Buhler Allied FK314, FK314 Operator's & Parts Manual

85” Snowblower

TABLE OF CONTENTS

DESCRIPTION PAGE

Warranty ......................................................................1

Safety Instructions .......................................................2

Safety Sign Locations..................................................3

Assembly Instructions..................................................4

Operating Instructions..................................................5

85” Allied Snowblower Drawings..................................6

85” Allied Snowblower Parts List..................................8

Manual Chute Control Instructions & Drawing.............10

Manual Chute Control Parts List..................................11

Hydraulic Chute Control Instructions & Drawing..........12

Hydraulic Chute Control Parts List...............................13

85” Allied Snowblower PTO Drawing...........................14

85” Allied Snowblower PTO Parts Lists .......................15

Gearbox Assembly Drawing.........................................17

Gearbox Assembly Parts List.......................................18

Cylinder Assembly Drawings & Parts Lists ..................19

Shipping Bundles.........................................................20

85” Snowblower

WARRANTY POLICY

Buhler Manufacturing products are warranted for a period of twelve (12) months (90 days for

commercial application) from original date of purchase, by original purchaser, to be free from

defects in material and workmanship under correct, normal agricultural use and proper

applications.

Buhler Manufacturing’s obligations under this warranty shall be limited to the repair or

exchange, at Buhler Manufacturing’s option, of any Buhler Manufacturing product or part which

proves to be defective as provided. Buhler Manufacturing reserves the right to either inspect

the product at the buyer’s location or have it returned to the factory for inspection.

The above warranty does not extend to goods damaged or subject to accident, abuse or misuse

after shipment from Buhler Manufacturing’s factory, nor to goods altered or repair ed by anyone

other than an authorized Buhler Manufacturing representative.

Buhler Manufacturing makes no Express Warranties other than those, which are specifically

described. Any description of goods, including any references and specifications in catalogues,

circulars and other written material published, is for the sole purpose of identifying goods and

shall conform to such descriptions. Any sample or model is f or illustrative purposes only and

does not create an Express Warranty that the goods conform to sample or model shown.

The purchaser is solely responsible for determining suitabilit y of goods sold. This warranty is

expressly in lieu of all other warranties expressed or implied. Buhler Manufacturing will in no

event be liable for any incidental or consequential damages whatsoever. Nor for any sum in

excess of the price received for the goods for which liability is claimed.

WARRANTY CLAIMS:

Warranty requests must be prepared on Buhler Manufacturing Warranty Claim Forms with all

requested information properly completed. Warranty Claim s must be submitted within a thirty

(30) day period from date of failure repair.

WARRANTY LABOR:

Any labor subject to warranty must be authorized by Buhler Manufacturing. The labor rate for

replacing defective parts, where applicable, will be credited at 100% of the dealer’s posted shop

rate. Defective parts will receive an extra 10% discount t o assist with freight or other incidental

costs.

GOVERNMENT LEGISLATION:

Warranty terms and conditions are subject to Provincial or State legislation.

IMPORTANT FACTS:

Buckets and Bucket Tines Carry No Warranty

Bent Spears Carry No Warranty

Snowblower Fan Shafts Carry No Warranty

Mower Blades Carry No Warranty

Portable Auger Parts Have Two (2) Year Warranty

Loader Parts Have Two (2) Year Warranty

IMPORTANT NOTE: This warranty does not apply to rentals

- 1 -

85” Snowblower

CAUTION

1. Always review operator’s manual before starting new machine.

2. Do not let inexperienced operators or children run this equipment.

3. Never service or clean unit while it is running.

4. Do not remove shields.

5. Stay clear of augers.

6. Stay clear of discharge chute. Rocks can be picked up and thrown.

7. Poor judgment results in accidents. Always be careful.

8. Remember a careful operator is the best insurance.

THIS SYMBOL MEANS

STAY ALERT! WATCH FOR IT!

- 2 -

85” Snowblower

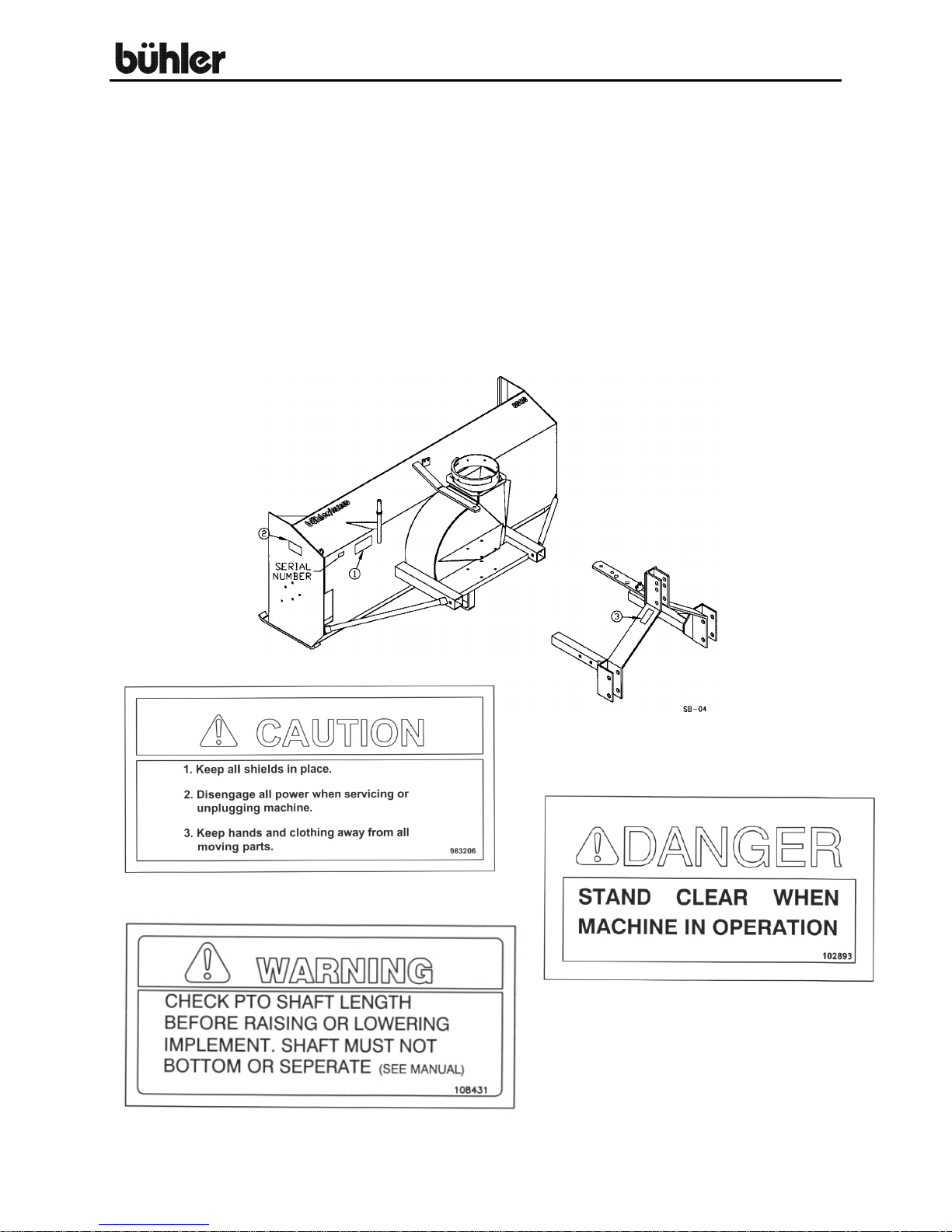

SNOWBLOWER

This manual covers the 85” model snowblower. When ordering parts, be sure to list the

serial number of your unit and blower width. The snowblower is the push type and will

mount to a tractor with a category 1 or 2 three point hitch and 540 rpm PTO. The 85"

model has a single auger and comes with a hydraulic control for the chute with a

manual control avail able as an optio n.

The auger and the blower are equipped with shear bolts to protect the machine from

damage in case a large object is picked up. Any gravel picked up in the snow will be

thrown with it and could cause serious injury. Be careful when operating the

snowblower. Do not let children play behind the tractor or in the area of the discharged

snow.

#

#2

#3

- 3 -

85” Snowblower

BASIC ASSEMBLY INSTRUCTIONS

STEP 1. Assemble the snow chute, referring to instructions under the appropriate

heading for “manual chute” or “hydraulic chute”.

STEP 2. Check the gearbox and fill to the lower level with a winter grade

transmission oil.

STEP 3. The snowblower is shipped with lower three point hitch pins for a category

2 hitch.

STEP 4. Using tape or bright colored marking pen, mark on the outer shields of the

PTO, the position where the shaft is completely pushed together and the

position where you have a 4” overlap. Watch these marks when moving

the blower through all possible operating angles to see that the PTO shaft

stays within this range.

STEP 5. With the engine on the tractor shut off, attach the PTO shaft. The tractor

end has a standard 6-spline end with a spring loaded locking collar. The

snowblower end has a clamp style yoke with a 3/8” keyway. Slide the

yoke onto the gearbox shaft with the 3/8” shaft supplied. Lock the yoke in

place with a ½” x 3” hex bolt and lock nut fitted through the groove in the

gearbox shaft. After tightening the bolt, insert and tighten the 3/8” socket

set screw supplied. CAUTION: Always check to see that

both ends of the PTO shaft are securely attached every time the

snowblower is used. This should always be done with the tractor shut off.

STEP 6. Check that the PTO shaft does not bottom or separate with the

snowblower in the extreme high and low positions. A longer optional PTO

shaft is available if the standard shaft is too short. Check for free

movement of all parts in various raised positions: particularly the PTO

shaft.

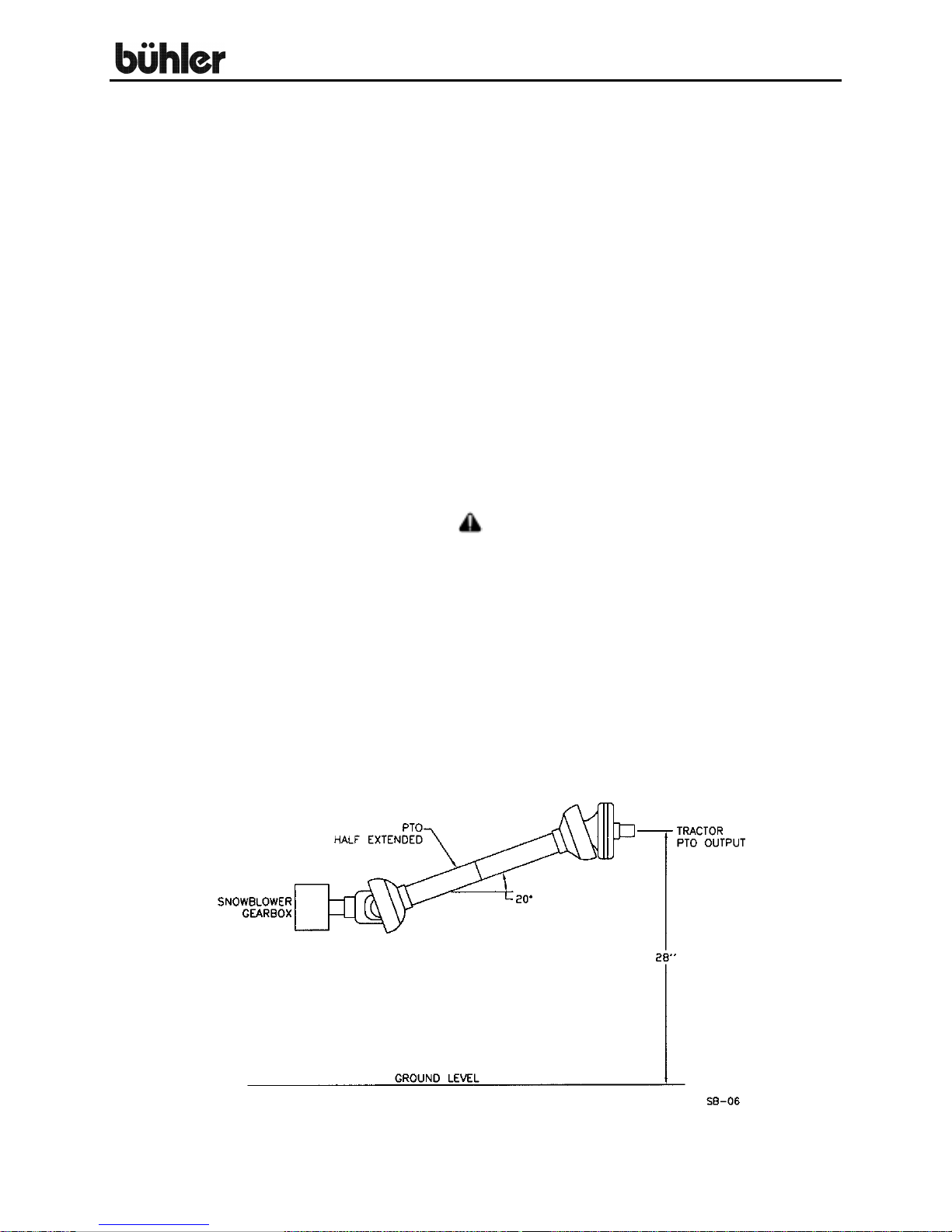

STEP 7. NOTE: Excessive u-joint wear and shear pin failure may result if the

PTO angle exceeds 20°. The drawing below gives an approximate way to

check this angle. With the PTO half extended, the tractor output should

not be over 28 inches high. Use 30 inches if the PTO is nearly fully

extended and 26 inches if it is nearly compressed.

- 4 -

85” Snowblower

OPERATING INSTRUCTIONS

1. Adjust the top link of the tractor hitch so that the snowblower is level when

resting on the ground.

2. Adjust the lower link sway chains or blocks on the tractor to restrict side

movement of the blower when operating.

3. Run the blower at low RPM to check operation.

4. The snowblower has two shear bolts to protect the tractor and blower in

case a large object enters the blower. PTO shear bolt – two 5/16" x 1"

(grade 5), auger shear bolt - 5/16" x 1 ¼” (grade 5). These bolts must be

checked every five operating hours and kept tight to prevent wear of the

bolts and bolt holes.

5. Daily check the auger bearing bolts on each side of the snowblower, the

drive sprocket bearings and the bolt holding the blower fan on the gearbox

shaft.

6. Grease the PTO and bearings every 40 hours of operation.

7. A little engine oil applied to the chain daily can double the life of the drive

chain.

8. Occasionally apply a light winter grade oil to the chute bottom ring to ease

turning.

9. Always disengage the PTO before dismounting from the tractor.

10. CAUTION: Always check to see that both ends of the PTO shaft

are securely attached as per instructions every time you are preparing to

use the snowblower.

11. Shear sprocket: The shear sprocket (#6) should be checked at the

beginning of every season to make sure it will spin freely. With time this

sprocket could corrode and seize which will not allow the shear bolt to

break if something jams in the snowblower auger. Clean to loosen if

necessary.

12. Gearbox: Use any 80-90 gear oil or multigrade with 80 minimum.

13. When replacing bearings or tightening a loose bearing collar, always

tighten collar in the direction of shaft rotation using a center punch or

similar tool.

- 5 -

Loading...

Loading...