Page 1

Installation instructions

63043970.01-1.SD

Solar Collector

63043970.01-1.SD

SKS 4.0 Series Flat Collector

FLAT ROOF AND WALL MOUNTED

SOLAR THERMAL SYSTEMS

For heating engineers

Please read carefully prior

to commissioning and

maintenance

7 747 019 102 (04/2006) UK

Page 2

Foreword

About this manual

This installation manual contains important information

for the safe and appropriate installation of the roof

mounted solar collectors.

Notes are included with important information for

situations in which there is no danger for persons or

equipment.

These technical documents should be retained in a safe

place. These may also be inspected at the

manufacturer's premises.

The activities described in the installation manual

assume expertise based on completed vocational

training in gas or water-related installation. Only carry

out these installation steps, if you possess these skills.

— Hand these installation instructions to the customer.

— Explain to the customer the function and operation of

the related devices.

2

SKS 4.0 Series - Flat roof and wall mounting -We reserve the right to make any changes due to technical modifications.

Page 3

Contents

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2 Notes structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3 Please observe these safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4 Before installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.2 Component description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3 Other equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Determining the angle of incidence of the collectors . . . . . . . . . . . . . . . . . . . . . 12

4.7 Determining space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Installing flat roof and wall mounting supports . . . . . . . . . . . . . . . . . . . . 17

5.1 Distances between collector braces for on-site base anchoring . . . . . . . . . . . . . . 18

5.2 Clearances between the collector braces when using loading trays (accessory) . . . . 20

5.3 Stabilising the flat roof supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Wall mounting supports - installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5 Installing the profile rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Collector installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1 Preparing to install the collectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Fastening the collectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Collector sensor connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Header connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.1 Fitting holder for flow line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Venting through pressure filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3 De-airing through air vent (accessory) at highest point in the system . . . . . . . . . . . 37

8.4 Connecting two arrays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9 Final activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1 Checking the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.2 Insulating the connection and header pipes . . . . . . . . . . . . . . . . . . . . . . . . . . 40

10 Quick reference guide for base anchoring and pressure filling . . . . . . . . 41

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

3

Page 4

1

General information

1 General information

This chapter details which technical rules and

regulations apply to this installation.

USER NOTE

Observe all standards and guidelines

applicable to the installation and operation

of this system in your country.

UK

Installation work on roof

The Health and Safety at Work etc

Act

1974

The Management of Health and Safety

at Work Regulations 1999

The Construction (Health Safety and

Welfare) Regulations 1996

The Construction (Design and

Management) Regulations 1994

The Lifting Operations and Lifting

Equipment Regulations 1998

Tab. 1 Technical rules for the installation of thermal solar thermal systems (selection) in UK

Lightning protection

If the building height (installation height) exceeds 20 m,

and there is no lightning conductor installed, ask your

local electrical contractor to connect the components on

the roof which conduct electricity with an electrical earth

cable of at least 16

Special measures regarding lightning protection are not

required for building heights (installation heights) of less

than 20

Where there is a lightning conductor system installed,

ask your local electrical contractor to check the inclusion

of the solar thermal system into the lightning protection

system.

m.

mm2 to the earth bonding.

Connection of thermal solar

systems

EN 12976: Thermal solar thermal

system and their components (prefabricated systems).

ENV 12977: Thermal solar thermal

system and their components

(bespoke systems).

BS 6795: Code of practice for solar

thermal systems for swimming pools.

Installation and equipment of DHW

BS 5546: 2000 Specification for

installation of hot water supplies for

domestic purposes, using gas-fired

appliances of rated input not

exceeding 70

BS 6700: 1997 Specification for

design, installation, testing and

maintenance, of servicing supplying

water for domestic use within

buildings and their curtilages.

USER NOTE

The installation of the thermal Solar

System must be carried out in accordance

with the relevant requirements for safety,

current IEE wiring regulations, local

building regulations, building standards

(Scotland) (Consolidation) regulations and

by-laws of the local water company and

health and safety document No 635

(Electricity at Work Regulations 1989).

BS 6795: Latest version

cylinders

kW.

4

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 5

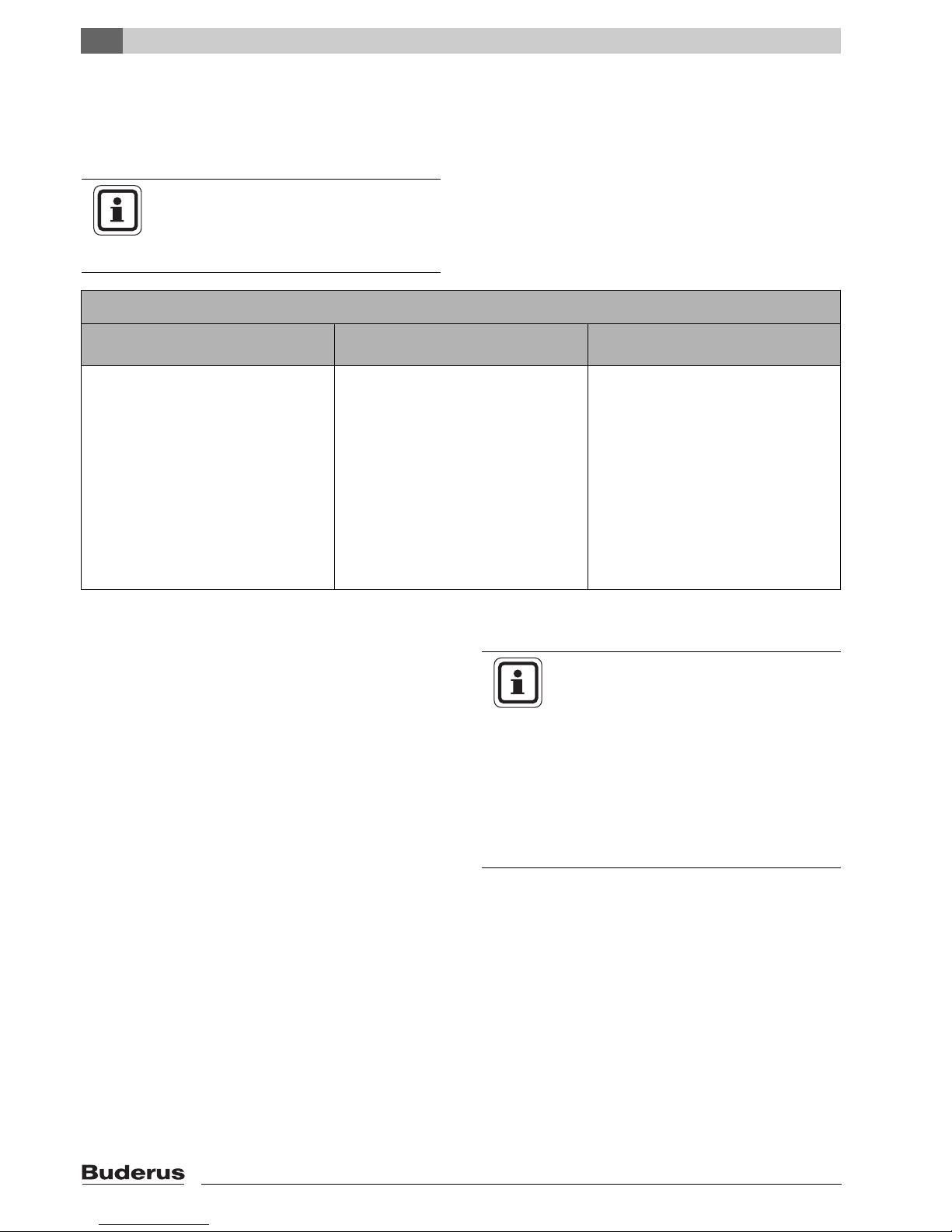

2 Specifications

SKS Solar collectors

Certificates

0036

DIN

Length 2,070 mm

Width 1,145 mm

Height 90 mm

Clearance between collectors 25 mm

Fluid content, portrait version Vf1.43 l

Fluid content, landscape version Vf1.76 l

Gross absorber surface area AG2.37 m²

Net absorber surface area 2.1 m²

Net weight, portrait version m 46 kg

Net weight, landscape version m 47 kg

Permissible operating pressure of the

collector

Tab. 2 Specifications

p

max

10 bar

Specifications

2

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

5

Page 6

3

Safety

3 Safety

This chapter details how the notes for the installation

instructions, as well as the general safety instructions,

necessary for safe and trouble-free operation, are

arranged in this manual.

Safety and user notes, which specifically refer to the

installation, in the installation manual immediately

following the individual installation steps, are found here.

Carefully read the safety instructions before

commencing the installation.

Severe injury and even death, as well as material losses

and environmental damage, may follow if you ignore

safety instructions.

3.1 Correct use

Install components only on roofs with sufficient strength.

Please take the additional roof load per flat roof support,

including solar collector, into consideration. If necessa

ry, ask a structural engineer for assistance.

Only install this system on flat roofs or roofs with a shallow pitch (≤ 25°).

The wall mounting support must only be installed at a

maximum height of 20

snow load of 2.0

-

m and with a maximum wind or

kN/m².

If there is a risk that larger quantities of snow might accumulate behind the collectors (towards the roof ridge),

prevent this by fitting a suitable protective grille.

On roofs with a shallow pitch, attach the system to the

roof on site.

Application conditions for flat roof supports

Only erect the installation set on roofs whose construction can support the weight.

The installation set is suitable for a max. standard wind

or snow load of 2.0

max.

20 m. Using appropriate accessories, the installation set can be used for a max. standard wind or snow

load of 3.8 kN/m² and a max. installation height of 100 m.

The flat roof installation set must not be used for fixing

any other objects to the roof. The kit is intended exclusi

vely for the safe fixing of solar collectors.

Conditions at use for wall mounting supports

Only landscape panel orientations are suitable for

wall mounting

Install the wall mounting support only on wall structures

with sufficient structural strength. If necessary, ask a

structural engineer for assistance.

kN/m² and an installation height of

-

6

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 7

Safety

3

3.2 Notes structure

Two levels are identified by signal terms:

RISK TO LIFE

Identifies possible dangers which might

WARNING!

CAUTION!

Further symbols identifying dangers and user notes:

WARNING!

lead to serious injury or death if appropriate

care is not taken.

RISK OF INJURY/SYSTEM DAMAGE

Identifies potentially dangerous situations,

which might lead to mild or slight injuries or

to material losses.

RISK TO LIFE

from electric shock.

USER NOTE

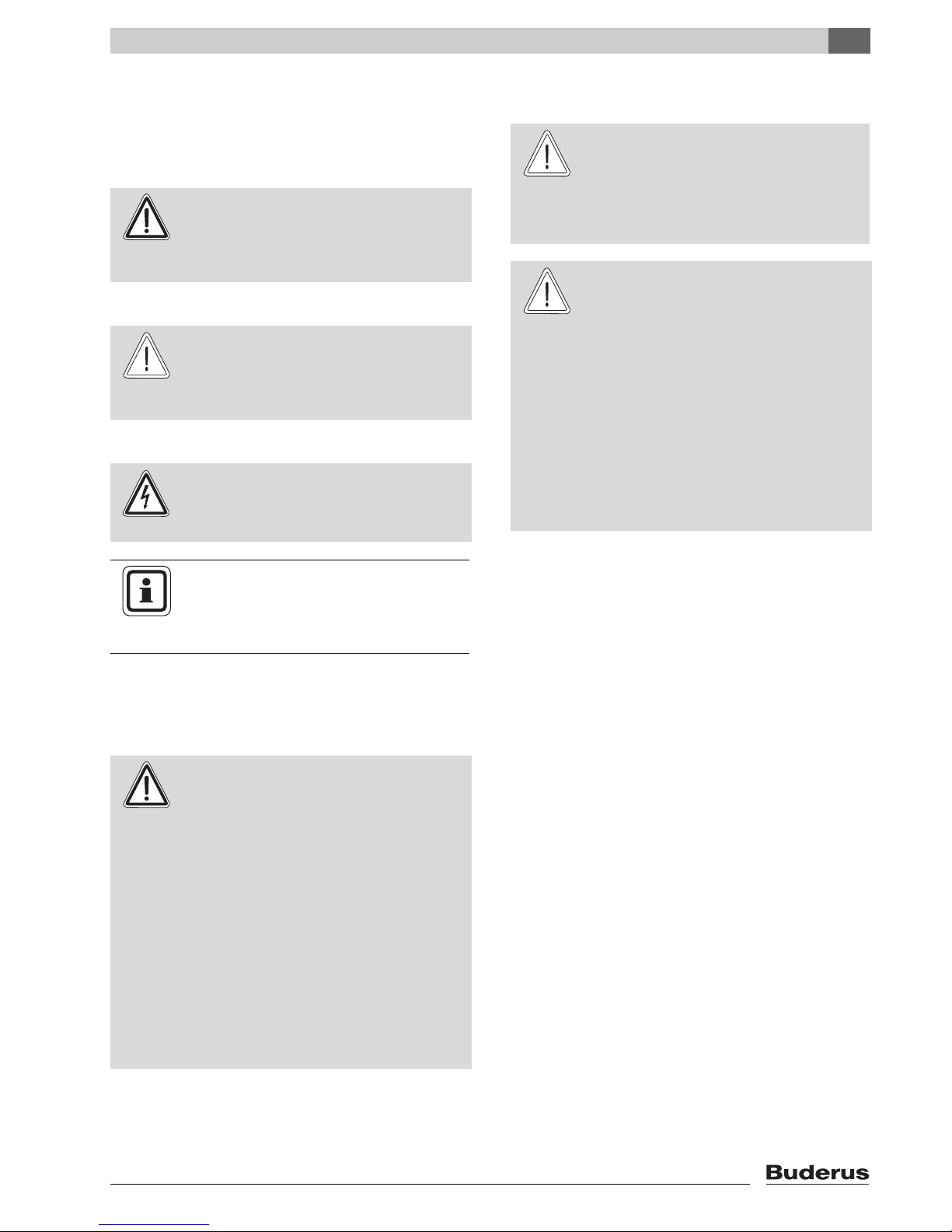

CAUTION!

CAUTION!

RISK OF INJURY

Injury and operating faults can result from

making changes to the system

construction.

z Never change the system construction.

RISK OF INJURY

Some parts may cause burns, if the

collector and installation materials are

exposed to solar radiation for longer

periods of time.

z Always wear your personal protective

clothing and safety equipment.

z Cover the collector (e.g. with a covering

sheet - available as an accessory) and

the installation material during the

installation as protection against high

temperatures resulting from solar

irradiation.

Tip for the optimum utilisation and setting

of the products plus other useful

information.

3.3 Please observe these safety

instructions

RISK TO LIFE

through a fall or falling parts.

WARNING!

z Ensure you have the correct safety

equipment for working on roofs.

z Take appropriate action to prevent

accidents when working on roofs.

z Whilst working on the roof, take all

necessary precautions against a

possible fall.

z Always wear your personal protective

clothing and safety equipment.

z After completing the installation, always

check the secure positioning of the

installed set and that of the collectors.

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

7

Page 8

4

63043970.02-1.SD

Before installation

4 Before installation

4.1 General notes

USER NOTE

It is recommended that the services of a

roofing company, who are fully experi

enced in working on roofs and will be aware of the risk of working at height, are

considered.

Make yourself familiar with the on-site conditions and local regulations before commencing the installation.

Check

z the delivery for completeness and perfect condition.

z the roof structure for sufficient strength and possible

damage (e.g. leaks).

z the building height and determine the type of fixings

required for the flat roof supports (

see Chapter 5.3

"Stabilising the flat roof supports", page 22).

z the optimum arrangement of the solar collectors.

Take the solar radiation into consideration

(angle of incidence, southerly orientation). Avoid the

shade of high trees or structures and match the coll

ector array to the shape of the building (e.g. flush with

windows, doors, etc.).

z the stability of the support surface. Remove gravel or

similar material.

-

-

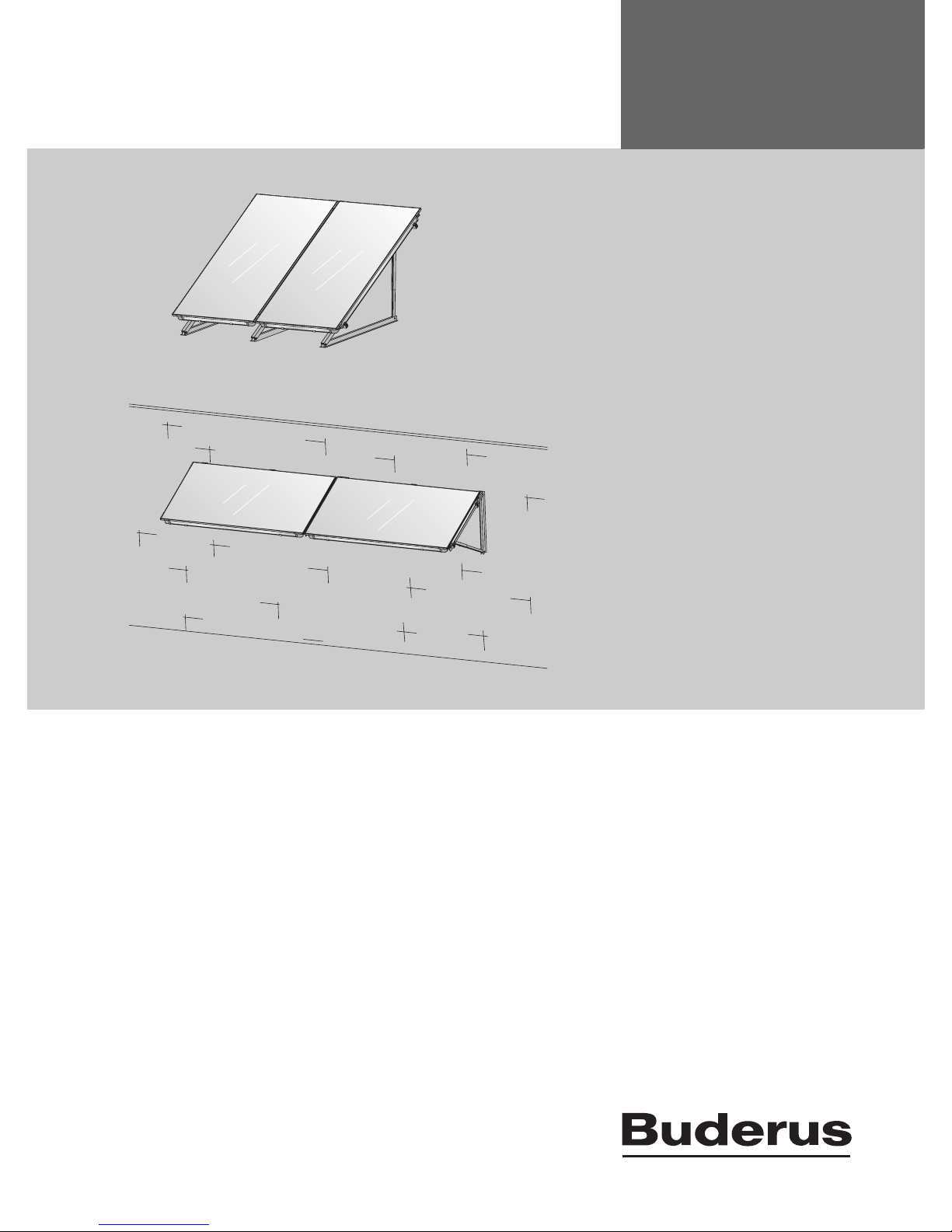

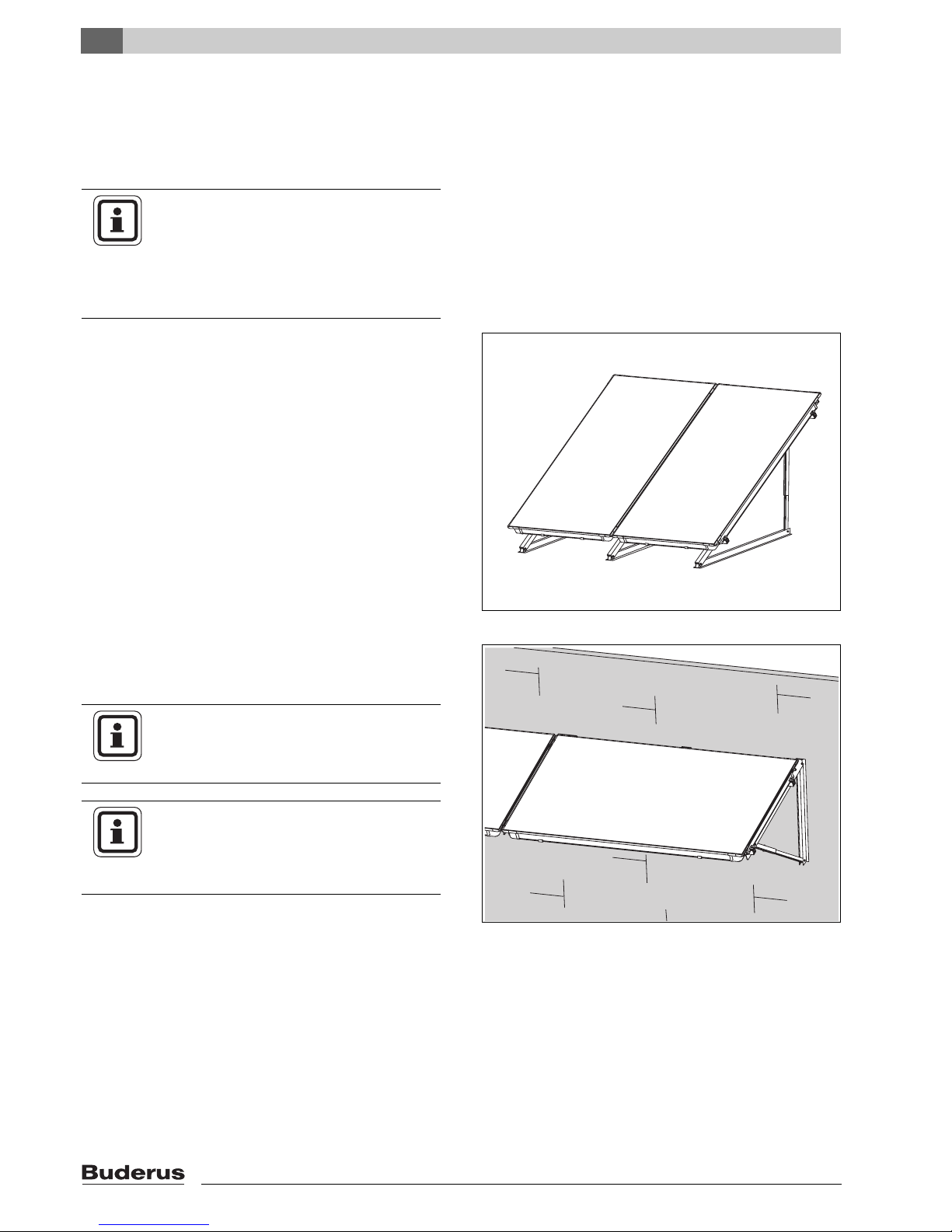

Fig. 1 General overview of collector pair — flat roof mounting

63043970.02-1.SD

USER NOTE

Only use OEM components and replace

any faulty parts immediately.

USER NOTE

Let a professional roofer carry out all difficult roof repairs, particularly weather-proofing of bitumen layers.

63043970.05-1.SD

Fig. 2 General overview of collector pair — wall mounted

installation

8

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 9

4.2 Component description

63043970.03-1.SD

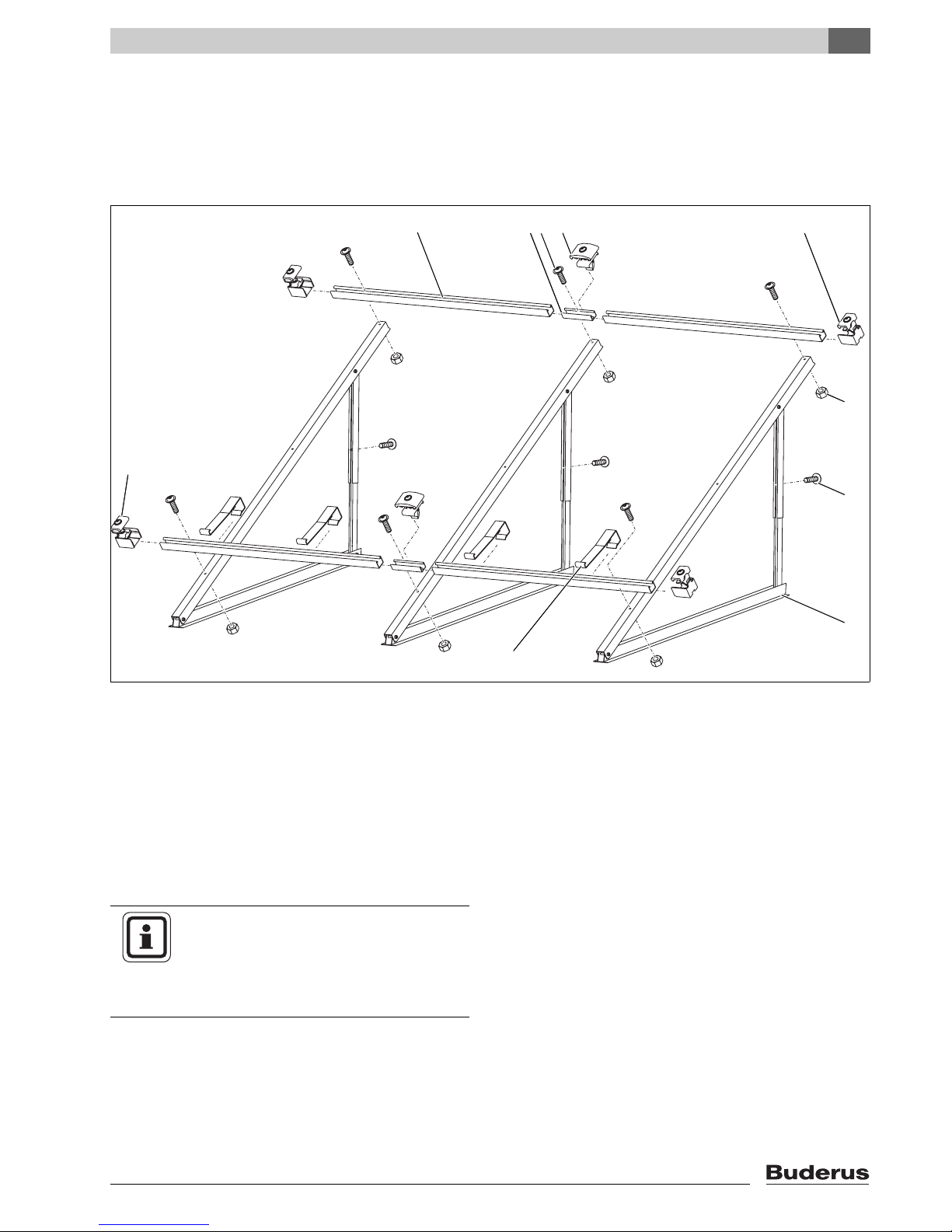

4.2.1 Installation set for the collectors

The installation sets are for mounting and fixing the collectors in place.

1

5

Before installation

3

2

4

4

5

6

8

Fig. 3 Installation set for 2 collectors - 1 basic installation set, 1 extended installation set

Basic installation set for each collector array and

for the first collector

Item 1: Profile rail 2 × Item 1: Profile rail 2 ×

Item 3: M8 screw × 20 6 × Item 2: Plug connector with threaded studs 2 ×

Item 5: Single-sided collector clamp 4 × Item 3: M8 screw × 20 3 ×

Item 6: M8 nut 4 × Item 4: Double-sided collector clamp 2 ×

Item 7: Collector brace 2 × Item 6: M8 nut 2 ×

Item 8: Anti-slip protection 2 × Item 7: Collector brace 1 ×

(Fig. 3):

Extended installation set for each additional

collector

Item 8: Anti-slip protection 2 ×

(Fig. 3):

63043970.03-1.SD

USER NOTE

3

7

Depending on the use of the flat roof support, auxiliary braces and additional profile

rails may be needed, and are dealt with in

the relevant sections.

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

9

Page 10

4

63043969.03-1.SD

63043966.04-1.SD

Before installation

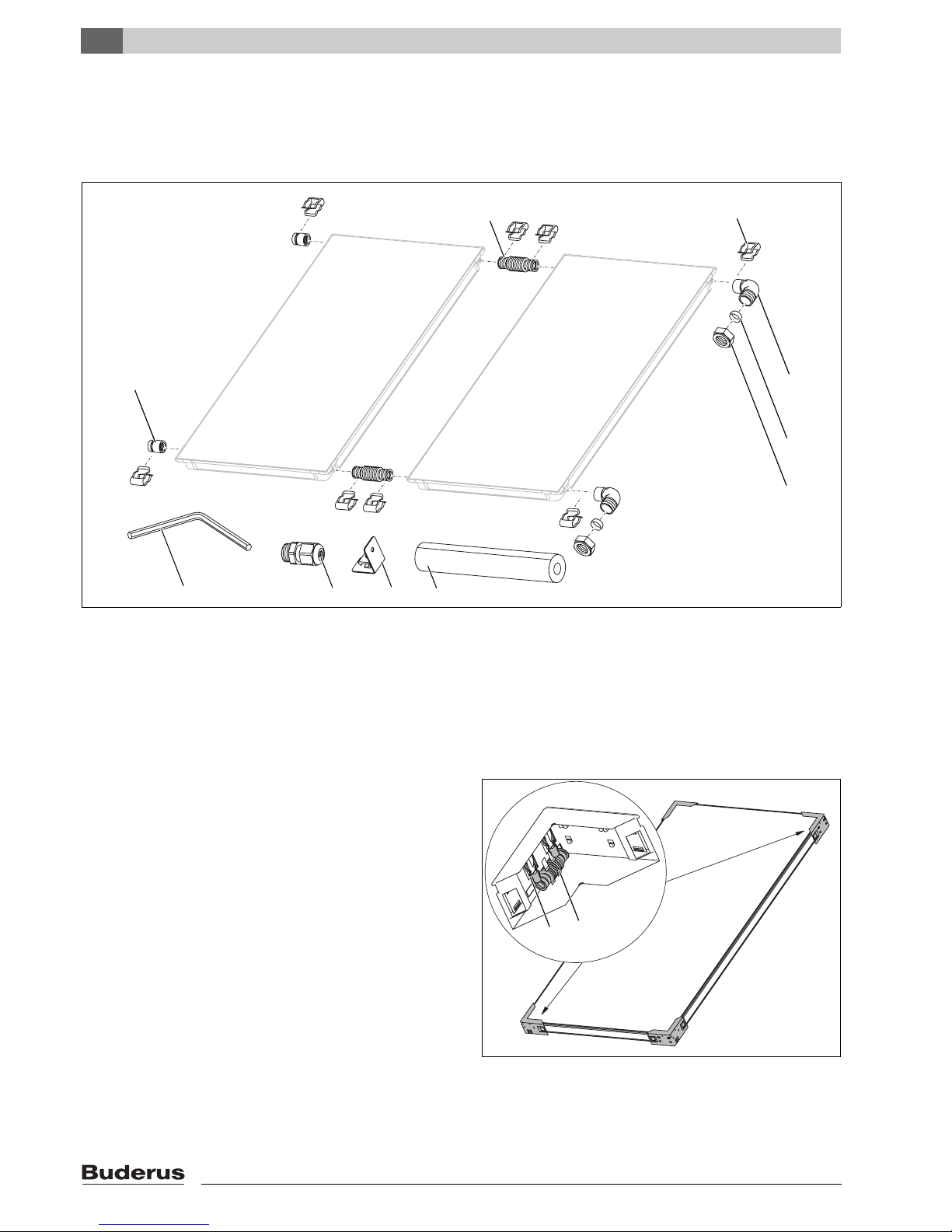

4.2.2 Pipework connection

One connection kit for each collector array is required.

The collectors are connected together by a connection

set.

1

10

9

Fig. 4 Connection kit and connection set (illustration shows 2 portrait collectors)

8

7

6

Connection kit, per collector array (Fig. 4)

2

3

4

5

63043969.03-1.SD

Item 2: Bracket (spare) 2 × Item 7: Holder for header pipe 2 ×

Item 3: Elbow 2 × Item 8: Compression fitting for collector sensor 1 ×

Item 4: Olive 2 × Item 9: Size 5 spanner 1 ×

Item 5: Nut 2 × Item 10: End cap 2 ×

Item 6: Insulation for corrugated pipe connector

710 mm

1 ×

Connection set between the collectors, for each

collector (in two corner protectors,

Item 1: Corrugated pipe connector 2 ×

Item 2: Connector clip 4 ×

Fig. 5)

1

2

63043966.04-1.SD

Fig. 5 Two corner protectors with one connection set

10

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 11

4.3 Other equipment

63043966.05-1.SD

— Spirit level

— Plumb line

— Filling pump

— Vest harness with safety rope

— Pipe insulation

— Scaffolding

— Roofing ladder

— Crane or mobile hoist

USER NOTE

When fitting the roof installation set and

water connection, the only tool reqiured is

the size 5 allen key

kit.

from the connection

Before installation

4

4.4 Transport and storage

Please ensure that the corner protectors are

retained. They contain pipework connection pieces

which are required for installation. All components

are protected by transport packaging.

USER NOTE

Dispose of the transport packaging in

an

environmentally friendly recycling

system.

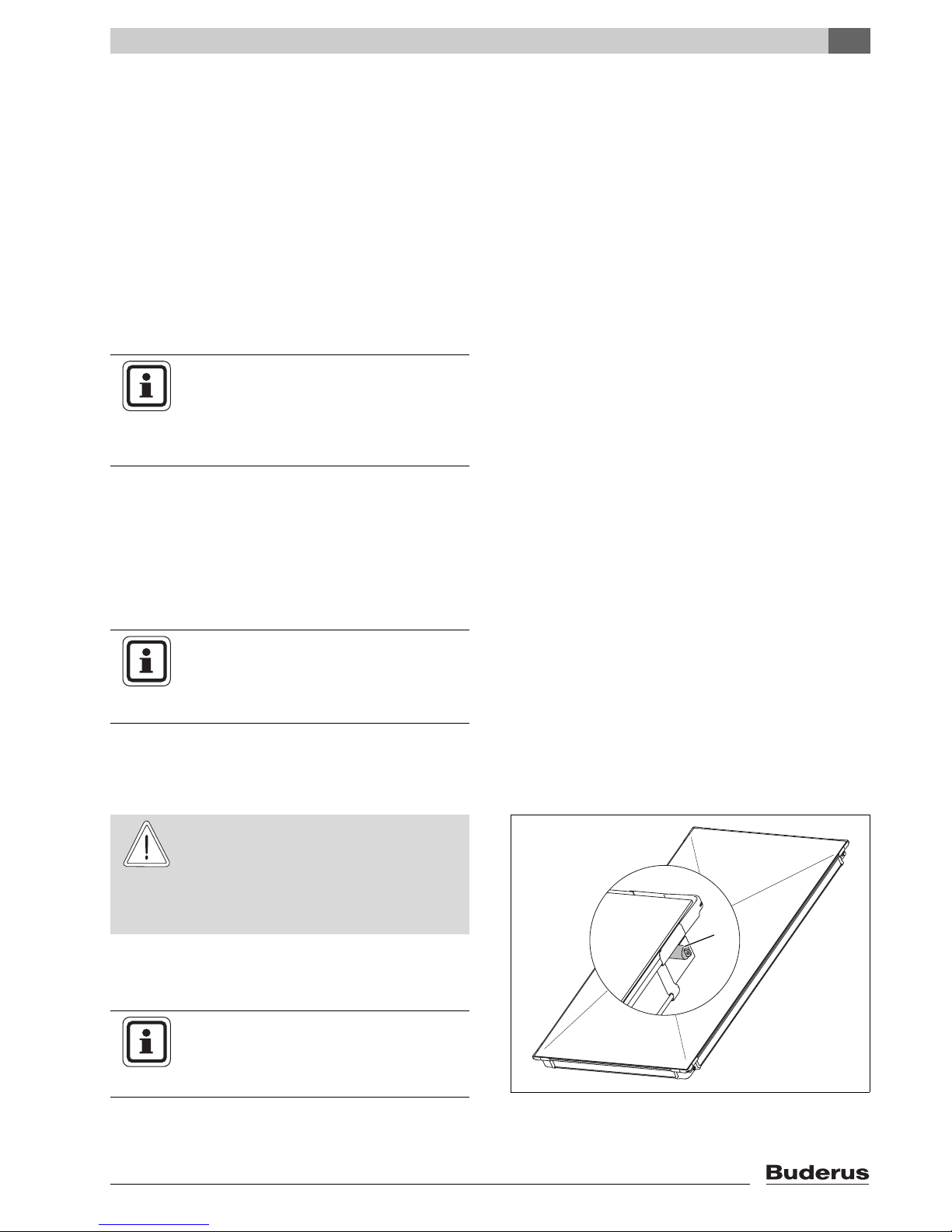

Transport protection for collector connections

The collector connections are protected against damage

by rubber caps.

SYSTEM DAMAGE

through damaged sealing faces.

CAUTION!

Storage

z Do not remove the rubber caps (Fig. 6,

Item 1) until immediately prior to

installation.

1

The collectors must be stored in dry conditions.

USER NOTE

Do not store collectors outside without

protection from the rain.

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

63043966.05-1.SD

Fig. 6 Plastic caps on collector connections

11

Page 12

4

6720613577.00-1.SD

63043970.06-1.SD

Before installation

4.5 Technical documentation

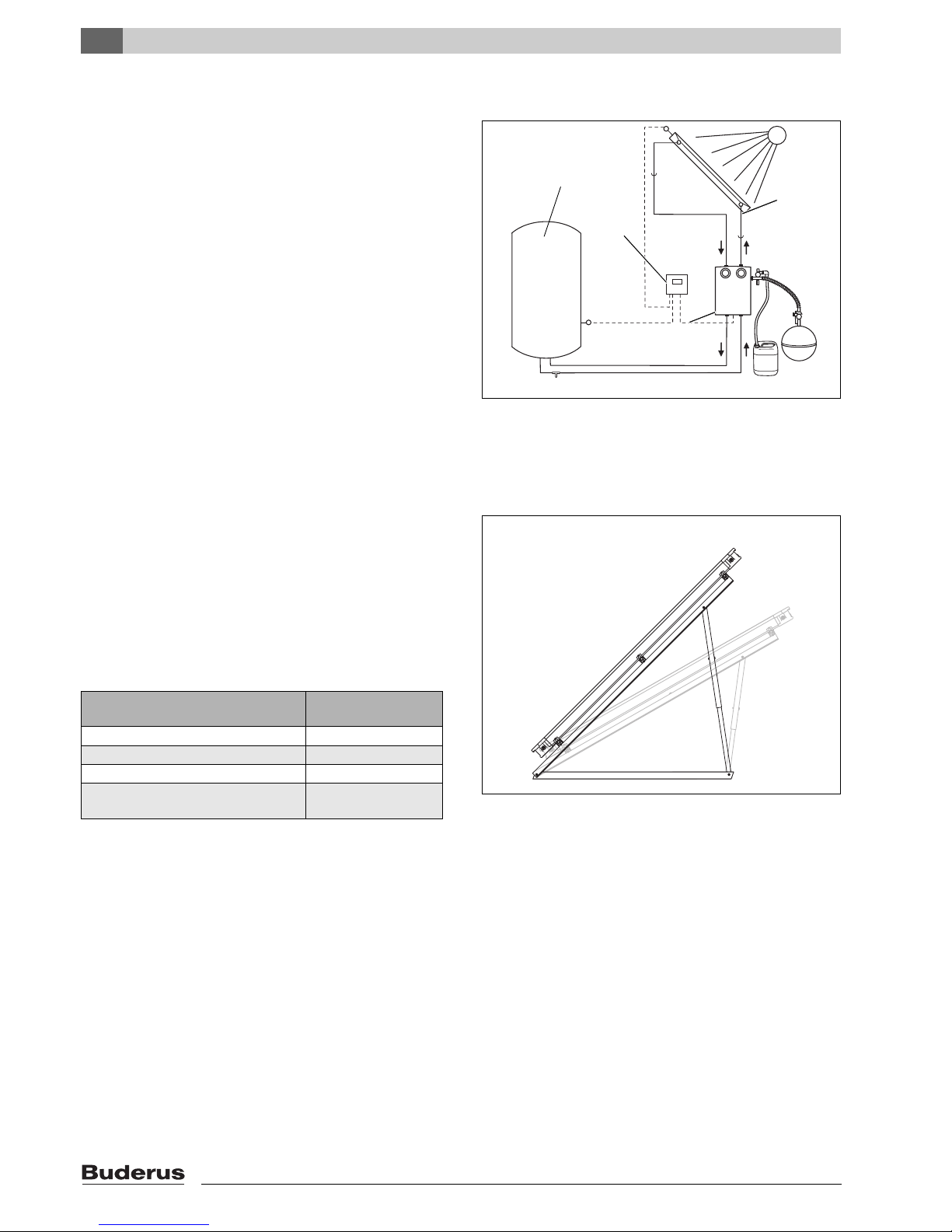

The solar thermal system consists of various components (Fig. 7). Installation, operation and maintenance

documentation is provided for each component. Accessories may be accompanied by a separate document.

Item 1:

Item 2:

Collector: instructions for roof installation

are

enclosed with the connection kit

Pump station: instructions enclosed with the

station

Item 3:

Solar Controller: instructions are enclosed

with the controller.

Item 4:

DHW Cylinder: instructions enclosed with the

DHW cylinder.

Fig. 7 Solar thermal system components and technical

documentation

4.6 Determining the angle of incidence of the collectors

4

1

3

2

6720613577.00-1.SD

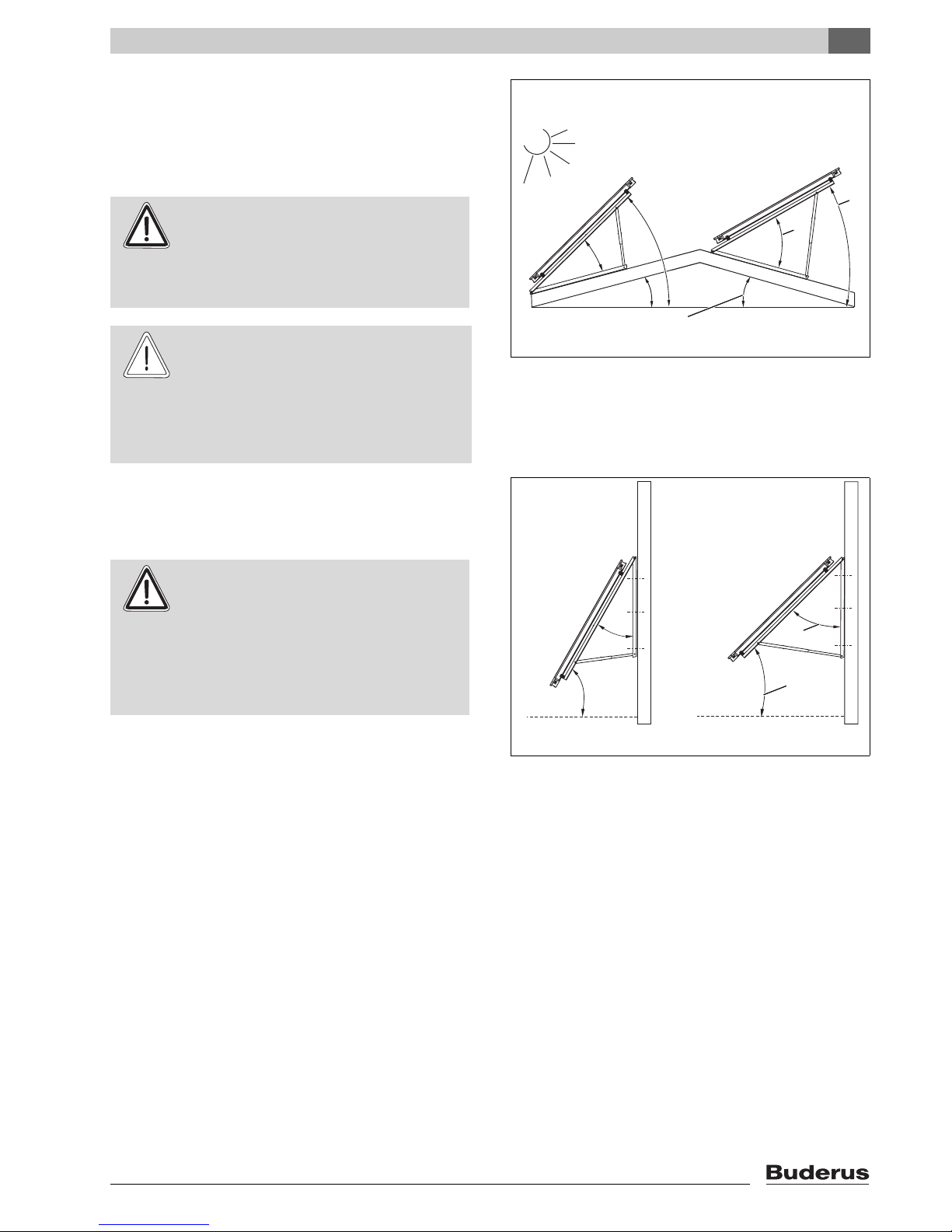

The collectors' angle of incidence to be selected depends on the desired area of application. It can be adjusted using the telescopic rails (Fig. 8).

4.6.1 Determining the area of application

The different areas of application of solar thermal systems provide angles of incidence that ensure an optimum solar yield for every season.

Applications Angle of incidence

range

DHW 30 — 45°

Domestic hot water + central heating 45 — 60°

Domestic hot water + swimming pool 30 — 45°

Domestic hot water + central heating +

swimming pool

Tab. 3 Area of application, angle of incidence range

45 — 60°

63043970.06-1.SD

Fig. 8 Angle of incidence of the collector on a flat roof

12

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 13

4.6.2 Sloping roofs

63043970.07-1.SD

63043970.27-1.SD

On roofs that slope slightly in a southerly direction, the

pitch angles are deducted from the angle of incidence.

On roofs that slope slightly in a northerly direction, the

pitch angles are added to the angle of incidence

(Fig. 9).

RISK TO LIFE

If there is a risk that larger quantities of

WARNING!

snow might accumulate behind the collec

tors (towards the roof ridge), prevent this

by fitting a suitable protective grille on site.

SYSTEM DAMAGE

through strong wind. On sloping flat roofs

CAUTION!

the flat roof supports must be secured on

site.

z Ask a roofing contractor to carry out the

installation on sloping flat roofs.

4.6.3 Walls

Before installation

4

1

45°

-

30°

15°

15°

45°

2

30°

3

63043970.07-1.SD

Fig. 9 Angle of incidence of the collector on a flat roof

Item 1: Angle of incidence (absolute angle to the horizontal

plane)

Item 2: Collector angle of inclination

Item 3: Roof pitch

The landscape collector braces can be used as flat roof

supports or wall-mounting supports.

RISK TO LIFE

from falling collectors, due to incorrect use.

WARNING!

z The collector angle of incidence

(Fig. 10, Item 1) to the horizontal must

be between 45° and 60° (or the angle of

inclination

Fig. 10, Item 2 of the collec-

tors must be between 30° and 45°)

45°

30°

45°

2

1

60°

63043970.27-1.SD

Fig. 10 Angle of incidence of the collector on a wall

Item 1: Angle of incidence (absolute angle to the horizontal

plane)

Item 2: Collector angle of inclination

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

13

Page 14

4

63043970.08-1.SD

63043970.39-1.SD

Before installation

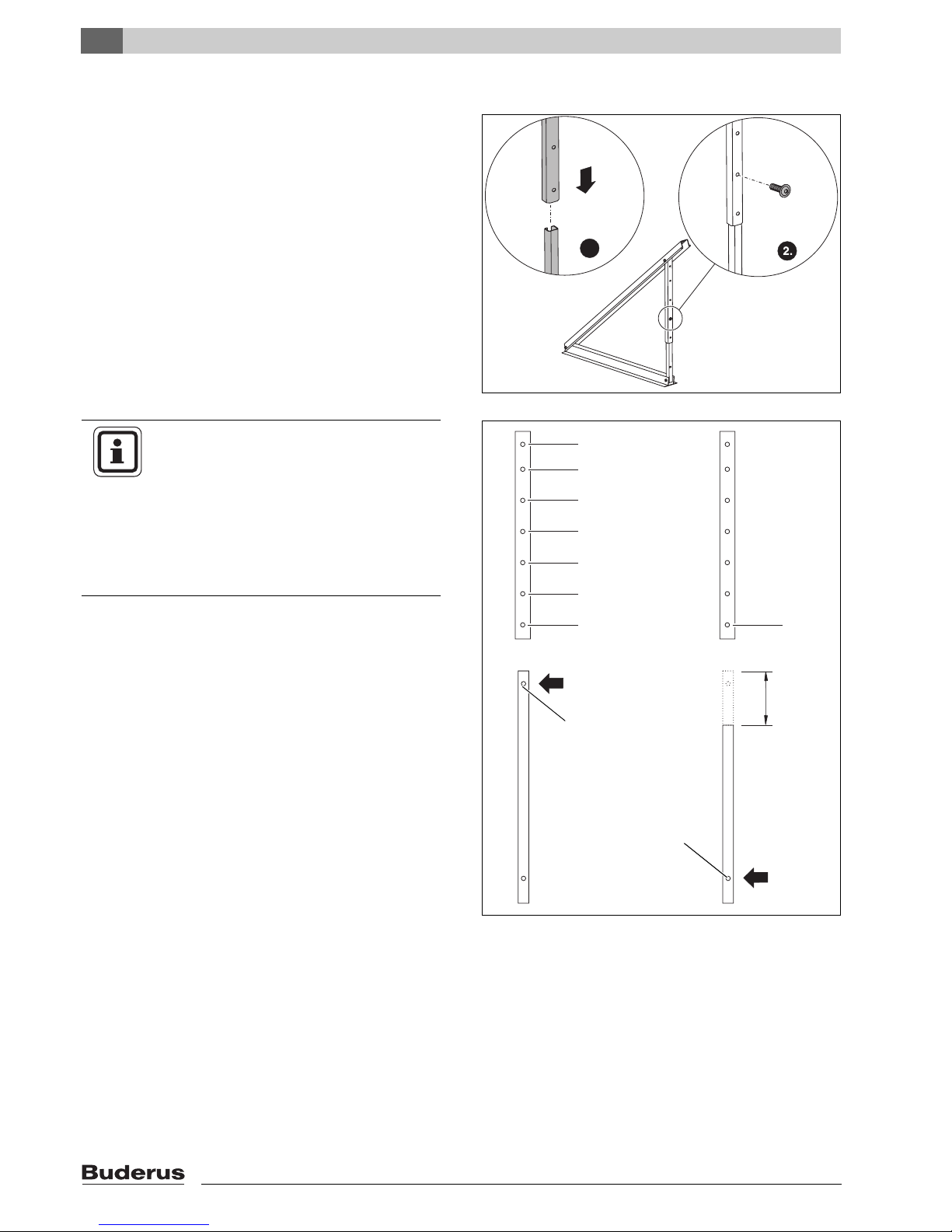

4.6.4 Fitting telescopic rails

Different angles of incidence can be set using the telescopic rails.

z Select holes on the upper and lower telescopic rails

as shown in

Fig. 12 and Fig. 13.

z Insert telescopic rails into each other and fasten with

M8

× 20 screw (Fig. 11).

1.

63043970.08-1.SD

Fig. 11 Connecting telescopic rails

USER NOTE

For vertical installation of a collector with

an angle of inclination of 30° to 60°, use

the uppermost hole on the lower telescopic

rail

(Fig. 12, Item 1).

For an angle of inclination of 25°, you must

shorten the top of the lower rail by 140 mm

and use the lower hole

(Fig. 12, Item 2).

30°

35°

40°

45°

50°

55°

60°

25°

140 mm

1

2

14

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

63043970.39-1.SD

Fig. 12 Adjust angle of inclination for portrait collectors

Page 15

Before installation

63043970.40-1.SD

63043970.09-1.SD

4

USER NOTE

For landscape installation of a collector

with an angle of inclination of 35° to 60°,

use the uppermost hole on the lower tele

scopic rail (Fig. 13, Item 3).

For an angle of inclination of 25° and 30°,

you must shorten the top of the lower rail

by 140 mm and use the lower hole

(Fig. 13, Item 2).

RISK TO LIFE

from falling collectors, due to incorrect use.

WARNING!

z For wall-mounted installation, use only

the positions for the collector angles of

inclination 30°, 35°, 40° and 45°

(Fig. 13, Item 1).

4.7 Determining space requirements

4.7.1 Ascertaining the clearance between collector

arrays

35°

40°

45°

-

50°

55°

60°

1

1

1

25°

30°

1

140 mm

3

2

63043970.40-1.SD

Fig. 13 Adjusting angle of inclination for landscape collectors

The minimum spacing between the collector arrays is

determined by the angle of inclination of the collector.

USER NOTE

When using multi-row arrays, note that the

clearance X

(Fig. 14) between the arrays

must be large enough to avoid shadows

falling over adjacent collectors.

Maintain the clearance stated in the tables or calculate

the require clearance (Technical Guide).

Angle of inclina-

tion — collector

installation

25° 4.74 m 2.63 m

30° 5.18 m 2.87 m

35° 5.58 m 3.09 m

40° 5.94 m 3.29 m

45° 6.26 m 3.46 m

50° 6.52 m 3.61 m

55° 6.74 m 3.73 m

60° 6.90 m 3.82 m

Tab. 4 Dependency of clearance X on the angle of

incidence and the minimum altitude of the sun (17°)

Portrait

Clearance X

Landscape

installation

X

63043970.09-1.SD

Fig. 14 Shadow — clearance X

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

15

Page 16

4

63043970.41-1.SD

63043970.10-1.SD

Before installation

4.7.2 Estimating your space requirements

SYSTEM DAMAGE

through wind, eddies and pressure peaks

CAUTION!

around the roof edges.

z Before commencing the installation,

ensure that at least one metre is allo

wed between the flat roof supports and

the edge of the roof

(Fig. 15).

Allow sufficient installation space for the different forms

of installation (landscape, portrait).

These dimensions (Tab. 5 and Tab. 6) relate to the roof

surface area which must be available.

>1 m

>1 m

63043970.41-1.SD

Fig. 15 Distance from the edge of the roof

The quoted dimensions are simply the width of the collector array. In addition, allow at least 0.5 m on either

side of the collector array for pipework.

A

Fig. 16 Space requirements — collector array — portrait

version

B

63043970.10-1.SD

Space requirements for portrait collectors: Space requirements for landscape collectors:

Number

of collectors

2 2.34 m 25° 1.84 m 2 4.18 m 25° 1.06 m

3 3.51 m 30° 1.75 m 3 6.28 m 30° 1.02 m

4 4.68 m 35° 1.68 m 4 8.38 m 35° 0.96 m

5 5.85 m 40° 1.58 m 5 10.48 m 40° 0.91 m

6 7.02 m 45° 1.48 m 6 12.58 m 45° 0.85 m

7 8.19 m 50° 1.48 m 7 14.68 m 50° 0.85 m

8 9.36 m 55° 1.48 m 8 16.78 m 55° 0.85 m

9 10.53 m 60° 1.48 m 9 18.88 m 60° 0.85 m

10 11.70 m 10 20.98 m

Tab. 5 Space requirement for portrait installed collectors Tab. 6 Space requirements for landscape installed

Dimension

A

Angle of

inclination

Dimension

B

Number

of collectors

collectors

Dimension

A

Angle of

inclination

Dimension

B

16

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 17

Installing flat roof and wall mounting supports

63043970.11-1.SD

63043970.23-1.SD

5 Installing flat roof and wall mounting supports

RISK TO LIFE

Whilst working on the roof, take all neces-

WARNING!

WARNING!

sary precautions against a possible fall.

RISK OF INJURY

through a fall or falling parts.

z Take appropriate action to prevent ac-

cidents when working on roofs.

z Always wear your personal protective

clothing and safety equipment.

5

USER NOTE

Please observe all national and local accident prevention regulations, as well as the

safety instructions in this manual when

working on roofs.

Ensure sufficient stability at the installation surface, and

removing any gravel and similar material.

USER NOTE

To protect the roof skin, lay commercially

available building protection mats, onto

which you can position the profiles. The

sealing membrane must not be damaged.

This installation method also applies to the flat roof

support for landscape collectors.

The following describes the installation of flat roof supports for portrait collectors. The landscape version is installed in the same way.

Notes identify any variations.

63043970.11-1.SD

Fig. 17 Portrait flat roof supports for 2 collectors

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

63043970.23-1.SD

Fig. 18 Landscape flat roof supports for 2 collectors

17

Page 18

5

63043970.44-1.SD

63043970.13-1.SD

63043970.42-1.SD

Installing flat roof and wall mounting supports

5.1 Distances between collector braces

for on-site base anchoring

The distances between the collector braces (middle/middle, in mm) depend on:

— the collector version (portrait, landscape)

— and the maximum wind or snow loads

USER NOTE

You must strictly observe the clearances

between the collector braces so that the

profile rails can still be installed at a later

stage.

5.1.1 Basic version

Two collector braces are required for the first collector.

For every additional portrait collector, another collector

brace is required

pe collector, two further collector braces are required

(Fig. 21).

(Fig. 19). For every additional landsca-

980 980

63043970.44-1.SD

Fig. 19 Basic version for 2 portrait collectors

The basic version can be used for the following loads:

— building height max. 20 m (installation height)

— max. 2.0 kN/m² wind or snow load

9801170980

last

x collectors

collector

Fig. 20 Basic version for 3 — 10 portrait collectors

275

first

collector

63043970.13-1.SD

18201820

18

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

63043970.42-1.SD

Fig. 21 Basic version for 2 landscape collectors

Page 19

5.1.2 Version with auxiliary brace (accessory)

63043970.14-1.SD

For greater loads, an auxiliary brace (and additional profile rails, page 27) is required for portrait installation for

the second and all further collectors (Fig. 22). This version can be used for the following loads:

— Building height max. 100 m (installation height)

— max. 3.8 kN/m² wind or snow load

USER NOTE

For landscape installation, a max. building

height of 100 m and a max. wind or snow

lo

ad of 3.8 kN/m² are permitted using the

basic version (

Fig. 21, provided that an ad-

ditional rail is fitted, page 27).

Installing flat roof and wall mounting supports

980980 980190 190

63043970.14-1.SD

Fig. 22 Auxiliary braces for 3 portrait collectors

5

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

19

Page 20

5

63043970.15-1.SD

Installing flat roof and wall mounting supports

5.2 Clearances between the collector

braces when using loading trays

(accessory)

The distances between the collector braces (middle/middle, in mm) depend on:

— the collector version (portrait, landscape)

— and the maximum wind or snow loads.

For portrait installation, an auxiliary brace must be erected for the 4th, 7th and 10th collectors (Fig. 23, Item 1).

USER NOTE

Strictly observe the clearances between

the collector braces so that the profile rails

can be installed.

5.2.1 Basic version

The basic version can be used for the following loads:

— Building height max. 20 m (installation height)

— max. 2.0 kN/m² wind or snow load

Number of

collectors

4 381 mm - -

5 381 mm - -

6 571 mm - -

7 571 mm 381 mm -

8 571 mm 381 mm -

9 571 mm 571 mm -

10 571 mm 571 mm 381 mm

Tab. 7 Distances between auxiliary braces

Dim. A Dim. B Dimension C

11

980980980980980980980

1

1.2.3.4.5.6.7.8.9.10.

ABC

980980980

Fig. 23 Basic version for up to 10 portrait collectors (in mm)

20

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

63043970.15-1.SD

Page 21

63043970.16-1.SD

USER NOTE

63043970.14-1.SD

Landscape installation can be carried out

using only the auxiliary brace (accessory).

For landscape installation, 3 collector braces must be fitted for each collector (Fig. 24).

5.2.2 Version for maximum loads (accessory,

Fig. 25)

For greater loads, ropes (page 23) and additional rails

(page 27) are also required. This version can be used

for the following loads:

— Building height max. 100 m (installation height)

Installing flat roof and wall mounting supports

980 980 135 980 980

63043970.16-1.SD

Fig. 24 Basic version for 2 landscape collectors

5

— max. 3.8 kN/m ²wind or snow load

USER NOTE

For distances between the landscape collector braces for maximum loads, refer to

Fig. 24.

980980 980190 190

63043970.14-1.SD

Fig. 25 Version for maximum loads, 3 portrait collectors

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

21

Page 22

5

Installing flat roof and wall mounting supports

5.3 Stabilising the flat roof supports

The following details refer to a single collector. These

details are based on DIN

buildings".

Individual flat roof supports may be secured in the following three ways to prevent slippage or tipping of the

structure due to the effect of the wind:

— Securing flat roof supports with anchor bolts (on-si-

te).

— Weigh down flat roof supports with concrete slabs,

gravel or similar material (loading trays required).

— Weigh down flat roof supports with concrete slabs,

gravel or similar material (loading trays required) and

make more secure using rope as necessary.

For all methods, please consider the structural integrity

of the roof.

USER NOTE

1055, part 4 "Design loads for

Using gravel in the loading trays, a maximum load of 320 kg is possible per collector (Tab. 8).

USER NOTE

For the following table, please also consider the clearances and number of additional collector braces (Chapter 5.1

"Distances between collector braces for

on-site base anchoring").

Stabilising a collector

Height of building Wind velocity Base anchor Weighting Ropes

Securing against

tipping

Number and type

screws

of

0 m to 8 m 102 km/h 2 × M8/8.8 270 kg 180 kg 1.6 kN

above 8 m up to 20 m 129 km/h 2 × M8/8.8 450 kg 320 kg 2.5 kN

above 20 m up to

1

100 m

Tab. 8 Values to stabilise one collector

1

With additional rail only

2

Per collector brace

151 km/h 3 × M8/8.8 — 450 kg 3.3 kN

2

Weight

(e.g. concrete slabs)

Weight

(e.g. concrete

slabs)

Securing against

slippage

Maximum rope

tension

22

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 23

5.3.1 Securing flat roof supports on site with base

63043970.46-1.SD

563

563

63043970.19-1.SD63043970.19-1.SD

63043970.20-1.SD

anchoring

Installing flat roof and wall mounting supports

5

You can fasten the flat roof supports with anchor bolts.

As an example, we describe fastening onto girders

(Fig. 26, Item 3).

Design the substructure so that the collectors can withstand the wind or snow loads and wind forces placed up-

on them.

In addition, a means of fixing should be provided on site

that

stabilises the structure and prevents damage to the

roof.

SYSTEM DAMAGE

through modifications to the design of the

CAUTION!

flat roof supports

.

z For example, never drill the flat roof

support profiles.

z Transfer the lower profile hole clearances (Fig. 26,

Item 2) onto the girders, and drill the corresponding

holes.

z Insert screws (see Tab. 8 and Fig. 26, Item 1) th-

rough the profiles and girders and screw tight with

nuts and washers.

1

2

3

63043970.46-1.SD

Fig. 26 Flat roof support on girders, dimensions in mm

(value in brackets = landscape version)

1

2

563

(353)

3

563

(353)

5.3.2 Securing flat roof supports with weights

z Erect collector braces (see Chapter 5.1 "Distances

between collector braces for on-site base anchoring").

z Insert loading trays (Fig. 27, Item 2) into lower profi-

les (Fig. 27, Item 1) and into each other (Fig. 27,

Item 3).

z Insert concrete slabs or similar into loading trays

(for

required weight, see Tab. 8).

5.3.3 Providing extra security for the flat roof

supports using rope

You may also additionally secure the weighted flat roof

support with ropes.

Select the rope depending on the expected loads

(see

Tab. 8).

z Fasten each collector on site to the screw on the lo-

wer profile and to a suitable point on the roof, using

at least 2 wire ropes

(Fig. 28, Item 1).

63043970.19-1.SD

Fig. 27 4 loading trays per collector

1

1

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

63043970.20-1.SD

Fig. 28 Flat roof support with ropes

23

Page 24

5

Installing flat roof and wall mounting supports

5.4 Wall mounting supports - installation

The landscape collector braces can also be used for

wall-mounted installation.

RISK TO LIFE

from falling collectors, due to incorrect use.

WARNING!

z Only landscape collector braces are al-

lowed for wall-mounted installation.

z Collectors may only be installed on

walls of buildings with a height up to

20

m (wind velocity = 129 km/h) and a

wind or

snow load of up to 2.0 kN/m².

z Each collector brace must be fastened

to the holes provided, using 3 screws

(provided by customer)

(Tab. 9).

z Install only on a sealed, windproof out-

side wall.

z Before installing the wall mounting sup-

port, check the load-bearing capability

of the fixing wall (i.e. of the wall base).

If necessary, ask a structural engineer

for assistance.

z Never modify the wall mounting struc-

ture.

z Never place objects in the space under-

neath the wall mounting support.

z Never fit facing to the collectors.

63043970.05-1.SD

Fig. 29 Wall mounting support

z Fasten as follows:

Wall structure

Steel-reinforced concrete min. B25

(min. 120 mm)

Steel base structure (e.g. girder) 3 × M8 (4.6) and 2 × washers

Tab. 9 Fasteners

1

A tensile strength of 1.63 kN or a shear strength of at least 1.56 kN must be able to be applied to each fixing.

2

3 × Screw diameter = outside diameter of washer.

3

Brickwork on request

3

3 × UPAT MAX Express anchors, type MAX 8 (A4)1 or similar

and 3 × washers

3 × Hilti HST-HCR-M8 1 or HST-R-M8

3 × washers

Fixings per collector brace Distance from the edge

2

1

2

2

or similar and

z Use 3 screws to fasten each collector brace to the

wall

(see Tab. 9, Fig. 30, Item 1).

of the wall

> 100 mm

> 100 mm

—

24

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 25

Installing flat roof and wall mounting supports

63043970.30-1.SD

5

980

980

135

1

Fig. 30 Fastening collector braces to the wall (for 2 collectors, dimensions in mm)

980

980

63043970.30-1.SD

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

25

Page 26

5

63043965.33-1.SD

63043970.43-1.SD

63043970.45-1.SD

Installing flat roof and wall mounting supports

5.5 Installing the profile rails

The profile rails must be joined together using plug connectors. Each collector is provided with an upper and lower profile rail.

5.5.1 Connecting profile rails

z Push plug connector (Fig. 31, Item 1) as far as it will

go into both profile rails (Fig. 31, Item 2).

z To lock, tighten both fitted M10 threaded studs

(Fig. 31, Item 3) in the plug connector using a size

5 spanner.

5.5.2 Installing profile rails

Positioning the profile rails depends on

— whether they are being installed portrait or landscape

3

Fig. 31 Connecting profile rails

1

1

2

63043965.33-1.SD

3

2

— and on the clearances between the collector braces.

If using base anchoring, begin fastening the profile rails

as follows:

Base anchoring

Basic version Auxiliary brace

portrait: Align with middle hole

on plug connector

(Fig. 32, Item 1)

landscape: Align with third slotted

hole from right

(Fig. 32, Item 2)

Tab. 10 Aligning the lower and upper profile rails when using

base anchoring

Align with second

slotted hole from right

(Fig. 32, Item 3)

--

If using loading trays, begin fastening the profile rails as

follows:

Loading trays

2 collectors 3 to 10 collectors

portrait: Align with middle hole

on plug connector

(Fig. 33, Item 1)

landscape: Align with second slot-

ted hole from right

(Fig. 33, Item 3)

Tab. 11 Aligning the lower and upper profile rails when using

loading trays

Align with sixth slotted hole from right

(Fig. 33, Item 2)

Align with second

slotted hole from right

(Fig. 33, Item 3)

63043970.43-1.SD

Fig. 32 Aligning the profile rails for on-site base anchoring

1

Fig. 33 Aligning the profile rails for loading trays

2

3

63043970.45-1.SD

26

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 27

z Lightly tighten the pre-assembled profile rails

63043970.21-1.SD

63043970.25-1.SD

63043970.24-1.SD

(Fig. 34, Item 2) with M8 x 20 bolts (Fig. 34, Item 1)

so that the profile rails can still be aligned.

z Align the sides of the upper and lower profile rails.

z Tighten bolts.

5.5.3 Fitting additional profile rails (accessory)

If the collector array is exposed to greater loads (building

or installation height of over 20 m and/or wind or

load

of over 2.0 kN/m²), additional rails must be fitted.

snow

z Fasten additional profile rails as described in

Chapter 5.5.2 "Installing profile rails", using the middle hole on the profile (Fig. 35, Item 1).

z Align sides of the profile rails.

z Tighten bolts.

Installing flat roof and wall mounting supports

1

63043970.21-1.SD

Fig. 34 Fitting profile rails (for two portrait collectors in this

example)

1

5

2

5.5.4 Installation of anti-slip protection

To prevent the collectors from slipping, you must fasten

two anti-slip protectors to the lower profile rails for each

collector.

z Push each anti-slip protector (Fig. 36, Item 3) into

the innermost slotted holes (Fig. 36, Item 1) over the

profile rails until it clicks into place (Fig. 36, Item 2).

63043970.25-1.SD

Fig. 35 Fitting additional profile rails

1

3

2

63043970.24-1.SD

Fig. 36 Attaching anti-slip protection

Item 1: Fixing holes for the anti-slip protection

Item 2: Clicking the anti-slip protection into place

Item 3: Anti-slip protection

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

27

Page 28

6

63043970.02-1.SD

Collector installation

6 Collector installation

Observe the following safety and user instructions when

commencing the collector installation.

RISK TO LIFE

through a fall or falling parts.

WARNING!

z Take appropriate action to prevent acci-

dents when working on roofs.

z Whilst working on the roof, take all ne-

cessary precautions against a possible

fall.

z Always wear your personal protective

clothing and safety equipment.

z After completing the installation, always

check that the installed set and the col

lectors are fastened securely.

RISK OF INJURY

-

Fig. 37 Flat roof installation: 2 collectors

63043970.02-1.SD

CAUTION!

CAUTION!

through interruption of work.

z Secure the collectors against falling.

z Stabilise the collector array.

SYSTEM DAMAGE

through damaged sealing faces.

z Do not remove the rubber caps on the

collector connections until immediately

prior to installation.

USER NOTE

Use lifting equipment as used by roofing

contractors, sufficiently strong 3-point suc

tion handles or special carry handles for

the installation (for easier lifting).

USER NOTE

Unsecured collectors may fall during handling and installation.

63043970.05-1.SD

Fig. 38 Wall mounted installation

-

28

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 29

Collector installation

63043966.09-1.SD

63043966.10-1.SD

63043966.08-1.SD

6

6.1 Preparing to install the collectors

Before beginning actual installation on the roof, preassemble the locking caps on the ground to make work on

the roof easier.

To secure the locking caps (and later the corrugated

pipe connectors and connecting pipes as well), attach

brackets to the connections.

SYSTEM DAMAGE

through leaks in the collector connections.

CAUTION!

6.1.1 Pipework connections

The collectors must be installed in such a way that the

sensor bushs for taking up the collector sensor

Item 1) are at the top.

The corrugated pipe connectors, connecting pipes and collector connections must

not display any signs of damage or conta

mination.

z The collector connections have had

special grease applied in the factory to

make installation easier. Do not use

any other grease.

(Fig. 40,

1

4

4

-

Fig. 39 Water connection (right) up to max. 5 collectors

Item 1: Corrugated pipe connector

Item 2: Flow line

Item 3: Return line

Item 4: Locking cap

1

3

63043966.09-1.SD

2

1

USER NOTE

The water connection pipes can be connected on the right (Fig. 39) or left

(Fig. 40). In this manual, the connection pipes are shown on the right.

The pipework in the collector is designed as a double

meander, which enables you to carry out two different

water connections:

Single-sided connection of up to 5 collectors

Up to 5 collectors can be connected to one side of a collector array (Fig. 39 and Fig. 40).

Two-way connection of up to 10 collectors

If there are more than 5 collectors installed in one

collector array, the water connection must be two-way

(Tichelmann principle,

Fig. 41).

The two-way connection can also be made if there are

fewer than 6 collectors

(Fig. 41).

If more than10 collectors are required then a further

AGS pump station is required.

63043966.10-1.SD

Fig. 40 Water connection (left) up to max. 5 collectors

63043966.08-1.SD

Fig. 41 Two-way pipework connections

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

29

Page 30

6

63043966.12-2.SD

63043970.26-1.SD

63043970.31-1.SD

Collector installation

6.1.2 Fitting the end cap

Not all the connections are needed when connecting a

collector array, so those that are not used must be

closed.

z Remove rubber caps (transport protection) from the

relevant collector connections.

z Push end cap with the O-rings (Fig. 42, Item 3) onto

the collector connection.

z Push bracket (Fig. 42, Item 2) over the end cap and

collector connection to secure the connection.

3

1

SYSTEM DAMAGE

from unsecured end caps.

CAUTION!

z Secure each end cap with a bracket

(Fig. 42, Item 1).

6.2 Fastening the collectors

The collectors are fastened to the profile rails using the

single-sided collector clamps

ginning and end of a collector array, and double-sided

clamps

(Fig. 43, Item 1) between each collector.

In addition, the anti-slip protectors (Fig. 43, Item 3) prevent the collector from slipping.

USER NOTE

The plastic parts on the collector clamps

do not have any support function. They are

simply intended to make installation ea

sier.

(Fig. 43, Item 2) at the be-

-

2

63043966.12-2.SD

Fig. 42 Securing end cap with bracket

1

3

Fig. 43 Fasteners for the collector

2

63043970.26-1.SD

Fitting the single-sided collector clamp on the right

z Push single-sided collector clamps (Fig. 44, Item 1)

into the profile rails at the right-hand end of the collector array until they click into place in the first slotted

hole on the profile rails.

USER NOTE

Do not fit the single-sided collector clamps

to the left-hand side of the collector array

until the last collector has been installed.

30

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

1

63043970.31-1.SD

Fig. 44 Pushing on the single-sided collector clamp

Page 31

Putting the first collector in place

63043970.32-1.SD

63043965.45-1.SD

63043969.02-1.SD

Lay the collector on the profile rails in such a way that

the sensor bush to receive the collector sensor is at the

top. Begin by laying the collectors on the right-hand side

of the profile rails.

Collector installation

6

RISK OF INJURY

Install collectors with at least one assis-

CAUTION!

tant.

z Place the first collector onto the profile rails and allow

it to slide into the anti-slip protectors

(Fig. 45, Item 2)

(Fig. 45).

The lower collector edge must lie in the opening of the

anti-slip protector

(Fig. 45, Item 1).

z Carefully push collector (Fig. 46, Item 1) up against

the single-sided collector clamp and align horizontally.

z Screw in single-sided collector clamp using size 5

spanner

(Fig. 46, Item 2).

USER NOTE

When the screw is tightened, the plastic

guide at the pre-determined cut-off points

breaks away and can be discarded.

The grip (Fig. 46, Item 2) on the collector clamp now

grips the lower collector edge.

1

2

63043970.32-1.SD

Fig. 45 Laying the first collector on the profile rails

1

2

63043965.45-1.SD

Inserting a double-sided collector clamp

z Insert the double-sided collector clamp, nut first, into

the opening made by the profile rail and plug connec

tor so that the plastic spacer (Fig. 47, Item 1) surrounds the profile rail.

z Push double-sided collector clamp up against the

collector frame.

USER NOTE

Do not tighten the screw until the second

collector has been pushed up against the

double-sided collector clamp.

Fig. 46 Single-sided collector clamp screwed in place

-

1

1

63043969.02-1.SD

Fig. 47 Fitting a double-sided collector clamp

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

31

Page 32

6

63043966.11-1.SD

63043966.15-1.SD

63043966.16-1.SD

Collector installation

Fitting corrugated pipe connectors to the first

collector

z Remove the rubber caps from the connections.

z Push corrugated pipe connectors (Fig. 48, Item 1)

onto the left-hand connections on the first collector.

z Push bracket (Fig. 48, Item 2) over the corrugated

pipe connector and collector connection to secure

the connection.

Putting the second collector in place

z Place the second collector onto the profile rails and

allow it to slide into the anti-slip protectors.

1

2

63043966.11-1.SD

Fig. 48 Fitting corrugated pipe connectors to the first

collector

SYSTEM DAMAGE

through damaged corrugated pipe

CAUTION!

connectors.

z Do not use any tools, e.g. pliers

(Fig. 49, Item 2). These could render

the corrugated pipe connector

unusable.

z Push the second collector on to the first in such a way

that the collector connections are pushed into the

preassembled corrugated pipe connectors

(Fig. 49,

Item 1) on the first collector.

z Place second bracket (Fig. 49, Item 3) over the

corrugated pipe connector and collector connection.

SYSTEM DAMAGE

through unsecured corrugated pipe

CAUTION!

connectors and end caps.

z Secure each end cap with one bracket

and each corrugated pipe connector

with two brackets

(Fig. 50, Item 1).

1

2

3

Fig. 49 Pushing second collector towards the first

2

63043966.15-1.SD

32

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

1

63043966.16-1.SD

Fig. 50 Corrugated pipe connector secured with brackets

Page 33

z Tighten the screw on the double-sided collector

63043965.48-1.SD

63043970.34-1.SD

clamp using the size 5 spanner.

USER NOTE

When the screw is tightened, the plastic

lugs at the pre-determined cut-off points

break away.

The grip (Fig. 51, Item 1) on the collector clamp now

grips the lower collector edge.

Repeat the procedure for all the other collectors.

Fitting the single-sided collector clamp on the left

Once all collectors are fitted, the two remaining one-sided collector clamps can be attached.

z Push single-sided collector clamp (Fig. 52, Item 1)

into upper and lower profile rails.

z Push collector clamp up against the collector frame

and screw in place using size 5 spanner

(Fig. 52,

Item 2).

The grip (Fig. 52, Item 2) on the collector clamp now

grips the lower collector edge.

Collector installation

6

1

63043965.48-1.SD

Fig. 51 Double-sided collector clamp between two collectors

2

1

USER NOTE

When the screw is tightened, the plastic

guide at the pre-determined cut-off points

breaks away and can be discarded.

63043970.34-1.SD

Fig. 52 Single-sided collector clamp (left)

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

33

Page 34

7

63043966.25-1.SD

63043966.26-1.SD

Collector sensor connection

7 Collector sensor connection

USER NOTE

The collector sensor is supplied with the

solar controller.

Observe the installation location for single

or dual row collector systems

(Fig. 53).

SYSTEM DAMAGE

through faulty sensor cable.

CAUTION!

z Protect the cable from possible dama-

ge.

Insertion point

The collector sensor must be fitted in the collector

nearest to the flow connection

(Fig. 53, Item 2).

— Insertion point (Fig. 53, Item A) for single row collec-

tor systems.

— Insertion point (Fig. 53, Item B) for dual row collector

systems.

Installing the collector sensor

B

A

1

2

63043966.25-1.SD

Fig. 53 Collector sensor installation location (schematic)

Item 1: Return line

Item 2: Flow line

1

2

For perfect functioning of the solar thermal system, the

collector sensor

(Fig. 54, Item 1) needs to be inserted

into the sensor guide tube as far as it will go

(approx.

250 mm).

z Using the collector sensor or screwdriver, push th-

rough the sealing membrane on the sensor bushing

(Fig. 54, Item 3).

z Screw compression fitting (Fig. 54, Item 2) into sen-

sor bushing.

z Insert collector sensor approx. 250 mm into the sen-

sor guide tube (as far as it will go).

z Tighten compression fitting (Fig. 54, Item 2), coun-

terhold if necessary.

USER NOTE

If you accidentally push through the sensor

bushing

(Fig. 54, Item 3) on the wrong collector, it can be resealed using the plug

from the connection kit. You must first re

move the nut in the sensor bushing using

the cable gland

(Fig. 54, Item 2).

3

2

Fig. 54 Inserting the collector sensor into the collector

Item 1: Collector sensor

Item 2: Compession fitting

Item 3: Sensor bushing

1

Kollektor

250 mm

63043966.26-1.SD

34

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 35

8 Header connection

63043969.01-1.SD

63043970.35-1.SD

Information on laying the header pipes can be found in

the complete station installation instructions.

SYSTEM DAMAGE

from leaks in the collector connection, due

CAUTION!

to movements caused by heat.

z Feed the on-site flow line (Fig. 55,

Item 1) alongside the collector, rather

than vertically downwards.

Header connection

1

63043969.01-1.SD

Fig. 55 Feeding header pipes to the collector array

Item 1: Flow line

Item 2: Return line

8

2

1

8.1 Fitting holder for flow line

Use the holder to fasten the insulated flow line to the collector.

USER NOTE

We recommend commercially available

hose clamps

the header to the M8 thread on the holder

(Fig. 56, Item 2).

Select the diameter on the hose clamp according to the outside diameter of the flow

line, incl. insulation.

z Place holder (Fig. 56, Item 3) onto collector frame

and tighten with size 5 spanner.

z Fasten insulated header to holder on site.

(Fig. 56, Item 1) for fastening

2

3

Fig. 56 Fastening holder to the collector frame

Item 1: Hose clamp (on building)

Item 2: M8 thread

Item 3: Holder

1

63043970.35-1.SD

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

35

Page 36

8

63043969.04-1.SD

Header connection

8.2 Venting through pressure filling

If venting of the solar thermal system is carried out using

a pressure filling pump, no vent is required on the roof.

z Remove rubber caps (transport protection) from the

relevant collector connections.

z Push elbow (Fig. 57, Item 2) with olive and union nut

onto collector connection.

z Secure elbow with bracket (Fig. 57, Item 1).

1

2

Perform the same procedure with the return connection.

3

4

63043969.04-1.SD

Fig. 57 Fitting flow line (with no vent on roof)

Item 1: Connector clip

Item 2: Elbow

Item 3: Olive

Item 4: Nut

36

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 37

Header connection

63043966.20-1.SD

63043966.21-1.SD

8.3 De-airing through air vent (accessory) at highest point in the system

8

If you intend to vent the solar thermal system with an

automatic air-vent valve (accessory) at the highest point

of the system, run the flow line rising to the air-vent valve

(Fig. 58, Item 2) and the return line rising to the collector

array (Fig. 58).

Avoid frequent changes in direction.

USER NOTE

For each change of direction downwards

and each new rise, install an additional air

pot with air vent.

If you cannot provide an automatic air vent valve due to

space restrictions, install a manual air vent valve.

Function of the grub screw and weather protection

cap on the automatic air vent valve

The solar thermal system is vented through the opened

grub screw. When in operation, the weather protection

cap

(Fig. 59, Item 1) must always be positioned over

the grub screw to prevent moisture entering through the

opened grub screw into the solar thermal system).

1

63043966.20-1.SD

Fig. 58 View — air pot with vent valve for flow connection

Item 1: Collector sensor

Item 2: Automatic air vent valve on roof

11

10

9

2

1

2

Open the air vent valve by unscrewing the grub screw

one full revolution.

Universal air vent set (Fig. 59):

Item 1: Weather protection cap 1 ×

Item 2: Automatic air vent 1 ×

Item 3: Ball valve 1 ×

Item 4: Gasket 1 ×

Item 5: Vent pot 1 ×

Item 6: Double threaded fitting with O-ring 1 ×

Item 7: Threaded fitting 1 ×

Item 8: Union nut 2 ×

Item 9: Gasket 1 ×

Item 10: Large diameter washer 1 ×

Item 11: Clamping disc 1 ×

8

7

63043966.21-1.SD

Fig. 59 Universal air vent set

3

4

5

6

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

37

Page 38

8

63043969.05-1.SD

63043969.06-1.SD

Header connection

Fitting the air vent

z Firmly screw threaded fitting (Fig. 60, Item 6) and

double threaded fitting (Fig. 60, Item 4) into air pot

(O-ring gasket).

z Push air pot (Fig. 60, Item 5) and fitting onto collector

connection and secure with clip.

z Connect header pipe to the compression fitting

(15

mm) (Fig. 60, Item 2).

1

4

3

6

Fig. 60 Connecting the air vent

Item 1: Connector clip

Item 2: Union nut for 15 mm compression fitting

Item 3: Olive

Item 4: Double threaded fitting with O-ring

Item 5: Air pot

Item 6: Threaded fitting

5

2

63043969.05-1.SD

8.4 Connecting two arrays

If connecting two collector arrays (Fig. 61, Item 1) you

will need a second connection kit.

z Fit individual parts as described in Chapter 8.2 "Ven-

ting through pressure filling".

z Make on-site connection between collector arrays

using copper pipe.

1

1

63043969.06-1.SD

Fig. 61 Two collector arrays, one behind the other

38

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 39

9 Final activities

9.1 Checking the installation

SYSTEM DAMAGE

through corrosion if water remains in the

CAUTION!

solar thermal system for an extended peri

od after it has been flushed or after a pressure test.

z Start up the solar thermal system im-

mediately after flushing/pressure test

with solar fluid (for instructions on flus

hing/pressure test see pump station instructions). Otherwise, carry out

flushing/pressure test later.

USER NOTE

Do not carry out the final insulating work

until the appropriate checks have been

performed.

Final activities

-

-

9

Checks

Corrugated pipe connector, end caps and

1.

connecting pipe bends secured with clips?

All collector braces connected to profile

2.

rails?

Anti-slip protection installed and clicked into

3.

place in profile rails?

Sensor inserted as far as it will go and secu-

4.

red with compression fitting?

Pressure test carried out and all connections

5.

leak-proof (see pump station instructions)?

USER NOTE

If you are venting the solar thermal system

with an automatic air-vent valve (accesso

ry), you must close the ball valve after the

venting procedure (see pump station in

stallation instructions).

-

-

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

39

Page 40

9

Final activities

9.2 Insulating the connection and header

pipes

z Cut enclosed insulation (710 mm long) into 88 mm

lengths and place around the corrugated pipe con

nectors between the collectors.

Insulation of the header pipes in internal or external

installations

— For the insulation of external pipework, use only UV

and high temperature resistant insulating materials,

rated to 150 °C.

— For the insulation of internal pipework, use only high

temperature resistant insulating materials, rated to

150 °C.

— Make the insulation bird-proof.

-

40

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 41

Quick reference guide for base anchoring and pressure filling

63043970.48-1.SD

63043966.31-1.SD

63043969.07-1.SD

10 Quick reference guide for base anchoring and pressure filling

These instructions are only intended as an overview of

the work to be carried out. You MUST follow the detailed

descriptions for the work on the pages mentioned, and

obey all safety and user instructions.

16

10

Fitting braces and profile rails

Insert telescopic rails into each other according to

1.

the

selected angle of inclination, and fasten.

Drill holes in girder (or similar), and fasten collector

2.

braces with screws.

Connect profile rails together using plug connectors. p. 26

3.

Fasten profile rails to collector braces. p. 27

4.

Align sides of the profile rails. p. 27

5.

Install anti-slip protectors into the two inner slotted ho-

6.

les on the lower profile rails.

Preparing to install the collectors

Push end caps onto those connections that are not

7.

required and secure using brackets.

Fastening the collectors

Push single-sided collector clamp (right) into profile

8.

rails.

Place first collector (right) onto profile rails and

9.

push

onto collector clamp.

Screw up collector clamp on the right. p. 31

10.

Place double-sided collector clamp into profile rail

11.

and push onto first collector.

Push corrugated pipe connectors onto the connec-

12.

tions on the first collector and secure with brackets.

Push second collector towards the first and fix in

13.

place with brackets.

Tighten screws on the double-sided collector clamp. p. 31

14.

Repeat the procedure for all other collectors. p. 33

15.

Fit single-sided collector clamps on the left. p. 33

16.

Header connection

Insert collector sensor as far as it will go into the coll-

17.

ector with the flow line to be connected,

and

screw tight.

Place holder for flow line onto collector frame and

18.

screw in place.

Fasten pipe bend to flow and return connections

19.

using clamping ring and nut.

Fix pipe bend with clips. p. 36

20.

Perform installation checks. p. 39

21.

Insulate header pipes with UV and high

22.

temperature

resistant material.

p. 14

p. 23

p. 27

p. 30

p. 30

p. 31

p. 31

p. 32

p. 32

p. 34

p. 35

p. 36

p. 40

11,14

6

3

Fig. 62 Installing on a flat roof

13

7

7

12

12

Fig. 63 Water connections

7

12

17

8,10

4

63043970.48-1.SD

1

2

9

63043966.31-1.SD

20

18

19

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

63043969.07-1.SD

Fig. 64 Fitting the collector sensor and connection parts

41

Page 42

Notes

42

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

Page 43

Notes

SKS 4.0 Series - Flat roof and wall mounting - We reserve the right to make any changes due to technical modifications.

43

Page 44

Buderus

Cotswold Way, Warndon, Worcester WR4 9SW

Customer service: 0870 421 5933

Technical support: 0870 421 5944

Fax: 01905 753130

www.buderus.co.uk

In the UK and IE, Buderus is a brand name of

Bosch Thermotechnology Ltd.

Loading...

Loading...