Page 1

For contractors

Read carefully prior

to installation and

maintenance.

Note:

This boiler must only be operated with

natural gas or liquid propane (LP)!

Installation and maintenance

instructions

Gas fired condensing

boiler

Logano plus SB615 Gas

6 720 640 266 - 08/2009 GB/IE

Page 2

Contents

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

2

Contents

1 Explanation of symbols and safety instructions . . 3

1.1 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Information about the appliance . . . . . . . . . . . . . . . 5

2.1 EU Declaration of Conformity . . . . . . . . . . . . . . . . 5

2.2 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Tools, materials and auxiliary equipment . . . . . . . 5

2.6 Specifications, dimensions, connections . . . . . . . 6

3 Regulations, standards and guidelines . . . . . . . . . . 9

3.1 Low water indicator installation . . . . . . . . . . . . . . . 9

3.2 Standards and guidelines/directives . . . . . . . . . . . 9

3.3 Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Safety limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Boiler positioning . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5.1 Foundation and recommended wall clearances 11

3.5.2 Levelling the boiler . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Transporting the boiler . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Means of transport . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1.1 Transporting the boiler using a forklift truck . . . . 13

4.1.2 Transporting the boiler using two pallet trucks . 13

5 Installation of the boiler . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Checking delivery for completeness . . . . . . . . . . 14

5.2 Disposing of packaging . . . . . . . . . . . . . . . . . . . . 14

5.3 Minimum clearances / product dimensions . . . . 14

5.4 Changing the hinging of the burner door . . . . . . 14

5.5 Installing the minimum pressure switch and

minimum pressure limiter . . . . . . . . . . . . . . . . . . 15

5.6 Low water indicator (accesory), fitting

(400 – 600kW) . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7 Connecting the boiler to the pipework . . . . . . . . 16

5.7.1 Connecting the return to the boiler . . . . . . . . . . . 16

5.7.2 Connecting the flow to the boiler . . . . . . . . . . . . 16

5.7.3 Connecting the safety line flow . . . . . . . . . . . . . . 16

5.8 Filling the heating system and checking

connections for leaks . . . . . . . . . . . . . . . . . . . . . 17

5.9 Fitting the lagging . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.10 Fitting the connection plates . . . . . . . . . . . . . . . . 19

5.11 Fitting the side panels . . . . . . . . . . . . . . . . . . . . . 20

5.12 Routing the burner cable . . . . . . . . . . . . . . . . . . . 21

5.13 Fitting the back plate . . . . . . . . . . . . . . . . . . . . . . 22

5.14 Fitting the front boiler cover . . . . . . . . . . . . . . . . . 23

5.15 Fit and connect the control unit (accessory) . . . 23

5.16 Installing the temperature sensor set . . . . . . . . . 25

5.17 Fitting the boiler cover sections . . . . . . . . . . . . . 26

5.18 Fitting the front panel . . . . . . . . . . . . . . . . . . . . . . 27

5.19 Securing the shield, device label

and data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.20 Connecting and filling the neutraliser

(accesory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.21 Installing condensate pipework . . . . . . . . . . . . . 29

5.22 Connecting the flue side of the heating system 30

5.22.1 General information on flue systems . . . . . . . . . 30

5.22.2 Fitting the flue pipe sealing collar (accessory) . 30

5.22.3 Fitting the flue temperature sensor (accessory) 30

5.23 Fitting burner (accessory) and connecting gas

supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.23.1 Fitting the burner plate . . . . . . . . . . . . . . . . . . . . 31

5.23.2 Fitting the burner to the burner plate . . . . . . . . . 32

5.23.3 Connecting the gas supply . . . . . . . . . . . . . . . . . 33

6 Initial operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.1 Flushing the heating system . . . . . . . . . . . . . . . . 34

6.2 Filling the heating system . . . . . . . . . . . . . . . . . . 35

6.3 Preparing the heating system for operation . . . 36

6.4 Commissioning the control unit and the burner 36

6.5 Commissioning report . . . . . . . . . . . . . . . . . . . . . 37

7 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1 Shutting down the heating system . . . . . . . . . . 38

7.2 Shutting down the heating system in an

emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8 Inspection/maintenance . . . . . . . . . . . . . . . . . . . . . . 39

8.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.2 Preparing the boiler for inspection and

maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8.3 Cleaning the boiler . . . . . . . . . . . . . . . . . . . . . . . 40

8.4 Cleaning the flue gas collector . . . . . . . . . . . . . 42

8.5 Checking the heating system water pressure . . 43

8.6 Inspection and maintenance reports . . . . . . . . . 44

Page 3

1

Explanation of symbols and safety instructions

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

3

1 Explanation of symbols and safety instructions

1.1 Symbols

Signal words indicate the hazard risk level resulting from

not following the instructions.

• Caution indicates that minor damage to property

could result.

• Warning indicates that minor personal injury or

serious material losses could result.

• Danger indicates that serious personal injury could

result. In particularly serious cases, lives could be at

risk.

Notes contain important information in cases where there

is no risk of personal injury or material losses.

1.2 Safety information

These installation and maintenance instructions contain

important information for the safe and appropriate

installation, commissioning and servicing of the Logano

plus SB615 Gas condensing boiler.

These installation and maintenance instructions are

designed for specialists, who, – through their vocational

training and experience, – are knowledgeable in handling

heating systems and gas installations.

Observe all standards and guidelines applicable to the

installation and operation of this system in your country.

Only use original Buderus spare parts. Losses caused by

the use of parts not supplied by Buderus are excluded

from the Buderus warranty.

Risk to life from gas explosion

There is a risk of explosion if you can smell gas!

B No open flames. Do not smoke. Do not use lighters.

B Prevent sparks. Do not operate electrical switches,

including telephones, plugs, door-bells, mobiles or

other electrical devices.

B Close the main gas shut-off valve.

B Open windows and doors.

B Warn all occupants of the building, but do not ring

doorbells.

B Do call your gas supplier from outside the building.

B If you hear gas escaping, immediately leave the

building, prevent others from entering and notify the

police and fire brigade from outside the building.

Customer information:

B Only qualified personnel may carry out the installation,

the main fuel and flue gas connections, the initial

start-up, electrical connections and any maintenance

or repair work.

B Work on gas-carrying equipment is to be carried out by

a licensed company.

Risk to life from poisoning

An insufficient supply of air can result in the escape of

dangerour flue gases!

B Prevent air inlet and outlet vents from becoming

blocked or restricted.

B Do not operate the boiler until any ventilation defects

have been rectified.

B Inform the system user in writing of the fault and its

associated dangers.

Safety information in the text is framed

and marked with a warning triangle on a grey

background.

Notes are identified by the symbol shown on

the left. They are bordered by horizontal lines

above and below the text.

Page 4

1

Explanation of symbols and safety instructions

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

4

Risk of injury from electric shock

B Isolate the heating system from the mains electricity

supply before starting work. Use either an emergency

isolation switch or the relevant circuit breaker.

A contact separation of at least 3mm must be achieved

across EACH pole.

B Prevent unintentional reconnection of the electricty

supply.

Risk of fire from flammable materials or liquids

B Never store flammable materials or liquids in the

immediate vicinity of the boiler.

Laws and regulations

B The appliance must be installed in accordance with

and comply to, the current: Statutory Instrument Laws,

Gas Safety Regulations, IEE Regulations, Building

Regulations, Local Water By-Laws, Health & Safety

document 635 (The Electricity at Work Regulations)

and any other local requirements. Observe all

European and local installation standards, building

regulations and the latest edition of the wiring

regulations. Chemically aggressive substances, can

corrode the appliance and invalidate any warranty.

Preventative maintenance

B Carry out annual maintenance and cleaning

procedures. In the course of this work, check the entire

heating system (including neutralisation device) for

correct function.

B Have faults corrected as quickly as possible in order to

prevent system damage and to help protect your

heating system.

Frost protection

The heating system may freeze in cold weather if the

control unit is not turned on.

B Protect your heating system against frost when

temperatures below zero are expected. If for some

reason the control unit is to be switched off, drain the

system water from the boiler, DHW cylinder and all

heating system pipework.

System damage and personal injury due to

operator errors

Operator errors can result in injury and damage to

property.

B Ensure that children never operate this appliance

unsupervised or play with it.

B Ensure that only personnel who can operate this

appliance correctly have access to it.

Instructing the customer

B Hand these installation and maintenance instructions

to your customer when handing over the system.

Request that these instructions are kept in a safe

location next to the boiler.

B Explain to the customer how the appliance works and

how to operate it.

Page 5

2

Information about the appliance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

5

2 Information about the appliance

2.1 EU Declaration of Conformity

The design and operation of this product conform to

European Directives and the supplementary national

requirements. Its conformity is demonstrated by the CE

designation.

You can view the Declaration of Conformity on the

internet at www.buderus.de/konfo or request a copy from

your local Buderus sales office.

2.2 Correct use

The Logano plus SB615 Gas condensing boiler has been

designed for wet heating systems in e.g. multiple dwelling

units or in industrial applications. Any gas burner

type-tested to EN 676 can be used if its operating range

matches the boiler specifications.

2.3 Data plate

2.4 Standard delivery

B Upon delivery, check all packaging for damage.

B Check the delivered package(s) for completeness.

• Boiler mounted on pallet

• Connection pipe for low water indicator, connected to

the boiler body (for boiler size ≥ 400 kW)

• Technical documents, attached to boiler block

• Siphon in the combustion chamber

• Boiler casing with thermal insulation and accessory

bag, packed in the wooden crate

• Control unit with wiring diagram and operating

instructions for electronic boiler and heating circuit

control, packed in carton (accessories ordered

separately).

• Neutralisation device, packed in individual carton

(accessory ordered separately)

It is possible that some of the standard accessories will

not be necessary for certain boiler types.

2.5 Tools, materials and auxiliary

equipment

For the installation and maintenance of the boiler, you

require standard tools, as used in space heating as well

as gas and water installations.

The information on the type plate is binding

and must be observed!

Page 6

2

Information about the appliance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

6

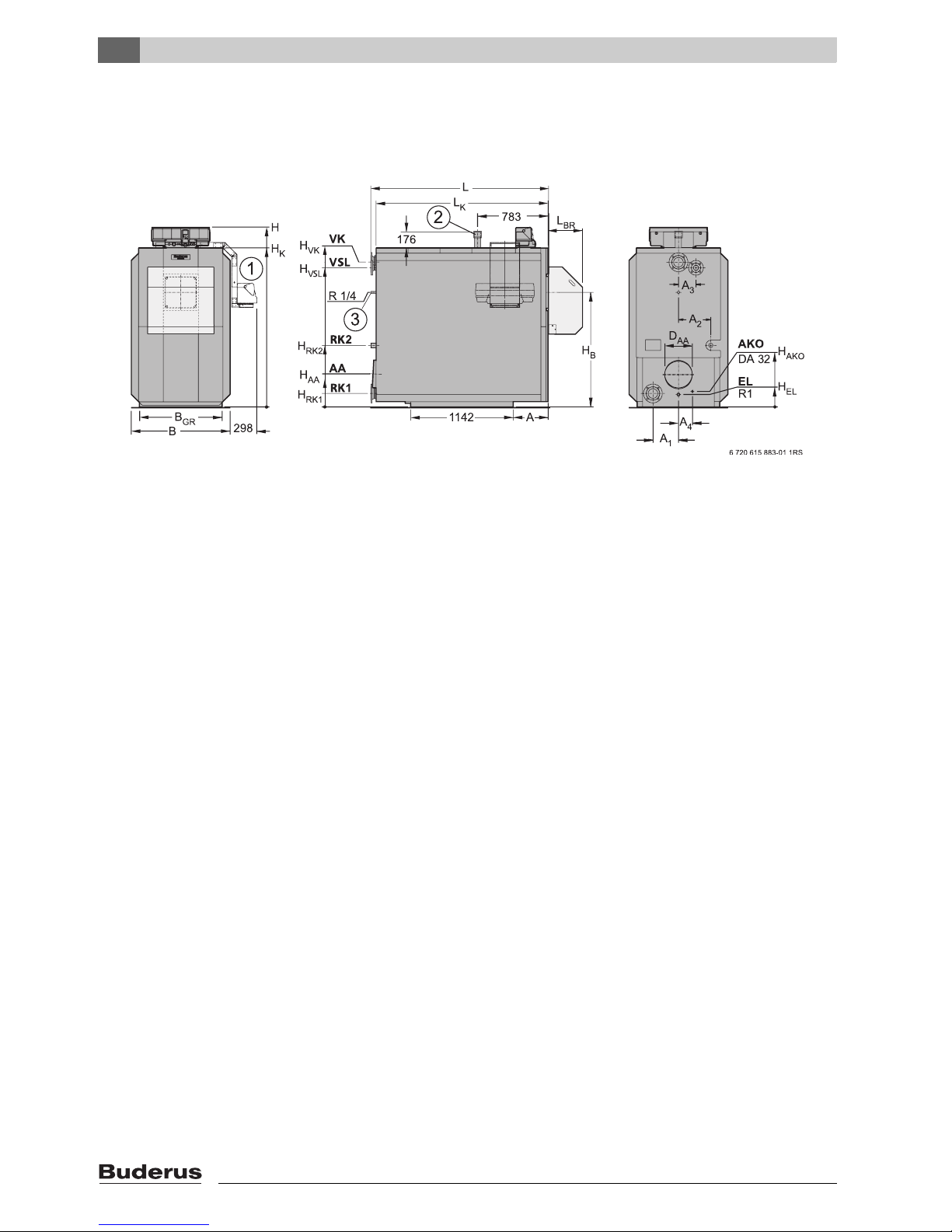

2.6 Specifications, dimensions, connections

The specification provides information on the output

profile of the Logano plus SB615 gas condensing boiler.

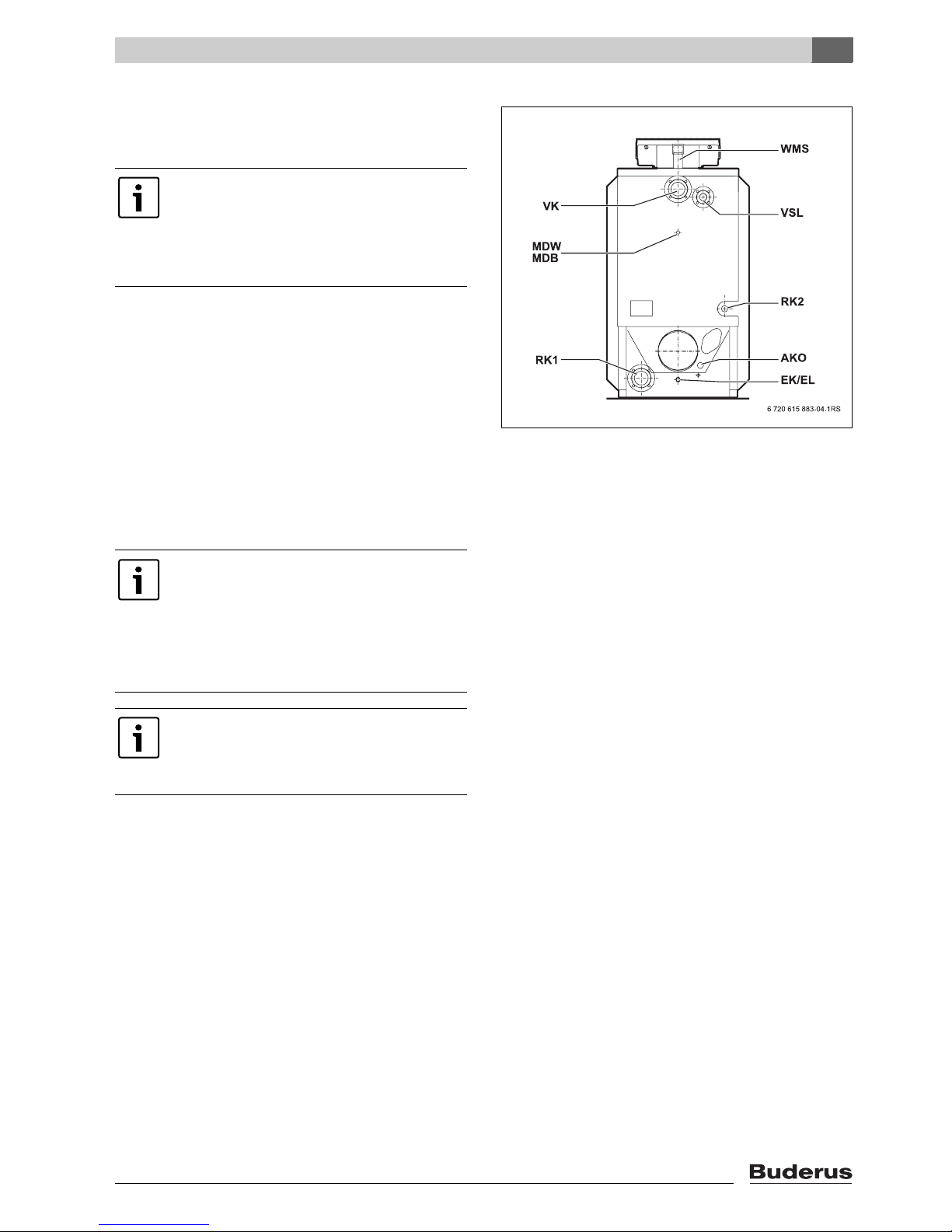

Fig. 1 Specifications, dimensions, connections

ØAAFlue pipe internal diamater

A Clearance

AKO Condensate outlet

B Boiler width incl. casing

B

GR

Base frame

DAAGas outlet

EL Cold water inlet/drain

H Boiler height including control unit, e.g. Logamatic

4311/12 control unit, = H + 235 mm

H

AA

Flue outlet height

HELDrain

HKBoiler height excl. control unit

L Boiler length incl. casing

L

BR

Burner length

LKBoiler block length

RK1 Boiler return 1

RK2 Boiler return 2

VK Boiler flow

VSL Flow safety line

1 Side-mounted control unit holder (left/right)

2 Spigot for low water indicator for boiler sizes 400 kW and

above

3 Minimum pressure monitor for boiler size 145 – 240 kW

or minimum pressure limiter for boiler size 310 kW as

accessory

Page 7

2

Information about the appliance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

7

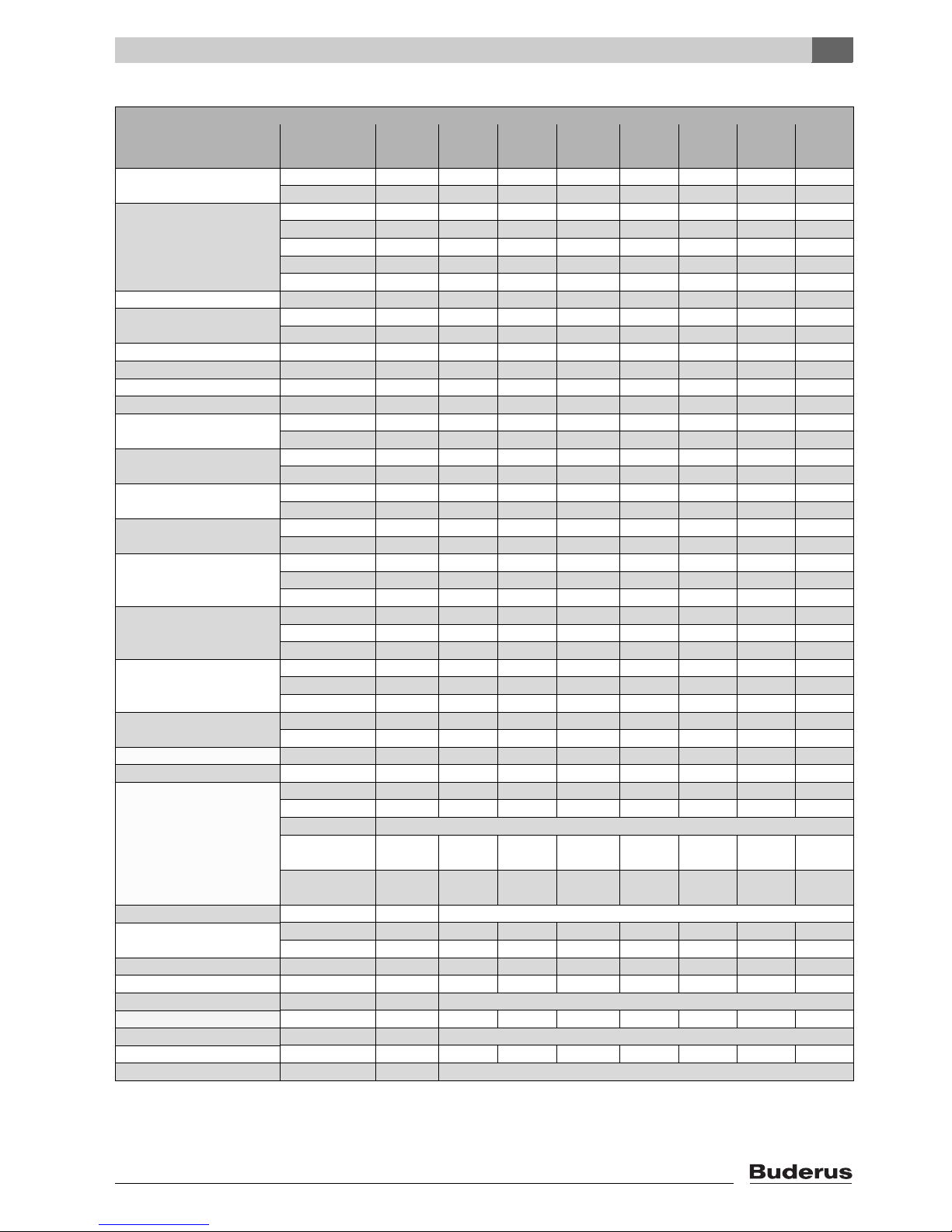

Specifications for Logano plus SB615 Gas

Boiler size Unit 145 185 2301)/240 310 400 510 640

Length

L mm 1816 1816 1845 1845 1845 1980 1980

L

K

mm 1746 1746 1774 1774 1774 1912 1912

Burner length

L

BR

- Logatop VM mm 376 376 376 376 – – –

L

BR

- WG mm 500 500 500 500 577 868 868

L

BR

- BS/M mm 280 301 – – – – –

L

BR

- RS/M mm – – 580 580 580 580 840

L

BR

- RS/M BLU mm – – – – – 840 –

Width

B mm 900 900 970 970 970 1100 1100

Height

H mm 1606 1606 1638 1638 1842 2000 2000

H

K

mm 1376 1376 1408 1408 1612 1770 1770

Width/height/ for transport mm 720/1340 720/1340 790/1370 790/1370 790/1570 920/1730 920/1730

Length mm 1735 1735 1760 1760 1760 1895 1895

Base frame B

GR

mm 720 720 790 790 790 920 920

Clearance A mm 285 285 285 285 285 367 367

Flue outlet

ØD

AA

inside DN 183 183 203 203 253 303 303

H

AA

mm 300 300 305 305 333 370 370

Combustion chamber

Length mm 1460 1460 1460 1460 1460 1594 1594

Ø mm 453 453 453 453 550 650 650

Burner door

Depth mm 185 185 185 185 185 185 185

H

B

mm 985 985 1017 1017 1135 1275 1275

Boiler flow

2)

ØVK DN656580 80100100100

H

VK

mm 1239 1239 1260 1260 1442 1613 1613

Boiler return 1

2)

Ø RK1 DN 65 65 80 80 100 100 100

H

RK1

mm 142 142 142 142 150 150 150

A

1

mm 275 275 300 300 290 284 284

Boiler return 2

2)

ØRK2 DN R 1½ R 1½ R 1½ 65 65 80 80

H

RK2

mm 495 495 512 512 597 685 685

A

2

mm 295 295 310 310 315 360 360

Flow, safety line

3)

Ø VSL DN R 1¼ R 1¼ 32 32 50 50 50

H

VSL

mm 1180 1180 1213 1213 1327 1549 1549

A

3

mm 160 160 170 170 210 195 195

Condensate outlet

H

AKO

mm 164 164 164 164 164 160 160

A

4

mm 100 100 120 120 140 155 155

Drain H

EL

mm 85 85 82 82 90 138 138

Logatop gas connection VM DN 1½ 1½ 1½ 2 – – –

Combustion heat output

of kW 54.3 69.3 89.8 116.0 149.5 191.6 239.9

up to kW 135.8 173.2 224.4 289.9 373.8 478.9 599.8

Logatop VM

Partial load

35% kW

47.5 60.6 75.3 101.5 – – –

Full load

kW

135.8 173.2 215 289.9 – – –

CO2 content % 10

Weight

net kg 613 620 685 705 953 1058 1079

With burner kg 648/643

1)

655/6501)720/7151)753/7351)1001 1156 1177

Water capacity l 560 555 675 645 680 865 845

Gas capacity l 327 333 347 376 541 735 750

Free draught Pa 501)/boiler-dependent4).

Hot gas resistance mbar 1.20 1.55 2.20 2.40 3.00 3.55 4.40

Permissible flow temperature

5)

°C 120

Permissible operating pressure bar 4 4 5 5 5.5 5.5 5.5

CE mark, boiler CE-0085 AT 0075

Tab. 1 Specification

Page 8

2

Information about the appliance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

8

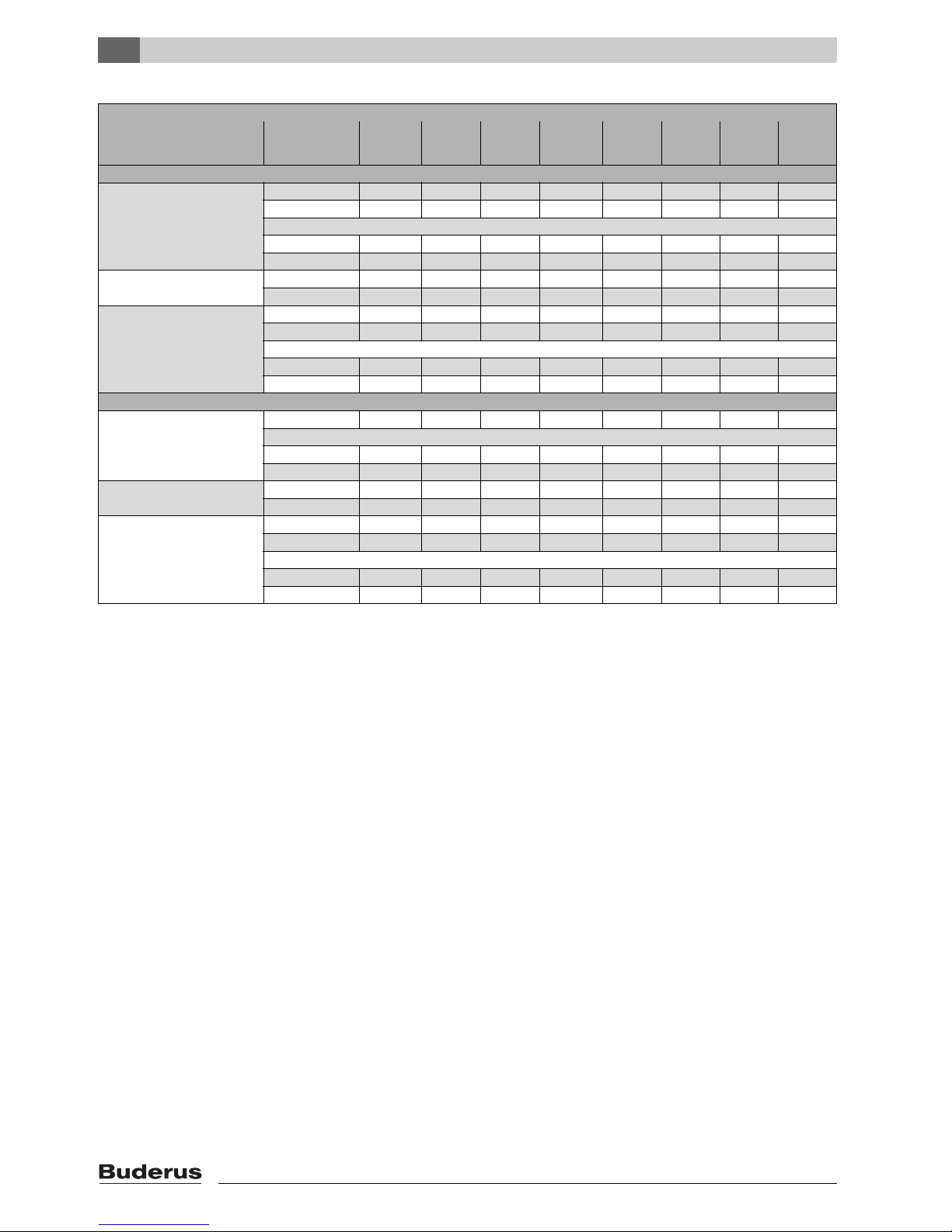

System temperatures 50/30 °C

Rated output

Full load kW 145 185 240 310 400 510 640

Partial load kW 59.2 75.6 97.8 126.3 162.4 208.8 261.5

Logatop VM

Full load kW 145 185 230 310 – – –

Partial load kW 51.8 66.1 82.1 110.6 – – –

Flue gas temperature

6)

Full load °C 40 40 46 46 42 44 44

Partial load °C 33 33 35 34 37 35 32

Flue gas mass flow rate

Full load kg/s 0.0552 0.0704 0.0928 0.1200 0.1528 0.1969 0.2466

Partial load kg/s 0.0217 0.0277 0.0360 0.0465 0.0603 0.0770 0.0958

Logatop VM

Full load kg/s 0.0633 0.0808 0.1010 0.1350 – – –

Partial load kg/s 0.0220 0.0283 0.0352 0.0474 – – –

System temperatures 80/60 °C

Rated output

Full load kW 132.7 169.2 218.9 282.8 365.2 467.9 585.4

Logatop VM

Full load kW 132.7 169.2 210.7 282.8 – – –

Partial load kW 50.6 64.5 80.2 108.1 – – –

Flue gas temp.

6)

Full load °C 66 66 71 71 68 69 71

Partial load °C 45 45 45 44 45 44 44

Flue gas mass flow rate

Full load kg/s 0.0579 0.0738 0.0956 0.1235 0.1592 0.2040 0.2555

Partial load kg/s 0.0231 0.0295 0.0383 0.0494 0.0637 0.0816 0.1022

Logatop VM

Full load kg/s 0.0633 0.0808 0.1010 0.1350 – – –

Partial load kg/s 0.0220 0.283 0.0352 0.0474 – – –

1) In conjunction with Logatop VM.

2) According to EN 1092-1 PN6

3) According to EN 1092-1 PN16

4) With Logano plus SB615 with third party burner

5) Safety limit (High limit safety cut-out). Max. possible flow temperature = safety limit (STB) – 18K.

Example: Safety limit (STB): 100 °C, max. possible flow temperature = 100 - 18 = 82 °C

6) To DIN EN 303. Minimum flue gas temperatures for chimney design calculations in accordance with EN 13394-1 Æ Technical Guide "Boiler

characteristic values for the dimensioning of flue gas systems".

Specifications for Logano plus SB615 Gas

Boiler size Unit 145 185 2301)/240 310 400 510 640

Tab. 1 Specification

Page 9

3

Regulations, standards and guidelines

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

9

3 Regulations, standards and guidelines

During installation and operation of the system, standard

engineering practices, the buildings regulations and any

legislative requirements must be observed.

3.1 Low water indicator installation

B For boilers > 300 kW, install a low water indicator,

following the manufacturer's technical documents for

installation and operation.

B If the LWI connection provided is not used for the

installation of an SYR 932.1 low water indicator

(Buderus accessory), seal the connection off with a

plug (Æ Chapter 5.6, page 15).

The Logamatic control system is used for this boiler.

3.2 Standards and guidelines/directives

This device meets all basic requirements of relevant

European standards and guidelines:

• 90/396/EC Gas Appliance Directive

• EN 677, EN 303-1, EN 303-3, DIN 4702-6, EN 267,

EN 303-2

• 92/42/EC Efficiency Directive

• 2006/95/EC Low voltage Directive

• 2004/108/EC Electro Magnetic Compatibility

Directive

• 97/23/EC Pressure equipment Directive

Standard: TRD 702

Observe the following during installation and

operation:

• Local Building Regulations concerning boiler room

installations

• Local Building Regulations regarding air supply and

extraction equipment as well as connection to a flue

• Latest edition of the IEE Wiring regulations governing

electrical connection to the mains power supply

• The technical rules of the gas supply utility regarding

the connection of the gas burner to the local mains gas

supply

• Regulations and standards regarding the safety

equipment in water-filled heating systems

• Installation instructions for heating engineers

• In Belgium, the standards NBN D 30-003,

NBN D 51-004 and addenda must be observed.

• In the Netherlands, technical rules, building regulations

and other legal requirements (e.g. NEN 1078 (GAVO),

NEN 3028 and NEN 1010) must be observed when

installing and operating the system.

• In Austria, observe local building regulations as well as

ÖVGW Directive G1 or G2 (ÖVGW-TR gas or LPG)

during installation. The requirements of the national

directive Article 15a B-VG, regarding emissions and

efficiency, are fulfilled.

•For Switzerland:

By carrying out measurements at the installation

location, it must be checked whether the LRV maximum

permitted limits concerning CO and NOx are being

observed. The boilers have been tested according to

VKF fire safety regulations. During installation, observe

the guidelines for installing and operating gas-fired

boilers G3 d/f, the gas guidelines G1 SVGW, and local

fire safety regulations in force within the canton.

The output figures shown in the tab. "Specifications"

are nominal output figures.

In practice, these values will sometimes not be reached

within the specified output range in order to adhere to

LRV regulations.

Permissible fuels

Logano SB615 Gas and Logano plus SB615 VM gas

condensing boilers can be operated using the following

fuels:

• Natural gas and liquid propane (LP) according to

DVGW (German certification body) worksheet G 260

• Natural gas and liquid propane (LP) supplied by public

gas utility (Austria, Switzerland)

B Only use burners that are compatible with these gas

types.

B Observe the specifications of the burner supplier.

Observe all standards and guidelines

applicable to the installation and operation of

this system in your country!

The details on the boiler rating plate are

definitive and must be observed.

For UK & Ireland:

B For boilers > 300 kW, install a low water

indicator as required by BS-EN 12828.

B For installation and operation, refer to the

technical documents provided by the

manufacturer.

For Poland:

B For boilers > 100 kW, equip the boiler

with a low water indicator as required by

PN-91/B-2414 (p2.5).

Page 10

3

Regulations, standards and guidelines

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

10

3.3 Leaks

B Carrying out the leak test.

The testing pressure is based on the normal operating

pressure of the heating system and should be 1.3 times

that pressure, and in any case no less than 1 bar.

3.4 Safety limits

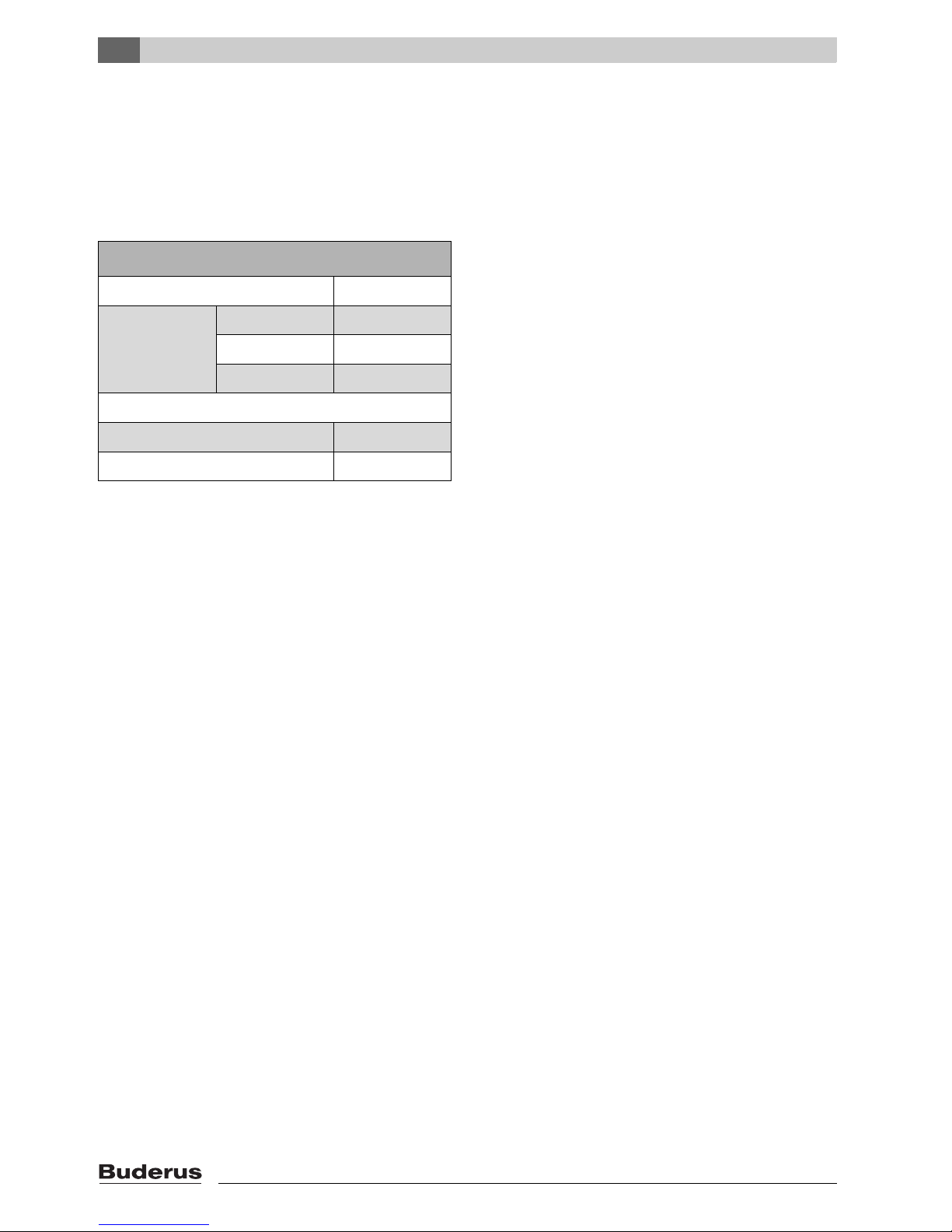

Safety limits

Maximum flow temperature 120 °C

1)

1) For Germany. Always follow the national standards and

regulations of the country where the appliance is installed.

Permissible

operating pressure

145 – 185 kW 4bar

210 – 310 kW 5 bar

400 – 640 kW 5.5 bar

Maximum time constant on:

High limit safety cut-out 40 s

Control thermostat 40 s

Tab. 2 Safety limits

Page 11

3

Regulations, standards and guidelines

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

11

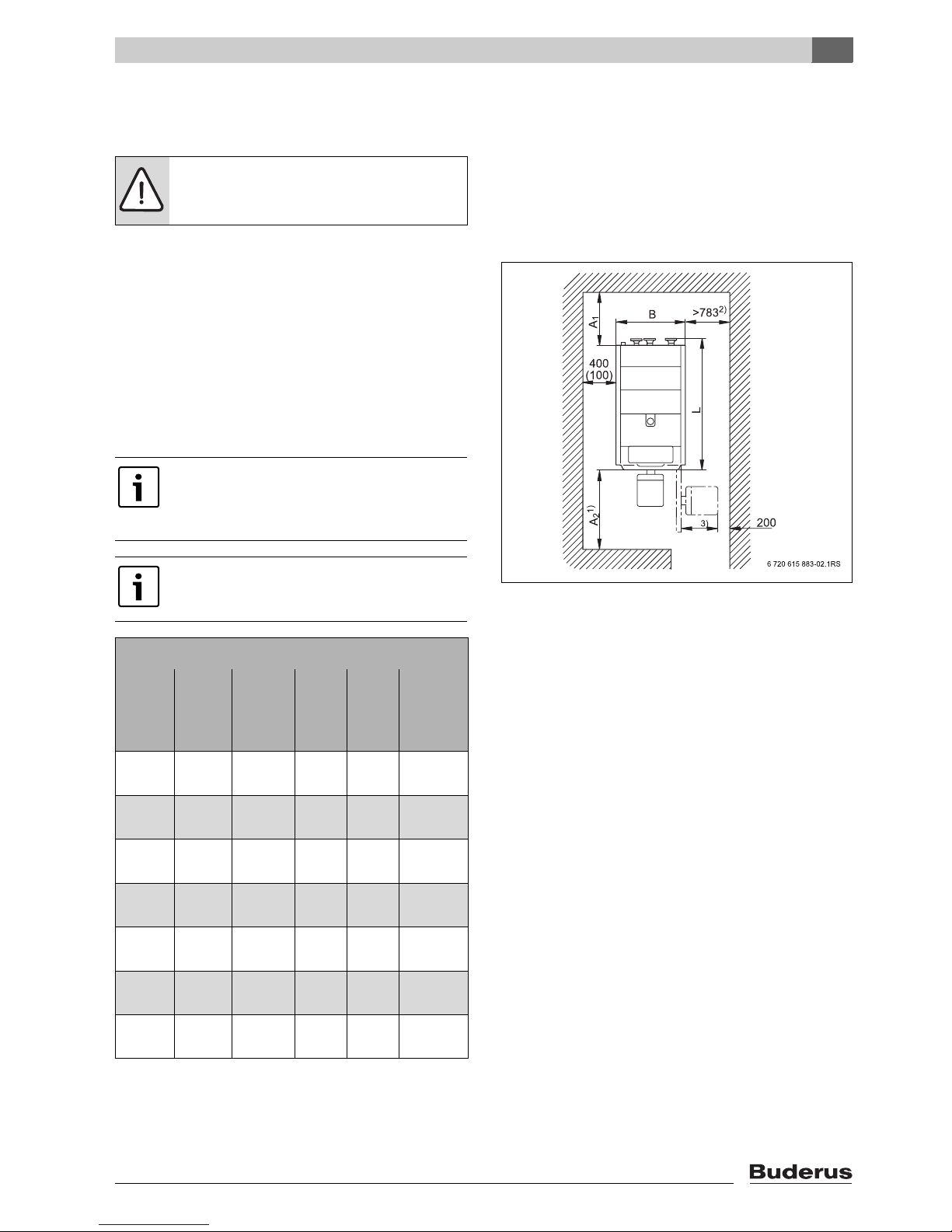

3.5 Boiler positioning

This chapter explains how to properly position the boiler.

3.5.1 Foundation and recommended wall

clearances

B When providing foundations or a support area, observe

the specified minimum wall clearances (values in

brackets) (Æ Fig. 2 and Tab. 4) so that the installation

and maintenance instructions can be followed without

difficulty. The front edge of the boiler should be flush

with the edge of the plinth.

It is useful if there is a drain outlet near the installation

location.

Fig. 2 Boiler room (for dimensions see Tab. 4),

dimensions in mm

1)

In addition to the burner length

3)

take dimension A2 into

consideration when installing a third party burner.

2)

When using a side-mounted control unit holder.

3)

Take account of burner dimensions.

CAUTION: System damage due to frost!

B Install the heating system in a room

protected from the risk of frost.

The support area must be flat and able to

support the applied weight, with a slight

incline to the rear to ensure ventilation of the

boiler.

Make sure there is additional space for noise

silencing.

Recommended (and minimum) wall clearances mm

Boiler

size kW

Clear-

ance

Clear-

ance

Length Width

Width/

Height

A

1

A

2

1)

1) For boiler installations with third party burners, dimension A2

also depends on the burner length

3)

.

L B Transport

145 760

(460)

1700

(1200)

1816 900 720/1340

185 760

(460)

1700

(1200)

1816 900 720/1340

240 800

(500)

1700

(1200)

1845 970 790/1370

310 800

(500)

1700

(1200)

1845 970 790/1370

400 900

(1600)

1750

(1250)

1845 970 790/1570

510 1000

(700)

2000

(1500)

1980 1100 920/1730

640 1000

(700)

2000

(1500)

1980 1100 920/1730

Tab. 3 Wall clearances

Page 12

3

Regulations, standards and guidelines

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

12

Allow extra space if a flue silencer is to be

installed.

If you wish to fix the control unit to the side of the boiler

using the holder (accessory), you have to ensure

additional clearance (Æ Fig. 2, page 11).

3.5.2 Levelling the boiler

B Level the boiler towards the back using a spirit level to

prevent air pockets forming inside the boiler.

Fig. 3 Level the boiler backwards

(for legend, see Fig. 1, page 6)

3.6 Disposal

Use metal shims to level the boiler.

Please note the following:

B Dispose of packaging in an

environmentally responsible manner.

B Dispose of all heating system components

that have to be replaced at an authorised

disposal site.

Page 13

4

Transporting the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

13

4 Transporting the boiler

This chapter describes how to handle the boiler safely

without risk of damage.

B When raising and transporting the boiler, make sure

that the weight is distributed evenly across the forks of

the forklift truck/pallet truck.

4.1 Means of transport

4.1.1 Transporting the boiler using a forklift truck

B Insert the forks of the forklift truck under the front and

the back of the boiler.

4.1.2 Transporting the boiler using two pallet

trucks

B Slide a pallet truck under the front and the back of the

boiler.

B Raise the boiler evenly using the two pallet trucks.

DANGER: Risk to life from incorrectly

secured boiler!

B Use suitable equipment when

transporting the boiler, e.g. two pallet

trucks or a forklift truck.

B When transporting, secure the boiler to

the method of transport to prevent it

slipping.

CAUTION: System damage due to

damaged boiler body!

B The boiler may only be transported with a

forklift truck if the forks are long enough to

extend from the front of the boiler to the

back.

B Prior to lifting the boiler body, check

whether the boiler front and back panels

are positioned on the fork of the forklift

truck.

Page 14

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

14

5 Installation of the boiler

This chapter explains how to correctly install the boiler.

5.1 Checking delivery for completeness

B Upon delivery, check all packaging for damage.

B Check the delivered package(s) for completeness

(Æ Chapter 2.4).

5.2 Disposing of packaging

B Dispose of packaging in an environmentally

responsible manner.

5.3 Minimum clearances / product

dimensions

5.4 Changing the hinging of the burner

door

The burner door can be moved from the right-hand side

(factory-set) to the left-hand side.

B Push the hinge bolts out of the hinges from underneath

[1].

B Refit the washer [2] and the two hinge pins to the

adjacent hinges. Make sure that the washer is

re-installed.

Fig. 4 Reversing the door hinges

1 Hinge pin

2 Washer

CAUTION: System damage due to open

combustion chamber!

The combustion chamber must remain

sealed by the burner door so that the

stainless steel combustion chamber is not

damaged by any welding or grinding work.

B Ensure when fitting the front thermal

insulation pad that the combustion

chamber remains sealed by the burner

door.

Observe the recommended minimum wall

clearances when positioning (Æ Tab. 3,

page 11).

DANGER: Risk of injury from unsupported

door!

B Change the door hinging only when the

door is closed and bolted.

Page 15

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

15

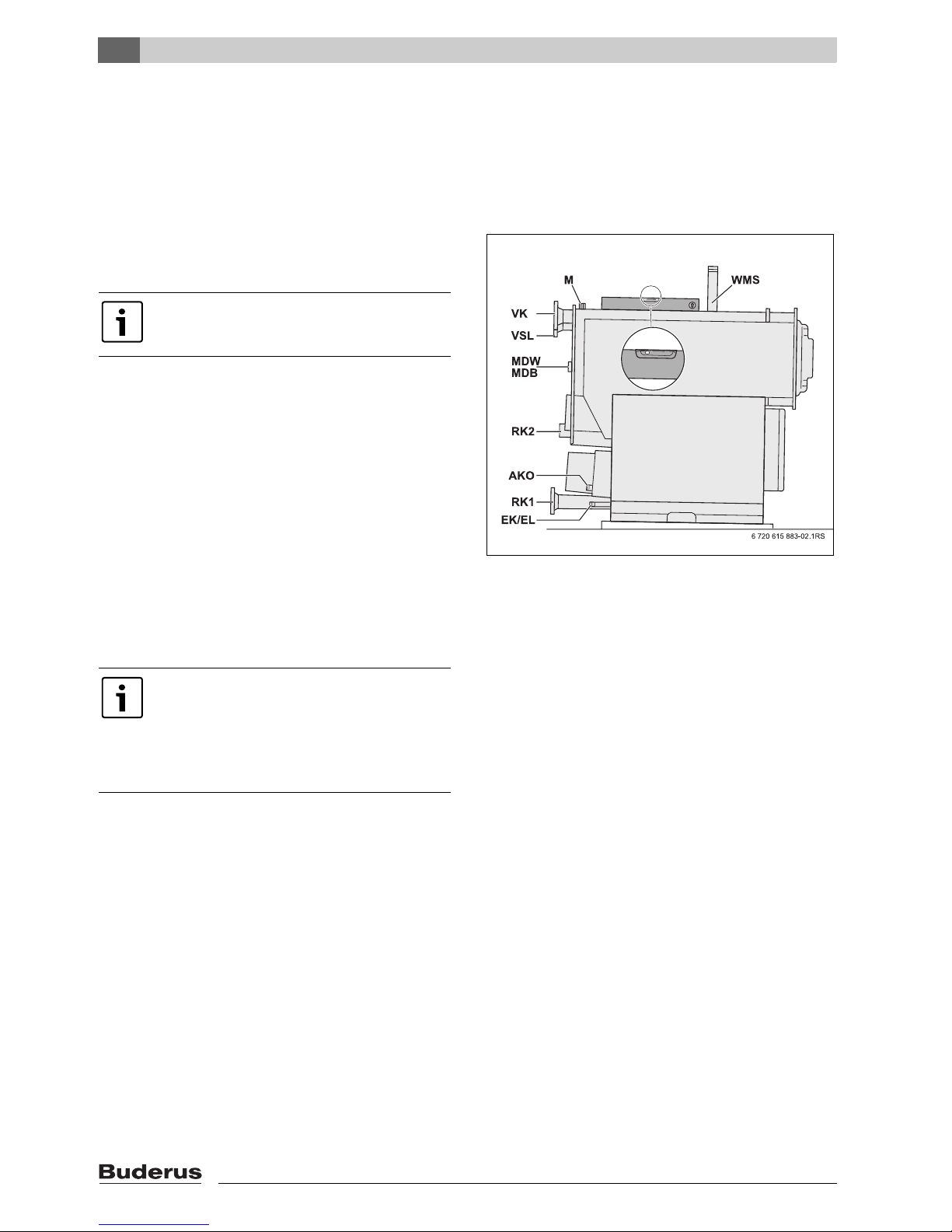

5.5 Installing the minimum pressure

switch and minimum pressure

limiter

B Connect the minimum pressure monitor or minimum

pressure limiter (with R½ to R¼ connection piece

adapter) to the MDW/MDB connection on the boiler

(Æ Fig 5).

Fig. 5 Logano plus SB615 Gas boiler connections

5.6 Low water indicator (accesory),

fitting (400 – 600 kW)

B Seal the flow pipe for the low water indicator into the

2" LWI connection on the boiler (Æ Fig. 5).

B Fit the low water indicator onto the low water indicator

tube.

B If the LWI connection is not being used for the

installation of a low water indicator, remove the plastic

plug and close off the LWI connection with a blanking

plug.

Note that a minimum pressure monitor must

be connected for 145 kW to 240 kW!

For 310 kW (145 kW and higher in Poland)

a minimum pressure limiter (MDB) must be

installed. This requires an R½ to connection

piece adapter R¼ .

For Germany

B For boilers > 300 kW, install a low water

indicator or minimum pressure limiter as

required by DIN-EN 12 828.

B For installation and operation, refer to the

technical documents provided by the

manufacturer.

For Poland

B For boilers > 100 kW, equip the boiler

with a low water indicator as required by

PN-91/B-2414 (p2.5).

Page 16

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

16

5.7 Connecting the boiler to the

pipework

Please observe the following information regarding the

boiler connection to the pipework. This is important for

fault-free operation.

5.7.1 Connecting the return to the boiler

B Connect the heating system return to the boiler return

connections RK1 and RK2 (Æ Fig. 6).

5.7.2 Connecting the flow to the boiler

B Connect the heating system flow to the boiler flow

connection VK (Æ Fig. 6)

5.7.3 Connecting the safety line flow

B Fasten the relief valve to the VSL safety line flow

connection using 4 screws (Æ Fig. 6).

Fig. 6 Logano plus SB615 Gas boiler connections

To protect the boiler from debris within the

system water, we strongly recommend the

installation of a dirt trap in the return leg of the

plant.

CAUTION: System damage due to leaking

connections!

B Ensure pipework connections to and from

the boiler are free of stress.

Install a dirt trap in the return close to the

boiler in order to protect the appliance from

debris within the system water.

CAUTION: System damage from

connecting the wrong components to the

pressure relief!

B Never connect a DHW cylinder or other

heating circuit to the VSL safety line flow

connection (Æ Fig. 6).

Page 17

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

17

5.8 Filling the heating system and

checking connections for leaks

Check the heating system for leaks before commissioning

to ensure there are no leaks when the system is in

operation.

B Fill the heating system with water

(Æ Chapter 6.2).

B Carrying out the leak test.

The testing pressure is based on the normal operating

pressure of the heating system and should be 1.3 times

that pressure, and in any case no less than 1 bar.

B Check all connections for leaks.

DANGER: Risk to health from drinking water

contamination!

B Always observe the regulations and

standards applicable in your country for

the prevention of contamination of

drinking water (e.g. by water from heating

systems).

B Observe EN 1717.

CAUTION: Risk of system damage from

excess pressure when testing for leaks!

Pressure, control and safety equipment may

be damaged through excessive pressure.

B Ensure that, whilst you are carrying out a

leak test, no pressure, control or safety

equipment is fitted, which cannot be shut

off towards the boiler water chamber.

CAUTION: System damage due to thermal

stresses!

B Only fill the system when cold (the flow

temperature must be no more than 40 °C).

B When the heating system is in operation,

do not fill it via the boiler fill and drain valve.

Instead, only use the filling valve in the

heating system (return).

B Pay attention to the water quality as

specified in the operator's log, and record

the volume and quality of the water used

to fill the system.

Page 18

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

18

5.9 Fitting the lagging

B Push the insulation underneath the boiler through to

the opposite side (Æ Fig. 7).

Fig. 7 Push the insulation underneath the boiler

through to the opposite side.

1 Hinge pin

B Wrap thermal insulation jackets overlapping around the

boiler and fix at the top with 5 spring clips [3].

B Close off the cut-out for the low water indicator [1] with

two spring hooks [3].

B Undo the door bolts and open the burner door.

B Place the lower front insulation section on the front of

the boiler body and secure to the right and the left onto

the wrap-around insulation with 2 spring hooks on each

side [3].

B Locate the insulation strip [2] at the top around the

boiler shell ring, and secure to the right and the left

onto the lower front insulation section with two spring

hooks on each side [3].

B Place the upper front insulation section on the front of

the boiler body.

Fig. 8 Fitting and fastening the lagging

1 Low water indicator

2 Strip of lagging material

3 Tension springs

B Close the door again and secure with door bolts.

DANGER: Risk of injury due to burner door

falling off when opened!

B Make sure that both hinge bolts

(Æ Fig. 7, [1]) are inserted.

When fitting the insulation, ensure that the

fabric backing is arranged on the outside and

the cut-outs at the rear.

Keep the cut-outs for the hinges and the

threaded sleeves for the burner door bolts

free.

Page 19

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

19

B Place the rear insulation section onto the rear of the

boiler in the position dictated by the openings and

secure to the right and the left onto the wrap-around

insulation with 4 spring hooks (Æ Fig. 9).

Fig. 9 Positioning and securing the rear insulation

section

1 Tension springs

5.10 Fitting the connection plates

B Insert front connection plate (with trapeze-shaped

cut-out facing downwards) over the threaded studs,

with the 2 holes at the top, and fasten with nuts

(Æ Fig. 10).

B Insert back connection plate (with trapeze-shaped

cut-out facing downwards) over the threaded studs,

with the 2 holes at the top, and fasten with nuts

(Æ Fig. 10).

B Balance the front and rear connection plates with a

spirit level.

Fig. 10 Locating and securing the front and rear

connection plates

The angled sections on the connection

plates should point outwards, and both the

front and rear connection plate should be

horizontally level (Æ Fig. 10).

Page 20

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

20

B Hook side connection plate with the "U" into the

cut-out on each of the front and back connection

plates. Each connecting plate is secured in the front

hole and the rear slot using 2 self-tapping screws.

Fig. 11 Inserting and securing the lateral connection

plates

5.11 Fitting the side panels

B Insert side panels with the flange behind the boiler

frame at the bottom and in the slot in the centre.

Fig. 12 Inserting side panels

The cutout in the flange of each side panel

section must be in the centre of the boiler.

6720615883-30.1RS

Page 21

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

21

B Lift side panels and hook into the folded edge in the

side connection plates [1].

B Press ends of the lagging behind the folded edge on

the side panel.

5.12 Routing the burner cable

B Insert the strain relief [2] for the burner cable [3] with

both pins into the holes on the angled section of the left

or right side panel.

B Adjust the burner cable [3] to the desired length, feed

through the strain relief [2], close tab and fasten to the

base rail with 2 self-tapping screws.

Fig. 13 Hook in the side panels and connect the burner

cable

Page 22

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

22

5.13 Fitting the back plate

For boiler sizes 145 kW to 310 kW, the rear wall is in two

parts (Æ Fig. 14), for boiler sizes 400 kW to 640 kW only

one part (Æ Fig. 15).

Boiler sizes 145 kW to 310 kW

B Secure the lower boiler cover [1] with 5 self-tapping

screws [2] to the side panels.

B Insert the upper rear panel section [4] with the Z-fold

behind the lower rear panel section, and secure onto

the side panels with four self-tapping screws [3].

B Make sure that the two upper self-tapping screws also

pass through the connection plates.

B Secure one or two cable clips [5] or a cable duct on the

fold on the upper rear panel section.

Fig. 14 Screwing the 2-part real panel in place (boiler

rating 145 to 310 kW).

1 Lower rear panel

2 5 self-tapping screws

3 4 self-tapping screws

4 Upper rear panel

5 Cable clamp/cable channel

Boiler sizes 400 kW to 640 kW

B Secure the boiler cover [1]with 4 self-tapping screws

on the right and left-hand side to the side panels.

B Make sure that the two upper self-tapping screws also

pass through the connection plates.

B Secure one or two cable clips [2] or a cable duct on the

fold on the rear panel section.

Fig. 15 Screwing rear panel in place (boiler rating 400

to 600 kW)

1 Back panel

2 Cable clamp/cable channel

Page 23

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

23

5.14 Fitting the front boiler cover

B Place front boiler cover on top of the folded edges of

the side panels and pull forwards until the right and

left-hand hooks click into place in the slot (Æ Fig. 16).

B Screw front boiler cover firmly into the side connection

plates by screwing 2 self-tapping screws through the

tabs on the boiler cover and the folded edge on the

side panels (Æ Fig. 16).

Fig. 16 Fitting the front boiler cover

5.15 Fit and connect the control unit

(accessory)

You can use the following control units with the boiler:

Logamatic 4211, 4212 as well as 4321 and 4322

(accessories).

The control unit can be fitted either on top of the boiler or,

with the side-mounted control unit holder (accessory),

onto the boiler side.

Refer to the enclosed installation instructions if using the

optional control unit side holder.

Fig. 17 shows the control unit and the front cover [1] from

the back.

B Undo both screws from cover [1]. Lift off the cover.

B Fit the control unit at the front by inserting the hooks [4]

into the oval holes in the front boiler cover [5].

B Pull the control unit forwards and then tip back. The

flexible hooks [2] must latch into the rectangular

openings at the rear of the front boiler cover [3].

B Screw the base of the control unit on the left and right

of the cable entry onto the front boiler hood [6] via the

holes [7] using two self-tapping screws.

Fig. 17 Fitting the control unit

1 Cover

2 Resilient hooks

3 Rectangular openings in the front boiler cover

4 Locking tabs

5 Oval holes in front boiler cover

6 Cable entry in the front boiler cover

7 Holes for self-tapping screws

Page 24

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

24

B If necessary, make knock-outs [1] in the rear panel of

the cable duct or remove the rear panel section [2].

Fig. 18 Preparing the cable entry

1 Knock-outs

2 Rear panel component

B Make the plug-in connection in the control unit in

accordance with the labelling on the terminal strip.

B Route the burner cable through the cable entry in the

front boiler cover to the control unit.

B Connect the burner cable to the control unit in

accordance with the labelling on the plug-in connector

strip.

B Make all electrical connections to the appropriate

plug-in connectors according to the wiring diagram.

Observe the following when connecting the

control unit:

B Carefully route the cables/leads and

capillary tubes.

B Never kink capillary tubes during

installation.

B Always have electrical work inside the

heating system carried out by a qualified

electrician or electrical contractor.

B Observe all local regulations.

B Create a permanent connection in

accordance with EN 50165.

The positions of the terminal strips in the

various Logamatic control units are not

identical, however the labelling abbreviations

and colour codes remain the same. E.g. The

outdoor temperature sensor connection is

always labelled FA.

Page 25

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

25

Secure all cables with cable clips (included with control

unit). To do this, carry out the following steps:

1. With the cable in place, insert the cable clips, as shown

in Fig. 19, from above into the slits in the clip frame.

2. Slide the cable clamp downwards.

3. Press in.

4. Flip the lever up.

B Put the cover (Æ Fig. 17, page 23) back on the control

unit.

B Tighten screws (Æ Fig. 17, page 23) to secure control

unit cover.

Fig. 19 Securing the cable with cable clips

5.16 Installing the temperature sensor

set

Test point M is located at the top rear of the boiler.

B Route the capillary tubes with temperature sensors and

quarter dummy plugs to the sensor well in test point M

and insert the temperature sensor into the sensor well

until it bottoms out.

Fig. 20 Inserting temperature sensor into the sensor

well

6720615883-31.1RS

.

.

.

.

.

Observe the following points before installing

the temperature sensor set:

B Take care to ensure correct cable and

capillary pipe routing.

B Create a permanent mains power

connection in accordance with EN 50165.

B Observe all local regulations.

Page 26

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

26

B The plastic coil [2] for holding together the temperature

sensor is pushed back automatically when it is

inserted.

B Coil up any excess cable, capillary tube and sensor

leads and place on the boiler body insulation.

B Connect the temperature sensors to the control unit.

Fig. 21 Inserting the plastic coil into the sensor well

1 Compensating spring

2 Plastic spiral

3 Sensor retainer

4 Sensor well

5.17 Fitting the boiler cover sections

Boiler sizes 145 kW to 400 kW

4 boiler cover sections

Boiler sizes 510 kW to 640 kW

5 boiler cover sections

B Loosely locate the boiler cover sections one after the

other on the right and left side panels.

Fig. 22 Fitting the boiler cover sections - Example

1 Recess for boiler sizes 400 kW and upwards

To ensure a good contact between sensor

well [4] and sensor surfaces, and thereby a

reliable temperature transfer, the

compensating spring [1] must be pushed in

between the sensors.

6720615883-32.1RS

1

2

3

4

From 400 kW upwards, the second cover

part is provided with a recess (Æ Fig. 22).

The rear parts are identical and are

positioned with their fold forward.

Page 27

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

27

5.18 Fitting the front panel

B Push the tabs on the lower connection plate from

below into the slots to the left and right on the side

panels and secure the connection plate with two

machine screws on the front of the boiler body.

Fig. 23 Securing the lower connection plate

B Hook the lower front panel section with the four hooks

[1] into the slots to the left and right on the side panels.

B Insert the upper front panel section with its hooks [2]

into the slots on the lower front panel, and hook the top

into the front boiler cover [3].

Fig. 24 Fasten lower and upper front panels

1 Hook lower front panel

2 Hook upper front panel

3 Hooking the upper front panel into the boiler cover

Page 28

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

28

5.19 Securing the shield, device label and

data plate

B Fit the decorative panel [1] by inserting the hooks into

the front panel.

B Fix appliance insignia plate [2] to front panel.

B Attach the data plate [3] to either the left or right side

panel, depending on which is most convenient.

Fig. 25 Attaching the data plate

1 Restrictor

2 Device label

3 Data plate

5.20 Connecting and filling the

neutraliser (accessory)

Please refer to the separate installation manual for

installation and maintenance of the neutralisation device.

B Fit the drain hose [1] with a hose clip to the condensate

outlet (siphon).

Fig. 26 Connecting and filling the neutraliser

1 Drain hose

CAUTION: System damage!

You must ensure that the condensate

generally runs via the flue pipe into the boiler.

If this is not possible, you must only use

stainless steel or plastic tees in the separate

pipe inlet.

B In ceramic flue systems, you must fit a silt

trap (pot).

Page 29

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

29

5.21 Installing condensate pipework

B Fit the siphon provided to the outlet on the flue gas

collector [5].

B Unscrew the locking cap and fill the siphon with about

two litres of water.

Fig. 27 Installing condensate pipework

1 Connection elbow

2 Locking cap

3 Siphon

4 Siphon outlet to neutralisation device or waste water pipe

5 Flue gas collector

When installing the condensate pipework,

observe the following:

B Carefully drain the condensate created

inside the boiler and possibly in the flue

pipe.

B Drain the condensate into the sewerage

system in accordance with the

requirements in your country.

B Observe regional requirements.

DANGER: Risk to life from poisoning!

Siphons which are not filled with water, or

open connections, can cause a risk to life

from escaping flue gas.

B Fill the siphon with water.

B Ensure that the siphon and flue gas

connections are sealed.

B Ensure that the sealing disc with gasket is

seated in the locking cap.

Neutralisation devices are available as

accessories.

B Install neutralisation device (accessory) as

detailed in the installation instructions.

Page 30

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

30

5.22 Connecting the flue side of the

heating system

This chapter explains how to install the boiler to the flue.

5.22.1 General information on flue systems

B The flue gases in question must be led outside into the

open air via flue pipes and flues.

B Use flue pipes and flues that conform to building

regulations and are resistant to humidity.

B Before commissioning the heating system, check that

the flue gas system used is suitable for the boiler.

B Follow guidelines in the planning instruction.

B Check the flue connection for leaks.

B Observe the flue system manufacturer’s installation

instructions.

5.22.2 Fitting the flue pipe sealing collar

(accessory)

B Fit the flue pipe sealing collar as described in the

separate installation manual.

5.22.3 Fitting the flue temperature sensor

(accessory)

B Fit the flue gas temperature sensor as described in the

separate installation manual.

Page 31

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

31

5.23 Fitting burner (accessory) and

connecting gas supply

This chapter explains how to fit a burner.

B A burner that is made dirty by building work must be

cleaned before being commissioned.

5.23.1 Fitting the burner plate

A burner plate without pre-drilled holes is included with

the boiler.

If you have not ordered the predrilled burner plates from

Buderus, the enclosed blanking plate will have to be

machined accordingly onsite.

B Drill or cut the burner plate to match the required blast

tube diameter.

B Drill holes for fastening the boiler using the burner

connecting flange as a template.

B Fasten the burner plate to the burner door using the

hex-head bolts and washers (seal with gasket).

CAUTION: System damage from incorrect

burner!

B Only use burners that meet the technical

requirements of the Logano plus SB615

Gas boiler.

CAUTION: Damage to system through

incorrect burner adjustment (overloading)!

B Make sure that the value set does not

exceed the combustion heat output

Qn (Hi) stated on the rating plate.

Do not work on the burner plate when

installed.

Predrilled burner plates are available from

Buderus upon request (accessory).

Page 32

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

32

5.23.2 Fitting the burner to the burner plate

B Depending on the burner make or type, you must use

the corresponding burner plate or make necessary

alterations. Adjust the hole in the burner door thermal

insulation if necessary.

B Seal the gap between blast tube and lagging [1]

on-site.

Fig. 28 Sealing the gap between burner and insulation

(dimensions in mm).

1 Area between blast tube and thermal insulation

When fitting the burner (accessory), you

must observe the burner manufacturer’s

instructions.

Page 33

5

Installation of the boiler

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

33

5.23.3 Connecting the gas supply

B Make the gas connection in accordance with all locally

applicable regulations.

B Connect the gas pipe without stress to the gas

connector.

B Install a gas shut-off valve in the gas supply pipe.

B Before initial start-up, check for external leakage on the

new length of piping up to the gas valve.

B If a leak is discovered, all connections must be

checked using a frothing agent.

We recommend that a gas filter be installed

in the pipework in accordance with local

regulations.

DANGER: Risk to life from gas explosion!

Leaks may have been created on pipes and

fittings following the commissioning work.

B Carry out the correct leak tests.

B Only use approved leak detection agents

for leak detection.

CAUTION: Risk of system damage due to

short circuit!

B Cover areas at risk prior to carrying out a

leak test.

B Do not spray the leak solution on wiring

openings, plugs or electrical connections.

Do not allow it to drip onto them either.

Page 34

6

Initial operation

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

34

6 Initial operation

This chapter describes how to start up the heating

system.

B Perform start up according to the user manuals for the

boiler, burner, low water indicator and electronic

heating circuit control.

B When handing over the system, show the operator how

it functions and how to operate it, and hand over the

technical documentation to them. Complete the

commissioning report.

B Draw the operator's attention to the maintenance

requirements and recommend arranging a

maintenance contract.

6.1 Flushing the heating system

Flush the heating system prior to commissioning to

prevent contamination that could e.g. block and damage

the circulation pump.

CAUTION: System damage due to heavy

dust deposits!

B Do not operate the boiler where heavy

dust contamination persists, e.g. through

building work inside the boiler room.

DANGER: Risk to health from drinking water

contamination!

B Always observe the regulations and

standards applicable in your country for

the prevention of contamination of

drinking water (e.g. by water from heating

systems).

B Observe EN 1717.

CAUTION: Boiler damage from corrosion

and sludge!

B It is essential to flush the entire heating

system before filling with heating water.

B Check the quality of the fill and top-up

water, so as to avoid scaling and

corrosion. (Note the “Water treatment...”

operator's log.)

If a heating system contains several heating

circuits, these must be flushed one after the

other.

Page 35

6

Initial operation

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

35

B Isolate the heating flow and return on the boiler.

B Connect the heating flow to a fresh water connection.

B Connect the hose to the heating system return.

B Put the hose from the heating return into a drain.

B Open all shut-off devices and radiator valves in the

heating system.

B Flush the heating system with fresh water until clear

water emerges from the heating return.

6.2 Filling the heating system

For the correct use and treatment of the fill and top-up

water, follow the Code of Practice K8 in the applicable

Buderus catalogue, as well as VDI 2035.

The pH value of the heating water will increase after the

heating system has been filled.

B After 3 – 6 months (during the first service), check

whether the pH value of the heating water has

stabilised.

DANGER: Risk to life from escaping flue

gases!

B Before commissioning the boiler or the

neutralisation device, pour about 10 litres

of water into the inspection opening or

into the heating space in order to fill up the

neutralisation holder and prevent the

escape of flue gases from the boiler

siphon.

DANGER: Risk to health from drinking water

contamination!

B Always observe the regulations and

standards applicable in your country for

the prevention of contamination of

drinking water (e.g. by water from heating

systems).

B Observe EN 1717.

CAUTION: System damage due to thermal

stresses!

B Only fill the system when cold (the flow

temperature must be no more than 40 °C).

B When the heating system is in operation,

do not fill it via the boiler fill and drain valve.

Instead, only use the filling valve in the

heating system (return).

B Pay attention to the water quality as

specified in the operator's log, and record

the volume and quality of the water used

to fill the system.

Page 36

6

Initial operation

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

36

6.3 Preparing the heating system for

operation

Observe the following when commissioning:

B Before commissioning, bleed the heating system via

the venting facility provided for this purpose.

B Check that the inspection opening of the flue gas

collector is closed (Æ Fig. 32, page 42).

B Ensure that the burner door is secured with door bolts.

B Check that the safety equipment is functioning

properly.

6.4 Commissioning the control unit and

the burner

B Use the control unit to start the boiler.

By commissioning the control unit, you also automatically

commission the burner. The burner can then be started via

the control unit. For further details, see the installation

instructions of the relevant control unit or burner.

B Complete the commissioning report in the technical

burner documentation.

Page 37

6

Initial operation

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

37

6.5 Commissioning report

B Sign all commissioning work as completed and enter

the date.

Commissioning tasks Page (individual steps) Comments

(signature)

1. Fill the heating system with water. page 35

2. Vent the heating system. page 36

3. Carry out leak testing (gas, flue gas, water). page 33, page 30, page 17

4. Start up the control unit. Æ control unit documentation

5. Start-up the burner. Æ burner documentation

6. Perform a leak test on the hot gas side. After being in

operation for a short time, retighten the burner door bolts

to prevent leaks around the door as a result of the packing cord settling.

7. Inform the system user, hand over the technical docu-

mentation, and enter the fuel used in this heating system

in the table of the operating instructions.

8. Confirm correct commissioning.

Company stamp/signature/date

Page 38

7

Shutdown

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

38

7Shutdown

7.1 Shutting down the heating system

Shut down your heating system using the control unit. The

burner is automatically shut down when the control unit is

shut down.

B Turn the switch on the control unit to the “0” (OFF)

position.

B Isolate the fuel supply to the burner.

7.2 Shutting down the heating system in

an emergency

B In other dangerous circumstances, immediately isolate

the main shut-off valve and the electrical power supply

of the heating system via the boiler room main circuit

breaker or the emergency isolation switch for the boiler

room.

B Isolate the fuel supply to the burner.

CAUTION: System damage due to frost!

When the heating system is switched off, the

system water can freeze up and expand in

cold weather.

B Protect your heating system against frost

when temperatures below zero are

expected. Where there are no frost stats

to protect the vulnerable parts of the

system, drain the heating water from the

lowest point of the heating system using

the fill & drain valve or the radiator. The air

vent valve at the highest point in the

system must also be open.

CAUTION: System damage due to frost!

The heating system can freeze up during a

power failure or if the power supply has been

switched off.

B Check the “Control unit settings” to

ensure the system remains operational

(especially when there is a risk of frost).

In an emergency (and only in an emergency),

switch OFF the heating system via the boiler

room circuit breaker or heating system

emergency isolation switch.

Page 39

8

Inspection/maintenance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

39

8 Inspection/maintenance

8.1 General notes

Offer your customer an annual contract covering

inspection and demand-dependent service. Refer to the

“Inspection and maintenance reports” Chapter 8.6 for

information about what such contracts should contain.

8.2 Preparing the boiler for inspection

and maintenance

B Shut down the heating system (Æ Chapter 7).

B Check the general condition of the heating system.

B Visually and functionally check the heating system.

B Check all system parts that carry fuel or water for leaks

and visible corrosion.

The operator is obliged under the terms of

paragraph 9 of the heating plant legislation to

arrange to have the heating system cleaned

and maintained.

B The entire condensing unit (including any

neutralisation device) must undergo

maintenance once a year.

B We recommend arranging an inspection

and maintenance contract.

B For burner maintenance, follow the burner

manufacturer’s maintenance instructions.

DANGER: Risk to life from electricution

when the heating system is open!

B Before opening the heating system,

disconnect the heating system from the

power supply by means of the emergency

isolation switch or the relevant circuit

breaker in the main fuse board.

B Prevent unintentional reconnection of the

electricty supply.

DANGER: Risk to life from gas explosion!

B Any work on components may only be

carried out by an approved contractor.

EN 303 permits an amount of leakage from

the hot gas side of the boiler.

Page 40

8

Inspection/maintenance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

40

8.3 Cleaning the boiler

B Remove upper and lower front panels.

B Remove the front thermal insulation.

B Undo the door bolts and open the burner door.

Fig. 29 Removing the front panel and thermal insulation

B Loosen nuts from the clamping angle, swivel the

clamping angle away and remove the return bonnet.

B Clean the combustion chamber and the heating

surfaces.

Fig. 30 Removing the return hood and opening the

burner door

DANGER: Risk of injury due to burner door

falling off when opened!

B Make sure that both hinge bolts

(Æ Fig. 7, [1], page 18) are inserted.

CAUTION: Boiler damage due to not using

the appropriate cleaning equipment!

B Only Buderus cleaning equipment may be

used for cleaning.

For wet-cleaning, we recommend

high-pressure cleaning equipment.

B Do not pour cleaning residues through the

neutralisation device.

B Do not block up the condensate drain

(Æ Fig. 32, page 42) when cleaning.

Page 41

8

Inspection/maintenance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

41

B Feed brushes through the secondary heating pipes.

B Use a vacuum cleaner if necessary to remove any

cleaning residues.

Fig. 31 Feed brushes through the secondary heating

pipes

If you do not push all the bristle part of

cleaning brush right through the secondary

heating pipe, you will find it very difficult to

remove the brush from the pipe.

B Push the bristle part of the cleaning brush

right through the secondary heating pipe

until the bristles emerge at the other end of

the pipe.

CAUTION: System damage due to faulty

seals!

B Check the seals around the burner door

and return bonnet, replacing if necessary.

Page 42

8

Inspection/maintenance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

42

If spray cleaning, follow the operating instructions

for the relevant cleaning equipment!

Spray must not enter the control unit!

B Bolt burner door shut.

B Put the return bonnet in place and seal it tight with the

clamping angle (Æ Fig. 30, page 40). Pay attention to

fitted position.

B Fasten front lagging with tension springs.

B Fit lower and upper front panels of the boiler

(Æ Fig. 29, page 40).

B Put system back into operation.

8.4 Cleaning the flue gas collector

To be able to remove combustion residues from the flue

gas collector, the clean-out cover has to be removed. This

is located on the rear panel.

B Undo the wing nuts on the cleaning cover [1] and

remove the cleaning cover.

B Remove all loose combustion residues from the flue

gas collector.

B Refit the clean-out cover in the reverse order of

removal.

B Check whether the siphon is filled with water.

Fig. 32 Inspection aperture flue gas collector

1 Cleaning access covers

DANGER: Risk to life from poisoning!

Siphons which are not filled with water, or

open connections, can cause a risk to life

from escaping flue gas.

B Fill the siphon with water.

B Ensure that the siphon and flue gas

connections are sealed.

B Ensure that the sealing disc with gasket is

seated in the locking cap.

Page 43

8

Inspection/maintenance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

43

8.5 Checking the heating system water

pressure

A distinction is generally made between open vented and

sealed unvented heating systems. In practice, open

heating systems are seldom installed. We will therefore

be using sealed systems to demonstrate how you can

check the water pressure.

Open heating systems

For open heating systems, the hydrometer needle [1]

should be within the red band [3].

Fig. 33 Hydrometer for open unvented heating systems

1 Hydrometer needle

2 Green needle

3 Red field

Sealed heating systems

In sealed systems, the pressure gauge needle [2] must lie

within the green field [3]. The red pressure gauge needle

[1] must be set to the required heating system pressure.

B Set the manometer pointer accordingly.

B Check the heating system water pressure.

Fig. 34 Pressure gauge for sealed unvented heating

systems

1 Red needle

2 Pressure gauge needle

3 Green band

6720615883-33.1RS

1

2

3

Generate the operating pressure required for

the heating system.

CAUTION: System damage due to frequent

topping up!

The heating system may be damaged,

depending on water quality, by corrosion or

scaling if you frequently need to top-up your

system with water.

B Ensure that the heating system is vented

correctly.

B Check the heating system for leaks and

proper operation of the expansion vessel.

B Observe the requirements in respect of

water quality.

6 720 615 876-59.1RS

3

2

1

Page 44

8

Inspection/maintenance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

44

8.6 Inspection and maintenance reports

The inspection and maintenance reports provide an

overview of the required inspection and maintenance

work.

B Initial and date the completed inspection work.

Inspection work Page (individual steps) Comments

1. Check the general condition of the heating system.

2. Visual and function check of the heating system.

3. Check the components in contact with fuel and water

throughout the system for the following:

• Tightness/leaks

• visible signs of corrosion

• Signs of ageing

4. Check the combustion chamber and the heating surface

for contamination; shut down the system for this step.

page 39

5. Check the burner. Æ burner documentation

6. Check the flue for function and safety. Æ burner documentation

7. Check the water pressure of the heating system and

pre-charge pressure of the diaphragm expansion vessel.

page 43

8. If necessary, check the function of the DHW cylinder and

the magnesium anode.

Æ DHW cylinder documentation

9. Check the control unit settings. Æ control unit documenta-

tion

10. Final inspection check; take measurements and document figures and test results.

Confirm professional inspection with signature, date and company stamp

Page 45

8

Inspection/maintenance

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

45

Condition-based maintenance Page (individual steps) Comments

1. Shut down the heating system. (Disconnect your heating

system from the main electrical supply, isolate main fuel

shut-off, disconnect flue pipe from burner.)

page 38

2. Cleaning hot gas flues (heating surfaces). page 40

3. Clean the combustion chamber.

Clean the condensate outlet.

Cleaning the flue collector.

page 40

4. Check and, if required, replace gaskets/packing cord on

the burner door.

5. Start up the heating system. page 34

6. Final maintenance check; take measurements and document figures and test results.

Æ burner documentation

7. Check the function and operational safety (safety equipment).

Confirm professional maintenance with signature, date and company stamp

Page 46

8

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

46

Notes

Page 47

8

Logano plus SB615 Gas - We reserve the right to make any changes due to technical modifications.

47

Notes

Page 48

Bosch Thermotechnik GmbH

Sophienstrasse 30-32

D-35576 Wetzlar

www.buderus.com

C & F Quadrant Ltd.

Unit L40 Cherry Orchard Industrial Estate

Cherry Orchard, Dublin 10

Tel.: 01.6305700

Fax.: 01.6305706 / 01.6305715

www.cfquadrant.ie

E-mail: sales@cfquadrant.ie

Buderus

Cotswold Way, Warndon, Worcester WR4 9SW

Customer service: 0870 421 5933

Technical support: 0870 421 5944

Fax: 01905 753130

www.buderus-commercial.co.uk

In the UK and IE, Buderus is a brand name of

Bosch Thermotechnology Ltd.

Loading...

Loading...