Page 1

Hot Water

Dispensers

Supercedes

10052.7000; 10010.7000; 10267.0000

10420.7000; 10889.7000; 39338.7000

39338.7001; 44306.7000

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION OF CANADA

PHONE: (905) 841-2866 FAX: (905) 841-2775

To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit

the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain

the latest catalog and manual updates. Contact Bunn-O-Matic Corporation at 1-800-263-2256 to obtain

a paper copy of the required Illustrated Parts Catalog mailed via Canada Post.

46819.7000A 06/12 © 2012 BUNN-O-MATIC CORPORATION

280 INDUSTRIAL PARKWAY SOUTH,

AURORA, ONTARIO, L4G 3T9

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corporation of Canada (“Bunn”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCP/MCA pod brewers

thermal servers and Thermofresh servers (mechanical and digital) - 1 year parts and 1 year labour.

2) All other equipment - 2 years parts and 1 year labour plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labour for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labour.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve

analysis - parts and labour for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation. Bunn warrants that the equipment manufactured

by it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component

or part that was not manufactured by Bunn or that, in Bunn’s judgement, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, non periodic cleaning and descaling,

equipment failures related to poor water quality, damage or casualty. In addition, the warranty does not apply to

replacement of items subject to normal use including but not limited to user replaceable parts such as seals and

gaskets. This warranty is conditioned on the Buyer 1) giving Bunn prompt notice of any claim to be made under

this warranty by telephone at (905) 841-2866 or by writing to 280 Industrial Parkway South, Aurora, Ontario, L4G

3T9. 2) if requested by Bunn, shipping the defective equipment prepaid to an authorized Bunn service location;

and 3) receiving prior authorization from Bunn that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, CONDITION,

WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY

OF EITHER MERCHANTABILITY, MERCHANTABLE QUALITY OR FITNESS FOR A PARTICULAR PURPOSE.The

agents, dealers or employees of Bunn are not authorized to make modifications to this warranty or to make

additional warranties that are binding on Bunn. Accordingly, statements by such individuals, whether oral or

written, do not constitute warranties and should not be relied upon.

If Bunn determines in its sole discretion that the defective equipment is covered by warranty, Bunn, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labour (during the applicable parts and labour warranty periods specified above) to repair the defective

components, provided that this repair is done by a Bunn Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE

SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT

BUNN’S SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall Bunn be liable for any other damage or loss, including, but not limited to, lost profits, lost

sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental, consequential or punitive damages.

CONTACT PLANT FOR RETURN MATERIAL AUTHORIZATION. ALL RETURNS MUST

BE AUTHORIZED BY BUNN-O-MATIC AND ARE SUBJECT TO A RETURN CHARGE.

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN

Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic,

Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design,

Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with

the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel,

Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh,

Titan, trifecta, Velocity Brew, A Partner You Can Count On, Air Brew, Air Infusion, Beverage Bar Creator, Beverage Profit

Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Daypart, Digital Brewer

Control, Nothing Brews Like a BUNN, Pouring Profits, Signature Series, Tea At Its Best, The Horizontal Red Line, Ultra are

either trademarks or registered trademarks of Bunn-O-Matic Corporation.

RETURN POLICY

2

46819 030912

Page 3

CONTENTS

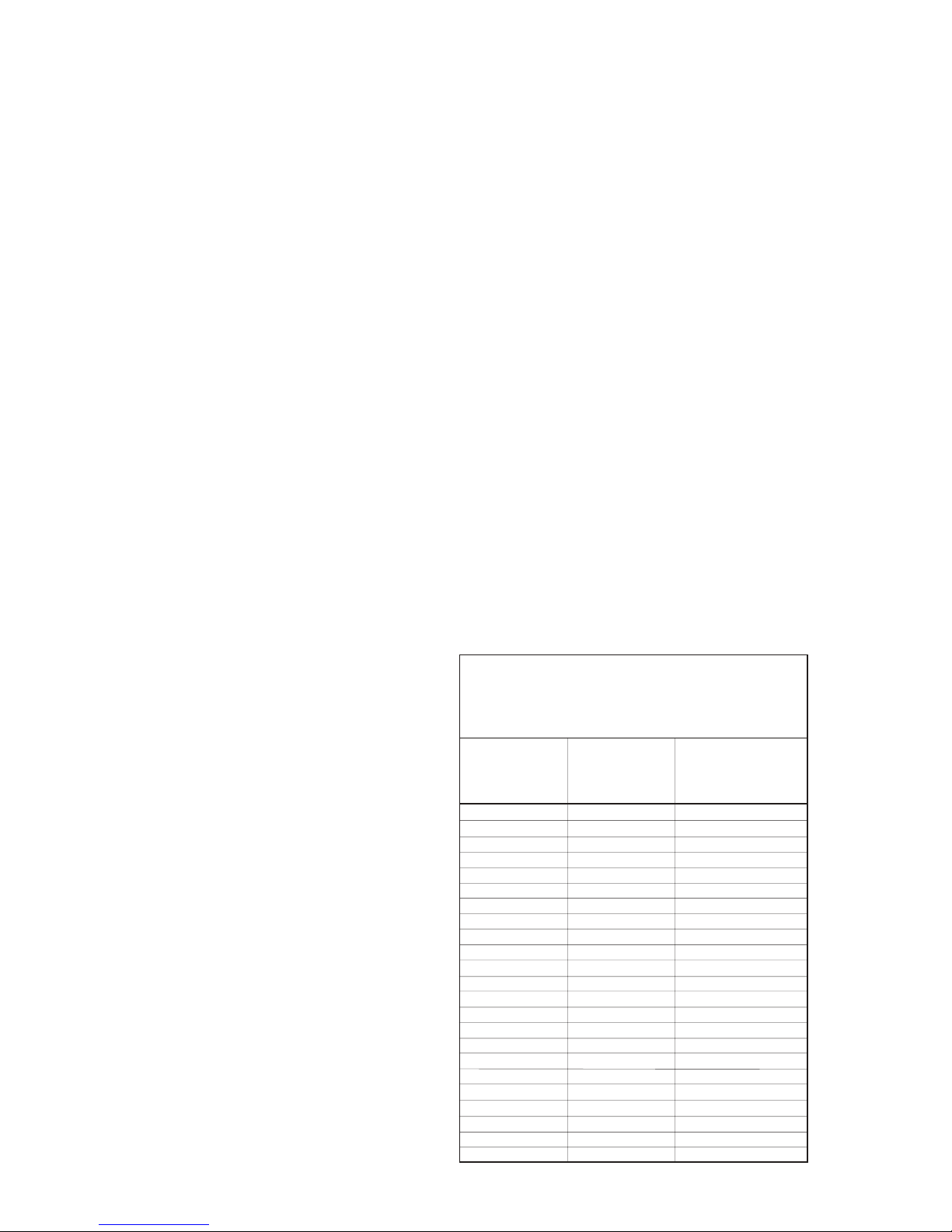

-1000 213.8 101.0 200 93.3

-500 212.9 100.5 200 93.3

0 212.0 100.0 200 93.3

500 211.1 99.5 200 93.3

1000 210.2 99.0 200 93.3

1500 209.3 98.5 200 93.3

2000 208.4 98.0 200 93.3

2500 207.4 97.4 200 93.3

3000 206.5 96.9 199 92.8

3500 205.6 96.4 198 92.2

4000 204.7 95.9 197 91.7

4500 203.8 95.4 196 91.1

5000 202.9 94.9 195 90.6

5500 201.9 94.4 195 90.6

6000 201.0 93.9 194 90.0

6500 200.1 93.4 193 89.4

7000 199.2 92.9 192 88.9

7500 198.3 92.4 191 88.3

8000 197.4 91.9 190 87.8

8500 196.5 91.4 189 87.2

9000 195.5 90.8 188 86.7

9500 194.6 90.3 187 86.1

10000 193.7 89.8 186 85.6

Brew water temperature is factory set at 200° F (93.3° C)

Areas of high altitude will require lowering this temperature to prevent boiling. This chart should be used as a

guide when readjusting the brew water temperature.

Altitude

(Feet)

Boiling point

of water

° F ° C

Recommended

water temperature

° F ° C

WARRANTY ........................................................................................................... 2

INTRODUCTION ..................................................................................................... 3

USER NOTICES ...................................................................................................... 4

ELECTRICAL REQUIREMENTS ............................................................................... 5

PLUMBING REQUIREMENTS ................................................................................. 6

INITIAL SET-UP (H5E, H5X, H5-PC, H5 ELEMENT, H10X) ..................................... 6

INITIAL SET-UP H5M, HW2, OHW ......................................................................... 7

OPERATING CONTROLS (H5-PC ONLY) ................................................................. 8

ADJUST DISPENSE VOLUME (H5-PC ONLY) ......................................................... 8

PROGRAMMING (H5E, H5X, H5-PC, H10X) .......................................................... 9

PROGRAMMING (H5 ELEMENT) ......................................................................... 11

DRAINING THE DISPENSER ................................................................................ 14

CLEANING ............................................................................................................ 14

INTRODUCTION

This equipment heats and dispenses water on demand for beverages and cooking purposes. It has a panel

above the faucet that indicates the status of the dispenser. This equipment is for indoor use, either wall-mounted

(H5E/X/PC) or on a sturdy counter or shelf.

3

46819 043012

Page 4

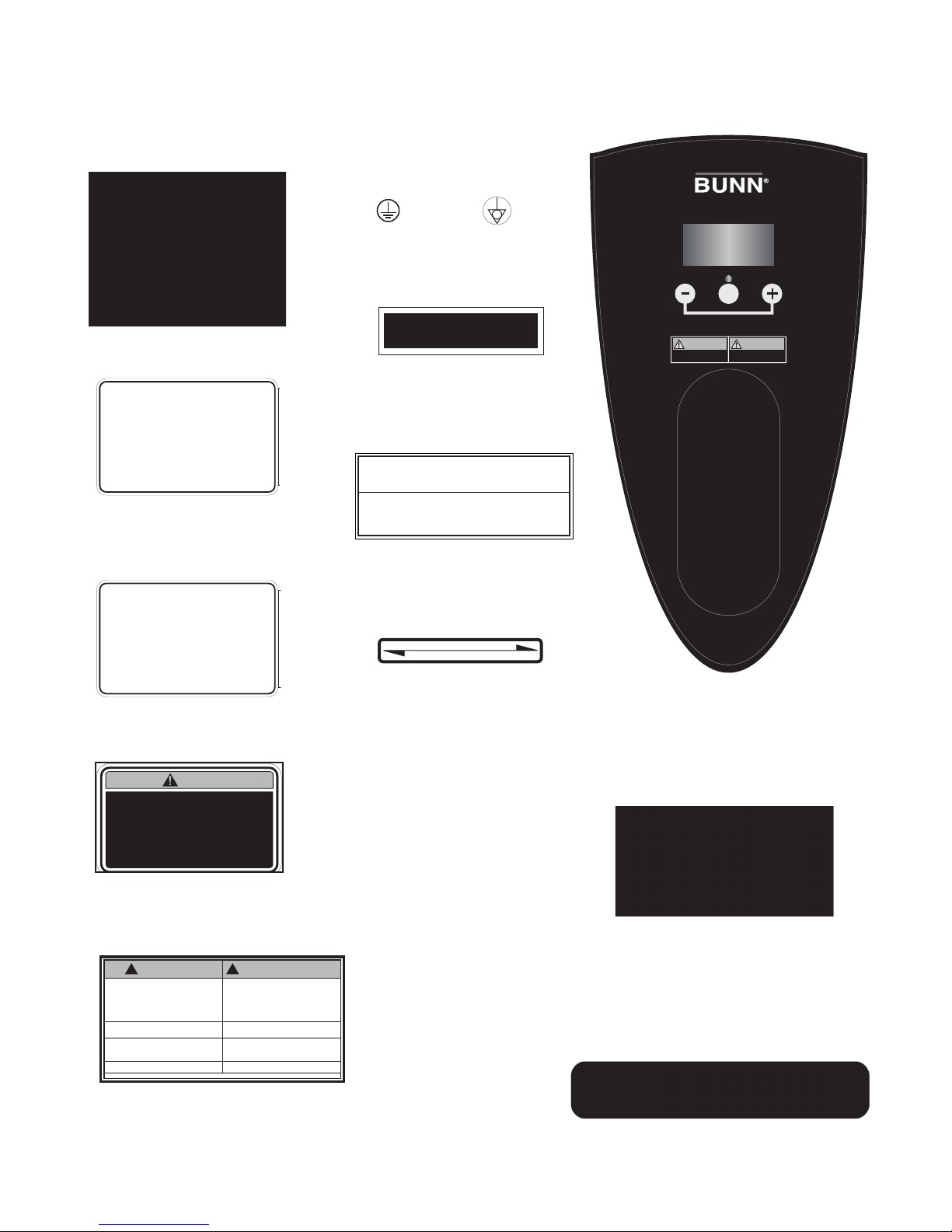

USER NOTICES

29710.7006C

29710.7018A

The notices on this dispenser should be kept in good condition. Replace unreadable or damaged labels.

00824.0002 00824.0001

READY / PRÊT

TEMP

00657.7002

Optional Field Wiring

120/208-240 V, 13-15 A, 2670-3550 W

1PH, 3-Wire + GND, 60HZ

Branchement électrique optionnel

120/208-240 V, 13-15 A, 2670-3550 W

monophase, 3-fils relié à la terre, 60HZ

29710.7006

Optional Field Wiring

120/208-240 V, 16.9A,

4050 W, 1PH,

3-Wire + GND, 60HZ

Branchement électrique optionnel

120/208-240 V, 16,9A,

4050 W, Monophasé,

3-fils relie à la terre, 60HZ

29710.7018

WATER ONLY

EAU SEULEMENT

00833.7001

This equipment must be installed to comply with Canadian

Plumbing Codes and applicable health and safety regulations.

For models installed outside Canada, comply with the

applicable Plumbing /Sanitation Code.

Cet équipement doit être installé conformément au code

Canadien de plomberie et aux règlements de santé et de

sécurité qui s’ appliquent. Les modèles destinés à être

installés ailleurs qu’au Canada doivent respecter les codes de

plomberie et d’hygiène de la localité.

00656.7000

120V

120/208-240V

00831.0000

ENERGY SAVER MODE

ÉCONOMISEUR D’ÉNERGIE

CAUTIONWARNING

Hot Water Eau Chaude

44025.7000

WARNING AVERTISSEMENT

To reduce the risk of electric shock, do not remove or

open cover. No user-serviceable parts inside.

Authorized service personnel only. Disconnect power

before servicing.

Afin d’éviter un risque d’électrocution, ne pas ouvrir ou

enlever le panneau. Aucune pièce utile pour

l’opérateur à l’intérieur. Seulement le personnel

autorisé peut effectuer les réparations. Débrancher de la

source de courant avant d’effectuer une réparation.

37881.7000

! WARNING

• FILL WATER TANK BEFORE PLUGGING IN UNIT OR

ENERGIZING THE THERMOSTAT.

• DO NOT OVERLOAD CIRCUIT.

• ALWAYS ELECTRICALLY GROUND THE CHASSIS.

• DO NOT DEFORM PLUG OR CORD.

• FOLLOW NATIONAL AND LOCAL ELECTRICAL CODES.

• KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT DAMAGE, FIRE OR

SHOCK HAZARD.

READ THE ENTIRE OPERATING MANUAL INCLUDING

THE LIMIT OF WARRANTY AND LIABILITY BEFORE

BUYING OR USING THIS PRODUCT.

THIS EQUIPMENT IS ENERGIZED AT ALL TIMES UNLESS

ELECTRICALLY DISCONNECTED.

! AVERTISSEMENT

• REMPLIR LE RÉSERVOIR D'EAU AVANT DE BRANCHER

L'APPAREIL OU DE METTRE LE THERMOSTAT SOUS TENSION.

• NE PAS SURCHARGER LE CIRCUIT.

• TOUJOURS METTRE LE BOITIER À LA MASSE.

• NE PAS DÉFORMER LA FICHE OU LE CORDON.

• SE CONFORMER AUX CODES NATIONAL OU LOCAL

D'ÉLECTRICITÉ.

• GARDER LES PRODUITS COMBUSTIBLES À DISTANCE.

TOUT MANQUEMENT À SE CONFORMER À CES DIRECTIVES PEUT

ENTRAINER DES DOMMAGES À L'ÉQUIPEMENT OU PRODUIRE DES

DANGERS D'INCENDIE OU D'ÉLECTROCUTION.

VEUILLEZ LIRE LE MANUEL DE FONCTIONEMENT

EN ENTIER, Y COMPRIS LES LIMITES DE GARANTIES ET

00831.0002K 17/11 © 1984 BUNN-O-MATIC CORPORATION

L' ÉQUIPEMENT EST TOUJOURS SOUS TENSION

RESPONSABILITÉS,AVANT D’ACHETER

OU D'UTILISER LE PRÉSENT PRODUIT.

LORSQU'IL N'EST PAS DÉBRANCHÉ.

00831.0002

12593.7000

37881.7002

4

46819 061212

Page 5

ELECTRICAL REQUIREMENTS

WARNING - The dispenser must be disconnected from the power source until specified in Initial Set-Up.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

120 volt ac models

Note: This electrical service consists of 2 current carrying conductors (L1 and Neutral) and a separate

conductor for earth ground.

230 volt ac models

Note: This electrical service consists of 2 current carrying conductors (L1 and Neutral) and a separate

conductor for earth ground.

Electrical Hook-Up

CAUTION – Improper electrical installation will damage electronic com-

ponents.

1. An electrician must provide electrical service as specified.

2. Using a voltmeter, check the voltage and color coding of each conductor

at the electrical source.

3. Turn off master switch (if equipped).

4. Remove the upper and lower rear panels.

5. Install the proper electrical wiring to the terminal block.

6. Connect the dispenser to the power source and verify the voltage at

the terminal block before proceeding. Reinstall both rear panels.

7. If plumbing is to be hooked-up later be sure the dispenser is disconnected from the power source. If Plumbing has been hooked-up, the

dispenser is ready for Initial Set-Up.

208 & 240 volt ac models

Note: This electrical service consists

of 2 current carrying conductors (L1

and L2) and a separate conductor for

earth ground.

120/208 & 120/240V ac

single phase models

Note: This electrical service consists

of 3 current carrying conductors

(Neutral, L1 and L2) and a separate

conductor for earth ground.

CE REQUIREMENTS

• This appliance must be installed in locations where it can be overseen

by trained personnel.

• For proper operation, this appliance must be installed where the tem-

perature is between 5°C to 35°C.

• Appliance shall not be tilted more than 10° for safe operation.

• An electrician must provide electrical service as specied in confor-

mance with all local and national codes.

• This appliance must not be cleaned by water jet.

• This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given instructions concerning use

of this appliance by a person responsible for its safety.

• Children should be supervised to ensure they do not play with the

appliance.

• If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel with a special cord available

from the manufacturer or its authorized service personnel in order to

avoid a hazard.

• Machine must not be immersed for cleaning.

DUAL VOLT TOGGLE SWITCH

5

46819 043012

Page 6

PLUMBING REQUIREMENTS - ALL EXCEPT OHW

This dispenser must be connected to a COLD WATER system with operating pressure between 20 and 90 psi

(138 and 620 kPa)from a ½˝ or larger supply line. A shut-off valve should be installed in the line before the dispenser. Install a regulator in the line when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345

kPa). The water inlet fitting is ¼˝ flare.

NOTE - Bunn-O-Matic recommends ¼˝ tubing for installations of less than 25 feet and 3⁄8˝ for more than 25 feet

from the ½˝ water supply line. At least 18 inches of an FDA approved flexible beverage tubing, such as reinforced

braided polyethylene or silicone, before the dispenser will facilitate movement to clean the countertop. BunnO-Matic does not recommend the use of a saddle valve to install the dispenser. The size and shape of the hole

made in the supply line by this type of device may restrict water flow.

This equipment must be installed to comply with the National Plumbing Code of Canada and the Canadian

Food Inspection Agency. For models installed outside Canada, you must comply with the applicable

Plumbing/Sanitation Code for your area.

Plumbing Hook-Up

1. Remove the shipping cap from the fitting on the rear of the dispenser, and attach the flare elbow fitting

(supplied separately with the dispenser) to the fitting.

2. Flush the water line and securely attach it to the flare fitting.

Plumbing Hook-Up Master ON/OFF switch

INITIAL SET-UP - H5E, H5X, H5-PC, H10X, Element

CAUTION - The dispenser must be disconnected from the power source throughout the initial set-up, except

when specified in the instructions.

1. Connect dispenser to the power source and turn on water supply.

2. Place Master ON/OFF switch in the ON position (if equipped). NOTE: (Digital models with display) When

power is applied to the dispenser, the display will show the software version for 5 seconds, and then it will

show the temperature.

3. Water will automatically flow into the tank to the proper level and shut-off. When filled, the water heater will

turn on automatically.

4. The tank will heat to the (set) temperature.

5. Refer to Programming to set the Tank Temperature and the Ready Temperature.

6

46819 043012

Page 7

INITIAL SET-UP - H5M

CAUTION - The dispenser must be disconnected from the power source throughout the

initial set-up, except when specified in the instructions.

1. Remove the upper rear panel and rotate the control thermostat knob fully coun-

terclockwise to the “OFF” position and replace the panel.

2. Connect the dispenser to the power source and turn-on the water supply.

3. Water will automatically flow into the tank to the proper level and shut-off. This

will take approximately 10 minutes.

4. Disconnect the dispenser from the power source, remove the upper rear panel

and place the control thermostat knob fully clockwise to the “ON” position, and

replace the panel.

5. Connect the dispenser to the power source and wait approximately twenty

minutes for the water in the tank to heat.

6. On models with ready indicator, the indicator will light up when the proper water

temperature is achieved.

INITIAL SET-UP - HW2

CAUTION - The dispenser must be disconnected from the power source throughout

the initial set-up, except when specified in the instructions.

1. Remove the center rear panel and rotate the control thermostat knob fully coun-

terclockwise to the “OFF” position and replace the panel.

2. Plug-in the dispenser.

3. Water will automatically flow into the tank to the proper level and shut-off.

4. Unplug the dispenser, remove the center rear panel and rotate the control ther-

mostat knob fully clockwise to the “ON” position, and replace the panel.

5. Plug-in the dispenser and wait approximately twenty minutes for the water in

the tank to heat. The dispenser is ready for use.

H5M

INITIAL SET-UP - OHW

CAUTION - The dispenser must be unplugged throughout the initial set-up,

except when specified in the instructions.

1. Place an empty vessel under the faucet, lift the pour-in lid, and pour a full pitcher

(64 oz) of tap water into the top of the dispenser. Hold open the faucet handle

to allow air to escape from the tank while it is filling.

2. Pour another full pitcher into the top. Close the faucet when water starts flow-

ing from the faucet.

3. Fill the top basin with additional water until it is approximately one inch from

the top lid.

4. Plug-in the dispenser and wait approximately 15 minutes for the water to

heat to the proper temperature.

5. The dispenser is now ready for use. (refer to the section on normal use.)

NORMAL USE

CAUTION - Water dispensed from this faucet is extremely hot . (Above 200° F.)

1. Hold open the faucet whenever a cup of hot water is desired.

2. Pour another full pitcher into the top whenever water is no longer available

at the faucet. No wait is needed, the faucet is ready to dispense another cup

of hot water.

NOTE - Due to the tank capacity and heater size, this product should be used

only for dispensing a few cups of hot water at a time. (Larger capacity

Bunn-O-Matic hot water dispensers are available.)

7

HW2

OHW

46819 043012

Page 8

OPERATING CONTROLS - PORTION CONTROL ONLY

(a) VOLUME SELECTOR BUTTONS

Press and release the button corre-

sponding to the Small, Medium, or

Large volume, to select the desired

amount of water to be dispensed.

Pressing a different button after a

cycle has been initiated does not

change the volume in progress.

(b) AUTO STOP/MANUAL DISPENSE

BUTTON

Press and release button to stop a

dispense cycle. Press and hold button

to dispense manually.

(c) HIDDEN PROGRAMMING BUTTON

(d) LED INDICATORS

(e) DISPENSE NOZZLE

c.

a.

d.

b.

e.

ADJUSTING DISPENSE VOLUMES

NOTE: The dispenser should be at operating temperature before setting dispense volumes.

1. Press and hold the hidden programming button (c) located under the ® next to the BUNN logo on the front

of the dispenser until the 3 LED's begin flashing from the left to the right. Release the button.

2. Place an empty graduated container under the dispense nozzle (e).

3. Press and release the batch size to be set (a). The LED's will stop flashing, and the LED over the button just

pressed will come on steady. Water will begin to dispense into the container.

4. When the desired amount of water is dispensed, press and release the same button (a). The water will stop

dispensing and the batch size is now set.

5. The LED's will begin flashing from left to right again. Repeat steps 2 thru 4 to set up the other batch sizes.

6. To exit the programming set up at any time, press and release the hidden button once (c). The dispenser is

now ready for use.

8

46819 043012

Page 9

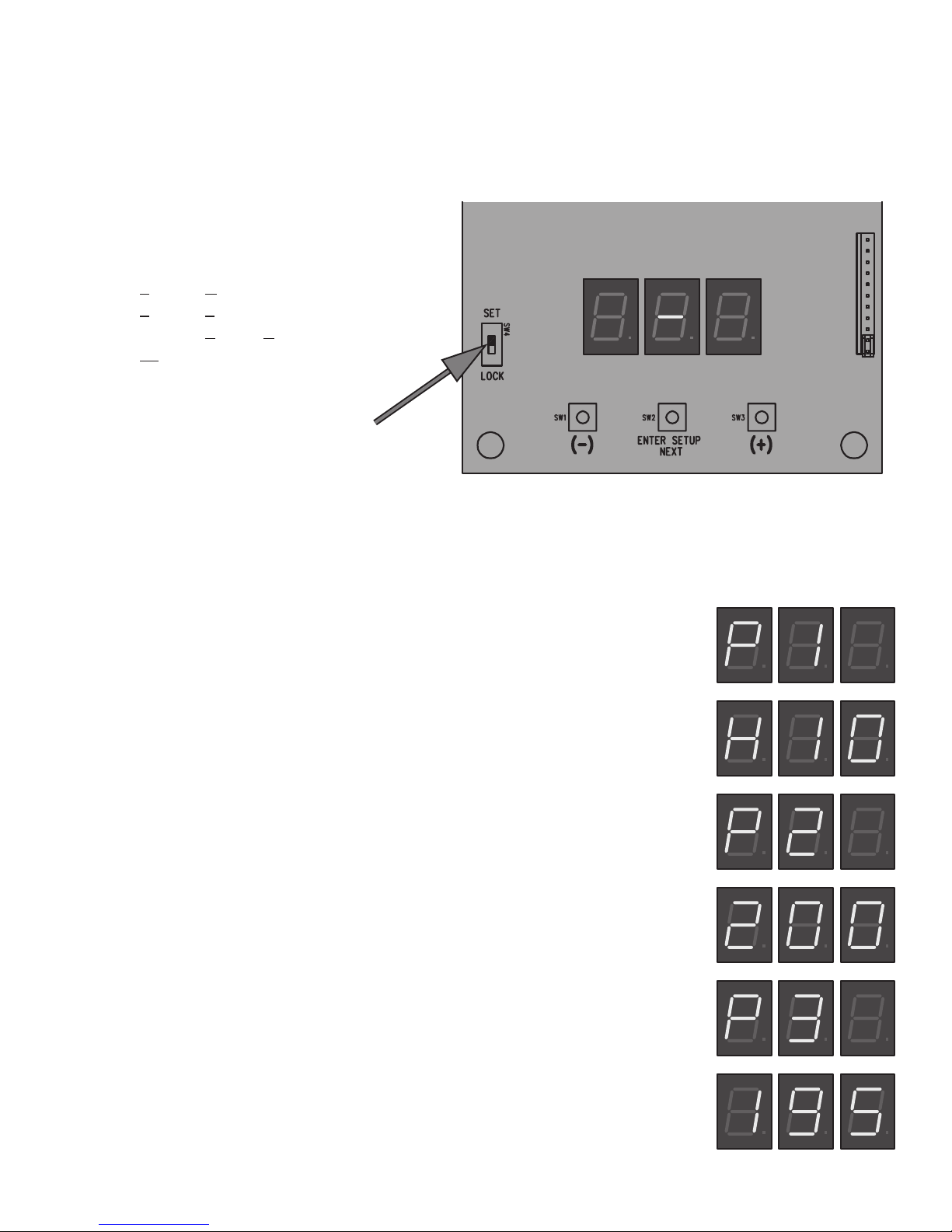

PROGRAMMING - H5-E, H5-PC, H5X, H10X

When power is applied to the dispenser, the display located on the bottom of the main circuit board will show

the software version for 5 seconds, and then it will show the model number (see chart below) it will then go

to (-). While the tank is filling, the display will read (FIL). When the tank is full the display will show the model

number and then go to (-).

MODEL DISPLAYS (P1)

(H5H) 5 Gallon High Voltage Unit (200-240V)

(H5L) 5 Gallon Low Voltage Unit (100-120V)

(HPC) 5 Gallon Portion Control Unit (all)

(H10) 10X (all)

Switch must be in “SET” position for

access into programming modes.

LEFT

BUTTON

CENTER

BUTTON

LEVEL 1 PROGRAMMING

1. Before programming any settings into the Control Board, confirm the correct model

number is entered.

2. Do this by pressing and holding down on the center button until P1 appears on the

display. Release the center button. The display will now show the model number

(ex: H5H). Now scroll with the

the display matches the model you are working with.

3. Press and release the center button once more. The display will show P2. Display

will now show the tank temperature (ex: 200).

temperature set point, or the (-) button to decrease the set point.

NOTE: If the unit is a H5X or H10X, set the Tank Temperature to 212°F.

4. After the Tank Temperature is entered, press and release the center button once

more. The display will read P3, then show the ready temperature set point. Factory

default is 195° F for most dispensers, and 85° F for some.

5. Press the (+) button to increase the set point, or the (-) button to decrease the set

point.

6. To exit Level 1 Program press and release the center button once more. The display

will show Software version, then model number, then (-).

(+/-) buttons

through the models listed above until

Press the (+) button to increase the

RIGHT

BUTTON

Continued

9

46819 043012

Page 10

PROGRAMMING - H5-E, H5-PC, H5X, H10X Continued

LEVEL 2 PROGRAMMING

H1 - DISPENSE TEMPERATURE LOCKOUT - PORTION CONTROL ONLY

(WILL NOT DISPLAY ON OTHER MODELS)

1. To enter Level 2 Programming, press and hold the center button until H1 appears on the display (approximately 6 seconds) then release button. The display

will either read noL (LOCKOUT DISABLED) or Loc (LOCKOUT ENABLED). When

(ENABLED), unit will not dispense if the Tank Temperature is below the (READY)

temperature setting.

2. Use the (+) or (-) buttons to alternate between Loc and noL.

3. Press and release the center button once more to advance to H2.

Or to exit Level 2, press and release the center button 3 times. Display will show,

software version, then model number, then (-).

H2 - F° OR C° SELECTION

NOTE: Skip step 1 if going from H1 to H2.

1. To enter Level 2 Programming, press and hold the center button until H2 appears

on the display (approximately 6 seconds). Release the center button, The display

will show either FAH (Degrees in Fahrenheit) or CEn (Degrees in Centigrade).

2. Press and release the (+) or (-) buttons to alternate between FAH and CEn.

3. After setting FAH or CEn, to exit Level 2 Programming, press and release the center

button twice. Display will show, software version, then model number, then (-).

H3 - RESTORING FACTORY DEFAULTS

1. To restore Factory Defaults (This clears all settings that were previously entered),

press and release the center button until H2 appears on the display (approximately

6 seconds). Release the Center Button, then press and release the Center Button

once more. The display will read H3, then show (- - -).

2. Press and hold both (+) and (-) buttons to initiate the resetting of the factory

default settings. The display (- - -) will flash on and off during this time (about 5

to 7 seconds).

3. When the factory default numbers are loaded in, the display will stop flashing,

then read don (DONE). You can now release the two buttons.

NOTE: If you release the two buttons at any time before the display reads don, the Factory Default numbers will not be entered. The old numbers will remain in the memory.

4. To exit Level 2 Programming press and release the center button once more. The display will show the

Software version, then model number, then (-).

10

46819 043012

Page 11

PROGRAMMING - H5-ELEMENT

Adjusting temperature:

The switch must be in the “SET” position in order to

access the program modes.

1. Press and hold “TEMP” button until display

flashes.

2. While display is flashing, press and release the

(+) to increase or (-) to decrease temperature.

NOTE: (Starting with software version 0.06)

If unit is “E” model, temp will stop at 210°F (99°C).

If unit is “X” model, temp display will jump from

210°F (99°C) to 212°F (100°C).

Refer to chart on page 3 and adjust temperature

requirements according to altitude.

Program lockout switch:

The switch must be in the “SET” position in order to

access the program modes.

1. Disconnect the dispenser from the power source.

2. Remove the 4-40 screws and the top cover.

3. Use a small screwdriver to move switch to set

position.

4. Install top cover, connect dispenser to power

source.

Manual Energy Saver Mode:

The energy save mode will allow the tank temperature

to drop down to 140°F (60°C).

1. Simultaneously press and release the (+) and (-)

to “manually” activate energy save mode.

2. The display will alternately flash between 140

and the current temperature to indicate it is in

the energy save mode.

3. Repeat procedure to exit energy save mode.

Step forward

READY / PRÊT

TEMP

LOCK

SET

ENERGY SAVER MODE

ÉCONOMISEUR D’ÉNERGIE

CAUTIONWARNING

Hot Water Eau Chaude

Step backward

Programming the dispenser:

1. Press and hold upper hidden button (bottom

center of “BUNN” logo) until “P1” is displayed.

Continued

11

46819 061212

Page 12

PROGRAMMING - H5-ELEMENT Continued

2. The display will now show the model number.

(H5H) 5 Gallon High Voltage Unit (200-240V)

(H5L) 5 Gallon Low Voltage Unit (100-120V)

Now scroll with the

matches the model you are working with.

3. Press and release the upper hidden button once more. The display will show P2.

Display will now show the “SET” temperature (ex: 200).

increase the temperature set point, or the (-) button to decrease the set point.

Range: 60°F (15°C) to 210°F (99°) NOTE: Temp will skip to 212°F (100°C) on H5X.

(+/-) buttons

through the models listed above until the display

Press the (+) button to

4. After the Tank Temperature is entered, press and release the

upper hidden

button

once more. The display will read P3, then show the ready temperature set point.

Range: 2° to 20° below the “SET” temperature.

5. Press the (+) button to increase, or the (-) button to decrease the set point.

6. Press and release the

upper hidden

button once more. The display will read P4.

This screen will allow you to turn the “Auto” energy save mode ON/OFF.

NOTE: Turning off this function will disable “P5” and “P6”.

7. Press and release the

upper hidden

button once more. The display will read P5.

This will toggle the energy save mode from 140°F (60°C) or tank heater “OFF”.

8. Press and release the

upper hidden

button once more. The display will read P6.

This is the time delay from the last refill to the activation of energy save mode.

Range: 4 hours to 24 hours.

Continued

12

46819 043012

Page 13

PROGRAMMING - H5-ELEMENT Continued

LEVEL 2 PROGRAMMING

H2 - F° OR C° SELECTION

1. To enter Level 2 Programming, press and hold the

appears on the display. Release the

upper hidden

upper hidden

button until H2

button. The display will show

either FAH (Degrees in Fahrenheit) or CEn (Degrees in Centigrade).

2. Press and release the (+) or (-) buttons to alternate between FAH and CEn.

3. After setting FAH or CEn, to exit Level 2 Programming, press and release the

hidden

button twice. Display will show, software version, then main screen.

upper

H3 - RESTORING FACTORY DEFAULTS

1. To restore Factory Defaults (This clears all settings that were previously entered),

press and release the

proximately 6 seconds). Release the

the

upper hidden

upper hidden

button until H2 appears on the display (ap-

upper hidden

Button, then press and release

Button once more. The display will read H3, then show (- - -).

2. Press and hold both (+) and (-) buttons to initiate the resetting of the factory

default settings. The display (- - -) will flash on and off during this time.

3. When the factory default numbers are loaded in, the display will stop flashing,

then read don (DONE). You can now release the two buttons.

NOTE: If you release the two buttons at any time before the display reads don, the Factory Default numbers will not be entered. The old numbers will remain in the memory.

13

46819 043012

Page 14

DRAINING THE DISPENSER - OHW

CAUTION - The dispenser must be disconnected from the power source throughout these steps.

1. Disconnect the dispenser from the power source and allow dispenser to cool.

2. Tilt dispenser forward over sink.

3. Open faucet.

4. Continue tilting dispenser forward over sink until water stops flowing.

NOTE - The dispenser must be full using the INITIAL SET-UP steps before reconnecting to the power source.

DRAINING THE DISPENSER - ALL 2, 5 & 10 GALLON MODELS

CAUTION - The dispenser must be disconnected from the power source throughout these steps.

1. Disconnect the dispenser from the power source.

2. Shut-off and disconnect the incoming water supply and allow dispenser to cool.

3. Remove the 4-40 screws and the top cover.

4. Gently remove one of the grommets from the tank lid.

5. Insert a tube to the bottom of the tank and syphon ALL of the water out.

CLEANING

The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all

surfaces on Bunn-O-Matic equipment.

WALL MOUNTED INSTALLATION - 5 GALLON MODELS ONLY

If the dispenser is wall mounted, the bottom of the dispenser should be at the same height as a counter or

table top. Use B.O.M. part #12542.0000 for side mounted Wall Bracket Kit or # 13125.0001 for front mounted

Wall Bracket Kit .

SUPPORT FOR LARGE RECEPTACLES

CAUTION: If the dispenser is to be used with larger receptacles such as pitchers or pots, those receptacles must

be adequately supported during dispensing of hot water to avoid spillage of very hot water. This support may be

provided by a table or counter top, or use B.O.M. part #12599.0000 Shelf Kit.

14

46819 043012

Page 15

46819 043012

14

système de tablettes B.O.M. pièce nº 12599.0000.

déversement. Pour ce faire, ils peuvent être déposés sur un comptoir ou une table, ou vous pouvez utiliser le

derniers doivent être maintenus en place pendant le remplissage en eau chaude pour éviter tout incident de

ATTENTION ! Si le distributeur doit servir à remplir de grands récipients comme des pichets ou des pots, ces

SUPPORT POUR GRANDS RÉCIPIENTS

frontal nº 13125.0001.

table. Utilisez la trousse de support mural latéral B.O.M. pièce nº 12542.0000, ou la trousse de support mural

Si le distributeur est fixé au mur, le dessous du distributeur doit être au même niveau qu’un comptoir ou une

INSTALLATION MURALE - MODÈLES 5 GALLONS SEULEMENT

toutes les surfaces des appareils Bunn-O-Matic.

L’usage d’un linge humide rincé dans un détergent liquide doux non abrasif est recommandé pour nettoyer

NETTOYAGE

5. Insérez un tube au fond du réservoir et siphonnez-y TOUTE l’eau.

4. Enlevez délicatement une des viroles du couvercle du réservoir.

3. Retirez les 4 vis nº 40 et le couvercle supérieur.

2. Coupez l’alimentation en eau, débranchez la conduite et laissez refroidir le distributeur.

1. Débranchez le distributeur de la prise de courant.

ATTENTION ! Le distributeur doit être débranché de la prise de courant pendant toutes ces étapes.

VIDANGE DU DISTRIBUTEUR- TOUS LES MODÈLES 2, 5 ET 10 GALLON

de courant.

NOTE : Le distributeur doit être rempli en suivant les étapes du Réglage initial avant d’être rebranché à la prise

4. Inclinez davantage le distributeur au-dessus de l’évier pour le vider complètement de son contenu.

3. Ouvrez le robinet.

2. Inclinez le distributeur au-dessus d’un évier.

1. Débranchez le distributeur de la prise de courant et laissez refroidir le distributeur.

ATTENTION ! Le distributeur doit être débranché de la prise de courant pendant toutes ces étapes.

VIDANGE DU DISTRIBUTEUR - MODÈLE OHW

Page 16

46819 043012

13

vous aurez entré seront celles qui sont conservées en mémoire.

n’affiche don (FAIT), les réglages par défaut ne seront pas restaurés. Les valeurs que

NOTE : Si vous relâchez les deux touches à n’importe quel moment avant que l’écran

clignoter, puis indiquera don (FAIT). Vous pouvez alors relâcher les deux touches.

3. Lorsque les réglages en usine par défaut seront mémorisés, l’écran cessera de

clignotant.

lancer la restauration des réglages par défaut. L’écran indiquera alors (- - -) en

2. Appuyez sur (+) et sur (-) simultanément et tenez les touches enfoncées pour

s’affiche, et après l’écran affichera (- - -).

de nouveau sur la touche dissimulée supérieure et relâchez-la jusqu’à ce que H3

jusqu’à ce que H2 s’affiche (environ 6 secondes). Relâchez la touche, puis appuyez

réglages que vous venez d’effectuer), appuyez sur la touche dissimulée supérieure

1. Pour restaurer les valeurs par défaut (cela a pour effet de remettre à zéro tous les

affichera la version du logiciel, puis reviendra à l’écran principal.

dissimulée deux fois pour quitter le mode de programmation de niveau 2. L’écran

3. Après avoir réglé soit FAH soit CEn, appuyez et relâchez la touche supérieure

et CEn.

2. Appuyez sur (+) ou sur (-) et relâchez la touche pour afficher en alternance FAH

la touche. L’écran affichera soit FAH (degrés Fahrenheit) ou CEn (degrés Celsius).

dissimulée supérieure et tenez-la enfoncée jusqu’à ce que H2 s’affiche, puis relâchez

1. Pour accéder au mode de programmation de niveau 2, appuyez sur la touche

H2 – CHOIX ENTRE °F ET °C

POGRAMMATION DE NIVEAU 2

PROGRAMMATION - MODÈLE H5-ELEMENT Suite

Page 17

46819 043012

12

Voir page suivante

l’activation du mode d’économie d’énergie. Valeurs de réglage : entre 4 et 24 heures.

P6. Cela représente le délai de temporisation entre le plus récent remplissage et

8. Appuyez sur la touche dissimulée encore une fois et relâchez-la. L’écran affichera

(60°C), soit mettre l’élément chauffant à la position « ARRÊT ».

P5. Vous pourrez alors soit mettre l’appareil en mode d’économie d’énergie à 140°F

7. Appuyez sur la touche dissimulée encore une fois et relâchez-la. L’écran affichera

et de P6.

NOTE: En mettant cette fonction hors tension, vous désactiverez les valeurs de P5

d’énergie automatique.

P4. Vous pourrez alors mettre sous tension ou hors tension le mode d’économie

6. Appuyez sur la touche dissimulée encore une fois et relâchez-la. L’écran affichera

préréglée.

5. Appuyez sur la touche (+) pour augmenter, ou sur (-) pour réduire, la température

préréglée. Valeurs de réglage : entre 2 °F et 20 °F sous la température préréglée.

supérieure dissimulée. L’écran affichera P3, puis la température de distribution

4. Après avoir réglé la température du réservoir, appuyez de nouveau sur la touche

passera à 212 °F (100 °C) sur les modèles H5X.

Valeurs de réglage : entre 60 °F (15 °C) et 210 °F (99 °C). NOTE : La température

(+) pour augmenter le réglage de la température, ou sur (-) pour la réduire.

L’écran affichera P2, puis la température préréglée (ex. : 200). Appuyez sur la touche

3. Appuyez sur la touche dissimulée encore une fois et relâchez-la.

ce que vous atteigniez le numéro de modèle de votre appareil.

Faites défiler les modèles indiqués ci-dessus à l’aide des touches (+/-) jusqu’à

(H5L) Unité de 5 gallons à basse tension (100-120 V)

(H5H) Unité de 5 gallons à haute tension (200-240 V)

2. L’écran affichera le numéro de modèle.

PROGRAMMATION - MODÈLE H5-ELEMENT suite

Page 18

46819 061212

logo « BUNN ») jusqu’à ce que P1 s’affiche.

tenez-la enfoncée (partie du centre inférieur du

Hot Water Eau Chaude

CAUTIONWARNING

ÉCONOMISEUR D’ÉNERGIE

ENERGY SAVER MODE

11

Suite

LOCK

SET

1. Appuyez sur la touche dissimulée supérieure et

Programmation du distributeur :

Pour revenir en arrière

TEMP

READY / PRÊT

Pour avancer

d’économie d’énergie.

3. Répétez la procédure pour quitter le mode

est entré en mode d’économie d’énergie.

pérature réelle du réservoir pour indiquer qu’il

2. L’écran affichera par alternance 140 et la temle mode d’économie d’énergie.

relâchez-les touches pour lancer manuellement

1. Appuyez sur (+) et sur (-) simultanément et

de réduire sa température à 140 °F (60 °C).

Le mode d’économie d’énergie permet au réservoir

Mode manuel d’économie d’énergie :

rebranchez l’appareil.

4. Remettez en place le couvercle supérieur et

à la position « RÉGLAGE ».

3. À l’aide d’un petit tournevis, mettez l’interrupteur

2. Enlevez les quatre vis no 40 du couvercle supérieur.

1. Débranchez l’appareil de la prise de courant.

accéder au mode de programmation.

L’interrupteur doit être à la position « RÉGLAGE » pour

Verrou de programmation :

pour régler la température selon l’altitude.

Consultez les valeurs du tableau de la page 3

passera de 210 °F (99 °C) à 212 °F (100 °C).

s’agit d’un modèle « X », la température affichée

maximale sera de 210 °F (99°C); si au contraire il

Si l’appareil est de modèle « E », la température

NOTE : (logiciel version 0.06 et suivantes)

réduire.

touche, ou appuyez sur (-) et relâchez-la pour la

pour augmenter la température, puis relâchez la

2. Pendant que l’écran clignote, appuyez sur (+)

jusqu’à ce que l’écran clignote.

1. Appuyez sur la touche « TEMP » et relâchez-la

accéder au mode de programmation.

L’interrupteur doit être à la position « RÉGLAGE » pour

Réglage de la température :

PROGRAMMATION

Page 19

46819 043012

10

L’écran affichera la version du logiciel et le numéro de modèle, puis (-).

4. Pour quitter la programmation de niveau 2, appuyez de nouveau sur le bouton du centre et relâchez-le.

effectués par après.

par défaut en usine ne seront pas restaurés. Les valeurs en mémoire seront les réglages

NOTE : Si vous relâchez les deux boutons avant que l’écran n’affiche don, les réglages

clignoter, puis affichera don (FAIT). Vous pouvez relâcher les deux boutons.

3. Lorsque les réglages par défaut en usine auront été effectués, l’écran cessera de

usine. L’écran (- - -) clignotera pendant ce temps (environ 5 à 7 secondes).

2. Tenez enfoncés les deux boutons (+) ou (-) pour lancer le réglage par défaut en

qui s’affichera est H3, puis (- - -).

le bouton, puis appuyez de nouveau sur le bouton du centre et relâchez-le. L’écran

relâchez-le jusqu’à ce que H2 apparaisse à l’écran (environ 6 secondes). Relâchez

tous les réglages effectués manuellement), appuyez sur le bouton du centre et

1. Pour restaurer les réglages par défaut en usine (cela a pour effet de supprimer

H3 - RESTAURER LES RÉGLAGES PAR DÉFAUT EN USINE

affichera la version du logiciel et le numéro de modèle, puis (-).

mation de niveau 2, appuyez sur le bouton du centre et relâchez-le 2 fois. L’écran

3. Après avoir réglé le choix d’affichage de la température, pour quitter la program-

Farenheit (FAH) et Celsius (CEn).

2. Appuyez sur les boutons (+) ou (-) et relâchez-les pour alterner entre les degrés

affichera soit FAH (degrés Farenheit), soit CEn (degrés Celsius).

jusqu’à ce que H2 apparaisse à l’écran (environ 6 secondes) et relâchez-le. L’écran

1. Pour accéder à la programmation de niveau 2, tenez enfoncé le bouton du centre

NOTE : Omettez l’étape 1 si vous passez de H1 à H2.

H2 - SÉLECTION DE LA TEMPÉRATURE EN ºF OU EN ºC

puis (-).

relâchez-le 3 fois. L’écran affichera la version du logiciel et le numéro de modèle,

Pour quitter la programmation de niveau 2, appuyez sur le bouton du centre et

3. Appuyez de nouveau sur le bouton du centre et relâchez-le pour accéder à l’écran H2.

2. Utilisez les boutons (+) et (-) pour alterner entre Loc et noL.

préréglée.

fera si la température du réservoir est en dessous de la température de distribution

ACTIVÉ). Lorsque le verrouillage est en mode ACTIVÉ, aucune distribution ne se

L’écran affichera soit noL (VERROUILLAGE DÉSACTIVÉ), soit Loc (VERROUILLAGE

tre jusqu’à ce que H1 apparaisse à l’écran (environ 6 secondes) et relâchez-le.

1. Pour accéder à la programmation de niveau 2, tenez enfoncé le bouton du cen-

(NE S’AFFICHERA PAS SUR LES AUTRES MODÈLES)

MODÈLES À CONTRÔLE DES PORTIONS UNIQUEMENT

H1 - VERROUILLAGE DE LA TEMPÉRATURE DE DISTRIBUTION :

PROGRAMMATION DE NIVEAU 2

PROGRAMMATION - MODÈLES H5-E, H5-PC, H5X, H10X Suite

Page 20

46819 043012

9

Suite

modèle, et finalement (-).

centre et relâchez-le. L’écran affichera la version du logiciel, puis le numéro de

6. Pour quitter la programmation de niveau 1, appuyez de nouveau sur le bouton du

5. Appuyez sur (+) pour augmenter la valeur ou sur (-) pour la réduire.

195 ºF, et 85 ºF sur certains autres.

réglée. La température réglée par défaut en usine sur la plupart des modèles est

du centre et relâchez-le. L’écran affichera P3, puis la température de distribution

4. Lorsque la température du réservoir est réglée, appuyez de nouveau sur le bouton

réservoir à 212 ºF.

NOTE : Si le modèle de l’appareil est H5X ou H10X, réglez la température du

la réduire.

Appuyez sur le bouton (+) pour augmenter la température ou sur le bouton (-) pour

L’écran affichera maintenant la température de l’eau dans le réservoir (ex. : 200).

3. Appuyez sur le bouton du centre encore une fois et relâchez-le. L’écran affichera P2.

jusqu’à ce que vous atteigniez le modèle de votre appareil.

l’aide des boutons (+) et (-), faites défiler la liste des modèles énumérés ci-dessus

Relâche le bouton du centre. L’écran affichera le numéro de modèle (ex. : H5H). À

2. Pour cela, tenez enfoncé le bouton du centre jusqu’à ce que P1 s’affiche sur l’écran.

de modèle du distributeur.

1. Avant d’effectuer quelconque réglage au panneau de commande, confirmez le numéro

DROITE

BOUTON

CENTRE

BOUTON

GAUCHE

BOUTON

PROGRAMMATION DE NIVEAU 1

fonctions de programmation.

« RÉGLAGE » pour accéder aux

L’interrupteur doit être à la position

(H10) 10X (tous les modèles)

gallons (tous les modèles)

(HPC) Appareil à contrôle de portions de 5

(100-120 V)

(H5L) Appareil à basse tension de 5 gallons

(200-240 V)

(H5H) Appareil à haute tension de 5 gallons

AFFICHAGE DES MODÈLES (P1)

numéro de modèle, puis (-).

affichera (-). Pendant le remplissage du réservoir, l’écran affichera (FIL). Lorsqu’il sera plein, l’écran affichera le

la version du logiciel pendant 5 secondes, puis le numéro du modèle (voir liste ci-dessous), et finalement il

En mettant le distributeur sous tension, l’écran situé au bas du circuit électronique principal affichera d’abord

PROGRAMMATION - MODÈLES H5-E, H5-PC, H5X, H10X

Page 21

46819 043012

8

une seule fois. Le distributeur est prêt à être mis en service.

6. Pour quitter le mode de programmation en tout temps, appuyez sur le bouton dissimulé (c) et relâchez-le

formats restants.

5. Les voyants DEL recommenceront à clignoter de gauche à droite. Répétez les étapes 2 à 4 pour régler les

La distribution de l’eau cessera et le volume de distribution sera réglé.

4. Lorsque la quantité d’eau voulue aura été versée, appuyez sur le même bouton (a) de nouveau et relâchez-le.

couler dans le contenant.

clignoter et celui qui correspond au bouton qui vient d’être appuyé s’allumera en continu. L’eau se mettra à

3. Appuyez sur un des trois boutons de sélection de volume (a) et relâchez-le. Les voyants DEL cesseront de

2. Placez un contenant gradué vide sous le déversoir (e).

distributeur jusqu’à ce que les trois voyants DEL clignotent de la gauche vers la droite. Relâchez le bouton.

1. Tenez enfoncé le bouton dissimulé (c) situé sous le symbole ® à côté du logo BUNN sur la façade du

NOTE : Le distributeur doit préalablement être à la température de distribution.

RÉGLAGE DES VOLUMES DE DISTRIBUTION

e.

b.

c.

a.

(e) DÉVERSOIR

(d) VOYANTS DEL

DISSIMULÉ

(c) BOUTON DE PROGRAMMATION

pour lancer la distribution manuelle.

bution. Maintenez le bouton enfoncé

pour mettre fin à un cycle de distri-

Appuyez sur le bouton et relâchez-le

MANUELLE

BOUTON DE DISTRIBUTION

(b) BOUTON D’ARRÊT AUTOMATIQUE /

effet de changer le volume en cours.

lancé un cycle, cela n’aura pas pour

puyez sur un autre bouton après avoir

ou grand et relâchez-le. Si vous aprespondant au volume petit, moyen

distribuer, appuyez sur le bouton cor-

Pour sélectionner la quantité d’eau à

(a) BOUTONS DE SÉLECTION DE VOLUME

d.

COMMANDES DE FONCTIONNEMENT - MODÈLES À CONTRÔLE DES PORTIONS

Page 22

46819 043012

OHW

HW2

7

Bunn-O-Matic.)

fois. (Notez que d’autres distributeurs de plus grande capacité sont offerts par

distributeur doit servir pour verser que quelques tasses d’eau chaude à la

NOTE : En raison de la capacité de son réservoir et de son élément chauffant, ce

une autre tasse d’eau chaude.

d’attendre que l’eau se réchauffe : le distributeur est toujours prêt à servir

fois que l’eau ne s’écoule plus du robinet. Il n’est pas nécessaire

2. Versez un pichet d’eau dans la partie supérieure du distributeur chaque

1. Ouvrez le robinet et tenez-le ouvert pour distribuer de l’eau chaude.

delà de 200 °F / 93.3 °C).

ATTENTION ! L’eau distribuée par cet appareil est extrêmement chaude (au-

USAGE NORMAL

de l’usage normal de l’appareil.)

5. Le distributeur est maintenant prêt à utiliser. (Référez-vous à la section qui traite

à la bonne température.

4. Branchez le distributeur et attendez environ 15 minutes pour que l’eau se réchauffe

environ un pouce (2.54 cm) sous le couvercle supérieur.

3. Remplissez encore le bassin supérieur d’eau jusqu’à ce que le niveau atteigne

commence à s’en écouler

2. Versez le contenu d’un deuxième pichet d’eau. Fermez le robinet lorsque l’eau

s’échapper du réservoir lors du remplissage.

le distributeur. Maintenez la poignée du robinet ouverte pour permettre à l’air de

versez le contenant d’un pichet rempli d’eau du robinet (64 oz / 1.9 litres) dans

1. Placez un contenant vide sous le robinet, soulevez le couvercle du verseur et

l’étape du réglage initial, sauf s’il y a des instructions contraires à cet effet.

ATTENTION ! Le distributeur doit demeurer débranché de la prise de courant à

H5M

RÉGLAGE INITIAL - MODÈLE OHW

du réservoir se réchauffe. Le distributeur est prêt à l’emploi.

5. Mettez le distributeur sous tension et attentez environ 20 minutes pour que l’eau

la position MARCHE, puis remettez le panneau en place.

et tournez le bouton du thermostat dans le sens des aiguilles d’une montre jusqu’à

4. Débranchez le distributeur de la prise de courant, retirez le panneau arrière central

fant se mettra alors en marche automatiquement.

3. L’eau s’écoulera dans le réservoir et s’arrêtera lorsqu’il sera plein. L’élément chauf-

2. Mettez le distributeur sous tension.

le panneau.

contraire des aiguilles d’une montre jusqu’à la position ARRÊT. Remettez en place

1. Retirez le panneau arrière central et tournez le bouton du thermostat dans le sens

la durée du réglage initial, sauf lorsque les instructions spécifient le contraire.

ATTENTION ! Le distributeur doit être débranché de la prise de courant pendant toute

RÉGLAGE INITIAL - MODÈLE HW2

qui en sont munis s’allumera.

5. Lorsque l’eau sera à la température idéale, le voyant sur les modèles de distributeurs

du réservoir se réchauffe.

4. Mettez le distributeur sous tension et attentez environ 20 minutes pour que l’eau

la position MARCHE, puis remettez le panneau en place.

et tournez le bouton du thermostat dans le sens des aiguilles d’une montre jusqu’à

3. Débranchez le distributeur de la prise de courant, retirez le panneau arrière supérieur

environ 10 minutes.

L’eau s’écoulera dans le réservoir et s’arrêtera lorsqu’il sera plein. Cela prendra

2. Branchez le distributeur dans la prise de courant et ouvrez l’alimentation d’eau.

place le panneau.

sens contraire des aiguilles d’une montre jusqu’à la position ARRÊT. Remettez en

1. Retirez le panneau arrière supérieur et tournez le bouton du thermostat dans le

la durée du réglage initial, sauf lorsque les instructions spécifient le contraire.

ATTENTION ! Le distributeur doit être débranché de la prise de courant pendant toute

RÉGLAGE INITIAL - MODÈLE H5M

Page 23

46819 043012

6

distribution.

5. Référez-vous à la section Programmation pour régler la température du réservoir et la température de

4. L’eau du réservoir se réchauffera à la température prédéterminée.

marche automatiquement.

3. L’eau s’écoulera dans le réservoir et s’arrêtera lorsqu’il sera plein. L’élément chauffant se mettra alors en

secondes, puis il affiche la température.

affichage) En mettant le distributeur sous tension, l’écran affichera d’abord la version du logiciel pendant 5

2. Mettez l’interrupteur principal à la position MARCHE (s’il y en a un). NOTE : (Les modèles numerique avec

1. Branchez le distributeur dans la prise de courant et ouvrez l’alimentation d’eau.

sauf lorsque les instructions spécifient le contraire.

ATTENTION ! - Le distributeur doit être débranché de la prise de courant pendant toute la durée du réglage initial,

RÉGLAGE INITIAL - MODÈLES H5E, H5X, H5-PC, H10X, Element

Raccordement de la tuyauterie L’interrupteur principal

2. Purgez la conduite d’alimentation en eau et fixez-la solidement au raccord évasé.

avec le distributeur) (le modèle H10X a un raccord évasé sans adapteur).

1. Retirez le capuchon d’expédition du raccord à l’arrière du distributeur et raccordez-y le coude évasé (fourni

Raccordement de la tuyauterie

ailleurs qu’au Canada doivent respecter les codes de plomberie et d’hygiène de la localité.

et des normes de l’Agence canadienne d’inspection des aliments. Les modèles destinés à être installés

Cet équipement doit être installé conformément aux normes du Code national de la plomberie du Canada

forme de l’orifice perforé dans la conduite d’alimentation par ce type de dispositif peut réduire le débit d’eau.

Bunn-O-Matic ne recommande pas d’utiliser un robinet-vanne à étrier pour installer le distributeur. La taille et la

polyéthylène ou en silicone tressé renforcé, permet de déplacer le distributeur pour nettoyer le dessus du comptoir.

Une longueur d’au moins 18 po de tuyau flexible pour boisson approuvé par la FDA américaine, par exemple en

po pour les longueurs de plus de 25 pieds menant à la conduite de ½ po d’alimentation en eau.

et des tuyaux de 3/8

NOTE : Bunn-O-Matic recommande d’utiliser des tuyaux de ¼ po en cuivre pour les longueurs de moins de 25 pieds

(345 kPa). Le raccord d’entrée d’eau est évasé à ¼ po.

2

(620 kPa) pour la réduire à 50 lb/po

2

à 90 lb/po

entre la conduite et le distributeur. Il faut installer un régulateur sur la conduite lorsque la pression est supérieure

(138 et 620 kPa) et passant par une conduite de ½ po ou plus. Un robinet d’arrêt doit être installé

2

20 et 90 lb/po

Le distributeur doit être relié à un système d’alimentation en eau froide utilisant une pression variant entre

TUYAUTERIE - TOUS SAUF OHW

Page 24

46819 043012

5

• L’appareil ne doit pas être nettoyé par immersion.

obtenu du fabricant ou d’un centre autorisé pour éviter tout risque d’accident.

• Si le cordon devenait endommagé, le fabricant ou un réparateur autorisé doit le remplacer par un cordon

• La supervision d’adultes est essentielle pour veiller à ce que les enfants ne jouent pas avec cet appareil.

reçu des instructions d’une personne responsable de sa sécurité à l’égard de l’utilisation de l’appareil.

réduites, ni même par des personnes non expérimentées ou non formées à son utilisation, à moins d’avoir

enfants) dont les capacités physiques, sensorielles ou mentales sont

• Cet appareil n’est pas destiné à être utilisé par des personnes (ni des

• L’appareil ne doit pas être nettoyé par jet d’eau.

codes local et national en vigueur.

• Un électricien doit effectuer l’installation électrique conformément aux

sécuritaire.

• L’appareil ne doit pas être incliné à plus de 10º pour une utilisation

la température varie entre 5ºC et 35ºC.

• Pour fonctionner adéquatement, l’appareil doit être installé dans un lieu où

eillance étroite de personnel qualifié.

• Cet appareil doit être installé dans un endroit où il peut être sous la surv-

NORME EUROPÉENNE (CE)

le distributeur est prêt pour le remplissage et le réchauffage initial.

teur est débranché de la prise de courant. Si la tuyauterie a été raccordée,

BASCULE BITENSION

INTERRUPTEUR À

7. Si la tuyauterie doit être raccordée par la suite, assurez-vous que le distribu-

bloc de jonction. Replacez les deux panneaux arrière.

6. Branchez le distributeur à la prise de courant et vérifiez la tension au

la terre indépendant.

L1 et L2) et un conducteur de mise à

conducteurs sous tension (neutre,

Note: Ce branchement nécessite 3

120/208 et 120/240V c.a.

Modèle monophasé

G

VERT

L1

L1 NOIR

N

BLANCNEUTRE

L2

CORDON D’ALIMENTATION

G

VERT

L1 NOIR

L1

L2

CORDON D’ALIMENTATION

L1 NOIR

NEUTRE

BLANC

L2 ROUGE L2 ROUGE

la terre indépendant.

et L1) et un conducteur de mise à

conducteurs sous tension (neutre

Note: Ce branchement nécessite 2

Modèle 208 et 240 V c.a.

VERT

L1 NOIR

L2 ROUGE L2 ROUGE

CORDON D’ALIMENTATION

la terre indépendant.

et L1) et un conducteur de mise à

conducteurs sous tension (neutre

Note: Ce branchement nécessite 2

Modèle 230 V c.a.

G

L1 NOIR

L1

L2

L1 NOIR

L2 ROUGE L2 ROUGE

G

VERT

L1 NOIR

L1

N

CORDON D’ALIMENTATION

BLANCNEUTRE

5. Raccordez les fils nécessaires au bloc de jonction.

4. Retirez les panneaux supérieur et inférieur arrière (latéral sur modèle H10X).

3. Mettez l’interrupteur principal en position arrêt (le cas échéant).

conducteur à la prise de courant.

2. À l’aide d’un voltmètre, vérifiez la tension et le code-couleur de chaque

1. Un électricien doit effectuer l’installation électrique telle que spécifiée

les composantes électriques.

ATTENTION ! – Une installation électrique inadéquate peut endommager

Branchement électrique

la terre indépendant.

et L1) et un conducteur de mise à

conducteurs sous tension (neutre

Note: Ce branchement nécessite 2

Modèle 120 V c.a.

L1 NOIR

NEUTRE

NOIR

connaître les besoins en alimentation électrique.

Consultez la plaque signalétique de l’appareil ainsi que les codes national et local de l’électricité pour

la section Branchement électrique.

MIS EN GARDE - Le distributeur doit demeurer débranché de la prise de courant jusqu’à indication contraire à

ALIMENTATION ÉLECTRIQUE

Page 25

Artwork for P/N: 00656.7000

Artwork Rev: F

Drawn: RN

Date: 06/27/08

46819 061212

37881.7002

12593.7000

4

00831.0002

00831.0002K 17/11 © 1984 BUNN-O-MATIC CORPORATION

LORSQU'IL N'EST PAS DÉBRANCHÉ.

L' ÉQUIPEMENT EST TOUJOURS SOUS TENSION

OU D'UTILISER LE PRÉSENT PRODUIT.

RESPONSABILITÉS,AVANT D’ACHETER

EN ENTIER, Y COMPRIS LES LIMITES DE GARANTIES ET

VEUILLEZ LIRE LE MANUEL DE FONCTIONEMENT

DANGERS D'INCENDIE OU D'ÉLECTROCUTION.

ENTRAINER DES DOMMAGES À L'ÉQUIPEMENT OU PRODUIRE DES

TOUT MANQUEMENT À SE CONFORMER À CES DIRECTIVES PEUT

• GARDER LES PRODUITS COMBUSTIBLES À DISTANCE.

D'ÉLECTRICITÉ.

• SE CONFORMER AUX CODES NATIONAL OU LOCAL

• NE PAS DÉFORMER LA FICHE OU LE CORDON.

• TOUJOURS METTRE LE BOITIER À LA MASSE.

• NE PAS SURCHARGER LE CIRCUIT.

L'APPAREIL OU DE METTRE LE THERMOSTAT SOUS TENSION.

• REMPLIR LE RÉSERVOIR D'EAU AVANT DE BRANCHER

! AVERTISSEMENT

ELECTRICALLY DISCONNECTED.

THIS EQUIPMENT IS ENERGIZED AT ALL TIMES UNLESS

BUYING OR USING THIS PRODUCT.

THE LIMIT OF WARRANTY AND LIABILITY BEFORE

READ THE ENTIRE OPERATING MANUAL INCLUDING

SHOCK HAZARD.

FAILURE TO COMPLY RISKS EQUIPMENT DAMAGE, FIRE OR

• KEEP COMBUSTIBLES AWAY.

• FOLLOW NATIONAL AND LOCAL ELECTRICAL CODES.

• DO NOT DEFORM PLUG OR CORD.

• ALWAYS ELECTRICALLY GROUND THE CHASSIS.

• DO NOT OVERLOAD CIRCUIT.

ENERGIZING THE THERMOSTAT.

• FILL WATER TANK BEFORE PLUGGING IN UNIT OR

! WARNING

37881.7000

source de courant avant d’effectuer une réparation.

autorisé peut effectuer les réparations. Débrancher de la

l’opérateur à l’intérieur. Seulement le personnel

enlever le panneau. Aucune pièce utile pour

Afin d’éviter un risque d’électrocution, ne pas ouvrir ou

before servicing.

Authorized service personnel only. Disconnect power

open cover. No user-serviceable parts inside.

To reduce the risk of electric shock, do not remove or

WARNING AVERTISSEMENT

44025.7000

CAUTIONWARNING

Hot Water Eau Chaude

ÉCONOMISEUR D’ÉNERGIE

ENERGY SAVER MODE

TEMP

READY / PRÊT

120/208-240V

00831.0000

120V

00656.7000

00833.7001

EAU SEULEMENT

WATER ONLY

plomberie et d’hygiène de la localité.

installés ailleurs qu’au Canada doivent respecter les codes de

sécurité qui s’ appliquent. Les modèles destinés à être

Canadien de plomberie et aux règlements de santé et de

Cet équipement doit être installé conformément au code

applicable Plumbing /Sanitation Code.

For models installed outside Canada, comply with the

Plumbing Codes and applicable health and safety regulations.

This equipment must be installed to comply with Canadian

29710.7018

3-fils relie à la terre, 60HZ

4050 W, Monophasé,

120/208-240 V, 16,9A,

Branchement électrique optionnel

3-Wire + GND, 60HZ

4050 W, 1PH,

120/208-240 V, 16.9A,

Optional Field Wiring

29710.7006

monophase, 3-fils relié à la terre, 60HZ

120/208-240 V, 13-15 A, 2670-3550 W

Branchement électrique optionnel

1PH, 3-Wire + GND, 60HZ

120/208-240 V, 13-15 A, 2670-3550 W

Optional Field Wiring

00657.7002

00824.0002 00824.0001

décalcomanie endommagée ou illisible.

Toutes les décalcomanies de mise en garde doivent être maintenues en bonne condition. Veuillez remplacer toute

AVIS À L’UTILISATEUR

Page 26

46819 043012

-1000 213,8 101,0 20093,3

-500 212,9 100,5 20093,3

0 212,0 100,0 20093,3

500 211,1 99,5 20093,3

1000 210,2 99,0 20093,3

1500 209,3 98,5 20093,3

2000 208,4 98,0 20093,3

2500 207,4 97,4 20093,3

3000 206,5 96,9 19992,8

3500 205,6 96,4 19892,2

4000 204,7 95,9 19791,7

4500 203,8 95,4 19691,1

5000 202,9 94,9 19590,6

5500 201,9 94,4 19590,6

6000 201,0 93,9 19490,0

6500 200,1 93,4 19389,4

7000 199,2 92,9 19288,9

7500 198,3 92,4 19188,3

8000 197,4 91,9 19087,8

8500 196,5 91,4 18987,2

9000 195,5 90,8 18886,7

9500 194,6 90,3 18786,1

10000 193,7 89,8 18685,6

Altitude

(pieds)

Point d’ébullition

de l’eau

° F ° C

Température

recommandée de l’eau

° F ° C

La température de l’eau est réglée en usine à 200

°

F (93,3

°

C). En haute altitude, il s’agira de réduire cette température

de sorte à éviter l’ébullition. Le tableau suivant doit servir de

guide pour ajuster la température de l’eau.

3

CONTENTS

tablette solide.

l’intérieur, soit fixé à un mur (modèles H5E, H5X, H5-PC seulement), soit bien assis sur un comptoir ou sur une

Il est muni d’un écran au-dessus du robinet qui indique l’état du distributeur. Il doit strictement être utilisé à

Cet appareil sert à réchauffer l’eau et à la distribuer sur demande autant pour les boissons que pour cuisiner.

INTRODUCTION

NETTOYAGE ......................................................................................................... 14

VIDANGE DU DISTRIBUTEUR ......................................................................... 14

PROGRAMMATION (H5 ELEMENT) ..................................................................... 11

PROGRAMMATION (H5E, H5X, H5-PC, H10X) ...................................................... 9

RÉGLAGE DES VOLUMES DE DISTRIBUTION (H5-PC SEULEMENT) .................... 8

COMMANDES DE FONCTIONNEMENT (H5-PC SEULEMENT) ................................ 8

RÉGLAGE INITIAL H5M, HW2, OHW ..................................................................... 7

RÉGLAGE INITIAL (H5E, H5X, H5-PC, H5 ELEMENT, H10X) .................................. 6

TUYAUTERIE .......................................................................................................... 6

ALIMENTATION ÉLECTRIQUE ................................................................................ 5

AVIS À L’UTILISATEUR .......................................................................................... 4

INTRODUCTION ..................................................................................................... 3

GARANTIE .............................................................................................................. 2

Page 27

46819 030912

2

Horizontal Red Line, Ultra sont des marques de commerce déposées de Bunn-O-Matic Corporation.

Heating System, Daypart, Digital Brewer Control, Nothing Brews Like a BUNN, Pouring Profits, Signature Series, Tea At Its Best, The

Brew, Air Infusion, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic

The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, Velocity Brew, A Partner You Can Count On, Air

Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard,

PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design,

Clear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew,

BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyGourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic,

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family

DOIVENT-ÊTRE PRÉCÉDEMMENT AUTORISÉS PAR BUNN-O-MATIC ET SONT SUJETS À DES FRAIS DE RETOUR.

COMMUNIQUEZ AVEC BUNN-O-MATIC POUR UNE AUTORISATION DE RETOUR. TOUS LES RETOURS

POLITIQUE DE RETOUR

touts autres dommages-intérêts spéciaux, accessoires, indirects ou punitifs.

des temps d’arrêt, le coût d’appareils de remplacement, de services de remplacement, ou des installations de remplacement, et

profits, les ventes perdues, la perte d’utilisation de l’appareil, les réclamations des clients de l’acheteur, le coût du capital, le coût

En aucun cas Bunn ne sera tenu responsable d’autres dommages ou pertes, y compris, mais sans y être limité à, la perte de

DISCRÉTION DE BUNN.

À LA RÉPARATION, AU REMPLACEMENT, OU AU REMBOURSEMENT DU PRIX D’ACHAT DE L’APPAREIL, À L’ENTIÈRE

VENTE DE CET APPAREIL, QU’IL RELÈVE OU NON DE GARANTIE, SERA LIMITÉ, TEL QUE PRÉCISÉ DANS LA PRÉSENTE,

LE RECOURS DE L’ACHETEUR CONTRE BUNN POUR LA VIOLATION DE TOUTE OBLIGATION DÉCOULANT DE LA

ou rembourser le prix d’achat de l’équipement.

condition que la réparation soit effectuée par un représentant de service autorisé par Bunn; soit 2) remplacer l’équipement

main-d’œuvre (pendant le délai applicable de garantie tel qu’indiqué ci-dessus) pour réparer les composants défectueux, à

exclusive, pendant que l’appareil est sous garantie, devra soit 1) fournir gratuitement des pièces de rechange et / ou de la

Si Bunn détermine à son entière discrétion que l’appareil défectueux est couvert par la garantie, Bunn, à sa discrétion

la responsibilité de Bunn.

Bunn. Ainsi, les déclarations de ces individus, orales comme écrites, ne constituent pas de garanties et n’engagent pas

ne sont pas autorisés à modifier cette garantie ou à apporter des garanties supplémentaires qui engageront ou affecteront

Les agents, concessionnaires ou employés de Bunn

MARCHANDE, OU DE CONFORMITÉ À UN USAGE PARTICULIER.

EXPRESSE OU IMPLICITE, Y COMPRIS MAIS NON LIMITÉE À TOUTE GARANTIE IMPLICITE DE QUALITÉ, DE QUALITÉ

LA GARANTIE CI-DESSUS EST EXCLUSIVE ET REMPLACE TOUTE AUTRE GARANTIE, CONDITION, ÉCRITE OU ORALE,

est sous garantie.

payé, à un centre de service autorisé par Bunn; et 3) reçoive une autorisation préalable de la part de Bunn que l’appareil défectueux

écrit au 280 Industrial Parkway South, Aurora, Ontario L4G 3T9; 2) fasse livrer, à la demande de Bunn, l’appareil défectueux, port

l’acheteur 1) avise Bunn ponctuellement de toute réclamation en vertu de cette garantie par téléphone au (905) 841-2866 ou par

n’est pas limité à des pièces remplaçables par l’utilisateur tels des joints d’étanchéité. Cette garantie est conditionnelle à ce que

remplacement des composantes des appareils devant être remplacées dans le cour normal de leur utilisation; cela comprend mais

d’équipement liées à une eau de mauvaise qualité, à des dommages ou à un accident. En outre, cette garantie ne s’applique pas au

ou un usage impropre, un entretien impropre ou une réparation impropre, un manque de nettoyage et détartrage, des défaillances

été fabriqués par Bunn ou qui, selon Bunn, auraient subi un usage abusif, une négligence, une altération, une installation impropre,

pendant la période couverte par la garantie. Cette garantie ne s’applique pas aux appareils, composants ou pièces qui n’ont pas

affectés d’aucun défaut commercial quant à leur matériel ou leur fabrication, existant au moment de fabrication, et se manifestant

Ces délais de garantie commencent à courir à partir de la date d’installation. Bunn garantit que les appareils fabriqués par elle ne sont

original de l’usine - 4 ans pièces et main-d’œuvre ou 40 000 livres de café, selon la première éventualité.

c) Bavures de mouture sur équipement de moulure de café pour mourde le café afin de répondre à l’analyse de passage au crible

b) Compresseurs inclus dans l’équipement de réfrigération - 5 ans pièces et 1 an main-d’œuvre.

a) Cartes de circuits électroniques et / ou de contrôle - 3 ans pièces et main-d’œuvre.

2) Tout autre appareil - 2 ans pièces et 1 an main-d’œuvre ainsi que les garanties additionnelles indiquées ci-dessous :

et 1 an main-d’œuvre.

nacelle de type MCP/MCA, serveurs thermiques et serveurs de type Thermofresh (mécanique et numérique) - 1 an pièces

1) Cafetières, carafes thermiques, carafes à décanter, serveurs GPR, distributrices de thé glacé / de café glacé, infuseursBunn-O-Matic Corporation of Canada (« Bunn ») garantit les appareils qu’elle fabrique ainsi :

BUNN-O-MATIC GARANTIE DE PRODUIT COMMERCIAL

Page 28

46819.7000A 06/12 © 2012 BUNN-O-MATIC CORPORATION

service technique, contactez la Bunn-O-Matic Corporation, au numéro 1 800-263-2256.

www.bunn.com. Ces manuels sont GRATUITS et le téléchargement des mises à jour est rapide. Pour le

le manuel de programmation ou le manuel d’entretien, visitez le site Internet de Bunn-O-Matic, à l’adresse

Pour obtenir la plus récente version du manuel d’utilisation ou pour visualiser le catalogue illustré de pièces,

TÉLÉPHONE : (905) 841-2866 TÉLÉCOPIEUR : (905) 841-2775

AURORA, ONTARIO, L4G 3T9

280 INDUSTRIAL PARKWAY SOUTH,

BUNN-O-MATIC CORPORATION OF CANADA

MANUEL D’INSTALLATION ET D’UTILISATION

39338.7001; 44306.7000

10420.7000; 10889.7000; 39338.7000

10052.7000; 10010.7000; 10267.0000

Remplace

d’Eau Chaude

Distributeurs

Loading...

Loading...