6302 2320 – 10/2003 US/CA For installers

Please read these instructions carefully!

Boiler Installation and

Maintenance Manual

Condensing Gas Boiler SB735

Series

2

Introduction

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Technical Changes!

Buderus Hydronic Systems, Inc. reserves the right to

this make changes due to continued technological and

engineering improvments.

Updating Technical Informations

Please contact us if you have suggestions for improving

this manual or when you have noticed incorrect

information.

Manufacturers Address:

Buderus Hydronic Systems, Inc.

50 Wentworth Ave

Londonderry, New Hampshire 03053

www.buderus.net

Document number: 6302 2320

Issue: 10/2003

F

This equipment conforms to the following

European and US requirements:

– 90/396/EWG European gas fired

guidelines

Standards: EN 677, EN 303-1,

EN 303-3, DIN 4702-6

– 92/42/EWG

European efficiency

guidelines

– 73/23/EWG

European low voltage

guidelines

– 89/336/EWG

EMV- European

electromechanical code

guidelines

– 97/23/EG European pressure

vessel guidelines

Standard: TRD 702

– ASME Boiler and Vessel Pressure

Code

Confirmation regarding confirmity with

respect to these guidelines can be obtained

upon request from Buderus Hydronic

Systems, Inc.

TABLE OF CONTENTS

3

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735• Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Regulations and Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Hydrostatic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Packaging and Components . . . . . . . . . . . . . . . . . . . . . . 5

3 Technical Data, Dimensions and Water Connections . . . . . . . . . 6

4 Boiler Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Anti-Vibration Supports . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Boiler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 Installation of the Thermal Insulation

and Jacket Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2 Boiler Jacket - Pack A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Boiler Jacket - Pack B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Installation of the Control Panel

and Sensor Well . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.5 Burner Door and Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.6 Boiler Jacket - Top Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.7 Rating Tag Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.8 Boiler Jacket - Pack C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.9 Venting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.10 Neutralization Equipment and Water Controls Installation. . . . . . . . . . 23

7 Placing the Boiler in Operation . . . . . . . . . . . . . . . . . . . . 24

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 Cleaning of the Boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

General Information1

4

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

1 General Information

1.1 General Information

This Boiler Installation and Maintenance Manual

contains important information regarding proper and

safe assembly, start-up and operating and maintenance

procedures for the SB735 series boilers!

The assembly and maintenance instructions are

designed for the installing contractor, who, due to

vocational training, is familiar, knowledgeable and

experienced in heating system and gas piping

installations.

1.2 Regulations and Guidelines

This document also makes reference to additional

accessories that may be used in conjunction with the

SB735 boilers. Observe the proper installation

instructions when installing these accessories.

The installation must conform to the requirements of the

authority having jurisdiction or, in absence of such

requirements, to the latest edition of the National Fuel

Code, ANSI Z223.1.

ADANGER!

due to combustion products.

Route flue gases via venting system to the

atmosphere. Use only approved venting

materials.

Have the system inspected by an authorized

person prior to start-up. Only start-up the

system after approval.

Check system for leaks.

The Buderus SB735 boiler is a condensing boiler

suitable for firing with natural gas or propane only.

The installation of a low water cut-off and pressure relief

valve must be based on local code requirements. Please

install these components per manufacturer’s

instructions and per detail on page 23.

JNOTICE

To avoid build-up of debris inside the heat

exchanger of the boiler, it is recommended to

install a filter on the boiler return connection(s).

1.3 Hydrostatic test

Perform a hydrostatic test. The test pressure should be

1.5 times the actual operating pressure in the heating

system, however a minimum of 14 psi.

JNOTICE!

Observe the listed boiler output ratings as

shown on the boiler rating plate.

Maximum Temperature and Pressure Ratings:

Permissible Fuels:

Logano SB735: Fuel Natural Gas or L.P

Please observe the guidelines of the gas supply

company!

Maximum Temperature and Pressure Ratings

Maximum Supply Temperature: 210 °F

Allowed System Pressure

(Models)

790 43.5 psi

970 43.5 psi

1200 43.5 psi

Maximum Time constant:

- Manual Reset High Limit 40 sec

- Adjustable High Limit 40 sec

Table. 1 Maximum Temperature and Pressure Ratings

Packaging and Components 2

5

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

2 Packaging and Components

The complete product is shipped in the following

components:

– Boiler vessel, bolted on transport woods

– Supply manifold, packaged with hydronic control

package

– Technical documentation, secured to the boiler

– VE insulation rings for burner and PVC condensate

drain (Siphon) secured to the boiler

– Boiler jacket panels and installation components,

packaged in a wooden crate and cardboard. The

assembly components are located in Pack A.

– The insulation blankets are packaged in 2 plastic

bags.

– A sound attenuating boiler base is supplied standard

with the SB735/1200 model.

– Electronic control panel, in cardboard box (optional).

– A condensate neutralization package can be ordered

separately.

– Hydronic control package, consisting of aquastat,

low water cut-off, relief valve and temperature

pressure gauge (when ordered from Buderus).

– Gas burner and gas train components, if ordered

from Buderus.

– Pre-cut burner mounting plate, if ordered from

Buderus.

Above mentioned components may differ slightly based

on the particular boiler model.

Technical Data, Dimensions and Water Connections3

6

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

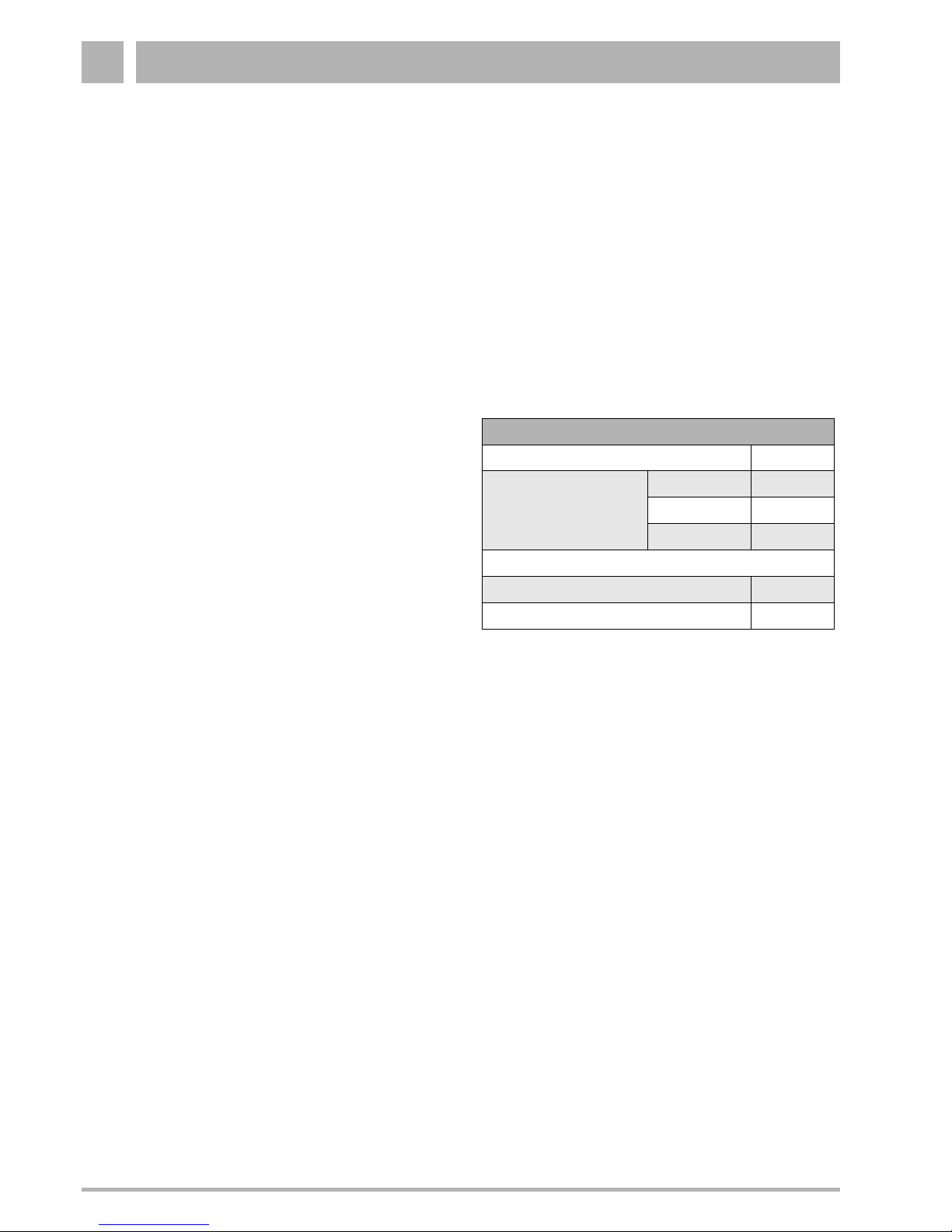

3 Technical Data, Dimensions and Water Connections

Fig. 1 Technical Data, Dimensions and Water Connections

VK = Boiler Supply Connection

RK1 = Low Temperature Return Connection

RK2 = High Temperature Return Connection

H* = Boiler Height with Logamatic 2107/2109=H+6 inch

AKO = Condensate Drain

EK = Water Feed

EL = Boiler Drain

M = Sensing Port for Temperature Sensor

Ø AA = Vent Pipe Diameter

L

L

K

H

B

H

AA

Ø AA

M

VK

RK

2

AKO

RK

1

EK/EL

Boiler Model 790 970 1200

Max. Input [MBH] 2751 3378 4179

Max. Output [MBH] 2605 3251 4079

IBR Net [MBH] 2265 2827 3547

Thermal Efficiency [%] 96.9 96.3 97.6

Combustion Efficiency [%] 94.7 95.6 96.5

Length L Inch 91 ½ 108 ¼ 108 ¼

Length L

K

Inch 75 ½ 92 92

Hight H Inch 81 ¼ 81 ¼ 81 ¼

Width BInch545454

Boiler Widthless Jacket Inch 44 ¼ 44 ¼ 46 ¼

Vent Connection-Ø inside Ø AA Inch 14 14 14

Vent Height H

AA

Inch 19 19 19

Weight Lbs. 4330 5441 5534

Boiler supply

1. First Return Connection

VK

RK

1

Inch

Inch

4

4

5

5

5

5

2. Second Return Connection RK

2

Inch 3 4 4

Boiler Drain/Water Feed EK/EL Inch 1½ 1½ 1½

Table. 2 Technical Data, Dimensions and Water Connections

Boiler Installation 4

7

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

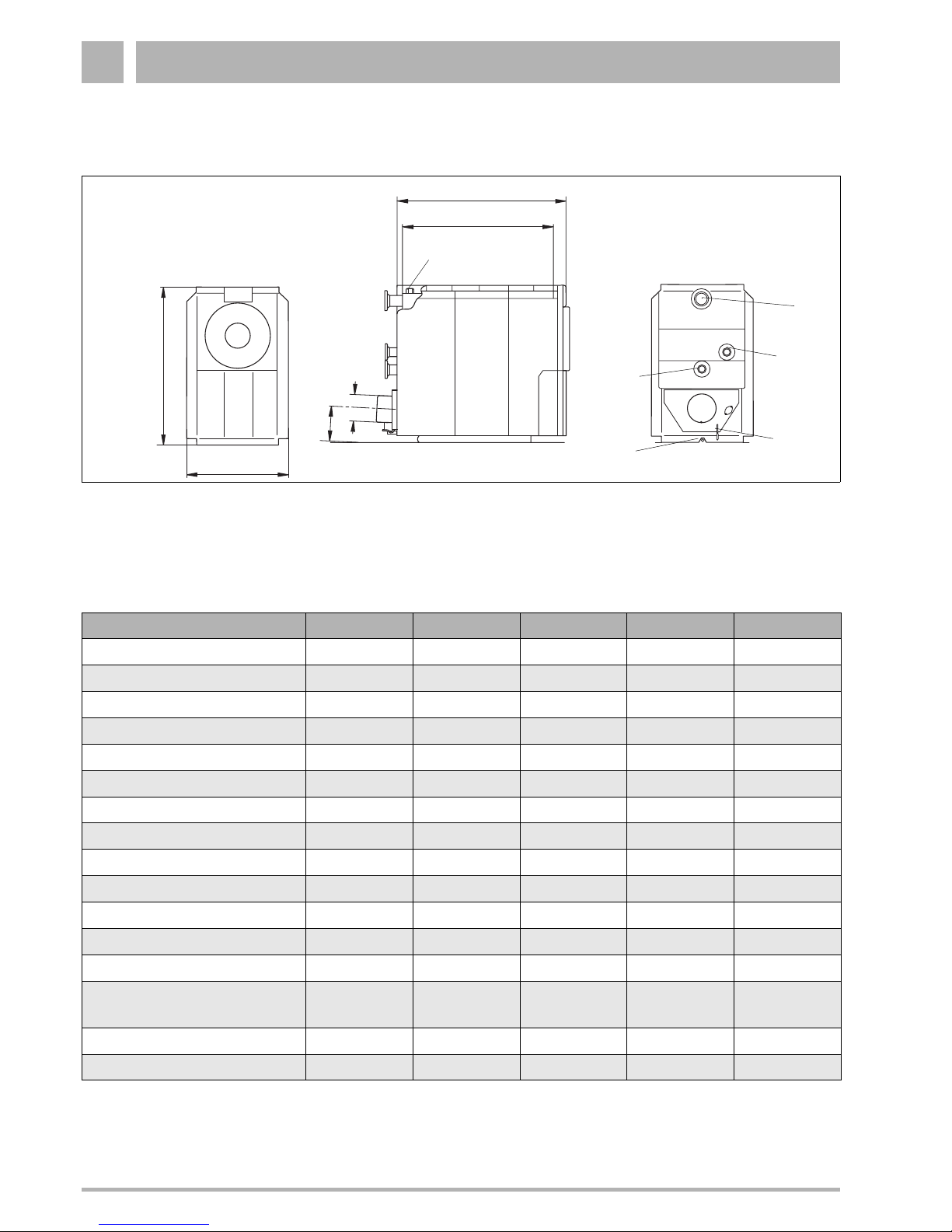

4 Boiler Installation

It is required to have a floor drain available near the

boiler.

It is recommended to place the boiler on solid foundation

of 2" to 4 " height. Use dimension B and L (Table 3) to

size this foundation.

The supporting floor must be level and of sufficient

strength.

Observe the indicated side clearances when placing the

boiler (Fig. 2). Dimensions shown indicate minimum

clearances to combustibles or space needed to swing

open burner door.

Place the boiler horizontally on the supporting

foundation.

JNOTICE!

Make sure to install the base supplied with the

SB735/1200.

Fig. 2 Clearance dimensions for SB735 boilers

Boiler

Model

L

[Inch]

BK

[Inch]

A

[Inch]

790 91 43 ¾ 98“(43“)*

970 107 ½ 43 ¾ 98“(43“)*

1200 107 ½ 46 98“(43“)*

Table. 3 Minimum Boiler Pad

Please observe the burner length L

Br

with respect to the front

clearance.

AL

8“

32“

1)

L

Br

(0)

B

k

(4“)

(40“)

Anti-Vibration Supports5

8

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

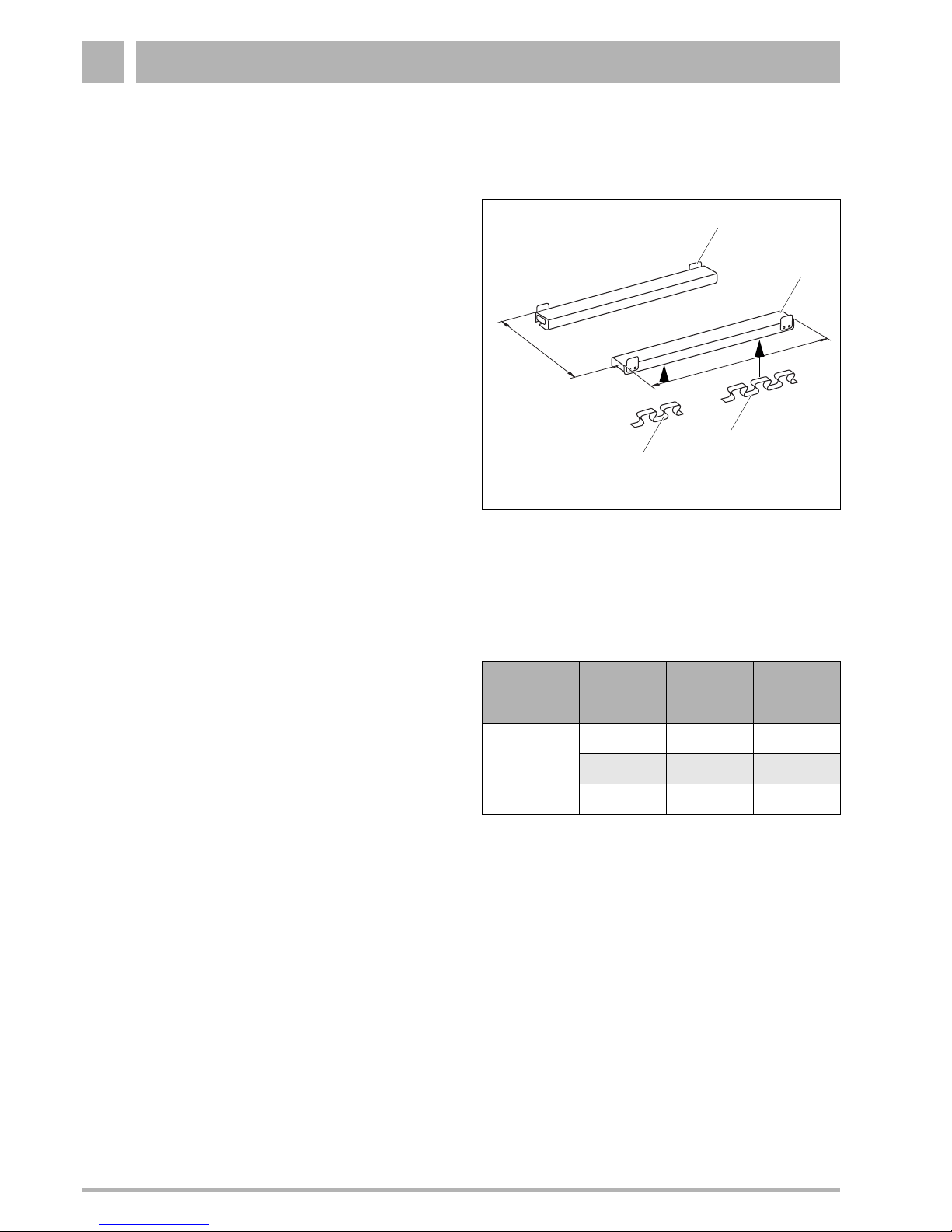

5 Anti-Vibration Supports

z Anti-vibration supports are standard equipment on

the SB735/1200 model; they can be ordered

separately for the other models.

z Insert the longer part of the longitudinal anti-vibration

bracket (Fig. 3, Item. 4) from the front and the

shorter part (Fig. 3, Item. 3) from the rear into the

channel sections (Fig. 3, Item. 2).

z Position both rails of the anti-vibration boiler support,

in accordance with dimensions shown in Table 4, on

the floor where the boiler is to be installed.

JNOTICE!

Prepare the foundation, where the anti-vibration

supports are to be located, with a smooth trowel

of ±1/8“ per linear foot and with a slight rise to

the back. This ensures an even load distribution

over the longitudinal anti-vibration brackets,

and adequate boiler ventilation.

z Position, align and place the boiler on the supports.

The boiler support should be flush with the boiler

back wall. The end-stop plates (Fig. 3, Item. 1)

should contact the channel section of the boiler.

Fig. 3 Anti-vibration support

Item. 1: End-stop plates

Item. 2: Channel section

Item. 3: Short anti-vibration bracket

Item. 4: Long anti-vibration bracket

Table. 4 Support dimensions

1)

Standard delivery

2)

Accessories

Boiler

Type

Boiler-

Model

Length

F

[Inch]

Distance

C

[Inch]

1200

1)

90 46

SB735

970

2)

90 43 ¾

790

2)

73 ½ 44

F

C

2

4

3

1

Boiler Assembly 6

9

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6 Boiler Assembly

JNOTICE!

Make sure, that when fitting the front thermal

insulation, the burner door of the combustion

chamber is closed, to prevent damage to the

stainless steel combustion chamber from

welding or grinding activities.

Order of installation:

1. Thermal insulation/Pack A

2. Pack B

3. Pack C

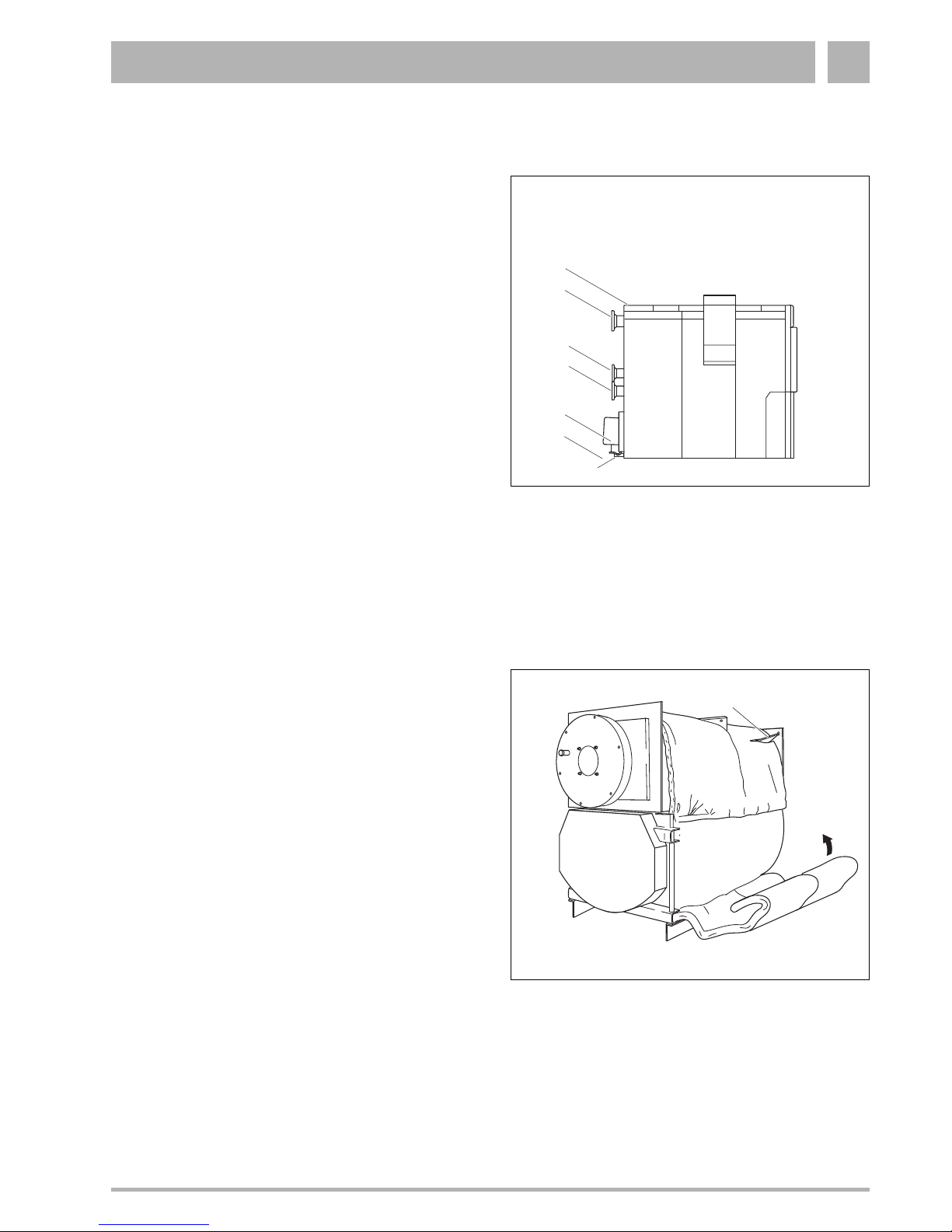

6.1 Installation of the Thermal Insulation

and Jacket Panels

JNOTICE!

Ensure that the fabric is on the outside when

fitting the insulation blankets.

z Position the insulation blankets for the boiler body so

that the cut-outs are located over the cross brackets

plates (Fig. 5, Item. 1).

JNOTICE!

Position the narrow insulation blanket for boiler

model 790 at the rear, and note the drain cutouts.

JNOTICE!

Note the cut-outs for the low water indicator and

the cross bracket holder

(Fig. 7, Item. 1 + 5)!

z Position the front insulation blanket with its cut-out,

over the cross bracket holder.

z Tuck the insulation blanket in underneath the boiler

(Fig. 5).

Fig. 4 Connections

M = Sensing port for temperature sensor

VK = Boiler supply and relief valve connection

RK2 = High temperature boiler return

RK1 = Low temperature boiler return

AA = Vent connection

AKO = Condensate drain

EK/EL = Water feed/boiler drain

Fig. 5 Insulation blanket

M

VK

RK2

RK1

AA

AKO

EK/EL

1

Boiler Assembly6

10

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

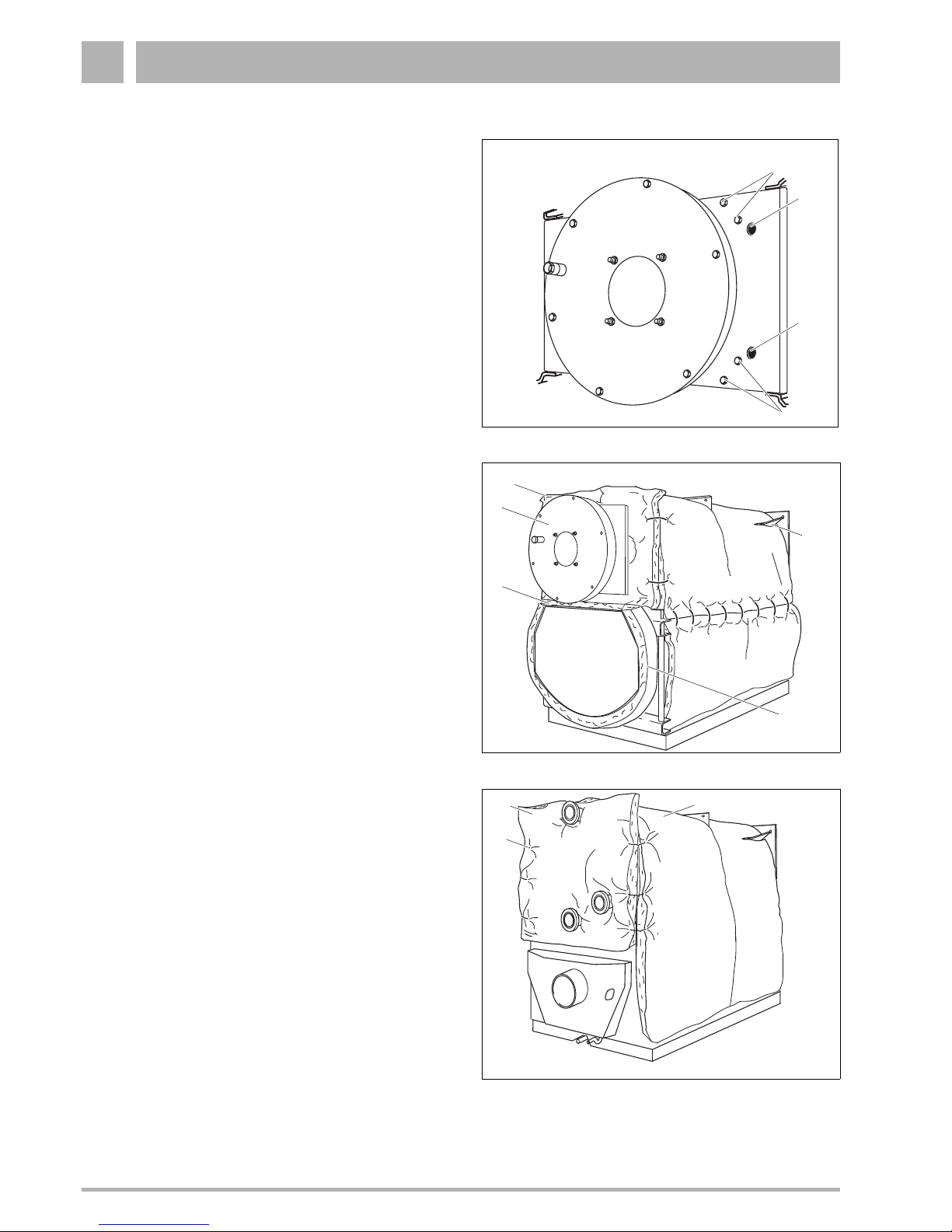

z Overlap the insulation blankets on the side and wrap

around the boiler body, then fasten with 8 clips.

z Unscrew four hexagon bolts (Fig. 6, Item. 1) from the

right side of the boiler door (Fig. 7, Item. 1) and four

from the left side.

ADANGER OF INJURY!

through falling parts.

Ensure that the hinge bolts (Fig. 21, Item. 1)

are in the boiler door before opening it.

JNOTICE!

The recesses (Fig. 6, Item. 2) in the boiler door

(2 on the left and 2 on the right side) have been

provided for lifting with a crane or hoist, for

example for the complete removal of the door.

z Open the burner door (Fig. 7, Item. 1)

z Place the insulation blanket with round cut-out

(Fig. 7, Item. 2), with its wide edge facing upwards,

on the left front of the boiler body (wide edge up) and

secure with four clips (2 left, 2 right) on the

surrounding thermal insulation.

ACAUTION!

Ensure that the wide edge is at the top at the

hinge bolts!

z Close the burner door and re-secure with eight

hexagon bolts.

z Position the thermal insulation strip (Fig. 7, Item. 3)

laminated on the front of the reversing door.

z Position the thermal insulation strips (Fig. 7, Item. 4)

for the reversing door from below around the side of

the reversing door and secure with two clips.

JNOTICE!

Observe the hinge bolt cut-outs!

z Locate the rear side thermal insulation (Fig. 8,

Item. 2) in accordance with the cut-outs on the rear

side of the boiler and secure with six clips (Fig. 8,

Item. 1, 3 left and 3 right) on the surrounding thermal

insulation (Fig. 8, Item. 3).

Fig. 6 Screws for opening the burner door

Fig. 7 Burner door insulation blanket

Fig. 8 Rear side insulation blanket

1

1

2

2

1

2

3

4

5

1

2

3

Boiler Assembly 6

11

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.2 Boiler Jacket - Pack A

z Locate the front cross bracket (trapezoidal cut-out

down) with its two top holes on the threaded studs

and secure with nuts (Fig. 9).

z Locate the rear cross bracket (V-shaped cut-out

down) with its two top holes on the threaded studs

and secure with nuts (Fig. 9).

JNOTICE!

The edge of the cross bracket must point

outwards (Fig. 9).

z Insert the insulation blanket from the burner door

(Fig. 7, Item. 2) and the rear side (Fig. 8, Item. 2) into

the upper edge and the front and rear cross bracket.

z Lightly insert two screws M8 x 80 (Fig. 10, Item. 3)

from the top into the central cross bracket (Fig. 10,

Item.1).

z Secure the central gross bracket (Fig. 10, Item. 1) at

the top to the fixing bracket using two bolts, washers

and nuts (Fig. 10, Item. 2).

JNOTICE!

Ensure that the edge of the central cross

bracket (Fig. 10, Item. 1) points forward.

z Lightly secure the central cross bracket front (Fig. 9,

Item.1) on the left and the right side using two bolts

and washers.

JNOTICE!

Initially secure the central cross bracket (Fig. 9,

Item. 1) only lightly. Tighten the cross brackets

after they have been aligned and secured to the

side wall closest to the front.

z Push the strain relief (Fig. 10, Item. 4) on the hinge

side of the burner door into the cross bracket.

z Secure the strain relief with two bolts (Fig. 10).

Fig. 9 Cross brackets

Fig. 10 Strain relief

Item. 1: Central cross bracket

Item. 2: Fixing bracket

Item. 3: M8 x 80 bolts

Item. 4: Strain relief

Item. 5: Bolt location central cross bracket for boiler models

790 and 970

Item. 6: Bolt location central cross bracket for boiler model

1200

1

1

1 2

3

4

5

6

3

Boiler Assembly6

12

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

z The horizontal brackets (L-brackets) comprise of two

components, which must be pre-assembled.

Join both bracket components with two bolts and two

nuts (Fig. 11).

z Hook the first bracket (Fig. 12, Item. 1) with the

U-shaped edge into the respective recess of the

front, center and rear cross brackets.

z The bracket is secured at the front hole and the rear

slot using one self-tapping screw each (Fig. 12).

z Hook the second bracket (Fig. 12, Item. 3) with the

U-shaped edge into the respective recess of the

front, centre and rear cross brackets.

z The bracket is secured at the front hole and the rear

slot using one self-tapping screw each (Fig. 12).

z Align the central cross bracket horizontally.

Fig. 11 Longitudinal (L-)bracket

Fig. 12 Secure the longitudinal bracket with bolts suppplied

Item. 1: Horizontal bracket

Item. 2: Central cross bracket

Item. 3: Horizontal bracket

1

2

3

Boiler Assembly 6

13

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Fig. 13 Bottom cross brackets (top view)

z Secure the lower front cross brackets (Fig. 13, Item.

3) to the boiler body using two bolts.

z Secure the lower rear cross bracket (Fig. 13, Item. 1)

to the boiler body using two bolts.

z Secure the left and right spacer plates (Fig. 13,

Item. 5) to the lower cross bracket using three bolts

and washers each (Fig. 13, Item. 6).

Use the holes Item. a for boiler models 790 and 970.

Use the holes Item. b for boiler model 1200.

z The lateral blue covers (Fig. 13, Item. 2) comprise

two components, which must be pre.assembled

(Fig. 13, Item. c: screw position for model 790 and

Item. d: screw position for models 970 and 1200).

Hook-in both covers centrally behind the bracket and

align horizontally, then join both pieces with two bolts.

z Secure the left and right side of the cover (Fig. 13,

Item. 2) to the front and rear using one bolt each.

z Secure the blue cover (Fig. 13, Item. 4) at the left and

right front of the cover (Fig. 13, Item. 2) using two

bolts respectively.

Item. 1: Rear cross bracket

Item. 2: Lateral covers

Item. 3: Front cross bracket

Item. 4: Front cross bracket cover

Item. 5: Spacer plate

Item. 6: Position of bolts on the spacer plate for boiler

models 790 and 970 and 1200 (top view)

Pos. a: Position of bolts on the spacer plate for boiler

models 790 and 970 (top view)

Pos. b: Position of bolts on the spacer plate for boiler model

1200 (top view)

Pos. c: Position of the bolts on the lateral blue covers for

boiler models 790 and 970 (side view)

Pos. d: Position of the bolts on the lateral blue covers for

boiler model 1200 (side view)

1

2

3

4

2

4

5

5

6

6

6

c

b

2

5

a

d

Boiler Assembly6

14

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

z Hook the rear and central side walls at the bottom

into the edge between the cover and the spacer plate

(Fig. 14).

JNOTICE!

Note the recesses (Fig. 14, Item. 1) in the side

walls:

- Rear side wall 1 recess

(towards the central side wall).

- Central side wall 2 recesses.

- Side wall nearest the front 1 recess (towards

the central side wall).

z Lift the side walls and hook the top into edge of the

horizontal brackets (Fig. 15).

z Push the side walls back.

z Push the ends of the insulation blankets behind the

side wall edge.

z Insert the small side sections (Fig. 15, Item. 3) into

the side and at the bottom.

z Secure the side wall nearest the front to the central

cross brackets using one self-tapping screw (Fig. 15,

Item. 2) and secure the central cross bracket.

z Secure the small side sections (Fig. 15, Item. 3) at

the front using two self-tapping screws each (Fig. 15,

Item.1).

z Align the side wall position with bolts Fig. 12.

JNOTICE!

Remove the smaller side sections before

opening the lower reversing door.

Fig. 14 Hooking in the side walls at the bottom

Fig. 15 Hooking in the side walls at the top

Item. 1: Self-tapping screw for the small side section

Item. 2: Self-tapping screw for the side wall nearest the front

Item. 3: Smaller side section

1

1

2

4

Boiler Assembly 6

15

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.3 Boiler Jacket - Pack B

z Position the front boiler cover (Fig. 16, Item. 1) on

top of the side wall edge and pull forward, until the left

and right hooks lock into the slots.

z Secure the front boiler cover by means of two self-

tapping screws (Fig. 16, Item. 2), which should be

inserted through the boiler cover brackets and the

side wall edge into the horizontal bracket.

Fig. 16 Install the boiler front cover

1

2

Boiler Assembly6

16

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.4 Installation of the Control Panel

and Sensor Well

The optional Buderus control panel „Logamatic“ is

secured by fixing two hooks into the two holes in the

front top cover.

Control panel „Logamatic“ 2000 series

z Unscrew both self-tapping screws from the top out of

the terminal cover and remove the cover (Fig. 17).

z Route the capillary tubes through the cable raceway

and unroll to the required length.

z Locate the control panel so that the insert hooks are

inserted at the front into the oval holes, pull the

control panel forward and then tilt it back, until both

resilient hooks snap into place on the right and left

side (arrows Fig. 17).

z Secure the control panel to the front top cover on left

and right inside in the cable raceway using two selftapping screws.

JNOTICE!

If necessary, break or cut out the knock-out

from the rear wall of the control panel (Fig. 18).

Make all electrical connections in accordance with the

wiring diagram and local code requirements.

z Insert cable clips into the clip frame and secure by

pivoting the lever (Fig. 18).

z Insert both lower hooks on the right and the left side

of the rear wall section into the clip frame, keeping

the slot in the upper edge (Fig. 18).

z Press both upper resilient sliding hooks slightly

inwards (arrows on Fig. 18) and insert the rear wall

section so that both hooks lock into place.

z Locate the terminal cover and re-fit using the self-

tapping screws (Fig. 17).

JNOTICE!

Pay particular attention to the cable and

capillary runs! Do not kink the capillaries.

Connect the appliance with a permanent main

electrical disconnect!

Observe the local code requirements!

Fig. 17 Install the control panel

Fig. 18 Installation of the cable clips

Boiler Assembly 6

17

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

z Install the well provided with the Logamatic control

into the M tapping.

z Route the capillary tubes with sensor to the sensor

well (Fig. 19).

z Insert the sensor into the sensor well, until it bottoms

out (sensor well M, see page 6 in Fig. 1) (Fig. 19).

z During the insertion, the plastic spiral (Fig. 20,

Item. 2) holding the sensor together slides back

automatically. To ensure a perfect contact between

the sensor well (Fig. 20, Item. 3) and the sensor

surfaces - thereby guaranteeing the safe

temperature transfer - push the compensating spring

(Fig. 20, Item. 1).

z Push the sensor holder (Fig. 20, Item. 4) from the

side or from above over the sensor well head.

Fig. 19 Sensor to the sensor well

Fig. 20 Capillary tubes with sensor and sensor well

Item. 1: Compensating spring

Item. 2: Plastic spiral

Item. 3: Sensor well

Item. 4: Sensor holder

M

1

2

3

4

Boiler Assembly6

18

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.5 Burner Door and Burner

The burner door can be installed to swing to the left or

right.

ADANGER!

through falling parts.

Change the door opening only when the door is

closed and bolted.

JNOTICE!

The recesses (Fig. 21, Item. 2) in the boiler

door (2 left and 2 right) have been provided for

lifting with a crane or hoist, for example for the

complete removal of the door.

z Push the hinge bolts (Fig. 21, Item. 1) out from the

bottom through the top.

z Insert both hinge bolts with washers on the opposite

side (Fig. 21).

Do not forget to use the washers!

Observe the burner manufacturer’s installation

instructions!

Use or modify (drilled burner plate - accessory) the

appropriate burner plate subject to burner make and

type.

JNOTIVCE!

Seal the gap between the blast tube (Fig. 22,

Item. 2) and the thermal insulation (Fig. 22,

Item. 1) on site using the insulation rings

supplied (Fig. 22, Item. 3)! Cut insulation rings

to required dimensions.

Fig. 21 Burner door

Fig. 22 Burner installation

Item. 1: Thermal insualtion

Item. 2: Blast tube

Item. 3: Insulation rings

1

1

2

2

8 ¼

1

2

3

Boiler Assembly 6

19

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.6 Boiler Jacket - Top Covers

z Locate the boiler top cover sections Fig. 23 with the

edges facing forward loosely onto the left and right

side walls.

z Push the boiler top cover sections forward.

JNOTICE!

The third top cover section provides a cut-out

(Fig. 23, Item. 3) for the low water indicator.

Cover the cut-out with a cover plate.

Table. 5 Dimensions of boiler top cover sections from Fig. 23,

Item. 1 to 5 (all dimensions in inches)

z Align and tightly secure the cross bracket.

z Insert the thermal insulation into the lower front wall

(Fig. 24, Item. 1).

z Hook the lower front wall with four offset hooks onto

the slots of the side wall edge (Fig. 24).

z Hook the offset brackets of the top front wall (Fig. 24,

Item. 2) into the slots of the lower front wall edge and

at the top into edge of the front top cover.

JNOTICE!

If the front wall can only be located with some

difficulties, re-align the central cross bracket.

z Hook the upper (Fig. 25, Item. 3) and the lower cover

part (Fig. 25, Item. 2) into the front wall sections

using the hook provided.

z Secure the rating tag plate to the side panel (Fig. 25).

6.7 Rating Tag Plate

z Affix the rating tag plate (Fig. 25, Item. 1) according

to the boiler location on the left or right side wall.

Fig. 23 Top cover sections

Fig. 24 Front cover panels

Fig. 25 Inserting front cover panels

Boiler

model

Item 1Item 2Item 3Item 4Item

5

790 17

¾ 17¾ 17¾ 11¼ 11¼

970 17¾ 17¾ 17¾ 19½ 19½

1200 17¾ 17¾ 17¾ 19½ 19½

1

2

3

4

5

1

2

2

hakghah

hakghah

hakg

1

3

2

Boiler Assembly6

20

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.8 Boiler Jacket - Pack C

JNOTICE!

The rear wall consists of seven parts (Fig. 26).

z Secure the rear wall section (Fig. 26, Item. 1) with

two self-tapping screws per side (left and right) on the

side wall edges.

z Secure the small central rear wall section (Fig. 26,

Item. 6) on the lower rear wall section (edge pointing

inwards) using two self-tapping screws (Fig. 26,

Item. 1).

z Locate the central rear wall section (Fig. 26, Item. 2)

with the Z-profile behind the lower rear wall section

on the edge of the side wall and secure on the left

and right side with two self-tapping screws each.

z Insert the upper rear wall section (Fig. 26, Item. 3)

with Z-profile behind the central rear wall section on

the edge of the side wall, and secure on the left and

right side with two self-tapping screws each.

z Hook the upper small rear wall section (Fig. 26,

Item. 4) with the bracket into the upper rear wall

section, and secure with a self-tapping screw.

z Secure one or two cable clips (Fig. 26, Item. 5) or a

cable duct on the upper rear wall section.

z Secure the left and right locking plate (Fig. 26,

Item. 7) on the side wall using two self-tapping

screws respectively.

Fig. 26 installation of the rear wall section

Item. 1: Lower rear wall section

Item. 2: Central rear wall section

Item. 3: Upper rear wall section

Item. 4: Upper small rear wall section

Item. 5: Cable clip

Item. 6: Central small rear wall section

Item. 7: Left and right locking plate

7

1

2

3

4

6

5

Boiler Assembly 6

21

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.9 Venting System

z The resulting combustion products must be

transported through a chimney system to the outside.

z It is required to use venting systems approved for use

with condensing, gas-fired equipment.

z Prior to placing the boiler in operation, it is required

to verify compatibility between boiler and venting

system.

z Check the venting system for air tightness!

z Install the venting system per manufacturer's

instructions.

SB Boiler Venting Requirements

The SB Boiler is a category II or IV appliance and the

exhaust vent materials must be UL listed for use with a

category IV appliance: operating temperatures of up to

240° F, positive pressure, condensing flue gas service.

Currently, UL Listed vents of AL29-4C or 316L Stainless

steel and/or CPVC must be used with the SB Boiler.

Proper clearances to combustibles must be maintained

per UL and vent manufacturer.

UL, NFPA 211 and NFPA 54 (National Flue Gas Code

ANSI Z223.1) guidelines are often the basis for state

and local codes. Buderus Hydronic Systems

recommendations follow the guidelines of these

recognized agencies unless there are codes applicable

to the installation site that are more stringent. The

venting and combustion air systems must meet all

applicable code requirements.

Code Required Vent Terminations:

Horizontal Terminations:

z Vent terminations should be at least 4 feet below, 1

foot above or 4 feet horizontally from any window,

door or gravity air inlet of a building.

z The termination shall be at least 3 feet away from any

other building opening, gas utility meter, service

regulator or the like.

z The termination shall be at least 6 feet away from the

combustion air intake of any other appliance.

z The bottom of the vent terminal should be at least 12

inches above both finished grade and any snow

accumulation point.

z Vent should not terminate over public walkways or

over an area where condensate or vapor could

create a nuisance or be detrimental to the operation

of regulators, meters and other equipment.

z Discharges should not be in wind-blocked areas,

corners, or directly behind vegetation.

Vertical Terminations:

z Roof penetrations should follow all applicable codes

and the vent manufacturer's instructions. The vent

should never be installed at less than the required

clearances to combustible materials per UL, NFPA,

and local codes. "Double-wall or thimble" assemblies

are required when penetrating combustible walls and

roofs.

z Vertical discharges should extend at least 2 feet

above the roof through properly flashed penetrations

and at least 2 feet above anything within a 10 foot

horizontal diameter. Discharges that extend more

than 2 feet above the roof must be laterally

supported.

z If the vent system is to be connected to an existing

stack, the stack must be UL Listed for Category II or

IV appliances (capable of 240°F, positive pressure

and condensing flue gas operation).

z Masonry stacks must be lined and the vent

penetration must terminate flush with and be sealed

to this liner. Vents may enter the stack through the

bottom or side.

z SB Boilers vent systems must not be interconnected

to any other venting system; The SB Boiler is

designed to maintain its own vent system.

z The exhaust vent must be pitched up toward the

termination a minimum of ¼" in. per foot of length.

Condensate must flow back to the SB Boiler freely,

without accumulating in the vent.

Combustion Air from Outside the Building

If outside combustion air is required, the room shall have

two permanent louvered openings to the outdoors. Each

opening must have a minimum free area of 1 square

inch for each 4,000 Btu/hr of total input rating of all fuel

burning equipment in the space.

When the air is supplied to the room via ducts, two ducts

must be used. Vertical ducts and openings must have a

minimum free area of 1 square inch for each 4,000 Btuh

of the total input rating of all fuel burning equipment in

the space. Horizontal ducts and openings must have a

minimum free area of 1 square inch for each 2,000 Btuh

of the total input rating of all fuel burning equipment in

the space.

The free area of the openings must be taken into

account restrictions from the louvers and screens. The

louver manufacturer should be consulted for the

percentage of free area available. When free area is not

known, metal louvers typically have 60 - 70% of free

area, wooden louvers have between 20 - 25% of free

area. Louvers should be in a fixed position or interlocked

with equipment so that they open automatically during

equipment operation.

Boiler Assembly6

22

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

The combustion air damper opening shall be located as

follows: top louver shall began within 12" of the ceiling

and the bottom louver within 12" of the floor as

prescribed in NFPA 54.

Combustion Air from an Adjacent Room

Where combustion air is to be used from within the

building, air must be provided into the equipment room

through two permanent openings into the interior

building. Each opening must have a minimum free area

of 1 square inch for each 1,000 Btuh of the total input

rating of all fuel burning equipment in the space. The

louvers shall be located as follows: top louver shall start

within 12" of the ceiling and the bottom louver within 12"

of the floor as prescribed in NFPA 54.

Exhaust Vent Systems

Positive-Pressure - The vent system is designed to be

under positive pressure at all firing rates. The minimum

vent size is 14" diameter. Horizontal vent pipe should be

supported at least every 6 feet and vertical vent should

be support to prevent excessive weight on the horizontal

runs.

AWARNING!

Use only an approved vent starter coupling and

approved vent pipe from the same

manufacturer for Buderus SB boilers. Do not

mix components from different systems. The

vent system could fail, causing flue gas spillage,

resulting in severe personal injury or death.

Permissible Equivalent Venting Length

Configurations for SB735 Boilers

ANOTICE!

Above lengths represent total equivalent vent

length combining horizontal and vertical runs

and any elbow. For each 45° elbow, deduct 4 ft,

for each 90° elbow, deduct 7 ft.

A positive breeching draft is not to exceed

positive + 0.2 Inches WC.

Condensate Removal

The exhaust vent pipe must be pitched at least ¼" per

foot of length back to the boiler. This will allow

condensate to drain back to the unit to be disposed. Low

spots in the venting where condensate may collect

should be avoided. A plastic hose or PVC drain pipe

may be used to remove discharge to a floor drain. Care

should be taken to avoid kinks and from raising the drain

line above the trap assembly. If the condensate must be

lifted above trap assembly to a drain, it should be drain

into a sump so that it can pump away to a drain.

Permissible Equivalent Venting Length

Configurations for SB735 Boilers

(in ft)

Model

Nom. Vent

Size

12“ 14“

790 14" 165 195

970 14“ 130 180

1200 14“ - 165

Table. 6 Maximum venting length for SB735 boilers

Boiler Assembly 6

23

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

6.10 Neutralization Equipment and Water

Controls Installation

DNOTICE

Observe the separate installation instructions

for the installation and maintenance of the

neutralization system (part of the standard

delivery of the neutralisation system).

z Push the siphon delivered onto the pipe connector on

the flue gas collector and tighten the union nut on the

siphon.

z Connect the drain hose to the connector (Fig. 27,

Item. 1) of the condensate drain (Siphon) (Fig. 27,

Item. 2) using a hose clip. When using Ø 1

½“ pipe

remove the tee piece on the siphon with a saw.

JNOTICE!

Generally, the condensate should be routed to

the boiler via the flue pipe. Where this is

impracticable, use only stainless steel or plastic

tee pieces in the separate feed hose pipe.

z Secure furnished supply manifold and gasket to

upper water connection (VK connection in (Fig. 1,

page 6)).

z Install furnished relief valve in supply manifold and

pipe discharge full port to nearby floor drain.

z Install low water cut-off and aquastat (s) in available

¾“ manifold tappings.

z Install pressure and temperature gauge in ½“

tapping.

z Plug any unused tappings.

z Refer to section 6.4 when installing Logamatic

control. Plug sensor port M (Fig. 1, page 6) with

¾“

plug when not

using a Logamatic control.

JNOTICE!

Lower return connection RK1 (Fig. 1, page 6)

must always

be used for connecting heating

systems return. Connect coldest return zone(s)

to RK1 for maximum efficiency. Connect higher

temperature return zone(s) to RK2 (Fig. 1,

page 6) if called for by engineering firm / design.

If the RK2 connection is not

used, close it off

with a blanking flange.

Fig. 27 Condensate

Item. 1: Connection for a drain hose

Item. 2: Siphon

Item. 3: Clean-out cover

3

1

2

Placing the Boiler in Operation7

24

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

7 Placing the Boiler in Operation

ADANGER!

due to combustion products.

Prior to placing the boiler in operation, put 3 or

4 gallons of water in the clean-out opening or

combustion chamber to fill the drain in the

condensate drain line (Fig. 27, Item. 3).

ABOILER DAMAGE!

due to corrosion and debris build-up.

Flush the entire heating system prior to firing the

boiler. To avoid corrosion and debris build-up

on the water side of the boiler. It is required to

test the fill and make-up water per Instructions

for Water Preparation for Boiler.

DNOTICE!

Observe the installation instructions for the

neutralization system!

Follow the instructions supplied with boiler,

burner, controls and low water cut-off

components during the start-up of the system.

Make the end user familiar with the function and

operation of the entire system and sign over the

technical documentation.

It is recommended to instruct the end user

regarding maintenance requirements and

procedures. An annual service contract is

recommended.

Maintenance 8

25

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

8 Maintenance

8.1 General Information

ADANGER!

due to unauthorized service work.

Maintenance work on gas components can only

be carried out by a gas certified service

company.

JNOTICE!

The end user or operator is required to have

regular scheduled maintenance performed. An

annual maintenance procedure on the entire

system is required.

JNOTICE!

We recommend an annual service contract for

the maintenance.

The factory required maintenance steps are

outlined in the check list (see section 9 „Check

List“).

Follow the burner manufacturer’s instructions

regarding burner maintenance!

8.2 Cleaning of the Boiler

ADANGER!

due to incorrect boiler brushers.

Use only brushes made available through

Buderus Hydronic System, Inc..

HDANGER!

due to current carrying wires.

Prior to maintenance shut down the electrical

power supply and pad lock.

JNOTICE!

A high pressure washer is recommended for a

wet cleaning of the heat exchanger.

Boiler debris should not be sent through the

neutralization system.

Check to make sure the condensate drain does

not get plugged (Fig. 27, Item. 2.).

Maintenance8

26

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

z Check and possibly clean the flue gas collector and

the condensate drain through the clean-out cover

(Fig. 27, Item. 3).

z Remove the upper (Fig. 28, Item. 4) and lower cover

part (Fig. 28, Item. 1).

z Remove the upper front wall (left and right) (Fig. 28,

Item. 3 und 5).

z Remove the lower front wall (Fig. 28, Item. 2).

z Remove the left and right side wall sections (Fig. 28,

Item. 6).

ADANGER!

through falling parts.

Ensure that the hinge bolts (Fig. 29, Item. 1 and

2) are in the boiler door and in the reversing

door, before opening the doors.

z Loosen the bolts on the reversing door (Fig. 29, Item.

1) and pivot the reversing door aside.

z Remove the hexagon bolts from the boiler door

(Fig. 29, Item. 2) and open the door.

z Clean the combustion chamber and the heating

surfaces.

z Brush out the secondary and third firetubes (Fig. 30).

JNOTICE!

When cleaning the secondary and third

firetubes, the entire brush head should protrude

from the firetube before the cleaning brush is

withdrawn again.

z Remove any cleaning residues with a vacuum

cleaner. Observe the opening instructions of the

cleaning equipment when cleaning by pressure

spray!

z Check the gaskets on the boiler door and the

reversing door and replace, if necessary.

ASYSTEM DAMAGE!

Spray must not enter into the control panel!

z Close and bolt down the boiler door.

z Close and bolt down the reversing door.

z Fit the insulation blanket.

z Install the side wall sections.

z Install the upper and lower front wall.

z Re-start the system.

Fig. 28 Remove the front wall

Fig. 29 Open the boiler door

Fig. 30 Cleaning the secondary and third firetubes

1

2

3

45

6

1

2

Check List 9

27

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

9 Check List

Check off the different maintenance steps, place an „X”

in the corresponding box and list date and service

company name below.

Follow recommended time frame for boiler and burner

maintenance work.

Heating system 01 02 03 04 05 06 07 08

1 Disconnect electrical supply to system

2 Shut off gas supply

3 Disconnect gas supply from burner

4 Remove front jacket panels, open burner door

5 Remove reversing door

6 Remove condensate drain hose from neutralization

system

7 Check and clean combustion chamber

8 Check and clean out fire tube passages

9 Flush condensate drain connection at boiler

10 Check and clean flue collector

11 Check burner gasket, replace if necessary

12 Check gasket on reversing door, replace if

necessary

13 Reattach condensate drain hose

14 Close off the reversing cover, bolt down and as-

semble jacket panels

15 Pour 3 gal. of water into the combustion chamber

16 Close the burner door, bolt down and assemble ja-

cket panels

17 Reattach the gasline to the burner

18 Check the gasline for leaks and correct if necessary

19 Check venting system for leaks, repair when needed

20 Check operation of the safety controls

21 Check operation of all operating controls

22 Bring the system back into regular operation

23

Check List9

28

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Neutralization system 01 02 03 04 05 06 07 08

1 Isolate the neutralization system from the main

electricity supply

2 Disconnect the inlet and outlet hose from the

granulate container

3 Remove the container lid of the neutralization

system

4 Remove used granulate (the container can be filled

by 180°), clean out the container

5 Fill with fresh granulate (in accordance with

instructions)

6 Replace and, if necessary, bolt down the container

lid of the neutralization system

7 Plug-in the mains cable of the neutralization system

into a main socket

8 Reconnect all hose connections and check for leaks

9 Start-up the neutralization system

10

Specialist contractor

__________ 01

Date:

Specialist contractor

___________ 02

Date:

Specialist contractor

__________ 03

Date:

Specialist contractor

___________ 04

Date:

Specialist contractor

__________ 05

Date:

Specialist contractor

___________ 06

Date:

Specialist contractor

__________ 07

Date:

Specialist contractor

___________ 08

Date:

Check List 9

29

We reserve the right to make any changes due to technical modifications!

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Notes

We reserve the right to make any changes due to techical modifications! Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Boiler Installation and Maintenance Manual SB735 • Issue 10/200330

31

Notes

We reserve the right to make any changes due to techical modifications! Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Boiler Installation and Maintenance Manual SB735 • Issue 10/2003

BBT North America Corporation

50 Wentworth Avenue

Londonderry, NH 03053

Tel. 603-552-1100

Fax 603-584-1681

www.buderus.net

Products manufactured by

BBT Thermotechnik GmbH

D-35573 Wetzlar

www.buderus.de

BBT North America Corporation reserves the right

to make changes without notice due to continuing

engineering and technological advances.

Loading...

Loading...