Page 1

63013628– 07/2001 US For Plumbers

Assembly and Maintenance

Instructions

Indirect Fired Hot Water Tank

Model S120 „US“

Save these instructions

Page 2

Imprint

NOTICE

Please observe and comply with all local

and state requirements pertaining to the

assembly and operation of an indirect fired

domestic hot water tank!

The Commonwealth of

Massachusetts requires that

the tank be installed by a

licensed plumber.

Buderus Hydronic Systems reserve the right to make

changes due to continued engineering improvement

without notice.

Updating of Product Documentation

Feel free to contact us regarding suggestions for

improvements of this product manual.

Address:

Buderus Hydronic Systems, Inc.

PO Box 647

Salem, NH 03079

http\\www.buderus.net

Document-number.: 6301 3628

Issue: 07/2001

We reserve the right to make any changes due to technical modifications!

2

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Page 3

Table of Contents

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 Tank Packaging and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Tank Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Dimensions and Piping Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Assembly and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.1 Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.2 Tank Piping Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.3 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3.1 Installation of Buderus Logamatic FB Sensor or Goldline SP30D Sensor Probe . . . . . . . . . .9

4.3.2 Installation of Honeywell Aquastat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5 Placing Tank in Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1 Testing of the Magnesium Anode Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2 Tank Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3 Recommissioning after Tank Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Parts Break-down for S120 Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Buderus Heiztechnik GmbH • http://www. heiztechnik.buderus.de

3

Page 4

General Information1

1 General Information

1.1 Tank Packaging and Components

The S120 indirect fired hot water tank is a 32 gal glass

lined steel tank. The tank is fully packaged with a high

density foam insulation and steel jacket panel. A Honeywell aquastat is standard supplied with the tank.

Additional components supplied with the tank are:

1 125 psi P and T valve

3 3/4“ brass couplings

1 3/4“ brass tee

1 Honeywell L4006 adjustable differential tank aquastat

1 Aquastat mounting bracket and 4 mounting screws

3 Adjustable tank leg leveling bolts

1 Roll of high quality teflon tape

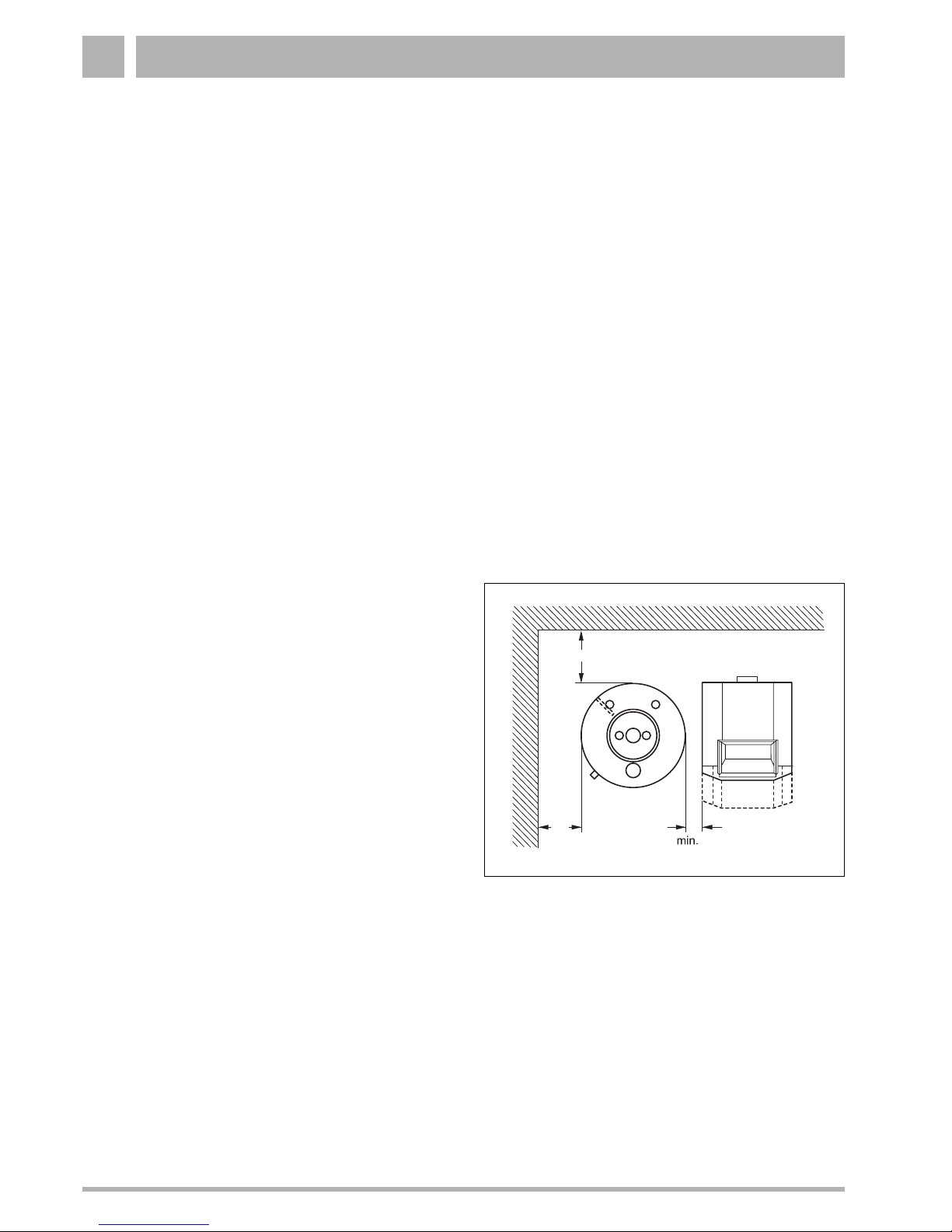

1.2 Tank Placement

Install the tank in a dry, frost free room.

Make sure that the tank is completely drained before

taking the tank out of use. Protect from freezing.

Place the tank on a level floor of sufficient strength.

Observe the recommended clearances as shown in

Fig.1. These dimensions are based on ample access for

installation and maintenance (Fig. 1). Maintain a

minimum clearance of 2“ between hot water piping or

tank surface to combustible surfaces.

16"

500

400

16"

Fig. 1 Recommended clearance for installation and

maintenance.

4"

min. 100

We reserve the right to make any changes due to technical modifications!

4

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Page 5

Transport 2

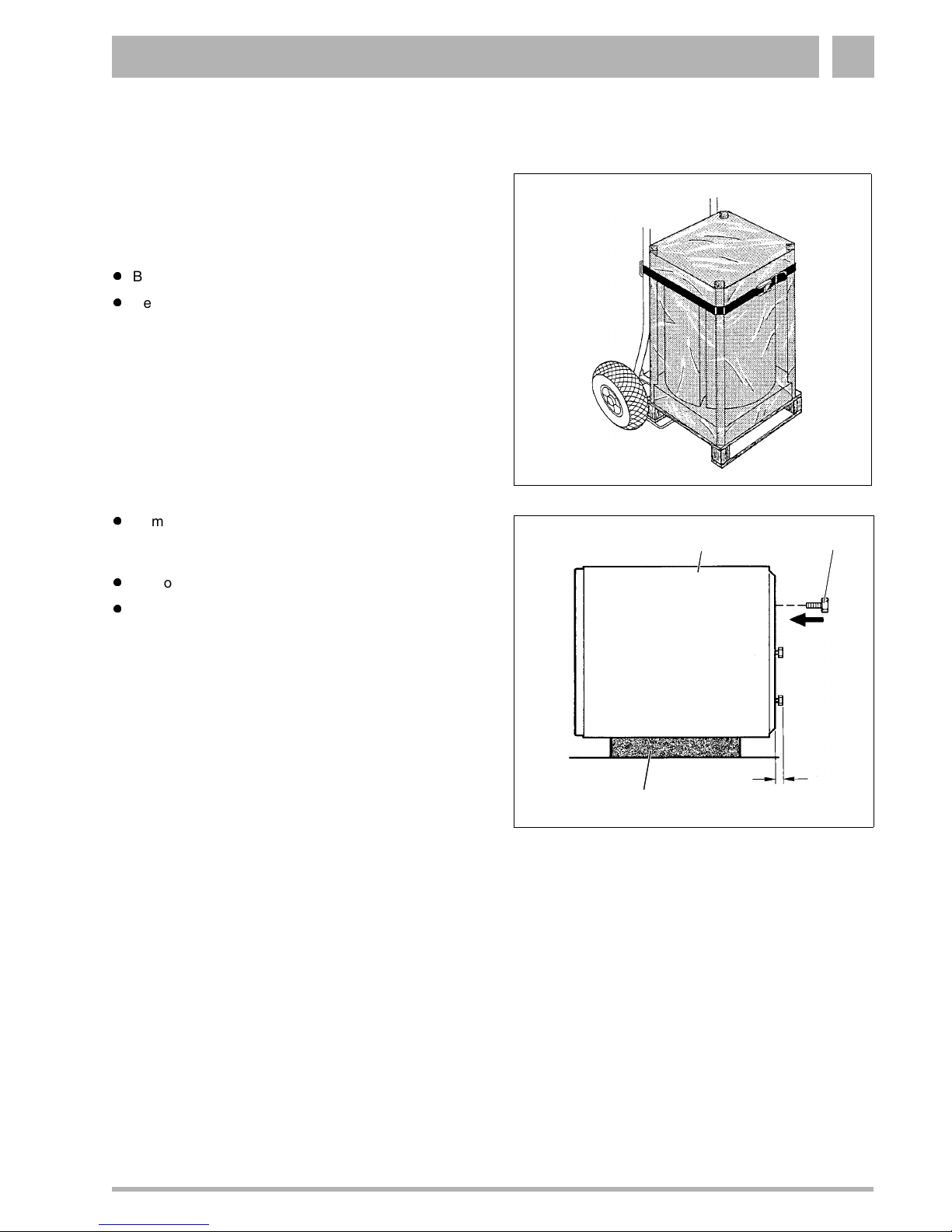

2 Transport

One can move the tank in its packaging as well as by

itself using a Buderus Kuli cart. (Must be ordered

separately). When using the Kuli cart, place tank on

bottom support and secure tank to the handle bars with

Kuli strap as shown in Fig. 2.

Bring the tank to its destination.

Remove plastic shrink wrap.

Fig. 2 Buderus-boiler-Kuli cart (sample picture)

Remove top styrofoam piece and wooden corner

posts. Place tank on its side on top of styrofoam

piece.(Fig. 3, Item. 1).

2 3

Remove bottom styrofoam piece from pallet.

Scew 3 M10x30 bolts in bottom of tank to serve as

tank leveling legs.(Fig. 3, Item. 3)

ca.3/4"

1

Fig. 3 Tank on top of styrofoam piece

(measurements in inches)

Item. 1: Styrofoam piece

Item. 2: Tank

Item. 3: Tank leveling bolts

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Buderus Heiztechnik GmbH • http://www. heiztechnik.buderus.de

5

Page 6

Dimensions and Piping Connections3

3 Dimensions and Piping Connections

1

37"

37"

3/4" - 1"

3/4" - 1"

20"

20"

Fig. 4 Dimensions and piping connections (measurements in inches)

Item. 1: Magnesium Anode Rod

Model VS RS EK/AB Anode Weight*

S120 ¾" ¾" ¾" 1" 158

Tab. 1 Dimensions and connections

*dry weight.

AB: DHW outlet (short dip tube)

EK: DHW inlet (long dip tube)

VS: boiler supply

RS: boiler return

MB: temperature measuring location (sensor or aquastat)

EL: tank drain

Lbs

We reserve the right to make any changes due to technical modifications!

6

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Page 7

Assembly and Installation 4

4 Assembly and Installation

Level tank by adjusting the leveling bolts under the

tank (Fig. 5).

Fig. 5 Adjusting tank leveling bolts (sample picture)

4.1 Safety Requirements

TANK DAMAGE

When exceeding critical values.

ATTENTION!

Critical Values

Temperature:

Heating water (boiler) 230 °F

Domestic water (tank) 203 °F

Operating pressure:

Heating water (boiler)* 87 psi

Domestic water (tank) 145 psi

* In the overall system, it is necessary to install a boiler pressure

relief value, expansion tank and P and T valve for the tank.

One must adhere to the following

critical values for safe operation.

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Buderus Heiztechnik GmbH • http://www. heiztechnik.buderus.de

7

Page 8

Assembly and Installation4

4.2 Tank Piping Installation

1. Install all piping and components per local and state

codes (Fig. 6).

Use threaded connections on all tank fittings. Fittings

are supplied. It is suggested to install shut off valves

in all water lines.

Install the 3/4“ brass tee fitting on the DHW outlet

connection (AB) with the teflon tape provided. Install

P and T valve (Fig. 6, Item. 2) into top of the brass

tee. Pipe the relief line full port to a nearby floor drain.

Add label to P and T relief valve stating: „Relief valve

may release water during heating of the tank“.

Install furnished 3/4“ brass couplings with teflon tape

provided on other three tappings located on top of the

tank. (See Fig. 4 for details)

Periodically test the operation of the P and T valve by

manually opening the valve.

All piping must be installed without undue stress!

Test all piping connections for leaks.

Fig. 6 Tank piping installation (sample picture)

Item. 1: Tank

Item. 2: P and T valve

Item. 3: Shut off valve with drain

Item. 4: Purge valve / vacuum breaker

Item. 5: Flow valve

Item. 6: Isolation valve

Item. 7: DHW recirculation pump (optional)

Item. 8: Pressure reducing valve (as required)

Item. 9: Test port ( as required per local code)

Item. 10:Back flow preventer ( as required per local code)

Item. 11:Pressure test port ( as required)

Item. 12:Tank drain

Safety Valve Requirements *

Minimum

Connection

Size

DN 15 (=1/2“) 200/53 255,000

*based on DIN norm 4753.

We reserve the right to make any changes due to technical modifications!

Net Water Volume

Liters/gals Btu/hr

8

AB: DHW outlet

EK: Cold feed

EZ: DHW recirc inlet

Max. Heating

Capacity

EL: Tank drain connection

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Page 9

Assembly and Installation 4

4.3 Temperature Control

For accurate control of the tank water temperature, one

has the option of using either the sensor supplied with

the Buderus Logamatic control or SP30D control, or the

Honeywell aquastat supplied with the S120 tank.

4.3.1 Installation of Buderus Logamatic FB Sensor

or Goldline SP30D Sensor Probe

Fully insert the suitable DHW sensor (Fig. 7, Item. 2)

together with the tension spacer (Fig. 7, Item. 1)

supplied with the tank into the factory installed tank

well (Fig. 7, Item. 3). Wire sensor leads to suitable

control terminals. (Sensor leads can be extended

using regular thermostat wiring.)

NOTICE

Ensure that the entire surface of the

sensor is in contact with the tank well.

3

2

1

Fig. 7 Installation of temperature sensor

Item. 1: Tension spacer

Item. 2: DHW tank sensor (FB sensor from Logamatic or

SP30D probe)

Item. 3: Tank dry well

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Buderus Heiztechnik GmbH • http://www. heiztechnik.buderus.de

9

Page 10

Assembly and Installation4

4.3.2 Installation of Honeywell Aquastat

Remove cover from aquastat by removing hex head

screw on top.

Secure mounting bracket (Fig. 8, Item. 3) furnished

with tank to base of aquastat (Fig. 8, Item. 2) using

the 2 screws (Fig. 8, Item. 1). (One may need to

remove prior mounting bracket).

Insert aquastat capillary with tension spacer (Fig. 9,

Item. 4 and 5) into tank dry well (Fig. 9, Item. 3).

Secure aquastat assembly (Fig. 9, Item. 2) with 2

screws (Fig. 9, Item. 1) to the tank jacket.

2

3

1

Fig. 8 Attaching bracket to aquastat

Item. 1: Screws C-ST 4,2 × 13 mm

Item. 2: Aquastat

Item. 3: Bracket

NOTICE

Wire the aquastat into suitable control and

set desired DHW tank temperature at

aquastat.

DANGER

due to electricity.

DANGER!

Shut down main switch before working

on the boiler/tank system.

Put aquastat cover back in place.

2

3

1

4

5

Fig. 9 Installation of Honeywell aquastat

Item. 1: Sheet metal screws C-ST 4,2 × 13 mm

Item. 2: Aquastat

Item. 3: Tank dry well

Item. 4: Aquastat capillary

Item. 5: Tension spacer

We reserve the right to make any changes due to technical modifications!

10

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Page 11

Placing Tank in Operation 5

5 Placing Tank in Operation

Prior to start-up, verify that the tank is filled with water

and that the cold feed is functional and unrestricted.

Check all connections for leaks.

Information regarding boiler/burner operation startup can be found in their respective manuals

The complete system must be placed in operation by

the installing contractor or one of his associates in

the presence of the end user. The end user shall be

informed about start-up procedure and system operation.

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Buderus Heiztechnik GmbH • http://www. heiztechnik.buderus.de

11

Page 12

Maintenance6

6 Maintenance

Unless specified in writing to the contrary, the S120 tank

should only be used for heating of domestic hot water.

A bi-annual inspection of the tank is recommended and

to be performed by a service technician. This inspection

involves assessing the status of the magnesium anode

rod and the need for cleaning of the tank interior.

In case of unfavorable water conditions (hard water) or

when operating the tank at high tank temperatures

(greater than 140 °F), an annual inspection is

recommended.

6.1 Testing of the Magnesium Anode Rod

DANGER

due to electricity.

DANGER!

Prior to inspection, disconnect

electricity.

Close off cold feed (EK), and drain tank. Open a

faucet at a higher location to vent the tank.

Remove plastic plugs (Fig. 10, Item. 1) from the

magnesium anode rod and clean-out opening.

Unscrew the magnesium anode rod (Fig. 10, Item. 2)

from the tank using a pipe wrench.

NOTICE

Keep surface of magnesium anode rod

free from oil or grease.

Clean surface of anode rod with water.

Check surface degradation of anode rod.

Change out the anode rod if its diameter is less than

1/2“ to 3/4“ or if its surface is severely pitted. No

corrosion protection of tank when anode rod is

severely degraded. Tank warranty is voided in this

case.

1

1

2

3

Fig. 10 Removal of magnesium anode rod

Item. 1: Plastic plugs

Item. 2: Magnesium anode rod

Item. 3: Tank inspection opening

We reserve the right to make any changes due to technical modifications!

12

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Page 13

Maintenance 6

6.2 Tank Cleaning

Remove tank inspection plug (Fig. 11, Item. 1) using

a 15/16“ Allen wrench.

Visually inspect tank interior and clean when

necessary. To remove scale and build-up from tank

coil, turn on boiler and tank circulator and circulate

hot boiler water through tank coil. Spray cold water

on coil surface to shock build-up from tank coil. Rinse

scale and debris form tank through tank drain.

TANK DAMAGE

due to contact with sharp objects.

ATTENTION!

Never attempt to remove coil build-up

with a sharp object, as it may damage

the tank’s protective surface coating.

Fig. 11 Removal of inspection plug

Item. 1: Inspection plug (1“)

Item. 2: Inspection and clean-out opening

1

2

6.3 Recommissioning after Tank Cleaning

Install magnesium anode rod (Fig. 10, Item. 2). Use

quality teflon tape for sealing. Wrap generously.

Install inspection plug (Fig. 11, Item. 1). Use quality

teflon tape for sealing. Wrap generously.

Place system back in operation.

Check all connections for leaks.

Put plastic plugs (Fig. 10, Item. 1) back in place on

magnesium anode and inspection plug.

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

13

Page 14

Parts Break-down for S120 Tank7

7 Parts Break-down for S120 Tank

Item.-Nr. in

Fig. 12

Page 15

5 Indirect fired hot water tank S120 „US“ complete. 6320 5018 1

Available individual parts:

10 Magnesium anode rod D26 × 505 mm, G1“ 3868 538 1

20 Inspection plug 6790 1380 1

30 Aquastat mounting bracket 6301 3510 1

40 Tank top cover, blue 6301 3260 1

50 Tank top screws, DIN 7981-C-ST6,3 × 19 - A3T x 2

60 Tension spacer 7099 268 1

70 Fill and drain valve (German model) 479 762 1

80 Plastic plugs, blue 6301 3463 2

90 Hexhead bolts, ISO 4017- M10 × 30 - 8.8 - A3K x 3

100 DHW outlet dip tube, 3“ long 5222 171 1

110 DHW inlet dip tube, 32“ long 5222 173 1

Tab. 2 Spare Parts for S120

Part Description Part-Nr. Quantity

We reserve the right to make any changes due to technical modifications!

14

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

Page 15

Parts Break-down for S120 Tank 7

5

80

10

80

100

50

20

50

40

110

60

Fig. 12 Spare Parts for S120

We reserve the right to make any changes due to technical modifications!

Installation and Maintenance Instructions Logalux S 120 „US“• Issue 07/2001

30

70

90

Buderus Heiztechnik GmbH • http://www.heiztechnik.buderus.de

15

Page 16

Boiler installed by:

(contractor’s address)

Boiler installed on:

(date of installation)

Buderus Hydronic Systems

50 Wentworth Avenue

Londonderry, NH 03053 USA

Tel: (603) 552-1100 • Fax: (603) 421-2719

www.buderus.net

Buderus Hydronic Systems, Inc. reserves the right to make changes without notice due to continuing

engineering and technological advances.

Loading...

Loading...