Page 1

For heating contractors

Pour le professionel

Please read carefully before

installing and servicing

A lire attentivement avant le

montage et l’entretien

MCM10

6 720 617 648 - 07.1O

en-us Installation Instructions 2

fr Notice d´installation 20

6 720 616 690 (08/2009)

Page 2

Table of contents

MCM10

2

Table of contents

1 Explanation of symbols and safety instructions 3

1.1 Symbols, explanation of 3

1.2 Safety instructions 3

2 Details about the MCM10 module 4

2.1 Declaration of conformity 4

2.2 Information regarding the documentation 4

2.3 Proper use 4

2.4 Scope of delivery 4

2.5 Accessories 4

2.6 Technical specifications 5

2.6.1 General 5

2.6.2 Dimensions 5

2.6.3 Power connection parameters 5

2.6.4 Measurement values supply temperature sensor 5

2.6.5 Measurement values outdoor temperature sensor 5

2.7 System integration of the MCM10 6

2.7.1 Principles of cascade control 6

2.7.2 Heating controls for MCM10 cascade systems 6

2.7.3 Water heating with MCM10 cascade systems 6

2.7.4 Internal frost protection function 6

2.7.5 Control of one heating pump 7

2.7.6 External switching contact 7

2.7.7 System versions overview 7

2.7.8 Connection of additional modules in case of heating

system controls with 2-wire BUS control 9

3 Installation 10

3.1 Installation 10

3.1.1 Wall mounting 10

3.2 Making the electrical connections 11

3.2.1 Connection of the low voltage part with BUS

connections 11

3.2.2 120 V AC connection 11

3.2.3 Connection of a remote fault indication with optical

and acoustic signal 12

3.2.4 Electrical connection of the outdoor temperature

sensor 12

3.2.5 Electrical connection of the supply temperature

sensor 12

3.2.6 Electrical connection of the external switching

contact 12

3.2.7 Disposal 12

3.3 Installing other accessories 12

4 Start-up and shut-down 13

4.1 Configuration 13

4.2 Commissioning 13

4.3 Configuration reset 13

4.4 Shutting down 13

5 Operating and fault indications 14

5.1 Operating and fault indications via the heating appliance

displays 14

5.2 Fault message via the remote fault indication 14

5.3 Operating and fault indications via LED 14

5.4 Operating and fault indications via the RC35 16

5.5 Replacing the fuse for the heating zone pump

connection 17

6 Environmental protection 18

7Appendix 19

Page 3

1

Explanation of symbols and safety information

MCM10

3

1 Explanation of symbols and safety information

1.1 Explanation of symbols

Warning symbols

Signal words indicate the seriousness of the hazard in

terms of the consequences of not following the safety

instructions.

• NOTICE indicates possible damage to property or

equipment, but where there is no risk of injury.

• CAUTION indicates possible injury.

• WARNING indicates possible severe injury.

• DANGER indicates possible risk to life.

Important information

Additional symbols

1.2 Safety precautions

B To ensure proper function, follow these instructions.

B Install and start up the heating appliance and all

accessories according to the associated instructions.

B Use this accessory exclusively in conjunction with the

controllers and heating appliances listed. Follow the

connection diagram!

B This accessory has inputs and outputs with different

voltages. Never connect the low voltage side to the

120 V power supply or vice-versa.

B In case of wall installation: never install this accessory

in wet areas.

B Work on electrical components only if you have the

required training and qualification.

B Before you start working on the system, disconnect the

heating system from electrical power by shutting off the

emergency shut-off switch or the heating system circuit

breaker.

B Secure against unintentional reconnection.

B It is not sufficient to simply shut off the controls.

B Observe all applicable electrical codes and

regulations.

Safety instructions in this document are

framed and identified by a warning triangle

which is printed on a grey background.

Electrical hazards are identified by a lightning

symbol surrounded by a warning triangle.

Notes contain important information in cases

where there is no risk of personal injury or

material losses and are identified by the

symbol shown on the left. They are bordered

by horizontal lines above and below the text.

Symbol Meaning

B a step in an action sequence

Æ a reference to a related part in the docu-

ment or to other related documents

•a list entry

– a list entry (second level)

Page 4

2

Details about the MCM10 module

MCM10

4

2 Details about the MCM10 module

2.1 Declaration of conformity

2.2 Information regarding the

documentation

We reserve the right to make technical modifications!

2.3 Proper use

The MCM10 modules are designed to control cascade

systems. A cascade system is a heating system where

several smaller heating appliances are connected in

parallel to achieve a higher output (Æ Fig. 12, page 19).

The MCM10 modules are only suitable for controlling

heating appliances with Logamatic EMS BUS.

For floor-standing heaters, the MCM10 module is only

suitable for the activation of gas heaters with modulating

burners without operating conditions.

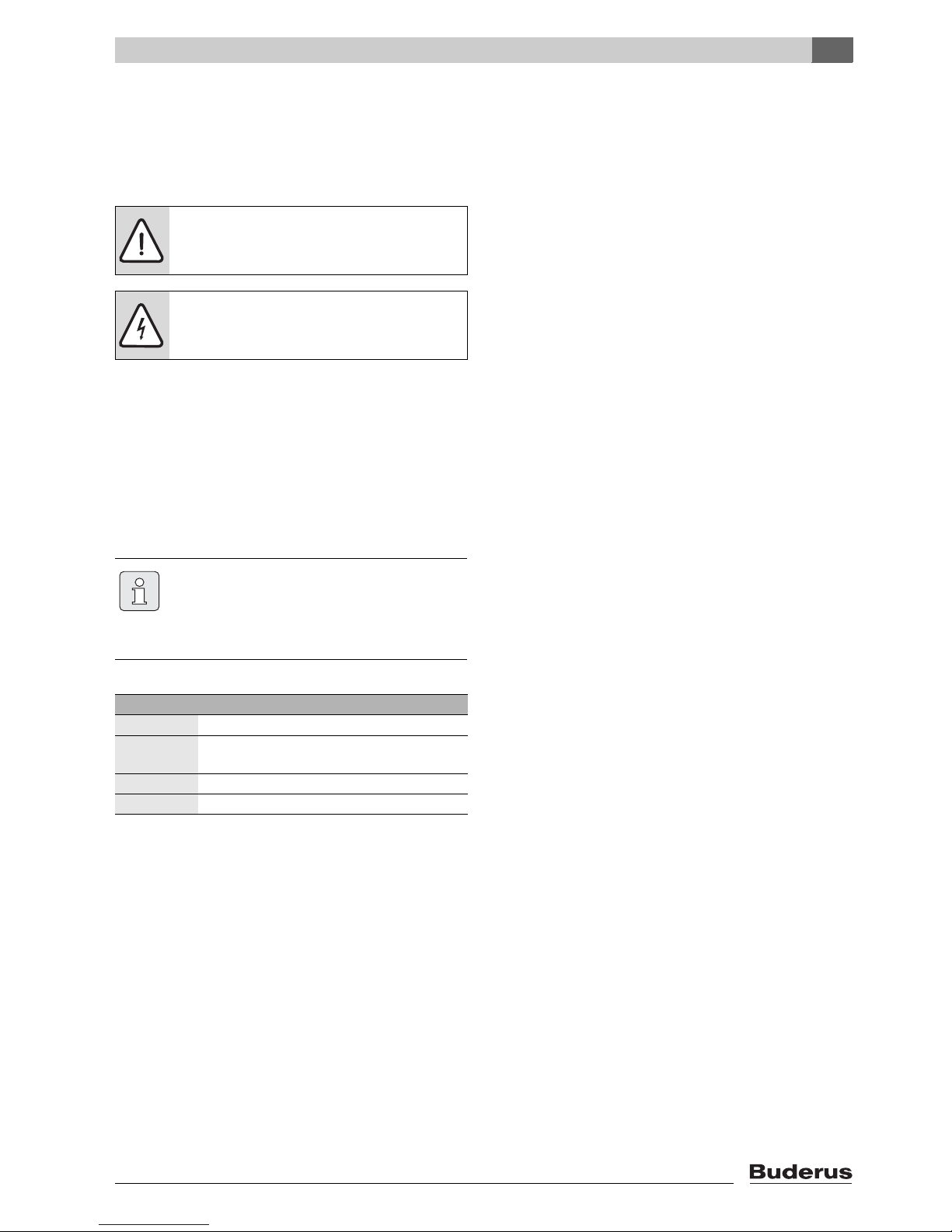

2.4 Scope of delivery

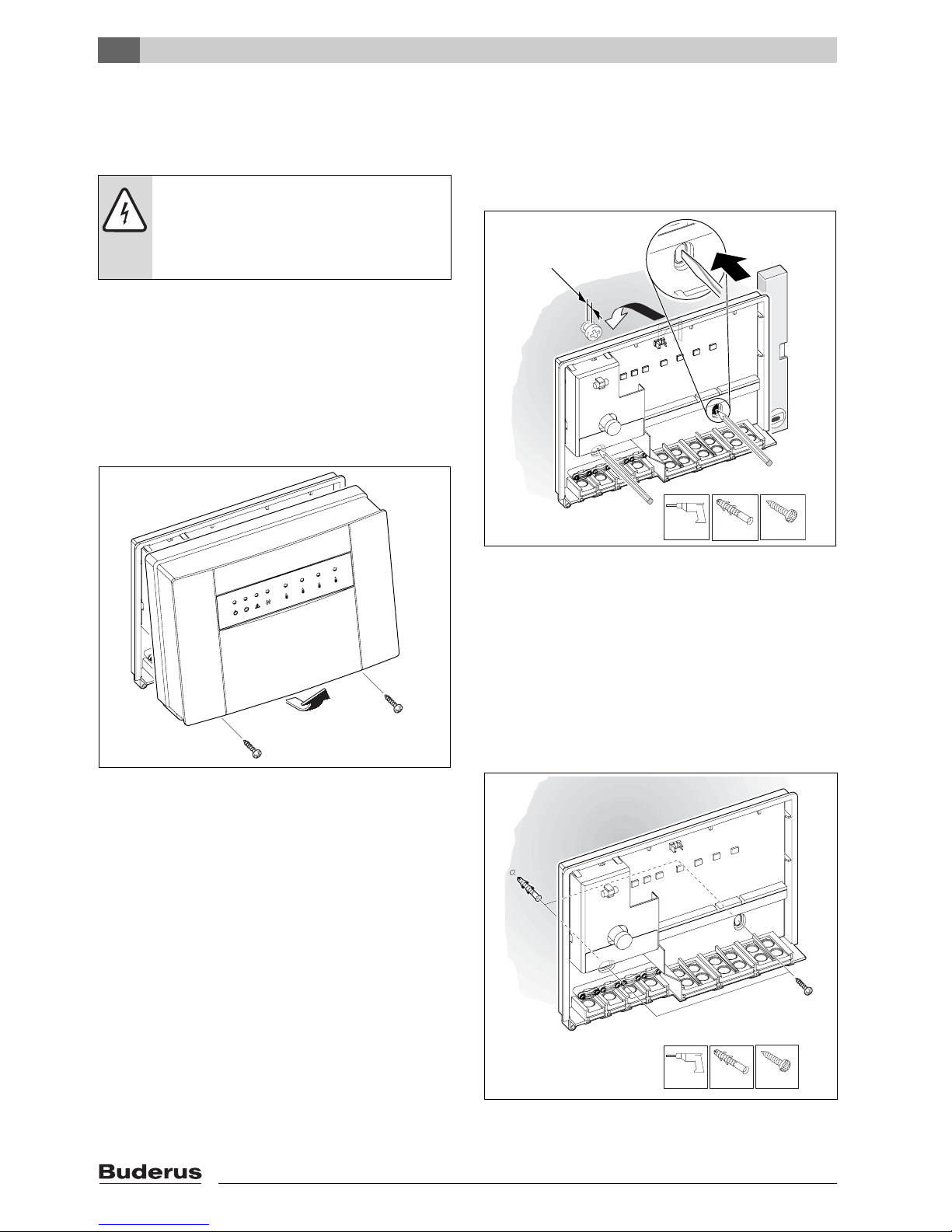

Fig. 1 Scope of delivery

1 MCM10

2 Duct connection box

3 Sensor well

4 Supply temperature sensor FV

5 Package with:

- 3 screws and 3 wall-plugs

- 4 strain relief clips and 8 screws

6 Installation and operating instructions

B Check that the delivery is complete.

2.5 Accessories

Here is a list with typical accessories. In order to get a

complete overview of all available accessories, please

contact the manufacturer.

• Outdoor temperature sensor FA for connection to

terminal F (only for system variant 1).

• RC35: Outdoor reset heating system controls with

plaintext display for controlling a heating system with

mixed or unmixed heating zones.

• WM10: Low loss header module for EMS.

• MM10: Mixer module for EMS.

• AM10: Outdoor reset controller with thermostat

connection.

The design and operation of this product

conform to the U.S. and Canadian Directives.

Its conformity is demonstrated by the CSA

designation.

The Declaration of conformity can be

claimed. See the address at the back of this

manual.

Hand all enclosed documents over to the user.

6 720 616 690-02.1TD

1

2

4

3

6

5

Page 5

2

Details about the MCM10 module

MCM10

5

2.6 Technical specifications

2.6.1 General

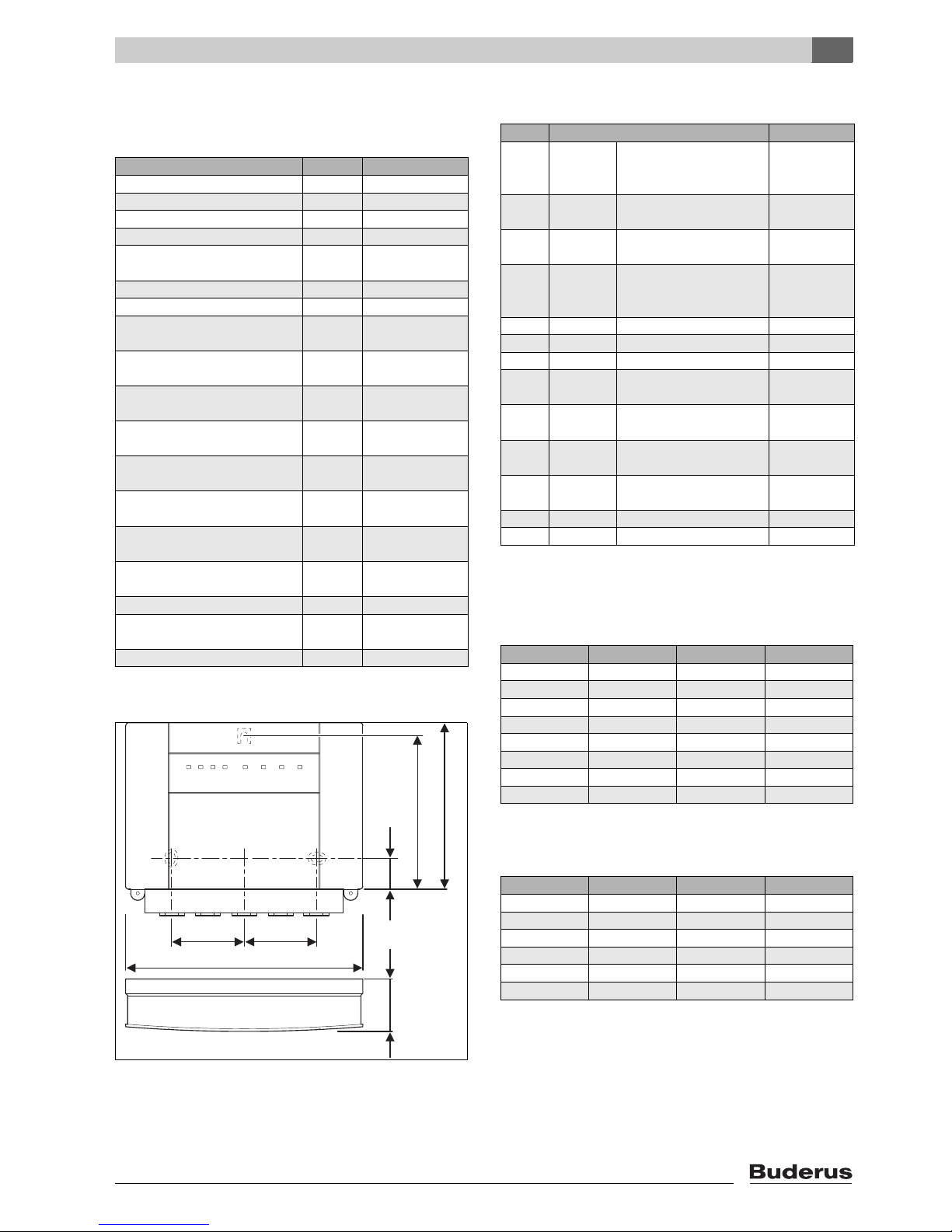

2.6.2 Dimensions

Fig. 2 Dimensions

2.6.3 Power connection parameters

2.6.4 Measurement values supply temperature

sensor

2.6.5 Measurement values outdoor temperature

sensor

Designation Unit

Dimensions (Æ Fig. 2)

Weight (without packaging) lb (kg) 1.76 (0.8)

Rated voltage MCM10 AC … V 120

Frequency Hz 60

Max. on-site fuse protection of the

input voltage

Amp 10

Power draw MCM10 W 5

Rated voltage BUS DC … V 15

Internal appliance fuse, heating

pump output

Amp 5 AF, ceramic, filled

with sand

Measuring range, supply

temperature sensor

° F ( °C) 32 … 212

(0 … 100)

Measuring range, outside

temperature sensor

° F ( °C) – 40 … 122

( – 40 … 50)

Permissible ambient

temperature MCM10

° F ( °C) 32 … 122

(0 … 50)

Permissible ambient temperature,

supply temperature sensor

° F ( °C) 32 … 212

(0 … 100)

Permissible ambient temperature

outdoor temperature sensor

° F ( °C) – 58 … 212

( – 50 … 100)

Maximum cable length,

2-wire BUS connections

ft (m) (ÆTab. 6, page 11)

Maximum lead lengths,

sensor leads

ft (m) (ÆTab. 7, page 11)

EMC suppression level to IEC 60730

Enclosure rating II in accordance

with IEC 60730

NEMA definition Type 2

Tab. 1 General

2-1/2" (62mm)

6 720 616 690-03.1TD

2-1/2" (62mm)

9-1/4" (235mm)

2-1/4" (58mm)

1-1/2" (37mm)

5-9/16" (142mm)

6-1/2" (165mm)

Pos.

1)

1) (Æ Fig. 12, page 19)

Interface

A Input Power supply from the power

line or from the previous module MCM10

120 V AC,

max. 10 Amp.

B Output Power supply for additional

MCM10

120 V AC,

max. 10 Amp.

C Output Pump 120 V AC,

max. 250 W

D Output Remote fault indication zero volt,

max. 120 V,

2Amp.

E Input Supply temperature sensor NTC (ÆTab. 3)

F Input Outdoor temperature sensor NTC (ÆTab. 4)

G Input External switching contact Zero volt

H Input Heating controls

(ON/OFF contact)

24 V DC

I Input Heating controls (propor-

tional interface)

0-10 V DC

J 2-wire BUS to the heating controller

(RC35, WM10, MM10)

–

K 2-wire BUS from the previous MCM10

module

–

L 2-wire BUS to the next MCM10 module –

M 2-wire BUS to the heating appliance –

Tab. 2 Power connection parameters

°F ( °C) Ω °F ( °C) Ω

68 (20) 12490 140 (60) 2488

77 (25) 10000 149 (65) 2083

86 (30) 8057 158 (70) 1752

95 (35) 6531 167 (75) 1481

104 (40) 5327 176 (80) 1258

113 (45) 4369 185 (85) 1072

122 (50) 3603 194 (90) 917

131 (55) 2986 203 (95) 788

Tab. 3 Measurement values supply temperature sensor

°F ( °C) Ω °F ( °C) Ω

– 4 ( – 20) 97070 50 (10) 19900

5 ( – 15) 72929 59 (15) 15708

14 ( – 10) 55330 68 (20) 12490

23 ( – 5) 42315 77 (25) 10000

32 (0) 32650 86 (30) 8057

41 (5) 25388 95 (35) 6531

Tab. 4 Measurement values outdoor temperature

sensor

Page 6

2

Details about the MCM10 module

MCM10

6

2.7 System integration of the MCM10

2.7.1 Principles of cascade control

When the heating appliance generates a heat demand

(Æ Tab. 5, system versions 1, 2, 3, and 4), initially one

heating appliance is started and, if required, its heat

output is raised to its maximum nominal power. Only then

will another heating appliance be started.

If excessive heat is being generated, heating appliances

are controlled one after another in sequence without

delay down to their respective minimum nominal power,

and then shut down until heat demand and generation

match. With system version 4 all appliances are shut

down simultaneously.

The MCM10 module automatically determines the

sequence in which the heating appliances are controlled.

The MCM10 module safeguards an even distribution of

the burner hours of operation for all heating appliances.

This takes into account heating and DHW. This increases

the heating appliance service life. If the power supply to

the MCM10 module is interrupted, the hours run meters

in the MCM10 module are reset to zero.

As soon as a heating appliance is not able to start (DHW

heating for a directly-connected hot water tank, heating

appliance fault, communication fault with MCM10

module), another heating appliance will be started

automatically to cover the heat demand.

2.7.2 Heating controls for MCM10 cascade

systems

The MCM10 modules stage the heating appliances

based on the heat demand calculated. For control

according to the heat demand, the MCM10 modules

always require heating system controls (Æ Fig. 12,

terminals H, I or J, page 19). Depending on the heating

system controls, there are four possible system versions

(ÆTab. 5).

One MCM10 module can control up to four heating

appliances. By connecting up to four MCM10 modules,

up to 16 heating appliances can be linked to form a single

cascade (Æ Fig. 12, page 19). In this case, one MCM10

module controls the cascade (MCM10 master).

Depending on the heating system controls used, a

cascade system with up to 4 or up to 16 heating

appliances can be created. The maximum number of

heating appliances that can be connected and the

number of MCM10 modules required for the different

systems are shown in Tab. 5, page 8.

The MCM10 module controls the entire boiler loop

(primary loop including the low loss header). All other

heating system components (secondary side of the low

loss header, such as the heating zones, hot water tank)

can be regulated by a weather-dependent heating

controller with a 2-wire BUS interface and additional

modules (WM10, MM10...). Contact the manufacturer for

further details. You will find the relevant address on the

back cover.

Heating appliances of any output can be part of a

cascade.

2.7.3 Water heating with MCM10 cascade

systems

Hot water tanks can be connected hydraulically and

electrically directly to a heating appliance (storage tank

model).

• Water heating is controlled by the heating appliance.

During a DHW demand, this heating appliance will not

be called by the MCM10 module. In case of demand,

another heating appliance may be started.

• If water heating is timed using a heating system control

with 2-wire BUS connection, the heating appliance

with the storage tank must be connected to the

MCM10 module (master) via terminals 17 and 18.

2.7.4 Internal frost protection function

The MCM10 module is equipped with an internal frost

protection function: if the supply temperature falls below

45 °F ( 7 °C ), a heating appliance starts and runs until a

supply temperature of 60 °F (15 °C) has been achieved.

Any heating pump that is connected to the MCM10

module will also run (Æ paragrahp 2.7.5).

B Connect the supply temperature sensor to the MCM10

master module if the internal frost protection function is

required.

Note that, for the correct function, only one

heating system control/building management

system may be connected.

The different system versions require the

connection of certain accessories (supply

temperature sensors, outdoor temperature

sensors, heating pumps, and heating system

controls) (Æ Tab. 5, page 8).

If the user wants to prepare hot water using

the 3-way valve of the heating appliance and

he wants to continue supplying the heating

zone, he must switch off the warm water

priority on the RC35 for all heating zones

since with the factory settings, hot water

priority is active by default.

The frost protection function of heating

system controls with 2-BUS interface

provides comprehensive system frost

protection. This requires the connection of an

outdoor temperature sensor.

Page 7

2

Details about the MCM10 module

MCM10

7

2.7.5 Control of one heating pump

In heating systems with only one heating zone, the heating

pump can be connected directly to the MCM10 module

(master).

The heating pump runs:

• as long as at least one heating appliance pump is

running (if required, set the pump run-on time on the

heating appliance accordingly Æ heating appliance

installation instructions); or

• briefly after remaining idle for 24 hours (anti-seizing

protection).

2.7.6 External switching contact

The MCM10 module is equipped with an external

switching contact (Æ Fig. 12, pos. G). For the

characteristics of this switch, see Æ Tab. 2, page 5.

This external switching contact can be used optionally,

e.g. to connect a temperature switch for protecting the

radiant floor heating against a too-high water temperature.

If the switching contact is opened, all heating appliances

are switched off via the MCM10 module. As soon as the

switching contact is closed again, the heating appliances

are ready for operation again.

2.7.7 System versions overview

As a manufacturer of advanced heating technology, we

give high priority to the development and manufacture of

economical and clean-burning heating appliances. To

guarantee this, our heating appliances are equipped with

modulating burners. To make optimum use of the burner

characteristics, heating system controls with 2-wire BUS

control should be used.

The anti-seizing pump protection lets the

heating pump run at least once every day

even without a heat demand (e.g. during

summer).

B Leave your heating system switched on all

year to prevent the pump (in summer) from

seizing up.

Page 8

2

Details about the MCM10 module

MCM10

8

System version 1: Modulating weathercompensated heating controller (RC35)

An advantage of this system is the ability of the modules

to communicate, enabling all heating zones to be

controlled (function module WM10 or MM10) with the

MCM10 module via a common BUS, parallel to terminal J

on the MCM10 module (Æ Fig. 12, page 19). This

ensures matching generated heat amount to the actual

heat demand of all heating zones in the system. With this

version, the heating system achieves optimum comfort

with maximum energy savings.

System version 2: Modulating weathercompensated heating controller (AM10)

The supply target temperature of the AM10 module

depends on the outdoor temperature. In contrast to

system version 1, it is not possible to use the WM10 and

MM10 modules.

System version 3: Modulating 0 - 10 V controller,

regulated acc. to output

In conjunction with a building management system with

0 - 10 V interface, the total output of the cascade can be

selected as control variable. Setting is achieved via a

jumper (Æ Fig. 3).

System version

Symbol forcontroller

connection

Heating controller to MCM10

master module

Type

Max. number MCM10

Max. number of heating

applianceswith BUS-enabled

Logamatic EMS

Required accessories with connection to MCM10

(Æ Fig. 12, page 19)

1 Modulating weather-compensated

controller 2-wire BUS control

RC35 4 16 • Outdoor temperature sensor.

• One WM10 module. The WM10 module is delivered with a

supply temperature sensor (see explanation on the following

page).

• Heating pump (secondary zone) is connected to the WM10

module.

2 Modulating weather-compensated

controller 2-wire BUS control

AM10

weathercompensated controller

4 16 • Connect outdoor temperature sensor to AM10.

• Common supply temperature sensor on terminal E (only for

internal frost protection).

• Heating pump (secondary zone) (Æ Fig. 12, [19]) on terminal C, only in case of one or several heating zones without

heating pump or in case of heating zones that do not communicate via BUS modules with the MCM10module.

3 Modulating

0 - 10 V controller,e.g. building management system;

control of the heat output

Any 4 16 • Common supply temperature sensor on terminal E (only for

internal frost protection).

• Heating pump (secondary zone) (Æ Fig. 12, [19]) on

terminal C, only with one or several heating zones without

heating pump or with heating zones that are not regulated

via the building management system.

4 Modulating

0 - 10 V controller, e.g. building management system;

supply temperature control

Any 4 16 • Common supply temperature sensor on terminal E

• Heating pump (secondary zone) (Æ Fig. 12, [19]) on

terminal C, only with one or several heating zones without

heating pump or with heating zones that are not regulated

via the building management system.

5 ON/OFF controller (zero volt) Any 4 16 • Common supply temperature sensor on terminal E (only for

internal frost protection).

• Heating pump (secondary zone) (Æ Fig. 12, [19]) on

terminal C.

Tab. 5 System versions overview

0 ... 10V

0 ... 10V

Page 9

2

Details about the MCM10 module

MCM10

9

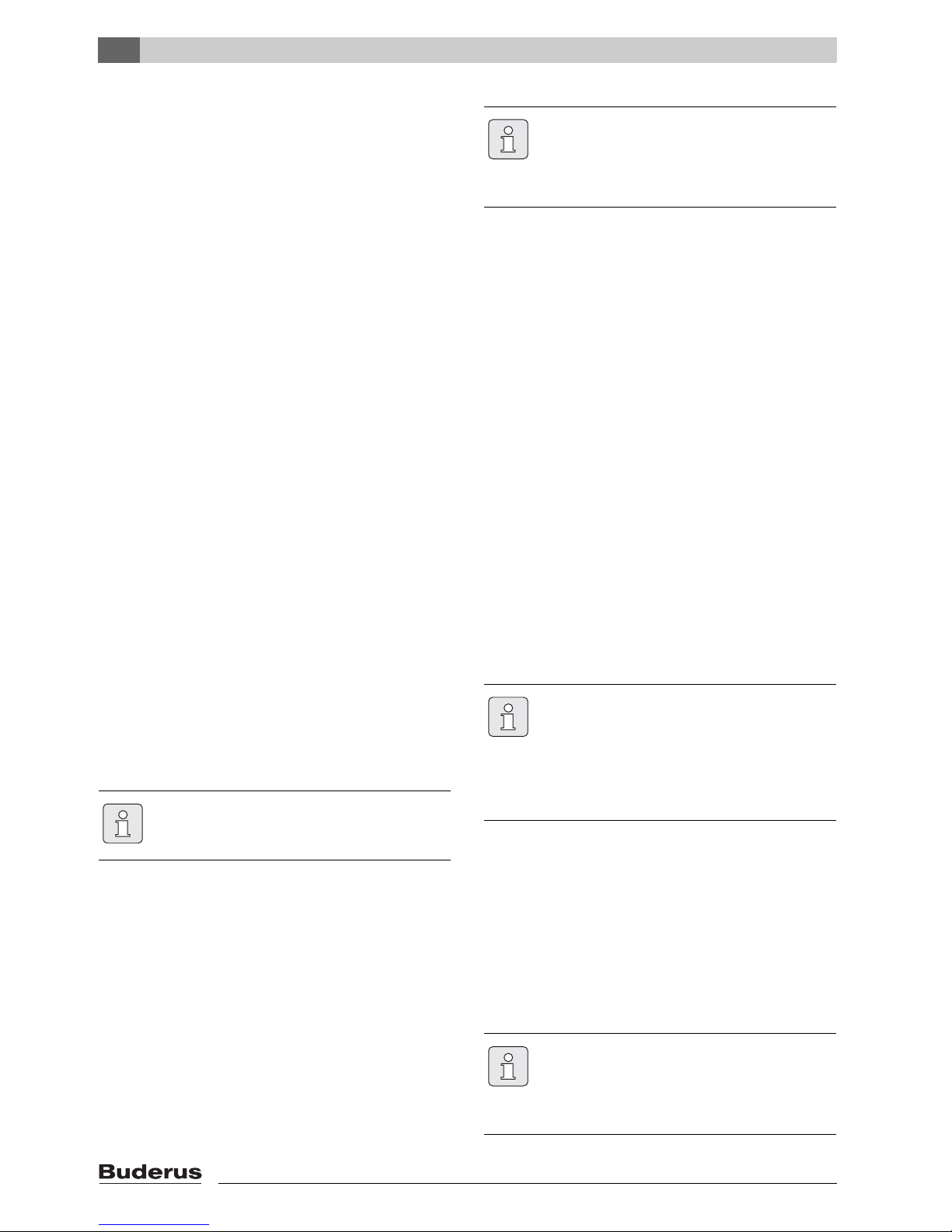

Fig. 3 Setting via jumper

Fig. 4 Correlation between the input voltage and heat

output

U Input voltage

P Output in % of the rated cascade output

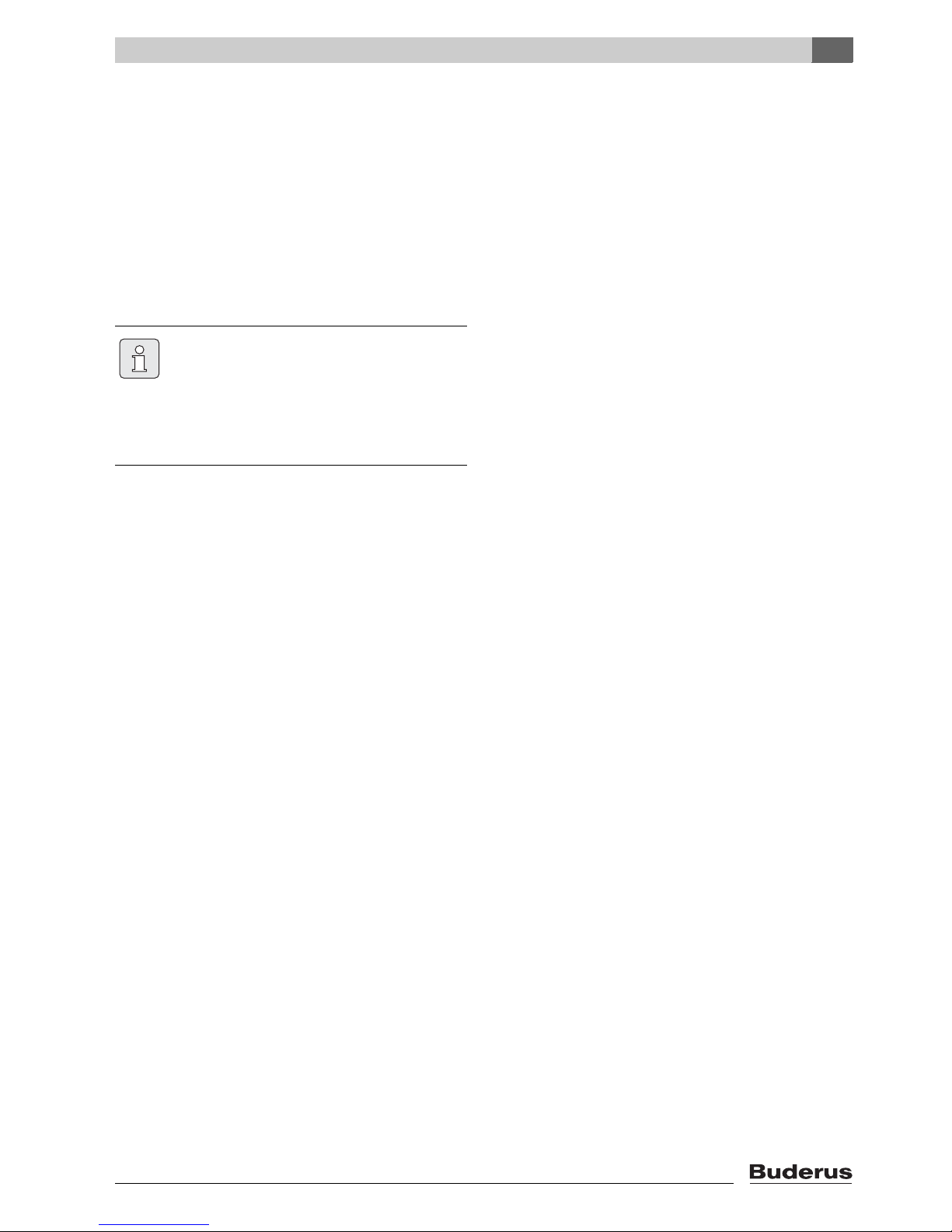

System version 4: Modulating 0 - 10 V controller,

regulated to supply temperature

In conjunction with a building management system with

0 - 10 V interface, the supply temperature can be

selected as control variable. Setting is achieved via a

jumper (Æ Fig. 3).

Fig. 5 Correlation between the input voltage and the

supply temperature

U Input voltage

VT Supply temperature

System version 5: Heating control with ON/OFF

contact

In conjunction with a control unit with ON/OFF contact,

module MCM10 regulates the cascade output in

accordance with the contact closure respectively up to

maximum output, by starting one appliance after another.

When the contact is opened, all heating appliances are

shut down simultaneously.

The ON/OFF contact of the heating system controls must

be a dry contact.

2.7.8 Connection of additional modules in case of

heating system controls with 2-wire BUS

control

Any additional modules, such as the WM10 and MM10

modules (Æ Fig. 12, [21], page 19), must be connected

to the BUS of the heating controller (parallel to terminal J

on the MCM10 module).

6 720 617 648-001.1TD

VT [˚F]

P [%]

0246810

6 720 617 648-09.1TD

0

30

50

70

90

U [V DC]

P [%]

194 (90)

167 (75)

140 (60)

113 (45)

86 (30)

59 (15)

0

0246810

6 720 617 648-10.1TD

U [V DC]

[˚F (˚C)] VT

Page 10

3

Installation

MCM10

10

3 Installation

3.1 Installation

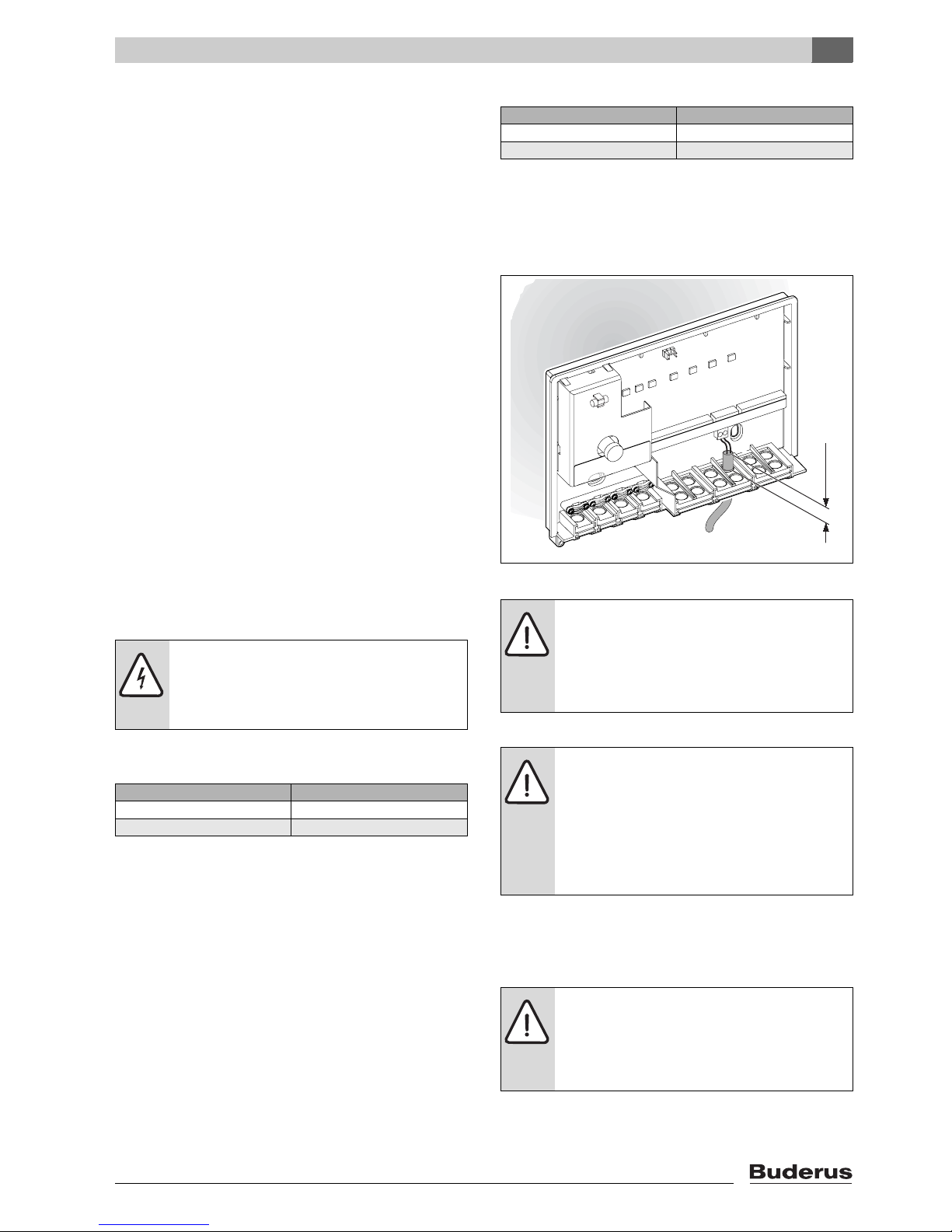

3.1.1 Wall mounting

B Determine the location on the wall in accordance with

the dimensions of the MCM10 module.

B Determine whether the main power cord is laid in stiff

or flexible ducts that require duct connection box and

appropriate free space under the MCM10.

B Undo two screws at the bottom of the MCM10 module,

pull the cover at the bottom forward and lift off upwards

(Æ Fig. 6).

Fig. 6 Removing the cover

B For the upper attachment screw, drill a Ø 1/4" (6 mm)

hole, insert an appropriate wall anchor, and insert the

screw until only 1/16" (1.5 mm) protrudes (Æ Fig. 7).

Fig. 7 Upper attachment screw

B In the back panel of the MCM10 module, create two

holes for the lower attachment screws using the

breakouts prepared.

B Attach the MCM10 module at the top attachment

screw.

B Mark the holes to be drilled on the wall through the

breakouts created.

B Remove the MCM10 module.

B Drill Ø 1/4" (6 mm) holes and insert wall anchors

(Æ Fig. 8).

Fig. 8 Insert wall anchor

DANGER: Risk of electric shock!

B Before connecting the power supply,

interrupt the power supply to the heating

appliances and to all other BUS

subscribers.

7 746 800 090-03.1O

1/4"

3,5 mm

0.05" (1,5mm)

6 720 617 648-02.1O

3.

4.

4.

2.

1.

1/4"

1/4"

3,5 mm

6 720 617 648-03.1O

1/4"

1/4"

Page 11

3

Installation

MCM10

11

B Hook in the MCM10 module at the top attachment

screw and secure with the two lower screws.

B With the use of stiff or flexible ducts:

– Remove all plastic grommets from the slits on the

lower side of the MCM10;

– push the duct connection to the intended place;

– break out the required number of cable entries by

knocking cautiously with a screwdriver handle;

– mount the duct according to the manufacturer's

instructions.

Note: When using ducts, no plastic grommets are

required.

3.2 Making the electrical connections

B Observe electrical code for the connection and use at

least cable AWG14 for the main power cord.

B Always route cables through the preassembled

grommets and apply the strain relief supplied to protect

the system against the ingress of dripping water.

B Wiring preferably with single core cable. When using

multi-strand (flexible) cables, fit them with wire ferrules.

B Cables can be pulled off the contact strip for their

connection to the screw terminals. The connectors are

color-coded and keyed to prevent mismatch of cable

terminals.

3.2.1 Connection of the low voltage part with

BUS connections

The minimum permissible cable cross-section of the 2wire BUS connection arises from the cable length:

B Route all low-voltage cables separately from cables

carrying 120V to avoid inductive interference (minimum

separation 4 inches)(100 mm).

B In case of inductive external influences, use shielded

cables.

This way, the cables are screened against external

influences (e.g. high-voltage cables, contact wires,

transformer stations, radio and TV devices, amateur

radio stations, microwave devices, etc.).

B When sensor leads are extended, apply the following

lead cross-sections:

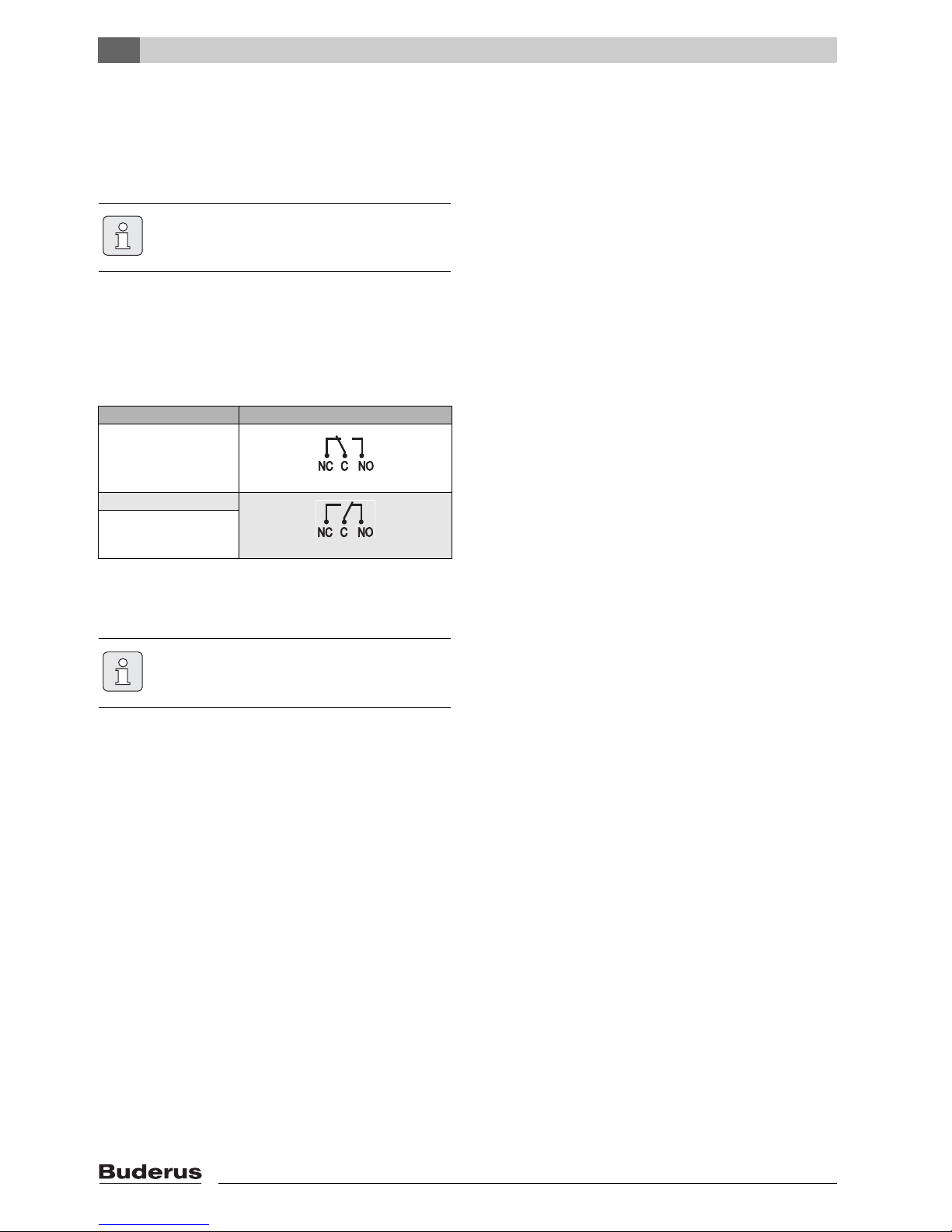

B To safeguard the splash-proof rating (IP):

Route cables so that the cable sheath protrudes at

least 0.8" (20 mm) into the cable grommet (Æ Fig. 9)

or the duct connection box.

Fig. 9 Splash-proof

3.2.2 120 V AC connection

B Only use electric cable of similar quality.

B Never connect additional controllers that regulate other

system components to outputs C (pump) and D (fault

signal).

CAUTION: Malfunction!

B Always wire in accordance with the wiring

diagram (Æ Fig. 12, page 19).

B Never connect one BUS to another.

Cable length Min. cross-section

< 325 ft (100 m) AWG 20

325 - 650 ft (100 - 200 m) AWG 18

Tab. 6 Minimum permissible cross-section of the

2-wire BUS connections

Cable length Min. cross-section

< 65 ft (20 m) AWG 20

65 - 100 ft (20 - 30 m) AWG 18

Tab. 7 Sensor lead extension

CAUTION: Risk of pole reversal.

Malfunction through interchanged

connection on the 0 - 10 V interface.

B Ensure connection to the correct poles

(9 = negative, 10 = positive).

CAUTION: The MCM10 module input is not

fuse-protected.

Overloading the outputs can damage the

MCM10 modules.

B Protect the MCM10 module power supply

(master) with a fuse with maximum rating

10 Amp.

CAUTION: Output C (pump) of the MCM10

module has a maximum load capacity of

250 W.

B Connect pumps drawing more current via

relays.

6 720 617 648 - 04.1O

≥1" (25 mm)

Page 12

3

Installation

MCM10

12

B Recommendation when using several MCM10

modules (cascade with more than four heating

appliances): Provide the additional modules with

power via the first MCM10 module (master). This

ensures simultaneous start-up.

3.2.3 Connection of a remote fault indication with

optical and acoustic signal

For example, a fault indicator can be connected to the

zero volt fault contact (Æ Fig. 12, terminal D, page 19).

The state of the fault contact is also indicated via an LED

on the MCM10 (Æ Tab. 9, page 14).

This is a dry contact that carries a maximum current of 2 A

at 120 V AC.

3.2.4 Electrical connection of the outdoor

temperature sensor

In conjunction with heating system controls with 2-wire

BUS control, always connect outdoor temperature sensor

to the MCM10 module (master) (Æ Fig. 12, page 19) and

not to the heating appliance.

3.2.5 Electrical connection of the supply

temperature sensor

For system version 1, the common supply temperature

sensor must be connected to the WM10 (Æ installation

instructions for WM10) and for the system versions 2, 3,

4, and 5, to the MCM10, terminal E (Æ Fig. 12, [18],

page 19).

3.2.6 Electrical connection of the external

switching contact

If an external switching contact must be connected, the

bridge on the plug must be removed first.

3.2.7 Disposal

B Dispose of packaging in an environmentally-

responsible manner.

B When replacing components, dispose of the old parts

in an environmentally-responsible manner.

3.3 Installing other accessories

B Install accessories according to the legal requirements

and the installation instructions supplied with them.

B The BUS subscribers RC35, WM10, and MM10 must

be connected to terminal J (Æ Fig. 12, page 19).

The maximum current drawn by the system

components (pump, etc.) must not exceed

specifications (Æ Tab. 2, page 5).

Situation Operating status contact

Current on, no fault

Current on, fault

No current

Tab. 8 Operating status contact

The remote fault indication is enabled when

the power supply to the MCM10 module is

interrupted (master) (function check).

Page 13

4

Start-up and shut-down

MCM10

13

4 Start-up and shut-down

4.1 Configuration

With this configuration, the control characteristics of the

MCM10 module (master) are adapted to the specific

heating system.

The MCM10 module is configured automatically:

• during the first start-up of a MCM10 module,

• during a restart following a reset of the configuration

(Æ paragrahp 4.3).

Configuration takes at least five minutes. During

configuration, the LEDs associated with the connected

heating appliances and possibly the LED to indicate BUS

communication (Æ Tab. 9) flash. Configuration is

completed and saved to the MCM10 when LEDs stop

flashing.

Any configuration saved remains in the memory, even in

case of power failure.

If, after configuration, a heating appliance (or a MCM10

module) is temporarily shut down during active operation

(e.g. for maintenance), the LED allocated to that

heating appliance or the LED to indicate BUS

communication begins to flash. Following a restart, the

heating appliance (or the MCM10 module) will be

recognized, and the associated LED stops flashing.

4.2 Commissioning

B Ensure the correct connection of all heating system

components.

B Provide the power supply (120 V AC) for all

components of the heating system, except for the

MCM10 modules.

B Start all heating appliances (switch ON).

B Provide the power supply via the power plug of the

(first) MCM10 module. If appropriate, the configuration

will then begin. This will take at least 5 minutes.

B Make the necessary adjustments on the individual BUS

subscribers in accordance with their installation

instructions.

4.3 Configuration reset

Resetting the configuration deletes the system

configuration stored in the MCM10 module. During the

next start, the current system configuration is saved to the

MCM10 module.

B Interrupt the power supply to all MCM10 modules.

B Open the MCM10 module cover (master) (Æ Fig. 6,

page 10).

B Remove jumper (Æ Fig. 3, page 9).

B Ensure the correct connection of all heating system

components.

B Provide the power supply (120 V AC) for all

components of the heating system, except for the

MCM10 modules .

B Start all heating appliances (switch ON).

B Provide the power supply via the power plug of the

(first) MCM10 module.

B Reinstall the jumper (Æ Fig. 3, page 9).

Configuration starts. This will take at least 5 minutes.

B Close the MCM10 module cover (Æ Fig. 6, page 10).

4.4 Shutting down

To take the heating system out of use:

B Interrupt the power supply to all MCM10 modules and

all heating appliances.

Troubleshooting in case of faults becomes

more difficult if the saved configuration does

not match the actual configuration of the

heating system.

B Execute a reset after any intended/

remaining modification of the system

configuration (Æ section 4.3) to save the

new system configuration in the MCM10

module (master).

The cascade configuration is set during startup and after a reset (Æ paragrahp 4.1).

B Monitor the LEDs during configuration to

detect cable breaks or wiring faults.

The heating system configuration is saved in

the MCM10 master. Resetting the MCM10

master deletes the entire configuration

(including from the other MCM10 modules).

CAUTION: Malfunction!

B When using system version 2 or 3, ensure

the correct position when reinstalling the

jumper.

WARNING: System damage due to frost.

B Ensure frost protection if the heating

system is to remain out of use for longer

periods (Æ heating appliance installation

instructions).

Page 14

5

Operating and fault indications

MCM10

14

5 Operating and fault indications

Operating state and faults can be indicated in four

different ways:

• via the heating appliance displays;

• via the remote fault indication;

• via the LEDs on the MCM10 module;

• via the display of the RC35 system controller.

5.1 Operating and fault indications via

the heating appliance displays

The operating and fault indications for each heating

appliance can be checked via the heating appliance

displays. For further details about the operating and fault

indications, see the heating appliance documentation.

5.2 Fault message via the remote fault

indication

For example, a fault indicator can be connected to the

zero volt fault contact (Æ paragrahp 3.2.3, page 12). The

state of the remote fault indication is also shown via an

LED on the MCM10 (Æ Tab. 9, page 14).

5.3 Operating and fault indications via

LED

Generally, three different states in the overall system can

be identified:

• Configuration (during start-up and after a reset);

• standard operation;

• fault.

Depending on the state of the overall system, the LEDs on

the MCM10 module (Æ Fig. 10, page 14) provide

indications about the operating and fault state of

individual components, and thereby enable specific

troubleshooting (Æ Tab. 9, page 14).

Fig. 10 Operating and fault indications via LED

1 Line voltage (green)

2 Heating pump (secondary zone) (green)

3 Switching contact for remote fault indication 120 VAC

(red)

4 Communication between MCM10s (green)

5 Heating appliance 1 (green)

6 Heating appliance 2 (green)

7 Heating appliance 3 (green)

8 Heating appliance 4 (green)

7 746 800 090-10.1O

123

4

5 6 7 8

LED OFF ON Flashing

No. Function Diagnosis Remedy Diagnosis Remedy Diagnosis Remedy

1 Line volt-

age

Fault: No line voltage.

Check power supply.

Replace MCM10

module.

Operation: Standard operation.

–

2 Heating

pump

Operation: Pump

OFF

Operation: Pump

ON.

–

Fault: Pump will not

start although the

LED is ON, as the

fuse for pump output has blown.

Replace fuse

(Æ paragrahp 5.5,

page 17).

Tab. 9 Operating and fault indications on the MCM10 module

Page 15

5

Operating and fault indications

MCM10

15

3 Switching

contact for

remote

fault indication

120 VAC

Operation: Switching contact not activated; not a fault.

– Fault: no heating

appliance attached

to the MCM10 operational.

Remove fault(s) on

the heating appliance(s).

Fault: Switching

contact activated,

but no line voltage.

Check power supply.

Replace MCM10

module.

Fault: Supply temperature sensor

defective.

Check temperature

sensor on the

MCM10 master and

its lead.

Replace the

MCM10 module.

Fault: System pressure too low.

Add water to the

system.

Fault: no communication between the

MCM10 module

and all connected

heating appliances

for at least 1 minute.

Check the corresponding connection cable.

Replace MCM10

module.

4 Communi-

cation

Operation: No

communication

between this

MCM10 module

and the previous

module or the heating controller

(2-wire BUS).

Standard operating

mode with only one

MCM10 module or

with the MCM10

master without

2-wire BUS controller.

Operation:

Communication

between this

MCM10 module

and the previous

module or the heating controller

(2-wire BUS).

– Configuration:

Communication

between this

MCM10 module

and the previous

module or the heating controller

(2-wire BUS).

Wait until the configuration has completed. The LED will

then be illuminated

steadily.

Fault: No communication between this

MCM10 module

and the previous

module or the heating controller

(2-wire BUS).

Check the corresponding connection cable.

Replace the

MCM10 module or

heating controller.

Fault: No communication between this

MCM10 module

and the previous

module or the heating controller

(2-wire BUS),

although these components are

installed.

Check the corresponding connection cable.

Replace the

MCM10 module or

heating controller.

Fault: No communication between this

MCM10 module

and the previous

module or the heating controller

(2-wire BUS)

because these components have been

deliberately

removed

Reset the configuration

(Æ paragrahp 4.3).

LED OFF ON Flashing

No. Function Diagnosis Remedy Diagnosis Remedy Diagnosis Remedy

Tab. 9 Operating and fault indications on the MCM10 module

Page 16

5

Operating and fault indications

MCM10

16

5.4 Operating and fault indications via

the RC35

The operating and fault indications of all heating

appliances and the MCM10 module can be checked on

the heating controller with 2-wire BUS control. The

meaning of the display indications of the MCM10 are

described in table 10. The meaning of the other display

indications are described in the documentation for the

controller and the boiler.

5,

6,

7,

8

Heating

appliance 1

heating

appliance 2

heating

appliance 3

heating

appliance 4

Operation: No heat

demand to the heating appliance; heating appliance

operational

– Operation: Heat

demand to the heating appliance; heating appliance in

operation

– Configuration:

Communication

between this heating appliance and

the MCM10 module.

Wait until the configuration has completed.

Operation: No

heating appliance

connected

– Fault: Heating

appliance fault

Remove fault on the

heating appliance.

Configuration/

Fault: No communi-

cation between the

MCM10 module

and this heating

appliance, although

it is installed.

Check the corresponding connection cable.

Remove fault on the

heating appliance.

Replace MCM10

module.

Fault: No communication between the

MCM10 module

and this heating

appliance because it

has been deliberately removed.

Reset the configuration

(Æ paragrahp 4.3).

Fault: Communication error between

the MCM10 module and heating

appliance.

1)

Check the corresponding connection cable.

Replace MCM10

module.

1) Another heating appliance will be enabled automatically in case of heat demand.

LED OFF ON Flashing

No. Function Diagnosis Remedy Diagnosis Remedy Diagnosis Remedy

Tab. 9 Operating and fault indications on the MCM10 module

Indicator

Description Remedy

5H Break in BUS communication • Display with fewer than 4 heating appliances.

• Check connecting cable between the boiler and the MCM10 module for cable breaks.

• Check whether the cable makes good contact.

• Check whether this fault originates from a boiler (Æboiler installation instructions).

• Replace MCM10 module.

4U

4Y

The contacts for the supply sensor

have been interrupted (4Y) or have

shorted (4U).

• Check supply temperature sensor and connecting lead.

• Replace MCM10 module.

EF Internal electronic fault • If the fault is indicated as being applicable to one of the boilers: Replace the PCB on the relevant

boiler.

• If the fault is not indicated as attributable to one of the boilers: Replace the MCM10 module.

8Y The external switch contact is open. • Check the cable of the external switching contact for cable breaks.

• Check whether the connection plug is present.

• Replace MCM10 module.

AE Jumper configuration error. • Check whether the jumper is attached correctly.

AU The calculated boiler water temper-

ature is not achieved in timely fashion.

• Check whether enough heating appliances are working.

AY An error has occurred on one or

more heating appliances.

• Eliminate the error on the corresponding boiler.

Tab. 10 Operating and fault indications via the RC35

Page 17

5

Operating and fault indications

MCM10

17

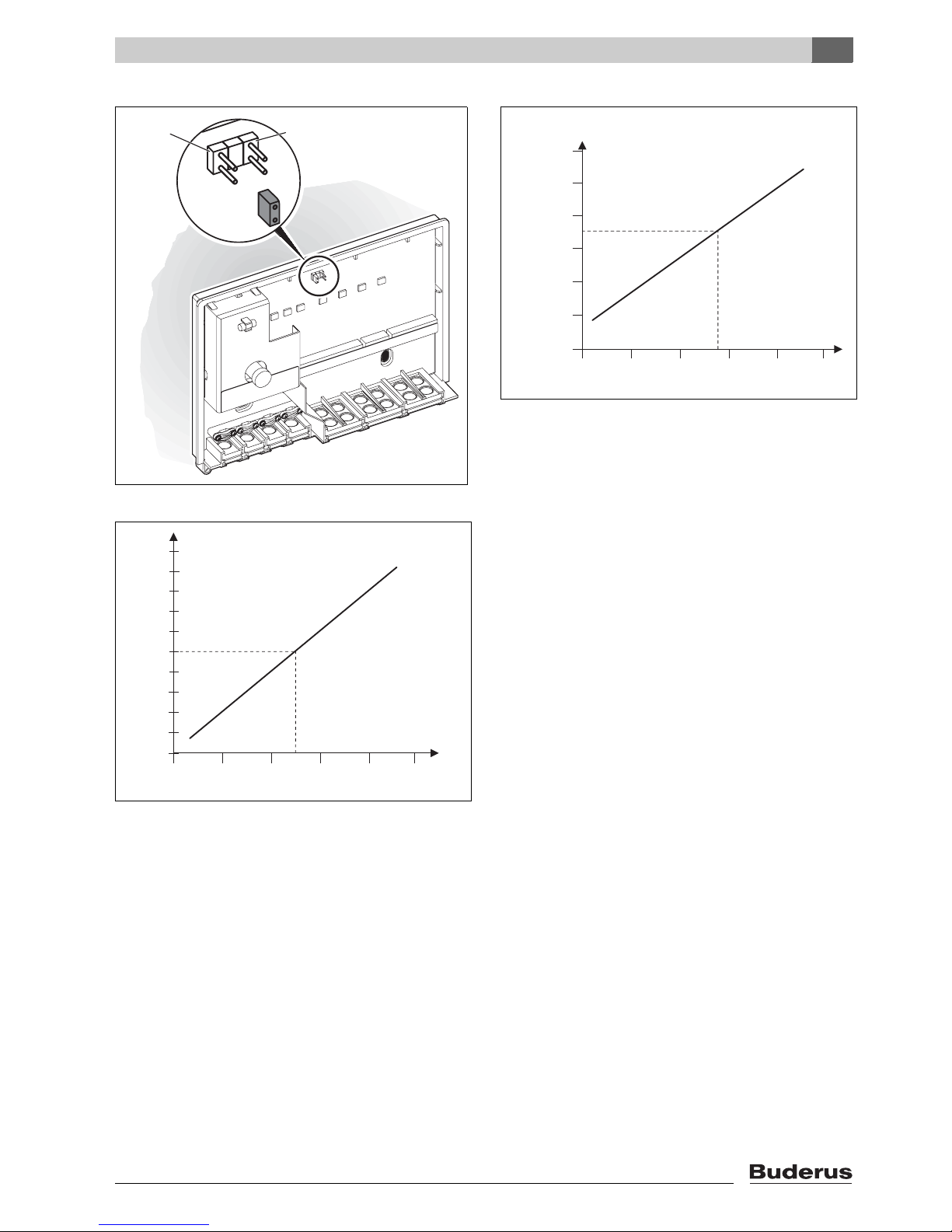

5.5 Replacing the fuse for the heating

zone pump connection

B Interrupt the power supply.

B Open the MCM10 module cover (master) (Æ Fig. 6,

page 6).

B Replace fuse [1] with one of the same type (5 AF,

ceramic, filled with sand). A spare fuse [2] is provided

in the MCM10 module cover.

Fig. 11 Replacing the fuse

B Close the MCM10 module cover (Æ Fig. 6, page 6).

7 746 800 090-11.1O

1

2

Page 18

6

Environmental protection

MCM10

18

6 Environmental protection

Environmental protection is a corporate principle of

Buderus.

We regard quality of performance, economy and

environmental protection as equal objectives.

Environmental protection laws and regulations are

adhered to strictly.

To protect the environment, we use the best possible

technology and materials taking into account economic

points of view.

Packaging

For the packaging, we participate in the country-specific

recycling systems, which guarantee optimal recycling.

All packaging materials used are environmentally-friendly

and recyclable.

Old appliances

Old appliances contain resources that must be submitted

for recycling.

The components are easy to separate and the plastics are

marked. This allows the various components to be sorted

for appropriate recycling or disposal.

Page 19

7

Appendix

MCM10

19

7 Appendix

Fig. 12 Wiring diagram

I MCM10 No. 1 (master)

II MCM10 No. 2 (slave)

III MCM10 No. 3 (slave)

IV MCM10 No. 4 (slave)

1…16 Heating appliance

17 Low loss header

18 Common supply temperature sensor FV

19 Heating pump

20 Fuse for heating zone pump connection

21 Replacement fuse

22 Heating zone

23 Jumper

A Main power connection

B Power supply for additional modules MCM10

C Heating zone pump connection

D Remote fault indication connection

E Supply temperature sensor (FV) [1-2]

1)

F Outdoor temperature sensor (FA)

connection [3-4]

1)

G Connection of external switching contact [5-6]

1)

H ON/OFF contact connection [7-8]

1)

I Building management system (0 - 10 V interface)

connection [9-10]

1)

J Heating controller with 2-wire BUS control connection

[11-12]

1)

K Connection from the previous MCM10 module [13-14]

1)

L Connection to the next MCM10 module [15-16]

1)

M Connection of heating appliances [17-18, 19-20, 21-

22, 23-24]

1)

IV

I

120

VAC

A

D

F

0 ... 10V

H I J

B C

E K L M M

A

K

III

A

K

B

M M M MM M M M

L

II

A

K

B

M M M M

L

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

M

M

19

22

18

17

20

21

23

120

120

5 Amp

G

AF

6 720 617 648 - 06.1o

1) terminals

Page 20

Table des matières

MCM10

20

Table des matières

1 Consignes de sécurité et explication des

symboles 21

1.1 Explication des symboles 21

1.2 Mesures de sécurité 21

2 Caractéristiques du module MCM10 22

2.1 Déclaration de conformité 22

2.2 Informations sur la documentation 22

2.3 Utilisation conforme 22

2.4 Pièces fournies 22

2.5 Accessoires 22

2.6 Caractéristiques techniques 23

2.6.1 Généralités 23

2.6.2 Dimensions 23

2.6.3 Paramètres du raccordement électrique 23

2.6.4 Valeurs mesurées par la sonde de température de départ

23

2.6.5 Valeurs de résistance de la sonde de température

extérieure 23

2.7 Intégration du système de l' MCM10 24

2.7.1 Principe de fonctionnement de la régulation en

cascade 24

2.7.2 Régulation du chauffage sur les systèmes en cascade

MCM10 24

2.7.3 Production d'eau chaude avec les systèmes en cascade

MCM10 24

2.7.4 Fonction antigel intégrée 25

2.7.5 Commande d'un circulateur secondaire 25

2.7.6 Contact de commutation externe 25

2.7.7 Vue d'ensemble des variantes du système 26

2.7.8 Raccordement d'autres modules à un thermostat avec

commande BUS bifilaire 27

3 Installation 28

3.1 Montage 28

3.1.1 Montage au mur 28

3.2 Branchement électrique 30

3.2.1 Raccordement de pièce à basse tension avec connexion

BUS 30

3.2.2 Raccord 120 V CA 30

3.2.3 Raccordement d'un système de signalement à distance

avec alarmes visuelles et acoustiques 31

3.2.4 Raccordement électrique de la sonde de température

extérieure 31

3.2.5 Raccordement électrique de la sonde départ 31

3.2.6 Raccordement électrique du contact de commutation

externe 31

3.2.7 Recyclage 31

3.3 Montage des accessoires 31

4 Mise en service et mise hors service 32

4.1 Configuration 32

4.2 Mise en service 32

4.3 Réinitialisation de la configuration 32

4.4 Mise hors service 33

5 Indication de fonctionnement et de panne 34

5.1 Indication de fonctionnement et de panne via l'écran des

chaudières 34

5.2 Indication des pannes via le système de signalement à

distance 34

5.3 Indication de fonctionnement et de panne via les

LED 34

5.4 Indication de fonctionnement et de panne via le

RC35 36

5.5 Remplacement du fusible pour le raccordement du

circulateur secondaire 38

6 Protection de l’environnement 39

7 Annexes 40

Page 21

1

Explication des symboles et mesures de sécurité

MCM10

21

1 Explication des symboles et mesures de sécurité

1.1 Explication des symboles

Avertissements

Les mots de signalement au début d’un avertissement

caractérisent le type et l’importance des conséquences

éventuelles si les mesures nécessaires pour éviter le danger ne sont pas respectées.

• AVIS signale le risque de dégâts matériels.

• PRUDENCE signale le risque d’accidents corporels

légers à moyens.

• AVERTISSEMENT signale le risque d’accidents cor-

porels graves.

• DANGER signale le risque d’accidents mortels.

Informations importantes

Autres symboles

1.2 Mesures de sécurité

B Respecter ces instructions afin d’assurer un fonction-

nement correct.

B Installer et mettre en service la chaudière et les autres

accessoires conformément aux indications fournies

dans les notices correspondantes.

B Utiliser cet accessoire uniquement en combinaison

avec les thermostats et chaudières indiqués. Respecter le schéma de connexion !

B Cet accessoire nécessite des tensions différentes. Ne

pas raccorder le côté basse tension au réseau 120 V

et inversement.

B En cas de montage mural : ne pas monter l'accessoire

dans une pièce humide.

B Les travaux réalisés sur les composants électriques

doivent être réalisés uniquement par des personnes

disposant d'une formation et des qualifications appropriées.

B Avant de travailler sur l'installation : mettre l'installation

de chauffage hors tension avec l'interrupteur d'arrêt

d'urgence ou le fusible principal.

B Sécuriser contre tout réenclenchement involontaire.

B Éteindre l'unité de contrôle ne suffit pas.

B Toutes les normes et prescriptions légales électriques

correspondantes doivent être respectées.

Dans le texte, les avertissements sont

indiqués et encadrés par un triangle de

signalisation sur fond grisé.

Pour les risques liés au courant électrique, le

point d’exclamation dans le triangle de

signalisation est remplacé par un symbole

d’éclair.

Les informations importantes ne concernant

pas de situations à risques pour l’homme ou

le matériel sont signalées par le symbole cicontre. Elles sont limitées par des lignes

dans la partie inférieure et supérieure du

texte.

Symbole Signification

B Etape à suivre

Æ Renvoi à d’autres passages dans le docu-

ment ou dans d’autres documents

• Enumération/Enregistrement dans la liste

– Enumération/Enregistrement dans la liste

(2e niveau)

Page 22

2

Caractéristiques du module MCM10

MCM10

22

2 Caractéristiques du module MCM10

2.1 Declaration of conformity

2.2 Informations sur la documentation

Sous réserve de modifications techniques !

2.3 Utilisation conforme

Les modules MCM10 sont destinés à réguler les systèmes en cascade. Un système en cascade est un système

de chauffage composé de plusieurs petites chaudières

branchées en parallèle, afin d'obtenir une puissance utile

plus importante (Æ Fig. 24, page 38).

Les modules MCM10 sont conçus exclusivement pour

commander les chaudières équipées d'un système Logamatic EMS compatible BUS.

Sur les chaudières installées au sol, le module MCM10

est uniquement adapté pour la commande de chaudières

gaz à brûleur modulant sans conditions de fonctionnement.

2.4 Pièces fournies

Fig. 13 Pièces fournies

1 MCM10

2 Prise

3 Doigt de gant

4 Sonde départ FV

5 Emballage comprenant :

- 3 vis et 3 chevilles

- 4 bornes serre-câbles et 8 vis

6 Notice de montage et d’utilisation

B Vérifier si le contenu du colisage est complet.

2.5 Accessoires

Vous trouverez ici une liste comprenant les accessoires

typiques. Si vous souhaitez une liste complète de tous les

accessoires disponibles, veuillez vous adresser au fabricant.

• Sonde de température extérieure FA pour le raccordement aux bornes F (uniquement pour la variante de système 1).

• RC35 : régulation à sonde extérieure avec affichagetexte destinée à réguler une installation de chauffage

avec circuits de chauffage mélangés et non mélangés.

• WM10 : module bouteille de mélange pour EMS.

• MM10 : module mélangeur pour EMS.

• AM10 : régulateur de température extérieure avec raccordement de thermostat.

The design and operation of this product

conform to the U.S. and Canadian Directives.

Its conformity is demonstrated by the CSA

designation.

The Declaration of conformity can be

claimed. See the address at the back of this

manual.

Remettre à l'utilisateur tous les documents

ci-joints.

6 720 616 690-02.1TD

1

2

4

3

6

5

Page 23

2

Caractéristiques du module MCM10

MCM10

23

2.6 Caractéristiques techniques

2.6.1 Généralités

2.6.2 Dimensions

Fig. 14 Dimensions

2.6.3 Paramètres du raccordement électrique

2.6.4 Valeurs mesurées par la sonde de tempéra-

ture de départ

2.6.5 Valeurs de résistance de la sonde de tem-

pérature extérieure

Dénomination Unité

Dimensions (Æ Fig. 14)

Poids (sans emballage) lb (kg) 1.76 (0.8)

Tension nominale MCM10 CA … V 120

Fréquence Hz 60

Valeur maxi de la protection par fusible à prévoir sur l'alimentation électrique de l'ICM maître

A10

Consommation interne MCM10 W 5

Tension nominale BUS CC … V 15

Valeur du fusible intégré à l'ICM et

protégeant l'alimentation du circulateur secondaire

A 5 AF, en cérami-

que, avec sable

Plage de mesure sonde de température de départ

° F ( °C) 32 … 212

(0 … 100)

Plage de mesure sonde de température extérieure

° F ( °C) – 40 … 122

( – 40 … 50)

température ambiante admissible

MCM10

° F ( °C) 32 … 122

(0 … 50)

température ambiante admissible

pour la sonde départ

° F ( °C) 32 … 212

(0 … 100)

température ambiante admissible

pour la sonde de température extérieure

° F ( °C) – 58 … 212

( – 50 … 100)

Longueur de câble maximale des

connexions BUS bifilaires

ft (m) (Æ Tabl. 6,

page 29)

Longueur maximale des câbles de la

sonde

ft (m) (Æ Tabl. 7,

page 29)

Antiparasitage (CEM) selon CEI 60730

Classe de protection II après CEI 60730

Définition NEMA Type 2

Tab. 1 Généralités

2-1/2" (62mm)

6 720 616 690-03.1TD

2-1/2" (62mm)

9-1/4" (235mm)

2-1/4" (58mm)

1-1/2" (37mm)

5-9/16" (142mm)

6-1/2" (165mm)

Pos.

1)

1) Æ Fig. 24, page 38

Interface

A Entrée Alimentation électrique du

réseau ou du module MCM10

précédent

120 V CA,

max. 10 A

B Sortie Alimentation électrique pour

d'autres MCM10

120 V CA,

max. 10 A

C Sortie Circulateur 120 V CA,

max. 250 W

D Sortie Signalement des pannes à dis-

tance

sans potentiel,

max. 120 V, 2 A

E Entrée Sonde départ NTC (Æ Tabl. 3)

F Entrée Sonde de température exté-

rieure

NTC (Æ Tabl. 4)

G Entrée Contact de commutation

externe

libre de potentiel

H Entrée Régulation

(chauffage tout-ou-rien)

24 V CC

I Entrée Régulation de chauffage

(Interface proportionnelle)

0-10 V CC

J BUS

bifilaire

pour la régulation de chauffage (RC35, WM10, MM10)

–

K BUS

bifilaire

Du module précédent MCM10 –

L BUS

bifilaire

Vers le bus du module suivant

MCM10

–

M BUS

bifilaire

Vers la chaudière –

Tab. 2 Paramètres du raccordement électrique

°F ( °C) Ω °F ( °C) Ω

68 (20) 12490 140 (60) 2488

77 (25) 10000 149 (65) 2083

86 (30) 8057 158 (70) 1752

95 (35) 6531 167 (75) 1481

104 (40) 5327 176 (80) 1258

113 (45) 4369 185 (85) 1072

122 (50) 3603 194 (90) 917

131 (55) 2986 203 (95) 788

Tab. 3 Valeurs mesurées par la sonde de température

de départ

°F ( °C) Ω °F ( °C) Ω

– 4 ( – 20) 97070 50 (10) 19900

5 ( – 15) 72929 59 (15) 15708

14 ( – 10) 55330 68 (20) 12490

23 ( – 5) 42315 77 (25) 10000

32 (0) 32650 86 (30) 8057

41 (5) 25388 95 (35) 6531

Tab. 4 Valeurs de résistance de la sonde de tempéra-

ture extérieure

Page 24

2

Caractéristiques du module MCM10

MCM10

24

2.7 Intégration du système de l' MCM10

2.7.1 Principe de fonctionnement de la régulation

en cascade

Si le régulateur (Æ Tabl. 5, Variantes de système 1, 2, 3

et 4) détecte la nécessité de chauffer, une chaudière est

d'abord mise en marche. Si nécessaire, la puissance calorifique augmente jusqu'à atteindre la puissance nominale

maxi. Ce n'est qu'alors qu'une autre chaudière est allumée.

Si la chaleur produite est trop élevée, la puissance est instantanément réduite sur une chaudière après l'autre

jusqu'à la puissance minimale puis elles sont arrêtées,

jusqu'à ce que la production de chaleur corresponde au

besoin thermique. Toutes les chaudières sont coupées

simultanément sur la variante du système 4.

L'ordre de commutation des chaudières est automatiquement fixé par le module MCM10. Le module MCM10

assure une répartition uniforme des heures de service du

brûleur entre toutes les chaudières. Pour ce faire, il tient

compte du nombre d'heures de service destinées au

chauffage et de celles destinées à la production d'eau

chaude sanitaire. Ce fonctionnement augmente la durée

de vie des chaudières. En cas de coupure de l'alimentation électrique du module MCM10, le compteur d'heures

de service du module MCM10 est réinitialisé.

Dès qu'une chaudière n'est pas disponible (production

d'eau chaude pour le ballon directement raccordé, dysfonctionnement de la chaudière, dysfonctionnement touchant la communication entre la chaudière et le module

MCM10), une autre chaudière est mise en marche afin de

couvrir les besoins énergétiques.

2.7.2 Régulation du chauffage sur les systèmes

en cascade MCM10

Les modules MCM10 pilotent les chaudières en fonction

des besoins calorifiques calculés par un thermostat. Pour

une régulation en fonction des besoins calorifiques, les

modules MCM10 doivent toujours être installés en association avec un thermostat (Æ Fig. 24, bornes H, I ou J,

page 38). Il existe 4 variantes de système possibles selon

le thermostat utilisé (Æ Tabl. 5).

Un module MCM10 peut commander au maximum 4

chaudières. En raccordant jusqu'à 4 modules MCM10, il

est possible de brancher en cascade 16 chaudières au

maximum (Æ Fig. 24, page 38). Un module MCM10 commande alors la cascade (MCM10 maître).

Selon le thermostat utilisé, un système en cascade composé de 4 ou de 16 chaudières maximum peut être réalisé. Le tableau 5 (Æ page 25) indique le nombre

maximum de chaudières raccordables et le nombre de

modules MCM10 nécessaires pour les différentes variantes de système.

Le module MCM10 régule l'ensemble du circuit de production de chaleur (circuit primaire incluant la bouteille

casse-pression). Tous les autres composants de l'installation de chauffage (côté secondaire de la bouteille cassepression comme p. ex. circuits de chauffage, ballons

d'eau chaude sanitaire) peuvent être pilotés par une régulation à sonde extérieure avec interface de BUS bifilaire et

d'autres modules (WM10, MM10, …). Pour obtenir des

informations complémentaires, veuillez contacter le fabricant. Vous trouverez l'adresse en dernière page.

Il est possible d'utiliser des chaudières de n'importe

quelle puissance dans un branchement en cascade.

2.7.3 Production d'eau chaude avec les systèmes

en cascade MCM10

Le ballon d'eau chaude sanitaire peut être raccordé

hydrauliquement et électriquement directement sur une

des chaudières (modèle avec raccordement ballon).

• La chaudière prend en charge la commande de la pro-

duction d'eau chaude. Durant la période où la production d'eau chaude est activée, cette chaudière n'est

plus commandée par le module MCM10. Une autre

chaudière est mise en marche si nécessaire en cas de

demande énergétique.

2.7.4 Fonction antigel intégrée

Le module MCM10 est équipé d'une fonction antigel

intégrée : si la température de départ descend en dessous de 45 °F (7 °C), une chaudière est mise en marche

et fonctionne aussi longtemps que nécessaire pour atteindre une température de départ de 60 °F (15 °C). Le circulateur secondaire éventuellement raccordé au module

MCM10 fonctionne également (Æ Chapitre 2.7.5).

B Raccorder la sonde départ au module maître MCM10,

lorsque la fonction antigel intégrée doit être utilisée.

Noter que pour permettre un fonctionnement

correct de l'installation, seul un thermostat/

système de Gestion Technique de Bâtiment

doit être raccordé.

Les différentes variantes exigent le

raccordement de certains accessoires

(sonde départ, sonde de température

extérieure, pompe de chauffage et régulation

de chauffage) (Æ Tabl. 5, page 25).

Si l'utilisateur veut faire chauffer de l'eau

sanitaire via la vanne à 3 voies de la

chaudière et continuer à alimenter les circuits

de chauffage, il doit arrêter la priorité ECS

sur le RC35 dans tous les circuits de

chauffage puisque celle-ci reste active selon

le réglage d'usine.

Page 25

2

Caractéristiques du module MCM10

MCM10

25

2.7.5 Commande d'un circulateur secondaire

Sur les installations ne disposant que d'un circuit de

chauffage, le circulateur secondaire peut être raccordé

directement au module maître MCM10.

La pompe de chauffage fonctionne :

• tant que le circulateur d'au moins une chaudière est en

fonctionnement (le cas échéant, régler de manière

appropriée la temporisation du circulateur sur la chaudière (Æ Notice d'installation de la chaudière) ou

• succinctement après 24 heures d'arrêt du circulateur

(dispositif antiblocage).

2.7.6 Contact de commutation externe

Le module MCM10 est équipé d'un contact de commutation externe (Æ Fig. 24, [G]). Pour les valeurs de référence de l'interrupteur (Æ Tabl. 2, page 23).

Ce contact de commutation externe peut être appliqué en

option, p. ex. pour le raccordement d'un contrôleur de

température pour la protection du chauffage au sol contre

la surchauffe de l'eau.

Si le contact de commutation est ouvert, tous les appareils de chauffage sont arrêtés par le module MCM10.

Dès que le contact de commutation est fermé, les appareils de chauffage sont à nouveau prêts à fonctionner.

2.7.7 Vue d'ensemble des variantes du système

En tant que fabricant des techniques de chauffage les

plus modernes nous accordons une importance capitale

au développement et à la fabrication de chaudières économiques et non polluantes. Afin de garantir ces qualités,

nos chaudières sont équipées d'un brûleur à action pro-

portionnelle. Pour assurer une utilisation optimale des

propriétés du brûleur, des thermostats à liaison BUS bifilaire doivent être utilisés.

La fonction antigel d'un thermostat avec

interface de BUS bifilaire garantit une

protection complète de votre installation

contre le gel. Le raccordement d'une sonde

de température extérieure est nécessaire à

cet effet.

Le dispositif antiblocage fait fonctionner le

circulateur secondaire une fois par jour

même lorsqu'il n'est pas nécessaire de

chauffer (p. ex. en été).

B Afin que le circulateur ne se bloque pas

(en été), maintenir l'installation de

chauffage allumée tout au long de

l'année !

Variante du système

Symbole pour

leraccordement

du thermostat

Thermostat du module maître

MCM10

Modèle

Nombre maxi. MCM10

nombre de chaudières

maxi.avec système Logamatic

EMS compatible BUS

Accessoire nécessaire avec raccordement au MCM10

(Æ Fig. 24, page 38)

1 Régulation à sonde extérieure avec

liaison BUS bifilaire

RC35 4 16 • Sonde de température extérieure.

• Un module WM10 Le module WM10 est livré avec des

sondes départ (voir explication sur la page suivante).

• La pompe de chauffage (circulateur secondaire) est raccordée au module WM10.

2 Régulation à sonde extérieure avec

liaison BUS bifilaire

Régulateur à

sonde extérieure AM10

en fonction

des conditions atmosphériques

4 16 • Raccorder la sonde de température extérieure au AM10.

• Sonde de température de départ commune sur les bornes

E (uniquement pour la fonction antigel intégrée)

• Circulateur secondaire (Æ Fig. 24, [19]) sur les bornes C,

uniquement pour un ou plusieurs circuits de chauffage sans

circulateur secondaire ou pour des circuits de chauffage ne

communiquant pas avec le module MCM10 via des modules BUS.

Tab. 5 Vue d'ensemble des variantes du système

Page 26

2

Caractéristiques du module MCM10

MCM10

26

Variante du système 1 : Régulation à action proportionnelle à sonde extérieure (RC35)

Cette variante présente un avantage : la possibilité de

communication des modules pour la commande des circuits de chauffage (module de fonction WM10 et MM10)

avec le module MCM10 via le BUS commun parallèle au

raccordement J sur le module MCM10 (Æ Fig. 24,

page 38). Ce système garantit l'adaptation optimale de la

quantité de chaleur produite par tous les circuits de l'installation de chauffage aux besoins réels. Grâce à cette

variante du système, l'installation de chauffage assure un

confort optimal pour une économie d'énergie maximale.

Variante du système 2 : Régulation à action proportionnelle à sonde extérieure (AM10)

La température de consigne de départ du module AM10

dépend de la température extérieure. À l'inverse de la

variante du système 1, il est impossible d'utiliser les

modules WM10 et MM10.

Variante du système 3 : Régulateur à action proportionnelle 0-10 V, modulation via la puissance

Associée à un système de Gestion Technique de Bâtiment avec une interface 0-10V, la puissance totale de la

cascade peut être définie comme valeur de référence. Le

réglage s'effectue via un cavalier enfichable (Æ Fig. 15).

Fig. 15 Réglage via le cavalier enfichable

3 Régulateur à action proportionnelle

0-10 Vp. ex. système de Gestion

Technique de Bâtiment ; modulation

de puissance

indifférent 4 16 • Sonde de température de départ commune sur les bornes

E (uniquement pour la fonction antigel intégrée)

• Circulateur secondaire (Æ Fig. 24, [19]) sur les bornes C,

uniquement pour un ou plusieurs circuits de chauffage sans

circulateur secondaire ou pour des circuits de chauffage

qui ne sont pas pilotés par le système de Gestion Technique de Bâtiment.

4 Régulateur à action proportionnelle

0-10 V p. ex. système de Gestion

Technique de Bâtiment ; modulation

de la température de départ

indifférent 4 16 • Sonde départ commune aux bornes E.

• Circulateur secondaire (Æ Fig. 24, [19]) sur les bornes C,

uniquement pour un ou plusieurs circuits de chauffage sans

circulateur secondaire ou pour des circuits de chauffage

qui ne sont pas pilotés par le système de Gestion Technique de Bâtiment.

5 Régulation tout-ou-rien (sans poten-

tiel)

indifférent 4 16 • Sonde départ commune sur les bornes E (uniquement pour

la fonction antigel intégrée).

• Circulateur secondaire (Æ Fig. 24, [19]) sur les bornes C.

Variante du système

Symbole pour

leraccordement

du thermostat

Thermostat du module maître

MCM10

Modèle

Nombre maxi. MCM10

nombre de chaudières

maxi.avec système Logamatic

EMS compatible BUS

Accessoire nécessaire avec raccordement au MCM10

(Æ Fig. 24, page 38)

Tab. 5 Vue d'ensemble des variantes du système

0 ... 10V

0 ... 10V

6 720 617 648-001.1TD

VT [˚F]

P [%]

Page 27

2

Caractéristiques du module MCM10

MCM10

27

Fig. 16 Rapport entre la tension d'entrée et la puissance

calorifique

U Tension d'entrée

P Puissance instantanée en % de la puissance nominale

totale de la cascade

Variante du système 4 : Régulateur à action proportionnelle 0-10 V, modulation via la température

de départ

Associée à un système de Gestion Technique de Bâtiment avec une interface 0-10V, la température de départ

peut être définie comme valeur de référence. Le réglage

s'effectue via un cavalier enfichable (Æ Fig. 15).

Fig. 17 Rapport entre la tension d'entrée et la tempéra-

ture de départ

U Tension d'entrée

VT Température de départ

Variante du système 5 : Régulation du chauffage

tout-ou-rien

Associé à une régulation tout-ou-rien, le module MCM10

régule la puissance de la cascade après fermeture du

contact de façon continue jusqu'à atteindre la puissance

maximale, en mettant en marche les appareils l'un après

l'autre. Toutes les chaudières sont coupées en même

temps à l'ouverture du contact.

Le contact tout-ou-rien de la régulation doit être sans

potentiel.

2.7.8 Raccordement d'autres modules à un thermostat avec commande BUS bifilaire

Les autres modules éventuels comme les modules

WM10 et MM10 (Æ Fig. 24, [21], page 38) doivent être

raccordés au BUS du thermostat (parallèle au raccordement J sur le module MCM10).

0246810

6 720 617 648-09.1TD

0

30

50

70

90

U [V DC]

P [%]

194 (90)

167 (75)

140 (60)

113 (45)

86 (30)

59 (15)

0

0246810

6 720 617 648-10.1TD

U [V DC]

[˚F (˚C)] VT

Page 28

3

Installation

MCM10

28

3 Installation

3.1 Montage

3.1.1 Montage au mur

B Choisir le lieu de fixation au mur en fonction des dimen-

sions du module MCM10.

B Déterminez si les cordons secteurs sont posés dans

des canaux rigides ou souples, qui requièrent une boîte

de dérivation pour canal ainsi qu'un espace libre supplémentaire correspondant sous le MCM10.

B Desserrer les 2 vis situées en bas du module MCM10,

tirer le couvercle simultanément vers le bas et l'avant et

le retirer par le haut (Æ Fig. 18).

Fig. 18 Retirer le couvercle

B Pour la vis de fixation supérieure, percer un trou d'un

Ø ¼" de 6 mm, insérer la cheville et enfoncer la vis de

0.05" (1,5 mm) (Æ Fig. 19).

Fig. 19 Vis de fixation supérieure

B Libérer deux ouvertures au dos du module MCM10 à

l'emplacement prévu à cet effet pour les vis de fixation

inférieures.

B Accrocher le module MCM10 à la vis de fixation supé-

rieure.

B Tracer les trous sur le mur à travers les ouvertures.

B Retirer le module MCM10.

B Percer des trous d'un Ø ¼" de 6 mm et insérer les che-

villes (Æ Fig. 20).

Fig. 20 Insérer les chevilles

DANGER : Risque d’électrocution !

B Avant d'effectuer le raccordement

électrique, couper l'alimentation des

chaudières et de tous les autres

composants reliés au BUS.

7 746 800 090-03.1O

1/4"

3,5 mm

0.05" (1,5mm)

6 720 617 648-02.1O

3.

4.

4.

2.

1.

1/4"

1/4"

3,5 mm

6 720 617 648-03.1O

1/4"

1/4"

Page 29

3

Installation

MCM10

29

B Accrocher le module MCM10 à la vis de fixation supé-

rieure et le fixer au mur à l'aide des vis de fixation inférieures.

B Lors de la pose des canaux rigides ou souples :

– retirer toutes les raccords tuyaux souples en plas-

tique des canaux sur la partie inférieure du

MCM10 ;

– glisser le raccordement du canal à l'emplacement

prévu à cet effet

– défoncer avec précaution le nombre nécessaire

d'entrées de câbles en tapant avec le manche

d'un tournevis ;

– monter le canal selon les instructions du fabri-

cant.

Remarque : les raccords tuyaux souples en plastique ne

sont pas nécessaires pour utiliser les canaux.

3.2 Branchement électrique

B Tenir compte des prescriptions en vigueur pour le rac-

cordement et utiliser des câbles électriques au minimum du modèle AWG14 pour le cordon secteur.

B Passer impérativement les câbles dans les raccords

tuyaux souples prémontés ou dans la boîte de dérivation pour canal fournie, afin de les protéger contre les

gouttes d'eau, et de monter les décharges de traction

comprises dans le colisage.

B Effectuer le câblage de préférence au moyen d'un

câble monoconducteur. Si vous utilisez du fil torsadé

(souple), placer des embouts sur les fils.

B Pour faciliter le raccordement des câbles aux bornes à

vis, celles-ci peuvent être détachées de la réglette enfichable. Un codage mécanique et de couleur empêche

toute inversion des bornes de câbles.

3.2.1 Raccordement de pièce à basse tension

avec connexion BUS

La section de câble minimale admissible de la liaison du

BUS bifilaire résulte de la longueur du câble :

B Pour éviter toute influence inductive : poser séparé-

ment tous les câbles basse tension et les câbles conducteurs 120 V (distance minimale 100 mm).

B En cas d'effets inductifs externes, utiliser des câbles

blindés.

Les câbles sont ainsi protégés contre des influences

inductives extérieures (p. ex. câbles à courant fort, conducteurs aériens, postes de transformation, postes de

radio ou de télévision, stations radioamateurs, microondes, ou autres).

B Pour rallonger les câbles des sondes, utiliser les sec-

tions suivantes :

B Protection contre les projections : disposer les câbles

de façon à ce que la gaine de câble pénètre d'au moins

20 mm dans le passage de câble (Æ Fig. 21) ou la

boîte de dérivation pour canal.

Fig. 21 Protection contre les projections d'eau

3.2.2 Raccord 120 V CA

PRUDENCE : Dysfonctionnement !

B Respecter impérativement les schémas

de connexion lors du câblage (Æ Fig. 24,

page 38).

B Ne pas raccorder les bus entre eux.

Longueur de câble Section minimale

< 325 ft (100 m) AWG 20

325-650 ft (100-200 m) AWG 18

Tab. 6 Section minimale admissible de la liaison du

BUS bifilaire

Longueur de câble Section minimale

< 65 ft (20 m) AWG 20

65-100 ft (20-30 m) AWG 18

Tab. 7 Prolongement des câbles de la sonde

PRUDENCE : Risque d'inversion de polarité

Dysfonctionnement dû à une inversion de

polarité lors du raccordement à l'interface

0-10 V.

B Respecter les polarités lors du

raccordement (9 = moins, 10 = plus).

PRUDENCE : L'entrée des modules

MCM10 n'est pas équipée de fusible.

Les modules MCM10 peuvent être

endommagés en cas de surcharge au niveau

des sorties.

B Protéger l'alimentation électrique du

module maître MCM10 par des fusibles

de 10 A maxi.

6 720 617 648 - 04.1O

≥1" (25 mm)

Page 30

3

Installation

MCM10

30

B Utiliser uniquement des câbles électriques de qualité

identique.

B Ne pas brancher de commandes supplémentaires pilo-

tant d'autres parties de l'installation sur les sorties C

(circulateur) et D (signal de pannes).

B Conseil pour l'utilisation de plusieurs modules MCM10

(cascade de plus de quatre chaudières) : établir l'alimentation électrique des autres modules MCM10 via

le premier module maître MCM10. Cela permet d'assurer une mise en service simultanée.

3.2.3 Raccordement d'un système de signalement à distance avec alarmes visuelles et

acoustiques

Un témoin lumineux de panne peut p. ex. être branché sur

un contact de dysfonctionnement libre de potentiel

(Æ Fig. 24, Bornes D, page 38). L'état du contact de dysfonctionnement est également indiqué via une LED sur le