Page 1

Installation and

maintenance instructions

Vacuum tube

collectors

6 720 647 042-00.1ITL

SKR6.1R, SKR12.1R

Rooftop installation

6 720 647 057 (2011/05) GB

For contractors

Read carefully

prior to installation

and maintenance.

Page 2

Table of contents

Table of contents

1 Key to symbols and safety instructions . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . 3

1.2 General safety information . . . . . . . . . . . . . . 3

2 Product information . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Components and instructions . . . . . . . . . . . 4

2.2 Correct usage . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 EU Declaration of Conformity . . . . . . . . . . . 5

2.4 Standard delivery . . . . . . . . . . . . . . . . . . . . . 6

2.4.1 Mounting bracket . . . . . . . . . . . . . . . . . . . . . 6

2.4.2 Installation set . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.3 Connection sets (hydraulic connection) . . . 7

2.4.4 Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Specification . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Before installation . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Determining space requirements . . . . . . . . 9

4.2 Planning the hydraulic connection . . . . . . 10

4.3 General notes . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Required tools and accessories . . . . . . . . 11

4.5 Lightning protection . . . . . . . . . . . . . . . . . . 11

4.6 Installation order . . . . . . . . . . . . . . . . . . . . . 11

7 Rail installation . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1 Installing the vertical rails . . . . . . . . . . . . . . 20

7.2 Installing horizontal rails and clamps . . . . . 21

7.3 Installing the clampings onto the

vertical rails . . . . . . . . . . . . . . . . . . . . . . . . . .22

8 Installing the collectors . . . . . . . . . . . . . . . . . . 23

8.1 Fitting the first collector . . . . . . . . . . . . . . . 23

8.2 Fitting the second collector . . . . . . . . . . . . 24

8.3 Installing the collector sensor . . . . . . . . . . 24

8.4 Fitting the bridging set (accessory) . . . . . . 25

9 Hydraulic connection . . . . . . . . . . . . . . . . . . . . 26

10 Final steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.1 Checking the installation . . . . . . . . . . . . . . 28

10.2 Pressure filling, flushing, venting . . . . . . . . 28

10.3 Adjusting the pre-charge pressure of

the expansion vessel . . . . . . . . . . . . . . . . . .28

10.4 Determining and setting the operating

pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

10.5 Adjusting the flow rate . . . . . . . . . . . . . . . . 28

10.6 Insulating piping . . . . . . . . . . . . . . . . . . . . . 28

11 Replacing individual tubes . . . . . . . . . . . . . . . 29

5 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Fitting the mounting bracket . . . . . . . . . . . . . 13

6.1 Determining distances . . . . . . . . . . . . . . . . 13

6.1.1 Vertical distances for the mounting

brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1.2 Horizontal distances for the mounting

brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Installing mounting brackets on roof

tile roofs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 Installing mounting brackets on plain

tile roofs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.4 Installing mounting brackets on roofs

with monk/nun tiles . . . . . . . . . . . . . . . . . . . 17

6.5 Installing mounting brackets on slate

roofs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12 Environmental protection/disposal . . . . . . . 30

13 Maintenance/inspection . . . . . . . . . . . . . . . . . 31

2

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 3

Key to symbols and safety instructions

1 Key to symbols and safety instructions

1

1.1 Explanation of symbols

Warning symbols

Safety instructions in this document are

framed and identified by a warning triangle

which is printed on a grey background.

Electrical hazards are identified by a lightning

symbol surrounded by a warning triangle.

Signal words indicate the seriousness of the hazard in

terms of the consequences of not following the safety

instructions.

• NOTICE indicates possible damage to property or

equipment, but where there is no risk of injury.

• CAUTION indicates possible injury.

• WARNING indicates possible severe injury.

• DANGER indicates possible risk to life.

Important information

Notes contain important information in cases

where there is no risk of personal injury or

material losses and are identified by the

symbol shown on the left. They are bordered

by horizontal lines above and below the text.

1.2 General safety information

Danger of falling when working on the roof

B If there are no general anti-fall safety devices, wear

personal protective clothing or safety equipment.

B Take appropriate action to prevent accidents during all

work on roofs.

B Observe accident prevention regulations.

Danger when installing collectors above walk/

driveways

Should the glass tubes be shattered, there is a risk of

injury through glass splinters if anyone is below the

collector array.

B Avoid installation above walkways.

Risk of burns on the collectors

Some parts may cause burns, if the vacuum tube collector

and installation materials are exposed to solar radiation for

prolonged periods of time.

B Wear personal safety equipment.

B Protect the collector and installation materials from

solar radiation (e.g. with a tarpaulin).

Installation

Installation and maintenance must only be carried out by

an authorised contractor. Never modify components.

Additional symbols

Symbol Meaning

B a step in an action sequence

Æ a reference to a related part in the

document or to other related documents

• a list entry

– a list entry (second level)

Tab. 1

B Please read these instructions carefully.

B Install the installation set only on roofs with sufficient

load-bearing capacity. If necessary, consult a structural

engineer and/or roofer.

B Collectors must never be walked on and must never be

subject to loads from other objects.

B After completing the installation, check that the

installation set and the collectors are securely

positioned.

Function checks

The operator is responsible for the safety and

environmental compatibility of the system.

B Customers are recommended to arrange a

maintenance and inspection contract with an approved

contractor.

B Only original spare parts must be used.

Instructing the customer

B Instruct customers in the functions and operation of the

appliance as well as the operation of the system as a

whole.

B Inform customers that they must not carry out any

modifications or repairs.

B Hand over the installation instructions to the customer

and inform him/her that these are to be retained and

passed on to any future owner/user.

SKR6.1R, SKR12.1R - Subject to technical modifications.

3

Page 4

2

Product information

2 Product information

Regarding these instructions

On the following pages, the vacuum tube collector will

simply be referred to as the collector. Roofing in the form

of pantiles, roof tiles, stone tiles, etc. will be uniformly

referred to as roof tiles.

These instructions describe the installation of collectors

(including their hydraulic connection) for the following

covers on pitched roofs:

• Roof tiles, plain tiles, monk/nun tiles and slate shingles.

2.1 Components and instructions

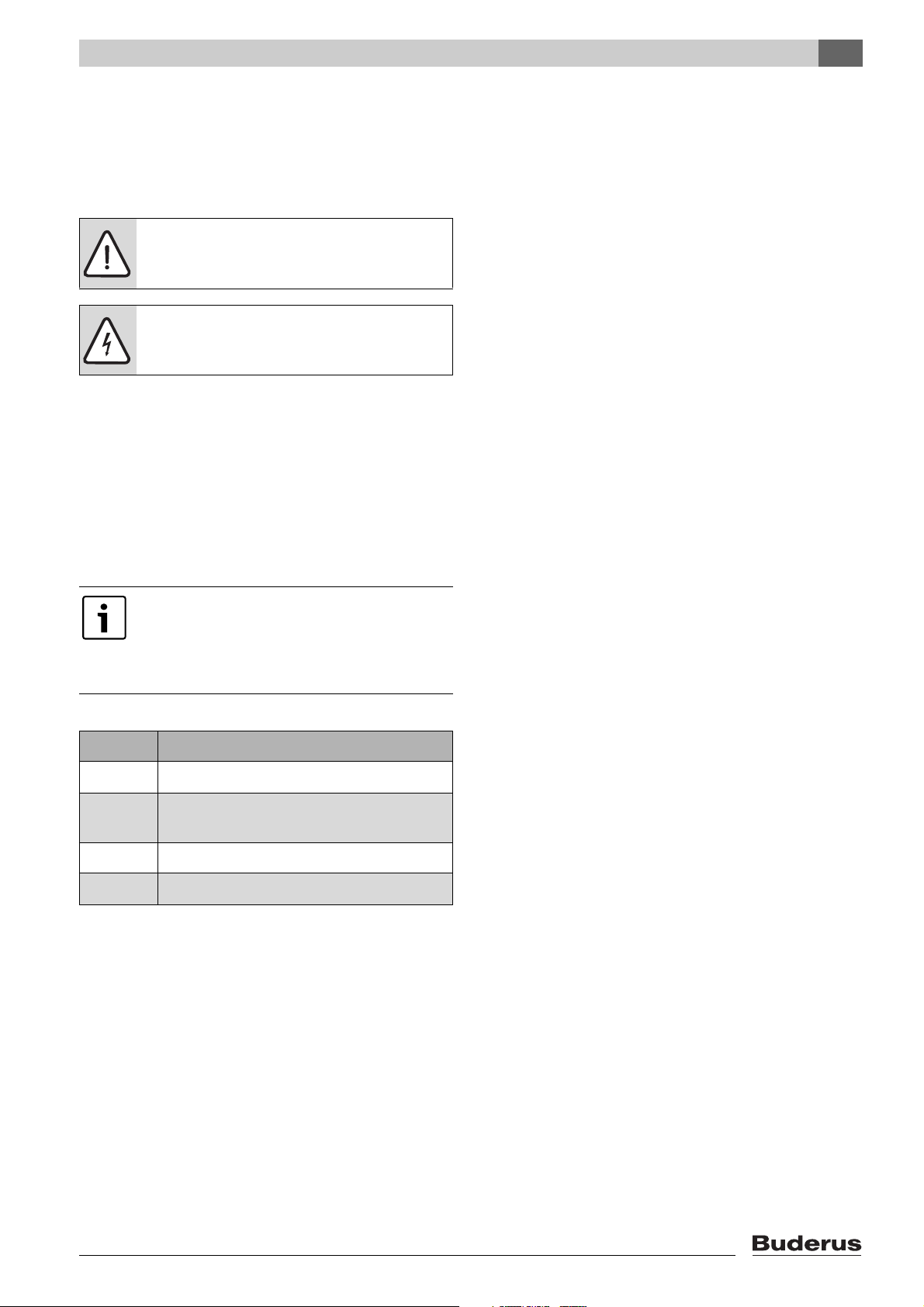

A solar thermal system for heating domestic hot water

and/ or central heating backup comprises various

components (Æ Fig. 1). These are supplied with

instructions regarding their installation, operation and

maintenance. Some accessories are supplied with

separate instructions. The following subjects are

described in the component instructions:

Collectors (Æ Fig. 1, [1])

• Installing the roof connections

• Securing collectors

• Hydraulic collector connection

• Collector maintenance

Solar pump station (Æ Fig. 1, [2])

• Installation of the solar pump station

• Pipework installation

• Commissioning the overall system

• Maintenance of the solar pump station

• Maintenance of the overall system

Cylinder (Æ Fig. 1, [3])

• Siting and installing the cylinder

• Commissioning the cylinder

• Cylinder maintenance

Solar controller (Æ Fig. 1, [4])

• Controller installation

• Operation of the controller and the overall system

6 720 647 042-11.1ITL

Fig. 1 Schematic diagram of a solar thermal system

1 Collectors

2 Solar pump station

3 Cylinder

4 Solar controller

4

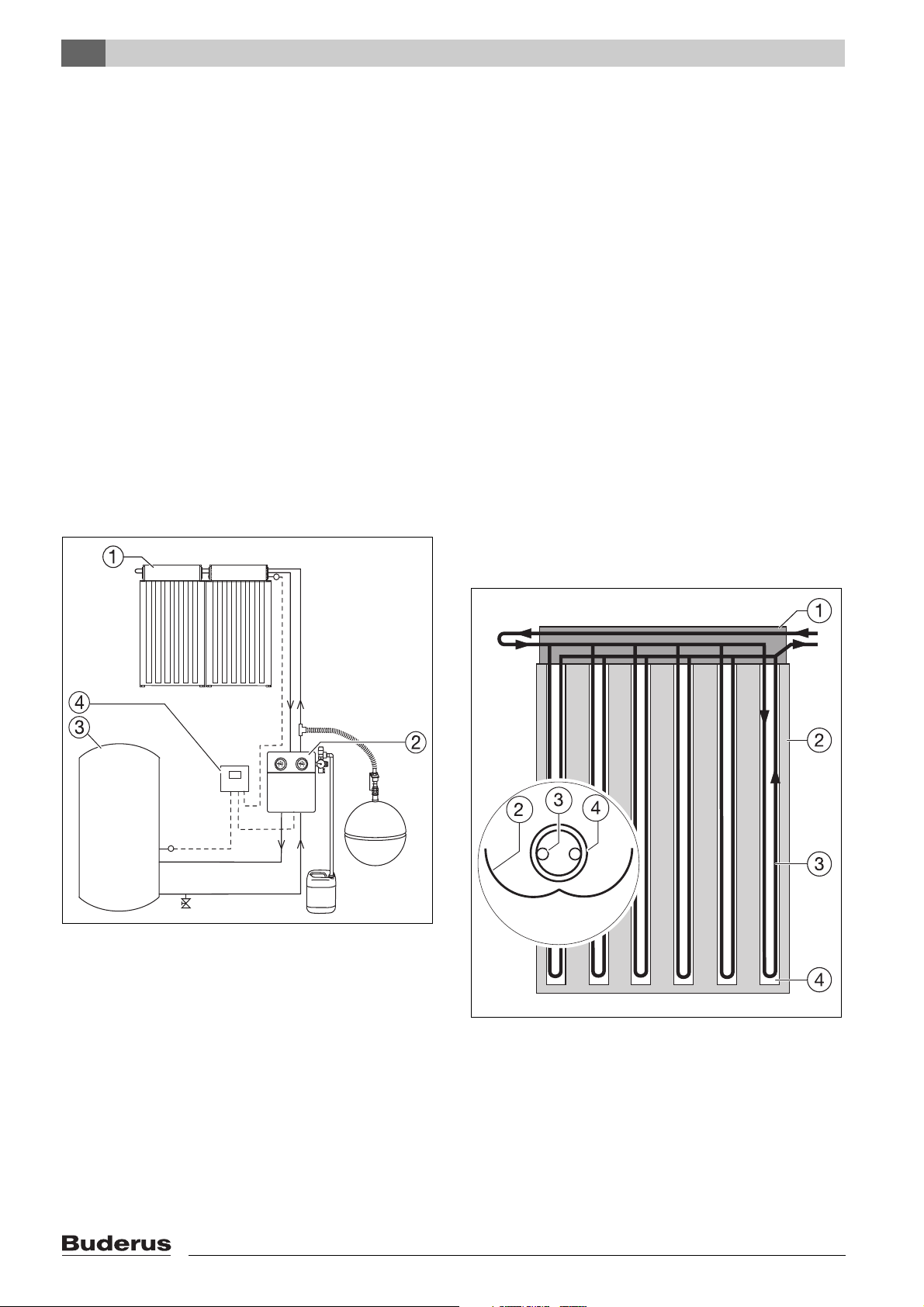

6 720 647 042-01.1ITL

Fig. 2 Vacuum tube collector layout; here: SKR6.1R =

6 tubes (type SKR12.1R = 12 tubes)

1 Header box

2 CPC mirror for optimum sunlight utilisation

3 Heat transfer medium tubes

4 Double glass tubes with vacuum for optimum thermal

insulation (tubes can be replaced without draining the

system)

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 5

Product information

2

2.2 Correct usage

The collectors are designed as the heat source for DHW

heating and central heating backup.

B Only operate these collectors in conjunction with

suitable solar controllers and in fail-safe sealed

unvented solar thermal systems.

These systems must be equipped with a suitable,

adequately sized expansion vessel.

Permissible roof pitch

The self-cleaning effect for the glass tubes and CPC

mirror will only work if the roof has a pitch of at least 15°.

The maximum roof pitch is 65°.

Permissible loads

The installation set is suitable for the following:

• a standard snow load of 1.5 kN/m

(Æ Tab. 4) and

• wind speeds of max. 129 km/h (corresponds to a

stagnation pressure of 0.8 kN/m

B Find out about the local standard snow loads.

B To determine the maximum wind speed, take into

account the following factors:

– the location of the solar thermal system

– the geographic height [above seal level]

– the topography

– the building height

2

or 2.0 kN/m2

2

)

• The following values in the installation and

maintenance instructions of the solar pump station

refer to flat-plate collectors:

– the pre-charge pressure to be set for the expansion

vessel

– the operating pressure to be set

– the flow rate to be set

For the values applicable to vacuum tube

collectors, see the chapter "Final steps"

(Æ page 28) in these instructions.

Apart from the information in the solar pump station

instructions, observe the following:

• The distance between the solar pump station

(expansion vessel connection) and the bottom edge of

the collector array must be at least 2 m (Æ Fig. 3).

• The minimum pipe length (straight length) between the

solar pump station (expansion vessel connection) and

the collector array must be at least 10 m.

If necessary, consult a building structural engineer.

Heat transfer medium

To protect the collectors against damage through frost

and corrosion, operate them with LS solar heat transfer

medium. This must never be mixed with other fluids.

Other applicable instructions and important notes

The installation and maintenance instructions for the solar

pump station include vital information regarding the use of

collectors in a solar thermal system. Observe particularly

the information on the following subjects:

• Never braze pipework near the collectors.

• If system is used for central heating backup or covers

more than 60 % of the DHW demand, install a precooling vessel upstream of the expansion vessel.

• Install the expansion vessel (EV) with a tee 20-30 cm

above the solar pump station in the return (Æ Fig. 3).

• Flush and fill the system with LS solar heat transfer

fluid, by using a filling pump (never use water, as the

collectors cannot be drained). Consequently, there is

no need for an air vent above the roof.

> 200 cm

20-30 cm

6 720 647 042-14.1ITL

Fig. 3 Minimum clearances

2.3 EU Declaration of Conformity

This product conforms in design and operation to the

European Directives and the supplementary national

requirements. Its conformity is demonstrated by the CE

designation.

The Declaration of Conformity can be requested from the

manufacturer (see the back cover for the address).

SKR6.1R, SKR12.1R - Subject to technical modifications.

5

Page 6

2

Product information

2.4 Standard delivery

B Check that the delivered material is complete and

undamaged.

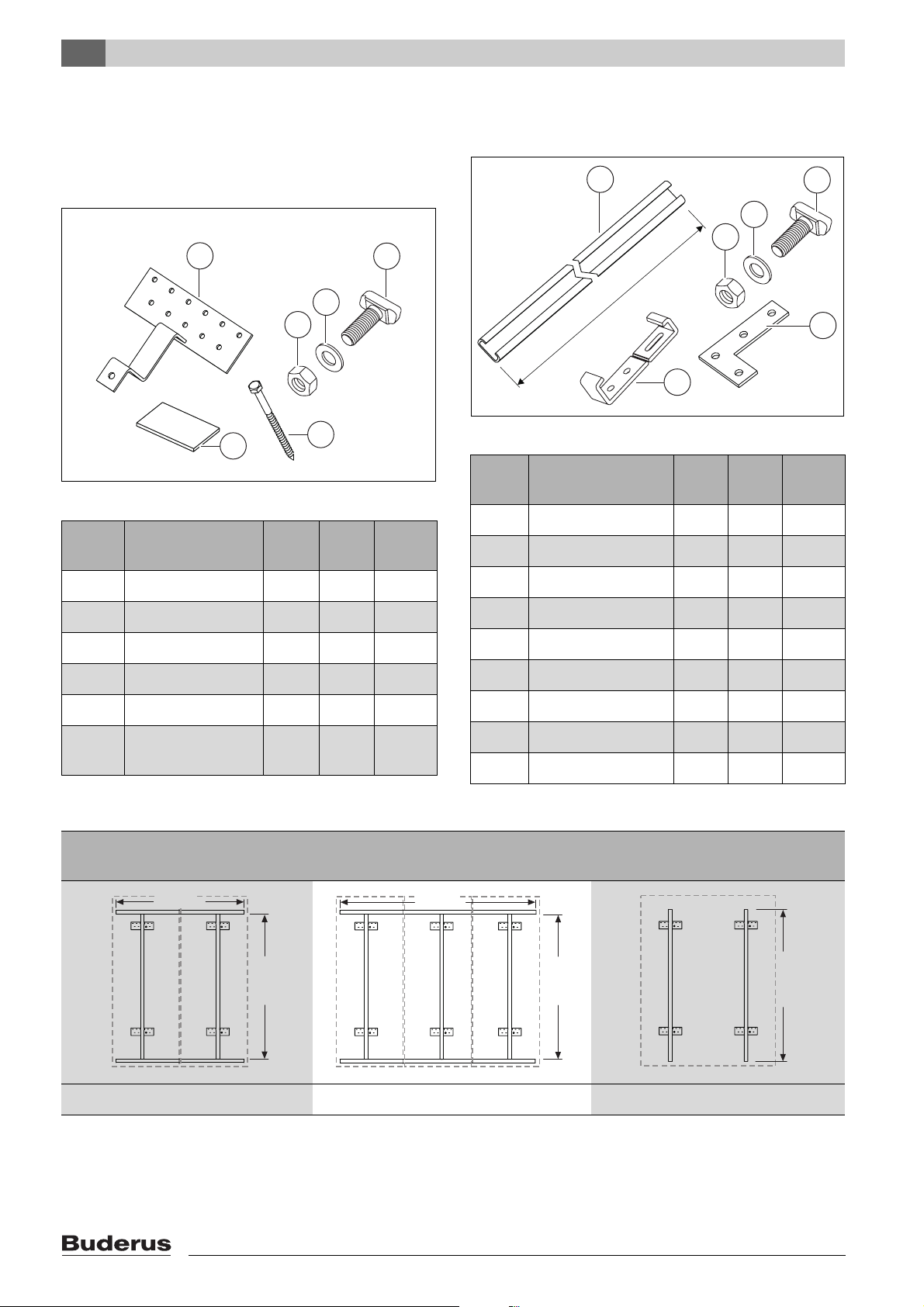

2.4.1 Mounting bracket

1

4

2.4.2 Installation set

7

4

3

2

3

2

6

Fig. 4 Standard delivery, roof connection for tiles

Item 1 Mounting bracket 4 6 4

Item 2 M10 nut 4 6 4

Item 3 Washer 4 6 4

Item 4 T-head bolt 4 6 4

Item 5 Screw 8 x 120 12 18 12

Item 6 Wooden support

100 x 150 x 8 mm

Tab. 2 Standard delivery, roof connection for roof tiles

subject to number of collectors

5

6 720 647 042-16.1ITL

2 x

SKR6

12 18 12

3 x

SKR6

1 x

SKR12

L

8

9

6 720 647 042-17.1ITL

Fig. 5 Standard delivery for installation set

2 x

SKR6

Item 2 M10 nut 24 36 6

Item 3 Washer 24 36 6

Item 4 T-head bolt 24 36 6

Item 7 Rail L=1300 mm 2 -- --

Item 7 Rail L=1953 mm 2 3 --

Item 7 Rail L=2007 mm -- 2 --

Item 7 Rail L=2022 mm -- -- 2

Item 8 L connector 4 6 --

Item 9 Clamp top/bottom 4 6 2

Tab. 3 Installation set subject to number of collectors

3 x

SKR6

1 x

SKR12

3 x SKR6.1

2 x SKR6.1

1300

1953

Standard snow load: max. 1.5 kN/m2Standard snow load: max. 1.5 kN/m

Tab. 4 Using the rails (Item 7) and maximum standard snow load (dimensions in mm)

6

(or 1xSKR6.1 + 1xSKR12.1)

2007

SKR6.1R, SKR12.1R - Subject to technical modifications.

1 x SKR12.1 or 1 x SKR6.1

1953

2

Standard snow load: max. 2.0 kN/m

2022

2

Page 7

Product information

2

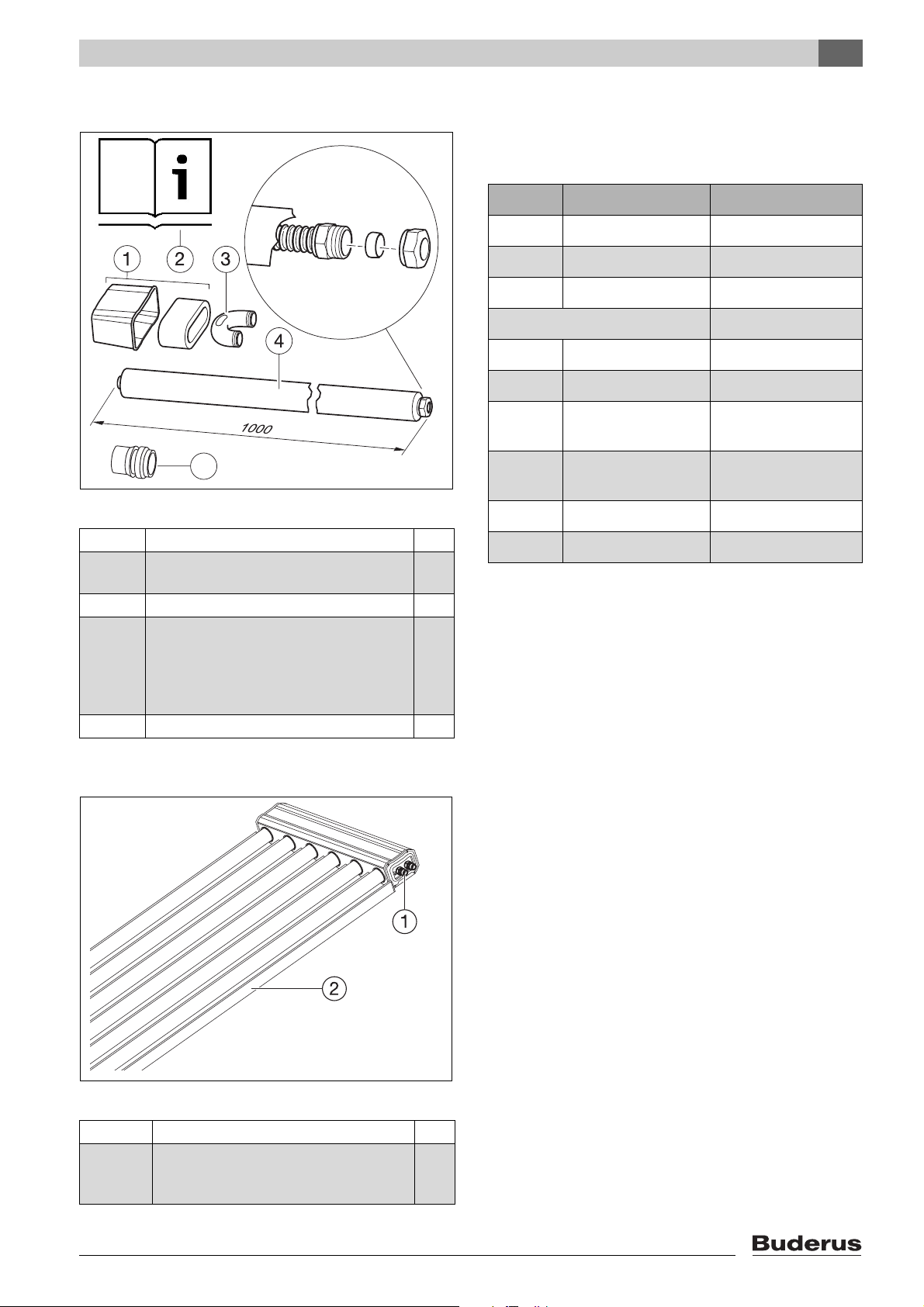

2.4.3 Connection sets (hydraulic connection)

5

6720648182-02.1ST

Fig. 6 Standard delivery, connection set, rooftop

Item 1 Cap, thermal insulation 1 x

Item 2 Installation and maintenance

instructions

Item 3 Return feed bend 1 x

Item 4 Connection pipe, fully assembled

(incl. corrugated stainless steel pipe,

thermal insulation and 18 mm locking

ring fitting for connection to the

common pipeline)

Item 5 Reducer 18 x 15 mm 2 x

Tab. 5 Standard delivery, connection set, rooftop

1 x

2 x

2.5 Data plate

The data plate is mounted on the header box and contains

all important information in the form of symbols.

Symbol Meaning Explanation

A

G

A

a

A

A

Dimensions Measurements

V

f

m mass Weight

t

stg

p

max

p

pr

y

prod

Tab. 7 Data plate information

area

gross

area

aperture

area

absorber

volume

fluid

temperature

pressure

pressure

year

maximum

test

production

stagnation

Gross area

Aperture area

Absorber area

Collector contents

Stagnation

temperature, max.

Max. operating

pressure

Test pressure

Year of manufacture

2.4.4 Collector

6 720 647 042-08.1ITL

Fig. 7 Collector with pre-assembled male connectors

Item 1 Male connectors to join the collectors 2 x

Item 2 Collector SKR6.1R/SKR12.1R

1 x

comprising: vacuum tubes,

CPC mirror and header box

Tab. 6 Standard delivery, collector

SKR6.1R, SKR12.1R - Subject to technical modifications.

7

Page 8

3

Regulations

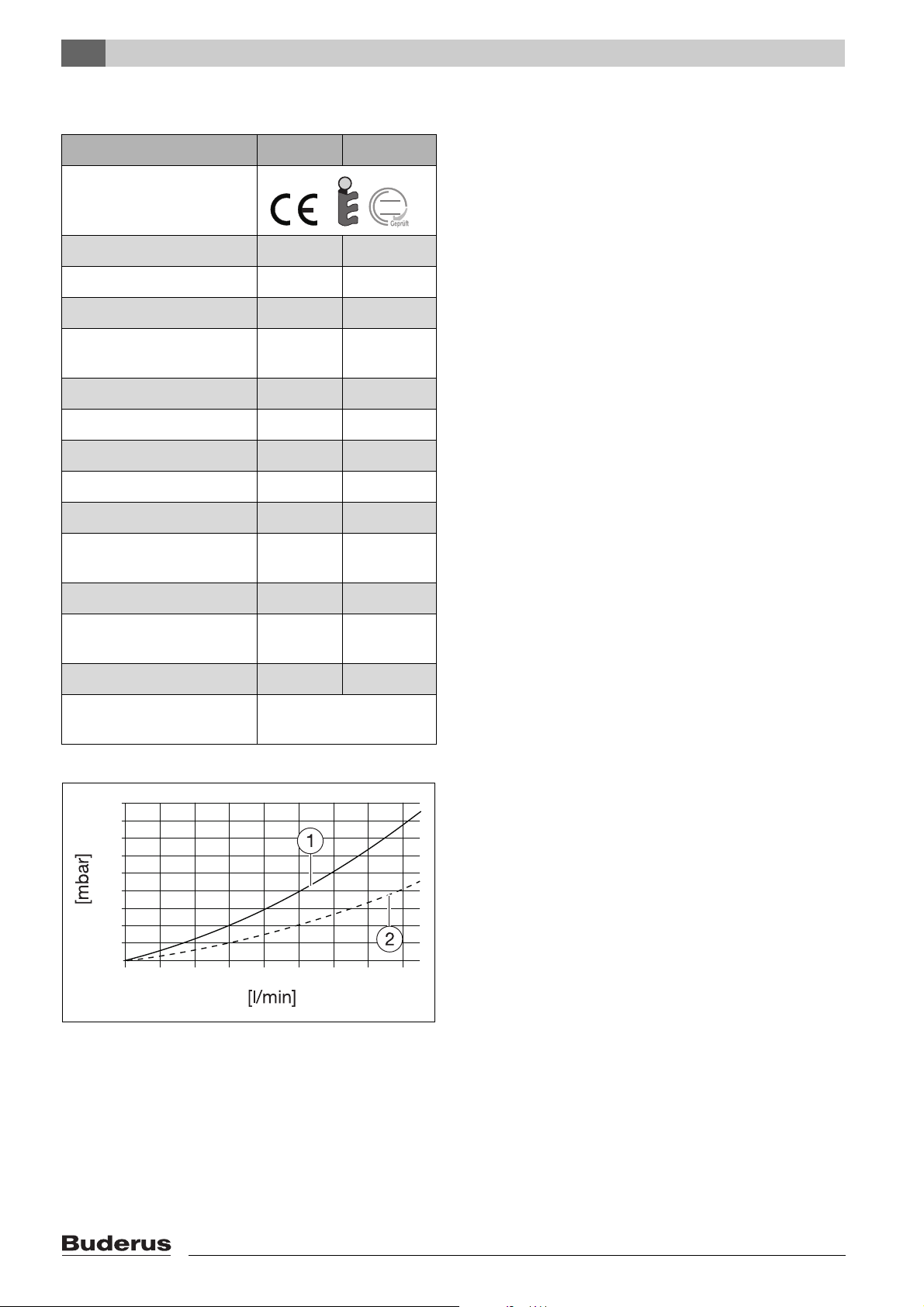

2.6 Specification

SKR6.1R SKR12.1R

Certificates

Width 0.70 m 1.39 m

Depth 0.10 m 0.10 m

Length 2.08 m 2.08 m

Collector connection,

flow and return

Collector contents 1.19 l 2.36 l

Gross area 1.46 m

Aperture area 1.28 m

Absorber area 1.29 m

Net weight 24 kg 44 kg

Permissible operating

pressure collector (p

max

Test pressure (ppr) 13 bar 13 bar

Stagnation temperature,

max.

Number of glass tubes 6 12

Glass tube: tube length /

external Ø / internal Ø

Tab. 8 Specification

180

160

140

120

100

80

60

40

20

0

012345678

Fig. 8 Collector pressure drop

1 Pressure drop curve for SKR12.1R

2 Pressure drop curve for SKR6.1R

15 mm 15 mm

10 bar 10 bar

)

301 °C 301 °C

1920 mm /

47 mm / 37 mm

2

2

2

2.90 m

2.57 m

2.58 m

6 720 647 042-15.1ITL

DIN

3 Regulations

B Observe all standards and guidelines applicable to the

installation and operation of the system in your country

and region.

• The Health and Safety at Work Act 1974

• Control of substances hazardous to health regulations

(COSHH) 1994

• The pressure equipment regulations 1999

• Construction (Design and Management) Regulation

(CDM) 2007

• The Work at Height Regulations 2005

• Manual Handling Operations Regulations 1992

2

2

2

• The Lifting Operations and Lifting Equipment

Regulations (LOLER) 1999

• Reporting of injuries, diseases or dangerous

occurrences regulations (RIDDOR) 1995

• Confined spaces regulations 1997

• Personal protective equipment at work regulations

1992

• Electricity at work regulations 1989

• Provision and uses of work equipment regulations

(PUWER) 1998

• BS 6795:1986 Code of practice for solar heating

systems for swimming pools for swimming pool

• BS5918: A code of practice for the installation of

DSHW systems for domestic hot water

• BS5546: 2000 Specification for installation of hot

water supplies for domestic purposes, using gas-fired

appliances of rated input not exceeding 70 kW

• BS6700: 2006 Specification for design, installation,

testing and maintenance, of servicing supplying water

for domestic use within buildings and their curtilages

• EN 12976: Thermal solar heating system and their

components (prefabricated systems)

• ENV 12977: Thermal solar heating system and their

components (bespoke systems)

• BS 6920: Suitability of non-metallic products for use in

contact with water intended for human consumption

with regards to their effect on the quality of water

• BSEN 12831:2003: Heating systems in buildings.

Methods for calculation of the design heat load

• BS 8000-15: 1990: Workmanship on building sites.

Code of practice for hot and cold water services

(domestic scale)

8

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 9

4 Before installation

b

a

a

Before installation

4

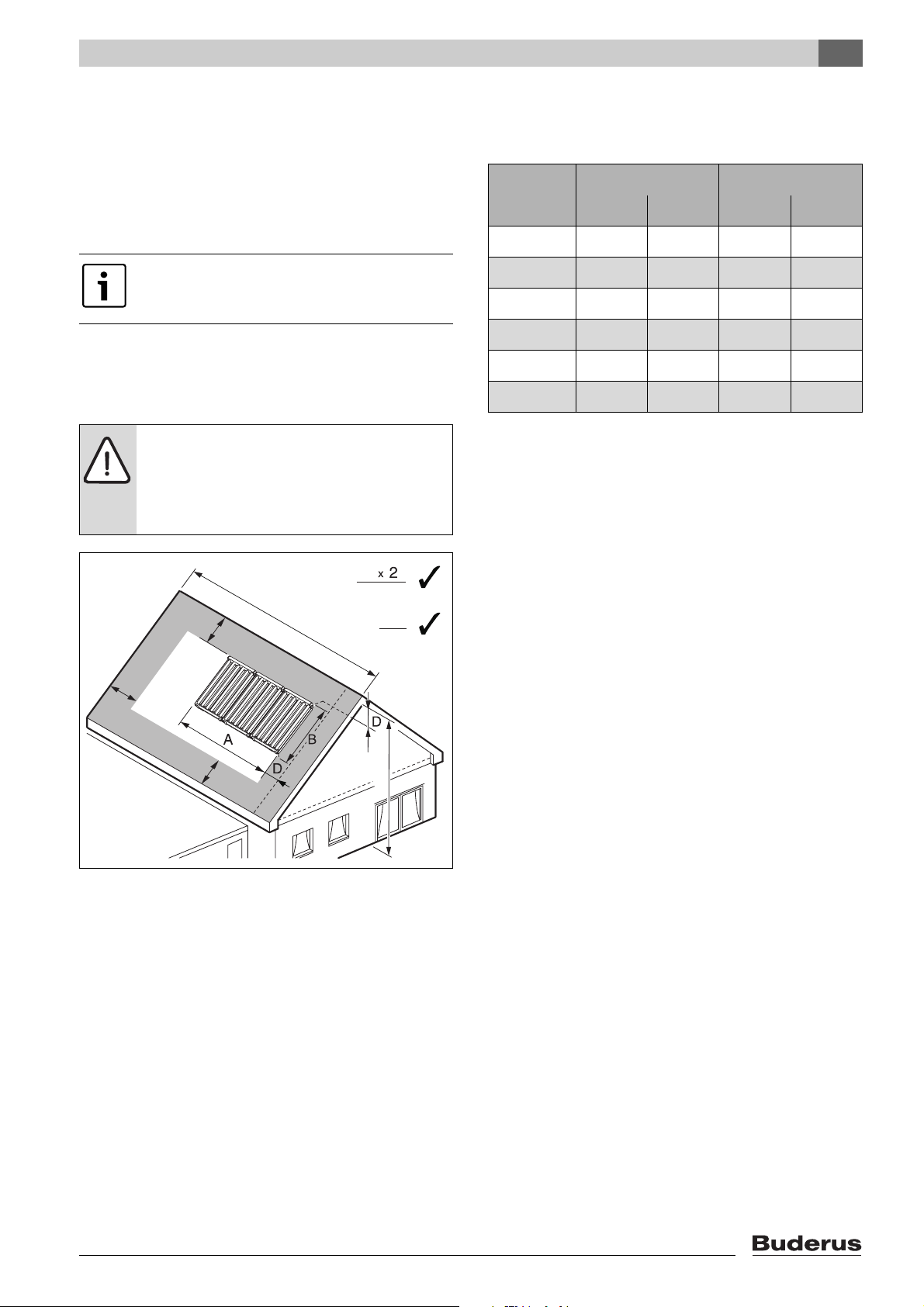

4.1 Determining space requirements

Also take account of the details concerning the optimum

arrangement of the collectors and the prevention of

shading (Æ chapter 4.3).

The clearance between the collector arrays

must be at least 15 cm to enable the correct

installation of the hydraulic connections.

The space requirement is determined by the installation

area of the collector array (Æ Tab. 9). When siting the

collector array ensure that the minimum are maintained

(Æ Fig. 9).

DANGER: Risk of fatal injury through

collectors that cannot withstand peak wind

and suction values.

B Maintain the minimum clearance to the

edge of the roof.

h

a =

10

C, a

b

a =

b

10

Number of

collectors

1 0.70 m 2.08 m 1.40 m 2.08 m

2 1.40 m 4.32 m* 2.80 m 4.32 m*

3 2.10 m 6.55 m* 4.20 m 6.55 m*

4 2.80 m -- -- --

5 3.50 m -- -- --

6 4.20 m -- -- --

Tab. 9 Space requirement (* for dimension B:

collectors arranged one above the other)

SKR6.1R SKR12.1R

Dim. A Dim. B Dim. A Dim. B

a

a

6720646203-10.1ST

Fig. 9 Minimum clearances of the collector array

• Dimension a: Use a formula, both are possible

• Dimensions A and B: Æ Tab. 9

• Dimension C: At least 3 rows of tiles to ridge or

chimney

• Dimension D: At least 0.5 m to the right and left of the

collector array as well as to the ridge for connection

lines below the roof.

h

SKR6.1R, SKR12.1R - Subject to technical modifications.

9

Page 10

4

Before installation

4.2 Planning the hydraulic connection

Please refer to the solar technology technical

guide for detailed information on planning the

hydraulic system and components.

Before you install the collectors you will need to know

how you can arrange the collectors.

Fit the collector sensor [1] in the collector

connected to the flow and return pipes [2]

and [3].

Maximum number of collectors per row:

• SKR6.1R: 6 collectors

• SKR12.1R: 3 collectors

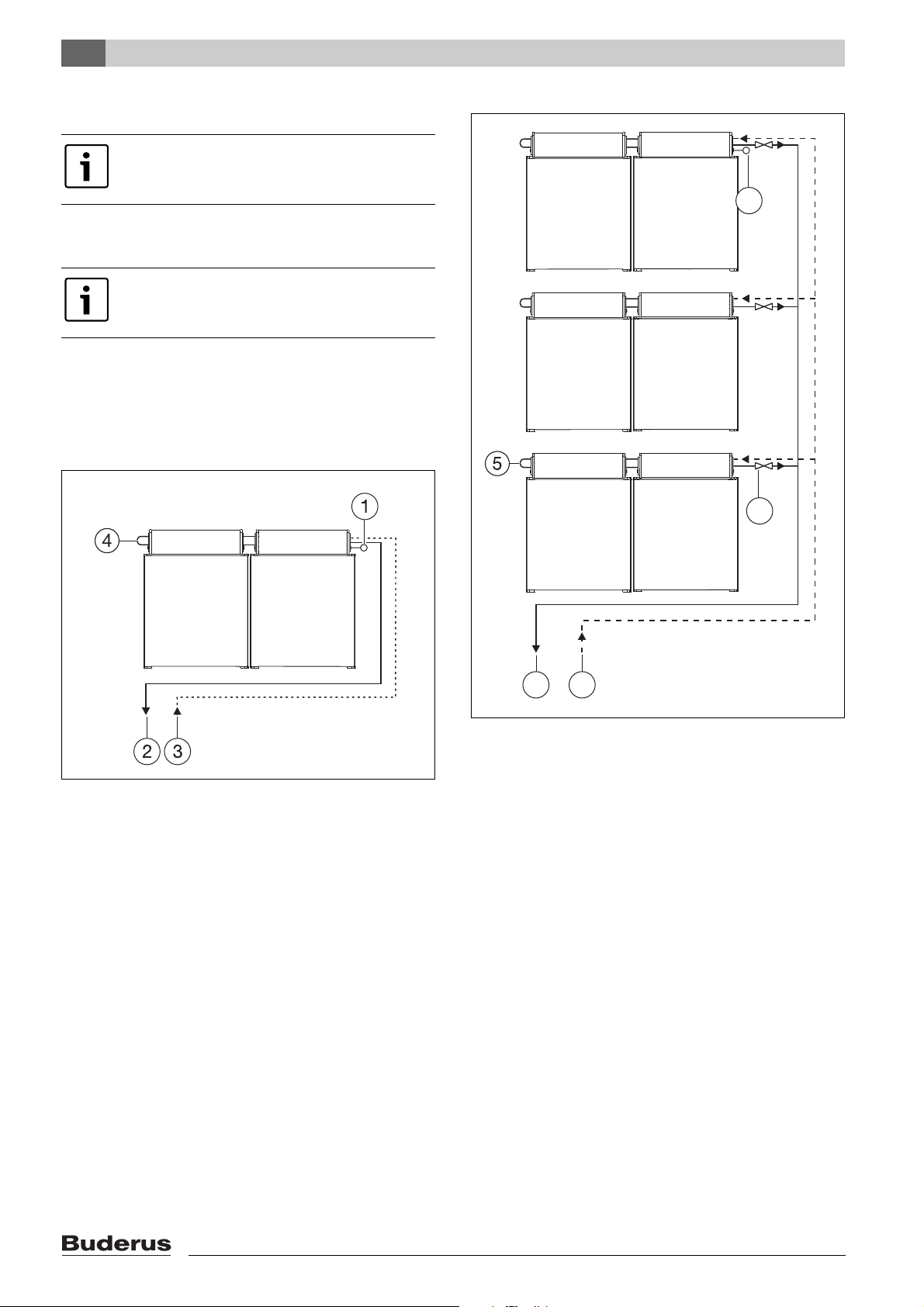

The following shows two examples of hydraulic layouts for collectors:

1

6 720 647 042-03.1ITL

Fig. 10 Connection in a single row

1 Collector sensor (always on the connection side)

2 Flow pipe (to the cylinder)

3 Return pipe (from the cylinder)

4 Return U-bend

4

32

Fig. 11 Triple row connection (with shut-off valve)

1 Collector sensor (always on the connection side)

2 Flow pipe (to the cylinder)

3 Return pipe (from the cylinder)

4 Shut-off valve (accessory)

5 Return U-bend

6 720 647 042-04.1ITL

10

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 11

Before installation

4

4.3 General notes

We recommend that you engage the

services of a roofing contractor, as they are

experienced in working on roofs and dealing

with the risk of falling.

• Obtain information about on-site conditions and local

regulations.

• Remove and replace broken roof tiles, shingles, etc.

• Always install collectors with the header box on the top

(Æ Fig. 12).

6 720 647 042-23.1ITL

Fig. 12 Permissible installation orientation

• Arrange collectors on the roof in an appealing pattern,

for example, so that the collector array is in line with

windows and doors (Æ Fig. 13). However, observe the

minimum clearances towards the edge of the roof for

this (Æ Fig. 9, page 9).

• Align the collector array facing south, wherever

possible (Æ Fig. 13).

N

WO

S

• Avoid shading from adjacent buildings, trees etc. falling

onto the collector array (Æ Fig. 14).

6720646203-09.1ST

Fig. 14 Avoiding shade

4.4 Required tools and accessories

• Power drill

• 6 mm, 9 mm drill bits for pre-drilling

• Spanner, sizes SW13, 17, 22, 24, 30

• Hammer (for roof tiles and connection set)

4.5 Lightning protection

The requirement for lightning protection can differ from

region to region.

B Check regional regulations as to whether a lightning

protection system is required.

Lightning protection is frequently required for buildings

higher than 20 m.

Lightning protection should be installed by a qualified

electrician.

Where there is a lightning protection system installed,

check the inclusion of the solar thermal system into this

system.

6720646203-08.1ST

Fig. 13 Aligning the collector array to the building's

shape

SKR6.1R, SKR12.1R - Subject to technical modifications.

4.6 Installation order

To secure collectors to the roof, install in the following

order:

1. Determine distances for mounting brackets

2. Install mounting brackets.

3. Install rails and clamps.

4. Fit the collectors and collector sensors.

5. Connect piping to collectors.

11

Page 12

5

Handling

5 Handling

The collectors and installation materials are heavy and

awkward. Observe the following information, as working

on the roof involves potential dangers.

DANGER: Risk to life through falling and

falling parts!

B Do not use a ladder to move components

onto the roof because the installation

materials and collectors are heavy and

difficult to handle.

B For all work on the roof, take appropriate

measures to prevent accidents.

B Secure the roof against parts falling off.

B Always wear your own protective clothing

or safety equipment.

B The installation on the roof must be

performed by at least 2 people.

B During handling and installation, secure

the collectors and installation components

against falling.

B After completing installation, check that

the installation set and collectors are

securely positioned.

DANGER: Risk to life through inadequately

secured collectors during transport.

B Ensure the straps are securely tied to the

collectors.

B To prevent oscillation, observe the wind

force and guide hanging collectors with

guy ropes.

B To make handling collectors and installation materials

easier, use the following aids. They must have sufficient

load bearing capacity:

– Site lift or crane

– Roofing ladder or equipment for roof access

–Lifting belt

– Scaffolding

B Dispose of shipping packaging by environmentally

responsible means.

WARNING: Risk of injury through glass

splinters.

B When handling collectors, always wear

safety gloves and goggles.

NOTICE: Collector damage through

transport.

B We recommend transporting the collector

to the roof in its transportation packaging.

B Use the straps at the top of the collector for transport.

12

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 13

6 Fitting the mounting bracket

Fitting the mounting bracket

6

The collectors are connected to the structural element

using mounting brackets. The distances shown are using

the example of the mounting bracket for roof tiles.

B Ensure there is safe access to the roof in compliance

with current legislation and health and safety

requirements.

NOTICE: Damage to the roof by stepping on

installed mounting brackets and installation

set.

B To prevent damage to the roof, do not

step on installed components.

Pre-assembly on the ground

In order to make installation on the roof easier for you, we

recommend that you pre-assemble the threaded

connections for all mounting brackets at ground level.

B Secure the T-head bolt with washer and M10 nut onto

the mounting bracket.

6.1 Determining distances

An example of the mounting bracket for roof

tiles is shown in the following tables. The

distances also apply to other mounting

brackets.

B In order to install the mounting brackets, you must

determine the distances for them. Please observe the

following guidelines (Æ Fig. 16):

– On tiled roofs, the position of tile valleys are used to

determine the true distance between the mounting

brackets.

– The rafter spacing does not always match the

required spacing for the mounting brackets. For

larger or smaller rafter spacing, you must install

suitable supports on site with adequate loadbearing capacity (in doubt, consult a structural

engineer).

– For multiple rows of collectors, you must choose the

distances for the mounting brackets in such a way

that there is a minimum distance of 150 mm

between the collectors on the top and bottom.

– The mounting brackets must be positioned at right

angles to each other.

6720646203-40.1ST

Fig. 15 Pre-fitting the T-head bolts on the ground

NOTICE: Collector damage through

incorrectly positioned mounting brackets.

B Maintain the distance between the

mounting brackets (Æ Fig. 16).

B Always choose the largest possible

distance between two vertical mounting

brackets (Æ Fig. 16, Dimension b).

B A rafter width of at least 88 mm is required

to fasten the mounting brackets with

3 screws. Provide for on-site

reinforcements in case of narrower rafters.

B Define mounting bracket positions (Æ Fig. 16 to 20

and Tab. 10).

SKR6.1R, SKR12.1R - Subject to technical modifications.

13

Page 14

6

90°

90°

Fitting the mounting bracket

6.1.1 Vertical distances for the mounting brackets

For roof batten spacing of 370 mm (SKR6.1,

SKR12.1) and 450/460/470 mm (SKR6.1),

install the mounting brackets at a distance

from the roof batten. Accurate spacing is

required to achieve the correct dimension b

(Fig. 16).

xx

Dimension a Roof batten spacing

Dimension b For SKR6.1

Dimension b For SKR12.1

320 mm - 340 mm 1520 mm -

1715 mm

350, 430 mm 1715 mm -

1760 mm

370, 470 mm 1895 mm

380 mm - 420 mm 1520 mm -

1520 mm 1840 mm

1715 mm

360, 440, 450 mm 1760 mm -

1810 mm

460 mm 1810 mm

Tab. 10 Vertical distances for the mounting brackets

> 0,15 m

90°

b

0,65-0,8 m 0,65-0,8 m

Fig. 18 3 x SKR6.1 (or 1 x SKR6.1 and 1 x SKR12.1)

for a standard snow load of up to 1.5 kN/m

0,45 m

0,26 m

Fig. 19 2 x SKR6.1 (and others) for a standard snow

load of up to 2.0 kN/m

1,395 m

0,45 m

2

6720646203-03.2ST

2

6720646203-46.1ST

90°

a

6720646203-33.1ST

Fig. 16 Distances to be maintained and rafter width

6.1.2 Horizontal distances for the mounting brackets

Subject to the type of collector and regional snow loads,

you will have to use different distances.

xx

0,70-0,93 m

Fig. 17 2 x SKR6.1 or 1 x SKR12.1) for a standard

snow load of up to 1.5 kN/m

2

6720646203-02.2ST

x x

0,70-1,05 m

Fig. 20 2 x SKR12.1 (and others) for a standard snow

load of up to 2.0 kN/m

x x

0,70-1,05 m

6720646203-26.1ST

2

The Dimension x stands for an identical

distance. The maximum difference between

these dimensions is 100 mm.

14

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 15

Fitting the mounting bracket

6

6.2 Installing mounting brackets on roof tile roofs

B Depending on the distances (Æ page 14), remove 2-3

roof tiles from a row in the area of the rafters.

B Position the mounting bracket:

– The mounting bracket must be in the tile valley.

– The mounting bracket must be installed directly

above the roof tile below it without touching this tile.

B Mark the mounting bracket positions on the roof.

B Place mounting bracket [1] on rafter and pre-drill using

a 6 mm drill bit. Fasten with the screws [3].

1

1.

B If required, use wooden spacer [5] for height

compensation (pre-drill 9 mm).

B Carefully remove the roof tiles' drip edges and profiles

[2] and [4] in the area of the mounting brackets.

B Screw mounting bracket with 3 screws 8 x 120 mm [3]

onto the rafter. Use a SW13 spanner for tightening.

B Put the roof tiles back on.

NOTICE: Roof leaks from fine, wind-driven

snow in the area of the mounting bracket.

B If there is a larger gap between the top

and the bottom roof tiles, close this gap

using UV-resistant sealant.

6

13

9

2

2.

3

3.

5

Fig. 21 Mounting brackets for roof tile roofs

1 Mounting bracket

2 Top roof tile

3 Screws 8 x 120 mm

4 Bottom roof tile

5 Wooden spacer 100 x 150 x 8 mm

4

6720646203-07.1ST

SKR6.1R, SKR12.1R - Subject to technical modifications.

15

Page 16

6

Fitting the mounting bracket

6.3 Installing mounting brackets on plain tile roofs

NOTICE: Roof leaks on plain tile roofs!

B Consult a roofing contractor for advice

and assistance.

B Depending on the distances determined (Æ page 14)

remove 2-3 plain tiles from a row in the area of the

rafters.

B Position the mounting bracket:

– The mounting bracket [1] must be installed in the

middle of the plain tile below.

– The mounting bracket must be installed directly

above the plan tile below it without touching this tile.

1

1.

4

B To make room for the mounting bracket, shorten the

plain tile at the top edge if necessary and/or make a

create a suitable fixing point to the roof.

B Mark the mounting bracket positions on the roof.

B Pre-drill rafter with 6 mm drill bit.

B If required, use wooden spacer [4] supplied for height

compensation (pre-drill 9 mm).

B Screw mounting bracket with 3 screws 8 x 120 mm [2]

onto the rafter. Use a SW13 spanner.

B Cut adjacent plain tiles [3] and re-install them.

NOTICE: Roof leaks from fine, wind-driven

snow in the area of the mounting bracket.

B If there is a larger gap between the top

and the bottom roof tiles, close this gap

using UV-resistant sealant.

6

13

9

3.

3

Fig. 22 Mounting brackets for plain tile roofs

1 Mounting bracket

2 Screws 8 x 120 mm

3 Plain tiles, trimmed

4 Wooden spacer 100 x 150 x 8 mm

2

2.

6720646203-11.1ST

16

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 17

Fitting the mounting bracket

6

6.4 Installing mounting brackets on roofs with monk/nun tiles

B Depending on the distances determined (Æ page 14),

remove 2-3 roof tiles from a row in the area of the

rafters.

B Position the mounting bracket:

– The mounting bracket must be installed in the

middle of the roof tile below.

– The mounting bracket must be installed directly

above the roof tile below it without touching this tile.

B Mark the mounting bracket positions on the roof.

1

2

3

B If required, use wooden spacer [3] supplied for height

compensation (pre-drill 9 mm).

B Screw mounting bracket [1] with 3 screws 8 x 120 mm

[2] onto the rafter. Use a SW13 spanner.

B Re-install the roof tiles.

NOTICE: Roof leaks from fine, wind-driven

snow in the area of the mounting bracket.

B If there is a larger gap between the top

and the bottom roof tiles, close this gap

using UV-resistant sealant.

6

13

9

Fig. 23 Mounting brackets on roofs with monk/nun tiles

1 Mounting bracket

2 Screws 8 x 120 mm

3 Wooden spacer 100 x 150 x 8 mm

SKR6.1R, SKR12.1R - Subject to technical modifications.

6720646203-12.1ST

17

Page 18

6

Fitting the mounting bracket

6.5 Installing mounting brackets on slate roofs

NOTICE: To avoid roof leaks on slate or

shingle roofs, consult a roofer for advice and

assistance.

B A competent person must carry out the

installation.

B Because the mounting bracket can rest on

the panel below, this panel must be

reinforced on-site using a suitable

material.

1

2

B Depending on the distances determined (Æ page 14),

remove sufficient slates in the area of the rafters.

B Position the mounting bracket:

– The mounting bracket must be installed directly

above the slate below it without touching this panel.

B Mark the mounting bracket positions on the roof.

B Screw mounting bracket [2] with 3 screws 8 x 120 mm

[1] onto the rafter. Use a SW13 spanner.

B Re-install slates.

13

6

Fig. 24 Mounting brackets for slate shingle roofs

1 Screws 8 x 120 mm

2 Mounting bracket

6720646203-17.1ST

18

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 19

7 Rail installation

1300

1300

The mounting brackets and the collector are connected

by the rails and clamps.

Examples of how the rails can be used

1 x SKR6.1 2 x SKR6.1 3 x SKR6.1

Rail installation

2007

7

2022

Tab. 11 Dimensions in mm

1 x SKR12.1 1 x SKR12.1 * 1 x SKR6.1 and 1 x SKR12.1

1300

2022

Tab. 12 Dim. in mm

* = appropriate for the combination 2 x SKR12.1 and 1 x SKR6.1

Preassembling on the ground

In order to make installation on the roof easier, we

recommend that you pre-assemble the following parts on

the ground using a SW17 spanner.

1953

1953

1953

2007

1953

B Pre-assemble hammer-head bolts with L connector:

Æ Fig. 29, page 21.

B Pre-assemble lower clamps onto the horizontal rail

(1300 mm or 2007 mm): Æ Fig. 29, page 21.

B Pre-assemble lower clamps onto the horizontal rail

(2022 mm): Æ Fig. 30, page 22.

SKR6.1R, SKR12.1R - Subject to technical modifications.

19

Page 20

7

A

B

Rail installation

7.1 Installing the vertical rails

Aligning the rails

When installing the rails, ensure they are aligned

accurately (Æ Fig. 25):

• perpendicular to the horizontal (i.e. align with battens

[1])

• same overhang on top and bottom (dimension x).

SKR6.1: Installing vertical rails for roof batten clearances of 350-370 mm and 430-470 mm

For these spaces between roof battens, it is necessary to

connect the L-shaped connector and the mounting

bracket with the vertical rail using the hammer-head bolts.

Roof batten

spacing

Position of

L-shaped

connector

Top, bottom of

mounting

bracket

350, 430, 440 mm A bottom only

360, 450 mm B bottom only

460 mm A top

B

bottom

370, 470 mm B top and bottom

Tab. 13 Fastening the L-shaped connector onto the

mounting bracket

B Fit rails as specified by Tab. 13 to L-shaped connector

and mounting bracket (Æ Fig. 27).

17

Fig. 25 Aligning the vertical rails

SKR12.1: Vertical rails for all clearances between roof battens

B Place top and bottom rails on mounting brackets and

fit using the hammer-head bolts (Æ Fig. 26). Use a

SW17 spanner.

SKR6.1: Installing vertical rails for roof batten clearances of 320-340 mm and 380-420 mm

B Place top and bottom rails on mounting brackets and

fit using the hammer-head bolts (Æ Fig. 26). Use a

SW17 spanner.

17

A

B

6720646203-45.1ST

Fig. 27 Screwing to L-shaped connector and mounting

bracket (here: at position A)

Checking correct fit of all hammer-head bolts

B Check correct fit of all hammer-head bolts [1].

1

Fig. 26 Installing rails onto mounting brackets

20

6720646203-21.1ST

6720646203-54.1ST

Fig. 28 Checking correct fit of all hammer-head bolts

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 21

Rail installation

7

7.2 Installing horizontal rails and clamps

Horizontal rails are not required in all cases

(Æ Tab. 11 and 12, page 19).

Pre-assembly of lower clamping brackets on the ground

B Split the top and bottom clamping [2] and [1] at their

pre-determined breaking point.

B Install the lower clamps [1] onto the bottom rail at the

distances indicated (Æ Fig. 29) and fit them using a

nut and a washer. Use a SW17 spanner.

7

x

90°

6

Do not fasten the upper clamps [2] onto the collector and

the top rail until after the collector has been installed.

Installing the rails

When installing the rails, ensure they are aligned

accurately (dimension x: same overhang on the right and

left Æ Fig. 29).

Ensure that the hammer-head bolt is installed correctly

[4].

B Using the L-shaped connector [5], 4 hammer-head

bolts, 4 washers and 4 nuts, install the horizontal rail [6]

onto the vertical rail [7].

17

90°

x

1

5

1953

2

90°

1

450-55020-90 160-

4

260

1300

450-550 20-90

3

450-55020-90 160-

260

450-550 20-90160-

260

2007

450-550

6720646203-19.2ST

Fig. 29 Rails and clips, all dimensions in mm

1 Lower clamp

2 Upper clamps

3 Horizontal rail 2007 mm

4 Hammer-head bolt (fitted)

5 L-shaped connector for connecting the rails

6 Horizontal rail

7 Vertical rail

SKR6.1R, SKR12.1R - Subject to technical modifications.

21

Page 22

7

Rail installation

7.3 Installing the clampings onto the vertical rails

No horizontal rails are installed onto the 2022 mm vertical

rail. Therefore, you must install the upper and lower

clamping brackets on the vertical rails.

Pre-assembly of the lower clamps onto the ground

B Separate the upper and lower clamps [1] and [2] at

their pre-determined breaking point.

Ensure that the hammer-head bolt is securely fastened

[3].

B To fasten the lower clamps [2], push the hammer-head

bolt into the rails as far as it will go. Fasten with a

SW17 spanner.

Do not fasten the upper clamps [1] to the collector and

the rail until after the collector has been installed.

17

1

2

2

2022 mm

6720646203-27.1ST

3

Fig. 30 Fitting clamping brackets

1 Upper clamps

2 Lower clamps

3 T-head bolt

22

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 23

8 Installing the collectors

Installing the collectors

8

Once the mounting brackets and the rails with the

clamping brackets have been installed, the collectors can

be fitted.

DANGER: Risk to life through falling objects!

B Secure the collectors against falling

during handling and installation.

WARNING: Risk of injury through glass

splinters.

B When handling collectors, always wear

protective gear including but not limited to

safety gloves and goggles.

NOTICE: Collector damage through

evaporation in the solar circuit.

B Leave the sun protection film on the

collector until the collector has been

flushed and filled. However, it should not

be exposed to weather for more than

4 weeks.

B Fit a suitable sun protection cover for

longer periods of time.

B Install the upper clamps (Æ Fig. 31, [1 or 2]) onto the

rails in the same way as the lower clamps [3]. Fasten

the upper clamps once the other collectors have been

installed.

6 720 647 042-06.1ITL

8.1 Fitting the first collector

Align the first collector in such a way that during

installation all collectors have the same overhang over the

vertical rails to the right and left.

B Place the collector still packaged onto the rails.

B Open the packaging at the bottom. This allows the

collector to slip into the lower clamps (Æ Fig. 31, [3]).

These clamps must provide secure grip into the

collector profile.

B Align the collector to the horizontal rails, push the

edges of the collectors onto the rails, ensure they

securely rest on the rails.

Once all the collectors are installed, the overhangs on

the sides will have to be identical.

Fig. 31 Collector fitted onto to the horizontal rails

1 Upper clamps for horizontal rail

2 Upper clamps if only vertical rails are available

3 Lower clamps

B Insert the upper clamping brackets [1] in the groove on

the back of the collector [2].

2

1

6 720 647 042-21.1ITL

Fig. 32 Upper clampis at the back of the collector

SKR6.1R, SKR12.1R - Subject to technical modifications.

1 Upper clamps

2 Collector back with groove

23

Page 24

8

Installing the collectors

8.2 Fitting the second collector

The male connectors act as the joining part between two

collectors (Æ Fig. 33).

B Position the second collector on the rails and slide next

to the fitted collector.

B Centre the collectors on the rails so that the overhang

on the left and right hand sides are equal.

NOTICE: Collector damage through twisted

internal pipes.

B Hold the connection nipple using a SW24

spanner.

B Tighten the nuts with a SW24 spanner.

8.3 Installing the collector sensor

The collector sensor is supplied either with the solar

pump station or with the control unit; fit it into the collector

connected to the flow and return pipes (Æ chapter 4.2,

page 10).

NOTICE: System damage through faulty

sensor lead.

B Protect the lead against possible damage

(e.g. rodent attack).

The correct operation of the solar thermal

system requires that the collector sensor is

fitted correctly.

B Push the collector sensor (Æ Fig. 34, [1]) 90 mm into

the sensor well (as far as it will go).

90 mm

6 720 647 042-09.1ITL

Fig. 33 Connecting the collectors hydraulically

1 Left-hand collector

2 Union nut (pre-fitted)

3 Olive 15 mm (pre-fitted)

4 Male connection ½ “

5 Right-hand collector

B Fit all other collectors likewise.

B Fit the return U-bend to the last collector (Æ Fig. 39,

page 26).

B Tighten upper clamps with a SW17 spanner

(Æ Fig. 31).

CAUTION: Risk of scalding through fittings

that have not been tightened.

B Check all fittings for correct tightness.

6 720 647 042-05.1ITL

Fig. 34 Installing the collector sensor

24

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 25

Installing the collectors

8

8.4 Fitting the bridging set (accessory)

To improve the appearance of the space between two

collectors, the bridging set can be fitted as an accessory.

Standard delivery

• 1 x thermal insulation (45 mm wide) with self-adhesive

closure

• 1 x cover panel

• 2 x connection plugs with metal pin

Installation

The installation requires the collectors to be aligned

precisely.

1. Place the thermal insulation over both fittings from

below and seal using the self-adhesive tab.

2. Push on the cover panel from above and lock in place

at the back of the header boxes.

The plug that is part of the bridging set holds both

collector frames together with the correct clearance.

1. Remove the original plugs from the collector frame

profiles.

2. Insert the new connection plugs into the profiles.

3. Drive the metal pin with a hammer into the side of the

plug.

1.

6 720 647 042-13.1ITL

Fig. 35 Top of collector at header box: installing thermal

insulation and cover panel

2.

6720646203-42.1ST

Fig. 36 Collector bottom: replacing the plugs

3.

SKR6.1R, SKR12.1R - Subject to technical modifications.

25

Page 26

9

Hydraulic connection

9 Hydraulic connection

For information regarding the routing of pipework

between the components (collectors, solar pump station,

solar cylinder), see the "Solar pump station" installation

instructions.

NOTICE: Roof leaks through inadequate

weather tightening.

B Use adequate roof fittings when feeding

the connection pipes through the roof.

B If necessary, contact a specialist for

assistance.

Route the sensor lead with the flow pipe to

the collector. On some solar twin pipes, the

sensor lead is already fitted underneath

thermal insulation.

Connecting pipework

The hydraulic connections to the individual pipes under

the roof are made using the 1 m long flexible connection

pipes. These can be bent a maximum of 90°.

NOTICE: Collector damage through twisted

internal pipes..

B Hold connection pipe (Æ Fig. 37, [4])

using a SW24 spanner.

B Use a second SW24 spanner to fasten

the union nuts [2].

B Connect the pipe [1] to the olive fittings of the

connecting pipes (15 mm or 18 mm pipe).

27

30

18

15

6720648182-01.1ST

Fig. 38 Fitted connection pipes and installation of the

pipeline penetrating the roof

B Fit the return U-bend [2] to the last collector.

B Insert the cap [1] with fitted thermal insulation into the

insulation on the collector [4]. By pressing and slightly

turning ensure that the cap fits correctly all around

inside the insulation profile.

42 31

24

6 720 647 042-12.1ITL

Fig. 37 Fitting connecting pipes to collectors

1 Collector

2 Union nut (pre-fitted)

3 Olive 15 mm (pre-fitted)

4 Connection pipe (already insulated)

24

6 720 647 042-18.1ITL

Fig. 39 Fitting the return feed bend and cap

1 Cap with thermal insulation

2 Return U-bend

3 Locking ring (preassembled)

4 Collector

CAUTION: Risk of scalding through fittings

that have not been tightened.

B Check all fittings for correct tightness.

26

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 27

Installing the shut-off valve (accessory)

For collector arrays consisting of several rows of

collectors connected in parallel, each collector array must

be flushed and vented individually. In order to do so, a

shut off valve has to be installed in the flow connection of

each row of collectors.

NOTICE: Collector damage through excess

pressure.

Never shut off the pipe between the collector

and the expansion vessel (EV) or safety valve.

B Fit the shut-off valve with the locking ring fittings

(2 pieces) supplied, into the collector flow.

1

Hydraulic connection

To flush and vent a row of collectors, always

open the shut-off valve for this row only. All

others remain closed. Open all shut-off

valves after flushing and venting.

Observe the information on pressurised

filling in the installation instructions of the

solar pump station and fill station using the

filling pump.

9

4

32

Fig. 40 Triple row connection (with shut-off valve)

1 Collector sensor

2 Flow pipe (to the cylinder)

3 Return pipe (from the cylinder)

4 Shut-off valve

5 Return U-bend

6 720 647 042-04.1ITL

SKR6.1R, SKR12.1R - Subject to technical modifications.

27

Page 28

10

Final steps

10 Final steps

10.1 Checking the installation

Final steps can only be carried out after the

following checks have been made.

Checks

1. Are all connection fittings tightened?

2. Are all threaded fittings on rails, mounting

brackets and clamps tightened?

3. Has the collector sensor been pushed

into the sensor well as far as it will go

(90 mm)?

Tab. 14 Checking the installation

10.2 Pressure filling, flushing, venting

The solar thermal system must be filled by means of

pressure filling, then flushed and vented. Observe the

notes on pressure filling in the installation instructions for

the solar pump station as well as the filling station.

10.4 Determining and setting the operating pressure

Following the pressurised filling and flushing as well as a

pressure test, determine and set the required operating

pressure. For information on how to proceed, please refer

to the instructions for the solar pump station.

The operating pressure is calculated from the

static system head plus 2.0 bar (static

system head = difference in head between

the expansion vessel connection and the top

edge of the collector; 1 metre difference in

head corresponds to 0.1 bar).

Example: 10 m height differential equals

1.0 bar plus 2.0 bar = 3.0 bar.

10.5 Adjusting the flow rate

Observe the information in the installation

and maintenance instructions for the solar

pump station (Æ chapter "Adjusting the flow

rate").

NOTICE: Collector damage through frost.

B Fill solar heat transfer medium LS under

pressure for filling and flushing the

system.

Never use water, as the collectors cannot

be drained.

10.3 Adjusting the pre-charge pressure of the expansion vessel

Prior to filling the solar thermal system, check the

expansion vessel pre-charge pressure (air side).

The expansion vessel pre-charge pressure is

calculated from the static system head plus

1.7 bar (static system head = difference in

head between the expansion vessel

connection and the top edge of the collector;

1 metre difference in head corresponds to

0.1 bar).

Example: 10 m height differential equals

1.0 bar plus 1.7 bar = 2.7 bar.

B If required, correct the expansion vessel pre-charge

pressure.

Flow rate l/min

(at a flow temperature 20 °C)

SKR6.1R

Number of collectors

1--2.0

22.04.0

33.05.5

44.0--

54.5--

65.5--

Tab. 15 Flow rate to be set for solar controllers without

speed control, subject to the number and type of

collectors

(l/min)

SKR12.1R

(l/min)

10.6 Insulating piping

On-site thermal insulation for pipework

B Outdoors, use UV and high temperature-resistant

thermal insulation.

B Use insulation and pipe clips resistant to high

temperatures for indoor piping.

B Make the insulation bird-proof.

28

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 29

Replacing individual tubes

11

11 Replacing individual tubes

You can recognise a faulty tube by the fact that the silver

coating in the lower section of the tube has changed to a

white mist.

WARNING: Risk of injury through glass

splinters.

B When handling collectors, always wear

safety gloves and goggles.

Fitting a tube

Install the new tube [4] in reverse order to the removal of

the old one.

Ensure the silicon ring [1] sits correctly inside the header

box.

B Coat the top of the tube with a soapy solution or

lubricating paste.

B Push the tube through the silicon ring into the header

box whilst turning it slightly.

B Place the tube holder [2] on the end of the tube, push

it in between the notches in the aluminium profile and

engage it in the groove.

B Pull down the tube into the tube holder as far as it will

go.

6 720 647 042-10.1ITL

Fig. 41 Replacing individual tubes

1 Silicone ring

2 Tube holder

3 Release lever

4 Tube

Removing a mechanically damaged tube

B Carefully remove glass splinters without damaging the

CPC mirror surface.

B Remove the bottom tube retainer [2].

Removing a mechanically undamaged tube

B In order to be able to remove the bottom tube retainer

[2],

– push the tube 5 mm upwards into the header box

and

– push down the two release levers [3] on the right

and left using your thumb and index finger.

B Release the tube retainer by lifting towards the header

box.

B Lift the tube slightly and turn it about the longitudinal

axis to pull it straight down and out.

If there is inadequate room to remove the

tube, the coil can be bent upwards up to 20°.

SKR6.1R, SKR12.1R - Subject to technical modifications.

29

Page 30

12

Environmental protection/disposal

12 Environmental protection/

disposal

Environmental protection is one of our principal policies.

Quality of performance, efficiency and environmental

protection are equally important objectives for us.

Statutory and other regulations concerning environmental

protection are strictly applied. To protect the environment,

we use the best possible technology and materials.

Disposal

At the end of their service life, materials should be

recycled using the most environmentally responsible

processes.

30

SKR6.1R, SKR12.1R - Subject to technical modifications.

Page 31

13 Maintenance/inspection

Maintenance/inspection

13

DANGER: Risk to life through falls and

falling parts!

B For all work on the roof, take appropriate

measures to prevent accidents.

B Secure the roof against falls.

B Always wear your own protective clothing

or safety equipment.

The collector array must be checked at regular intervals

(inspection). Defects/faults must be remedied without

delay (maintenance). We recommend conducting the first

maintenance/inspection after about 500 hours run, and

then at intervals of 1-2 years.

Use the table as a copy template so that you will have

documentation available even after the third maintenance.

B Fill out the report and tick off the tasks performed.

Owner: Site location:

Maintenance and inspection tasks Page Maintenance/inspection

Date

1. Visual inspection of the collectors carried out

(correct seating of glass tubes, visual impression)?

2. Collector sensor is positioned correctly and is inserted into

the sensor well as far as it will go?

3. Visual inspection of the installation system carried out?

4. Visual inspection for leaks carried out at points where the

mounting system meets the roof?

24

5. Visual inspection of pipe insulation carried out?

Notes

The collector array has been serviced as specified by these

instructions.

Date, stamp,

signature

Date, stamp,

signature

Tab. 16 Inspection and service report

Date, stamp,

signature

SKR6.1R, SKR12.1R - Subject to technical modifications.

31

Page 32

Buderus

Cotswold Way, Warndon, Worcester WR4 9SW

Customer service: 0844 892 3004

Technical support: 0844 892 4224

www.buderus.co.uk

In the UK and IE, Buderus is a brand name

of Bosch Thermotechnology Ltd.

Loading...

Loading...