Page 1

For contractors

Please read carefully before

use.

Installation and service

instructions

Fan-assisted

low temperature/

condensing boiler

6 720 615 876-00.1RS

Logano G225/Logano plus

GB225 with BE burner

6 720 616 282 - 02/2008 EN

Page 2

Contents

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

2

Contents

1 General safety instructions and

explanation of symbols 4

1.1 Safety instructions 4

1.2 Explanation of symbols 5

2 Product details 6

2.1 EU Declaration of Conformity 6

2.2 Intended use 6

2.3 Standards, regulations and directives 6

2.4 Notes on installation and operation 6

2.5 Heating system water quality 6

2.6 Tools, materials and equipment 6

2.7 Disposal 7

2.8 Product description 8

2.9 Contents 9

2.10 Dimensions and specifications 10

2.10.1 Logano G225 BE dimensions 10

2.10.2 Boiler room and ambient conditions 11

2.10.3 Conditions for combustion air supply 12

2.10.4 Conditions for fuel 12

2.10.5 Conditions for the power supply 13

2.10.6 Conditions for the system configuration and

water quality 13

3 Transporting the boiler 14

4 Boiler positioning 15

5 Boiler block assembly 16

5.1 Assembly when delivered in sections 16

5.1.1 Preparation of boiler sections 16

5.1.2 Driving nipples home 17

5.1.3 Preparing the centre section 18

5.1.4 Inserting the packing cord 18

5.1.5 Knocking the centre section into place 19

5.1.6 Boiler section alignment 19

5.1.7 Joining the boiler sections at the upper

and lower boiler hubs with nipples 20

5.1.8 Fitting the anchor rods 22

5.1.9 Installation of the feed pipe and connection

profile 23

5.1.10 Fitting the temperature sensor 25

5.1.11 Fitting the flue outlet 26

5.1.12 Closing the boiler hubs 26

5.2 Checking for leaks 27

5.2.1 Preparing for a leak test 27

5.2.2 Carrying out the leak test 27

5.3 Installation of pre-assembled boiler heat

exchanger 28

5.4 Assembly steps for boilers supplied in

sections and as ready assembled block 28

5.4.1 Fitting the adjustable feet 28

5.4.2 Inserting the hot gas baffle plates 28

5.4.3 Installing the burner door 29

5.4.4 Installing the boiler casing 30

5.5 Positioning and levelling the boiler 37

6 Installing the boiler 38

6.1 Installing the flue pipe 38

6.1.1 Flue pipe sealing collar for negative pressure

flue (pressure at boiler outlet < 0 mbar) 38

6.1.2 Flue pipe sealing collar for positive pressure

flue (pressure at boiler outlet > 0 mbar) 39

6.2 Fitting the water connections 39

6.2.1 Connecting the central heating flow

and return 39

6.2.2 Connecting the safety flow and return 40

6.2.3 Connecting the DHW cylinder 40

6.2.4 Fitting the boiler fill & drain valve

(not supplied) 40

6.3 Filling the heating system and checking

for leaks 41

6.4 Connecting the fuel supply 42

6.5 Electricity connection 42

6.5.1 Fitting the control unit 42

6.5.2 Connecting the mains power supply and other

components 43

6.5.3 Fitting a strain relief 43

6.6 Installing casing parts 44

7 Commissioning the heating system 45

7.1 Bringing the system up to operating pressure 45

7.2 Preparing the heating system for operation 46

7.3 Switching on the heating system 46

7.4 Starting the burner 46

7.5 Raising the flue gas temperature 47

7.5.1 Removing hot gas baffle plates 47

7.5.2 Removing the hot gas check plate 47

7.6 Installing the burner hood 48

7.7 Setting the room controller/control unit 48

7.8 Commissioning report 49

8 Shutting down the heating system 50

8.1 Normal shutdown 50

8.2 Shutting down the heating system

in emergencies 50

8.2.1 What to do in an emergency 50

9 Heating system servicing 51

9.1 Why is regular servicing important? 51

9.2 Preparing the boiler for servicing 51

Page 3

Contents

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

3

9.3 Cleaning the boiler 52

9.3.1 Cleaning the boiler with cleaning brushes 52

9.3.2 Wet cleaning (chemical cleaning) 53

9.4 Checking the heating system operating

pressure 54

9.5 Servicing and maintenance reports 55

10 Troubleshooting 58

Index 59

Page 4

1

General safety instructions and explanation of symbols

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

4

1 General safety instructions and explanation of symbols

1.1 Safety instructions

If you smell flue gas

V Switch off the heating system (Æ page 50).

V Open windows and doors.

V Inform an authorised contractor.

Risk of poisoning. An insufficient supply of air can

result in dangerous escape of flue gas.

V Ensure that air inlet or outlet vents are not closed off or

their size is reduced.

V Ensure that no mechanical air extraction equipment

draws combustion air from the boiler room, e.g. cooker

extractor hoods, tumble dryers, ventilation equipment.

V Only operate the boiler with chimneys that provide the

required draught during operation.

V The boiler must not be operated until any deficiency

has been rectified.

V Inform the system operator in writing of the problem

and associated danger.

Danger from escaping flue gases

V Ensure that the flue pipes and seals are not damaged.

V Use silicon as sealing compound.

Dangers posed by explosive and easily

combustible materials

V Never use or store combustible materials (paper, lace

curtains, clothing, thinners, paints, etc.) in the vicinity of

the boiler.

Combustion air

V Keep the combustion air free of corrosive substances

(e.g. halogenated hydrocarbons that contain chlorine

or fluorine compounds). In that way you will prevent

corrosion.

Risk of electric shock when the boiler is open

V Before opening the boiler:

Disconnect the heating system from the power supply

by means of the emergency stop switch or the relevant

circuit breaker in the main fuse board.

V It is not sufficient just to switch off the control unit.

V Safeguard the heating system to prevent unintentional

re-connection.

Danger due to short-circuits

To prevent short circuits:

V Only use genuine Buderus wiring.

Installation and conversion

V Correct and proper installation and adjustment of the

burner and the control unit are the fundamental

requirements for safe and economical operation of the

boiler.

V The boiler may only be installed or converted by an

approved heating contractor.

V Never modify any parts that carry flue gas.

V Only qualified electricians are permitted to carry out

electrical work. Installation regulations must be

complied with.

V With open flue appliances: do not cover or reduce

the size of air vents in doors, windows or walls. If

draught-proof windows are fitted, ensure there is an

adequate supply of combustion air to the room.

V The DHW cylinder may only be used for storing

domestic hot water.

Inspection/maintenance

Heating systems must be regularly maintained.

In that way, you will obtain a high level of efficiency and

low fuel consumption.

You will achieve a high level of operational safety and

reliability.

And you will obtain the cleanest possible combustion.

V Recommendation for users: take out a maintenance

and service contract with an approved heating

contractor covering annual servicing and demanddependent maintenance.

V Servicing and repairs may only be carried out by a

approved heating contractor.

V Have any faults immediately rectified to prevent

damage to the system.

V The operator is responsible for the general and

environmental safety of the heating system.

V Use only genuine spare parts. Damage caused by the

use of parts not supplied by Buderus is not covered by

the Buderus warranty.

Instructing the customer

V Explain to the customer how the boiler works and how

to operate it.

V Inform the customer not to carry out any alterations or

repairs.

Page 5

1

General safety instructions and explanation of symbols

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

5

1.2 Explanation of symbols

The terms indicate the seriousness of the ensuing risk if

measures for minimising losses are not taken.

– Caution means that minor material losses may occur.

– Warning means that minor injury or severe material

losses may occur.

– Danger means that severe injury may occur. Very

serious cases may result in death.

Notes contain important information for situations in

which there is no risk to the user or the appliance.

Cross-references to particular places in the document or

to other documents are marked with an arrow Æ.

Warnings are indicated by a warning

triangle and a grey background.

Notes are identified in the text by this

symbol. They are bounded by horizontal lines

above and below the text.

Page 6

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

6

2 Product details

These installation and servicing instructions contain

important information regarding the safe and proper

installation, commissioning and servicing of the boiler.

Product designation:

Logano G225 = fan-assisted, low temperature boiler

Logano plus GB225 = fan-assisted, low temperature

condensing boiler (complete system consisting of Logano

G225 with fitted oil condensing heat exchanger)

The Logano G225 fan-assisted, low temperature boiler

and the Logano plus GB225 fan-assisted, low

temperature condensing boiler are generally referred to in

the remainder of this document simply as the boiler.

These installation and servicing instructions are intended

for qualified heating contractors, who – as a result of their

technical training and experience – are skilled in dealing

with heating systems and oil installations.

2.1 EU Declaration of Conformity

The design and operation of this product conforms to

European Directives and the supplementary national

requirements. Its conformity is demonstrated by the

CE designation. You can view the Declaration of

Conformity on the Internet at www.buderus.de/konfo

or request a copy from your local Buderus office.

2.2 Intended use

The boiler is designed for heating central heating system

water and indirect heating of domestic hot water (e.g. in a

DHW cylinder) in detached houses or apartment

buildings.

Please note the details on the rating plate and the

specifications (Æ Chapter 2.10, page 10) to ensure the

correct use of this appliance.

2.3 Standards, regulations and

directives

2.4 Notes on installation and operation

When installing and operating the heating system

observe the following:

– Local building regulations regarding the installation

conditions

– Local building regulations regarding air supply and

venting systems and the chimney flue connection

– Regulations governing electrical connection to the

mains power supply

– Regulations and standards relating to the safety

systems for the central heating system

– Remember that regional approvals may be required for

the flue system and connecting the condensate outlet

to the public sewer system.

2.5 Heating system water quality

As pure water cannot be used for heat transfer, water

quality is important. Poor water quality can damage

heating systems due to scale formation and corrosion.

2.6 Tools, materials and equipment

For the installation and maintenance of the boiler, you will

need the standard tools used for central heating, gas and

water systems plus set of a metric open-ended spanners

and Allen keys.

The following may also prove useful:

– Sack truck with securing strap or Buderus boiler trolley

–Timber supports

– Cleaning brushes and/or chemical cleaning agent for

wet cleaning

The operations to be carried out for assembly

and installation are identical for the Logano

G225 and the Logano plus GB225 and are

described in these instructions for the

Logano G225.

The differing dimensions, technical

specifications and wall clearances, and the

additional operations for commissioning,

maintenance and servicing of the Logano

plus GB225 can be found in the enclosed

supplement.

Observe all standards and guidelines

applicable to the installation and operation of

this heating system in the country in which it

is used.

Caution: Risk of system damage due to

unsuitable heating system water.

V If oxygen-permeable pipes are used, e.g.

for underfloor heating systems, the

systems must be separated from one

another by heat exchangers. Unsuitable

heating system water promotes sludge

and corrosion formation. That may result in

heat exchanger malfunction and damage.

Page 7

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

7

If the boiler is delivered in sections, you will also require

the following:

– Size 1.2 compression tool (compression tool docu-

mentation)

– Flat board

– White spirit

– Installation kit (accessory)

– Steel hammer and wooden or rubber mallet

– Half-round bastard file

– Screwdriver (Philips and flat head)

– Flat chisel

– Spanners, sizes 13 mm, 19 mm, 24 mm and 36 mm,

and socket size 19 mm

– Support wedge, flat iron

– Cleaning rags and cloth

– Fine emery cloth

– Wire brush

– Lubricating oil

– Spirit level, ruler, chalk, straight edge

– Blanking flange with vent facility (for pressure test)

2.7 Disposal

V Dispose of boiler packaging in an environmentally

responsible manner.

V All heating system components that have to be

replaced should be disposed of in an environmentally

responsible manner at an authorised disposal site.

Page 8

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

8

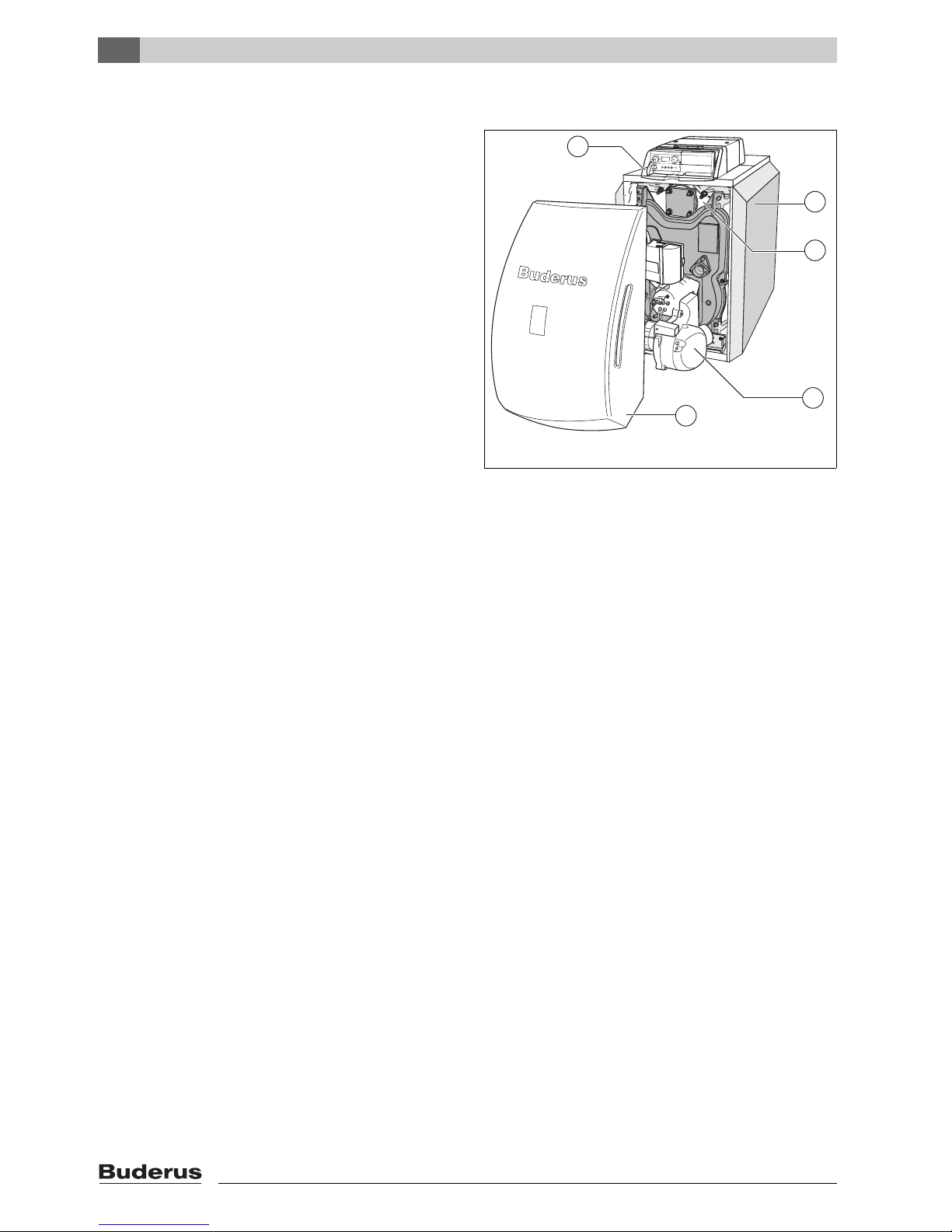

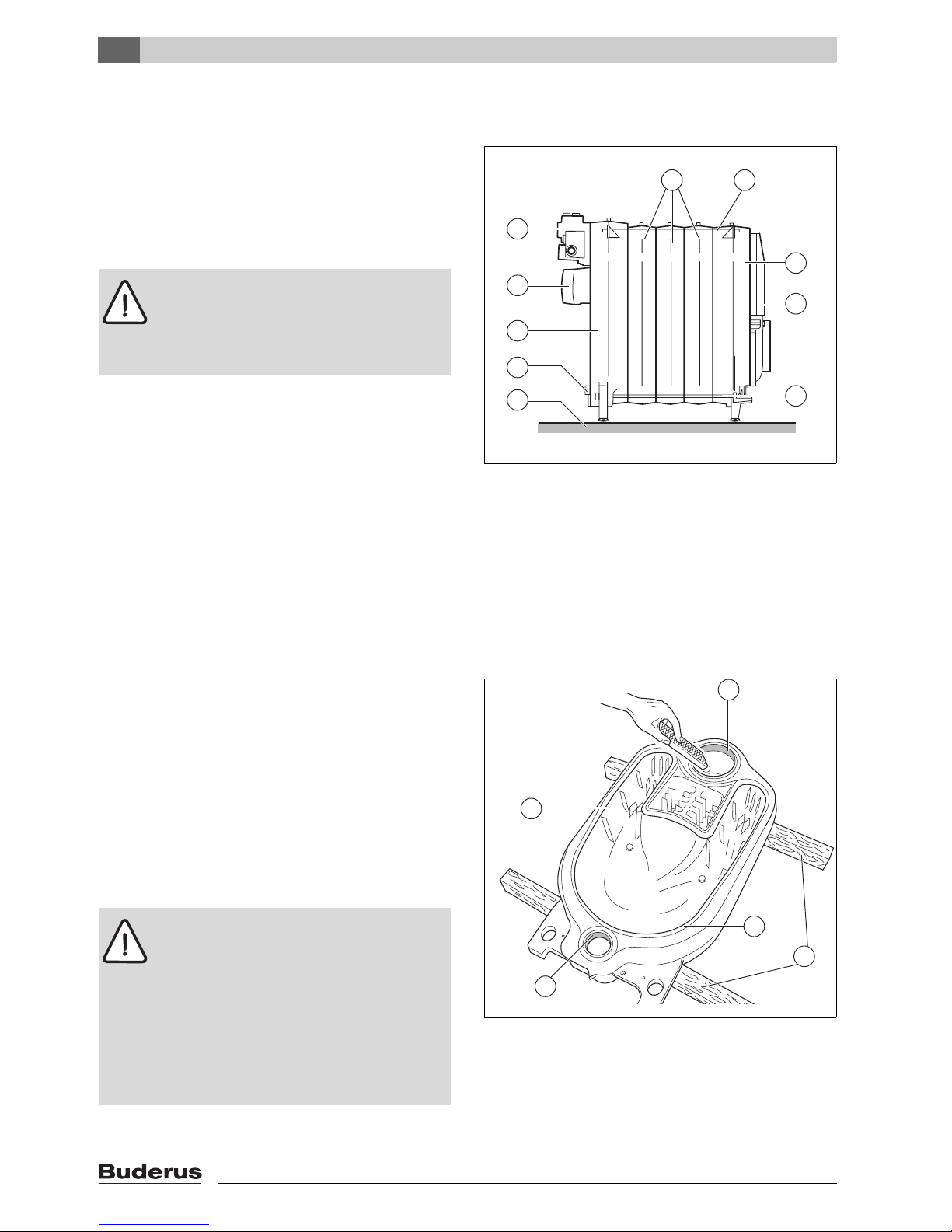

2.8 Product description

The G225 boiler is a fan-assisted, low temperature boiler

and the GB225 boiler is fan-assisted, low temperature

condensing boiler; both of them feature modulating

control of boiler-water temperature.

The boiler comprises:

– Control unit [1]

– Boiler casing [2]

– Boiler heat exchanger and insulation [3]

– Burner [4]

– Heat exchanger system (GB225 only)

The control unit [1] monitors and regulates all electrical

boiler components.

The boiler outer casing [2] prevents heat loss and acts as

a noise insulator.

The boiler heat exchanger [3] transfers the heat

generated by the burner to the heating water.

The insulation [3] prevents radiation losses.

Fig. 1 G225/GB225 boiler

1 Control unit

2 Boiler casing

3 Boiler heat exchanger and insulation

4 Burner

5 Burner hood

6 720 615 876-01.1RS

1

2

3

4

5

Page 9

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

9

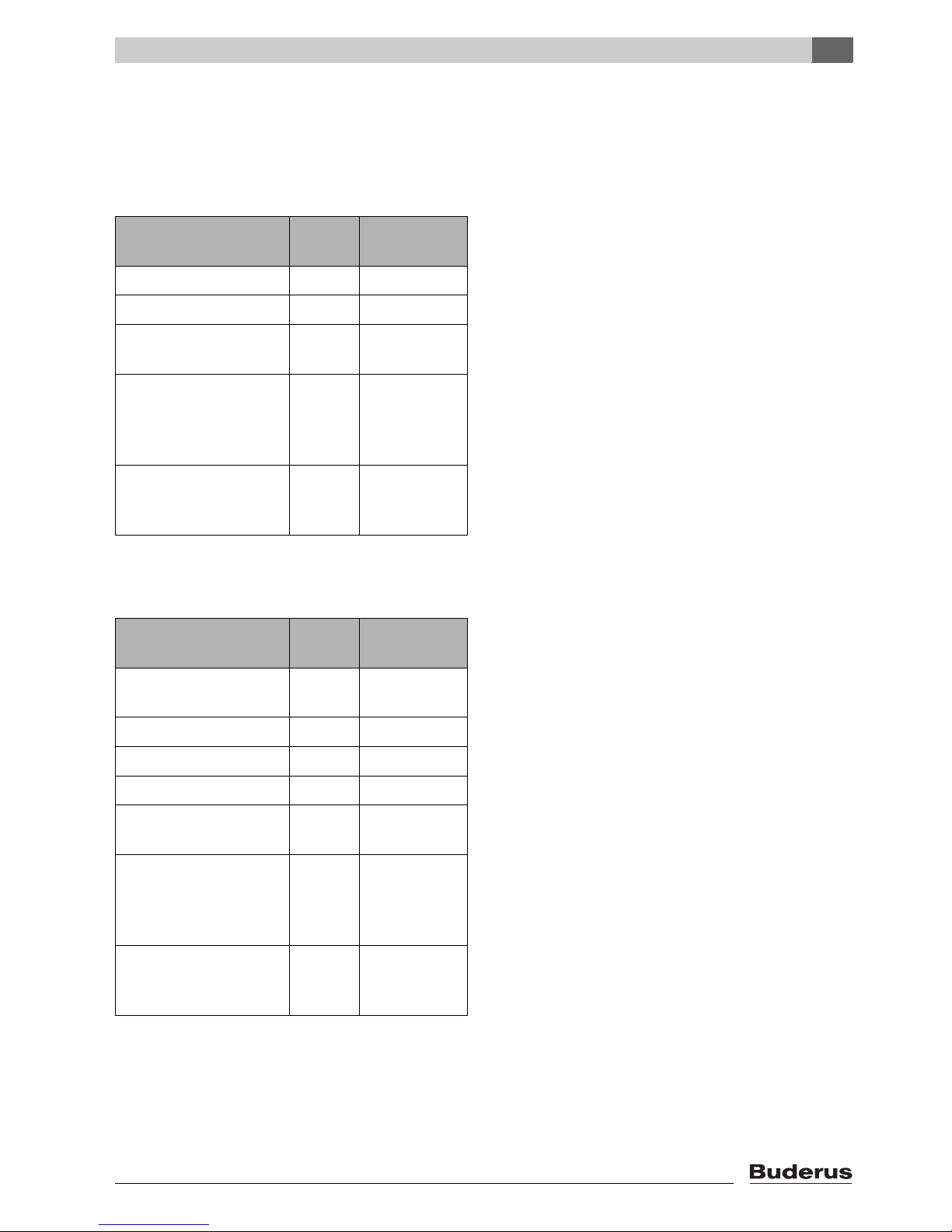

2.9 Contents

V Upon delivery, check that the packaging is

undamaged.

V Check that all components have been delivered.

Boiler as assembled block

Boiler supplied in sections

Component

Quantity

Packaging

Boiler block 1 1 pallet

Boiler casing 1 1 box

Thermal insulation 1 1 shrink-

wrapped pack

Burner, burner hood,

burner door and fixings

1)

,

technical documentation

for burner and boiler.

1) The adjustable feet are packed with the burner hood

11 box

Control unit, technical

documentation for

controller

11 box

Tab. 1 Contents

Component

Quantity

Packaging

Front and rear boiler sections

11 pallet

Centre sections loose

Furniture 1 1 box

Boiler casing 1 1 box

Thermal insulation 1 1 shrink-

wrapped pack

Burner, burner hood,

burner door and fixings

1)

,

technical documentation

for burner and boiler.

1) The adjustable feet are packed with the burner hood

11 box

Control unit, technical

documentation for

controller

11 box

Tab. 2 Contents

Page 10

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

10

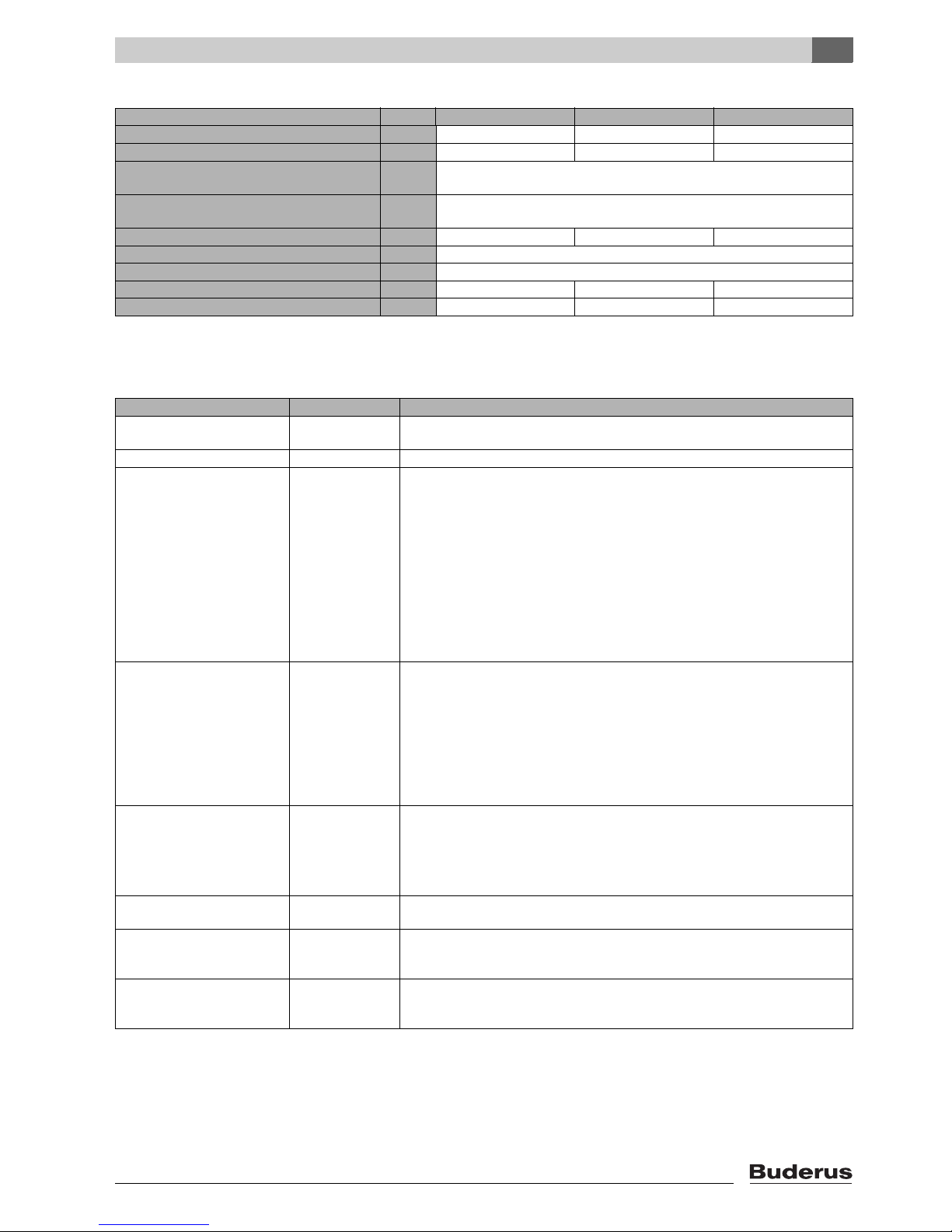

2.10 Dimensions and specifications

2.10.1 Logano G225 BE dimensions

Fig. 2 Connections and dimensions (sizes in mm)

Connections (for sizes see tables below):

VK = Boiler flow

RK = Boiler return

EL = Boiler drain (connection for drain tap)

VS = DHW cylinder flow

RS = DHW cylinder return

VSL = Pressure relief flow pipe (connection for automatic air

vent valve provided by installer)

Connections and sizes:

6 720 615 876-02.1RS

Boiler size 45 55 68

Oil burner Type BE2.3-45 BE2.3-55 BE2.3-68

Boiler sections Number 456

Rated output KW 45 55 68

1)

1) 65 kW (for Spain)

Combustion output KW 48.1 59.0 73.0

2)

2) 69.8 kW (for Spain)

Boiler water content l Approx. 61 Approx. 73 Approx. 85

Gas content l 68.8 85.1 101.4

Flue gas temperature

3)

3) Flue gas temperature to EN 303.

°C 165 180 180

Flue gas mass flow rate kg/s 0.0197 0.0242 0.0299

4)

4) 0.0287 kg/s (for Spain)

CO2 content, oil % 13.5

Available draught Pa 50 50 30

Flue gas back pressure mbar 0.35 0.20 0.35

Permissible flow temperature

5)

5)Safety limit (high limit safety cut-out, STB)

Maximum possible flow temperature = Safety limit (STB) - 10 K

Example: Safety limit (STB) = 100 °C, maximum possible flow temperature = 100 - 10 = 90 °C

The safety limit must meet the national regulations of the country concerned.

°C 100

Permissible operating pressure bar 4

Maximum time constant of temperature control s ≤ 1

Maximum time constant of temperature

monitor and high limit safety cut-out (STB)

s ≤ 1.2

Power supply rating 230 VAC, 50 Hz, 10 A IP 40

Tab. 3 Specifications

Page 11

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

11

2.10.2 Boiler room and ambient conditions

Boiler size 45 55 68

Boiler overall length (L) mm 1102 1222 1342

Boiler heat exchanger length (LK) mm 626 746 866

Boiler section handling clearance

(width/height/depth)

mm 460/820/150

Boiler heat exchanger handling clearance

(width/height/depth)

mm 460/820/L

K

Combustion chamber length mm 548 668 788

Combustion chamber diameter mm 337

Burner door depth mm 95

Distance between boiler feet (FL) mm 455 575 695

Net weight

1)

kg 246 291 336

Tab. 4 Dimensions, weight and other details

1) Weight inc. packaging approx. 6 – 8 % greater.

Operating conditions Notes - detailed requirements

Temperature in the installation

room

+5 to +40 °C

Relative air humidity max. 90 % No condensation or dripping damp inside the boiler room

Dust/airborne seed − When the boiler is in operation, it is essential to prevent excessive dust levels in

the boiler room, e.g.

– building dust through very dusty building work

The supply of combustion air must not contain excessive amounts of dust or

airborne seed; if necessary, entry should be prevented by means of air filters,

e.g.:

– Air supply loaded with dust from dirt roads and paths.

– Air supply contaminated with dust from production and processing facilities, e.g.

quarries mines, etc.

– Airborne seed from plants.

Halogenated hydrocarbon

compounds

− The combustion air must be free of halogen-hydrocarbon compounds.

– Identify the source of halogenated hydrocarbon compounds and eliminate their ingress.

Where this is impossible, route combustion air from areas which are not contaminated

by halogenated hydrocarbon compounds.

Observe the following:

– Buderus catalogue - Heating Technology Germany

– Code of Practice K3 in the Buderus catalogue

Fans, which extract air from the

installation room.

− While the burner is in operation, no mechanical air extraction equipment that draws air from

the boiler room must be operated, e.g.:

– cooker hood

–dryer

– ventilation equipment

Small animals − Prevent small animals from entering the boiler room, particularly through the air inlet vents –

by fitting the vents with grilles.

Fire safety − Maintain clearances between the boiler and flammable materials in accordance with local

regulations. A minimum clearance of 40 cm should always be maintained. Never store

flammable materials or liquids in the vicinity of the boiler.

Flooding − If flooding is imminent, disconnect the boiler in good time from its fuel and power supply

before water enters the room. Any general and burner components or control equipment,

which come into contact with water, must be replaced before re-commissioning.

Tab. 5 Installation room and environment

Page 12

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

12

2.10.3 Conditions for combustion air supply

2.10.4 Conditions for fuel

Country-specific fuels

Operating conditions

Boiler output (in case of

multi-boiler systems = total output)

Air intake flow cross-sectional area in cm

2

(clear area)

Air intake flow cross-sectional

area for combustion air drawn

from outside (divided between

max. two apertures)

<50 kW min. 150cm

2

> 50 kW min. 150 cm2 plus 2 cm2 for each kW

in excess of 50 kW

Tab. 6 Combustion air supply – observe national regulations for boilers which draw their air supply from the boiler

room.

Operating conditions Notes – detailed requirements

Permissible fuels for boilers

with Logatop oil burner

– Boilers with a built-in oil burner may only be run on domestic fuel oil (DIN 51603). The

kinematic viscosity of the oil must not exceed 6 mm

2

/s (at 20 °C). That is equivalent to a

Redwood I viscosity of 41.0 s (UK) or Sayboldt viscosity of 45.5 s (USA). If oil of poorer

quality is used, the service/cleaning intervals should be reduced accordingly.

Contamination – Technically free of contamination (e.g. dust, moisture, fluids), i.e. continuous operation will

not result in any accumulations likely to restrict the flow through valves or filters.

Tab. 7 Fuels and remarks

Country Germany

Fuels Domestic fuel oil type EL to DIN 51 603

Remarks The boiler may only be operated with the specified fuel.

Country Austria

Fuels EL fuel oil

Remarks The boiler may only be operated with the fuel specified.

The requirements as per Art. 15 a B-VG regarding emissions and efficiency are satisfied.

Country Switzerland

Fuels EL fuel oil

Remarks The boiler may only be operated with the fuel specified.

The output figures shown in the table "Specifications" are rated output figures.

In some cases, the actual figures attained in practice will be below those stated to comply with LRV

requirements within the specified output range.

Tab. 8 Country-specific fuels and remarks

Page 13

2

Product details

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

13

2.10.5 Conditions for the power supply

2.10.6 Conditions for the system configuration and water quality

Operating conditions Notes – detailed requirements

Supply voltage 195 – 253 V The outer casing/boiler must be earthed for safety reasons and to function correctly.

Fuse 10 A

Frequency 47.5 – 52.5 Hz Sine wave

Enclosure rating − IP40 (protected against penetration by foreign bodies > 1 mm dia., not protected against

water ingress)

Tab. 9 Mains power supply

Operating conditions Notes – detailed requirements

Operating pressure (above

atmospheric)

0.5 – 4.0 bar

Permissible testing pressure 1.0 – 5.2 bar

Protection against excess

temperatures via TR thermostat

50–90°C

Protection against excess

temperatures via STB high limit

safety cut-out

100 °C

Water quality − The heating system may only be filled and topped up with water of domestic water quality.

We recommend a pH value of 8.2 – 9.5.

Tab. 10 System configuration and water quality

Page 14

3

Transporting the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

14

3 Transporting the boiler

This chapter details how you safely transport your boiler.

Caution: Risk of system damage from

impact shocks.

Fragile components could be damaged.

V Observe the transport instructions on the

packaging.

Protect boiler connections from damage and

dirt if the boiler is not to be installed

immediately.

Dispose of packaging in an environmentally

responsible manner.

Warning: Risk of injury if load is

inadequately secured during transportation.

V Use suitable means of transportation, e.g.

the Buderus boiler hand truck with strap.

V Secure the load against falling.

Page 15

4

Boiler positioning

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

15

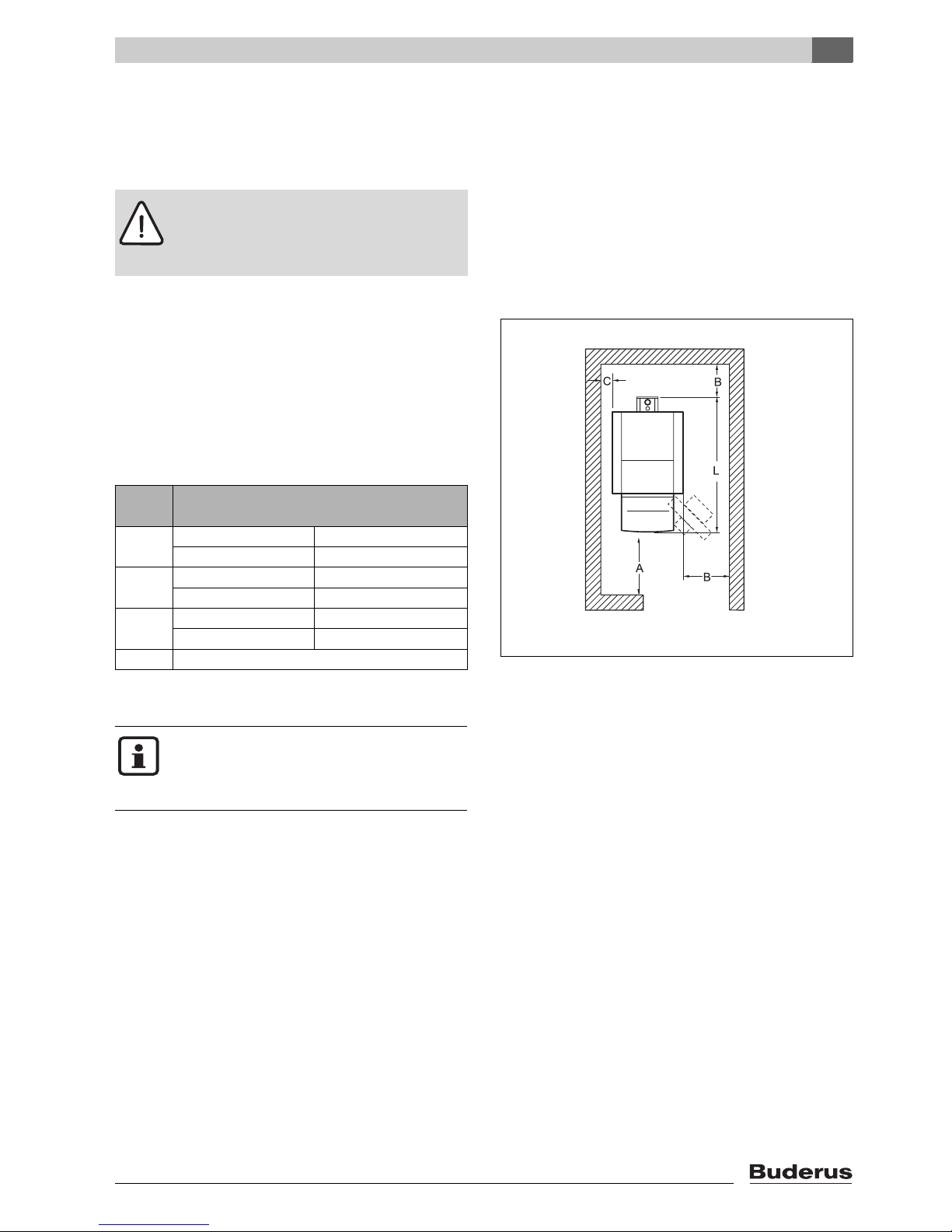

4 Boiler positioning

This section explains how to erect and position the boiler

in the boiler room.

Wall clearances

Wherever possible, position the boiler with the

recommended wall clearances. Reducing the clearances

to the minimum makes the boiler more difficult to access.

The boiler base or foundation must be perfectly flat and

level.

At the factory, the burner door hinges are fitted on the

right hand side. The burner door can be reversed so as to

hinge on the left.

Fig. 3 Boiler room clearances (boiler positioned on the

left-hand or right-hand side)

Caution: Risk of system damage due to

frost!

V Set up the heating system in a room safe

from the risk of frost.

Dimension

Wall clearance

A Recommended 1300

minimum 1000

B Recommended 700

minimum 400

C Recommended 400

minimum 100

L Æ Chapter 2.10.1, page 10

Tab. 11 Recommended and minimum wall clearances

(dimensions in mm)

6 720 615 876-03.1RS

Where applicable, allow extra wall

clearances for additional components such

as DHW cylinder, pipe connections, flue

silencer or other flue components, etc.

Page 16

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

16

5 Boiler block assembly

The on-site installation is carried out using individual

sections if, because of physical limitations, a boiler block

cannot be handled as a complete unit.

For details of assembling the remainder of the boiler if the

heat exchanger is delivered pre-assembled,

Æ Chapter 5.4, page 28.

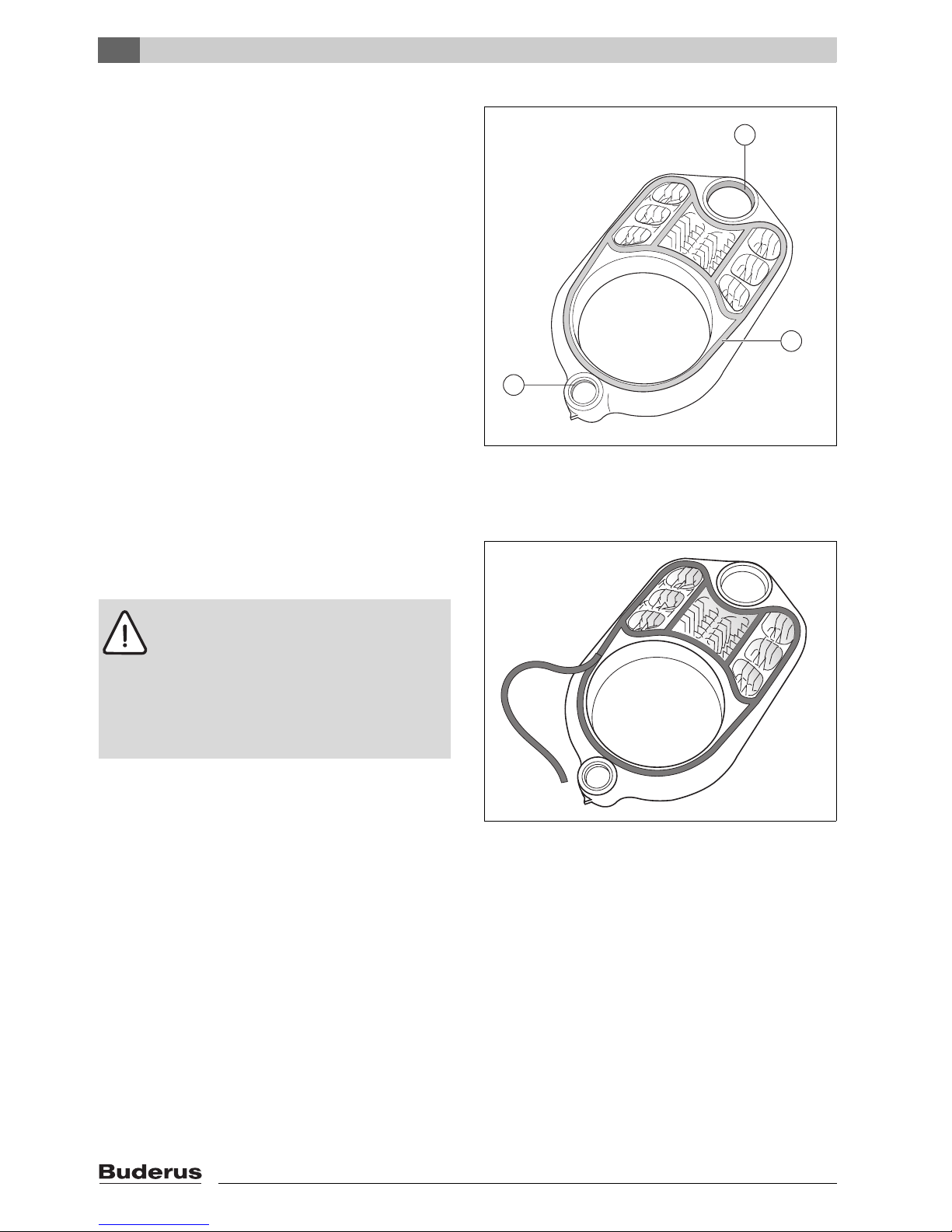

Fig. 4 Fully assembled boiler heat exchanger

1 Foundation/installation location

2 Drain

3 Rear section

4 Flue outlet

5 Connecting block

6 Centre sections

7 Anchor rods

8 Front section

9 Burner door

5.1 Assembly when delivered in

sections

V Assemble all boiler sections in accordance with the

following instructions and illustrations.

5.1.1 Preparation of boiler sections

V Lay rear section [2] across two wooden battens [3].

V Clean the boiler bosses [1] with emery paper and a rag.

V Remove any burrs which might have been created with

a file.

V Clean the joint lip/groove [4] using a wire brush and

rag.

Fig. 5 Filing off flash

1 Boiler bosses

2 Rear section

3 Wooden battens

4 Joint lip

Warning: Risk of injury if load is

inadequately secured during transportation.

V Use suitable means of transportation, e.g.

the Buderus boiler hand truck with strap.

V Secure the load against falling.

6 720 615 876-04.1RS

1

2

3

4

5

6

7

8

7

9

Warning: Health risk and risk of injury from

release of vapours and easily combustible

cleaning agents.

V Ensure adequate ventilation inside the

boiler room when using red lead putty,

adhesives and cleaning agents.

V When using a cleaning agent, avoid naked

flames, glowing embers and sparks.

V Observe the manufacturer's handling and

safety instructions.

6 720 615 876-05.1RS

3

4

1

1

2

Page 17

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

17

V Clean the sealing faces of the boiler bosses [1] with a

cloth soaked in white spirit.

V Evenly coat the boiler boss sealing faces with red lead

putty.

V Coat the joint lip/groove [2] with adhesive (primer).

Fig. 6 Coating the boiler hubs with red lead putty

1 Boiler boss sealing face

2 Packing groove

5.1.2 Driving boss liners home

V Clean the boss liners with a cloth soaked in white spirit.

V Evenly coat the boss liners with red lead putty.

V Insert the boss liners straight into the upper and lower

hub of the rear section and hammer home securely with

alternate heavy blows.

V Remove any burrs with a file.

Fig. 7 Driving boss liners home

1 Boss liner in the upper boiler hub

2 Boss liner in the lower boiler hub

2

1

1

6 720 615 876-06.1RS

Leave the two boss liners protruding approx.

30 mm from the boiler boss in each case.

6 720 615 876-07.1RS

2

1

Page 18

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

18

5.1.3 Preparing the centre section

Prepare the centre section in the same way as the rear

section (Æ 5.1.1, page 16).

Fig. 8 Preparing the centre section

1 Boiler boss sealing face

2 Packing grooves

5.1.4 Inserting the packing cord

V Unroll the required length of packing cord from the roll

supplied.

V Peel the backing paper from the packing cord, as you

insert the cord into the packing groove.

V Insert the flexible packing cord into the packing groove,

starting in the upper boiler hub area, and lightly press

in.

V Where the 2 ends meet, overlap the packing cord by

2 cm and press firmly together.

Fig. 9 Inserting the packing cord

6 720 615 876-08.1RS

2

1

1

Caution: Risk of system damage due to

leaking boiler sections.

V To ensure that the joint faces between the

boiler sections are properly sealed, the

packing cord must not be stretched

during fitting.

V Carefully insert the packing cord into the

boiler packing grooves.

6 720 615 876-09.1RS

Page 19

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

19

5.1.5 Knocking the centre section into place

V Turn the centre section around and locate with the

upper and lower boiler hubs on the boss liners of the

rear section.

V Drive the centre section onto the rear section [2] using

a wooden or a rubber mallet [1].

Fig. 10 Knocking the centre section into place

1 Wooden or rubber mallet

2 Rear section

5.1.6 Boiler section alignment

V Right the part assembled block comprising two boiler

sections.

V Position a flat board [1] underneath the centre section

[2] so that the boiler heat exchanger is slightly tilted to

the rear for the subsequent assembly process.

Fig. 11 Righting the part assembled block

1 Flat board

2 Centre section

6 720 615 876-10.1RS

2

1

Warning: Risk of injury due to inadequately

secured boiler sections.

V Secure the partly assembled boiler heat

exchanger against tipping over.

6 720 615 876-11.1RS

2

1

Page 20

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

20

5.1.7 Joining the boiler sections at the upper and

lower boiler bosses with boss liners

Fig. 12 Assembling the pull rods

1 Pull rod threaded connection (incorrectly joined)

2 Pull rod threaded connection (correctly joined)

V Push one pull rod each through the lower and the

upper boiler hub of the part assembled block.

Fig. 13 compression tool fitted to the top boiler boss

1 Compression unit

2 Pressure plate (dia. 135 × 25, top boiler boss)

3 Brace plate (dia. 135 x 25, top boiler boss)

4 Wedge

5 Pull rod in the upper boiler hub

Caution: Risk of boiler damage due to

unsuitable compression tool.

V Use only the size 1.2 compression tool

suitable for your boiler (Æ observe

documentation supplied with

compression tool).

Caution: Risk of damage to compression

tool

The compression tool may be damaged or

destroyed, if you compress pull rods with

loose threaded connections.

V After each compression operation, check

the screwed joints of the pull rods [1, 2]

and tighten if necessary.

The pull rods [2] is correctly assembled

when it is fully fitted together and no

thread is visible.

V Keep the thread of the compression tool

clean. Dirty threads can cause damage to

the compression tool when in use.

6 720 615 876-12.1RS

2

1

Caution: Risk of boiler damage due to

incorrectly positioned pressure plate.

If the pressure plate is seated against the

joint lip/groove of the boiler section during

the compression operation, the joint may be

damaged and subsequently leak.

V Ensure that the pressure plate is seated

flat against the boiler boss.

6 720 615 876-13.1RS

54

3

2

1

Page 21

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

21

V Slide the pressure plates onto the pull rods in the top

and bottom boiler bosses.

V Push the mating flange onto the pull rod of the lower

and upper boiler bosses, and secure with the

respective wedges.

V Thread the compression units onto the pull rod threads.

V Hold the pull rods at the centre of the boiler bosses and

slightly draw together the compression tools using the

compression unit.

Fig. 14 Compression tool assembled at the lower boiler

hub

1 Compression unit

2 Pressure plate (dia. 80 x 25)

3 Brace plate (dia. 80 x 25, bottom boiler boss)

4 Wedge

5 Pull rod in the lower boiler boss

V Place the two ratchet spanners [1] on the clamp nuts

[2] of the compression tools and press the boiler

sections together by evenly tightening the nuts.

V Release and remove the compression tool.

V Hammer the boss liners into the bosses of the partly

assembled boiler heat exchanger (Æ Chapter 5.1.2,

page 17).

V Prepare all other centre sections as described above

and then join using boss liners.

Fig. 15 Locating the ratchet

1 Spanners

2 Clamping nuts

Push the compression units so far onto the

pull rod threads, that two threads protrude

from the compression units.

6 720 615 876-14.1RS

5

4

3

2

1

Caution: Risk of boiler damage due to

leaking boiler sections.

V Ensure that in each compression

operation only one boss/liner joint (one

boss/liner joint consists of two sections) is

being pressed together.

V Never jam boss liners into the boiler

bosses of the boiler section.

V Stop pressing the sections together when

the boiler bosses meet.

6 720 615 876-15.1RS

2

1

Page 22

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

22

Front section assembly

Due to the threaded studs, never use the auxiliary flange

at the front of the upper boiler hub when assembling the

front section.

V Push the pull rod together with the compression unit

through the upper boiler hub.

V Carry out all remaining steps as described above

(Æ Chapter 5.1.7, page 20).

Fig. 16 Fitting the compression tool to the front section

5.1.8 Fitting the anchor rods

V Slot the anchor rods [1] fitted with spring washers [3]

into the cast lugs [4] near the boiler bosses on the right

and left and at the bottom.

V Screw the nuts onto the threads of the anchor rods [1]

by hand.

V Tighten the nuts on the anchor rods 1 to 1½ turns.

V Undo the compression tool [5] and remove.

Fig. 17 Fitting the anchor rods – arrangement of the

dished washers

1 Anchor rods

2 Nut

3 Spring washers

4 Cast lugs

5 Compression tool

6 720 615 876-16.1RS

Insert the anchor rods [1] before removing

the compression tool [5].

Never remove the compression tool first.

Caution: Risk of system damage due to

incorrect fitting of spring washers.

V Ensure that the spring washers [3] are

facing each other on the anchor rods [1].

6 720 615 876-17.1RS

5

4

3

3

2

1

1

Page 23

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

23

5.1.9 Installation of the feed pipe and connection

profile

The feed pipe [3] and connecting block [1] are already

fitted if the boiler heat exchanger is supplied preassembled.

V Secure the feed pipe [3] with gasket in place to the

connecting block using M 8 × 16 screws.

Fig. 18 Installation of the feed pipe to the connecting

block

1 Connecting block

2 Gasket

3 Feed pipe

4 M 8 ×16 screws (brass)

V Remove the nuts from the threaded studs.

V Slide gasket [1] over the feed pipe.

V Slide feeder pipe with connection fitting attached and

gasket [1] in place into the top boiler boss from the

back.

Fig. 19 Installation of the feed pipe and connecting

block

1 Gasket

If there is insufficient space behind the boiler,

insert the feed pipe [3] from the front of the

boiler (not forgetting the gasket for the boiler

boss) before fitting the connection profile [1].

6 720 615 876-18.1RS

4

3 2 1

6 720 615 876-19.1RS

1

Page 24

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

24

V Position the connecting block onto the threaded studs,

and tighten four nuts by hand.

V Evenly tighten the connection profile nuts in a diagonal

sequence using a torque wrench [1]

(torque: max. 60 Nm).

Fig. 20 Assembling the connection profile

1 Torque wrench

You can seal off the connections that are not required

using the blanking plugs [1] supplied. When the boiler is

supplied as ready assembled block, these plugs have

already been fitted.

V Insert blanking plugs [1] fitted with plain washers [2]

into connections that are not required.

Fig. 21 Sealing off connections that are not required

1 Blanking plug

2 Plain washer

6 720 615 876-20.1RS

1

6 720 615 876-21.1RS

2

2

1

1

Page 25

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

25

5.1.10 Fitting the temperature sensor

The temperature sensor is delivered in the pack

containing the burner, burner hood and burner door.

The temperature sensor is fitted to a reducer.

V Fit the reducer with temperature sensor attached.

Fig. 22 Temperature sensor fitted to reducer

Fig. 23 Fitting the temperature sensor

1 Temperature sensor

6 720 615 876-22.1RS

6 720 615 876-23.1RS

1

Page 26

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

26

5.1.11 Fitting the flue outlet

The flue outlet is fitted with a cord gasket.

V Remove the washers and nuts from the threaded studs.

V Position the flue outlet onto both threaded studs on the

rear section and secure with nuts.

Fig. 24 Fitting the flue outlet

5.1.12 Closing the boiler hubs

The reducer supplied is required for fitting the boiler fill &

drain valve (not supplied).

V Fit and seal the reducer into the bottom rear boiler

boss.

V Fit the boiler fill & drain valve to the reducer.

Fig. 25 Fitting and sealing the reducer

1 Reducer (R 1½" to Rp ½")

V On the front boiler section, seal off the top boiler boss

with the blanking plate [1].

V Insert the blanking plug [2] with plain washer in place

into the bottom boiler boss.

Fig. 26 Closing the boiler hubs at the front section

1 Dummy flange

2 Blanking plug

6 720 615 876-24.1RS

6 720 615 876-25.1RS

1

6 720 615 876-26.1RS

2

1

Page 27

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

27

5.2 Checking for leaks

Only carry out a leak test if the boiler heat exchanger has

not been delivered pre-assembled.

5.2.1 Preparing for a leak test

V Seal off all boiler bosses

(Æ Chapter 5.1.12, page 26).

V Seal off the flow and return connections. (Fit a air vent

valve to the Rp ¾ connection profile.)

5.2.2 Carrying out the leak test

Carry out a leak test at a test pressure of 5.8 bar (in

accordance with the requirements of the European

Pressure Vessel Directive).

V Slowly fill the boiler block via the boiler fill & drain valve.

While filling, keep the air vent valve at the highest point

of the boiler open until water runs out of it.

Hub joints leaking?

V If a hub joint is leaking, first drain the water through the

boiler fill & drain valve.

V Remove the water pipes.

V Remove the feed pipe.

V Release and remove the anchor rods.

V Split the leaking boiler heat exchanger at the leaking

joint by driving in wedges or chisels.

For the remaining stages of boiler installation, refer to

Æ Chapter 5.4, page 28.

Fig. 27 Separating the boiler block

Observe the specifications on the rating

plate.

Use a class 1.0 pressure gauge for the

pressure test.

Caution: Risk of system damage from

excessive pressure.

V Ensure that no pressure, control or safety

equipment is fitted while the leakage test

is being carried out.

Clean the bosses before reassembling.

Always fit new boss liners and new packing

cord when reassembling.

Press the boiler heat exchanger back

together.

Fit the anchor rods and feed pipe.

Connect the water pipes.

Repeat the leak test.

6 720 615 876-27.1RS

Page 28

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

28

5.3 Installation of pre-assembled boiler

heat exchanger

Pre-assembled boiler blocks are leak tested in the factory

prior to delivery.

V Cut through the securing straps [1].

V Remove the pallet prior to positioning the boiler block.

Fig. 28 Boiler block on a pallet (as delivered condition)

1 Securing straps

5.4 Assembly steps for boilers supplied in sections and as ready assembled block

Carry out the steps detailed in this chapter for deliveries

in sections or as block. Any assembly discrepancies

between the sectional and block delivery are highlighted

in this text.

5.4.1 Fitting the adjustable feet

You can level the boiler using the adjustable feet (for

packing details see package contents) to prevent air

pockets forming inside the boiler.

V Tip the boiler or support it on a square timber.

V Insert adjustable feet 5 – 10 mm.

V Gently set the boiler down.

Fig. 29 Fitting the adjustable feet

5.4.2 Inserting the hot gas baffle plates

V Remove the corrugated cardboard packaging when

the block is supplied ready assembled.

V If the boiler is supplied in sections, remove the hot gas

baffles from the box containing the loose fittings.

V Insert the hot gas baffles into the centre 2nd hot gas

flues as indicated in the table below. The cast lugs

should point towards the centre of the boiler.

Fig. 30 Inserting hot gas baffles into 2nd hot gas flue

(in this case in the centre)

Danger: Risk of fatal injury from falling

objects.

V Ensure that there is a suitable means of

supporting the load.

V Observe all locally applicable health &

safety regulations regarding lifting

equipment.

6 720 615 876-28.1RS

1

6 720 615 876-29.1RS

6 720 615 876-30.1RS

Page 29

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

29

V Insert the hot gas baffles into the centre 3rd hot gas

flues as indicated in the table below. The cast lugs

should point outwards.

Fig. 31 Inserting hot gas baffles into 3rd hot gas flue

The flue gas temperature can be increased by removing

the hot gas baffles (Æ Chapter 7.5, page 47).

5.4.3 Installing the burner door

You can fit the burner door with the hinges on the right or

left. In the following points, assembly on the right hand

side is described.

V Secure the two hinge pins to the front boiler section

with one M 12 × 35 hexagon bolt [1] in each case.

Fig. 32 Fitting the hinge pins (on the right in this exam-

ple)

1 M 12 × 35 hexagon bolt

V Fit the twin-slooted hinge lobe brackets to the burner

door with an M 12 x 25 bolt in each case.

V Hook the burner door with the hinge lobes onto the

hinge pins.

V Close the boiler door.

Fig. 33 Hanging the burner door (on the right in this

case)

1 M 12 × 25 hexagon bolt

Boiler size incl. oil burner 45 55 68

2nd hot gas flue Top - - -

central - 2 -

bottom - 2 -

3rd hot gas flue 2 - -

Tab. 12 Hot gas baffle plate arrangement

6 720 615 876-31.1RS

6 720 615 876-32.1RS

1

1

Caution: Risk of system damage due to

leaking burner door.

V Tighten the hexagon bolts on the burner

door evenly.

6 720 615 876-33.1RS

Page 30

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

30

5.4.4 Installing the boiler casing

Fitting the boiler rear panel

V Insert the spacer pins into the rear section.

Fig. 34 Fitting the spacer bolts

V Secure the boiler back panel with nuts to the threaded

and spacer pins.

Fig. 35 Fitting the boiler rear panel

Installation of the upper tie bar

V Secure the top crossmember to threads of the anchor

rods [1] using the nuts supplied.

Fig. 36 Installation of the upper tie bar

1 Anchor rods

6 720 615 876-34.1RS

6 720 615 876-35.1RS

6 720 615 876-36.1RS

1

Page 31

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

31

Installation of the lower tie bar

V Secure the lower tie bar with hexagon bolts to the front

section.

Fig. 37 Installation of the lower tie bar

Installation of the thermal insulation

V Position the thermal insulation over the boiler block.

V Push the thermal insulation below the boiler block, in

the direction of the arrow.

V Position the tabs of the thermal insulation [2] in front of

the top crossmember and pull them together with a

spring clip [1].

Fig. 38 Installation of the thermal insulation

1 Spring strap

2 Thermal insulation tabs

6 720 615 876-37.1RS

6 720 615 876-38.1RS

2

1

Page 32

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

32

Fitting the temperature sensor and communication

cable

V Press the cable grip [1] into the holes provided in the

bottom crossmember.

V Lay the cables over the thermal insulation.

V Insert the cables into the strain relief. The clear length

must be 70 to 75 cm.

V Secure the cables via the strain relief using two self-

tapping screws.

The cables must always be laid as shown, regardless of

whether the door opens to the right or to the left.

Fig. 39 Fitting the temperature sensor and communica-

tion cable

1 Strain relief

2 Temperature sensor and communication cable

A Push the strain relief into the holes of the lower tie bar

B Insert and secure the cables

Fitting the mains power cable

V Fit the cable clip [1].

V Insert mains supply cable into the cable clip [1].

The mains power cable must always be laid as shown,

regardless of whether the door opens to the right or to the

left.

Connecting cables to the SAFe

V Connect temperature sensor [2], communication [3]

and mains power cables to the SAFe [4] as shown in

the wiring diagram (Æ burner documentation).

Fig. 40 Fitting the mains power cable

1 Cable clip for mains power cable

2 Temperature sensor lead

3 Communication cable

4 SAFe

6 720 615 876-39.1RS

A

B

2

1

6 720 615 876-40.1RS

4

3

21

Page 33

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

33

Fitting the side panels

The side panel installation for the left-hand and right-hand

side is identical (in this example on the right-hand side

panel).

V Push the snap nut onto the angled sheet steel of the

side panel, until it locks into the hole provided.

Fig. 41 Fitting the snap-on nut (in this example on the

right-hand side panel)

V Slot the side panel into the end flange of the bottom

crossmember [1].

Fig. 42 Pushing the front lower side panel into place

1 Angled part of the lower tie bar

V Slightly lift the side panel.

V Hook the top cutout in the side panel over the top

crossmember [A].

V Hook the rear part of the side panel over the protruding

hook [B].

Fig. 43 Hooking-in the side panel

A Top crossmember

B Protruding hook

6 720 615 876-41.1RS

1

A

B

6 720 615 876-43.1RS

Page 34

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

34

V Push the side panel in at the bottom and fix to the rear

panel with the snap-lock catch [1].

Fig. 44 Securing the side panel to the rear panel

1 Snap-lock catch

V Fit brackets [1] for fixing the burner hood to left and

right side panels.

Fig. 45 Fitting brackets to side panels

1 Bracket

6 720 615 876-44.1RS

1

1

6 720 615 876-45.1RS

Page 35

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

35

Fitting the front boiler cover

V Hook the front boiler cover with its cutout into the top

crossmember and push back.

V Secure the front boiler cover with two self-tapping

screws to the side panels.

Fig. 46 Fitting the front boiler cover

Fitting the temperature sensor

(pre-assembled boiler only)

If the boiler is delivered pre-assembled, the temperature

sensor must now be fitted.

The temperature sensor [1] is packed in the pack

containing the burner, burner hood and burner door.

The temperature sensor [1] is fitted to a reducer.

V Fit the reducer with temperature sensor [1] attached.

Fig. 47 Fitting the temperature sensor

1 Temperature sensor

For details of fitting the rear boiler top panel,

Æ Chapter 6.6, page 44.

6 720 615 876-46.1RS

6 720 615 876-47.1RS

1

Page 36

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

36

Installing the cable entry

V Secure the cable entry to the boiler back panel hole.

V Slide rubber hood [1] over the temperature sensor and

connect temperature sensor lead.

Fig. 48 Installing the cable entry

1 Rubber sleeve

Insulating the connecting block

V Cut out the insulating shells of the connecting block at

the indicated and required positions.

Fig. 49 Cutting out the insulating shells

V Slide the two halves of the insulation box onto the

connection profile.

Fig. 50 Insulating the connection profile.

6 720 615 876-48.1RS

1

6 720 615 876-49.1RS

6 720 615 876-50.1RS

Page 37

5

Boiler block assembly

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

37

V Push the heat shield onto the insulating shells.

Fig. 51 Installation of the heat shield

5.5 Positioning and levelling the boiler

V Move the boiler into its final location.

V Level the boiler by inserting the adjustable feet uo or

down as required and using a spirit level.

Fig. 52 Levelling the boiler horizontally

6 720 615 876-51.1RS

Protect boiler connections from damage and

dirt if the boiler is not to be installed

immediately.

7 747 019 141-11.1RS

Page 38

6

Installing the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

38

6 Installing the boiler

This chapter details how you install your boiler correctly.

The individual steps involved are:

– Flue connection

– Connecting the water pipes

– Making the electrical connections

For information on connecting the fuel supply, please

consult the burner documentation.

6.1 Installing the flue pipe

V Make the flue gas connection in accordance with the

requirements applicable in your country.

6.1.1 Flue pipe sealing collar for negative pressure flue (pressure at boiler outlet < 0 mbar)

We recommend fitting a flue pipe sealing collar (option) in

order to achieve the best possible seal.

V Slide jubilee clips [4] over the flue pipe [1].

V Push flue pipe [1] fully home onto the boiler flue outlet

[3].

V Wrap flue pipe sealing collar [2] around the flue pipe/

flue outlet joint so that it overlaps the joint.

V Position one jubilee clip [4] on the flue pipe and the

other on the flue outlet.

V Tighten the jubilee clips [4] so that the flue pipe sealing

collar [2] sits snugly and evenly in place.

Fig. 53 Fitting the flue pipe sealing collar (example)

1 Flue pipe

2 Flue pipe sealing collar

3 Boiler flue outlet

4 Jubilee clip

6 720 615 876-53.1RS

1

23

4

Page 39

6

Installing the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

39

6.1.2 Flue pipe sealing collar for positive pressure flue (pressure at boiler outlet > 0 mbar)

The overpressure-tight flue pipe sealing collar

(accessories, part no. 535 4404) must be fitted.

V Slide the flue pipe sealing collar [3] and two jubilee

clips [2] over the flue pipe [4].

V Push flue pipe [4] and flue pipe sealing collar [3] onto

the boiler flue outlet [1].

V Tighten jubilee clips [2].

Fig. 54 Making the flue pipe sealing collar

1 Flue outlet

2 Jubilee clip

3 Flue pipe sealing collar

4 Flue pipe

6.2 Fitting the water connections

6.2.1 Connecting the central heating flow and

return

V Connect central heating return to connection RK.

V Connect the central heating flow to connection VK.

Fig. 55 Connecting the central heating flow and return

Key to fig. 55 - 58:

VSL: Flow safety line

VK: Boiler flow

RK: Boiler return

VS: DHW cylinder flow

RS: DHW cylinder return

EL: Drain

6 720 615 876-54.1RS

2 2

4

3

3

1

Caution: Risk of system damage from

leaking connections.

V Fit the connecting pipes to the boiler in

such a way that they are not under stress.

Caution: Risk of system damage due to lack

of water.

The boiler requires a minimum pressure

switch to protect it against lack of water. You

can obtain this as an accessory.

V Observe the installation instructions for

the accessory.

We recommend fitting a dirt filter (option) to

the central heating return to prevent

contamination of the boiler by the water.

6 720 615 876-55.1RS

VK

RK

Page 40

6

Installing the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

40

6.2.2 Connecting the safety flow and return

We recommend you fit a boiler safety assembly

(accessory) and an air vent valve (accessory) to

connector VSL.

Fig. 56 Connecting the air vent valve to the safety flow

6.2.3 Connecting the DHW cylinder

V Connect the DHW cylinder return to connection RS.

V Connect the DHW cylinder flow either at VS1 or VS2.

V Seal off the surplus VS and RS connector.

Fig. 57 DHW cylinder connection

6.2.4 Fitting the boiler fill & drain valve (not supplied)

V Fit and seal the boiler fill & drain valve to connection EL.

Fig. 58 Fitting boiler fill & drain valve

Caution: Risk of system damage due to

incorrect components connected to

connection VSL.

V Never connect a solar heating system,

DHW cylinder or other heating circuit to

connection VSL.

VSL

6 720 615 876-56.1RS

RS1

VS1

VS2

RS2

6 720 615 876-57.1RS

EL

6 720 615 876-58.1RS

EL

Page 41

6

Installing the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

41

6.3 Filling the heating system and

checking for leaks

Check the heating system for leaks before commissioning

to ensure there are no leaks when the system is in

operation. Pressurise the heating system to 1.3x

permissible operating pressure (observe the response

pressure of the safety valve).

Fig. 59 Pressure gauge for sealed unvented systems

1 Red needle

2 Pressure gauge needle

3 Green range

V Close the pressure expansion vessel against the

system by closing the cap valve.

V Check the connections and pipework for leaks.

V Open the mixing and shut-off valves on the heating

water (primary) side.

V Connect hose to the water tap. Push a hose filled with

water onto the hose ferrule of the boiler fill & drain valve

and open the valve.

V Open the cap of the automatic air vent valve by one full

turn to allow air to escape.

V Slowly fill the heating system. Observe the pressure

gauge (Æ fig. 59) while doing so.

V Close the water tap and the boiler fill & drain valve once

the required operating pressure has been reached.

V Vent the heating system via the radiator bleed valves.

V Top up with water if the pressure drops as a result of

venting the system.

V Remove the hose from the boiler fill & drain valve.

Caution: Risk of system damage from

excess pressure when testing for leaks.

Pressure, control and safety equipment may

be damaged by excessive pressure.

V When you carry out the leakage test,

ensure that no pressure, control or safety

equipment that cannot be isolated from

the boiler water chamber is fitted.

6 720 615 876-59.1RS

3

2

1

Page 42

6

Installing the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

42

6.4 Connecting the fuel supply

Make the fuel connection in accordance with all locally

applicable regulations. We recommend the installation of

a fuel filter.

V Visually inspect the fuel pipe and clean or replace, if

necessary.

V Install the shut-off valve into the fuel supply pipe.

V Connect the fuel pipe to the boiler in such a way that it

is not under stress.

V Check the flue pipe for tightness.

V Connect up the fuel supply in accordance with the

locally applicable regulations.

6.5 Electricity connection

6.5.1 Fitting the control unit

V Place the push-in hooks of the control unit into the oval

holes.

V Push the control unit towards the burner door.

V Let the resilient hooks of the control unit click into the

openings by pushing the control unit down.

Fig. 60 Fitting the control unit

Danger: Risk of fatal electric shock.

V Only qualified electricians are permitted to

carry out electrical work. Installation

regulations must be complied with.

V Before opening the boiler:

Disconnect the heating system from the

power supply by means of the emergency

stop switch or the relevant circuit breaker

in the main fuse board.

V Safeguard the heating system to prevent

unintentional re-connection.

V Observe all installation instructions.

6 720 615 876-60.1RS

Page 43

6

Installing the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

43

6.5.2 Connecting the mains power supply and

other components

V Undo the two screws on the control unit cover and

remove the cover.

Create a permanent mains power connection in

accordance with local regulations.

V Route all cables through the cable entries to the control

unit and connect in accordance with the wiring

diagram.

Fig. 61 Removing the cover

6.5.3 Fitting a strain relief

Secure all cable runs with cable clamps (standard control

unit delivery):

1. Insert the cable clamp together with the cable from the

top into the slots in the frame.

2. Slide the cable clamp downwards.

3. Press in.

4. Flip the toggle up.

Fig. 62 Securing cables with a cable clamp

Danger: Risk of fire

Hot boiler components may damage cables.

V Ensure that all cables are routed through

the cableways provided or along the

boiler's insulation material.

6 720 615 876-61.1RS

6 720 615 876-62.1RS

Page 44

6

Installing the boiler

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

44

6.6 Installing casing parts

V Slot the control unit cover [1] into the guides and slide

downwards.

V Secure the controller cover [1] with the two screws.

V Slide the tabs of the rear boiler top panel [3] under the

front boiler top panel [4].

V Lower the rear boiler top panel [3] onto the side panels.

Fig. 63 Fitting hoods

1 Control unit cover

2 Tabs

3 Rear boiler cover

4 Front boiler cover

5 Side panel

V Place rear control unit cover [2] on rear boiler top panel

and fasten with two screws.

Fig. 64 Fitting the end hood

1 Controller cover

2 End hood

6 720 615 876-63.1RS

1

2

2

3

45

6 720 615 876-64.1RS

1

2

Page 45

7

Commissioning the heating system

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

45

7 Commissioning the heating system

This chapter details the commissioning independent of

the installed control unit.

V Complete the commissioning report during the

commissioning procedure (Æ Chapter 7.8, page 49).

For further information on boiler room conditions and

requirements, combustion air supply and flue systems,

and boiler operation, see Chapter 2.10.1, page 10 to

Chapter 2.10.6, page 13.

7.1 Bringing the system up to operating pressure

Bring the system up to the standard operating pressure

before commissioning.

V Adjust the red pointer [1] of the pressure gauge to the

required operating pressure of at least 1 bar (applies to

sealed unvented systems).

V Replenish the heating water or drain via the boiler fill &

drain valve until the required operating pressure is

obtained (Æ Chapter 6.3, page 41).

V Vent the heating system during filling.

Fig. 65 Pressure gauge for sealed unvented systems

1 Red needle

2 Pressure gauge needle

3 Green range

Warning: Risk of boiler damage from

excessive dust and airborne seed levels.

V Never operate the boiler when there is a

lot of dust in the boiler room, e.g. due to

building work.

V Fit an air filter if the supply of combustion

air contains large amounts of dust (e.g.

from unsurfaced roads and tracks or dusty

workplaces such as quarries, mines, etc.)

or airborne seeds from plants of the

Asteraceae family.

Caution: Risk of damage to system due to

material stresses caused by temperature

differentials.

V Only fill the heating system when cold

(the flow temperature should not exceed

40 °C).

Danger: Health risk from contaminated

domestic water.

V Observe all national standards and

regulations regarding prevention of

domestic water contamination (e.g. by

water from heating systems).

6 720 615 876-59.1RS

3

2

1

Page 46

7

Commissioning the heating system

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

46

7.2 Preparing the heating system for operation

V Turn on the fuel supply at the main shut-off valve.

V Switch ON the heating system emergency stop switch

(if installed) and/or insert the corresponding domestic

mains fuse.

7.3 Switching on the heating system

V Turn the "maximum boiler temperature" selector [8]

and set "DHW temperature" [2] to 0.

This ensures that the burner will not start yet (there is no

heat demand).

V Set the ON/OFF switch [1] on the standard controller

to position "1".

The entire heating system is switched ON. When first

commissioned, the display [6] briefly shows a flashing "-"

before showing fault message "6Y". The fault message

"6Y" is displayed, since the burner is delivered in a fault

state.

V Wait about 1 minute for the EMS connection to the

room controller (available separately) to be established.

V Press the "Reset" button on the BC10. The status

display [6] on the BC10 lights up and shows the

current boiler water temperature in °C.

Adjust the date and time on the room controller if fault

message "A11" appears. Only then will the current boiler

water temperature be displayed.

Before continuing with commissioning, enter the correct

parameters on the room controller. In particular the DHW

configuration (DHW circulation pump with three-way

valve or heating circuit pump and cylinder primary pump)

must be adjusted correctly to safeguard the correct

function of the heating system. To set these parameters,

carefully read the relevant sections in the installation and

service instructions for the room controller.

Fig. 66 Logamatic BC10 standard controller

1 ON/OFF switch

2 "Set DHW temperature" rotary selector

3 "Reset" button

4 "Emissions test" button for flue gas test and manual mode

5 "Status display" button

6 Display

7 "Burner (ON/OFF)" LED

8 "Maximum boiler temperature" rotary selector in heating

mode

7.4 Starting the burner

For further commissioning steps, follow the sequence of

burner commissioning. To do so, it is essential that you

consult the burner documentation.

6 720 615 876-65.1RS

1

2

3 567

4

8

Page 47

7

Commissioning the heating system

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

47

7.5 Raising the flue gas temperature

You can find out the specified flue gas temperature for the

boiler by referring to the specifications (Æ Chapter 2.10,

page 10).

If you discover when testing the system that the flue gas

temperature is too low for the flue (risk of condensation

formation), you can raise the flue gas temperature by one

or more of the following measures:

– Removing hot gas baffle plates

– Removing the hot gas check plate

V Shut down the heating system (Æ Chapter 8.1,

page 50).

7.5.1 Removing hot gas baffle plates

You can remove the hot gas baffles in pairs to raise the

flue gas temperature.

V Open the burner door; to do this, remove the two

lateral hexagon bolts.

V Remove the hot gas baffles towards the front.

V Close the burner door with both hexagon bolts. Tighten

the hexagon bolts evenly to properly seal the burner

door.

V Re-check the flue gas temperature.

Fig. 67 Removing the hot gas baffels (2nd hot gas flue

shown)

7.5.2 Removing the hot gas check plate

You can remove the hot gas check plate to further raise

the flue gas temperature if, after the removal of the hot gas

baffle plates, the flue gas temperature is still too low.

V Open the burner door; to do this, remove the two

lateral hexagon bolts.

V Remove the hot gas check plate; to do this remove the

screw.

V Re-check the flue gas temperature.

Fig. 68 Removing the hot gas check plate

Warning: Risk of burning from touching hot

boiler parts.

V Wear appropriate protective gloves or use

pliers.

6 720 615 876-66.1RS

6 720 615 876-67.1RS

Page 48

7

Commissioning the heating system

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

48

7.6 Installing the burner hood

V Locate the burner hood on the hooks on the boiler

outer casing.

V Secure the burner hood with screws.

Fig. 69 Installing the burner hood

7.7 Setting the room controller/control

unit

V Check/make following settings on the room controller:

– Automatic operating mode

– Required room temperature

– Required DHW temperature

– Required heating program

Fig. 70 Room controller

After completion of the commissioning steps

V Set both rotary selectors on the control unit to "AUT"

(automatic mode). In this setting, the room controller

takes over control.

Fig. 71 Setting the control unit

Danger: Risk of fatality from electric shock.

V Only operate the boiler with the burner

hood fitted.

6 720 615 876-68.1RS

For further information about operating the

system, e.g. setting the temperatures, refer to

the room controller documentation.

6 720 615 876-69.1RS

6 720 615 876-70.1RS

Page 49

7

Commissioning the heating system

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

49

7.8 Commissioning report

V Sign all commissioning work as completed and enter

the relevant date.

Commissioning steps Page

Readings

taken

Comments

1. Fill heating system and check all connections for leaks. 41

__________ bar

2. Operating pressure, building

– Adjust the green field on the pressure gauge

– Vent the heating system

– Adjust the expansion vessel pre-charge pressure (Æ observe

expansion vessel documentation)

45

__________ bar

3. Check the combustion air supply and the flue gas routing 46

4. Switch on the control unit (Æ control unit documentation) 46

5. Starting the burner (Æ burner documentation)

6. Check and raise the flue gas temperature, if required 47

__________ °C

7. Adjust the control unit settings to suit the customer's requirements

(Æ control unit documentation)

8. Inform operator, hand over technical documentation

Confirm correct commissioning

Company stamp/signature/date

Inform the customer of the correct fuel and

enter it in the table (Æ boiler operating

instructions).

This report lists only the commissioning

steps required for the Logano G225. Details

of the additional commissioning operations

required for the Logano plus GB225 are

given in the enclosed supplement.

Page 50

8

Shutting down the heating system

Logano G225/Logano plus GB225 - We reserve the right to make any changes due to technical modifications.

50

8 Shutting down the heating system

8.1 Normal shutdown

V Switch the ON/OFF switch on the control unit OFF

(position "0"). This switches off the boiler and all its

components (such as the burner).

Fig. 72 Switching the heating system off

V Turn off the fuel supply at the main shut-off valve.

8.2 Shutting down the heating system in emergencies

8.2.1 What to do in an emergency

Explain to the customer what to do in an emergency, e.g.

a fire.

V Never put yourself at risk of fatal injury. Your own safety

is paramount.

V Close the mains gas shut-off valve.

V Isolate the heating system from the mains power

supply by means of the heating system emergency

stop switch or the appropriate electrical fuse/circuit

breaker.

Caution: Risk of system damage due to

frost.