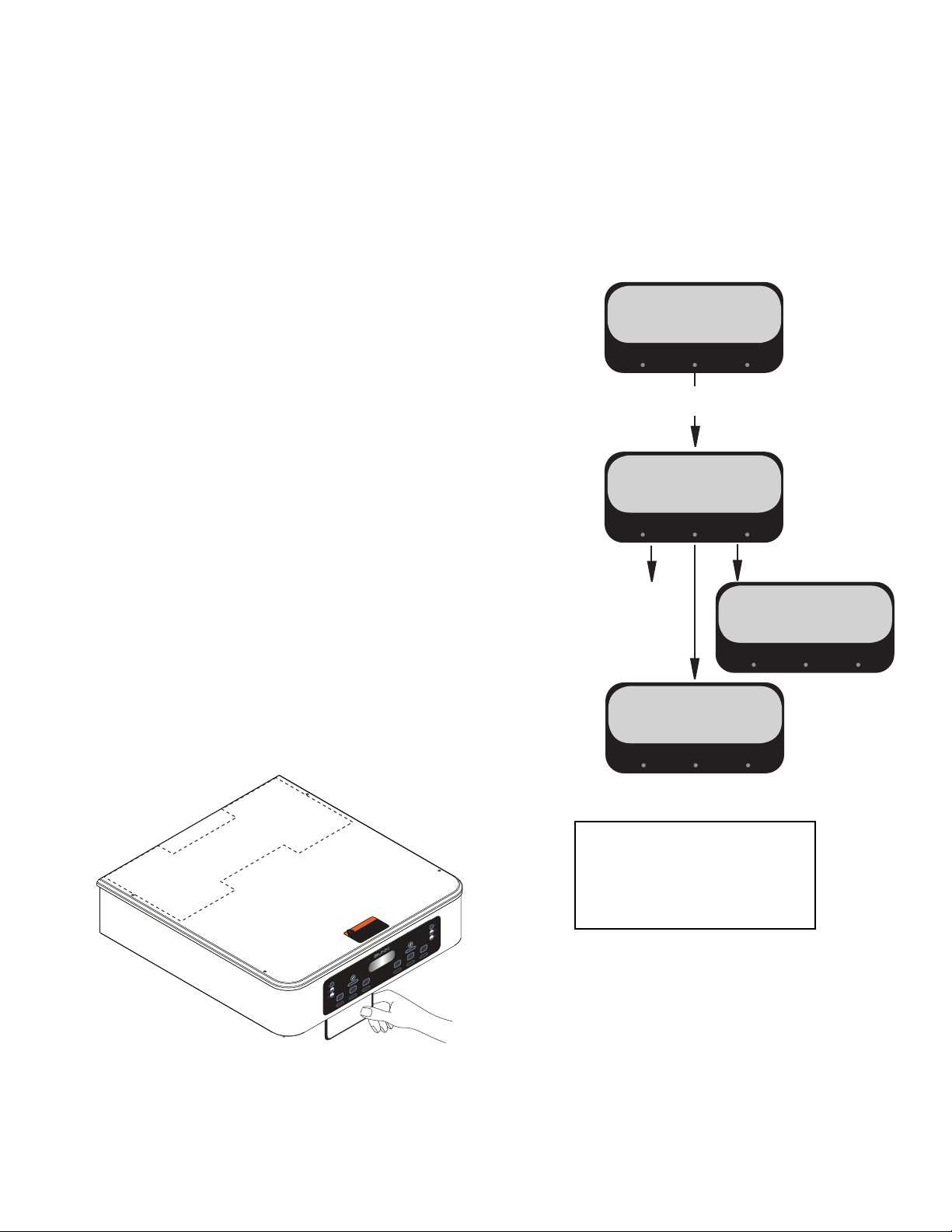

PROGRAMMING WITH AD CARD

Using an AD CARD to load ADS:

The information is loaded into the brewer’s memory by

holding the chip area up to the brewer’s SENSING COIL.

NOTE: Instructions to program the brewer are printed

on the AD CARD.

Procedure to program the AD:

1. Remove the funnel(s) if present.

2. Position the RECIPE CARD vertically, so that the

top end of the CHIP is beneath the (Left on Twins)

SENSING COIL (located on the underneath side of

the front display panel).

3. After a short pause the display will read CARD

CONTAIN ADS/SHOW-QUIT-SAVE.

4. To show (view) this information, select "SHOW".

The display will scroll through all of the ad on that

chip. The display will then return to CARD CONTAIN

ADS/SHOW-QUIT-SAVE.

5. If message is correct, press SAVE. The display will

read AD MESSSAGE SETUP COMPLETE. The ad is

now stored in the brewer’s memory.

6. If the ad is not correct, or it is desired to exit the

setup before the ad is loaded into the brewer’s

memory, press QUIT. The display will then return

to the MAIN SCREEN.

READY TO BREW

WATER TEMP XXX°

POSITION CARD UNDER

SENSOR COIL

CARD CONTAIN ADS

SHOW QUIT SAVE

SCROLLS THROUGH

COMPLETE MESSAGE

AD MESSAGE

SETUP COMPLETE

BREW

A

WARNIN G

To reduce the risk of electric shock,

do not remove or open cover.

No user-serviceable parts inside.

Authorized service personnel only.

Disconnect power before servicing.

I

O

ENABLE BREW

BREW

B

READY TO BREW

WATER TEMP 200°

NOTE: ENABLE ADS must be

turned on in order for the newly

programmed ad message to be

displayed.

I

O

BREW

C

ENABLE BREW

BREW

B

BREW

A

BREW

C

9

Page 10

PROGRAMMING BREWER

BREW LOCKOUT

This function allows the operator to prevent or allow brewing if the water temperature is less than the set READY

temperature.

Procedure for setting Brew Lockout:

1. Press and hold the right hidden button until the display reads RECIPES. Press the right hidden button until

the display reads SETTINGS, then press SELECT. Press the right hidden button until the display reads BREW

LOCKOUT:

BREW LOCKOUT?

NO DONE YES

Press here

for NO

Press here

for DONE

Press here

for YES

2. The YES or NO should be flashing. Select YES to prevent brewing if the water temperature is below the set

READY temperature. Select NO to permit brewing at any water temperature.

3. When finished, select DONE. This will exit this function screen and return to the MAIN SCREEN.

PROGRAMMING FUNCTIONS

The functions in the second level of programming allow the operator to adjust brew settings and other feature

options.

To access the level 2 function screens press and hold the right hidden button for approximately 5 seconds.

Release when the display reads:

SET LANGUAGE

This function allows the operator to select the language used for the display.

Procedure for setting Language:

1. Press and hold the right hidden button until the display reads RECIPES. Press the right hidden button until

the display reads SETTINGS, then press SELECT. Press the right hidden button until the display reads SET

LANGUAGE?

2. Press YES to proceed. The display should now read ENGLISH. Using (-) and (+), scroll through the available

languages until the desired language is shown on the display.

3. When finished, press SELECT. If the language selected is different from the current settings,the display will

read CHANGE LANGUAGE? ARE YOU SURE? and then will change to CHANGE LANGUAGE? To convert the

display to the new language, select YES. To retain the current language, select NO.

4. The display should now read UNITS. To exit programming and return to the MAIN SCREEN, press ENABLE

BREW ON/OFF switch.

(cont.)

10

Page 11

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

UNITS

This function allows the operator to select if numeric settings are displayed in English or Metric units.

Procedure for setting the Units:

1. Press and hold the right hidden button until the display reads RECIPES. Press the right hidden button until

the display reads SETTINGS, then press SELECT. Press the right hidden button until the display reads UNITS.

The METRIC or ENG should be flashing.

2. Select METRIC to have settings displayed in Metric units. Select ENG for English units.

NOTE: Changing the UNIT settings will restore ALL settings to Factory Default.

3. Select DONE to advance to the next programming screen. To exit programming and return to the Main Screen,

press ENABLE BREW ON/OFF switch.

NOTE: This manual is written based on Factory Default Settings (English Units). If brewer is set for Metric Units,

displays will be different (ex: Brew oz will become Brew liters, Temperature changes from F° to C°).

ADJUSTMENT RANGES

ICB/ICB TWIN SH

BREW OZ OFF/10-224

% BYPASS 0-90%

DILUTE OZ

DILUTE DELAY

PULSE BREW 1st On Time – OFF to 1 Min

Off Time – OFF - 20 seconds

Last On Time – Pre-Infuse to 1 Min

DRIP TIME OFF to 5 Min

REVIEW RECIPES (Modify or Show recipes)

This function has two parts:

1. It allows the operator to view the brew settings for

the various coffee recipes stored into the brewer.

2. It allows the operator to modify (change) any of

the brew settings for a particular recipe stored in

the brewer.

DEFAULT RECIPE CHART - ICB SH/ICB TWIN SH

No Name Coffee Jamaica Blue Mtn

Regular Guatemalan

Decaf Light Roast

Colombian Dark Roast

Colombia Supremo Espresso

Costa Rican Amaretto

Ethiopian Hazelnut

Kona French Vanilla

Kenya AA Irish Creme

Sumatran Vanilla Nut

French Roast Caramel

Italian Roast Raspberry

Mocha Java Almond

House Blend Dark Mtn Roast

Breakfast Blend Hot Tea

Procedure for reviewing the recipes:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden but-

ton until the display reads SETTINGS, then press

SELECT. Press the right hidden button until the

display reads REVIEW RECIPES. Select YES.

2. The display should now read the name of the first

recipe, along with MODIFY SHOW and NEXT.

(cont.)

DEFAULT ASSIGNMENTS

BREW A BREW B BREW C

ICB SH Regular Decaf Brkfst Blnd

ICB TWIN SH Regular Decaf Brkfst Blnd

11

Page 12

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

3. Select SHOW. The screen will scroll through all the brew settings for that particular recipe. When finished,

the display will return to the recipe name just viewed.

4. To see the settings again, select SHOW. To change settings, select MODIFY. Then the screen will display

BREW OZ and a batch light will be blinking.

5. Using (-) or (+), set the amount of brew water to be dispensed for that batch size.

6. When finished, press the other batch size and repeat step #8.

7. When finished setting both batch sizes, select DONE. The display should read 3 BATCHES DONE?

8. If both batch sizes are not correct press and release NO to return to the BREW OZ setup screen and repeat

steps #8, 9 and 10.

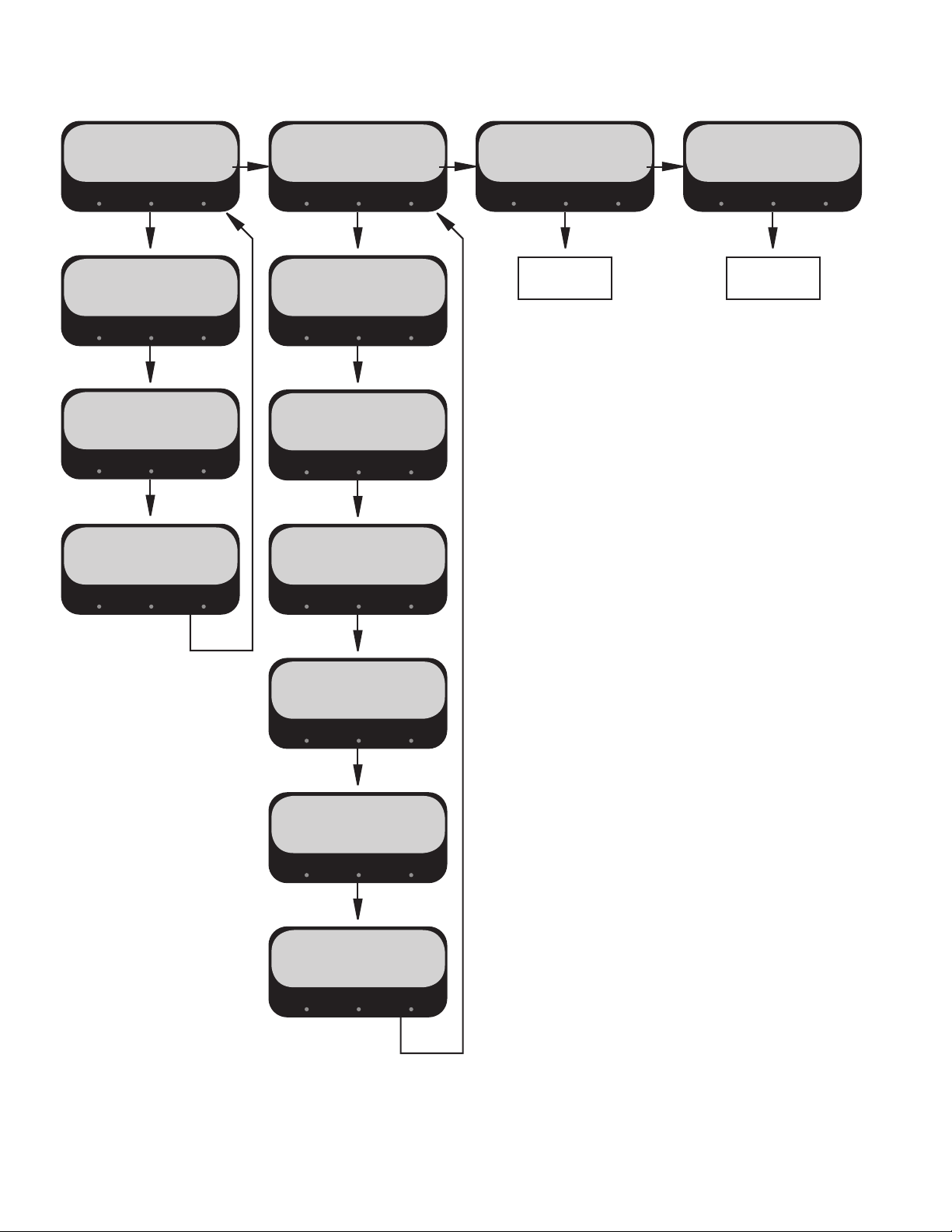

VIEW/MODIFY ITEMS

ICB SH/ICB TWIN SH

% Bypass

Pulse Brew/Preinfusion Times

BY PRESSING "MODIFY", YOU CAN STEP

THROUGH & CHANGE ALL THE BREW

SETTINGS FOR THAT RECIPE, SIMPLY

FOLLOW THE ON SCREEN PROMPTS

Brew Ounces

Drip Times

REVIEW RECIPES

NO YES

PRESSING NO WILL

ADVANCE TO NEXT

FUNCTION SCREEN

NO NAME COFFEE

MODIFY SHOW NEXT

MODIFY SHOW NEXT

REGULAR

SCROLLS THROUGH

ALL DEFAULT RECIPES

BY PRESSING "SHOW", THE

DISPLAY WILL AUTOMATICALLY

SCROLL THROUGH ALL THE BREW

SETTINGS FOR THAT RECIPE

12

(RECIPE NAME)

MODIFY SHOW NEXT

THAT WAS THE

LAST RECIPE

Page 13

TES UNTIL

PRE-INFUSION

PROGRAMMING FUNCTIONS (cont.)

PROGRAMMING BREWER (cont.)

9. If both batch sizes are correct, press YES. This will

advance to the BYPASS %

10. Using (-) or (+), set the amount of bypass water for

that particular batch size to be dispensed around

the filter/grounds.

11. When finished, press the other batch size and repeat

step #10.

12. When finished setting both batch sizes, press and

release DONE. The display should read 3 BATCHES

DONE?

13. If all batch sizes are not correct, select NO to return

to the BYPASS % function and repeat steps #10-12.

14. If both batch sizes are correct, press YES. This will

advance to the SET PULSE BREW.

15. To set PULSE BREW press YES. The display

should now read SELECT METHOD. To set the

EASY method, continue to step #16. To set by

MANUAL method, jump to step #21.

INITIAL SPRAY

INITIAL SPRAY

OFF-

TIME

OFF-TIME

ON-

TIME

REMAINING ON

OFF-

TIME

ON-

TIME

OFF-

TIME

ON-

TIME

ALTERNA

BREW CYCLE IS

COMPLETED

Setting Pulse Brew – EASY Pulse Brew

Range: Minimum: will adjust to the minimum time

required to brew that batch using the set brew volumes

and flow rate for the sprayhead. Maximum – will adjust

depending on settings and will always be minimum time

+ 3 minutes. The brewer will automatically calculate what

the 1ST ON TIME, OFF TIMES, and LAST ON TIME will

be using THE INITIAL ON TIME, plus a 7 pulse routine.

16. Select EASY. With EASY flashing, select NEXT.

17. The display should now read BREW TIME: and a

batch light will be blinking. Select the batch size to

be modified.

18. Using (-) or (+), set the total brew time desired

including spray times and off times.

19. When finished, press the other batch size and repeat

step #18.

20. When finished setting both batch sizes, press

DONE. The display will show the pulse settings to

accommodate the brew time entered. Press and

release each batch size to display the settings for

that batch. After a delay, the display should read 3

BATCHES DONE?

21. If both batch sizes are not correct, press NO to

return to the BREW TIME setup screen and repeat

steps 18-20.

Setting Pulse Brew/PreInfusion – MANUAL

22. Select MANUAL. With MANUAL flashing, select

NEXT.

23. The display should now read, 1st ON TIME and a

batch light will be blinking. Select the batch size to

be modified.

ST

24. Using (-) or (+), adjust the 1

ON TIME.

25. When finished, press the other batch size and repeat

step #24.

NOTE: To disable pulse brew, set 1

ST

ON TIME to OFF.

Brewer will automatically pulse on tea recipes with a

brew volume greater than 86.0 oz.

26. When finished setting both batch sizes, press DONE.

27. The display should now read OFF TIME. Adjust the

OFF TIME using (-) or (+).

28. When finished, press the other batch size and repeat

step # 27.

29. When finished setting both batch sizes, press and

release DONE.

30. The display should now read LAST ON:. Adjust the

LAST ON TIME using (-) or (+). If PREINFUSION

is desired, set the LAST ON TIME to PreI.

31. When finished, press the other batch size and repeat

step # 30.

32. When finished setting both batch sizes, press and

release DONE.

33. The display will show the three times just entered.

Press and release each batch size to display the set-

ST

tings for that batch. If the 1

ON TIME is set to OFF,

the display will read PULSE BREW DISABLED. After

a 5 second delay, the display will read 3 BATCHES

DONE?

(cont.)

13

Page 14

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

34. If all the pulse brew settings for both batch sizes

are not correct, press and release NO to return to

the 1ST ON TIME setup screen and repeat steps 18

through 33.

35. If all batch sizes are correct, press YES. The display

should now read DRIP TIME.

Setting DRIP TIME:

NOTE: Drip time also controls the solenoid on time

for models with optional funnel locks.

26. The display should now read DRIP TIME, along with

either the word OFF or a time showing. A batch

light will also be blinking.

27. Using (-) or (+), set the amount of time from when

the brew spray ends to when the funnel is emptied

of hot liquid.

28. When finished, press the other batch sizes and

repeat step #27.

29. When finished setting all batch sizes, press and

release DONE. The display should read 3 BATCHES

DONE?

30. The display will read SH TEMP XXX°.

31. Using (-) or (+), set temp for SH Server to maintain

if that recipe is brewed.

32. When finished, press the other batch sizes and

repeat step #31.

33. When finished setting all batch sizes, press and

release DONE. The display should read 3 BATCHES

DONE?

34. The display will now read FRESH X:XX HRS.

35. Using (-) or (+), set fresh time for recipe.

36. When finished, press the other batch sizes and

repeat step #35.

37. When finished setting all batch sizes, press and

release DONE. The display should read 3 BATCHES

DONE?

38. Select YES. The screen should show the name of

the recipe being programmed (modified) along with

SETUP COMPLETE.

14

Page 15

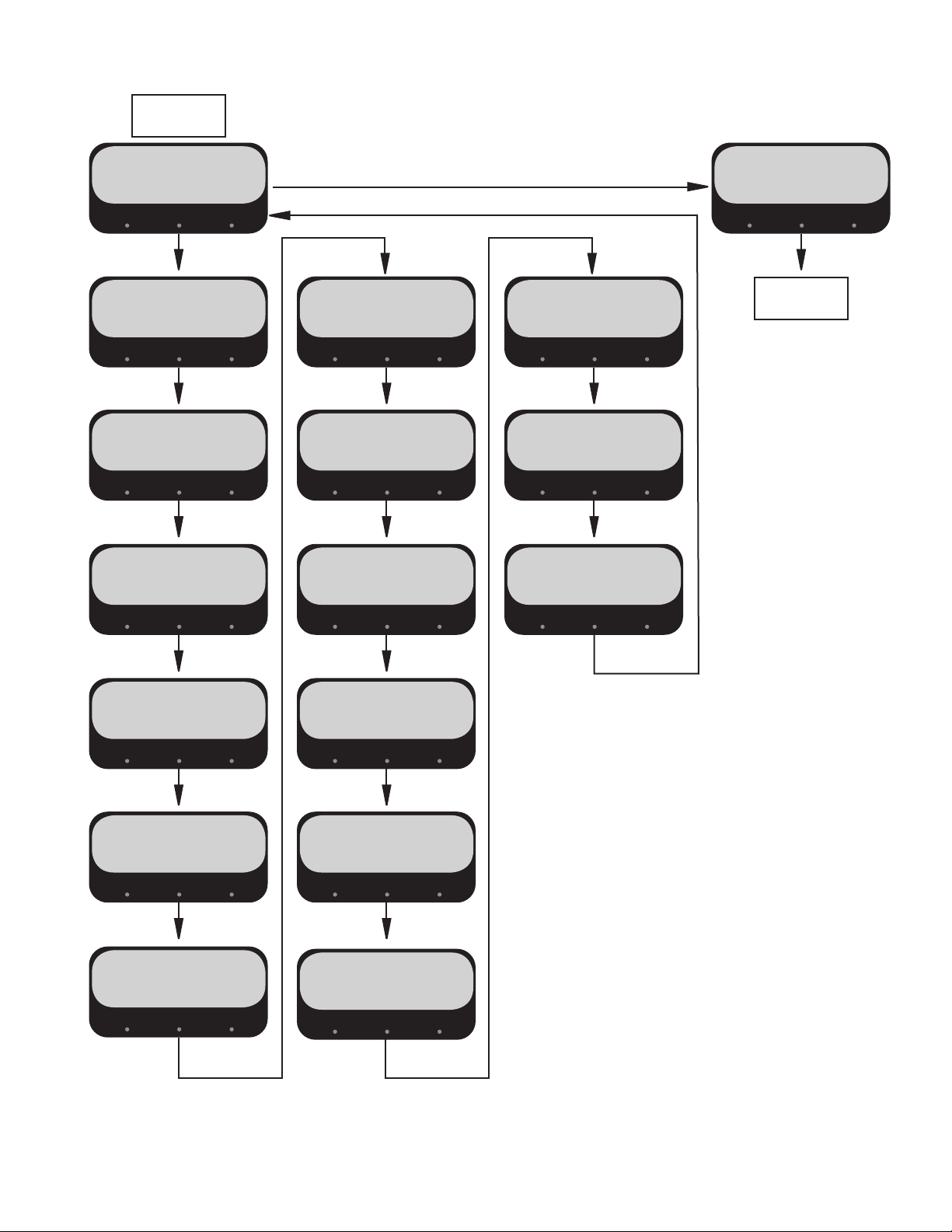

PROGRAMMING FUNCTIONS (cont.)

PROGRAMMING BREWER (cont.)

ICB TWIN SH

REVIEW RECIPES

NO YES

NO NAME COFFEE

MODIFY SHOW NEXT

BREW OZ: 64

(-) DONE (+)

% BYPASS: 20

(-) DONE (+)

SET PULSE BREW?

NO YES

OVERVIEW ONLY -

SOME SCREENS OMITTED

DRIP TIME: 0:30 SELECT METHOD

(-) DONE (+) EASY MANUAL

SH TEMP XXX°

(-) DONE (+)

FRESH X:XX HRS

(-) DONE (+)

15

Page 16

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

ASSIGN RECIPE to or disable BREW SWITCH(S)

This function allows the operator to assign a recipe to

(or disable) each of the 3 brew switches (A, B, C). Any

saved recipes listed under "REVIEW RECIPES" can be

assigned to a brew switch. Only one recipe per brew

switch is allowed.

Procedure to select switch recipes

1. Press and hold the right hidden switch until the

display reads RECIPES. Press the corresponding

button under select. Press hidden right switchn

until display reads ASSIGN RECIPE. Press SELECT.

2. The display should now read SELECT RECIPE BREW

SWITCH A, and then REGULAR.

3. Using (-) and (+), scroll through the stored recipes

in the brewer’s memory until the desired recipe

name is reached.

4. Select DONE to set that recipe for brew switch A.

5. The display should now read SELECT RECIPE BREW

SWITCH B, and then DECAF.

6. Using (-) and (+), scroll through the stored recipes

in the brewer’s memory until the desired recipe

name is reached.

7. Select DONE to set that recipe for brew switch B.

8. The display should now read SELECT RECIPE BREW

SWITCH C, and then BREAKFAST BLEND.

9. Using (-) and (+), scroll through the stored recipes

in the brewer’s memory until the desired recipe

name is reached.

10. Select DONE to set that recipe for brew switch C.

11. Repeat steps 2 - 10 for right side of Twins.

ASSIGN RECIPE

NO YES

ADVANCE TO

NEXT FUNCTION

SCREEN

SCROLL THROUGH

STORED RECIPES IN

BREWER MEMORY

SCROLL THROUGH

STORED RECIPES IN

BREWER MEMORY

SELECT RECIPE

<< BREW SWITCH A

"RECIPE NAME"

(-) DONE (+)

SELECT RECIPE

<< BREW SWITCH B

"RECIPE NAME"

(-) DONE (+)

SELECT RECIPE

<< BREW SWITCH C

Procedure to disable a Brew Switch:

1. Follow the same procedure as above. Choose

DISABLED instead of recipe name.

2. Select DONE to disable that brew switch.

16

SCROLL THROUGH

STORED RECIPES IN

BREWER MEMORY

"RECIPE NAME"

(-) DONE (+)

REPEAT FOR BREW

SWITCH A, B, C FOR

RIGHT SIDE

SET NEW RECIPE?

NO YES

Page 17

PROGRAMMING FUNCTIONS (cont.)

PROGRAMMING BREWER (cont.)

SET NEW RECIPE (COFFEE ONLY)

To set a new COFFEE recipe using a Smart Funnel

and a G9-2T DBC or MHG Grinder:

This function allows the operator to set BREW VOLUMES, BYPASS %, PULSE BREW/PREINFUSION

TIMES AND DRIP OUT TIMES for each coffee name

stored in the grinder’s memory.

Certain coffee names are stored in the grinder’s memory.

When a particular name of coffee is ground into the

Smart Funnel, that name and the batch size selected

are transferred from the grinder to the programming

CHIP located in the funnel handle. The funnel is then

inserted into the brewer’s funnel rails. The SENSING

COIL on the brewer reads the information contained in

the handle. The name of the coffee flavor will then appear on the display. This allows the operator to set the

BREW VOLUMES, BYPASS % (N/A on ITCB), PULSE

BREW/PREINFUSION TIMES AND DRIP OUT TIMES

for that particular coffee name. Each coffee name can

be set individually to provide optimum brewing quality.

SET NEW COFFEE ITEMS

ICB SH/ICB TWIN SH

Brew Ounces

% Bypass

Dilution Delay Time

Pulse Brew/Preinfusion Times

Drip Times

3. On the brewer, press and hold the right hidden

switch until the display reads RECIPE, then press

SELECT. Press and release the right hidden switch

until the display reads SET NEW RECIPE.

4. Select YES. The display should read INSERT FUN-

NEL WITH NEW NAME, then QUIT SETUP? These

two displays will repeatedly cycle.

5. Insert the funnel into the rails on the brewer (Left

on Twins). The display should read the name of

the coffee that was ground into the funnel, along

with a NO and YES. If the name on the display is

correct, press YES.

6. If, for some reason, the name of the coffee from

the grinder did not load properly into the funnel,

or if a grind has not yet been done, the display will

read MUST GRIND INTO FUNNEL FIRST. It will be

necessary to grind another batch following steps

1, 2 & 5.

NOTE: If brewer memory is full, the display will read

RECIPE STORAGE AREA IS FULL and then REMOVE A

FLAVOR? To remove a recipe press and release YES.

Press NEXT to scroll through the stored recipes. When

the display reads the name of the recipe to be removed,

press and release REMOVE. The display will read RE-

MOVE? Press CANCEL to exit the SET NEW RECIPE

function. Press OK to remove that recipe. The display

will then show BEGIN SETUP OF (COFFEE NAME).

7. If the grind is acknowledged by the brewer, the

display will read BEGIN SETUP OF (COFFEE NAME).

Then the screen will display BREW OZ and a batch

light will be blinking. Follow steps on page 11

(Review Recipes) to adjust recipe settings.

Procedure for Setting the Recipe:

NOTE: Before beginning setup, place a server beneath

the brew funnel.

1. Insert the funnel into the grinder and select the

small batch size to grind. It is not necessary to have

coffee beans in the hopper(s) in order to program

the brewer. The coffee name is pre-selected and

stored in the grinder’s memory for the side being

ground.

2. Press the GRIND switch. When the grinder stops

grinding, remove the funnel.

17

Page 18

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

SET TEMP - ICB SH/ICB TWIN SH

This function allows the operator to adjust the brew

water temperature in the tank. This also sets the hot

water faucet dispense temperature.

Procedure for setting the Set Temp

Range: 185° to 205° F (85° - 96° C)

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SETTINGS, then

press SELECT. Press the right hidden button until

the display reads SET TEMP.

2. Using (-) and (+), adjust the brew and faucet

temperature.

3. When finished, press and release DONE to save

the new setting and to advance to the next function

screen, READY DEGREE. Press ENABLE BREW ON/

OFF switch to exit programming and return to the

MAIN SCREEN.

READY DEGREE

This function allows the operator to set the minimum

temperature allowable to start a brew cycle. The range

can be from 2° to 20° F below the set temperature. The

water must be at the READY temperature or higher

for the display to indicate READY TO BREW. If brew

lockout is enabled, the brewing process will not start

below this READY temperature.

Procedure to set ready temperature

Range: 2° to 20° F (2° to 10° C) below set temp

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SETTINGS, then

press SELECT. Press the right hidden button until

the display reads READY DEGREE.

2. Using (-) and (+), adjust the ready temperature.

3. When finished, select DONE to save the new setting

and to advance to the next screen, ENABLE ADS.

Press ENABLE BREW ON/OFF switch to exit.

ENABLE ADS

This function allows the operator to choose whether

or not to display an advertising message. An ad can be

saved to the brewer by either writing the ad using the

programming commands, or by entering the ad into

the brewer using an AD CARD. This message will be

displayed when the brewer is not in use.

Procedure to Enable/Disable Ads:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SETTINGS, then press

SELECT. Press the right hidden button until the

display reads ENABLE ADS. The YES or NO will be

flashing to indicate the current selection.

2. Select NO to disable this function, or:

3. Select YES to enable this function.

4. When finished, select DONE to save the new setting

and advance to the next function screen.

5. If NO was selected, the display should now read

ENABLE SANITATION. To exit programming and

return to the MAIN SCREEN, press ENABLE BREW

ON/OFF switch.

6. If YES was selected, the display should now read

NEW AD?. This screen allows the operator to select

between using an ad card to read in a new ad, or

writing an ad through the control panel.

Procedure to WRITE an Ad:

NOTE: Writing and saving a new ad will erase any

previously saved ad in the brewer’s memory.

7. From the NEW AD? screen, select WRITE.

8. The display should now read 2 LINES 16 CHARS

AVAILABLE, and then SCROL THRU ALPHA, NEXT

-> NEXT LETTER, and then WRITE TOP LINE?. The

ad can be up to 32 characters long, 16 per line. The

ad will be written in two steps, first the top line,

then the bottom line.

9. To write the top line of a new ad, select YES. To skip

the top line and only write a bottom line, select NO

and proceed to step 13.

10. The display will now read A with a flashing cursor

below it. Press the SCROLL button to scroll through

the alphabet and available characters. When the

desired character is shown on the display, select

NEXT to move to the next character in the top line.

18

Page 19

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

11. Repeat step 10 until the top line is complete.

12. Select DONE. The display should now read WRITE

BTM LINE?.

13. To write the bottom line, select YES.

14. To skip the bottom line, select NO.

a. If neither a top nor bottom line was written, the

display should now read ENABL SANITATION.

b. If only a top line was written, the ad will be

displayed followed by SAVE? Proceed to step 18.

15. The display will now read A with a flashing cursor

below it. Scroll through the alphabet and available

characters. When the desired character is shown

on the display, select NEXT to move to the next

character in the bottom line.

16. Repeat step 15 until the bottom line is complete.

17. Select DONE. The display will now show the written

ad, and then SAVE?

18. To cancel saving the ad, select NO. The display

should now read ADVERTISEMENT NOT SAVED!

and then will return to the NEW AD screen.

19. To correct or edit the ad, select EDIT. The display

should now read WRITE TOP LINE? Repeat steps

10 though 17.

20. To save the ad as it is shown, select YES. The

display should now read ADVERTISEMENT SETUP

COMPLETE, and then ENABL SANITATION. To exit

programming and return to the MAIN SCREEN,

press ENABLE BREW ON/OFF switch.

Procedure to READ in a new Ad:

NOTE: Saving a new ad will erase any previously saved

ad in the brewer’s memory.

7. From the NEW AD? screen, select CARD.

8. The display will show INSERT AD CARD. Place

the AD CARD vertically so that the top end of the

"chip" is beneath the sensing coil (located on the

underneath side of the front display panel).

9. After a short pause, the display will read CARD

CONTAINS AD. To view the ad, press and release

SHOW. To save the ad to the brewer's memory,

select SAVE. To cancel, select QUIT.

10. After the ad is saved, the display will read AD

MESSAGE SETUP COMPLETE.

19

Page 20

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

ENABLE ENERGY SAVER

This function allows the operator to enable the ENERGY

SAVINGS mode function and set the idle time. Once

the set idle time has expired, the operator can choose

to have the heaters either turn off, or reduce the tank

holding temp to 140° F (60° C).

Procedure to enable energy savings mode:

Range: 0.5 to 24.0 hrs

If enabled, default setting is 140° F (60° C) tank

temperature after 4.0 hrs. idle time.

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SETTINGS, then press

SELECT. Press and release the right hidden switch

until the display reads ENABLE ENERGYSAVR. The

YES or NO will be flashing to indicate the current

selection.

2. Select NO to disable or:

3. Select YES to enable this function.

4. When finished, press and release DONE to save the

new setting and advance to the next screen.

5. If NO was selected, the display should now read

EnableFreshTimer. To exit programming and return

to the MAIN SCREEN, press ENABLE BREW ON/

OFF switch.

6. If YES was selected, the display should now read

X.X HRS -> IDLE. This screen allows the operator

to set the amount of time the brewer is not in use

before energy save mode engages. Using (-) and (+),

adjust the idle time. When finished, select DONE.

7. The display should now read AFTER IDLE TIME?

Once the set idle time has expired, the heaters can

either be shut off or held at 140° F.

8. To have the heaters shut off after the set idle time,

select OFF and then DONE to save the settings.

The display should read MACHINE OFF AFTER X.X

HRS, and then EnableFreshTimer.

9. To have the temperature reduce to 140° F, select

140° and then DONE to save the settings. The display

should read MACHINE AT 140° AFTER X.X HRS,

and then EnableFreshTimer.

10. Once the idle time has expired, the display will

read either ENERGY SAVER...NO TEMPERATURE

or ENERGY SAVER...REDUCED TEMPERATURE,

depending on the settings. This screen will alternate

with PRESS ANY SWITCH TO RE-HEAT.

ENABLE FRESH TIMER

This function allows the operator to enable the Freshness Alert and set the expiration time. The expiration

time is the amount of time the product is allowed to sit

in the server/dispenser before a fresh batch is brewed.

Procedure for enabling/setting the Freshness Timer:

Range: Coffee 0.5 to 4.0 hrs

Hot Tea 0.5 to 8.0 hrs

If enabled, default setting is 2.0 hrs. for Coffee and 2.0

hrs. for Hot Tea.

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SETTINGS, then press

SELECT. Press and release the right hidden button

until the display reads ENABLE FRESHTIMER.

2. Select NO to disable or:

3. Select YES to enable this function (the unit will

display a message once the set time has expired).

4. When finished, select DONE to save the new setting

and advance to the next screen.

5. If NO was selected, the display should now read

REFILL. To exit programming and return to the

MAIN SCREEN, press either ENABLE BREW ON/

OFF switch.

6. If YES was selected, the display should now read

COFFEE. This screen allows the operator to set the

amount of time from the end of brewing a batch

of coffee until a Freshness Alert message will be

displayed. Using (-) and (+), adjust the freshness

time for coffee. When finished, select DONE.

7. The display should now read HOT TEA. Using (-)

and (+), adjust the freshness time for hot tea. When

finished, select DONE.

8. This display should now read REFILL. To exit

programming and return to the MAIN SCREEN,

press ENABLE BREW ON/OFF switch.

9. Once the set time has expired, the display will

read FRESHNESS ALERT BREW (A,B or C), and

then FRESHNESS ALERT BREW FRESH BATCH

alternating with the MAIN SCREEN.

10. Empty the server/dispenser the previous batch was

brewed into and replace under the funnel.

11. Brew a new batch

12. The freshness timer will reset. The display should

now return to the MAIN SCREEN.

20

Page 21

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

REFILL

Range: 0 to 155

This function allows the operator to adjust the sensitivity of the refill circuit. This is mainly a troubleshooting

feature. Water in different geographical locations can

have different conductivities. By adjusting the sensitivity

of the refill circuit, this will allow the brewer to operate

under various water conditions.

Procedure to set the sensitivity threshold of the refill

circuit:

NOTE: Make sure the water in the tank is touching the

refill probe.

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SETTINGS, then press

SELECT. Press and release the right hidden switch

until the display reads REFILL and shows a number

on both sides of the word.

2. To adjust the threshold setting, press (-) to decrease

or (+) to increase the setting.

NOTE: Always make sure that the number on the right

is larger than the number on the left when water is in

contact with the refill probe in the tank.

3. When finished, select DONE. This saves the new

setting and advances to the next function screen

(L) SPRAY OZ/M. To exit programming and return

to the MAIN SCREEN, press ENABLE BREW ON/

OFF switch.

SPRAY OZ/M

This function allows the operator to view or enter the

actual flow rate coming out of each sprayhead. This is

NOT used to control the actual flow rate, but to tell the

internal processor how fast the water is flowing.

2. If the actual flow rate of the sprayhead is known

but is different than the number on the display, use

the (-) and (+) to enter the correct flow rate.

3. Select DONE.

4. Repeat procedure for right side of Twins.

5. When finished, press and release DONE to advance

to the next screen. To exit programming and return

to the MAIN SCREEN, press ENABLE BREW ON/

OFF switch.

NOTE: If the flow rate is unknown, proceed to the

CALIBRATE FLOW screen.

BYPASS OZ/M (ICB Twins SH only)

This function allows the operator to view or enter the

actual flow rate coming out of each bypass fitting. This

is NOT used to control the actual flow rate, but to tell

the internal processor how fast the water is flowing.

Procedure to adjust the bypass flow rate setting:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads CALIBRATION, then

press SELECT. Press and release the right hidden

switch until the display reads BYPASS OZ/M. The

number represents what the brewer thinks is the

flow rate out of that bypass.

2. If the actual flow rate of the bypass is known but is

different than the number on the display, use the

(-) and (+) to enter the correct flow rate.

3. Select DONE.

4. Repeat procedure for right side of Twins.

5. When finished, press and release DONE to advance

to the next screen. To exit programming and return

to the MAIN SCREEN, press ENABLE BREW ON/

OFF switch.

NOTE: If the flow rate is unknown, proceed to the

CALIBRATE FLOW screen.

Procedure to set the sprayhead flow rate:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads CALIBRATION, then

press SELECT. Press and release the right hidden

switch until the display reads SPRY OZ/M. The

number represents what the brewer thinks is the

flow rate out of that sprayhead.

21

Page 22

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

CALIBRATE FLOW

This function allows the operator to test and enter the

actual flow rate of the sprayhead(s) and the bypass/

dilution for each side of the brewer by dispensing each

separately for one minute. The volumes are then entered

into the brewer.

Procedure to calibrate the sprayhead flow rate:

1. Place a container, accurately graduated with a

minimum capacity of 60 ounces, under the funnel.

2. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads CALIBRATION, then

press SELECT. Press and release the right hidden

switch until the display reads CALIBRATE, then

press SELECT.

3. Select to advance to SPRAY HEAD CAL screen.

4. Select side to calibrate.

The display should read CONTAINER READY? If

container is under the funnel, select YES.

5. The display should read CALIBRATE SPRAY. Press

and release any BREW button on the side to be calibrated to begin the sprayhead flow for calibration.

The display should read CALIBRATE SPRAY...60

SEC TO FINISH. The 60-second timer on the display

will count down to zero. When the counter reaches

zero, the display will change to LEFT or RIGHT OZ,

along with a number.

6. Measure the amount of water in the container and

use (-) and (+) to match the display to the amount

in the container. Then select DONE.

7. The display should now read NEW L or NEW R

SPRY FLOW, along with the correct flow rate of

the sprayhead. After about 5 seconds, the display

will return to the CALIBRATE FLOW screen.

8. Repeat steps 1-7 to calibrate the other side.

9. To exit the CALIBRATE FLOW function and advance

to the next screen, select NO. To exit programming

and return to the MAIN SCREEN, press either

ENABLE BREW ON/OFF switch.

Procedure to calibrate the bypass flow rate:

1. Place a container, accurately graduated with a

minimum capacity of 60 ounces, under the funnel.

2. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads CALIBRATION, then

press SELECT. Press and release the right hidden

switch until the display reads CALIBRATE, then

press SELECT.

3. Select to advance to BYPASS CAL screen.

4. Select side to calibrate.

The display should read CONTAINER READY? If

container is under the funnel, select YES.

5. The display should read CALIBRATE BYPASS. Press

any BREW button on the side to be calibrated to

begin the flow for calibration. The display should

read CALIBRATE BYPASS...60 SEC TO FINISH. The

60-second timer on the display will count down to

zero. When the counter reaches zero, the display

will change to LEFT or RIGHT OZ/M, along with a

number.

6. Measure the amount of water in the container and

using the (-) and (+), adjust the amount on the

display to match the amount in the container. Then

select DONE.

7. The display should now read NEW L or NEW R

BYPS FLOW, along with the correct flow rate of

the bypass. After about 5 seconds, the display will

return to the CALIBRATE FLOW screen.

8. Repeat steps 1-7 to calibrate the other side.

9. To exit the CALIBRATE FLOW function and advance

to the next function screen, select NO. To exit

programming and return to the MAIN SCREEN,

press ENABLE BREW ON/OFF switch.

22

Page 23

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

BREW COUNTERS

This function allows the operator to track the total number of brew cycles completed, as well as the number of

batches brewed using each of the brew buttons. There

are (up to) six resettable counters, and one life counter

that is not resettable.

Procedure to view/reset the brew counters:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SERVICE, then press

SELECT. Press and release the right hidden switch

until the display reads BREW COUNTERS.

2. Pressing NO will advance to the next programming

function. Select YES to view the first brew counter

(TOTAL LIFE BREWS). This number represents the

total number of brew cycles this brewer has completed. This counter is non-resettable. Press NEXT

to advance to the next brew counter, <- <- BREW

A (left side).

3. This counter represents the number of brews for

Brew A on the left side of the brewer. To reset the

counter to zero, press and release RESET. Press

and release NEXT to advance to the next counter.

4. Repeat step 3 for the remaining two left counters,

BREW B and BREW C.

5. Repeat step 4 for the three right side brew counters.

(Twin only)

6. When finished, press NEXT to advance to the next

programming function, ENTER ASSET #. To exit

programming and return to the MAIN SCREEN,

press ENABLE BREW ON/OFF switch.

PRESSING NO WILL

ADVANCE TO

ENTER ASSET #

ICB Twin

shown.

others

similar

BREW COUNTERS?

NO YES

TOTAL LIFE BREWS

XXXX NEXT

<< XXX BREW A

RESET NEXT

<< XXX BREW B

RESET NEXT

<< XXX BREW C

RESET NEXT

BREW A XXX >>

RESET NEXT

23

BREW B XXX >>

RESET NEXT

BREW C XXX >>

RESET NEXT

ENTER ASSET #?

NO YES

Page 24

PROGRAMMING BREWER (cont.)

PROGRAMMING FUNCTIONS (cont.)

ASSET NUMBER

This function allows the operator to enter the machine's

asset number. This can be useful for tracking the usage

or service of an individual machine within a group.

Procedure to enter the asset number:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SERVICE, then press

SELECT. Press and release the right hidden switch

until the display reads ENTER ASSET #?

2. Select YES. The display will now read ANXXXXXX.

3. Scroll down (-) or up (+), to set the asset number

of the machine. NOTE: Starting from the right, each

digit will control the next digit, like an odometer.

4. When finished, press and release DONE. The display

will now read SERVICE #. To exit programming and

return to the MAIN SCREEN, press ENABLE BREW

ON/OFF switch.

NOTE: To view the Asset Number, press and hold the

left hidden switch until the display reads ASSET

NUMBER. After releasing the switch, the display will

read SERIAL NUMBER then the software version.

SERVICE NUMBER

This function allows the operator to enter in the telephone number to call if service is needed. The service

number will be displayed anytime there is a fault message displayed.

Procedure to enter the service number:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SERVICE, then press

SELECT. Press and release the right hidden switch

until the display reads ENTER SERVICE #?

2. Press and release YES. The display will now read

SCROL THRU #'S NEXT ->NEXT NUMBER, followed

by 000-000-0000. UP TO 16 CHARACTERS ARE

AVAILABLE.

3. Press the SCROL button to scroll through the numbers. When the desired number is shown, press

and release NEXT to move to the next digit in the

phone number.

4. Repeat Step 3 until the entire number is entered.

5. Press and release DONE. The display will now read

BREW COUNTERS

SERVICE

(FOR AUTHORIZED SERVICE PERSONNEL ONLY)

This function allows the testing of individual components

and the ability to check switches for proper function. This

function also tests the funnel sensor coil’s frequency

(diagnostic tool for troubleshooting purposes only).

Refer to Service Manual for in depth procedures.

Test Outputs:

The following components can be individually tested:

(L/R) Brew Valve(s)

(L/R) Bypass Valve(s) ITCB HV/ICB(TWIN)

(L/R) Dilution Valve(s) ITB/ITCB/HV (w/Dual Dilution)

Refill Valve

Tank Heater Relay

Tank Heater Triac

L/R Funnel Lock (Optional)

Sweetener Solenoid (Optional)

Test Switches:

The following components can be individually tested:

Membrane Switches

Test Frequency: (NOT AVAILABLE ON ITB)

The following components can be individually tested:

L/R Smart Funnel read coils.

FACTORY DEFAULTS

This function allows the operator to erase ALL of the

previously entered recipes and ad messages. Factoryset default values will replace ALL previous settings.

Procedure to set factory defaults:

1. Press and hold the right hidden button until the

display reads RECIPES. Press the right hidden

button until the display reads SERVICE, then press

SELECT. Press and release the right hidden switch

until the display reads FACTORY DEFAULTS.

2. Press YES to restore defaults. The display will read

WILL REPLACE ALL BREW SETTINGS followed with

ARE YOU SURE?

3. Selecting NO, will exit without resetting. Select

YES to load the defaults. After factory defaults have

been restored, the display will return to the MAIN

SCREEN. The factory default values will have replaced

ALL previously entered values. It will NOT reset the life

brew counter. If factory defaults are restored, it will be

necessary to recalibrate the flow rates.

24

Page 25

USB Flash Drive Programming:

The port on the right side of the hood allows a user to update software on brewer.

Procedure for copying settings from one brewer

and loading onto a brewer of the same model.

1. Insert empty flash drive into brewer. Screen

should read “USB DETECTED” and then read

“SAVE TO.” Select “USB” which will be the only option.

USB DETECTED USB DETECTED

2. When finished the screen will read “SAVE

COMPLETE REMOVE DRIVE.” Remove the

flash drive.

3. When in front of the next brewer, insert flash

drive into brewer.

4. The screen should then read “USB DETECTED”

and then read “SAVE TO.” Select “BREWER” and

the screen will read “Please Wait” as it is saving

the settings to your brewer. When completed

the screen will read “SAVE COMPLETE REMOVE

DRIVE.”

Procedure for loading new software versions

into brewers.

1. Place new software file from computer onto

empty flash drive.

2. Insert flash drive into brewer. The screen should

read Screen should read “USB DETECTED” and

then “Fil Infus###.## PROGRAM?”. Select “YES”

and the screen will read “Please Wait” as it is

saving the settings to your brewer. When

completed the screen will read “SAVE COMPLETE

REMOVE DRIVE.”

SAVE TO SAVE TO

USB USB BREWER

SAVE COMPLETE

REMOVE DRIVE

USB DETECTED

Fil Infus###.##

NO PROGRAM? YES

Please Wait

............

SAVE COMPLETE

REMOVE DRIVE

Please Wait

............

SAVE COMPLETE

REMOVE DRIVE

Procedure for loading recipe into brewers.

1. Place recipe file from computer onto empty

flash drive.

2. Insert flash drive into brewer. The screen should

read Screen should read “USB DETECTED” and

then read “SAVE TO.” Select “BREWER” and the

screen will read “Please Wait” as it is saving the

settings to your brewer. When completed the

screen will read “SAVE COMPLETE REMOVE

DRIVE.”

USB DETECTED

USB BREWER

25

SAVE TO

Please Wait

............

SAVE COMPLETE

REMOVE DRIVE

Page 26

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

• All electronic components have 120-240 volt ac and low voltage dc potential on their terminals. Shorting of

terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If an

intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a terminal

or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will help

to avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• This brewer is heated at all times. Keep away from combustibles.

WARNING

- Exercise extreme caution when servicing electrical equipment.

- Unplug the brewer when servicing, except when electrical tests are specified.

- Follow recommended service procedures.

- Replace all protective shields or safety notices.

26

Page 27

TROUBLESHOOTING (cont.)

PROBABLE CAUSE REMEDYPROBLEM

Temperature Too Low

Heating Time Too Long

Fill Time Too Long

Temp Sensor Out Of Range, Check

For Bad Connections

1. Water temperature in the tank

does not meet the ready temperature.

1. Tank Heater failure.

2. Control Board/Thermistor failure

1. Water shut off to brewer

2. Inlet Solenoid failure

3. Control Board Failure

4. ON/OFF switch is OFF

1. Temperature Sensor Probe

wire(s) broken or not making

connection

A) Wait for the brewer to heat to the

proper temperature.

B) Disable the BREW LOCKOUT

function. See page 10 for procedure.

Service required

Service required

Check water supply shut-off

Service Required

Service Required

Turn switch ON

Check wire and connection of both

black and white wires of temperature

probe.

Temp Sensor Out Of Range, Check

Wire For Shorts

Equipment will not operate

1. Temperature Sensor Probe

wire(s) shorted to housing or to

each other.

1. No power or incorrect voltage

Check to confirm that wire(s) are

not pinched between two surfaces

or connected to each other.

Measure the voltage at the terminal

block and confirm that it matches

the voltage specified on the brewer

data plate withing +/- 10%.

27

Page 28

TROUBLESHOOTING (cont.)

PROBLEM

Brew cycle will not start

PROBABLE CAUSE REMEDY

1. No water

2. No power or incorrect voltage to

the brewer

3. ON/OFF switch

4. Brew switch

5. Brew valve

6. Control Board

Check plumbing and shut-off valves

Check for voltage across the

terminals at the terminal block.

Test the ON/OFF switch.

Test the BREW switch.

Test the brew valve.

Substitute a control board known

to be in good working order.

Check plumbing and shut-off valves

28

Page 29

TROUBLESHOOTING (cont.)

PROBLEM

Automatic refill will not operate or

display shows FILL TIME TOO LONG

PROBABLE CAUSE REMEDY

1. No water

2. Refill probe or Sensitivity setting

Remove the strainer and check for

obstructions. Clear or replace.

Check the sensitivity setting. Refer

to the REFILL function. If the left

three digit number is less than the

right number, the machine “thinks”

it is full and the refill valve should

be off. If the left number is larger

than the right, then the refill valve

will automatically be turned on to

fill the tank. The right number is

the threshold setting and can be

adjusted to compensate for extreme water conditions: very pure,

low conductance water requires a

higher setting, while high mineral

content, high conductance water

requires a lower setting. Note that

the left number changes from a high

value when water is NOT touching

the refill probe to a low valve when

water IS touching the probe. For best

operation, the right number should

be set to a value midway between

these low and high numbers. Before changing the setting, confirm

that the refill probe is free of scale

buildup and the connection to it is

secure. Test the refill valve.

3. Refill valve

Refill valve – Disconnect the brewer

from the power source and remove

wires from refill valve coil. Check

for continuity across the terminals

of the solenoid coil. If continuity is

29

Page 30

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Automatic refill will not operate or

display shows FILL TIME TOO LONG

(Continued)

4. Control Board

5. ON/OFF Switch

not present, replace the refill valve.

If continuity is present, the coil may

be stuck closed. Shut water off to

brewer. Press the ON/OFF switch to

turn off the brewer. Open the faucet

and drain water down in the tank

until flow stops or slows to a trickle.

Attach a voltmeter to the terminals

of the refill solenoid. Connect the

brewer to the power source. Press

the ON/OFF switch to turn the brewer

on. Within five seconds, voltage

should be present at the solenoid

terminals. If voltage is not present,

refer to the wiring schematic and

check the wiring harness.

Substitute a control board known

to be in good working order.

ON/OFF switch must be ON for the

refill circuit to operate. Turn ON.

30

Page 31

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Water flows into tank continuously

with power removed from brewer.

1. Refill valve

2. Refill probe or sensitivity setting

Foreign material lodged in valve,

holding it in open state.

Check the sensitivity setting. Refer

to the REFILL function. If the left

three digit number is less than the

right number, the machine “thinks”

it is full and the refill valve should

be off. If the left number is larger

than the right, then the refill valve

will automatically be turned on to

fill the tank. The right number is

the threshold setting and can be

adjusted to compensate for extreme water conditions: very pure,

low conductance water requires a

higher setting, while high mineral

content, high conductance water

requires a lower setting. Note that

the left number changes from a high

value when water is NOT touching

the refill probe to a low valve when

water IS touching the probe. For

best operation, the right number

should be set to a value midway

between these low and high numbers. Before changing the setting,

confirm that the refill probe is free

of scale buildup and the connection

to it is secure.

3. Control Board

Substitute a control board known

to be in good working order.

31

Page 32

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Water will not heat or display shows

HEATING TIME TOO LONG.

1. Limit Thermostat

2. Temperature probe

3. Tank heaters

Remove power from the brewer.

Check for continuity through the

limit thermostat. CAUTION: Do not

eliminate or bypass limit thermostat. Use only replacement part

29329.0001.

Remove the probe from the grommet and submerge in a water bath

of approximately 70°F (21°C).

Connect an ohmmeter to the pins

in the connector. At 60°F (16°C),

the reading should be 15.3k ± 2k

OHMS, at 70°F (21°C) the reading

should be 11.8k ± 2k OHMS, and

at 80°F (27°C) the reading should

be 9.3k ± 2k OHMS. If the probe is

within these parameters, reconnect

to the control board.

Remove power from the brewer.

Check for continuity through the

tank heaters. If no continuity is

present, check for a wiring problem

(consult wiring schematic), then

replace the tank heater if no wiring

problem is found.

4. Control Board

Remove power from the brewer.

Connect a voltmeter across the tank

heater. Reapply power to the brewer

and refer to testing outputs. If the

voltage measured when the tank

heater is turned on is very low or

zero, then substitute a control board

know to be good working order.

32

Page 33

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

No bypass water

Spitting or unusual steaming from

sprayhead or air vent.

1. Bypass valve

2. Recipe settings

1. Lime buildup

2. Temperature probe

Test the bypass valve. Refer to the

test outputs.

Check to make sure bypass % has

been set for the current recipe.

Inspect the probe and tank assembly

for excessive lime deposits. Delime

as required.

Remove the probe from the grommet and submerge in a water bath

of approximately 70°F (21°C).

Connect an ohmmeter to the pins

in the connector. At 60°F (16°C),

the reading should be 15.3k ± 2k

OHMS, at 70°F (21°C) the reading

should be 11.8k ± 2k OHMS, and

at 80°F (27°C) the reading should

be 9.3k ± 2k OHMS. If the probe is

within these parameters, reconnect

to the control board.

3. Control Board

Remove power from the brewer.

Connect a voltmeter across the tank

heater. Reapply power to the brewer

and refer to testing outputs. If the

voltage measured when the tank

heater is turned on is very low or

zero, then substitute a control board

know to be good working order.

33

Page 34

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Inconsistent beverage level in

server/dispenser

1. Improper water pressure

2. Brew valve

3. Bypass valve

Check operating water pressure to

the brewer. It must be between 20

and 90 psi (138 and 620 kPa).

Test the brew valve. Refer to test

outputs on page 48. Turn the valve

on for 30 seconds and collect the

water dispensed from the sprayhead. Repeat the test several times

to confirm a consistent volume of

dispensed water. If not consistent,

check the valve, tubing and sprayhead for lime buildup.

If bypass is being used on the inconsistent brewing recipe, test the

bypass valve. Refer to test outputs.

Turn the valve on for 30 seconds and

collect the water collected from the

funnel. Repeat the test several times

to confirm a consistent volume of

dispensed water. If not consistent,

check the valve, tubing and fittings

for lime buildup.

4. Lime buildup

5. Brew volume adjustment

Inspect for lime buildup that could

block the tank, tank fittings, tubing,

valves and sprayhead.

Adjust the brew volume, calibrate

sprayhead and bypass as required

to achieve the desired volume for

each brew cycle.

34

Page 35

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Dripping from sprayhead.

Water overflows filter.

Beverage overflows server.

Brewer is making unusual noises.

1. Brew valve

1. Type of paper filter

2. No sprayhead

1. Beverage left in server from

previous brew

2. Brew volume adjustment

1. Solenoids

2. Plumbing lines

Repair or replace leaky valve

BUNN paper filters should be used

for proper extraction

Check sprayhead

The brew cycle should be started

only with an empty server under

the funnel.

Adjust the brew volume, calibrate

sprayhead and bypass as required

to achieve the desired volume for

each brew cycle

The mounting screws on the solenoids must be tight or they will

vibrate during operation

Plumbing lines should not be resting

on the countertop.

3. Water supply

4. Tank heaters

The brewer must be connected to

a cold water line. Water pressure

to the brewer must not be higher

than 90 psi (.620 mPa). Install a

regulator if necessary to lower the

working pressure to approximately

50 psi (.345 mPa).

Remove and clean lime off tank

heaters.

35

Page 36

TROUBLESHOOTING (cont.)

PROBLEM PROBABLE CAUSE REMEDY

Weak beverage. BUNN paper filters should be used

1. Type of paper filter

2. Coffee

3. Sprayhead

4. Funnel Loading

5. Water temperature

for proper extraction

For coffee, a sufficient quantity of

fresh drip or regular grind should

be used for proper extraction.

Bunn-O-Matic sprayhead should

be used to properly wet the bed of

ground coffee in the funnel

The BUNN paper filter should be

centered in the funnel and the bed of

grounds leveled by gently shaking.

Empty the server, remove its cover,

and place the server beneath the

sprayhead. Place empty funnel over

the server entrance (not in the funnel

rails). Press brew. Check the water

temperature immediately below

the sprayhead with a thermometer.

The reading should not be less than

195°F (90°C).

6. Incorrect recipe

Consider adjusting brew volumes,

bypass percentage and pulse brew

routines. Contact Bunn-O-Matic for

suggestions.

36

Loading...

Loading...