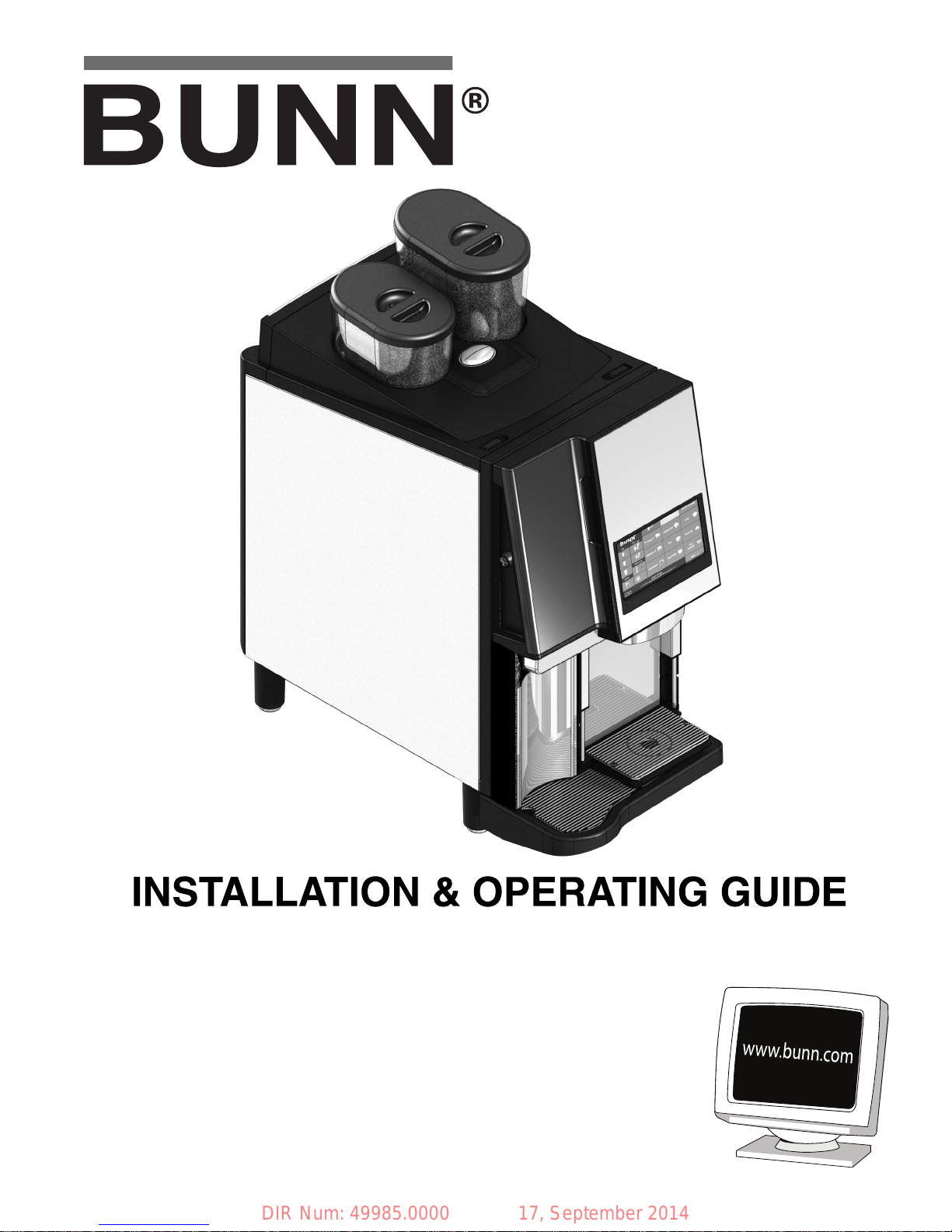

Page 1

RELEASED FOR PRODUCTION

SURE TAMP AUTO

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

PHONE: (217) 529-6601 FAX: (217) 529-6644

49985.0000A 09/14 ©2014 Bunn-O-Matic Corporation

DIR Num: 49985.0000 17, September 2014

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

http://www.bunn.com/espresso/index.html

Page 2

RELEASED FOR PRODUCTION

Bunn-O-Matic® COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants the BUNN Espress®, Espresso Systems as further described below

for a warranty period of 1 year parts and labor.

These warranty periods run from the date of installation. BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component

or part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or operation, improper maintenance or repair, non periodic cleaning and

descaling, equipment failures related to poor water quality, damage or casualty. This warranty is conditioned

on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217)

529-6601 or by writing to Post Offi ce Box 3227, Springfi eld, Illinois 62708-3227; 2) if requested by BUNN,

shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from BUNN that the defective equipment is under warranty. Additionally, the following is excluded

from the warranty period:

Warranty Exclusions:

• Parts such as, but not limited to, hoppers and lids, drip trays, steam wand sheaths, and plastic parts damaged due to improper handling or cleaning agents.

• Replacement of wear items such as, but not limited to, O-rings, gaskets, silicone tubes, hoses, and valve seats.

• Repairs made necessary due to poor water quality such as dispense valves, water inlet valves, scaling in the

steam or hot water boilers. (Total Hardness recommended range of 4-7 gpg constant).

• Improper voltage. (See equipment operations manual for voltage specifi cations).

• Failure to use BUNN approved cleaning supplies constitutes improper maintenance.

• Failure to have required preventive maintenance performed by BUNN technician or authorized espresso service provider.

• Parts replaced under the terms of this warranty carry the remainder on the machine’s parts warranty term, or

60 days, whichever is greater.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not

authorized to make modifi cations to this warranty or to make additional warranties that are binding on BUNN.

Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should

not be relied upon. If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the equipment is under warranty, shall either 1) provide at no charge

replacement parts and/or labor (during the applicable parts and labor warranty periods specifi ed above) to

repair the defective components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND. In no event shall BUNN be

liable for any other damage or loss, including, but not limited to, lost profi ts, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities

or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not

Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic,

BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE

with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear,

EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My

Café, Phase Brew, PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the

stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart

Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, TRIFECTA (sylized logo), Velocity Brew, Air Brew, Beverage Bar Creator,

Beverage Profi t Calculator, Brew better, not bitter., Build-A-Drink, BUNNSource, Coffee At Its Best, Cyclonic

Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN,

Picture Prompted Cleaning, Pouring Profi ts, Signature Series, Sure Tamp, Tea At Its Best, The Horizontal Red

Line, Ultra are either trademarks or registered trademarks of Bunn-O-Matic Corporation. The commercial

trifecta® brewer housing confi guration is a trademark of Bunn-O-Matic Corporation.

DIR Num: 49985.0000 17, September 2014

Page 2

49985 031314

Page 3

RELEASED FOR PRODUCTION

CONTENTS

Site Requirements................................................................................................4

Installation...........................................................................................................5

Operating Controls...............................................................................................6

Operation.............................................................................................................7

Cleaning...............................................................................................................8

Menu Options......................................................................................................9

Troubleshooting.................................................................................................11

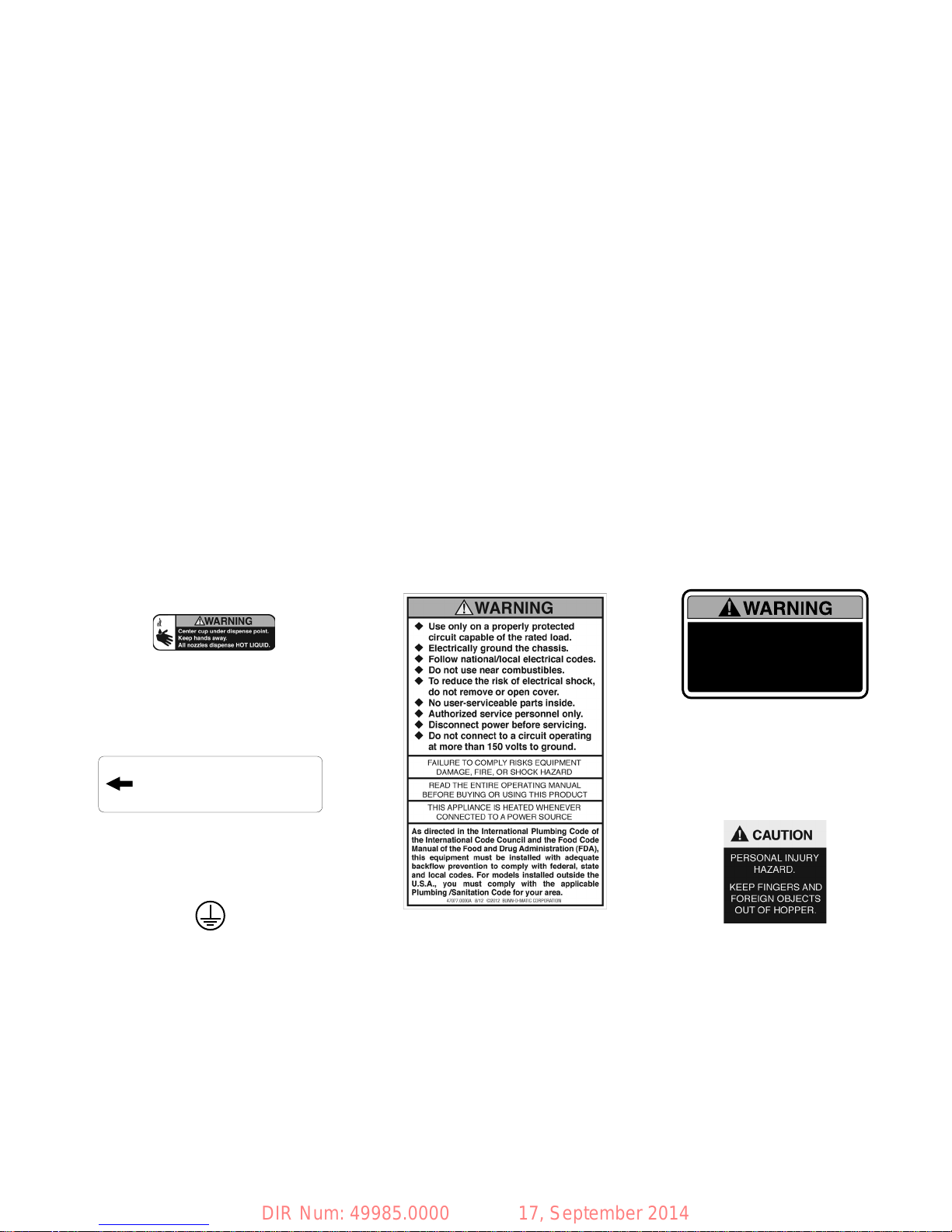

USER NOTICES

Carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should

be kept in good condition. Replace any unreadable or damaged labels.

To reduce the risk of electric shock,

do not remove or open cover.

No user-serviceable parts inside.

#47075.0000

MAIN ON/OFF SWITCH

BEHIND THIS PANEL

#47074.0000

#47077.0000

#00824.0002

Authorized service personnel only.

Disconnect power before servicing.

#37881.0000

#47150.0000

Warnings

• Unplug the machine or turn off the main switch before servicing the interior components of the machine.

• Never operate the machine without water.

• Never touch brew module, spouts, and hot water dispense pipes. They are HOT and could cause burns.

• The machine must be operated with clean water. Make sure to use water fi lters and/or softeners as needed.

DIR Num: 49985.0000 17, September 2014

Page 3

49985 090514

Page 4

RELEASED FOR PRODUCTION

SITE REQUIREMENTS

Plumbing

1. Quick connect assembly with adapter (supplied).

2. 3/8˝ NPT fi tting on water fi lter.

3. These brewers must be connected to a cold water

system with operating pressure between 20 and 90

psi (0.138 and 0.620 MPa) from a 1⁄2" or larger supply line. A shut-off valve should be installed in the line

before the brewer. Install a regulator in the line when

pressure is greater than 90 psi (0.620 MPa) to reduce

it to 50 psi (0.345 MPa).

4. Shut off valve should be present between water

supply and machine.

5. Vented drain available within 3.3 feet (1 meter) of

machine.

6. Flush the water line and securely attach it to the

inlet fi tting at the rear of the brewer.

7. Turn on the water supply.

NOTE - Bunn-O-Matic recommends 1⁄4" copper tub-

ing for installations of less than 25 feet and 3⁄8" for

more than 25 feet from the 1⁄2" water supply line. A

tight coil of copper tubing in the water line will facilitate moving the brewer to clean the counter top.

Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The size and shape of

the hole made in the supply line by this type of device

may restrict water fl ow.

REMOVE/INSTALL PUCK BIN

ater Treatment

W

1. No Chlorine.

2. Water Hardness 3 to 6 grains

3. Water Filtration System

NOTE: The water connections are at the lower rear of

the machine.

Location of the Serial Number

The serial number is located behind the puck bin on

the right wall across from the power switch.

The complete serial number will need to be documented on all work orders and warranty tags.

As directed in the International Plumbing Code

of the International Code Council and the Food

Code Manual of the Food and Drug Administration (FDA), this equipment must be installed with

adequate back fl ow prevention to comply with federal, state and local codes. For models installed

outside the U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

Page 4

POWER SWITCH LOCATION

Optional Under Counter Puck Disposal

NOTE: This will require hole cut through

counter top.

1. Remove puck bin.

2. Remove small cover.

3. Install optional puck bin.

49985 090814

DIR Num: 49985.0000 17, September 2014

Page 5

RELEASED FOR PRODUCTION

SITE REQUIREMENTS

Site Requirements

1. Counter able to support at least 150 pounds (68kg).

2. Counter area large enough for machine and refrigerator.

3. Minimum clearance of 2˝ around machine.

Electrical-SureTamp

1. 208VAC, 2 wires with ground.

2. Dedicated 30A circuit with proper breaker and receptacle.

3. Receptacle within 5 feet (1.5 meter) of machine.

4. Power cord with or without plug supplied with machine.

Electrical-refrigerator

1. 120VAC, 2 wires with ground.

2. Dedicated 15A circuit with proper breaker and receptacle.

3. Receptacle within 5 feet (1.5 meter) of machine.

4. Power cord with plug supplied with machine.

5. Requires minimum 2 inches (50mm) in back and top.

WARNING -

The brewer must be disconnected from the power source until specifi ed in Initial Set-Up.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

ELECTRICAL REQUIREMENTS

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service.

2. Determine the available on-site electrical service.

3. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

4. If wiring the machine for operation on 208 volts with a power supply cord, the power supply cord must

be UL Listed Flexible Cord Type SOO or SOOW, 600V, No. 10 AWG, 3 Conductor, Rated 90°C minimum.

Attachment Plug Cap must be UL Listed, NEMA 6-30P or L6-30P Confi guration. Rated 250V, 30 AMPS.

The Power supply Cord must be at least 3 feet long and maximum 6 feet long (measured from strain

relief to end of the attached Plug Cap).

DIR Num: 49985.0000 17, September 2014

Page 5

49985 090914

Page 6

RELEASED FOR PRODUCTION

INSTALLATION-SURETAMP

Drain Install

1. Install drip tray bracket with 3 screws (included in bag).

1. Attach the short drain hose to the drip tray fi tting.

2. Slide drip tray onto guide rails on front of machine.

3. Attach other end of drain hose to manifold as shown.

4. Attach long drain hose to back of manifold and route to

fl oor drain or sink, fl owing downhill at all times.

5. Secure hose above the drain to maintain the air gap.

Water Supply Install

1. Ensure water is turned off.

2. Install the water fi ltration system between the water

supply and the machine inlet per manufacturer’s installation recommendations.

3. Connect one end of the inlet hose assembly to the

adapter and the other end to the water supply.

4. DO NOT TURN ON THE MAIN WATER SUPPLY UNTIL

REFRIGERATOR IS COMPLETELY CONNECTED. Check

for leaks; resolve any leak issues before proceeding.

INSTALL DRAIN HOSE AND DRIP TRAY

Electrical Install

WARNING – Improper electrical installation will damage

electronic components.

1. Determine the available electrical service.

2. Ensure the proper voltage at the electrical source.

WARNING -

The brewer must be disconnected from the power source

until specifi ed in Initial Set-Up.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

ELECTRICAL HOOK-UP (All Models)

CAUTION – Improper electrical installation will dam-

age electronic components.

1. An electrician must provide electrical service.

2. Determine the available on-site electrical service.

3. Using a voltmeter, check the voltage and color

coding of each conductor at the electrical source.

4. Uncoil the power cord completely and plug securely into the outlet or hard wire into electrical

box.

INSTALL DRAIN HOSES TO MANIFOLD

L2 RED L2 RED

L1 BLACK

L1 BLACK

L2

L1

GREEN

G

POWER CORD

208vac 2 wire + ground

DIR Num: 49985.0000 17, September 2014

Page 6

49985 090814

Page 7

RELEASED FOR PRODUCTION

INSTALLATION-REFRIGERATOR

Milk Module Installation-counter top

1. Align hoses and harnesses through holes

in back of refrigerator and slide module into

cabinet on the pre-installed brackets.

Milk Module Installation-under counter

1. Align hoses and harnesses through hole

on top of refrigerator and slide module into

cabinet on the pre-installed brackets. Ensure

holes in back are plugged.

A

B

C

D

E

Connect hoses and harnesses to machine as shown.

A. Water supply to espresso machine.

B. Water line to milk module.

C.

D. 8 pin connector from milk module.

E. 14 pin connector from milk module.

INSTALL SUPPLY LINES

Load milk containers.

A. Load a container of "non fat" milk towards the back

and insert the number "2" hose into container.

B. Load a container of "whole" milk towards the front and

insert the number "1" hose into container.

Milk line from milk module.

1

DIR Num: 49985.0000 17, September 2014

Load milk containers.

A. Adjust refrigerator thermostat control knob as needed.

B. Temperature may be monitored with the thermometer

hanging inside the cabinet (1).

C. Refer to manufacturers manual included with refrig-

erator for additional information.

Page 7

49985 082114

Page 8

RELEASED FOR PRODUCTION

OPERATING CONTROLS

1

9

2

3

1. Bean hopper:

Right-regular

Left-decaf

2. Touch screen display:

3. Dispense nozzles:

4. Small cup shelf:

5. Puck bin:

6. Drip tray:

7. Key Lock:

8. Milk module:

9. Cafi za coffee cleaning

tablet chute:

7

8

Start up

1. Pull puck bin out, turn the main switch on, replace puck

bin.

2. The fi lling process will proceed automatically. When the

boilers are fi lled, unit will automatically start heating. You

will see a message " Please wait - heating in progress".

3. Install hoppers on top of brewer. NOTE: Brewer will not

operate without hoppers in place. Open front door and pull

each slide gate tab forward. (This also locks hoppers in

place). Close door and fi ll hoppers as needed.

4. Select "Care &cleaning", select rinse to introduce fresh

water into the system if desired.

5. Select "Care &cleaning", select "Milk prime" 1 then 2 to

introduce milk through the lines into brewer. Press "right"

bean icon to return to home screen.

6. The machine is ready to use when "Ready to brew" is

displayed.

5

4

6

PULL HOPPER SLIDE GATE

TABS FORWARD

NOTE: POUR IN ONLY ENOUGH BEANS FOR THE DAY'S USE.

DO NOT STORE BEANS IN HOPPER OVERNIGHT, FRESHNESS WILL BE COMPROMISED.

DIR Num: 49985.0000 17, September 2014

Page 8

49985 082114

Page 9

RELEASED FOR PRODUCTION

OPERATION

Right bean hopperLeft bean hopper

Small

Medium

Large

Syrup

Whole milk

Low fat milk

Hot milk

Cold milk

DRINK TYPES

1. Americano (hot water added to espresso).

2. Cappuccino (traditionally prepared with espresso, hot milk, and steamed-milk foam).

3. Espresso: x1=single shot; x2=double shot (coffee brewed by forcing a small amount of nearly boiling water under pressure through fi nely ground coffee).

4. Latte (hot milk added to espresso).

5. Macchiato: espresso added to a small amount of milk foam.

6. Milk (hot milk for hot chocolate).

7. Mocha (espresso, chocolate, and hot milk).

8. Syrup icon leaves room in the drink volume to allow manually adding syrup without overfl owing the cup.

9. Select "cup preheat" to dispense hot water into cup before running a brew cycle.

DO NOT USE CUP PREHEAT WITH PAPER OR STYROFOAM (OR SIMILAR) CUPS.

BREWING

1. Select between left or right bean hopper from the tabs on the top of touchscreen.

2. Place appropriate size cup on drip tray or shelf.

3. Select drink size.

4. Select desired options:

Small cow for "non fat"

"C" for cold milk;

Syrup for additional room

5. Select one of the drink types.

STOP

STOP: Pressing the STOP button will stop brewing function, and will reset unit back to ready mode.

NOTE: Empty puck drawer when prompted.

DO NOT ALLOW USED PUCKS TO BACK UP INTO BREW CHAMBER AREA AS THIS CAN

CAUSE DAMAGE!

The operation of the equipment may allow a condition where milk or traces of dairy components are in cross-contact with recipes that are considered non-dairy. These traces of allergenic proteins can cause reactions in individuals having food allergies to those proteins.

DIR Num: 49985.0000 17, September 2014

Page 9

49985 082114

Page 10

RELEASED FOR PRODUCTION

RINSING/CLEANING

RINSING

Press the "care & cleaning" tab to access. Place container under dispense heads.

Coffee rinse: – Press "coffee rinse".

Milk rinse: – Press "milk rinse".

DAILY CLEANING

NOTE: You will need pitcher (supplied), brush, "Cafi za Coffee" cleaning tablets, Rinza Acid tablets and cleaning

tube on hand.

1. Press the "care & cleaning" tab on the touch screen.

2. Press the "clean" icon. Follow the picture prompted cleaning guide.

3. Wipe off dispense nozzle tips.

WEEKLY CLEANING

1. Press the "care & cleaning" tab on the touch screen, follow the picture prompted cleaning guide.

2. Open brew chamber door.

3. Push hopper slide gate all the way in.

4. Lift hopper with both hands. DO NOT LIFT HOPPER BY THE LID.

5. Empty beans from hopper and wash/rinse with mild nonabrasive detergent and fresh water.

DIR Num: 49985.0000 17, September 2014

Page 10

49985 090314

Page 11

RELEASED FOR PRODUCTION

MENU OPTIONS

Press and hold "BUNN" logo

to enter "menu options"

standby

regional settings

size milk type

syrup

11:46 am

05-20-12

right care & cleaningleft

cappuccino

latte

milk

foam top

milk temp

espresso x1

espresso x2

H

americano

C

READY TO BREW

macchiato

cup

preheat

stop

Set date/time, language and units

Manually enter "standby" mode. Screen will

go blank. to reactivate,

press anywhere on the

touch screen.

press to return to

previous screen

cup count

machine statistics

View/reset usage of various recipes

SEE PAGE 12

View/reset usage of water, grinders,

brew and cleaning cycles (resettable)

advanced

menu options

Reserved for authorized

service technicians only.

Password protected.

DIR Num: 49985.0000 17, September 2014

CONTINUED ON NEXT PAGE

Page 11

49985 082114

Page 12

RELEASED FOR PRODUCTION

MENU OPTIONS

regional settings

date ( mm/dd/yyyy )

time ( hh/mm/AM )

)

)

1. Press to highlight box.

2. Press arrows to adjust.

3. Press "save" when fi nished.

language units

English English

Cycle through:

press this box press this box

English, Spanish, French

NOTE: Cup volumes will always be

displayed in ml rather than ounces.

Always press "save" before exiting.

1411

AM008

Toggle between:

English-Metric

save

machine statistics

0

right grinder clean cycles

0 lbs

left grinder

0 lbs

highlight box then press "reset"

clean cycle

0 gal

0

errors

0

reset

steam timewater usagecycle counts

0 sec

whole

0

non fat

0

lifetime

totals

DIR Num: 49985.0000 17, September 2014

Page 12

49985 082114

Page 13

cup count

RELEASED FOR PRODUCTION

MENU OPTIONS

size milk type

espresso x1

right cup countsleft

cappuccino

1030

milk

americano

20

mocha

select cup counts

then press reset

add milk

4

reset

1. Press left or right (hopper).

2. Press to highlight/un-highlight box(s).

milk temp

espresso x2

H

C

15

latte

25 28

DAILY

lifetime

By default, all items on this screen start out highlighted (for totals). De-select individual items as desired to

obtain individual counts by hopper, drink size/type and temperature. NOTE: only "daily" counters can be reset.

HIGHLIGHTED NOT highlighted

DAILY

lifetime

PRESS “RESET” FOR

DAILY

COUNTERS ONLY

daily

LIFETIME

NO RESET FOR

LIFETIME

COUNTERS

DIR Num: 49985.0000 17, September 2014

Page 13

49985 082114

Page 14

RELEASED FOR PRODUCTION

TROUBLESHOOTING

Notices Description

“cleaning interrupted”, Redo cleaning cycle to remove this error

“cleaning due now - shut down”, Machine will not dispense until cleaning is completed

“check right hopper”, Right hopper is out of beans.

“check left hopper”, Left hopper is out of beans.

“right brew time too long”, Grind size on right hopper needs to be adjusted. Coarsen by one turn at

a time until error is cleared.

“left brew time too long”, Grind size on left hopper needs to be adjusted. Coarsen by one turn at a

time until error is cleared.

Milk 1 or 2 empty Refer back to "loading" section.

On screen troubleshooting feature: Should there be an error message shown, additional help can be accessed

by pressing the pop up, . This will start a picture prompted troubleshooting instruction.

DIR Num: 49985.0000 17, September 2014

Page 14

49985 082114

Loading...

Loading...